Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53results about How to "No shrinkage deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

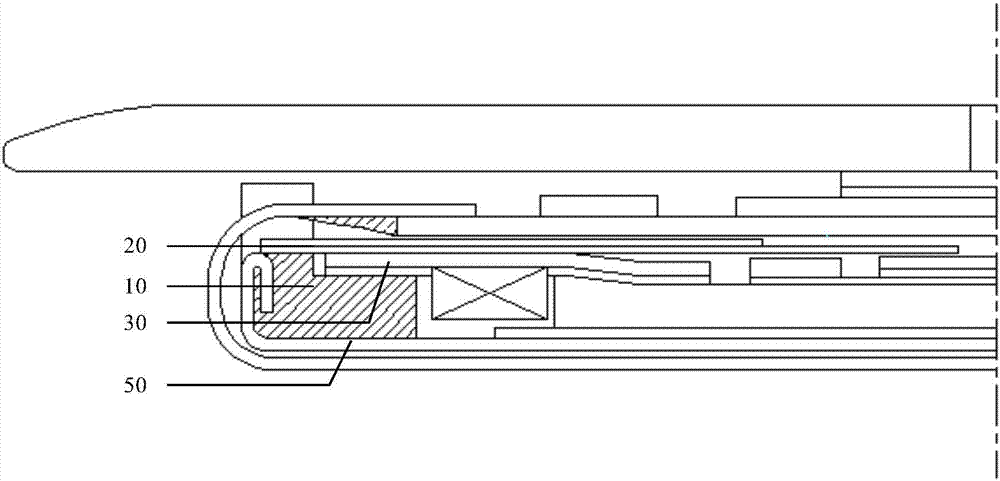

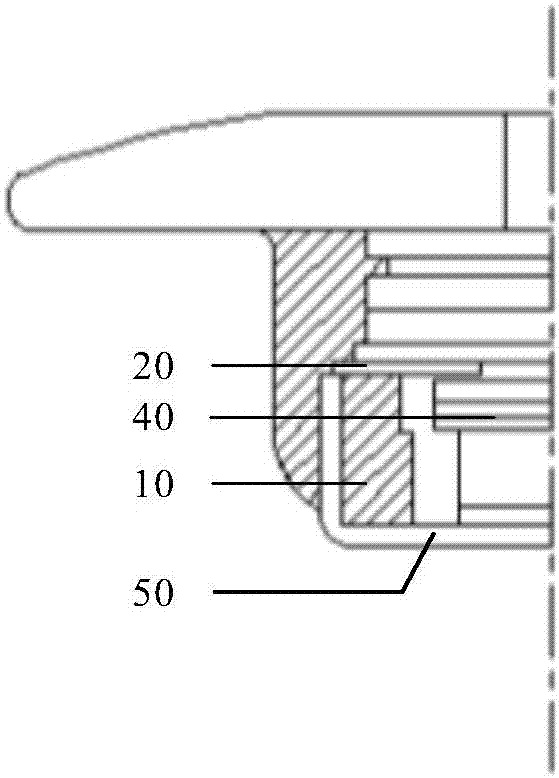

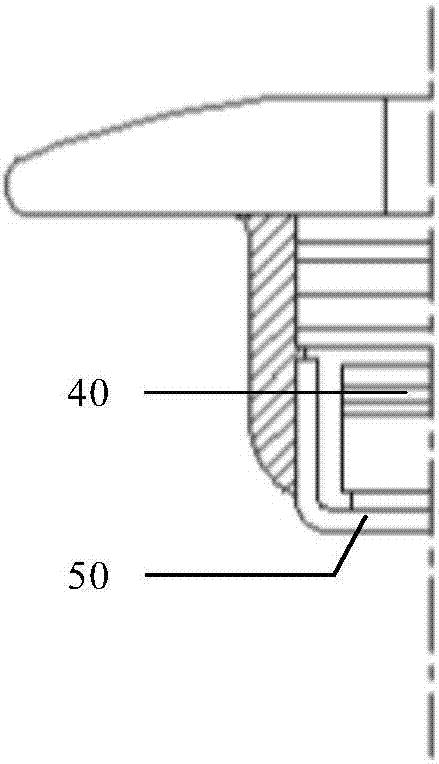

Backlight module and display device

InactiveCN107272262ASimple moldingNo shrinkage deformationPlanar/plate-like light guidesNon-linear opticsDisplay deviceEngineering

The invention provides a backlight module and a display device, and relates to the technical field of display. The backlight module comprises a back plate and a light source; the back plate comprises a back plate body and a first bending structure perpendicular to the back plate body; on one side of the light source, the back plate further comprises a second bending structure which is connected with the first bending structure and extends in the same direction as the back plate body; the second bending structure comprises a plurality of protrusions arranged at intervals, and concave portions between the adjacent protrusions are used for containing light-emitting parts of the light source. A rubber frame does not need to be arranged, the width of the frame can be reduced, and the flatness of the back plate can be improved.

Owner:BOE TECH GRP CO LTD +1

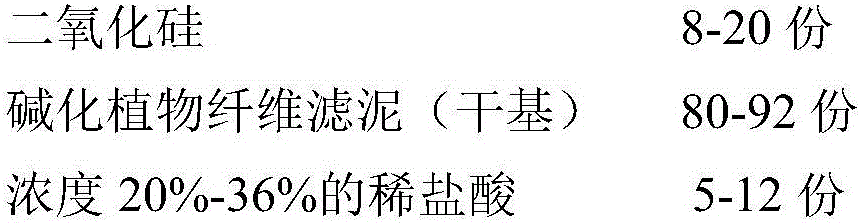

Degradable lightweight polyolefin composite for injection molding and preparation method of composite

The invention provides a degradable lightweight polyolefin composite for injection molding and a preparation method of the composite. The polyolefin composite is prepared from secondarily modified fiber mixed filler, polyolefin resin, a toughening agent, a compatilizer, a lubricant and the like through blending and extrusion granulation by a tri-screw extruders which are arranged triangularly and meshed in the same direction, wherein the modified fiber mixed filler is prepared as follows: a natural plant fiber material such as rice husks, chaff and the like are mixed with a nano-silica colloidal solution, a dispersant and a surfactant are added and a blending reaction, drying and other technologies processes are performed; then the modified mixed fiber filler is subjected to secondary surface coupling hydrophobic treatment and blended with polyolefin resin, the toughening agent, the compatilizer and the lubricant. The polyolefin composite has degradability specific to the natural plant fiber filler, has lower density than inorganic mineral filler and has excellent thermoplastic processing characteristics and mechanical properties in the injection molding process.

