Vehicle equipped with motor and inverter

a technology of inverter and motor, which is applied in the direction of electric generator control, dynamo-electric converter control, dynamo-electric gear control, etc., can solve the problems of increasing the conduction loss of inverter, increasing the heat generation amount, and not being able to sufficiently increase the carrier frequency fc relative to output frequency fv, etc., to reduce noise, reduce cost, and improve fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

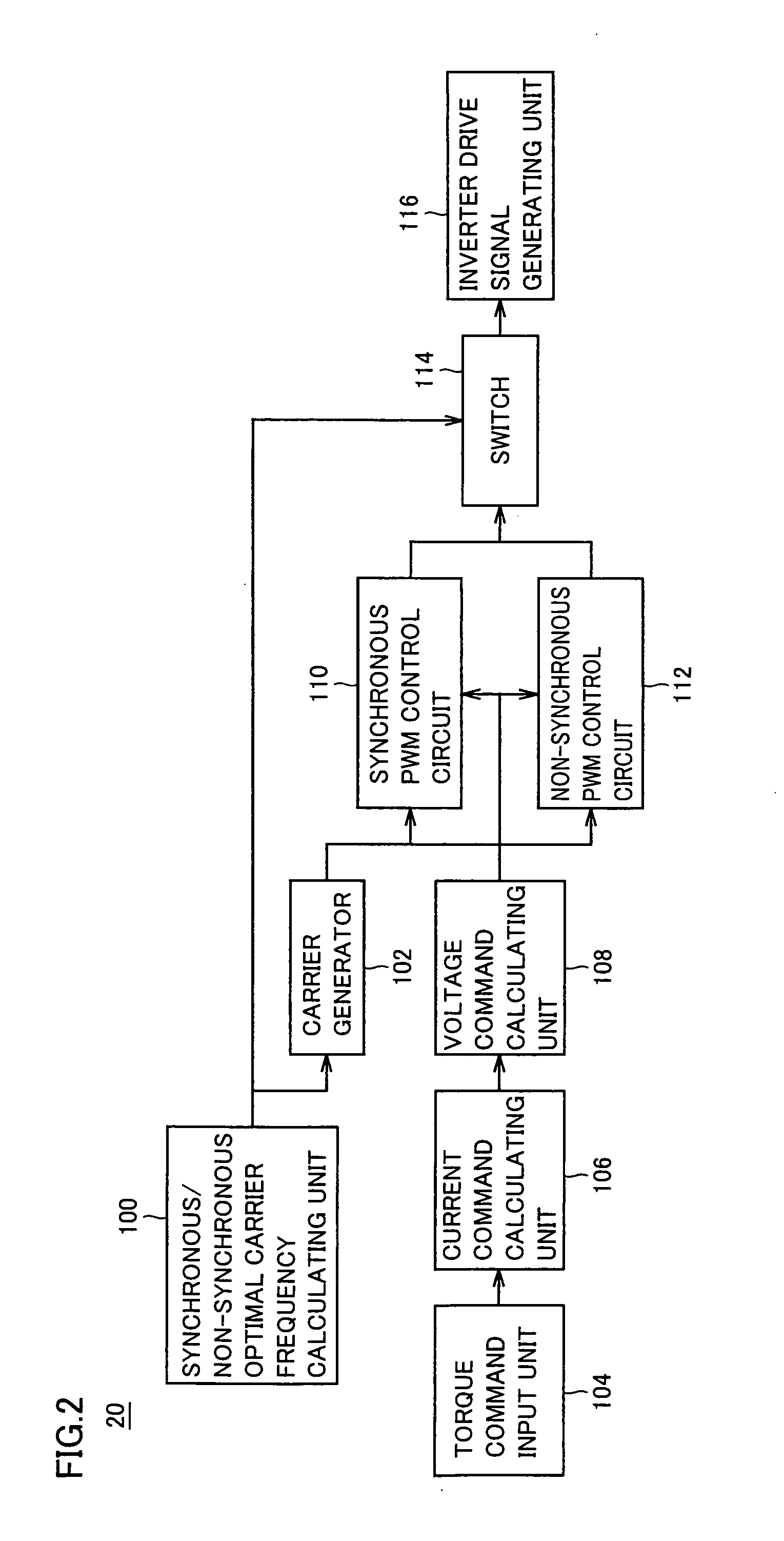

first embodiment

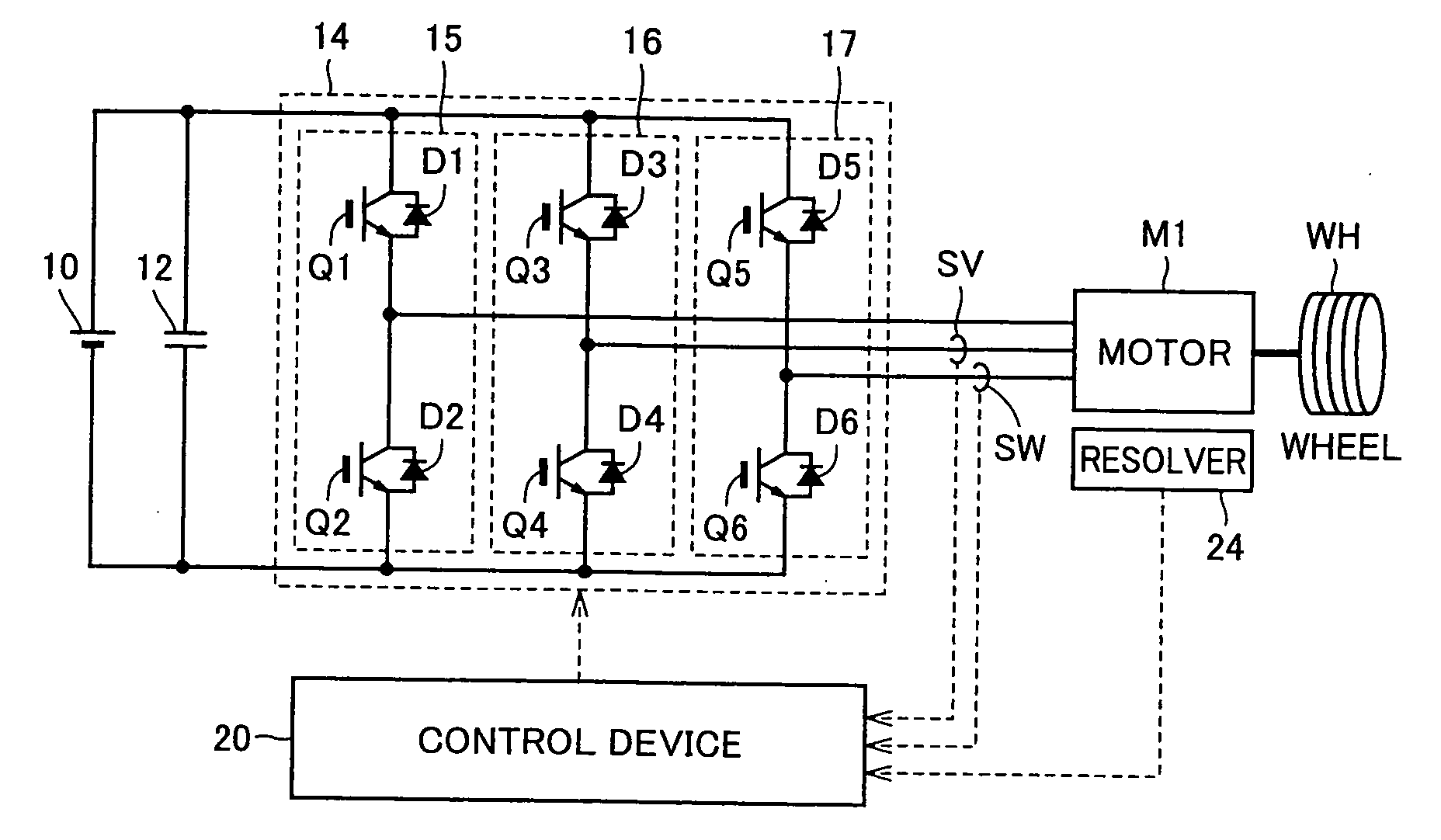

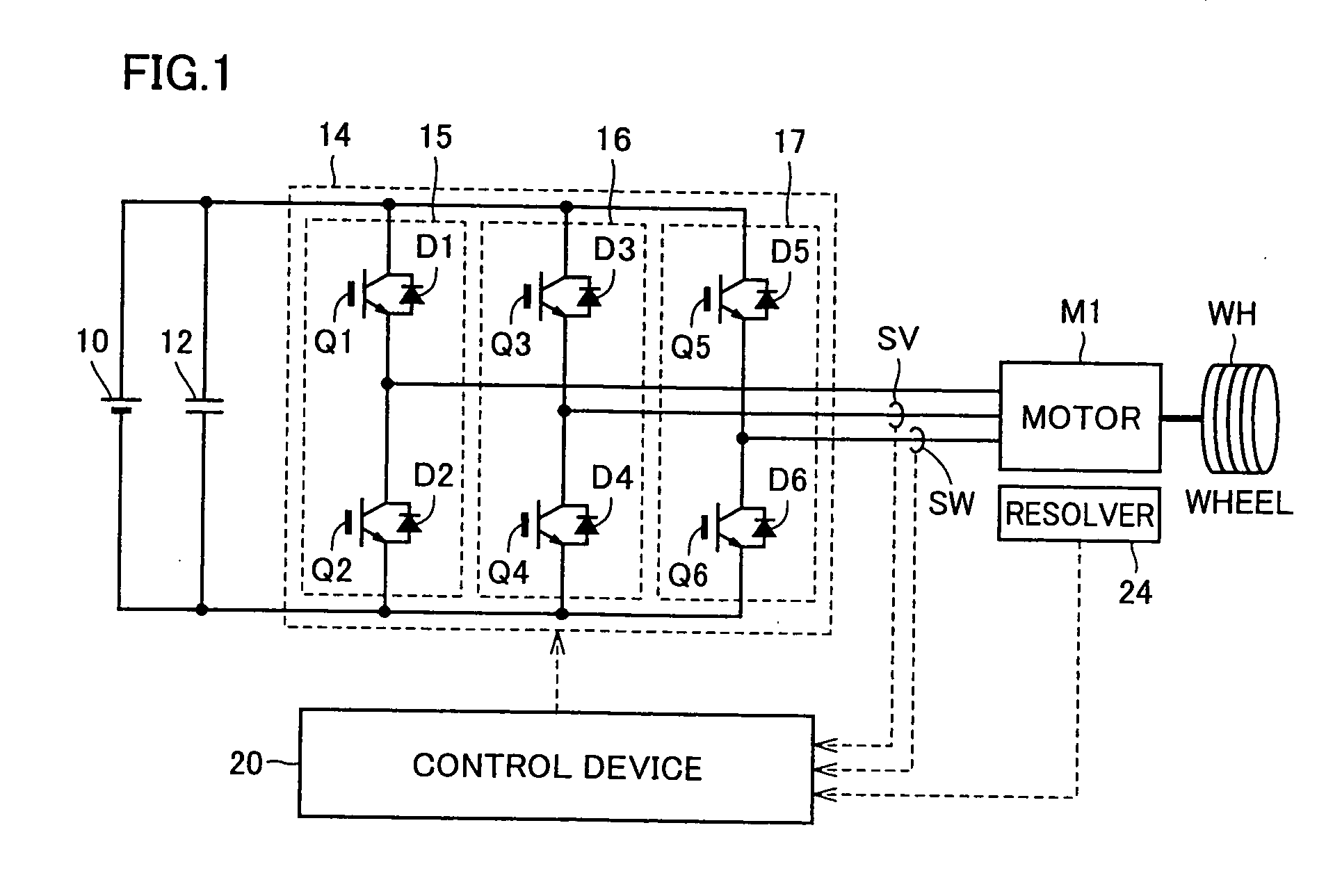

[0035]FIG. 1 is a circuit diagram showing a configuration of a motor drive device used in the present invention.

[0036]With reference to FIG. 1, this motor drive device includes a DC power supply 10, a capacitor 12, an inverter 14, current sensors SV and SW, a motor M1, a resolver 24, and a control device 20.

[0037]The DC power supply may be made of a secondary battery such as a nickel hydride battery, a lithium ion battery and a lead battery and the like. A large-capacity capacitor or a fuel cell may also be used together with or instead of the secondary battery.

