Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "No flying phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

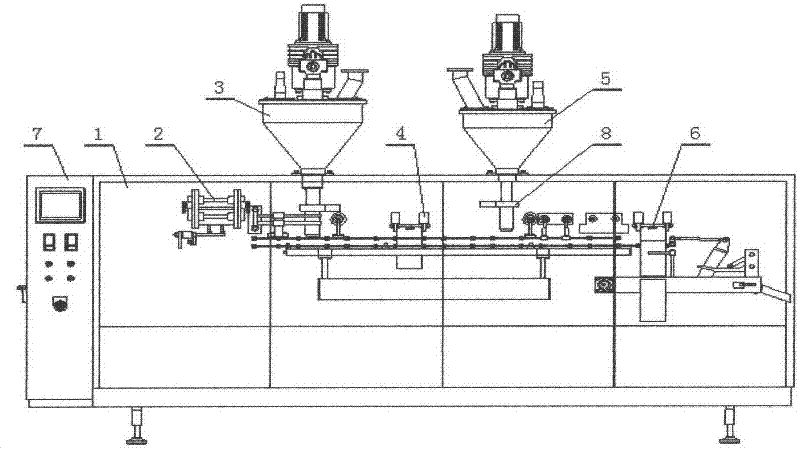

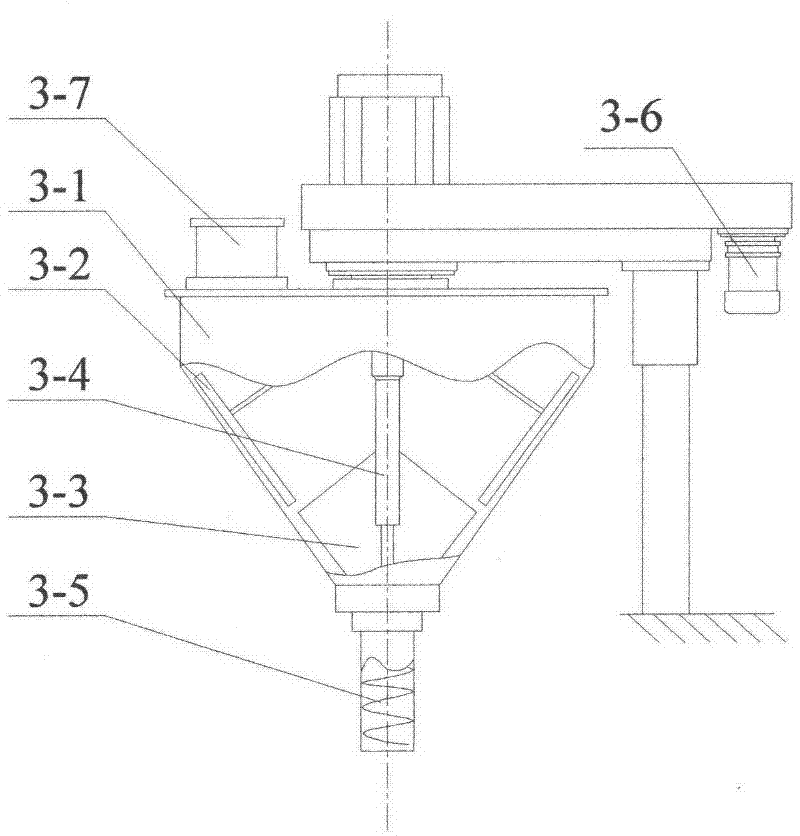

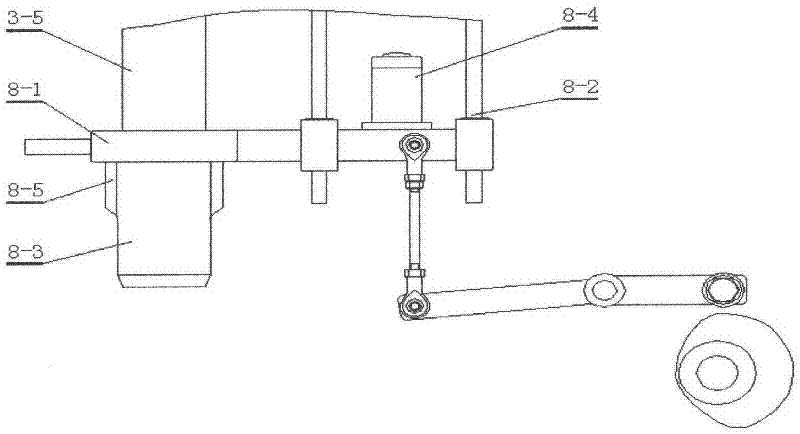

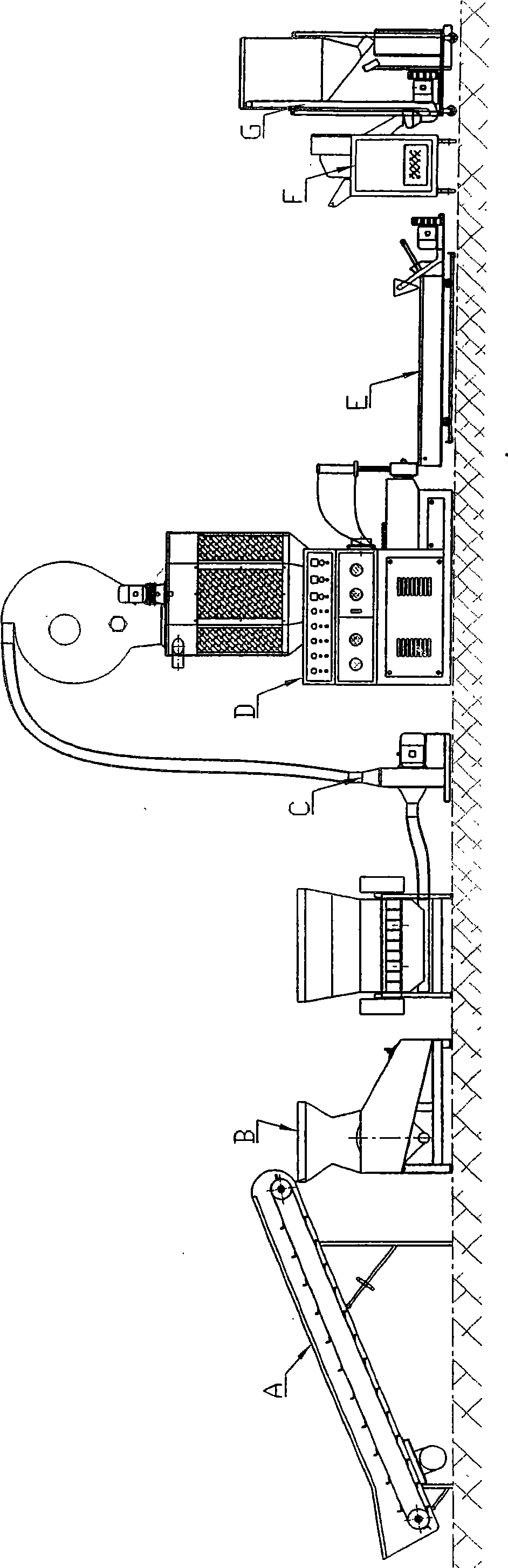

Accurate weighing type packaging machine system and filling method

InactiveCN102351051AHigh precisionNo flying phenomenonSolid materialLiquid materialFilling materialsPackaging machine

The invention discloses an accurate weighing type packaging machine system and a filling method, which solves the technical problem of accurately filling materials in a material packaging process, and makes a material filling quantity be possibly close to a standardized weight, so as to make the material filling quantity achieve an allowed error range through at least two filling processes; a filling mechanism structure of a packaging bag comprises at least two material filling machines; a sub-packaging quantity monitoring device is arranged between the two material filling machines, the packaging bag is located; the former-stage material filling machine conveys the filled packaging bag to the sub-packaging quantity monitoring device to weight, and conveys the packaging bag to the next-stage material filling machine to refill after feeding back information, and finally conveys the refilled packaging bag to a sub-package post-processing mechanism until weight precision of the materials in the packaging bag achieves the allowed error range of the design.

Owner:石增明

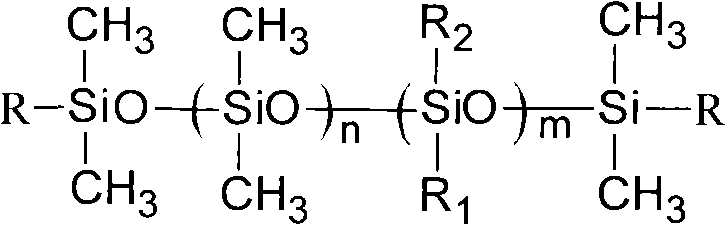

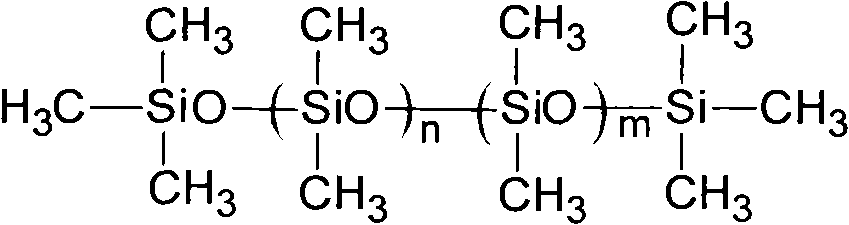

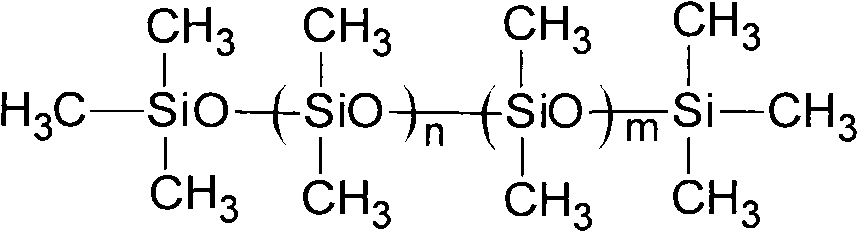

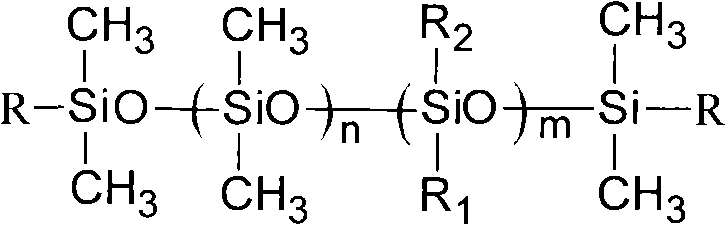

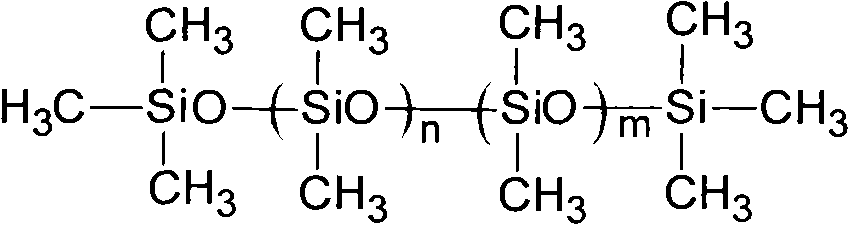

Silicone oil electric force compound grease and preparation method thereof

InactiveCN102024505AImprove high temperature resistanceImprove low temperature resistanceNon-conductive material with dispersed conductive materialCable/conductor manufactureSilicone oilMetal powder

The invention discloses electric force compound grease and a preparation method thereof. The silicone oil electric force compound grease mainly comprises silicon oil, white carbon black and conductive metal powder, wherein the white carbon black is subject to surface treatment with a lipophilic processing agent. The silicone oil electric force compound grease comprises the following components in parts by weight: 100 parts of silicon oil, 20-33 parts of precipitated silica subject to the surface treatment with the lipophilic processing agent, 65-90 parts of conductive metal powder, 0-2 parts of stabilizing agent and 0-2 parts of anti-oxygen agent, or the silicone oil electric force compound grease is also composed of the following components in parts by weight: 100 parts of silicon oil, 10-15 parts of fumed silica subject to the surface treatment with the lipophilic processing agent, 65-90 parts of conductive metal powder, 0-2 parts of stabilizing agent and 0-2 parts of anti-oxygen agent. The silicone oil electric force compound grease disclosed by the invention has the advantages of high dropping point temperature, good attachment property, stable rationalizing property, long service life and good economic property.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV +2

