Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

477results about How to "No jitter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

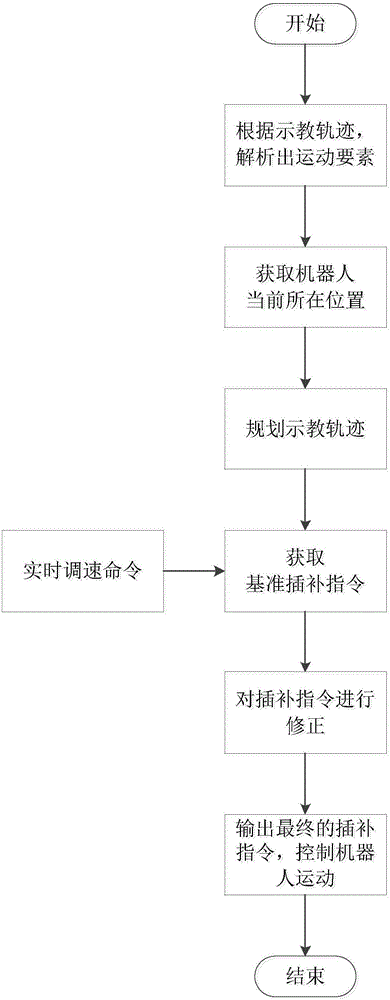

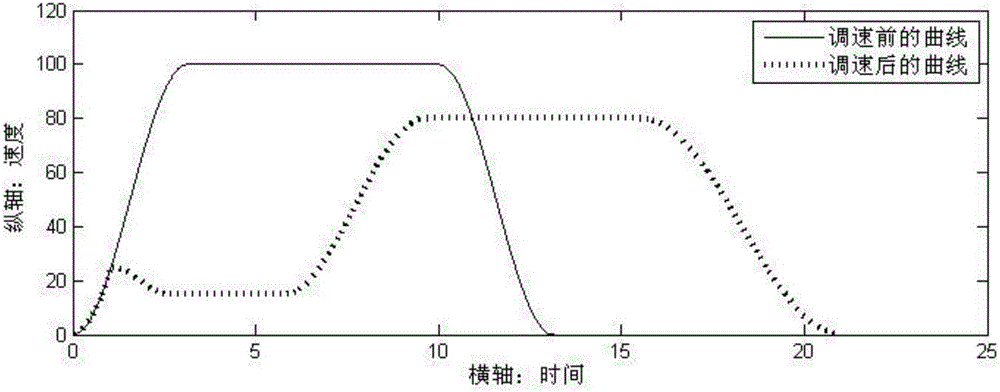

Method for adjusting running speed of robot in real time

ActiveCN106584462AExtend working lifeGuaranteed continuityProgramme-controlled manipulatorPosition/course control in two dimensionsControl systemEngineering

The invention discloses a method for adjusting running speed of a robot in real time. Movement elements are analyzed through a demonstrating track, track planning and interpolation are carried out, and an interpolation command is corrected by inputted speed adjusting parameters to achieve the purpose of adjusting the speed in real time. According to the control command corrected by the method, a curve can be changed smoothly and continuously, so that stress on a mechanical system is not impacted or changed suddenly, a control effect is soft, and loss on moving parts is reduced. Meanwhile, the method is simple in control logic and small in calculated amount, and meets control requirements on instantaneity of a robot control system. When the speed is adjusted, only a standard process requires to be demonstrated according to actual working conditions, then a monitoring terminal is debugged to transmit different speed adjusting commands, a robot control system responds the received speed adjusting parameters so that the effect of changing the running speed of the robot can be achieved, work complexity of operators is greatly simplified, the field processing efficiency is improved, and standardized operation of the robot is facilitated.

Owner:NANJING ESTUN AUTOMATION CO LTD +1

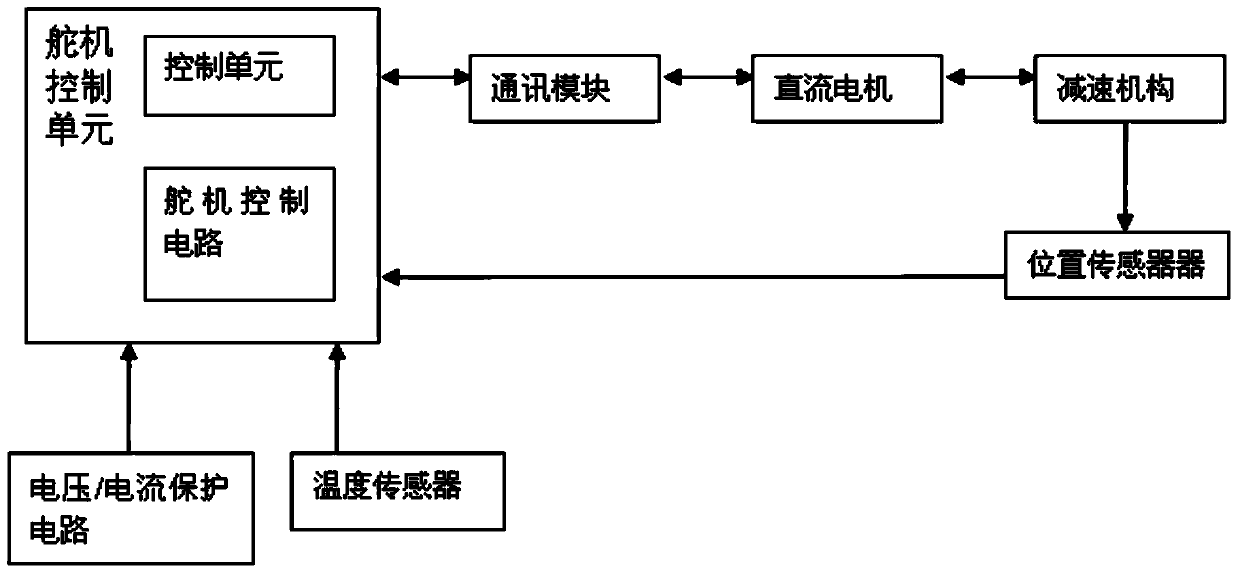

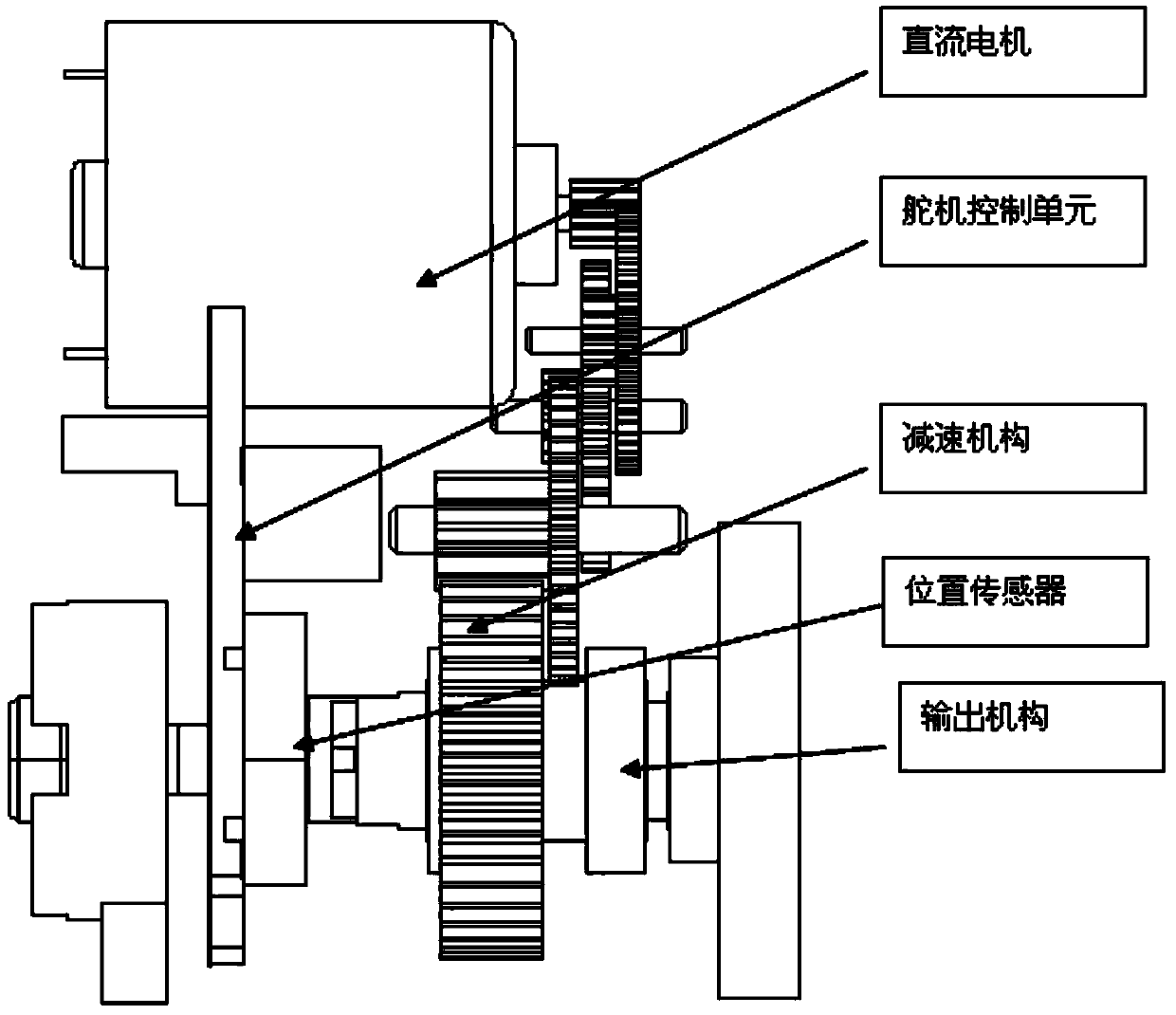

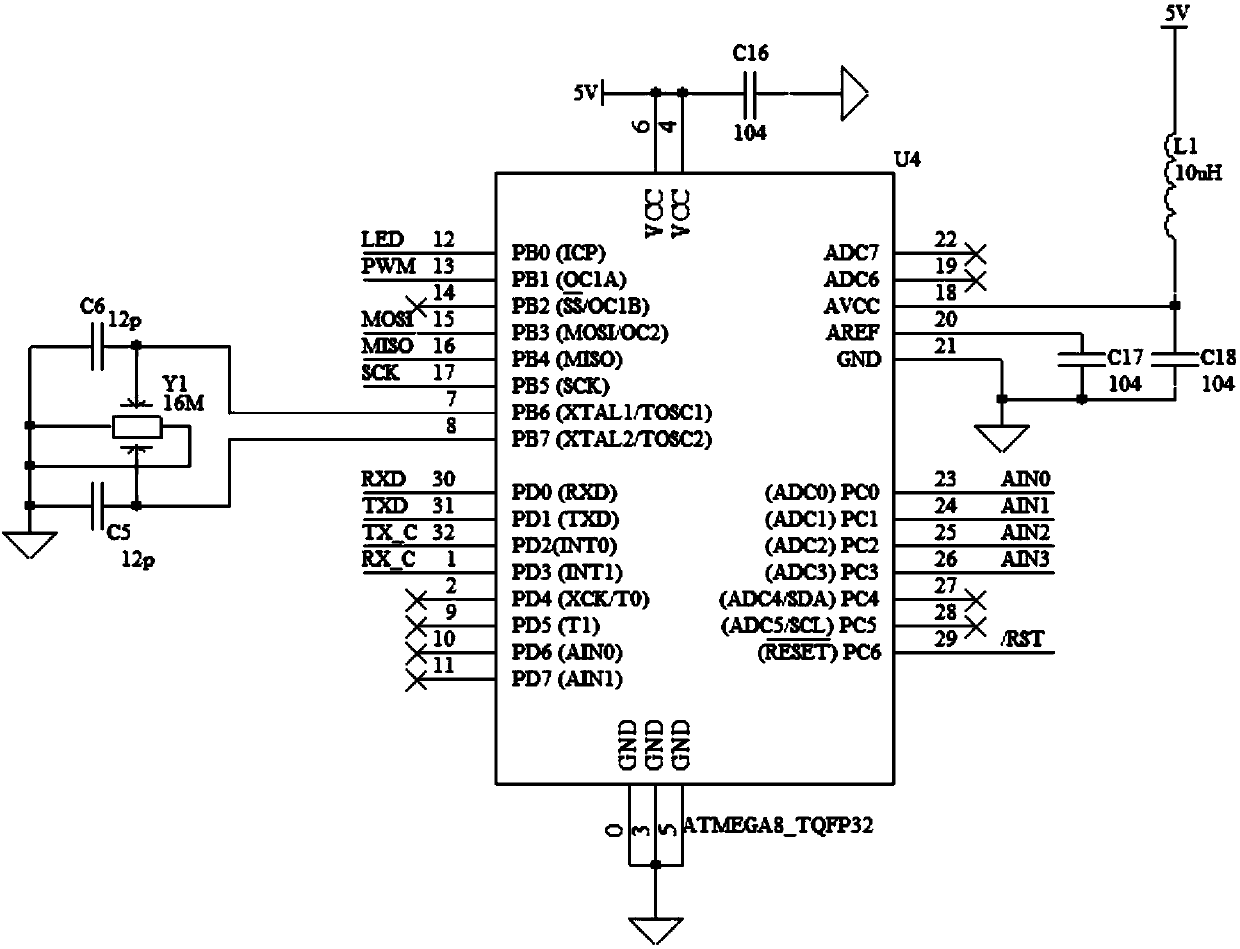

Device and method for controlling single-bus modular digital actuator of robot

ActiveCN103753535AImprove performanceQuick responseProgramme-controlled manipulatorJointsOvervoltageClosed loop

The invention relate to a device and a method for controlling a single-bus modular digital actuator of a robot. The device comprises an actuator control unit, a direct-current motor, a communication module, a speed reduction mechanism, position and temperature sensors and a current protection circuit. The method includes that the actuator control unit computes control parameters according to the running temperatures, driving currents of the motor and the position of the actuator and outputs the control parameters to a motor control circuit; the communication module receives control instructions of an upper computer and feeds information of the current position of the actuator, the current speed of the actuator and the like to the upper computer; a high rotational speed and low torque of the motor are converted into a low rotational speed and high torque by the speed reduction mechanism and an output mechanism, and the low rotational speed and the high torque are outputted by the speed reduction mechanism and the output mechanism; the position sensor, the temperature sensor and the current protection circuit are respectively used for feeding current position signals of the actuator, the running temperatures and the driving currents of the motor to the actuator control unit, so that closed-loop high-precision safety control can be implemented. The device and the method have the advantages of overcurrent, overvoltage and over-temperature protection, capability of preventing overload or over-temperature damage, high response speed, zero dead zones and high control precision.

Owner:UBTECH ROBOTICS CORP LTD +1

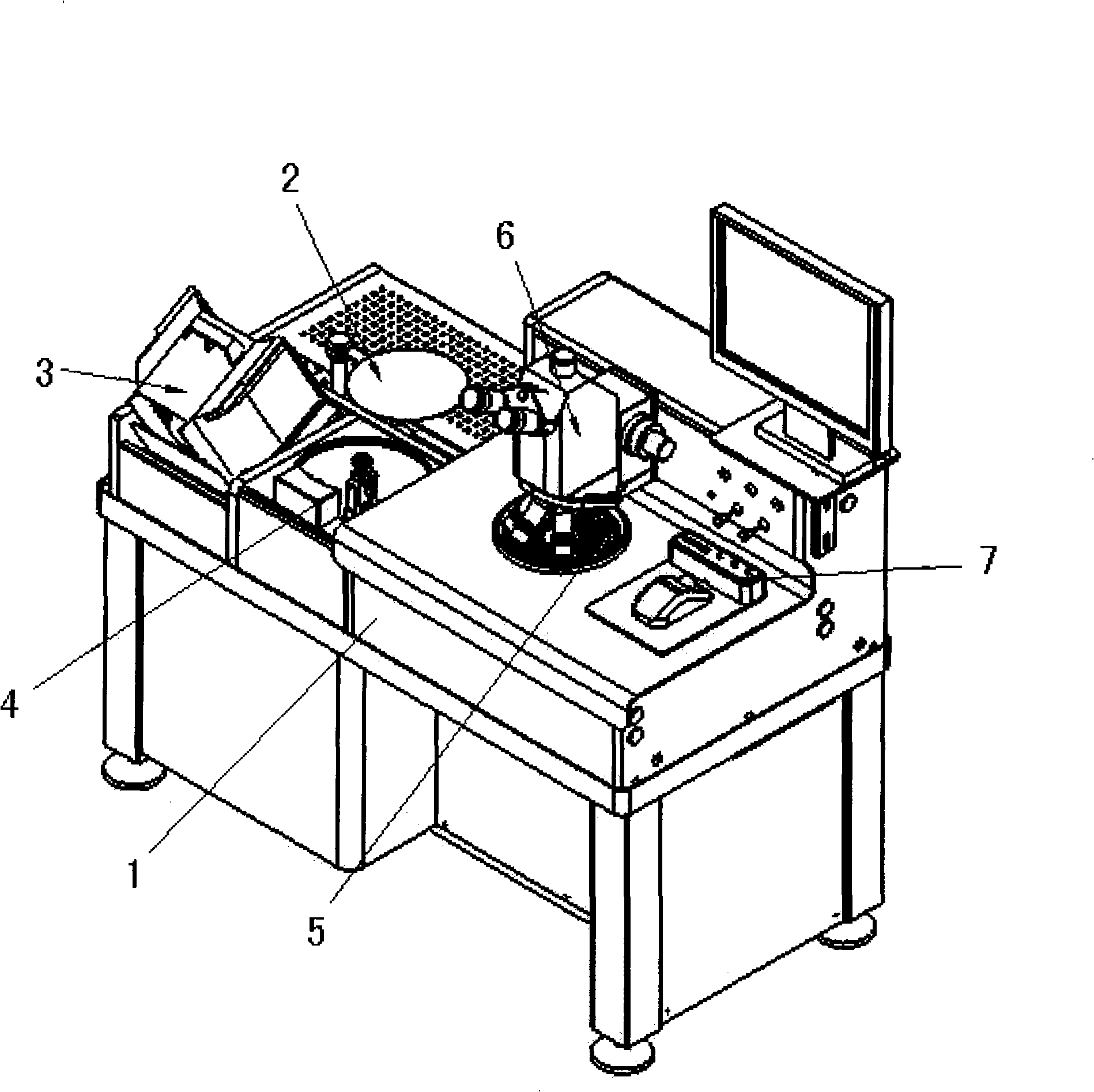

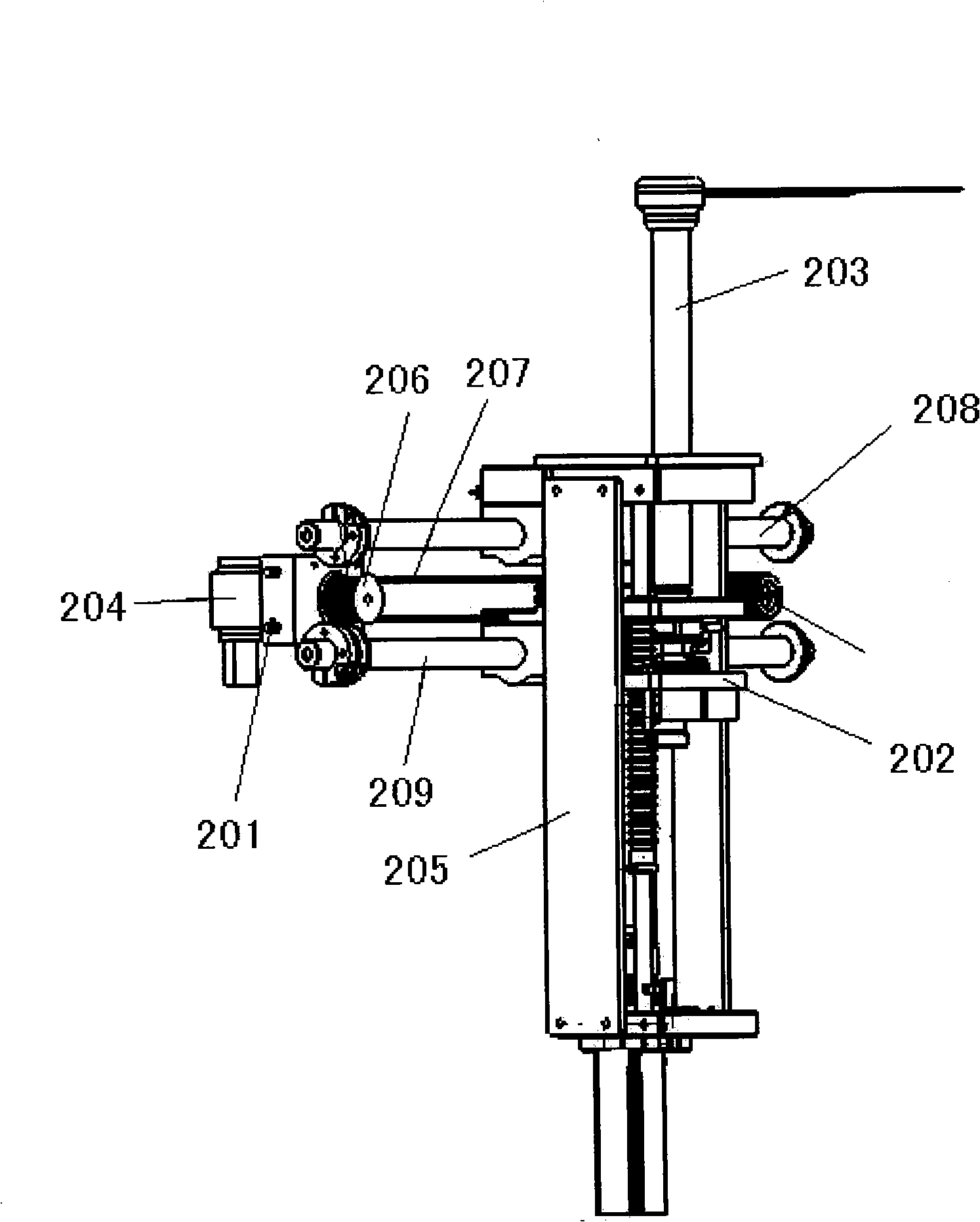

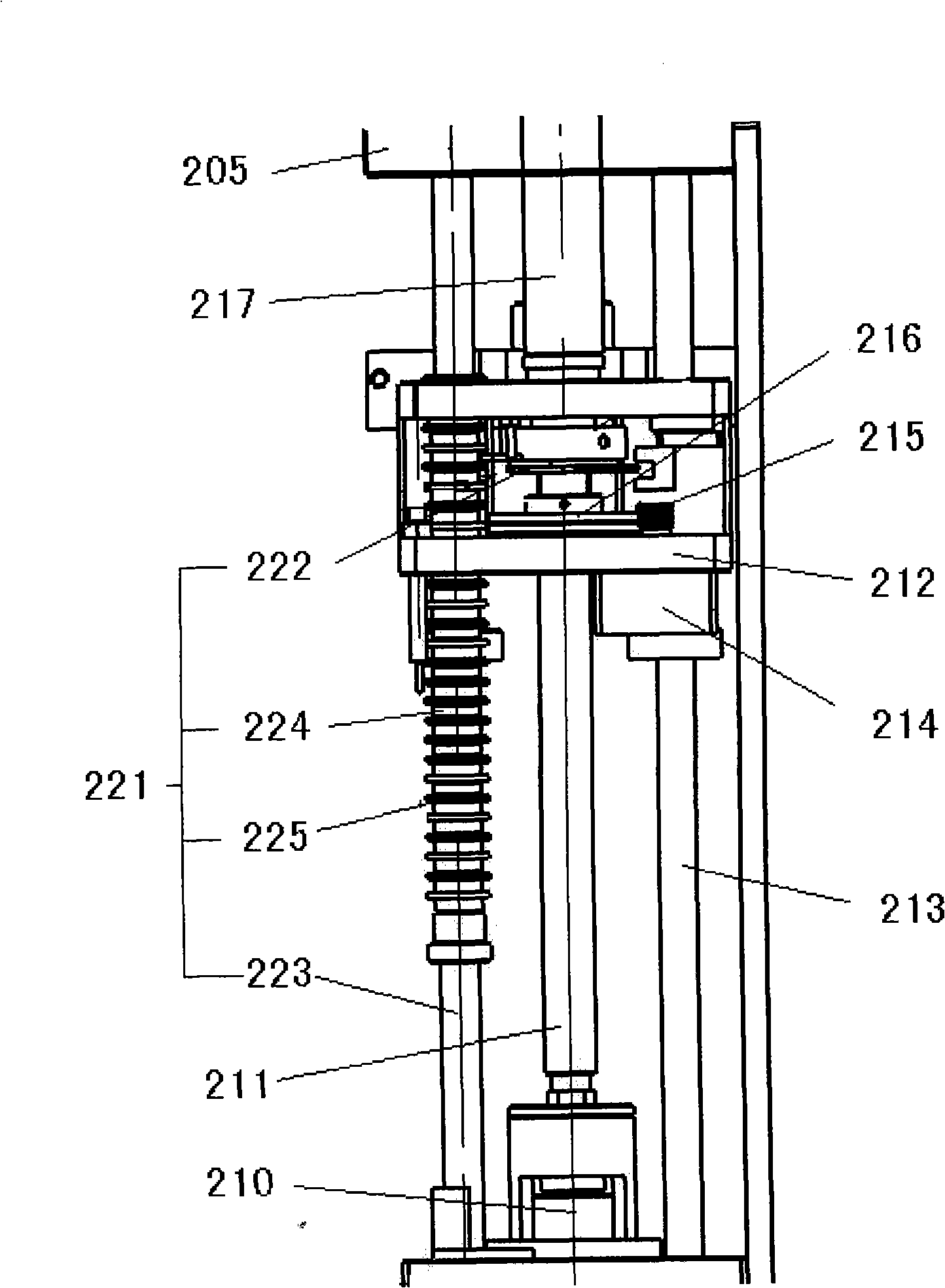

Automatic control silicon chip check system

ActiveCN101409245AFew structural partsReduce mechanical frictionSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingAutomatic controlSilicon chip

The invention relates to an automatic control silicon wafer detection system which comprises an operation table provided with a mechanical hand for taking and sending a silicon wafer, a silicon wafer box platform, a silicon wafer surface detection mechanism, an object stage, a lens set and a vacuumizing device, and the automatic control silicon wafer detection system also comprises a computer system used for controlling all devices. The mechanical hand comprises a three-dimensional horizontal, vertical and rotary motion mechanism which finishes the linear movement which forms certain angle with the horizontal movement direction at certain altitude. The silicon wafer box platform comprises a crank link mechanism. A connecting bar supports a pitching swing turnover plate. A silicon wafer box is arranged on the turnover plate. The silicon wafer surface detection mechanism is provided with a vacuum chuck which can process horizontal revolution, pitching swing and autorotation. The silicon wafer is arranged on the chuck. The object stage comprises a lower layer guideway set which drives an upper layer guideway set and the object stage for coarse positioning, the upper layer guideway set drives the object stage for precise positioning, and the lens set is arranged above the object stage. The automatic control silicon wafer detection system takes, sends and observes the silicon wafer fast and conveniently, and each device can be used in a combination way and can also be used separately.

Owner:陈百捷 +1

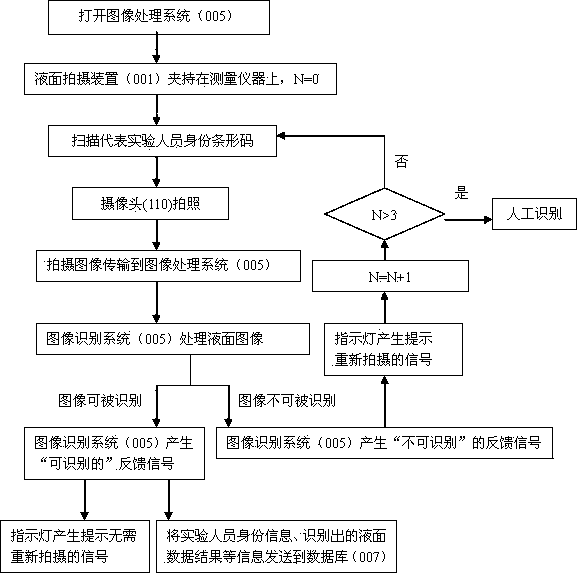

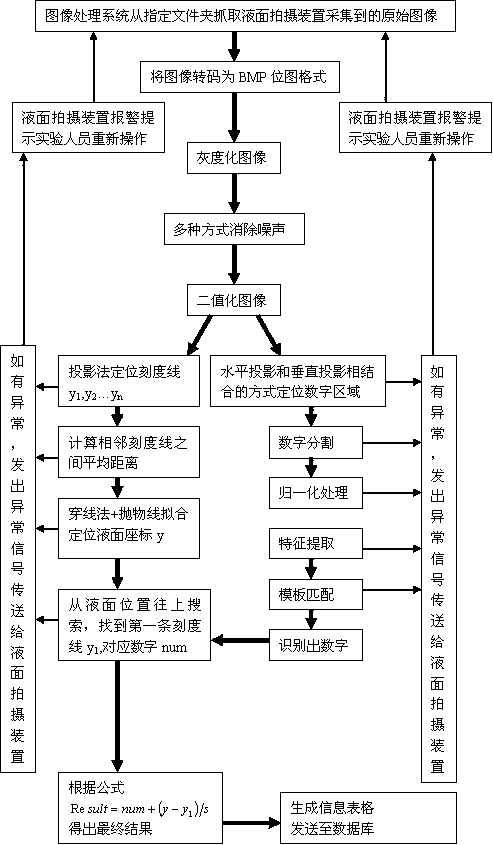

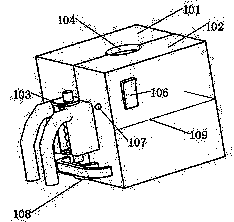

System and method for collecting and identifying images of capillary pipe liquid level type data

InactiveCN103487104ANo jitterNo distractionMachines/enginesLevel indicatorsImaging processingMeasuring instrument

The invention provides a system and a method for collecting and identifying images of capillary pipe liquid level type data of a measuring instrument, which are used for intelligently reading and recording the capillary pipe liquid level type data needing to be manually read in the measuring instrument. The system for collecting and identifying the images of the capillary pipe liquid level type data in the measuring instrument comprises a liquid level shooting device, a bar code scanning module, a data transmission module, a computer, an image processing system, a client user interface module, a database and a monitoring module. The system and the method have the advantages that the liquid level shooting device which can be closed is fixed in the capillary pipe liquid level position of the measuring instrument by a movable clamping mechanism, and an image is shot under the control of the bar code scanning module when a camera and a bracket are not touched, so the liquid level image can be obtained without dithering and interference by other object images, and the intelligent identification difficulty of the liquid level data is reduced.

