Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Low coat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Barrier coating of a mixture of cured and uncured elastomeric polymers and a dispersed layered filler in a liquid carrier and coated articles

Barrier coating mixtures include (a) a mixture of pre-vulcanized and non-vulcanized elastomeric polymers; (b) an acid or base treated dispersed, substantially exfoliated silicate filler material that has not been functionalized with organic cations having an aspect ratio greater than 25; and (c) at least one additive, wherein the total solids content is less than 30% and the amount of filler is between 5% to about 60% of the total solids content. The coating retains its permeability properties under strain and has a strain to first damage of at least 10% biaxial elongation at 0% RH.Coated articles, free standing films and membranes, which are flexible and elastomeric, are produced using the barrier coating mixtures. Methods of manufacturing of such coated products are also encompassed.

Owner:INMAT INC

Barrier coating of a non-butyl elastomer and a dispersed layered filler in a liquid carrier and coated articles

InactiveUS7078453B1Reduce penetrationIncrease flexibilityPigmenting treatmentMaterial nanotechnologyElastomerTotal solid content

Barrier coating mixtures include (a) a non-butyl elastomeric polymer; (b) an acid or base treated dispersed, substantially exfoliated silicate filler material that has not been functionalized with organic cations having an aspect ratio greater than 25; and (c) at least one additive, wherein the total solids content is less than 30% and the amount of filler is between 5% to about 60% of the total solids content. The coating retains its permeability properties under strain and has a strain to first damage of at least 5% biaxial elongation at 0% RH.