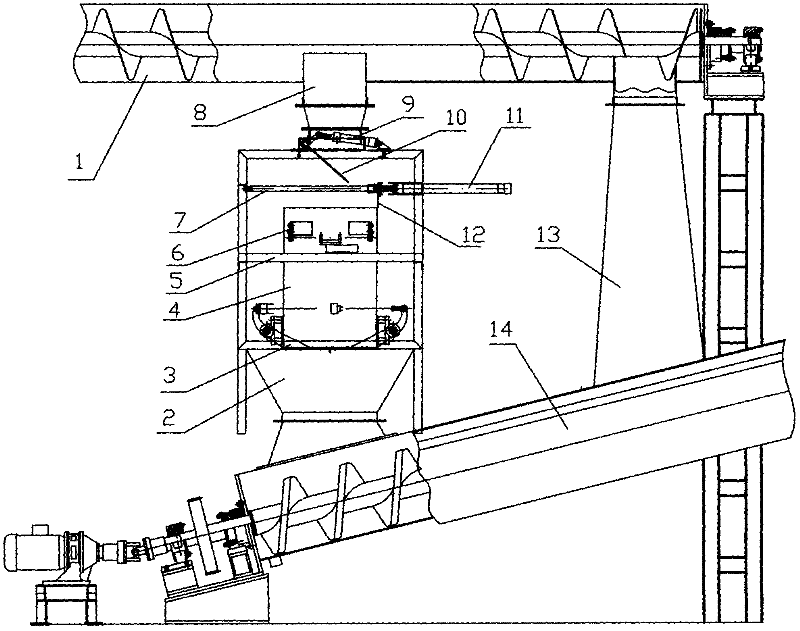

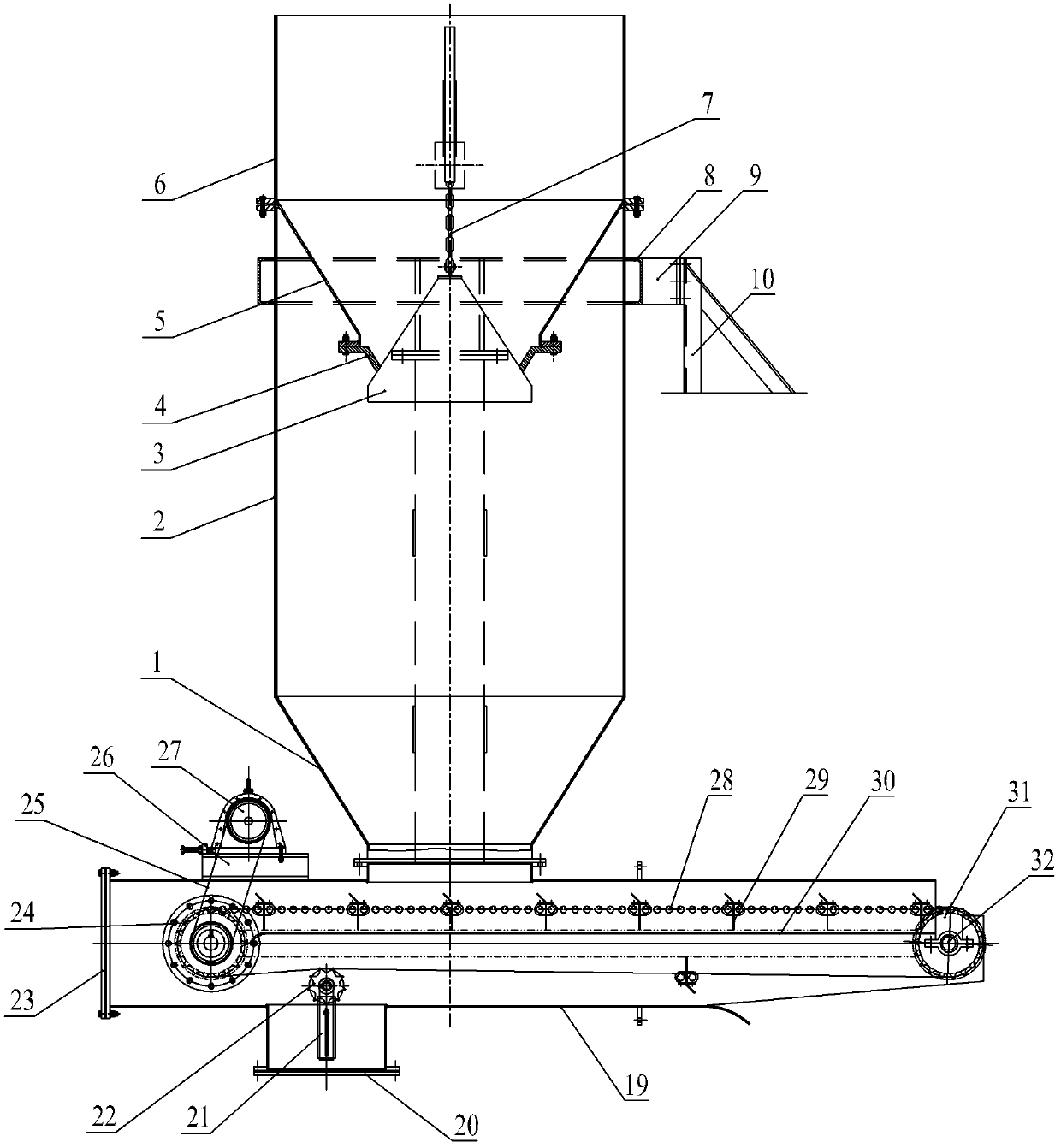

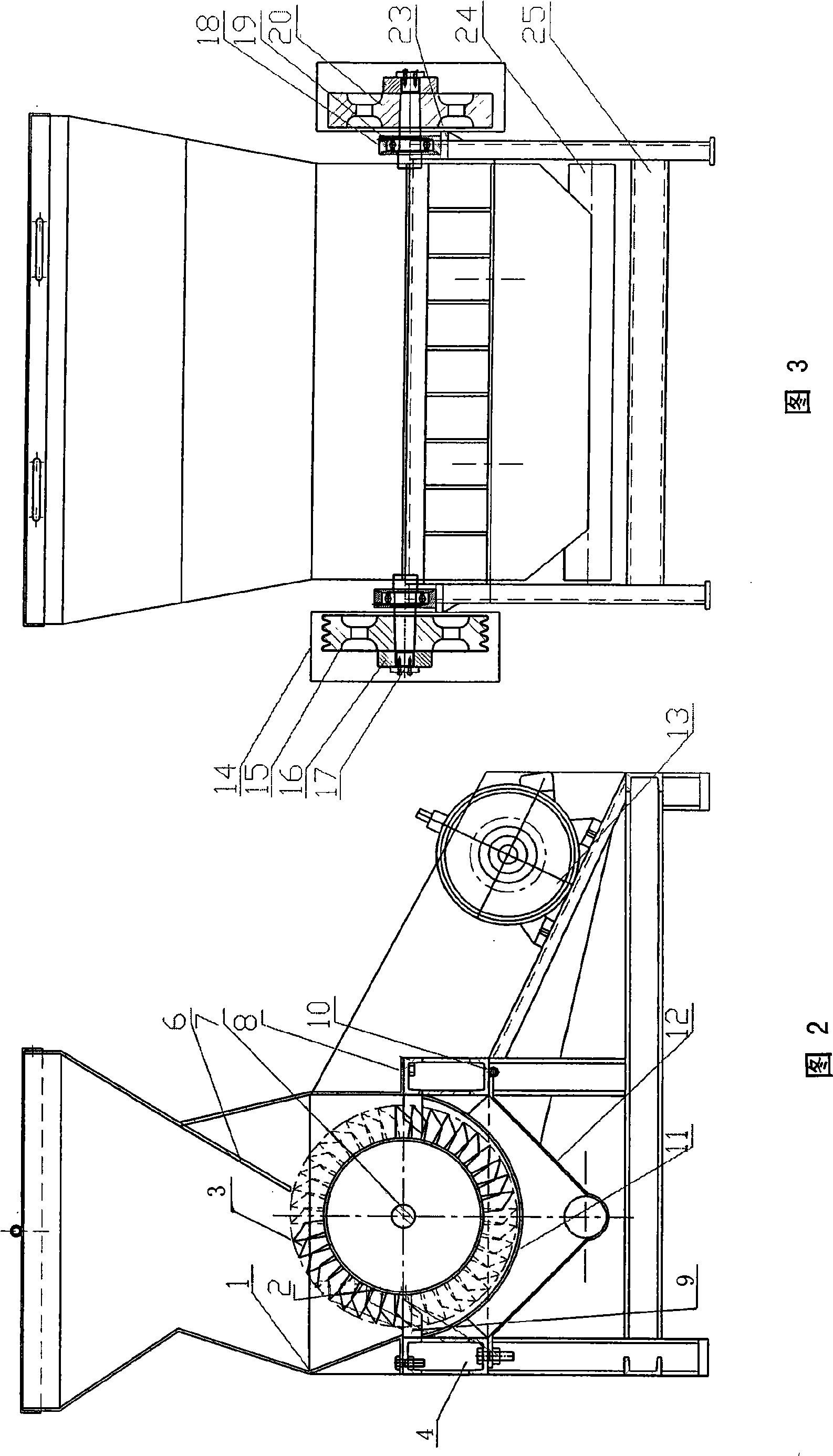

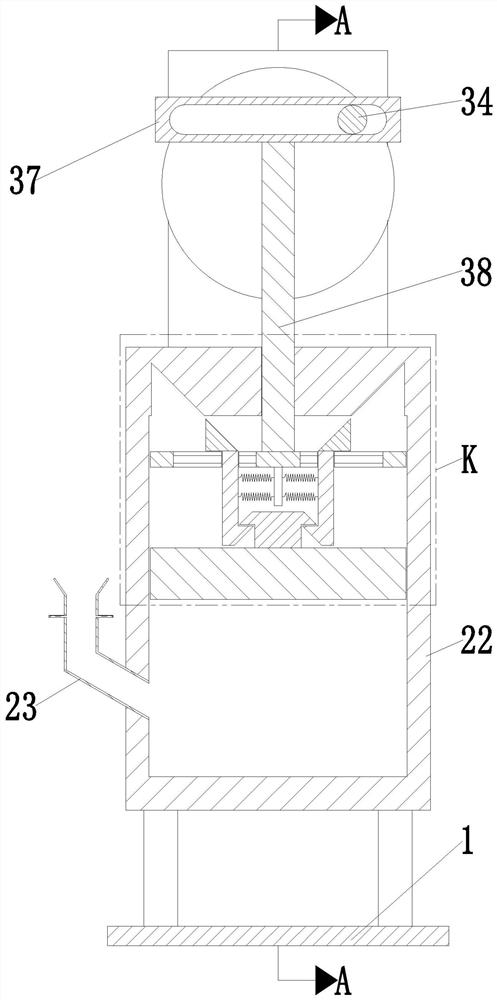

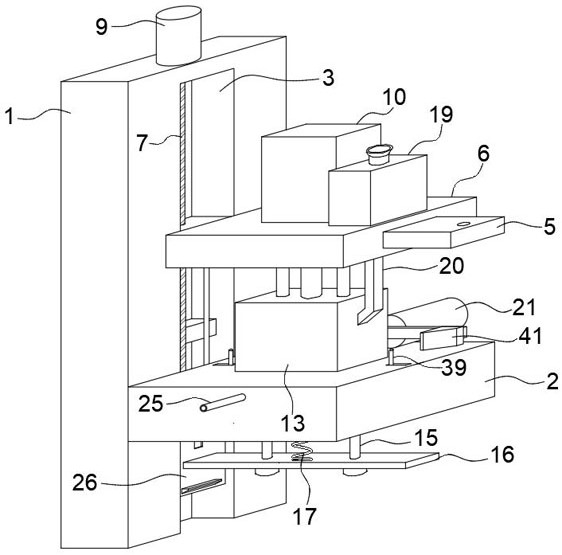

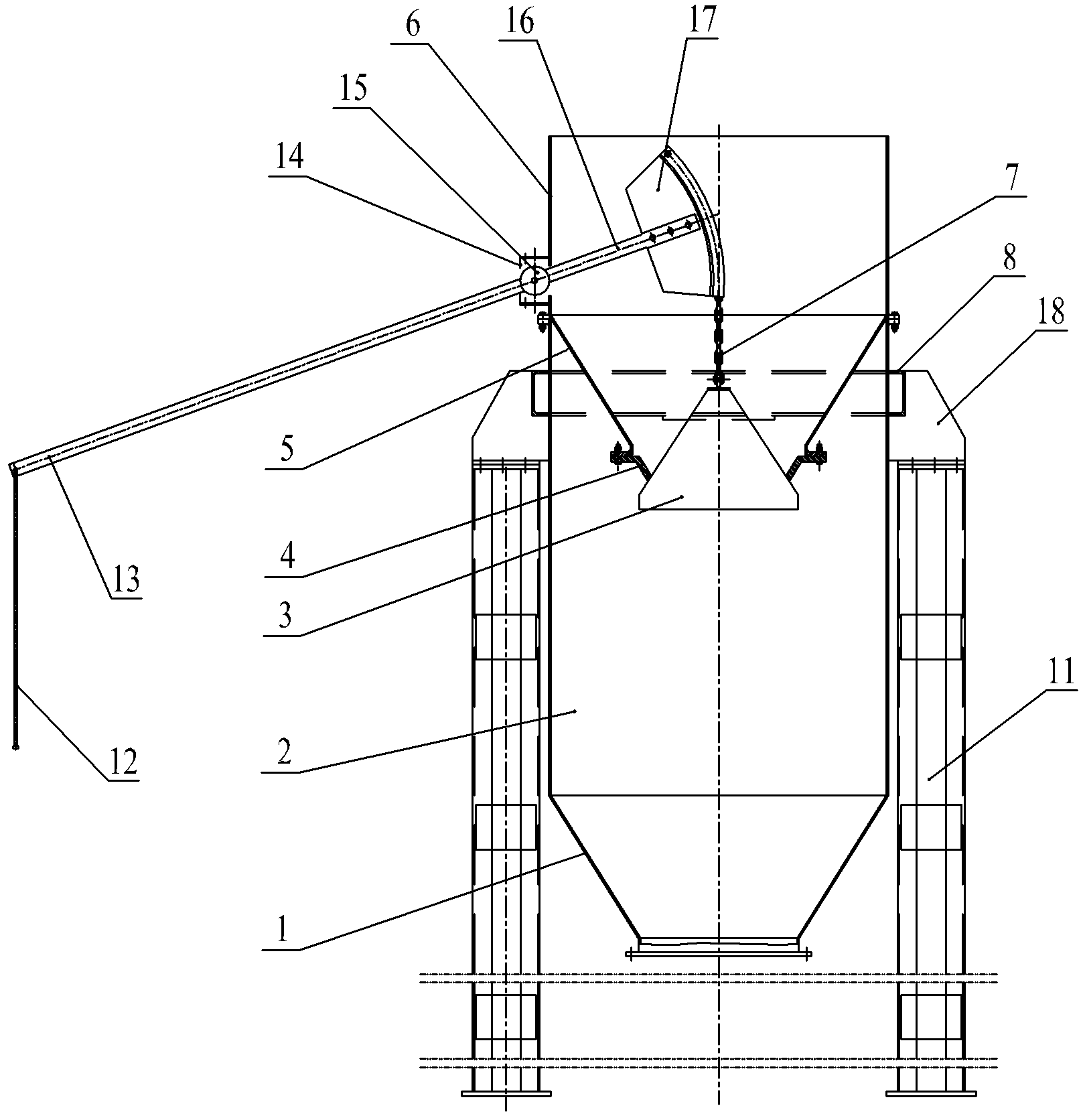

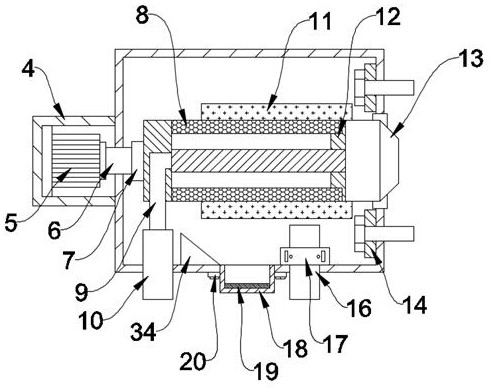

Method and device for automatically detecting powder material accumulation density

ActiveCN102175566ADetectiveFunctionalSpecific gravity measurementControl systemProgrammable logic controller

The invention relates to a method and a device for automatically detecting powder material accumulation density, relating to a device for detecting powder (granular) material accumulation density. The method comprises the following steps of: (1) connecting a material dividing hopper with an original spiral conveyer pipe; (2) opening a material dividing valve at the lower part of the material dividing hopper so that materials fall to a material weighing hopper supported by a weighing sensor; (3) scraping stacks at the top of the material weighing hopper through a material pushing scraping plate driven by a material pushing cylinder; (4) transmitting weight information of the material weighing hopper to a PLC (programmable logic controller) control system for calculating, comparing and displaying by the weighing sensor; (5) opening a material discharging valve at the lower part of the material weighing hopper so that the materials fall to a material receiving hopper and enter to a secondary spiral conveyer; and (6) pushing the materials falling from the material receiving hopper to be combined with the materials falling from an original spiral conveyer material discharging tube and sending to next procedure together by the secondary spiral conveyer. The device disclosed by the invention has the advantages of automatic identifying function, high accuracy, fast speed and high efficiency; and the device is capable of realizing full check, and effectively controlling the product quality.

Owner:青海海西东诺化工有限公司

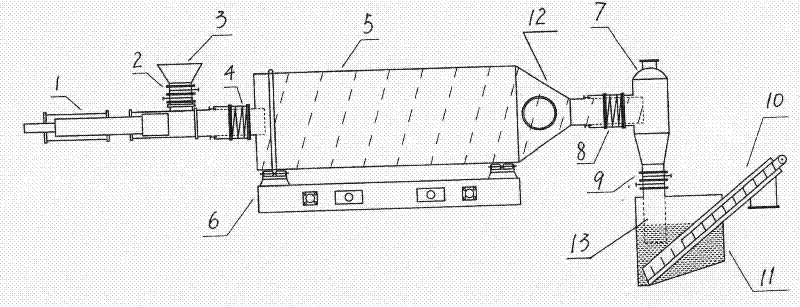

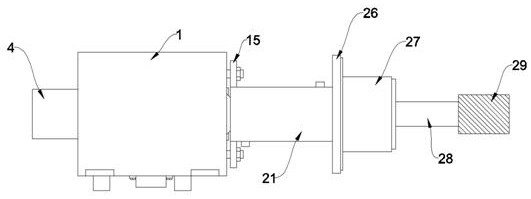

Intermittent type waste rubber cracking device

ActiveCN102504857ANo flying phenomenonIncrease the feeding speedLiquid hydrocarbon mixture productionCombustionSlag

The invention provides an intermittent type waste rubber cracking device, which is composed of a hydraulic feeding machine, a cracking kettle, a gas-slag separator, a combustion furnace, a deslagging water tank and a high temperature cut-off valve, wherein the hydraulic feeding machine is connected with the cracking kettle through a dynamic and static sealer; one high temperature cut-off valve is connected between a feeding hopper of the hydraulic feeding machine and the hydraulic feeding machine; a cone is arranged at a discharge end of the cracking kettle with an inner screw; and a deslagging end of the gas-slag separator is connected with a deslagging opening through one high temperature cut-off valve. The deslagging opening of the gas-slag separator is arranged in the deslagging water tank below the gas-slag separator and the lower end of a scraper deslagging machine is arranged below the deslagging opening of the gas-slag separator. The intermittent type waste rubber cracking device provided by the invention has the advantages of fast feeding speed and short deslagging time; after materials are completely cracked, the continuous feeding and the continuous deslagging at a high-temperature state can be realized; a wet-type deslagging way is adopted, so that a phenomenon that ash residue flies off does not happen, the work environment is improved and the safety and environmental protection are realized.