Owner:QINGDAO UNIV

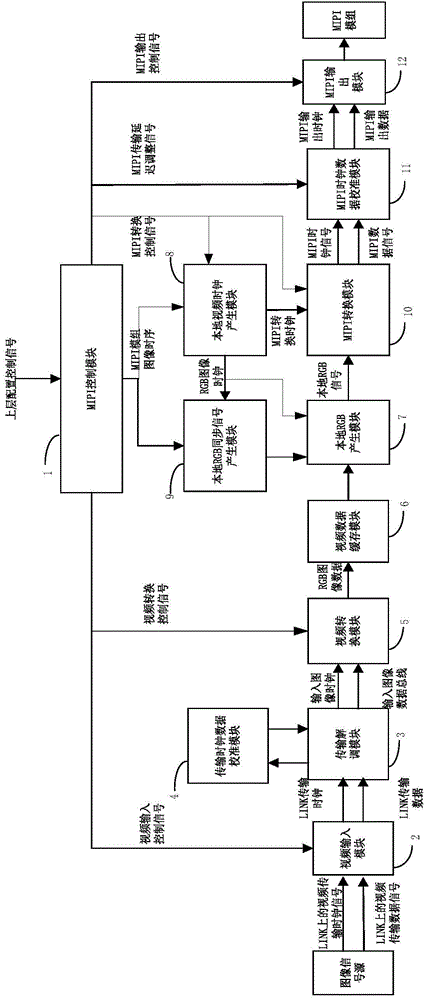

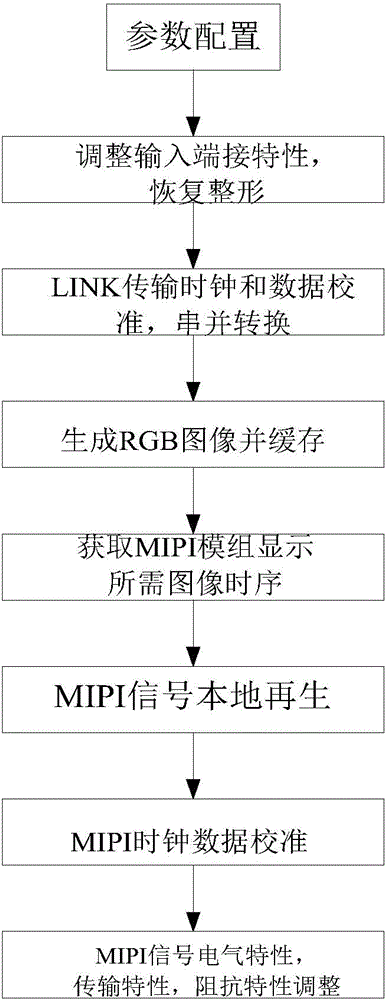

Method and system for generating MIPI (mobile industry processor interface) signals for MIPI module detection

ActiveCN104952421AData received correctlyAvoid demodulation errorsCathode-ray tube indicatorsRgb imageFpga chip

The invention discloses a method and a system for generating MIPI (mobile industry processor interface) signals for MIPI module detection. RGB image data are acquired through link video signals and then MIPI signals are acquired through the RGB image data. To be specific, the method comprises steps as follows: before the RGB signals are converted into the MIPI signals, the RGB image data converted from the video signals are cached; a local RGB image pixel clock is acquired according to required image timing sequence parameters displayed by an MIPI module; a stable local image timing sequence is generated under the control of the RGB image pixel clock according to the image timing sequence parameters, and image synchronization signals meeting the MIPI module detection requirement are generated; under the control of the image synchronization signals, MIPI conversion is performed on the cached RGB image data, and the MIPI signals meeting the MIPI module detection requirement are acquired. The system for generating MIPI signals for MIPI module detection can be realized on one FPGA (field programmable gate array) chip and has the characteristics of easiness in implementation, lower cost, convenience in operation, work stability, high reliability and the like.

Owner:WUHAN JINGCE ELECTRONICS GRP CO LTD

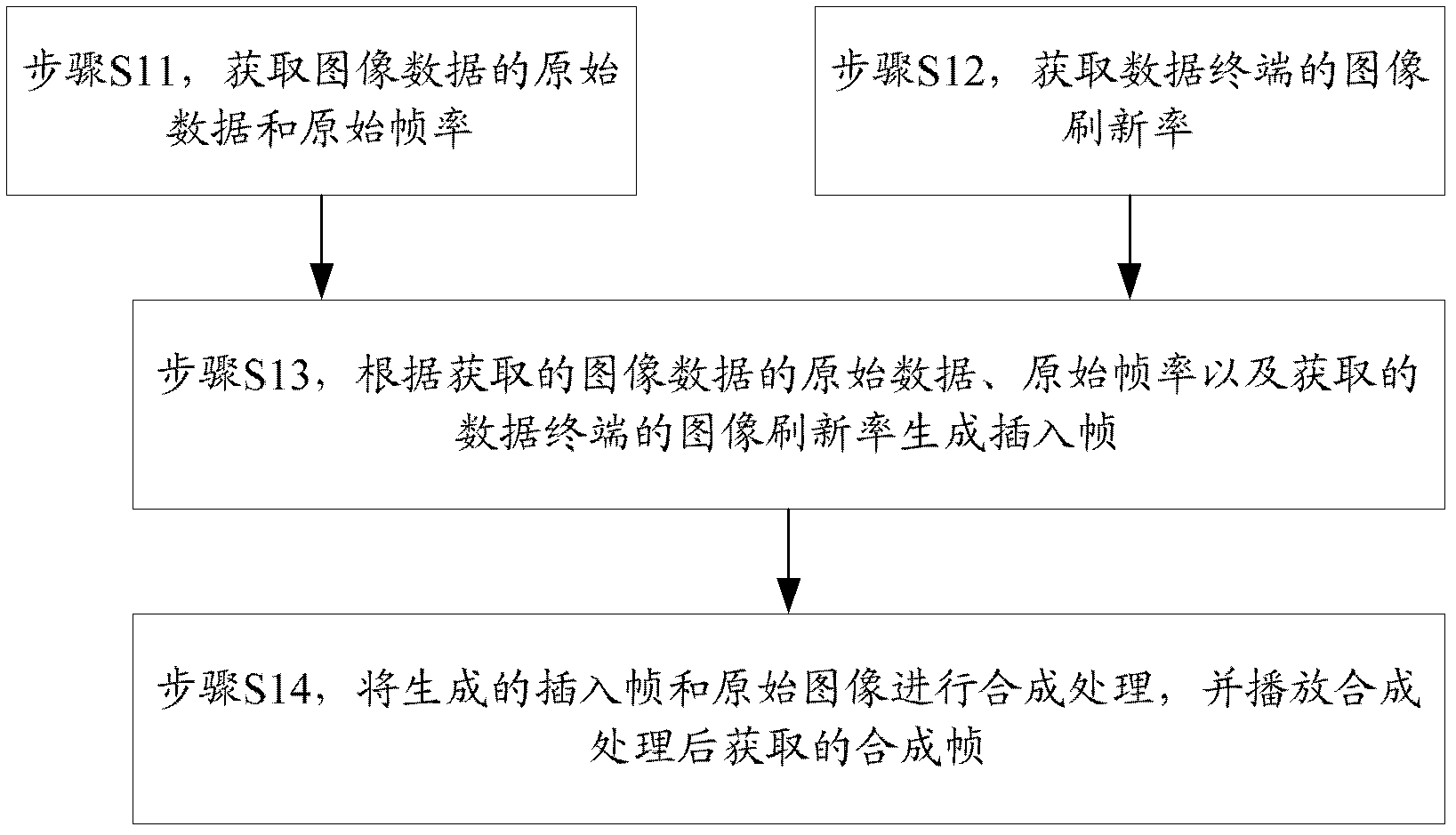

Method and monitor for compensating video image

InactiveCN102685437APlay a compensatory roleNo jitterCathode-ray tube indicatorsStandards conversionData terminalImaging processing

The invention is suitable for the field of processing a video and provides a method and a monitor for compensating a video image. The method comprises the steps of: obtaining primary data and primary frame rates of image data; obtaining an image refresh rate of a data terminal; generating an insert frame according to the obtained primary data and the obtained frame rates of the image data and the obtained image refresh rate of the data terminal; and carrying out synthesis processing for the generated insert frame and a primary image, and playing a synthesis frame obtained after the synthesis processing. In the embodiment of the invention, the image data of the insert frame are calculated according to an obtained motion vector of the primary data by processing the primary date without directly adopting the primary data of the image, thus the image data of the insert frame can reflect a motion trail of an object and can play a corresponding compensation role for images under various scenes, the synthesis frame comprising the insert frame can be smoothly played, and the played image processing effect can be more ideal.

Owner:SHENZHEN SKYWORTH QUNXIN SECURITY TECH

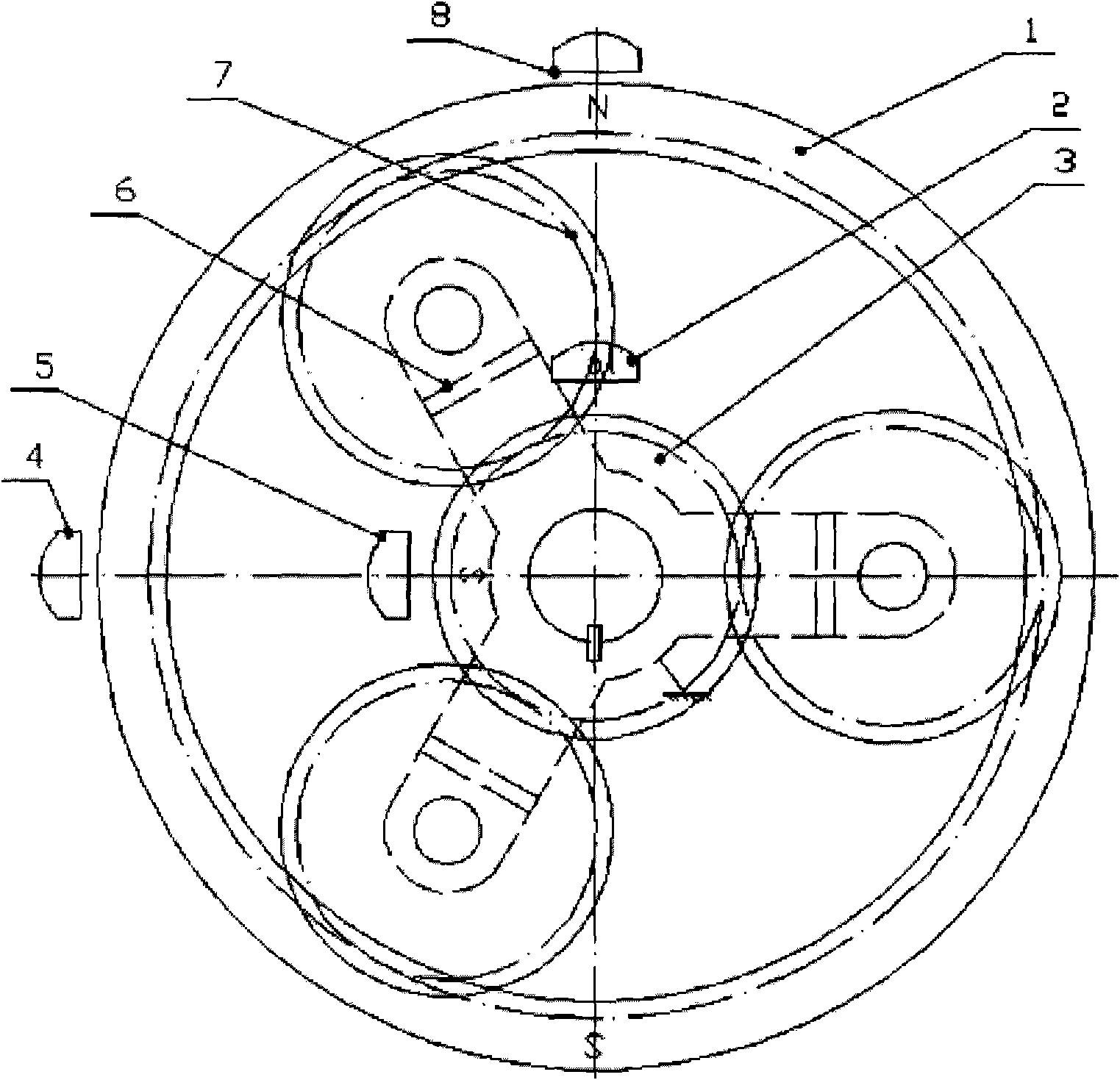

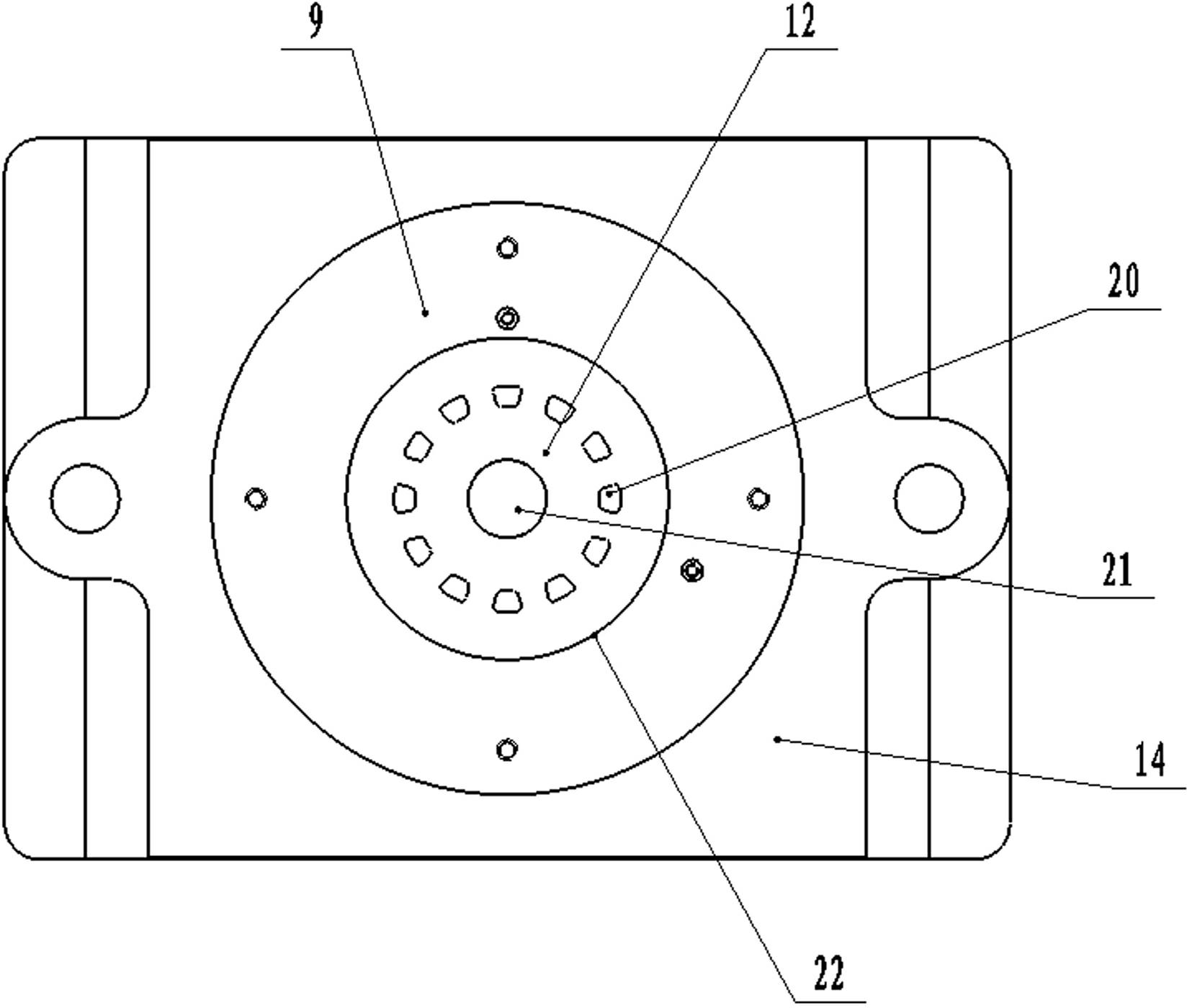

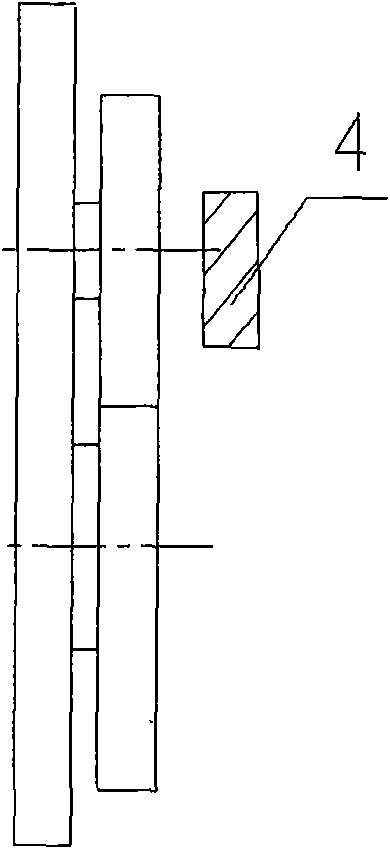

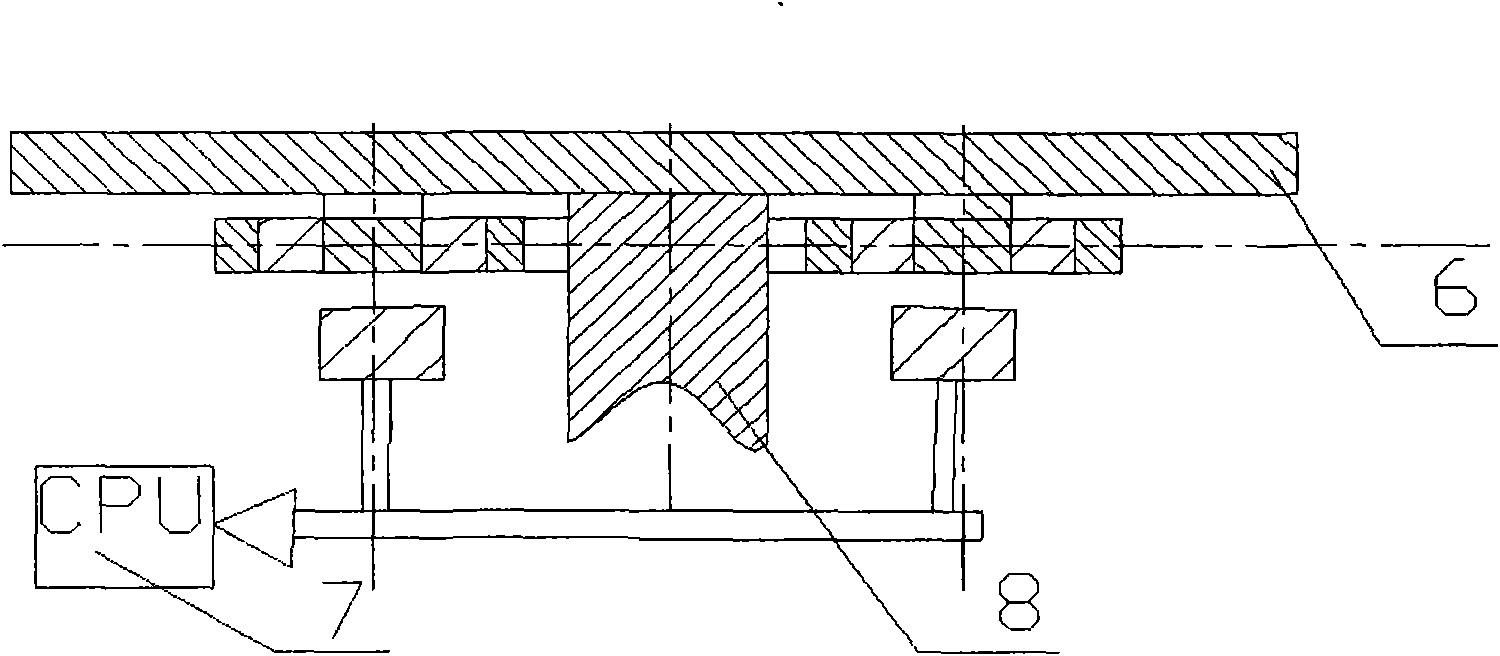

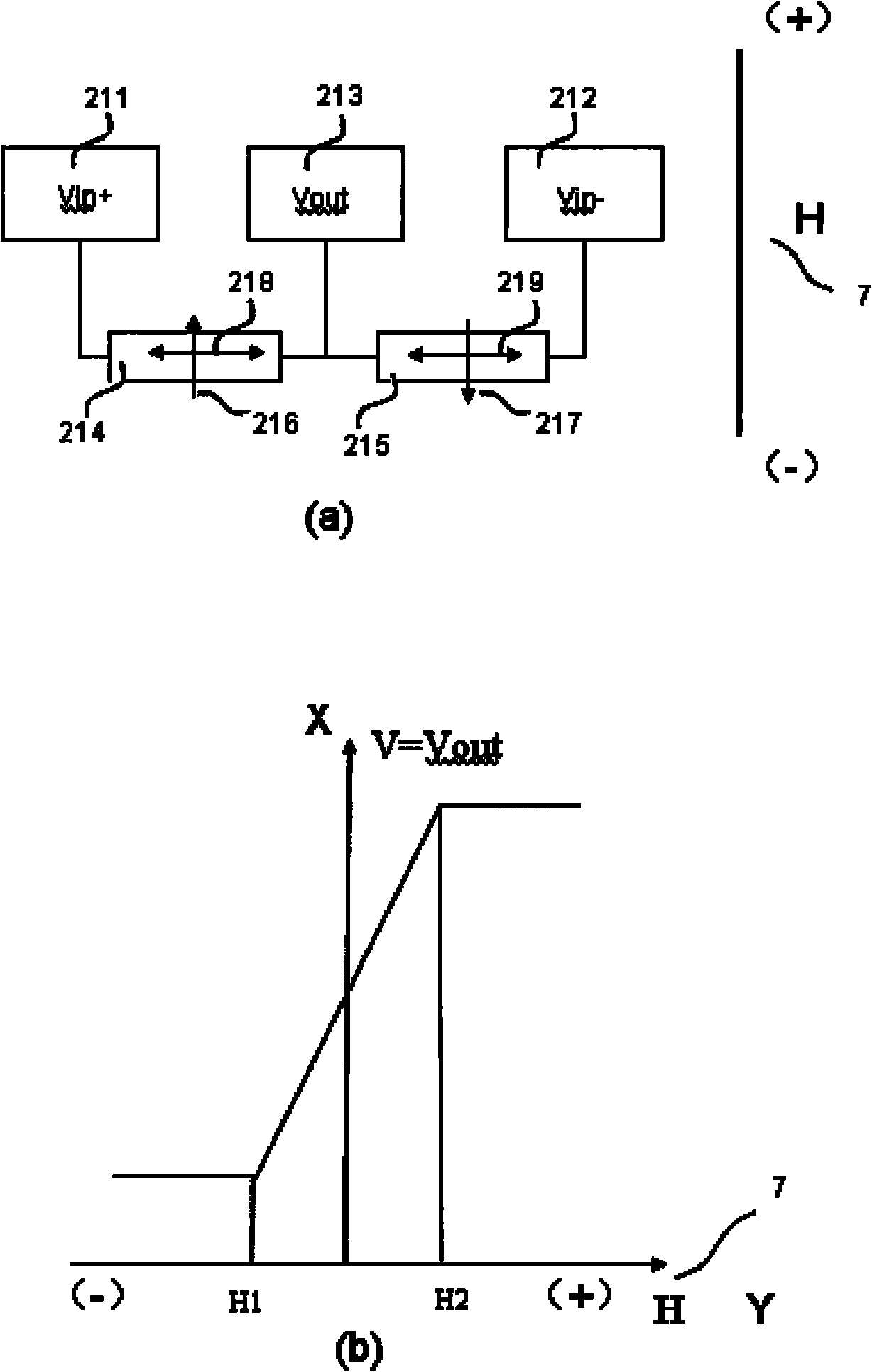

Steering system planetary gear absolute angle output corner sensor

InactiveCN101608898ALow environmental requirementsImprove performanceUsing electrical meansElectrical steeringGear wheelMagnetic poles

The invention relates to a steering system planetary gear absolute angle output corner sensor, mainly composed of a gear ring (1), a sun gear (3), planetary gears (7), a CPU control unit (11) and Hall sensors; wherein the sun gear is a magnetic gear, and the sun gear and the gear ring are all provided with a pair of magnetic poles; the sun gear is fixed on a steering column (9), and the steering column is fixedly connected with an auto steering wheel; the quantity of the planetary gears is three, the planetary gears are evenly distributed and fixedly arranged on a planet carrier (9) and are connected with the sun gear and the gear ring in a meshed way, and the planet carrier is fixed at the upper part of a sleeve; a pair of Hall sensors are respectively arranged near the sun gear and the magnetic poles of the gear ring, and each pair of Hall sensors are arranged in 90 degrees; and the Hall sensors are connected with the CPU control unit (11) by a data line. The invention has the advantages of low requirement on environment, high cost performance, wide measurement range, insensitivity to error caused by temperature and convenient installation.

Owner:WUHAN UNIV OF TECH +1

Optimized stamping process of dst structure diaphragm spring

The invention discloses an optimized stamping process for a diaphragm spring with a DST structure, comprising the following steps of: placing a wear-free 50CrVA cold-rolled sheet on a punch press to blank and stamp a mesopore, blanking a diaphragm outer circle shape, a mesopore and a window shape with gaps by a window mould, then stamping a separated finger slot at one time on the punch press viaa separated finger slot stamping die; directly pressing a window fillet at one time on a press via a window fillet mould; and finally performing heat treatment according to a conventional method. In the invention, the two separated procedures of blanking and stamping a mesopore and a window are combined into one procedure to process, which increases the production efficiency, decreases the production cost, decreases the accumulated error of a plurality of procedures and increases the dimensional precision of product; moreover, the problems of unreasonable distribution, non-uniform separated finger width, bad window positional tolerance and the like of diaphragm spring processing are solved; moreover, the product fatigue life is greatly increased; and shaking phenomenon while starting is avoided.

