Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Less likely to interfere" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

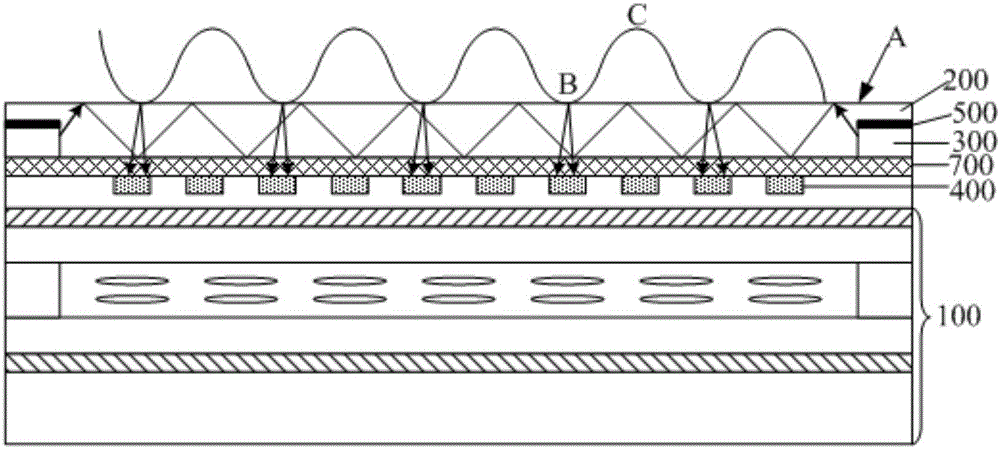

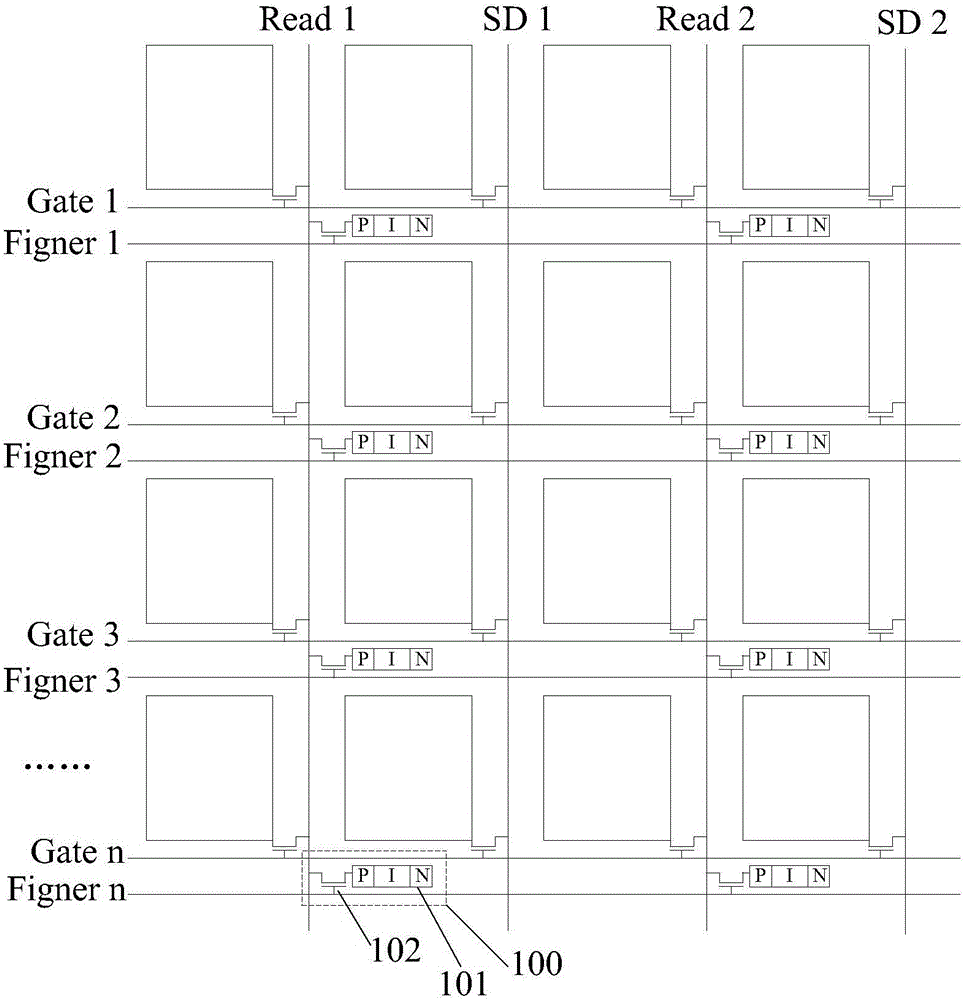

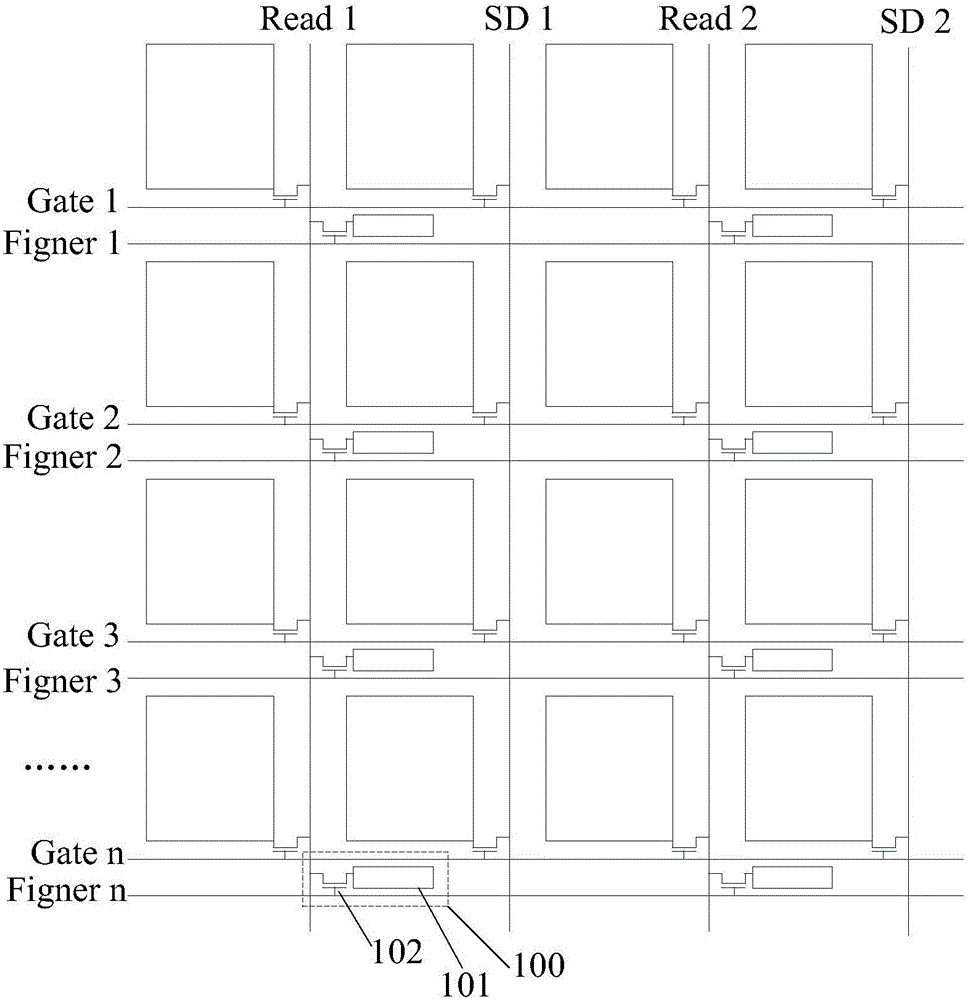

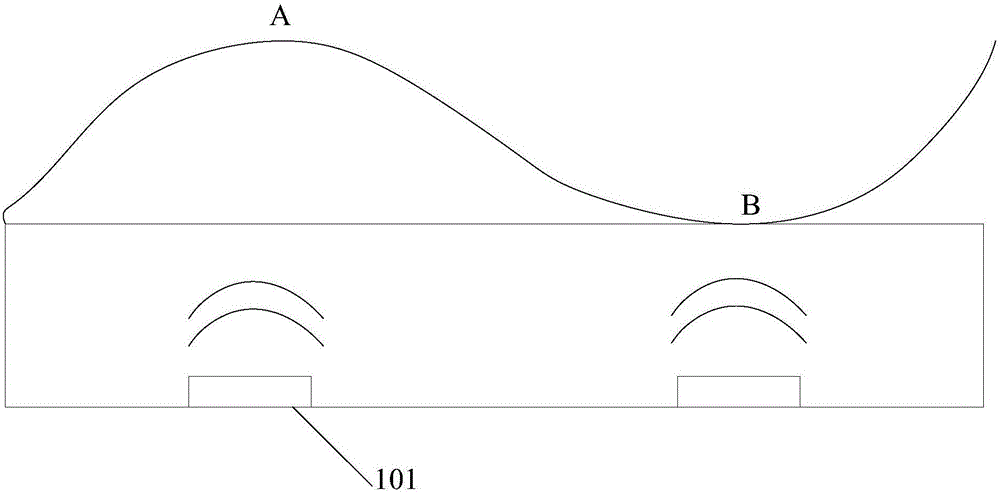

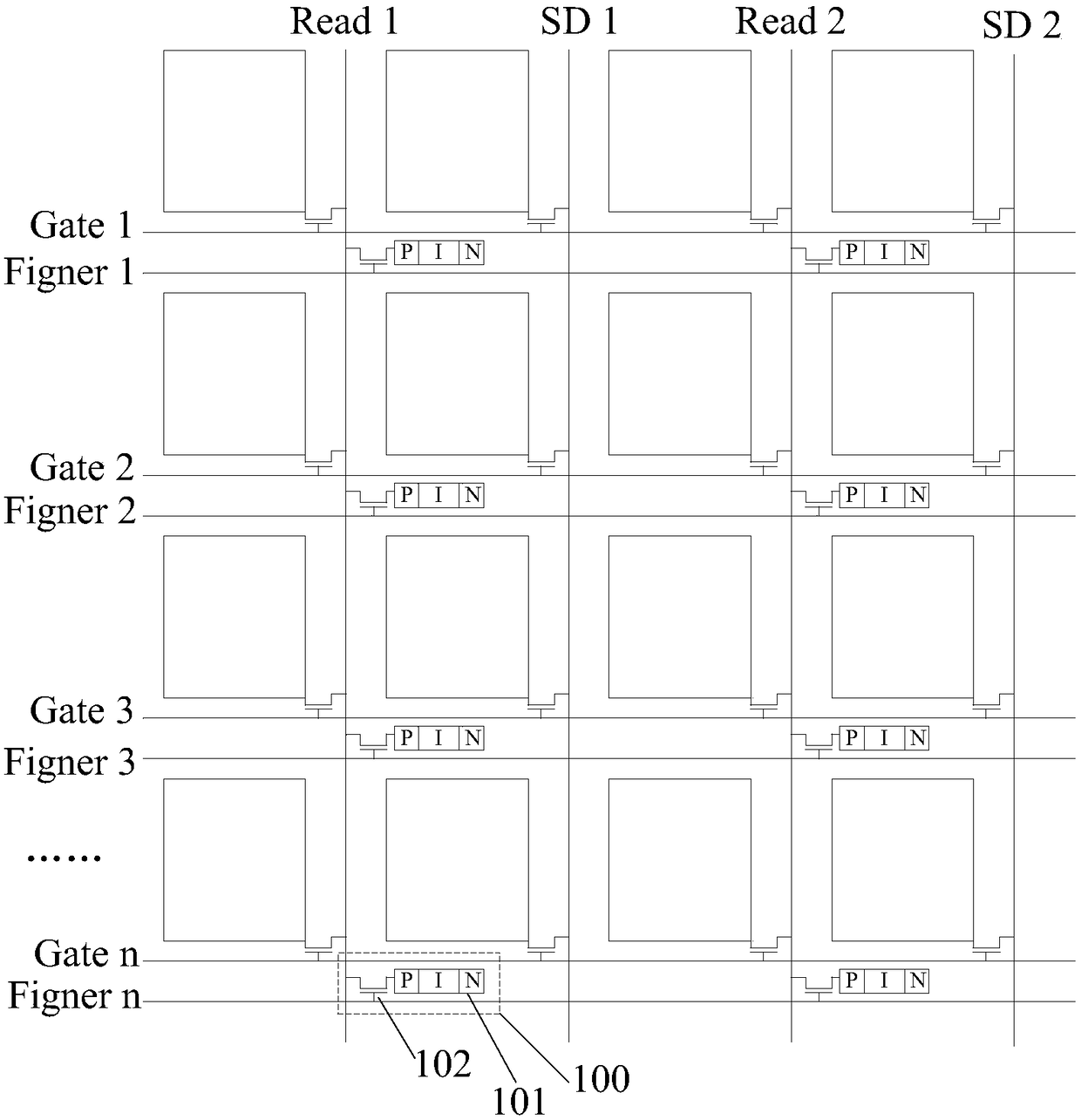

Fingerprint recognition display device

PendingCN106228144ATotal reflection transmission does not affectLess likely to interferePrint image acquisitionInput/output processes for data processingLight guideDisplay device