Owner:水发信达(山东)再生资源科技有限公司

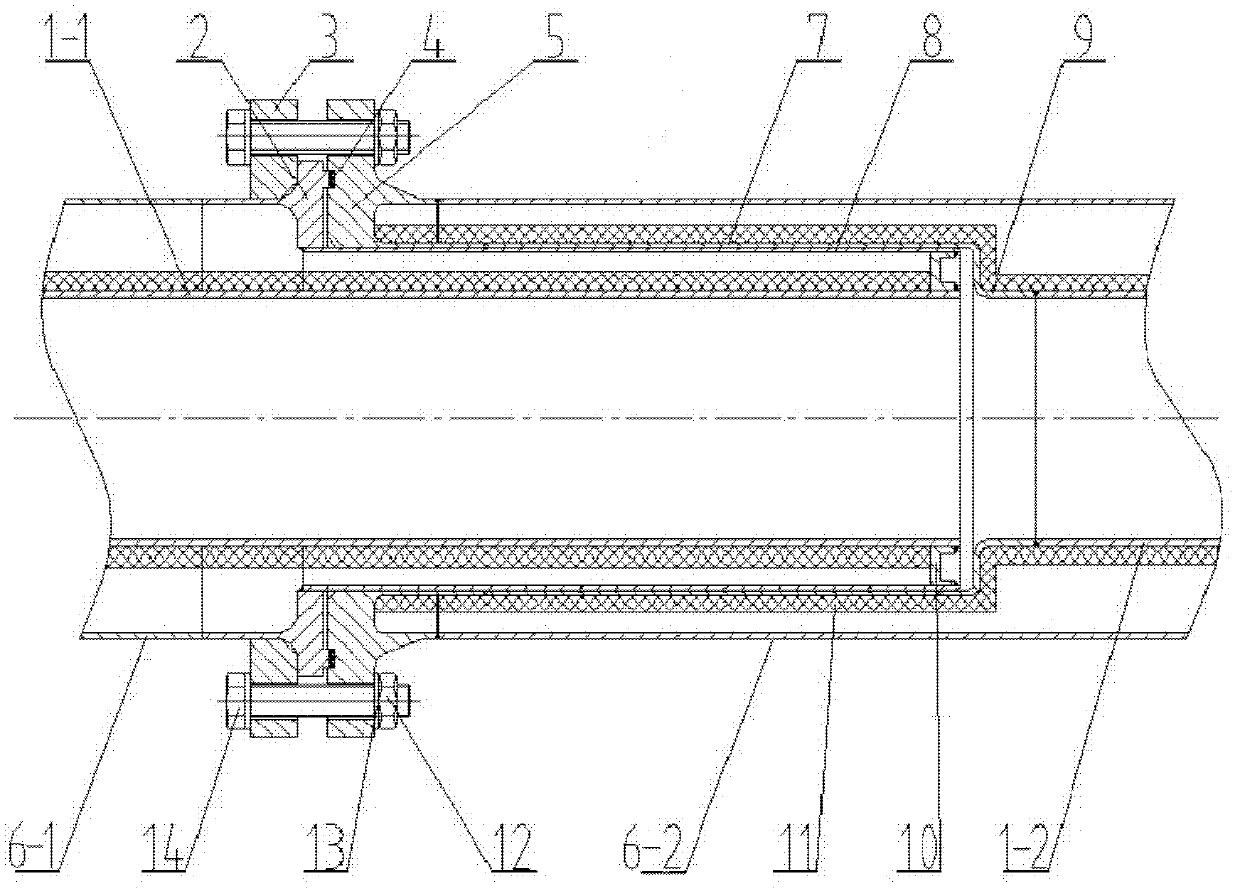

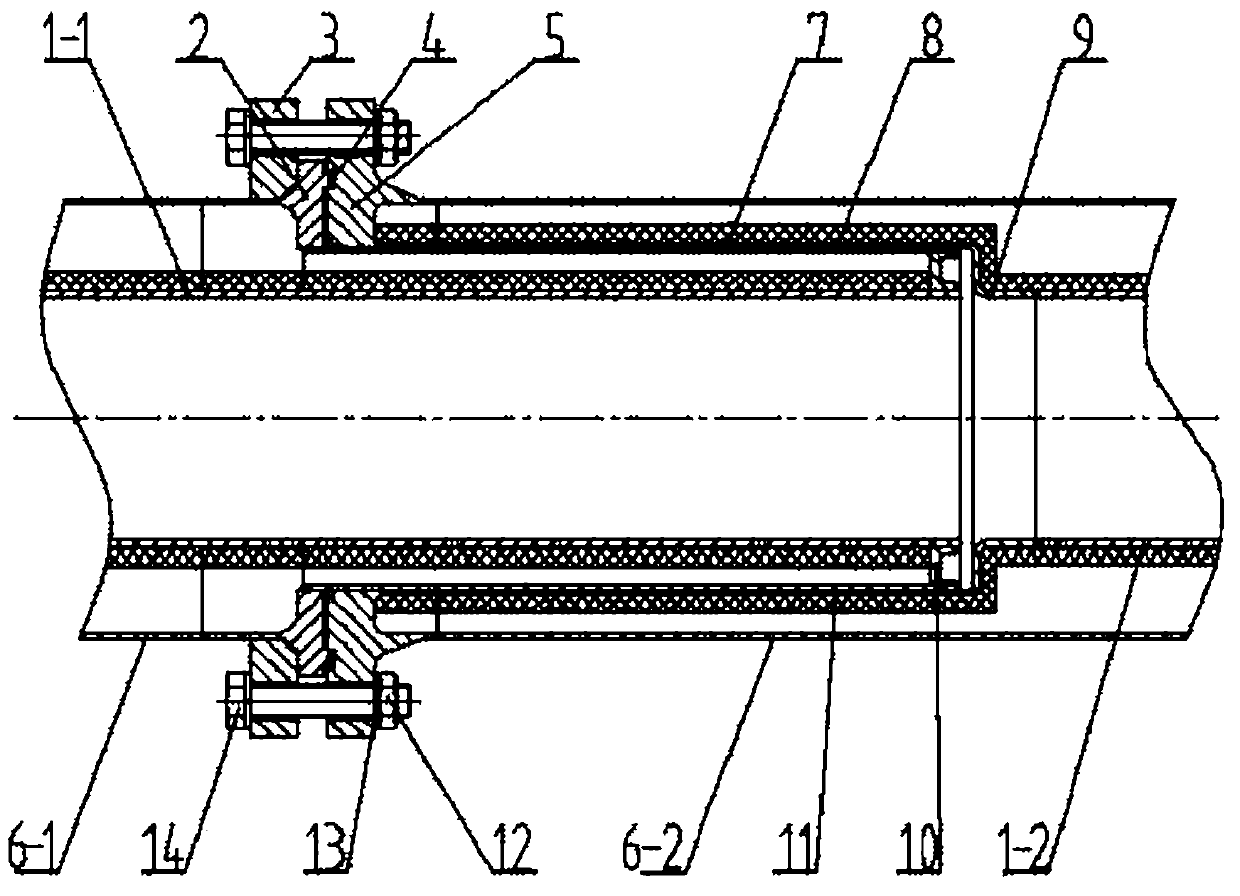

Flange connector for vacuum insulation low-temperature pipelines

InactiveCN102606820AIdeal barrier sealing effectNo shrinkage deformationFlanged jointsThermal insulationButt jointEngineering

The invention relates to a flange connector for vacuum insulation low-temperature pipelines, belonging to the technical field of pipeline connection. A first pipeline and a second pipeline of the connector are respectively composed of an inner pipe and an outer pipe, the end tip of the outer pipe of the first pipeline is provided with a connector plate, and an inner hole of the connector plate axially extends outwards to form a convex edge heat bridge; the end tip of the outer pipe of the second pipe is provided with a flange plate, and an inner hole of the flange plate axially extends outwards to form a concave edge heat bridge; during the assembly, the connector plate and the flange plate are butt-jointed, sealed and fixed in a way that a convex ring is clamped into a groove in which a sealing ring is embedded; meanwhile, the convex edge heat bridge is inserted into the concave edge heat bridge and keeps an air gap with the concave edge heat bridge. The flange connector disclosed by the invention adopts a reasonable structure, and ingeniously uses separation sealing of the air gap to replace an inner sealing part, so that the sealing performance is guaranteed.

Owner:AEROSUN CORP

Polyvinyl chloride (PVC) injection molding pipe material

The invention discloses a polyvinyl chloride (PVC) injection molding pipe material. The material is prepared from the following ingredients in parts by weight: 30-70 parts of PVC resin, 10-15 parts of active light calcium carbonate, 4-5 parts of polyvinyl butyral, 2-4 parts of triphosphate, 0.4-0.6 part of hydroquinone, 5-12 parts of stearic acid, 3-5 parts of triphenyl phosphate, 1-5 parts of cyclohexanone, 5-10 parts of industrial paraffin and 10-20 parts of wood fiber. According to the material, the traditional plastic-based injection molding materials are replaced with a novel woody injection molding material, which is recyclable and environment-friendly and is free from any injury to human bodies, and the raw materials, which can be tree wood, tree leaves, wood sawdust, leftover materials of industrial sheets and the like, are cheap and are easily obtained, so that the consumption of plastics can be greatly reduced, and the unity of injection molding materials is changed; meanwhile, products are strong in stability, are free from contraction distortion and can be repeatedly recycled.

