Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

82results about How to "Minimizing heat generation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

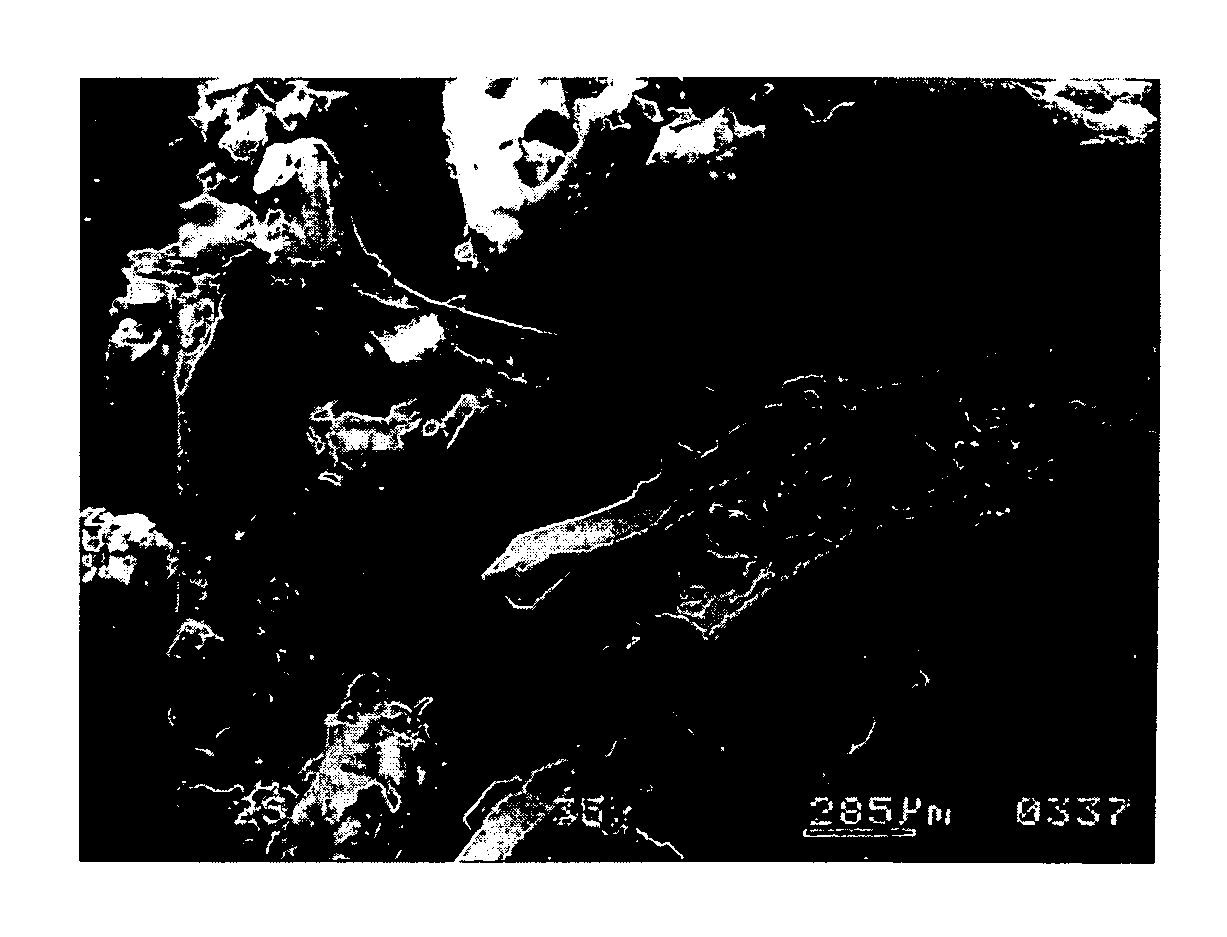

Abrasive tools having a permeable structure

ActiveUS20070074456A1Compromising surface-finish qualityCompromising structural opennessPigmenting treatmentOther chemical processesThree dimensional shapeAgglomerate

A bonded abrasive tool comprises a blend of abrasive grains and a bond component. The blend of abrasive grains comprises a filamentary sol-gel alumina abrasive grain and agglomerated abrasive grain granules. A bonded abrasive tool comprising an agglomerate of filamentary sol-gel alumina abrasive and non-filamentary abrasive grains, and a bond component is also disclosed. The filamentary sol-gel alumina abrasive grain has a length-to-cross-sectional-width aspect ratio of greater than 1.0. The agglomerated abrasive grain granules comprise a plurality of abrasive grains held in a three-dimensional shape by a binding material. A method of making such a bonded abrasive tool as described above is also disclosed.

Owner:SAINT GOBAIN ABRASIVES INC

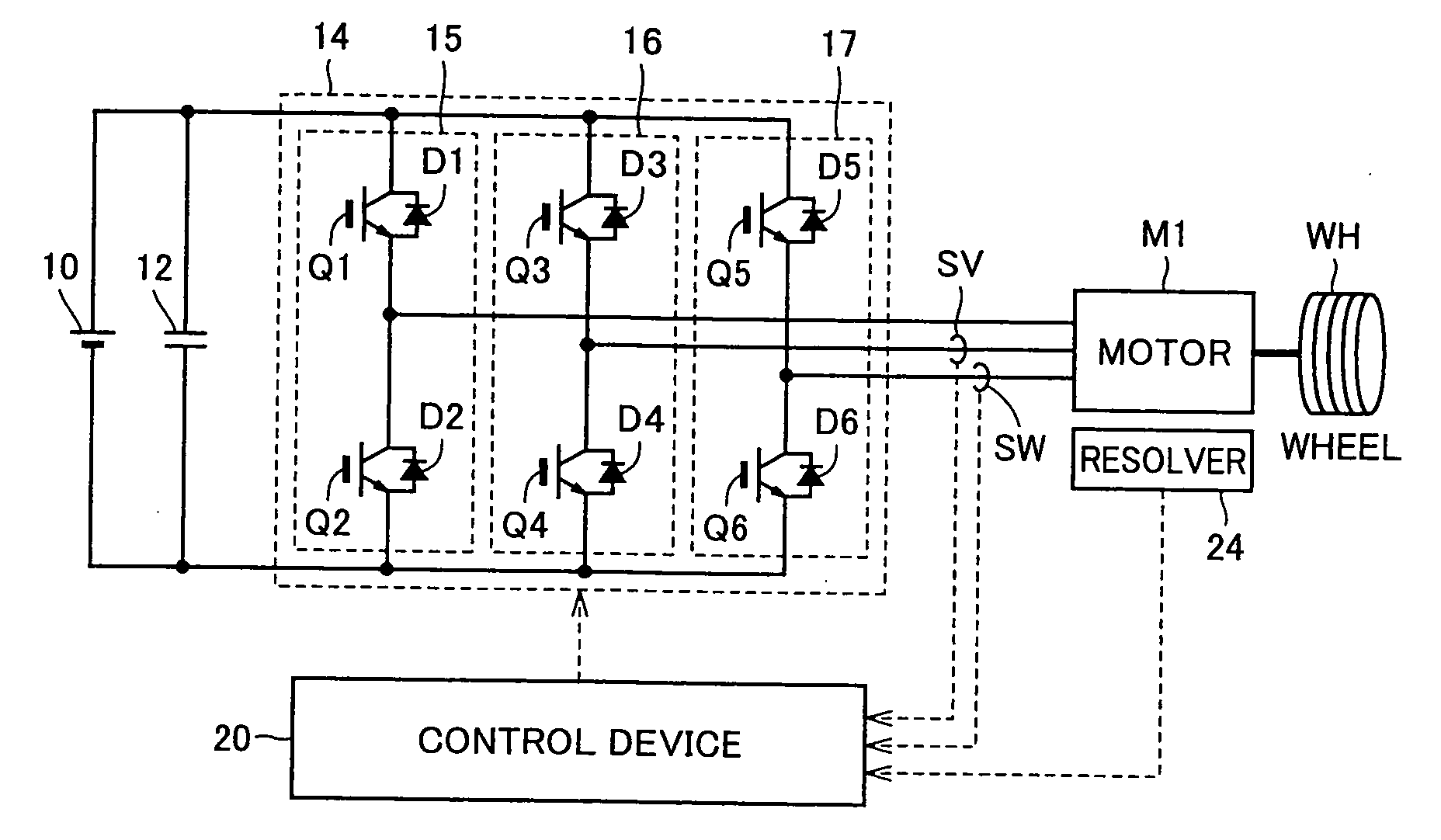

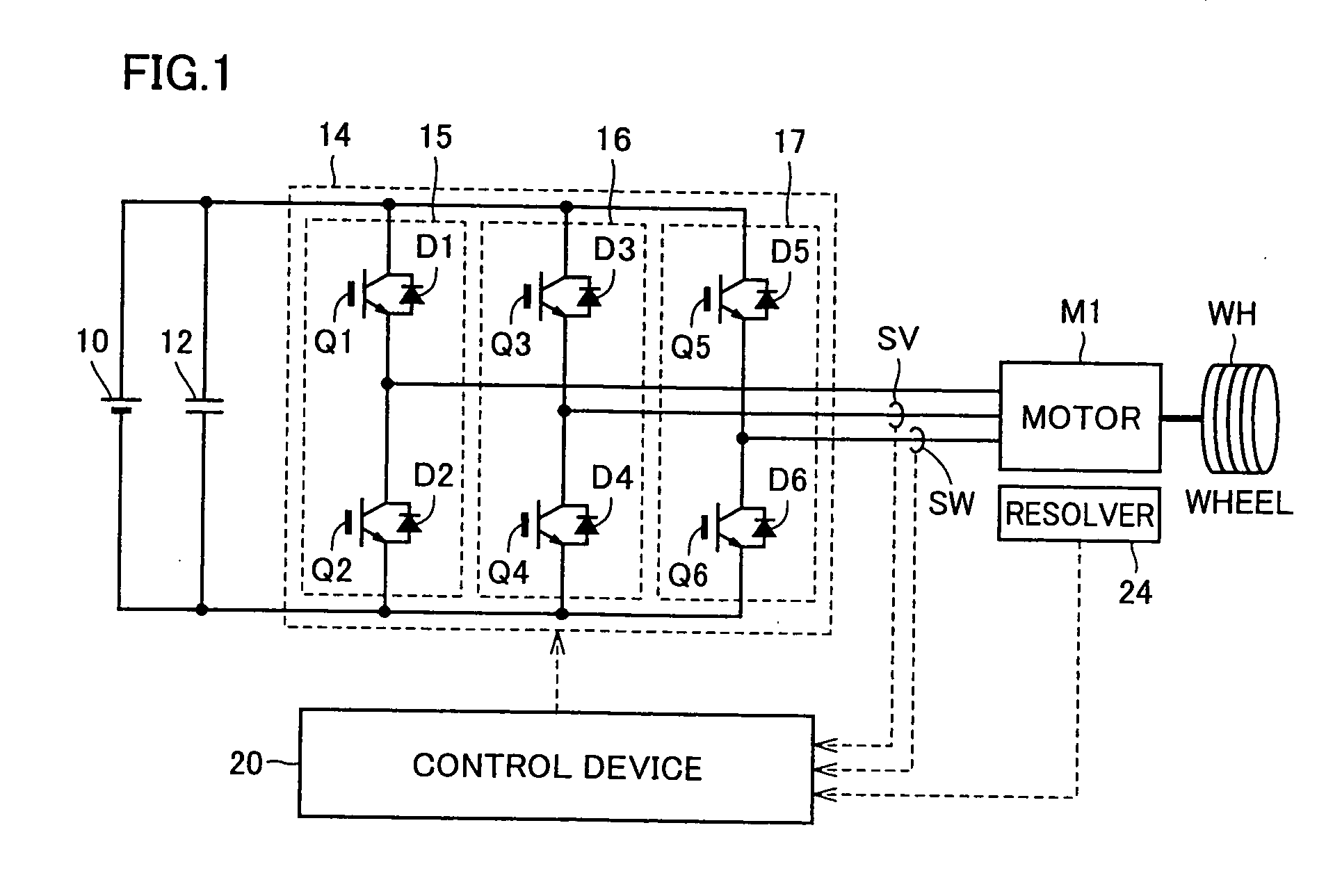

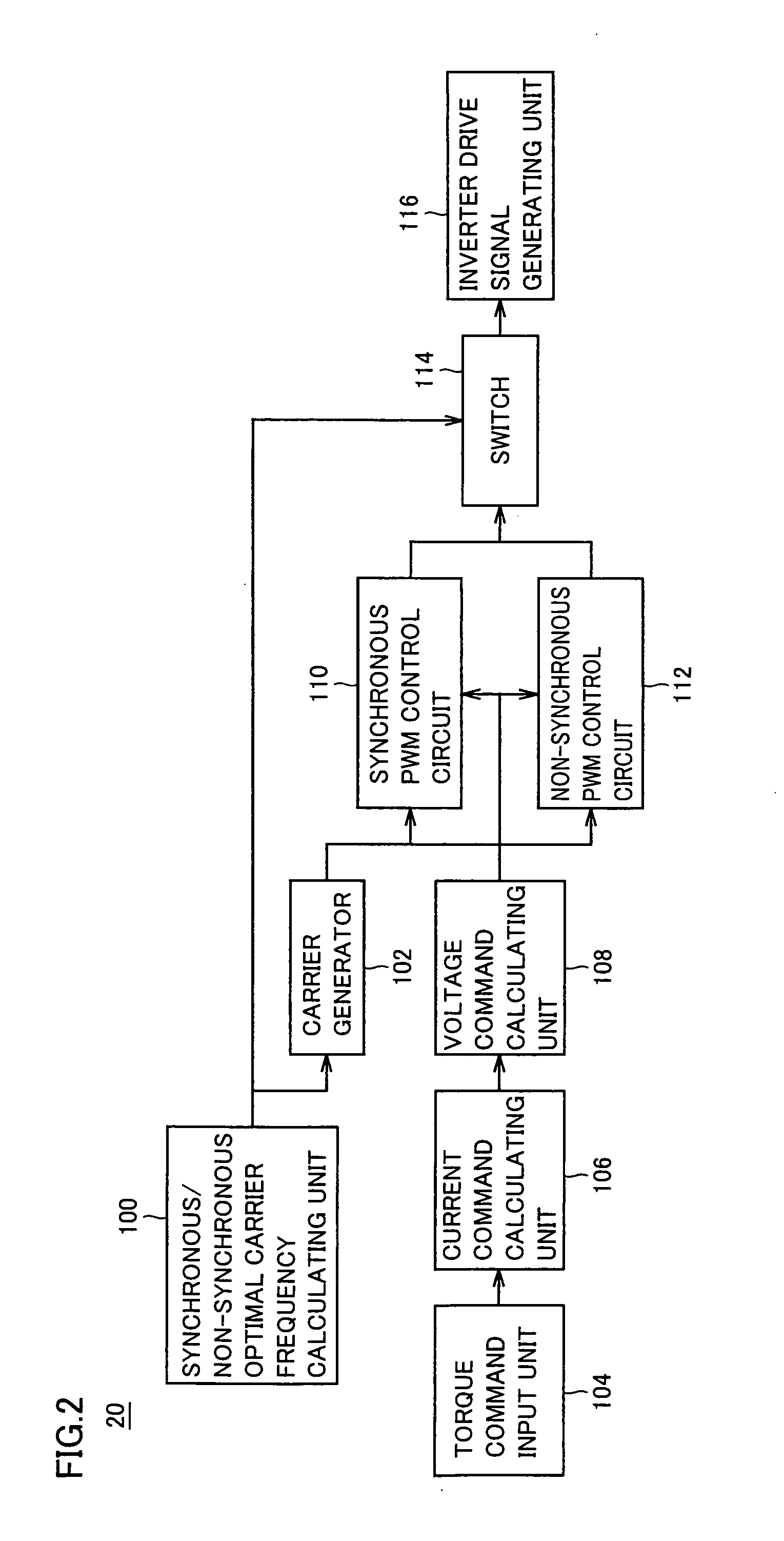

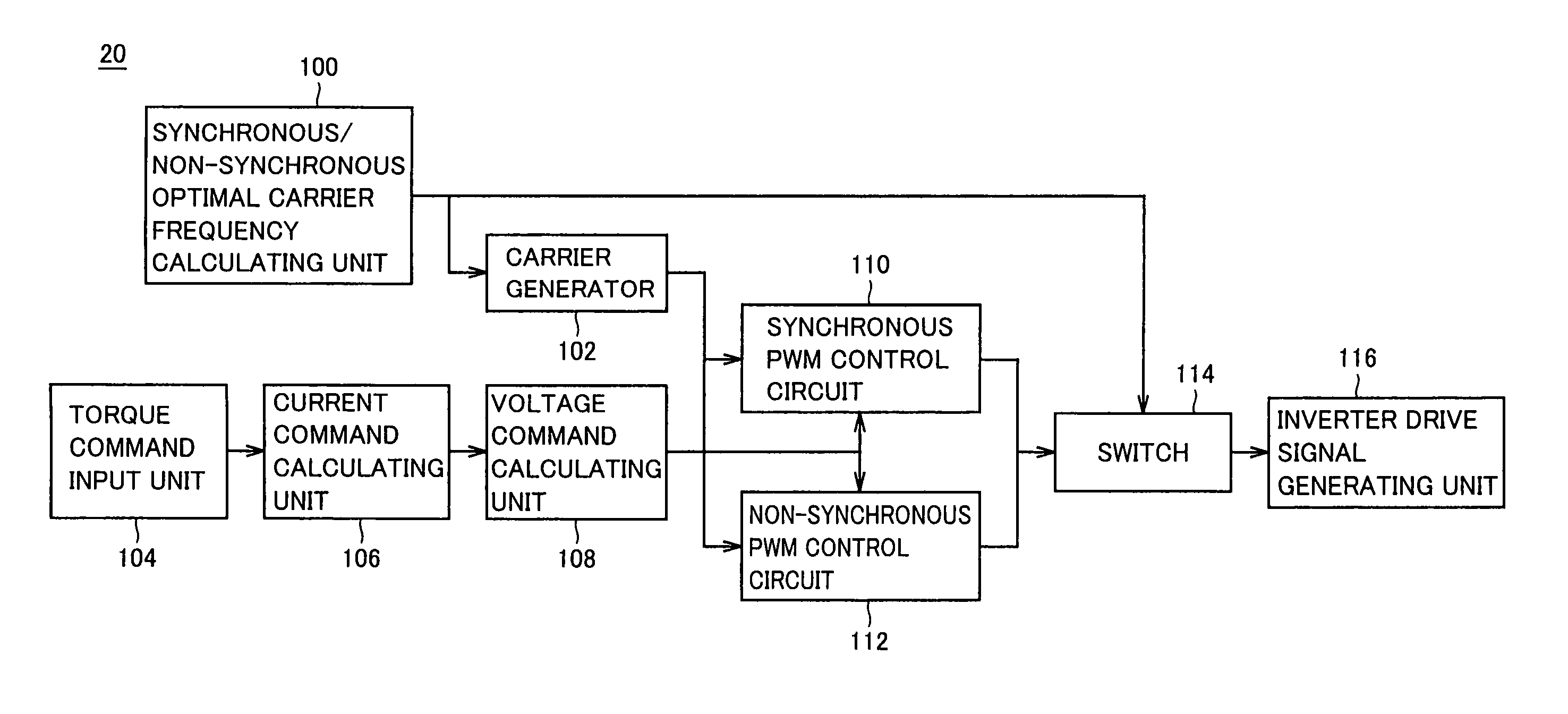

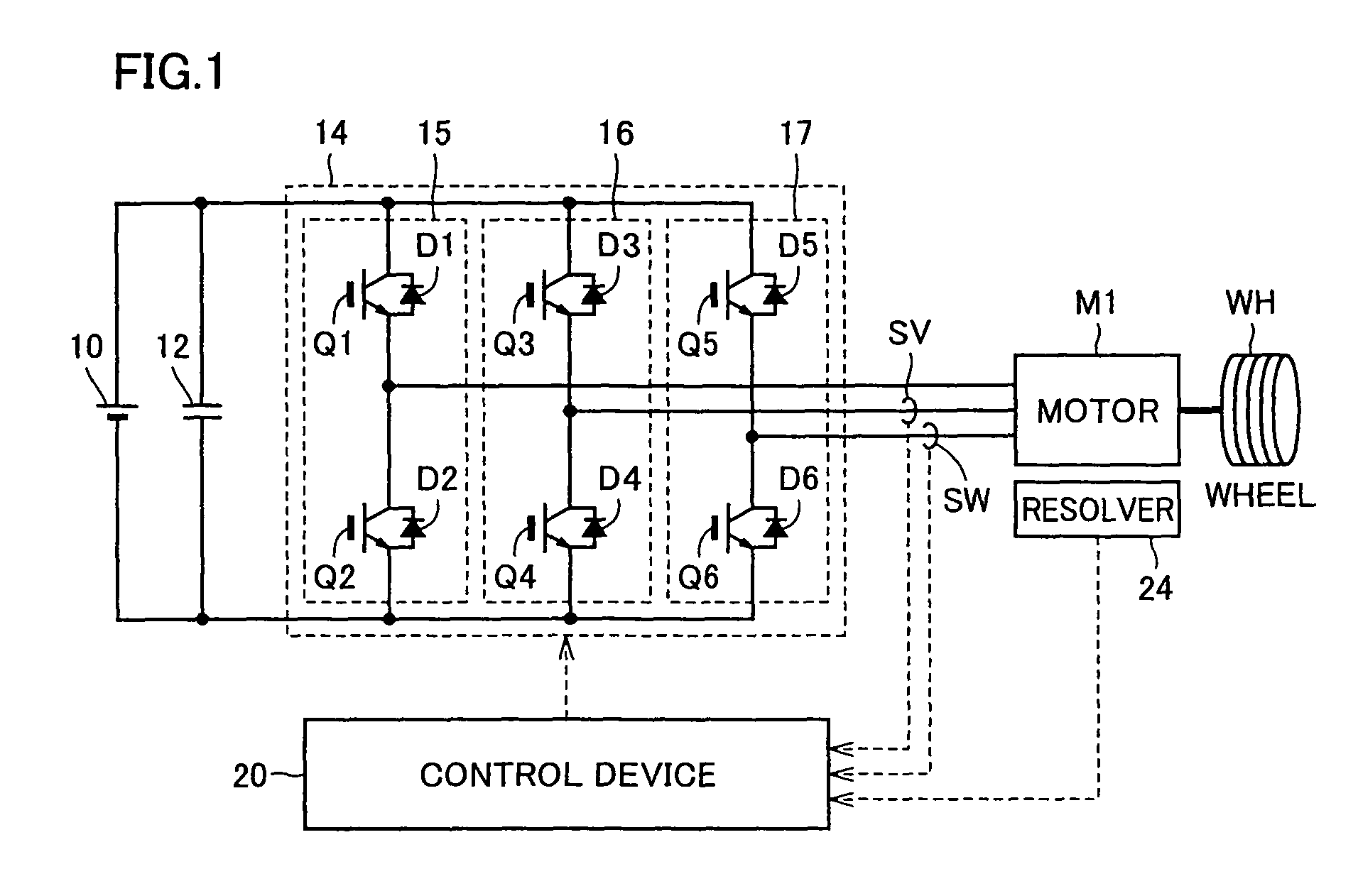

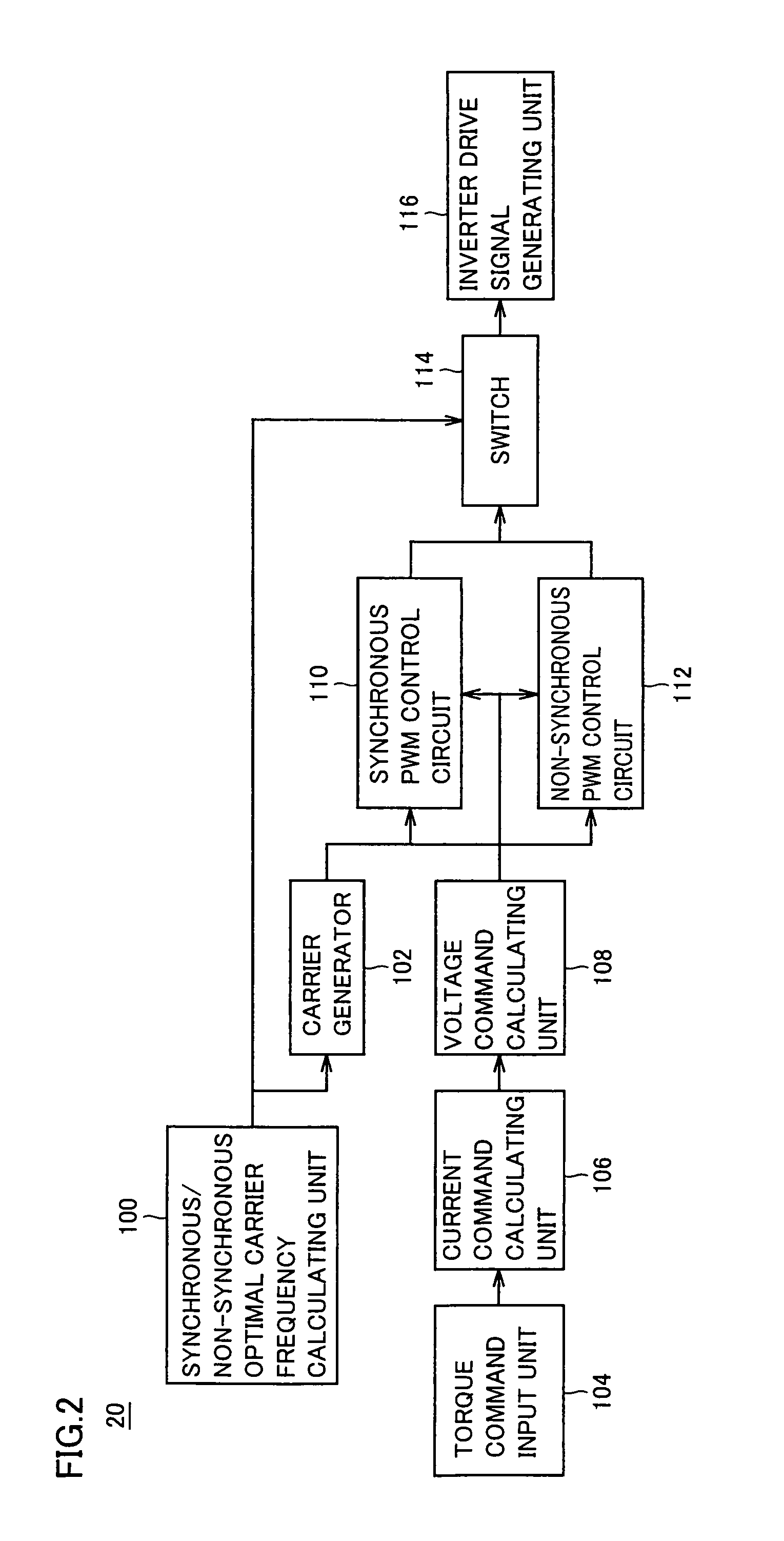

Vehicle equipped with motor and inverter

ActiveUS20100052583A1Reduce noiseIncrease fuel consumptionSynchronous motors startersVector control systemsFrequency changerDrive wheel

A vehicle includes a motor for driving wheels WH, an inverter to drive the motor, and a control device to perform PWM control of the inverter. The control device performs synchronous PWM control in a case where an electric current supplied to the motor by the inverter or torque generated in the motor is larger than a threshold value; and performs the synchronous PWM control or non-synchronous PWM control in a case where the electric current or the torque is smaller than the threshold value and sets carrier frequency or a pulse number of the PWM control to be higher than the case where the electric current or the torque is larger than the threshold value. Thereby, it is possible to provide a vehicle of achieving reduction of noise, reduction of cost and improvement of fuel consumption in a balanced manner.

Owner:DENSO CORP

Low temperature horticultural light apparatus

InactiveUS6267483B1Heat generation is minimizedMinimizing heat generationElongate light sourcesElectric lighting sourcesEngineeringRadiant heat

A horticultural light apparatus that reduces heat transmitted to plants that are being illuminated is provided. The Inventive Device includes a hollow, transparent, cylindrical tube, preferably made of glass. The tube is open at both ends and adapted to receive spigot members, the spigot members also being open ended. A support bracket to mount a lightbulb is affixed to at least one of the spigots. A reflector is also installed on the interior of the tube. In use, a lightbulb is inserted into the tube and secured by the spigots. Because of the open ends, air can flow through the tube, thus eliminating over-heating of the lightbulb. The glass absorbs much of the radiant heat generated by the lightbulb while emitting substantially all of the light generated by the lightbulb. The reflector directs the light in a generally downward direction. Means for suspending the Device are also included.

Owner:HEMBERY DANIEL

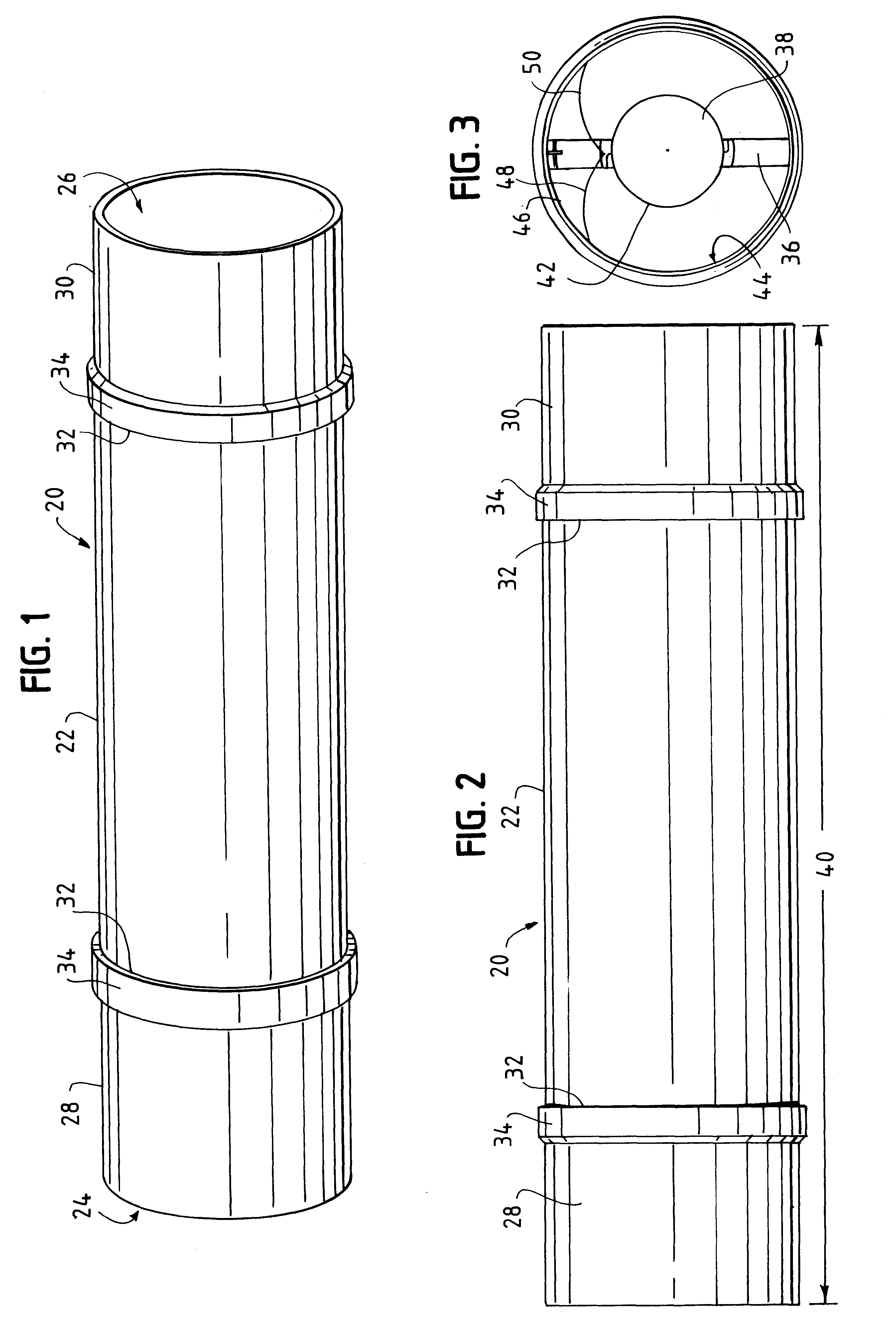

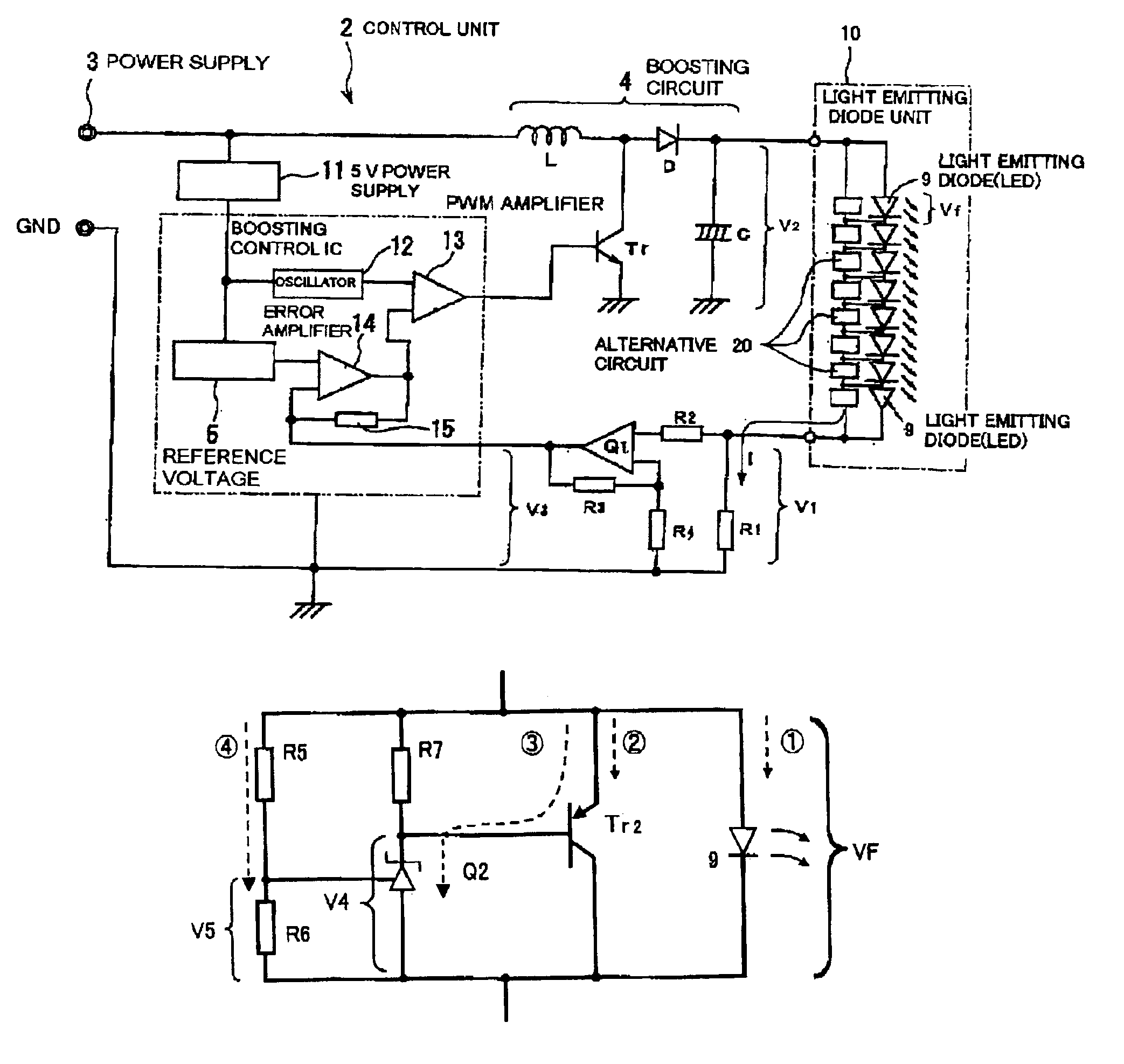

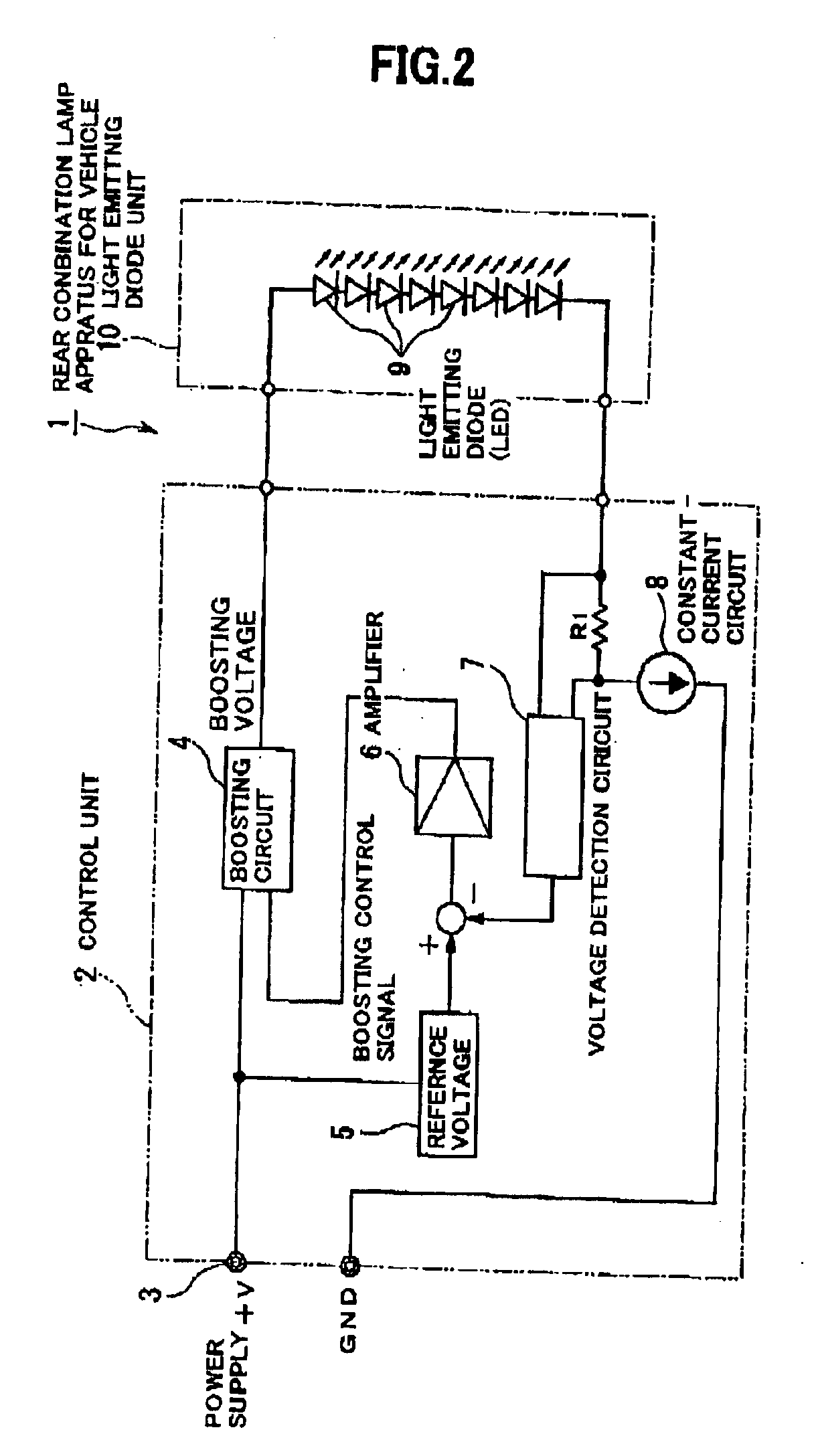

LED lamp apparatus for vehicles

InactiveUS6870328B2Prevent brightnessMinimizing heat generationElectrical apparatusElectroluminescent light sourcesVoltage referenceAudio power amplifier

In an LED unit, all of eight LEDs are connected in series. The voltage of a power supply, that is, a battery of a vehicle, 12 V, is insufficient for the eight LEDs. To cope with this, a boosting circuit is provided within the control unit to boost the voltage to about 16 V which is then applied to the eight LEDs. The front end of the LED unit is connected to a constant-current circuit, and a voltage detection circuit is provided near and connected to this constant-current circuit for detecting the voltage applied to the constant-current circuit. The voltage detected by the voltage detection circuit is compared with a reference voltage drawn from the power supply, is amplified in an amplifier, and is input as a boosting control signal into the boosting circuit. The boosting control signal is output so as to regulate the boosted voltage in such a manner that the voltage detected in the voltage detection circuit is a lowest possible voltage.