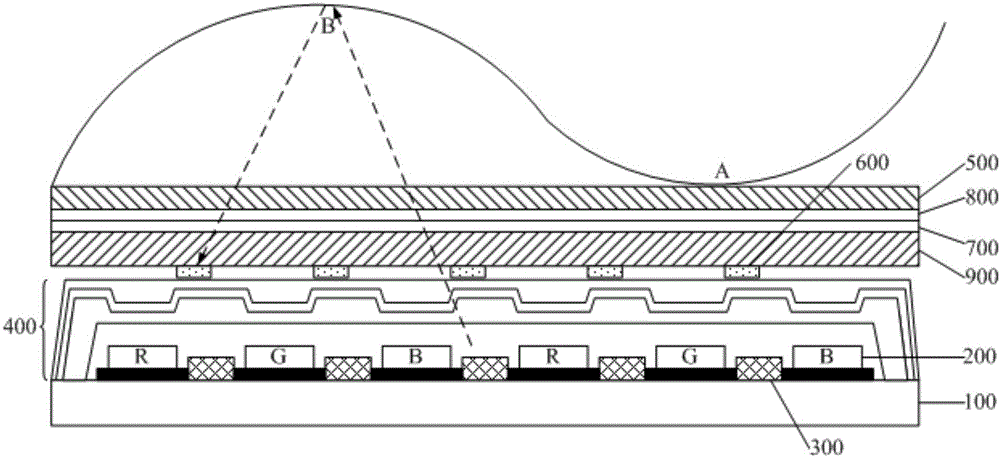

The invention discloses a fingerprint recognition display device. The display device comprises a light guide plate, a light emitting component and a plurality of photosensitive induction units, wherein the light guide plate is arranged on an emergent light face of a display panel, the light emitting component is capable of emitting modulating light which is transmitted between the light guide plate and a display face of the display device by adopting a manner of total reflection, and the photosensitive induction units are arranged below the light guide plate and arranged in an array manner. When a user touches the display face of the display device with a finger, the fingerprint ridge position contacts the display face to destroy the total reflection transmission of the modulating light at the position, and the modulating light is reflected to the photosensitive induction units below the modulating light, the fingerprint valley position does not contact the display face and cannot affect the total reflection transmission of the modulating light, and the photosensitive induction units below the modulating light cannot receive the modulating light, thus, the detection on fingerprint can be realized by the photosensitive induction units on the basis of photodynamic action, interference with inner part of the display device is not liable to occur, the influence caused by the distance between the photosensitive induction units and the display face of the display device is not liable to occur, and high-quality fingerprint detection can be easily realized.