Owner:QINGDAO HI TECH PATENT TECH TRANSFER PLATFORM

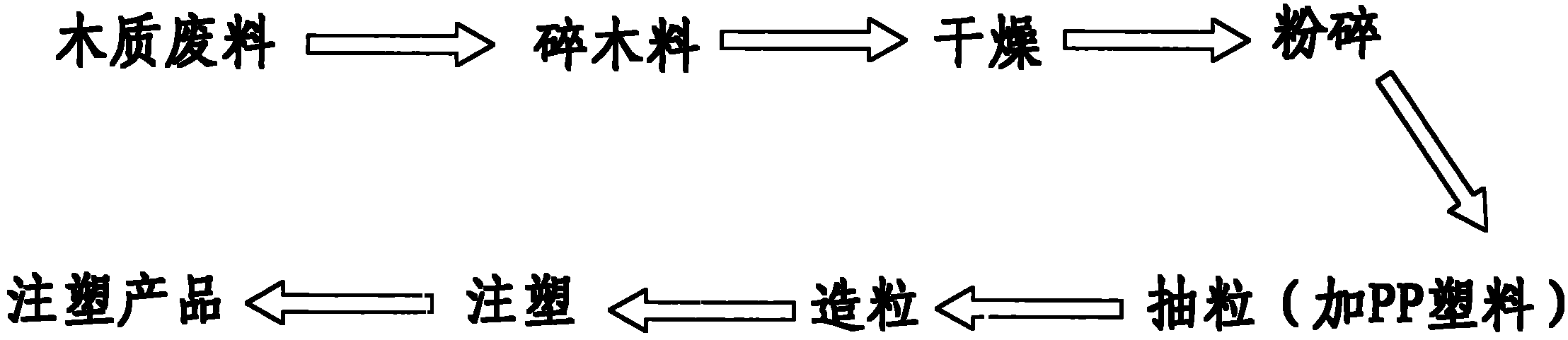

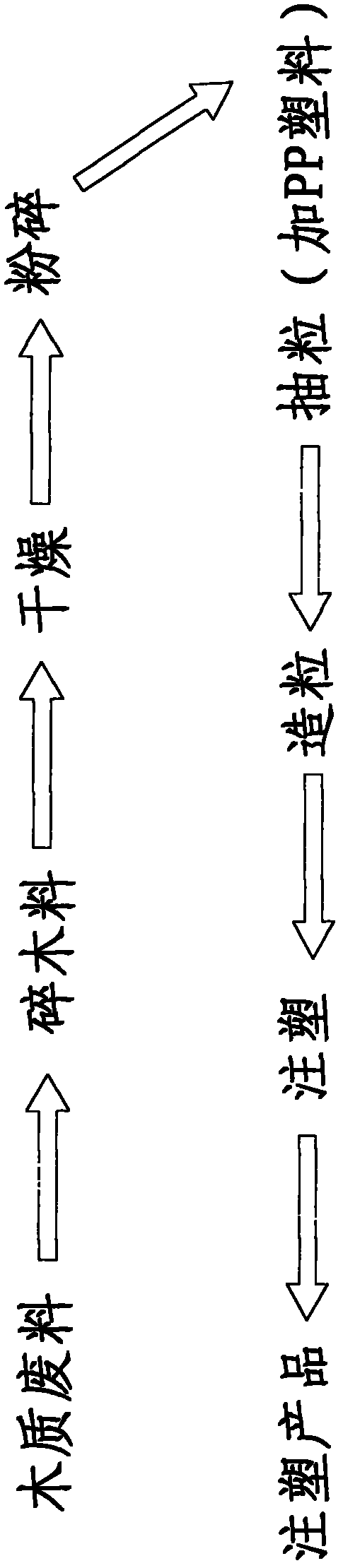

Wood plastic injection molding material and preparation method thereof

InactiveCN102093733AChange the singularityImprove breathabilityPlastic injection moldingEnvironmentally friendly

The invention relates to a wood plastic injection molding material and a preparation method thereof. The plastic injection material comprises 40 to 80 weight percent of wood particle material and 20 to 60 weight percent of polypropene (PP) plastic. The preparation method comprises: crushing and drying one or more than two wood waste materials to form a wood particle material; and fully mixing the wood particle material and the PP plastic according to the composition of the wood plastic injection molding material to obtain a target product. The wood plastic injection molding material, which can be recycled, is environmentally-friendly and safe to human bodies; the raw materials of the wood plastic injection molding material (such as trees, tree leaves, saw dust, and leftovers of industrial plates) are readily available, the consumption of plastic can be reduced greatly, the singleness of plastic injection molding material is changed, and the prepared product is very stable, free from contraction deformation and can be recycled; and the operation process is simple, easy to operate and low in cost. The wood plastic injection molding material can be widely used for making plastic products with wood appearance and has very breathable plant cultivating vessels, food and health-care package boxes and the like.

Owner:YOSHIYAMA PLASTIC

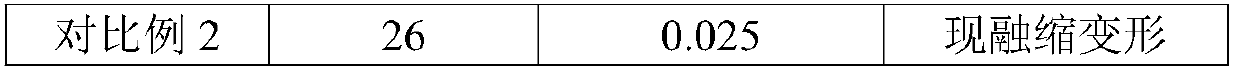

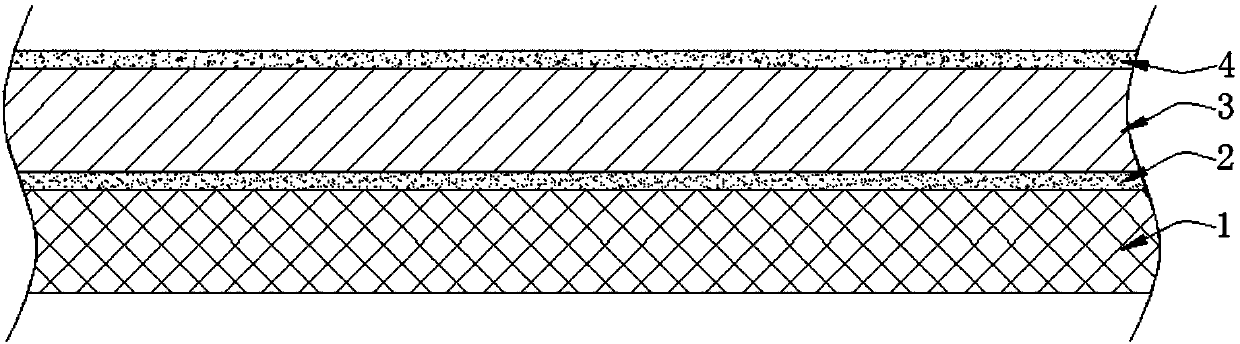

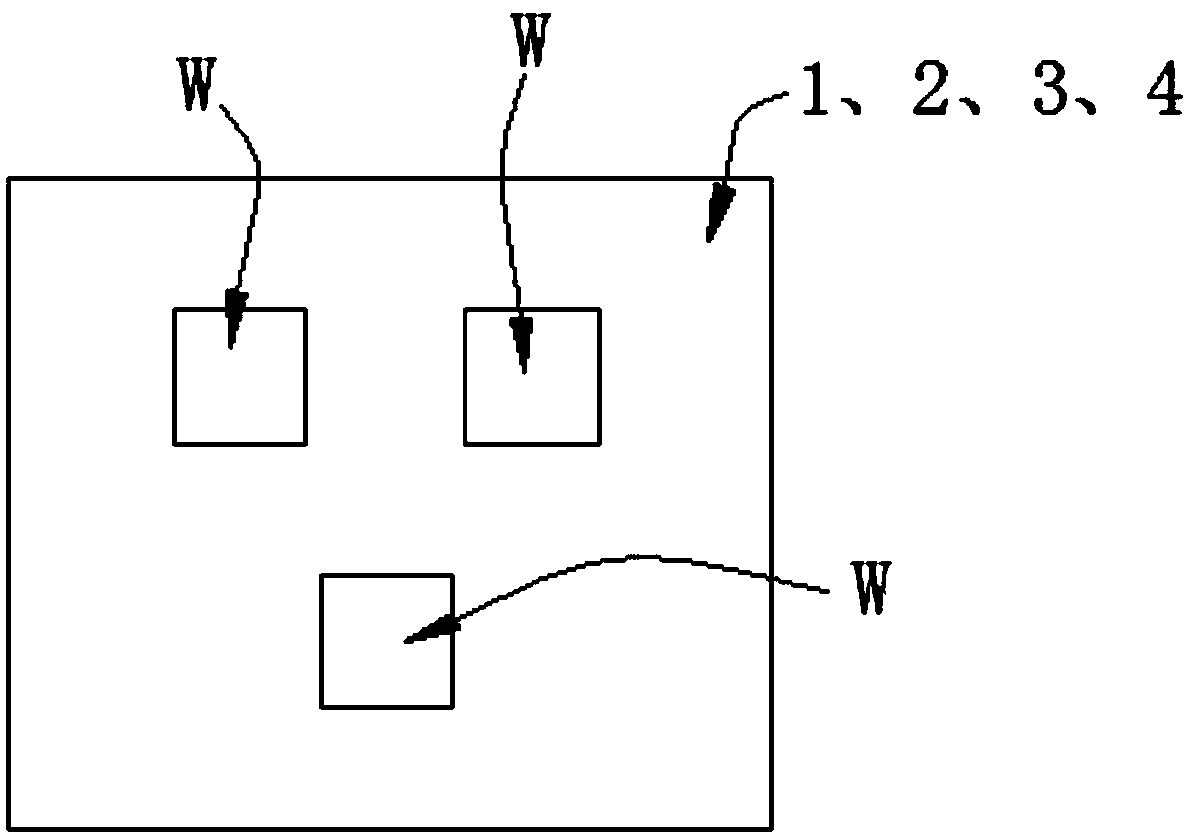

Buffer pad for hot pressing of printed circuit board and preparation method

ActiveCN108770203ANo shrinkage deformationNot much shrinkage deformationLaminating printed circuit boardsEnvironmental resistanceCushioning