Owner:IPL

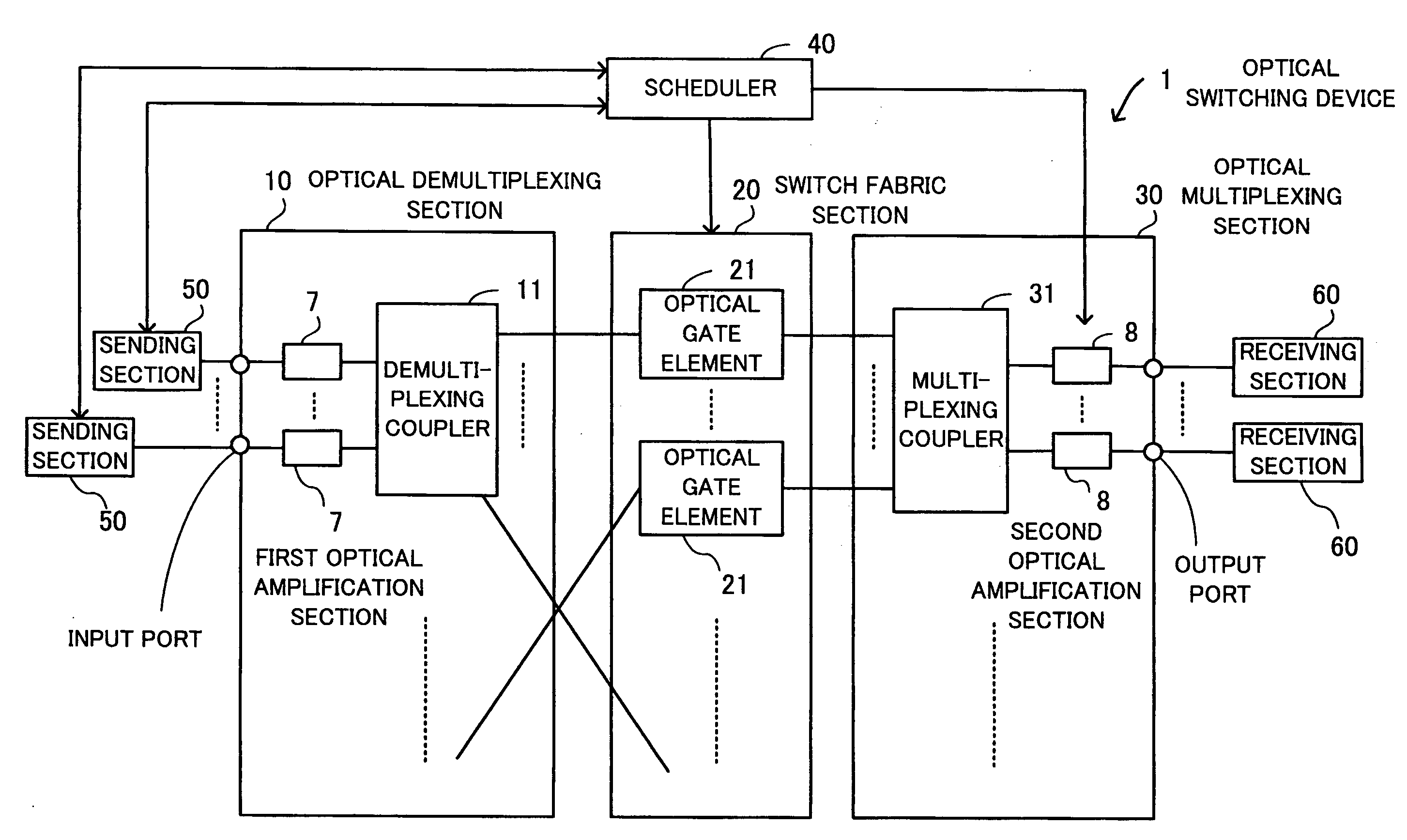

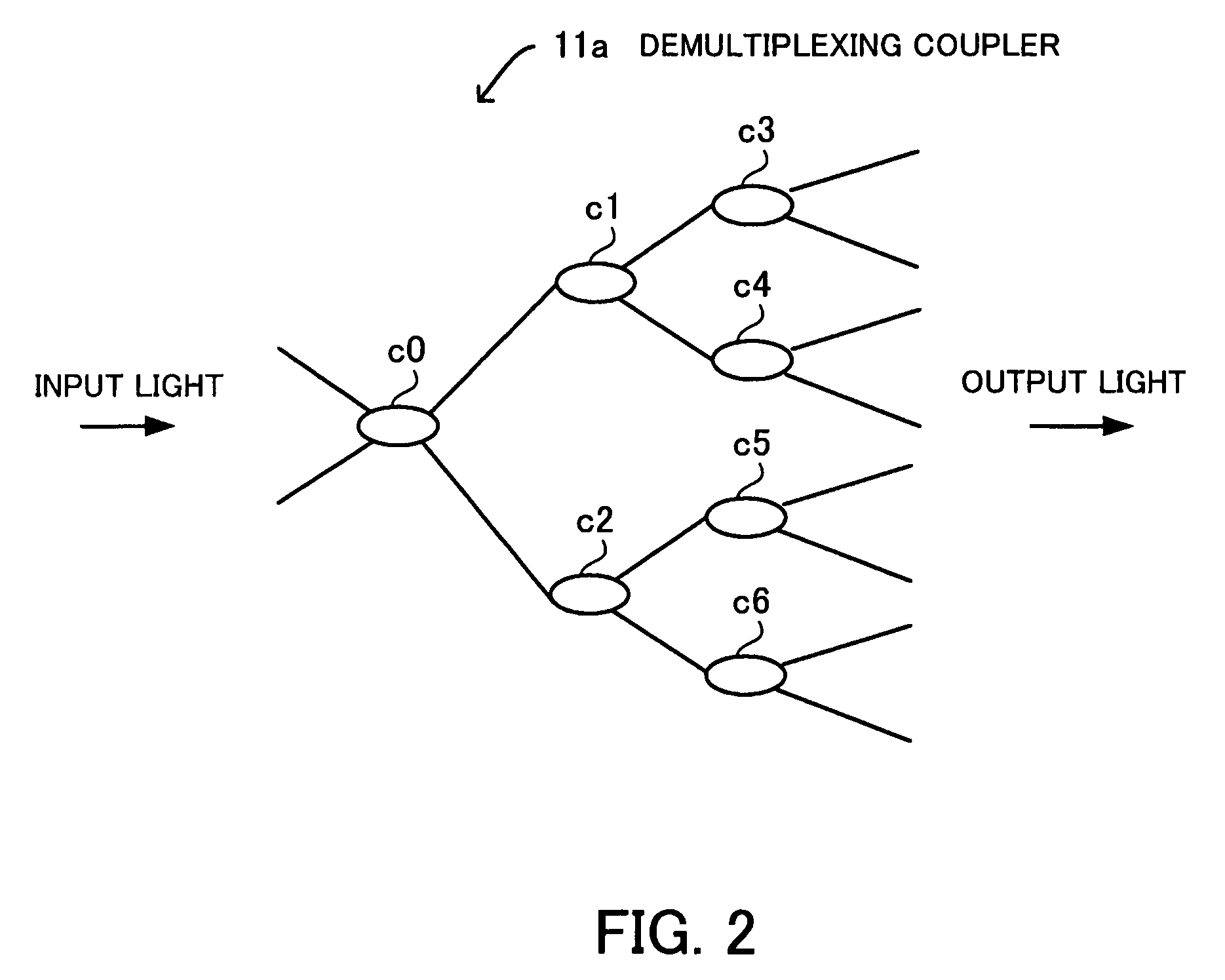

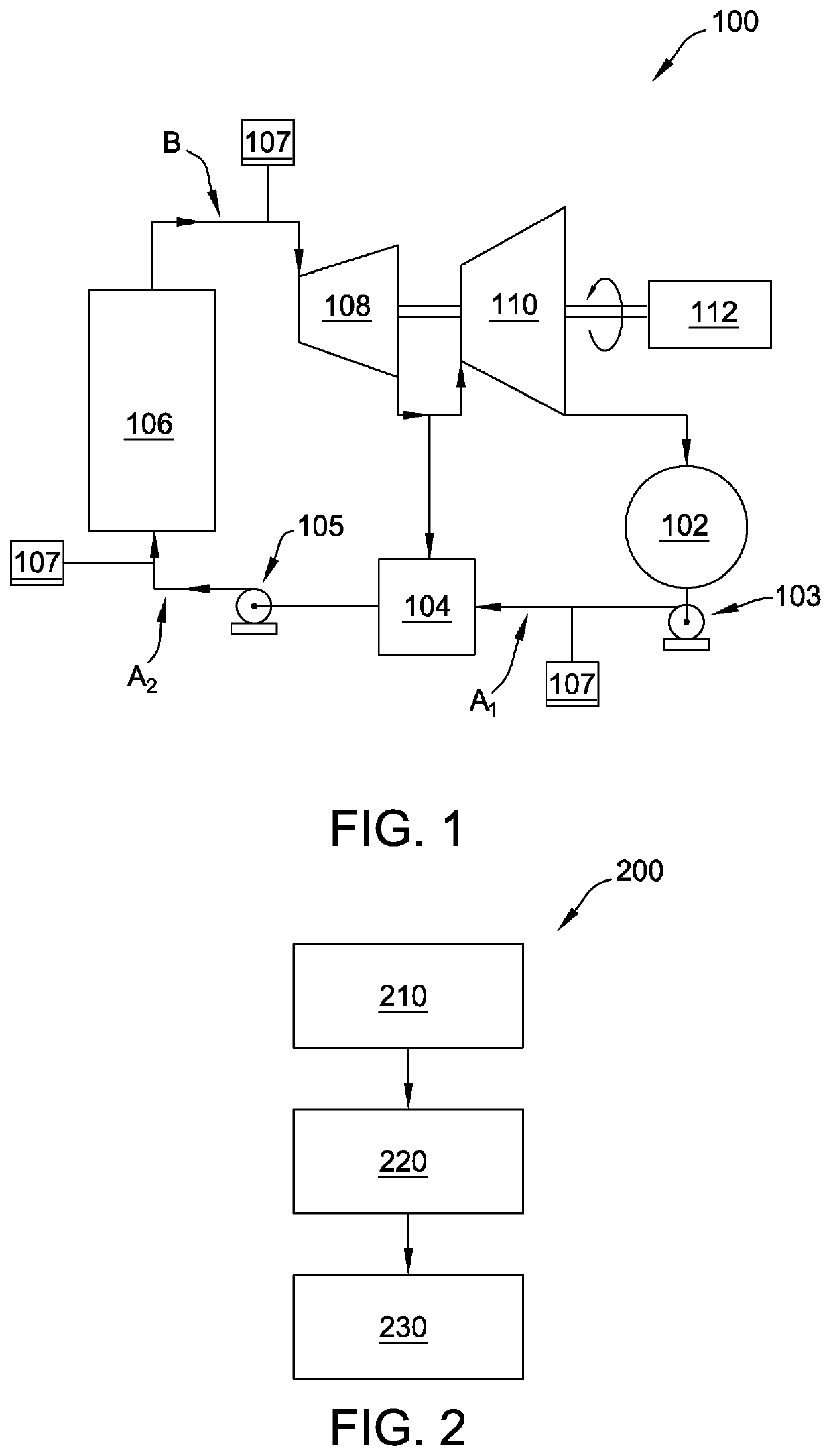

Optical switching device

ActiveUS20090003827A1Low coatScale upMultiplex system selection arrangementsOptical multiplexMultiplexingOptical packet

An optical switching device the size and costs of which are reduced by decreasing the number of switching elements and which can flexibly accommodate the expansion of the number of ports. An optical demultiplexing section has 2n (n=1, 2, 3, . . . ) input ports and 2m (m>n) output ports and includes demultiplexing couplers for demultiplexing input optical packets. A switch fabric section includes optical gate elements for switching optical packets outputted from the optical demultiplexing section by switch drive control. An optical multiplexing section has 2m input ports and 2n output ports and includes multiplexing couplers for multiplexing the optical packets which pass through the optical gate elements. A scheduler exercises control over an entire optical packet switching process.

Owner:FUJITSU LTD

Polyaniline in the form of an easily dispersible powder and its use in corrosion protection and electrostatic dissipation

InactiveUS6060116AReadily dispersibleLow surface area and oil absorptionLiquid surface applicatorsGlass/slag layered productsParticulatesConductive polymer

Conductive polymer sheathed polymeric particulate powders comprise a polymeric core powder; and from about 5 to about 30 percent by weight of an intrinsically conductive polymer forming a sheath around the core powder. A method of providing corrosion protection to metal substrates comprises applying a conductive polymer sheathed polymeric particulate powder to a metal substrate to form a coating at least about 0.5 mils thick; wherein the conductive powder comprises a polymeric core powder; and from about 5 to about 30 percent by weight of an intrinsically conductive polymer forming a sheath around the core powder, the resulting conductive polymer powder having a particle size greater than about 1 micron.

Owner:AMERICHEM INC

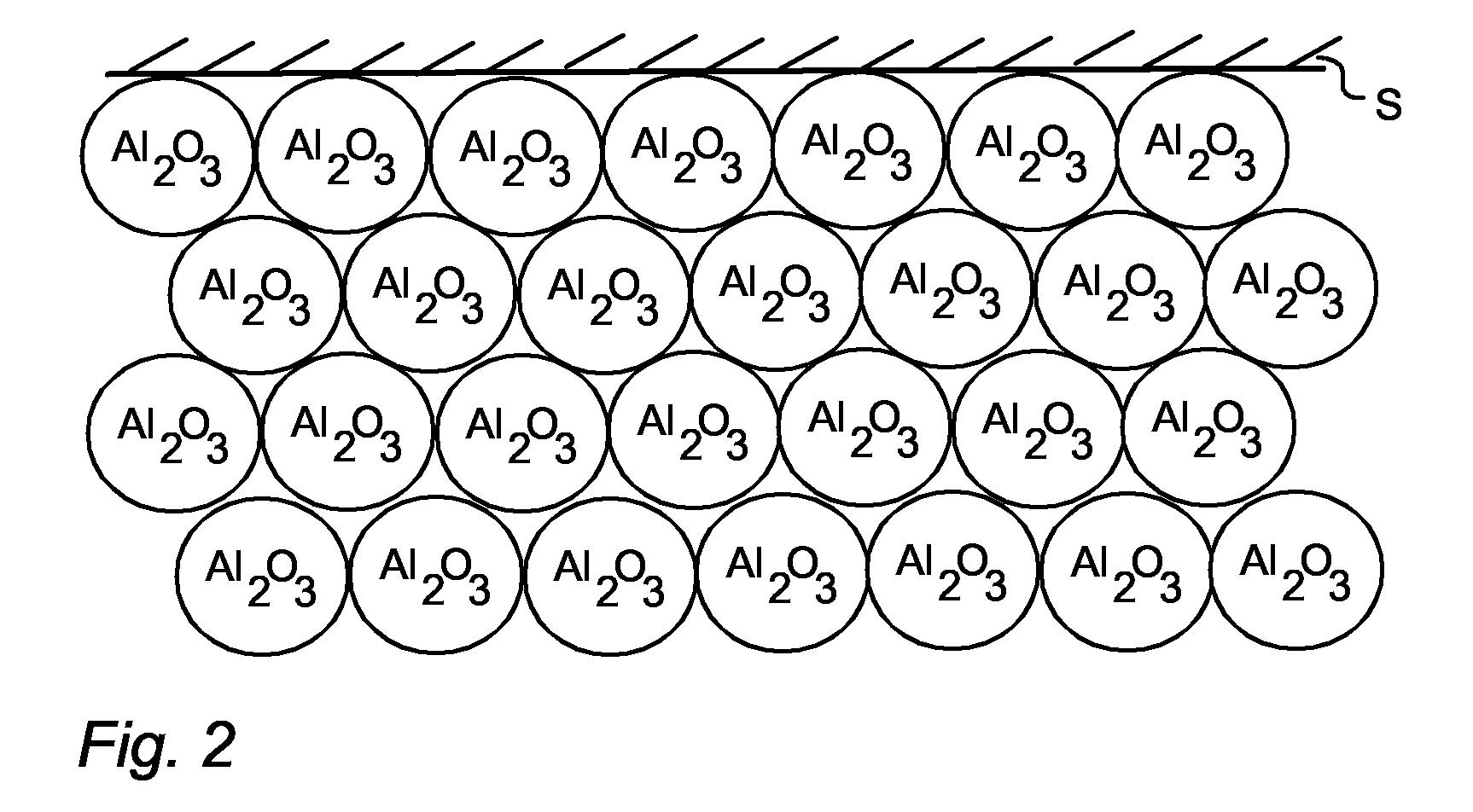

Protective Coating of Silver

ActiveUS20090004386A1Avoid tarnishingThin coatingJewelleryChemical vapor deposition coatingAtomic layer depositionFilm-coated tablet

In the method, silver is protected against tarnishing using an Atomic Layer Deposition method. In the Atomic Layer Deposition method, a thin film coating is formed 5 on the surface of silver by depositing successive molecule layers of the coating material. For example aluminium oxide (Al 2O3) or zirconium oxide may be used as the coating material.

