Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Lower specific capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium-sulphur battery anode material and preparation method thereof

InactiveCN102683659AImprove cycle performanceIncrease contentCell electrodesPorosityComposite electrode

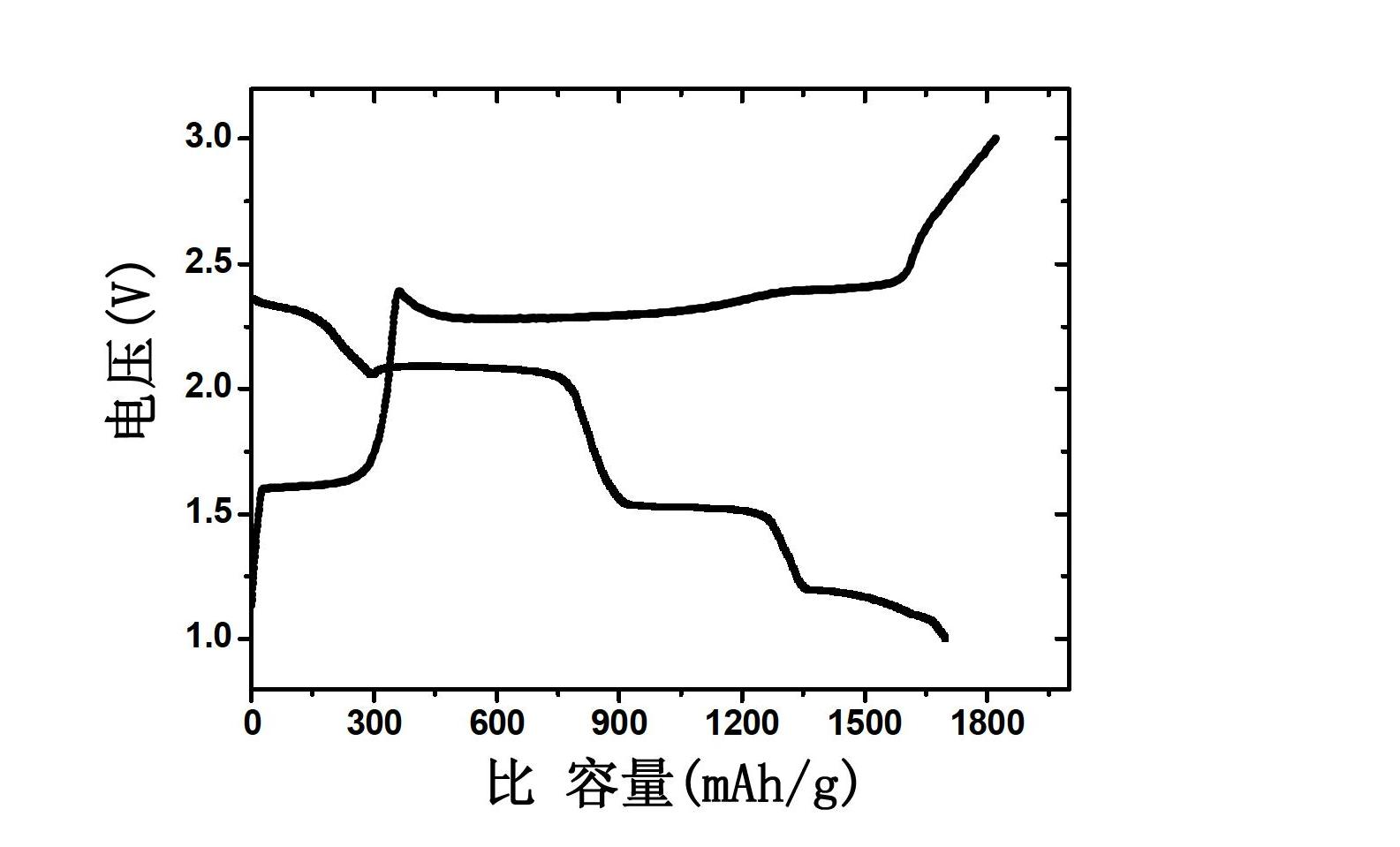

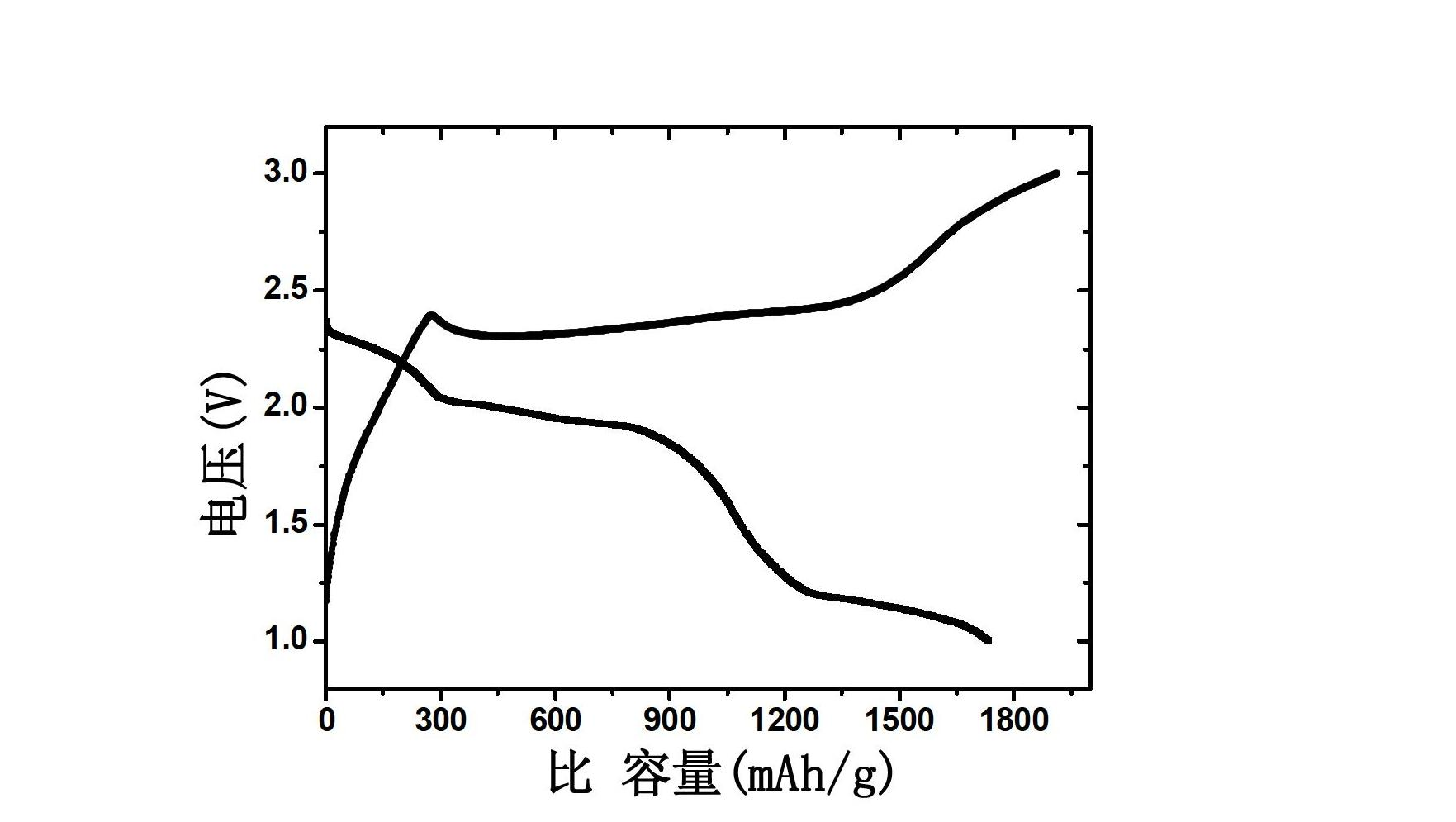

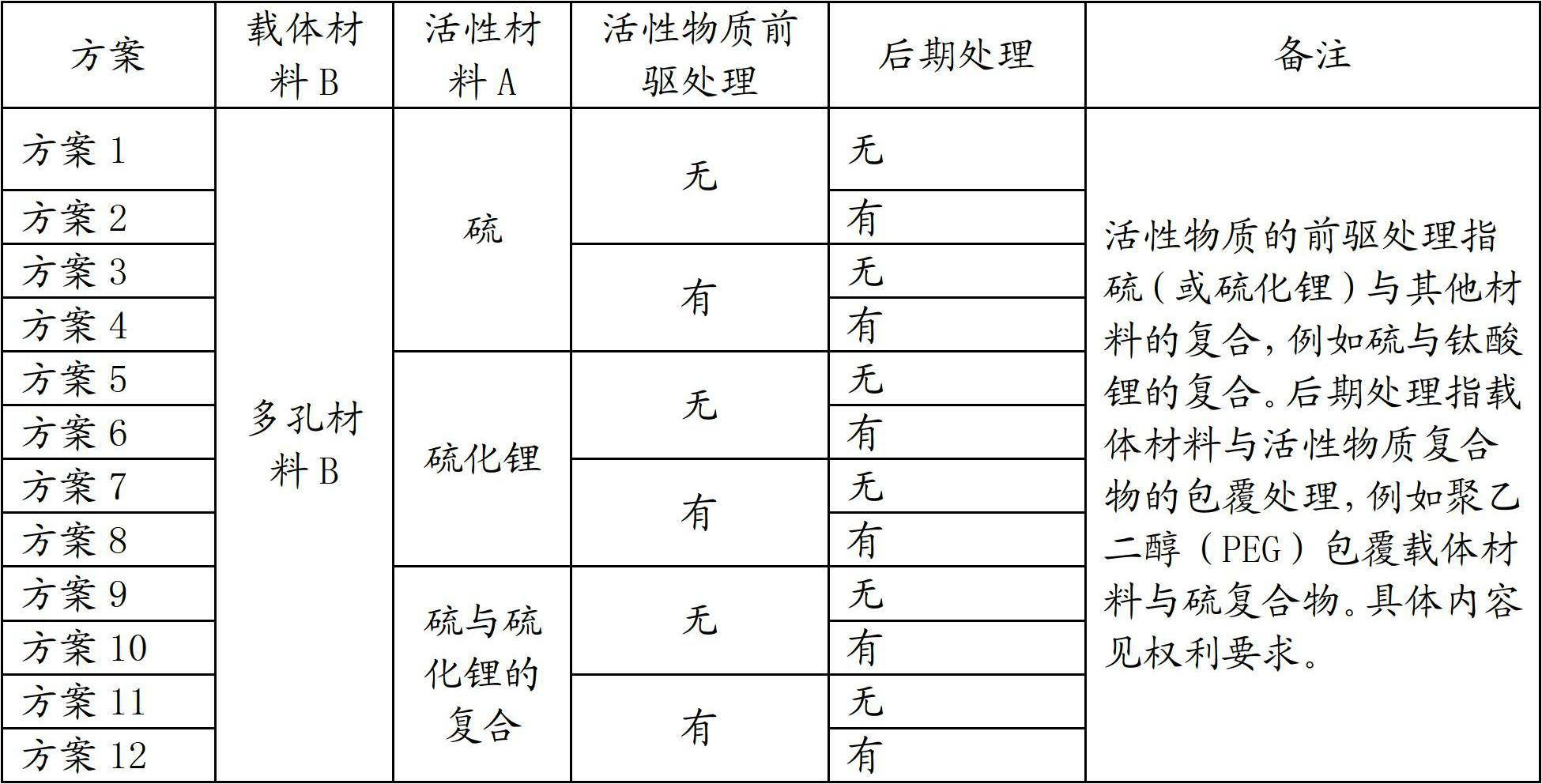

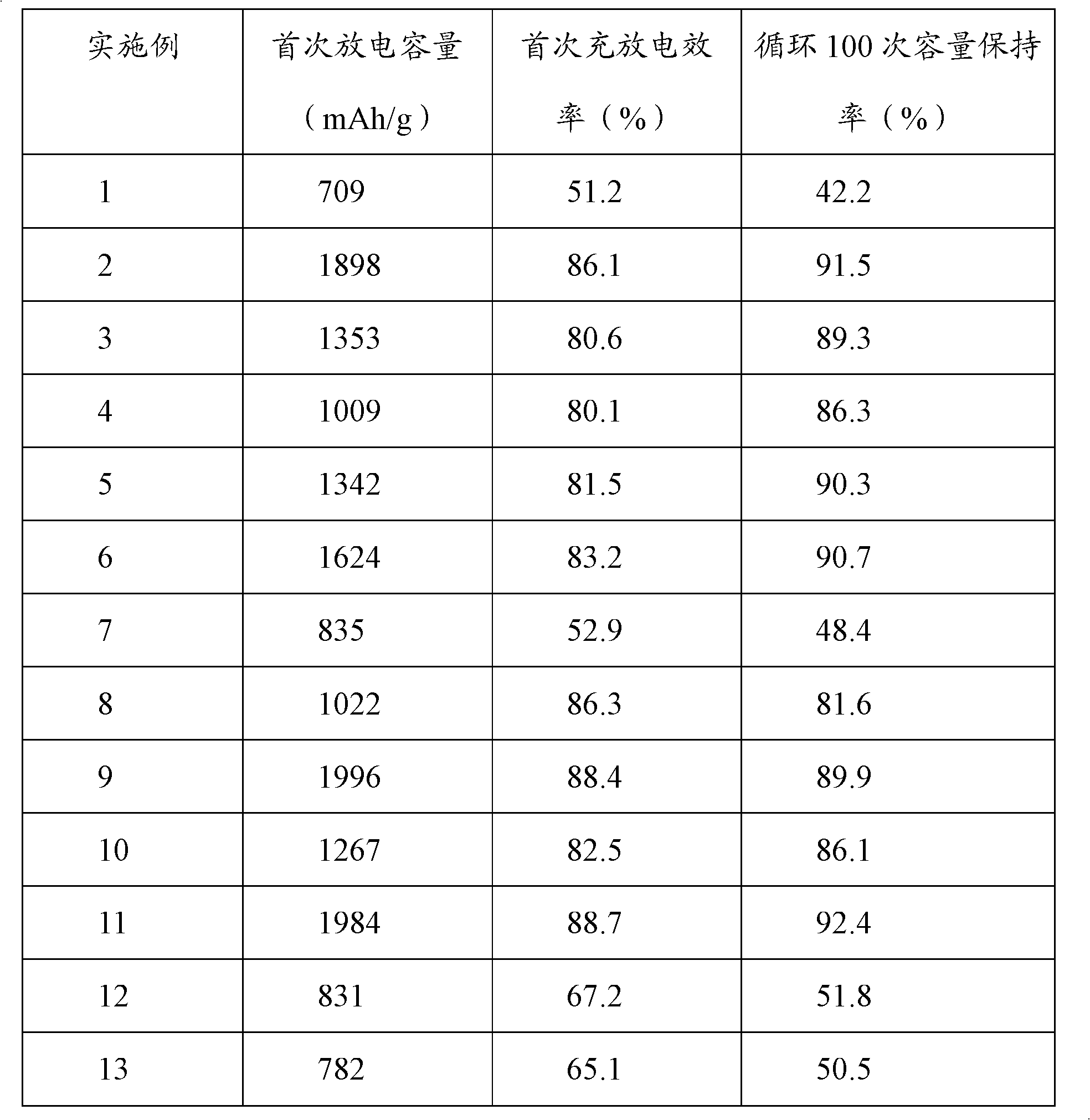

The invention discloses a lithium-sulphur battery anode material, which adopts the technical scheme that elemental sulphur or lithium sulfide is loaded into one or various carrier materials to form a novel composite electrode for a lithium-sulphur battery. The carrier material (s) is (are) characterized in that within the operation voltage range of the elemental sulphur or the lithium sulfide, the carrier material (s) is (are) also provided with electrochemical activity, that is, is (are) provided with considerable lithium storage capacity, and simultaneously has (have) characteristics of high specific surface and high porosity. The invention also discloses a preparation method of the lithium-sulphur battery anode material. The system of the electrode solves problems that the carrier material of a conventional lithium-sulphur battery anode material is not provided with the electrochemical activity and is low in composite material specific capacity within the operation voltage range of the elemental sulphur or the lithium sulfide, and the integral specific capacity of the composite electrode and the energy density of the lithium-sulphur battery are improved.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

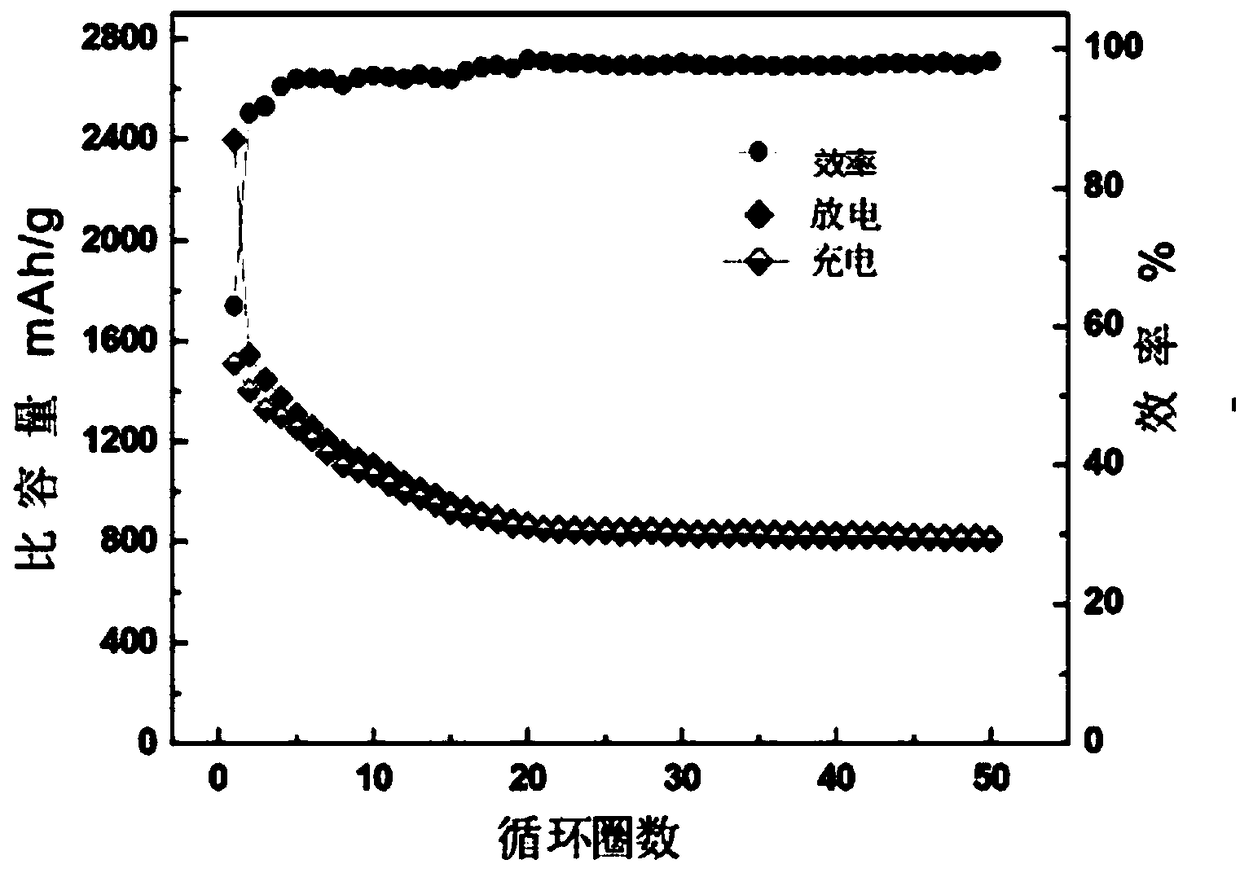

Sulphidepolymer coated sulfur / carbon composite material and preparation method thereof

InactiveCN104241612AIncrease specific volumeImprove cycle stabilityCell electrodesLi-accumulatorsCarbon compositesHigh rate

A sulfide polymer coated sulfur / carbon composite material and a preparation method thereof. The composite material includes composite containing carbon with high surface area and sulfur and a sulfide polymer cladding layer. The preparation method is as below: conducting ball-milling on sulfur and carbon with high surface area in a ball mill and conducting heat treatment on the product under protective atmosphere; dispersing the product in a solution containing polymer monomers and adding a initiator to initiate polymerization; filtering, washing and drying; and conducting heat treatment on the product under protective atmosphere, so as to obtain the sulfide polymer coated sulfur / carbon composite material. The composite material provided by the invention as an anode material for lithium sulfur battery has the following advantages: high surface area carbon material can improve the electronic conductivity of sulfur, and inhibit polysulfide erosion; the sulfide polymer coating layer not only inhibits the loss of polysulfide but also provides part of the capacity. Lithium sulfur battery composed of the composite material has the advantages of high specific capacity, long service life, high rate capability, simple preparation and low cost, and has good application prospect.