The invention discloses a buffer pad for hot pressing of a printed circuit board and a preparation method thereof. The buffer pad for hot pressing of the printed circuit board comprises a high-temperature-resistant high-pressure fiber felt, a high-temperature-resistant high-pressure fiber layer and a high-temperature-resistant adhesive, wherein the high-temperature-resistant high-pressure fiber felt is a hexahedron; the six faces of the high temperature and high pressure resistant fiber felt are wrapped by the high temperature and high pressure resistant fiber layer through the high temperature resistant adhesive. As the six sides of the high-temperature-resistant high-pressure fiber felt of the invention are wrapped by high temperature and high pressure resistant fiber cloth / paper, the fiber drop can be effectively reduced when the high temperature and high pressure resistant fiber cloth / paper is used as a cushion, the PCB product quality is improved, and the product defect risk is greatly reduced. In addition, the cushion has a significant increase in cushioning pressure and cushioning temperature. In addition, since the cushion is fully wrapped on all six sides, there is not much lateral and longitudinal shrinkage deformation during the pressing process or after the pressure is removed. The invention is environmentally friendly and economical, and is convenient for PCB manufacturer to automated production.

Owner:昆山市柳鑫电子有限公司

Heat-resistant modified polypropylene film master batch and preparation method thereof

InactiveCN104231434AImprove heat resistanceNo shrinkage deformationLow-density polyethyleneLinear low-density polyethylene

The invention discloses heat-resistant modified polypropylene film master batch and a preparation method thereof. The master batch comprises raw materials in parts by mass as follows: 78-80 parts of polypropylene, 18-21 parts of linear low density polyethylene, 1-3 parts of light calcium carbonate, 0.4-0.6 part of oxidized polyethylene and 0.6-0.8 part of tertiary butyl hydroquinone. According to the preparation method, the polypropylene is modified, and the linear low density polyethylene, the light calcium carbonate, the oxidized polyethylene and the tertiary butyl hydroquinone are compounded, so that the obtained polypropylene master batch has excellent heat resistance, the obtained master batch is subjected to two-way stretch to form a film, and the film is good in heat resistance, shrinkage deformation can be avoided during heat sealing.

Owner:SUZHOU YUNSHU NEW MATERIAL TECH

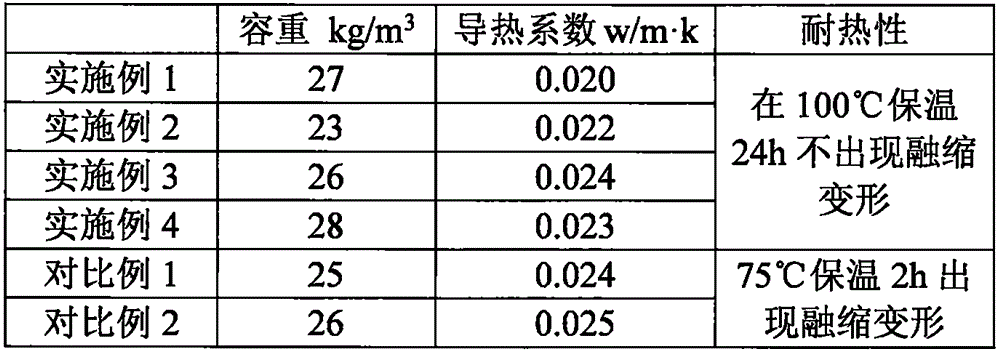

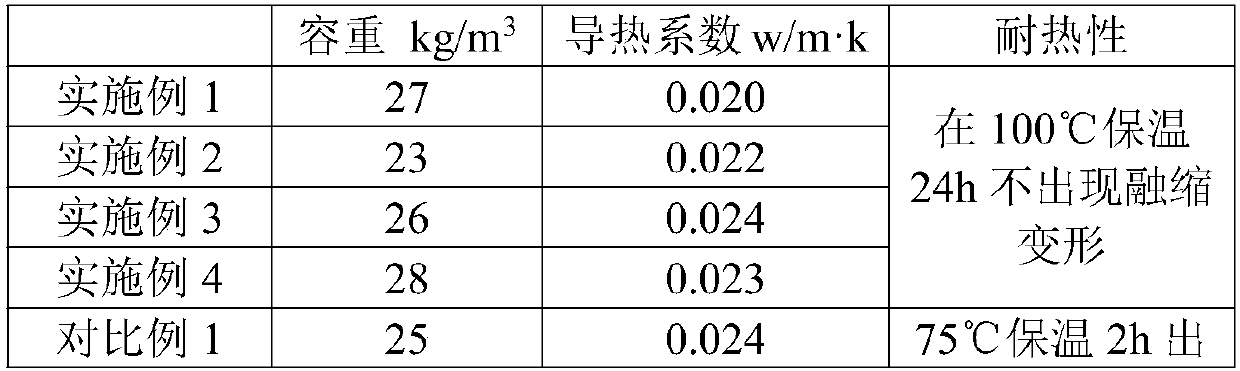

Thermal-deformation-resisting polyethylene foam plastic and preparation method thereof

ActiveCN105837905ANo mechanical propertiesSolve the phenomenon of emptinessLow-density polyethylenePolyvinyl butyral

The invention provides a thermal-deformation-resisting polyethylene foam plastic and a preparation method thereof .The polyethylene foam plastic is prepared from bisphenol-A epoxy resin 4, polyvinyl butyral, diethylenetriamine, epoxy-modified organosilicon resin, potassium acetate, azodicarbonamide and low-density polyethylene in a molding foaming mode.

Owner:芜湖格川新材料科技有限公司

Processing technique of color-fastness waterproof buffed leather surface

InactiveCN105755182APure colorColorful and purePre-tanning chemical treatmentLeather pressing/rollingHigh colorStain

The invention discloses a processing technique of a color-fastness waterproof buffed leather surface. The processing technique comprises the following specific steps of cleaning, polishing the leather surface, spraying filler, performing hot compression and fixation, spraying colors, fastening color and performing final treatment. The buffed leather surface prepared by the processing technique disclosed by the invention has the advantages of bright, pure and natural colors, high waterproof property, no shrinkage distortion, high color fastness and slight color fading; an original style and features are basically restored, and soft texture is also guaranteed; stains on suede buffed leather clothing can be better removed; operation steps are simple, convenient and feasible, the integral effect of leather clothing can be maintained, and the service life is prolonged.

Owner:GUANGZHOU HONGGU LEATHER PRODS

Thermal deformation resistant polyethylene foamed plastic and preparation method thereof

InactiveCN107759885ANo mechanical propertiesSolve the phenomenon of emptinessLow-density polyethylenePolyvinyl butyral

The invention provides a thermal deformation resistant polyethylene foamed plastic and a preparation method thereof. The polyethylene foamed plastic is prepared by performing molding foaming on the following raw materials: bisphenol A epoxy resin 4, polyvinyl butyral, diethylenetriamine, epoxy-modified organic silicon resin, potassium acetate, azodicarbonamide and low density polyethylene.

Owner:NINGBO XIAYUAN TECH

Injection material

The present invention discloses an injection material, including by weight: 40-80 parts of a wood granular material; 10-20 parts of nano-calcium carbonate; 20-50 parts of stearic acid; 10-20 parts of an impact modifier; 15 parts of a flexibilizer; 10-20 parts of industrial paraffin; and 5-10 parts of titanium dioxide. According to the present invention, the novel wood plastic material which is recyclable, environmental-friendly and without any harm to human body is used for replacing the conventional molding material taking plastic as the main material; the raw materials are cheap and available (such as trees, leaves, wood chips, and leftover bits and pieces of industrial sheets); the use of plastic can be significantly reduced; simplicity of the injection material is changed; and the products are high in stability, and have no shrinkage distortion.

