Intelligent flow meter adopting TMR (Tele Meter Reading) magnetic sensor

A magnetic sensor and flowmeter technology, applied in the field of flowmeters, can solve the problems of low output amplitude, unfavorable signal remote transmission, etc., and achieve the effects of small power consumption, firm structure, and wide operating temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

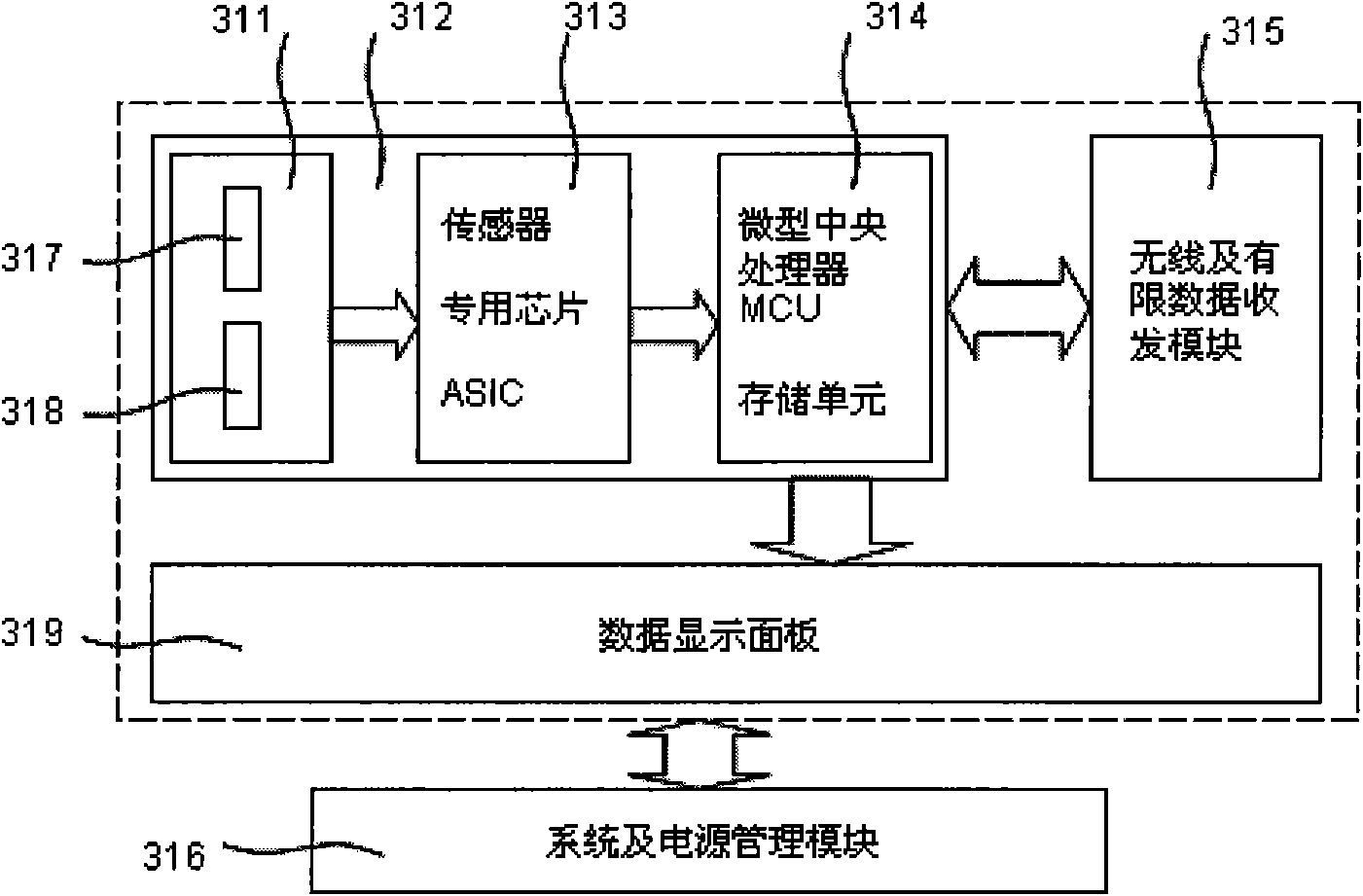

[0023] The invention relates to an intelligent flow meter using a TMR magnetic sensor. Including: flowmeter casing, rotating impeller, rotating impeller bracket, a small magnet with N pole facing upward and a small magnet with S pole facing upward, inlet and outlet of flowmeter, magnetic shielding layer, protective layer to isolate flowmeter chip from fluid , Flow meter chip (TMR sensor chip, wireless and wired data transceiver module, data display panel and system and power management module).