Owner:BOE TECH GRP CO LTD

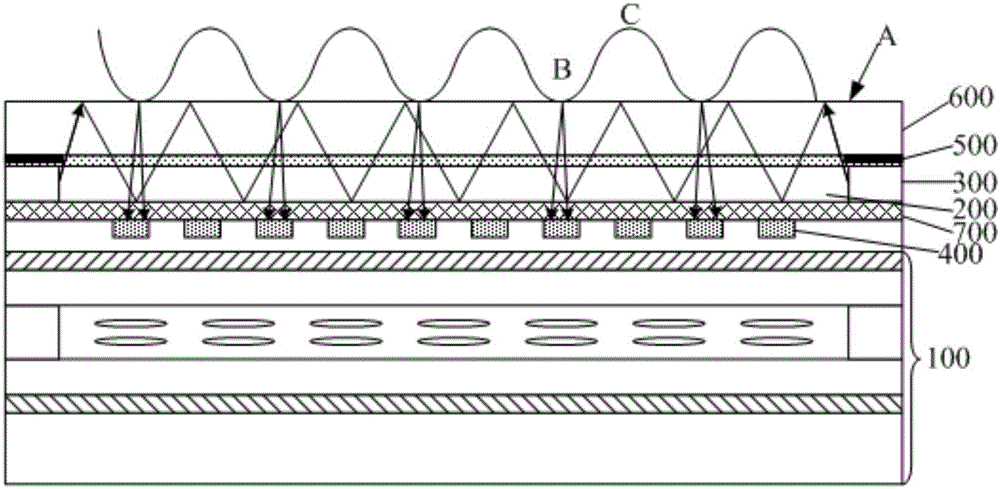

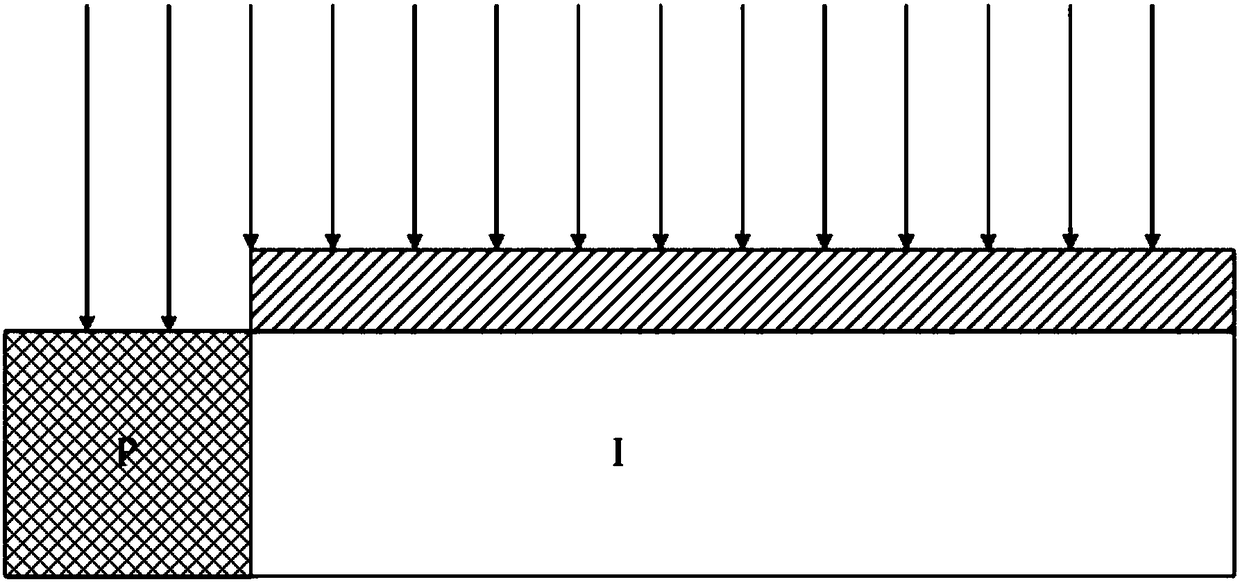

Fingerprint identification display panel and display device

InactiveCN106056099AQuality improvementLess likely to interfereSolid-state devicesPrint image acquisitionElectricityPower flow