Owner:TOYODA GOSEI CO LTD

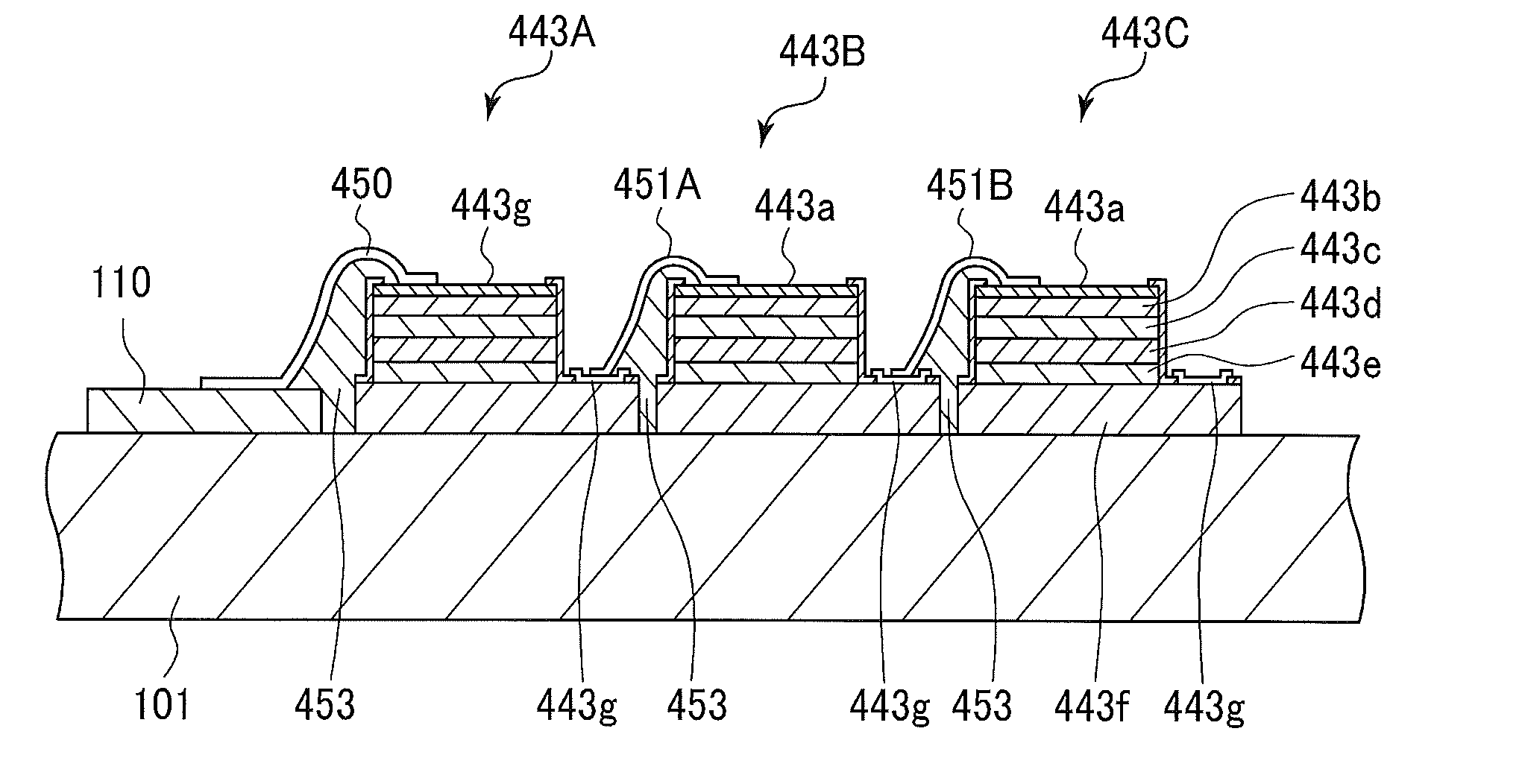

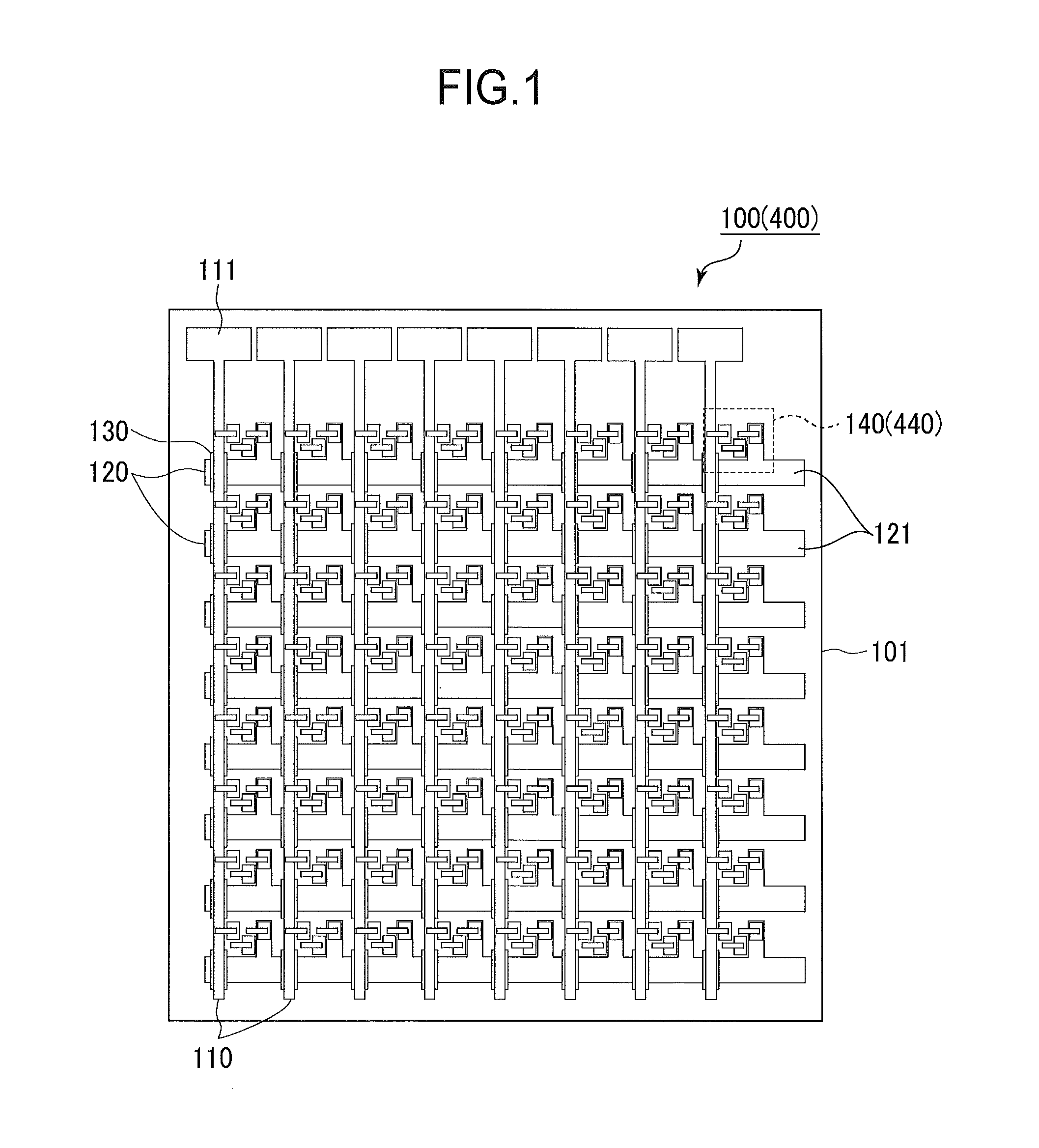

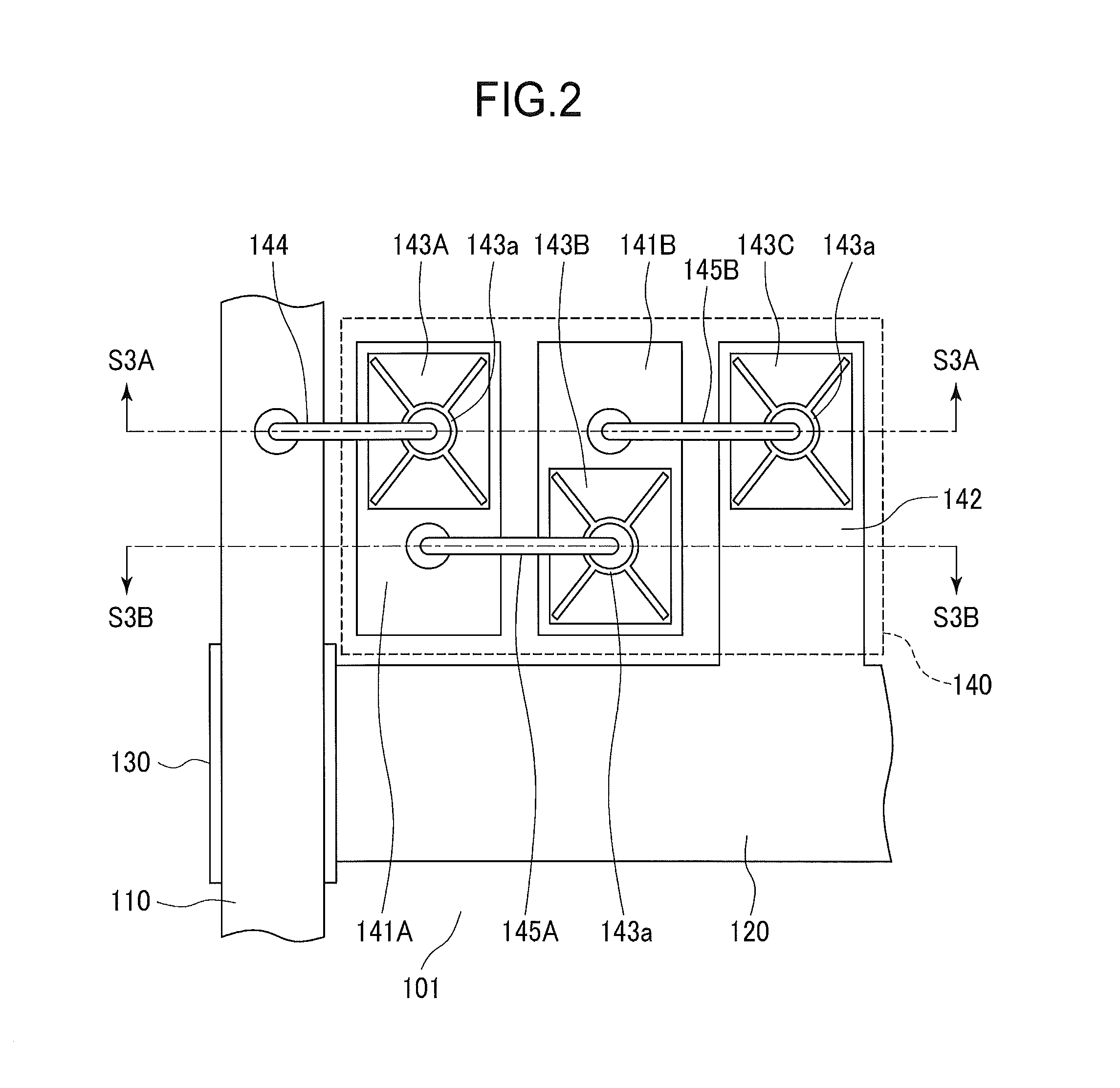

Semiconductor light emitting apparatus, image displaying apparatus, mobile terminal, head-up display apparatus, image projector, head-mounted display apparatus, and image forming apparatus

ActiveUS20130208026A1Heat generation is minimizedMinimizing heat generationSolid-state devicesCathode-ray tube indicatorsHead-up displayImage formation

A semiconductor light emitting apparatus includes a substrate. A plurality of first electrode wirings are formed on the surface of the substrate. At least one second electrode wiring is formed on the surface of the substrate. A light emitting section is connected between a corresponding one of the plurality of first electrode wirings and the at least one second electrode wiring. The light emitting section includes a plurality of light emitting elements.

Owner:OKI ELECTRIC IND CO LTD

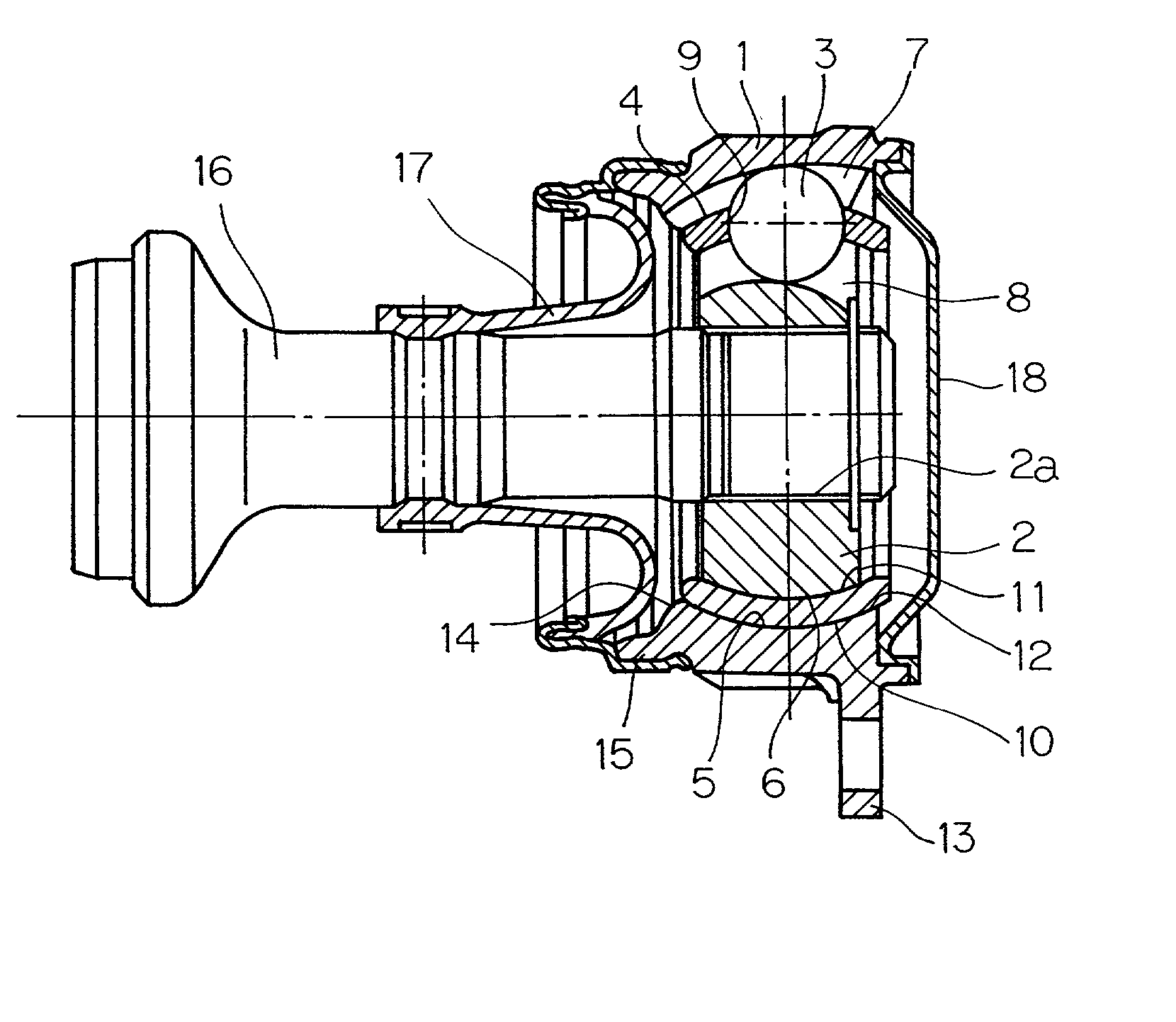

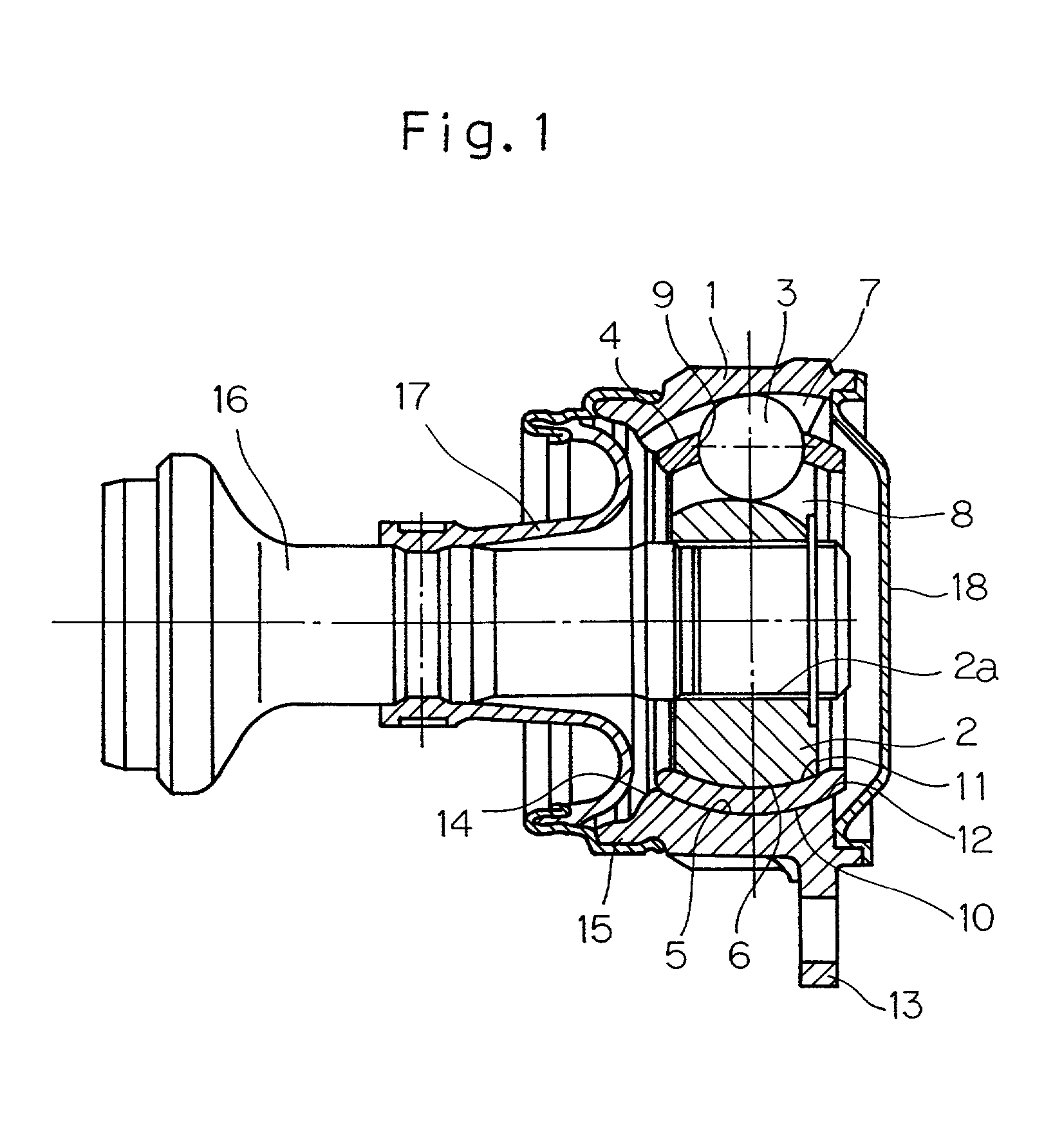

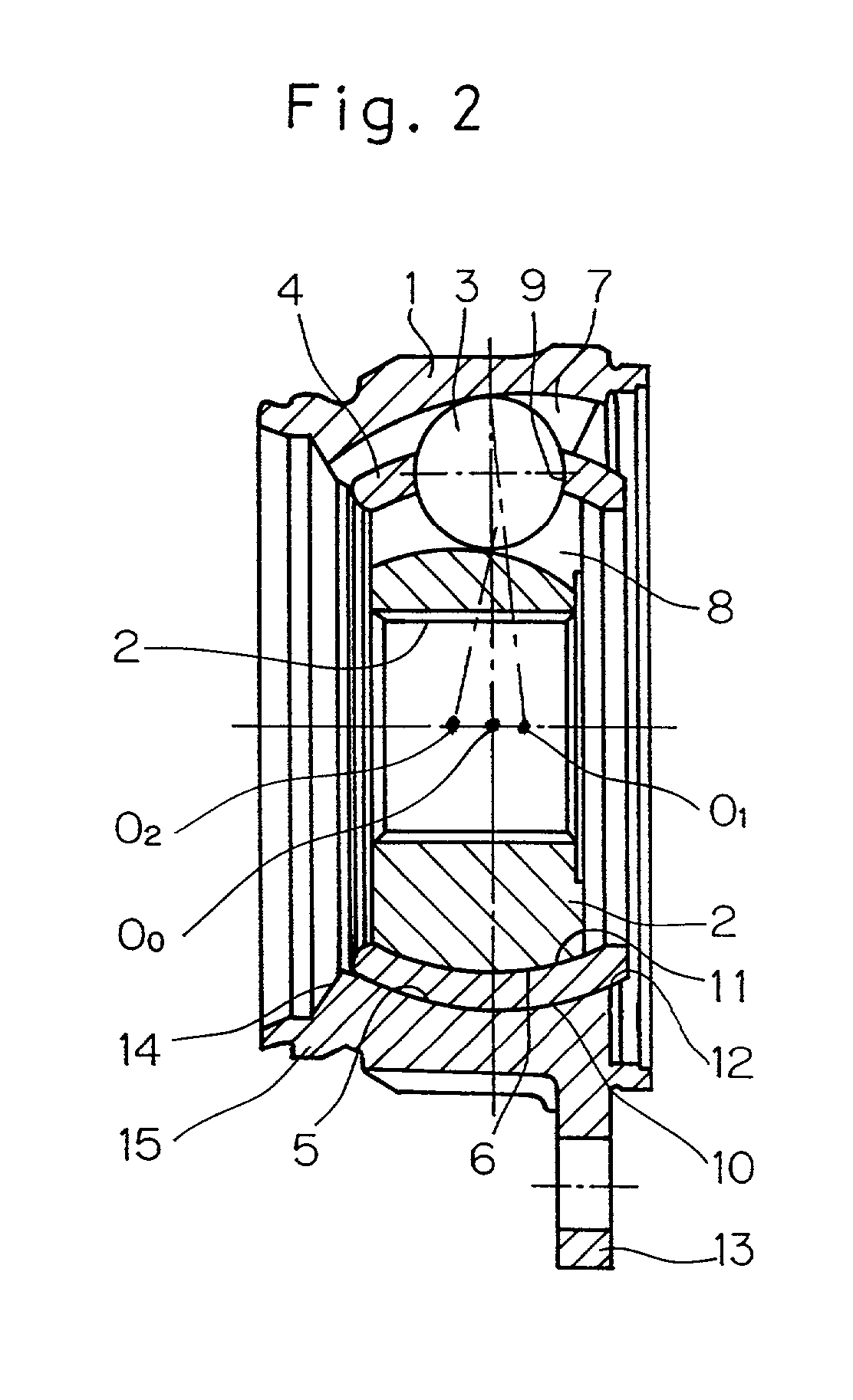

Constant velocity universal joint

InactiveUS20020077186A1Required machining timeMinimizing heat generationClutchesYielding couplingUniversal jointEngineering

A spherical inner surface 5 of the outer race 1 and track grooves in the outer race 1 are each defined by a post-hardening cut surface. A spherical outer surface 6 of the inner race 2 and track grooves in the inner race 2 are also each defined by a post-hardening cut surface. A retainer 4 has a spherical outer surface 10, a spherical inner surface 11 and inner surfaces of the pockets 9, all of which are defined by a post-hardening cut surface. Respective surfaces of the retainer 4, the outer race 1 and the inner race 2 which contact with each other are formed with a surface treatment layer for reducing a frictional resistance.

Owner:NTN CORP

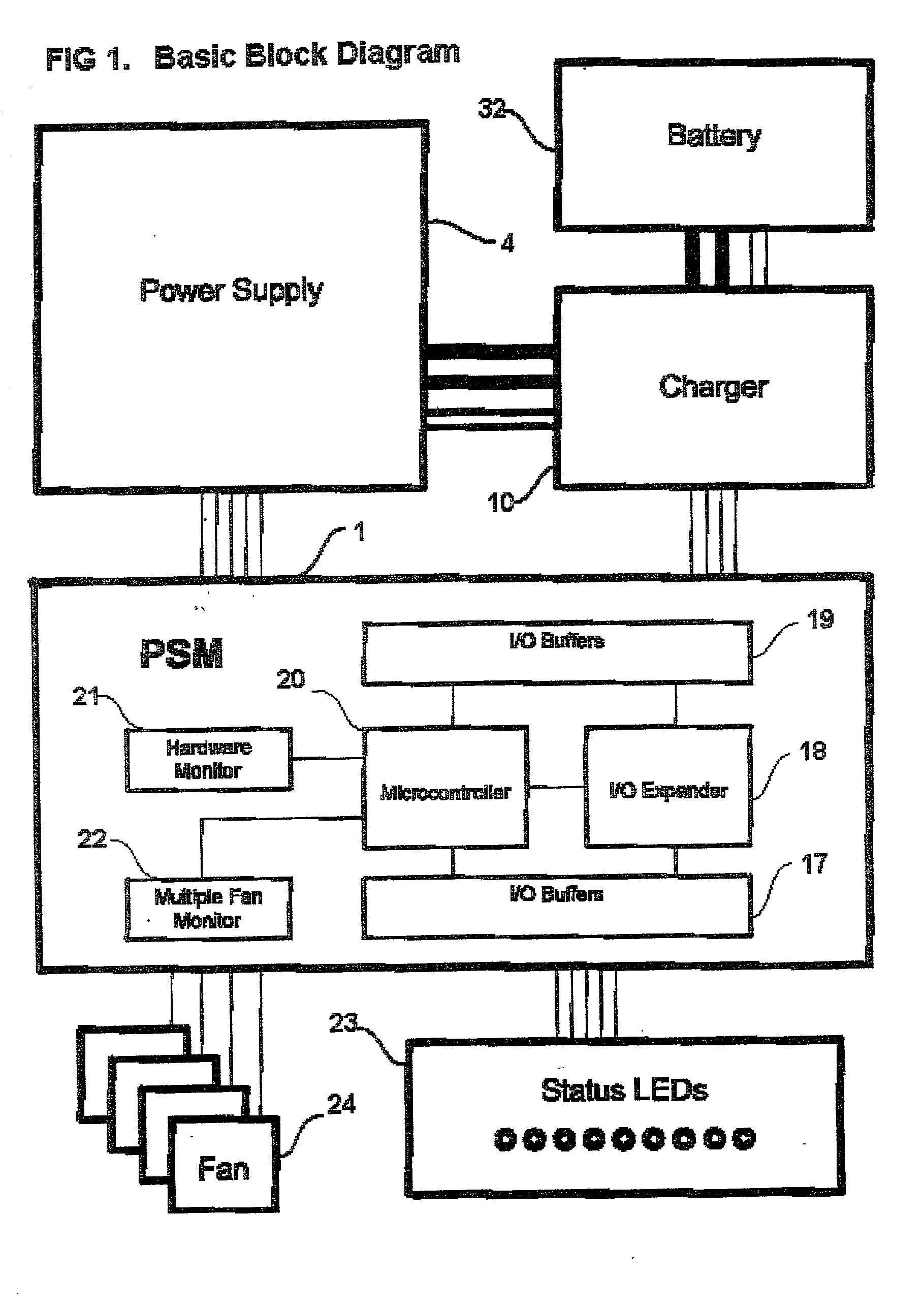

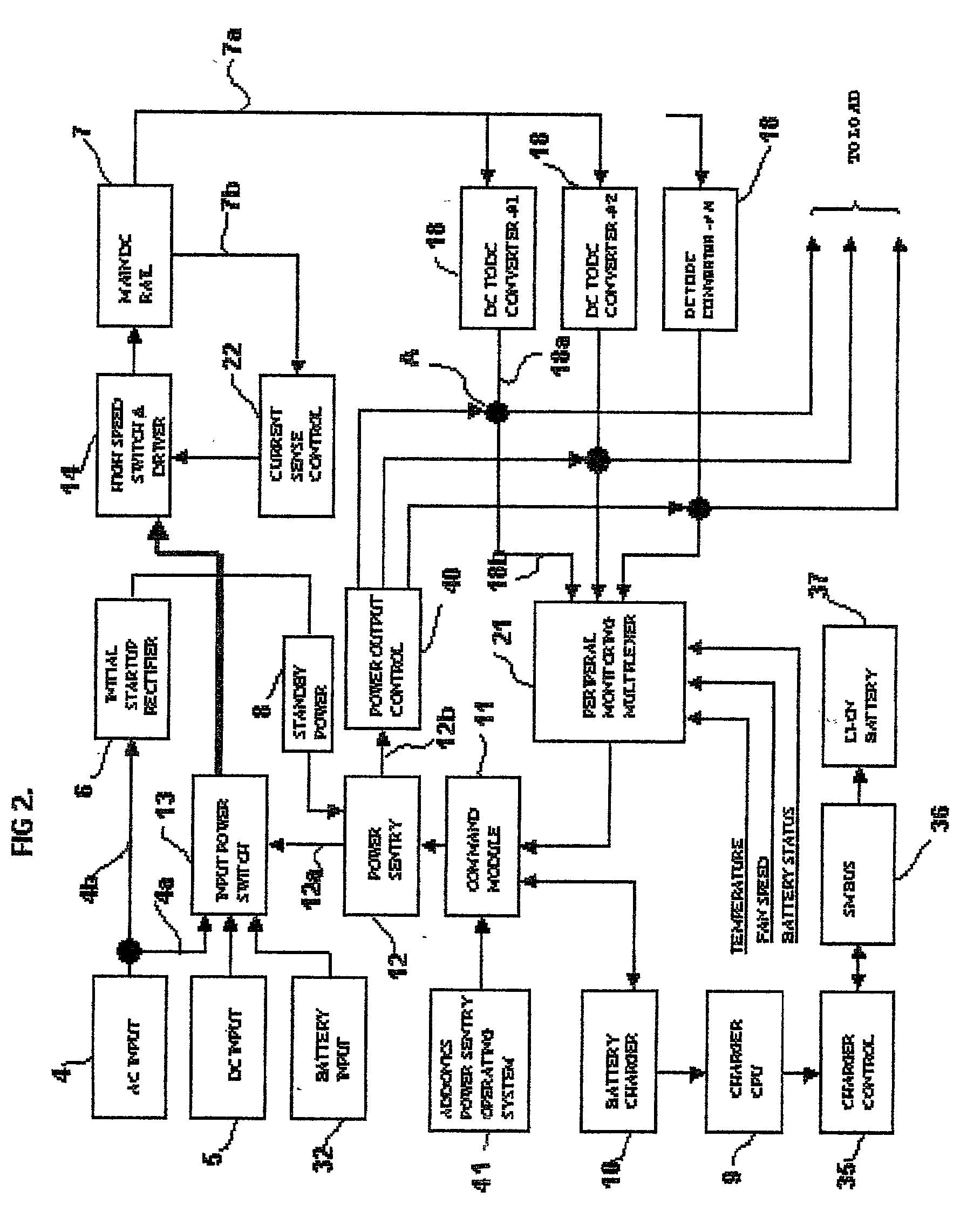

Intelligent power system

InactiveUS20010045779A1High frequency switchingMinimizes core lossBatteries circuit arrangementsElectric powerElectric power systemSTI Outpatient

This invention provides a design for the uninterruptible power supply system to make it more compact in size, more intelligent in handling primary power source and other power source failure, more efficient and reliable. This 600 to 1000 watt power system is capable of taking AC, DC and battery power inputs and distributes to multiple loads after conversion. Its power sentry monitors and controls all power inputs and outputs, and capable of switching power inputs without affecting the outputs in case of power source failure. The power sentry also controls the speeds of the cooling fans, charges the batteries, communicates with the operator, displays status, manages power consumption, prepares the substitute power source before switching power source, and shuts down the whole system incase of emergencies.

