Optimized stamping process of dst structure diaphragm spring

A stamping and leaf spring technology, applied in the field of optimized stamping process of DST structure diaphragm spring, can solve the problems of low product dimensional accuracy, low production efficiency, and many technological processes, and achieves elimination of errors, improvement of fatigue life, extraction of The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

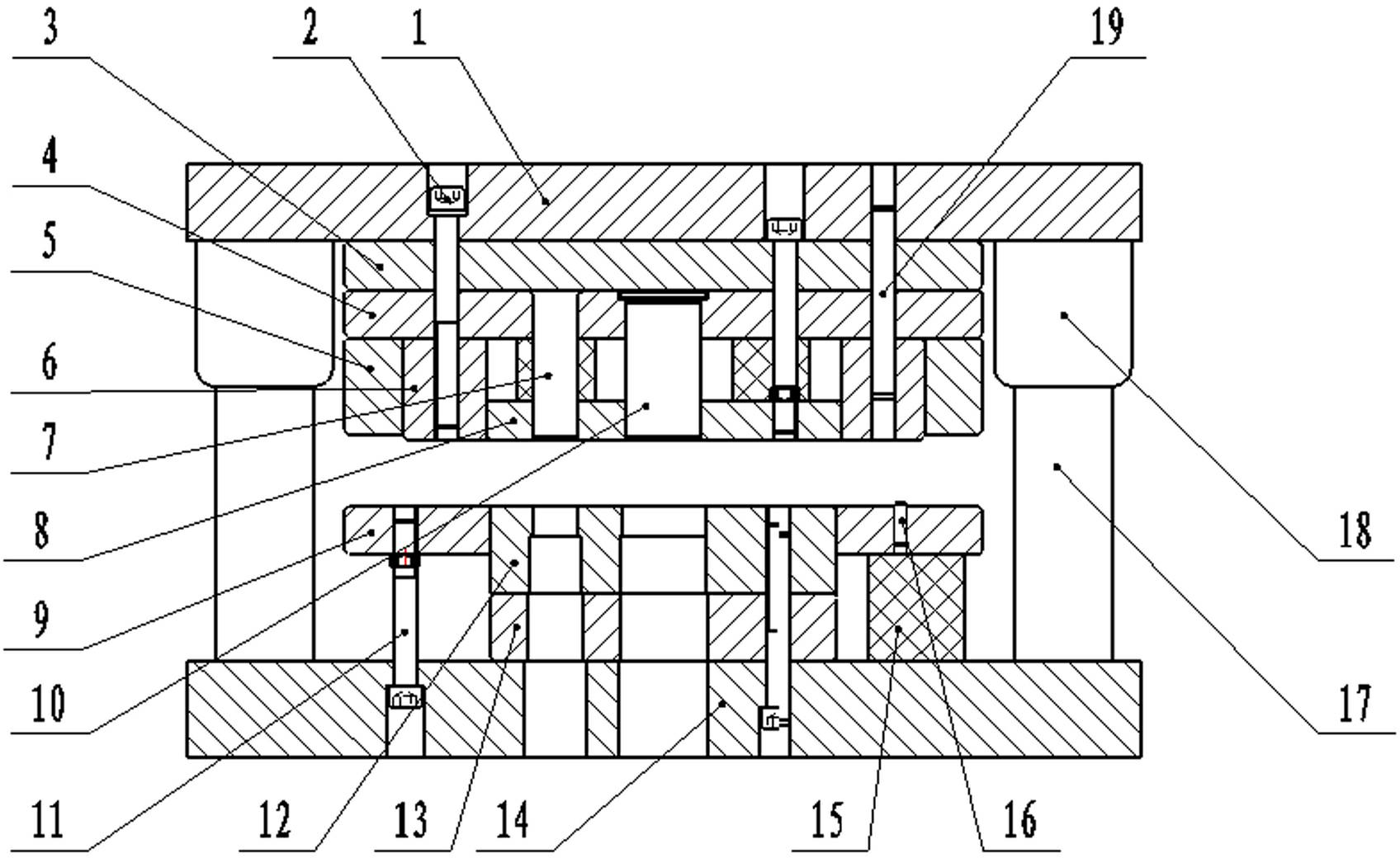

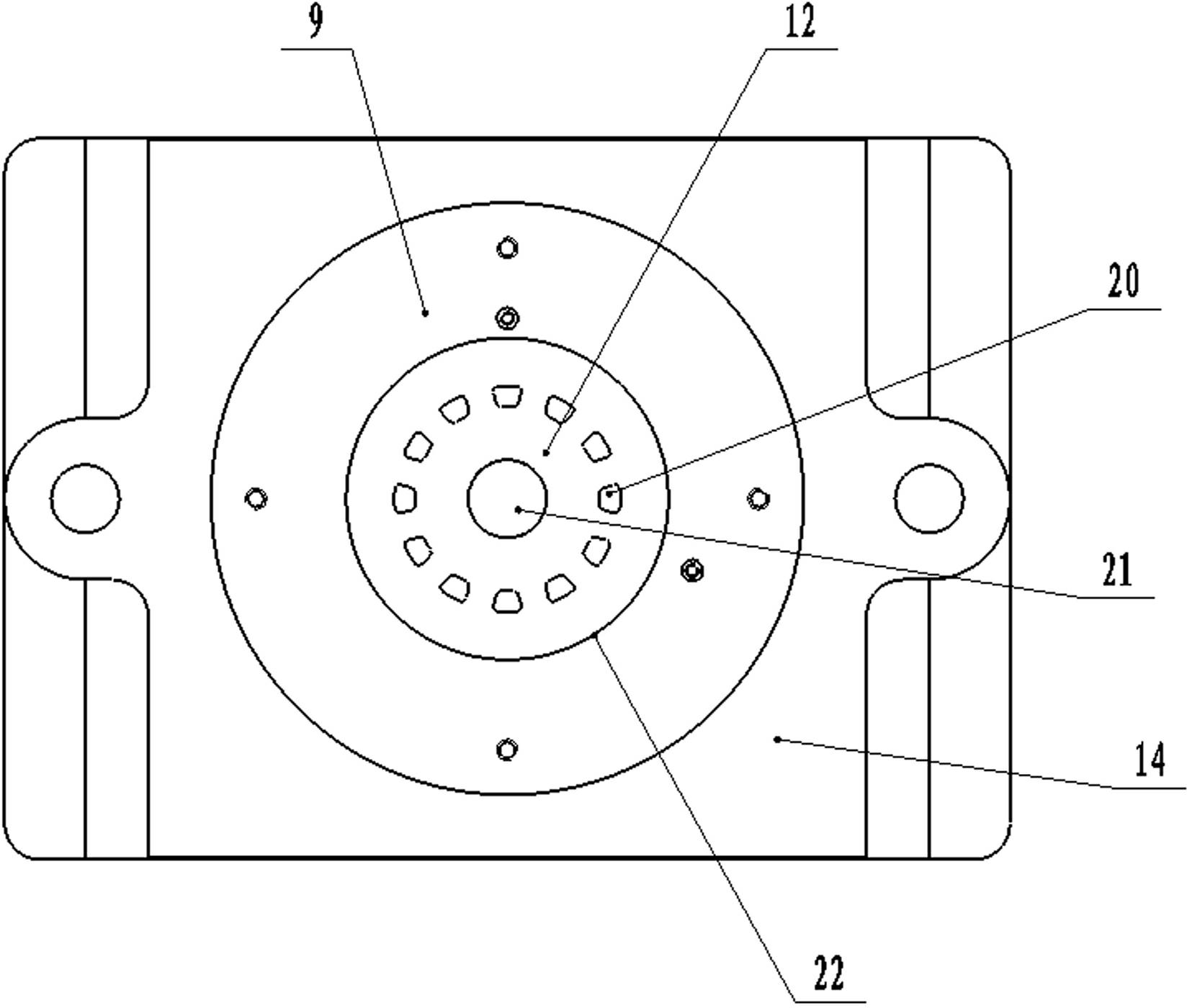