Owner:BENEQ OY

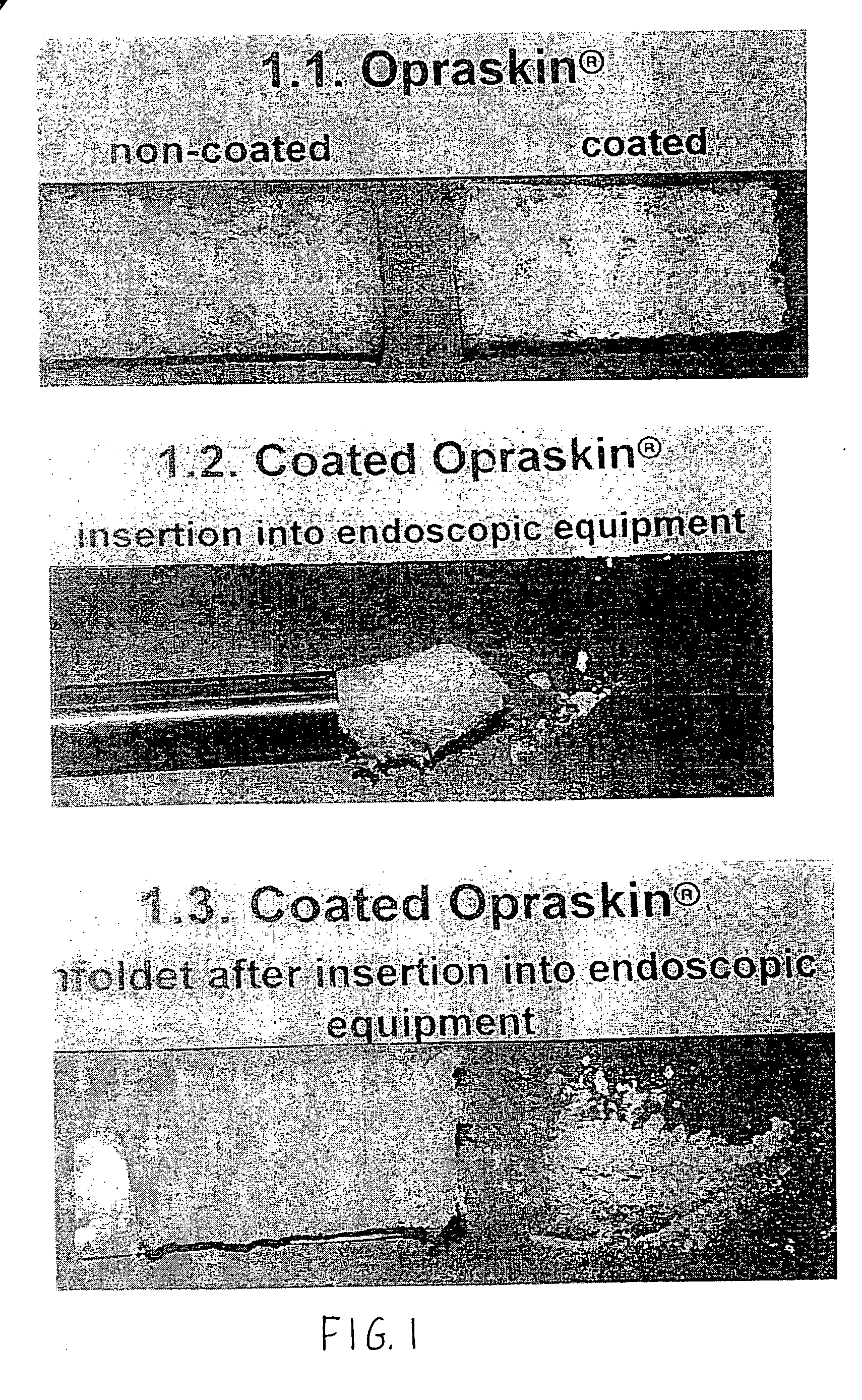

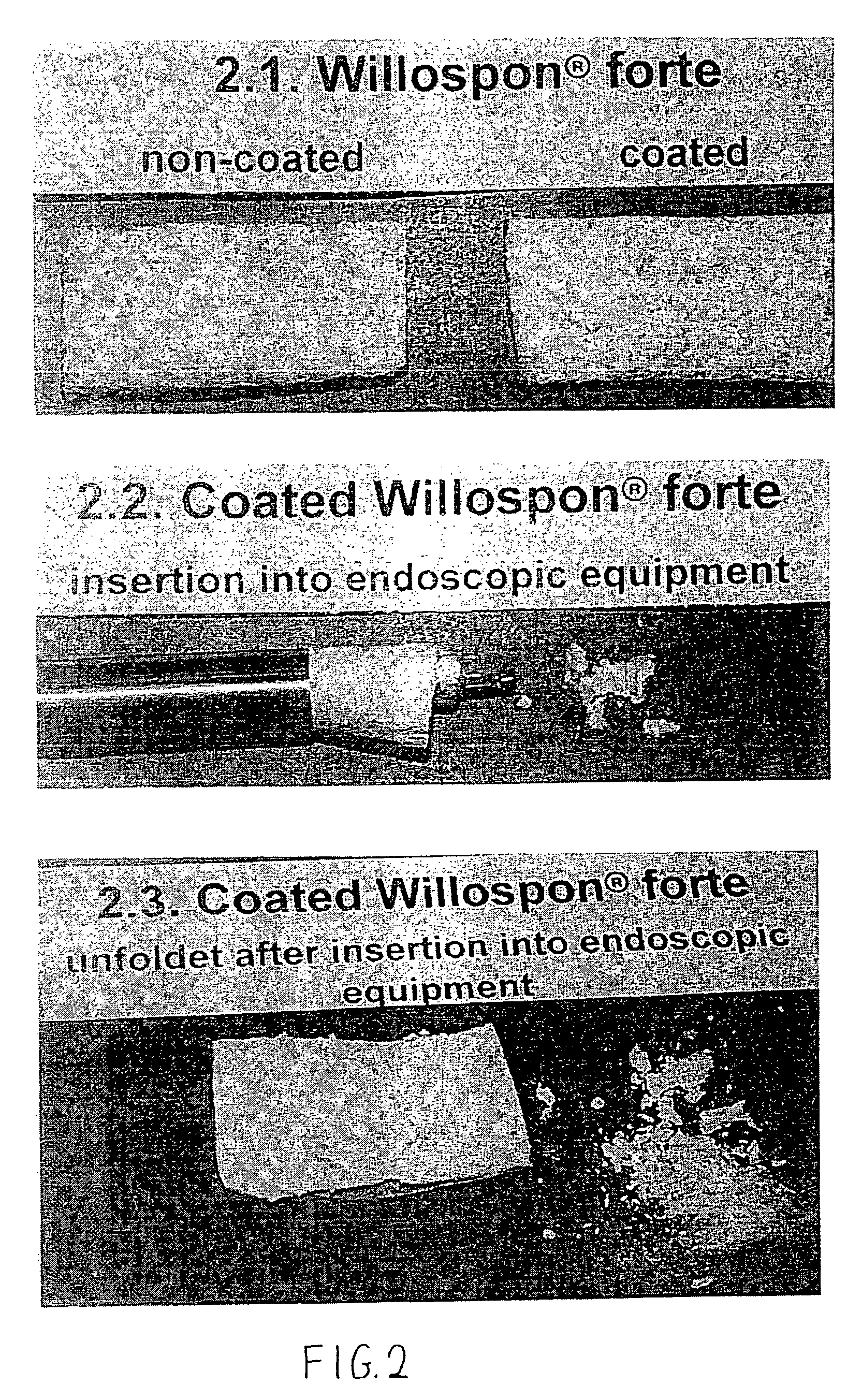

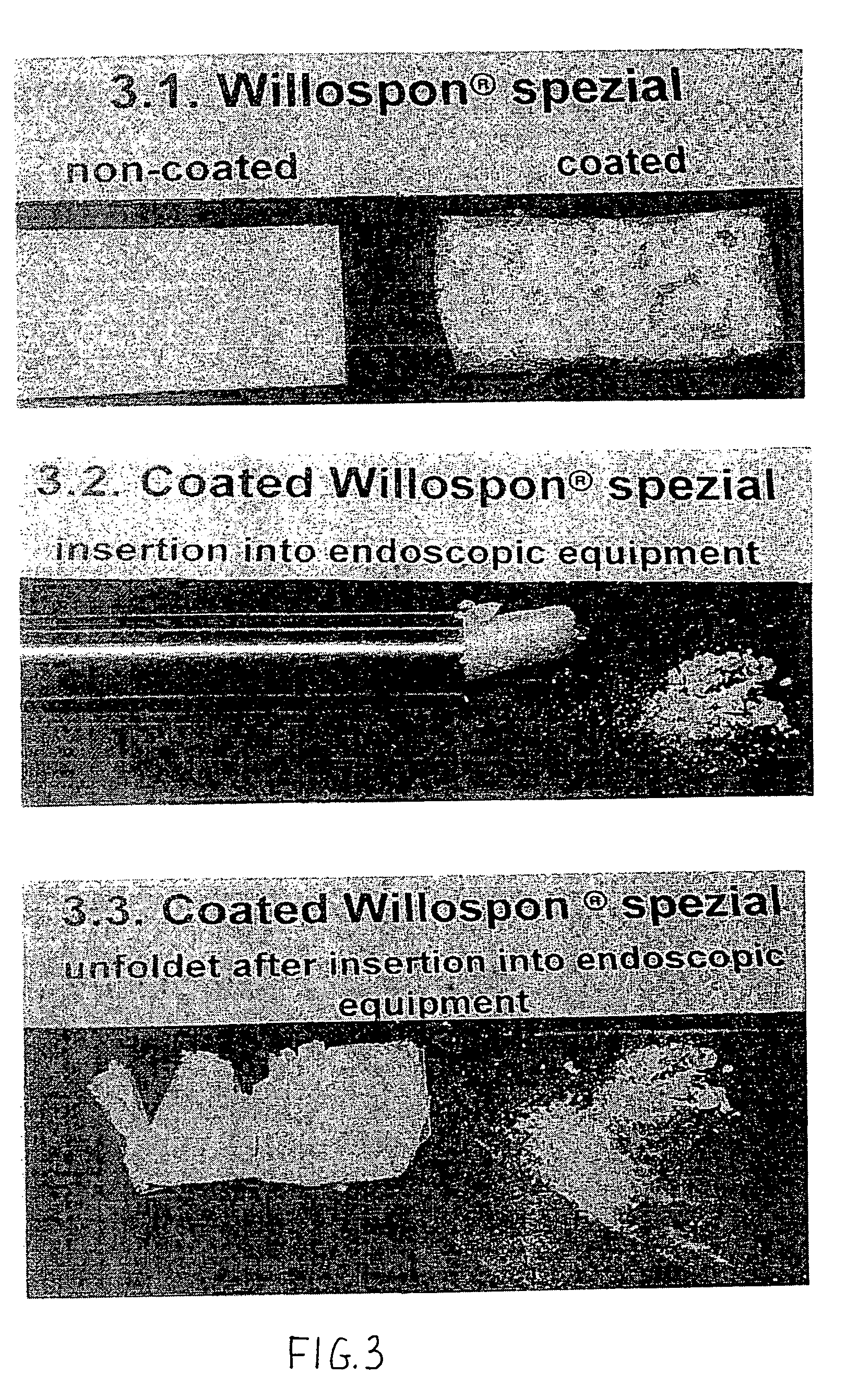

Suspension comprising fibrinogen, thrombin and alcohol, a method for preparing such a suspension, a method for coating a carrier with such a suspension, a method of drying a coating of a carrier, and a coated collagen sponge

InactiveUS20050214277A1Easy to identifySatisfy fixationSurgical adhesivesFibrinogenFiberMean diameter

A suspension of fibrinogen, thrombin, alcohol and optionally aprotinin is obtained by mixing fibrinogen in alcohol with thrombin in alcohol. The suspension contains fibrinogen and thrombin particles with a Folk Ward mean diameter of 25-100 μm. The thrombin may be human, bovine or recombinant. The fibrinogen may be human or recombinant. A method for coating a carrier, such as a collagen sponge, with the suspension, and a method for drying the coating is disclosed. The coated collagen carrier may be used as a ready-to-use absorbable composition for tissue gluing, tissue sealing and hemostasis wherein the carrier is coated with solidly fixed components of fibrin glue, i.e. fibrinogen and thrombin.

