Centrifugal clamping device

A technology of clamping device and centrifugal device, which is applied in the direction of positioning device, clamping, support, etc., can solve the problems of high clamping pressure, safety accidents, poor clamping and positioning, etc., and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

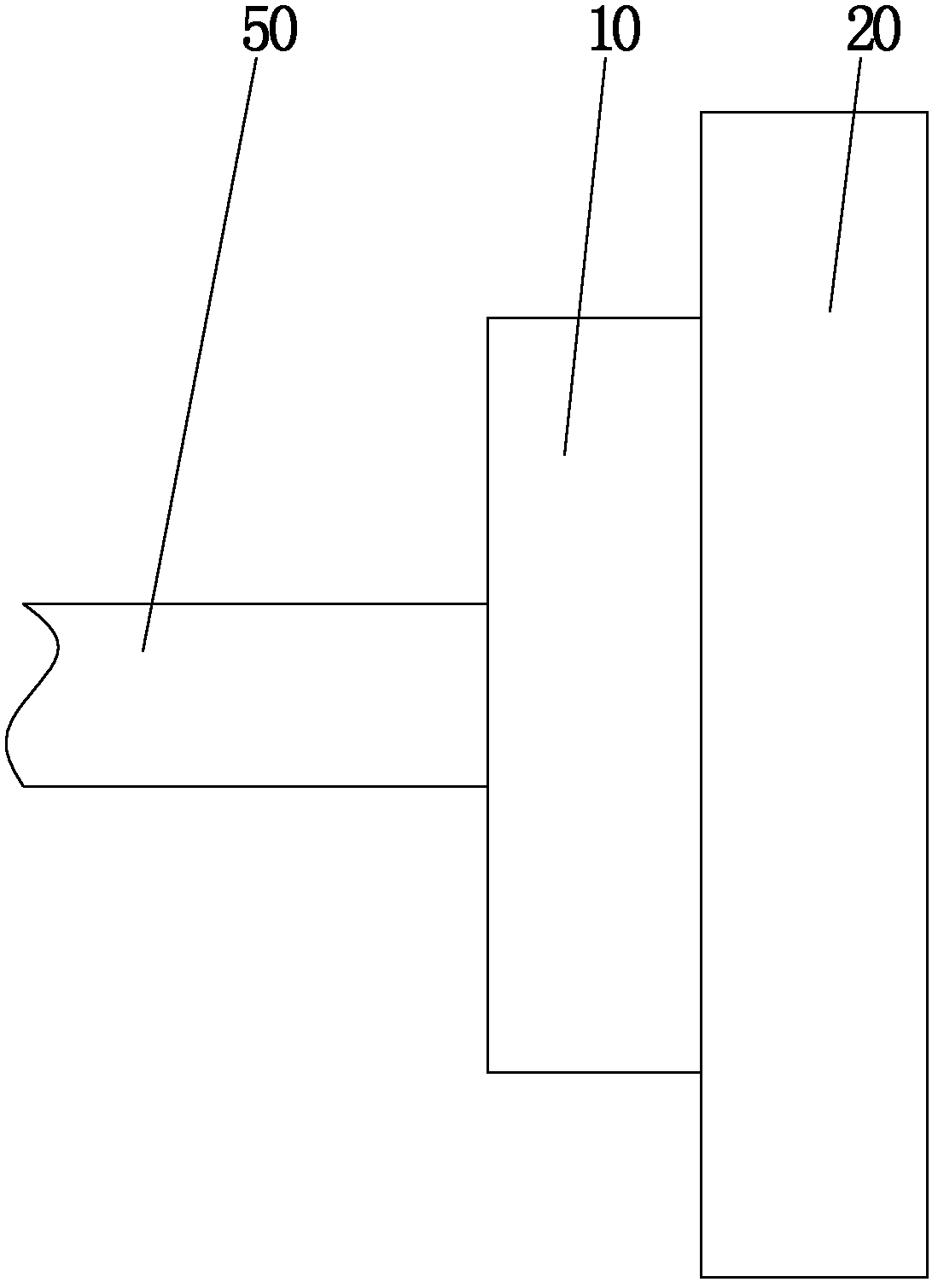

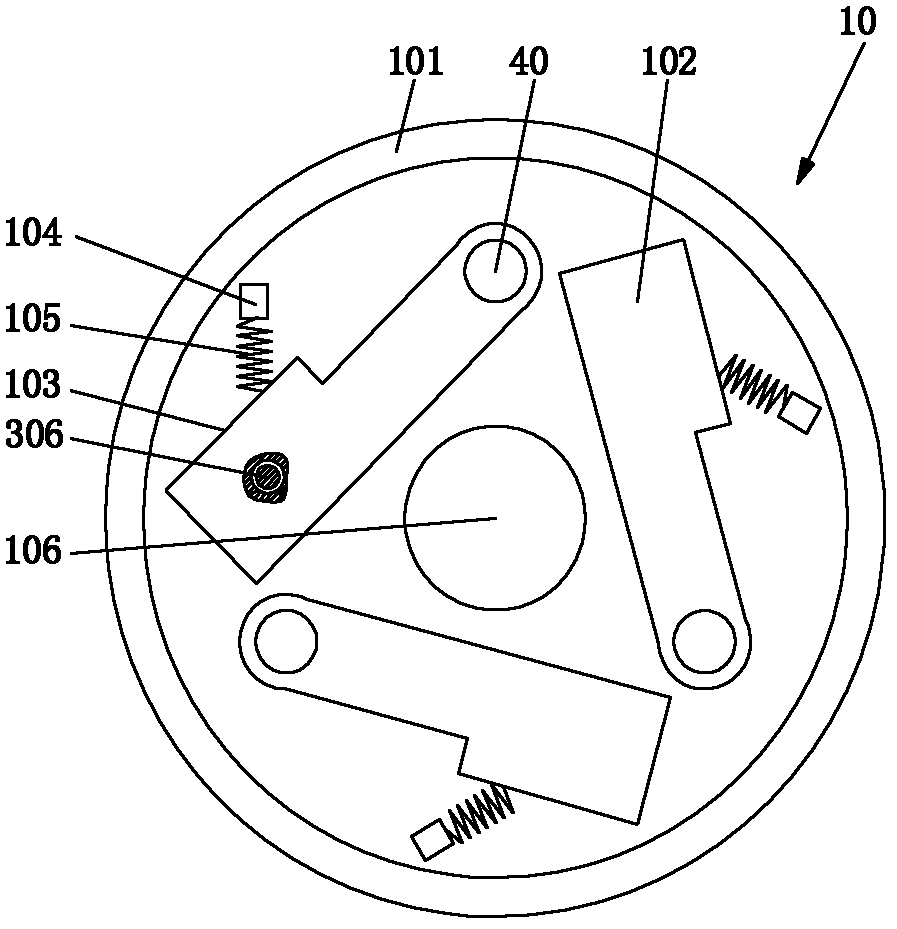

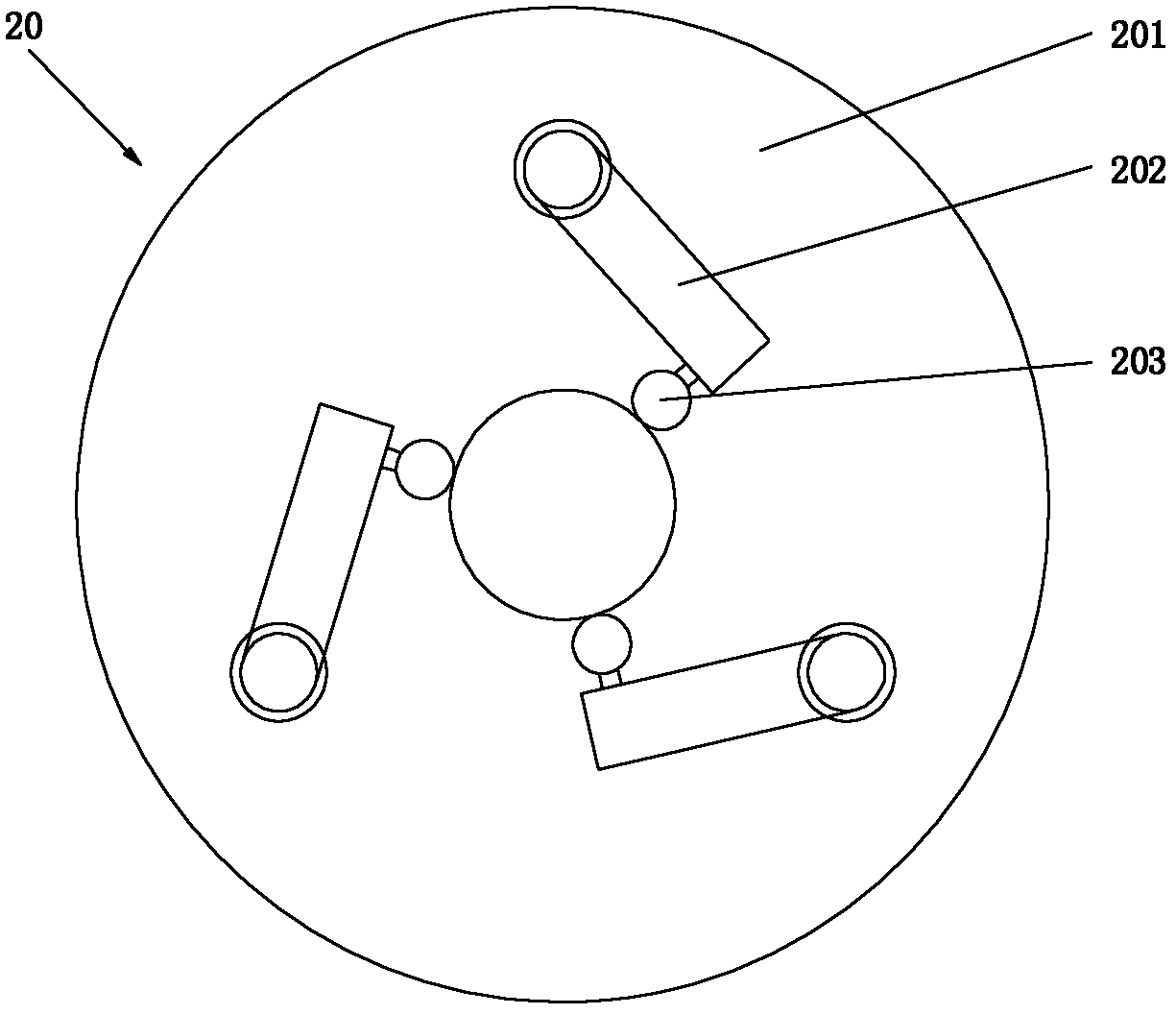

[0018] refer to figure 1 , the centrifugal clamping device of the present invention is mainly composed of a centrifugal device 10, a clamping device 20 and a locking device 30. The structure of each part and the combination between them will be described in detail below:

[0019] refer to figure 1 and figure 2 , the centrifugal device 10 includes a rotating disk 101 for generating centrifugal force, a plurality of centrifugal blocks 102, and a reset device. A central hole 106 for installing the power shaft 50 for generating torque is provided in the middle of the rotating disk 101, and an axial end surface of the rotating disk 101 is provided with a concave cavity, and the centrifugal block 102 and the reset device are installed in the concave cavity. The arrangement of the centrifugal blocks is as follows: each centrifugal block 101 is evenly distributed on the same axial end surface of the rotating disk, and one end of each centrifugal block 101 is circumferentially fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com