Bending machining device applied to strip parts

A processing device and parts technology, applied in the field of bending processing devices, can solve problems such as the influence of bending angle, the influence of processing accuracy, and the jumping of strip parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

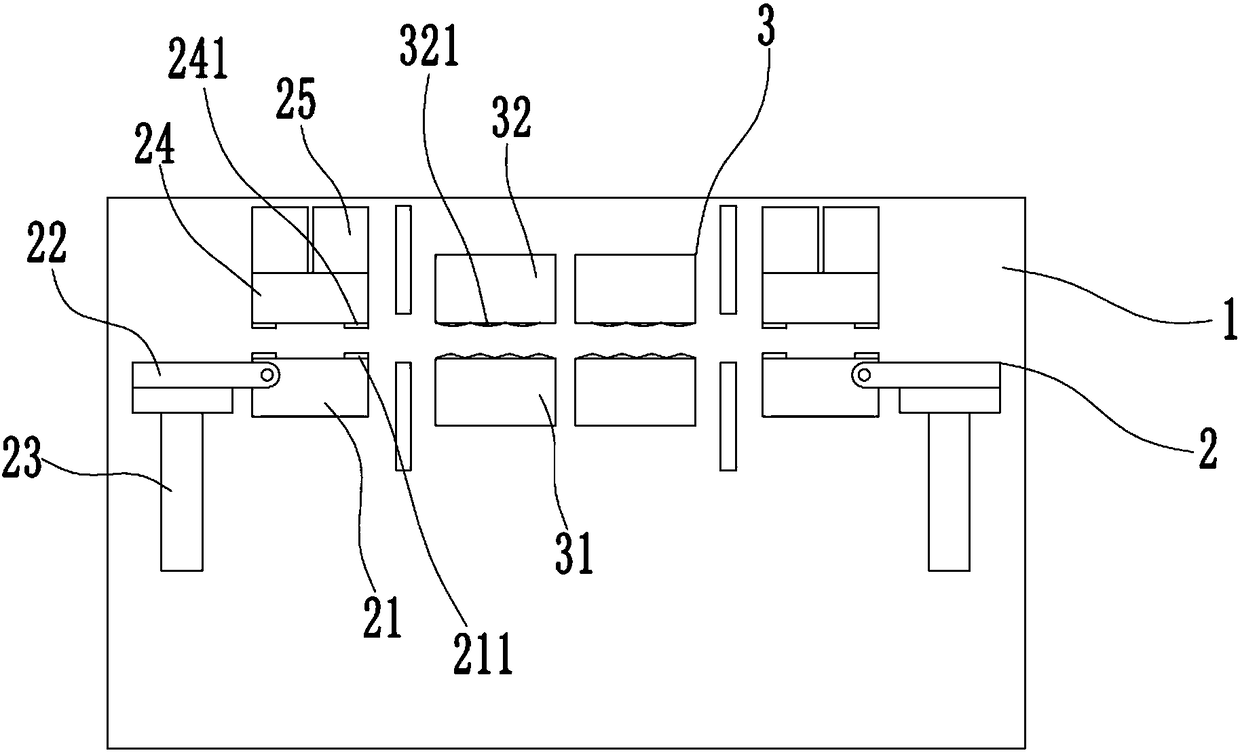

[0018] see figure 1 , the figure shows a bending processing device applied to strip-shaped parts provided by Embodiment 1 of the present invention, which includes a base 1, and two bending mechanisms arranged symmetrically are installed on the base 1, and the bending mechanism includes a bending Part 2 and guide part 3, the bending part 2 includes a fixed first positioning block 21, one side of the first positioning block 21 is hinged with a push rod 22, the push rod 22 is connected to the first driving part 23, and the base 1 is movably installed There is a second positioning block 24 opposite to the first positioning block 21, and the second positioning block 24 is connected to the second driving part 25. The guide part 3 includes a first guiding block 31 and a second guiding block 32 arranged oppositely. The first guiding block 31 Arranged in a straight line with the first positioning block 21 , the second guide block 32 is arranged in a straight line with the second positi...

Embodiment 2

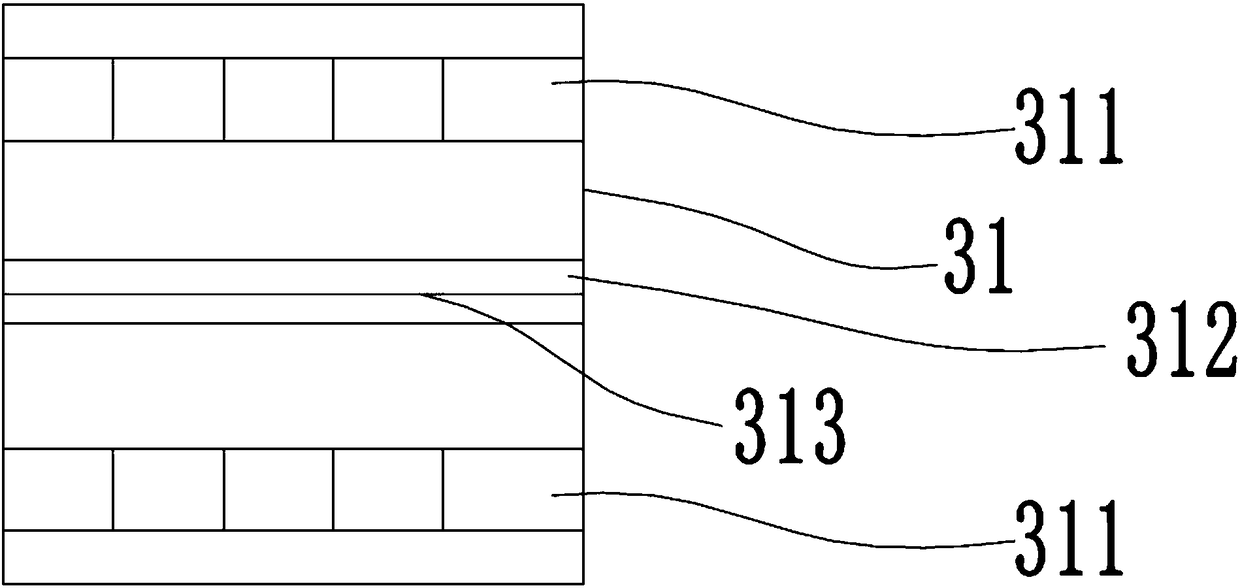

[0021] see figure 1 , the figure shows a bending processing device applied to bar-shaped parts provided by Embodiment 2 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above embodiments: The shape surface includes two racks 311 oppositely arranged; a through groove 312 opened on the side of the first guide block 31 is arranged between the two racks 311 ; a boss 313 is arranged at the bottom of the through groove 312 . Through the arrangement of the above structure, accurate guidance in the vertical direction can be formed, and the adsorption force to the product can be improved in the vertical direction.

Embodiment 3

[0023] see figure 1 , the figure shows a bending processing device applied to bar-shaped parts provided by Embodiment 3 of the present invention. On the basis of the above embodiments, this embodiment further makes the following technical solutions as improvements: the first The side surfaces of the two guide blocks 32 are provided with wave surfaces 321 . Through the setting of the above structure, the beating of the product can be further reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com