Owner:SCHAUFLER ALFRED

Powder coating composition for coating surfaces of thermoplastic composites

ActiveUS20070036969A1Low bake powder coatingImprove adhesionSynthetic resin layered productsPretreated surfacesCarvacryl acetateThermoplastic composites

A powder coating composition for coating on thermoplastic composites comprising an intimate mixture comprising: A) 50 to 99 wt % of at least one ethylene vinyl acetate copolymer with a vinyl acetate content in the range of 10 to 30 wt %, B) 1 to 50 wt % of at least one thermoplastic and / or thermosetting binder resin, and C) 0 to 20 wt % of at least one pigment and / or filler, the wt % amounts are based on the total weight of the powder coating composition A) to C); the powder coating composition has excellent adhesion to thermoplastic composite as well as an enhanced impact resistance; and is suitable for use as a pigmented or unpigmented coating composition for thermoplastic substrates based on a composite of glass and thermoplastic fibers and provides a completely recyclable thermoplastic composite coated with the thermoplastic powder coating composition.

Owner:DUPONT POLYMER POWDERS SWITZERLAND

Process for producing reactive silane oligomers

InactiveUS6329489B1Low coatHigh solid contentGroup 4/14 element organic compoundsCoatingsOligomerPolymer science

The invention is directed to a process for making a reactive silane oligomer having low polydispersity, viscosity and volatility. The process utilizes reacting unsymmetrical difunctional silane monomers with water, diol monomers, or a combination thereof to make the reactive silane oligomer. The unsymmetrical difunctional silane monomers are with silane reactive groups having significantly different reactivities. Use of such reactive silane oligomers results in multi-component coating compositions having high miscibility, low VOC, low viscosity and high percentage of solids.

Owner:EI DU PONT DE NEMOURS & CO

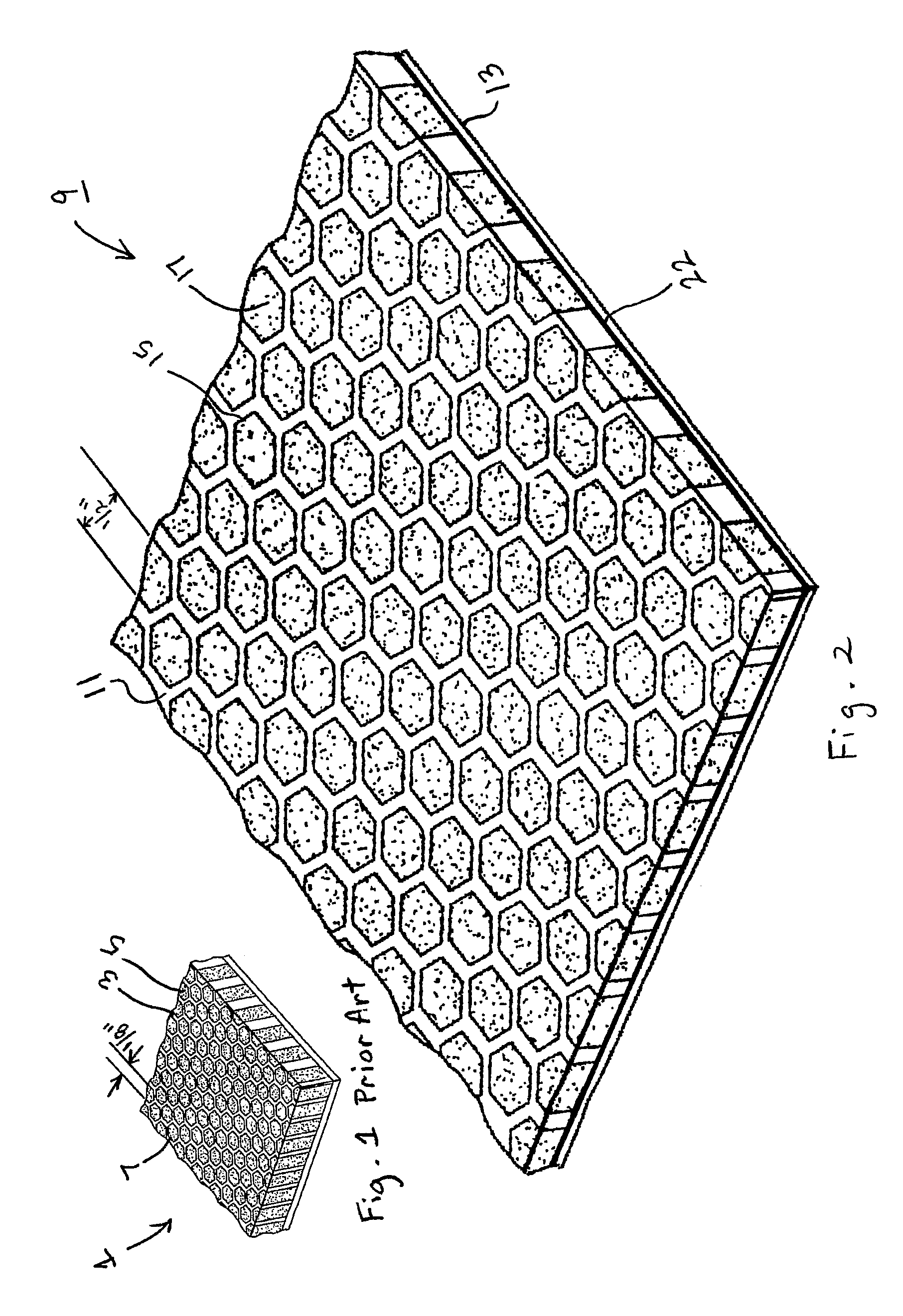

Method and apparatus for reducing the infrared and radar signature of a vehicle

ActiveUS7345616B2Reducing radar/microwaveReducing thermal/infrared signatureMixing methodsWingsRadarHoneycomb

A radar-absorbing panel (9) includes a honeycomb core (11) and a lower skin (13), where the lower skin (13) is attached to the bottom of the honeycomb core (11). The honeycomb core (11) is made up of individual cells (15), which may be filled with aerogel. The individual cells (15) are approximately ½ of an inch in size with polygonal shape.

Owner:TEXTRON INNOVATIONS

Curable resin composition for convering a fingernail or artificial fingernail

ActiveUS20120276028A1Good lookingSuperior property in waterCosmetic preparationsToilet preparationsEmulsionPolyethylene glycol

The present invention provides a curable resin composition for coating natural or artificial nails, which in particular exhibits an excellent appearance after coating, high water and scratch resistances, and low levels of odor, damage to nails, and dermal irritancy, resulting in a high level of safety to human bodies and superior storage stability. The curable resin composition for coating a natural or artificial nail of the present invention comprises (A) an aqueous emulsion of a polymer having functional groups polymerizable by exposure to active energy radiation, (B) polyethylene glycol, and (C) a photo radical initiator containing no nitrogen atom in its molecule.