Owner:中科派思储能技术有限公司

Silicon-based cathode composite material for lithium ion battery and preparation method thereof

ActiveCN102324501ARelief of mechanical stressEliminate volume effectCell electrodesSodium-ion batteryLithium-ion battery

The invention discloses a silicon-based cathode composite material for a lithium ion battery and a preparation method thereof. The cathode composite material is a Si / CuOx / C composite material (0<=x<=1) with a porous structure. Silicon with a porous structure is used as a base, and CuOx particles are inserted in the pores, and carbons with different forms are distributed on a surface and pore walls of the silicon-based material. The preparation method of the cathode composite material comprises steps that silicon material realizes pore-forming through an in situ catalytic reaction between silicon and halogenated hydrocarbon, and reaction condition parameters are regulated to control pore size, distribution and amount of porosity of the silicon material; a post-modification technology is employed to carry out modifications on the surface and the pore walls of the porous silicon, so as to obtain the Si / CuOx / C composite material with a porous structure. The porous silicon-based cathode composite material has low production costs, simple process and no pollution, and is suitable for industrialized production; besides the porous silicon-based cathode composite material has high charge and discharge capacity, small initial irreversible capacity and good cycle performance.

Owner:河北中芯凤华科技发展有限公司

Lithium NCM (nickel cobalt manganese) material and preparation method thereof

InactiveCN107180963AReduce solubilityChange the band structureCell electrodesSecondary cellsManganeseCobalt

The invention discloses a lithium NCM (nickel cobalt manganese) material. The lithium NCM material is prepared by doping Mg (magnesium), Al (aluminum) or Ti (titanium) and F (fluorine) into a 811 type lithium NCM cathode material. The lithium nickel manganese cobalt material has the advantages that by simultaneously doping Mg, Al or Ti and F into the 811 type NCM electrode material, the rate discharge property and specific capacity of the material are effectively improved; the corrosion of HF (hydrogen fluoride) to the material is effectively inhibited, the dissolving of Co is reduced, and the structure stability and thermal stability of the material are greatly improved.

Owner:四川新锂想能源科技有限责任公司

Method for improving electrochemical performance of positive material LiNi0.5Mn1.5O4 of lithium ion battery

InactiveCN101859895AReduce internal volumeImprove electrochemical performanceCell electrodesElectricityFree cooling

The invention discloses a method for improving the electrochemical performance of a positive material LiNi0.5Mn1.5O4 of a lithium ion battery, and belongs to the field of the positive material of the lithium ion battery. The method reduces the using amount of Cr<3+> for improving the electrochemical performance of LiNi0.5Mn1.5O4 by a conventional bulk phase doping method, reduces the environmental pollution and the human health hazard caused thereby and eliminates the hidden trouble of striping of a covering layer existing in a covering modification method. The method comprises the following steps of: dissolving chromium nitrate in aqueous solution of ethanol; adding LiNi0.5Mn1.5O4 into the solution and dispersing and stirring the mixture until the liquid phase is eliminated; and calcining the mixture and naturally cooling the mixture to obtain the positive material LiNi0.5Mn1.5O4 of the lithium ion battery with high electrochemical performance. The method improves the electrochemical performance of the positive material LiNi0.5Mn1.5O4 of the lithium ion battery, reduces the using amount of the chromium salt, ensures no obvious boundary between the doped Cr<3+> layer and the body of the positive material, reduces the environmental pollution, and also reduces the hazard to the human health.