Owner:QINGDAO XINWANTONG PLASTIC IND

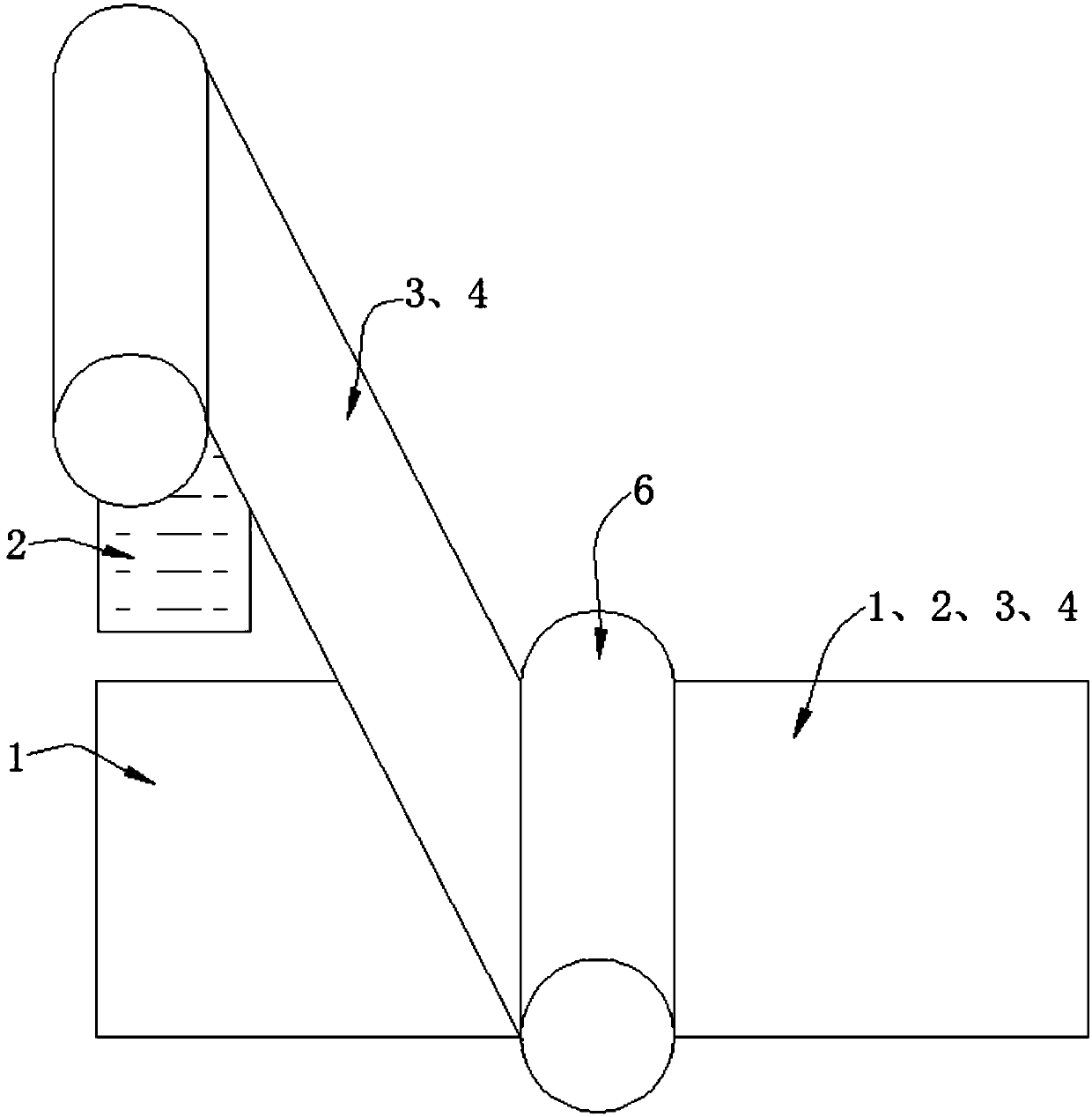

Window lamination method for paper

InactiveCN107599598ARealize window coatingBonded firmlyLamination ancillary operationsLaminationWork in processEngineering

The invention discloses a window lamination method for paper. The window lamination method comprises the following steps: step 1, a two-sided corona film with one side pre-coated with hot melt glue isadopted, the other side of the two-sided corona film is bonded with the surface of the paper to be subjected to window lamination, full lamination of the two-sided corona film on the paper is realized, and an early semi-finished product is obtained; step 2, windowing is performed on the early semi-finished product, that is, a window is die-cut in a predetermined position of the early semi-finished product, scraps produced in die cutting are removed, and an intermediate semi-finished product is obtained; step 3, a heat seal film provided with co-polypropylene on at least one side is adopted, hot melt glue of the intermediate semi-finished product is covered with the side, provided with co-polypropylene, of the heat seal film, the heat seal film and the intermediate semi-finished product are bonded together through hot pressing by a hot pressing roller, and a finished paper product subjected to window lamination is obtained. The window lamination method has the advantages that the process difficulty is low, the effect of the window lamination finished product is good and the production efficiency is high.

Owner:广州市恒远彩印有限公司

A film drying method applied to sol coating technology

ActiveCN103966577BPrevent shrinkage deformationReduce energy consumptionLiquid/solution decomposition chemical coatingSubstrate typePolymer science

The invention belongs to the technical field of functional films, and particularly relates to a film drying method applied to a sol film coating technology. The invention develops a film heating and drying process applied to the sol film coating technology. The process is different from a whole surface uniform heating manner for a traditional sol film, directional thermal fields are exerted on the symmetrical left side and right side of the film, and quick temperature rising treatment is utilized, so that larger temperature gradient distribution can be formed on the surface of the film, and finally film formation from the edge to the center of the film gradually is realized. According to the process, shrinkage distortion in the film drying process can be effectively inhibited, the energy consumption is low, the preparation period is short, the process is simple and controllable, no expensive equipment is needed, meanwhile no special requirement is needed on the to-be-prepared film material, the size and the substrate types, and a new technology with low cost and short period and capable of realizing industrialized implementation is provided for the drying process in the sol film coating.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Polyvinyl chloride injection molding pipeline

The invention discloses a polyvinyl chloride injection molding pipeline. The pipeline is prepared from the following components in parts by weight: 30-70 parts of PVC resin, 10-15 parts of active light calcium carbonate, 4-5 parts of methyl silicon oil, 4-5 parts of isocaprylic acid, 2-4 parts of p-nitrophenol, 0.4-0.6 part of polysiloxane, 5-12 parts of stearic acid, 3-5 parts of triphenyl phosphate, 1-5 parts of cyclohexanone, 5-10 parts of commercial paraffin and 10-20 parts of wood fibers. The novel wood injection molding material which is recyclable and environment-friendly and does not hurt human bodies is adopted to replace traditional injection molding materials which is mainly prepared from plastic, and is prepared from low-price and easily available raw materials, such as woods, leaves, wood shavings, scraps of industrial plates and the like, so that use of plastics can be greatly reduced, simplicity of plastic materials can be changed, and the prepared product has strong stability, no shrinkage strain and recycling availability.

Owner:QINGDAO JIASHANG CREATIVE CULTURE

Anti-ultraviolet environmentally-friendly PE pipe material

The invention discloses an anti-ultraviolet environmentally-friendly PE pipe material. The anti-ultraviolet environmentally-friendly PE pipe material is characterized by being prepared from the following raw materials in parts by weight: 60 to 85 parts of high-density polyethylene, 1 to 3 parts of color masterbatches, 3 to 7 parts of a light stabilizer and a heat stabilizer, 1 to 2 parts of an anti-ultraviolet agent, 0.5 to 2 parts of a POE toughening agent, 8 to 12 parts of dioctyl phthalate, 4 to 6 parts of cyclohexanone, 3 to 9 parts of coumarone resin, 5 to 9 parts of melamine, 4 to 8 parts of chlorinated paraffin, 3 to 7 parts of methacrylic acid and 3 to 8 parts of titanium dioxide. According to the invention, through addition of a certain proportion of the light stabilizer, the heatstabilizer and the anti-ultraviolet agent into a polyethylene raw material to avoid generation of free radicals, the macromolecular chain of the polyethylene is guaranteed from being affected by ultraviolet energy, infrared high-temperature energy, oxidation, harmful gases released by microorganisms, acceleration of inorganic substances like soil to absorb energy, etc.; thus, the anti-ultravioletenvironmentally-friendly PE pipe material provided by the invention has the function of prolonging the original service life of a polyethylene product, and has the characteristics of environmental friendliness, no damage to the human body, recyclability, high-temperature resistance, insusceptibility to combustion, etc.