Owner:GUILIN FUDA

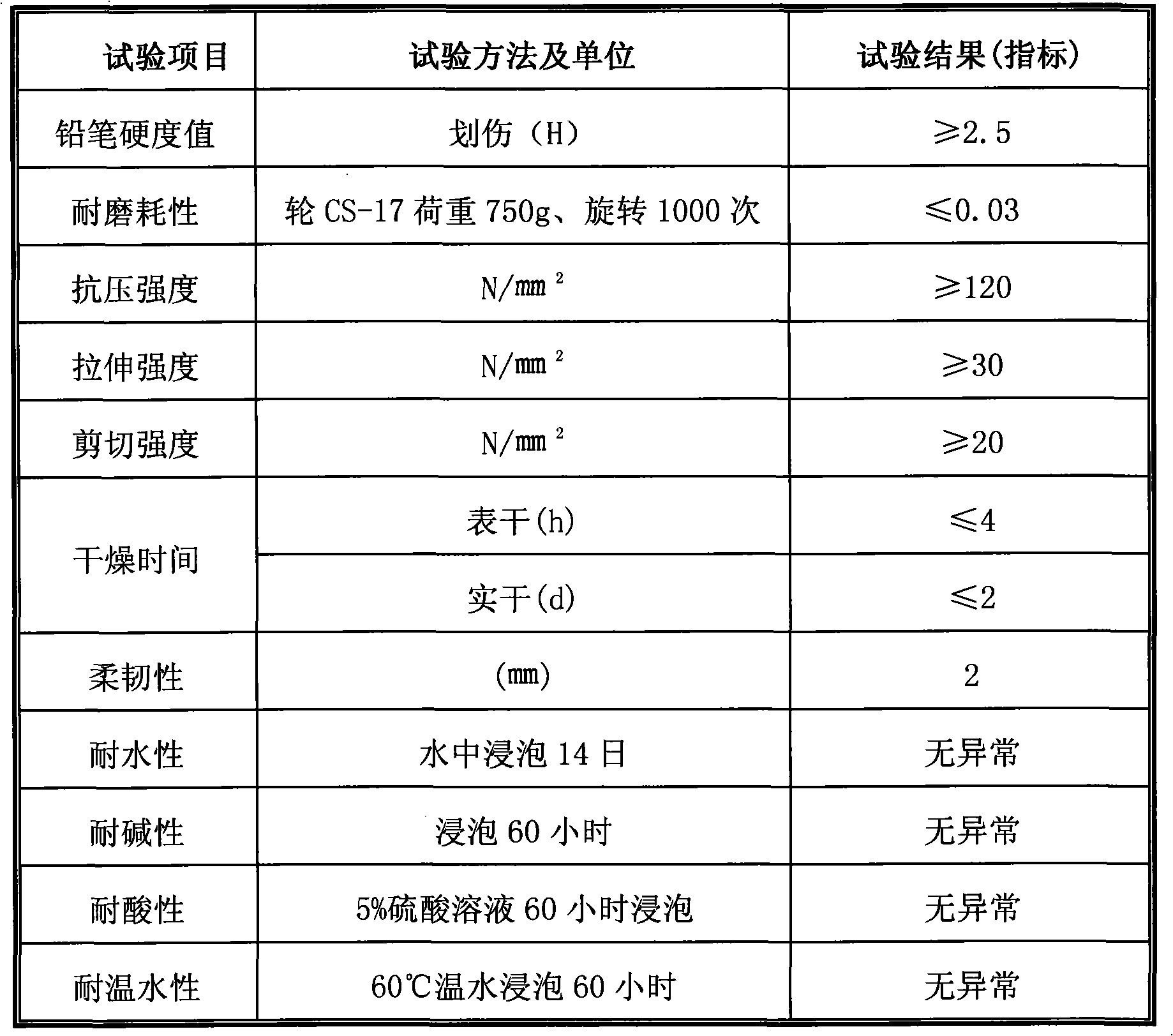

Construction method of wear-resistant non-slip ramp

InactiveCN101914886AStrong orientationReduce driving noiseIn situ pavingsClimate change adaptationWeather resistanceWear resistant

The invention discloses a construction method of a wear-resistant non-slip ramp, which comprises the following steps: clearing a concrete base, coating a base finishing agent, constructing a base coat, painting a high-strength putty layer, constructing wear-resistant non-slip size, processing a closing cover layer, constructing polished surface coating and maintaining. The ramp prepared by the invention has simple structure, convenient construction, low cost, slip prevention, wear resistance, pressure resistance, impact resistance, oil stain resistance and weather resistance.

Owner:LONGXIN CONSTR GRP

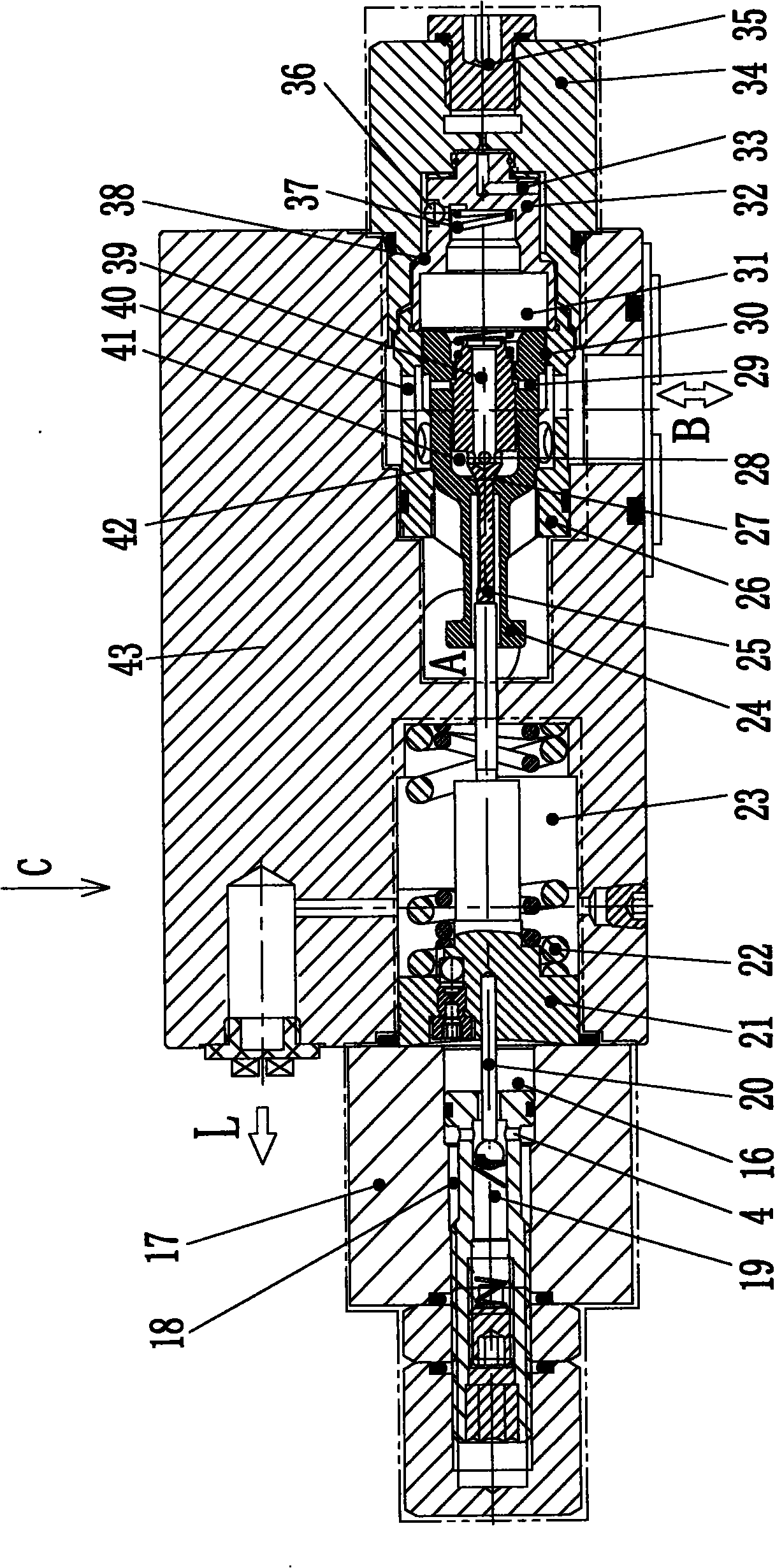

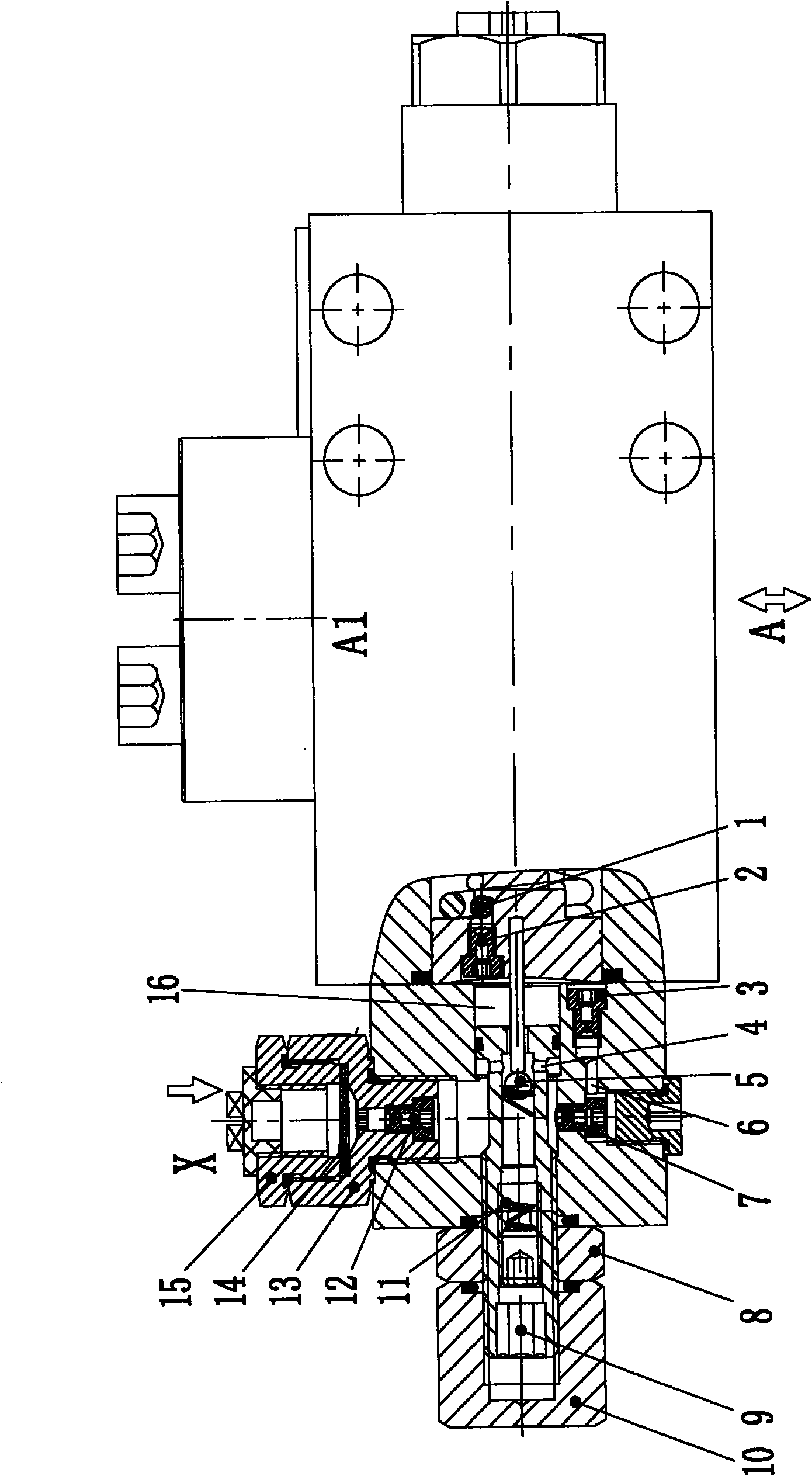

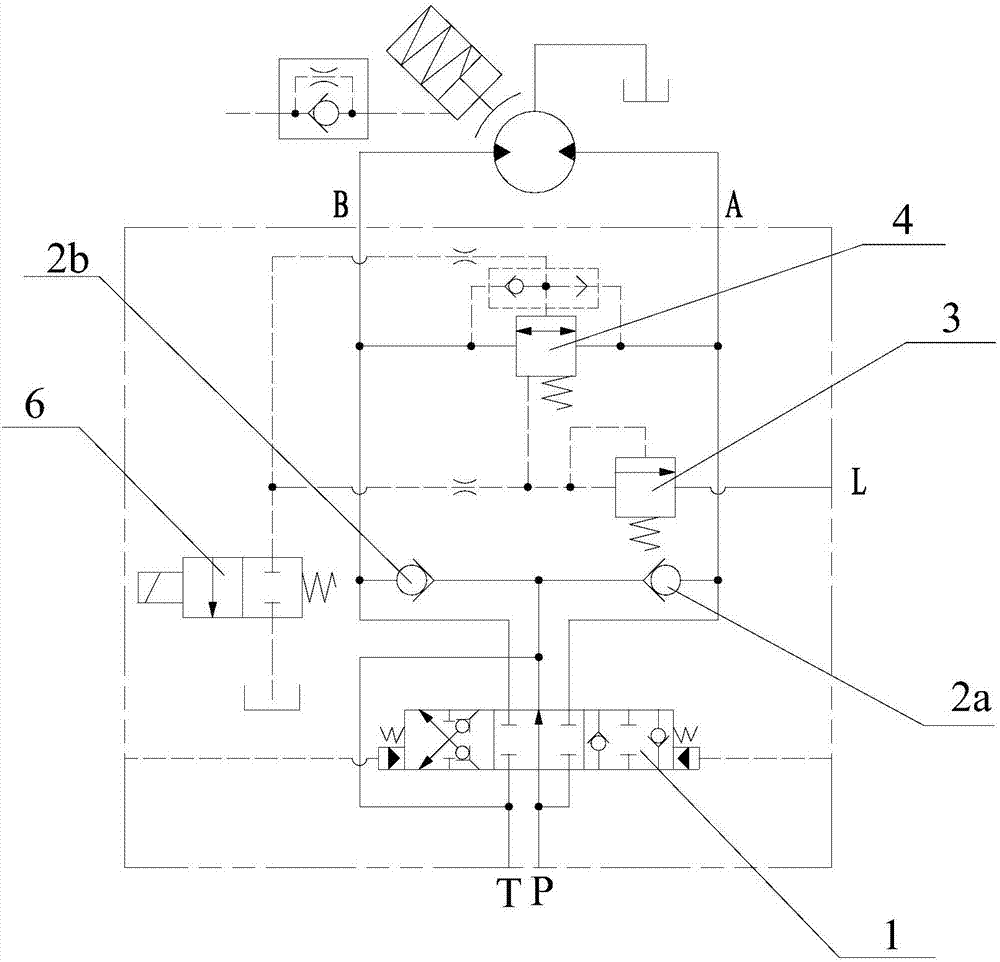

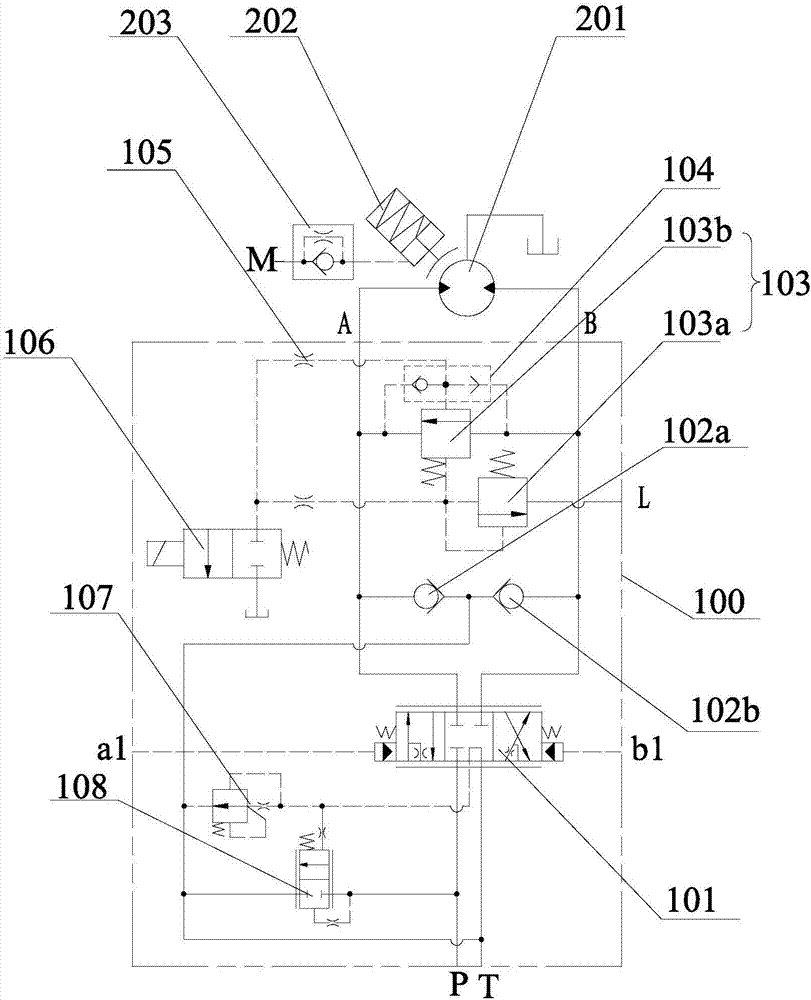

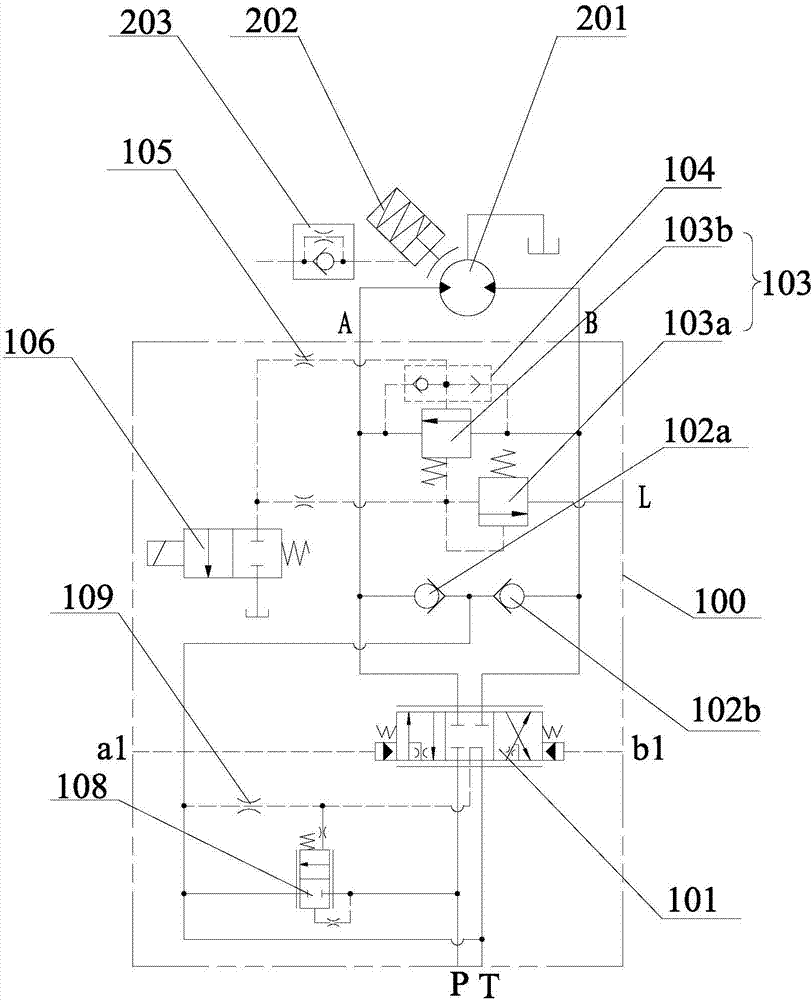

Hydraulic balanced valve

ActiveCN101893010AFast response timeShort response timeServomotor componentsSteel ballControl valves

The invention relates to a hydraulic balanced valve. The hydraulic balanced valve comprises a main valve and a pilot valve, wherein a push rod base is arranged in a pilot valve body main hole of the pilot valve; a radial pore is formed on the push rod base; an axial hole is formed in the push rod base; a first steel ball is placed in the axial hole; a pressure adjusting spring is arranged betweenthe first steel ball and the push rod base; an axial pore is formed on the right end face of the push rod base; one end of a push rod passes through the axial pore and abuts against the first steel ball, while the other end is inserted into a blind hole on the left end face of a control valve core; the control valve core is arranged in a valve body of the main valve; and an ejector rod at the right end of the control valve core is extended into a main valve core to be opposite to a pilot valve core. The hydraulic balanced valve has the advantage of adjusting the response time of the control valve core so as to change the opening speed of a main valve port, effectively control the flowing amount of hydraulic oil and avoid the shaking phenomenon of a descending heavy object when a hanging arm operates.