Owner:ACCEL POWER

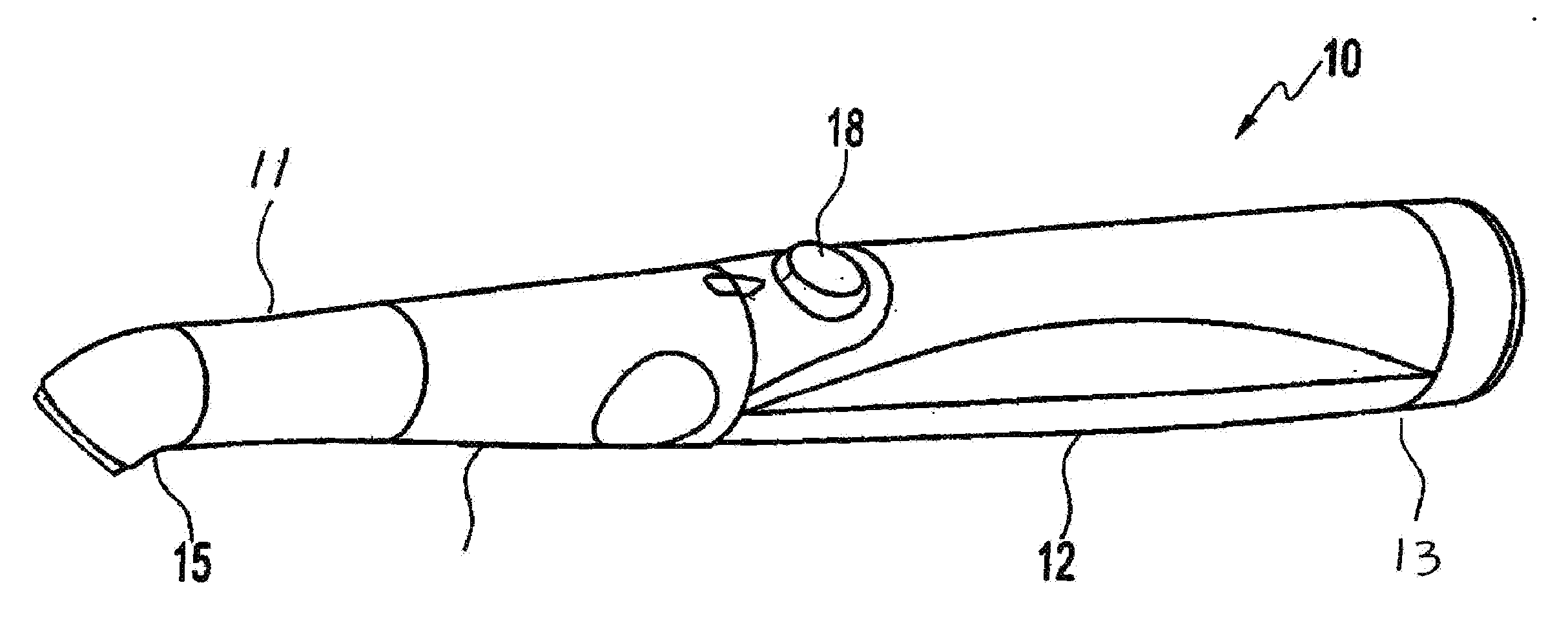

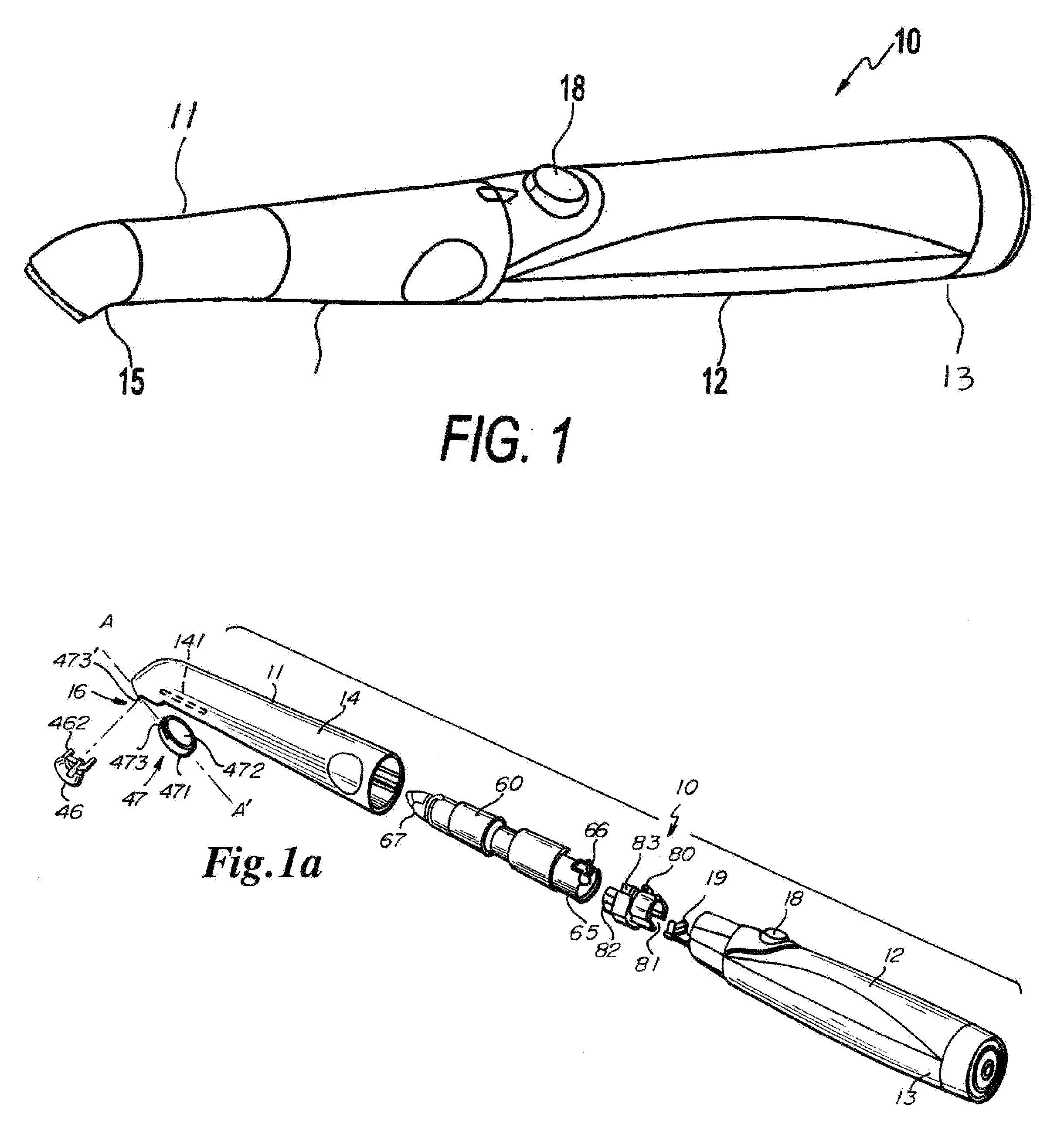

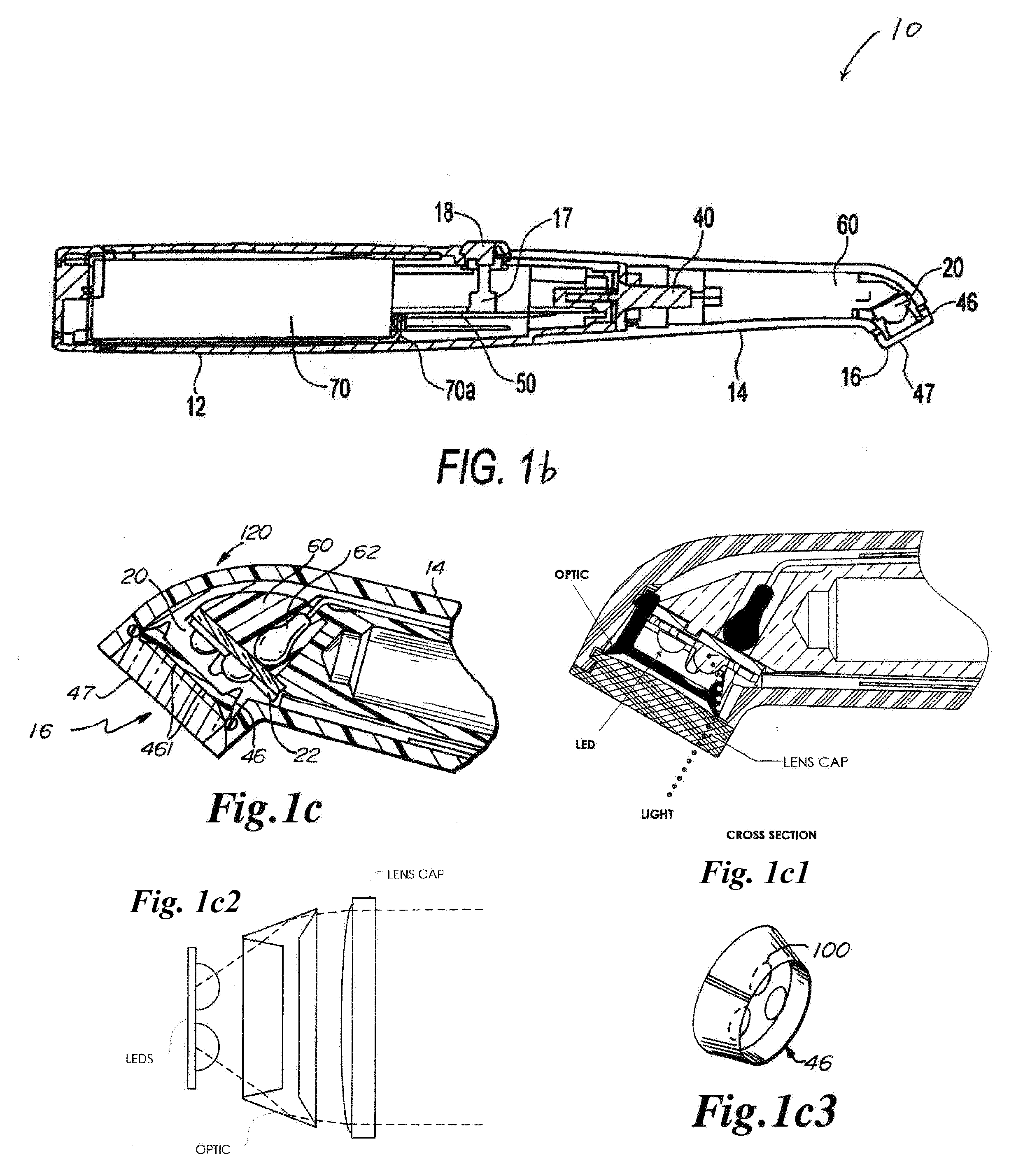

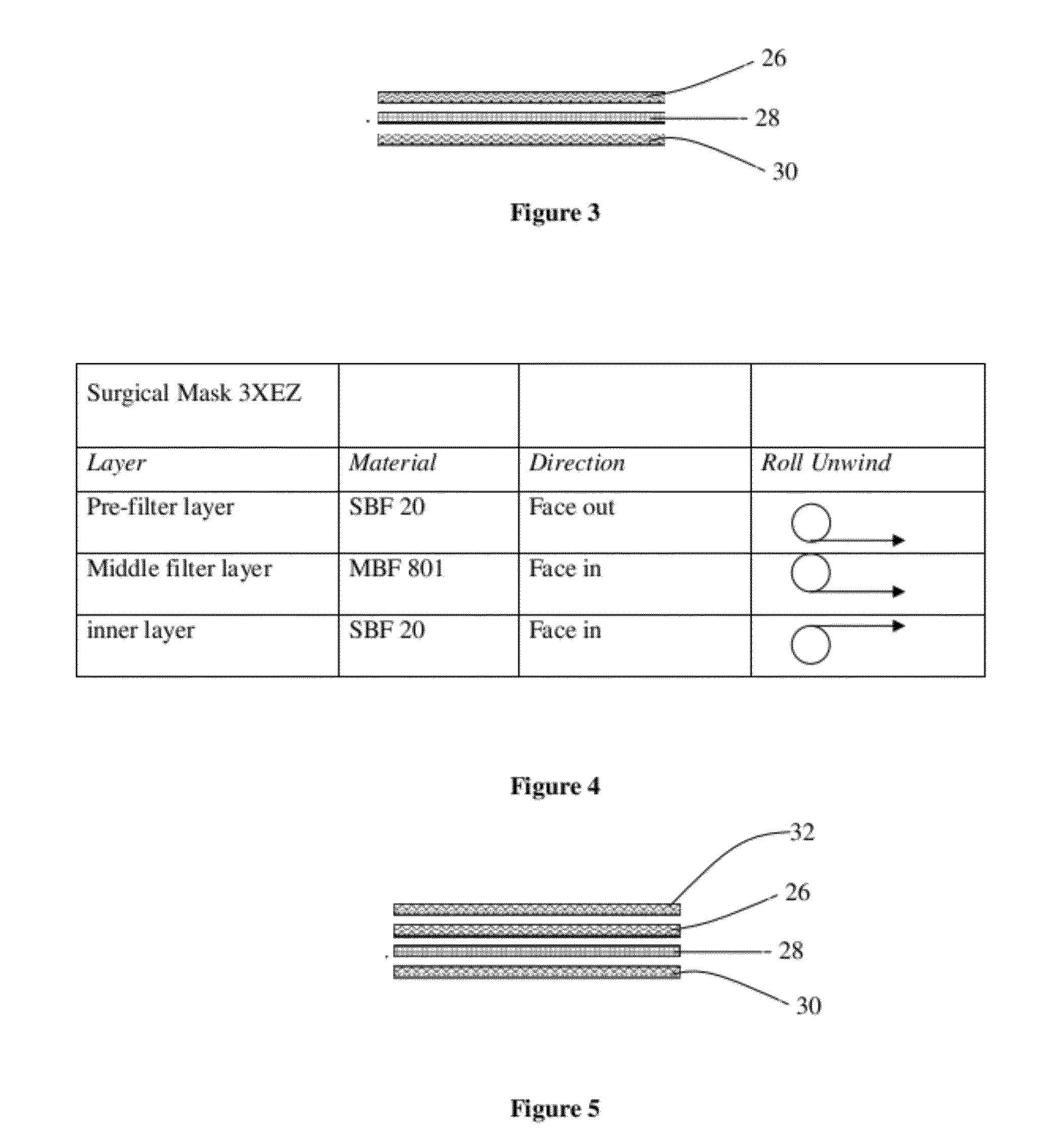

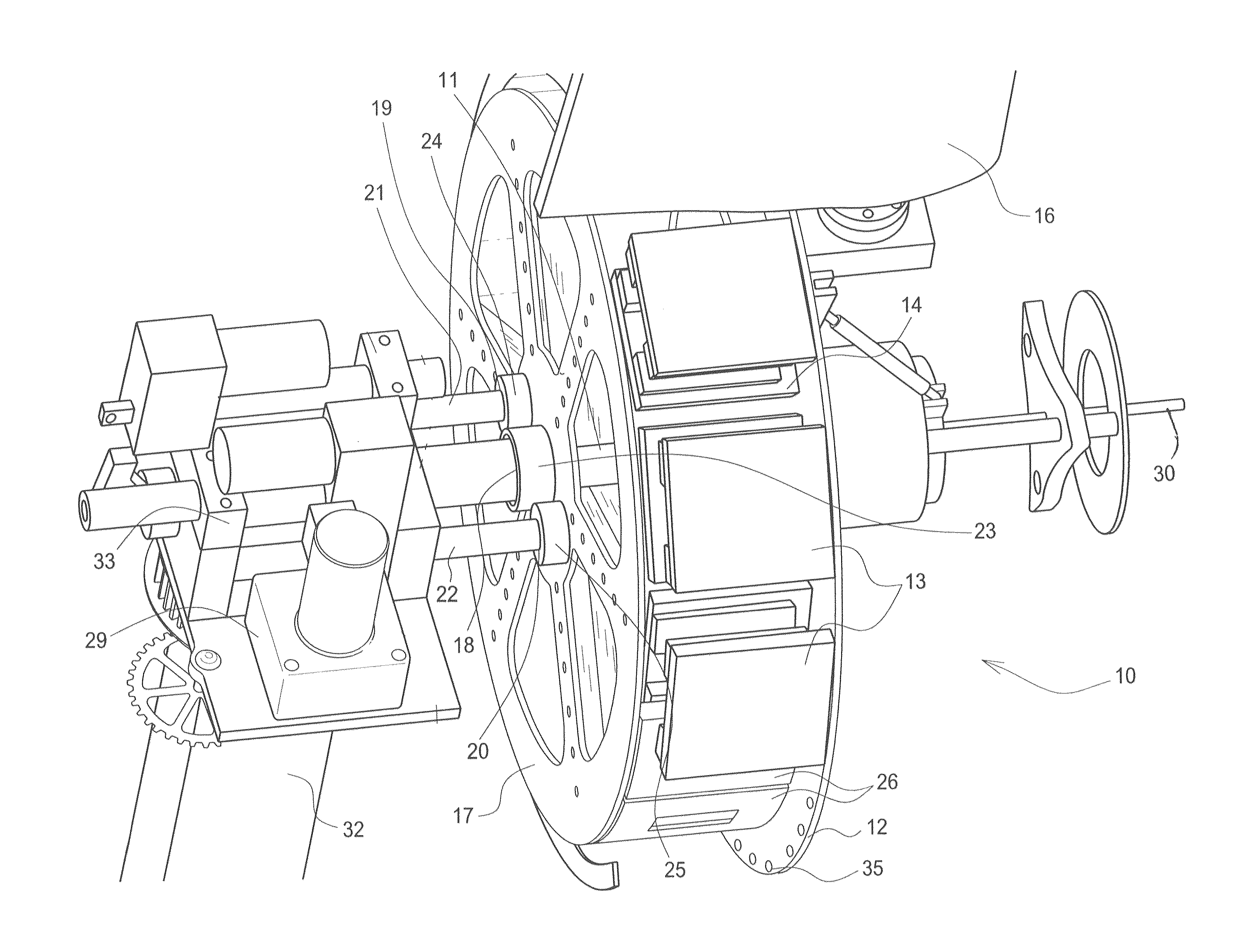

Curing Light

InactiveUS20090208894A1Large effective beam diameterSlow fall offDental toolsLight therapyCamera lensBeam diameter

The present invention relates to curing light devices for use in dentistry. Specifically, this invention relates to curing light devices generating convergent and uniform light with high intensity. The curing light device has a handle portion and a front portion wherein a light module is located in a desirable position in the interior of the front portion. The light module may include a light source comprising at least three LEDs in a compact manner, an optical element adapted to direct and / or focus the LEDs, and a lens cap to protect the LEDs and the optical elements. The lens cap may include a peripheral groove extending more than half of the periphery of the lens cap, which provides a longer engagement portion and thus a more secured attachment when “over-centeredly” engaging with a receiving edge on the light emitting end. A substantially precise alignment is achieved between the LEDs and corresponding lenses on the optical element to minimize heat dissipation and to increase the runtime and intensity of the curing light device. The curing light has an effective beam diameter of at least about 9 mm with output homogeneity of up to about 6 mm away from the emitting end.

