Flange connector for vacuum insulation low-temperature pipelines

A pipeline flange and vacuum insulation technology, which is applied in the direction of flange connection, pipeline protection through heat insulation, pipe/pipe joint/pipe fitting, etc., to achieve reliable sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

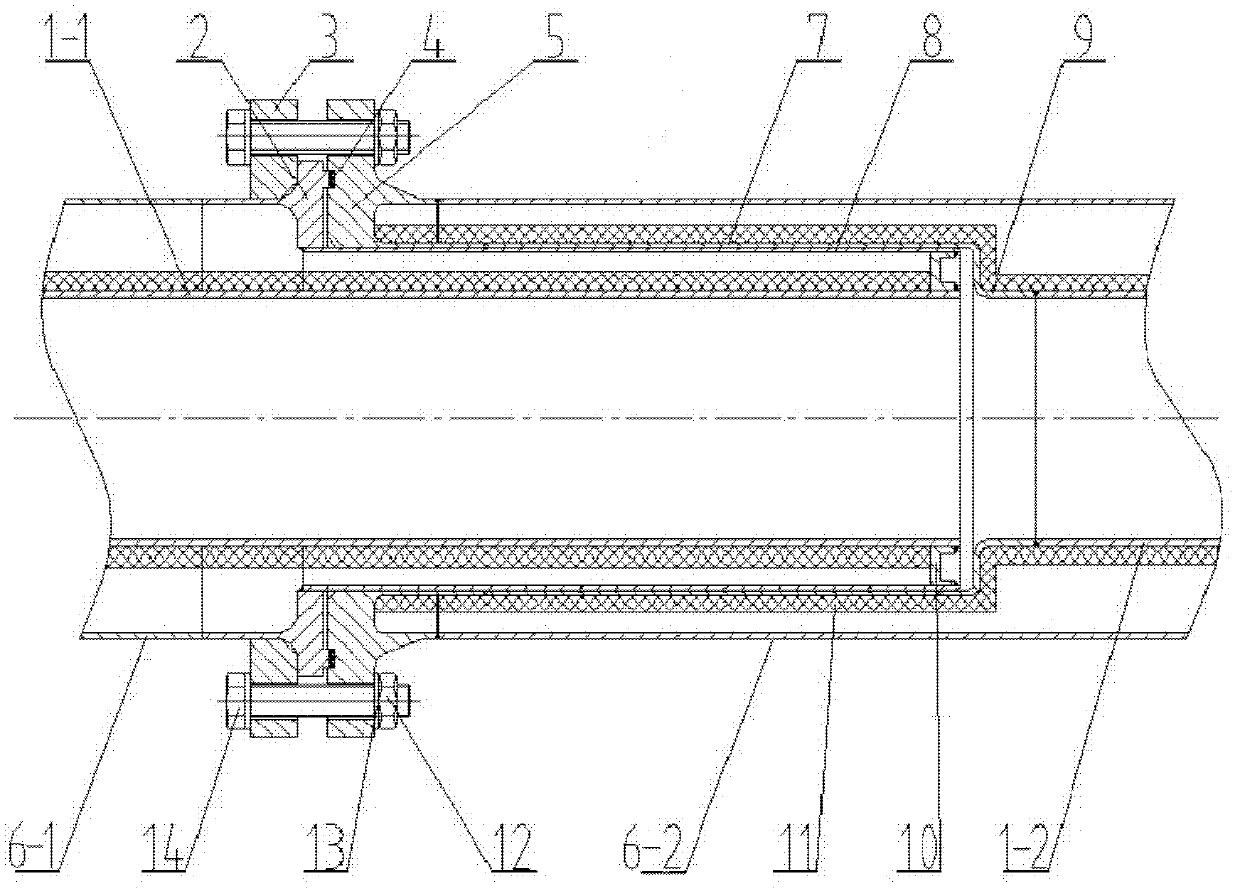

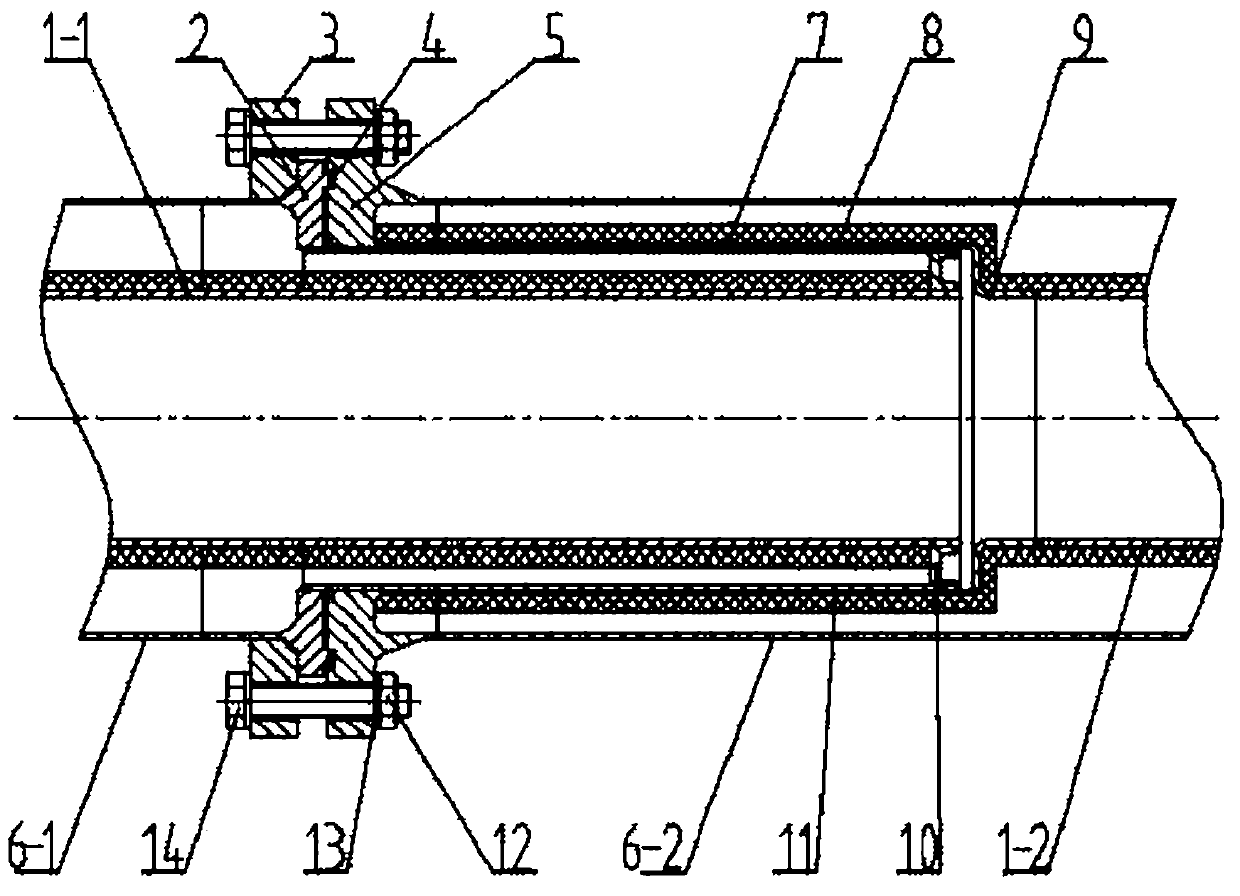

[0013] This embodiment is a vacuum insulation cryogenic pipeline flange connection joint, and its specific structure is as follows figure 1 As shown, the first pipeline and the second pipeline that are connected to each other are respectively composed of inner tubes 1-1, 1-2 coated with heat insulating material 11 and outer tubes 1-1, 1-2 that are sleeved outside to form a vacuum interlayer. The tubes 6-1 and 6-2 are composed; the end surface of the inner tube 1-1 of the first pipeline exceeds the port of the outer tube 6-1 of the first pipeline, and the end surface of the outer tube 6-2 of the second pipeline exceeds the inner tube 1-1 of the second pipeline 2 ports.

[0014] The end of the first pipeline outer tube 6-1 on the left has a joint plate 2 extending radially inward and outward, the inner hole of the joint plate 2 extends axially outward to form a sleeve-shaped flange heat bridge 8, and the end of the flange heat bridge 8 It is welded with the port of the inner pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com