Owner:瑞新环境科技民权县有限公司

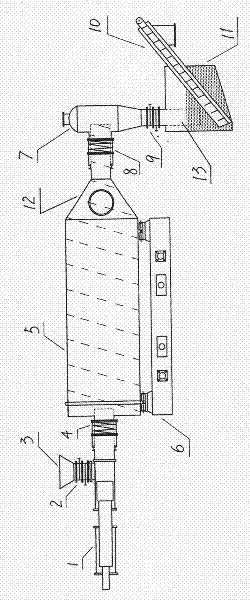

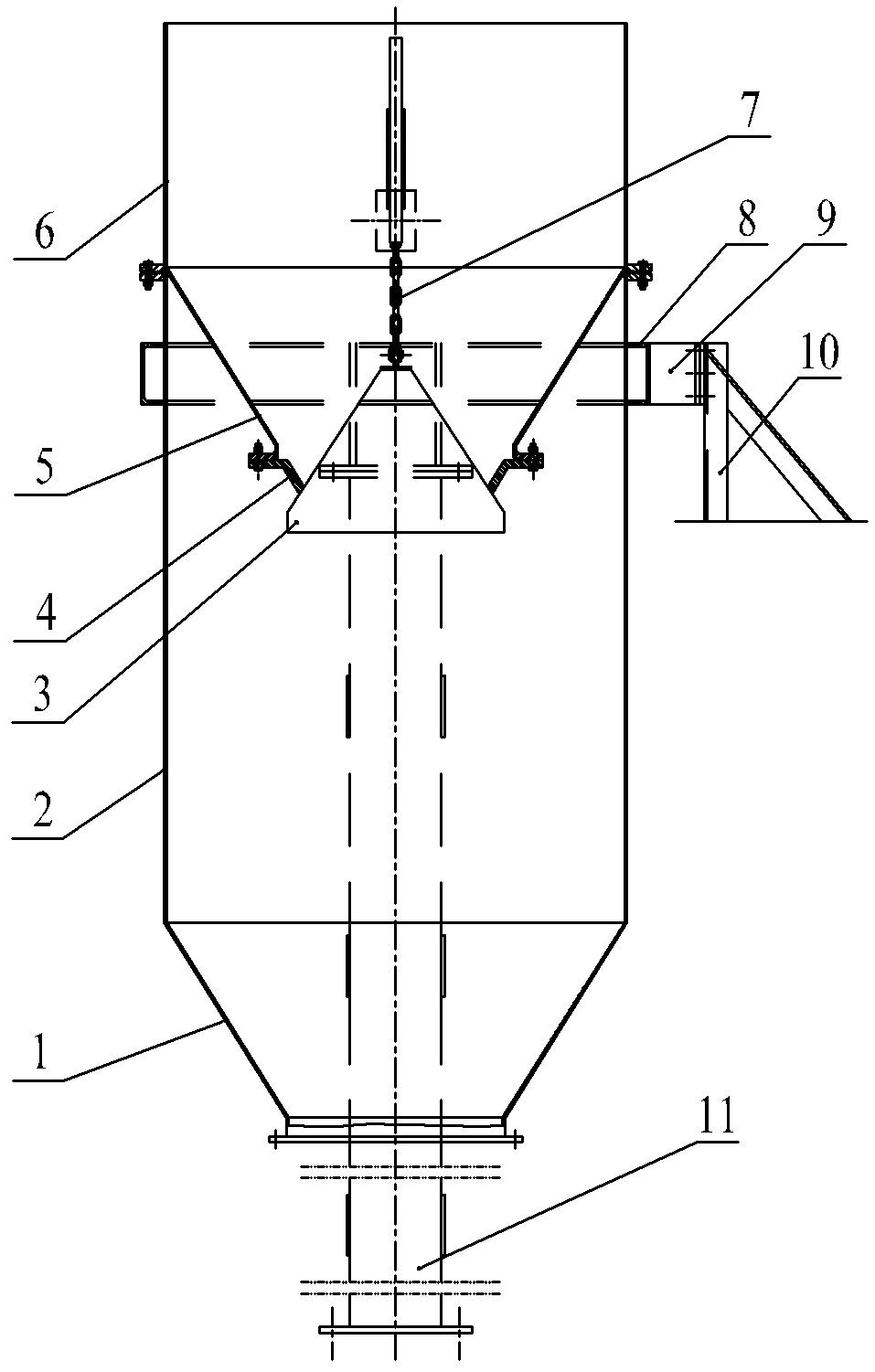

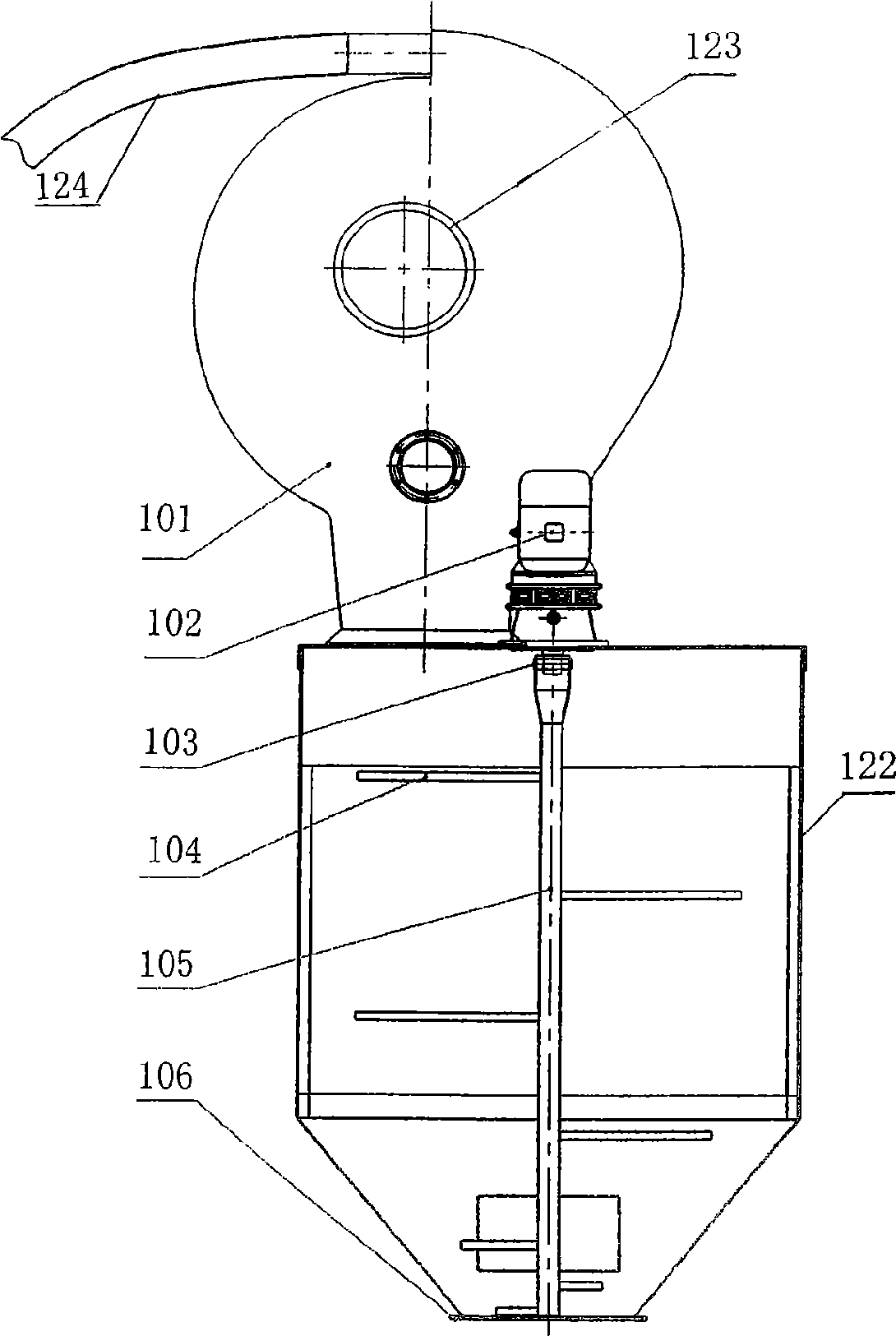

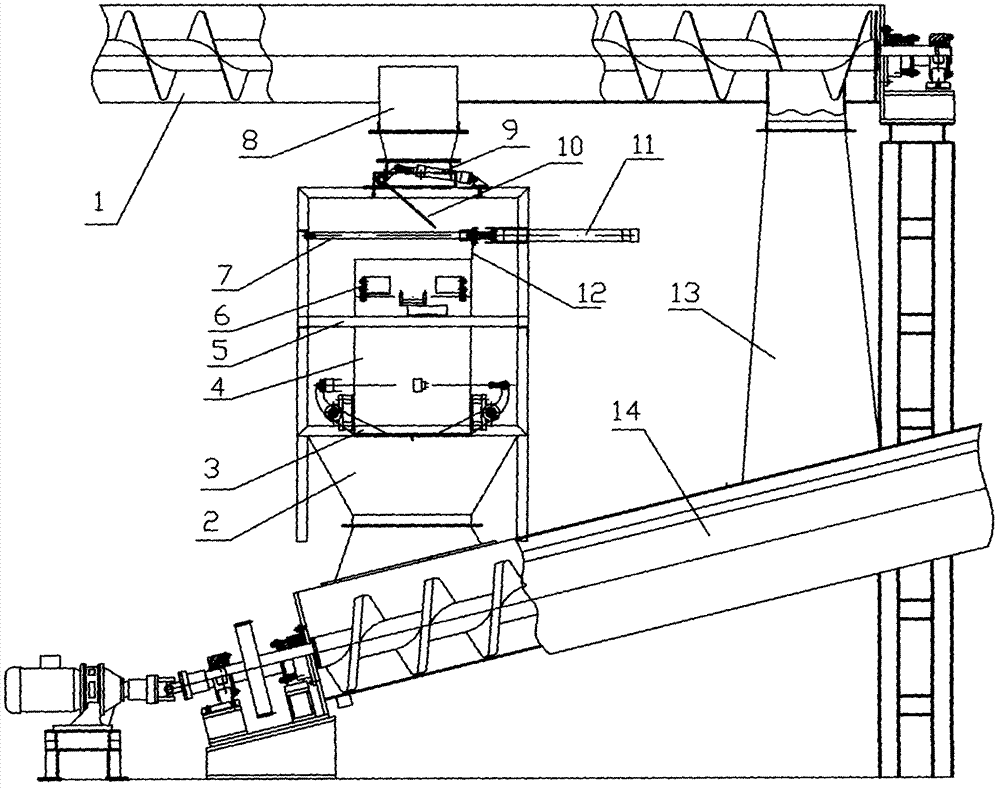

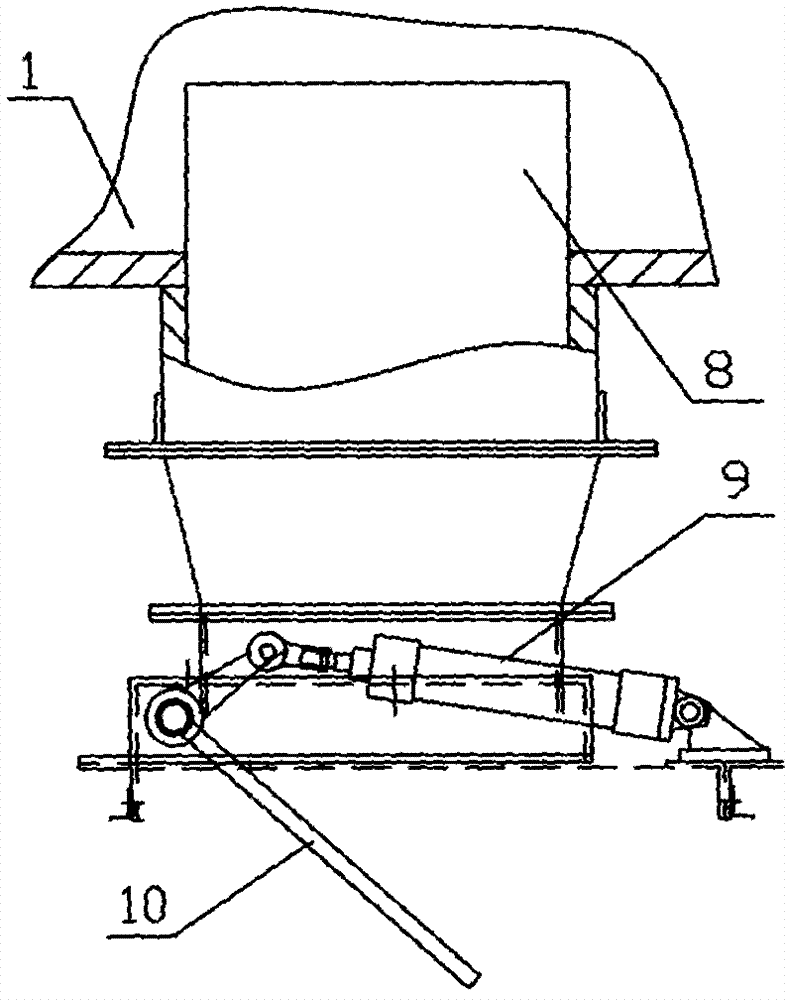

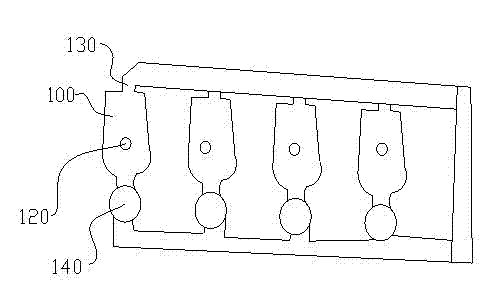

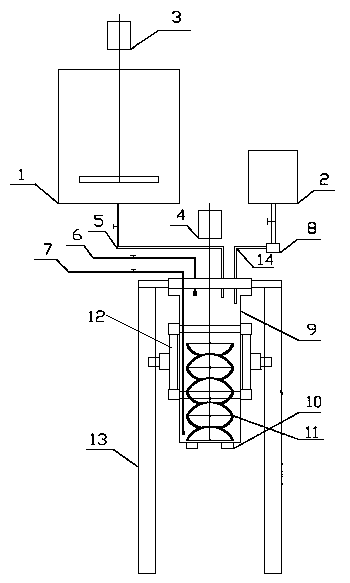

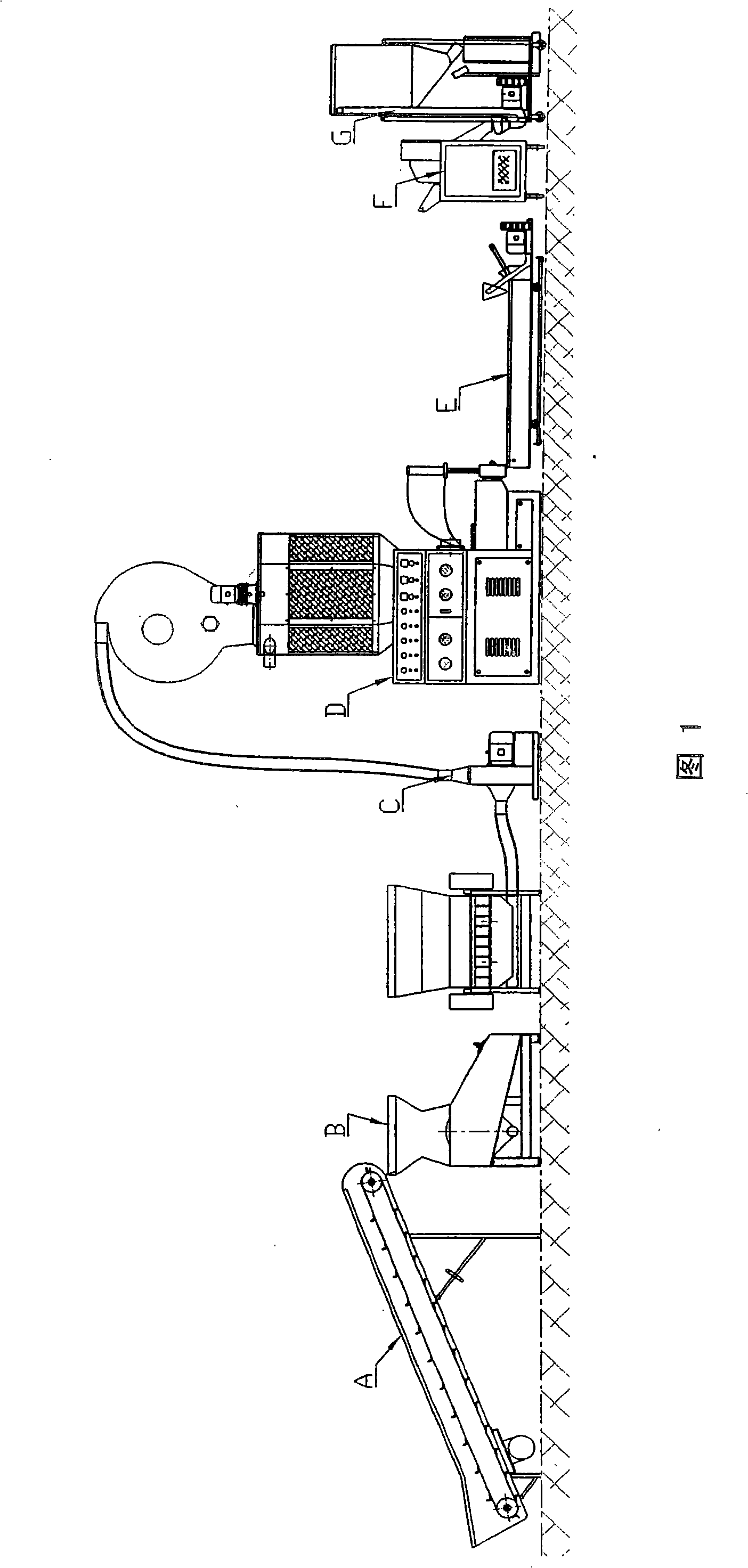

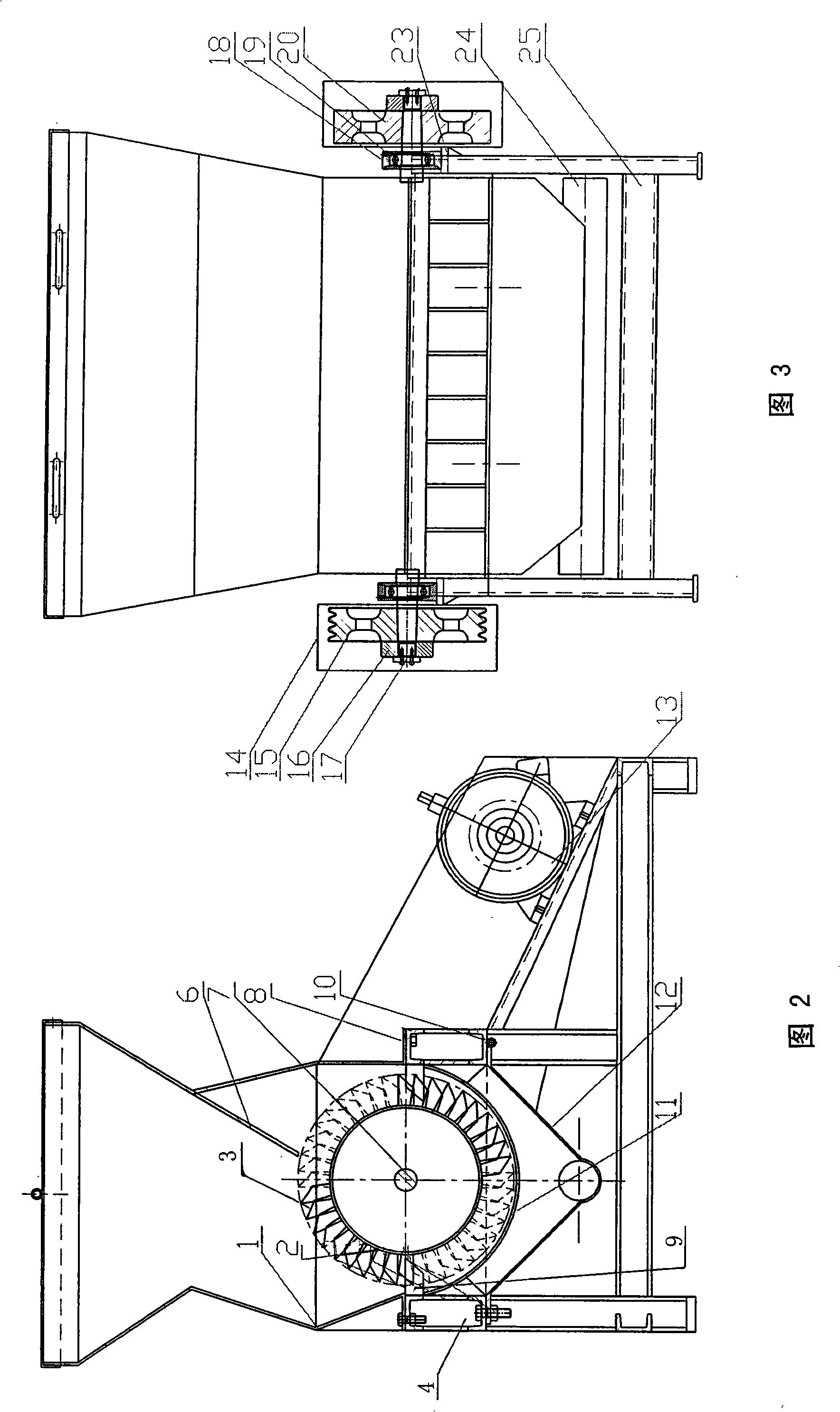

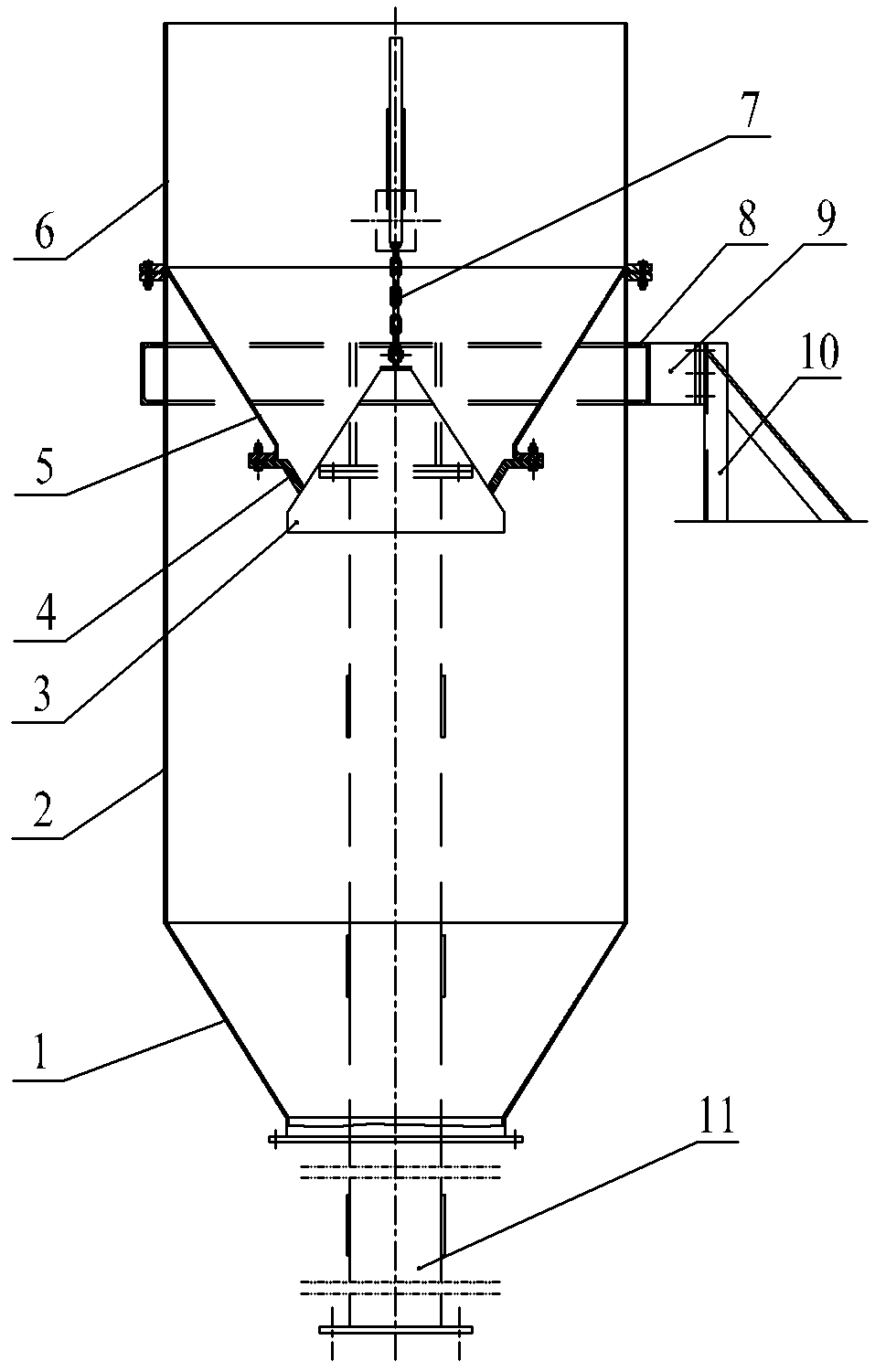

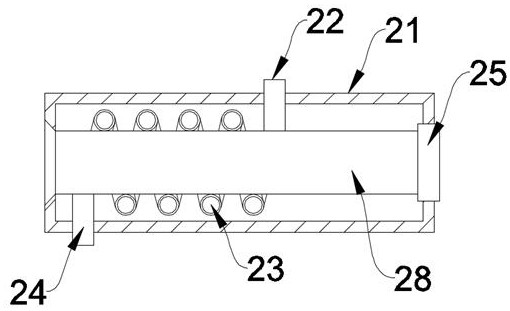

Feeding equipment of biomass gasification furnace

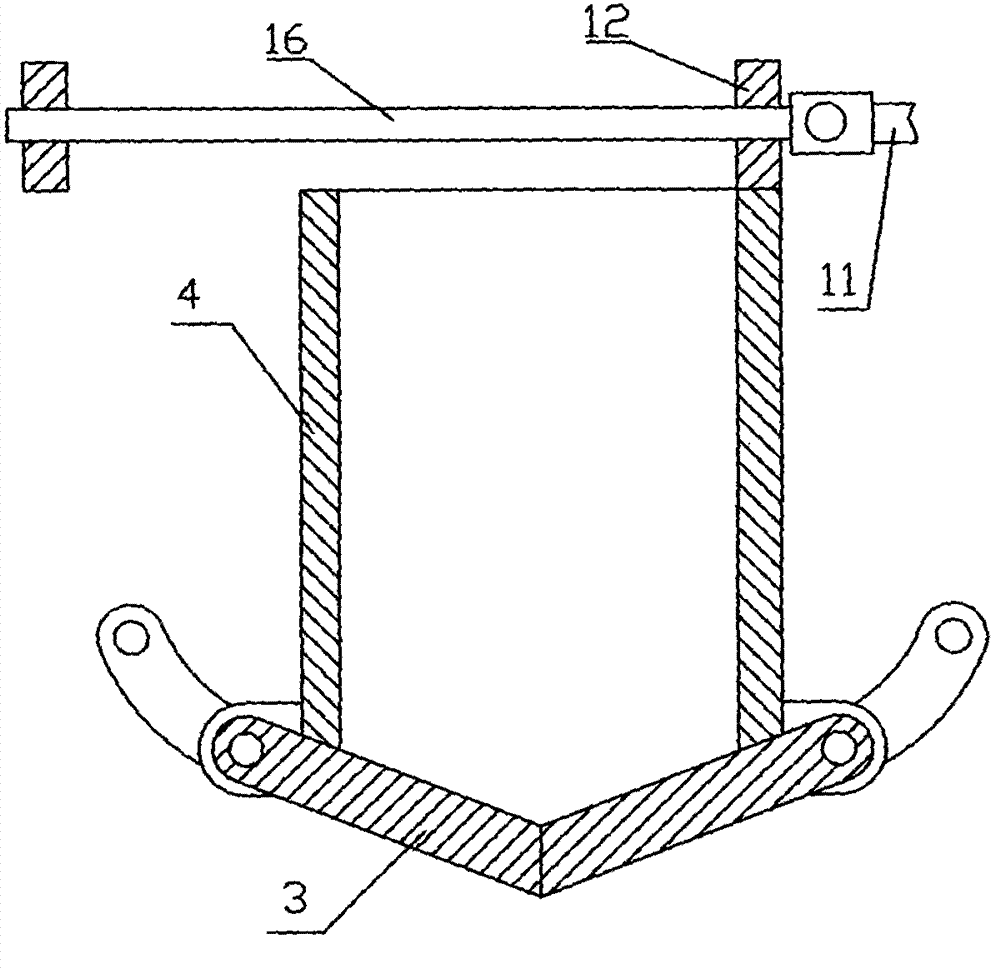

ActiveCN102703125AGuaranteed sealing performanceStable pressureProductsReagentsEngineeringBiomass gasifier

The invention relates to feeding equipment of a biomass gasification furnace. The feeding equipment comprises a discharge device and a feeding conveyor, wherein the discharge device is arranged in the middle; a lower cylinder is supported through a bracket mechanism, the lower end of the lower cylinder is provided with a connecting seat for connecting the feeding conveyor, and the upper end of the lower cylinder is connected with the lower end of an upper cylinder through a flange; the edge of upper end of a conical seat and the inner edge of the lower end of the upper cylinder are in soldering fixation; a valve seat is arranged at the lower end of the conical seat; a bearing sealed frame is arranged on the outer wall of the upper cylinder, and is internally provided with a rotating shaft; one end of a first rod is arranged on the rotating shaft and synchronously rotate along with the rotating shaft; the other end of the first rod is provided with a chain box; a bell type wall clock cover valve body is suspended on the chain box through a suspending chain, and is matched with the valve seat to control entering of biomass; and one end of a second rod is arranged on the rotating shaft and synchronously rotates along with the rotating shaft, and a pull rod is hinged at the other end of the second rod. The feeding equipment of the biomass gasification furnace has the advantages of being smart and reasonable in structure, continuous in feeding without halt, safe in operation, stable in pressure in the furnace, uniform in feeding and clean.