Owner:DEN MAT HLDG

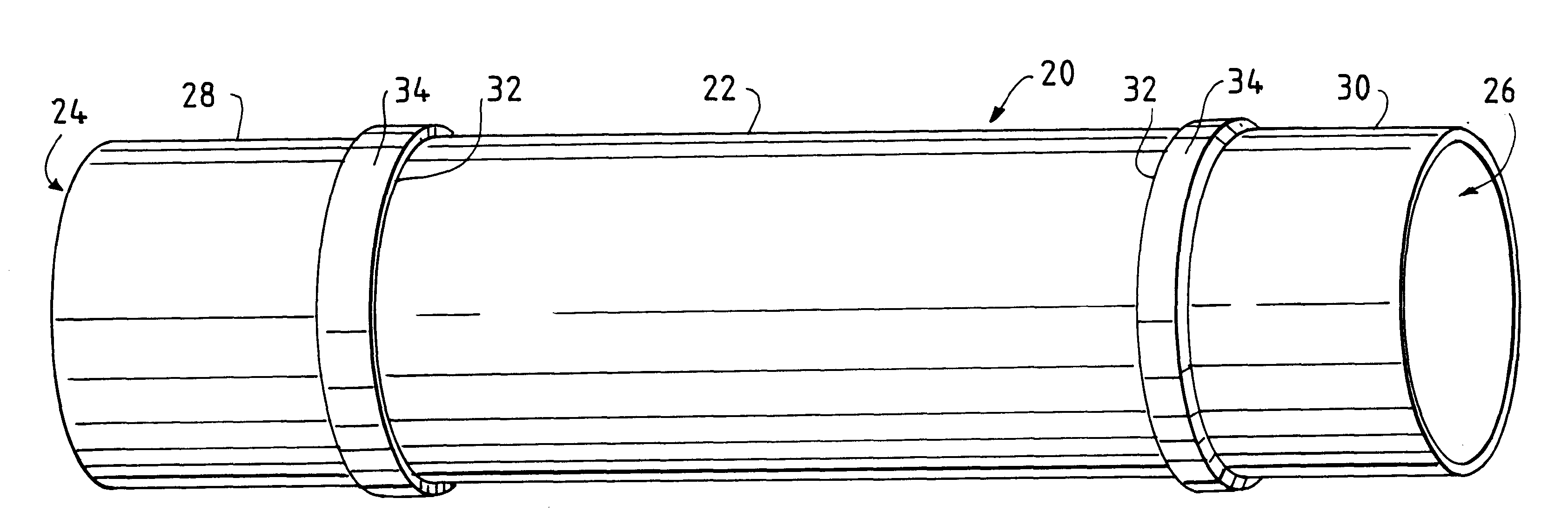

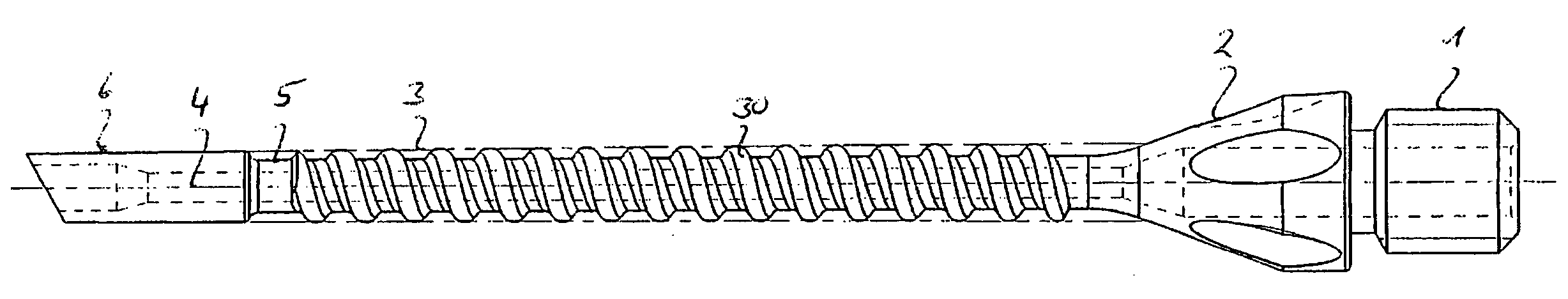

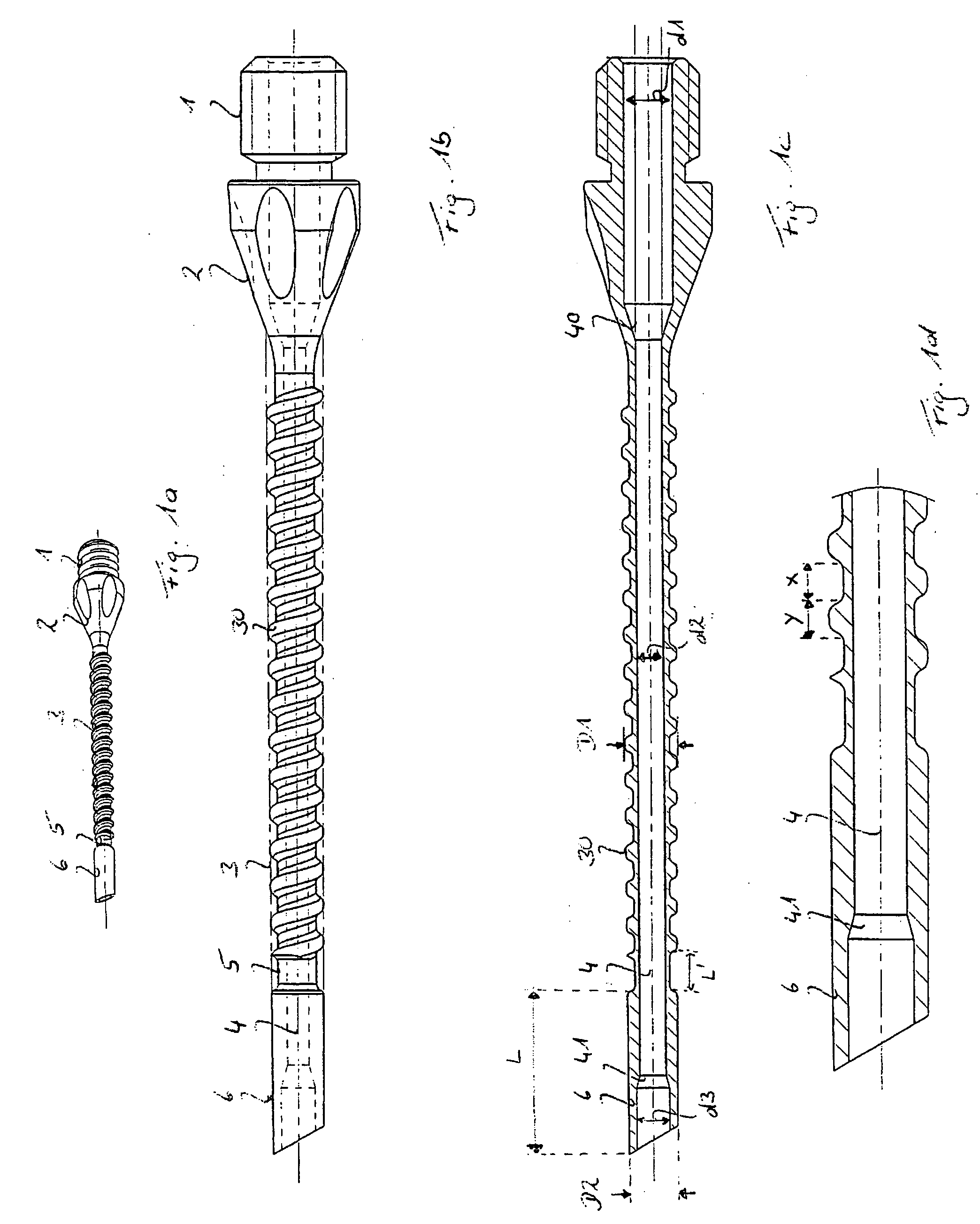

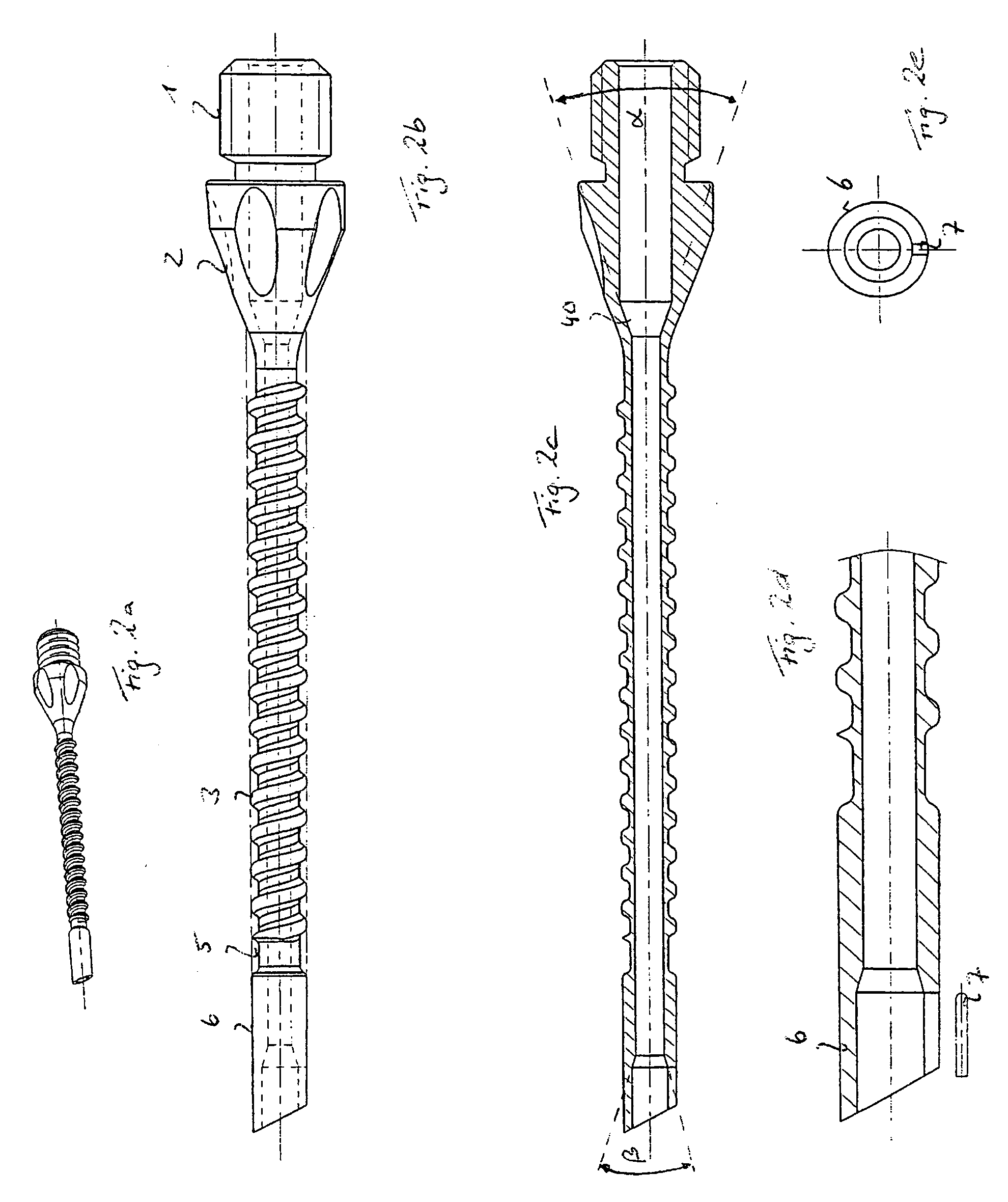

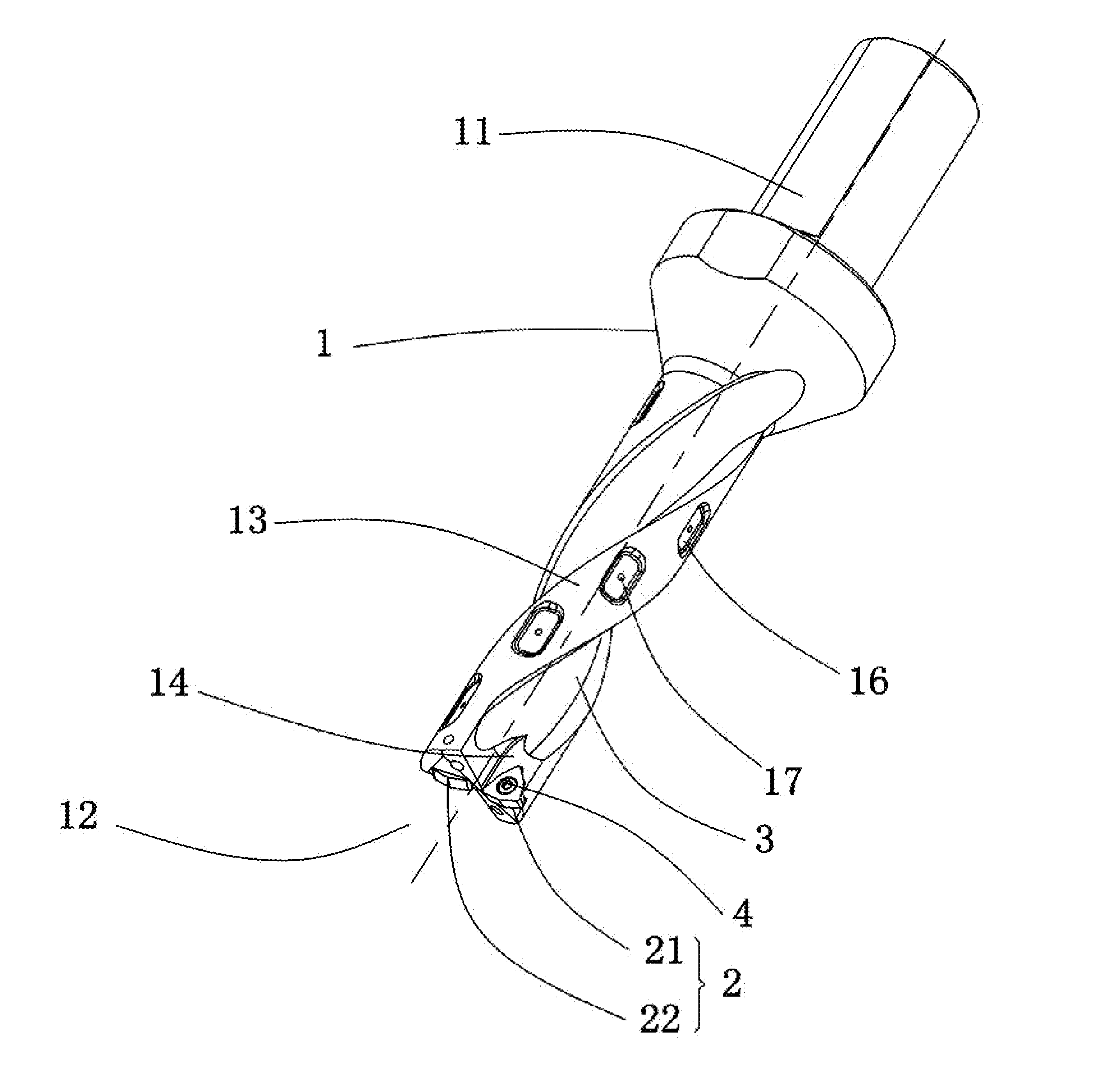

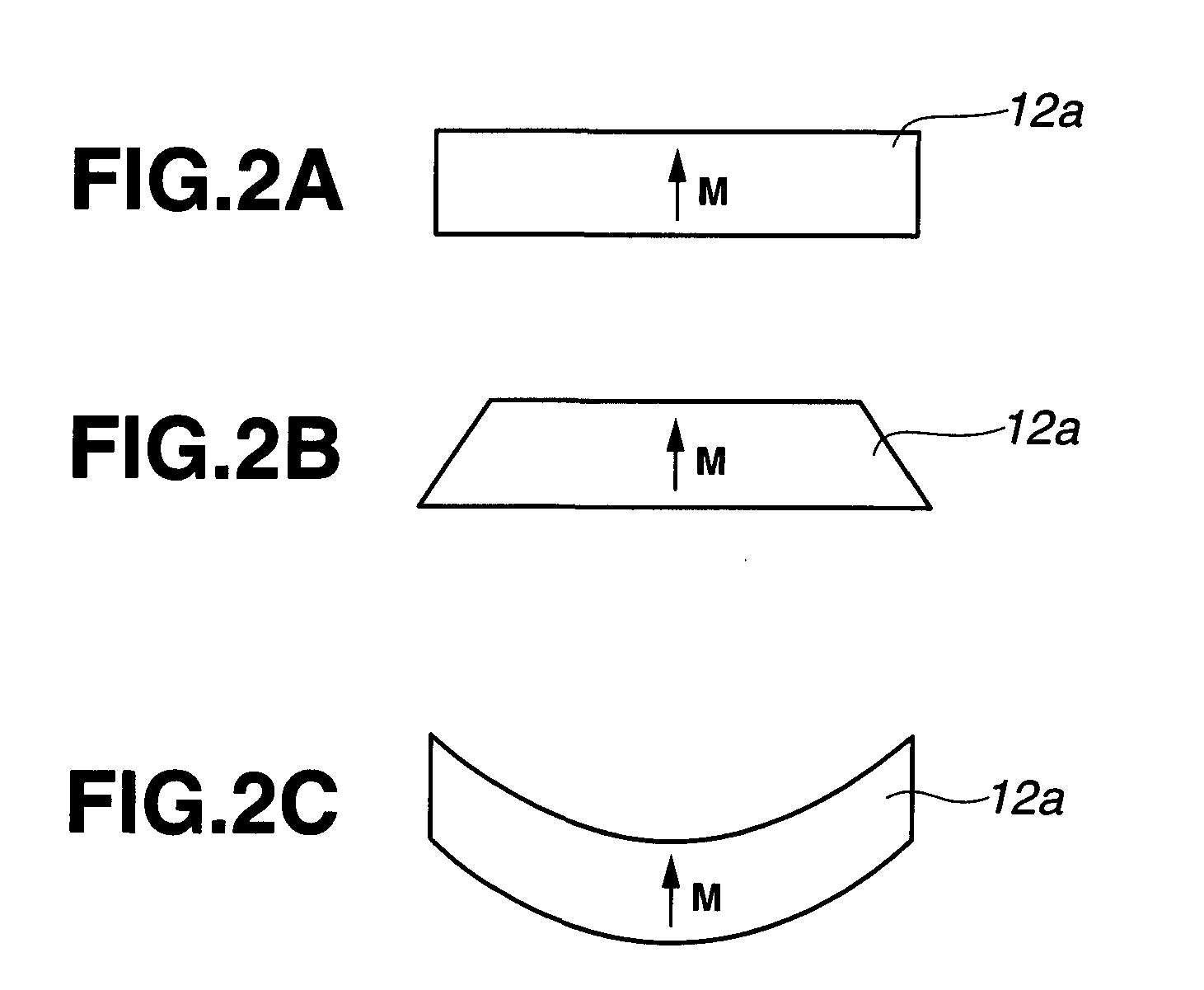

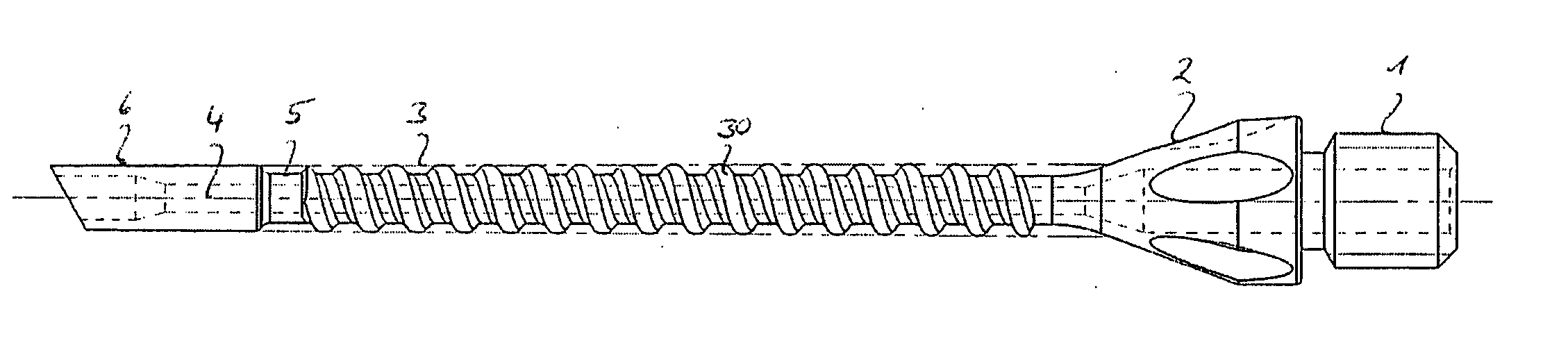

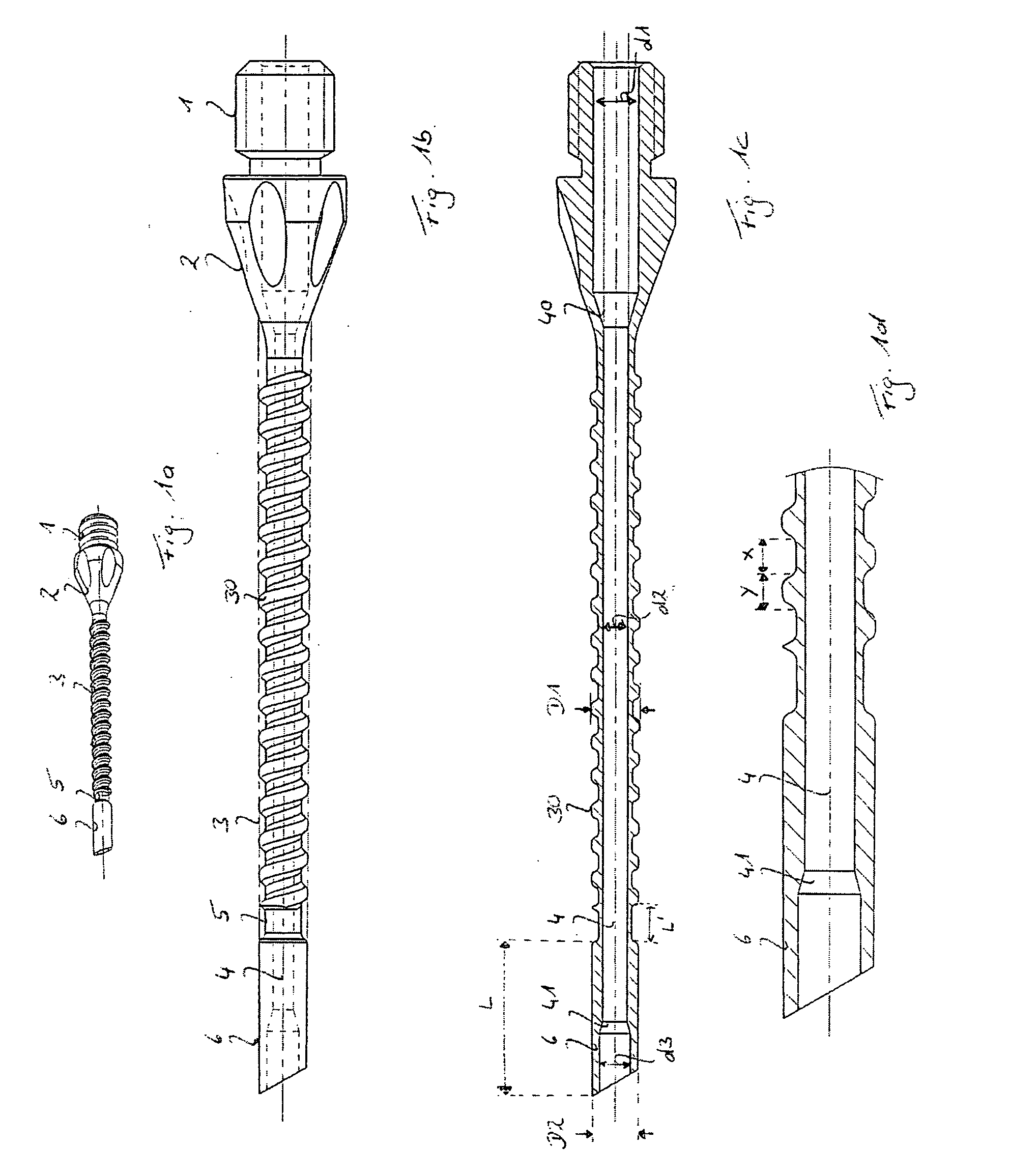

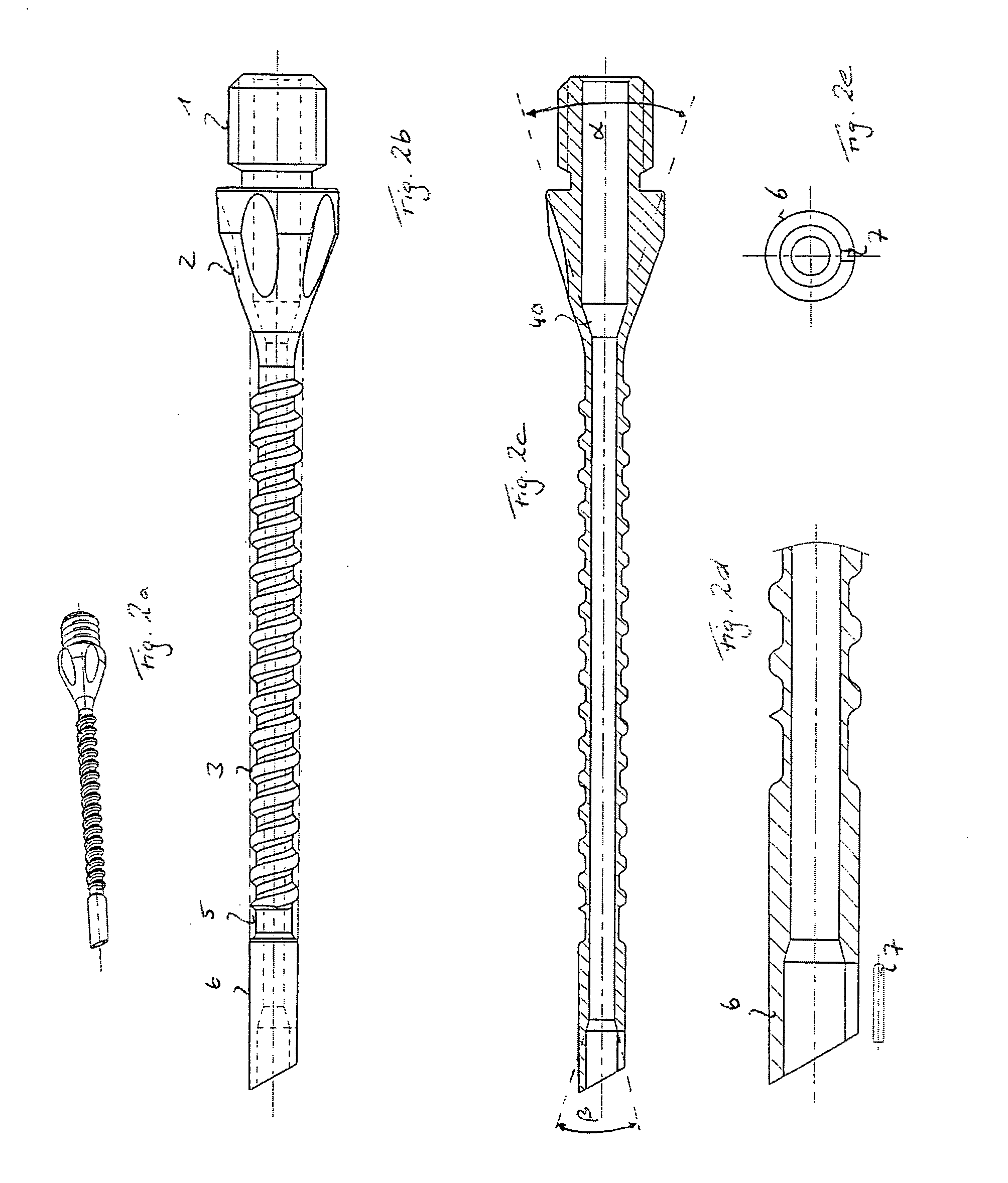

Phacoemulsification needle

InactiveUS20060047254A1Heat generation is minimizedMinimizing heat generationEye surgeryInfusion needlesPhacoemulsificationBiomedical engineering

A phacoemulsification needle according to the invention comprises a shaft, a tip disposed at a distal end of said shaft and an aspiration lumen extending through said shaft and said tip. The tip has an opening communicating with said aspiration lumen. The shaft comprises at least a portion which has a ribbed outer surface. This needle minimizes heat generation and can therefore be used with or without sleeve.

Owner:RAVI NALLAKRISHNAN +1

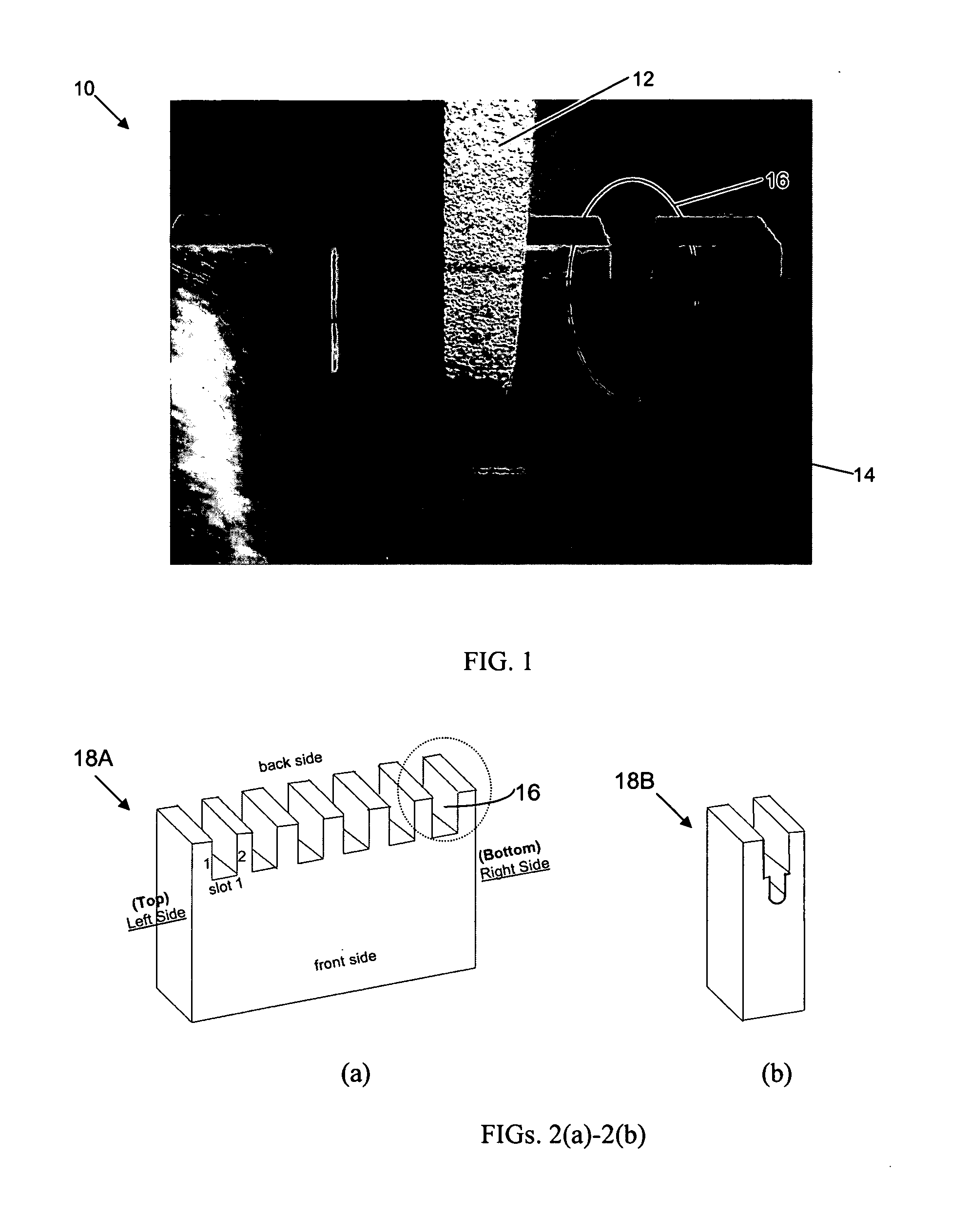

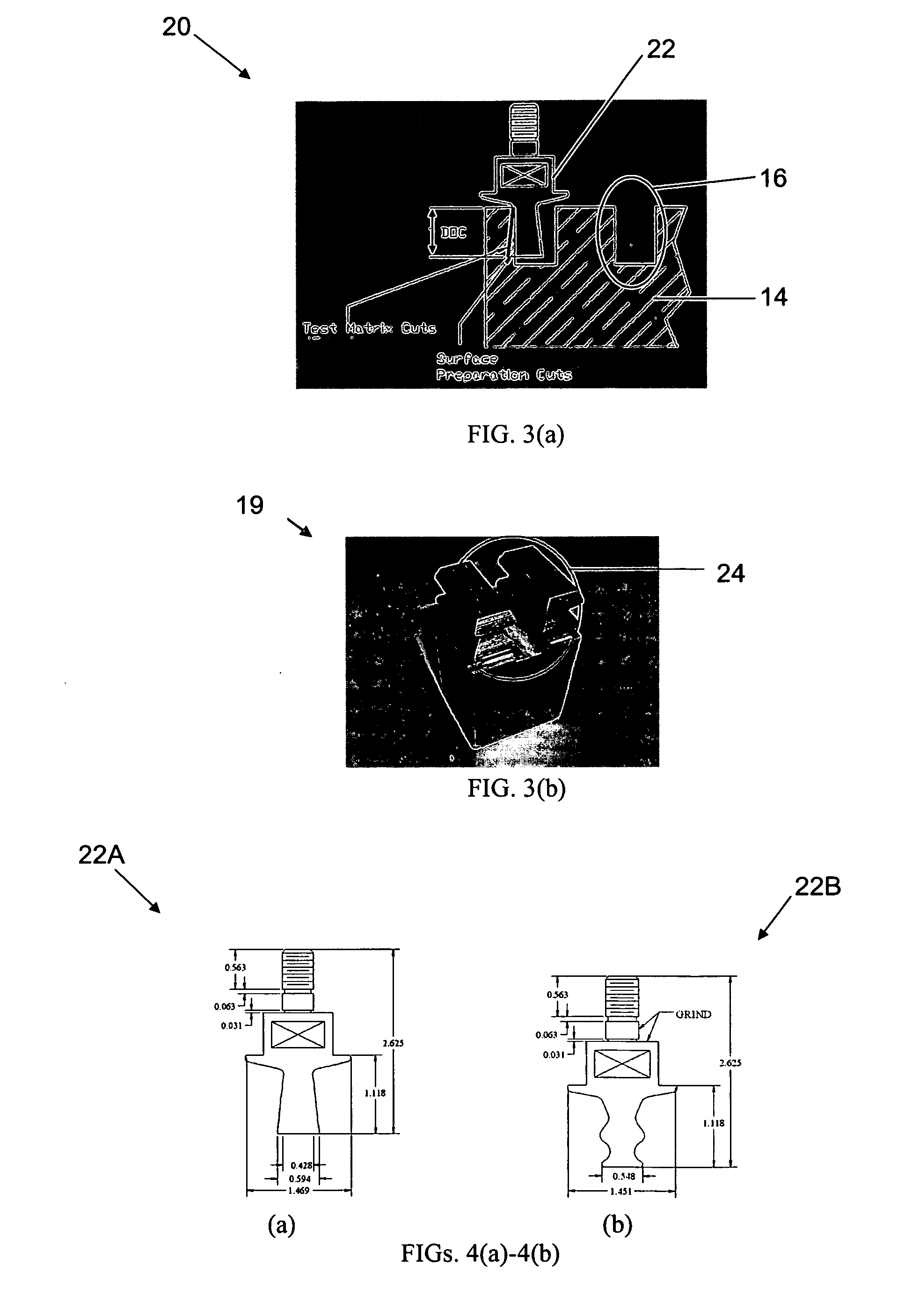

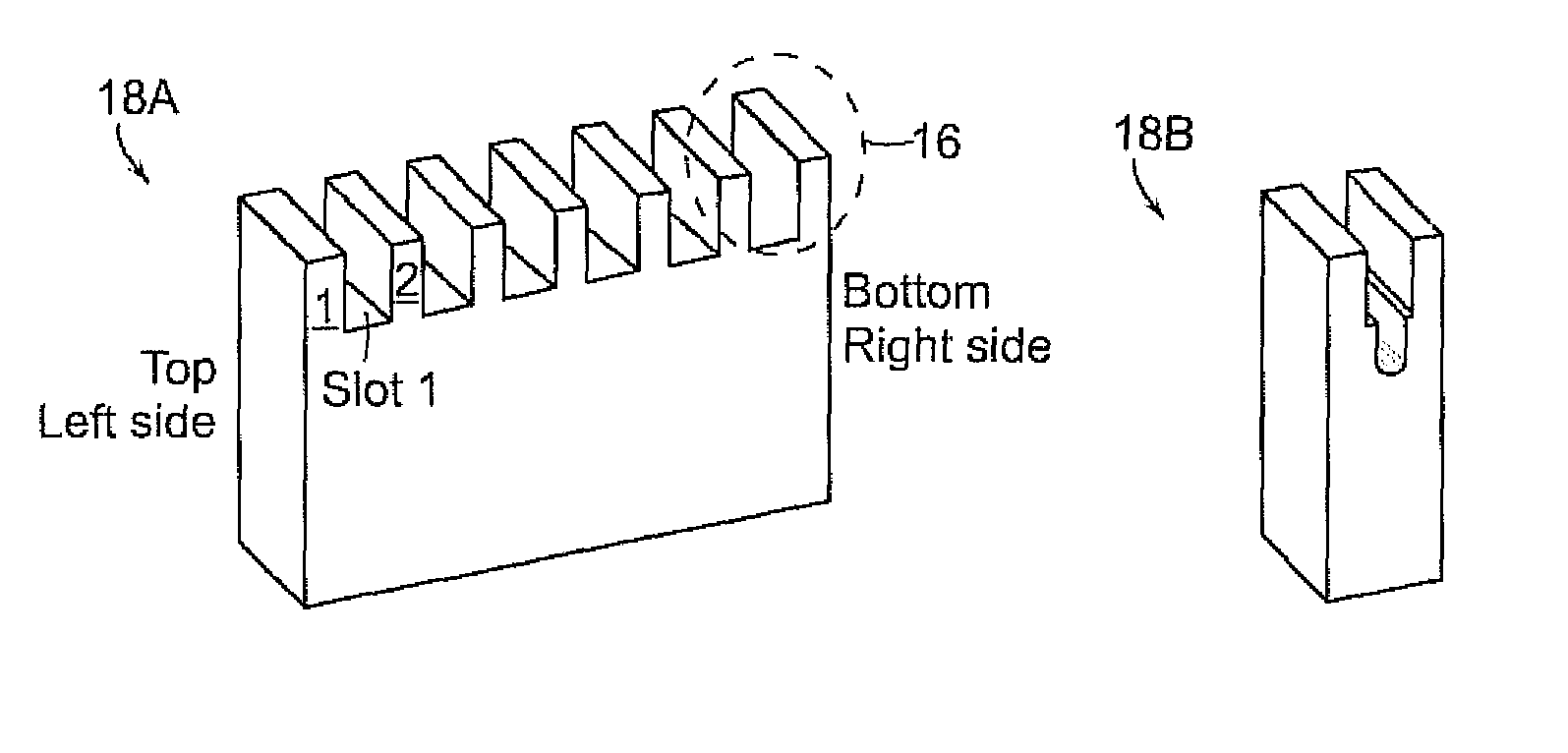

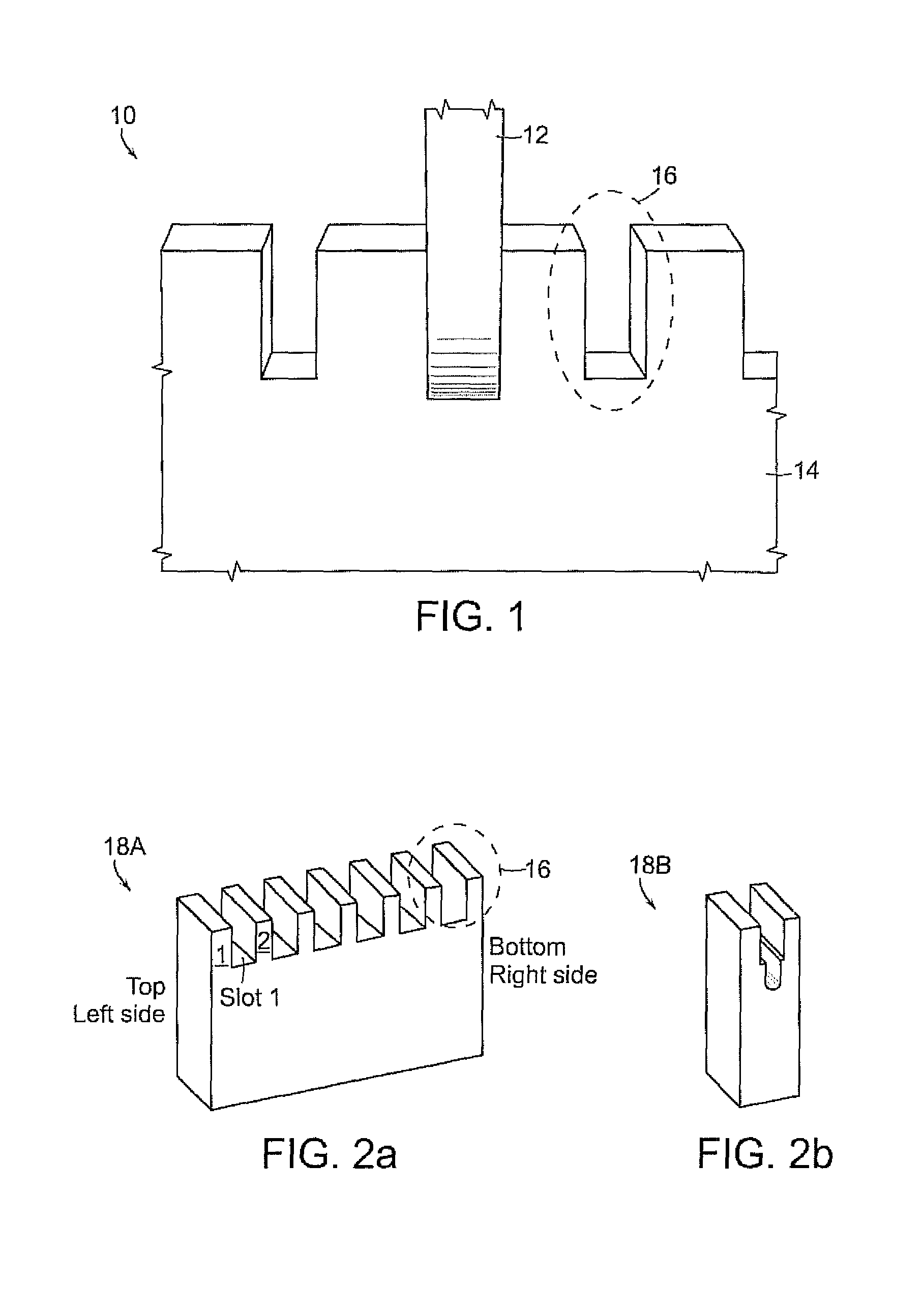

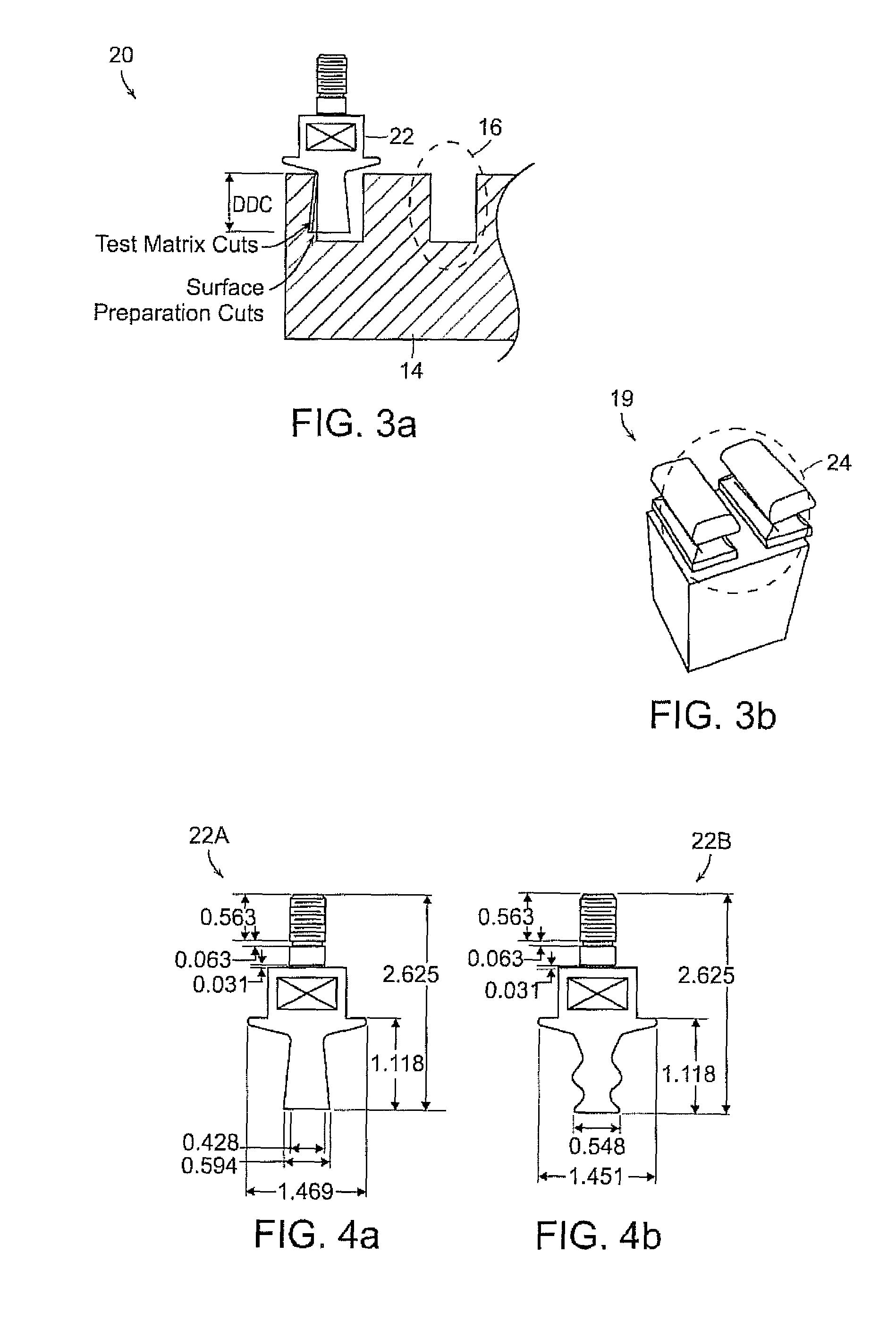

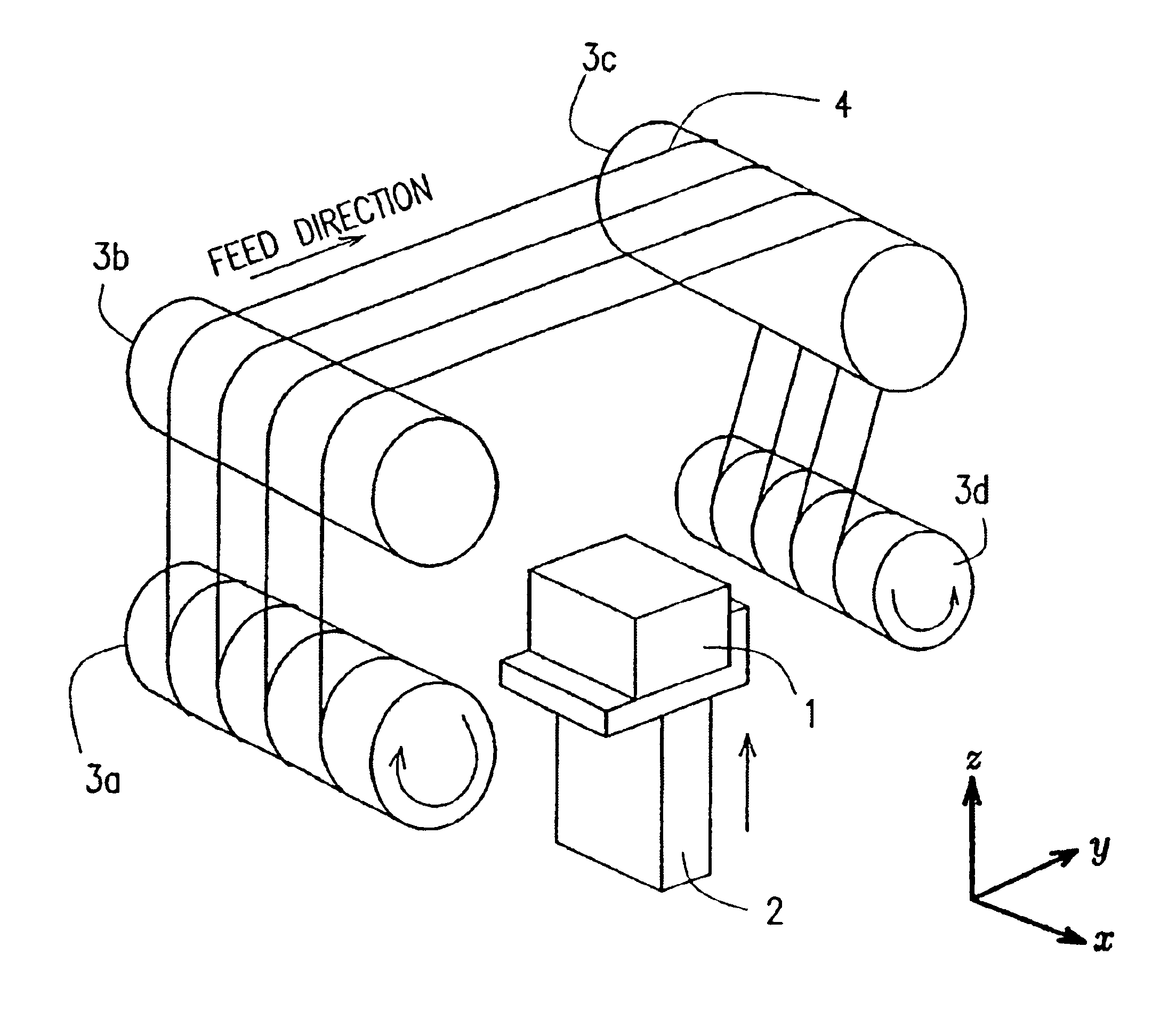

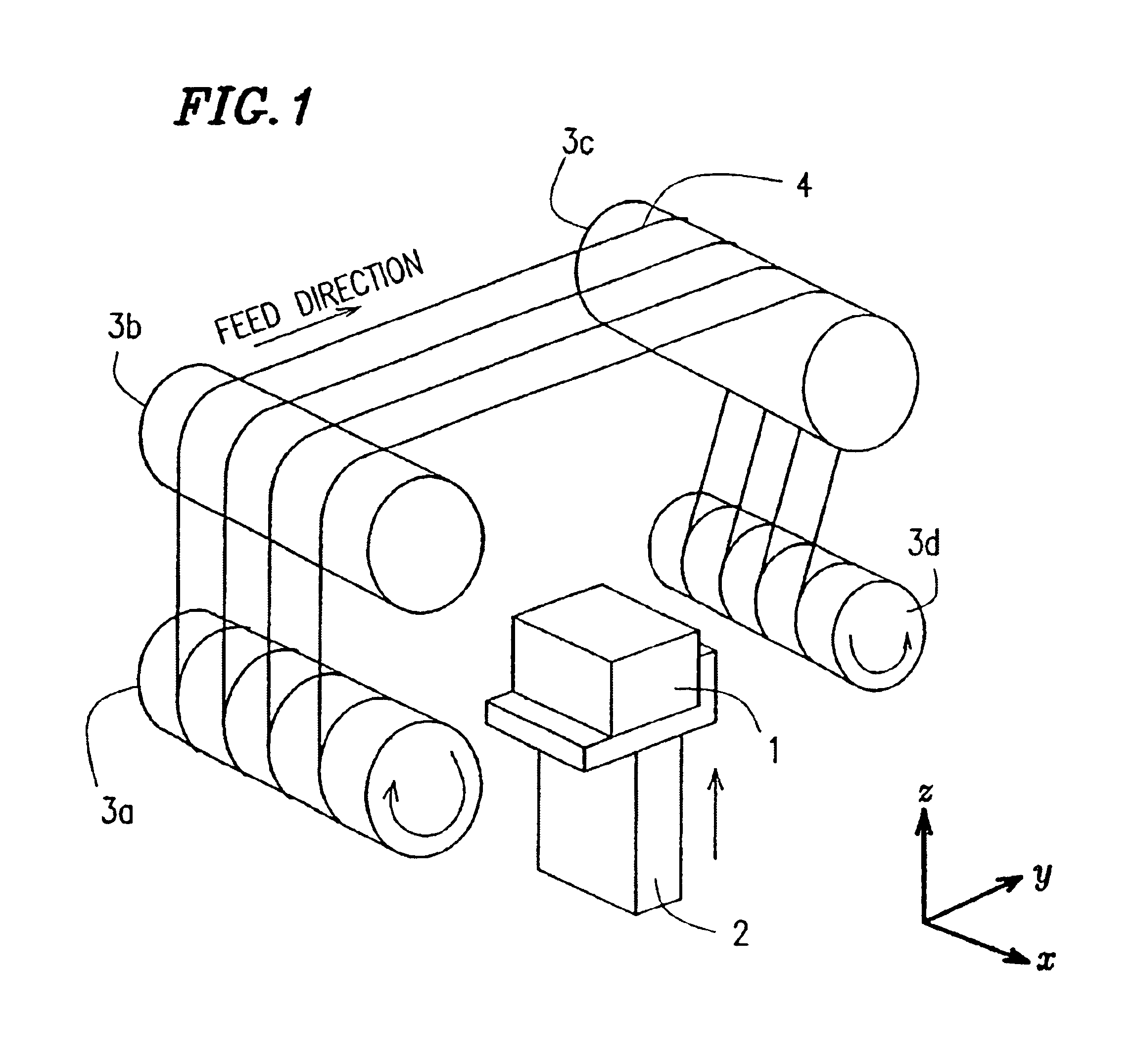

Method for grinding complex shapes

ActiveUS20070275641A1Minimize amount of materialReduce arc of contactAbrasion apparatusGrinding feed controlMaterial removalHardness

A method of producing a complex shape in a workpiece includes the steps of: i) grinding a workpiece at a maximum specific cutting energy of about 10 Hp / in3·min with at least one bonded abrasive tool, thereby forming a slot in the workpiece; and ii) grinding the slot with at least one mounted point tool, thereby producing the complex shape in the slot. The bonded abrasive tool includes at least about 3 volume % of a filamentary sol-gel alpha-alumina abrasive grain having an average length-to-cross-sectional-width ratio of greater than about 4:1 or an agglomerate thereof. A method of producing a slot in a metallic workpiece having a maximum hardness value of equal to, or less than, about 65 Rc includes the step of grinding the workpiece with a bonded abrasive tool at a material removal rate in a range of between about 0.25 in3 / min·in and about 60 in3 / min·in and at a maximum specific cutting energy of about 10 Hp / in3·min.