Owner:浙江华力管业股份有限公司

Polyvinyl chloride injection molding pipe material

InactiveCN106928584AStrong stabilityThe preparation process is easy to operateScrapPlastic injection molding

The invention discloses a polyvinyl chloride injection molding pipe, which is composed of the following components in parts by weight: PVC resin 30-70 parts; active light calcium 10-15 parts; iodine tincture 4-5 parts; lithopone 2-4 parts; sorbitol 0.4-0.6 parts ; Stearic acid 5-12; Triphenyl phosphate 3-5; Cyclohexanone 1-5; Industrial paraffin 5-10; Wood fiber 10-20. The present invention replaces the traditional plastic-based injection molding material with a new type of wood injection molding material that is recyclable, environmentally friendly, and has no harm to the human body. Leftovers, etc.), can greatly reduce the use of plastics and change the singleness of injection molding materials. At the same time, the products made have strong stability, no shrinkage and deformation, and can be recycled repeatedly.

Owner:王太梅

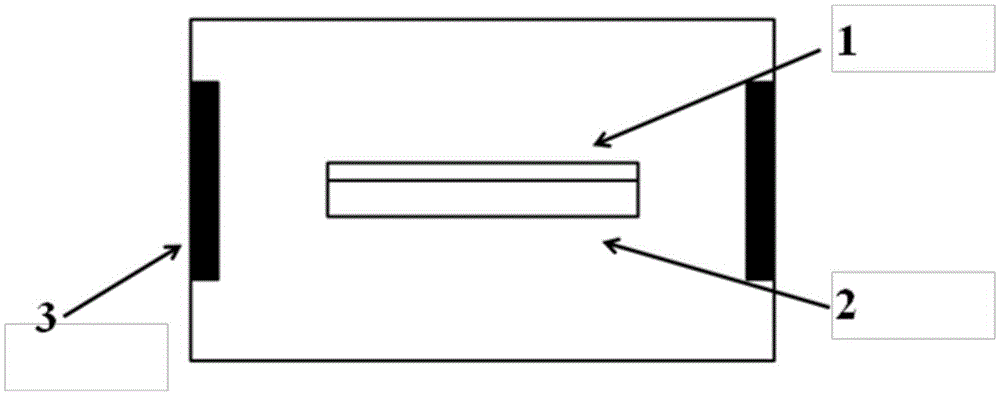

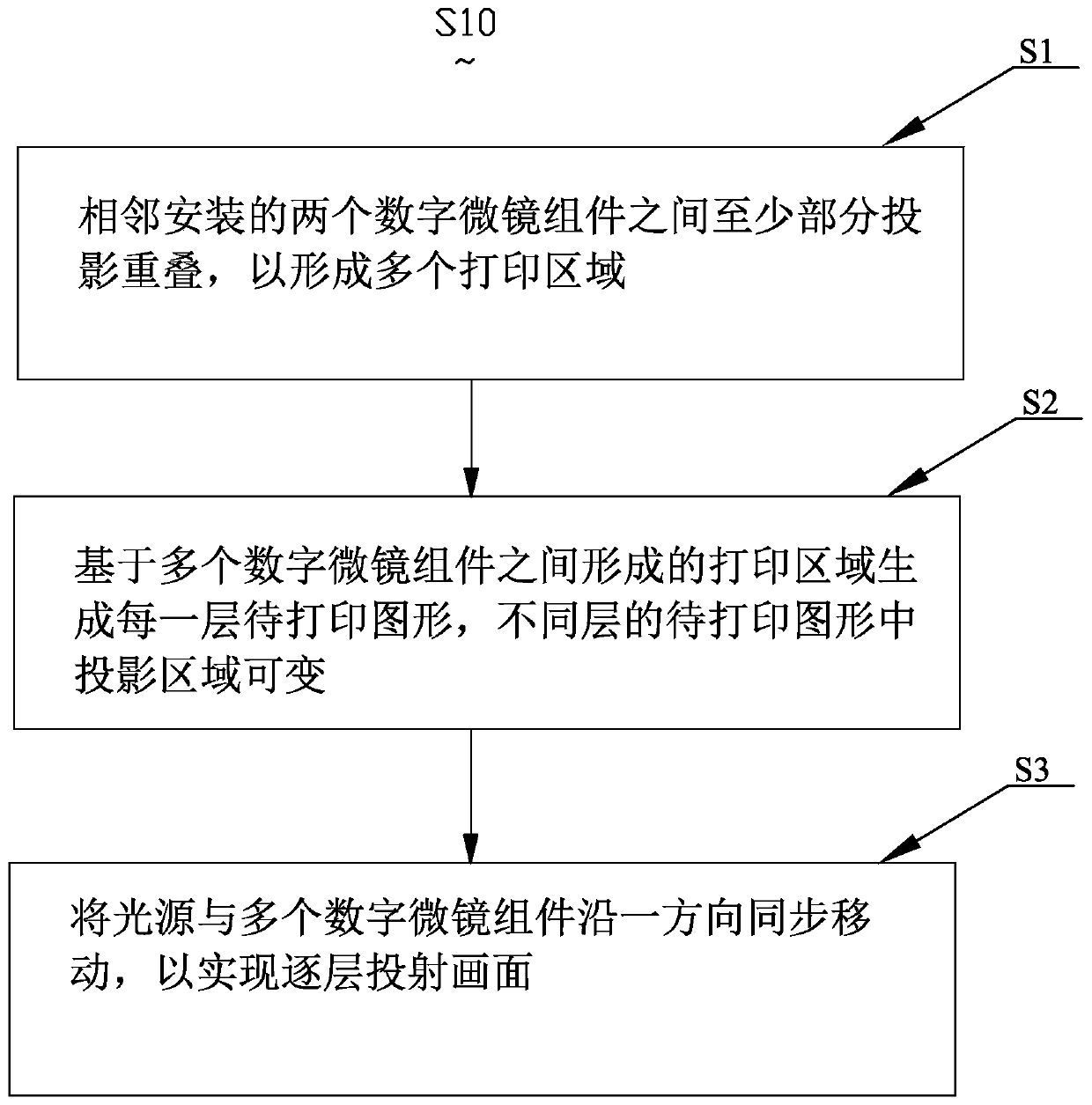

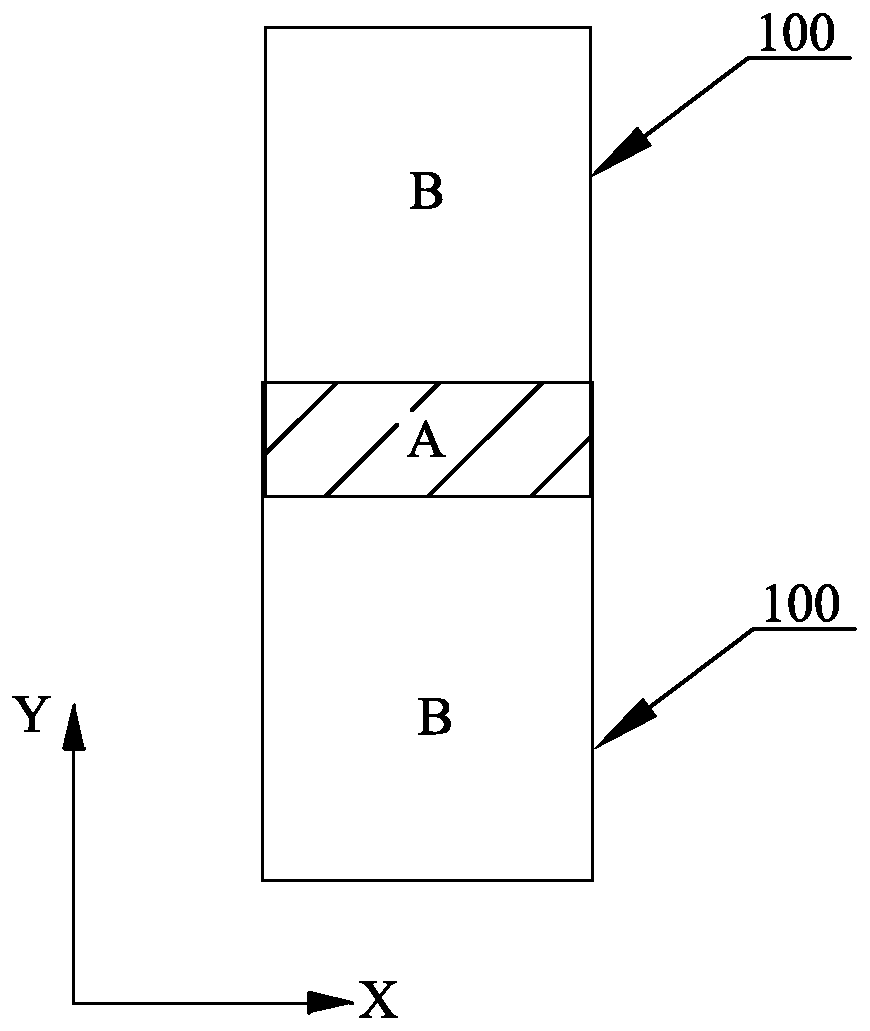

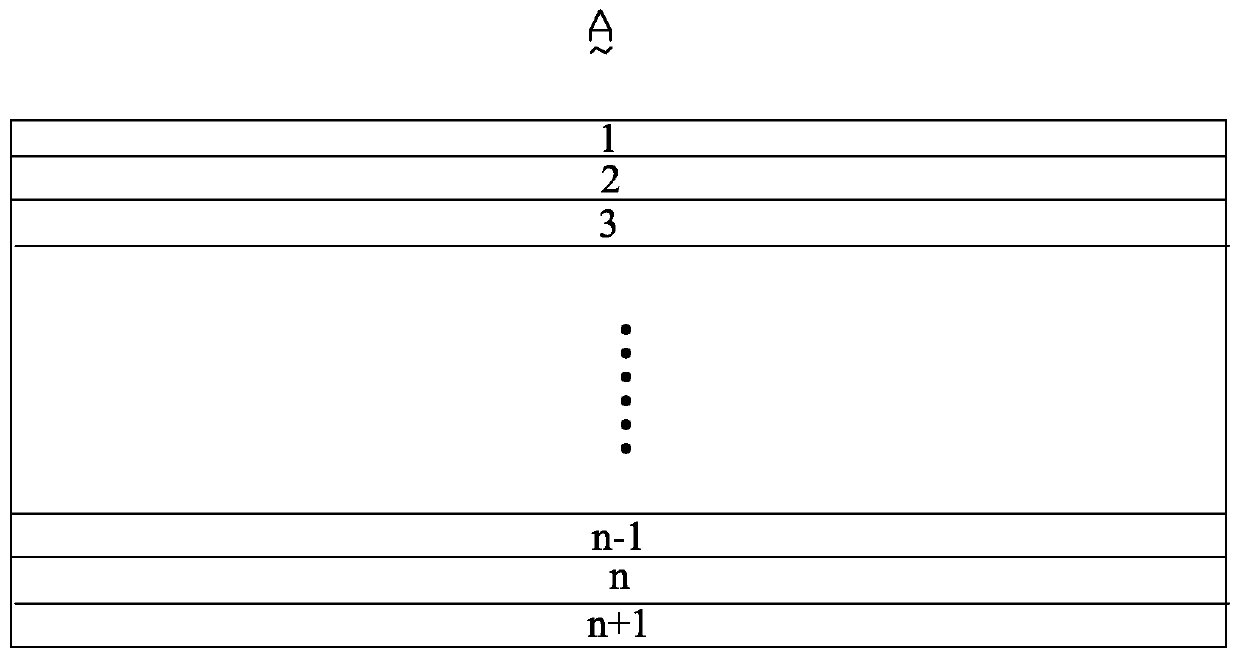

3D printing method and 3D printing equipment

PendingCN110625935ARealize splicingImprove mechanical propertiesAdditive manufacturing apparatus3D object support structuresStress concentrationGraphics

The invention relates to the technical field of 3D printing, in particular to a 3D printing method and 3D printing equipment. The 3D printing method comprises the steps that (1) at least partial projections overlap between two digital micromirror assemblies arranged adjacently to form a plurality of printing areas; (2) each layer of graph to be printed is generated on the basis of the printing areas formed among the plurality of digital micromirror assemblies, wherein projection areas in the graphs to be printed of different layers are variable; and (3) a light source and the plurality of digital micromirror assemblies are synchronously moved along one direction so as to realize layer-by-layer picture projection. By using the 3D printing method, the projection overlapping areas among the plurality of digital micromirror assemblies can be dispersed, so that stress concentration is avoided, and the mechanical property of a final product is improved.

Owner:李佳

Plasticized wood injection molding material

The invention discloses a plasticized wood injection molding material which is prepared from the following components in parts by weight: 10-20 parts of PVC (polyvinyl chloride) resin, 20-50 parts of wood meal, 5-12 parts of zinc borate, 10-15 parts of shock-resistant agent, 2-5 parts of butyl epoxy oleate, 0.1-0.3 part of phytosterin, 1-3 parts of chlorhexidine hydrochloride, 1-2 parts of sodium alginate, 0.5-0.7 part of expanded perlite, 3-5 parts of magnesium oxide, 20-30 parts of ligneous plant fiber and 3-5 parts of paraffin. By using the novel recyclable environment-friendly wood injection molding material harmless to the human body instead of the traditional injection molding material mainly composed of plastics, the wood injection molding material has the advantage of cheap and accessible raw materials (such as trees, leaves, wood dust, industrial board scraps and the like), thereby greatly reducing the plastic consumption and changing the singleness of the injection molding material; and the prepared product has the advantages of high stability and no shrinkage distortion, and can be repeatedly recycled and reused.

Owner:QINGDAO HI TECH PATENT TECH TRANSFER PLATFORM

Wood injection molding material