Owner:无锡湖光工业炉有限公司

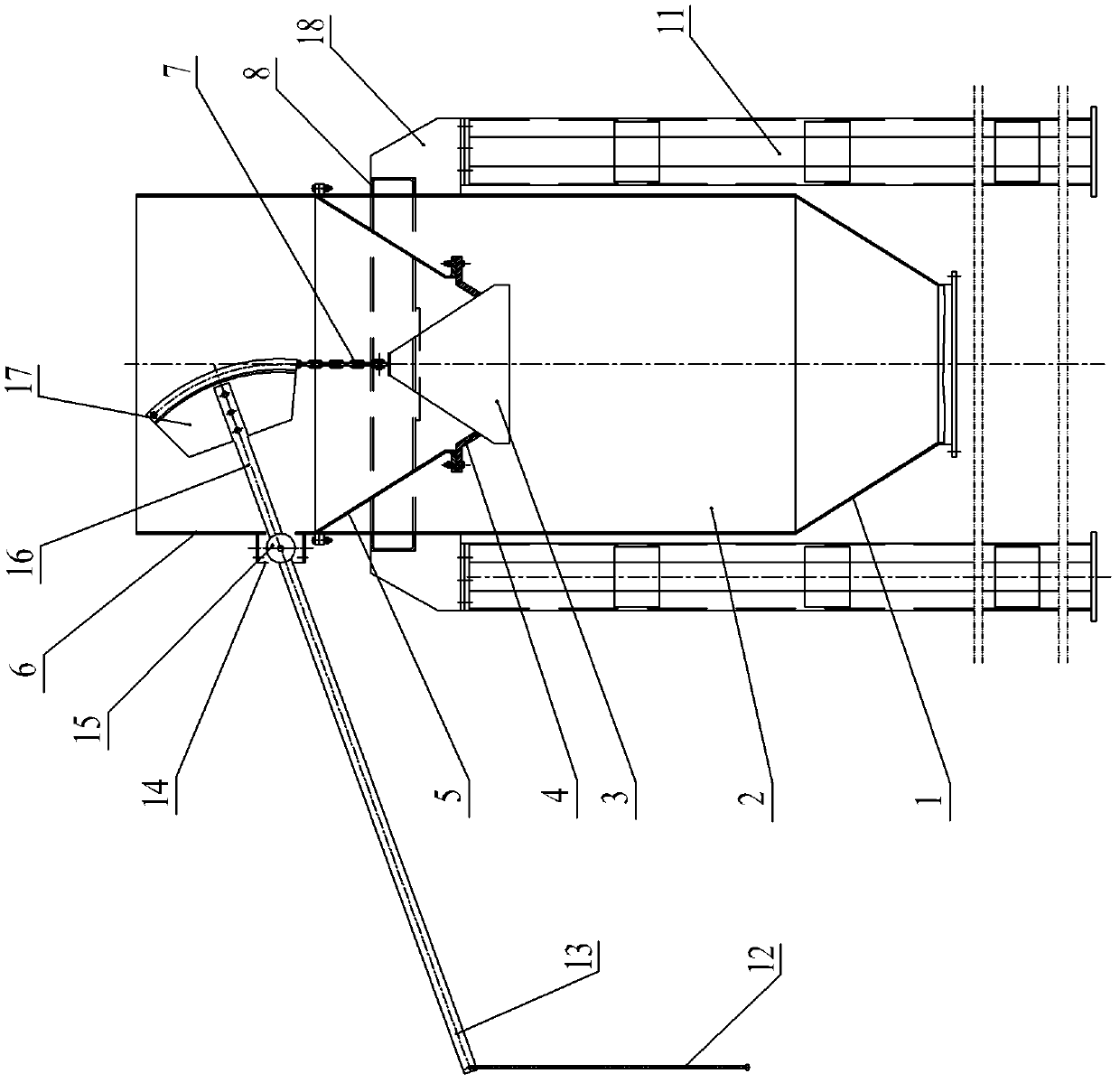

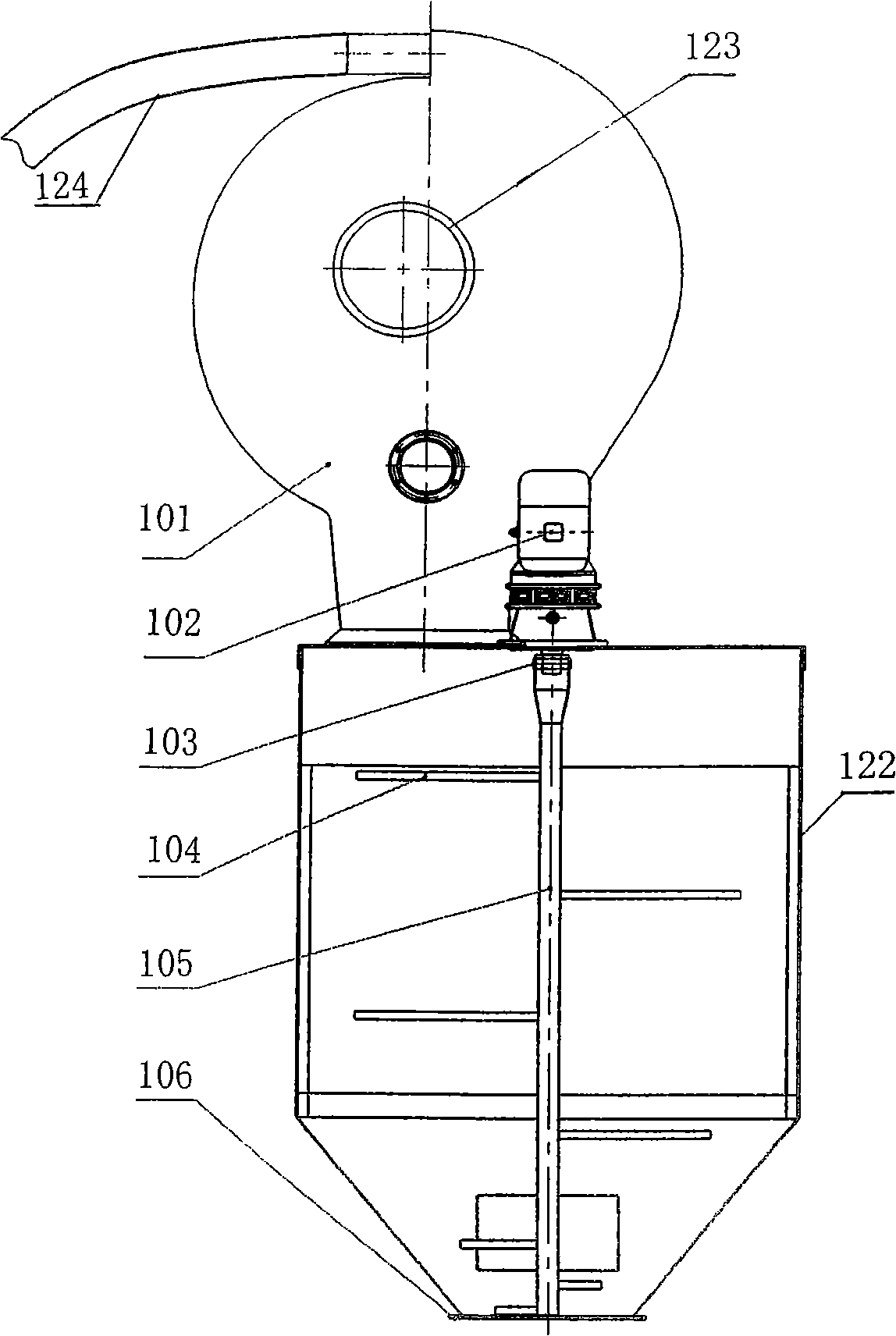

Delivery conduit of plastic foam environment friendly recycling prilling unit

The invention relates to a conveyor pipeline for a formed plastic environment-friendly recovering and granulating machine set, which is characterized in that the conveyor pipeline comprises a radial material loading pipeline consists of a material loading blower and a pipeline, a tangential feeder which is connected with the radial material loading pipeline and a regular polygon feeding tank which is connected with the tangential feeder, wherein the inside of the feeding tank is provided with a stirrer; a main body of the tangential feeder is cylindrical, the top of the main body is provided with a tangential air inlet pipe, and the middle of the main body is provided with a middle separating air pipe which is vertical to the tangential air inlet pipe; and the feeding tank is a regular polygon cube, and the top of the regular polygon cube is provided with an upper cover, wherein the main body of the regular polygon cube is divided into an upper part, a middle part and a lower part, the upper part is a sealing structure, the middle part is a detachable net structure, the lower part is a tapered sealing structure, and the three parts are connected through a frame body. The conveyor pipeline adopts a closed circular material supply system, improves the environment-friendly regeneration utilization rate, reduces the recovery cost, saves the energy loss, and reduces the recovery secondary pollution.

Owner:余姚市绿岛橡塑机械设备有限公司

Lead-free steam turbine seal grease and preparation method thereof

InactiveCN102690630AImprove adhesionImprove corrosion resistanceOther chemical processesIron powderFerrotitanium

The invention provides lead-free steam turbine seal grease and belongs to the field of sealant preparation. The lead-free steam turbine seal grease is composed of refined grease and inorganic filler, and the inorganic filler is made of compound ferrotitanium powder, graphite powder, white carbon black, whisker calcium carbonate and reduced iron powder. The reduced iron powder and the compound ferrotitanium powder are innovatively added into the inorganic filler without red lead powder. The prepared seal grease has the advantages of uniformity in viscosity, high resistance to corrosion, high temperature and high pressure and environment friendliness.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV

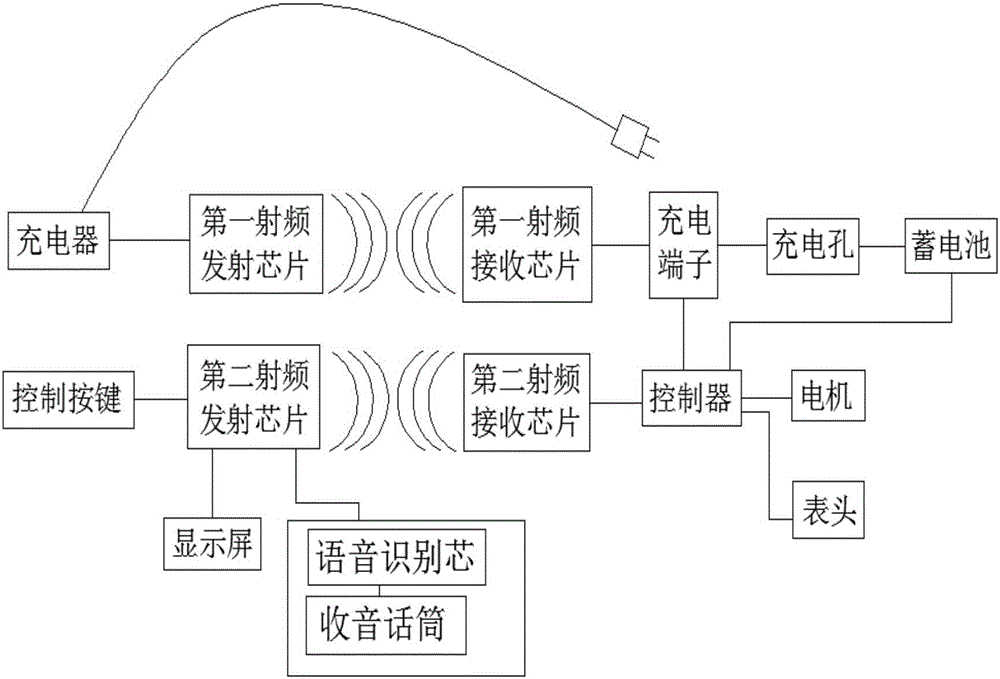

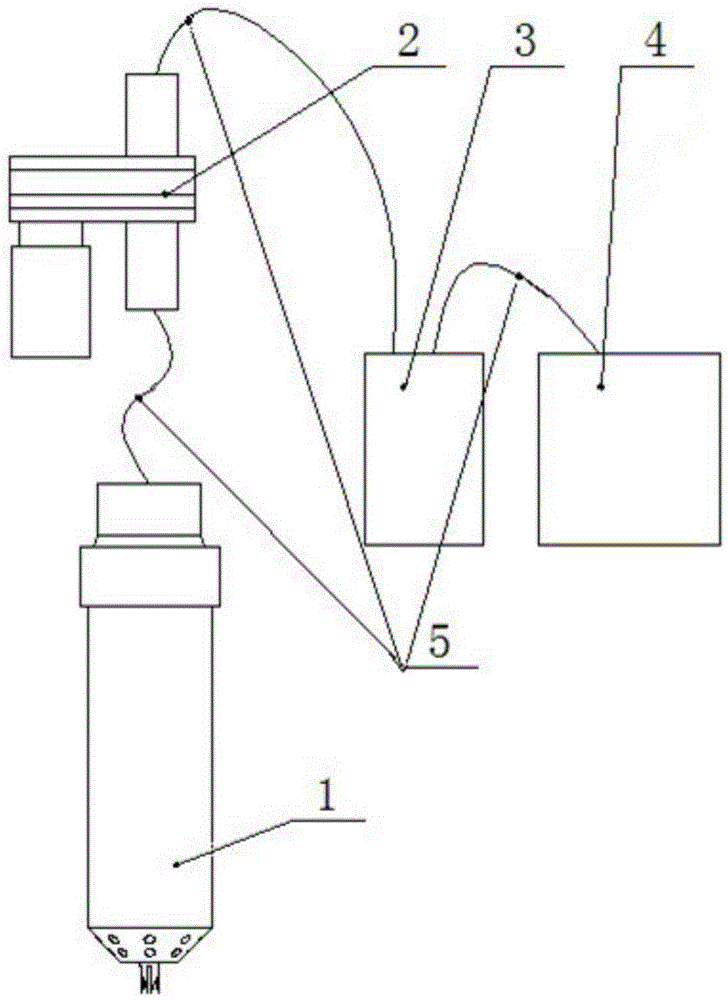

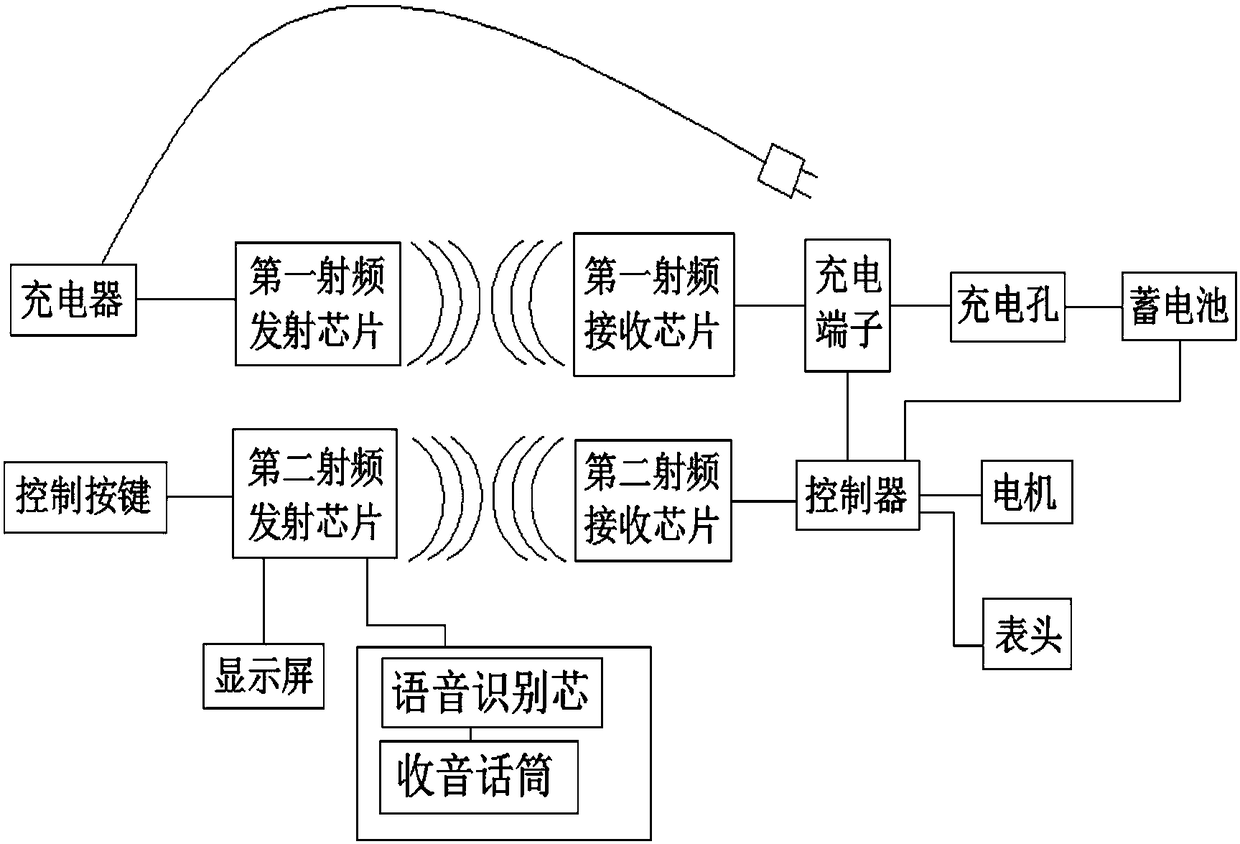

Safe and intelligent electric car

ActiveCN106183859AAvoid failureEasy to assembleCharging stationsElectric vehicle charging technologyElectricityEngineering

The invention provides a safe and intelligent electric car. The car comprises a charger, a charging hole, a storage battery, a controller, a motor and a header and further comprises a first radio-frequency emission chip, a first radio-frequency reception chip, a control button, a second radio-frequency emission chip and a second radio-frequency reception chip. The first radio-frequency emission chip is arranged on the charger and electrically connected with the charger. The first radio-frequency reception chip is arranged in the charging hole and electrically connected with a charging terminal. The charging hole is electrically connected with the storage battery. The control button and the second radio-frequency emission chip are arranged on a car handle. The control button is electrically connected with the second radio-frequency emission chip. The second radio-frequency reception chip is electrically connected with the controller. A control output end of the controller is connected with the motor and the header. The storage battery is used for supply energy and connected with the controller electrically connected with the charging terminal.

Owner:小刀科技股份有限公司

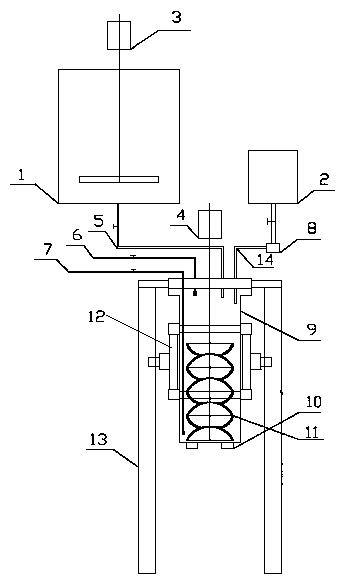

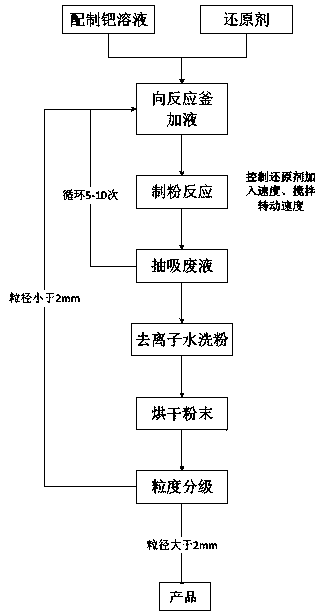

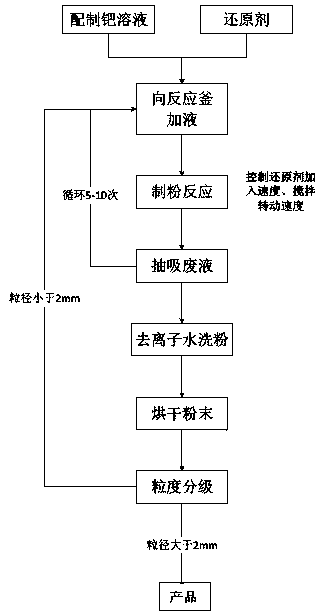

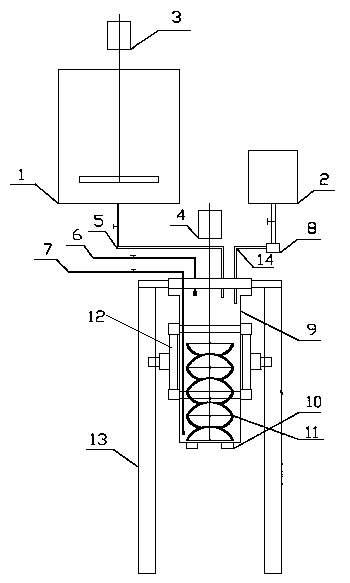

Device and method for preparing large-diameter palladium powder

The invention discloses a device and method for preparing large-diameter palladium powder. A palladium solution storage tank, a reducing agent storage tank, a palladium solution guiding tube, a negative pressure liquid suction tube, a reaction kettle, a reaction kettle lifting mechanism, a fixing frame and a reducing agent liquid guiding tube are included; the reaction kettle is installed on a suspension frame through the reaction chamber lifting mechanism in a matched manner, the two sides of the suspension frame are mounted on the fixing frame through a rotating shaft in a matched manner, the upper part of the reaction kettle is connected with a kettle cover through a fastening mechanism, the kettle cover is fixedly arranged on the upper portion of the fixing frame, the top of the kettlecover is connected to a liquid outlet of the bottom of the palladium solution storage tank through the palladium solution guiding tube, a valve is arranged on the palladium solution guiding tube, thetop of the kettle cover is connected to a liquid outlet of the bottom of the reducing agent storage tank through a reducing agent liquid guiding tube, the reducing agent liquid guiding tube is provided with a valve, one end of the negative pressure liquid suction tube is connected with a suction device, the other end of the negative pressure liquid suction tube is provided with a negative pressure filter nozzle in a matched manner, and the negative pressure filter nozzle is arranged at the bottom of the inner wall of the reaction kettle.