Owner:SHANGHAI LIXIN HYDRAULIC

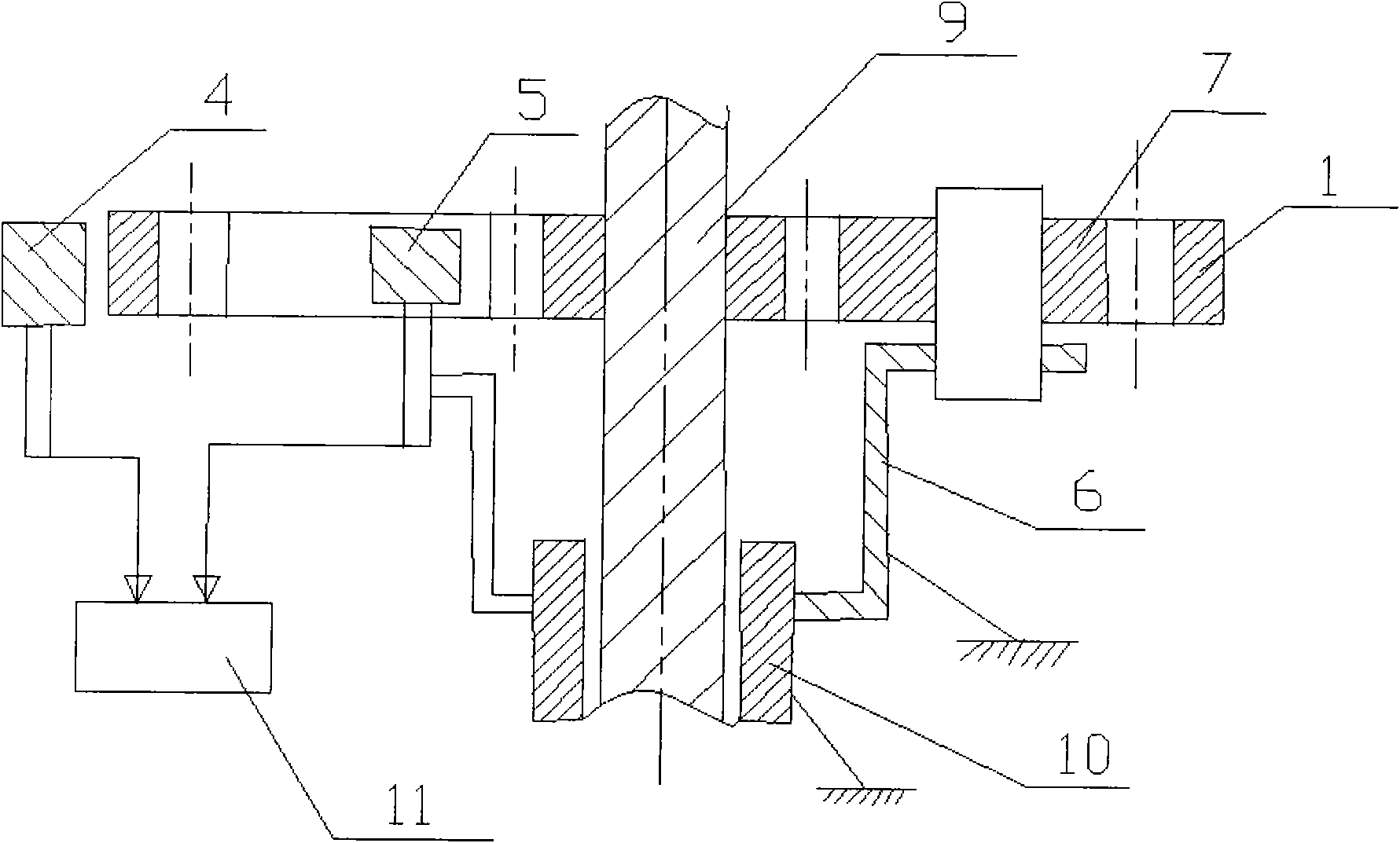

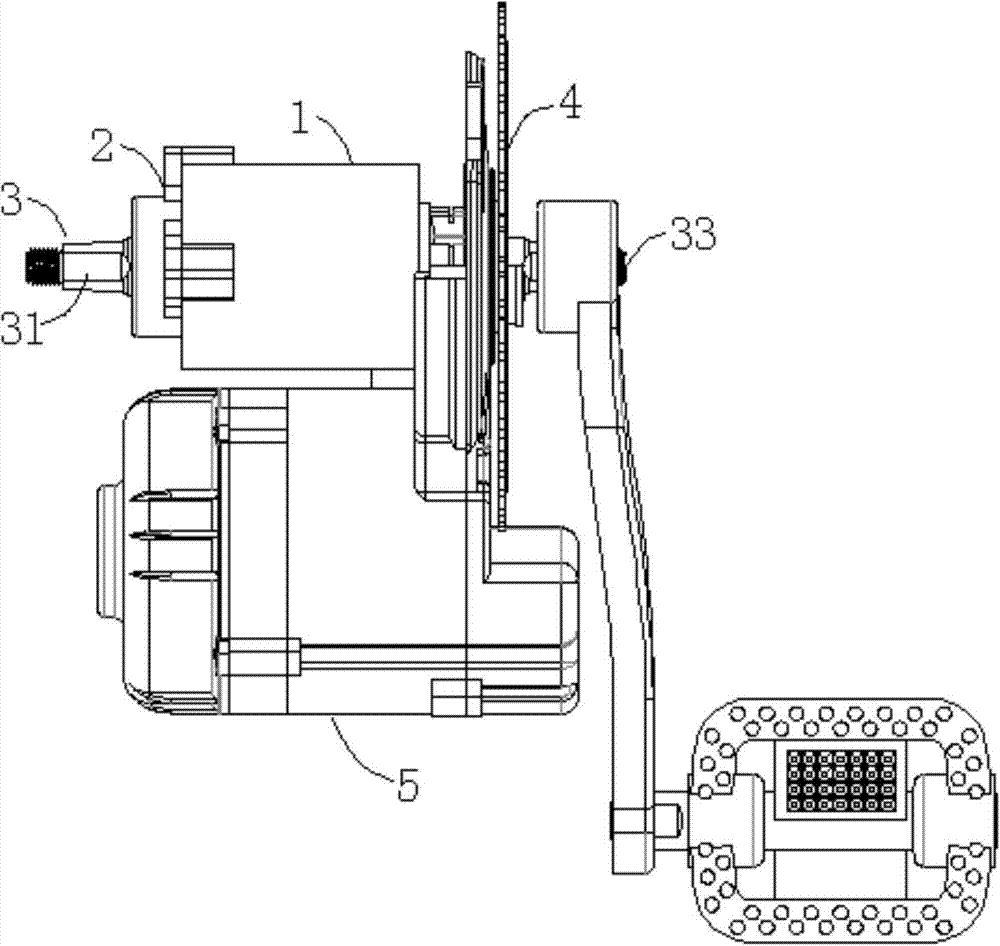

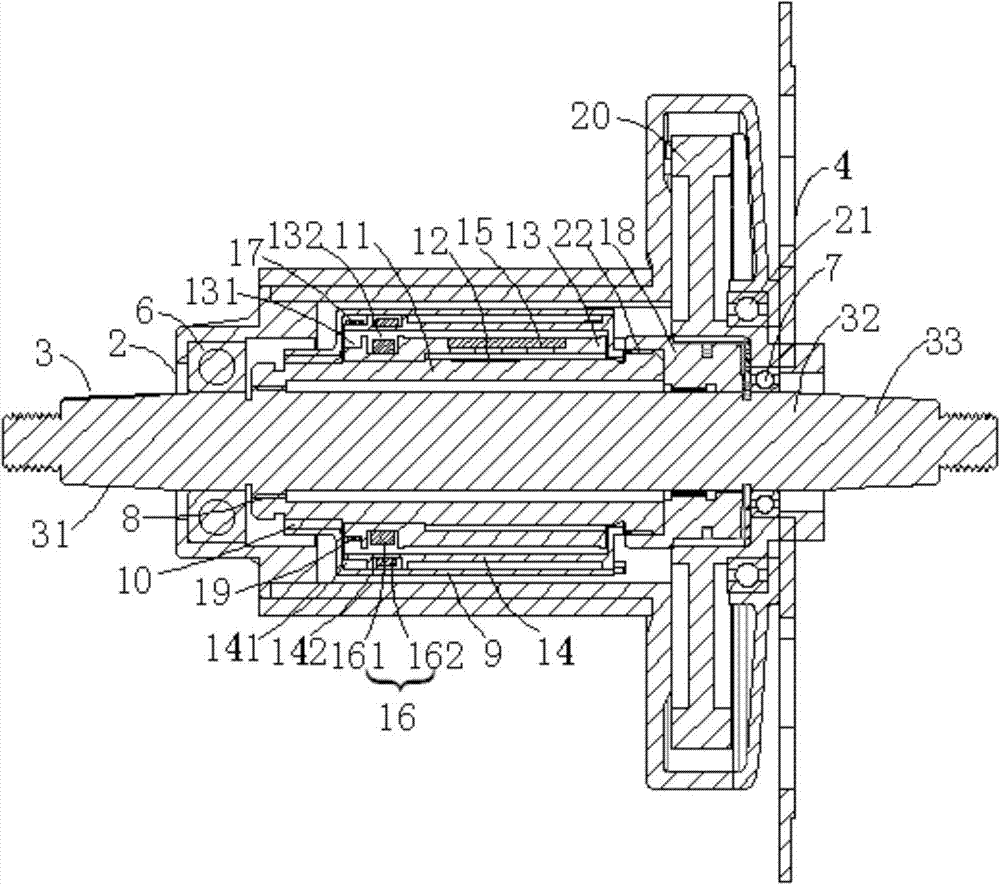

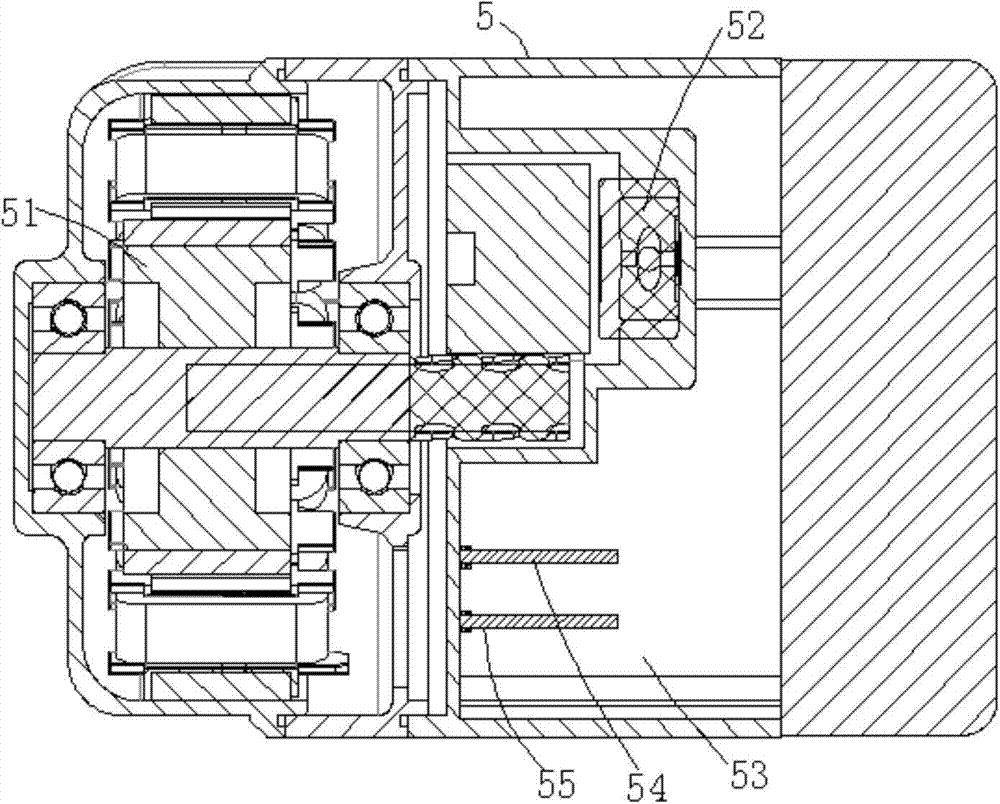

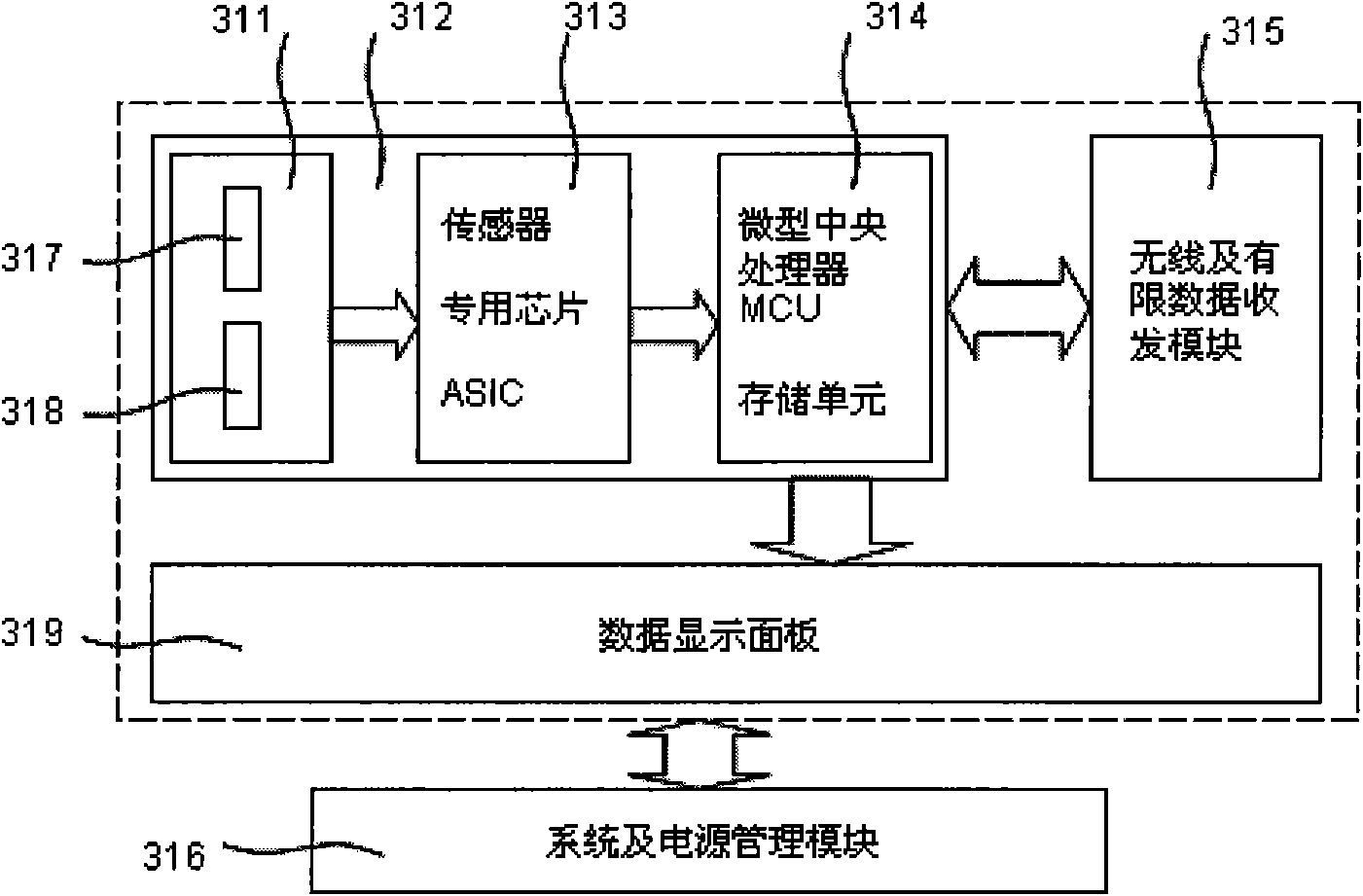

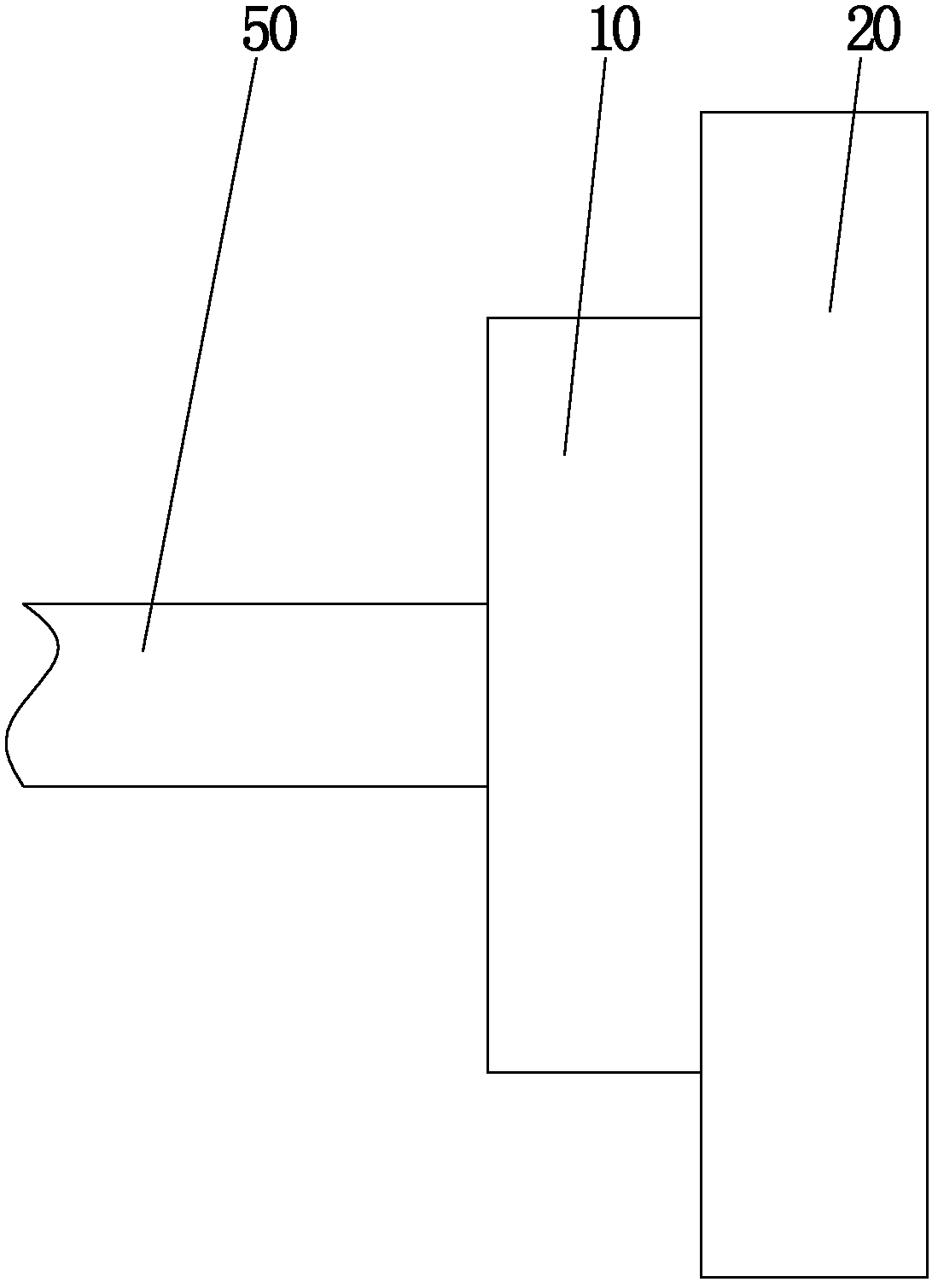

Central system based on wireless torque detection

The invention discloses a central system based on wireless torque detection. The system comprises a first shell, an intermediate shaft, a crankset and a second shell, wherein the intermediate shaft penetrates through the first shell, the crankset is fixed to the intermediate shaft through a clutch, the second shell is fixedly connected with the first shell, the first shell comprises a torsion barrel, a torque transducer and a first clutch, the torsion barrel is arranged on the intermediate shaft in a sleeved mode, and one end of the torsion barrel is fixedly connected to the first clutch; the torque transducer is fixed to the torsion barrel, and when the intermediate shaft is stressed, the torque is transmitted in the sequence of a left / right side pedal-the intermediate shaft-the torsion barrel-the first clutch-the crankset. The system can achieve zero starting, and the riding effect is outstanding; the system adapts to all road conditions, better assistance effect can be obtained on both low-speed riding and high-speed riding, the system has the advantages of being convenient to install and maintain, stable in work and the like, and the real relax riding purpose can be achieved for a user.

Owner:SUZHOU WANJIA ELECTRIC

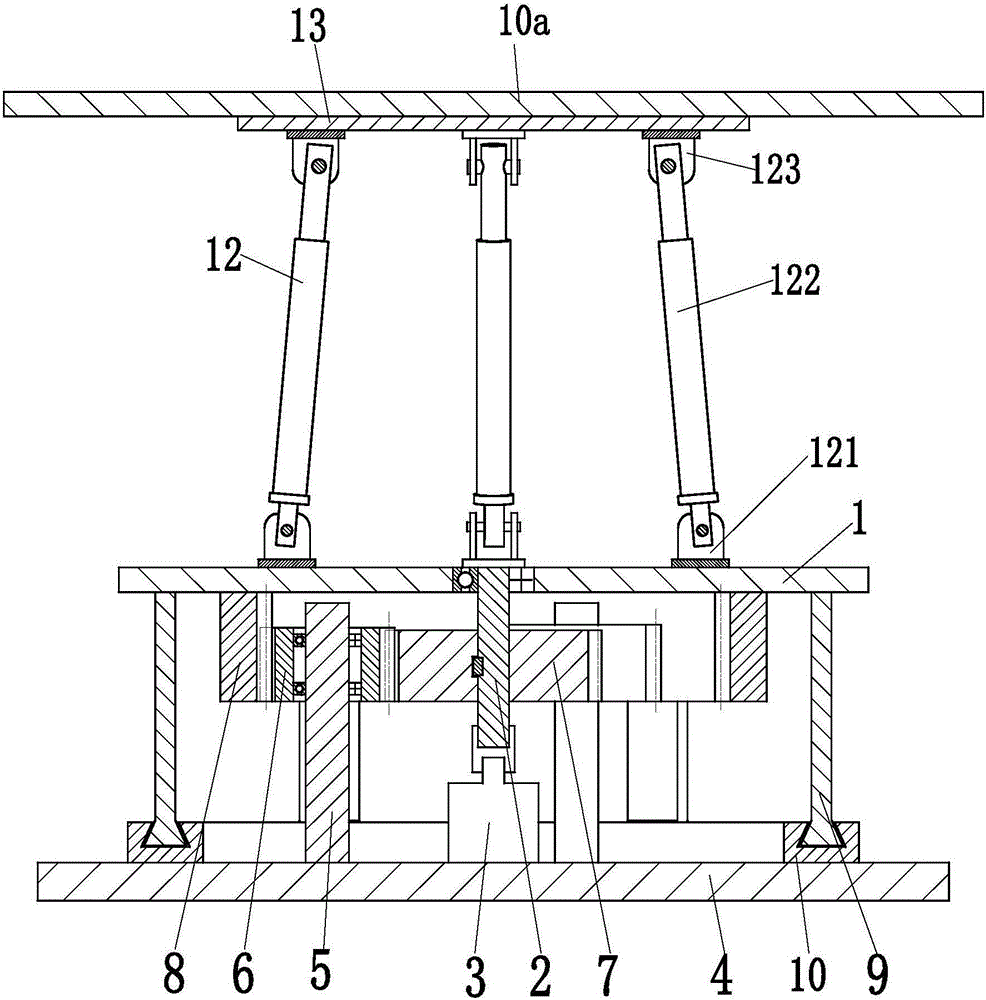

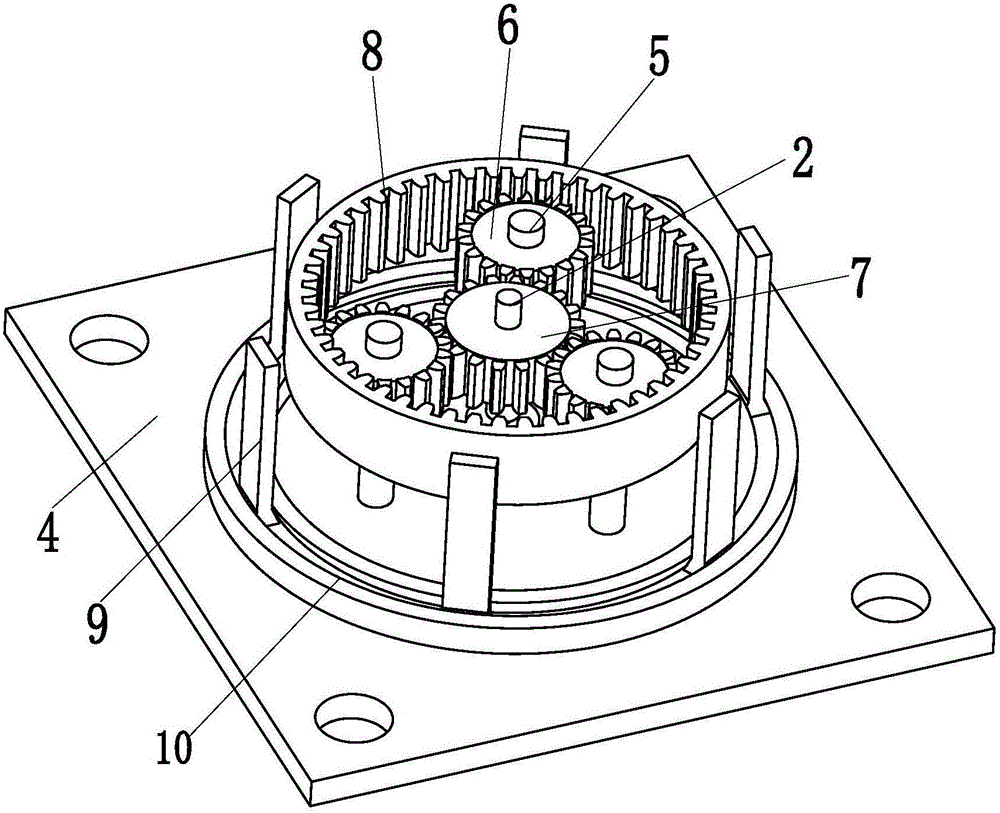

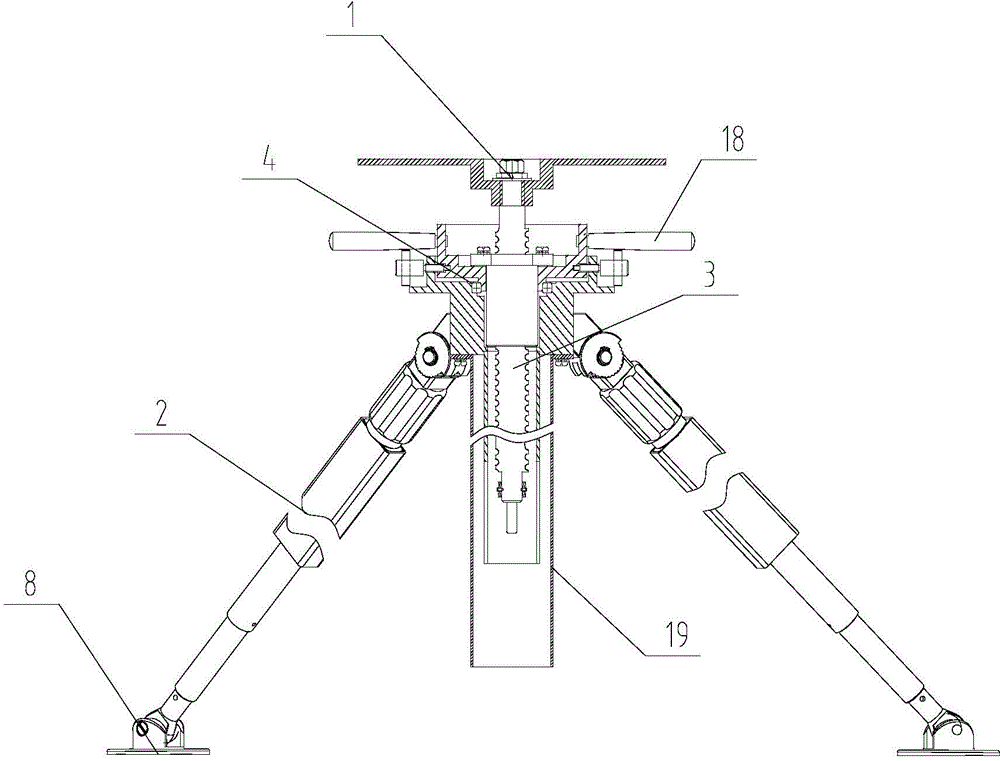

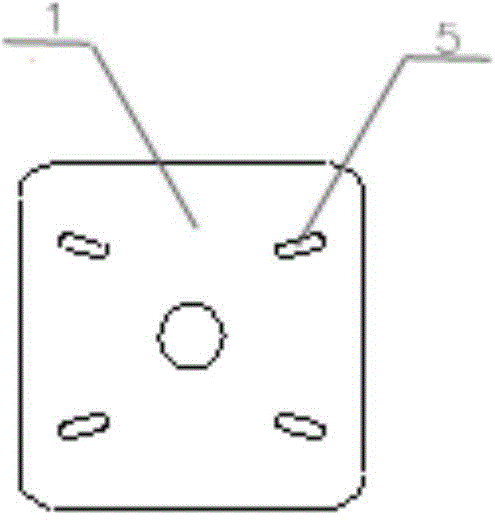

Electric power overhauling supporting device

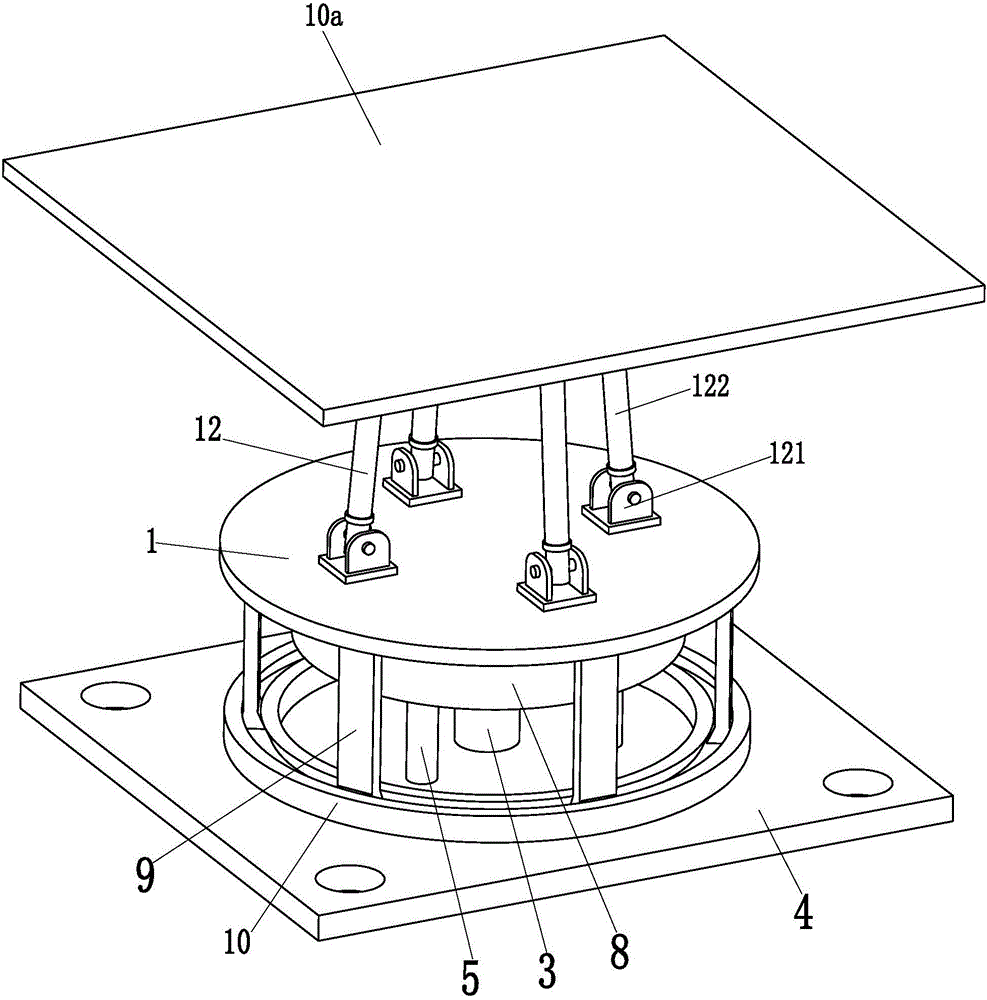

ActiveCN105858535AIncrease stiffnessHigh movement precisionLifting framesSwitchgearElectric power systemCoupling

The invention relates to an electric power overhauling supporting device. The electric power overhauling supporting device comprises a fixed platform. Four parallel supporting chains are symmetrically installed on the upper end surface of the fixed platform. An operating platform is installed at the top ends of the four parallel supporting chains. A rotating shaft is installed in the middle of the lower end surface of the fixed platform through a bearing. A rotating motor is connected to the lower end of the rotating shaft through a coupler and installed on a bottom plate through a motor base. Three fixing shafts are uniformly arranged on the upper end surface of the bottom plate in the axis direction of the fixed platform. Three planetary wheels are installed at the upper ends of the three fixing shafts through bearings correspondingly. The inner sides of the three planetary wheels are all engaged with a sun wheel. The sun wheel is installed on the rotating shaft through a key. The outer sides of the three planetary wheels are all engaged with an inner gear ring. The electric power overhauling supporting device is capable of solving the problems that an existing substation rigid support is poor in dynamic adjustment performance, nonadjustable in height, small in application scope and the like and has the advantages of being good in rigid supporting performance, height adjustment performance and stability performance, wide in application scope, high in working efficiency and the like.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO LTD SUQIAN POWER SUPPLY BRANCH +2

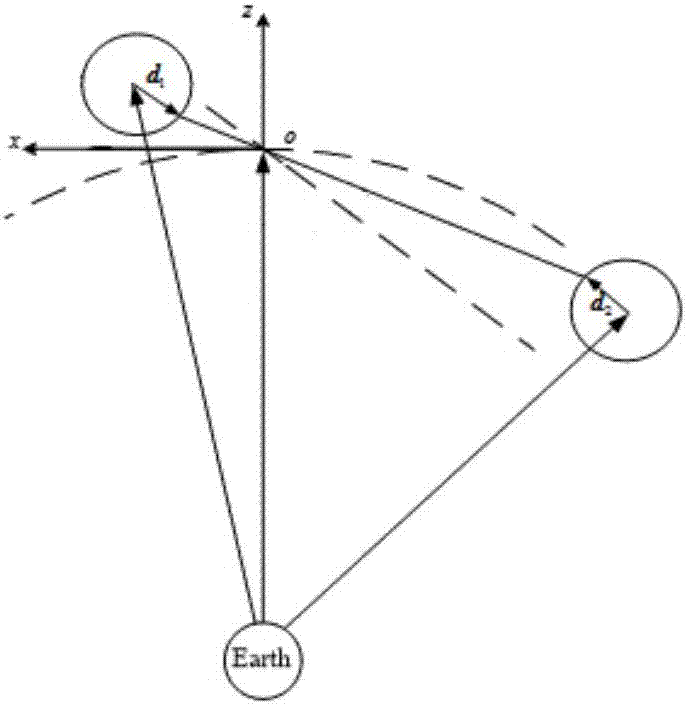

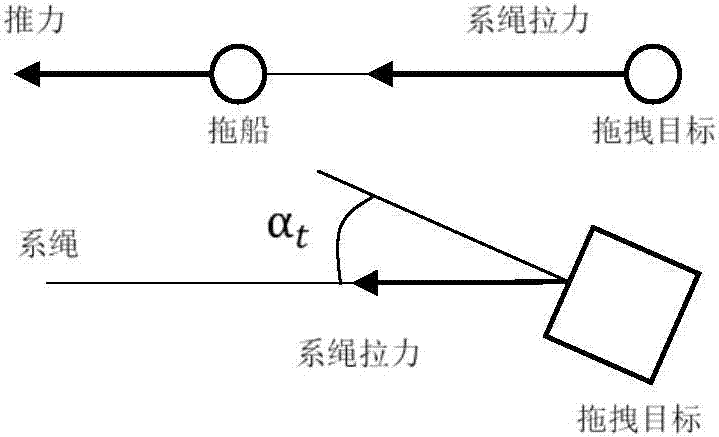

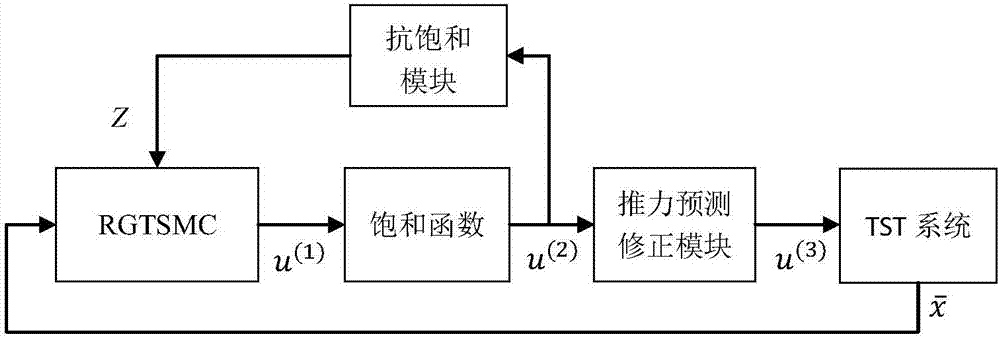

Dragged target attitude stability control method based on thrust control of tethered space tug

The invention provides a dragged target attitude stability control method based on thrust control of a tethered space tug. The method includes following steps: 1, performing a system hypothesis, wherein the tethered space tug is an integral body including a tug, a target, and an elastic-connection tie rope, and the tug and the target are located at two ends of the tied rope; 2, calculating a reference trajectory based on optimization; 3, deducing a robust global terminal sliding mode controller; and 4, adding an anti-saturation module and a thrust prediction and correction module. By the above steps, the robust global terminal sliding mode controller obtained in step 3 and the anti-saturation module and the thrust prediction and correction module obtained in step 4 are combined so that the designed dragged target attitude stability controller based on thrust control of the tethered space tug and the control method thereof are obtained, the controller designed by the method can satisfy the constraint demand, and the loosening of the tied rope is also prevented by the designed thrust prediction and correction module.