The invention discloses a wood injection molding material which is prepared from the following components in parts by weight: 10-20 parts of PVC (polyvinyl chloride) resin, 20-50 parts of wood meal, 5-12 parts of zinc borate, 10-15 parts of shock-resistant agent, 2-5 parts of butyl epoxy oleate, 4-5 parts of iodine, 2-4 parts of lithopone, 0.4-0.6 part of turpentine, 3-5 parts of magnesium oxide, 20-30 parts of ligneous plant fiber and 3-5 parts of paraffin. By using the novel recyclable environment-friendly wood injection molding material harmless to the human body instead of the traditional injection molding material mainly composed of plastics, the wood injection molding material has the advantage of cheap and accessible raw materials (such as trees, leaves, wood dust, industrial board scraps and the like), thereby greatly reducing the plastic consumption and changing the sameness of the injection molding material; and the prepared product has the advantages of high stability and no shrinkage distortion, and can be repeatedly recycled and reused.

Owner:QINGDAO HI TECH PATENT TECH TRANSFER PLATFORM

Formula of PVC pipeline

The invention discloses a formula of a PVC pipeline, which is prepared from the following raw materials in parts by weight: 14-18 parts of dioctyl phthalate, 6-10 parts of cyclohexanone, 3-9 parts of coumarone resin, 12-17 parts of calcium carbonate, 7-12 parts of melamine, 4-8 parts of chlorinated paraffin, 12-18 parts of chlorinated polyethylene, 30-50 parts of PVC resin, 5-10 parts of methylacrylic propyl trimethylfluorosilane and 5-10 parts of titanium dioxide. According to the invention, the formula of the PVC pipeline has the characteristics of environment friendliness, no human body damage, recyclability and the like, can resist high temperature and is not easy to combust.

Owner:QINGDAO JISHUNLONG TRADING

Novel injection molding material

The invention discloses a novel injection molding material which is prepared from the following components in parts by weight: 40-80 parts of wood granular material, 10-20 parts of active light calcium carbonate, 20-50 parts of stearic acid, 3-5 parts of compound foaming agent, 1-5 parts of oxidizer, 5-10 parts of industrial paraffin and 10-20 parts of wood fiber. By using the novel recyclable environment-friendly wood injection molding material harmless to the human body instead of the traditional injection molding material mainly composed of plastics, the novel injection molding material adopts cheap and accessible raw materials (such as trees, leaves, wood dust, industrial board scraps and the like), thereby greatly reducing the plastic consumption and changing the singleness of the injection molding material; and the prepared product has the advantages of high stability and no shrinkage distortion, and can be repeatedly recycled and reused.

Owner:QINGDAO SANLI XINYUAN ELECTRICAL APPLIANCES

Polyvinyl chloride (PVC) injection molding tube

The invention discloses a polyvinyl chloride (PVC) injection molding tube which is prepared from the following components in parts by weight: 30-70 parts of PVC resin, 10-15 parts of active light calcium carbonate, 0.1-0.3 part of phytosterin, 1-3 parts of chlorhexidine hydrochloride, 1-2 parts of sodium alginate, 0.5-0.7 part of expanded perlite, 5-12 parts of stearic acid, 3-5 parts of triphenyl phosphate, 1-5 parts of cyclohexanone, 5-10 industrial paraffin and 10-20 parts of wood fiber. By using the novel recyclable environment-friendly wood injection molding material harmless to the human body instead of the traditional injection molding material mainly composed of plastics, the PVC injection molding tube has the advantage of cheap and accessible raw materials (such as trees, leaves, wood dust, industrial board scraps and the like), thereby greatly reducing the plastic consumption and changing the singleness of the injection molding material; and the prepared product has the advantages of high stability and no shrinkage distortion, and can be repeatedly recycled and reused.

