A hard alloy hydraulic product mold tooling

A cemented carbide and hydraulic technology, applied in the field of cemented carbide hydraulic product mold tooling, can solve the problems of raw material waste, eye damage, heavy metal poisoning, etc., and achieve the effect of ensuring safety and cleanliness, improving work efficiency and high processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

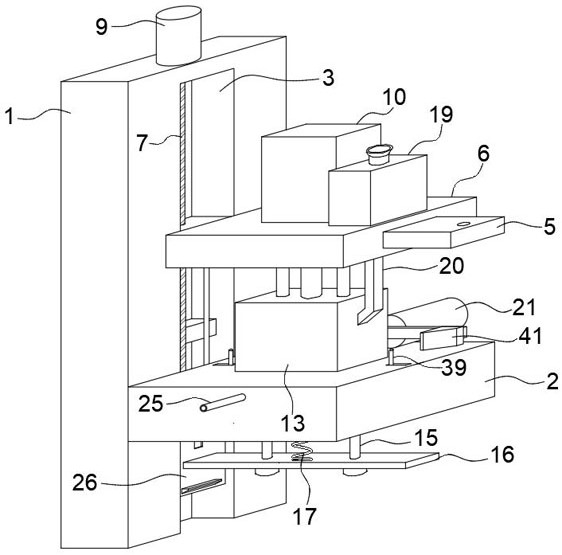

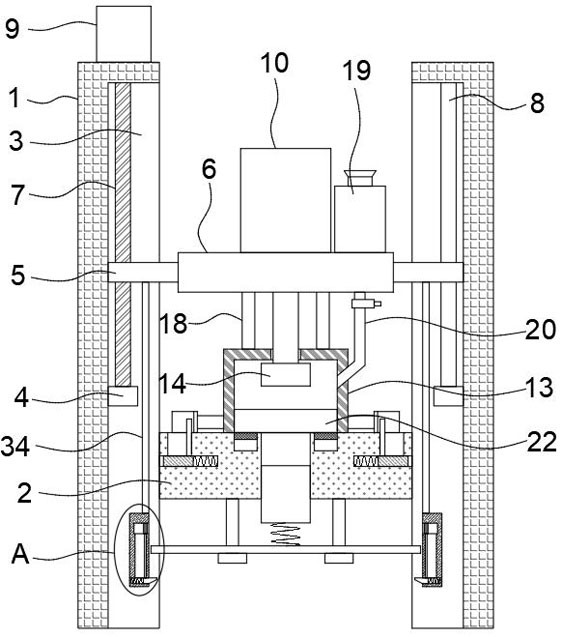

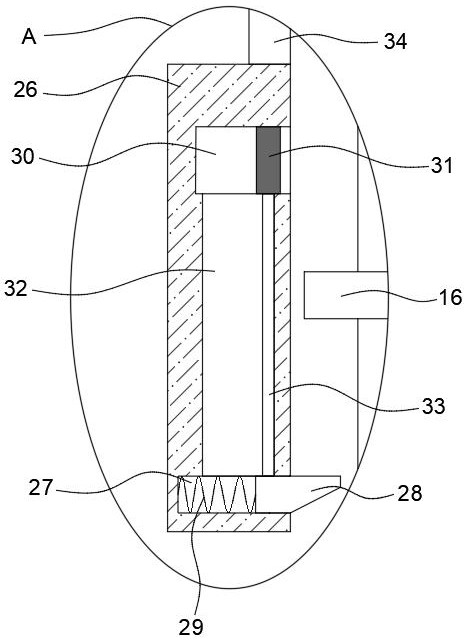

[0026] refer to Figure 1-6 , a hard alloy hydraulic product mold tooling, including two vertical plates 1 arranged opposite to each other, a pressing table 2 is fixedly connected between the two vertical plates 1, and the opposite sides of the two vertical plates 1 are provided with lifting and lowering Slot 3, a fixing block 4 is fixedly connected in the two lifting slots 3 and above the pressing table 2, a lifting plate 5 is slidably connected in the two lifting slots 3 and above the fixing block 4, and the two lifting plates 5 are slidably connected. A threaded rod 7 and a sliding vertical rod 8 are respectively penetrated. The upper and lower ends of the threaded rod 7 are respectively connected with the corresponding fixing block 4 and the inner top wall of the lifting groove 3. The upper and lower ends of the sliding vertical rod 8 are respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com