Welding gun clamping device based on welding visual system

A vision system and a clamping device technology, which are applied to the device supporting electrode clamps, welding equipment, welding accessories, etc., can solve the problems such as the lens and camera cannot be well protected, difficult to operate, and the field of view is skewed and jittered. To achieve the effect of good monitoring effect, small adjustment amount and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

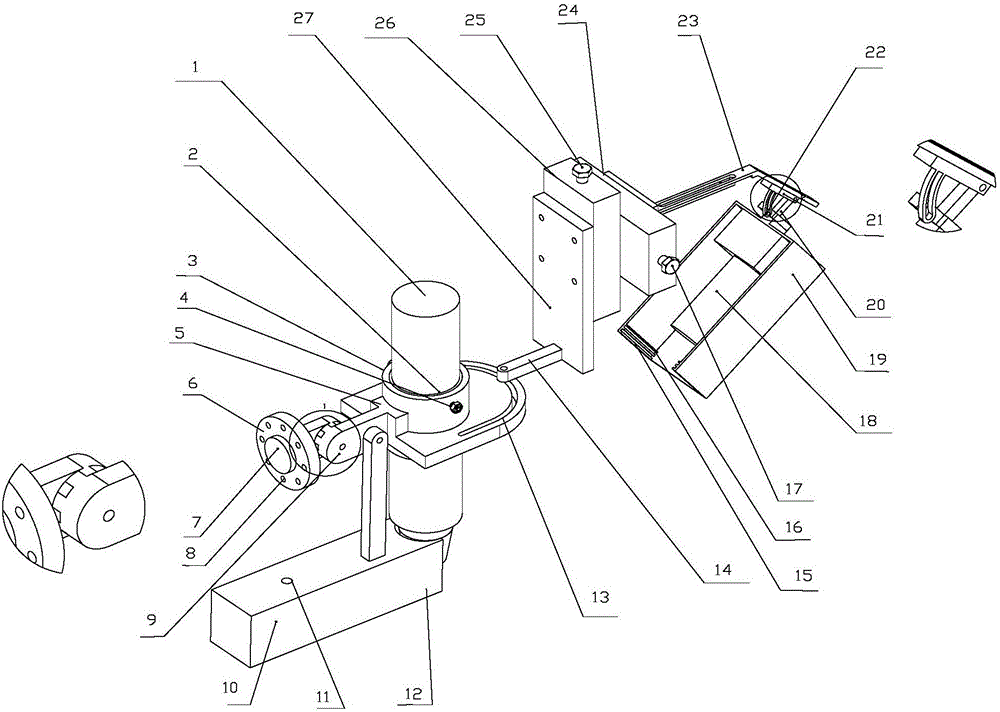

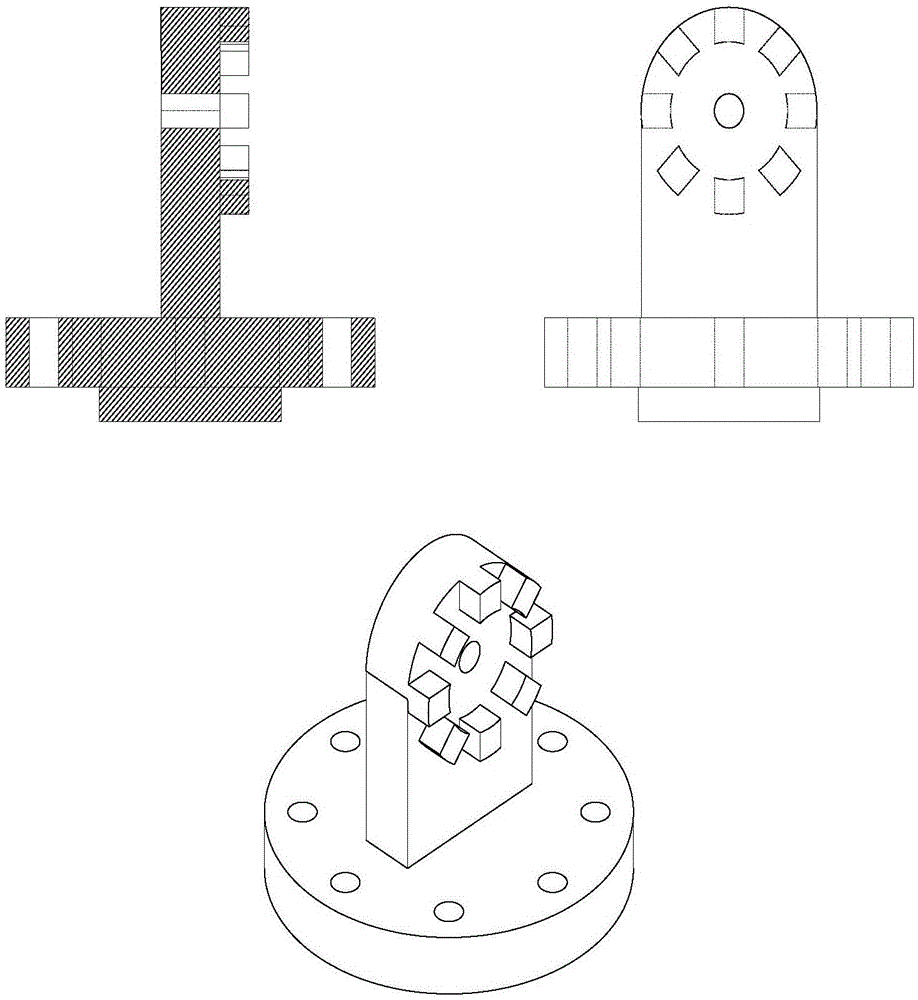

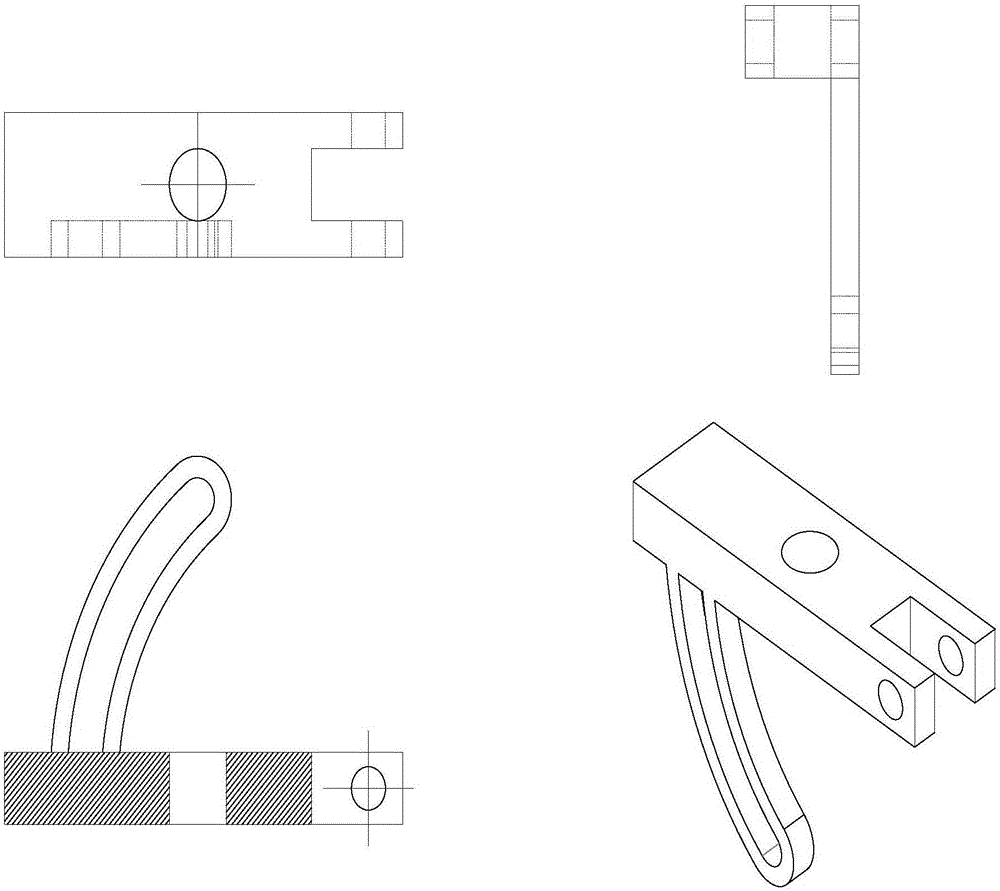

[0025] Such as figure 1 , figure 2 and image 3 Shown is the structure of the welding torch clamping device based on the welding vision system, including: welding torch 1, flange plate 6, cross slide mechanism, horizontal moving guide rail, camera box 19, coupling 8, nylon ring and welding torch outer cylinder;

[0026] The nylon ring and the outer barrel of the welding torch are sleeved on the outside of the welding torch, and the nylon ring 2 is used to wrap the welding torch;

[0027] The flange connection is provided with a bracket;

[0028] The coupling is used to connect the welding torch outer cylinder 3 and the bracket connected to the flange; the coupling can be disassembled, and the couplings are fastened with bolts 9, and the trapezo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com