Owner:HARBIN INST OF TECH

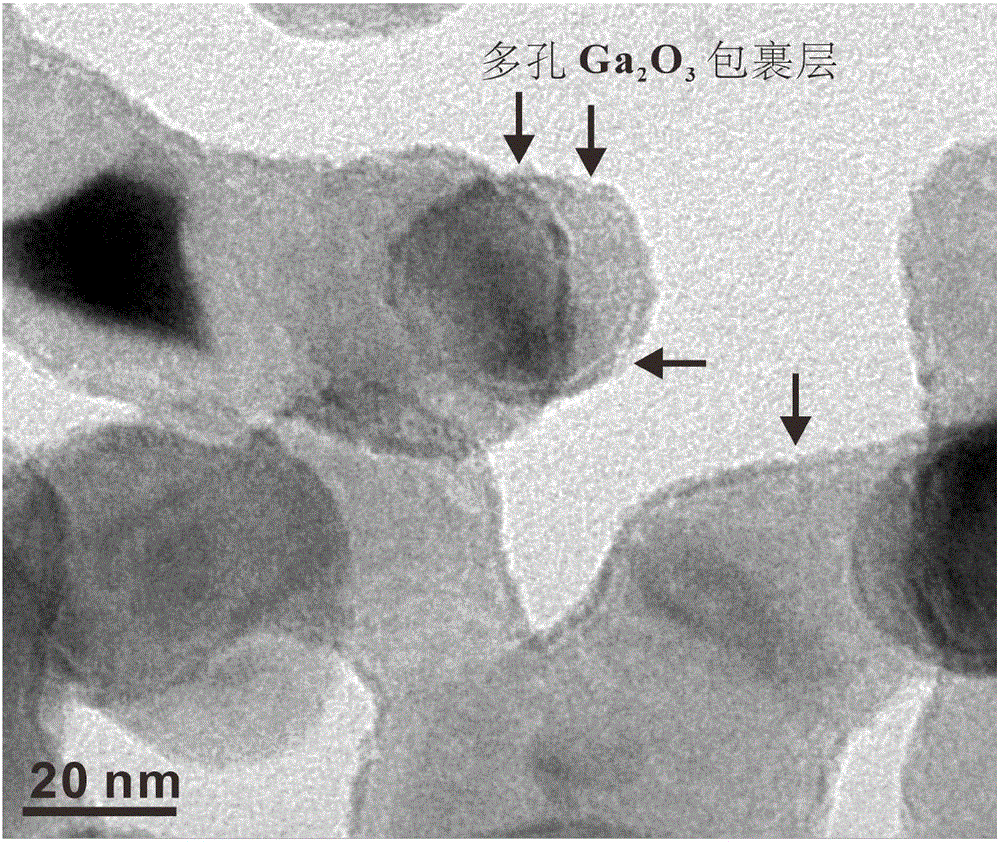

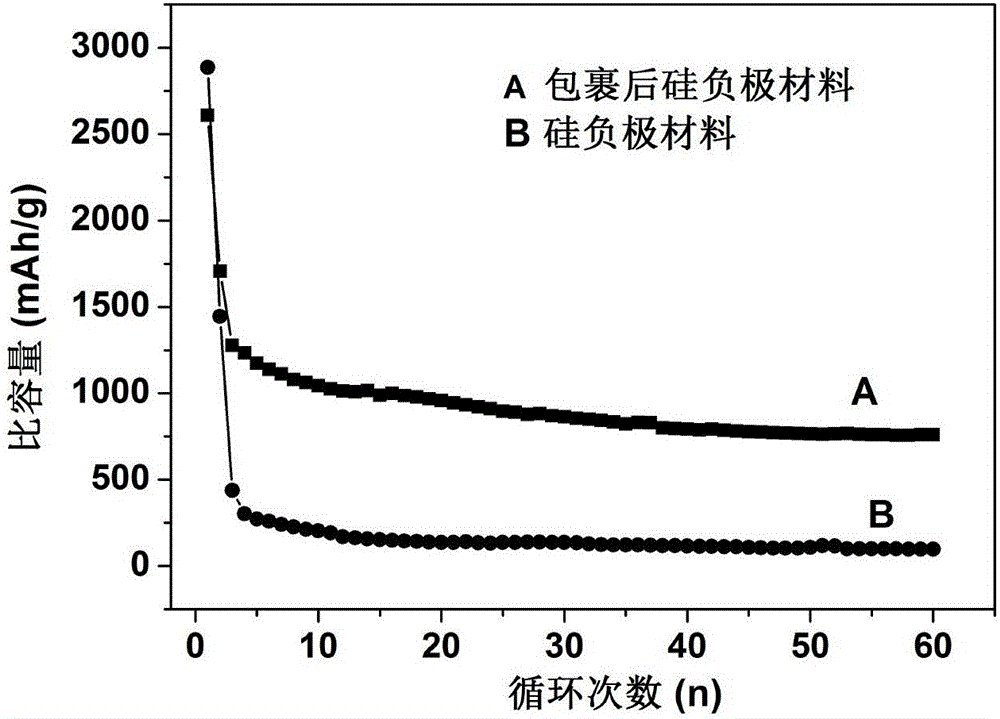

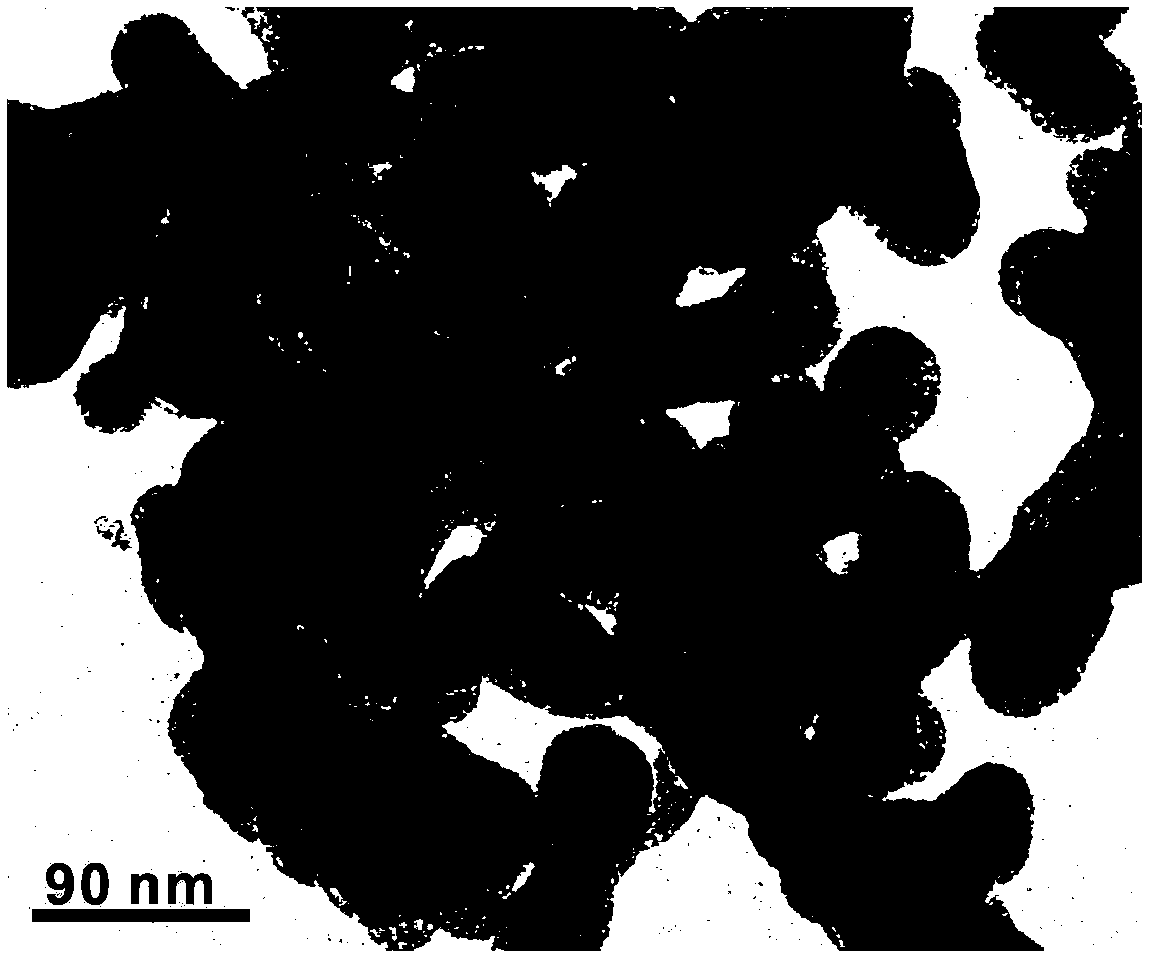

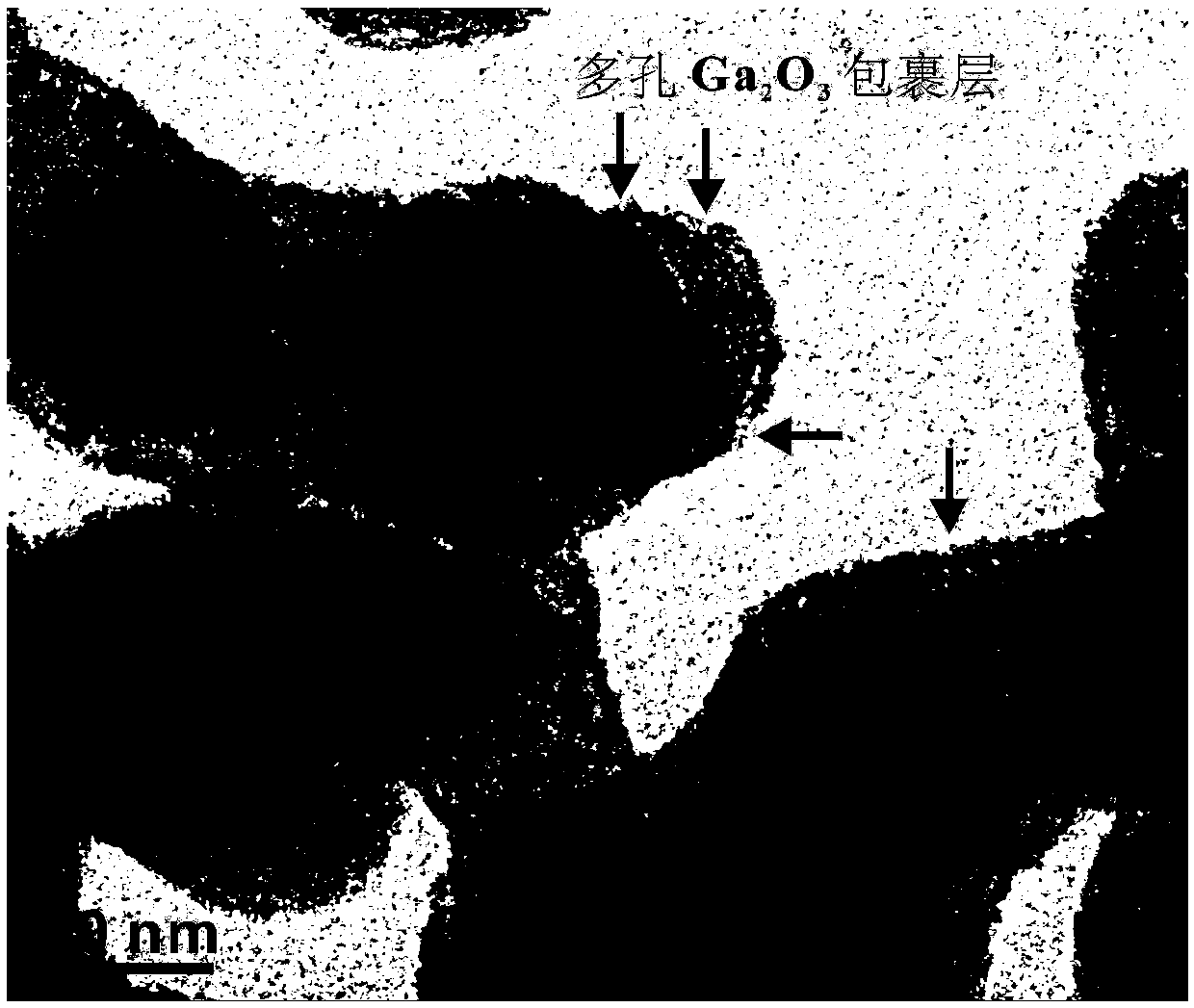

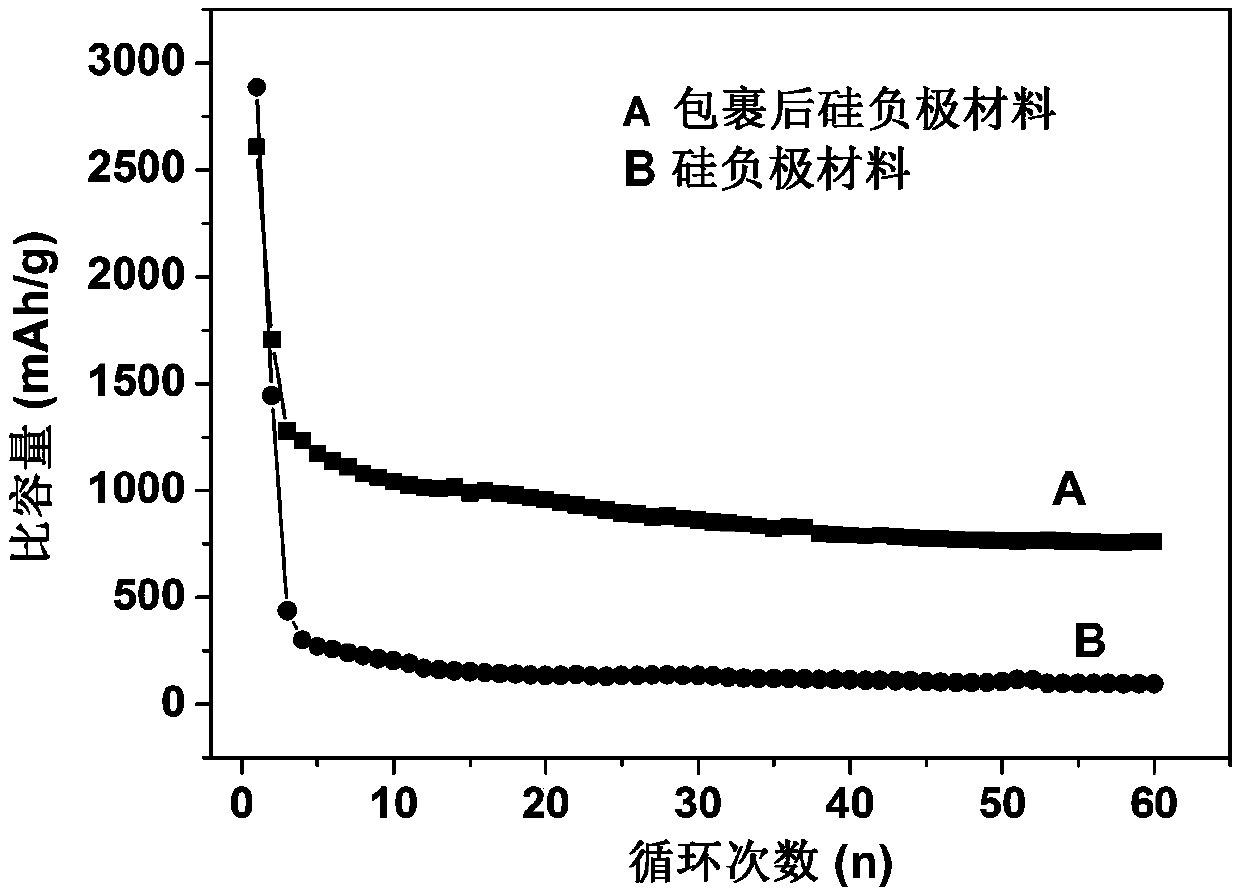

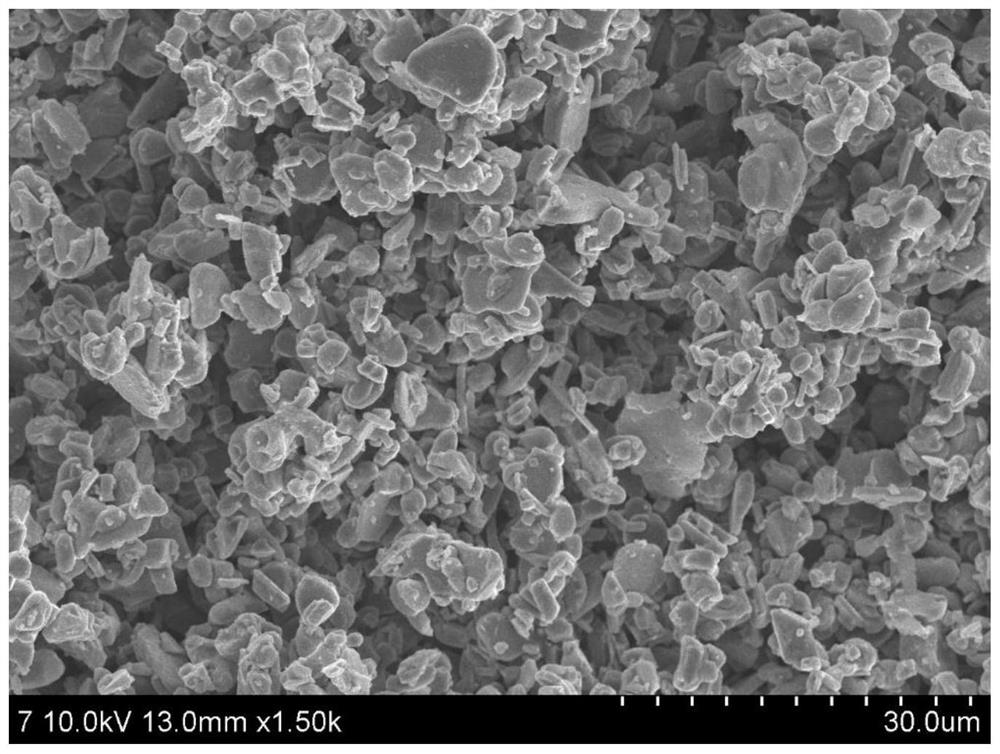

Preparation method of porous oxide-coated battery silicon anode material

ActiveCN106784763ALower specific capacityReduce the numberCell electrodesGas phaseSodium-ion battery

The invention provides a preparation method of a porous oxide-coated battery silicon anode material and relates to the technical field of preparation of lithium ion battery anode materials. The preparation method provided by the invention comprises the following steps: performing silicon anode material drying treatment; performing surface passivation treatment on a silicon anode material with ethyl alcohol; performing set cyclic cycle deposition in a gas-phase atomic layer deposition chamber to obtain the porous oxide-coated battery silicon anode material. The preparation method provided by the invention is simple and good in repeatability; the prepared lithium ion battery silicon anode material not only has large specific capacity, but also can inhibit the expansion of the silicon anode material in the charting and the discharging processes of a lithium ion battery, so that the lithium ion battery silicon anode material has good charging and discharging cycle performance.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

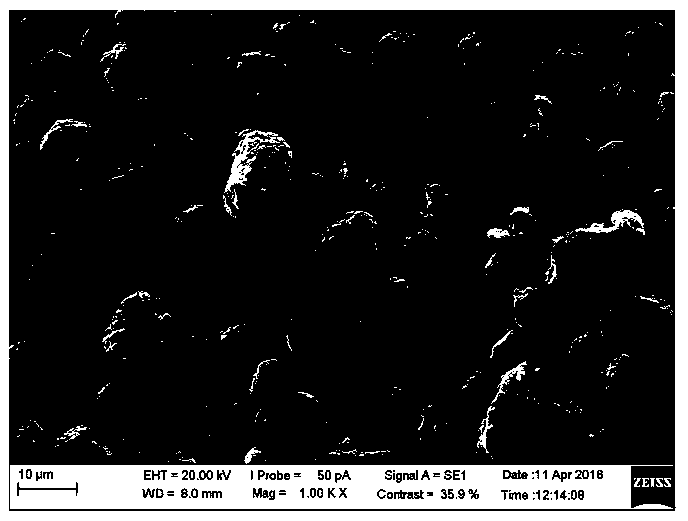

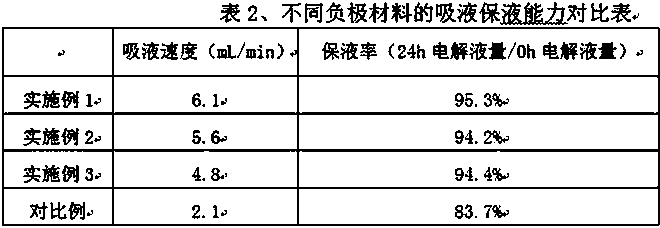

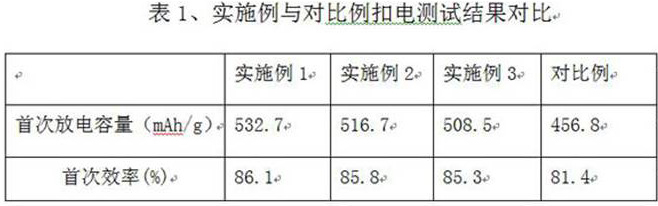

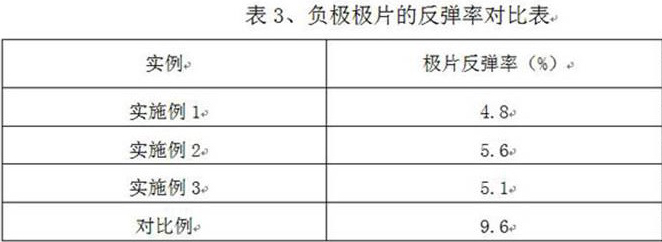

Sulfur/nitrogen/silicon co-doped graphite composite negative electrode material and preparation method thereof

ActiveCN109659546AImprove consistencyReduce bloatMaterial nanotechnologyCell electrodesAbsorption capacityCarbonization

The invention relates to a sulfur / nitrogen / silicon co-doped graphite composite negative electrode material and a preparation method thereof, and belongs to the technical field of the technical field of lithium ion battery material preparation. The technical solutions are as follows: (1) weighing 1 to 5 g of sulfur-containing organic compounds and 1 to 5 g of nitrogen-containing organic compounds,adding the compounds to 500 g of organic solvent, stirring evenly, adding 100 g of graphite into the solution, stirring evenly, filtering, then transferring the solution to a tube type furnace, raising the temperature to 200-500 DEG C under an inert atmosphere, then keeping the temperature for 1 to 6 h, and reducing the temperature to the room temperature in an inert atmosphere to obtain a graphite composite material A; (2) implanting the nano-silica in the surface layer of the graphite composite material A through high-speed particle beam bombardment and then carrying out carbonization to obtain the sulfur / nitrogen / silicon co-doped graphite composite anode material. According to the invention, the specific capacity of the graphite material is improved by doping sulfur in the graphite material, and nitrogen doping is carried out to improve the conductivity of the sulfur; the expansion of the material can be reduced; and the liquid absorption capacity of the material can be improved.