Owner:SAINT GOBAIN ABRASIVES INC +1

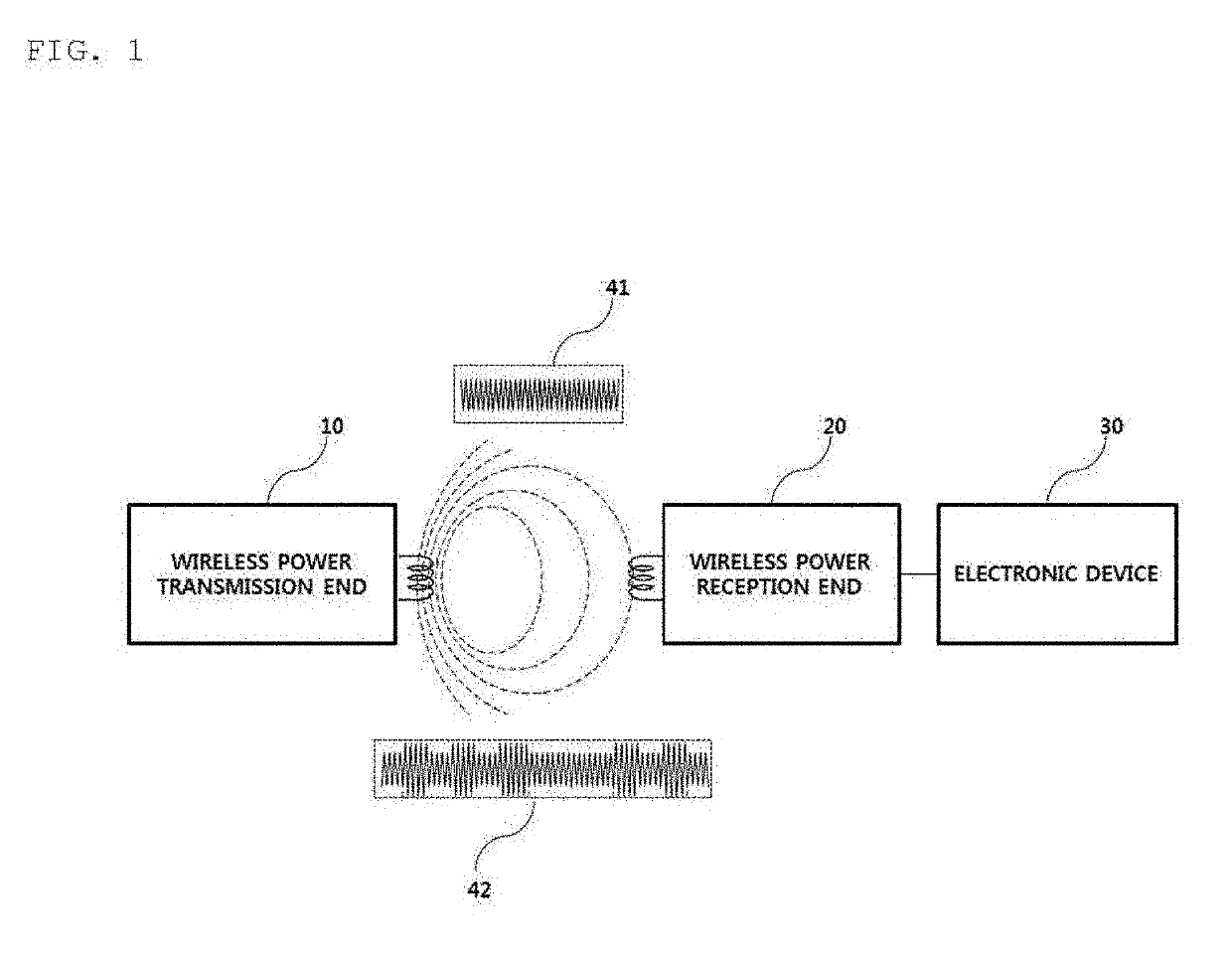

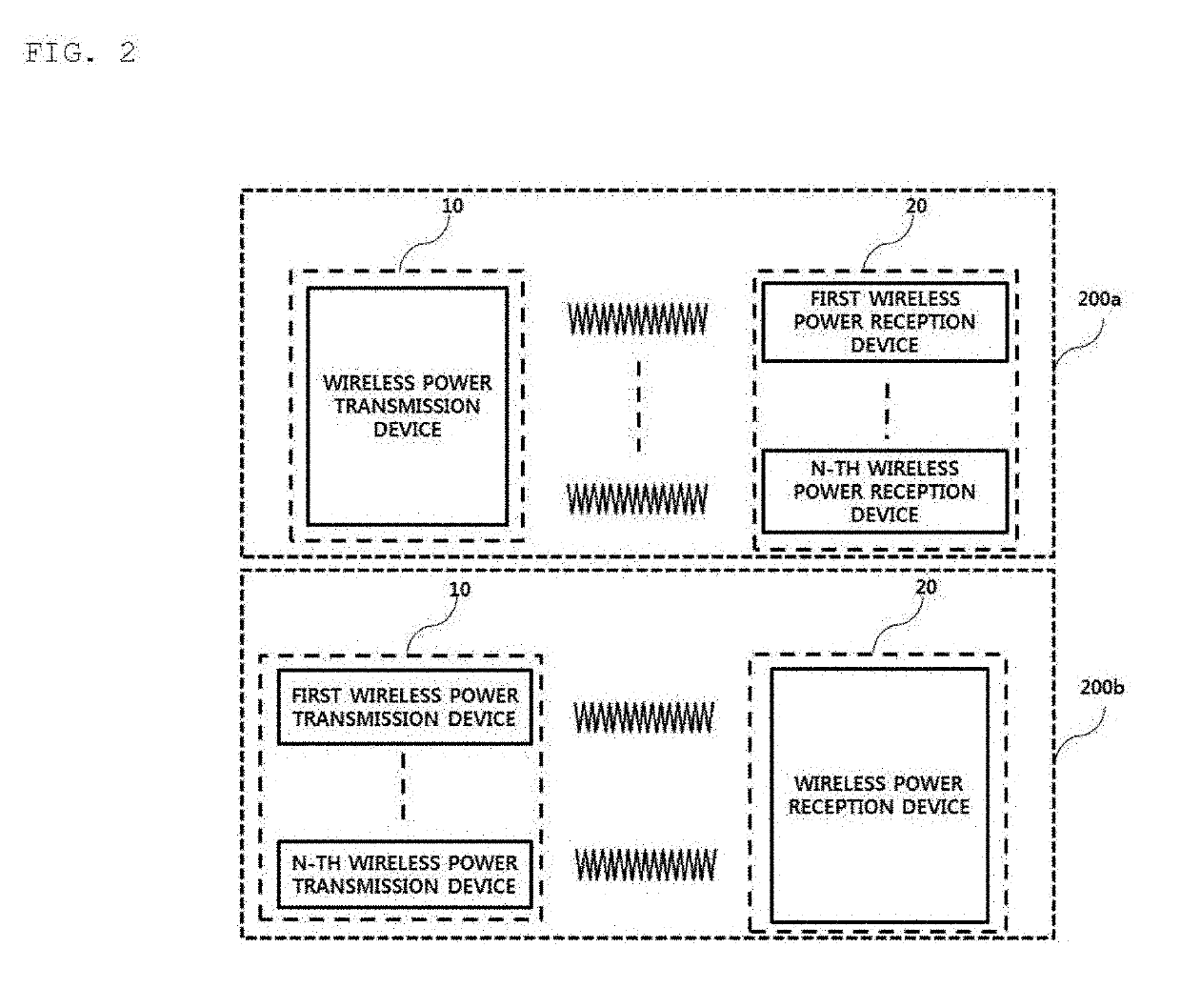

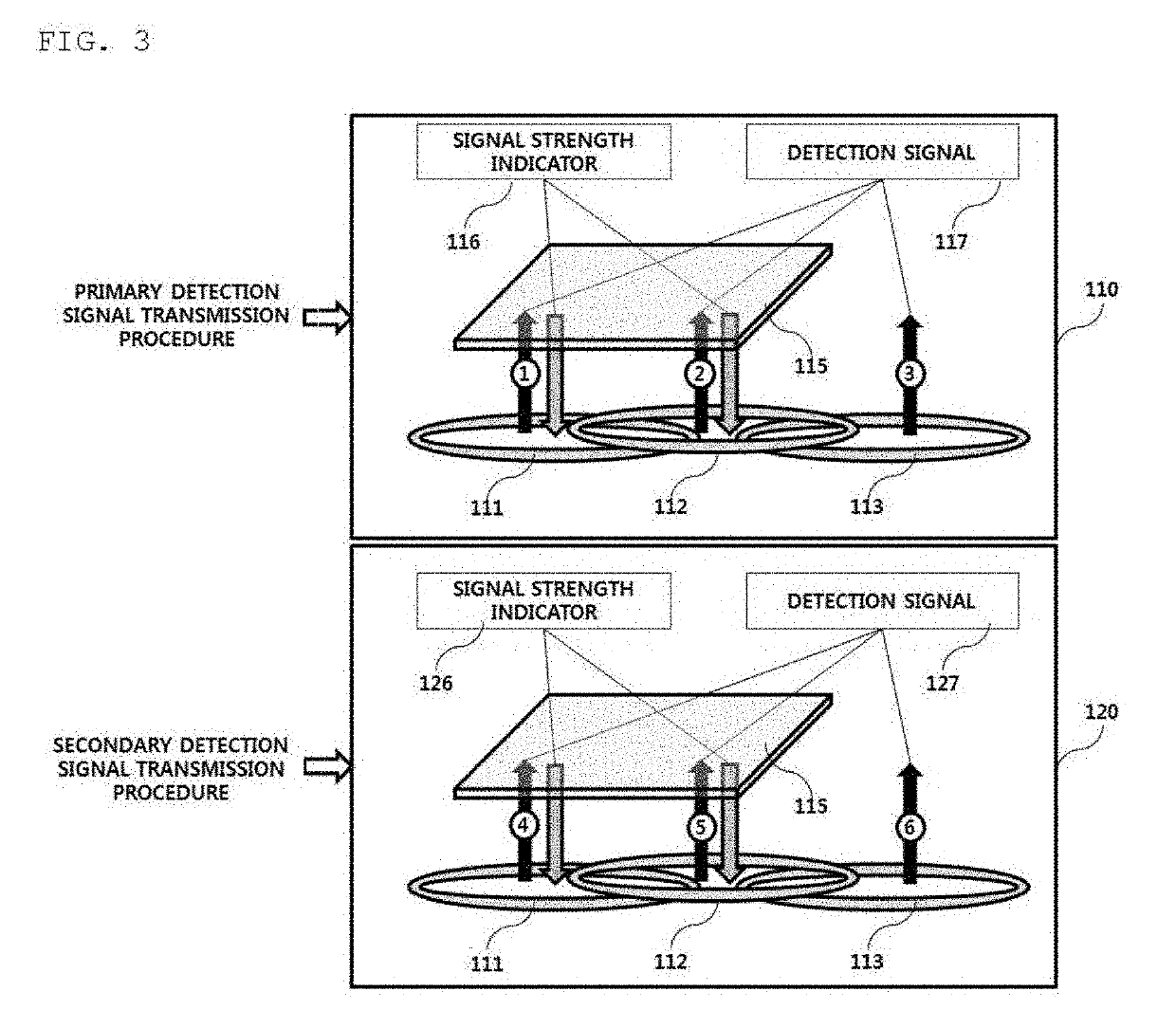

Wireless power control method and device for wireless charging

ActiveUS20190214852A1Avoid feverHeat generation is minimizedBatteries circuit arrangementsTransformersPower inverterEngineering

The present invention relates to a wireless power control method and device for wireless charging, and the wireless power control method of a wireless power transmitter according to an embodiment of the present invention may comprise: a step of receiving, from a wireless power receiver, a first feedback signal requesting power control; a step of determining the intensity of a first transmission power on the basis of the first feedback signal; a step of determining an inverter type and a power control method which correspond to the determined intensity of the first transmission power; a step of activating an inverter corresponding to the determined inverter type; and a step of controlling the intensity of alternating current power outputted from the inverter, by using the determined power control method.

Owner:LG INNOTEK CO LTD

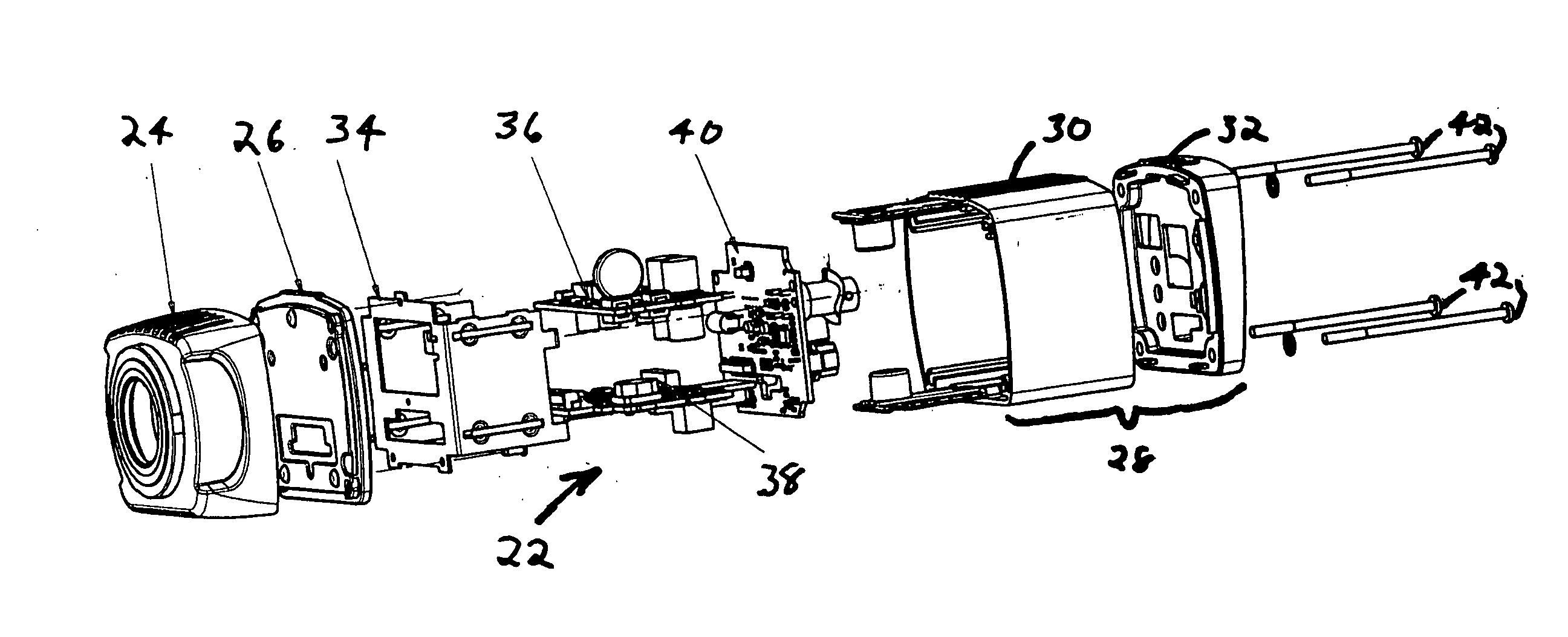

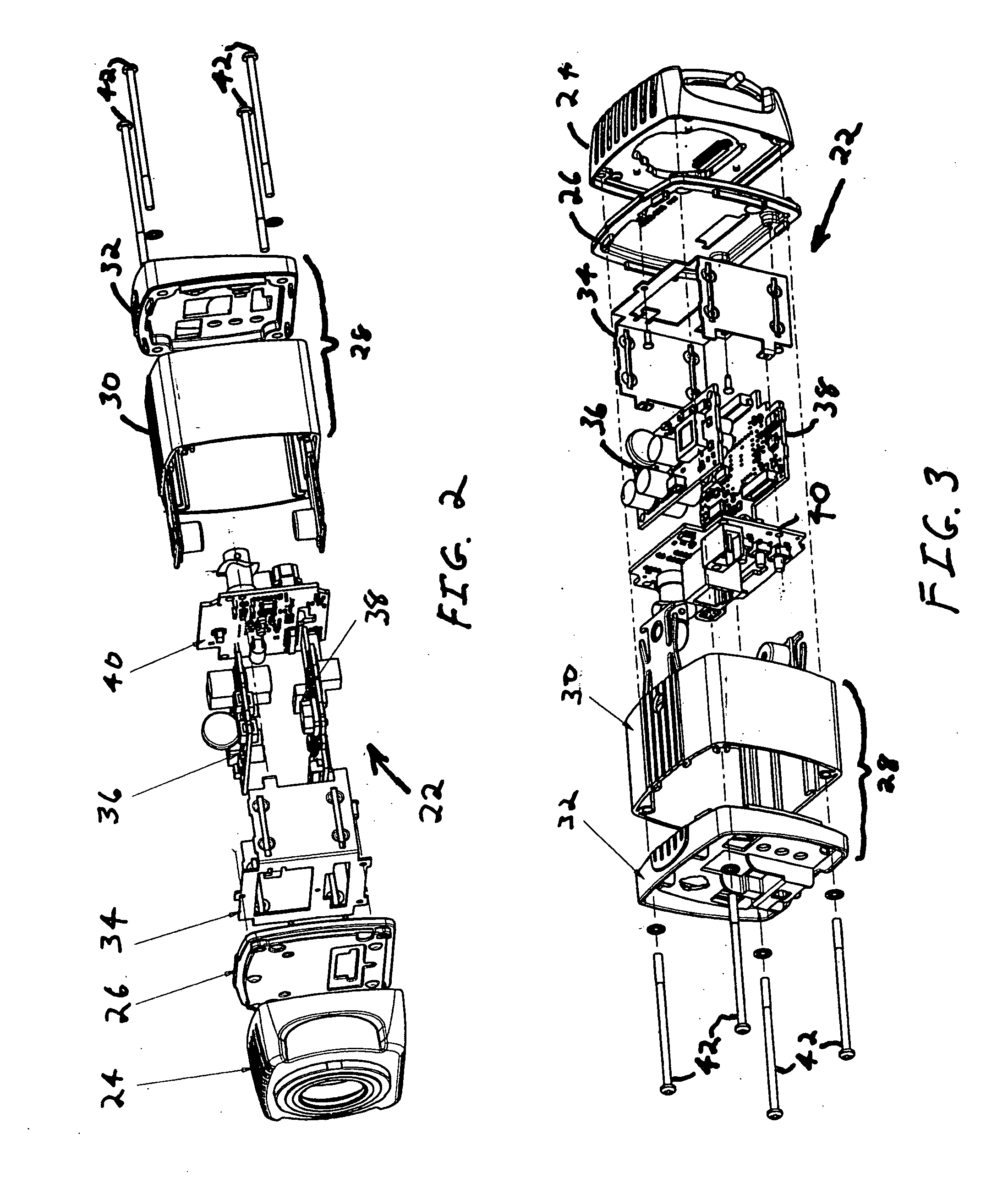

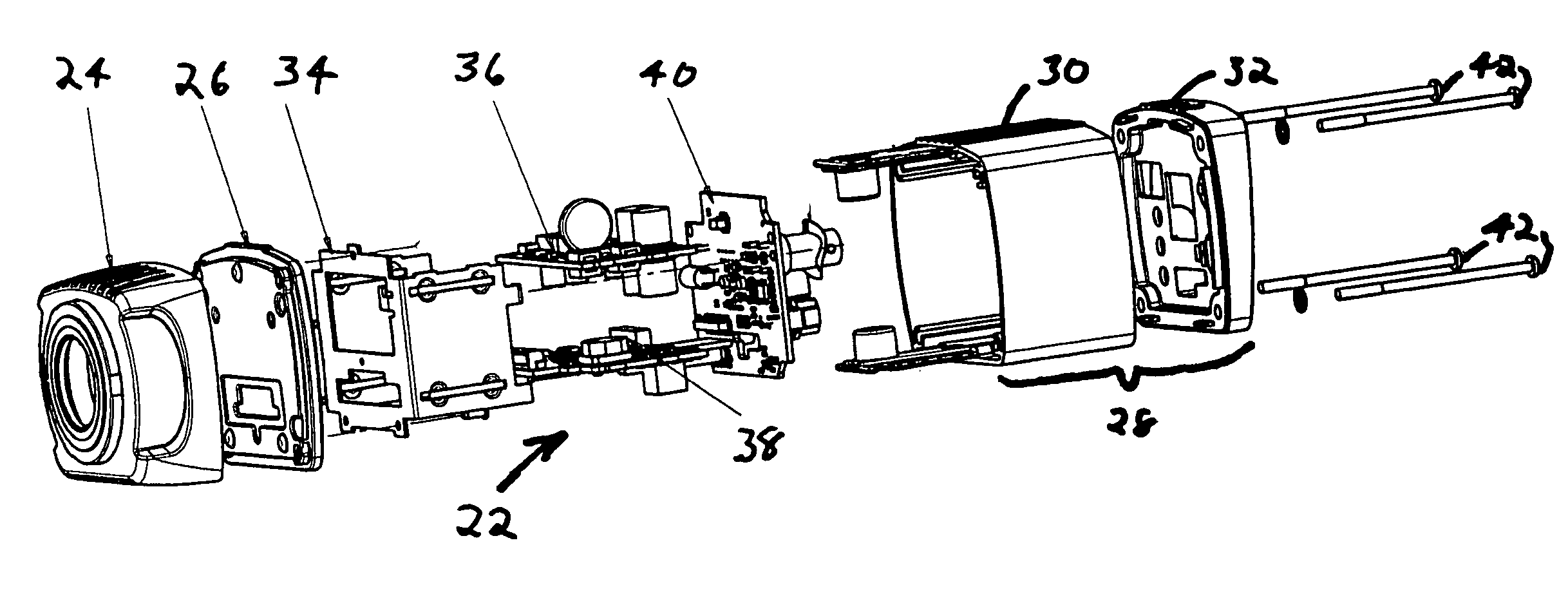

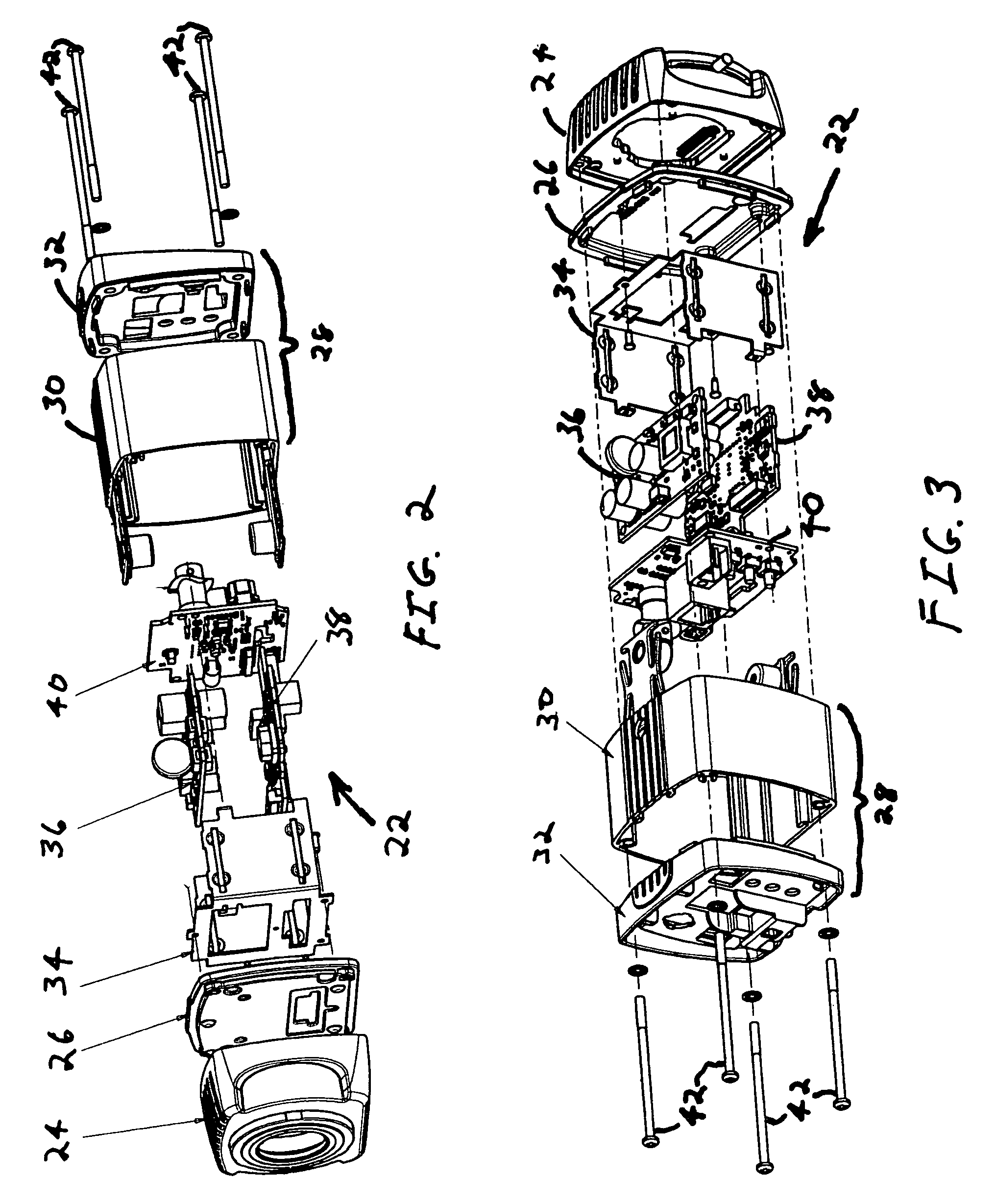

Video surveillance camera

ActiveUS20060055820A1Heat generation is minimizedMinimize heat transferTelevision system detailsColor television detailsVideo monitoringSurveillance camera

A video surveillance camera comprising an image sensor, first housing, second housing, electronic circuit, and thermal barrier. The image sensor is located in the first housing, and the electronic circuit is located in the second housing. The thermal barrier has first and second sides with the first side located adjacent to the first housing and the second side located adjacent to the second housing. The image sensor and other electronics, such as the processor board associated with the image sensor or the camera power supply, are located in separate housings or chambers that are separated and insulated from each other by a thermal barrier, thereby minimizing the heat generated by the processor electronics or power supply from being transferred to the area of the image sensor.

Owner:PELCO INC

Antimicrobial compositions and fibres incorporating the same

InactiveUS20120082711A1Reduces difficulty and disadvantagePreventing the growth of a broad spectrum of bacteriaBiocideInorganic active ingredientsMasterbatchMechanism of action

The present application defines an antimicrobial composition comprising (a) at least two antimicrobial agents having different antimicrobial mechanisms of action and being present in amounts that together provide a synergistic antimicrobial effect or (b) an antimicrobial agent and a surface modifying agent, an antimicrobial masterbatch comprising antimicrobial composition (a) or (b) and a polymer carrier, an antimicrobial fibre composition comprising the antimicrobial masterbatch and a fibre substrate, an antimicrobial fibre comprising a fibre body or a fibre surface having the antimicrobial fibre composition, and a process for producing antimicrobial fibres.

Owner:NOVEKO

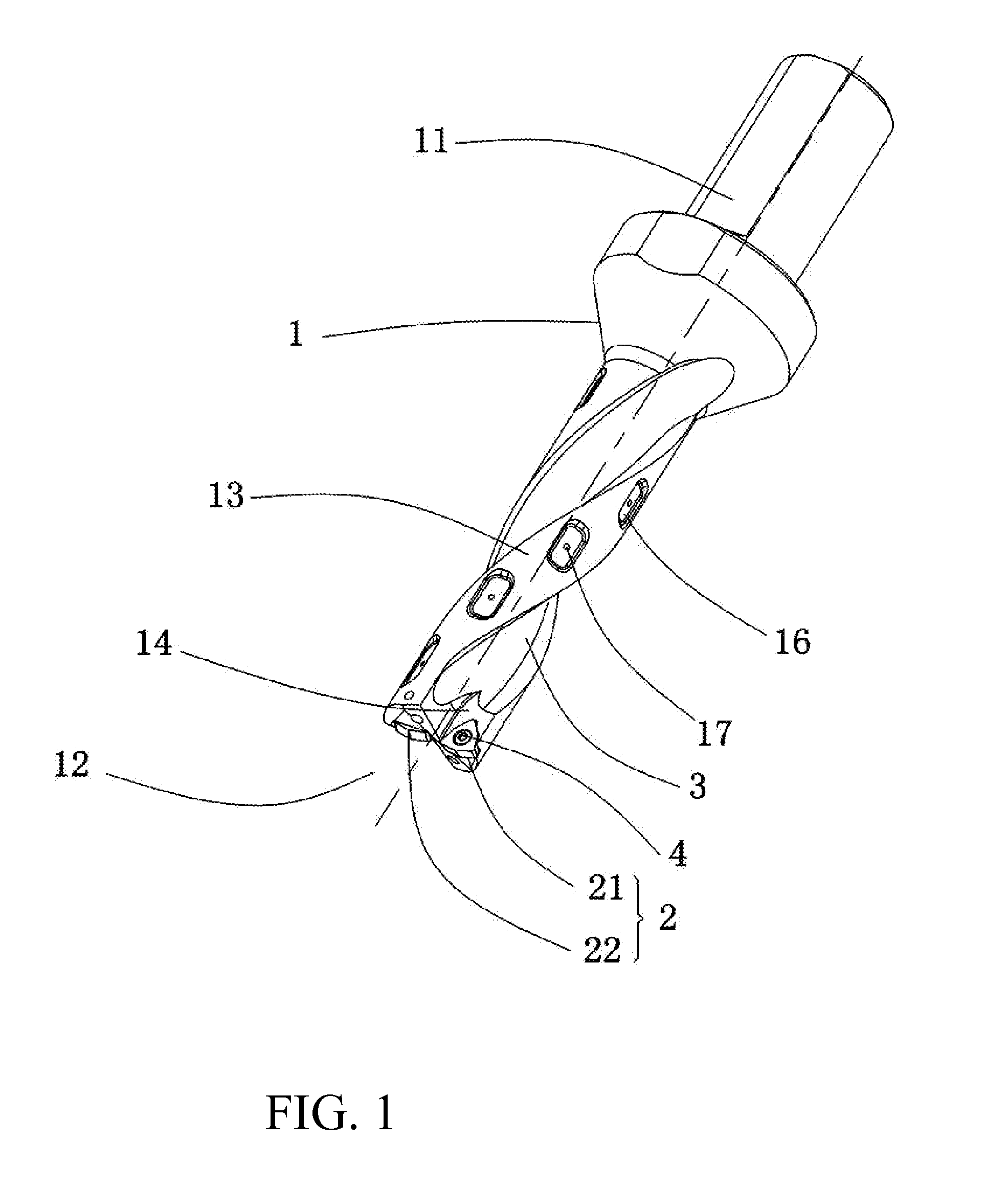

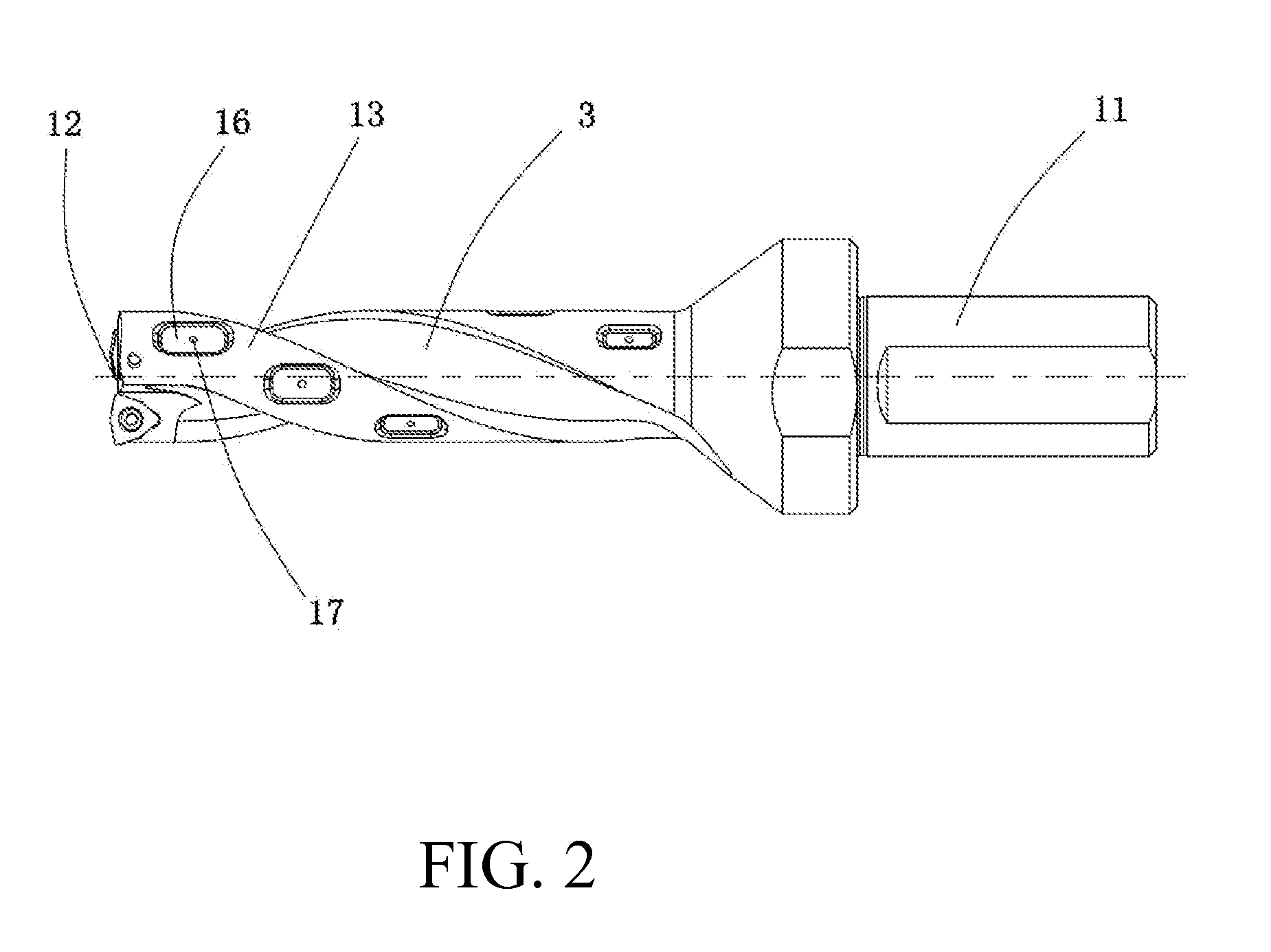

Boring Cutter

InactiveUS20150328696A1Minimize tool deflectionMinimize drilling vibrationTransportation and packagingMulti-purpose machinesFluteEngineering

A boring cutter includes a tool body and a cutting insert. The tool body includes a shaft handle and a cutting end, and defines a circumferential face extended between the shaft handle and the cutting end. The tool body further has an insert pocket extended to the cutting end to secure the cutting insert at the insert pocket, and a flute formed on the circumferential face to communicate with the insert pocket. The tool body further has a cooling channel extended through the shaft handle to the cutting end, and a plurality of discharging chambers spacedly formed on the circumferential face to communicate with the cooling channel. During a drilling process, cooling fluid is released to the discharging chambers from the cooling channel to create a pressure between the tool body and an inner wall of a hole of a workpiece to prevent the tool deflection and drilling vibration.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Method for grinding complex shapes

ActiveUS7708619B2Improve metal removal rateHigh surface finishAbrasion apparatusGrinding feed controlMaterial removalHardness

A method of producing a complex shape in a workpiece includes the steps of: i) grinding a workpiece at a maximum specific cutting energy of about 10 Hp / in3·min with at least one bonded abrasive tool, thereby forming a slot in the workpiece; and ii) grinding the slot with at least one mounted point tool, thereby producing the complex shape in the slot. The bonded abrasive tool includes at least about 3 volume % of a filamentary sol-gel alpha-alumina abrasive grain having an average length-to-cross-sectional-width ratio of greater than about 4:1 or an agglomerate thereof. A method of producing a slot in a metallic workpiece having a maximum hardness value of equal to, or less than, about 65 Rc includes the step of grinding the workpiece with a bonded abrasive tool at a material removal rate in a range of between about 0.25 in3 / min·in and about 60 in3 / min·in and at a maximum specific cutting energy of about 10 Hp / in3·min.

