Die for processing movable piece and production method for die

A technology for processing molds and moving pieces, applied to the field of molds for moving pieces, can solve the problems of scrap jumping, poor machining accuracy, and affecting product quality, to prevent scrap jumping, improve quality, and improve product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing, the present invention will be further described:

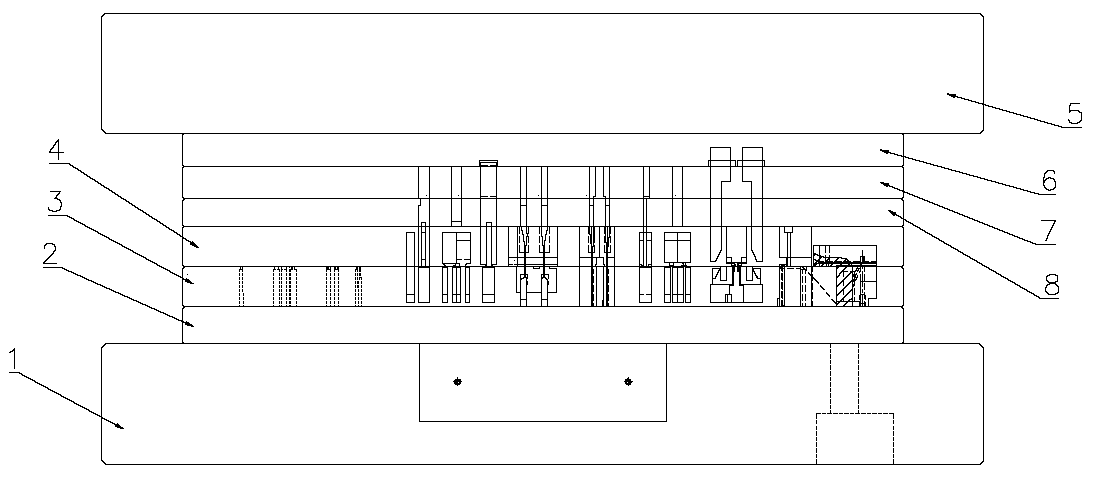

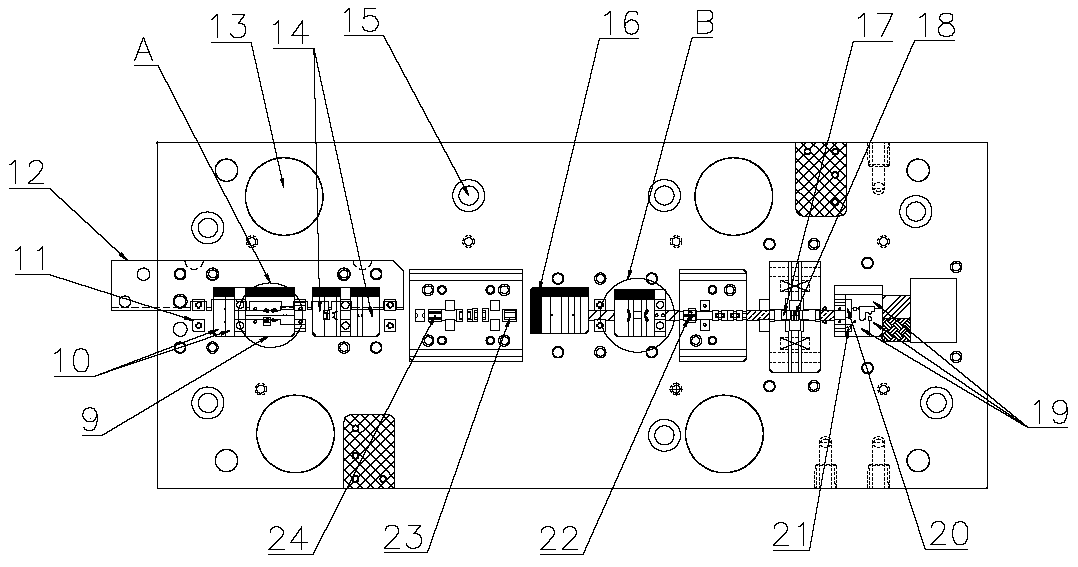

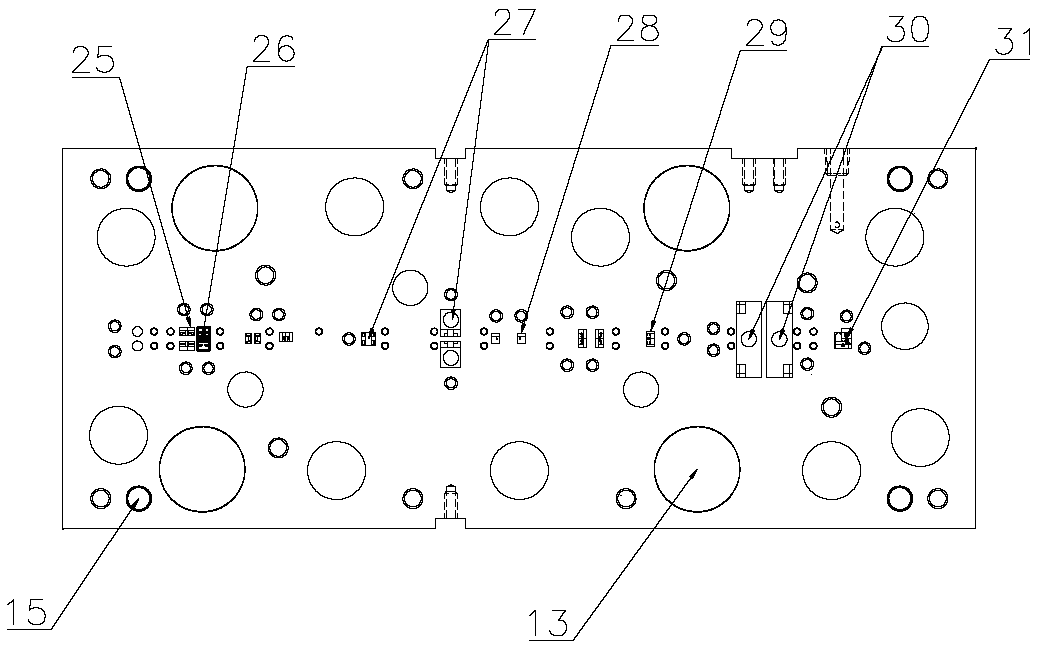

[0039] Such as Figure 1~10 As shown, the present invention provides a mold for processing a movable piece, which includes an upper mold base 5 and a lower mold base 1, such as figure 1 As shown, between the upper mold base 5 and the lower mold base 1, an upper mold backing plate 6, an upper template 7, a discharge back plate 8, a discharge plate 4, a lower template 3 and a lower mold backing plate 2 are installed in sequence, as figure 2 , Figure 4 and Figure 6 As shown, the lower formwork 3 is provided with embedding holes 9 of different sizes along the length direction of the bar. Die inserts 10 (14, 17, 19, 32 and 37 are detachably installed in the embedding holes 9, for convenience of description. , hereinafter, the mark "37" is used to uniformly represent "die insert), and the shape and size of the die insert 37 are adapted to the processing part of the movable...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com