Owner:CHENGDU EMINENT NEW ENERGY TECH CO LTD

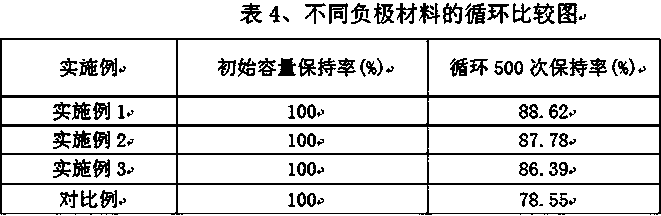

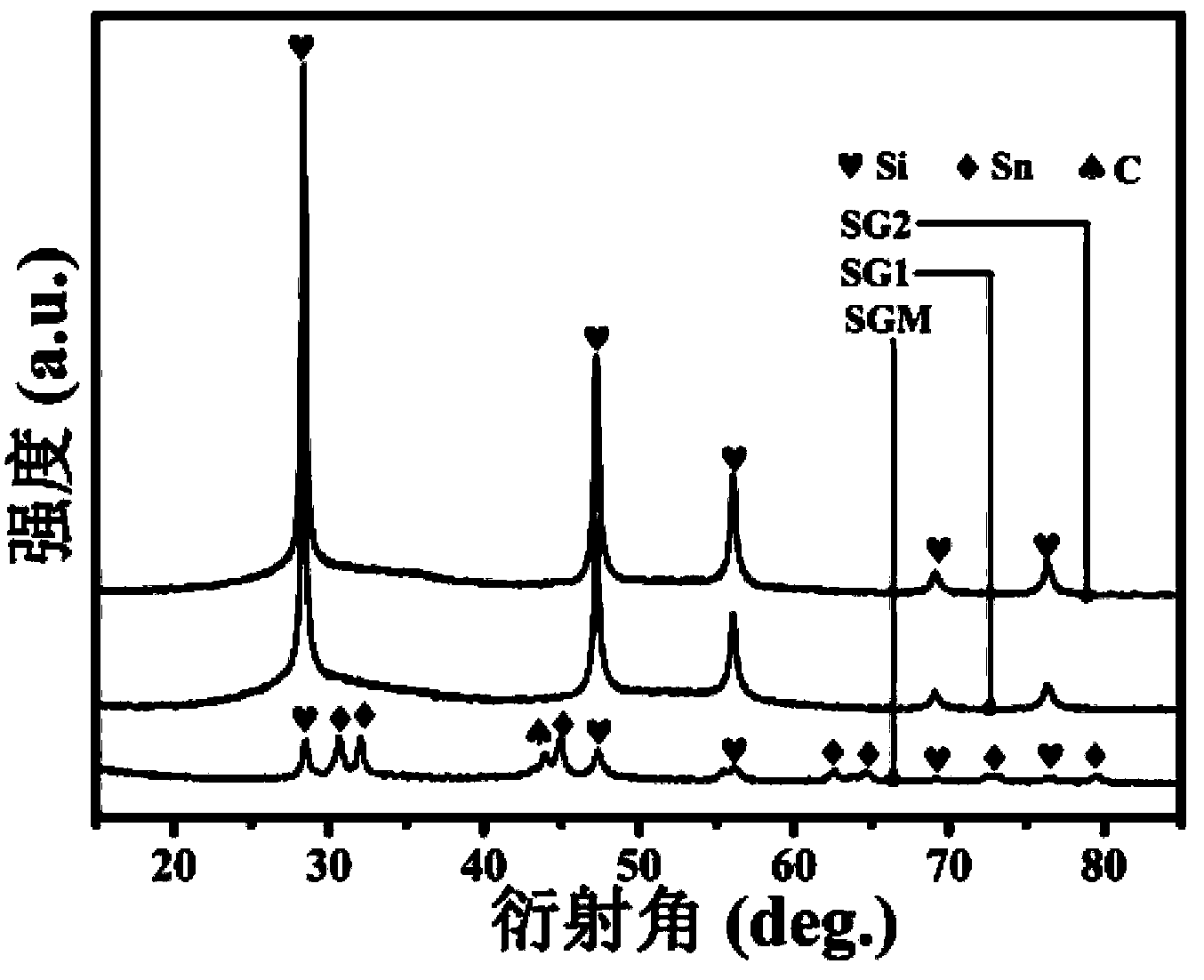

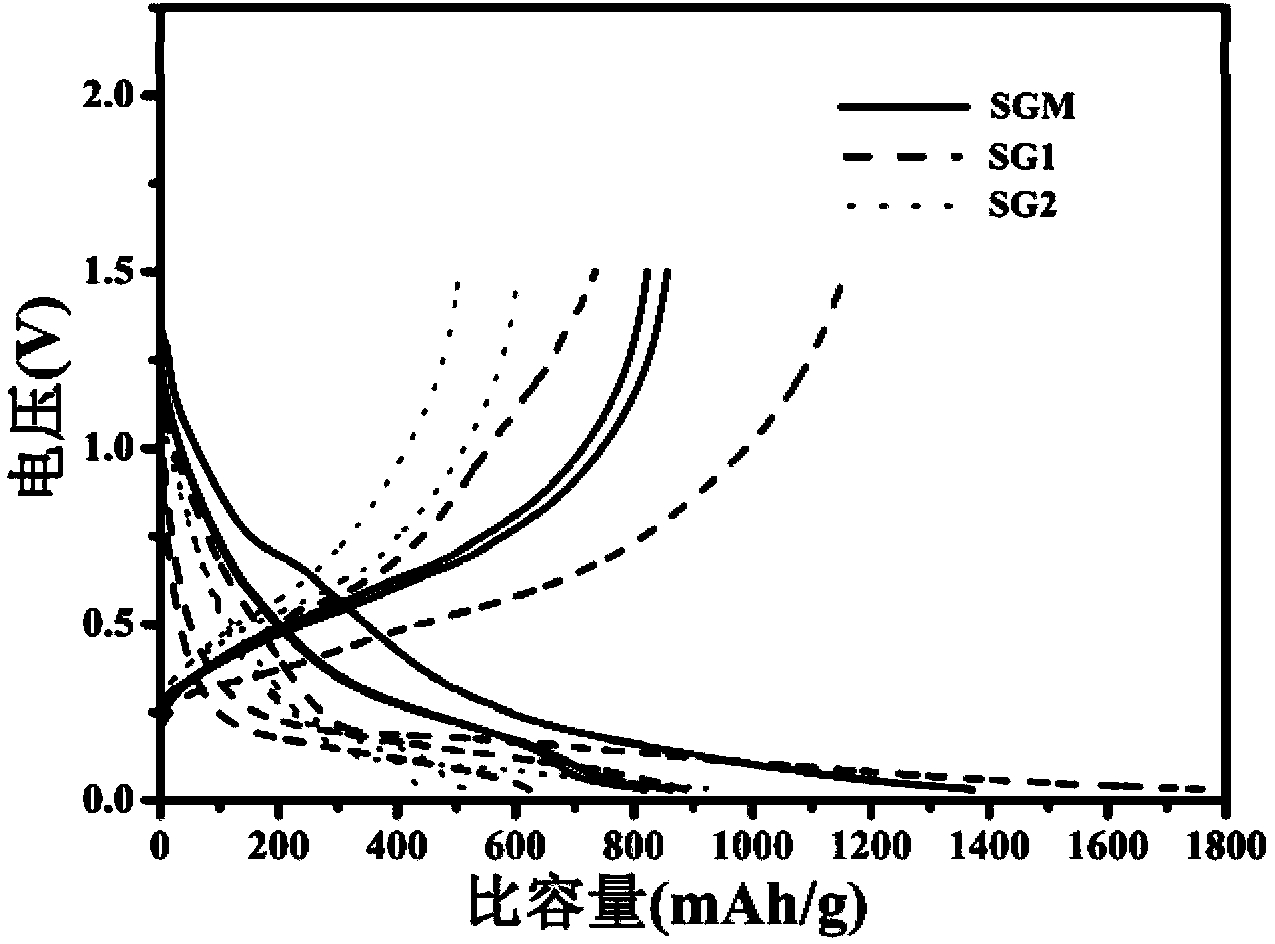

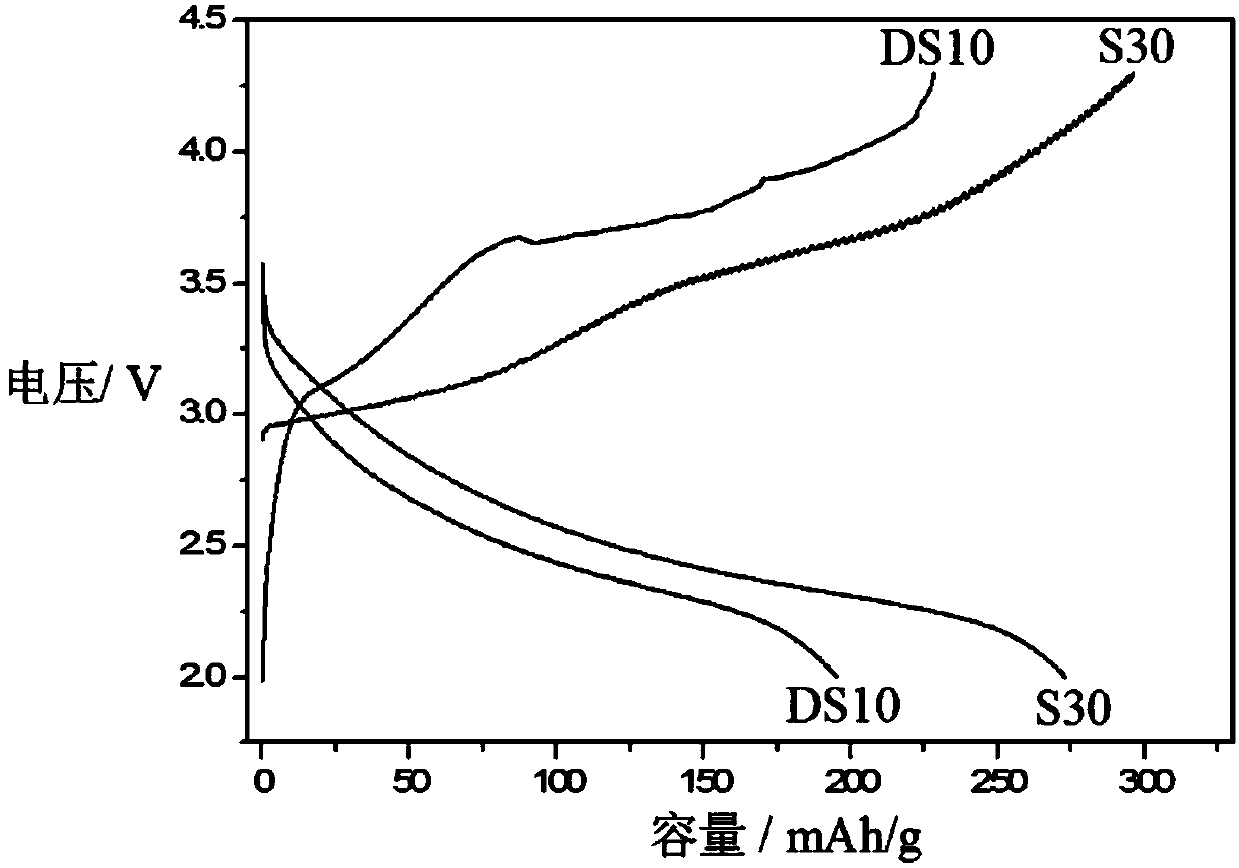

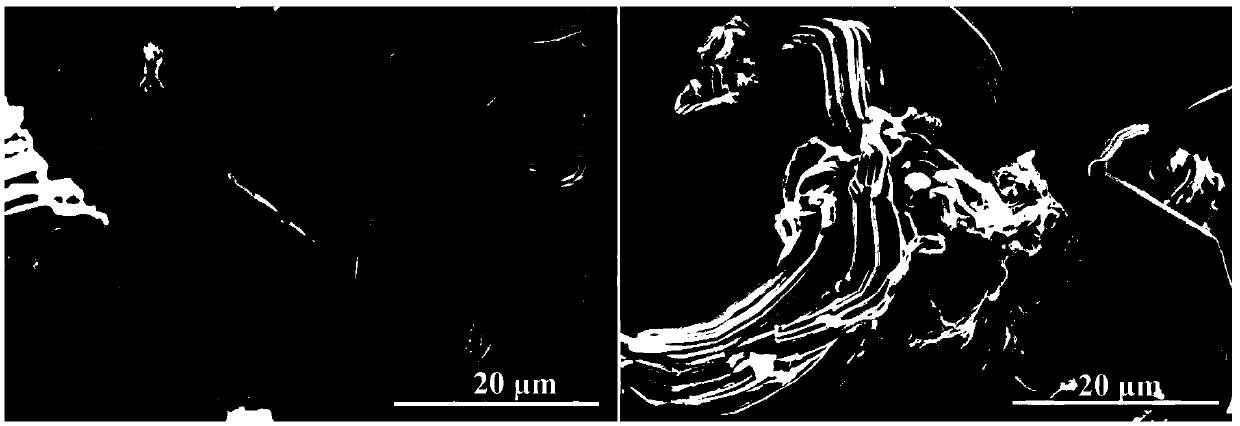

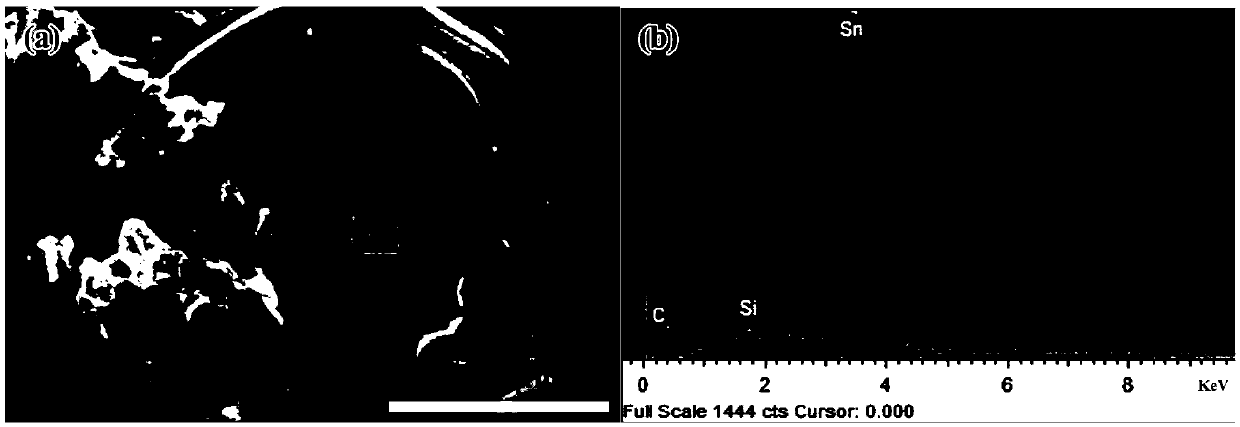

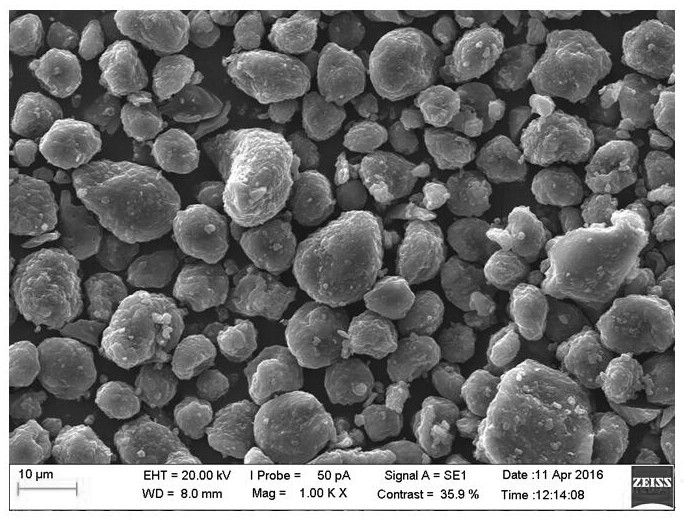

Silicon-based nanometer composite anode material for lithium ion battery and preparation method of silicon-based nanometer composite anode material

ActiveCN104282897AIncrease capacityLower specific capacityMaterial nanotechnologyCell electrodesLithium electrodeElectrochemistry

The invention discloses a novel silicon-based nanometer composite material for a lithium ion battery anode and a preparation method of the novel silicon-based nanometer composite material, belonging to the field of electrochemical sources. The preparation method comprises the following steps: adding a small amount of graphite and ductile metal element tin, thereby preparing a silicon-based nanometer bicontinuous phase structure composite material by adopting a high energy ball milling method. Generally, the atomic percent of silicon in the selected alloying component is over 50 percent, properly 65-80 percent. The high energy ball milling is performed under argon atmosphere protection, and compounding between silicon and the ductile metal tin is realized by utilizing continuous cold welding and tearing under high-energy impact, so that the silicon and the metal element tin with high deformation capacity are interpenetrated, and an open three-dimensional mesh structure is formed in the space. The novel silicon-based nanometer bicontinuous phase structure composite material is simple in preparation process and low in cost and has excellent electrochemical performance and excellent application prospects.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Positive electrode active material and preparation method thereof as well as lithium ion battery

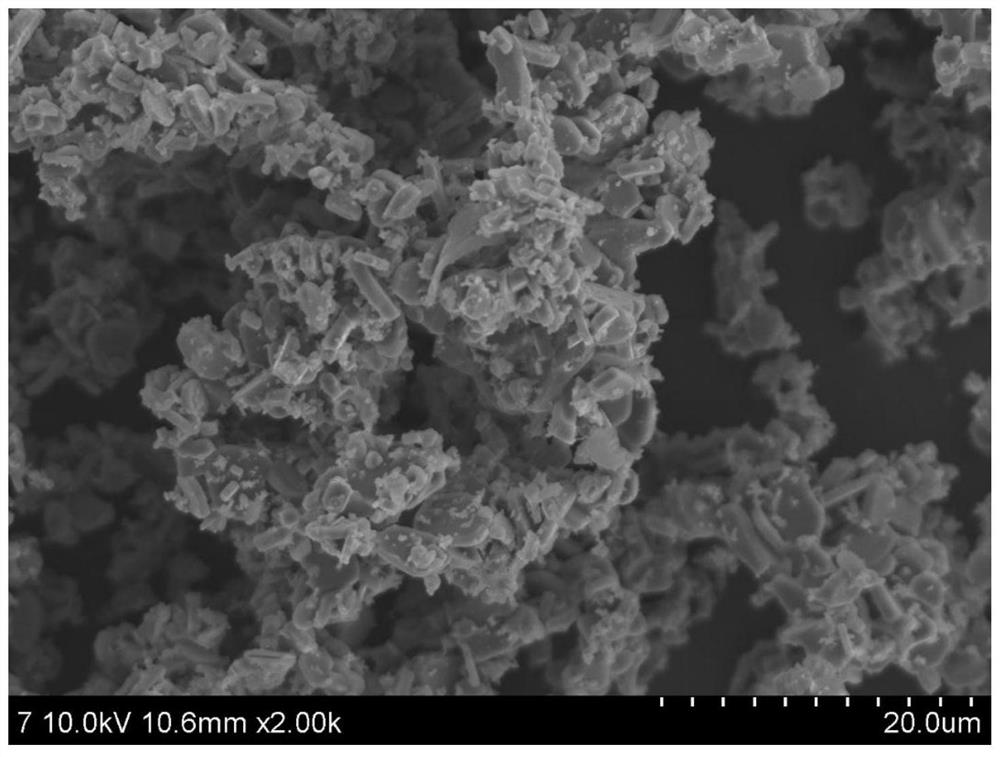

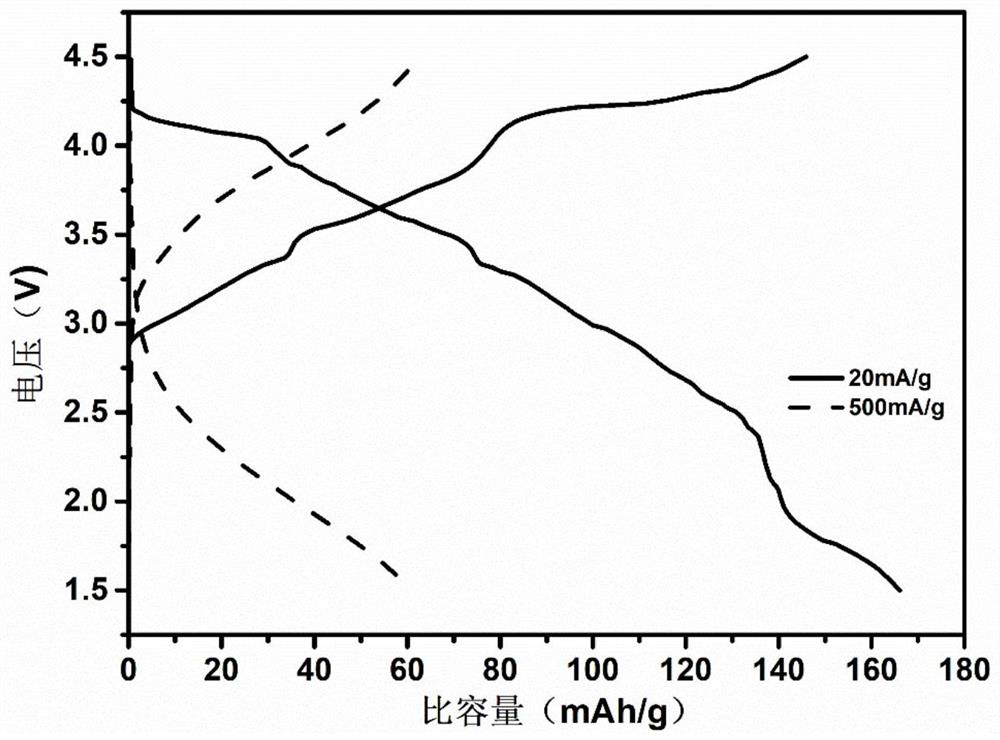

ActiveCN107565099ALower specific capacityEnhanced interactionCell electrodesSecondary cellsMolybdenum carbideLithium-ion battery

The invention relates to a positive electrode active material, comprising a composite material of Li2MoO3 and molybdenum carbide. The invention also provides a preparation method of the positive electrode active material and a lithium ion battery. The lithium ion battery prepared by the invention is good in electrical conductivity and high in charge and discharge capacity.

Owner:SHANGHAI BYD

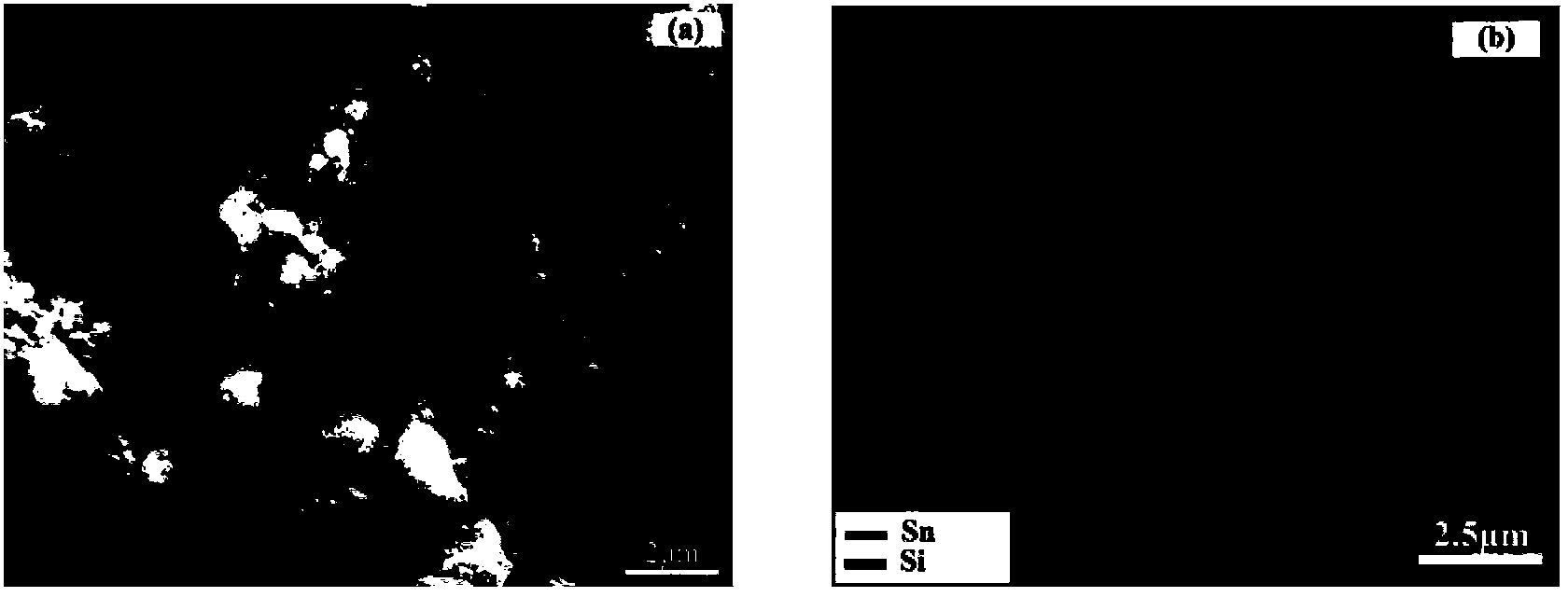

Si-Sn composite material used for Li-ion battery anode and preparation method thereof

ActiveCN105375012AHigh specific capacityImprove toughnessNegative electrodesSecondary cellsIonFiber structure

The invention discloses a Si-Sn composite material used for a Li-ion battery anode and a preparation method thereof. The composite anode material is of a Sn-fiber-wound Si particle composite structure and composed of two elements Si and Sn, wherein the Si content is 20-70at.% and the balance is Sn. According to the preparation method of the composite anode material, Si and Sn powder are mixed and the mixed powder is ball milled by using a high-energy ball milling method in an argon atmosphere; under the action of high-energy impact, metal Sn particles deform seriously, are subjected to cold welding and torn to form Sn fibers; through further ball milling, fiber-structured ductile-phase metal Sn formed after high-energy ball milling and Si particles smashed under high-energy impact in the ball milling process are composited to form a Sn-fiber-wound Si particle composite structure. The novel Sn-fiber-wound Si composite material is simple in preparation process and low in cost; in addition, the composite material is novel and unique in structure and excellent in electrochemical performance and therefore has excellent application prospect.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Silicon-based cathode composite material for lithium ion battery and preparation method thereof

ActiveCN102324501BRelief of mechanical stressEliminate volume effectCell electrodesSodium-ion batteryLithium-ion battery

The invention discloses a silicon-based cathode composite material for a lithium ion battery and a preparation method thereof. The cathode composite material is a Si / CuOx / C composite material (0<=x<=1) with a porous structure. Silicon with a porous structure is used as a base, and CuOx particles are inserted in the pores, and carbons with different forms are distributed on a surface and pore walls of the silicon-based material. The preparation method of the cathode composite material comprises steps that silicon material realizes pore-forming through an in situ catalytic reaction between silicon and halogenated hydrocarbon, and reaction condition parameters are regulated to control pore size, distribution and amount of porosity of the silicon material; a post-modification technology is employed to carry out modifications on the surface and the pore walls of the porous silicon, so as to obtain the Si / CuOx / C composite material with a porous structure. The porous silicon-based cathode composite material has low production costs, simple process and no pollution, and is suitable for industrialized production; besides the porous silicon-based cathode composite material has high charge and discharge capacity, small initial irreversible capacity and good cycle performance.