Owner:SAINT GOBAIN ABRASIVES INC +1

Vehicle equipped with motor and inverter

ActiveUS7923961B2Reduce noiseLow costVector control systemsControllers with pulse-train output signalDrive wheelControl theory

A vehicle includes a motor for driving wheels WH, an inverter to drive the motor, and a control device to perform PWM control of the inverter. The control device performs synchronous PWM control in a case where an electric current supplied to the motor by the inverter or torque generated in the motor is larger than a threshold value; and performs the synchronous PWM control or non-synchronous PWM control in a case where the electric current or the torque is smaller than the threshold value and sets carrier frequency or a pulse number of the PWM control to be higher than the case where the electric current or the torque is larger than the threshold value. Thereby, it is possible to provide a vehicle of achieving reduction of noise, reduction of cost and improvement of fuel consumption in a balanced manner.

Owner:DENSO CORP

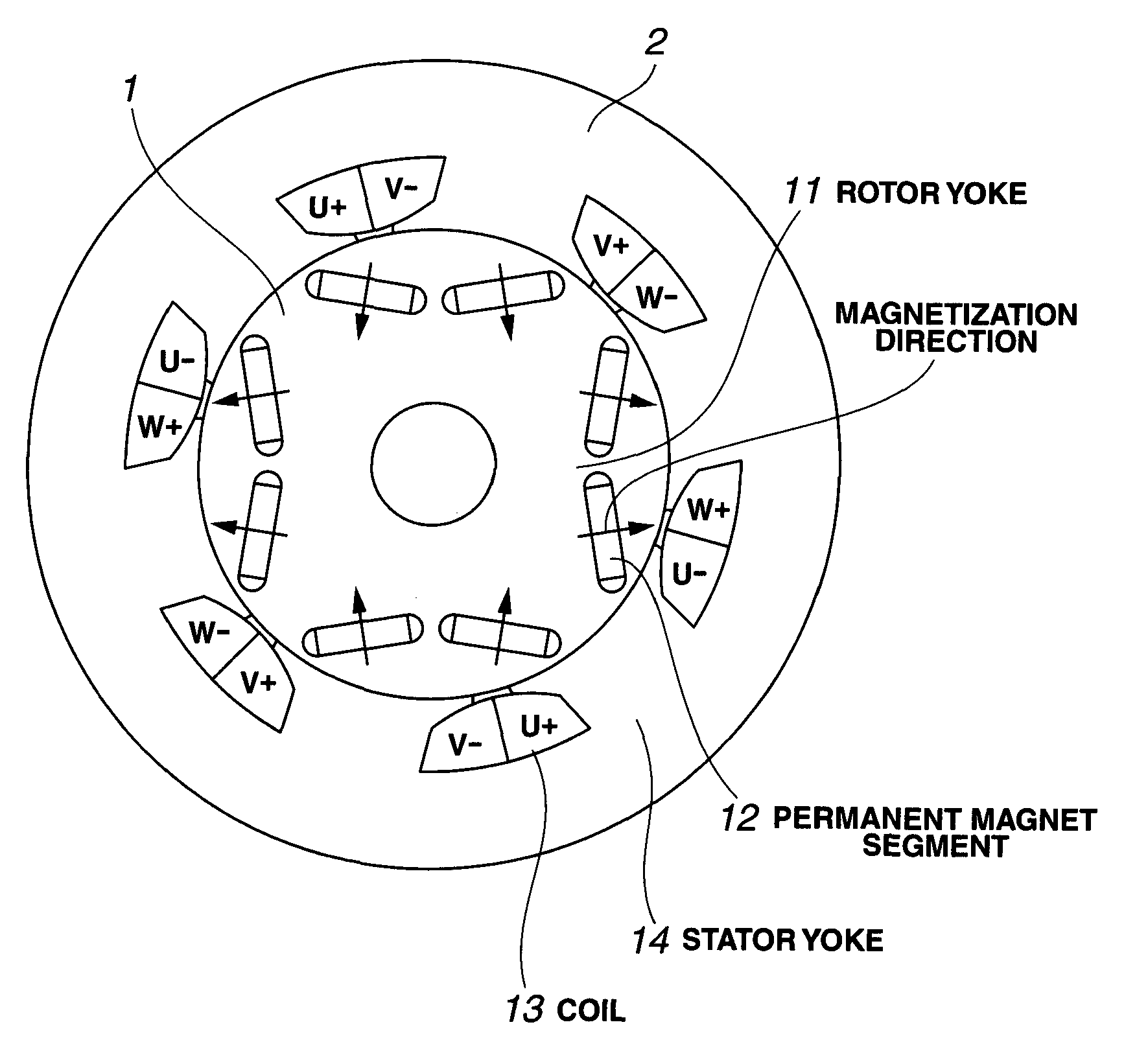

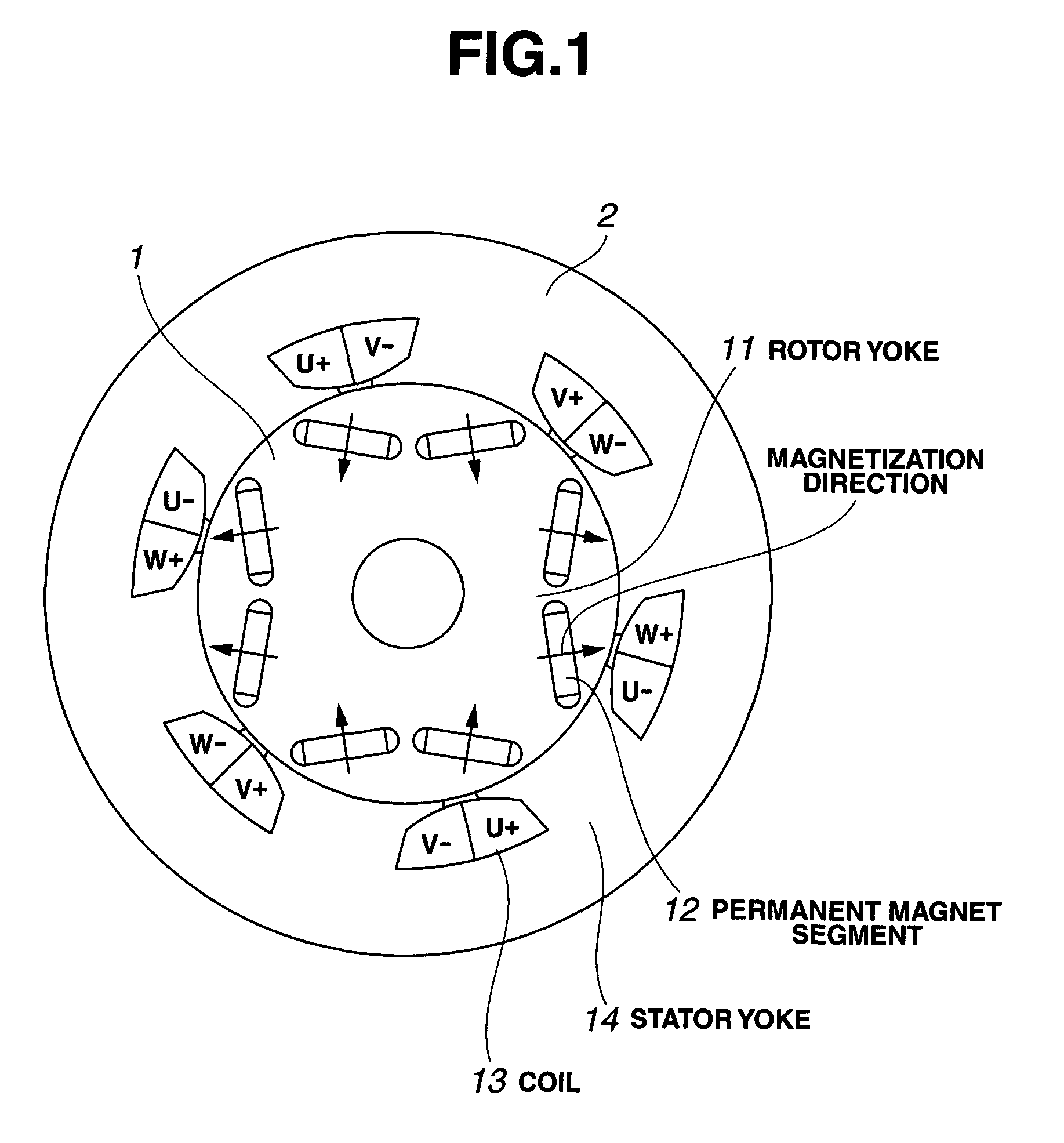

Rotor for permanent magnet rotating machine

ActiveUS20110068651A1High heat resistanceHigh output resistanceMagnetic circuitSynchronous machines with stationary armatures and rotating magnetsConductor CoilMagnet

In connection with a permanent magnet rotary machine comprising a rotor comprising a rotor core and a plurality of permanent magnet segments embedded in the rotor core and a stator comprising a stator core having a plurality of slots and windings therein, the rotor and the stator being disposed to define a gap therebetween, or a permanent magnet rotary machine comprising a rotor comprising a rotor core and a plurality of permanent magnet segments mounted on the surface of the rotor core and a stator comprising a stator core having a plurality of slots and windings therein, the rotor and the stator being disposed to define a gap therebetween, the rotor wherein each of the permanent magnet segments is an assembly of further divided permanent magnet pieces, and the coercive force near the surface of the magnet piece is higher than that in the interior of the magnet piece.

Owner:SHIN ETSU CHEM IND CO LTD

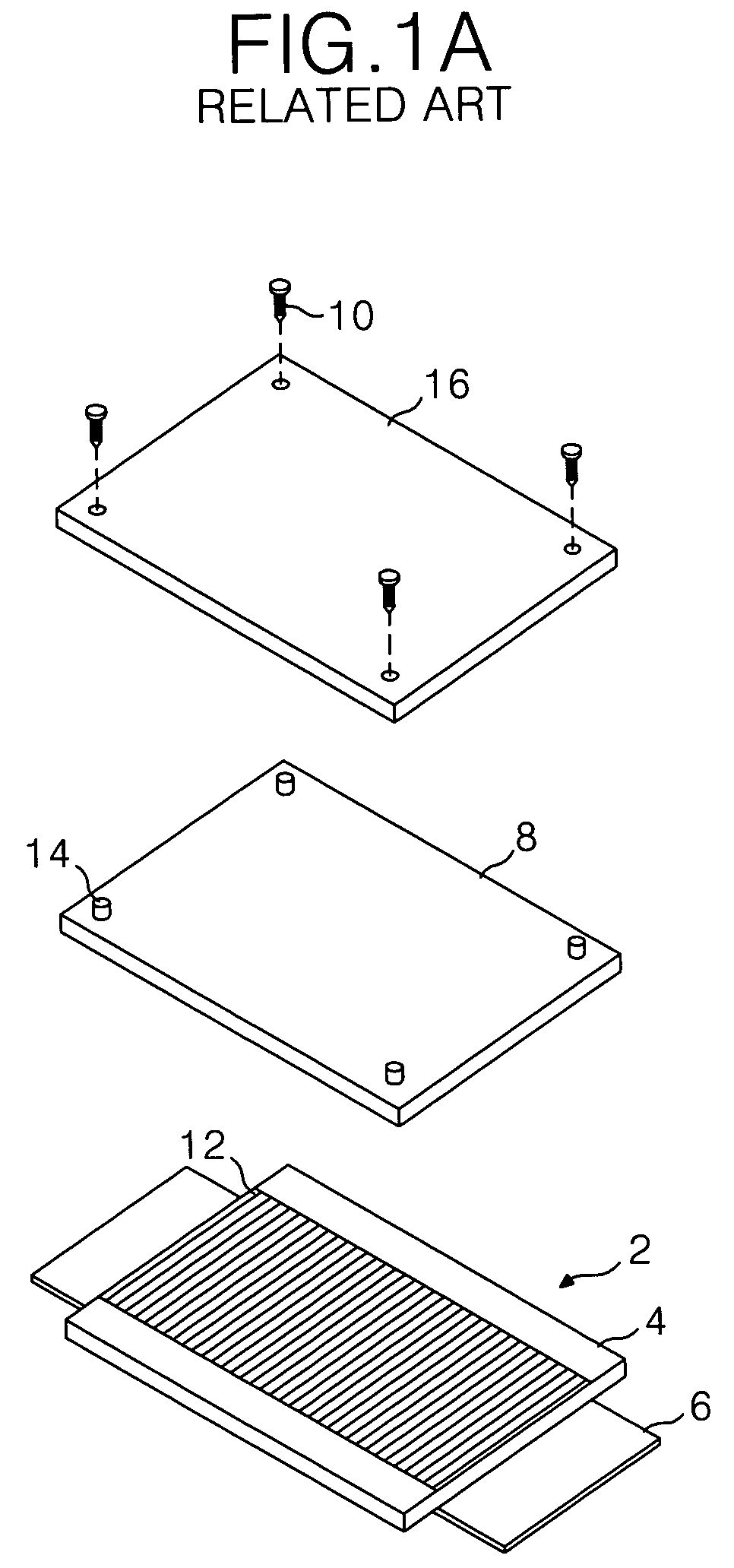

Plasma display panel with porous pad

InactiveUS7235922B2Minimizing noise/vibrationMinimizing heat generationAlternating current plasma display panelsSolid cathode detailsPrinted circuit boardPlasma display

A plasma display panel adapted to minimize noise / vibration as well as a heat generated therefrom. In the plasma display panel, a display panel displays a picture while a porous pad is provided behind the display panel to prevent the transfer of noise / vibration to an associated heat proof panel. When the PDP is mounted within a case, a second porous pad can be provided on an inner surface of the case opposite the display panel and adjacent to an associated printed circuit board for additional noise / vibration damping.

Owner:LG ELECTRONICS INC

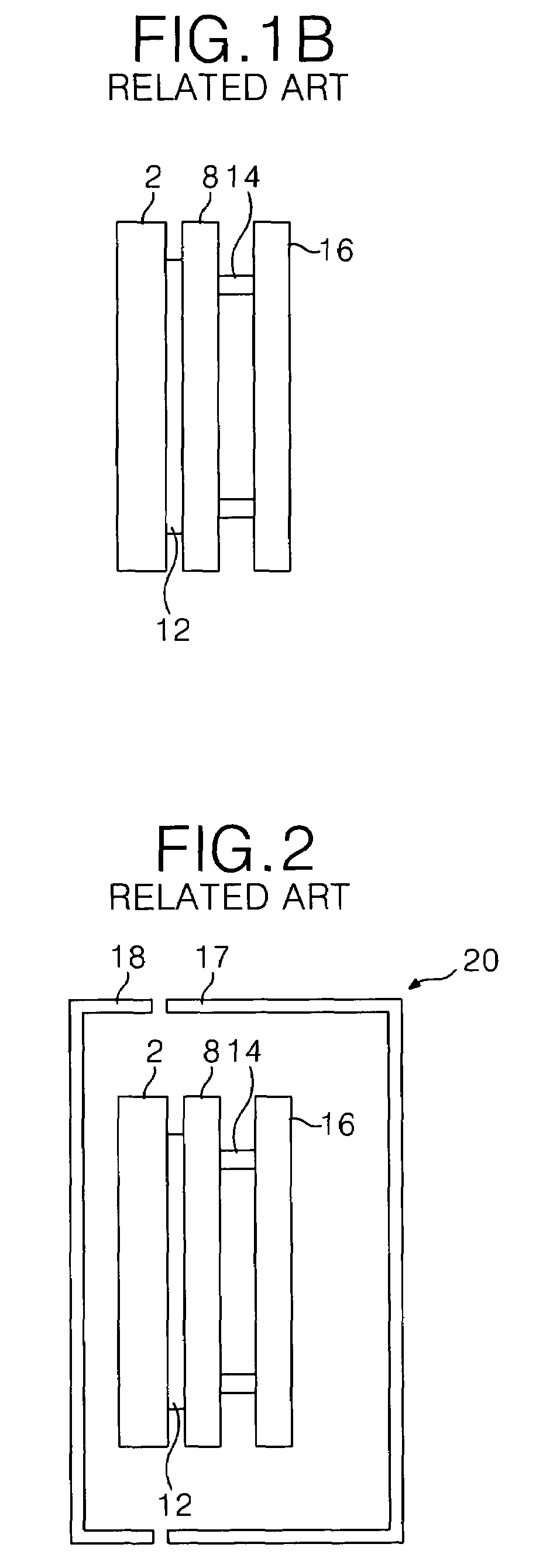

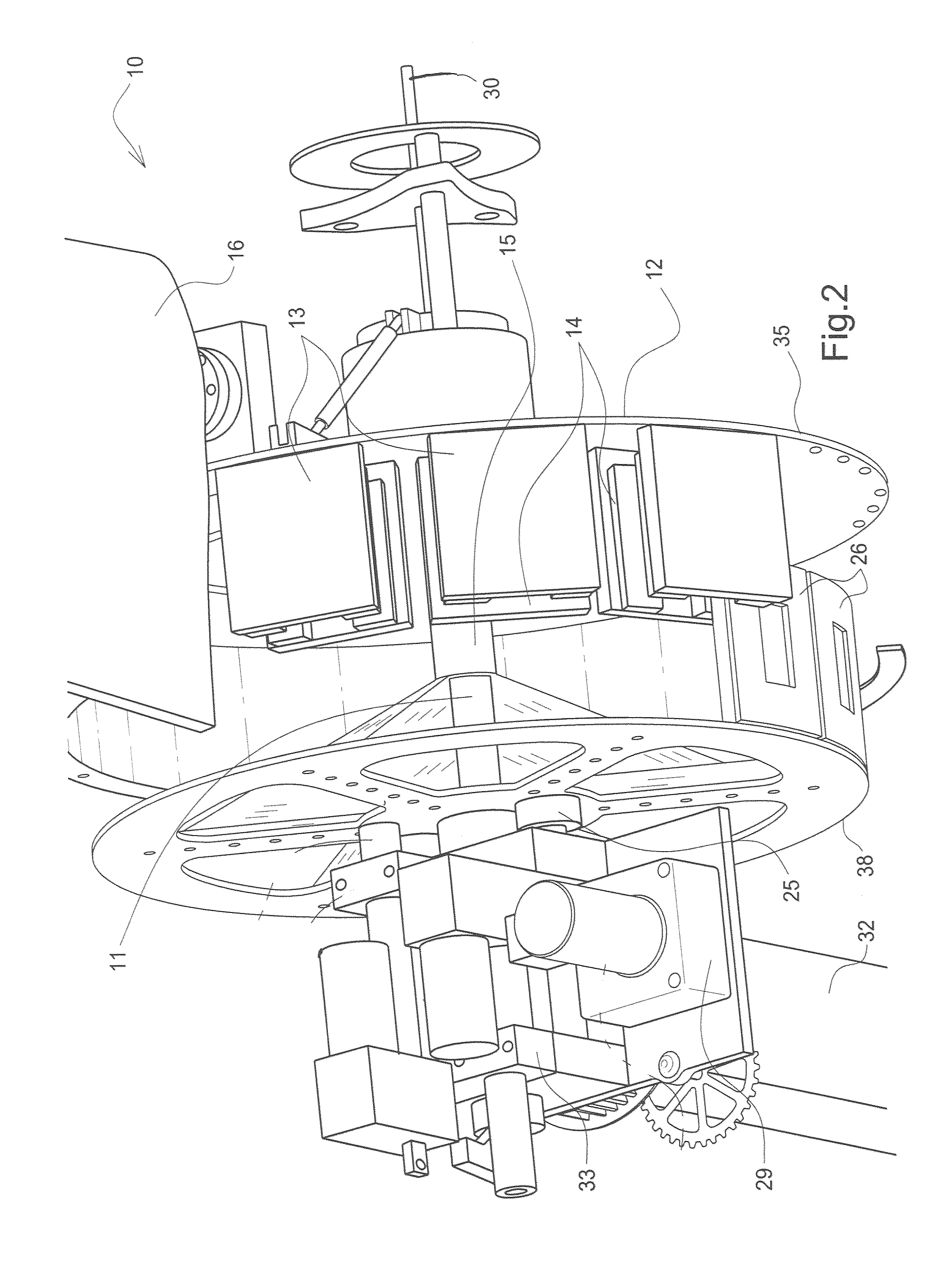

Electrical energy generator and method

InactiveUS8269389B1Reduce loadHeat generation is minimizedWindingsWind motor controlElectricityElectric generator

An electrical energy generator for generating optimal electrical energy at very low wind speeds and at very high wind speeds. The electrical energy generator includes a support assembly having an elongate support member, and also includes a rotor assembly being rotatably disposed upon the support assembly and having a plurality of vanes being movable by air for rotating the rotor assembly, and further includes a stator assembly being mounted upon the support assembly and including a stator member being movably disposed upon the support assembly for generating energy in cooperation with the rotor assembly, and an assembly for moving the stator member relative to the rotor assembly upon the support assembly.

Owner:SOMERVILLE CRIS D

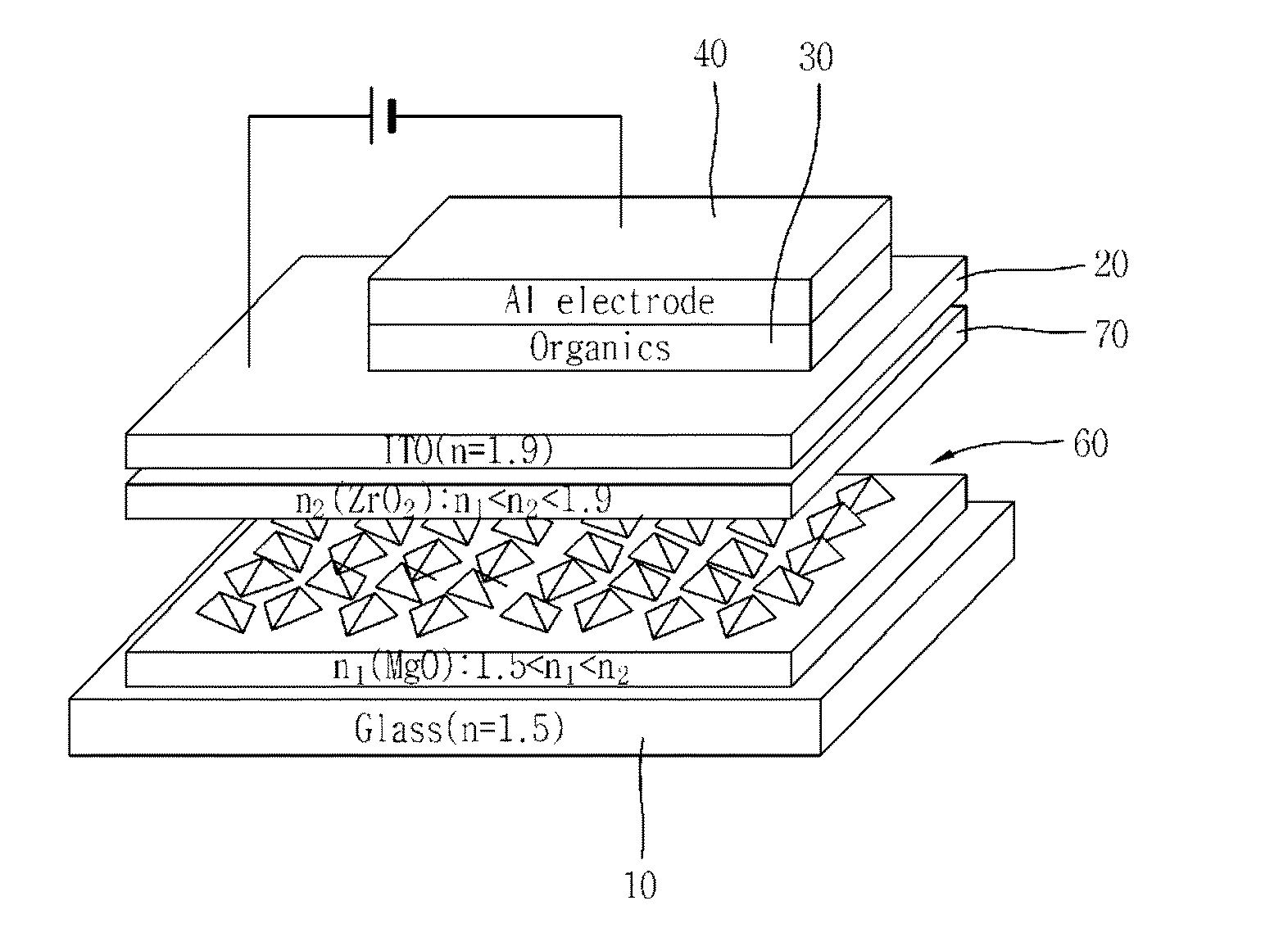

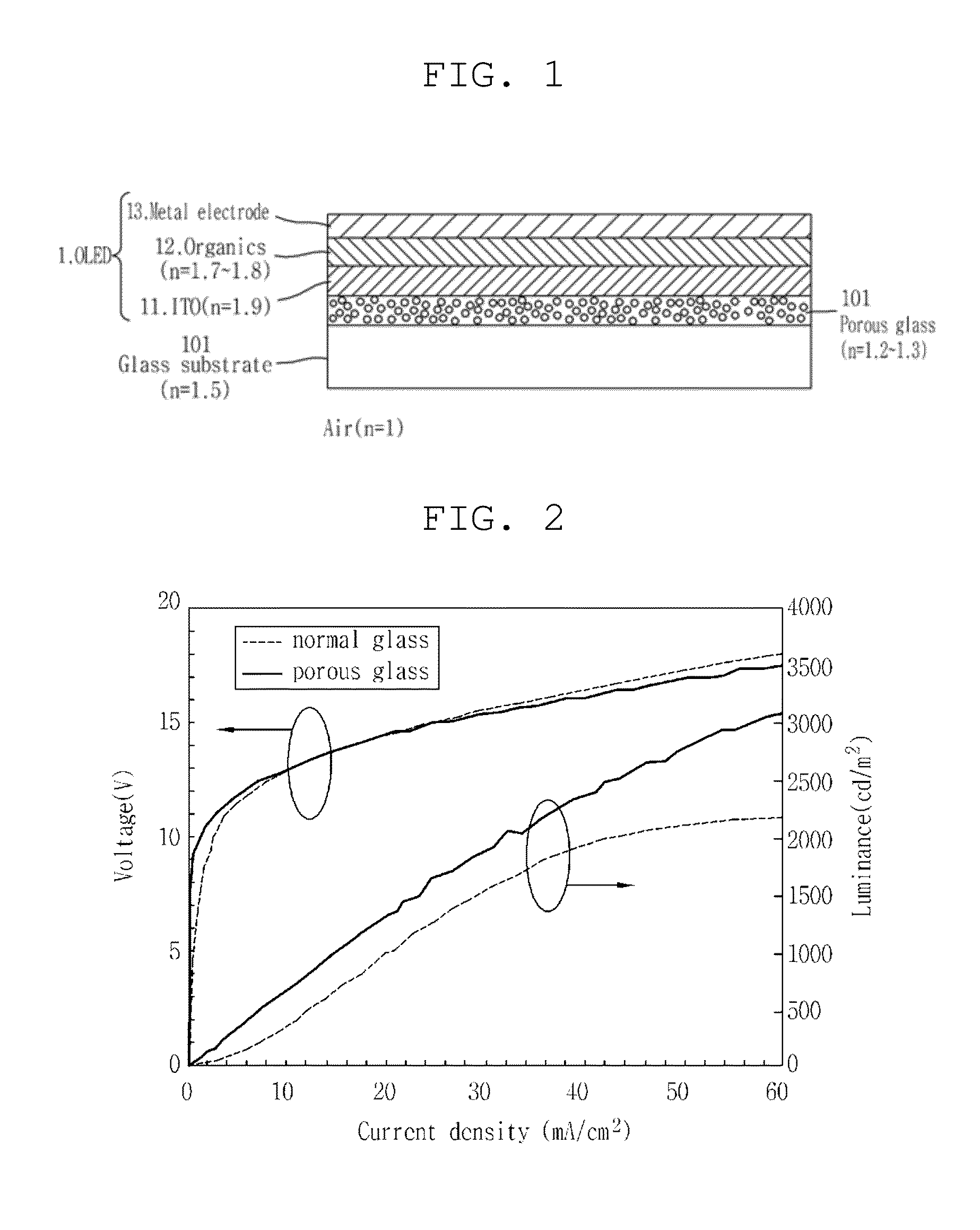

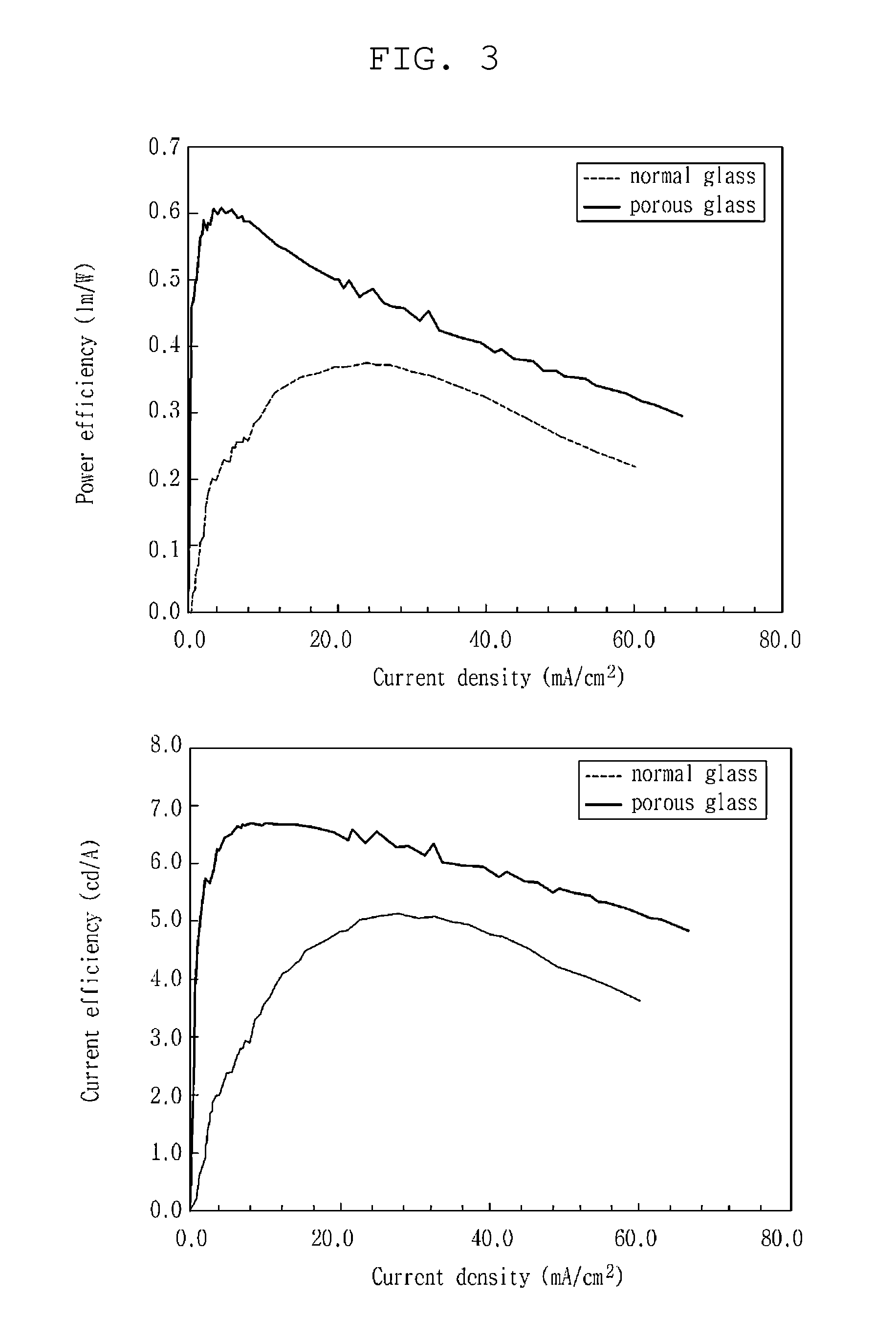

Porous Glass Substrate For Displays And Method Of Manufacturing The Same

ActiveUS20130299792A1Reduce manufacturing costEliminate dangerLayered productsFinal product manufacturePorous layerOrganic light emitting device

A porous glass substrate for displays and a method of manufacturing the same, with which the optical characteristics of a display such as an organic light-emitting device (OLED) can be improved. The porous glass substrate includes a glass substrate and a porous layer formed in at least one portion of one surface of the glass substrate and extending into the glass substrate, the refractive index of the porous layer being smaller than the refractive index of the glass substrate. The porous layer has a plurality of pores which is formed in the glass substrate such that at least one component of the glass substrate except for silicon dioxide (SiO2) is eluted from the glass substrate.