Owner:JINCHUAN GROUP LIMITED

Method and device for automatically detecting powder material accumulation density

InactiveCN102175566BImprove accuracyImprove efficiencySpecific gravity measurementControl systemProgrammable logic controller

The invention relates to a method and a device for automatically detecting powder material accumulation density, relating to a device for detecting powder (granular) material accumulation density. The method comprises the following steps of: (1) connecting a material dividing hopper with an original spiral conveyer pipe; (2) opening a material dividing valve at the lower part of the material dividing hopper so that materials fall to a material weighing hopper supported by a weighing sensor; (3) scraping stacks at the top of the material weighing hopper through a material pushing scraping plate driven by a material pushing cylinder; (4) transmitting weight information of the material weighing hopper to a PLC (programmable logic controller) control system for calculating, comparing and displaying by the weighing sensor; (5) opening a material discharging valve at the lower part of the material weighing hopper so that the materials fall to a material receiving hopper and enter to a secondary spiral conveyer; and (6) pushing the materials falling from the material receiving hopper to be combined with the materials falling from an original spiral conveyer material discharging tube and sending to next procedure together by the secondary spiral conveyer. The device disclosed by the invention has the advantages of automatic identifying function, high accuracy, fast speed and high efficiency; and the device is capable of realizing full check, and effectively controlling the product quality.