Owner:THREEBOND FINE CHEM CO LTD

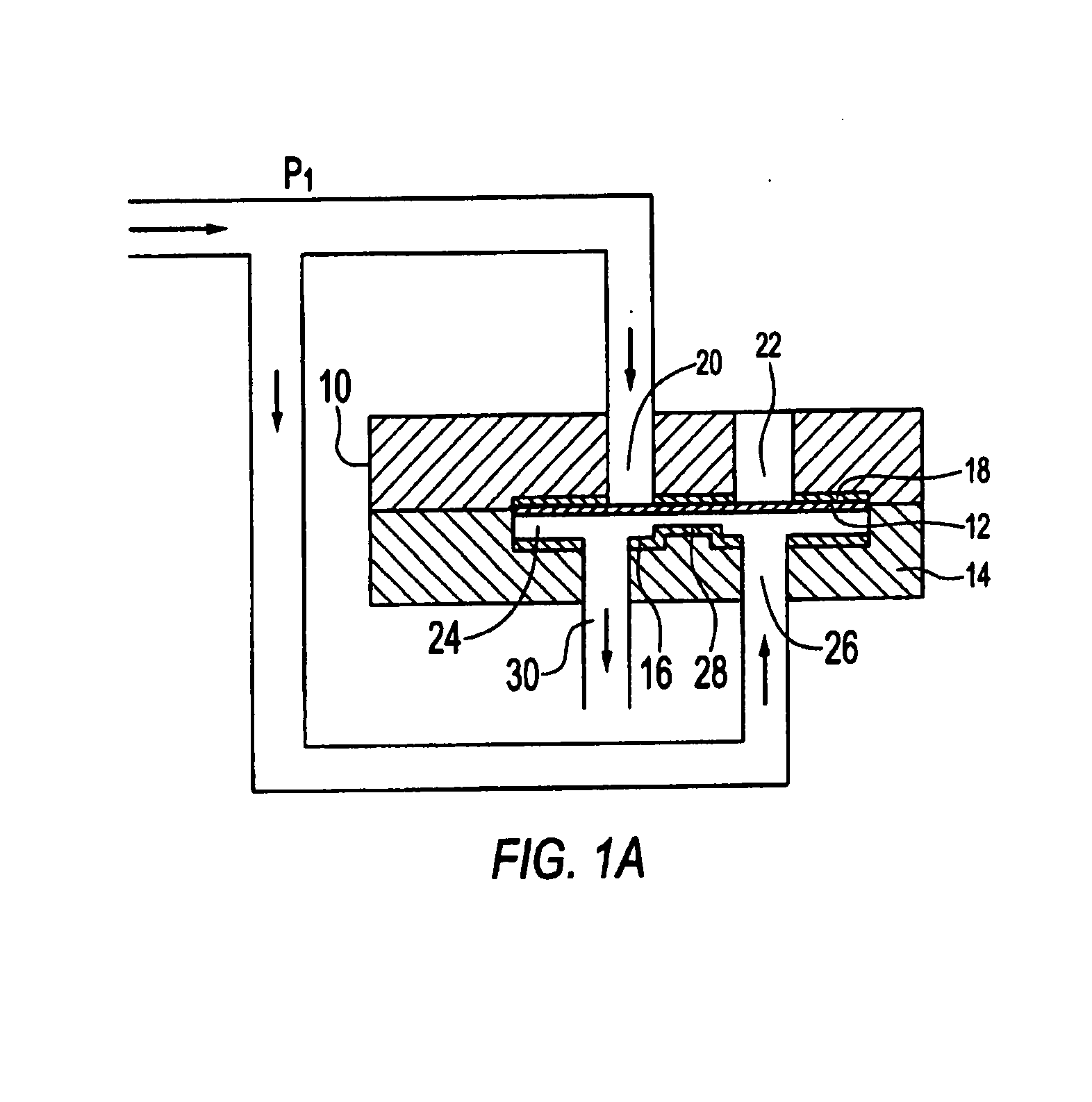

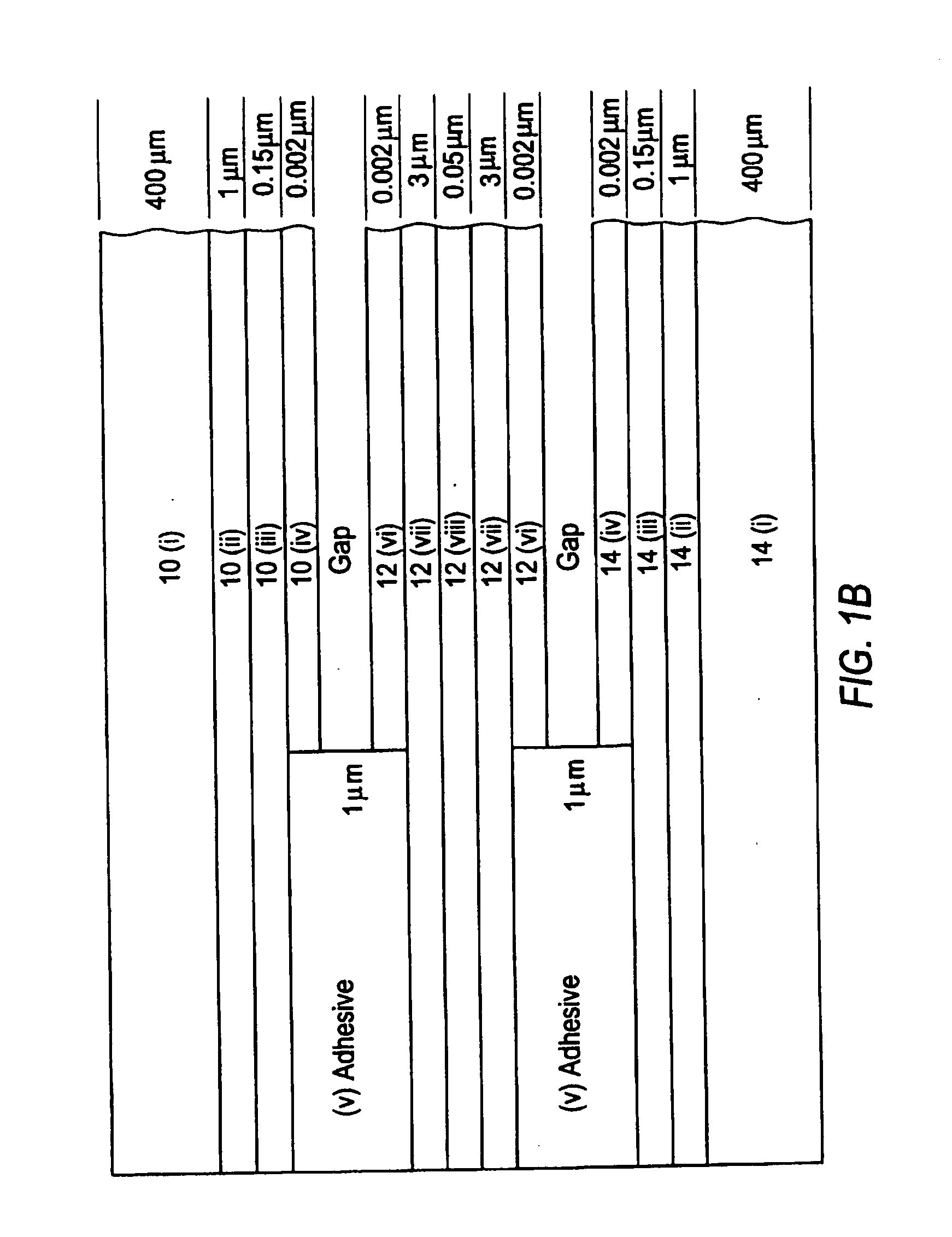

Bi-direction rapid action electrostatically actuated microvalve

InactiveUS20080149869A1Reduces film squeeze pressureQuickly actuateAdditive manufacturing apparatusOperating means/releasing devices for valvesSurface energyMicro valve

A bi-directional electrostatic microvalve includes a membrane electrode that is controlled by application of voltage to fixed electrodes disposed on either side of the membrane electrode. Dielectric insulating layers separate the electrodes. One of the fixed electrodes defines a microcavity. Microfluidic channels formed into the electrodes provide fluid to the microcavity. A central pad defined in the microcavity places a portion of the second electrode close to the membrane electrode to provide a quick actuation while the microcavity reduces film squeezing pressure of the membrane electrode. In preferred embodiment microvalves, low surface energy and low surface charge trapping coatings, such as fluorocarbon films made from cross-linked carbon di-fluoride monomers or surface monolayers made from fluorocarbon terminated silanol compounds coatings coat the electrode low bulk charge trapping dielectric layers limit charge trapping and other problems and increase device lifetime operation.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

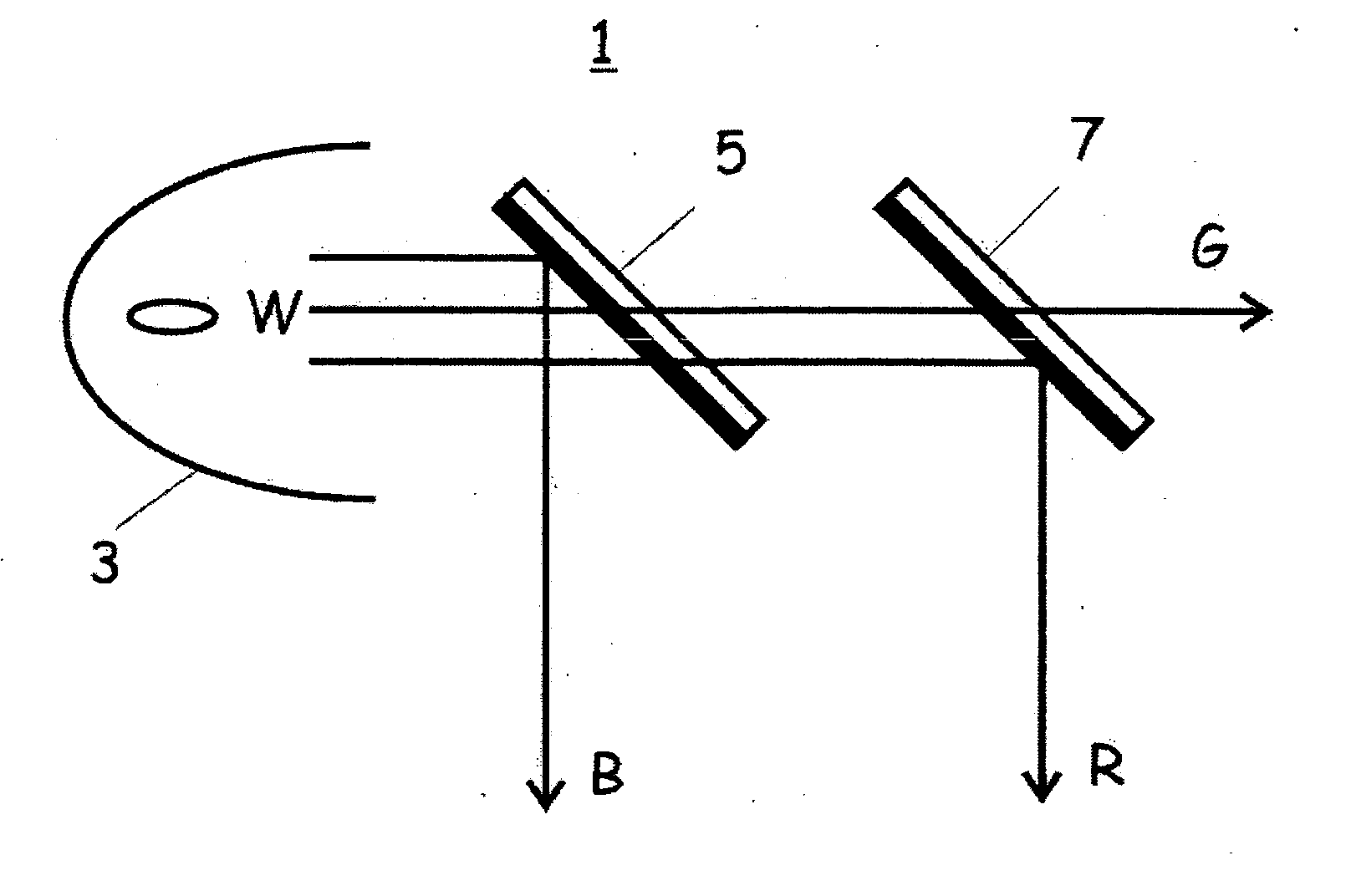

Device for combination of light of different wavelengths

ActiveUS20060256445A1Produced cost-effectivelyEffective combinationOptical elementsLight beamLength wave

The present invention relates to a method for combining or for splitting the beam paths of substantially nonpolarized light of at least three different wavelength intervals. The splitting or the combining of the beam path of light of those wavelength intervals located between the other wavelength intervals takes place when the beam paths of the light of the two other wavelength intervals are already or still combined. The present invention also relates to an illumination unit comprising a white light source and utilizing this method by means of interference filters for splitting the white light into red, blue and green light beams. The invention also relates to an illumination unit comprising a red, green and blue light source and utilizing these methods by means of interference filters for the combination of the beam paths of the light sources.