Owner:河北中芯凤华科技发展有限公司

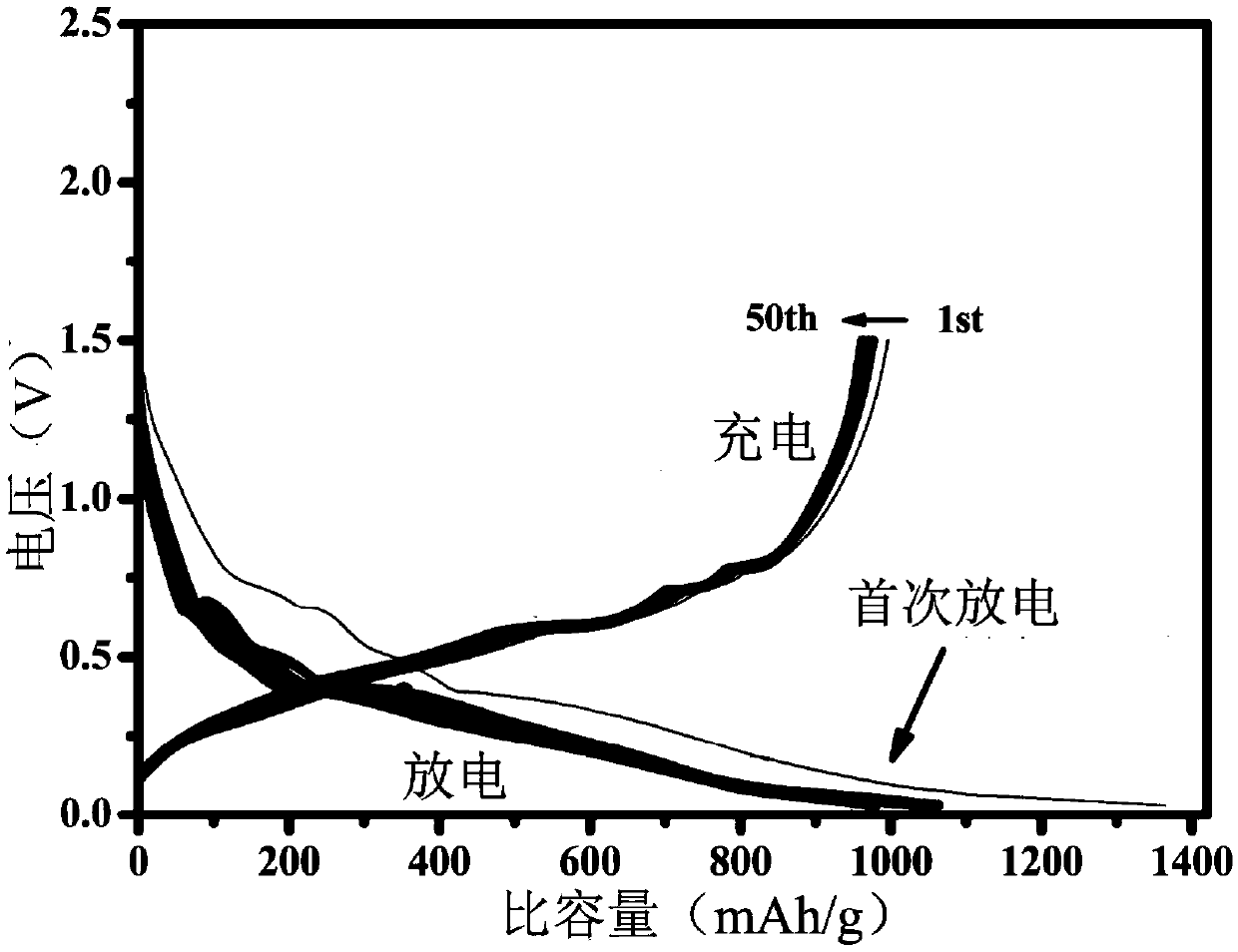

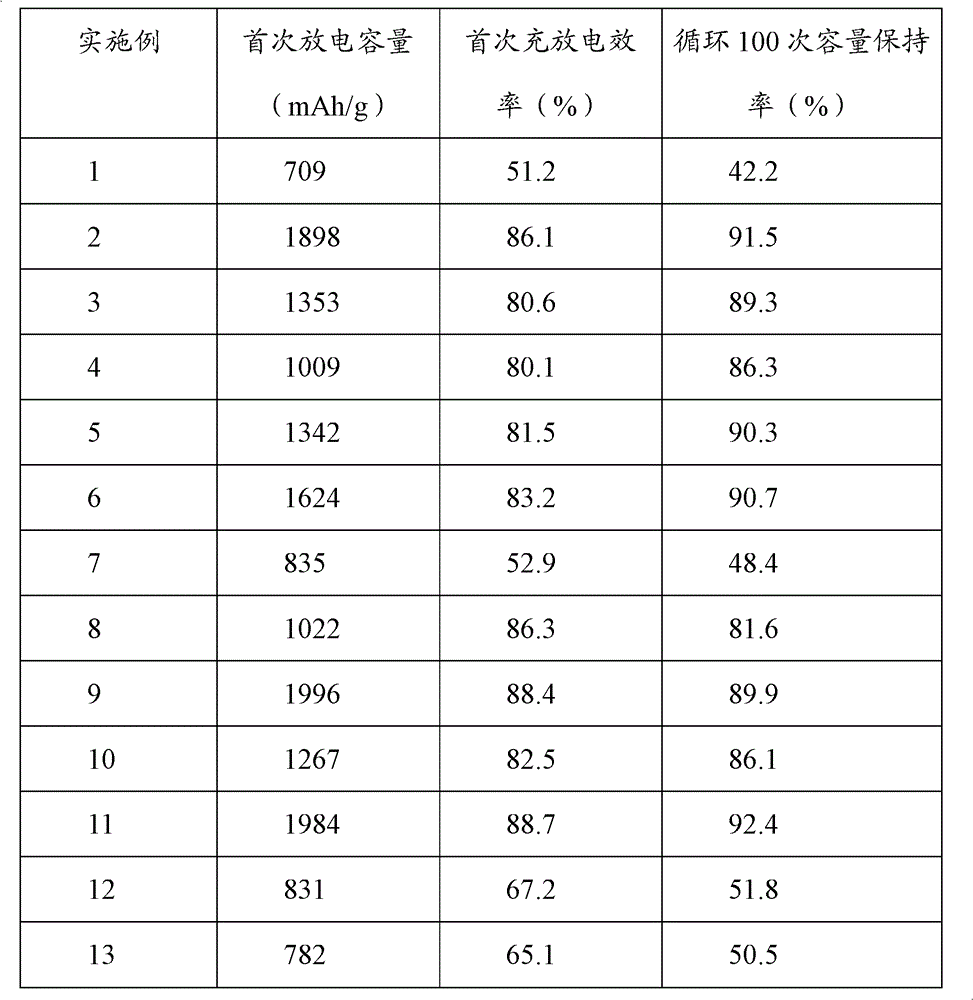

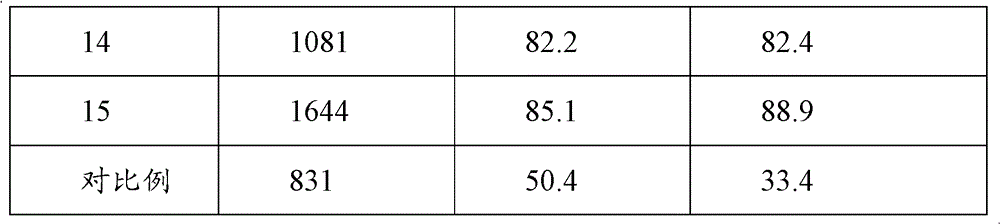

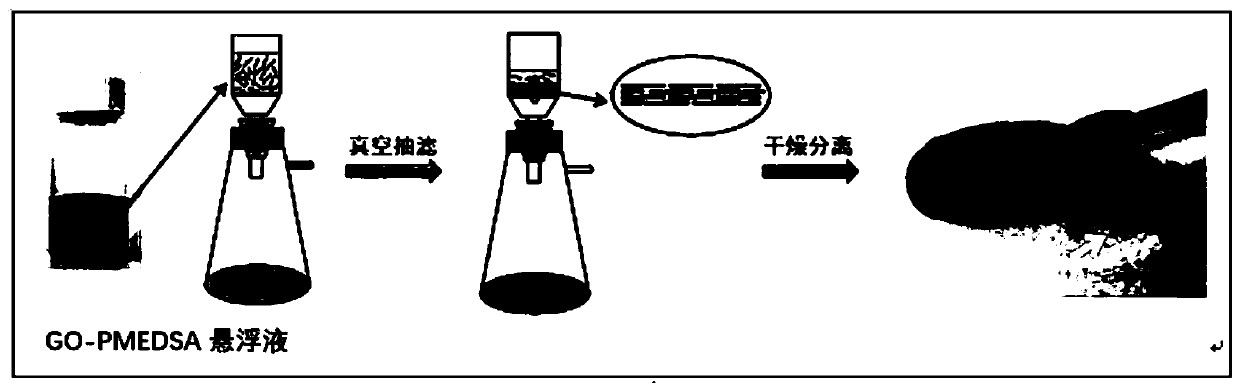

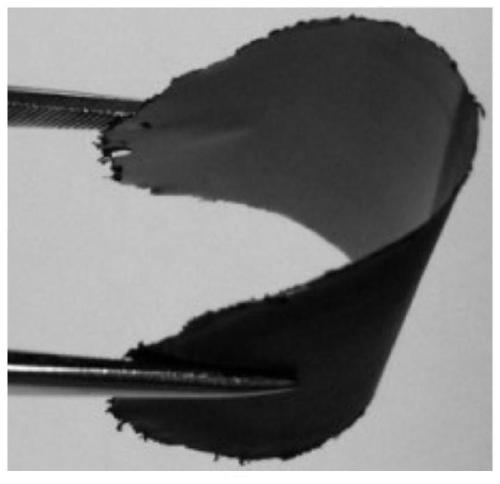

Temperature-sensitive diaphragm, preparation method thereof and application of temperature-sensitive diaphragm

InactiveCN111081952AExcellent ionExcellent molecular transport propertiesHybrid capacitor separatorsCell component detailsOrganic groupSide reaction

The invention discloses a temperature-sensitive diaphragm, a preparation method thereof and application of the temperature-sensitive diaphragm. The temperature-sensitive diaphragm is prepared from a composite material; the composite material comprises a matrix layer and a polymer layer grafted on the matrix layer; the matrix layer is graphene oxide (GO); and the polymer layer is polysulfobetaine.The preparation method comprises the following steps that: hydroxylation treatment is performed on GO, so that GO-OH can be obtained; an organic Br group is introduced to the surface of GO-OH; polysulfobetaine is covalently grafted to the surface of GO, and a composite material is obtained; the composite material is dispersed, and the dispersed composite material is prepared into a composite filmthrough vacuum filtration. According to the temperature-sensitive diaphragm, the preparation method thereof and the application of the invention, the temperature-sensitive polymer polysulfobetaine isintegrated into a diaphragm, so that the temperature-responsive intelligent diaphragm can be obtained; and on the basis of the temperature response behavior of the polysulfobetaine, reversible controlover lithium ion transmission by the diaphragm at different temperatures is realized, and exothermic side reaction and thermal runaway are sensed and inhibited in time.

Owner:CENT SOUTH UNIV

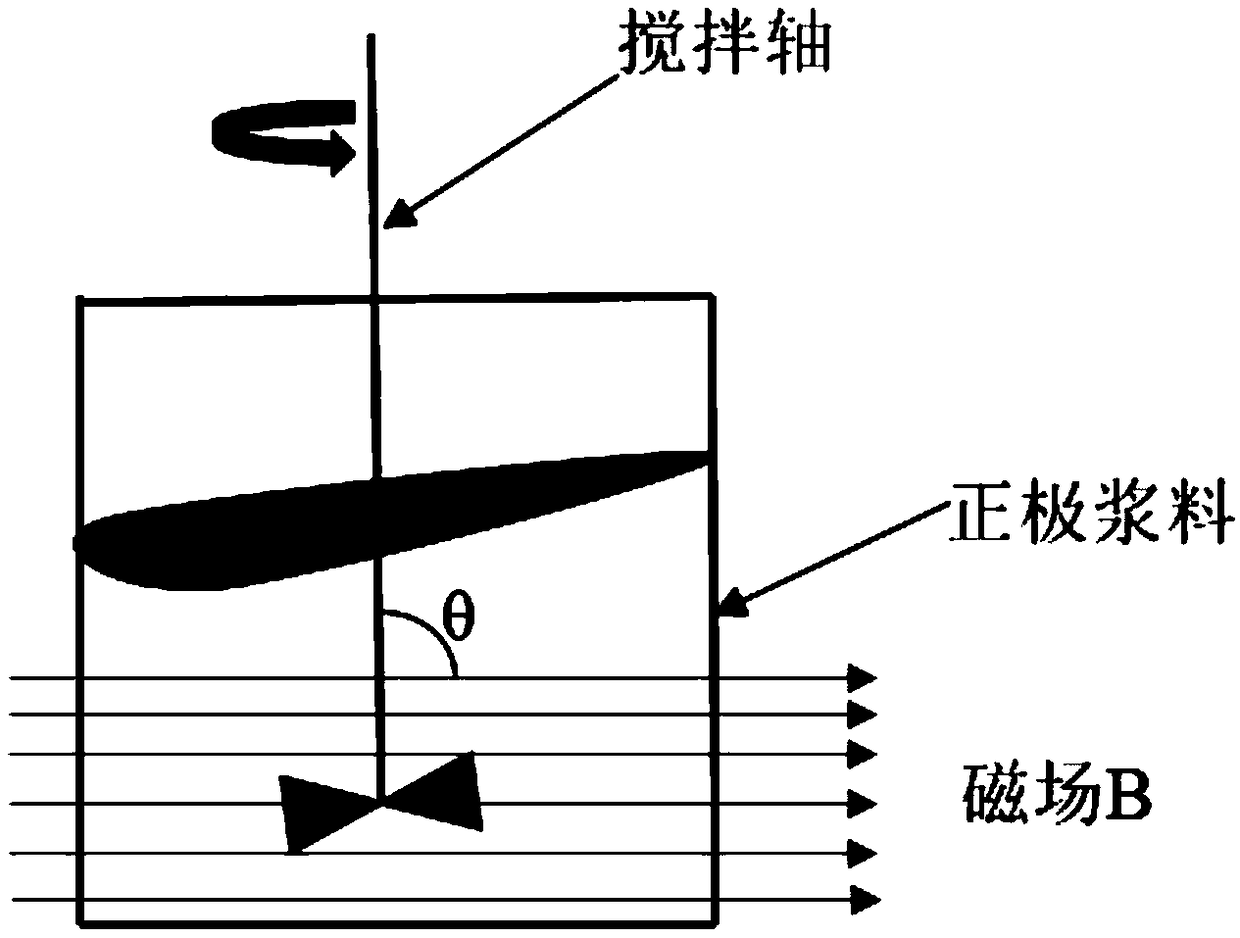

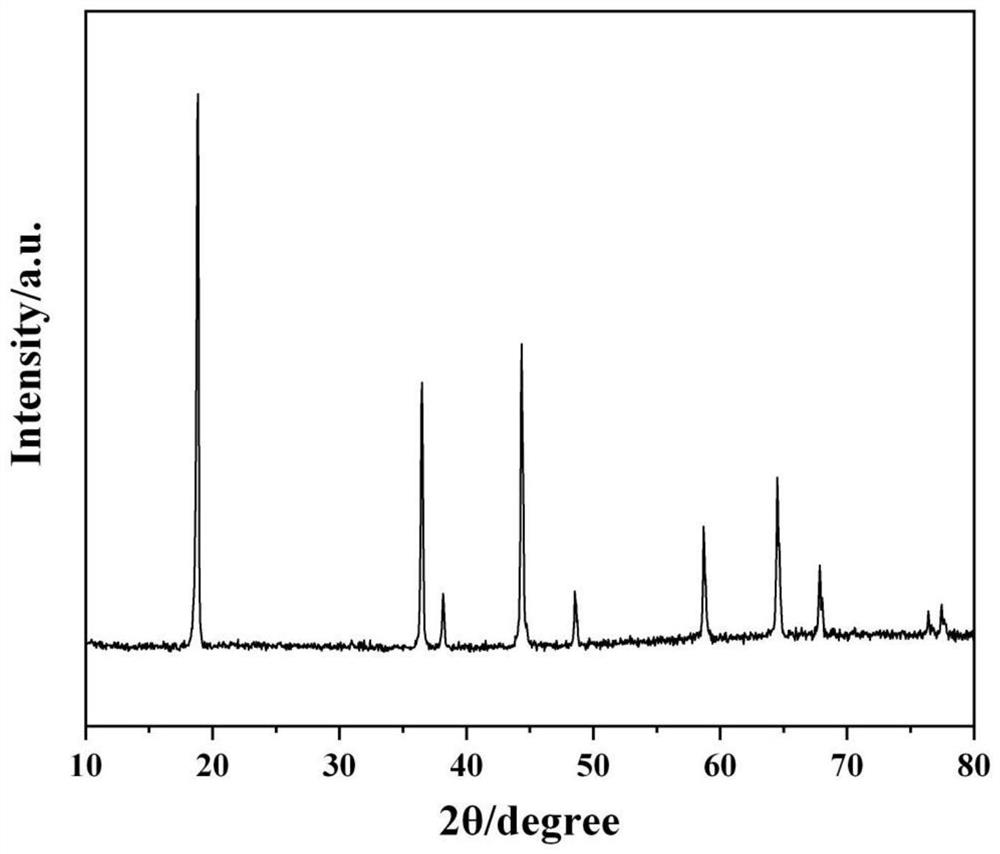

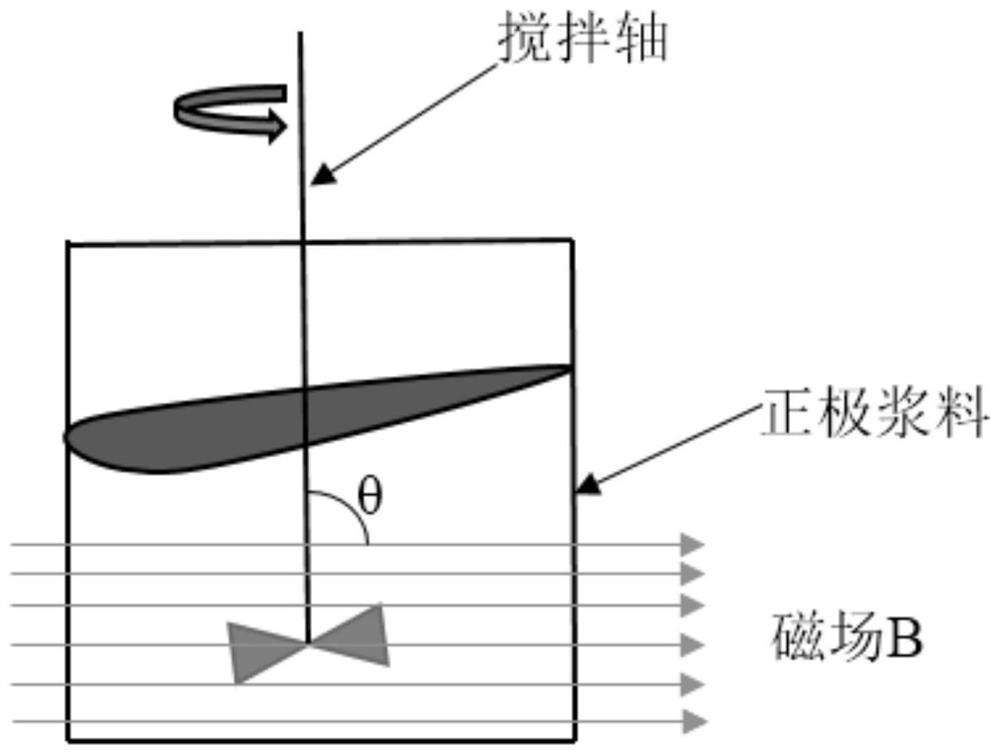

Method of preparing nickel-manganese spinel cathode material through magnetic field texturing

ActiveCN109279658AIncrease energy densityPromote circulationCell electrodesSecondary cellsNickel saltManganese

The invention discloses a method of preparing nickel-manganese spinel cathode material through magnetic field texturing, which includes steps of: 1) performing coprecipitation to nickel salt and manganese salt to prepare a Ni-Mn precursor; 2) uniformly mixing the Ni-Mn precursor with a lithium source, and calcining the mixture to prepare a nickel-manganese spinel material; 3) crushing and sievingthe nickel-manganese spinel material and stirring and mixing the nickel-manganese spinel material with an additive in a stirrer, and during the stirring, applying an external magnetic field to the slurry. By means of interaction between Mn<3+> and the magnetic field, texturing is achieved in the magnetic field, so that the cathode slurry can face to the contact direction of an electrolyte with (111) crystal face as most as possible when coating an aluminum foil, thereby solving the problems of capacity degradation and poor high temperature cycle performance during charge / discharge process of the nickel-manganese spinel material; in the invention, when being used for assembling a battery, a cathode plate has excellent cycle and rate performance, is high in energy density, and has excellentapplication prospect in the fields such as power cars, large-size power plants and the like.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