Owner:青海海西东诺化工有限公司

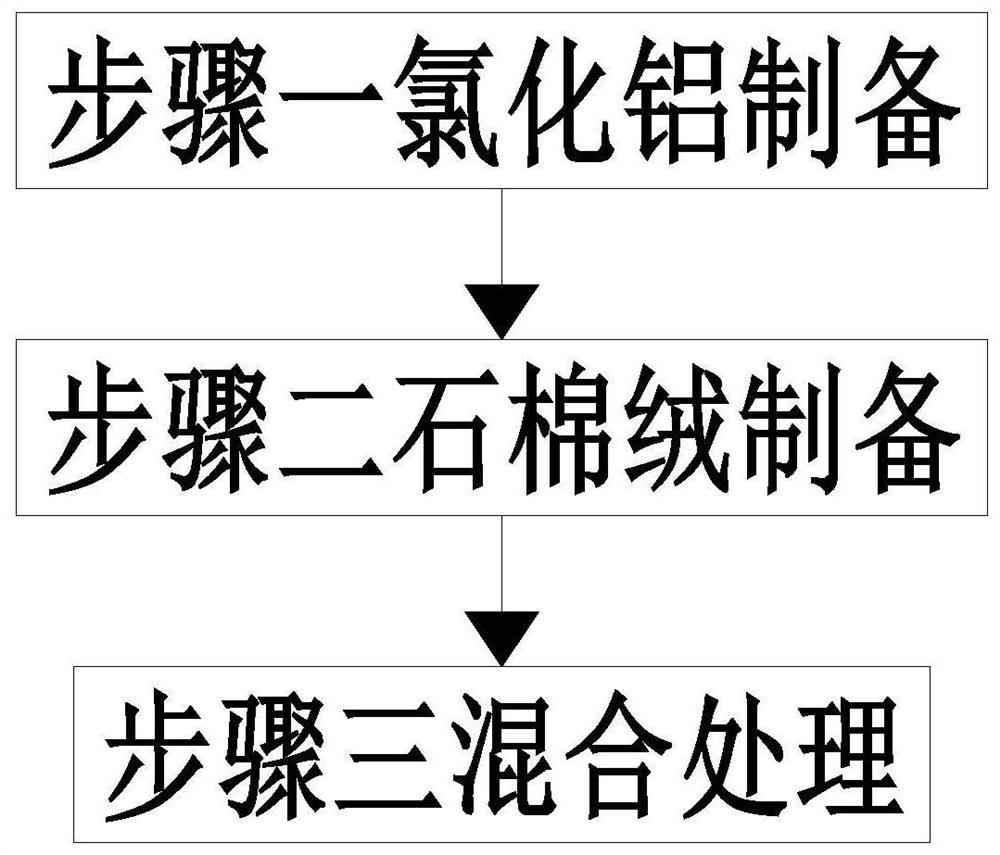

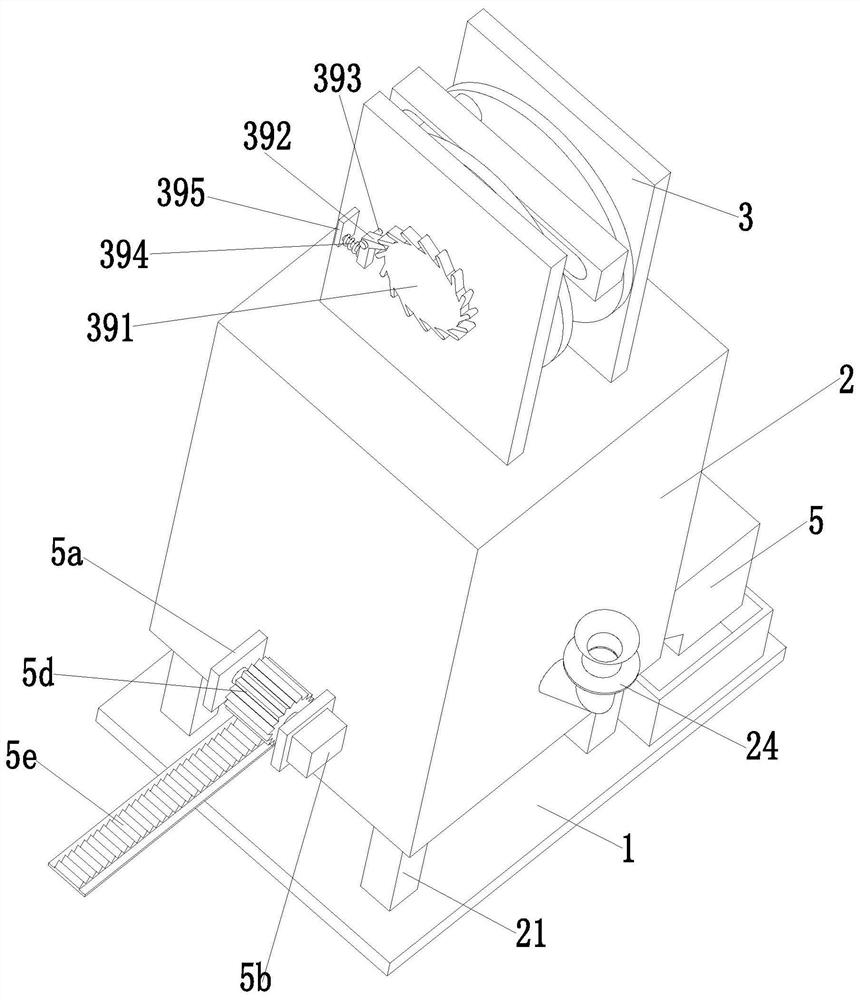

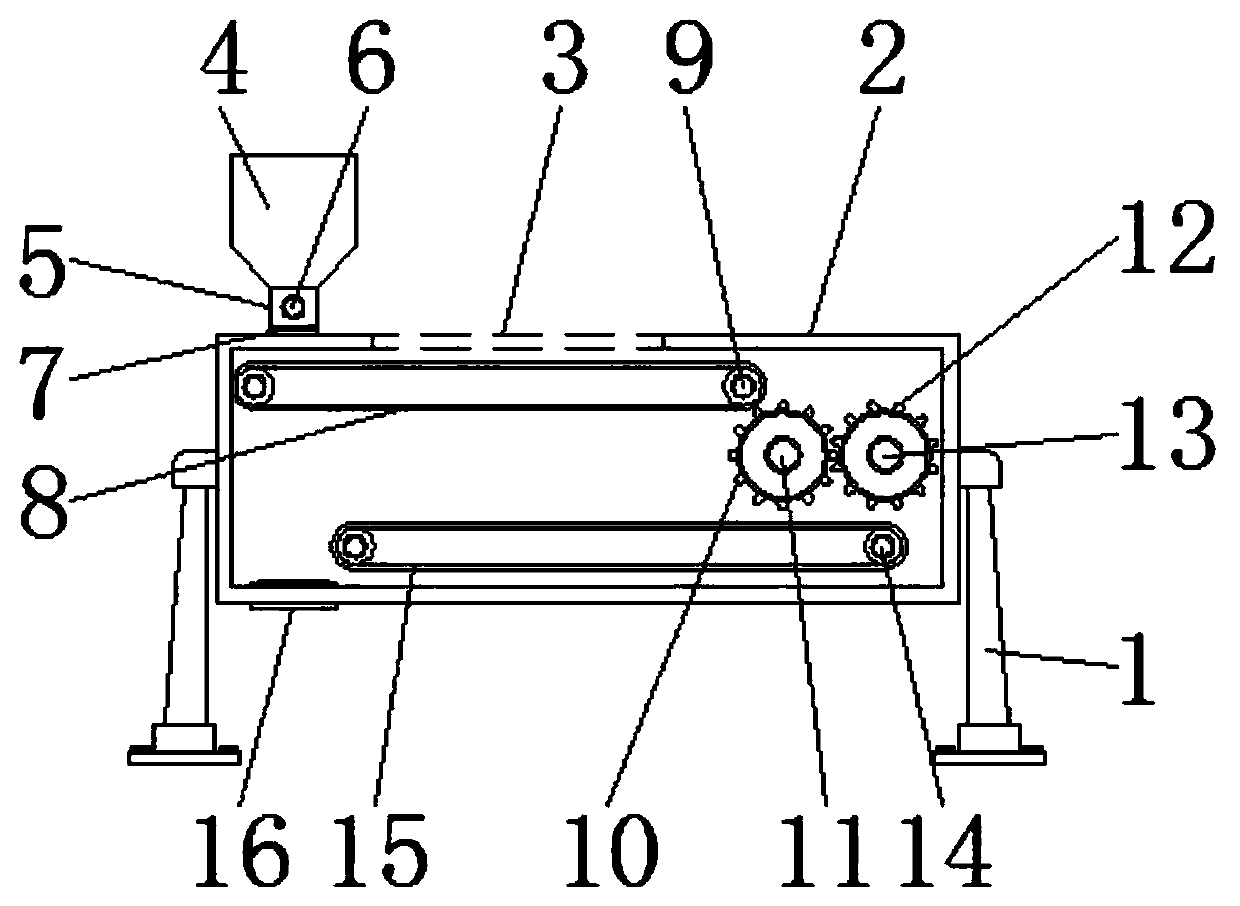

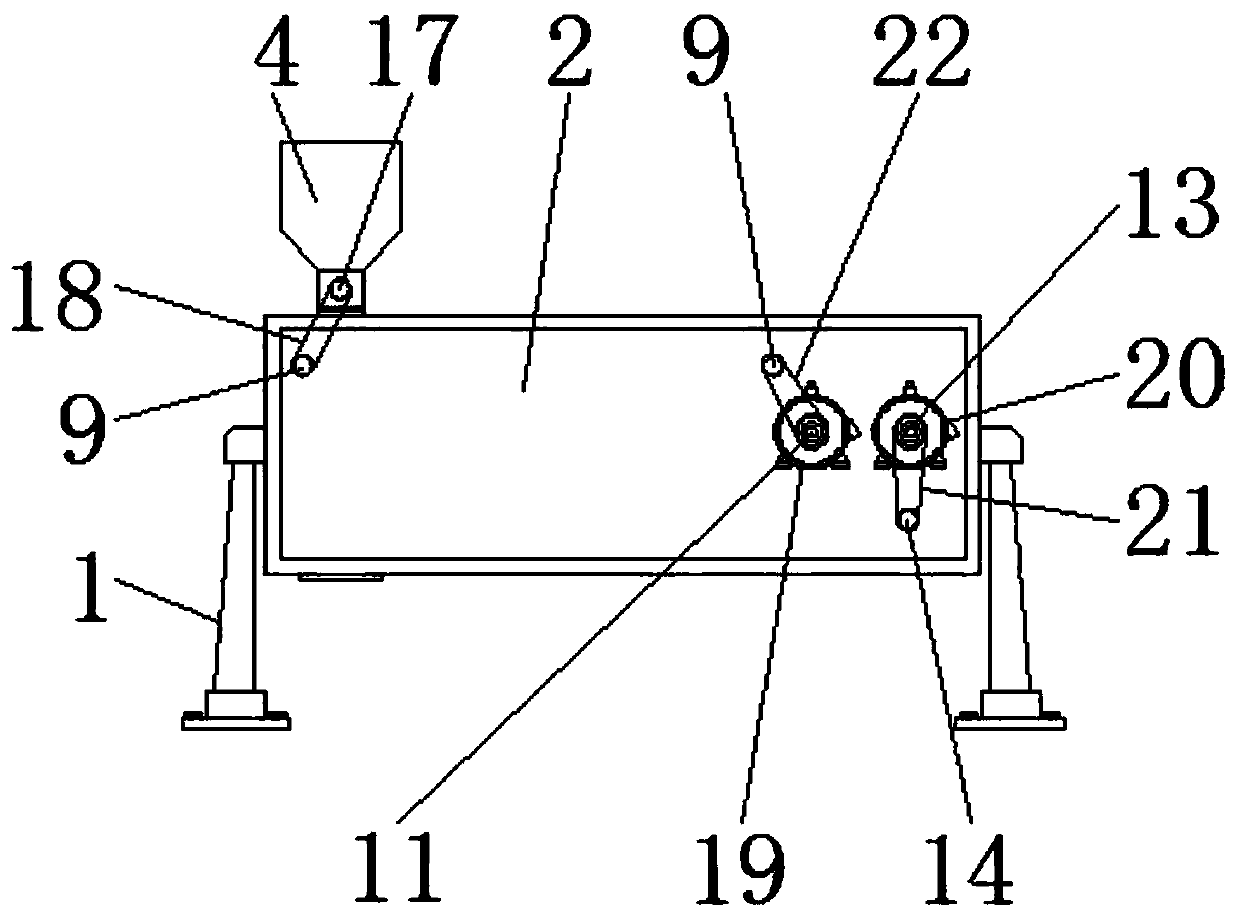

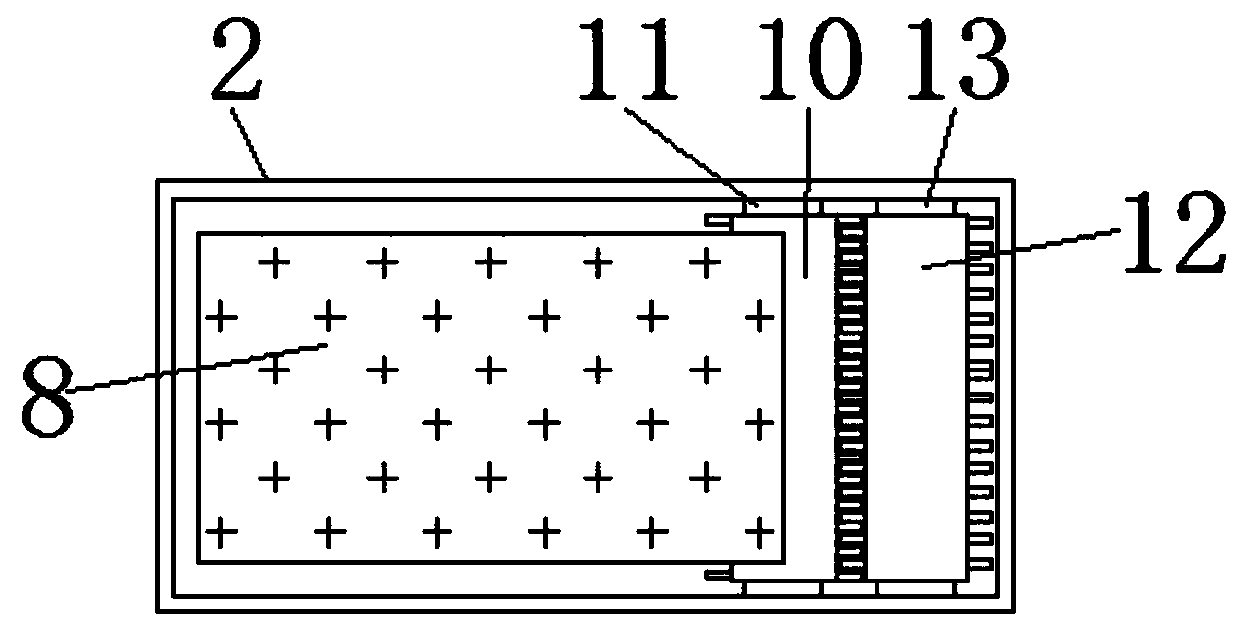

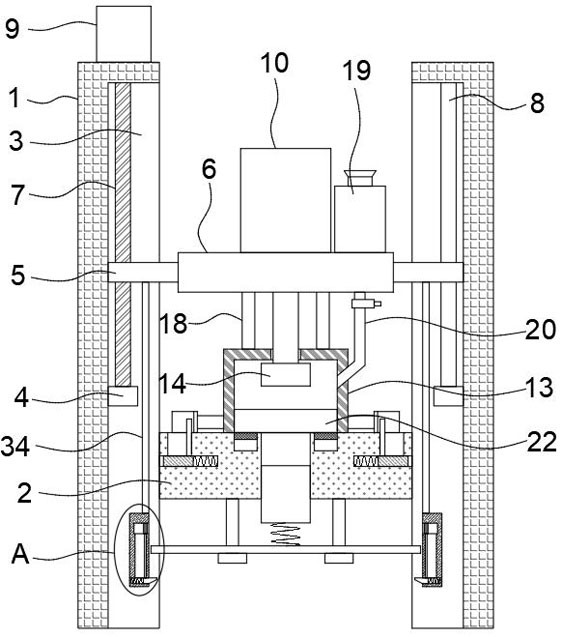

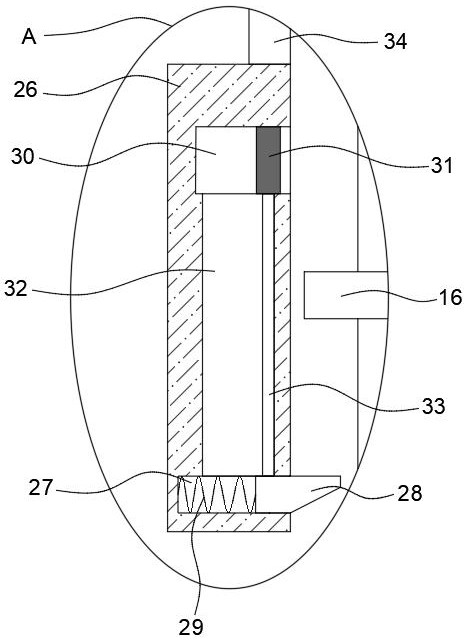

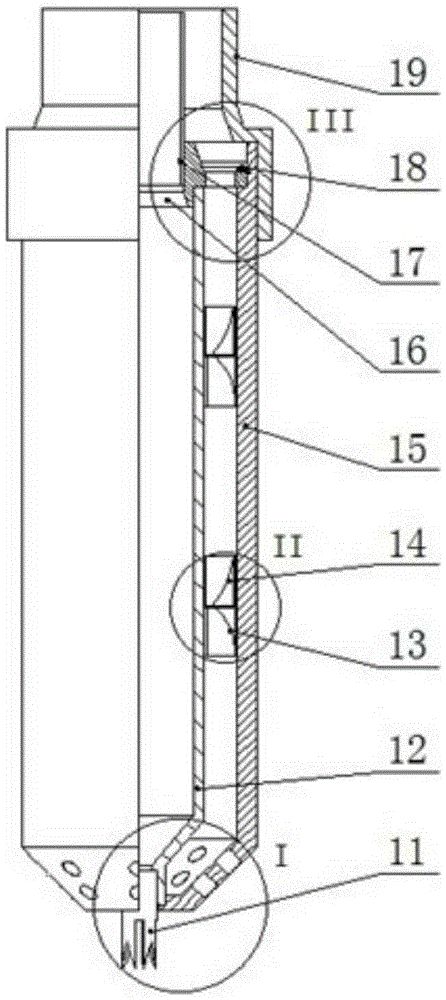

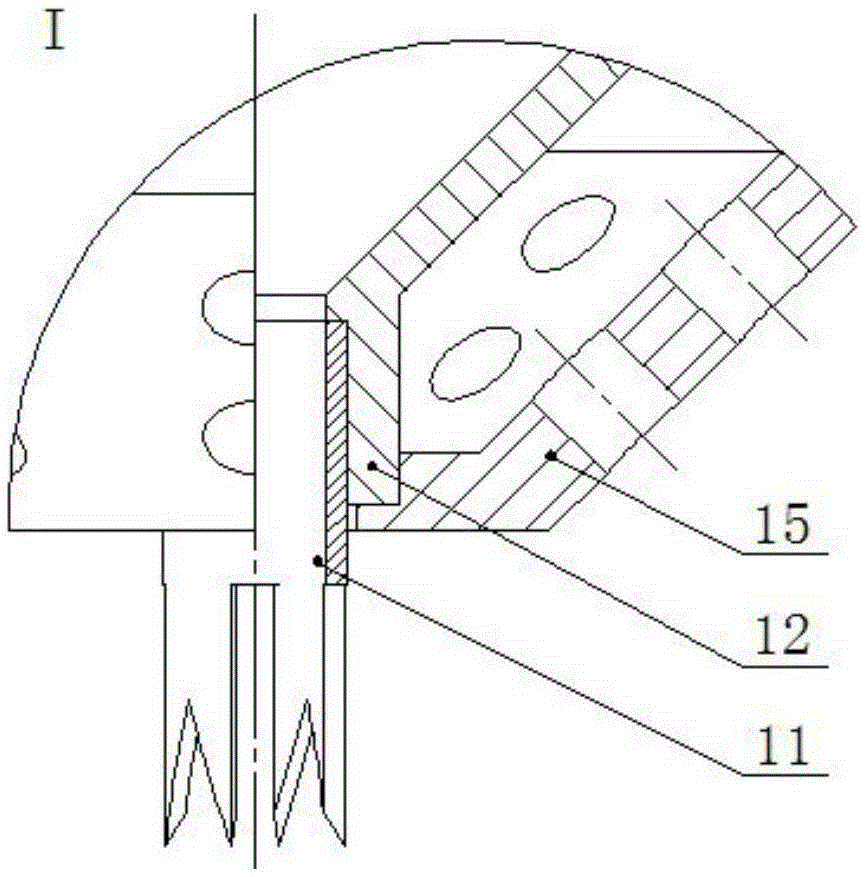

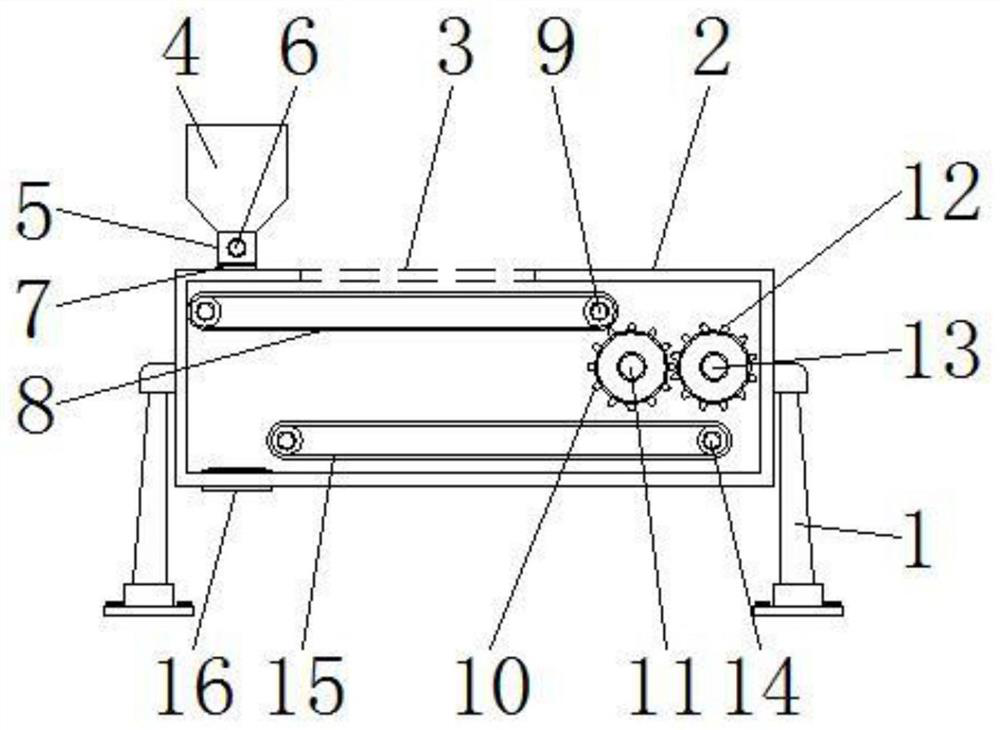

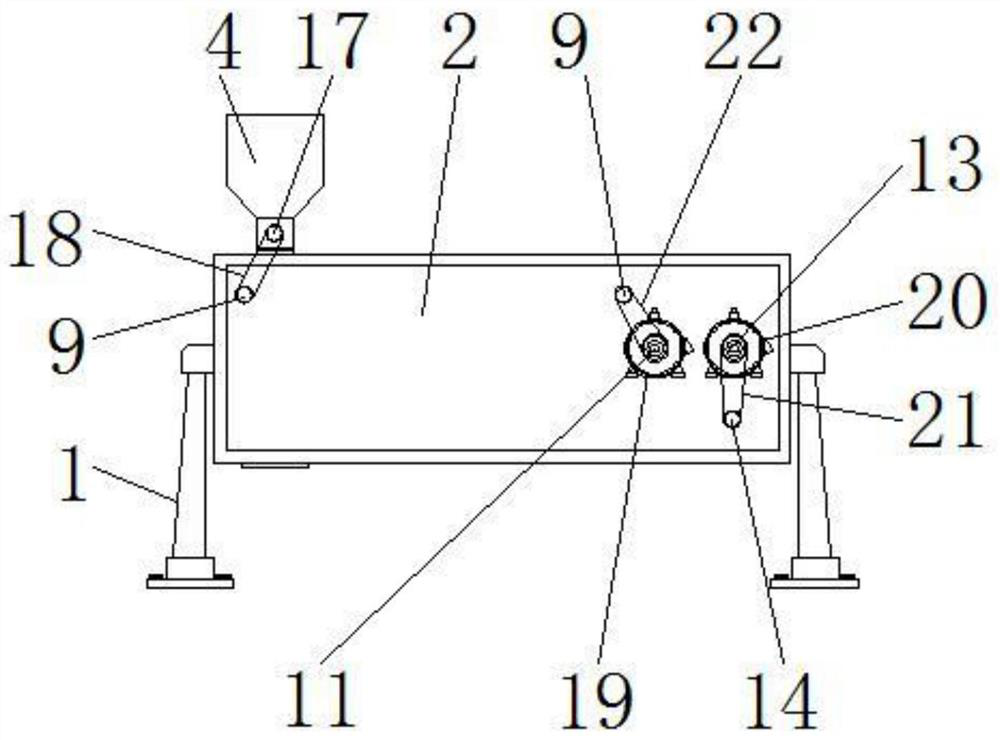

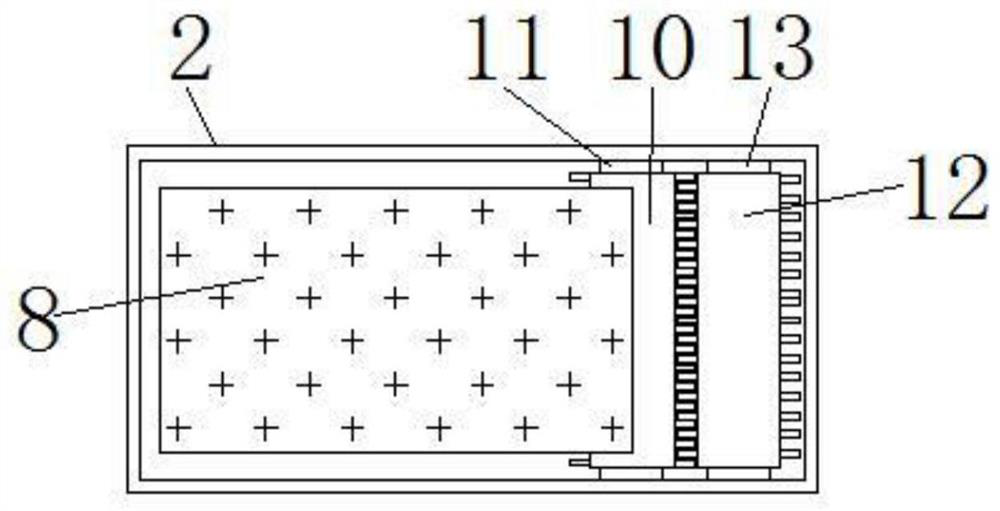

Preparation method of retarding superplasticizer

InactiveCN113072319ANo flying phenomenonImprove crushing efficiencyGrain treatmentsAluminium chlorideSuperplasticizer

The invention relates to a preparation method of a retarding superplasticizer, which mainly comprises the following steps of: aluminum chloride preparation, asbestos wool preparation, mixing treatment and other processes. Asbestos wool crushing equipment used in the method comprises a bottom plate, a charging device, a lifting device, a drop hammer device and a discharging device. The method can solve the following problems existing in existing asbestos wool crushing: a, when asbestos wool is crushed in a traditional mode, most of the asbestos wool is manually beaten and crushed by using a crushing tool, and the working environment of workers and the body health of the workers are influenced due to the fact that the asbestos wool is relatively light in weight and easy to fly; and b, when asbestos wool is crushed at present, the asbestos wool cannot be comprehensively crushed, so that the crushing of the asbestos wool is not uniform, and the crushing quality of the asbestos wool is influenced.

Owner:马东东

Dust-free crushing device for construction waste treatment

The invention discloses a dust-free crushing device for construction waste treatment. The device comprises a base, a device main body, a feeding bin, a feeding opening and a discharging opening, wherein the device main body is connected to the middle of the base, a reserved opening is formed in the middle of the upper portion of the device main body, the feeding opening is formed in the left sideof the upper portion of the device main body, a feeding pipeline is connected to the upper portion of the feeding opening, a second conveying belt is arranged between two second rolling rollers, and the top end of the left side of the second conveying belt is arranged at the position, close to the right side, of the upper portion of the discharging opening. According to the dust-free crushing device for construction waste treatment, dust removal work can be carried out at the positions of the feeding opening and the discharging opening of the whole device, the whole device cannot be blocked inthe feeding and crushing processes, the influence, from the process of using the whole device, on the environment is small, the fault occurrence rate of the whole device during working is low, and the dust-free crushing device is more convenient to use and operate.

Owner:徽仁(宁夏)环保科技有限公司

Small punching spring sheet

InactiveCN102856697ANo flying phenomenonSimple processContact member manufacturingCoupling contact membersPunch pressEngineering

The invention discloses a small punching spring sheet which comprises spring sheet blocks made by aluminum plates. The aluminum plates are cut into small square blocks and processed on a punching machine which can be adjusted to be in an automatic mode, the spring sheet blocks cannot break on the aluminum plates and concentrate on one aluminum plate, each spring sheet block is provided with a wide middle and two narrow ends, and a circular fastener is arranged in the middle of each spring sheet block. The small punching spring sheet can be applied to hardware processing, production process is simplified, flying everywhere of spring sheets during processing can be avoided, the spring sheets are effectively divided during processing, transportation is quite convenient, the spring sheet blocks can be demounted at destinations, the spring sheet blocks can automatically shed by only slight force applied by hands, and the small punching spring sheet is high in practicability and beneficial to popularization and use, and is a scheme novel in design.

Owner:昆山铭佳利电子制品有限公司

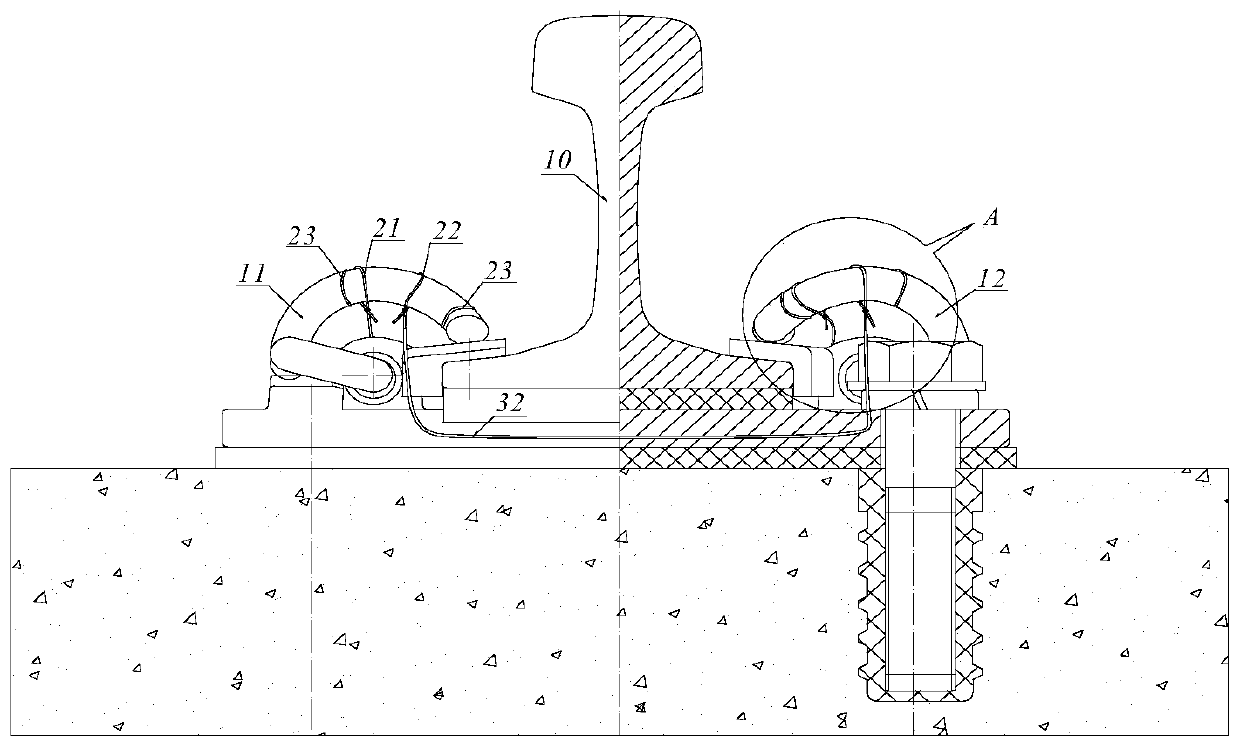

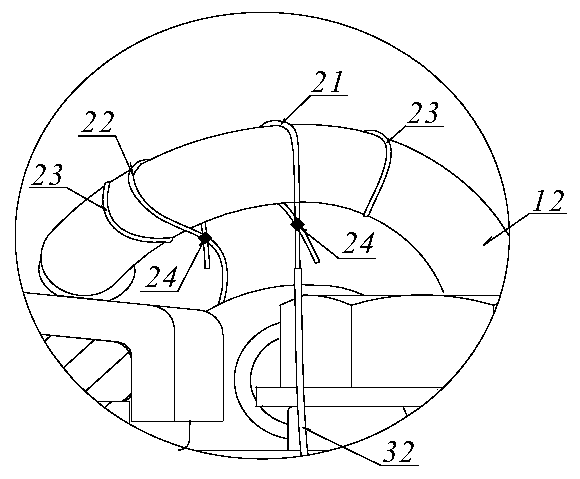

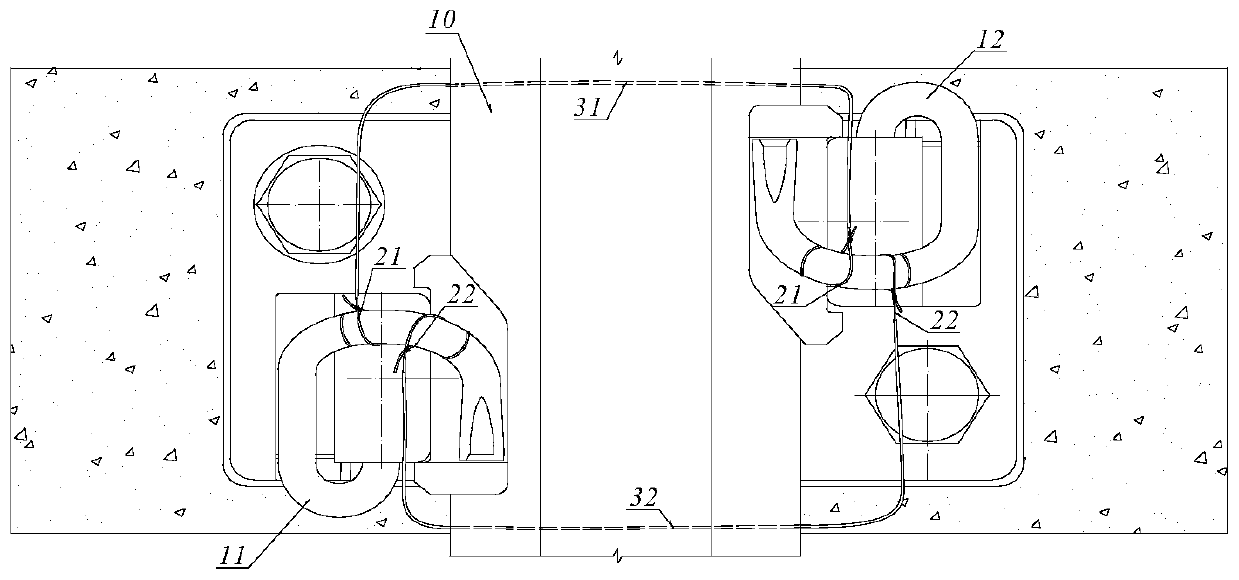

Elastic strip flying-proof structure device for bolt-free fastener

PendingCN110306385AImprovements in anti-flying performance of clipsAnti-fly function is effectiveRail fastenersSelf lockingEngineering

The invention relates to an elastic strip flying-proof structure device for a bolt-free fastener, which is used for ensuring that the elastic strip anti-flying function is effective, and no matter theelastic strip on one side of a steel rail or the elastic strips on two sides are simultaneously broken, no matter the breakage of the elastic strip occurs at a large arc part of a front arch or a small arc part of a rear arch, the breakage part can be restrained and the flying phenomenon cannot occur. A first e-shaped elastic strip and a second e-shaped elastic strip, which are positioned at twotransverse sides of a steel rail, are provided. Two sides of the front arch large circular arc parts of the first e-shaped elastic strip and the second e-shaped elastic strip are respectively providedwith a first steel wire rope and a second steel wire rope, which penetrate through the steel rail downwards, and two ends of the first steel wire rope and the second steel wire rope are respectivelybound and connected with the front arch large circular arc parts of the first e-shaped elastic strip and the second e-shaped elastic strip to form a self-locking system. Except for the binding connecting sections at the two ends, the sections of the first steel wire rope and the second steel wire rope are disposed in the insulating structure.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

A kind of device and method for preparing large particle size palladium powder

The invention discloses a device and method for preparing large-diameter palladium powder. A palladium solution storage tank, a reducing agent storage tank, a palladium solution guiding tube, a negative pressure liquid suction tube, a reaction kettle, a reaction kettle lifting mechanism, a fixing frame and a reducing agent liquid guiding tube are included; the reaction kettle is installed on a suspension frame through the reaction chamber lifting mechanism in a matched manner, the two sides of the suspension frame are mounted on the fixing frame through a rotating shaft in a matched manner, the upper part of the reaction kettle is connected with a kettle cover through a fastening mechanism, the kettle cover is fixedly arranged on the upper portion of the fixing frame, the top of the kettlecover is connected to a liquid outlet of the bottom of the palladium solution storage tank through the palladium solution guiding tube, a valve is arranged on the palladium solution guiding tube, thetop of the kettle cover is connected to a liquid outlet of the bottom of the reducing agent storage tank through a reducing agent liquid guiding tube, the reducing agent liquid guiding tube is provided with a valve, one end of the negative pressure liquid suction tube is connected with a suction device, the other end of the negative pressure liquid suction tube is provided with a negative pressure filter nozzle in a matched manner, and the negative pressure filter nozzle is arranged at the bottom of the inner wall of the reaction kettle.

Owner:JINCHUAN GROUP LIMITED

Delivery conduit of plastic foam environment friendly recycling prilling unit

InactiveCN101486248BUniform Compression ExtrusionFall into smoothGrain treatmentsEngineeringMaterial supply

The invention relates to a conveyor pipeline for a formed plastic environment-friendly recovering and granulating machine set, which is characterized in that the conveyor pipeline comprises a radial material loading pipeline consists of a material loading blower and a pipeline, a tangential feeder which is connected with the radial material loading pipeline and a regular polygon feeding tank which is connected with the tangential feeder, wherein the inside of the feeding tank is provided with a stirrer; a main body of the tangential feeder is cylindrical, the top of the main body is provided with a tangential air inlet pipe, and the middle of the main body is provided with a middle separating air pipe which is vertical to the tangential air inlet pipe; and the feeding tank is a regular polygon cube, and the top of the regular polygon cube is provided with an upper cover, wherein the main body of the regular polygon cube is divided into an upper part, a middle part and a lower part, the upper part is a sealing structure, the middle part is a detachable net structure, the lower part is a tapered sealing structure, and the three parts are connected through a frame body. The conveyor pipeline adopts a closed circular material supply system, improves the environment-friendly regeneration utilization rate, reduces the recovery cost, saves the energy loss, and reduces the recovery secondary pollution.

Owner:余姚市绿岛橡塑机械设备有限公司

A hard alloy hydraulic product mold tooling

The invention discloses a hard alloy hydraulic product mold tooling, comprising two vertical plates arranged opposite to left and right, a pressing table is fixedly connected between the two vertical plates, and the opposite sides of the two vertical plates are A lifting slot is opened, a fixing block is fixedly connected in the two lifting slots, a lifting plate is slidably connected in the two lifting slots and above the fixing block, and a threaded rod and a threaded rod are respectively penetrated through the two lifting plates. Slide the vertical rod, the upper and lower ends of the threaded rod are respectively rotatably connected with the corresponding fixing block and the inner top wall of the lifting groove, and the upper and lower ends of the sliding vertical rod are respectively fixedly connected with the corresponding fixing block and the inner top wall of the lifting groove, wherein A driving motor for driving the threaded rod to rotate is fixedly installed on the upper end of the vertical plate. The advantages are: the present invention can automatically carry out the continuous pressing of the cemented carbide, improve the working efficiency, and at the same time, the metal powder will not be scattered during the pressing, and the working environment is safe and tidy.