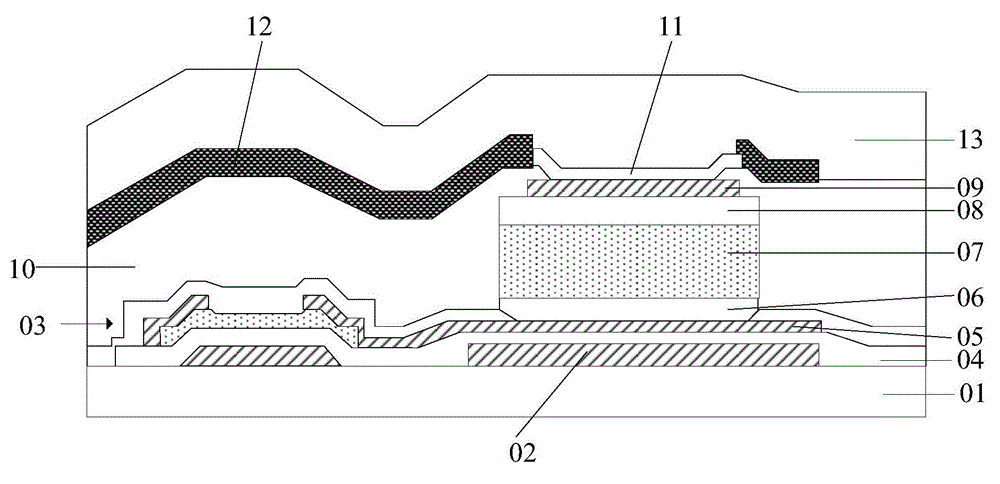

The invention discloses a fingerprint identification display panel and display device. A plurality of infrared light emitting units based on the infrared photosensitive effect are integrated on a driving circuit backboard, and a plurality of infrared photosensitive sensing units are arranged inside a protective cover plate above a packaging component for packaging an electroluminescence unit and the infrared light emitting units, namely between the protective cover plate and a film layer of the infrared light emitting units. When a finger of a user is close to the surface of the display panel, because the skin surface of the finger has uneven ridges and valleys, the intensities of infrared light emitted by the infrared light emitting units, irradiated to the ridges and valleys of the finger and reflected to the infrared photosensitive sensing units are different, and the light intensity difference is converted into a current signal difference to detect fingerprints; and the infrared photosensitive sensing units for detecting the fingerprints based on the infrared photosensitive effect are unlikely to interfere with internal components of the display panel, so that high-quality fingerprint detection is easily realized.