[0024] The present invention will be further elaborated below in conjunction with the accompanying drawings.

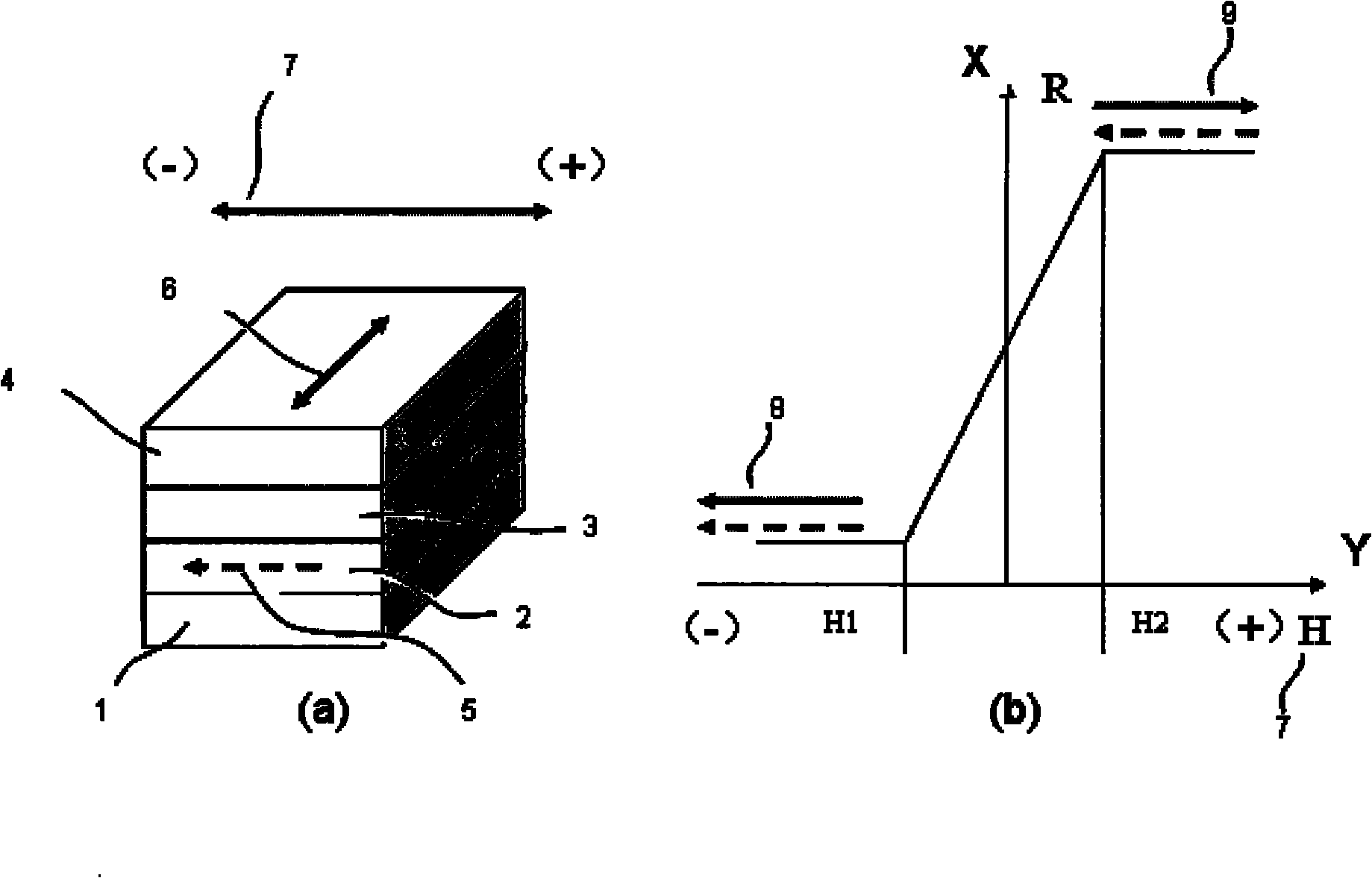

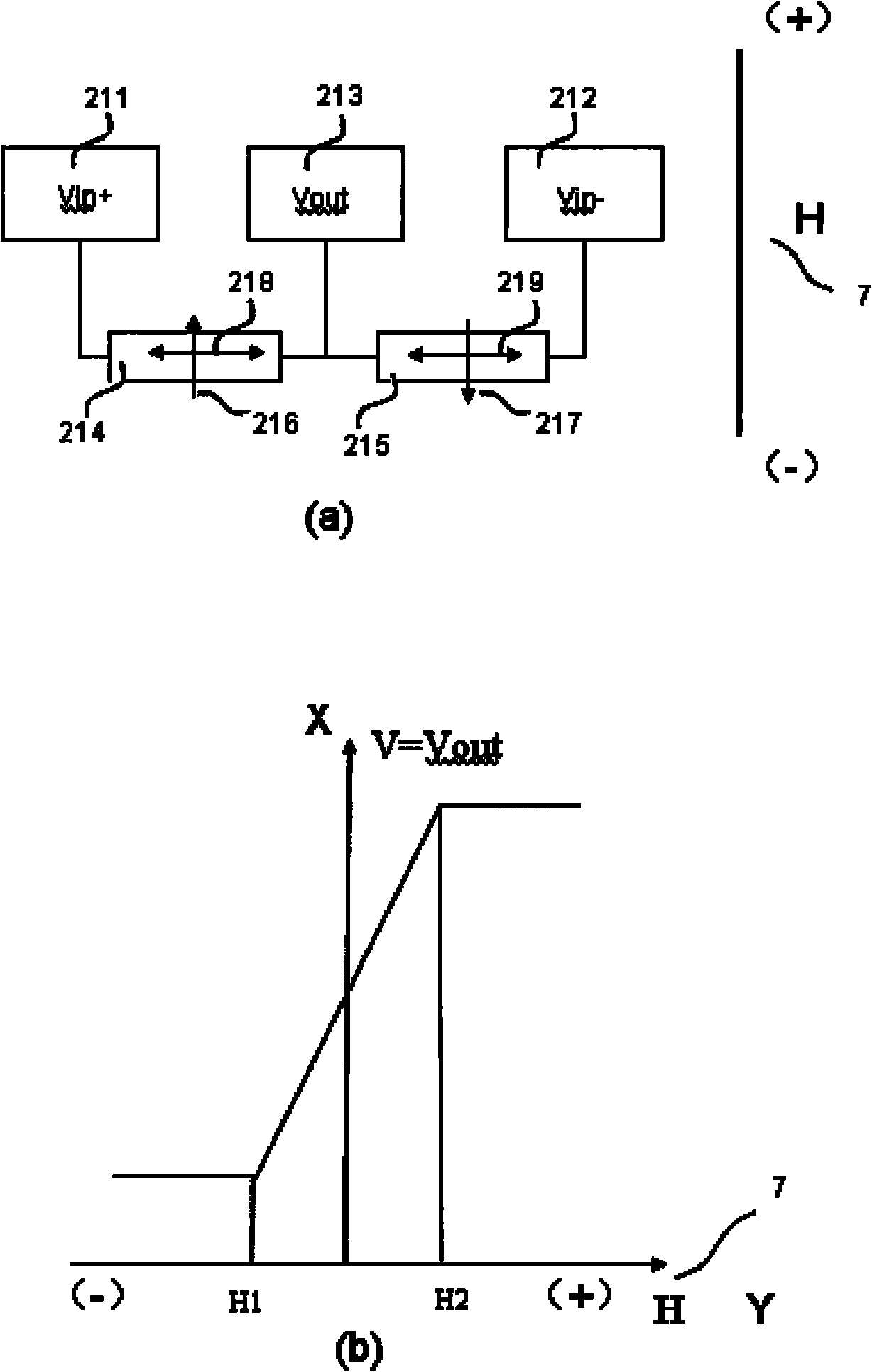

[0025] The structure of the TMR tunnel junction magnetoresistance effect element, such as figure 1 As shown in (a), it consists of nanoscale multilayer films: pinned layer 1, magnetic pinned layer 2, nonmagnetic oxide layer 3, and magnetic free layer 4. The magnetic moment direction of the magnetic pinned layer 2 is shown in FIG. 5 . The magnetic moment direction of the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com