Owner:OERLIKON SURFACE SOLUTIONS AG PFAFFIKON

Bondably Coated Metallic Member

InactiveUS20080286514A1Low coatHigh surface energyRadiation applicationsPretreated surfacesHigh surfacePolymer

The present provides a bondably coated metallic member comprising a metallic member having a low surface energy polymeric coating, said low surface energy polymeric coating having been surface activated on at least a portion thereof, and having on said surface-activated portion a bondable high surface energy polymeric coating. The present invention also provides a bondably-coated metallic pipe comprising metallic pipe having a low surface energy mainline polymeric coating thereon extending over the pipe except at a bare zone adjacent each end of the pipe that is free from said main-line coating; a portion of said mainline coating adjacent each bare zone having been surface activated and having on said surface activated portion a bondable high surface energy polymeric coating.

Owner:SHAWCOR LTD

Color filter and process for producing the same

There is provided a color filter which comprises a transparent substrate, a picture element part provided on the transparent substrate by the predetermined pattern of a plurality of colors with an ink jet system, a shading part provided on a border part of this picture element part, and a wettability-variable layer, in which the wettability can be changed, provided for forming the picture element part or the picture element part and the shading part.

Owner:DAI NIPPON PRINTING CO LTD

Optical switching device

ActiveUS8170416B2Low coatScale upMultiplex system selection arrangementsOptical multiplexMultiplexingOptical packet

An optical switching device the size and costs of which are reduced by decreasing the number of switching elements and which can flexibly accommodate the expansion of the number of ports. An optical demultiplexing section has 2n (n=1, 2, 3, . . . ) input ports and 2m (m>n) output ports and includes demultiplexing couplers for demultiplexing input optical packets. A switch fabric section includes optical gate elements for switching optical packets outputted from the optical demultiplexing section by switch drive control. An optical multiplexing section has 2m input ports and 2n output ports and includes multiplexing couplers for multiplexing the optical packets which pass through the optical gate elements. A scheduler exercises control over an entire optical packet switching process.

Owner:FUJITSU LTD

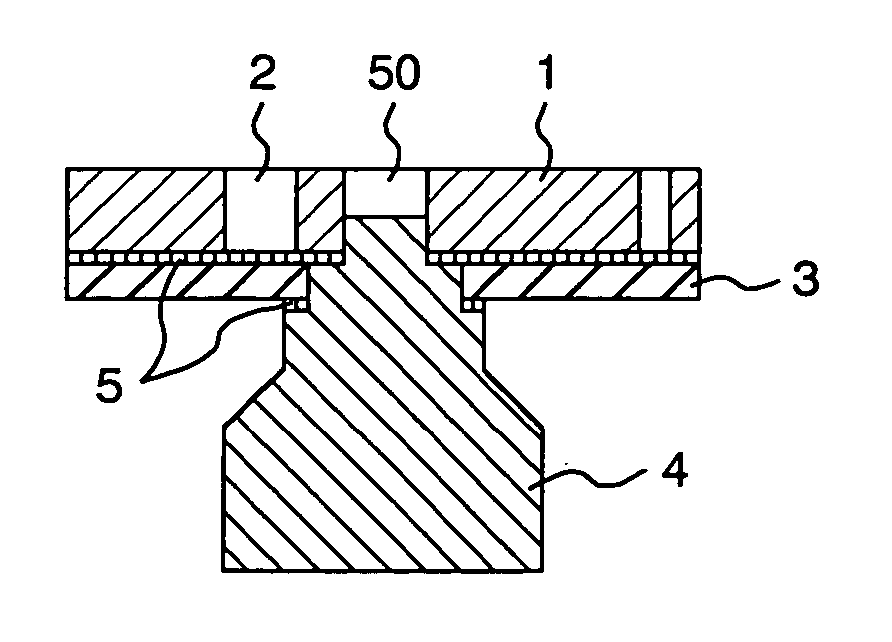

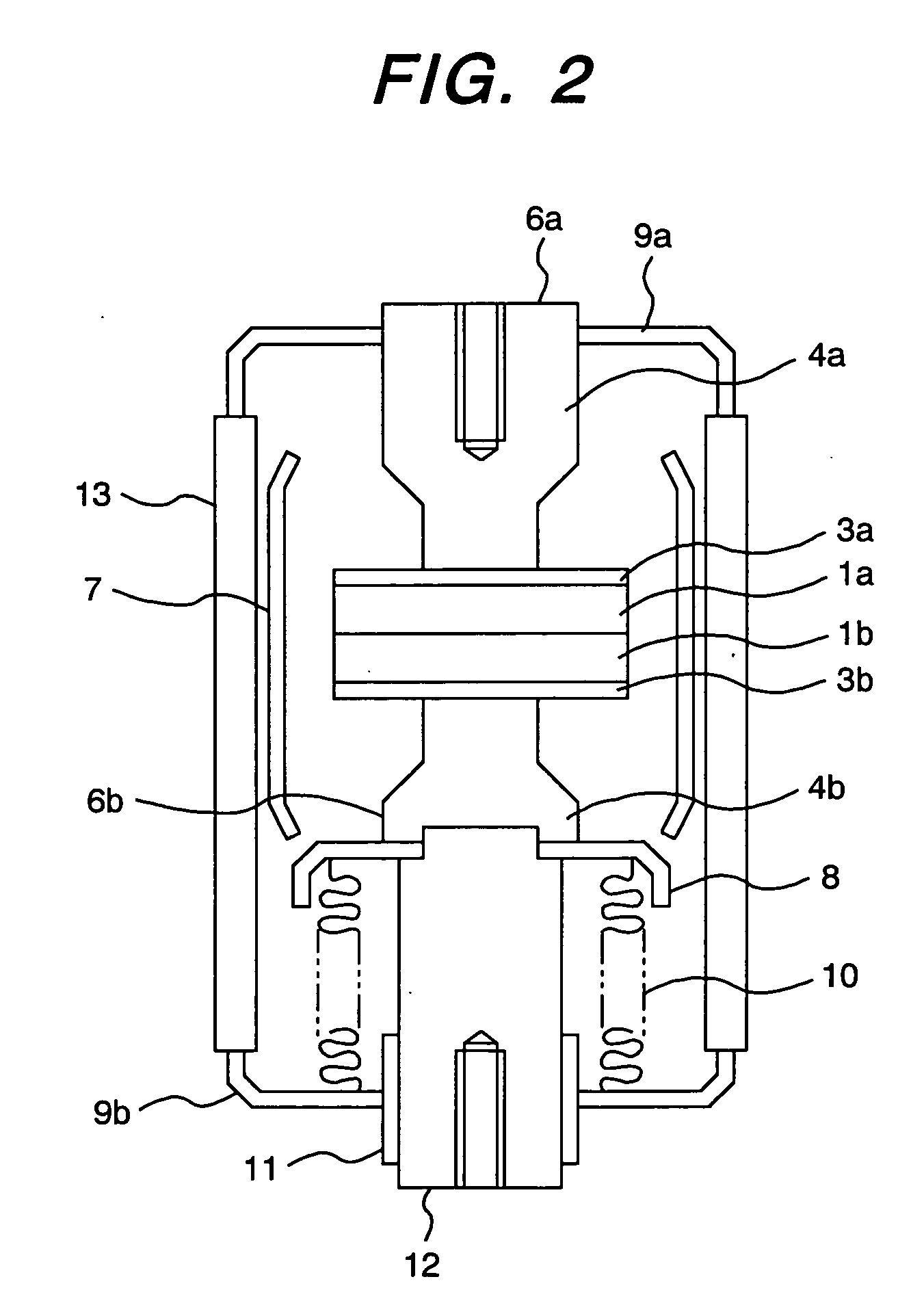

Electrical contact, method of manufacturing the same, electrode for vacuum interrupter, and vaccum circuit breaker

InactiveUS20050092714A1Solution to short lifeDecrease productivityContact materialsContact surface shape/structureMetallurgyVacuum interrupter

The present invention relates to an sintered electric contact containing Cr in an amount of 15 to 30% by weight and Cu being balance as main components, 0.05 to 0.5% by weight of Te, 100 to 3000 ppm of O, 7.5 to 900 ppm of Al, and 15 to 750 ppm of Si.

Owner:JAPAN AE POWER SYST

Method for applying a coating to a polymeric substrate

ActiveUS20150240115A1Avoid adsorptionThe method is simple and reliablePretreated surfacesPolyether coatingsAnalytePolymer substrate

A single-step method for applying a coating to a polymeric substrate comprising: exposing a photoreactive compound and a polymeric compound in an aqueous solvent to ultraviolet radiation in the presence of said polymeric substrate to obtain a covalently bound coating thereon comprising a reaction product of the photoreactive compound and the polymeric compound. More particularly, the present invention relates to a method of applying a coating to a polymeric substrate in order to reduce the adsorption of analytes in solution to said substrate by imparting properties to the substrate similar to the properties of the coating applied.