Owner:BOE TECH GRP CO LTD

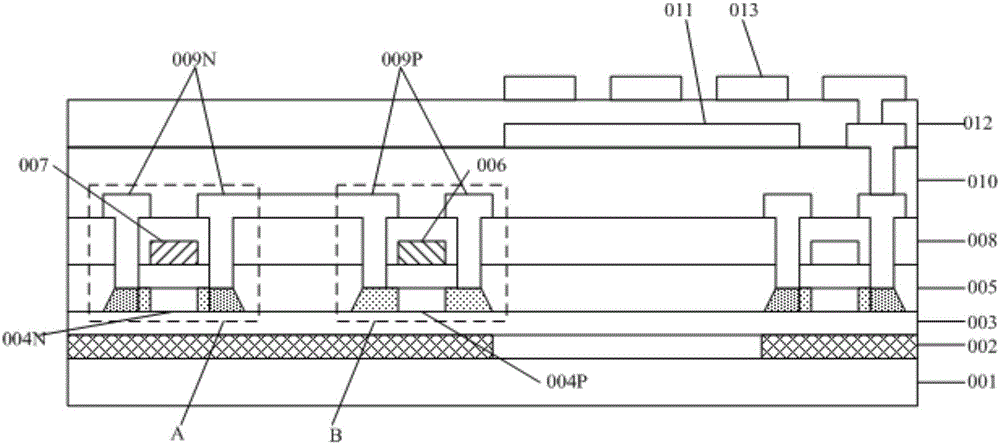

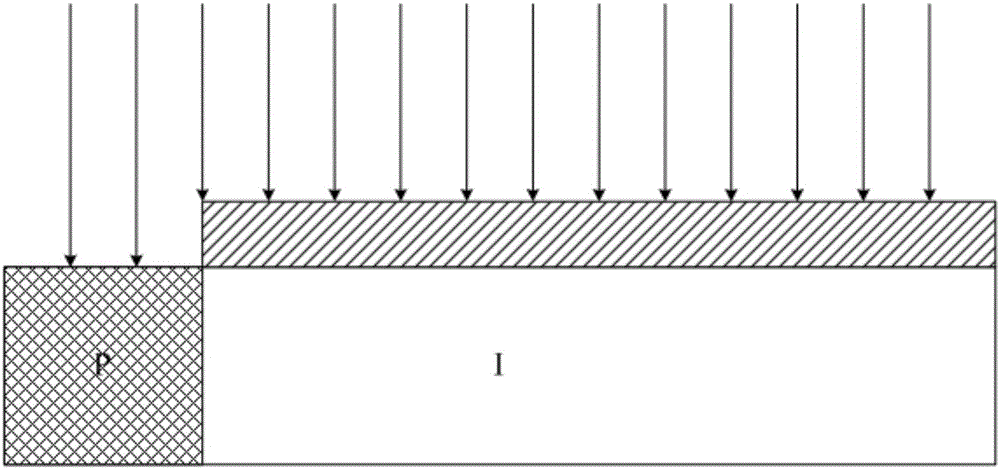

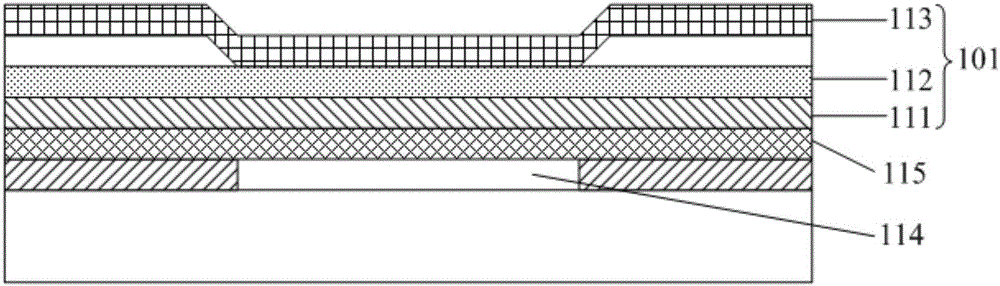

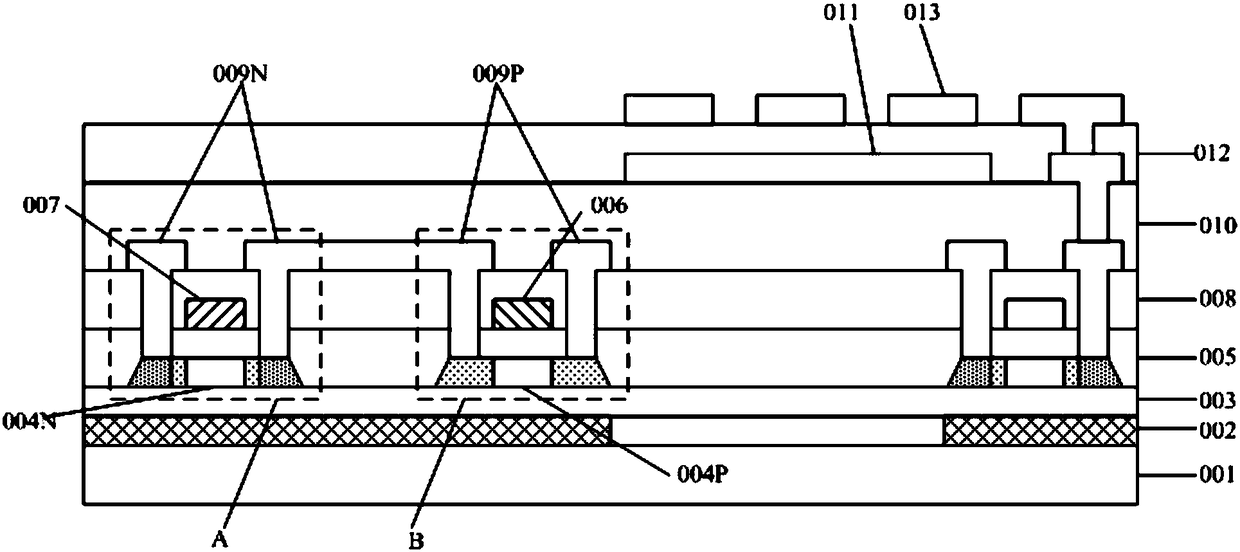

Photoelectric sensor and manufacturing method thereof

ActiveCN105336751AHigh-resolutionReduce thicknessRadiation controlled devicesImage resolutionEngineering

The invention provides a photoelectric sensor and a manufacturing method thereof. The photoelectric sensor comprises a pixel unit arranged on the substrate; and the pixel unit includes a photodiode and a thin-film transistor. A drain structure of the thin-film transistor servers as a cathode structure of the photodiode, so that the area occupied by the pixel can be reduced and the resolution ratio of the photoelectric sensor can be improved. Moreover, the anode structure and the cathode structure of the photodiode are arranged in a transverse mode, so that the thickness of the photoelectric sensor can be effectively reduced and thus the photoelectric sensor has advantages of small size and high resolution ration. Besides, the manufacturing method of the photoelectric sensor can be combined with the traditional LCD manufacturing method, thereby simplifying the production process of the photoelectric sensor, reducing the production cycle, and effectively reducing the production cost.