[0038]Inverter 14 receives power supply voltage from DC power supply 10 and drives AC motor M1. Preferably, inverter 14 performs a regenerative operation at the time of braking motor M1 and returns electric power generated in AC motor M1 to DC power supply 10.

[0039]Inverter 14 includes a U phase arm 15, a V phase arm 16 and a W phase arm 17. U phase arm 15, V phase arm 16 and W phase arm 17 are connected in parallel between o...

second embodiment

[0080]In the first embodiment, the control is performed by focusing on a point of switching between the synchronization of the carrier frequency with the voltage command value and the non-synchronization thereof In a second embodiment, the control is performed by focusing on a loss of the inverter and a total loss of the motor and the inverter.

[0081]That is, in the second embodiment, the carrier frequency is determined so that the inverter loss is minimized in the region of a large electric current with high heat generation of the inverter, and the carrier frequency is determined so that the total loss of the motor and the inverter is minimized in other regions.

[0082]FIG. 9 is a diagram showing changes of the inverter loss and the total loss in a case where the carrier frequency is changed.

[0083]In FIG. 9, the carrier frequency is indicated by a lateral axis and the losses are indicated by a vertical axis. When the carrier frequency is increased, the inverter loss is increased in ac...

third embodiment

[0101]A third embodiment is to combine the first and second embodiments.

[0102]FIG. 12 is a diagram for illustrating carrier switching control executed in the third embodiment.

[0103]With reference to FIG. 12, a region A7 is a region where the IGBT device is driven with the minimum-required pulse number in the synchronous PWM control so as to protect the inverter from the overheat. A region A8 is a region where the IGBT device is driven with using the carrier frequency to minimize the total loss of the motor and the inverter so as to improve the fuel consumption with the best efficiency. A region A9 is a region where the torque is small, that is, acceleration and deceleration are not executed very often, and also a region where the carrier frequency to minimize the noise inside the vehicle is selected.

[0104]FIG. 13 is a flowchart for illustrating control executed in the third embodiment. Processing of this flowchart is invoked from the main routine of the traveling control of the vehi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com