Owner:SOPHION BIOSCI

Powder coating

ActiveUS9505946B2Maintain good propertiesIncrease resistanceSynthetic resin layered productsPretreated surfacesParticulatesOrganic acid

Owner:JOTUN POWDER COATINGS N

Protective coating of silver

InactiveUS20140335272A1Avoid tarnishingThin coatingJewelleryChemical vapor deposition coatingAtomic layer depositionMaterials science

In the method, silver is protected against tarnishing using an Atomic Layer Deposition method. In the Atomic Layer Deposition method, a thin film coating is formed on the surface of silver by depositing successive molecule layers of the coating material. For example aluminium oxide (Al2O3) or zirconium oxide may be used as the coating material.

Owner:BENEQ OY

Bi-direction rapid action electrostatically actuated microvalve

InactiveUS8628055B2Reduces film squeezing pressureStart fastAdditive manufacturing apparatusOperating means/releasing devices for valvesCross-linkTrapping

A bi-directional electrostatic microvalve includes a membrane electrode that is controlled by application of voltage to fixed electrodes disposed on either side of the membrane electrode. Dielectric insulating layers separate the electrodes. One of the fixed electrodes defines a microcavity. Microfluidic channels formed into the electrodes provide fluid to the microcavity. A central pad defined in the microcavity places a portion of the second electrode close to the membrane electrode to provide a quick actuation while the microcavity reduces film squeezing pressure of the membrane electrode. In preferred embodiment microvalves, low surface energy and low surface charge trapping coatings, such as fluorocarbon films made from cross-linked carbon di-fluoride monomers or surface monolayers made from fluorocarbon terminated silanol compounds coatings coat the electrode low bulk charge trapping dielectric layers limit charge trapping and other problems and increase device lifetime operation.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Article of manufacture comprising surfaces of thermoplastic composites coated with a powder coating composition

ActiveUS7976947B2Improve adhesionImproved covering of abrasive glass fibersSynthetic resin layered productsCeramic layered productsAcetic acidThermoplastic composites

A powder coating composition for coating on thermoplastic composites comprising an intimate mixture comprising:A) 50 to 99 wt % of at least one ethylene vinyl acetate copolymer with a vinyl acetate content in the range of 10 to 30 wt %,B) 1 to 50 wt % of at least one thermoplastic and / or thermosetting binder resin, andC) 0 to 20 wt % of at least one pigment and / or filler,wherein the wt % amounts are based on the total weight of the powder coating composition A) to C); and the powder coating composition has excellent adhesion to the thermoplastic composite and enhanced impact resistance.

Owner:DUPONT POLYMER POWDERS SWITZERLAND

Two component powder coating system and method for coating a heat sensitive substrate therewith

InactiveUSRE36742E1Without their problemLow glossPretreated surfacesPowdery paintsPowder coatingExtrusion

[Wood] A heat sensitive substrate is [electrostatically] coated with a thermosetting powder coating system in which a mixture of a self-curing epoxy resin and a catalyst therefore is extruded and pulverized and a low temperature curing agent [are both] a pulverized and the powders are blended with conventional additives to make a coating powder which is deposited on [a wooden] the substrate and heated to cure. The mixture of resin and catalyst does not cure within the extruder but it is made to cure at low temperatures by the separate addition of the curing agent. A small amount of the low temperature curing agent, insufficient to cause substantial curing during extrusion may be used in place of the catalyst.

Owner:ROHM & HAAS CHEM LLC

Monolithic LCD projector

ActiveUS10509306B1Small volumeNovel shapeProjectorsPicture reproducers using projection devicesLong axisLCD projector

A monolithic liquid crystal display (LCD) projector includes a light emitting diode (LED) light source, a condenser, a collimating lens, an LCD light valve, a field lens and a projection lens. The LCD light valve is disposed between the collimating lens and the field lens. The condenser is disposed between the LED light source and the collimating lens. The projection lens is disposed behind the field lens. A first reflector is disposed between the field lens and the projection lens. The first reflector conducts mirror reflection along a long axis thereof. The present disclosure has the characteristics of small volume, novel shape, good color uniformity of the image, good radiating performance and long service life.

Owner:CHEN LING

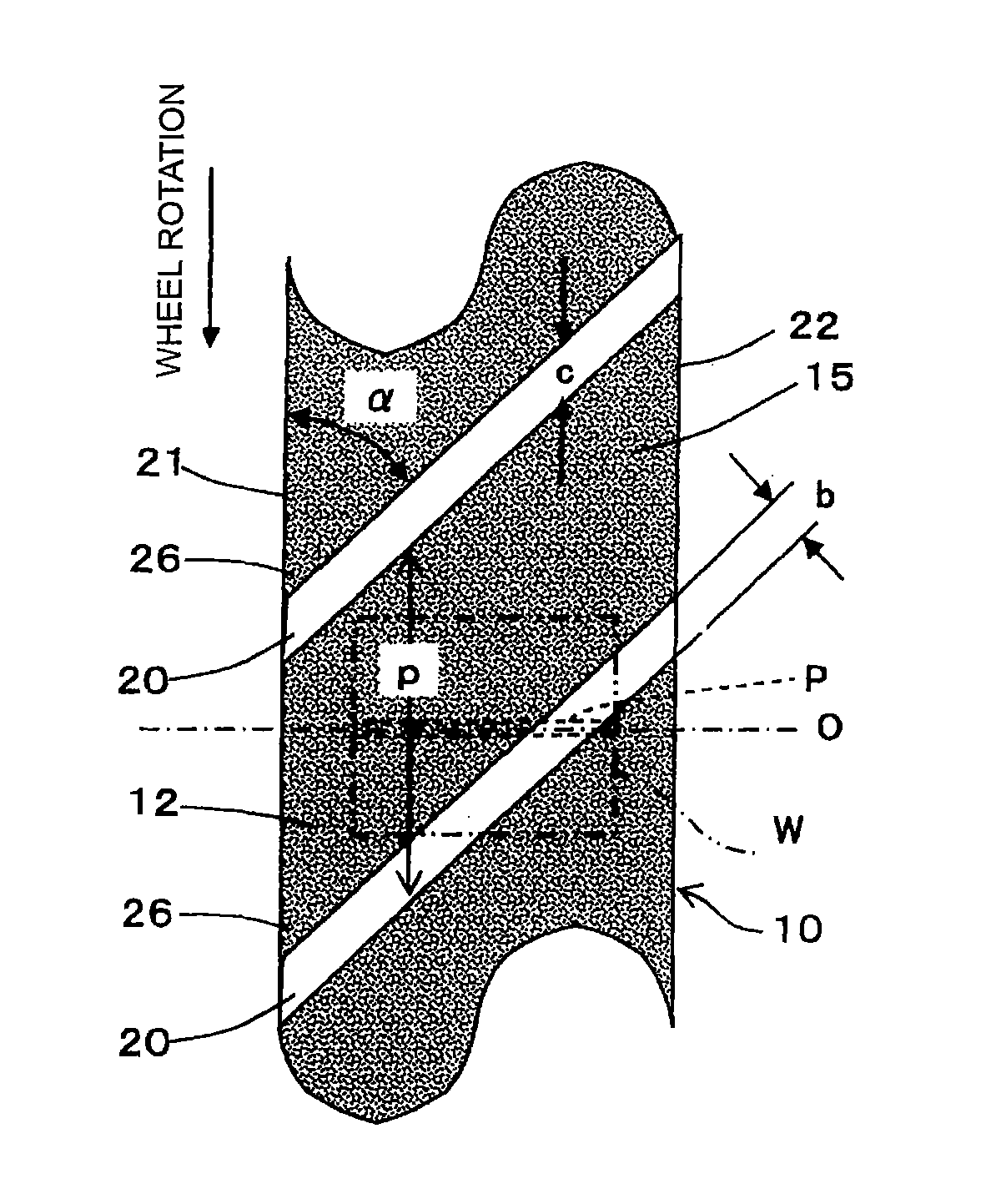

Method for manufacturing grinding wheel having depressions on grinding surface thereof

InactiveUS8444726B2Reduce retentionIncreased durabilityOther chemical processesBonded abrasive wheelsWear particleMetallurgy

Owner:JTEKT CORP +1

Method for applying a coating to a polymeric substrate

ActiveUS10519339B2Avoid adsorptionThe method is simple and reliablePretreated surfacesPolyether coatingsAnalytePolymer substrate

A single-step method for applying a coating to a polymeric substrate comprising: exposing a photoreactive compound and a polymeric compound in an aqueous solvent to ultraviolet radiation in the presence of the polymeric substrate to obtain a covalently bound coating thereon comprising a reaction product of the photoreactive compound and the polymeric compound. More particularly, a method of applying a coating to a polymeric substrate in order to reduce the adsorption of analytes in solution to the substrate by imparting properties to the substrate similar to the properties of the coating applied.