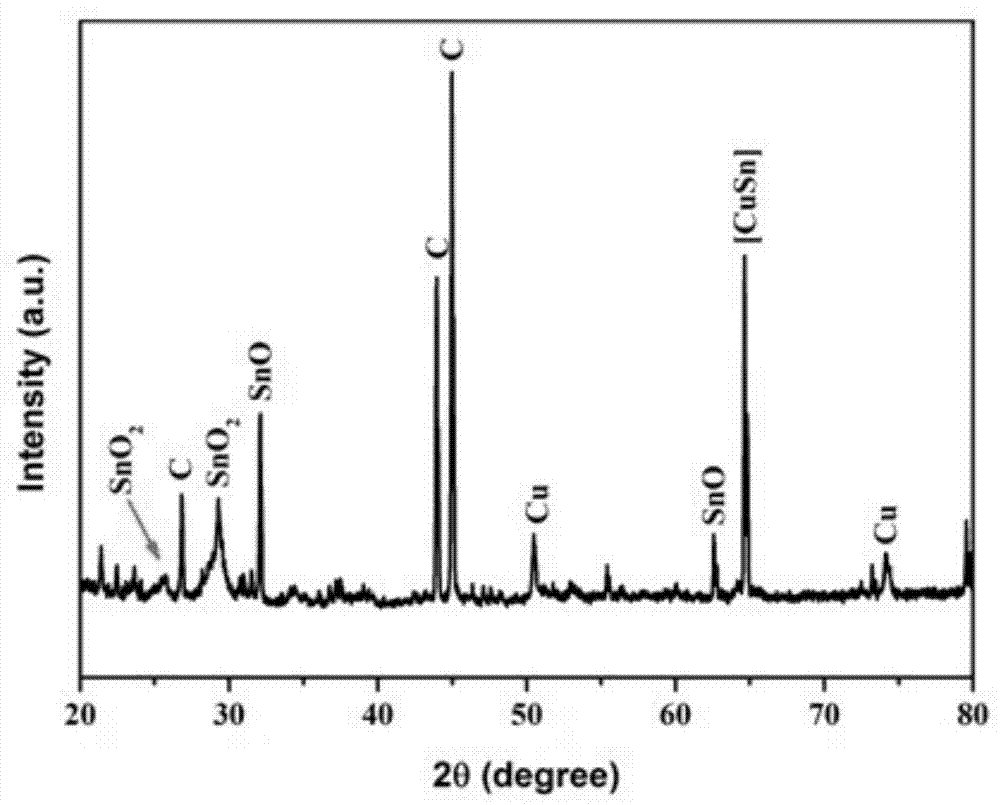

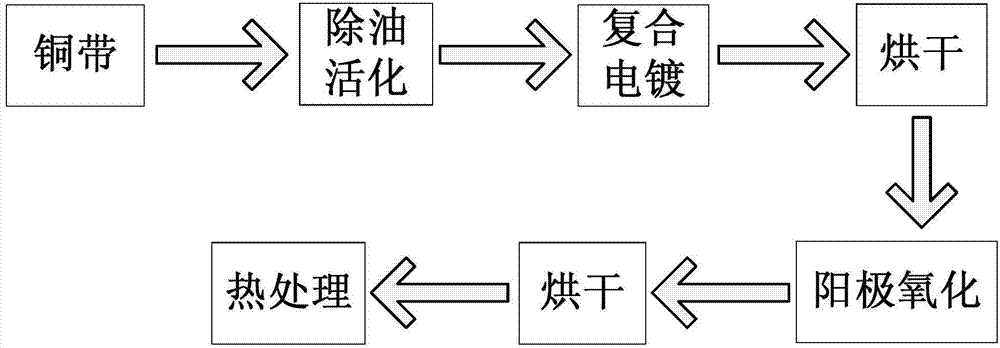

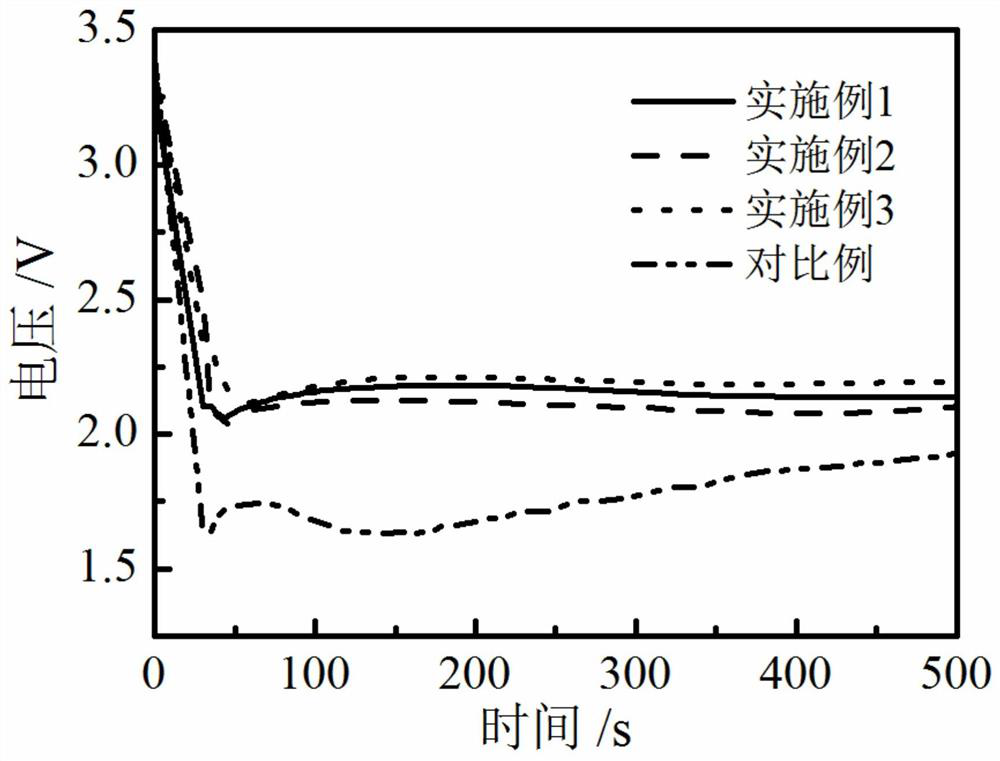

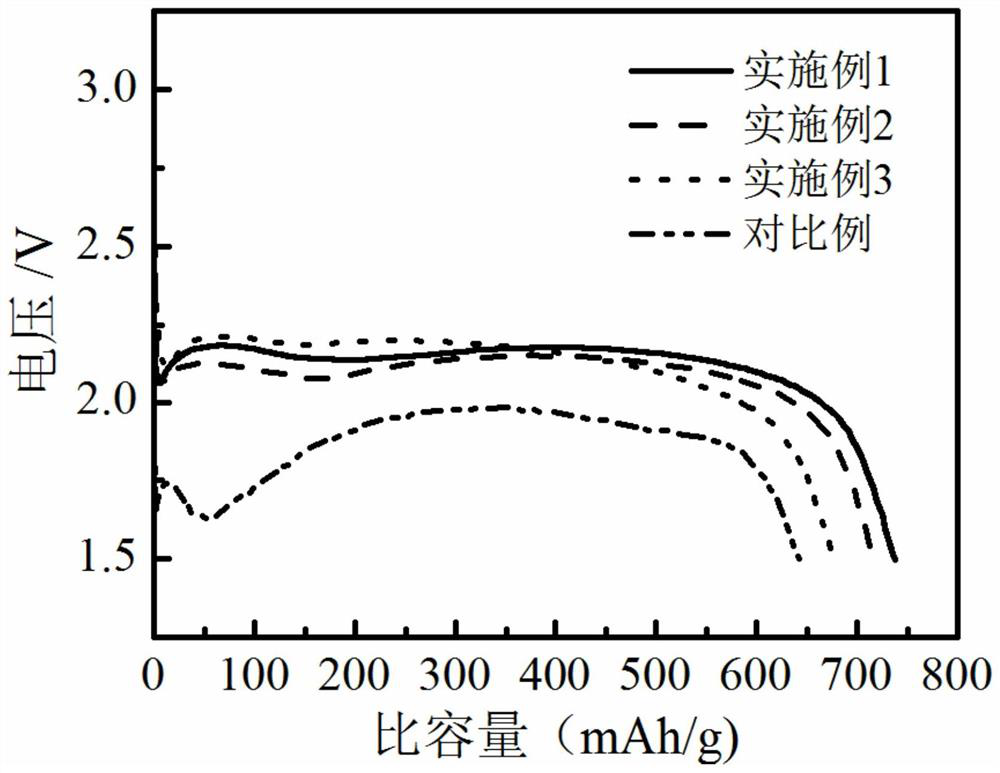

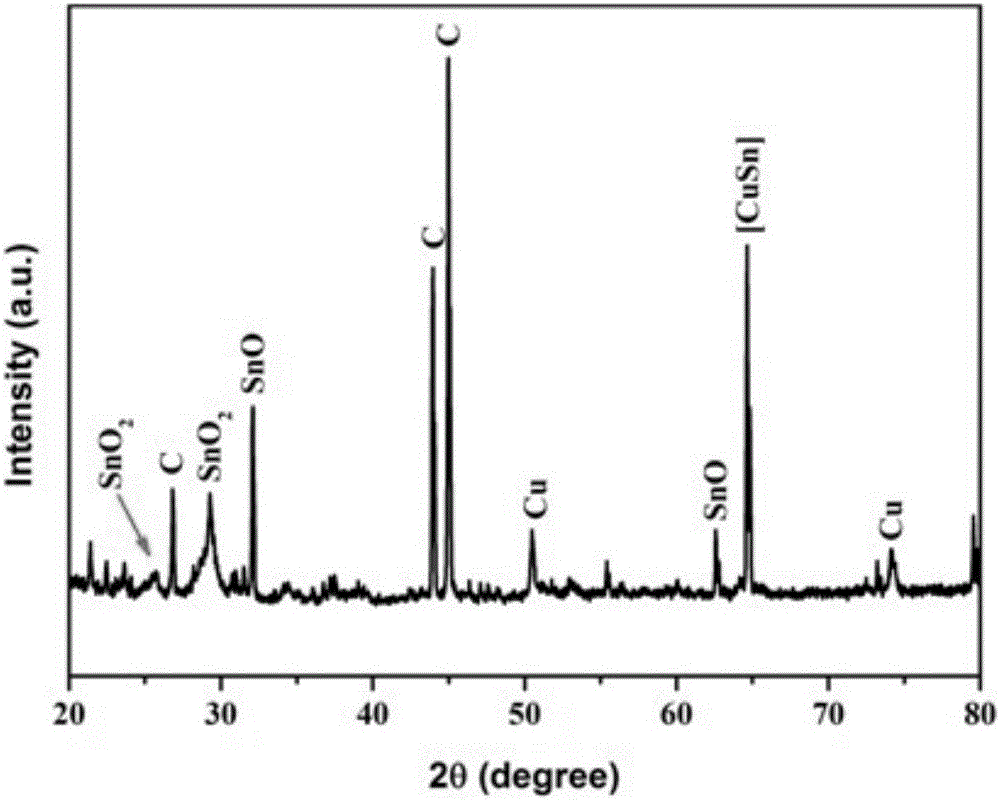

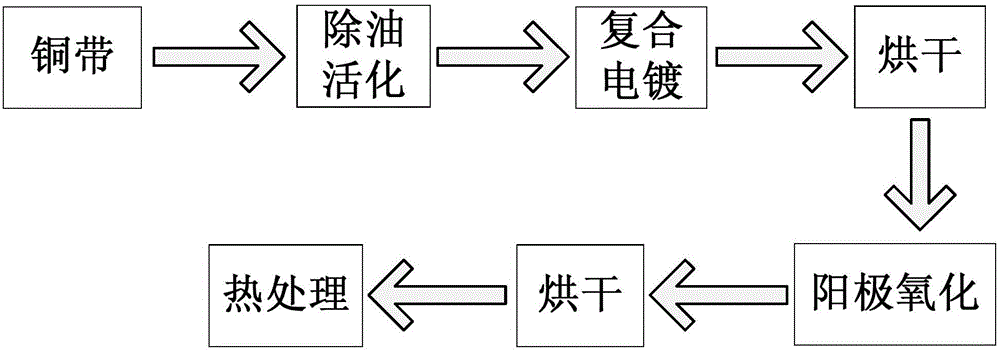

CNTS-doped tin oxide negative electrode material for lithium-ion battery and preparation method thereof

ActiveCN103490053AImprove electrical conductivityDecreased specific capacity fadeCell electrodesSecondary cellsAnodic oxidationCarbon nanotube

The invention discloses a CNTs (carbon nanotubes)-doped tin oxide negative electrode material for a lithium-ion battery and a preparation method thereof. The preparation method comprises the following steps: firstly, compositely electroplating a CNTs-doped tin plating layer with the thickness of 10-15 microns on one side of the surface of a substrate of a pretreated copper strip; and secondly, anodizing the material obtained in the first step to obtain a mesoporous oxide, and performing heat treatment to finally obtain the lithium-ion battery negative electrode material with CNTs-uniformly-doped mesoporous tin oxide layer on one side of the surface of the substrate of the copper strip. The mesoporous diameter is 3-10nm and the obtained oxide layer has the thickness of 5-10 microns. The first specific discharge capacity of the lithium-ion battery negative electrode material can be as high as 650mAh / g, and after 50 cycles, the specific capacity is attenuated by only 0.8%-5%. The preparation method is simple in process, and large-scale industrial production can be carried out.

Owner:XIANGTAN UNIV

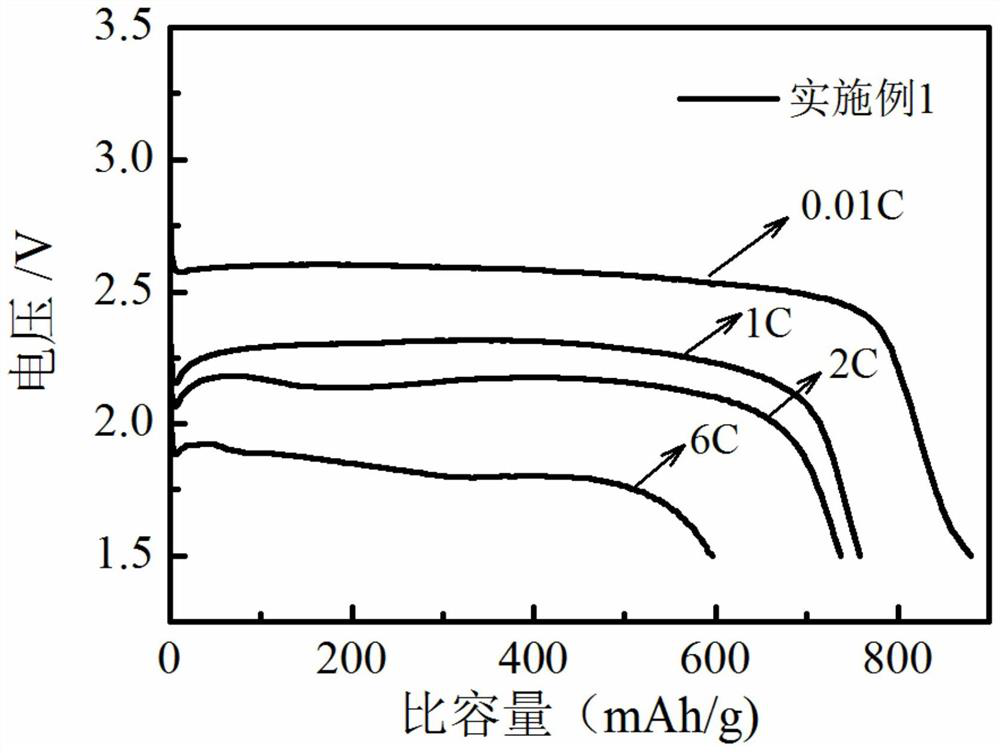

Carbon fluoride composite positive active material for lithium-carbon fluoride battery as well as preparation method and application of carbon fluoride composite positive active material

PendingCN113299912AImprove voltage hysteresisHigh specific capacityCell electrodesOrganic electrolyte cellsBattery cellMaterials science

The invention relates to a carbon fluoride composite positive active material for a lithium-carbon fluoride battery as well as a preparation method and application of the carbon fluoride composite positive active material. The invention aims to solve the technical problem that it is difficult for an existing carbon fluoride composite positive electrode active material for the lithium-carbon fluoride battery to simultaneously consider high specific capacity, high rate capability and improvement of voltage hysteresis phenomenon. The material is prepared by ball-milling and mixing carbon fluoride and ketjen black, and the mixing mass ratio of the carbon fluoride to the ketjen black is (1: 0.01)-(1: 0.1). The preparation method comprises the following steps: 1) preparing carbon fluoride by adopting a gas phase fluorination method; and 2) mixing the carbon fluoride and the ketjen black through ball milling to obtain the uniformly mixed carbon fluoride composite material mixed with the ketjen black. When the carbon fluoride composite positive electrode active material is applied to the carbon fluoride composite positive electrode active material for the lithium-carbon fluoride battery, relatively high specific capacity can be reserved, the rate capability can be improved, the discharge rate can reach 6C, and the voltage hysteresis phenomenon at the initial stage of discharge can be improved.

Owner:NORTHWEST INST OF NUCLEAR TECH

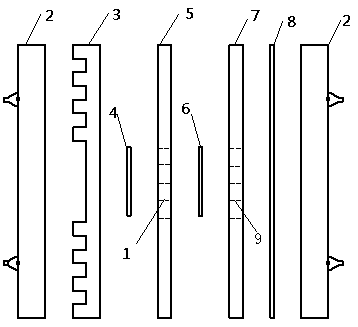

Double-electrolyte aluminum air battery

InactiveCN110233314ALower specific capacityReduces clogging defectsFuel and primary cellsFuel cellsHigh oxygenCorrosion

The invention relates to the field of aluminum air batteries, and discloses a double-electrolyte aluminum air battery. The double-electrolyte aluminum air battery comprises an aluminum anode (8), an anode reaction room (7), a diaphragm (6), a cathode reaction room (5) and an air cathode (4), wherein the cathode reaction room (5) and the anode reaction room (7) are separated by the diaphragm (6); electrolyte channels are arranged on the reaction rooms; electrolyte filling can be performed outside; and a cathode electrolyte and an anode electrolyte can enter the cathode reaction room (5) and theanode reaction room (7) from the respective electrolyte channels to participate in reaction. According to the double-electrolyte aluminum air battery, self-corrosion of the aluminum anode of the aluminum air battery in a high-concentration strong-basicity solution can be effectively avoided; high oxygen reduction reaction activity of the air cathode can be ensured; and the double-electrolyte aluminum air battery has the biggest characteristic that a common aluminum sheet can serve as the aluminum anode without a special alloy. Compared with a single-electrolyte neutral solution, the double-electrolyte aluminum air battery avoids a defect of electrode and reaction room blocking caused by quick sediment generation.