Owner:SAMSUNG CORNING PRECISION MATERIALS CO LTD

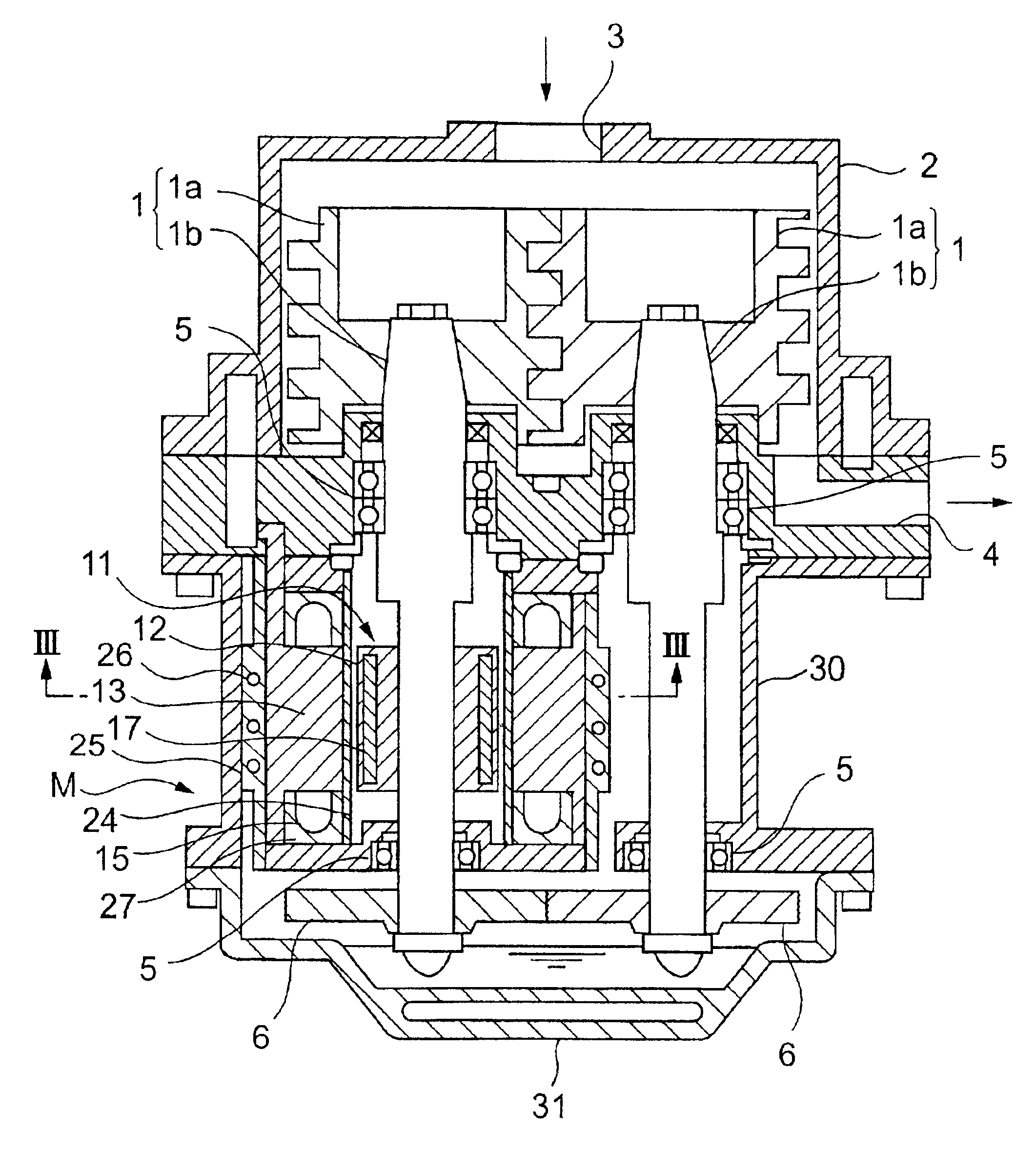

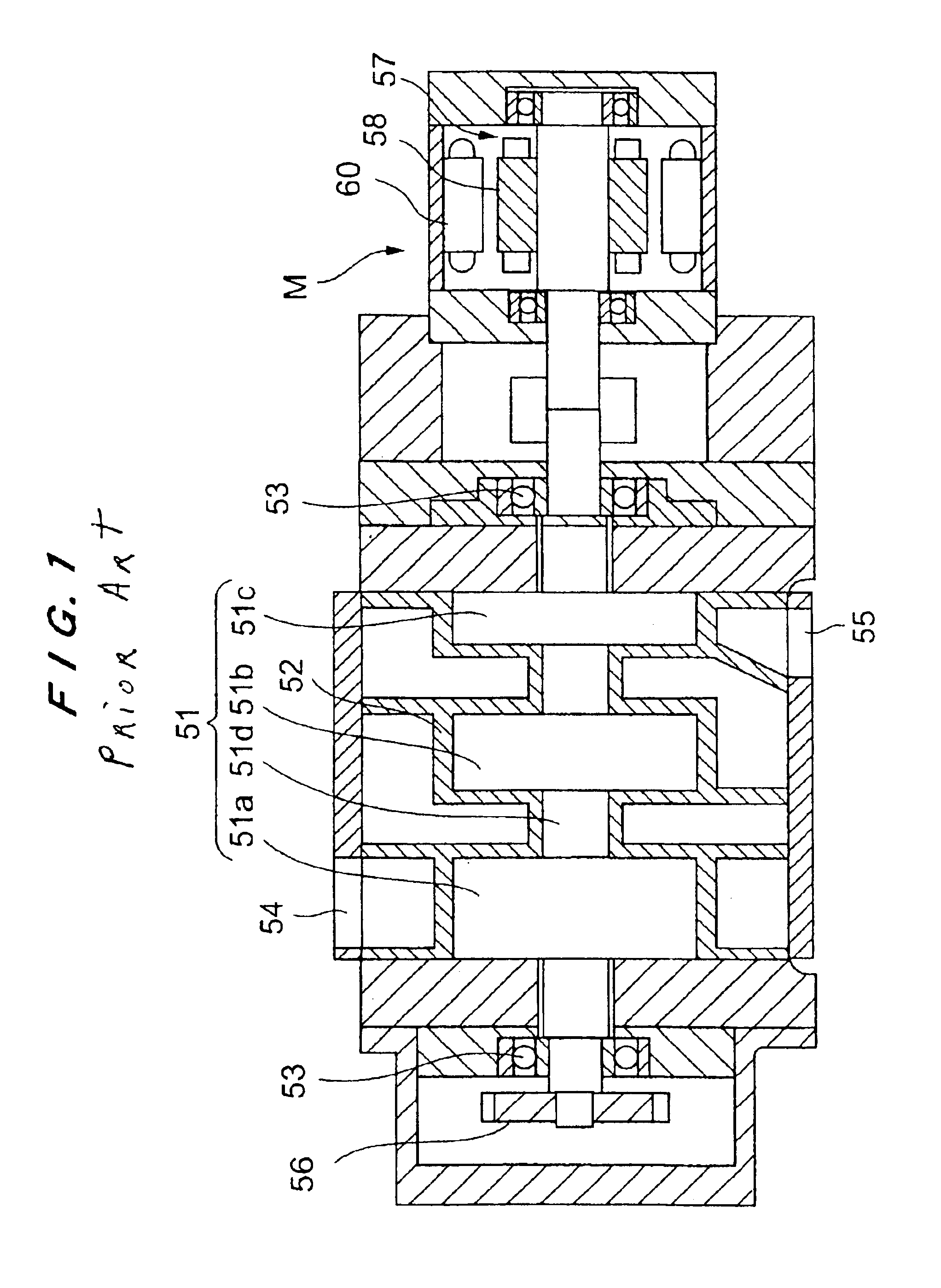

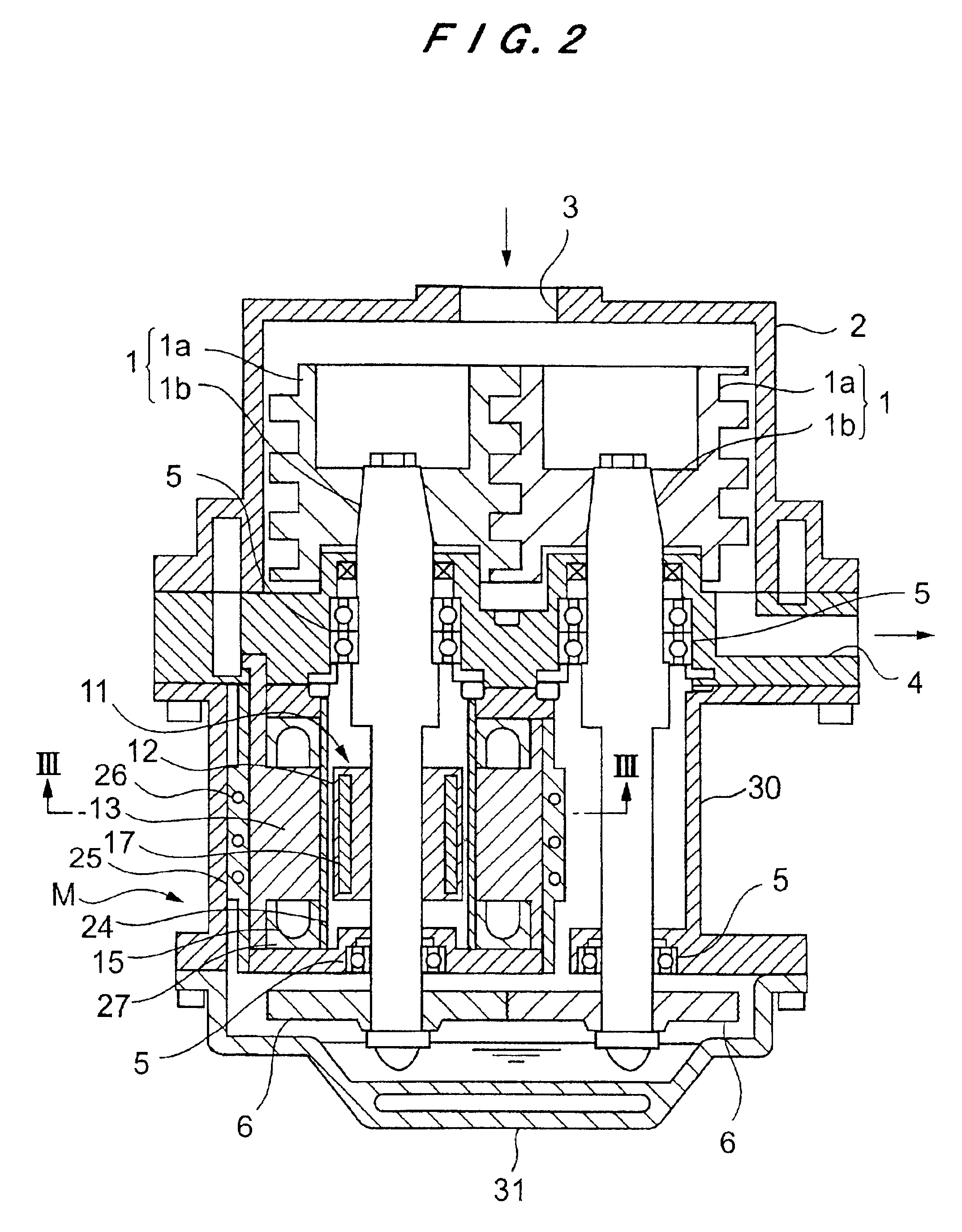

Vacuum pump with pump rotor pairs and permanent magnet motor

InactiveUS6902380B2Improve reliable operationHeat generation is minimizedRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsPermanent magnet motorEngineering

A vacuum pump has a casing having an inlet port and an outlet port, and a pair of confronting pump rotors which are provided inside the casing and synchronously rotatable for drawing in a gas from the inlet port and discharging the gas from the outlet port. A motor for rotating the confronting pump rotors is a permanent magnet motor having a stator and a motor rotor. The motor rotor has an iron core and permanent magnets disposed within the iron core.

Owner:EBARA CORP

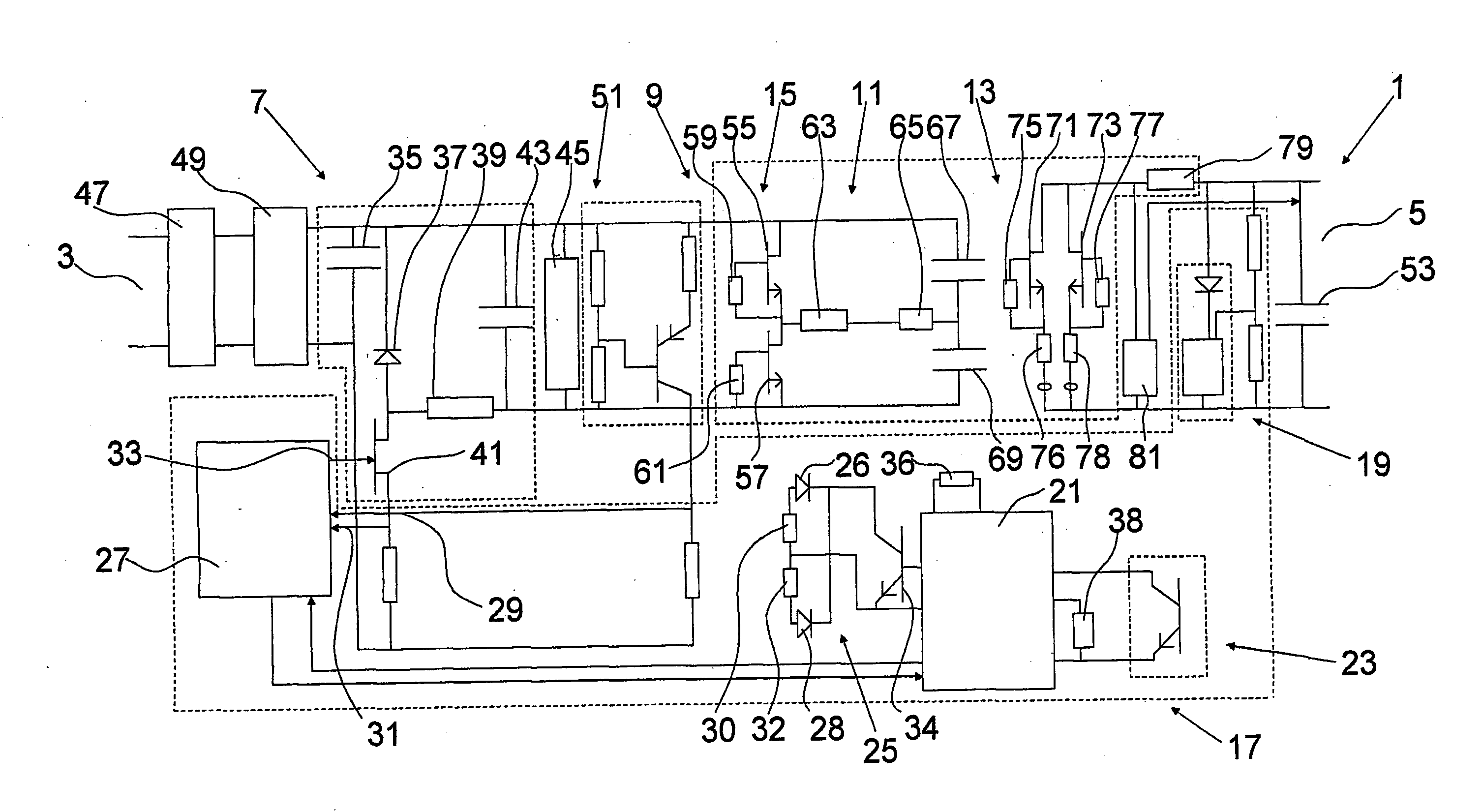

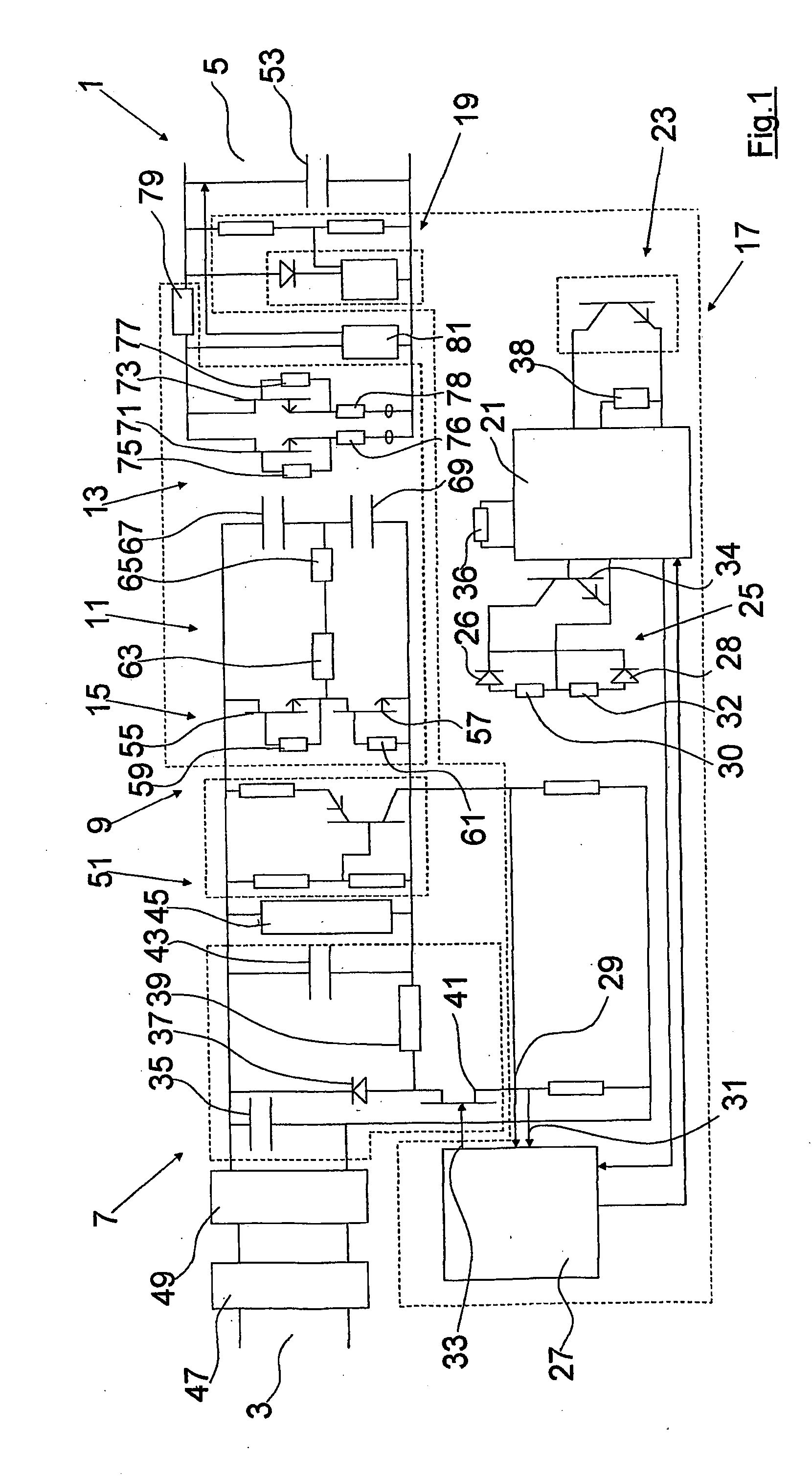

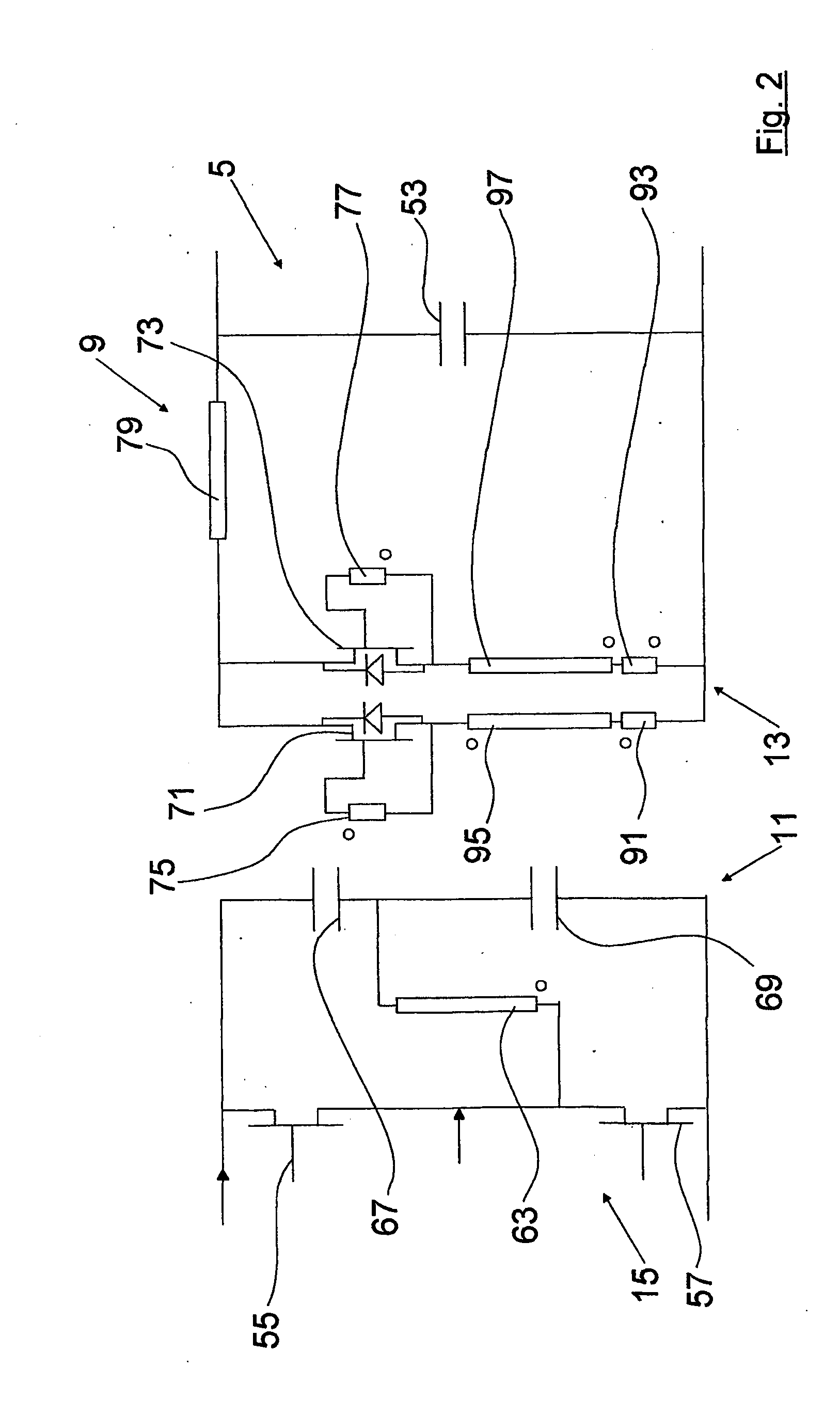

Acdc converter

ActiveUS20090279331A1Minimizing heat generationLower requirementAc-dc conversion without reversalEfficient power electronics conversionMode controlControl signal

This invention relates to an ACDC converter (1) comprising a converter input (3) and a converter output (5), a pre-regulation stage (7) and a DC transformer stage (9) comprising a transformer input stage (11) and a transformer output stage (13). The transformer input stage comprises a double ended converter and there is further provided a controller (17) for providing a control signal to the double ended converter. The controller (17) operates the ACDC converter using burst mode control and by sending control signals comprising pulse sets that are designed to provide substantially zero net magnetising current in the double ended converter. The pre-regulation stage preferably comprises a buck converter which in turn also provides power factor correction to the input of the ACDC converter.

Owner:TEXAS INSTR INC

Phacoemulsification needle

InactiveUS20050020990A1Heat generation is minimizedMinimizing heat generationEye surgerySurgical instrument detailsPhacoemulsificationBiomedical engineering

A phacoemulsification needle according to the invention comprises a shaft, a tip disposed at a distal end of said shaft and an aspiration lumen extending through said shaft and said tip. The tip has an opening communicating with said aspiration lumen. The shaft comprises at least a portion which has a ribbed outer surface. This needle minimizes heat generation and can therefore be used with or without sleeve.

Owner:RAVI NALLAKRISHNAN +1

Balanced mechanical seal assembly

A mechanical seal having a single rotatable seal ring having a pair of concentric seal faces to form a radially inner seal face and a radially outer seal face. The mechanical seal also includes first and second stationary seal rings, each having a seal face, where the seal face of the first stationary seal ring contacts the radially outer seal face of the rotatable seal ring and the seal face of the second stationary seal ring contacts the radially inner seal face of the rotatable seal ring. The seal also includes a sleeve adapted to be mounted about the rotating shaft and rotatably coupled thereto and to the rotatable seal ring, said sleeve having a flange portion that is configured for housing at least a portion of the rotatable seal ring, and a gland for housing at least partially the single rotary seal ring and the first and second stationary seal rings. Under positive and negative pressure conditions, the combined area of the seal piston areas are substantially identical to provide a balanced seal arrangement without requiring the use of axially movable components.