Owner:SOPHION BIOSCI

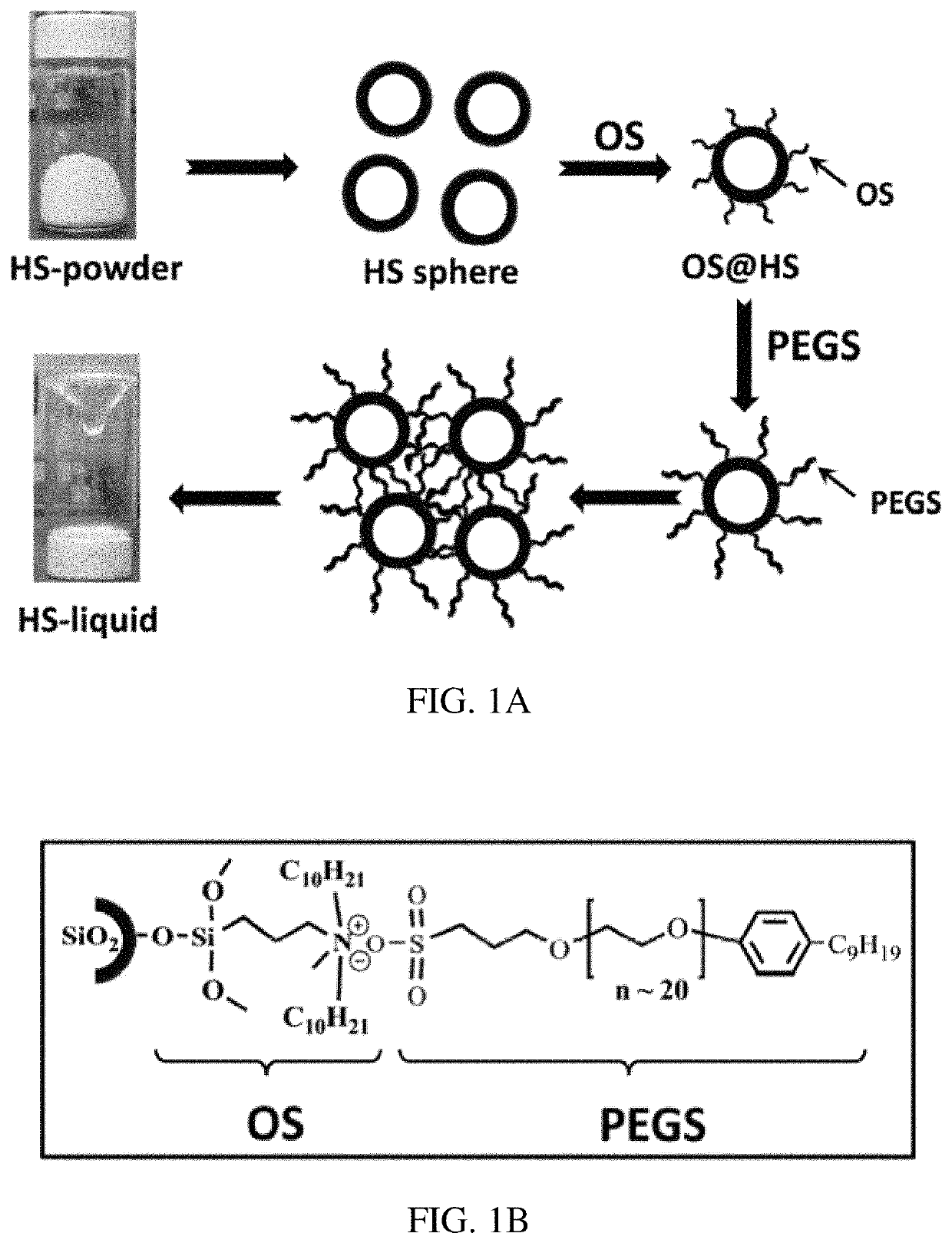

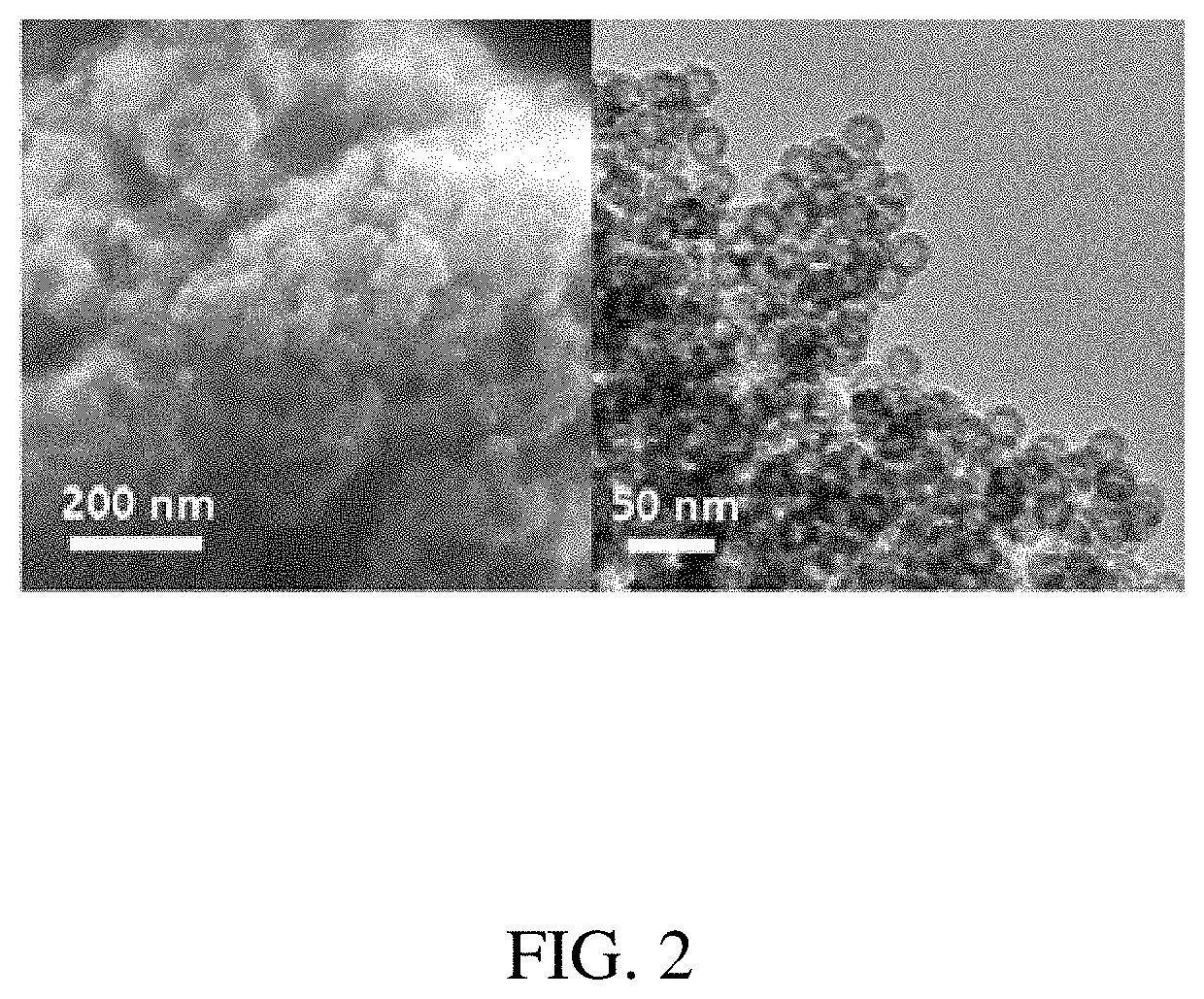

Porous thermally insulating compositions containing hollow spherical nanoparticles

ActiveUS10738202B2Weakened ionic interactionHigh viscosityThermal insulationInorganic active ingredientsNanoparticleParticle-size distribution

A method of thermally insulating a surface, the method comprising applying a coating of a thermally insulating composition onto said surface, wherein said thermally insulating composition comprises: (i) hollow spherical nanoparticles having a mean particle size of less than 800 nm in diameter and a particle size distribution in which at least 90% of the hollow spherical nanoparticles have a size within ±20% of said mean particle size, and a first layer of cationic or anionic molecules attached to said surfaces of the hollow spherical nanoparticles; and (ii) a second layer of molecules of opposite charge to the first layer of molecules, wherein said second layer of molecules of opposite charge are ionically associated with said first layer of molecules, wherein the molecules in said second layer have at least eight carbon atoms.

Owner:UNIV OF TENNESSEE RES FOUND +1

Boron-containing stainless steel having excellent hot workability and surface property

A boron-containing stainless steel having excellent hot workability and weldability and a good surface quality is proposed and is a boron-containing stainless steel comprising C: 0.001˜0.15 mass %, Si: 0.1˜2 mass %, Mn: 0.1˜2 mass %, Ni: 5˜25 mass %, Cr: 11˜27 mass %, B: 0.05˜2.5 mass %, Al: 0.005˜0.2 mass %, O: 0.0001˜0.01 mass %, N: 0.001˜0.1 mass %, S: not more than 0.005 mass %, one or both of Mg: 0.0001˜0.005 mass % and Ca: 0.0001˜0.005 mass % and the remainder being Fe and inevitable impurities provided that a part of Si, Al, Mg, Ca and S is included as a non-metallic inclusion made of sulfide and / or oxysulfide.

Owner:NIPPON YAKIN IND KK

Improving steam power plant efficiency with novel steam cycle treatments

ActiveUS11261762B2Improve efficiencyLow coatSteam regenerationSteam/vapor condensersSteam powerProcess engineering

A process for improving the efficiency of a steam power generation plant, the process providing utilizing steam or water from a steam cycle of a steam power plant; and supplying a steam cycle treatment to the steam cycle, thereby generating a hydrophobic coating within the steam cycle.

Owner:BL TECH INC

Improving steam power plant efficiency with novel steam cycle treatments

ActiveUS20200291825A1Improve efficiencyIncrease steam plant efficiencySteam regenerationSteam/vapor condensersSteam powerProcess engineering

A process for improving the efficiency of a steam power generation plant, the process providing utilizing steam or water from a steam cycle of a steam power plant; and supplying a steam cycle treatment to the steam cycle, thereby generating a hydrophobic coating within the steam cycle.

Owner:BL TECH INC

Protective coating of silver

ActiveUS8883258B2Avoid tarnishingThin coatingJewelleryChemical vapor deposition coatingAtomic layer depositionZirconium oxide

In the method, silver is protected against tarnishing using an Atomic Layer Deposition method. In the Atomic Layer Deposition method, a thin film coating is formed 5 on the surface of silver by depositing successive molecule layers of the coating material. For example aluminum oxide (Al 2O3) or zirconium oxide may be used as the coating material.

Owner:BENEQ OY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com