Owner:JIANGSU UNIV +1

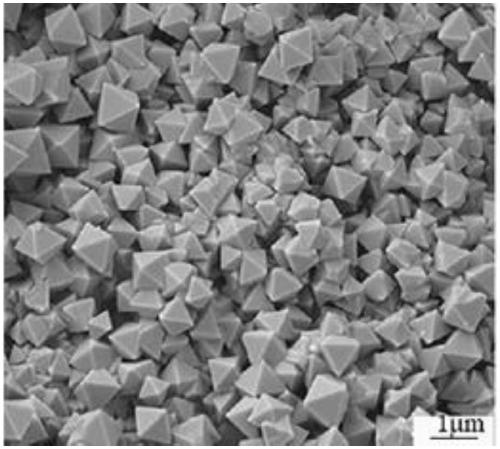

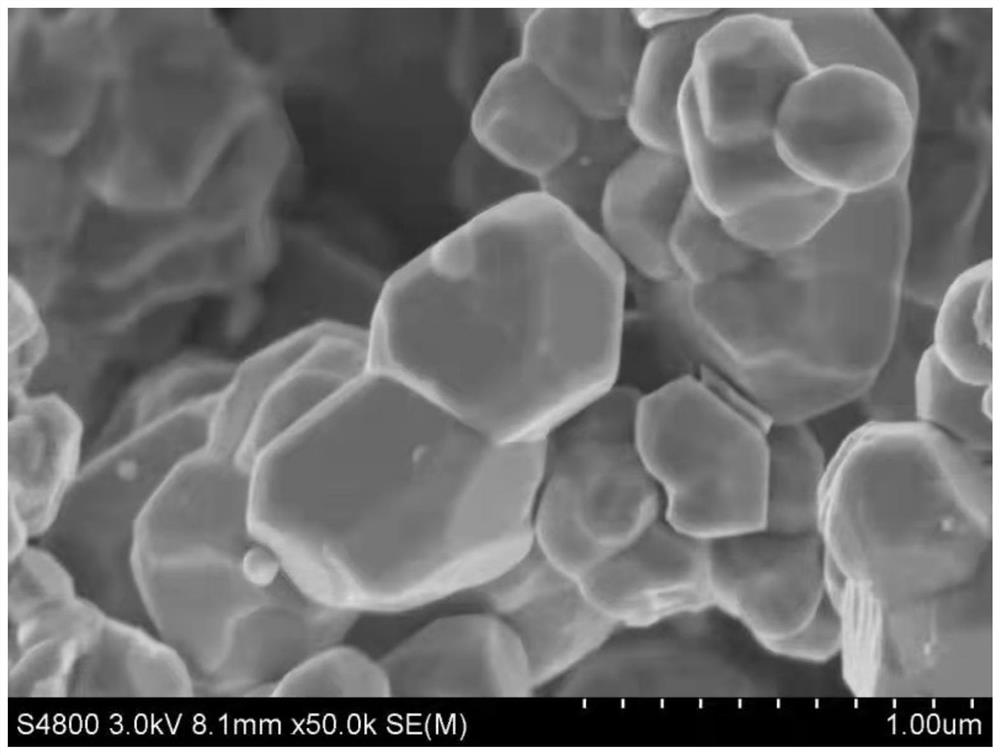

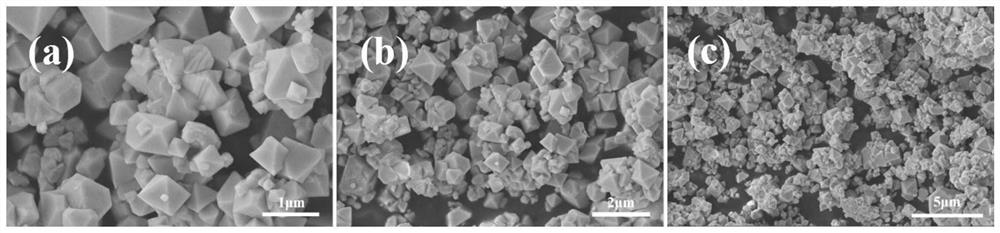

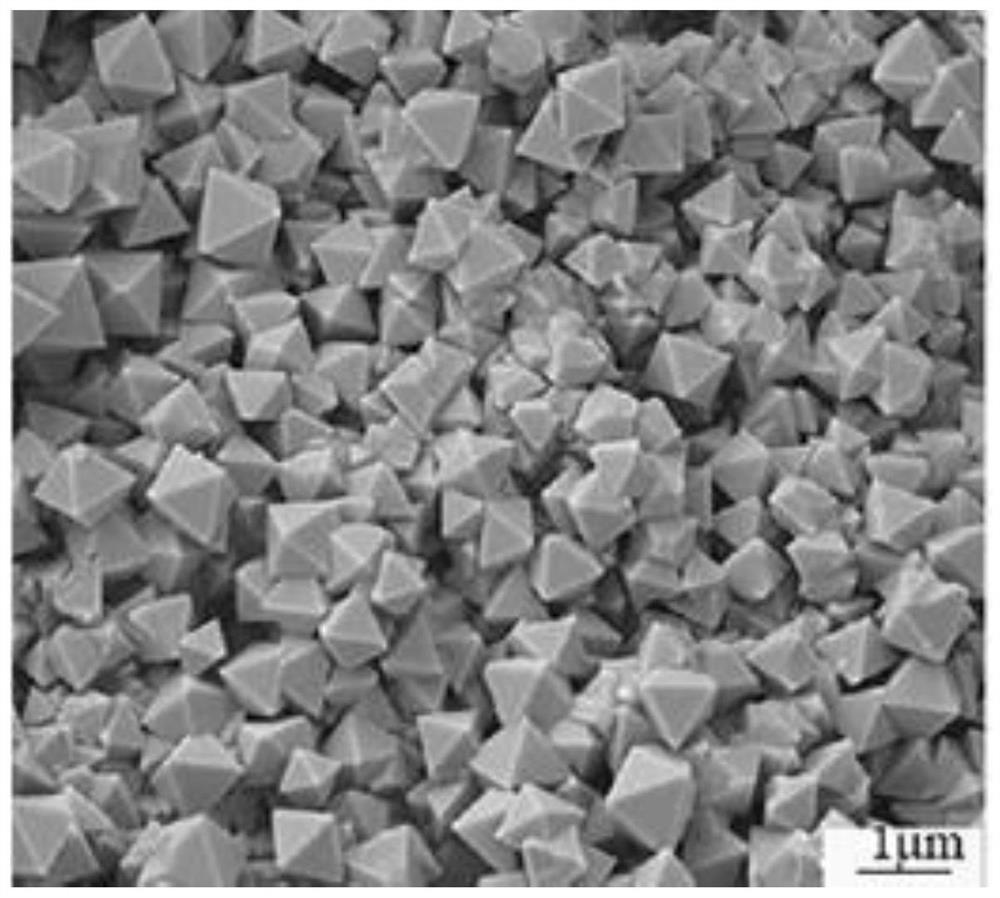

Preparation method of Al<3+>-doped regular-octahedron-shaped lithium nickel manganese oxide material

ActiveCN110335995AGood value for moneyClear and uniformSecondary cellsPositive electrodesLithiumOxalate

The invention discloses a preparation method of an Al<3+>-doped regular-octahedron-shaped lithium nickel manganese oxide material. The method is characterized by, accurately weighing an aluminium source, a manganese source, a nickel source and a lithium source according to stoichiometric ratio; mixing the weighed manganese source, the nickel source and Al2O3 and carrying out ball milling; drying the mixture obtained after ball milling into powders; weighing oxalic acid powders and mixing the oxalic acid powders with the mixture dried into powders; adding PEG into the obtained mixture, carryingout stirring to obtain grey-black colloidal mixture, and preheating the grey-black colloidal mixture to obtain black precursor powders; mixing and ball milling the obtained black precursor powders and the weighed lithium source; and keeping the obtained mixture for 5-24 h under the temperature of 800 DEG C, and then, reducing the temperature to less than 600 DEG C and keeping the mixture for 5-24h and then, carrying out annealing to reach room temperature to obtain a submicron-level Al<3+>-doped regular-octahedron-shaped lithium nickel manganese oxide material. The method obtains the Al<3+>-doped regular-octahedron-shaped lithium nickel manganese oxide material by combining a low-cost high-temperature solid phase method and a polymer auxiliary method; and the material is high in cost performance.

Owner:DALIAN UNIV OF TECH

Preparation method of high performance oxide coated nano-SnO2 negative electrode material

InactiveCN108767207AEasy to prepareGood repeatabilityMaterial nanotechnologyCell electrodesCharge and dischargeOxide

The invention discloses a preparation method of a high performance oxide-coated nano-SnO2 negative electrode material, and the preparation method comprises the following steps: firstly, surface-passivation treatment is performed on nano-SnO2 particles, and then the surface of the nano-SnO2 particles is coated with an oxide. The negative electrode material prepared by the method has a large specific capacity, the volume expansion effect of the negative electrode material during charging and discharging of a lithium ion battery can be inhibited, and the high performance oxide-coated nano-SnO2 negative electrode material has good charge and discharge cycle performance, and has simple preparation method and good repeatability.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

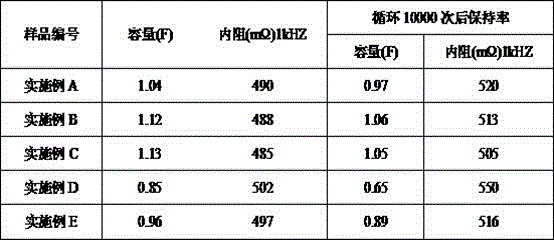

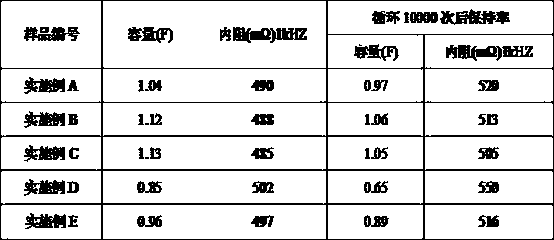

Preparation method for low-internal-resistance and high-specific-energy graphene-based button type supercapacitor

ActiveCN106653397AAvoid the undesirable phenomenon of reunionLower specific capacityHybrid capacitor separatorsHybrid capacitor electrodesLiquid stateInternal resistance

The invention provides a preparation method for a low-internal-resistance and high-specific-energy graphene-based button type supercapacitor. The preparation method is characterized in that the low-internal-resistance and high-specific-energy graphene-based button type supercapacitor is prepared by the procedures of preparation of an electrode, preparation of a conductive glue solution, preparation of the button type supercapacitor and the like. By adding graphene, the preparation of the low-internal-resistance and high-specific-energy graphene-based button type supercapacitor is realized and the preparation process of the supercapacitor is lowered; by adding graphene to the electrode and the conductive glue in a powder state and in a liquid state, an adverse phenomenon of graphene agglomeration is avoided consequently; meanwhile, by introducing the high-conductivity and high-purity graphene material to the preparation process of the button type supercapacitor, the specific capacity of the supercapacitor is improved, and the internal resistance value of the supercapacitor is also lowered; and in addition, water content is not added in the electrode preparation process, so that internal electrode corrosion and generation of gas of the supercapacitor can be avoided.

Owner:芜湖洛菲斯企业管理咨询有限公司

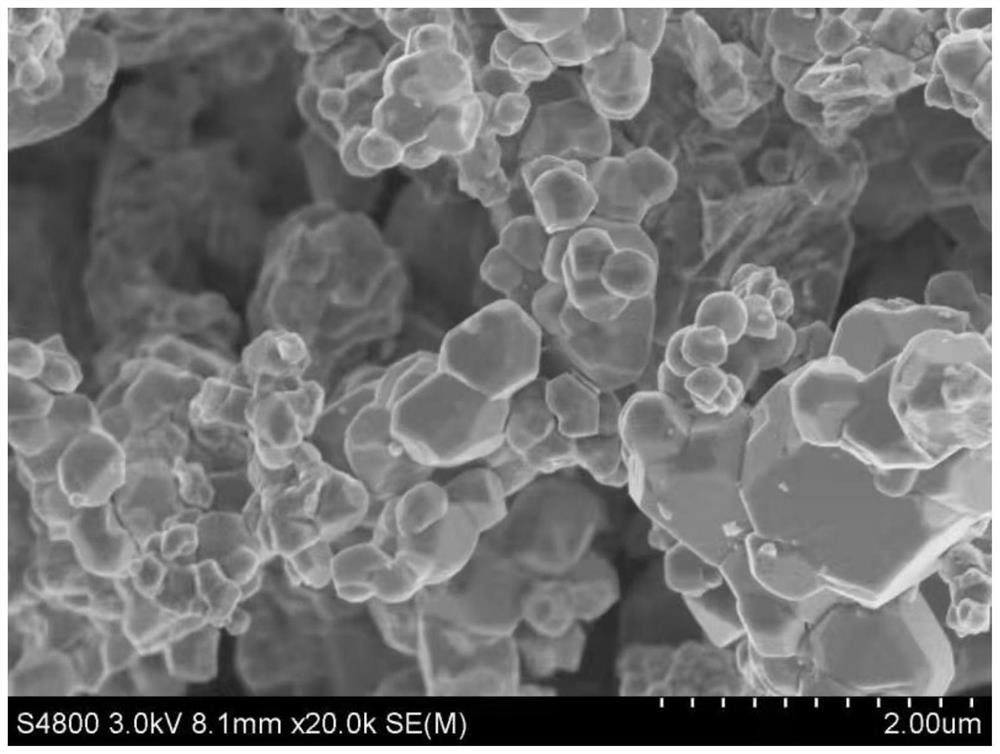

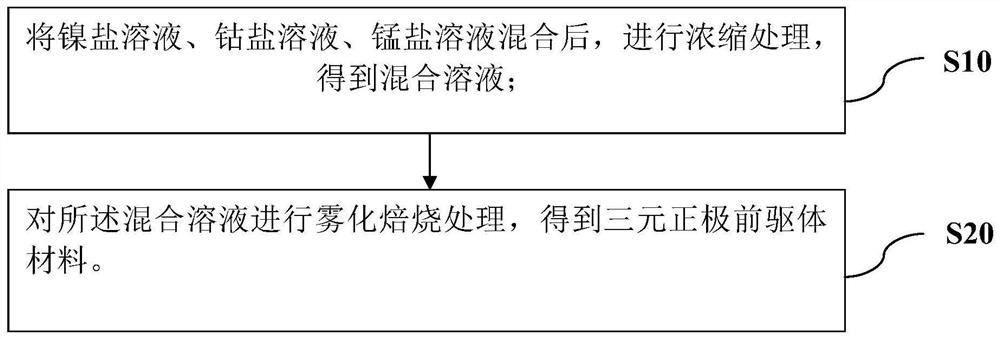

Ternary positive electrode precursor material, preparation method and ternary positive electrode material

PendingCN114590847AIncrease unit capacityIncrease productionMaterial nanotechnologyCell electrodesElectrical batteryCyclic stability

The invention belongs to the technical field of battery materials, and particularly relates to a ternary positive electrode precursor material, a preparation method thereof and a ternary positive electrode material. Wherein the ternary positive electrode precursor material comprises a ternary oxide precursor with a chemical general formula of Ni (1-y-z) CoyMnzOx, x is greater than or equal to 1 and less than or equal to 1.2, y is greater than or equal to 0.03 and less than or equal to 0.1, and z is greater than or equal to 0.2 and less than or equal to 0.35. The material provided by the invention is a ternary positive electrode precursor material, and the content of nickel in the ternary positive electrode precursor material is effectively improved and the content of cobalt is reduced by regulating and controlling the ratio of main metal elements in the ternary oxide precursor, so that the ternary positive electrode precursor material has relatively good structural stability and high capacity at the same time; therefore, the cycling stability and the gram volume of the corresponding ternary positive electrode material are improved.

Owner:湖南力合厚浦科技有限公司

a doped al 3+ Preparation method of lithium nickel manganese oxide material with regular octahedral morphology

ActiveCN110335995BGood value for moneyClear and uniformSecondary cellsPositive electrodesOXALIC ACID DIHYDRATEPhysical chemistry

The invention discloses a preparation method of an Al<3+>-doped regular-octahedron-shaped lithium nickel manganese oxide material. The method is characterized by, accurately weighing an aluminium source, a manganese source, a nickel source and a lithium source according to stoichiometric ratio; mixing the weighed manganese source, the nickel source and Al2O3 and carrying out ball milling; drying the mixture obtained after ball milling into powders; weighing oxalic acid powders and mixing the oxalic acid powders with the mixture dried into powders; adding PEG into the obtained mixture, carryingout stirring to obtain grey-black colloidal mixture, and preheating the grey-black colloidal mixture to obtain black precursor powders; mixing and ball milling the obtained black precursor powders and the weighed lithium source; and keeping the obtained mixture for 5-24 h under the temperature of 800 DEG C, and then, reducing the temperature to less than 600 DEG C and keeping the mixture for 5-24h and then, carrying out annealing to reach room temperature to obtain a submicron-level Al<3+>-doped regular-octahedron-shaped lithium nickel manganese oxide material. The method obtains the Al<3+>-doped regular-octahedron-shaped lithium nickel manganese oxide material by combining a low-cost high-temperature solid phase method and a polymer auxiliary method; and the material is high in cost performance.

Owner:DALIAN UNIV OF TECH

Method for manufacturing lithium ion battery cell by using nano silicon material

ActiveCN114784232AEasy to slideNot easy to slideNegative electrodesSecondary cellsNano siliconPolymer network

The invention discloses a method for manufacturing a lithium ion battery cell by using a nano silicon material, which belongs to the field of lithium ion batteries, and comprises the following steps: preparing a negative electrode by using a self-made conductive binder; preparing a positive electrode; and winding the positive electrode, the negative electrode and the diaphragm to obtain a pole group, and then putting the pole group into a shell, injecting liquid and sealing to obtain the lithium ion battery cell. According to the invention, through the self-made conductive binder, a spatial three-dimensional polymer network structure is formed on the surfaces of the binder nano silicon particles, so that the silicon negative electrode material has relatively strong mechanical properties, and the stability of the silicon negative electrode material in charging / discharging operation is remarkably improved; the conductive carbon black is uniformly bonded and dispersed in the binder, so that not only can the addition amount of free carbon black in the positive electrode slurry be reduced, but also a three-dimensional conductive network system can be formed, and excellent conductivity can be realized with a small amount, thereby effectively improving the capacity and power of a lithium battery cell.