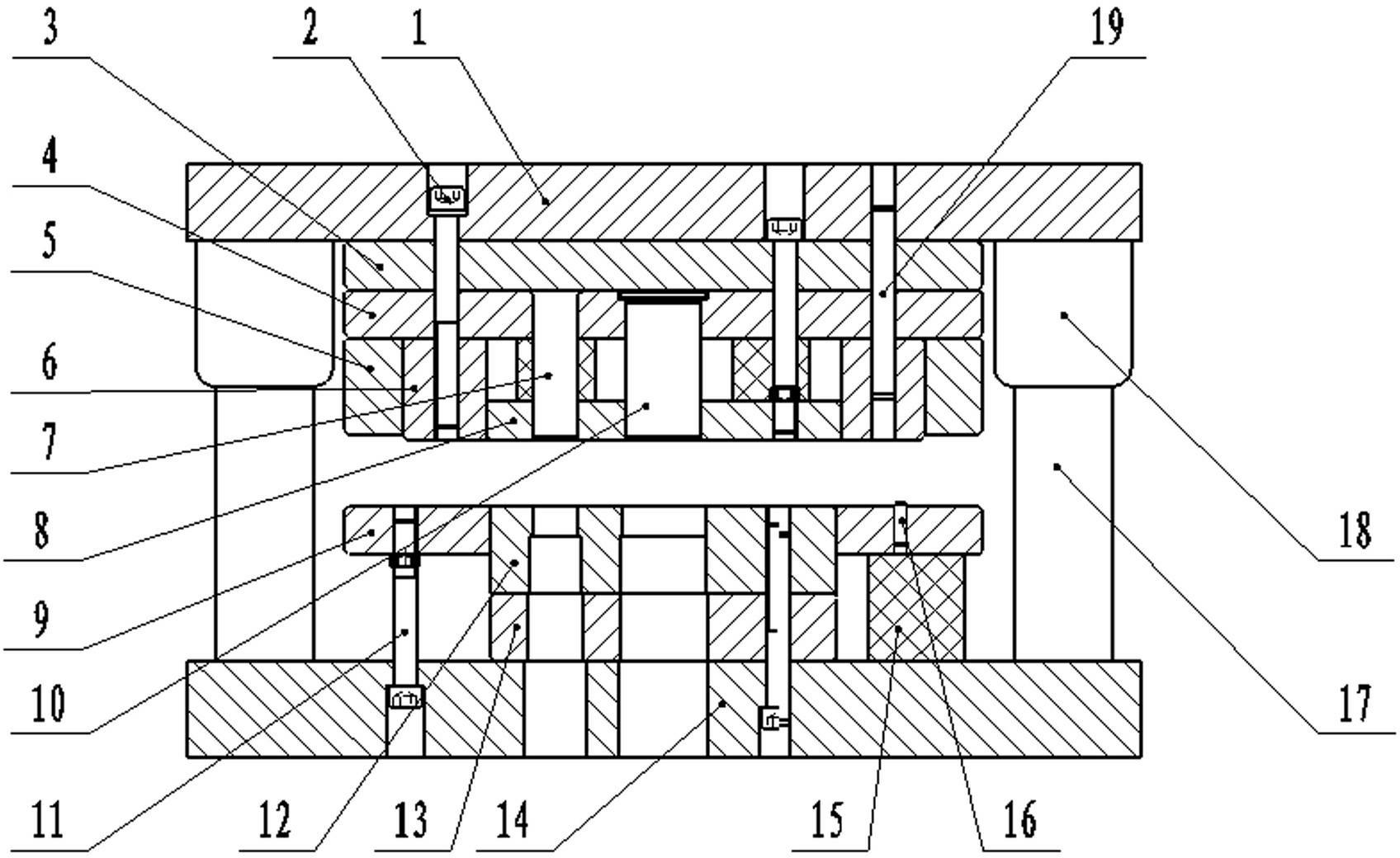

[0021] refer to figure 1 , the DST structure diaphragm spring blanking, punching hole, and window mold of the present invention include an upper template 1, a screw 2, an upper backing plate 3, a punch fixing plate 4, a die holding plate 5, a die 6, Window punch 7, upper unloading plate 8, lower unloading plate 9, middle hole punch 10, unloading screw 11, convex and concave die 12, lower backing plate 13, lower template 14, rubber 15, stopper pin 16, guide post 17 , guide sleeve 18 and cylindrical pin 19, window punch 7 and center hole punch 10 are fixed on the punch fixing plate 4, the die 6 is connected and fixed on the punch fixing plate 4 by screws 2 and the die holding plate 5 is held tightly , in order to prevent the sheets from being stuck, an upper unloading plate 8, a lower unloading plate 9 and an unloading screw 11 are also provided. The upper unloading plate 8 is fixed on the punch fixing plate 4 through the unloading screw 11, and the lower unloading plate The pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com