Owner:BEIHANG UNIV

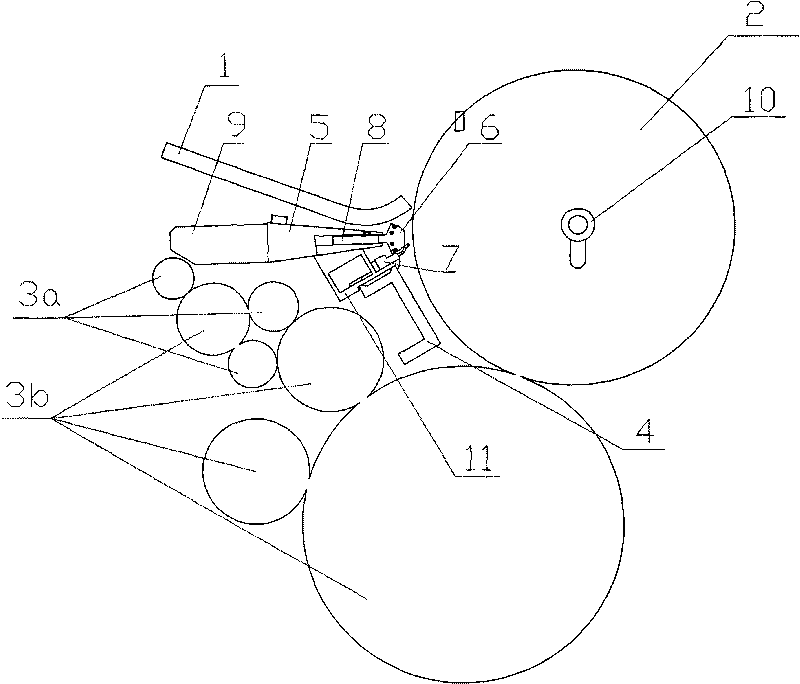

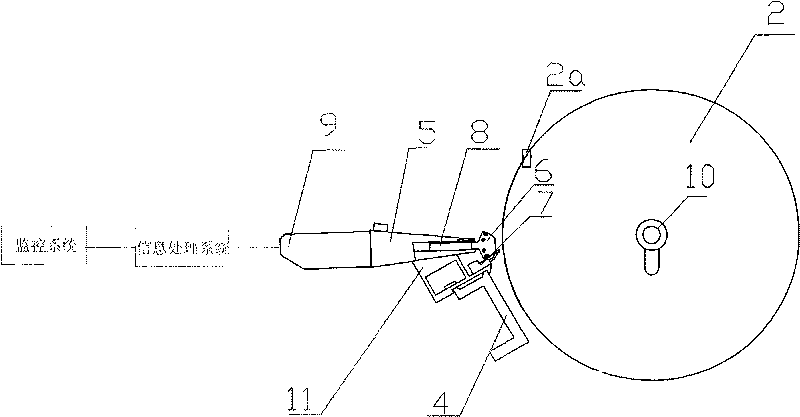

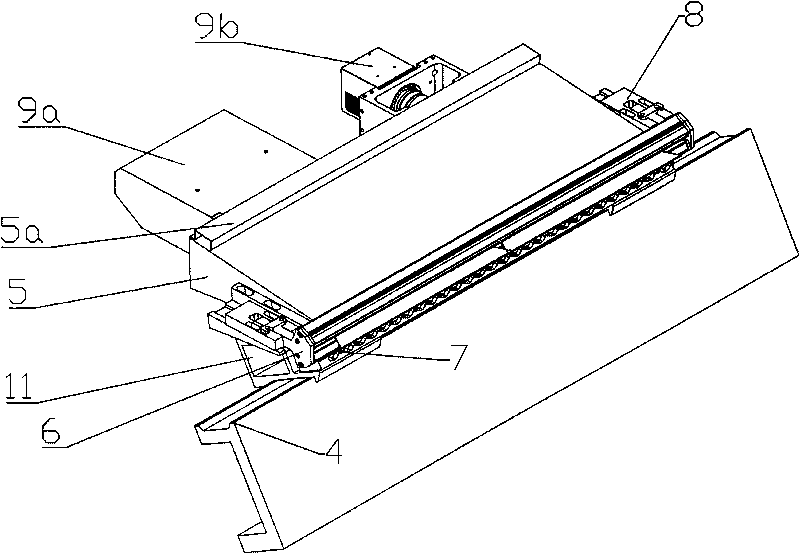

Printing material quality online visual inspection system

InactiveCN101750420ACompact structureNo jitterOptically investigating flaws/contaminationVisual inspectionPrinting press

In order to solve the defect of low inspection precision of the printing material quality online visual inspection device, the invention provides a printing material quality online visual inspection system. An inspection machine box and an inspection assembly arranged on the inspection machine box are arranged in a small space formed by a printing cylinder, a transmission link, series inking rollers and an ink delivering roller which are arranged in the printer; one end of the inspection machine box, which is close to the printing cylinder, is provided with a slit which faces to the surface of the printing cylinder and is parallel to the rotating shaft of the printing cylinder; a light source assembly is positioned on one end, which is close to the printing cylinder, of the inspection machine box; a linear array cameral assembly is positioned on one end, which is far away the printing cylinder, of the inspection machine box, and shoots the picture of the printing material on the printing cylinder through the slit; and a coder is arranged on the rotating shaft of the printing cylinder. The invention can perform online inspection for the printing material on the printing cylinder, not only has high inspection precision, but also has smart design and small size, can not occupy additional space, and is suitable for the online inspection for special printing material and common printing material.

Owner:BEIJING LUSTER LIGHTTECH

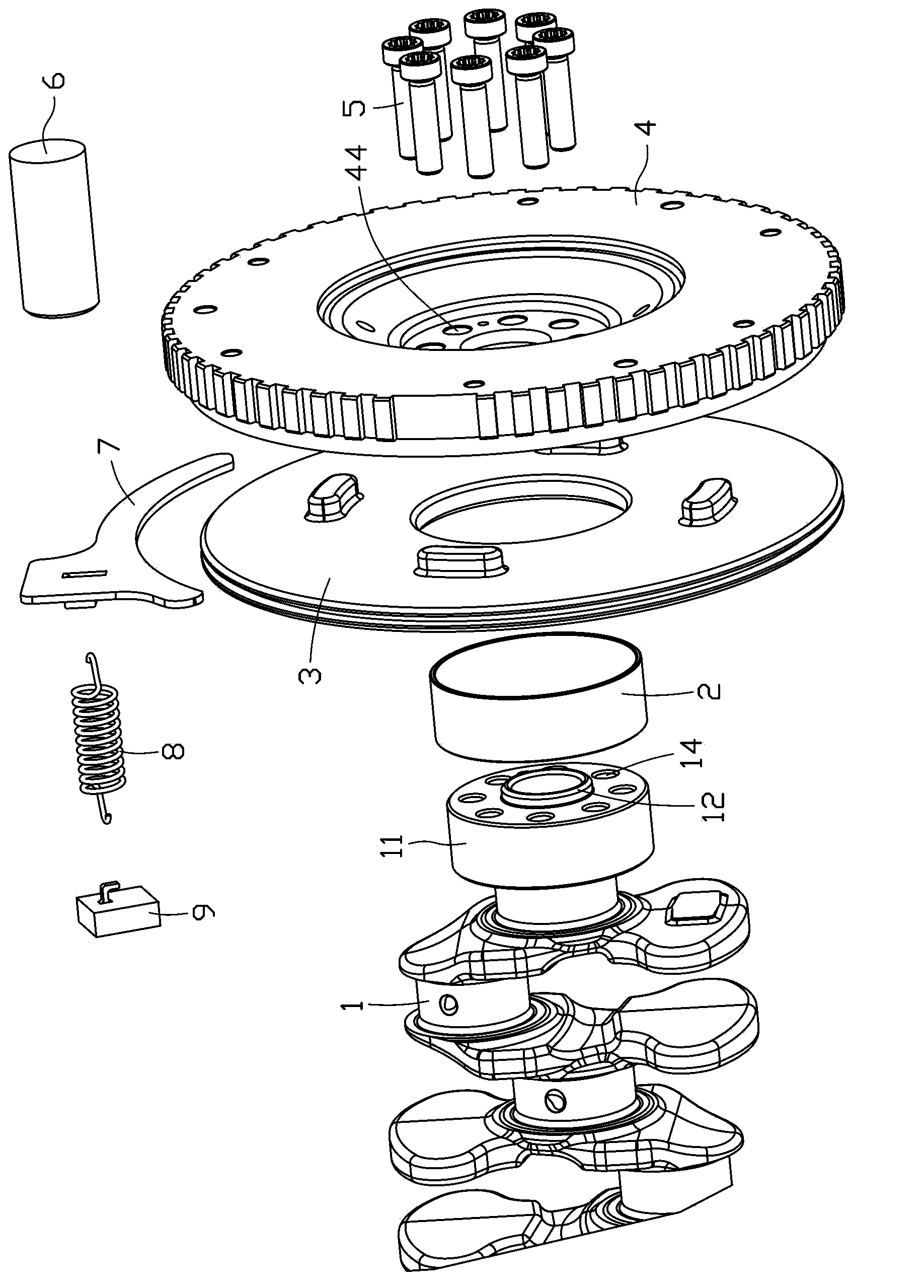

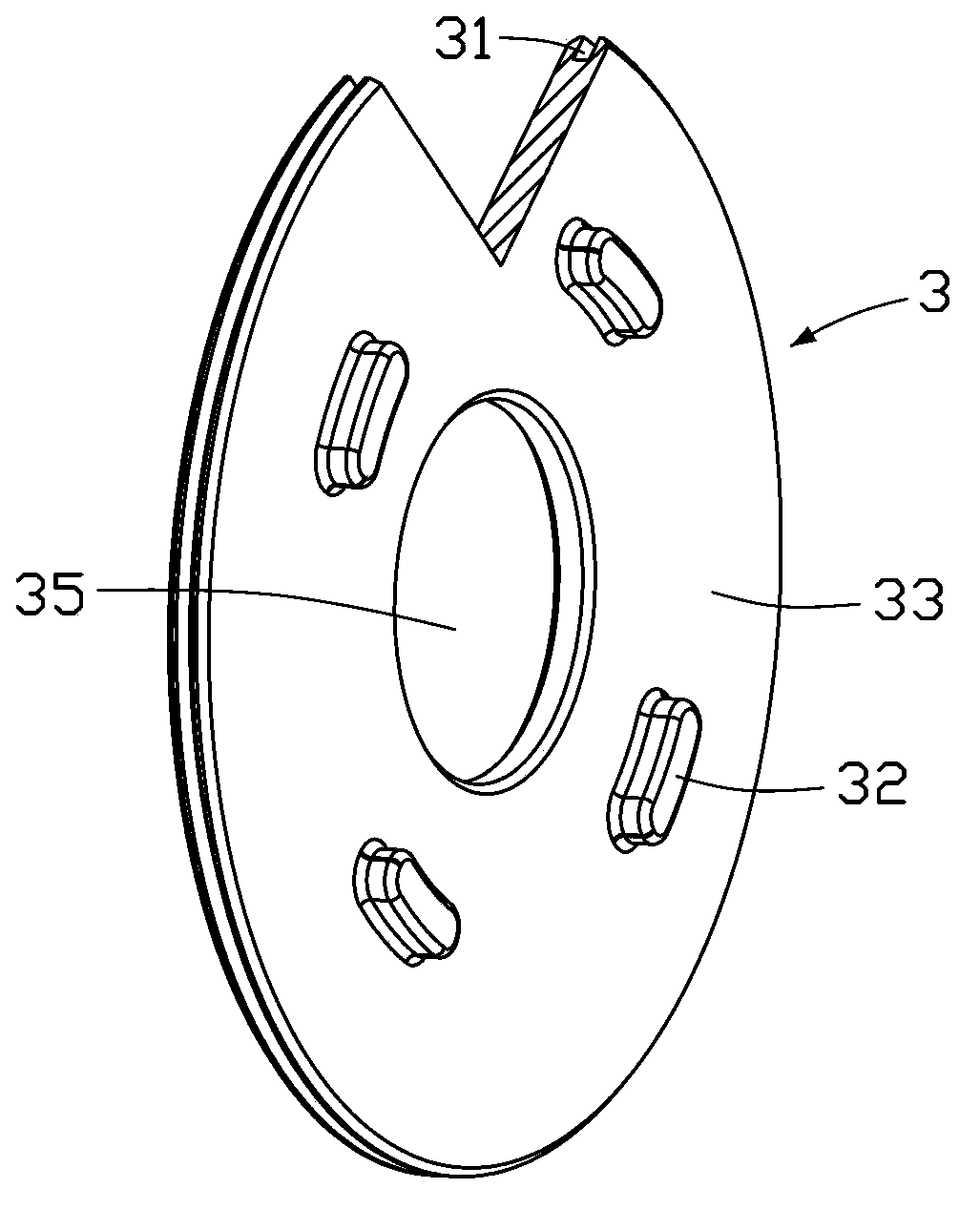

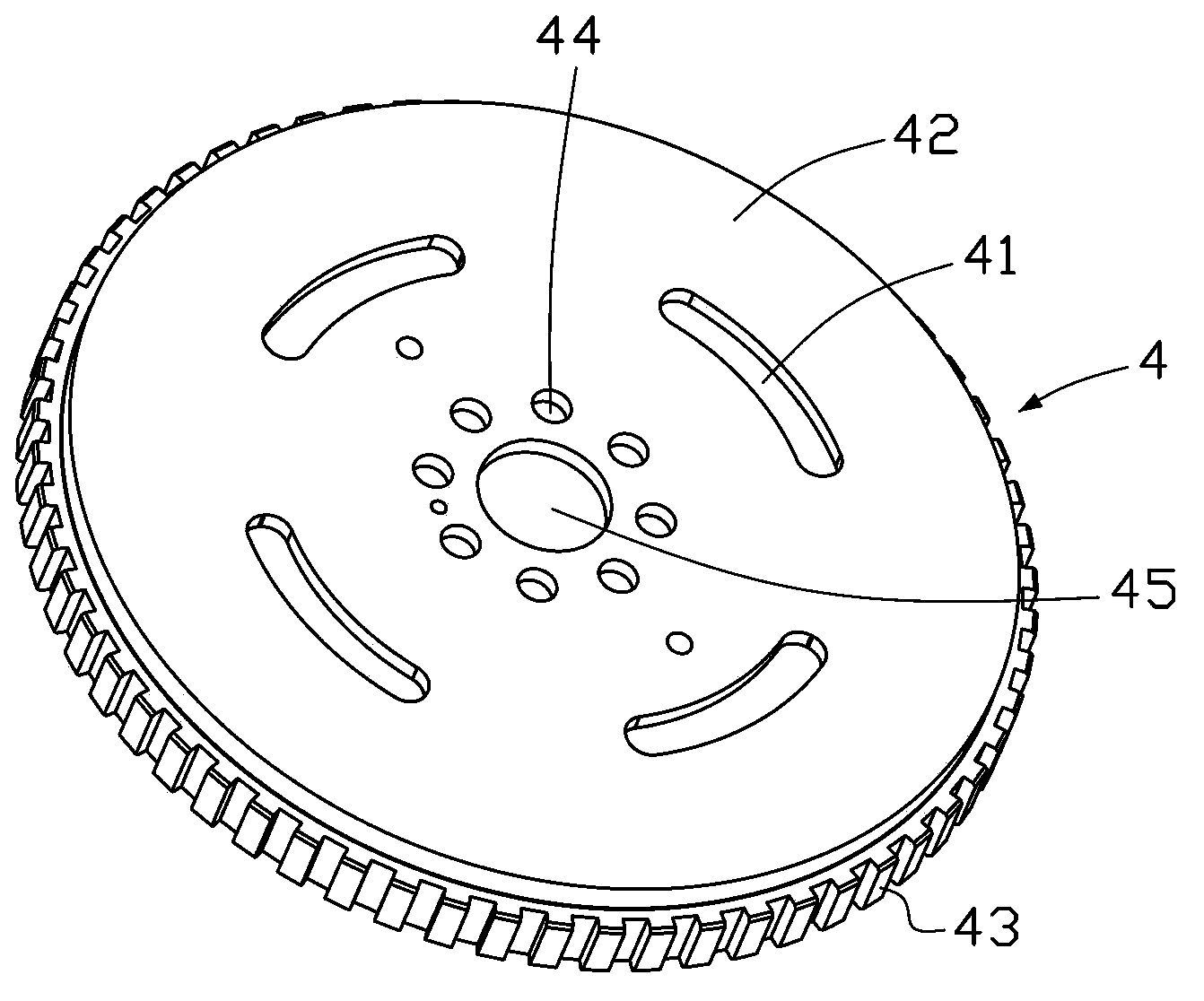

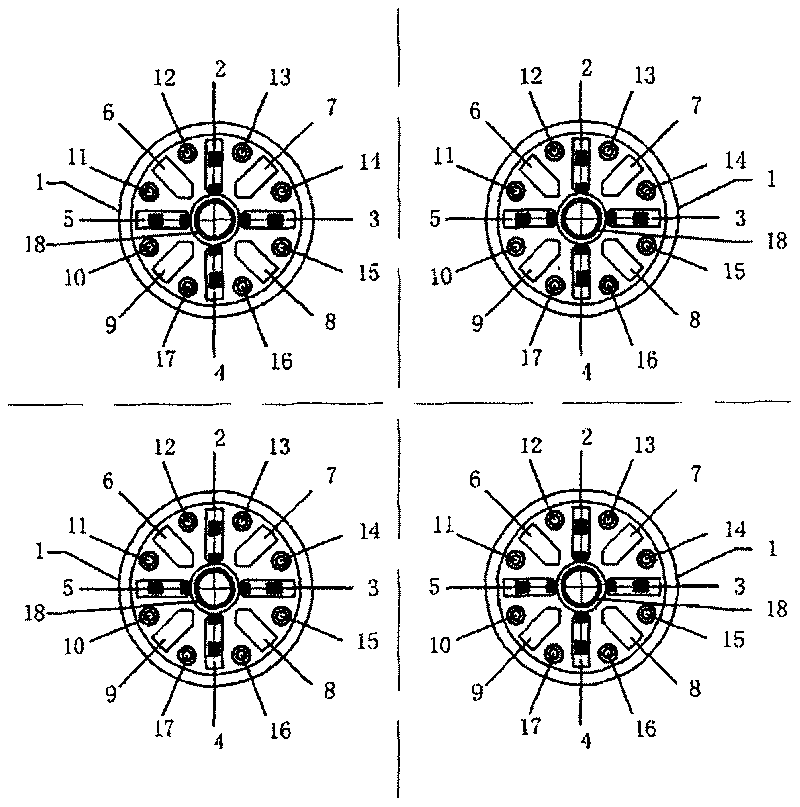

Variable inertia flywheel structure

The embodiment of the invention discloses a variable inertia flywheel structure, which comprises a first flywheel and a second flywheel, wherein the first flywheel is used for being fixedly connected with a crankshaft, and the first flywheel comprises a first flywheel disk; the second flywheel comprises a second flywheel disk, and a pawl slot is arranged on a disc surface of one of the first flywheel disk and the second flywheel disk; and a pawl is convexly arranged on a disc surface of the other one of the first flywheel disk and the second flywheel disk, and the pawl is correspondingly matched with the pawl slot. When the large inertia of the flywheel is needed, the pawl extends into the pawl slot, and the first flywheel drives the second flywheel to rotate together; when the small inertia of the flywheel is needed, the pawl is separated from the pawl slot, and the first flywheel rotates and the second flywheel does not rotate with the first flywheel. According to the variable inertia flywheel structure, when an engine runs at low speed, the inertia of the flywheel increases so as to improve the smoothness of operation; and when the engine runs at high speed, the moment of inertia of the flywheel is reduced, and the fuel consumption is saved.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

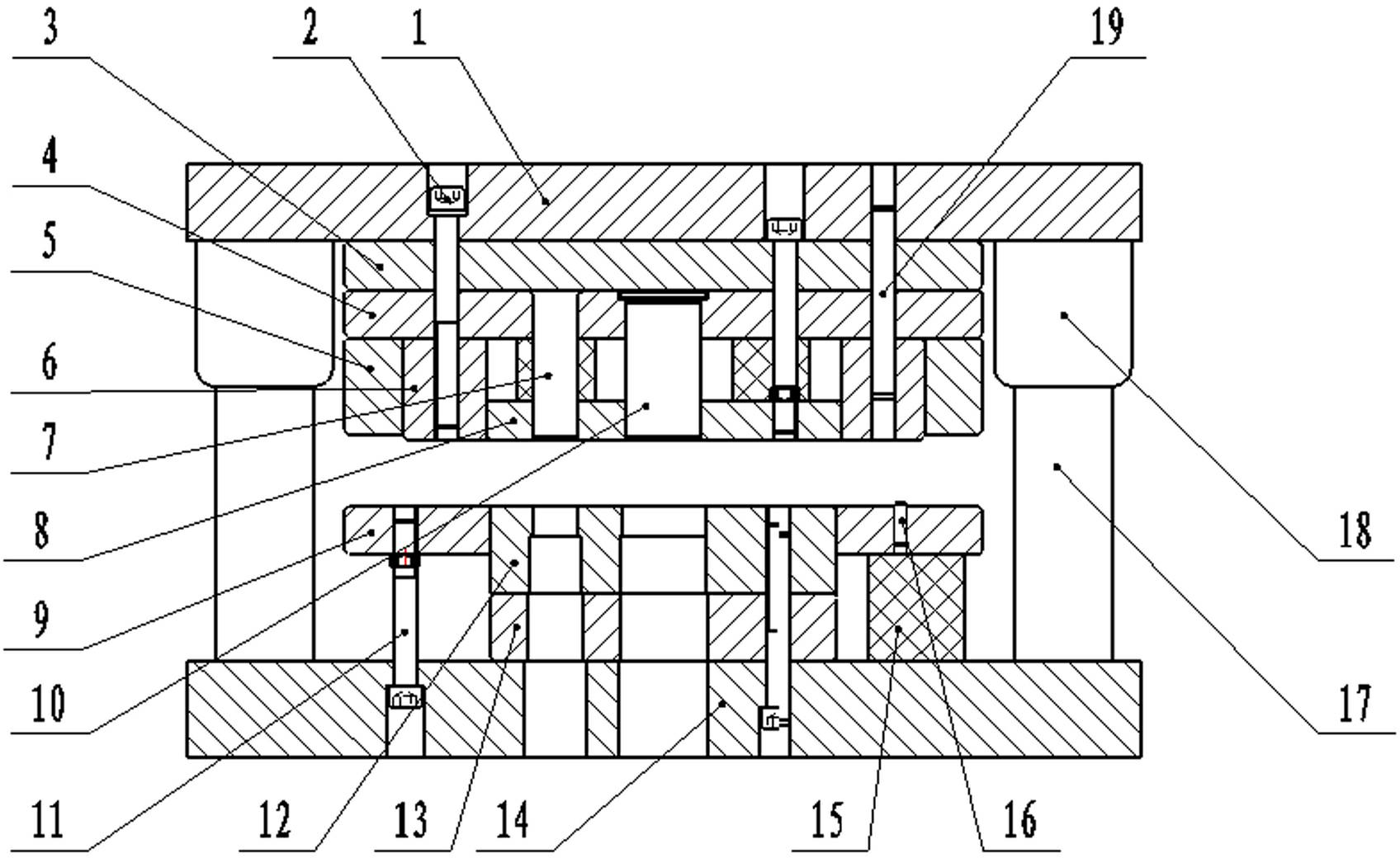

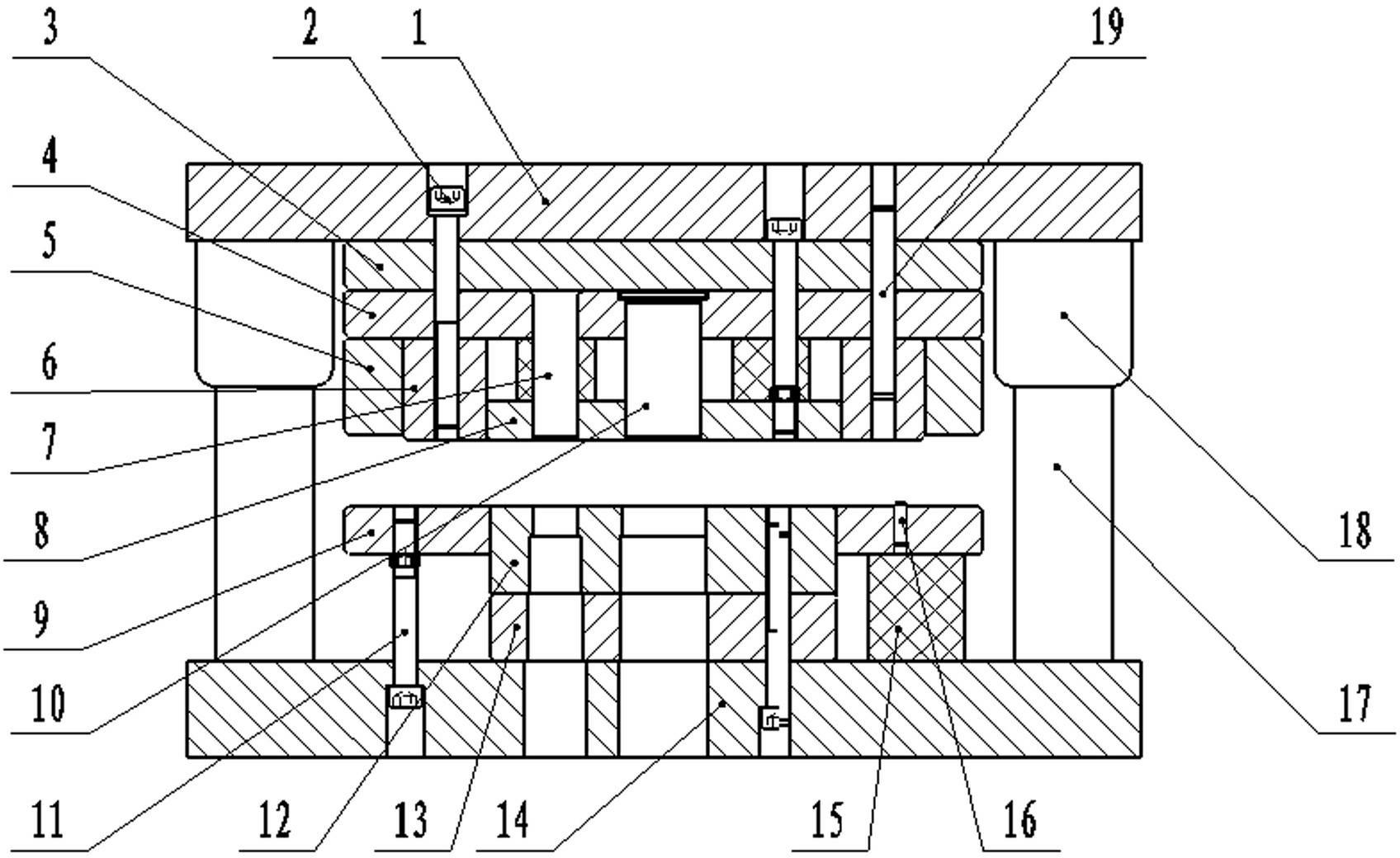

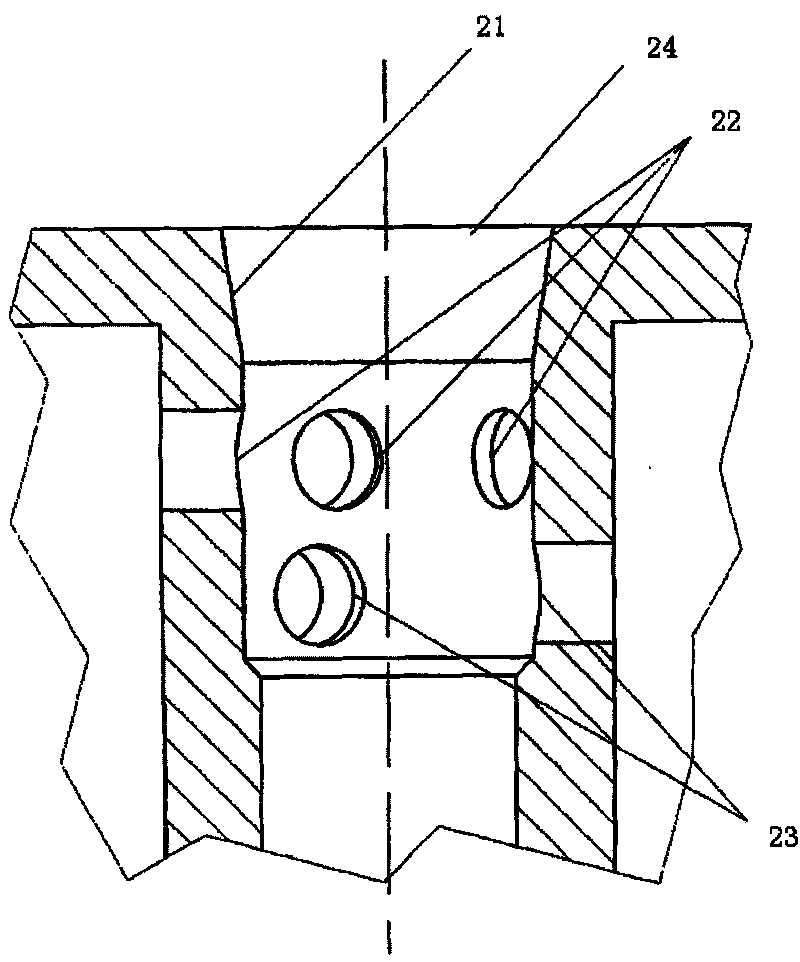

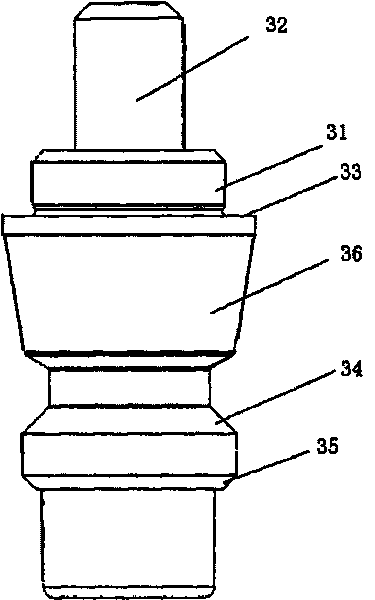

Resetting device using flexible positioning and rigid clamping in combination and positioning method thereof

ActiveCN101704200ASolve the problem of batch transfer at the same timeExtension of timePositioning apparatusMetal-working holdersCircular coneEngineering

The invention relates to a resetting device using flexible positioning and rigid clamping in combination and a positioning method thereof. The invention is characterized in that a cartridge comprises two to four radially-arranged positioning gears, the lateral side of each positioning gear is provided with a positioning slant surface, Z-direction stopping planes are arranged between two adjacent positioning gears, a workpiece supporting board is provided with positioning slots fit with the positioning gears and positioning planes fit with the Z-direction stopping planes, a pop-rivet comprises a pop-rivet body which is connected with the workpiece supporting board by bolts, the pop-rivet orifices on the cartridge is provided with positioning cone surfaces, the lateral side of the pop-rivet body is provided with cone-shaped positioning contact planes fit with the positioning cone surfaces. The device can simultaneously realize precise resetting and rigid clamping, and ensure high safety and reliability of mechanical processing and high manufacture preciseness and efficiency of the processed object.