Owner:A W CHESTERTON

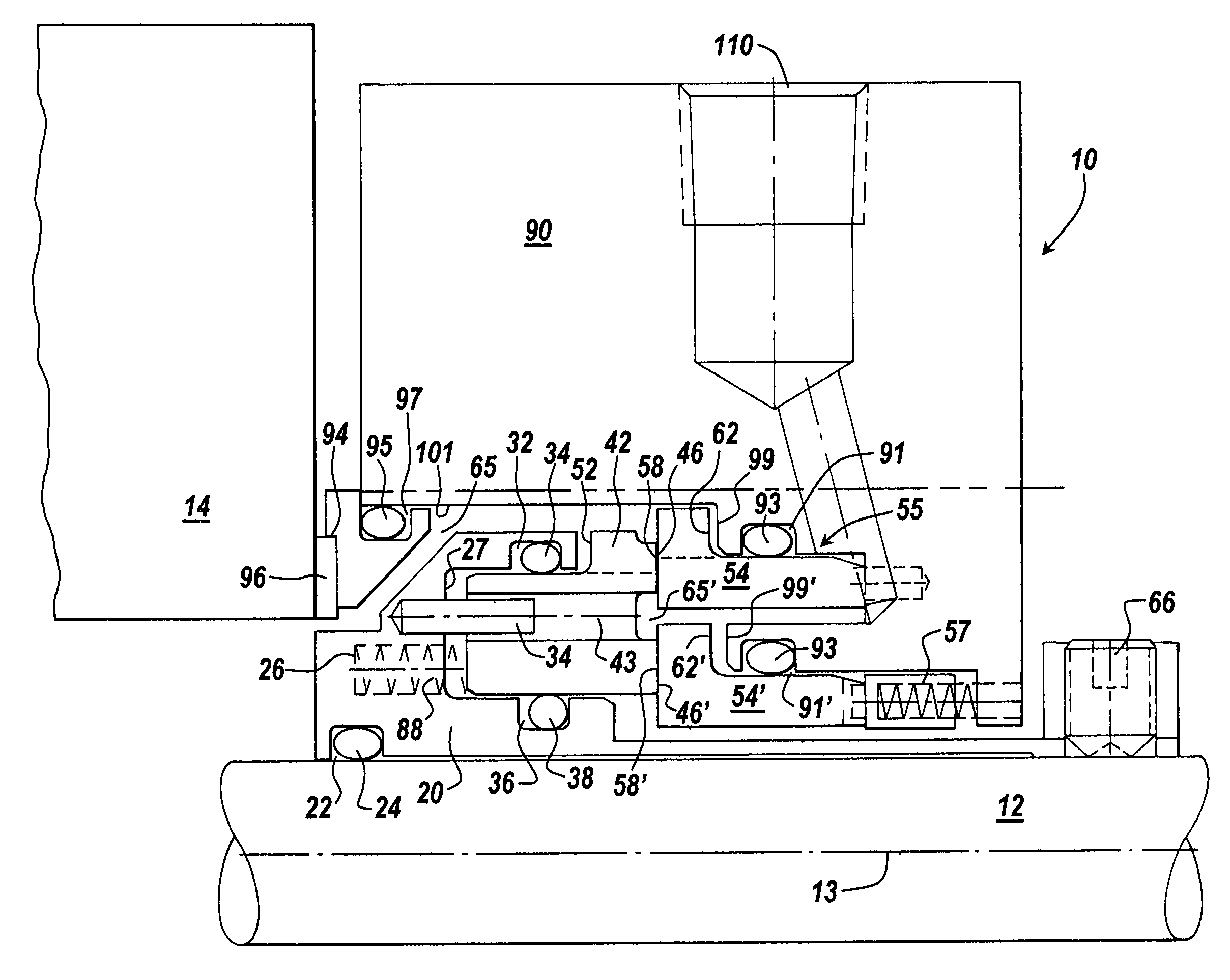

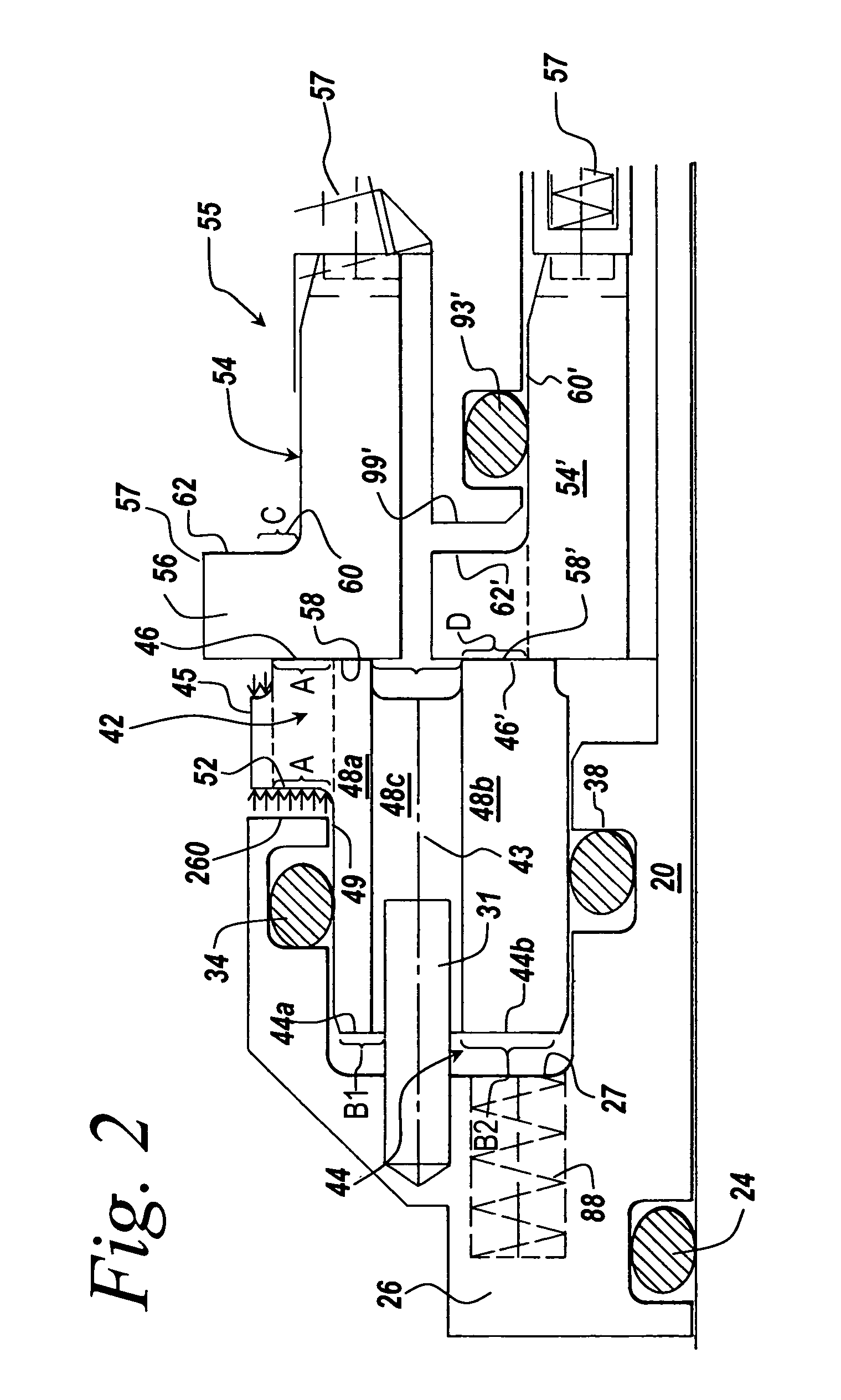

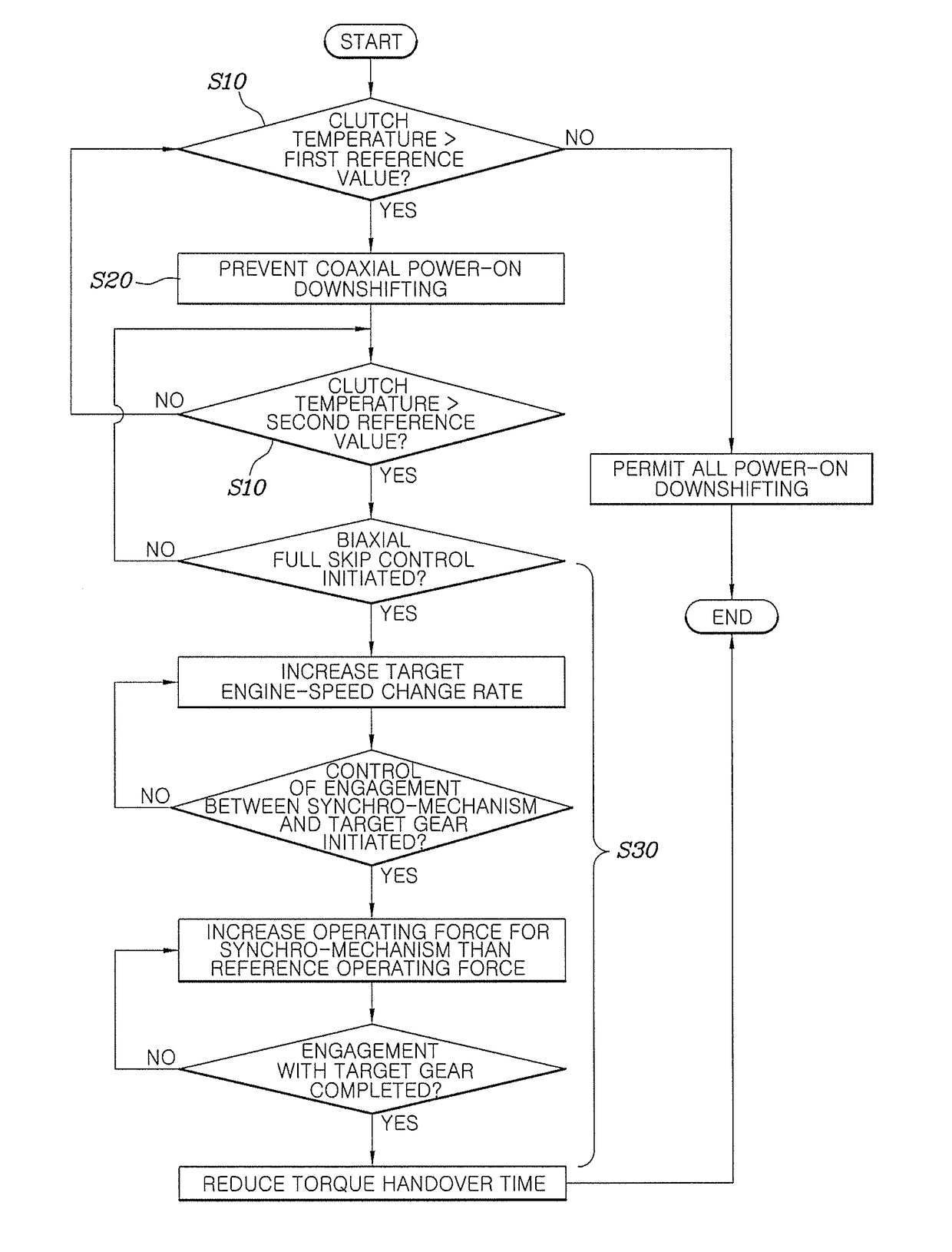

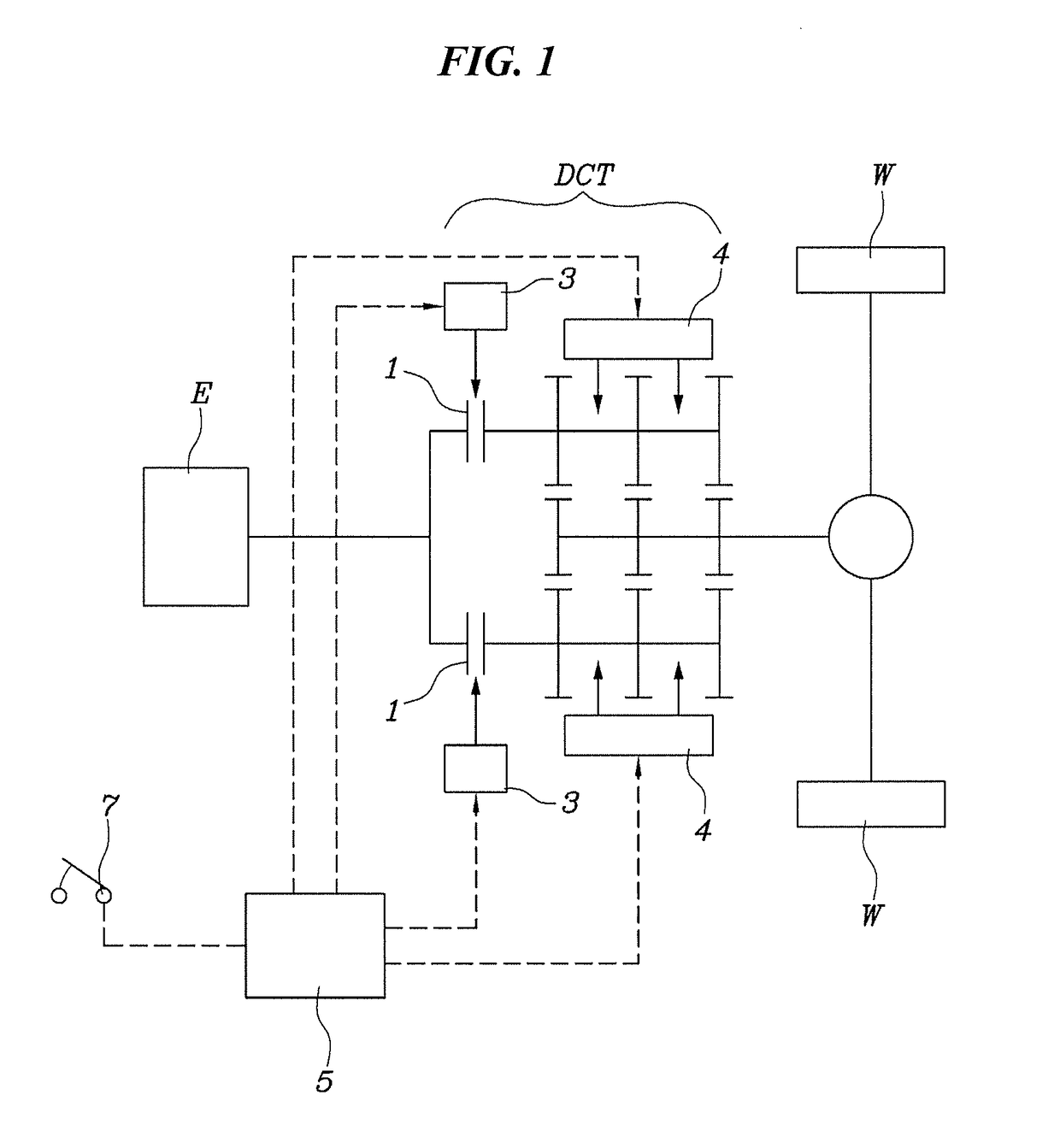

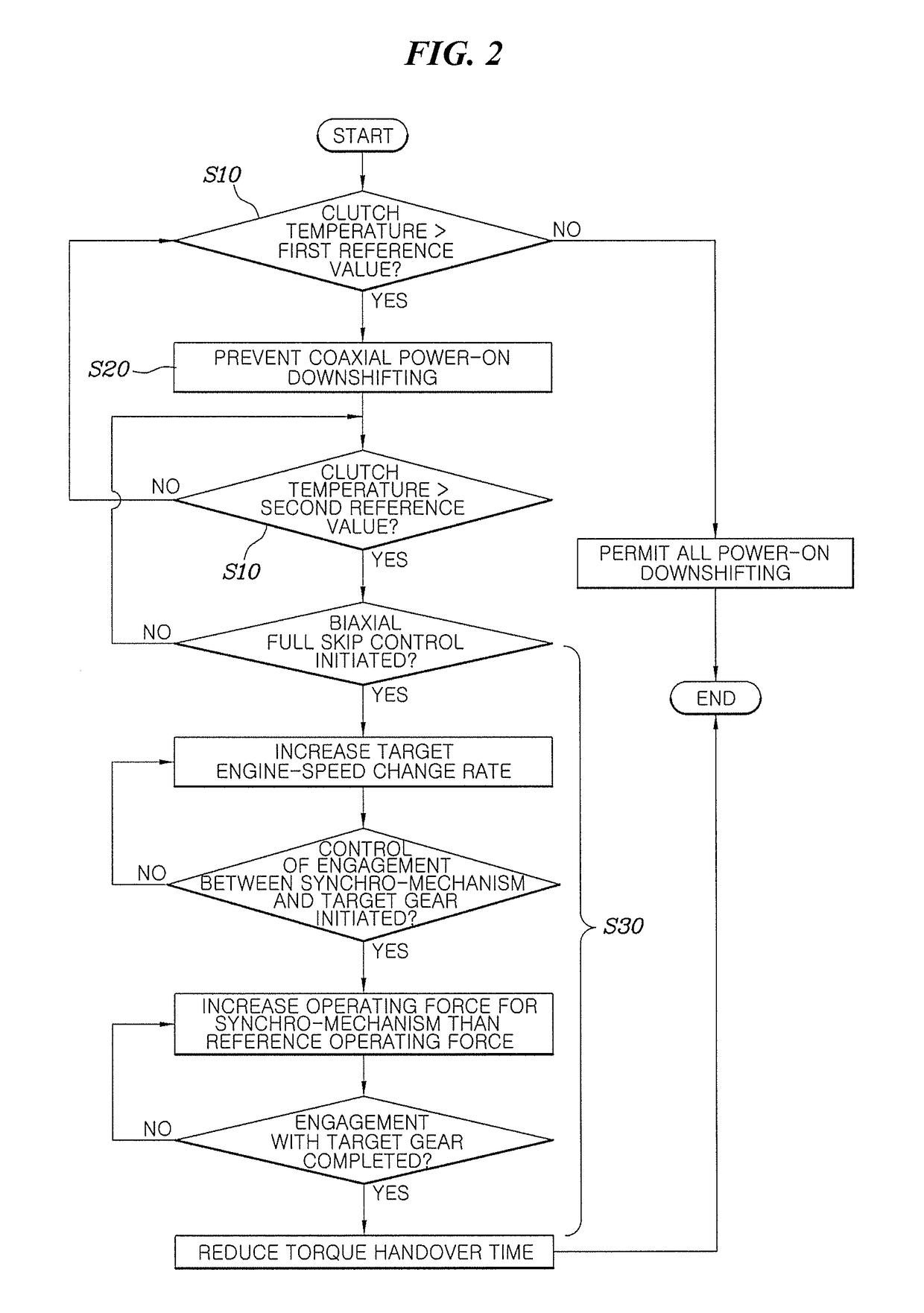

Shift control method for vehicle with dual clutch transmission

ActiveUS20170122431A1Minimizing heat generationIncreased durabilityGearing controlEngineeringShift time

A shift control method for a vehicle with a Dual Clutch Transmission (DCT) includes comparing, by a controller, a current clutch temperature with a first predetermined reference value and a second predetermined reference value, the second predetermined reference value being greater than the first reference value, preventing, by the controller, coaxial power-on downshifting when the clutch temperature is greater than the first reference value, and reducing, by the controller, a shift time by preventing coaxial power-on downshifting when the clutch temperature is greater than the second reference value and then increasing a shift speed when biaxial full skip shifting is required.

Owner:HYUNDAI MOTOR CO LTD

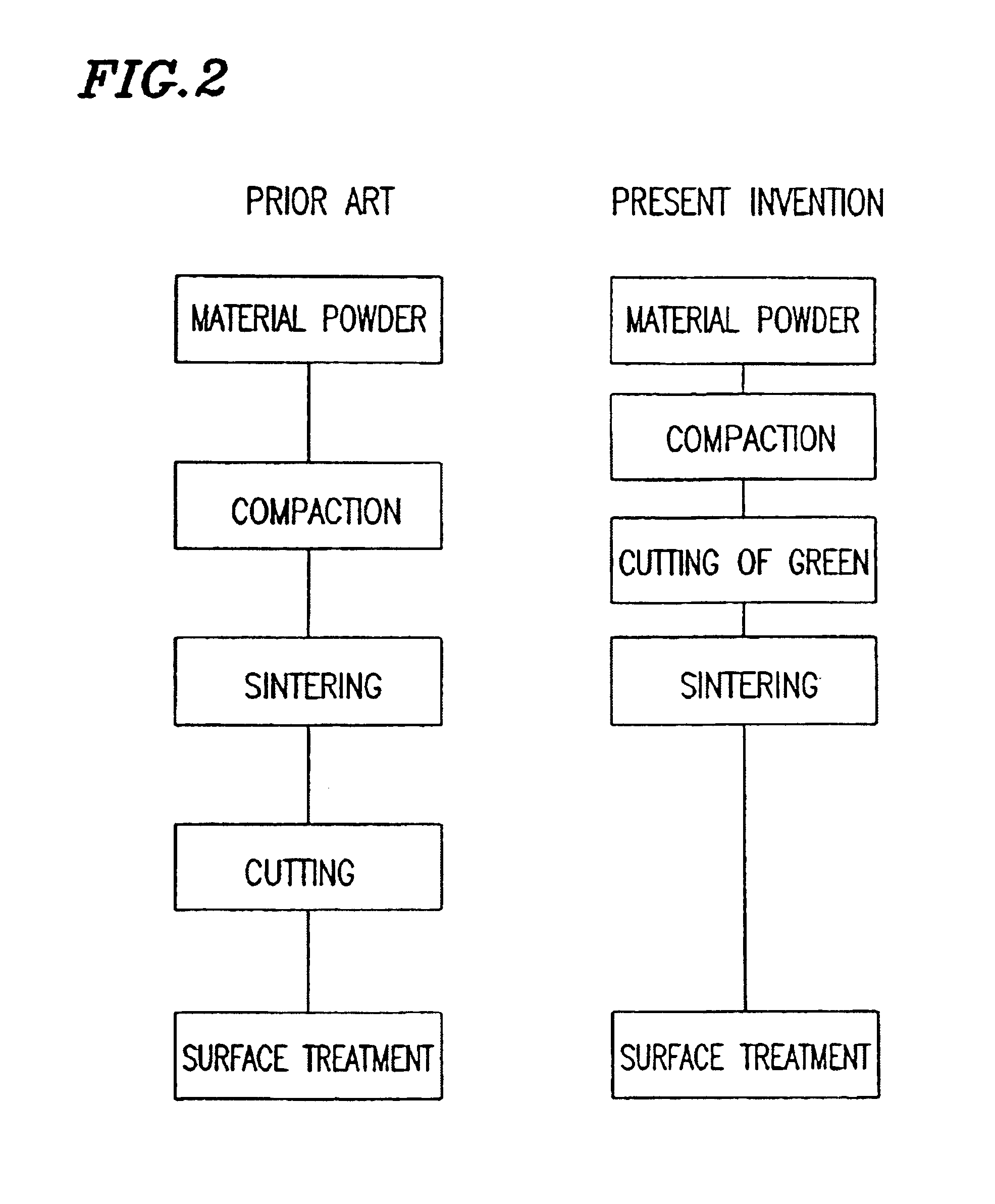

Method for manufacturing sintered magnet

InactiveUS7045093B2Reduce machine loadHeat generation is minimizedInorganic material magnetismInductances/transformers/magnets manufactureSintered magnetsWire saw

Owner:HITACHI METALS LTD

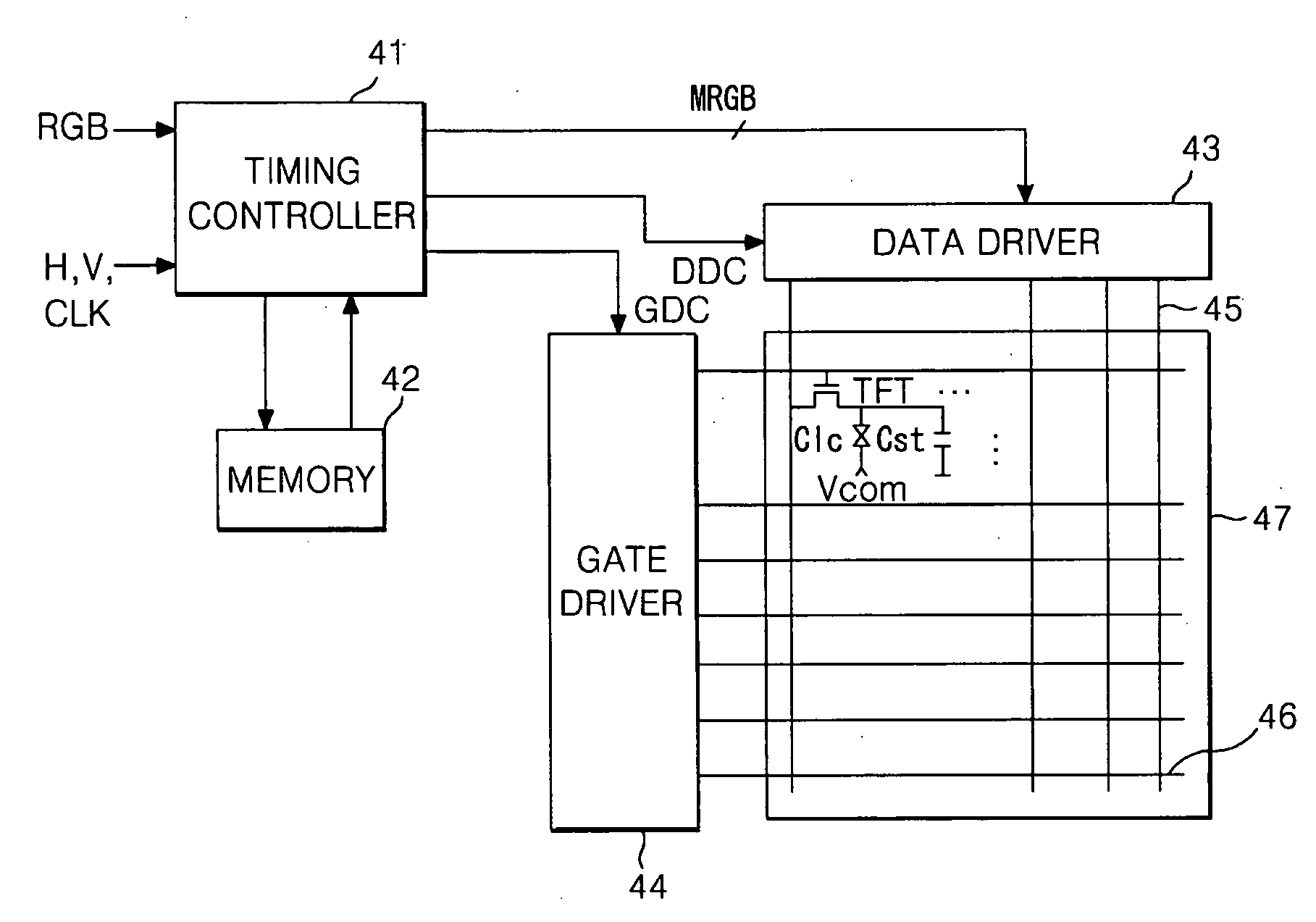

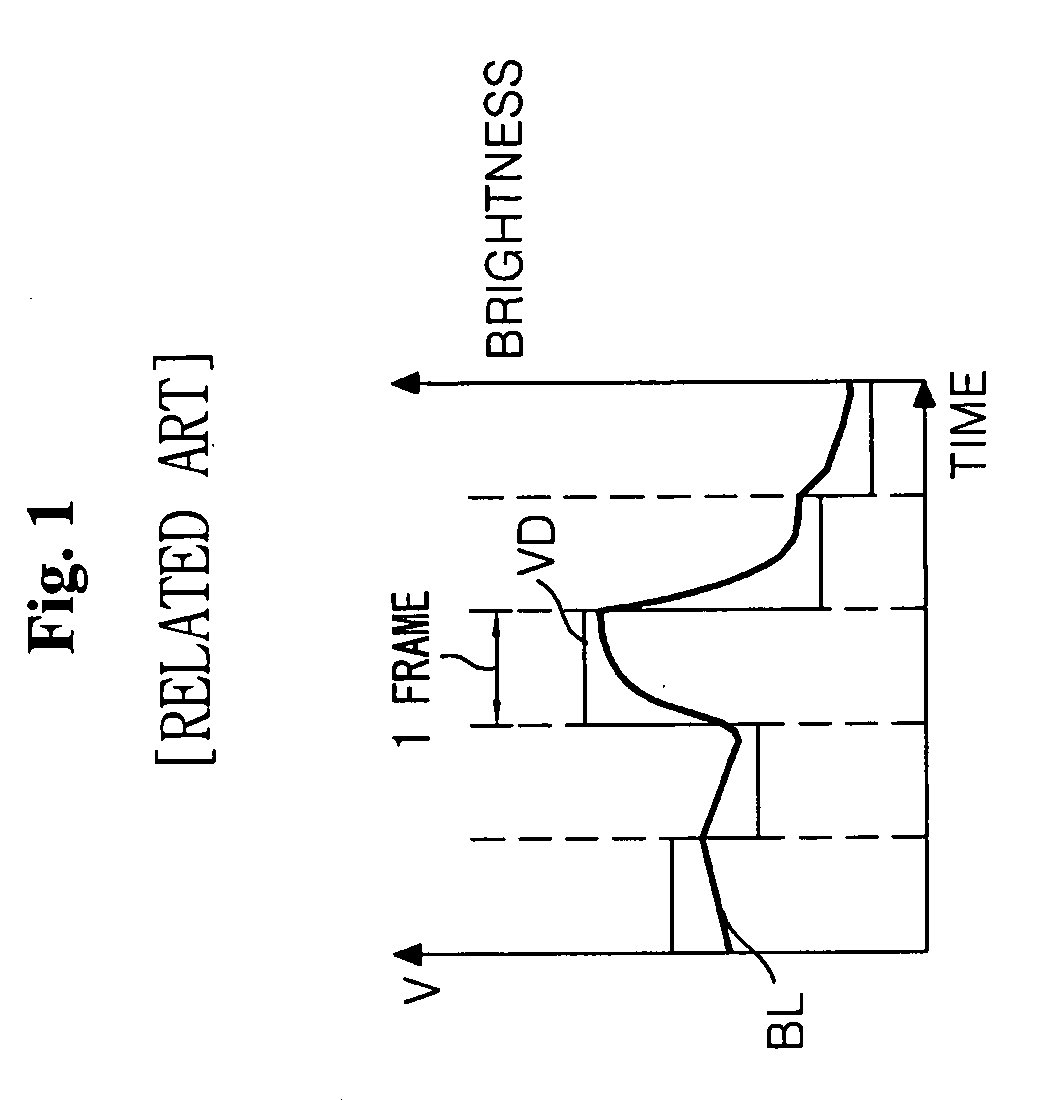

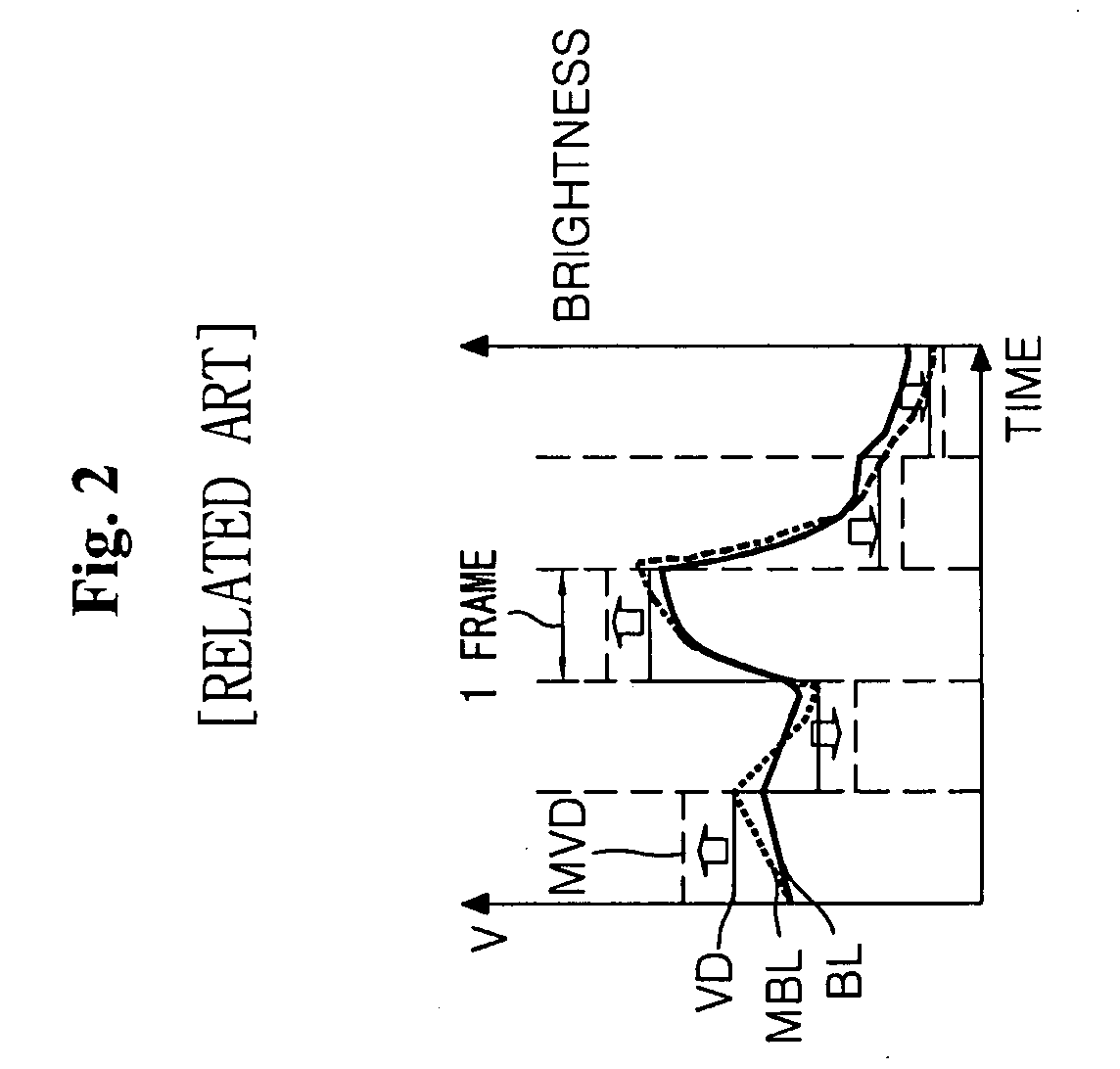

Liquid crystal display and driving method thereof

ActiveUS20090002292A1Heat generation is minimizedImprove responsivenessStatic indicating devicesNon-linear opticsLiquid-crystal displayData selection

A liquid crystal display device includes a data transition part to compare a number of transitions between a previous data and a current data to selectively invert the current data and to generate a reverse signal, a memory to store the data from the data transition part and to output the stored data as the previous frame data, a data reverse transition part to reversely convert the data from the memory using the reverse signal, a lookup table to compare the current data and the previous frame data reversely converted by the data reverse transition part to select a modulated data, and a display drive circuit to display the data from the lookup table on a liquid crystal display panel.

Owner:LG DISPLAY CO LTD

Video surveillance camera

ActiveUS7362372B2Minimizing heat generationMinimizing physical contactTelevision system detailsColor television detailsVideo monitoringSurveillance camera

Owner:PELCO INC

Abrasive tools having a permeable structure

ActiveUS7722691B2Improve performanceHighly porous and permeable structurePigmenting treatmentOther chemical processesThree dimensional shapeAgglomerate

Owner:SAINT GOBAIN ABRASIVES INC

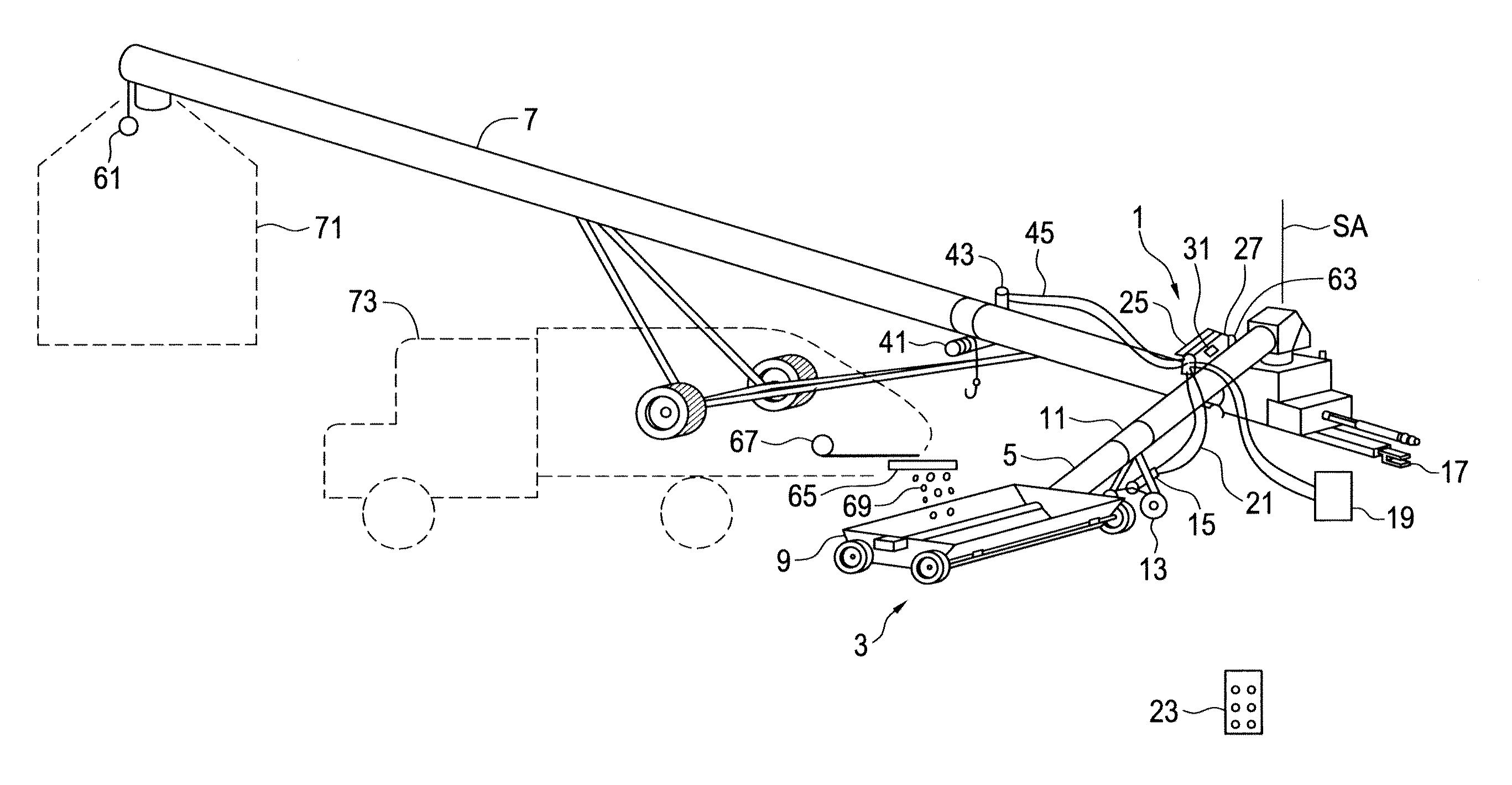

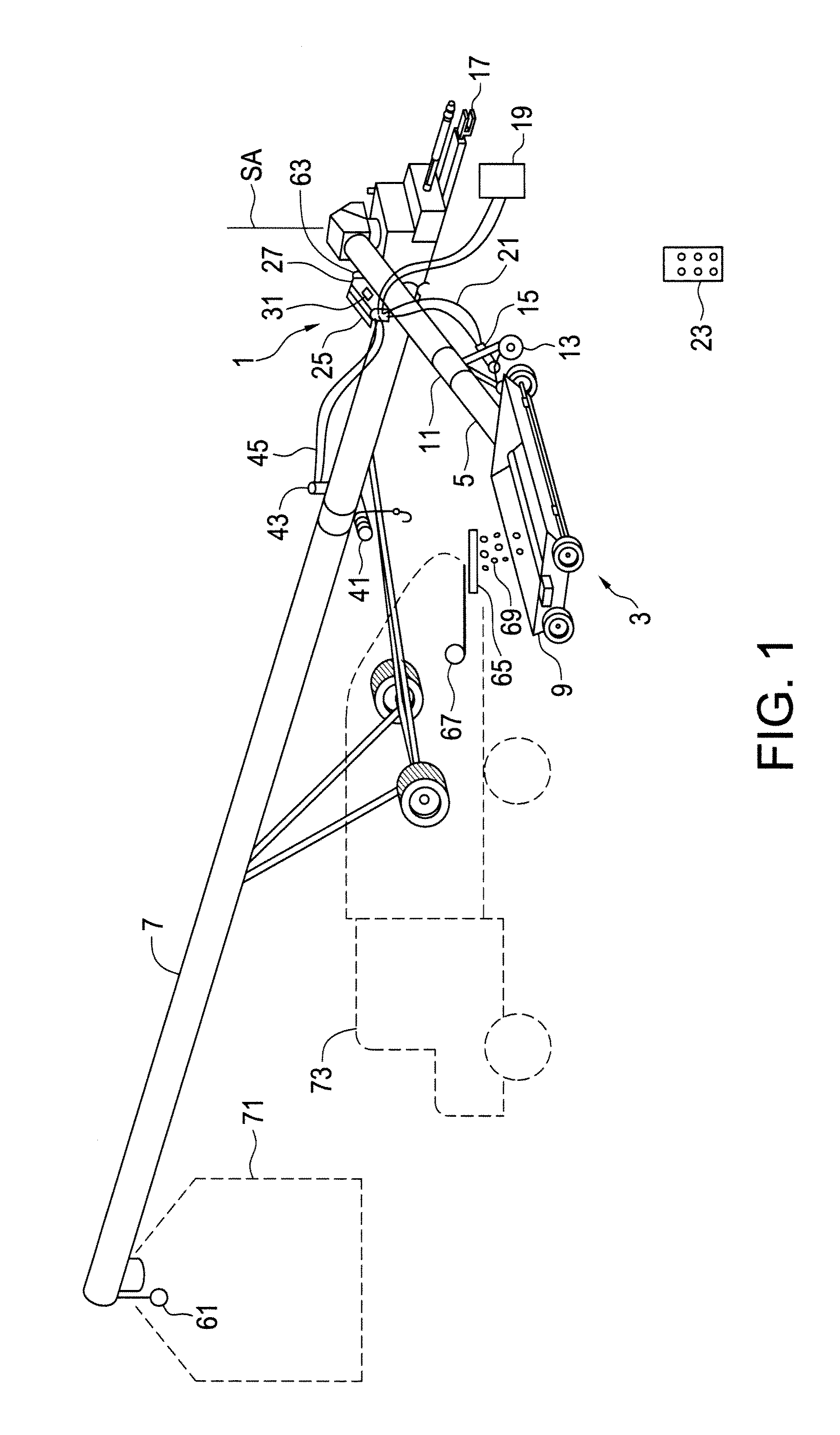

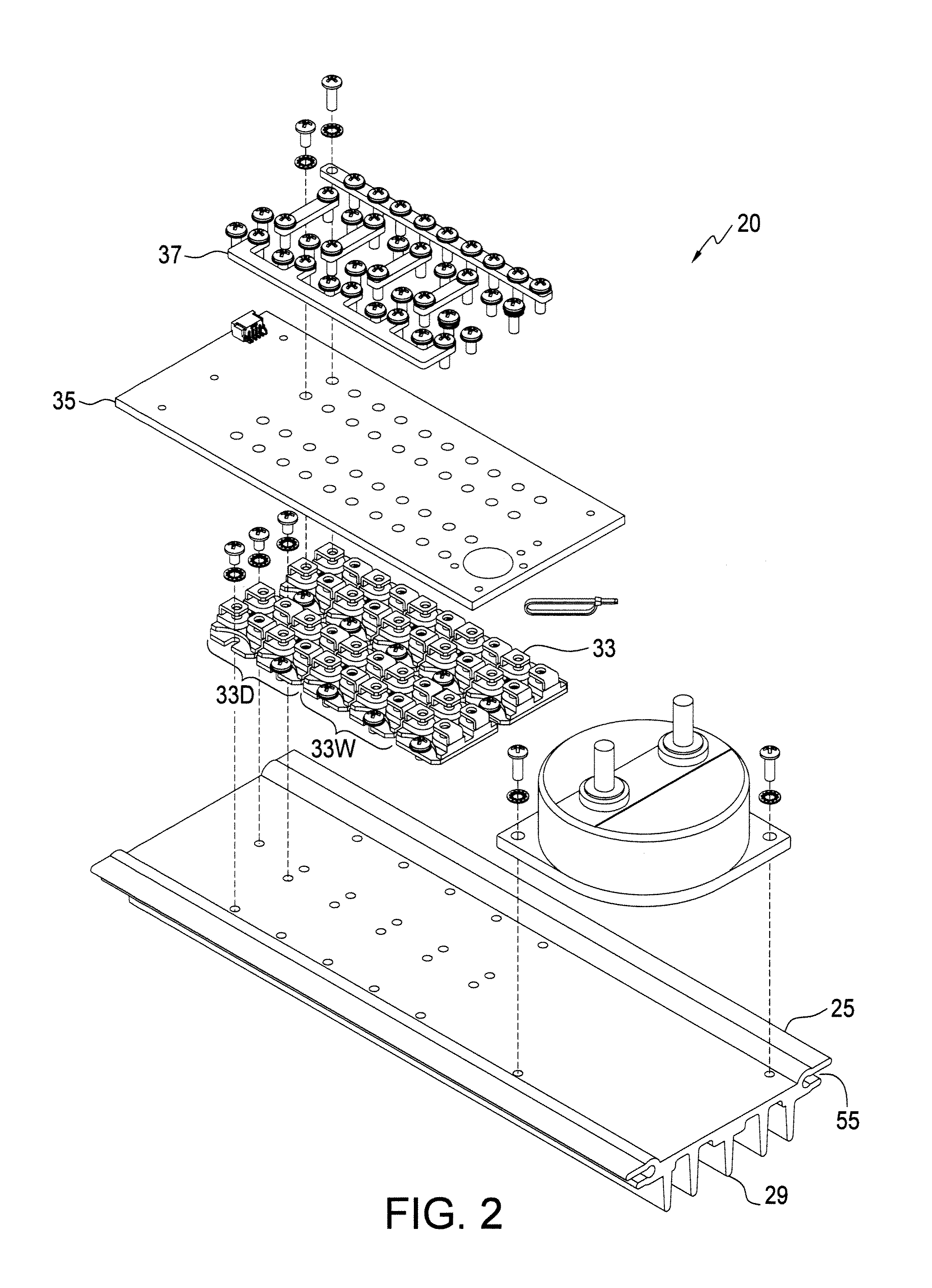

Electric mover for swing away conveyor

InactiveUS20140343723A1Minimizing heat generationHeat dissipationDigital data processing detailsControl devices for conveyorsElectricityDrive wheel

An electric drive apparatus for attachment to a swing away auger assembly includes a bracket and drive wheel adapted to be attached to the assembly and configured to pivot an attached swing auger. An electric drive motor rotates the drive wheel, and a control circuit assembly is connected to the electric drive motor by drive wires. The control circuit assembly is operative to activate the electric drive motor in response to forward, stop, and reverse drive signals received from a remote control unit. The control circuit is mounted to a heat sink plate such that heat generated in the control circuit assembly is conducted to the heat sink plate, and the heat sink plate forms an external wall of a circuit housing enclosing the control circuit assembly. The circuit housing is sealed. A bin spill prevention system has a sensor that shuts a discharge gate directing material into the conveyor.

Owner:BRANDT AGRI PROD LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com