Owner:南通尧成机械设备制造有限公司

an air drill

ActiveCN103949695BRealize the function of automatic online punchingRounded incisionTransportation and packagingMetal working apparatusImpellerPunching

The invention relates to a pneumatic drill. The pneumatic drill comprises an air filter and an air pump. The pneumatic drill is characterized in that the pneumatic drill further comprises a negative-pressure pneumatic drill and a chip separator, wherein the negative-pressure pneumatic drill, the chip separator, the air filter, and the air pump are sequentially connected into a whole through air pipes; the negative-pressure pneumatic drill comprises a drill bit, a rotor blade holder, guide impellers, rotor impellers, a sleeve, a gas distribution disc, a casing pipe, an elastic retainer ring and an air pipe connector, wherein the chip separator comprises a lower housing, an upper housing, a chip accommodating bottle and separating impellers. The pneumatic drill provided by the invention not only achieves the function of the pneumatic drill, but also achieves the function of automatic online punching of deformable and soft hollow thin-walled materials; positions of the punching points are accurate and the incision of punching holes is round and uniform; chips and powders produced during the working process are less, so that the pneumatic drill has the advantage of high efficiency and environmental protection. The hollow drill bit is adopted and each group of cutting edges has the same shapes; the chips are discharged from the interior. Therefore, regardless of the positive direction or the reverse direction, a reversing valve is not required; the structure is simpler and more reliable.

Owner:HEBEI DELE MACHINERY TECH

A safe intelligent electric vehicle

ActiveCN106183859BStable charging systemNo short circuitCharging stationsElectric vehicle charging technologyElectricityElectric vehicle

The invention provides a safe and intelligent electric car. The car comprises a charger, a charging hole, a storage battery, a controller, a motor and a header and further comprises a first radio-frequency emission chip, a first radio-frequency reception chip, a control button, a second radio-frequency emission chip and a second radio-frequency reception chip. The first radio-frequency emission chip is arranged on the charger and electrically connected with the charger. The first radio-frequency reception chip is arranged in the charging hole and electrically connected with a charging terminal. The charging hole is electrically connected with the storage battery. The control button and the second radio-frequency emission chip are arranged on a car handle. The control button is electrically connected with the second radio-frequency emission chip. The second radio-frequency reception chip is electrically connected with the controller. A control output end of the controller is connected with the motor and the header. The storage battery is used for supply energy and connected with the controller electrically connected with the charging terminal.

Owner:小刀科技股份有限公司

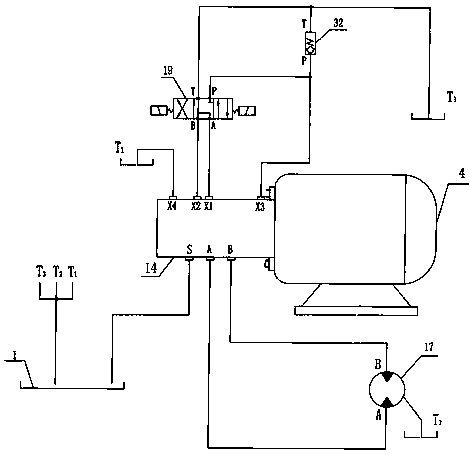

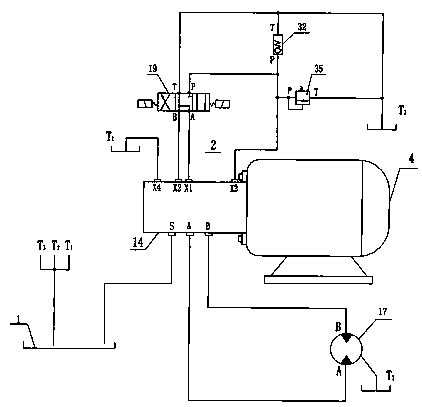

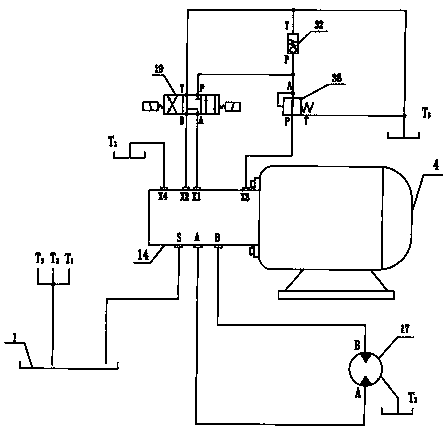

Driving device with safety device

InactiveCN109519448ANo flying phenomenonPrevent flying car phenomenonFluid-pressure actuator safetyFluid-pressure actuator componentsAutomatic controlCirculating pump

The invention provides a driving device with a safety device. The driving device comprises a motor, a self-circulating pump, the safety device and a hydraulic system. The driving device cannot happenthe galloping phenomenon; and when a fault occurs in a speed regulating portion of the driving device and the maximum operating speed of the driving device cannot be controlled, the safety device in the driving device can automatically control the maximum operating speed of the driving device to not exceed a set value, so that the galloping phenomenon is avoided.

Owner:常州钟楼高新技术创业服务有限公司

Feeding equipment of biomass gasification furnace

ActiveCN102703125BGuaranteed sealing performanceStable pressureProductsReagentsEngineeringBiomass gasifier

The invention relates to feeding equipment of a biomass gasification furnace. The feeding equipment comprises a discharge device and a feeding conveyor, wherein the discharge device is arranged in the middle; a lower cylinder is supported through a bracket mechanism, the lower end of the lower cylinder is provided with a connecting seat for connecting the feeding conveyor, and the upper end of the lower cylinder is connected with the lower end of an upper cylinder through a flange; the edge of upper end of a conical seat and the inner edge of the lower end of the upper cylinder are in soldering fixation; a valve seat is arranged at the lower end of the conical seat; a bearing sealed frame is arranged on the outer wall of the upper cylinder, and is internally provided with a rotating shaft; one end of a first rod is arranged on the rotating shaft and synchronously rotate along with the rotating shaft; the other end of the first rod is provided with a chain box; a bell type wall clock cover valve body is suspended on the chain box through a suspending chain, and is matched with the valve seat to control entering of biomass; and one end of a second rod is arranged on the rotating shaft and synchronously rotates along with the rotating shaft, and a pull rod is hinged at the other end of the second rod. The feeding equipment of the biomass gasification furnace has the advantages of being smart and reasonable in structure, continuous in feeding without halt, safe in operation, stable in pressure in the furnace, uniform in feeding and clean.

Owner:无锡湖光工业炉有限公司

A kind of silicone oil electric compound grease and preparation method thereof

InactiveCN102024505BImprove high temperature resistanceImprove low temperature resistanceNon-conductive material with dispersed conductive materialCable/conductor manufactureElectric forceElectricity

The invention discloses electric force compound grease and a preparation method thereof. The silicone oil electric force compound grease mainly comprises silicon oil, white carbon black and conductive metal powder, wherein the white carbon black is subject to surface treatment with a lipophilic processing agent. The silicone oil electric force compound grease comprises the following components in parts by weight: 100 parts of silicon oil, 20-33 parts of precipitated silica subject to the surface treatment with the lipophilic processing agent, 65-90 parts of conductive metal powder, 0-2 parts of stabilizing agent and 0-2 parts of anti-oxygen agent, or the silicone oil electric force compound grease is also composed of the following components in parts by weight: 100 parts of silicon oil, 10-15 parts of fumed silica subject to the surface treatment with the lipophilic processing agent, 65-90 parts of conductive metal powder, 0-2 parts of stabilizing agent and 0-2 parts of anti-oxygen agent. The silicone oil electric force compound grease disclosed by the invention has the advantages of high dropping point temperature, good attachment property, stable rationalizing property, long service life and good economic property.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV +2

Sampling probe with good heat resistance for flue gas detection

PendingCN112229688AAvoid damageExtended service lifeCombination devicesDispersed particle filtrationFlue gasCoupling

The invention discloses a sampling probe with good heat resistance for flue gas detection, relates to the related field of flue gas detection, and aims to solve the problem in the prior art that a probe damage phenomenon caused by too high internal temperature of a to-be-detected area cannot be treated. According to the invention, a filter element is arranged in a sampling box, a shaft sleeve is arranged on one side of the filter element, the shaft sleeve is in a circular ring sleeve shape and fixedly connected with the filter element, a rotating shaft is arranged on one side of the shaft sleeve, the rotating shaft is attached to the shaft sleeve, the rotating shaft is fixedly connected with the filter element, a motor is arranged on one side of the rotating shaft, the motor is connected with the rotating shaft through a coupling, a motor protection shell is arranged on one side of the motor, the motor protection shell is fixedly connected with a sampling box, four mounting plates arearranged on one side of the rear end of the sampling box, the mounting plates are in a rectangular plate shape, the mounting plates are fixedly connected with the sampling box, and mounting holes areformed in the mounting plates.

Owner:河南海恩德环保科技有限公司

Rear earth calsibar deoxidizer and preparation technique thereof

InactiveCN101250609BNo flying phenomenonProtect the working environmentSteelmakingElectric arc furnace

The invention discloses rare-earth silicon-barium-calcium alloy deoxidizer for steelmaking. The invention is prepared through processing the following raw materials such as calcium carbide, silica dioxide, barium sulfate and rare earth. The process of preparing the deoxidizer comprises evenly mixing the raw materials according to proportioning, feeding into an electric arc furnace, striking with arc, then disintegrating into grains, and packaging with double peritoneal. Compared with the traditional technology, the oxidizer of the invention has the following advantages and effects through adopting the technical scheme that firstly rare-earth silicon-barium-calcium alloy deoxidizer has excellent deoxidizing effect, which effectively increases manganese silicon recovery in liquid steel, andincreases the quality of steel, secondly the flow-ability of liquid steel is increased after using the rare-earth silicon-barium-calcium alloy deoxidizer to purify liquid steel, and the difficulty ofladle nozzle nodulation is solved, and thirdly the deoxidizer has low cost and small piece yardage, which effectively reduces the comprehensive cost of steel industry.

Owner:XICHUAN COUNTY SENLI IRON STEEL FURNACE CHARGE

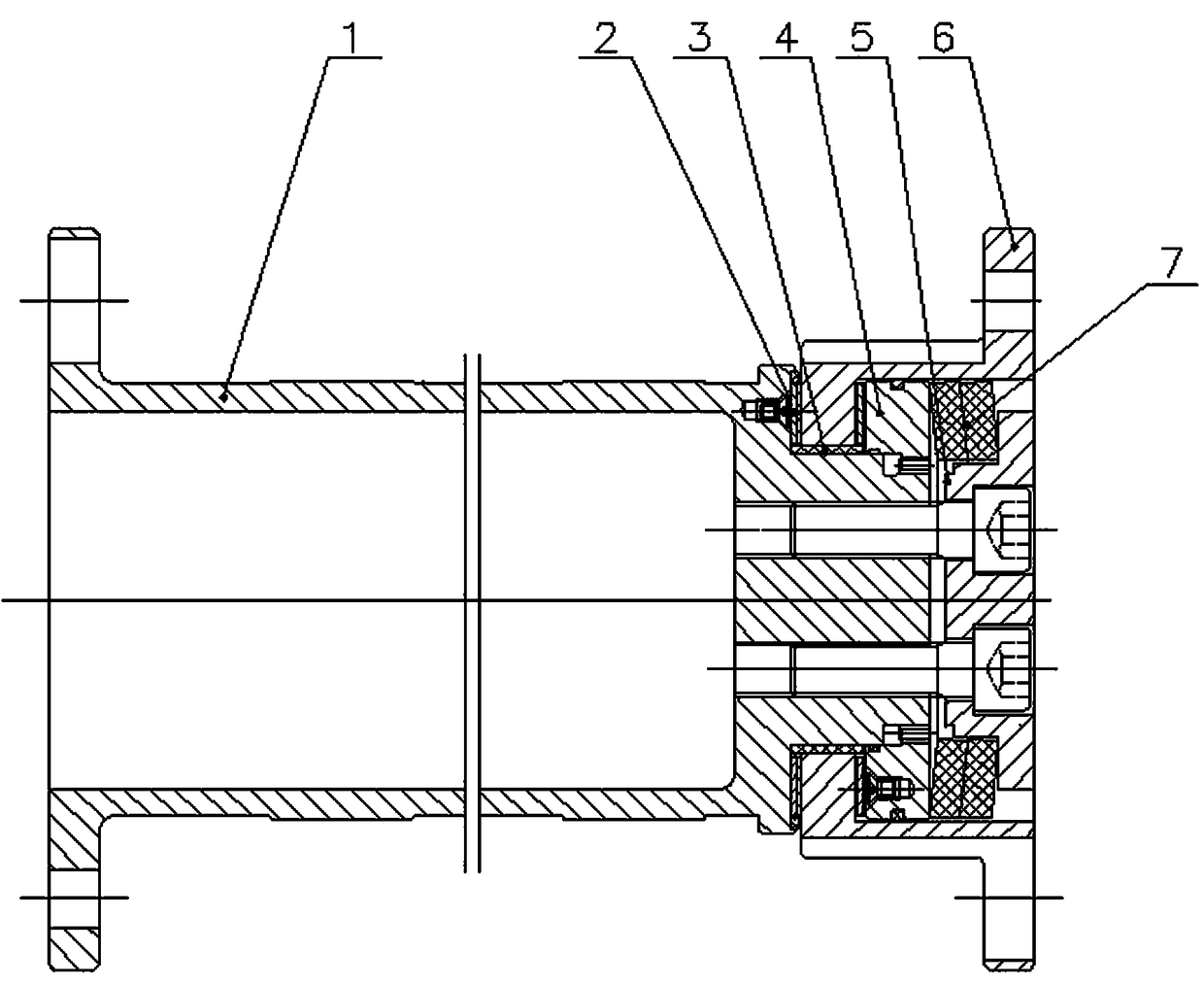

Friction overtorque protecting structure

The invention discloses a friction overtorque protecting structure and relates to the technical field of friction overtorque protecting structures. The friction overtrorque protecting structure comprises a drive end flange, friction plates, a copper bush, a pressure plate, a pressing plate, a driven end flange and a disc spring. One end of the drive end flange is sleeved with the pressure plate. The driven end flange is arranged between the pressure plate and the drive end flange. The friction plates are arranged on the end surfaces of the upper and lower sides of the driven end flange correspondingly. The friction plates make contact with the drive end flange. The copper bush is arranged in the position, making contact with the drive end flange, of the inner side of the driven end flange.The end, away from the drive end flange, of the pressure plate is connected with one end of the disc spring. The other end of the disc spring is connected with the pressing plate. When the friction overtorque protecting structure is disengaged, torque can still be transmitted, normal operation of a unit can be guaranteed, and it is guaranteed that a main machine has no runaway phenomenon; disengaging can be tolerated for a plurality of times; automatic reset is achieved, no operation is needed, and after overload torque is eliminated, synchronous reset can be achieved as a main machine is started; and the slipping torque precision is high and adjustable, the slipping torque is mainly achieved by adjusting the compression amount of the disc spring, and since the disc spring is stable in performance, the adjusting precision and repeating precision are high.

Owner:中国船舶重工集团公司第七0三研究所

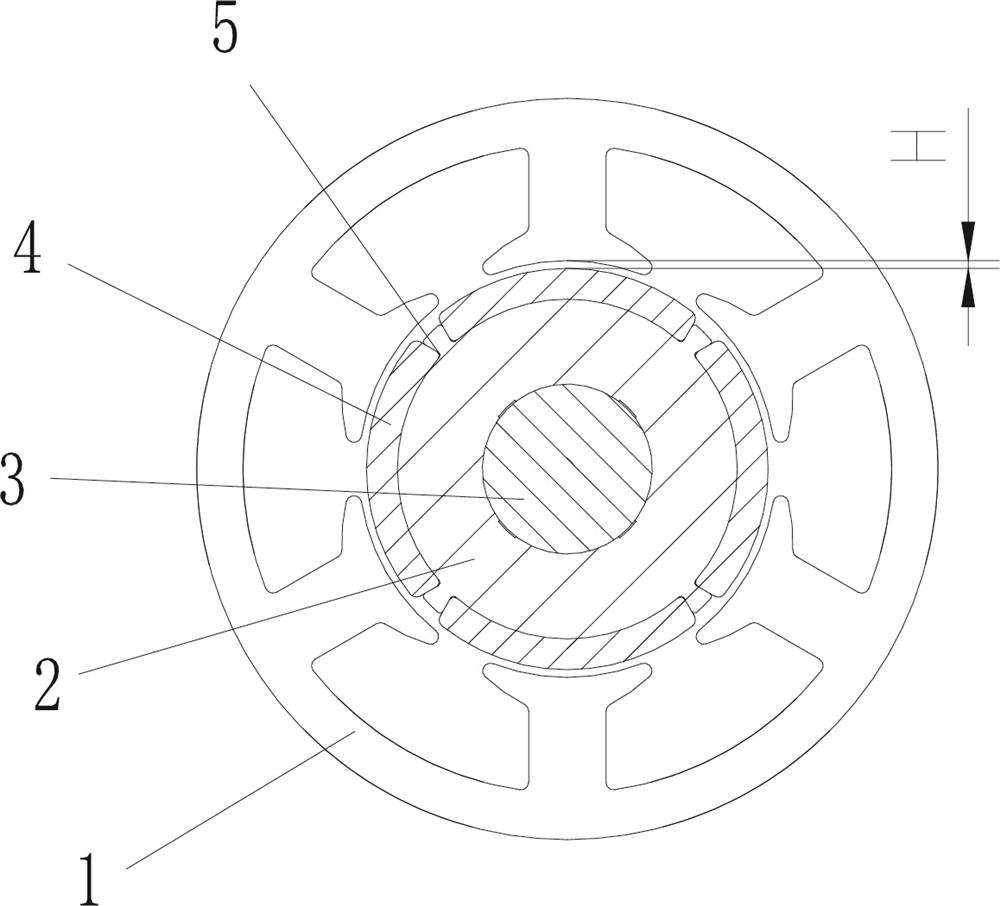

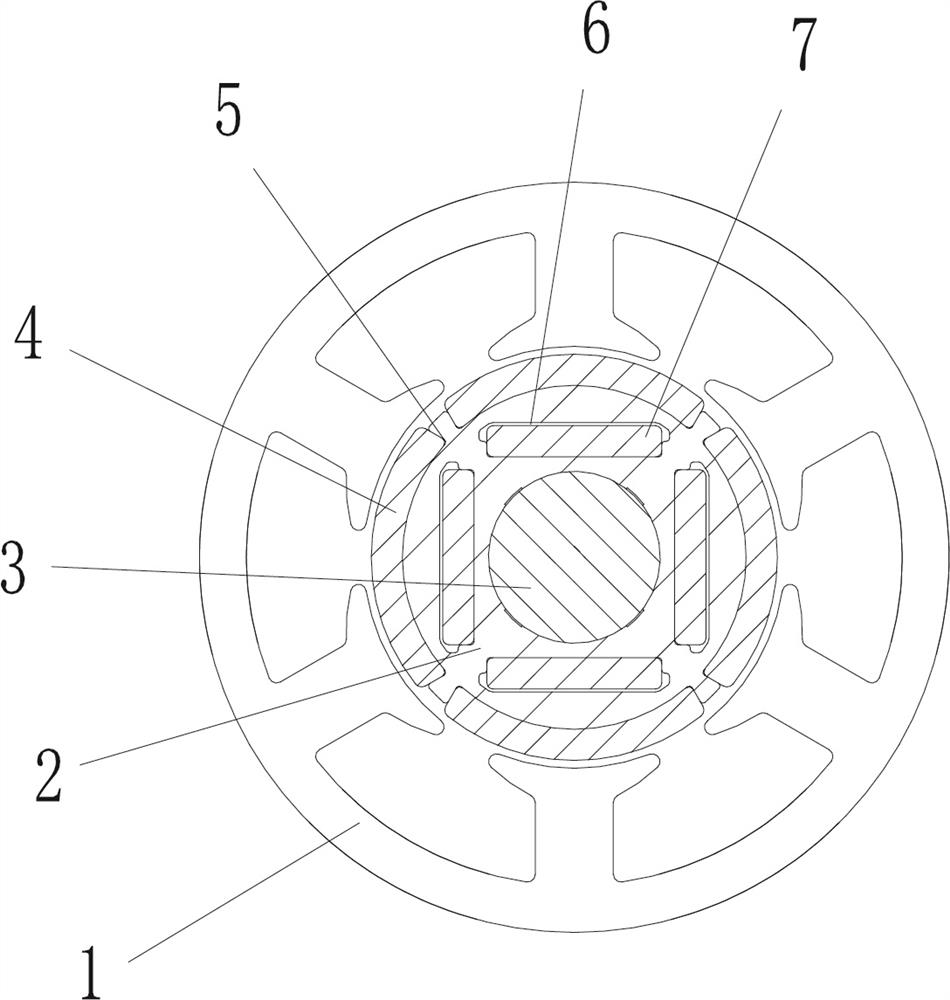

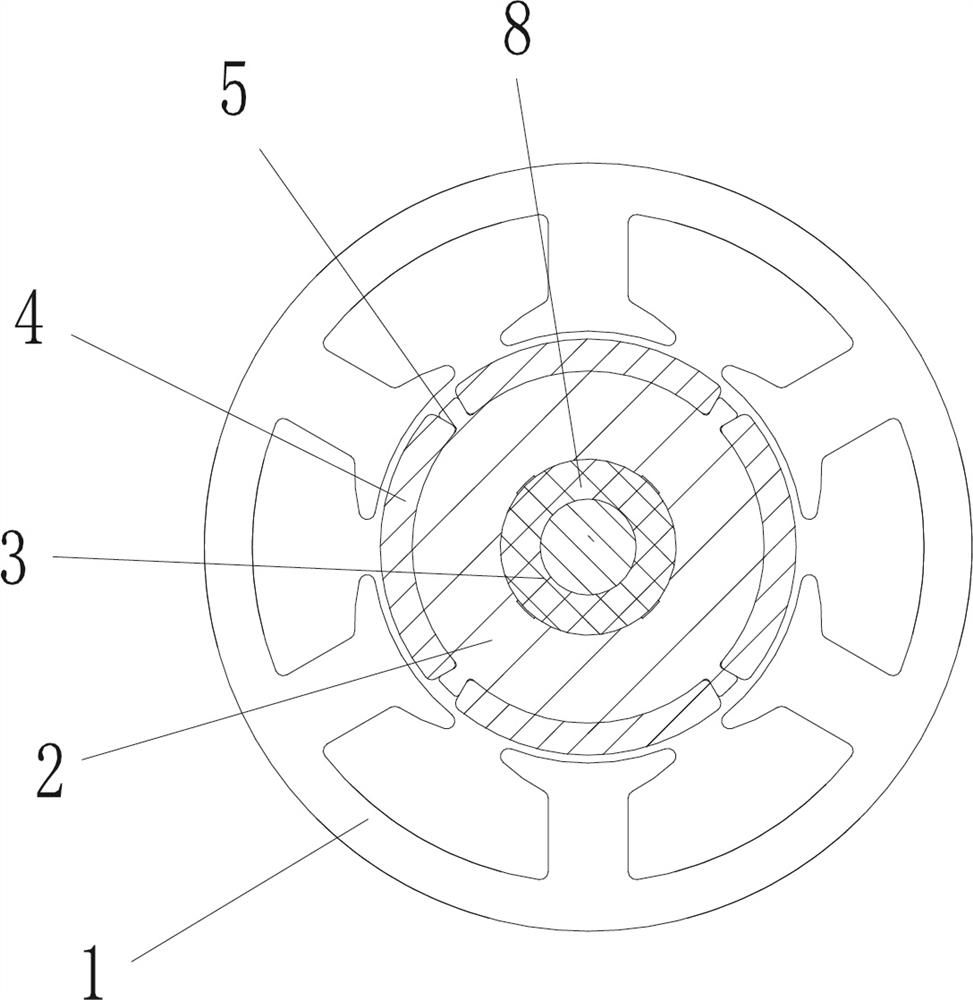

Direct-current brushless motor of electric tool

PendingCN114552820ANo flying phenomenonIncrease torqueMagnetic circuit rotating partsBrushless motorsElectric machine