Owner:上海麦迅机床工具技术有限公司

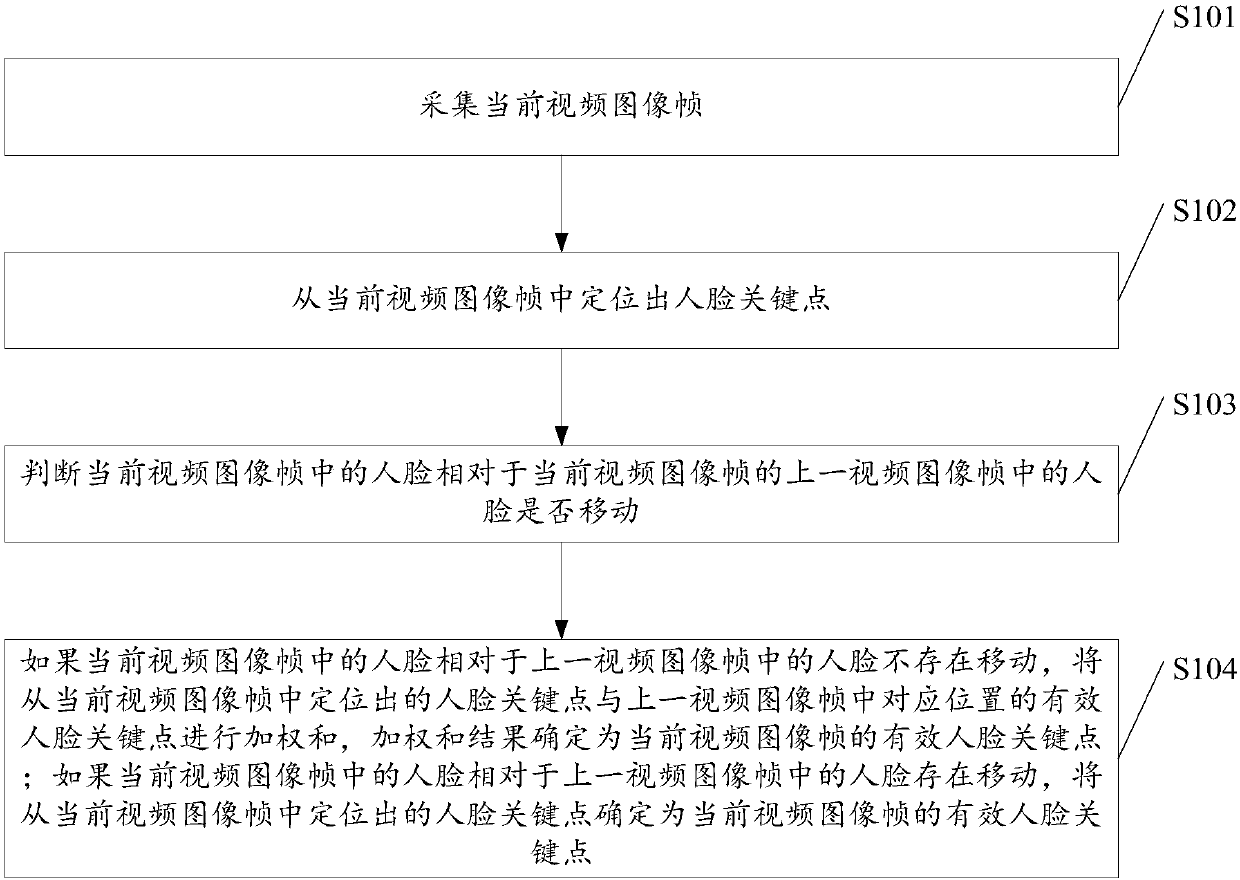

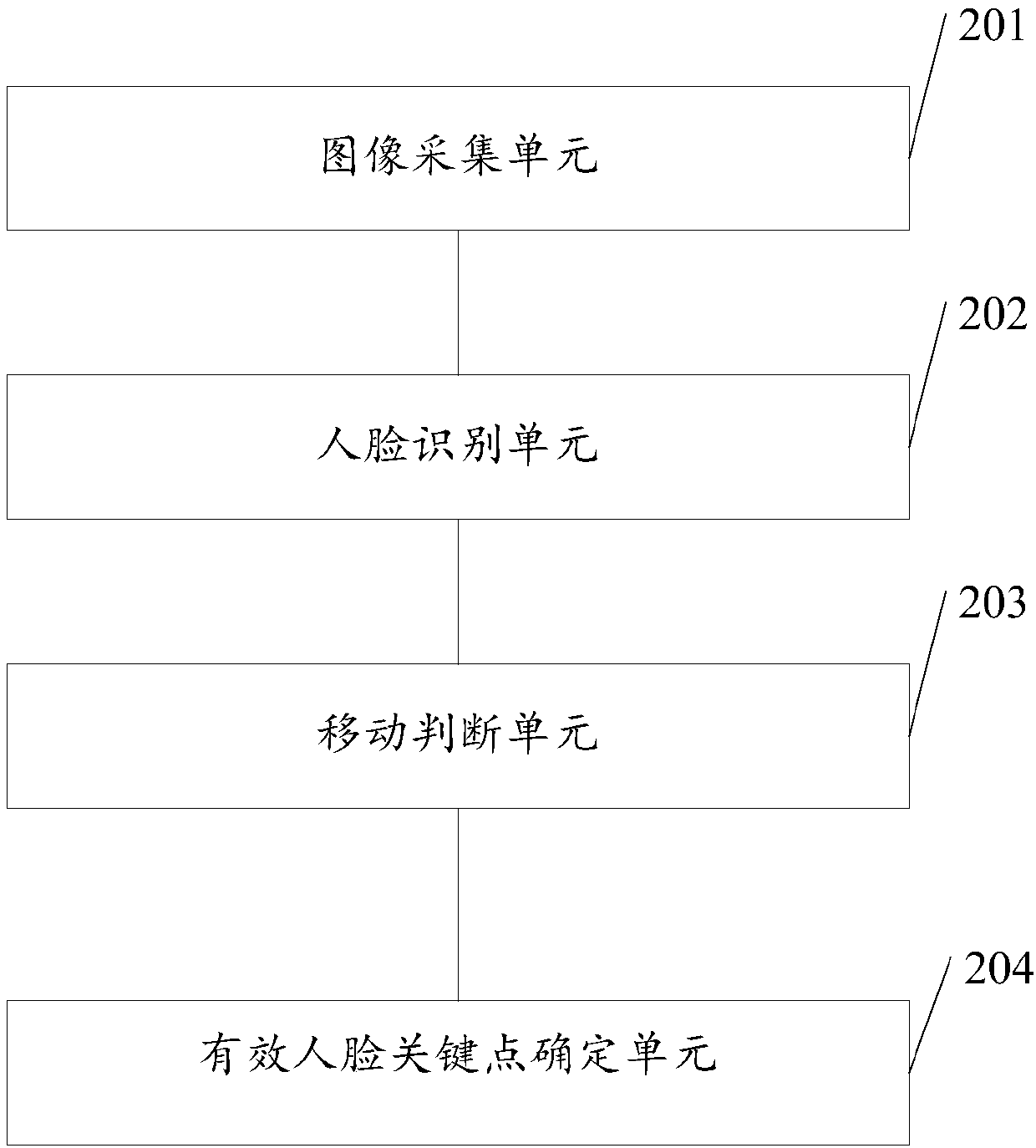

Human face key point tracking method, application and device thereof

ActiveCN107704829ANo jitterAvoid jitterCharacter and pattern recognitionPattern recognitionCrucial point

The invention discloses a human face key point tracking method, an application and a device thereof. The method comprises the following steps of acquiring a current video image frame; positioning a human face key point from the current video image frame; judging whether a human face in the current video image frame is moved relative to a human face in a previous video image frame of the current video image frame or not; if the human face in the current video image frame is moved relative to the human face in the previous video image frame, determining the human face key point positioned in thecurrent video image frame as an effective human face key point in the current video image frame; if the human face in the current video image frame is not moved relative to the human face in the previous video image frame, determining the weighted sum result of the human face key point positioned in the current video image frame with an effective human face key point at a corresponding position of the previous video image frame as the effective human face key point in the current video image frame. According to the invention, the shaking of human face key points in a video during the trackingprocess is completely avoided.

Owner:WUHAN DOUYU NETWORK TECH CO LTD

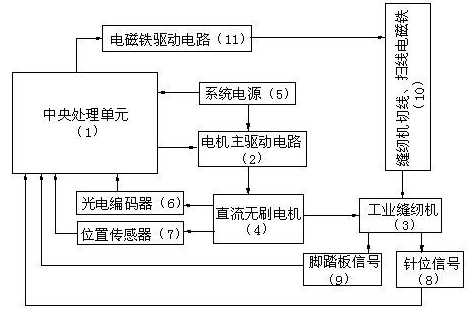

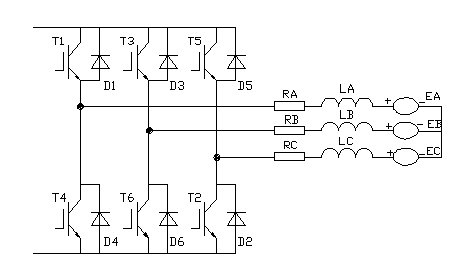

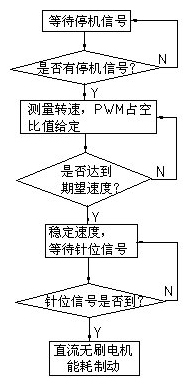

Quick shutdown system and method of industrial sewing machine

The invention relates to a quick shutdown system and method of an industrial sewing machine. The system comprises a central processing unit, a bridge rectifier circuit composed of six switching tubes and a DC brushless electric machine used for controlling the operation of the industrial sewing machine, wherein the input end of the bridge rectifier circuit is connected with a system power supply; the triple outputs of the bridge rectifier circuit are connected with the three-phase winding of the DC brushless electric machine in turn; the control ends of the switching tubes are separately connected with the six-way PWM control signals of the central processing unit; an optical-electricity encoder and a position sensor which are arranged on the DC brushless electric machine and the pin signal and pedal signal of the industrial sewing machine are separately connected with the central processing unit; and the central processing unit continuously collects the motor speed, calculates the PWM duty ratio of six-way drive waveform and controls the on / off state of the three switching tubes of the middle and lower bridge arms of the bridge rectifier circuit, thus realizing quick shutdown. By using the system of the invention, the shutdown time of the industrial sewing machine can be greatly shortened, the production efficiency can be increased, the shutdown process is stable without causing motor vibration, and the reliability is good.

Owner:YIWU HUACHEN ELECTROMECHANICAL CO LTD

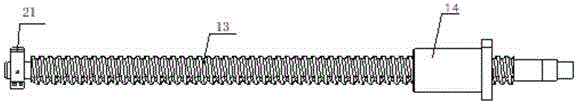

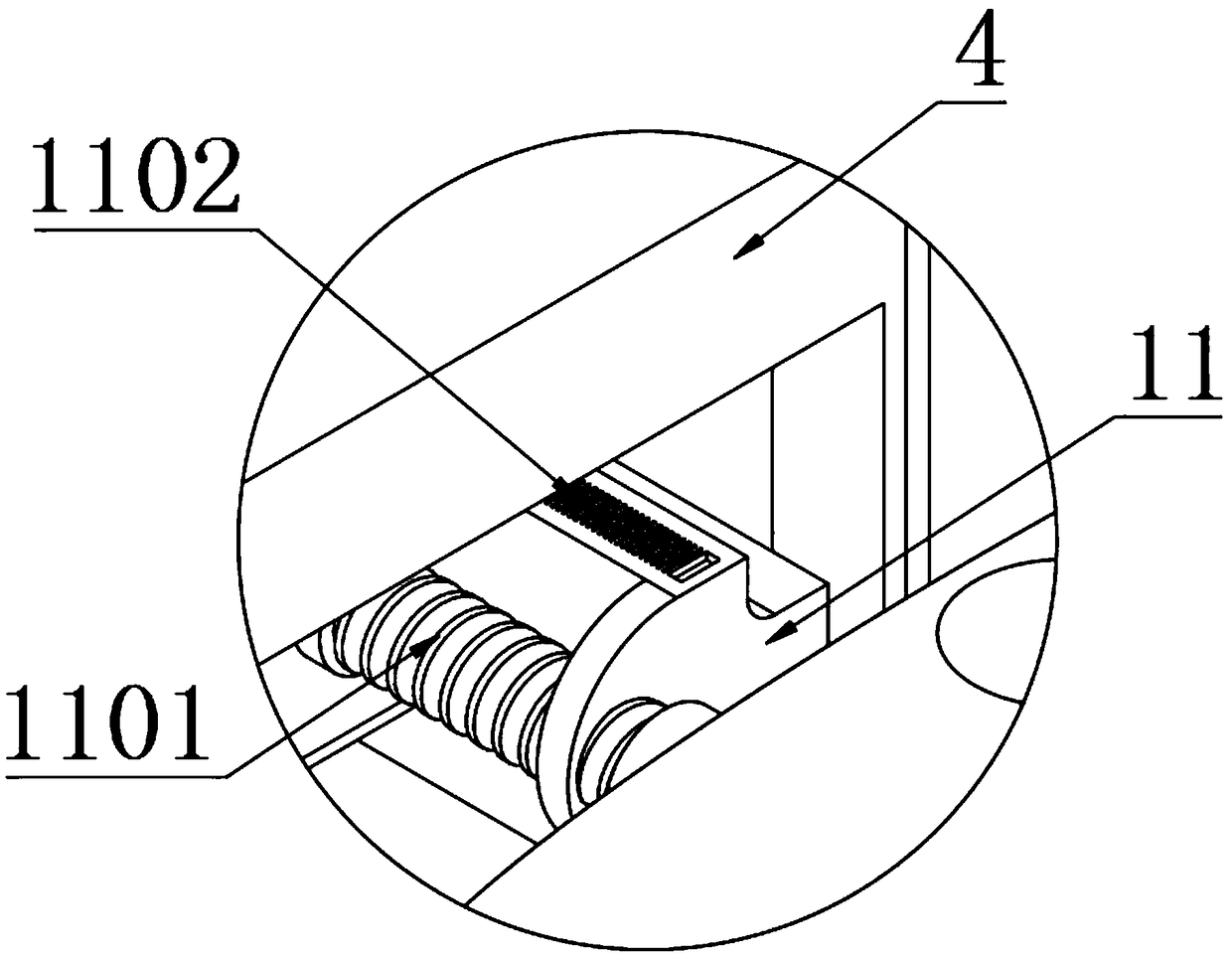

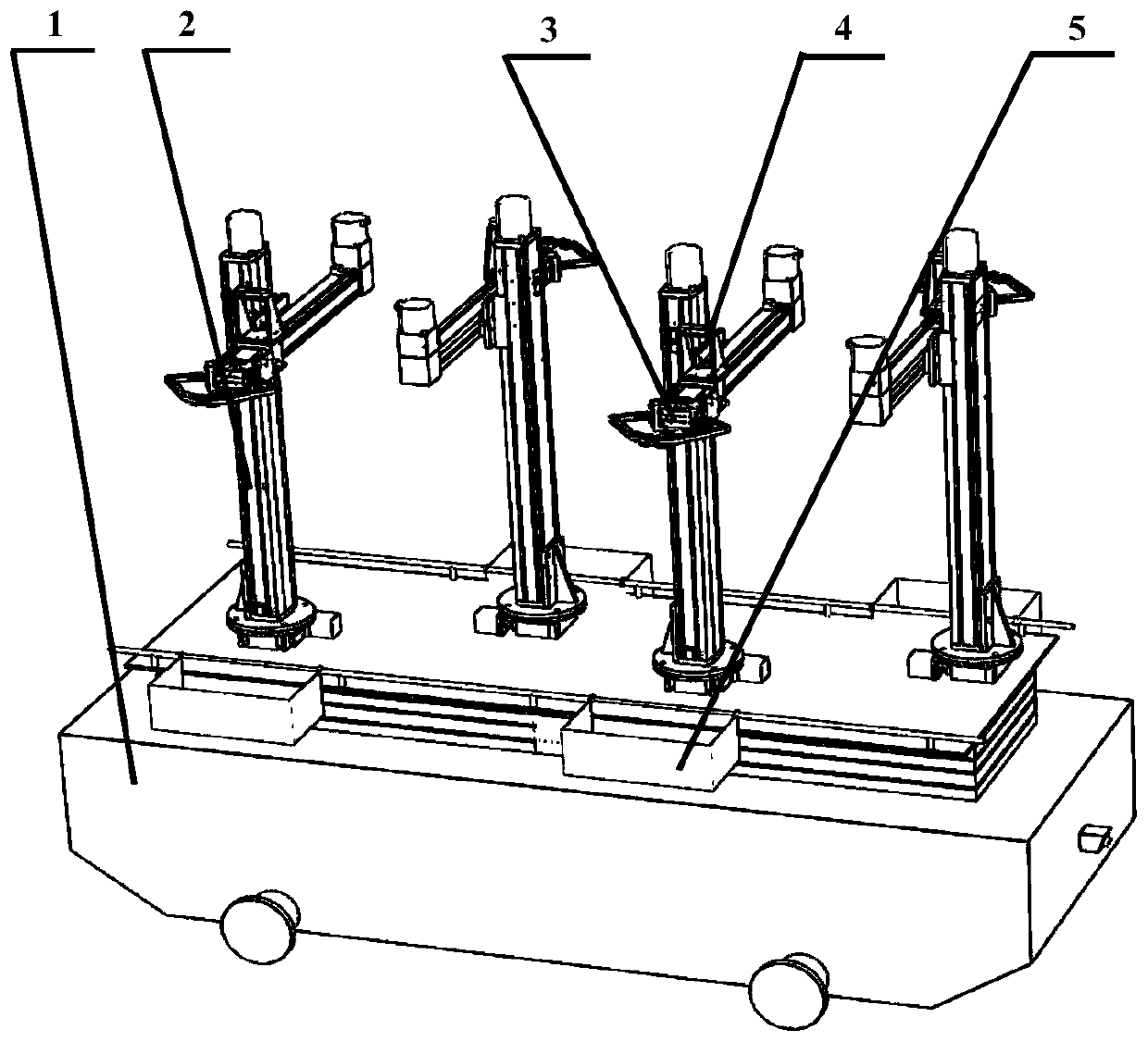

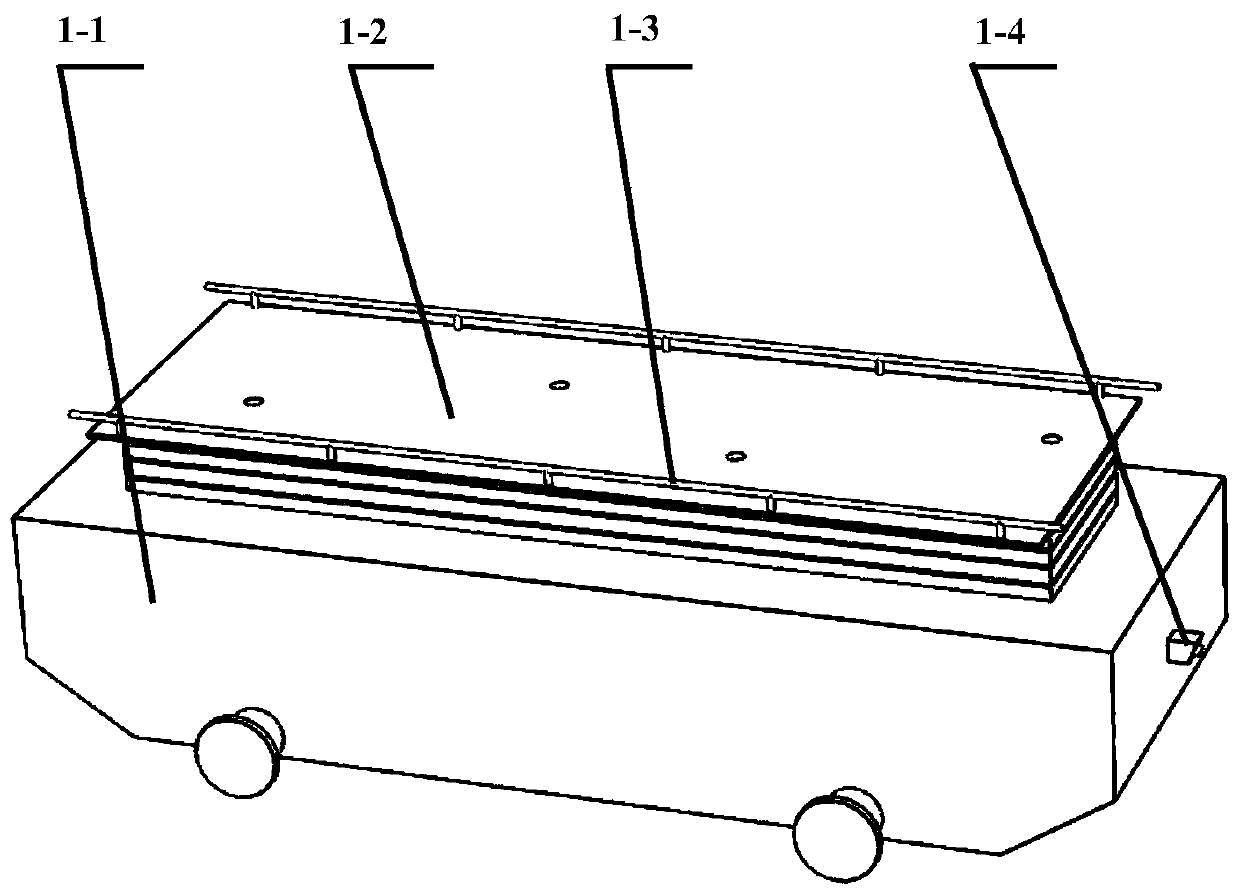

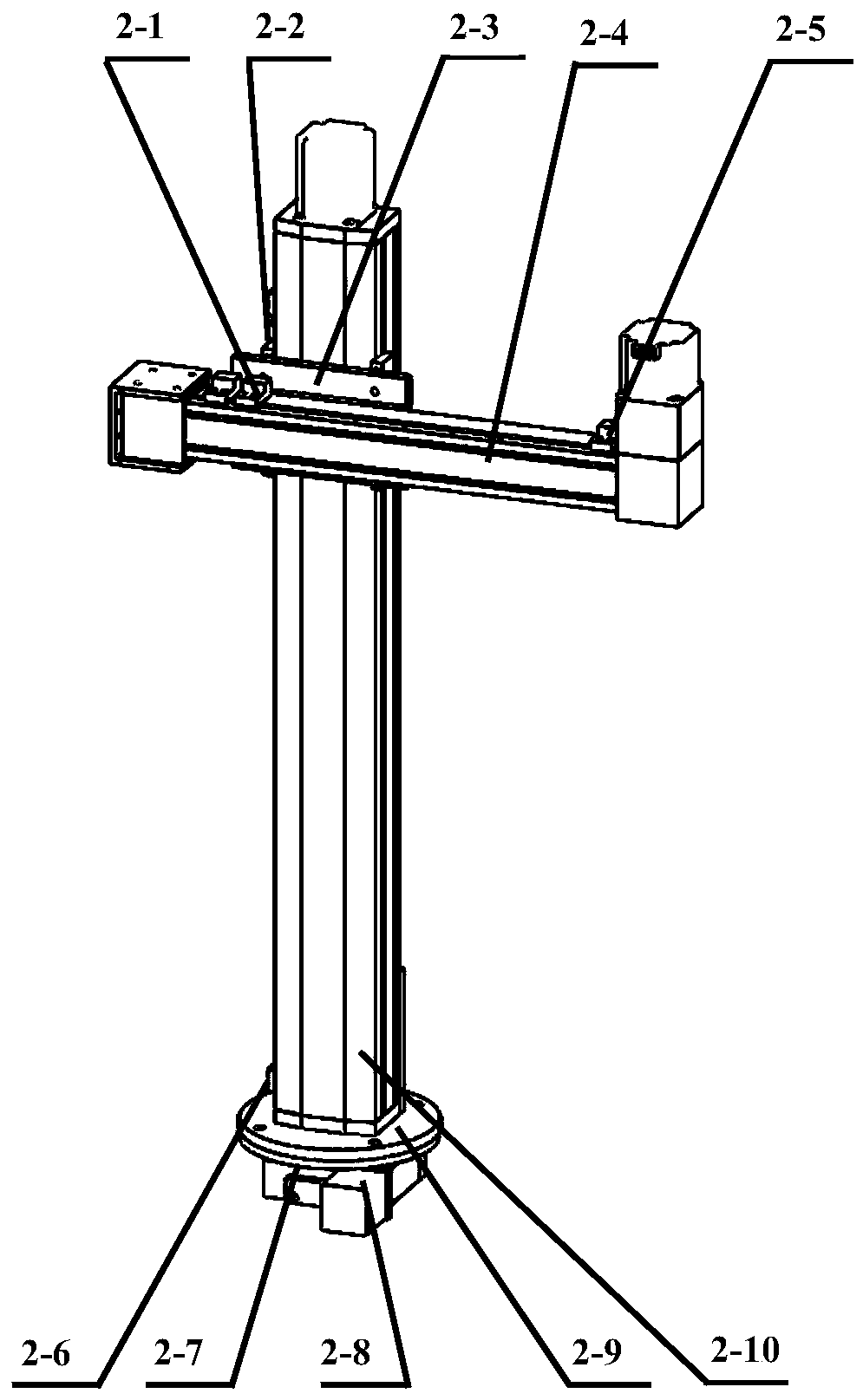

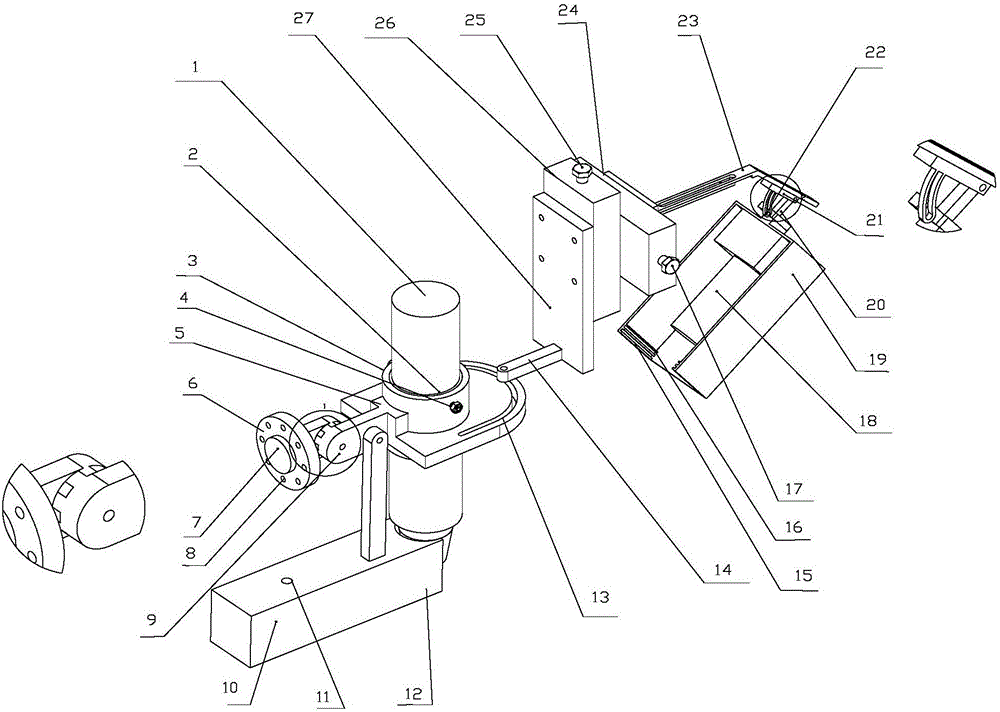

Vibration exciter fixed mounting device and using method thereof

The invention discloses a vibration exciter fixed mounting device which mainly comprises a vibration exciter fixing platform assembly, supporting foot assemblies, a screw rod sliding assembly and a rotary table assembly. The vibration exciter fixing platform assembly is fixed at one end of the screw rod sliding assembly by a nut; the screw rod sliding assembly is arranged on the rotary table assembly; the supporting foot assemblies are connected with the rotary table assembly so as to support the vibration exciter fixing platform assembly. The vibration exciter fixed mounting device is flexible to regulate, is reliable to fix, is simple to mount, has a compact structure, has a lighter weight, is convenient to use in the external field and has better adaptability.