Owner:安徽国洁新能源科技有限公司

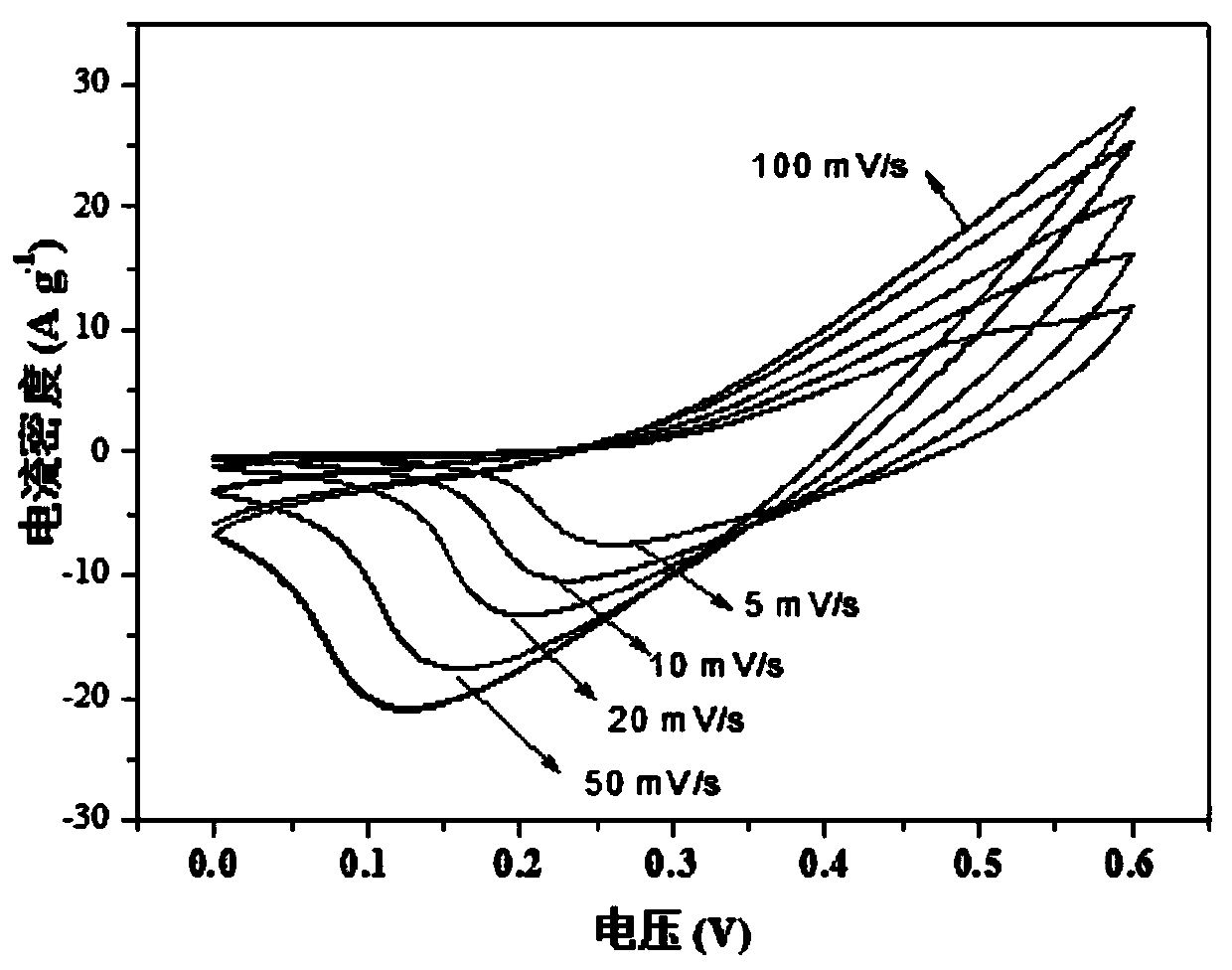

A kind of preparation method of nickel-iron sulfide/nickel foam nanocomposite electrode material

ActiveCN109243851BLower specific capacitySimple process routeHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceNano structuring

The invention discloses a preparation method of a nickel iron sulfide / foam nickel nano composite electrode material, The nickel-iron sulfide was prepared by calcination method combined with alcoholicheat method. The nickel-iron sulfide was directly grown on the surface of nickel foam, the material does not need processing and can be used as that electrode material of the supercapacitor directly,The invention can overcome the shortcomings of easily falling off active material and increasing electrode impedance in the process of electrochemical cycle of electrode material, and innovatively combines cobalt-nickel sulfide nanostructure and foam nickel to construct three-dimensional hollow interconnected nanostructure, increases ion nanochannels, and effectively improves the comprehensive capacitance performance of electrode material.

Owner:JIANGSU SOPO GRP +2

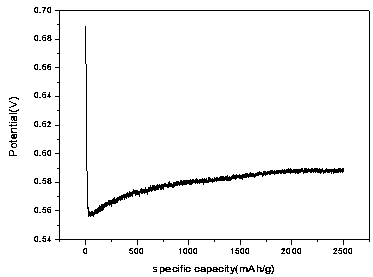

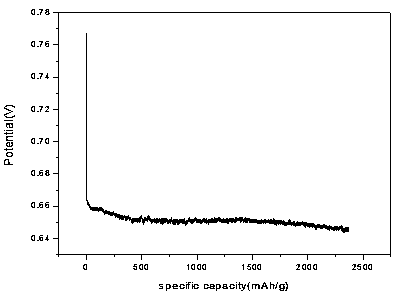

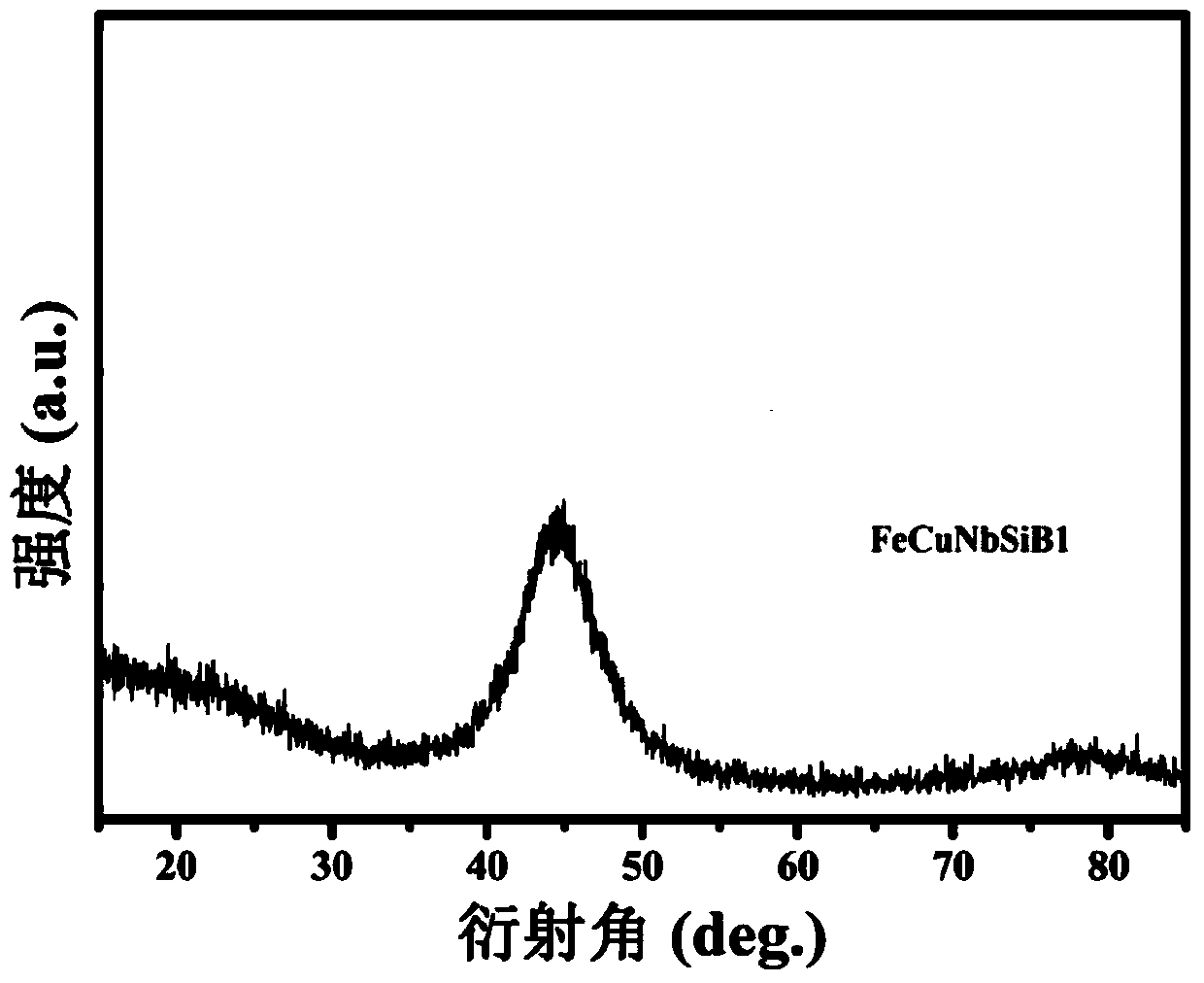

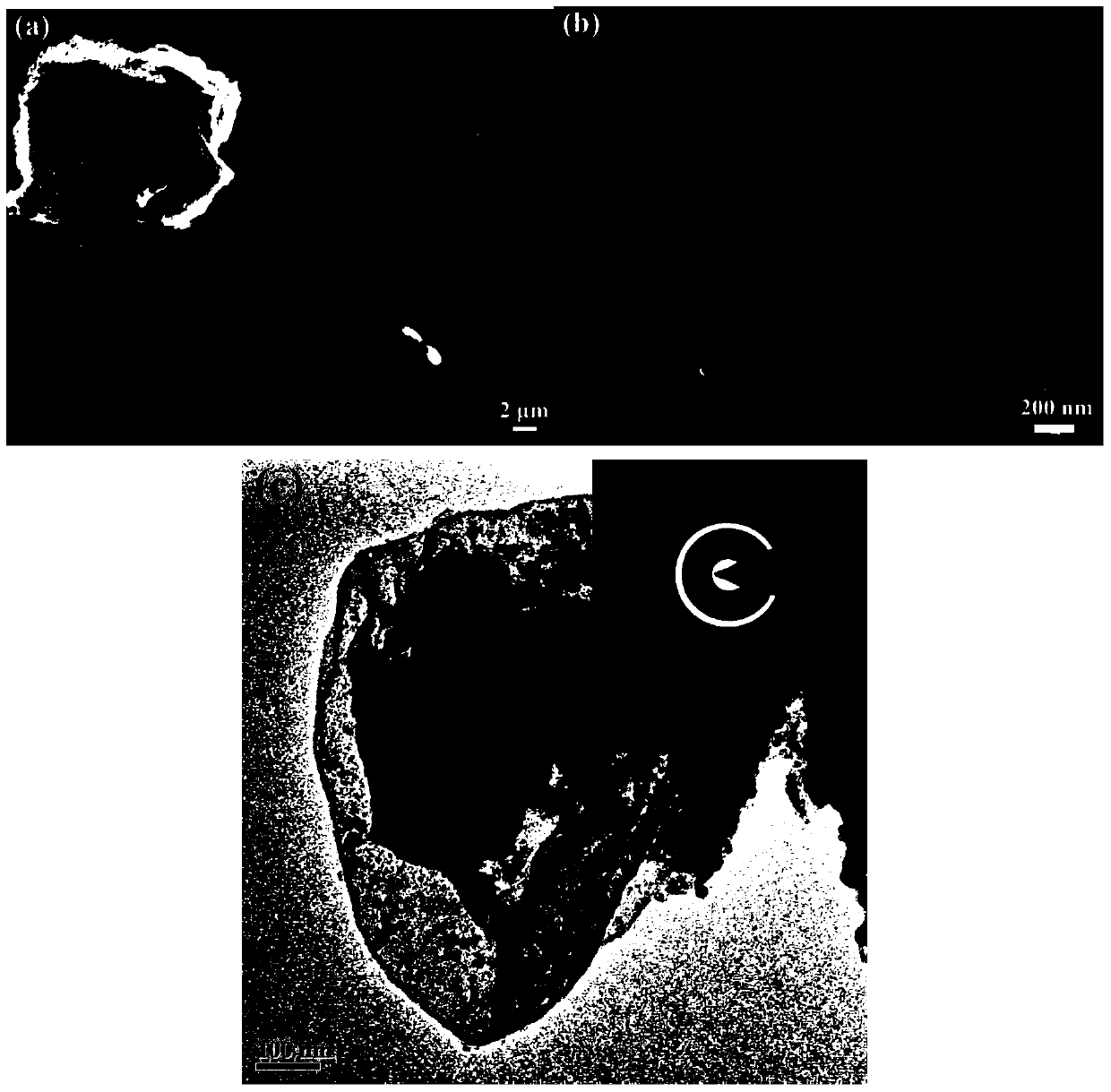

A kind of silicon-containing porous amorphous alloy lithium-ion battery negative electrode material and preparation method thereof

ActiveCN106159246BLower specific capacityImprove lithium intercalation capacityCell electrodesSecondary cellsFiltrationAlloy

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

A kind of preparation method of carbon nanotube doped tin oxide negative electrode material for lithium ion battery

ActiveCN103490053BNo pollution in the processImprove conductivityCell electrodesSecondary cellsCarbon nanotubeTin plating

The invention discloses a CNTs (carbon nanotubes)-doped tin oxide negative electrode material for a lithium-ion battery and a preparation method thereof. The preparation method comprises the following steps: firstly, compositely electroplating a CNTs-doped tin plating layer with the thickness of 10-15 microns on one side of the surface of a substrate of a pretreated copper strip; and secondly, anodizing the material obtained in the first step to obtain a mesoporous oxide, and performing heat treatment to finally obtain the lithium-ion battery negative electrode material with CNTs-uniformly-doped mesoporous tin oxide layer on one side of the surface of the substrate of the copper strip. The mesoporous diameter is 3-10nm and the obtained oxide layer has the thickness of 5-10 microns. The first specific discharge capacity of the lithium-ion battery negative electrode material can be as high as 650mAh / g, and after 50 cycles, the specific capacity is attenuated by only 0.8%-5%. The preparation method is simple in process, and large-scale industrial production can be carried out.

Owner:XIANGTAN UNIV

A method for preparing nickel-manganese spinel cathode material by magnetic field texturing

ActiveCN109279658BIncrease energy densityPromote circulationCell electrodesSecondary cellsElectrolytic agentNickel salt

The invention discloses a method of preparing nickel-manganese spinel cathode material through magnetic field texturing, which includes steps of: 1) performing coprecipitation to nickel salt and manganese salt to prepare a Ni-Mn precursor; 2) uniformly mixing the Ni-Mn precursor with a lithium source, and calcining the mixture to prepare a nickel-manganese spinel material; 3) crushing and sievingthe nickel-manganese spinel material and stirring and mixing the nickel-manganese spinel material with an additive in a stirrer, and during the stirring, applying an external magnetic field to the slurry. By means of interaction between Mn<3+> and the magnetic field, texturing is achieved in the magnetic field, so that the cathode slurry can face to the contact direction of an electrolyte with (111) crystal face as most as possible when coating an aluminum foil, thereby solving the problems of capacity degradation and poor high temperature cycle performance during charge / discharge process of the nickel-manganese spinel material; in the invention, when being used for assembling a battery, a cathode plate has excellent cycle and rate performance, is high in energy density, and has excellentapplication prospect in the fields such as power cars, large-size power plants and the like.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

A kind of sulfur/nitrogen/silicon co-doped graphite composite negative electrode material and preparation method thereof

ActiveCN109659546BImprove consistencyReduce bloatMaterial nanotechnologyCell electrodesCarbonizationLithium-ion battery

The invention relates to a sulfur / nitrogen / silicon co-doped graphite composite negative electrode material and a preparation method thereof, belonging to the technical field of preparation of lithium ion battery materials. The technical solution is: (1) Weigh 1~5g of sulfur-containing organic compound and 1~5g of nitrogen-containing organic compound into 500g of organic solvent, stir evenly, add 100g of graphite into it and stir evenly, after filtering, transfer to the tube type In the furnace, under an inert atmosphere, heat up to 200-500°C and keep it warm for 1-6 hours, then cool down to room temperature in an inert atmosphere to obtain graphite composite material A; into the surface layer of the graphite composite material A, and then carbonized to obtain a sulfur / nitrogen / silicon co-doped graphite composite negative electrode material. The invention improves the specific capacity of the graphite material by doping sulfur in the graphite material, and improves the electrical conductivity of the sulfur through nitrogen doping; the expansion of the material can be reduced and the liquid absorption capacity of the material can be improved.

Owner:CHENGDU EMINENT NEW ENERGY TECH CO LTD

A preparation method of graphene-based button-type supercapacitor with low internal resistance and high specific energy

ActiveCN106653397BAvoid the undesirable phenomenon of reunionLower specific capacityHybrid capacitor separatorsHybrid capacitor electrodesLiquid stateInternal resistance

The invention provides a preparation method for a low-internal-resistance and high-specific-energy graphene-based button type supercapacitor. The preparation method is characterized in that the low-internal-resistance and high-specific-energy graphene-based button type supercapacitor is prepared by the procedures of preparation of an electrode, preparation of a conductive glue solution, preparation of the button type supercapacitor and the like. By adding graphene, the preparation of the low-internal-resistance and high-specific-energy graphene-based button type supercapacitor is realized and the preparation process of the supercapacitor is lowered; by adding graphene to the electrode and the conductive glue in a powder state and in a liquid state, an adverse phenomenon of graphene agglomeration is avoided consequently; meanwhile, by introducing the high-conductivity and high-purity graphene material to the preparation process of the button type supercapacitor, the specific capacity of the supercapacitor is improved, and the internal resistance value of the supercapacitor is also lowered; and in addition, water content is not added in the electrode preparation process, so that internal electrode corrosion and generation of gas of the supercapacitor can be avoided.

Owner:芜湖洛菲斯企业管理咨询有限公司

A preparation method of porous oxide-wrapped battery silicon negative electrode material

ActiveCN106784763BLower specific capacityReduce the numberCell electrodesGas phaseSodium-ion battery

The invention provides a preparation method of a porous oxide-coated battery silicon anode material and relates to the technical field of preparation of lithium ion battery anode materials. The preparation method provided by the invention comprises the following steps: performing silicon anode material drying treatment; performing surface passivation treatment on a silicon anode material with ethyl alcohol; performing set cyclic cycle deposition in a gas-phase atomic layer deposition chamber to obtain the porous oxide-coated battery silicon anode material. The preparation method provided by the invention is simple and good in repeatability; the prepared lithium ion battery silicon anode material not only has large specific capacity, but also can inhibit the expansion of the silicon anode material in the charting and the discharging processes of a lithium ion battery, so that the lithium ion battery silicon anode material has good charging and discharging cycle performance.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

A kind of preparation method of sodium ion transition metal oxide cathode material

ActiveCN112510190BWeaken the Jahn-Teller effectImprove structural stabilityCell electrodesSecondary cellsSodium acetateElectrical battery

The invention discloses a method for preparing a sodium ion transition metal oxide positive electrode material. The preparation steps include the following steps: S1, mixing: first, stoichiometrically mix sodium acetate trihydrate, manganese acetate tetrahydrate, nickel acetate tetrahydrate, and acetic acid tetrahydrate Cobalt, magnesium acetate, zinc acetate dihydrate and citric acid were taken out and uniformly dissolved in a certain amount of water, then fully stirred and dissolved, then transferred to a water bath and continued to stir until gelatinous. The sodium ion positive plate prepared by the present invention can effectively weaken the Jahn-Teller effect of Mn3+ ions by doping Zn element inside it, and better improve the structural stability of the positive electrode material in the cycle process, thereby The cycle life and rate performance of the prepared material are effectively improved, and the amount of Zn doping can be further increased to continue to improve the cycle stability of the material. When used, it has excellent cycle performance and rate performance. This kind of positive electrode material can effectively promote sodium ion The practical application of the battery has strong practicability.

Owner:徐州浩华能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com