The invention discloses a direct current brushless motor of an electric tool, which comprises a stator fixed on the inner wall of a casing of the electric tool and a rotor core sleeved by the stator but not in contact with the stator, a rotating shaft is mounted on the rotor core, and the rotating shaft is fixed on a machine body of the electric tool through a bearing. Furthermore, a plurality of dovetail arc-shaped grooves are formed in the circumferential outer wall of the rotor core, and arc-shaped magnetic steel is fixedly installed on the dovetail arc-shaped grooves, so that the arc-shaped magnetic steel cannot be disengaged in the radial direction of the rotor core. Furthermore, a plurality of second limiting grooves can be formed in the rotor iron core, rectangular magnetic steel is arranged in the second limiting grooves, and the rectangular magnetic steel is located between the rotating shaft and the arc-shaped magnetic steel. According to the direct-current brushless motor of the electric tool provided by the invention, the torque of the motor can be improved as much as possible under the conditions of low cost and simple structure and process, and the output power ratio of the motor is improved.

Owner:ZHEJIANG MINLI POWER TOOLS CO LTD

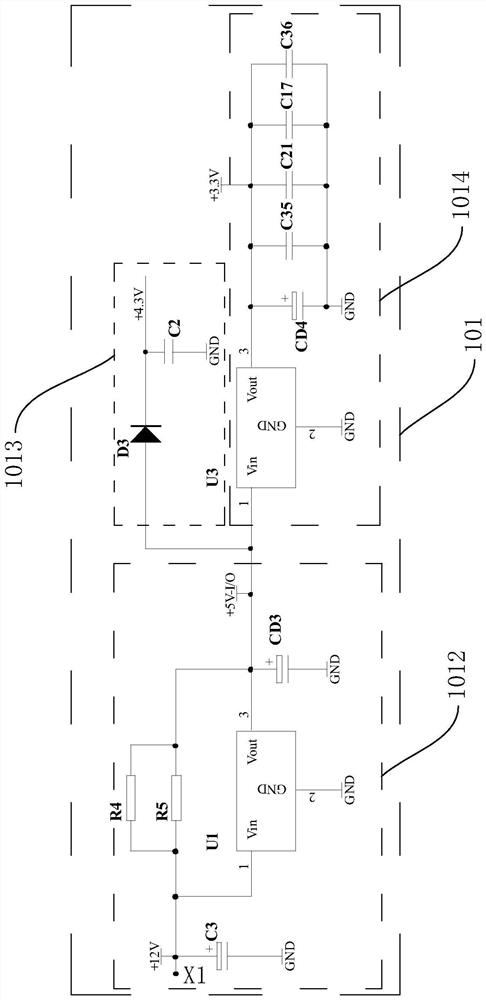

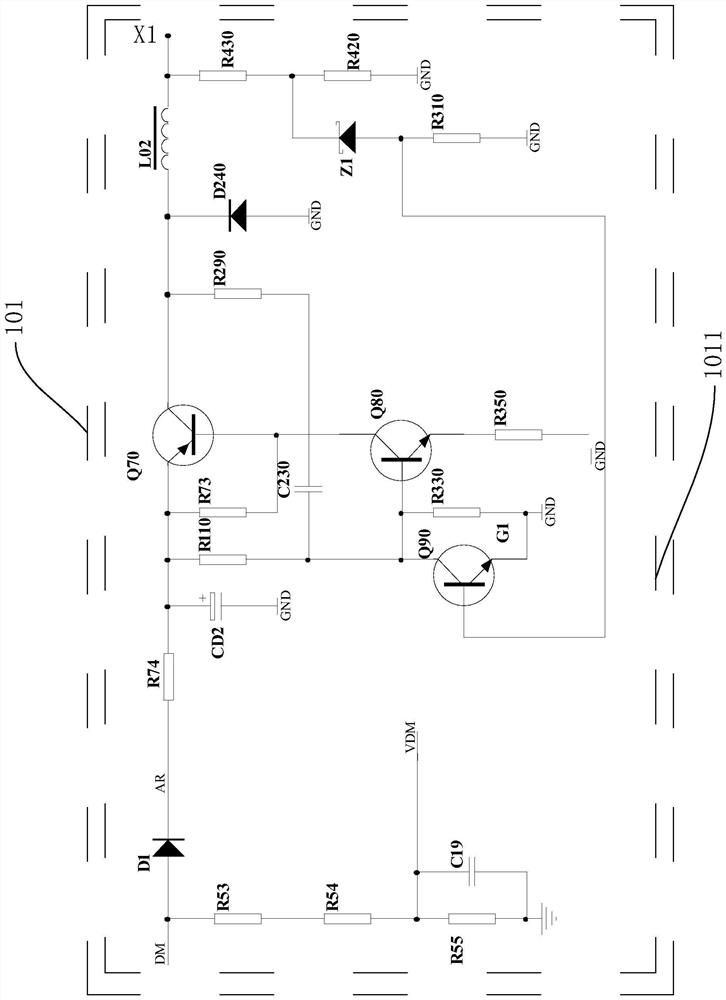

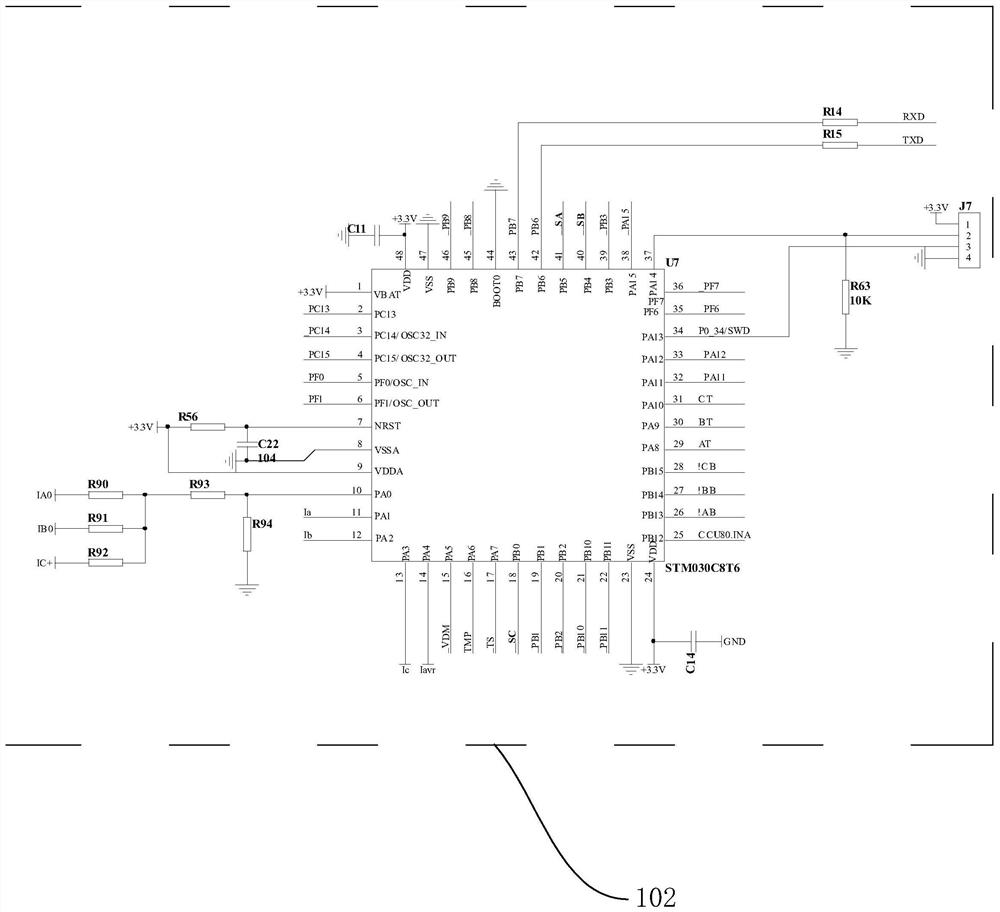

Lock motor self-learning circuit and control method thereof

InactiveCN114257129ANo flying phenomenonReduce self-learningMotor/generator/converter stoppersAC motor controlElectric machineControl engineering

The invention relates to a lock motor self-learning circuit and a control method thereof, and belongs to the technical field of steam lock motors, the lock motor self-learning circuit comprises a power supply module, a control module, a signal amplification module and a three-phase electricity detection module, the power supply module outputs a first voltage signal to the control module to supply power to the control module; the control module outputs a second voltage signal corresponding to the signal amplification module and the three-phase electricity detection module to supply power to the signal amplification module and the three-phase electricity detection module, the control module outputs a detection voltage signal to the three-phase electricity detection module, and the three-phase electricity detection module outputs the detection voltage signal to the signal amplification module. The signal amplification module outputs an amplified signal to the control module. The method has the technical effects that the possibility that the motor locking efficiency is reduced due to the fact that self-learning is carried out on the motor locking is reduced, and therefore the motor locking efficiency is improved.

Owner:易宏科技(江苏)有限公司

Returning recycling method for MOX fuel pellet with unqualified density

ActiveCN109949960AMeet the requirements of development materialsNo flying phenomenonRadioactive decontaminationMetallurgyImpurity

Owner:THE 404 COMPANY LIMITED CHINA NAT NUCLEAR

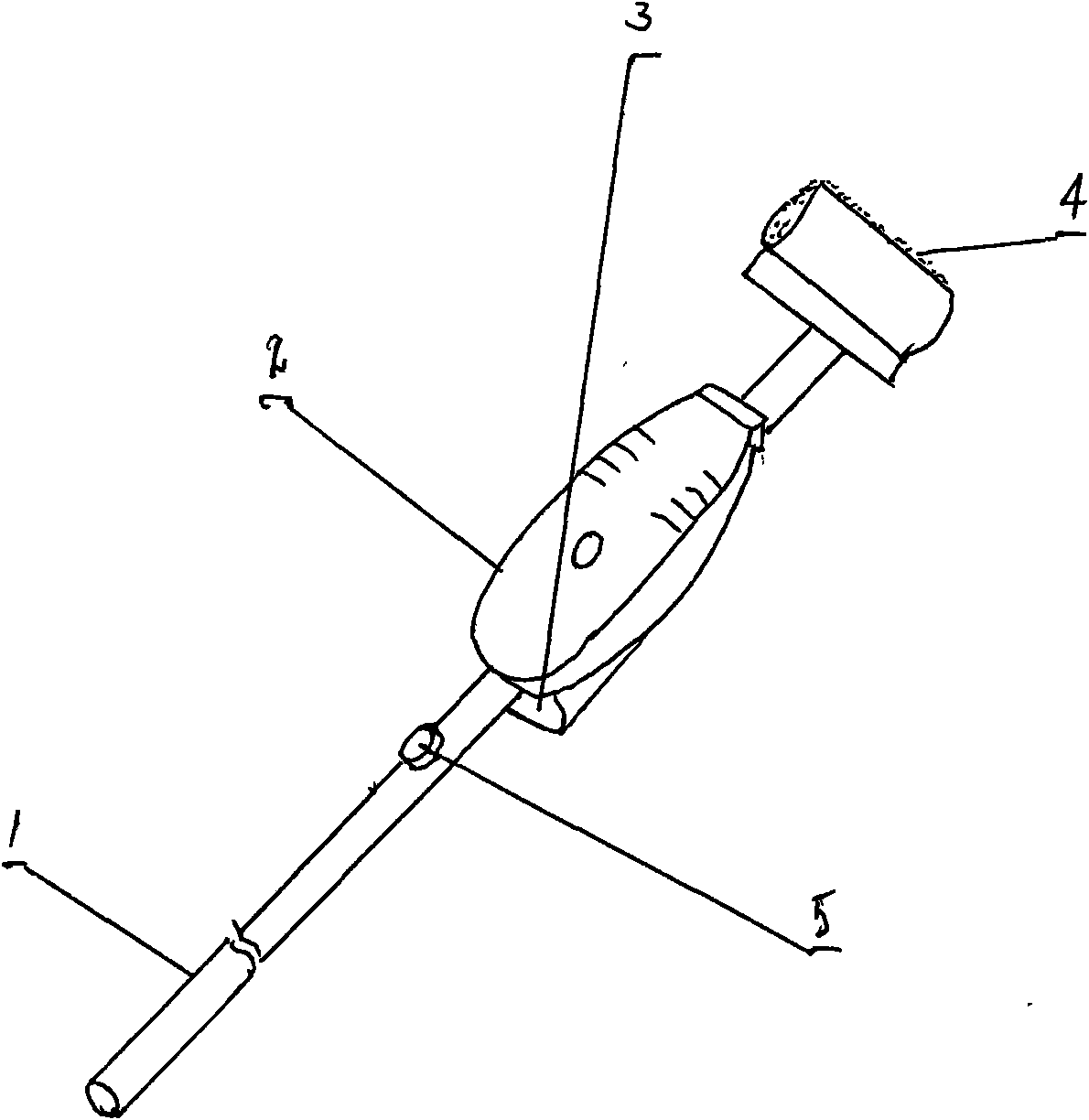

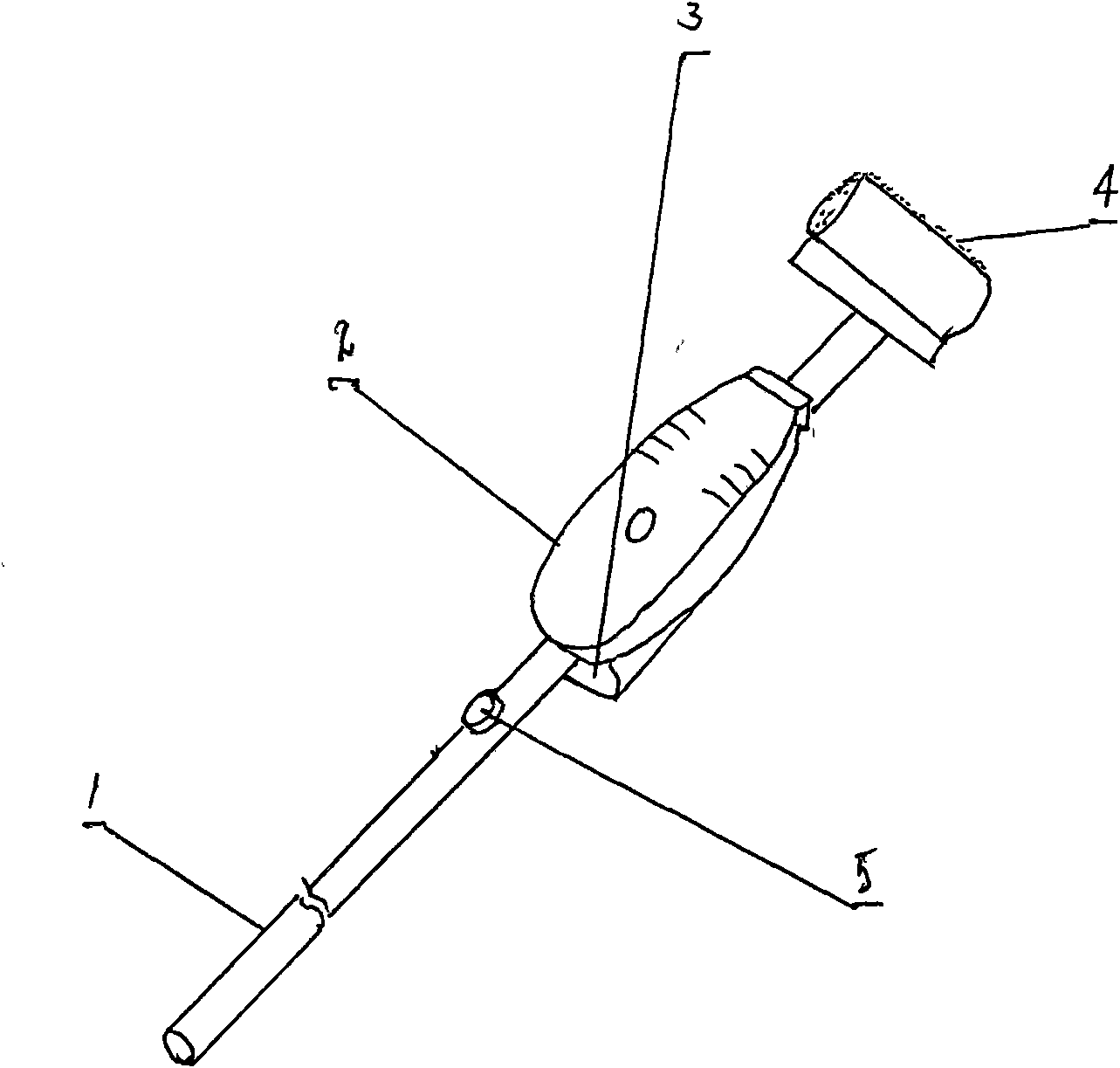

High-position electrical dust collector

InactiveCN102038452ANo flying phenomenonGood cleaning environmentCarpet cleanersFloor cleanersMOPSEngineering

The invention discloses a high-position electrical dust collector which relates to an electrical appliance. The high-position electrical dust collector is provided with a telescopic mop; a computer dust collector is fixed to the front end of a mop rod; a sucking opening of the dust collector faces to a mop head; a dry cell box and a control switch are fixed to the mop rod at one side of the dust collector; and the width of a spongy head of the mop is slightly larger than that of the sucking opening of the computer dust collector. The high-position electrical dust collector has the advantages of cleaning dust at high positions, such as glass, roofs, room corners, and the like, not generating the phenomenon of dust flying and ensuring good cleaning environment.

Owner:金晨龙

A dust-free crushing equipment for construction waste treatment

ActiveCN110586241BNo cloggingReduce failure rateGrain treatmentsEnvironmental engineeringConveyor belt

The invention discloses a dust-free crushing device for construction waste treatment, which comprises a base, a device main body, a feeding bin, a feeding port and a discharging port. There is a reserved opening, and a discharge port is provided on the left side above the main body of the device, and a discharge pipeline is connected above the discharge port, and the second conveyor belt is arranged between two second rolling rollers, and the second The left top of the conveyor belt is set on the right side above the discharge opening. The dust-free crushing equipment for construction waste treatment can not only perform dust removal work at the position of the entire equipment's feeding and discharging ports, but also prevent the entire equipment from being blocked during the process of feeding and crushing, ensuring that the entire During the use of the equipment, the impact on the environment is small, and the failure rate of the entire device is low, and the use and operation are more convenient.

Owner:徽仁(宁夏)环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com