Non-setting adhesive cutter

A cutting machine and thread cutting technology, which is applied in metal processing and other directions, can solve the problem of cutting edge arc size and inconsistency, and achieve the effect of avoiding jumping and solving the effect of cutting arc edges and inaccurate sizes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

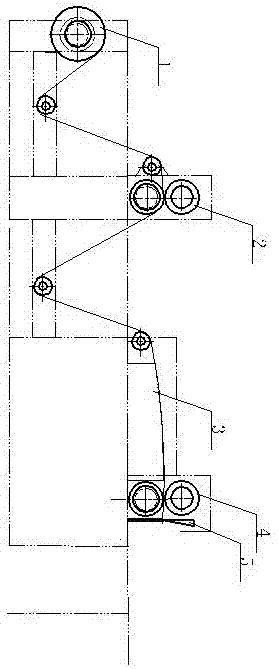

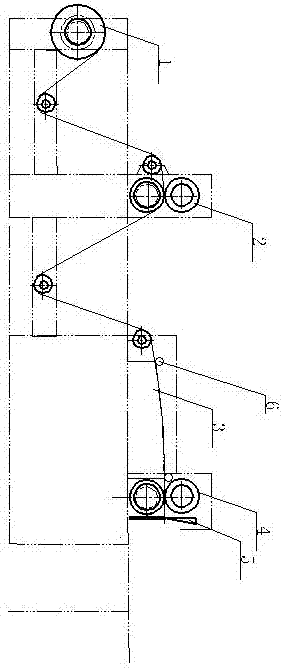

[0014] Embodiment 1: A self-adhesive cutting machine, which sequentially includes a discharge shaft 1, a front traction roller 2 for traction of self-adhesive, an arc-shaped material receiving platform 3, and a rear traction roller 4 for traction of self-adhesive . A cutter 5 for cutting stickers, the upper surface of the arc-shaped material receiving platform 3 is an arc-shaped curved surface with an angle of 10° with the horizontal line. The whole roll of self-adhesive is stringed on the unwinding shaft, and the front traction roller 2 runs to drive the self-adhesive unwinding. The self-adhesive after unwinding passes through the arc-shaped material receiving platform 3, and the angle of the arc surface is 10° compared with the horizontal line. The soft self-adhesive is close to the arc-shaped material receiving platform at 33°, and is subject to the same traction force in the horizontal direction. The force on each point on the arc-shaped self-adhesive is relatively low, and...

Embodiment 2

[0015] Embodiment 2: The curved curved surface is provided with roller shafts 6 opposite to the sides of the front traction roller 2 and the rear tractive roller 4, and the roller shafts 6 are used to press the self-adhesive tightly on the curved curved surface. The arc tangent of the arc surface relative to the rear traction roller 4 is parallel to the horizontal plane, and the height of the arc tangent is the same as the center height of the rear traction roller 4, so that the adhesion between the self-adhesive and the arc surface is better.

[0016] The flat table before cutting is replaced with an arc table, which avoids the jumping phenomenon of the soft self-adhesive when it is pulled, and then solves the problem of cutting arc edges and inaccurate sizes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com