Owner:NO 60 RES INST OF GENERAL STAFF DEPT PLA

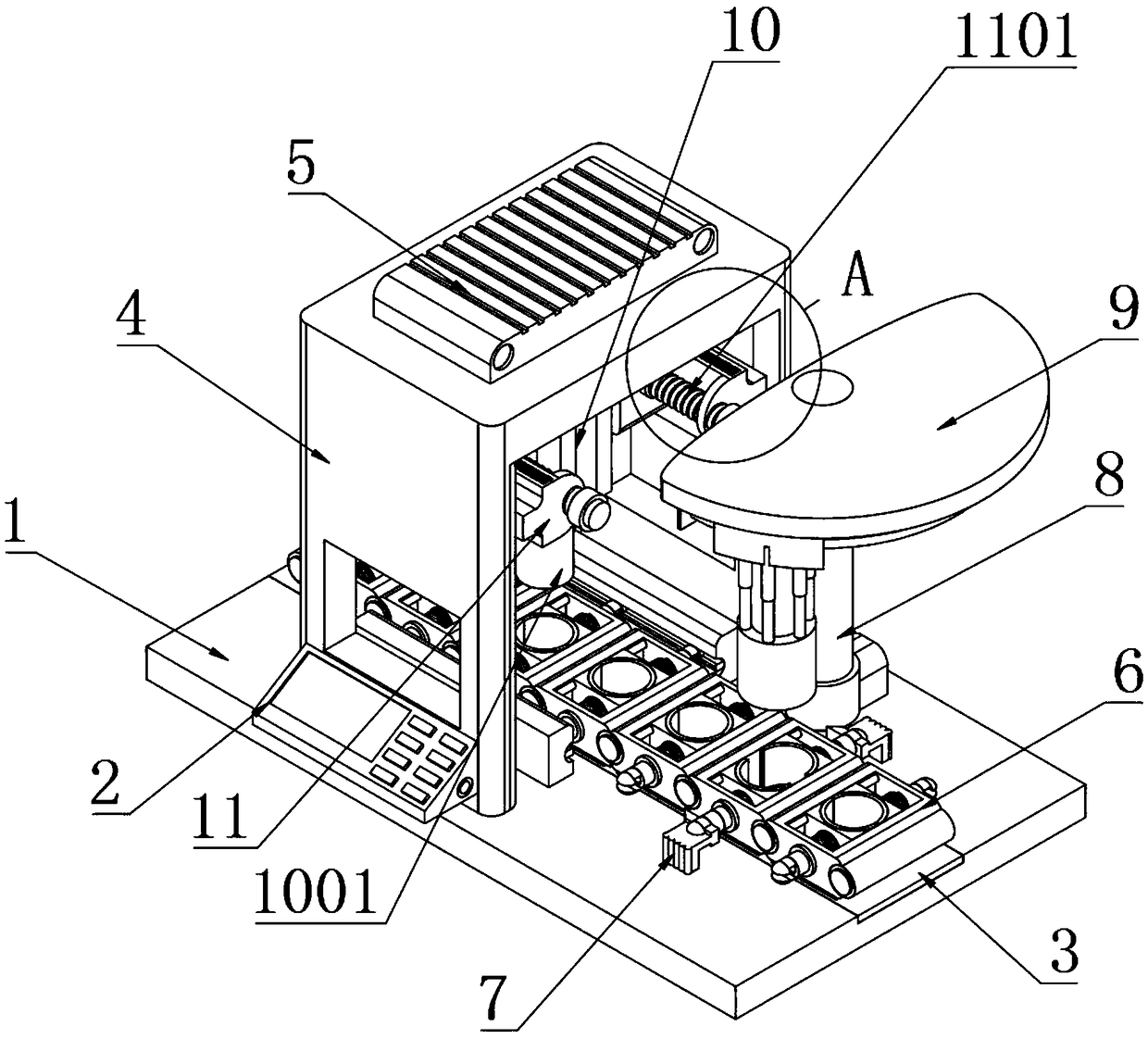

Press-fitting device of battery cover cap

PendingCN108620855AStrong adsorptionEasy to take outWork holdersMetal working apparatusAutomationIndustrial engineering

The invention provides a press-fitting device of a battery cover cap. The device comprises an operation table, a conveyor belt is arranged on the operation table, a pressing and fitting table frame which extends along the direction of the conveyor belt is arranged above the conveyor belt, a clamping block is arranged on the inner wall of the press and fitting table frame, the clamping block is provided with at least one clamping hole allowing a spiral screw rod to penetrate through, and the spiral screw rod is connected with a press fitting head; and a supporting column is arranged on one side, of the conveyor belt, behind the press fitting head in the direction of the conveyor belt, a sucking head which is capable of being telescopic is arranged on the supporting column, and a plurality of battery fixing devices are further arranged on the conveyor belt. By adopting of the design, the automation degree is more accurate and efficient on the basis that automation electric appliance elements are reduced as much as possible, so that manufacturing cost and maintenance cost are indirectly reduced.

Owner:WUXI INST OF ARTS & TECH

Multi-manipulator truss tomato picking robot and picking method thereof

The invention relates to a multi-manipulator truss tomato picking robot and a picking method thereof. The truss tomato picking robot comprises a movable platform car, mechanical arms, end executors, visual identification devices and a control module, wherein the mechanical arms which are arranged in the travelling direction of the movable platform car at equal intervals are vertically fixedly connected to the plane of the top of a lifting mechanism; each end executor comprises an electric clamping jaw, rockers, a first connecting rod, a main clamping body, a second connecting rod, a cutter blade and an auxiliary clamping body; every two rockers, the corresponding first connecting rod, the corresponding second connecting rod and two gears which are arranged in the electric clamping jaw and mutually meshed form a five-link mechanism, and enveloping of truss tomatoes is achieved. The structure is simple, the operation is convenient, the cost is low, the picking efficiency and the success rate are high, whole-bunch harvesting of the truss tomatoes is achieved without damaging the truss tomatoes, and the damage rate of the truss tomatoes and main stems is reduced.

Owner:SUZHOU AGRIBOT AUTOMATION TECH

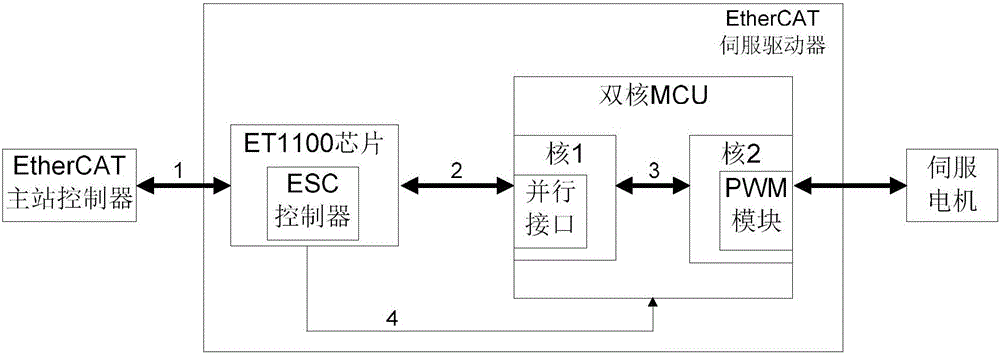

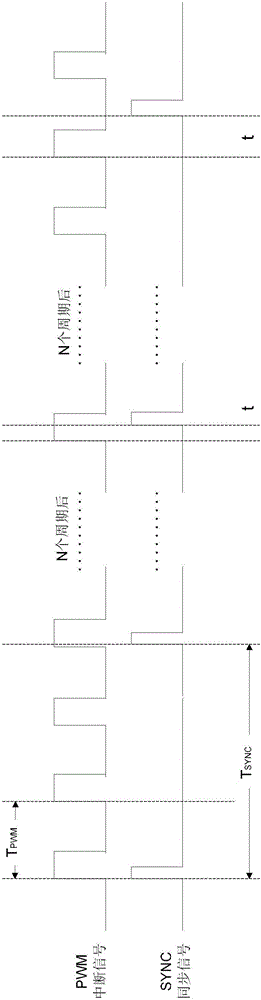

Method of controlling slave station servo driver synchronization master station

ActiveCN105824275AAvoid the problem of receiving exceptionsNo jitterProgramme controlComputer controlProcess moduleMaster station

The invention discloses a method of controlling a slave station servo driver synchronization master station. The method of controlling a synchronization master station comprises the following steps: after a second core detects a SYNC signal, acquiring the current value of a CNT signal, wherein the CNT signal is the real-time count value of PWM triangular carriers generated in a PWM interrupt processing module; comparing the current value of the CNT signal with K / 2, wherein K is a PWM triangular carrier count value corresponding to a set allowable time drift value between the starting moment of PWM interrupt and the rising edge of the SYNC signal; when the current value of the CNT signal is greater than or equal to K / 2, judging the counting direction, and setting the value of CNT to an interrupt value or an integer value which is a set threshold range from the interrupt value according to the counting direction; and making the PWM interrupt processing module generate PWM interrupt at each starting moment of the PWM triangular carriers. Through the control method of the invention, the problem of abnormal real-time instruction reception caused by non-synchronization is avoided, and a controlled servo motor is jitter-free.

Owner:SHENZHEN LEADSHINE INTELLIGENT CONTROL CO LTD +1

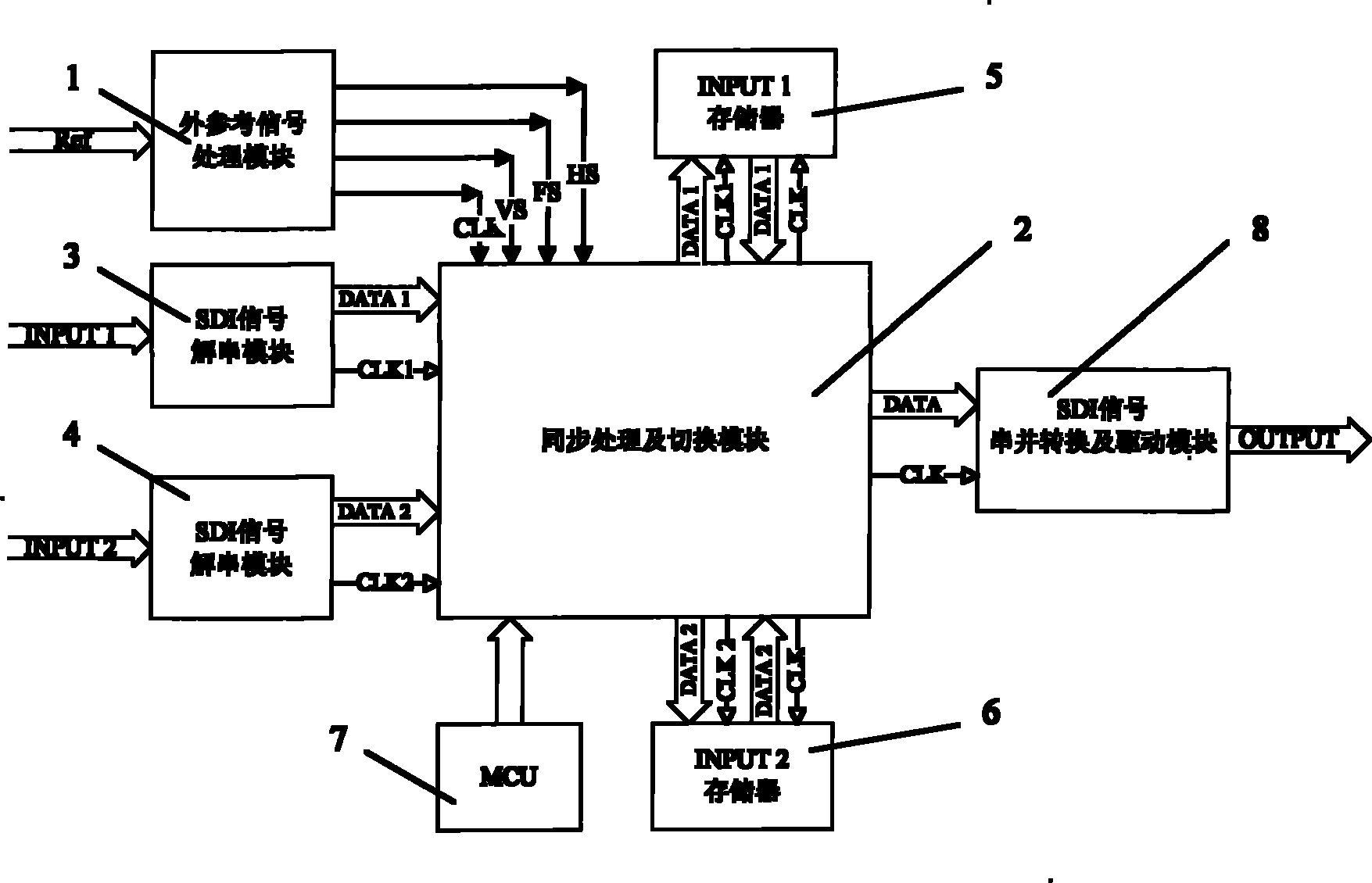

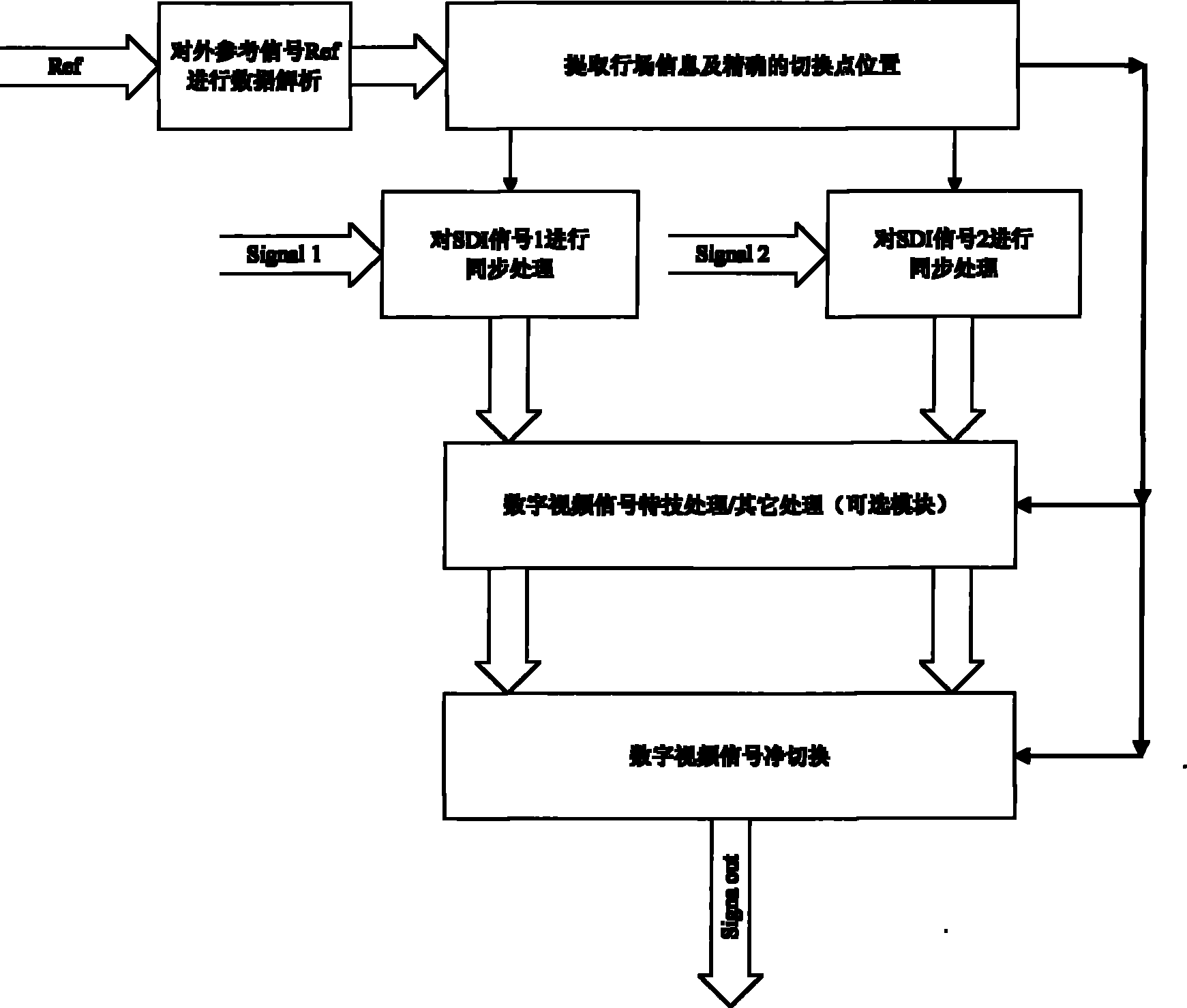

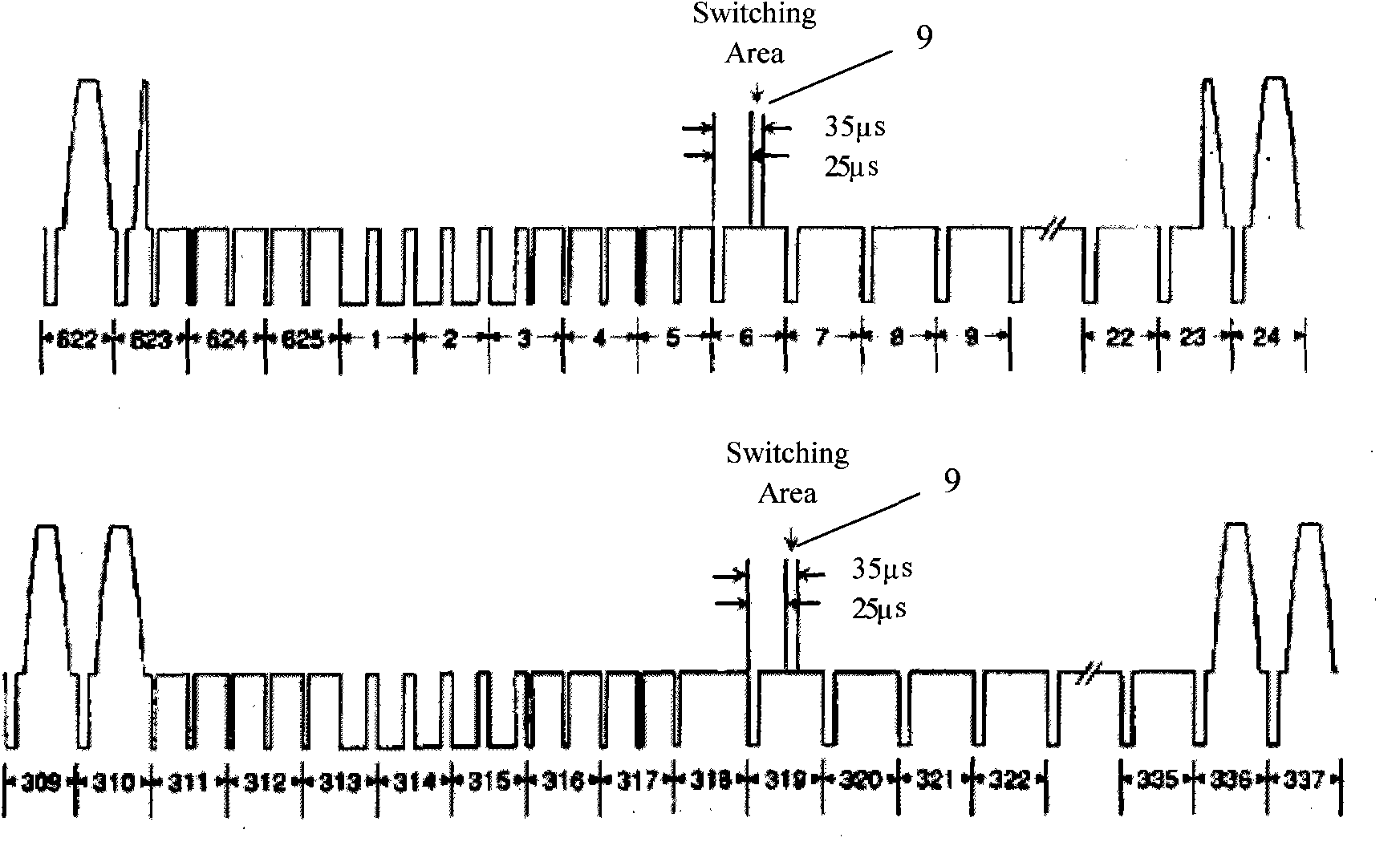

Digital video signal switching circuit and method

InactiveCN101924884ASwitch completelyNo jitterTelevision system detailsColor television detailsDigital videoExternal reference

The invention discloses digital video signal switching circuit and method. The circuit comprises an external reference signal processing module, a synchronous processing and switching module, an SDI deserializing signal module A, an SDI deserializing signal module B, an INPUT1 memory, an INPUT2 memory, an MCU controller and an SDI signal serializing, converting and driving module which are integrated on the same circuit board. The method comprises the following steps of: synchronizing a digital video signal, and purely switching the digital video signal. In the invention, the synchronous processing and switching module is used for reading data in the memories according to a clock signal CLK of an external reference signal, the synchronization type required by a product and a row / field signal extracted by the external reference signal processing module by using an H / V / F signal as a reference, thus read signals are completely synchronized; and then the synchronous processing and switching module switches the signals according to a command sent by the controller MCU, thereby the signal switching is guaranteed to be complete and is free from dithering and flashing.

Owner:DALIAN GIGATEC ELECTRONICS

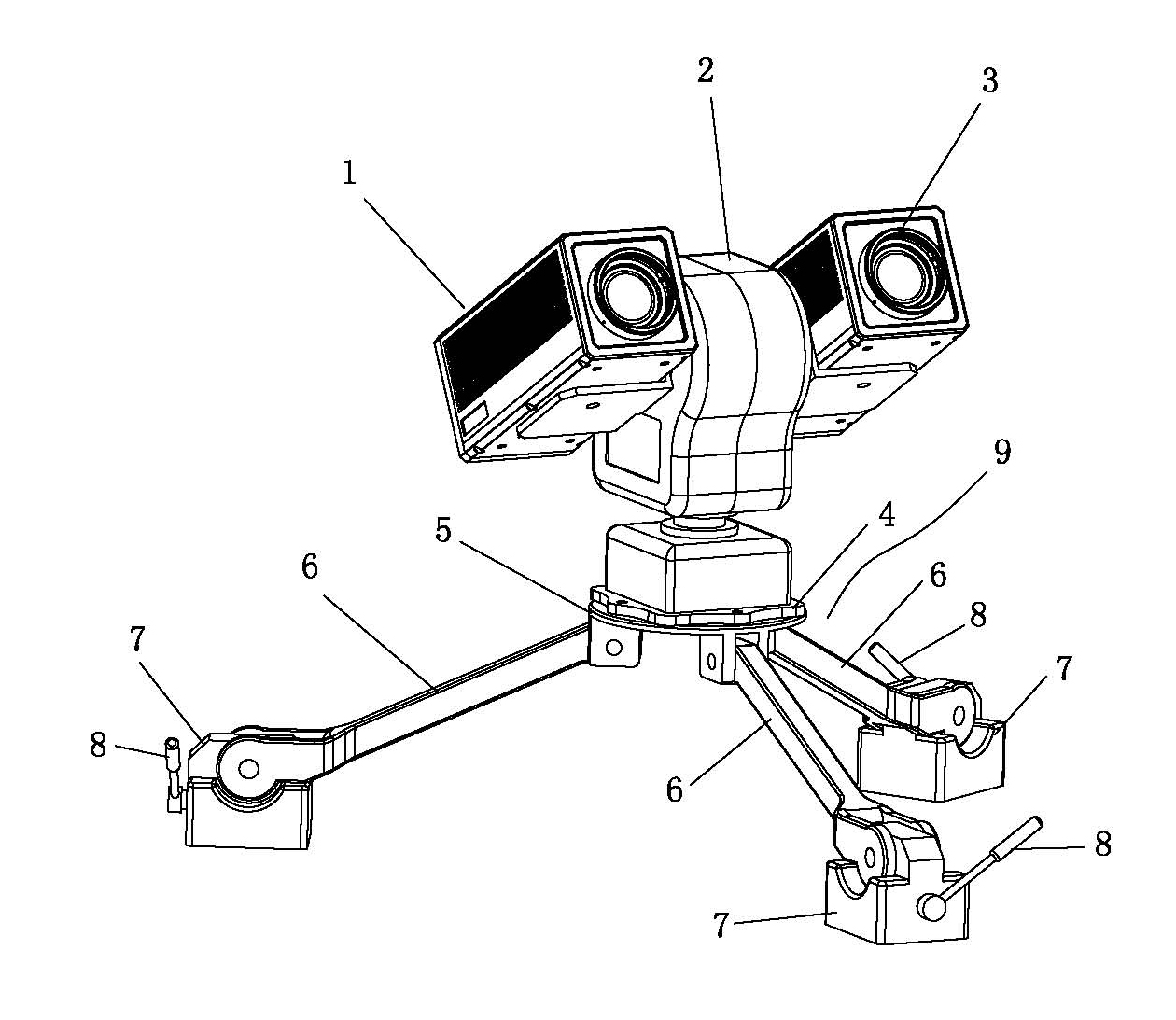

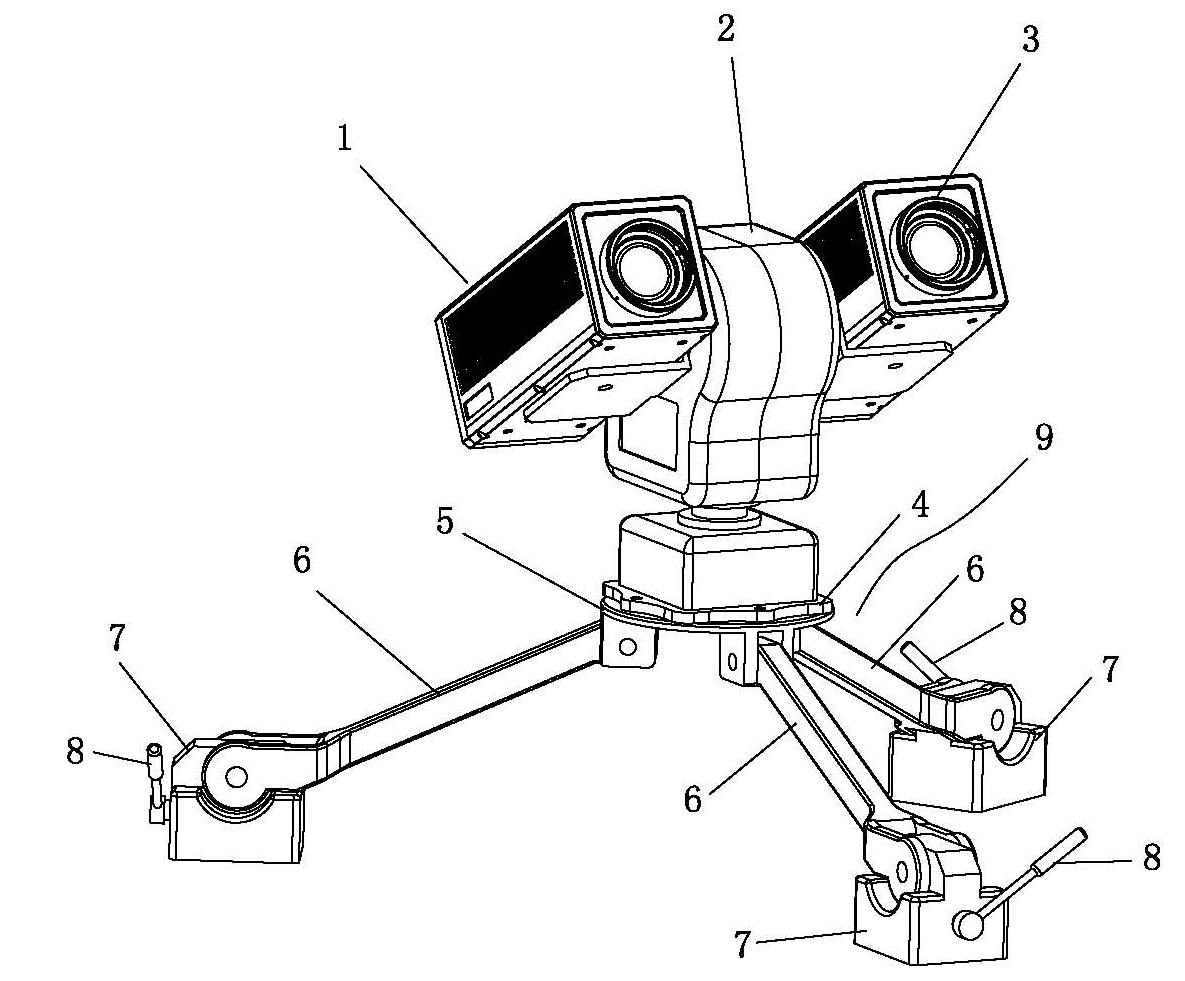

Vehicular power line detection device

InactiveCN101833057AReduce labor intensityImprove securityTelevision system detailsColor television detailsEngineeringTripod head

The invention discloses a vehicular power line detection device which comprises an infrared thermal imager, a visible light camera, a cradle head and a supporting frame which is arranged on a vehicle roof, wherein the infrared thermal imager and the visible light camera are arranged on both sides of the cradle head; and the cradle head is arranged on the supporting frame. The vehicular power line detection device is used for replacing manual detection, thereby reducing the labor intensity of power line detection and enhancing detection efficiency and safety of detection personnel. The vehicular power line detection device is convenient to assemble and disassemble and the obtained image information does not generate shake.