Owner:QINGDAO HI TECH PATENT TECH TRANSFER PLATFORM

A kind of buffer pad for hot pressing of printed circuit board and preparation method thereof

ActiveCN108770203BNo shrinkage deformationNot much shrinkage deformationLaminating printed circuit boardsFiberAdhesive

The invention discloses a buffer pad for hot pressing of printed circuit boards and a preparation method thereof. The printed circuit board hot-pressing buffer pad includes: high temperature and high pressure resistant fiber felt, high temperature and high pressure resistant fiber layer and high temperature resistant adhesive, the high temperature and high pressure resistant fiber felt is a hexahedron; the six high temperature and high pressure resistant fiber felt The surface is wrapped by the high temperature and high pressure resistant fiber layer through the high temperature resistant adhesive. The high temperature and high pressure resistant fiber felt of the present invention is wrapped with high temperature and high pressure resistant fiber cloth / paper on six sides, which can effectively reduce fiber drop when used as a cushion, improve the quality of PCB products, and greatly reduce the risk of product defects. In addition, the cushion pad has a great improvement in cushioning pressure and cushioning temperature. In addition, since the cushion pad is wrapped on all six sides, there is no large shrinkage deformation in the horizontal and vertical directions during the pressing process or after the pressure is removed. The invention is environmentally friendly and economical, and is convenient for automatic production of PCB manufacturers.

Owner:昆山市柳鑫电子有限公司

Injection molding material

The invention discloses an injection molding material which is prepared from the following components in parts by weight: 10-20 parts of PVC (polyvinyl chloride) resin, 20-50 parts of wood meal, 5-12 parts of zinc borate, 10-15 parts of shock-resistant agent, 2-5 parts of butyl epoxy oleate, 4-5 parts of iodine, 2-4 parts of lithopone, 0.1-0.3 part of sodium alginate, 1-3 parts of panthenol, 1-2 parts of expanded perlite, 3-5 parts of magnesium oxide, 20-30 parts of ligneous plant fiber and 3-5 parts of paraffin. By using the novel recyclable environment-friendly wood injection molding material harmless to the human body instead of the traditional injection molding material mainly composed of plastics, the injection molding material has the advantage of cheap and accessible raw materials (such as trees, leaves, wood dust, industrial board scraps and the like), thereby greatly reducing the plastic consumption and changing the singleness of the injection molding material; and the prepared product has the advantages of high stability and no shrinkage distortion, and can be repeatedly recycled and reused.

Owner:QINGDAO HI TECH PATENT TECH TRANSFER PLATFORM

Injection molding pipe

The invention discloses an injection molding pipe. The injection molding pipe comprises the following components in parts by weight: 30 to 70 parts of PVC resin, 10 to 15 parts of active light calcium, 0.1 to 0.3 part of Triclosan, 1 to 3 of chlorhexidine hydrochloride, 1 to 2 parts of lauryl polyoxyethylene ether, 3 to 5 parts of triphenyl phosphate, 1 to 5 parts of cyclohexanone, 5 to 10 parts of industrial paraffin, and 10 to 20 parts of wood fibers. The injection molding pipe disclosed by the invention adopts a novel wood injection molding material which can be recycled, is environmentallyfriendly and does no harm to human bodies, to replace the traditional plastic-based injection molding material, the raw materials are cheap in price and easy to obtain, for example, the materials canbe trees, leaves, wood chips, leftover materials of industrial boards and the like, so that the use of plastic can be greatly reduced and the singleness of the injection molding material can be changed. In addition, the finished product has strong stability and no shrinkage and deformation, and can be recycled repeatedly.

Owner:HUBEI TUNCANG PIPE TECH DEV CO LTD

Polyvinyl chloride injection-molding tube material

The invention disclosed a polyvinyl chloride injection-molding tube material composed of the components of, by weight: 30-70 parts of PVC resin, 10-15 parts of active light calcium, 5-12 parts of stearic acid, 3-5 parts of tricresyl phosphate, 1-5 parts of cyclohexanone, 5-10 parts of industrial paraffin, and 10-20 parts of wood fiber. According to the invention, the novel wood injection-molding material which is recyclable, environment-friendly, and non-harmful to human body is used for replacing a traditional injection-molding material with plastic as a main component. The raw materials are cheap and are easy to obtain (as the raw materials can be trees, leaves, sawdust, industrial sheet scraps, and the like). With the material, plastic use can be greatly reduced, and injection-molding material monotonicity can be changed. The prepared product has high stability and no shrinkage deformation. The material can be repeatedly recycled and reused.

Owner:QINGDAO HI TECH PATENT TECH TRANSFER PLATFORM

Novel injection molding material

The invention discloses a novel injection molding material. The material is prepared from, by weight, 10-20 parts of polyvinyl chloride resin, 20-50 parts of wood powder, 5-12 parts of zinc borate, 10-15 parts of impact modifier, 2-5 parts of epoxy butyl oleate, 4-5 parts of sodium molybdate, 2-4 parts of liquid paraffin, 0.4-0.6 part of sodium metasilicate pentahydrate, 3-5 parts of magnesium oxide, 20-30 parts of lignified plant fiber and 3-5 parts of paraffin. According to the novel injection molding material, the novel wood injection molding material which is recyclable, environmentally friendly and free of harm to the human body takes the place of a traditional injection molding material mainly composed of plastic, the raw materials are low in price and easy to obtain and can be trees, tree leaves, sawdust, leftover materials of industrial plates and the like, use of plastic can be greatly reduced, the unicity of the injection molding material can be changed, and meanwhile the product is high in stability, free of shrinkage distortion and capable of being recycled and repeatedly used.

Owner:王太梅

Injection molding pipeline

The invention discloses an injection molding pipeline. The pipeline is prepared from the following components in parts by weight: 30-70 parts of PVC resin, 10-15 parts of active light calcium carbonate, 1-3 parts of ethylene glycol butyl ether, 1-2 parts of lauryl alcohol polyoxyethylene ether, 0.5-0.7 part of potassium iodide, 5-12 parts of stearic acid, 5-10 parts of commercial paraffin and 10-20 parts of wood fibers. The novel wood injection molding material which is recyclable and environment-friendly and does not hurt human bodies is adopted to replace traditional injection molding materials which is mainly prepared from plastic, and is prepared from low-price and easily available raw materials, such as woods, leaves, wood shavings, scraps of industrial plates and the like, so that use of plastics can be greatly reduced, simplicity of plastic materials can be changed, and the prepared product has strong stability, no shrinkage strain and recycling availability.

Owner:QINGDAO HAIFALI GRAIN & OIL MACHINERY

A heat-resistant deformation polyethylene foam plastic and its preparation method

ActiveCN105837905BNo mechanical propertiesSolve the phenomenon of emptinessLow-density polyethyleneDiethylenetriamine

The invention provides a thermal-deformation-resisting polyethylene foam plastic and a preparation method thereof .The polyethylene foam plastic is prepared from bisphenol-A epoxy resin 4, polyvinyl butyral, diethylenetriamine, epoxy-modified organosilicon resin, potassium acetate, azodicarbonamide and low-density polyethylene in a molding foaming mode.

Owner:WUHU GECHUAN NEW MATERIAL TECH CO LTD

Injection molding material

The invention discloses a wood injection molding material. The material is prepared from the following components in parts by weight: 10-20 parts of polyvinyl chloride resin, 20-50 parts of wood powder, 5-12 parts of zinc borate, 10-15 parts of impact modifier, 0.1-0.3 part of glyoxal, 1-3 parts of panthenol, 1-2 parts of cycloacetic acid chlorhexidine, 0.5-0.7 part of saccharomycetin, 20-30 parts of lignified plant fibers and 3-5 parts of paraffin. The novel wood injection molding material which is recyclable and environment-friendly and does not hurt human bodies is adopted to replace traditional injection molding materials which is mainly prepared from plastic, and is prepared from low-price and easily available raw materials, such as woods, leaves, wood shavings, scraps of industrial plates and the like, so that use of plastics can be greatly reduced, simplicity of plastic materials can be changed, and the prepared product has strong stability, no shrinkage strain and recycling availability.

Owner:QINGDAO KERUN PLASTIC MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com