Owner:GUANGZHOU KEII ELECTRO OPTICS TECH

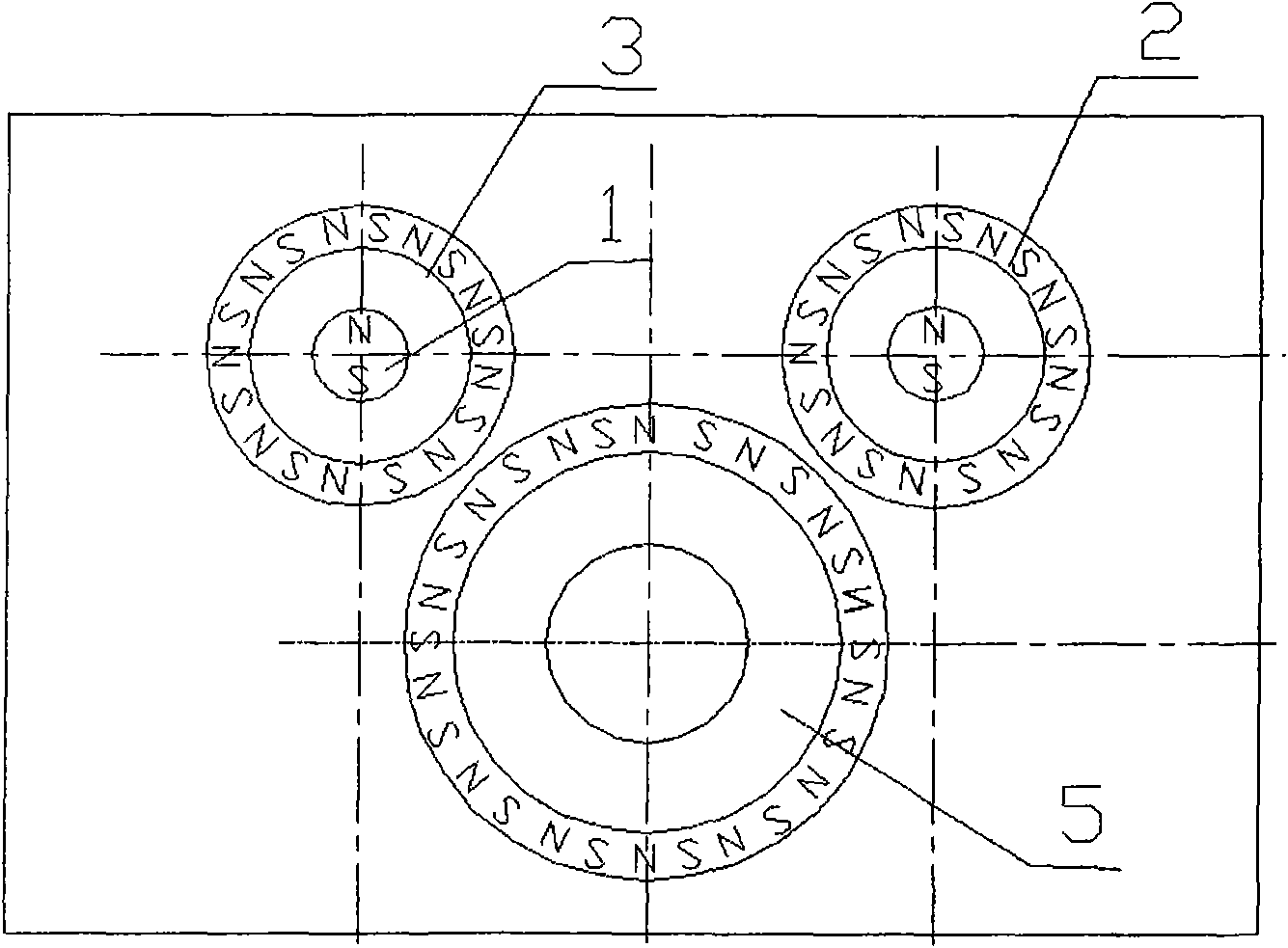

Non-contact magnetic transmission absolute angle sensor for steering system of automobile

InactiveCN101603808AOvercome the disadvantages of high price and high environmental requirementsLow environmental requirementsUsing electrical meansSteering columnEngineering

The invention relates to a non-contact magnetic transmission absolute angle sensor for a steering system of an automobile, comprising a magnetic cylinder (1), a CPU control unit (7), a magnetic wheel mechanism and Hall sensors, wherein the magnetic wheel mechanism comprises two driven magnetic gears and a driving magnet wheel (5) which is in mesh connection with the driven magnetic gears, and one magnetic steel (1) is installed on the central part of each driven magnetic gear; the driving magnet wheel is fixed on a steering column (8); and one Hall sensor is installed adjacently to each magnetic steel, and the Hall sensors are connected with the CPU control unit by data wires. The invention has the advantages of low requirement on environment, high cost performance, wide range of measurement, insensitivity to error caused by temperature, convenient installation, etc.

Owner:WUHAN UNIV OF TECH

Manufacture process improvement of diaphragm springs

InactiveCN101664788AReduce Cumulative ToleranceReduce working pressure attenuationMetal-working apparatusPunch pressEngineering

The invention discloses a manufacture process improvement of diaphragm springs, comprising the following steps: 1) blanking raw materials: namely, punching the blanking into an excircle shape of a diaphragm spring on a punch; 2) punching a window and a groove at once, namely, punching the window and the groove which forms a separated finger on the punch at the same time; 3) pressing a window fillet and an excircle fillet, namely, pressing the window fillet and the excircle fillet by a mould of the window fillet and the excircle fillet on the punch at once; 4) punching a mesopore; and 5) carrying out heat processing. The invention can improve manufacturing efficiency of diaphragm springs, reduce accumulated error of multiple working procedures, and improve dimensional accuracy of products.

Owner:浙江龙华汽配制造有限公司

Load-sensitive rotation buffer valve and crane rotation hydraulic system

ActiveCN107355437ALarge operating rangeSwing open smoothlyServomotor componentsCranesMarine engineeringOil intake

The invention discloses a load-sensitive rotation buffer valve and a crane rotation hydraulic system. A middle path of a rotation reversing valve is sequentially connected with a guide oil port of a three-way pressure compensation valve and an oil inlet of a constant flow valve through an LS feedback oil path, an oil inlet of the three-way pressure compensation valve is communicated with an oil inlet of a valve body, an oil outlet of the three-way pressure compensation valve is communicated with an oil returning opening of the valve body, an oil outlet of the constant flow valve is divided into two paths, one path is directly connected with the oil returning opening of the valve body, the other path is communicated with an oil inlet of a first one-way valve and an oil inlet of a second one-way valve at the same time, a speed adjusting valve is formed by the three-way pressure compensation valve and the rotation reversing valve, flow adjustment of a work oil port A and a work oil port B is achieved, flow is output proportionally, influences of the load are avoided, in the whole operation process, action is stable, fast and slow action is avoided, stable opening is achieved, during stopping, pressure impact is small, and a crane cannot rotate and swing.

Owner:ANHUI LIUGONG CRANE

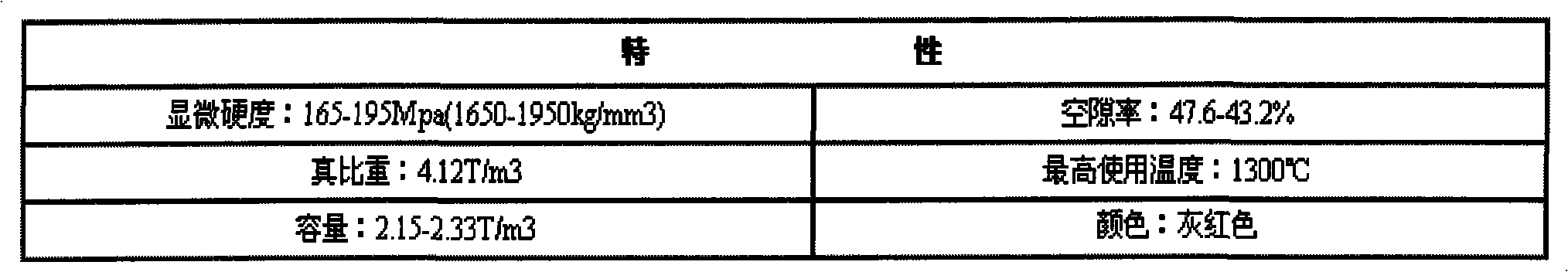

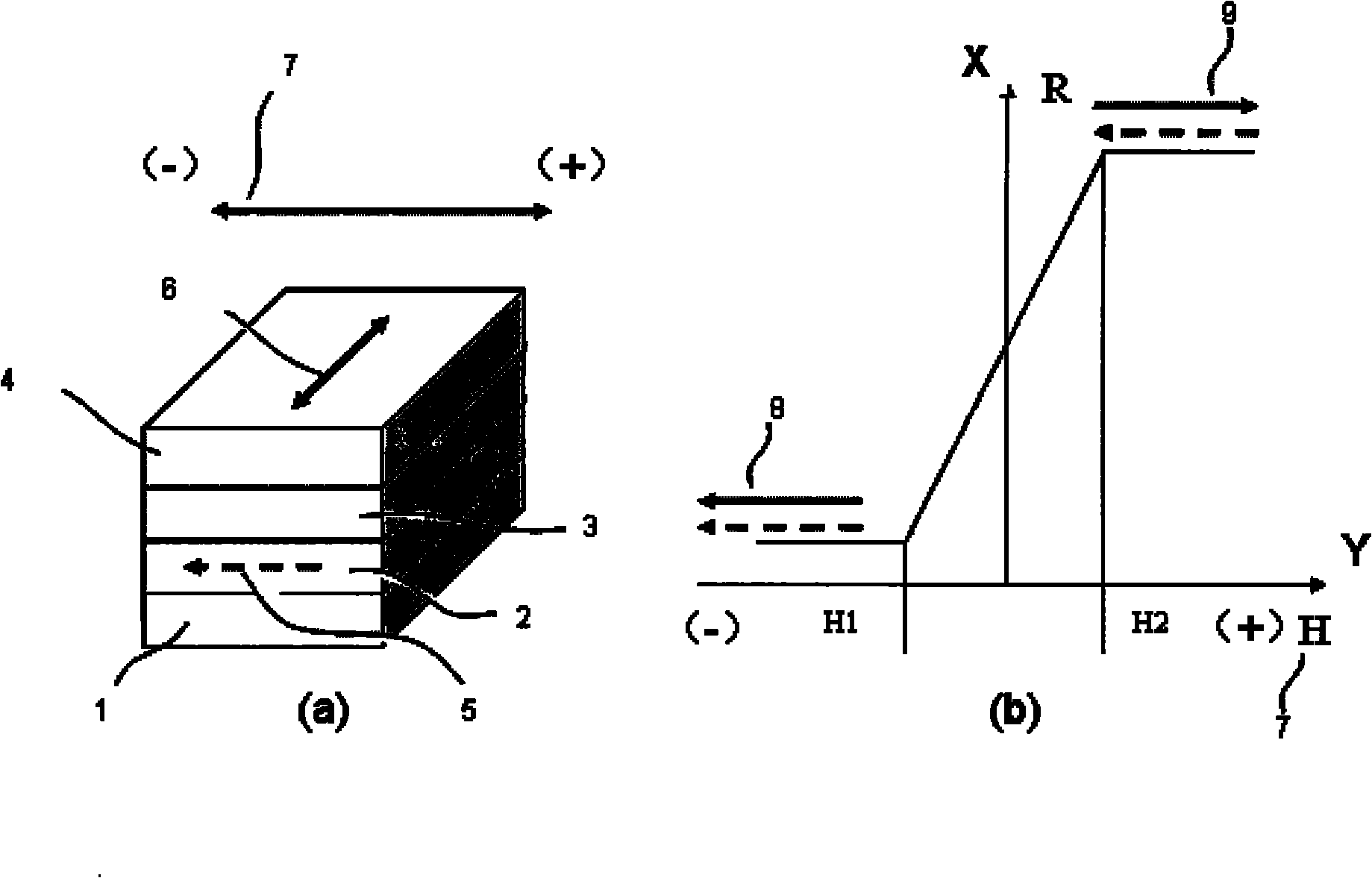

Intelligent flow meter adopting TMR (Tele Meter Reading) magnetic sensor

ActiveCN101871801AReduce power consumptionReduce volumeVolume/mass flow by electromagnetic flowmetersWorking temperatureShock resistance

The invention relates to an intelligent flow meter adopting a TMR (Tele Meter Reading) magnetic sensor, comprising a TMR flow meter sensor, a flow meter shell, a rotational impeller, a rotational impeller stand, a small magnet with an upward N pole, a small magnet with an upward S pole, a flow meter inlet / outlet, a magnetic shielding layer and a protection layer isolated a flow meter chip from fluid. When fluid to be measured exists, the measured fluid drives the rotational impeller to rotate so as to drive the small magnet with the upward N pole and the small magnet with the upward S pole to rotate simultaneously, and the TMR magnetic sensor induces a magnetic field so as to achieve the purpose of metering. The invention has the advantages of tiny power consumption, wide working frequency range and working temperature range, firm structure, small size, long service life, convenient installation, shock resistance, clear output wave shape without vibration, high position repeating accuracy, simple electromagnetic shielding structure, reverse rotation error prevention calculation, and the like.

Owner:王建国 +1

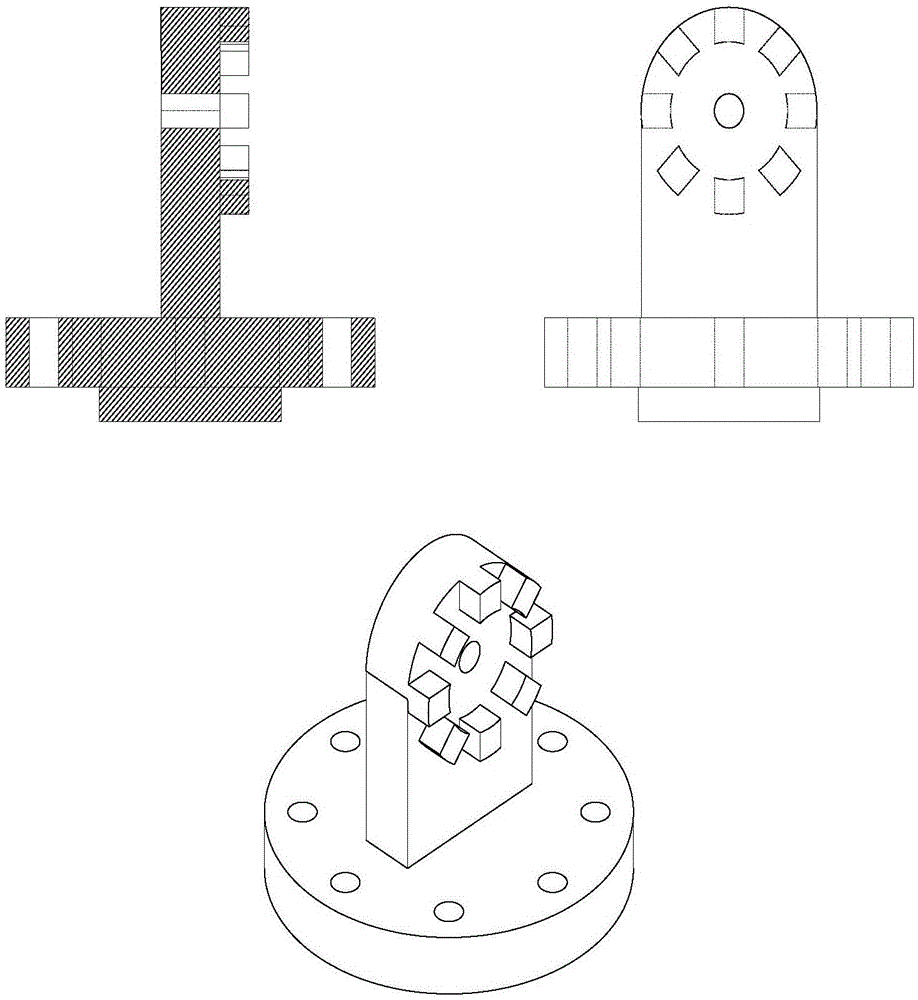

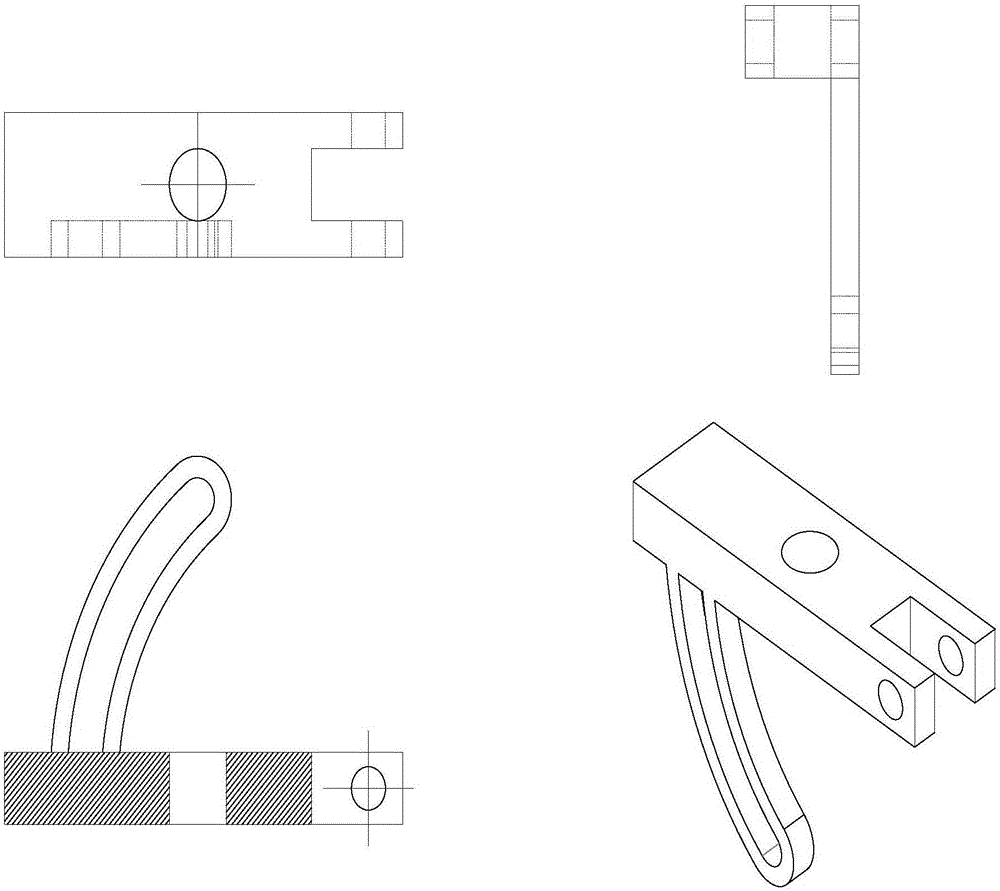

Welding gun clamping device based on welding visual system

ActiveCN106735784ASimple designEasy to useElectrode holder supportersWelding accessoriesCouplingEngineering

The invention discloses a welding gun clamping device based on a welding visual system. The clamping device is used for welding of robot deep penetration welding and comprises a welding fun, a flange plate, a cross sliding table mechanism, a horizontal moving guide rail, a camera box, a coupling, a nylon ring and a welding gun outer barrel. The welding gun is sleeved with the nylon ring and the welding outer barrel. The nylon ring is used for wrapping the welding gun. A support is arranged on the flange plate in a connected mode. The coupling is used for connecting the welding gun outer barrel and the support connected to the flange plate. The welding gun outer barrel is circular, a support is arranged on the welding gun outer barrel in a connected mode, a reinforcing rib is arranged at the tail end of the support, a gas protection holding cover is connected to the lower portion of the support, and a U-shaped groove is formed in the edge of the welding gun outer barrel. The cross sliding table mechanism is fixed to the welding gun outer barrel through a connected U-shaped groove support. The horizontal moving guide rail is fixed to the cross sliding table mechanism. The camera box is mounted on the horizontal moving guide rail and moves horizontally on a horizontal sliding table through the horizontal moving guide rail.

Owner:GUANGDONG FUWEIDE WELDING

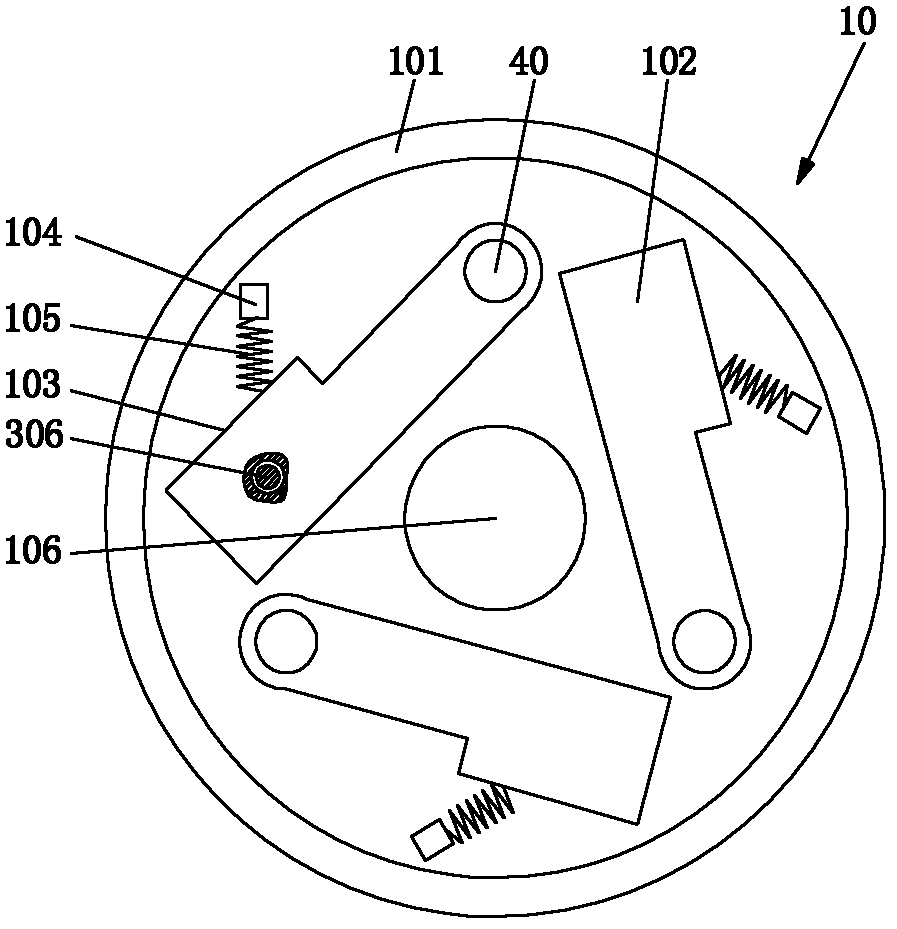

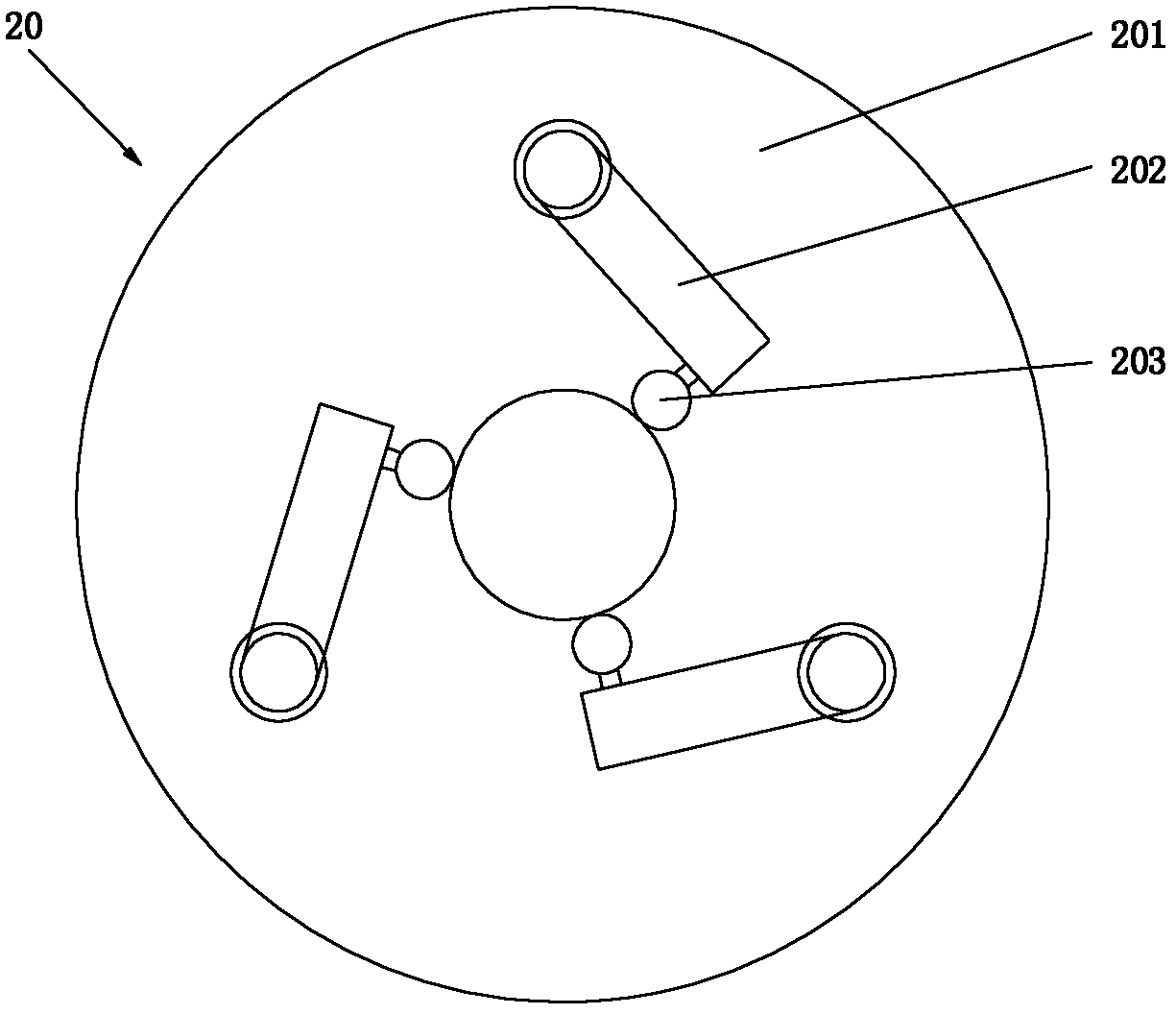

Centrifugal clamping device

InactiveCN102366899APrecise positioningQuality improvementPositioning apparatusMetal-working holdersEngineeringCentrifugal force

The invention discloses a centrifugal clamping device, which comprises a centrifugal device, wherein the centrifugal device comprises a rotary disk for generating a centrifugal force, a plurality of centrifugal blocks, a resetting device and a clamping device, wherein the centrifugal blocks are uniformly distributed on the same axial end surface of the rotary disk; one end of each centrifugal block is circumferentially fixed with a rotating shaft which is in sliding fit with the interior of an axial hole of the rotary disk; the other end of each centrifugal block is a free end and the centrifugal blocks are also connected with the resetting device; the clamping device comprises a supporting disk, a supporting rod and a centering and clamping part; a cavity for accommodating the rotary disk is arranged on one axial end surface of the supporting disk; the rotary disk can be rotatably matched with the interior of the cavity; the other end of the rotating shaft connected with the centrifugal blocks penetrates through the supporting disk, reaches the other axial end surface of the supporting disk and then is fixedly connected with one end of the supporting rod; and the centering and clamping part is fixedly arranged at the other end of the supporting rod. The centrifugal clamping device has the advantage of bringing convenience for clamping and positioning of bars.

Owner:CHANGZHOU SHENGFA BULB FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com