Owner:SHANGHAI OXI TECH

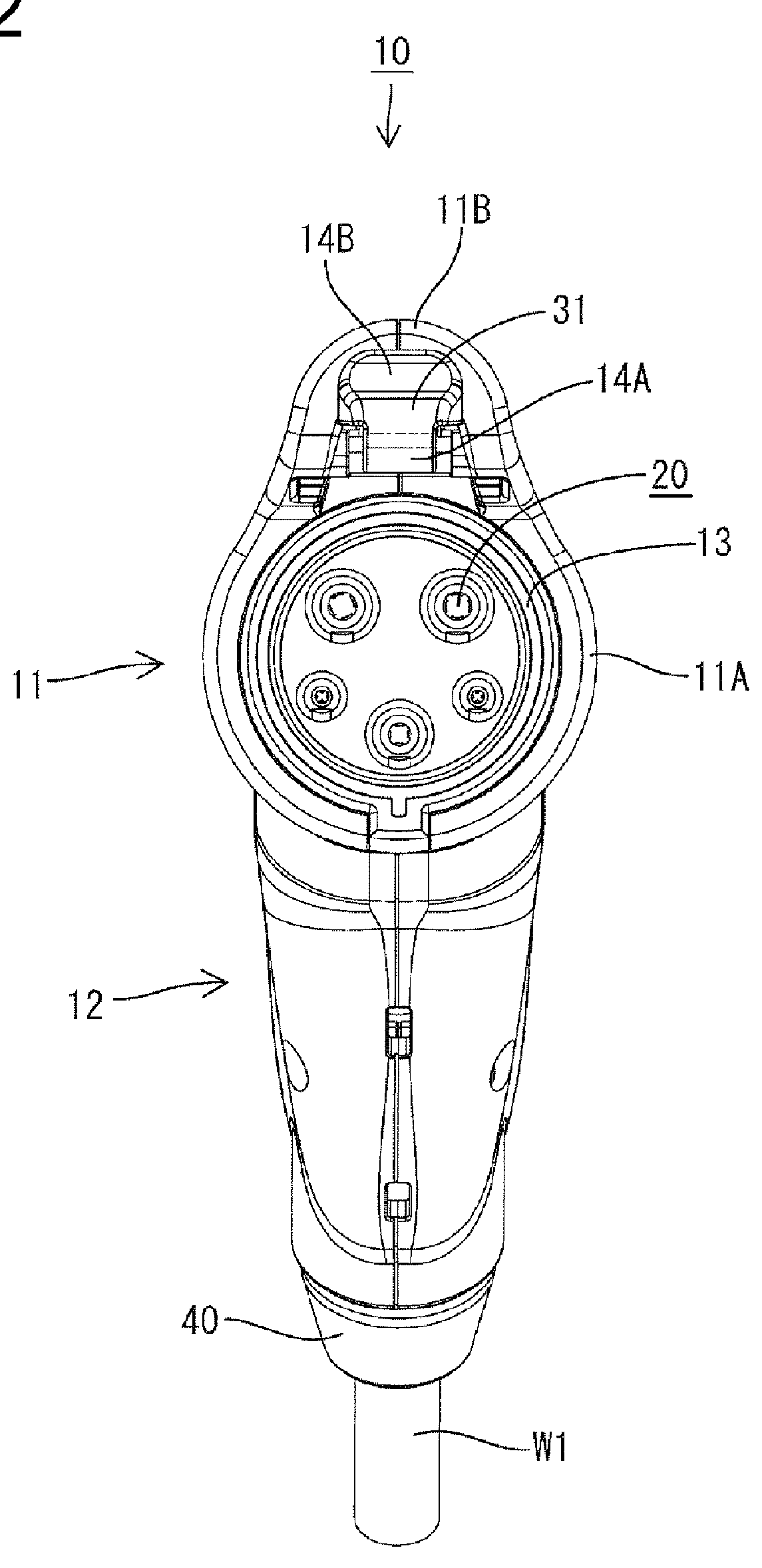

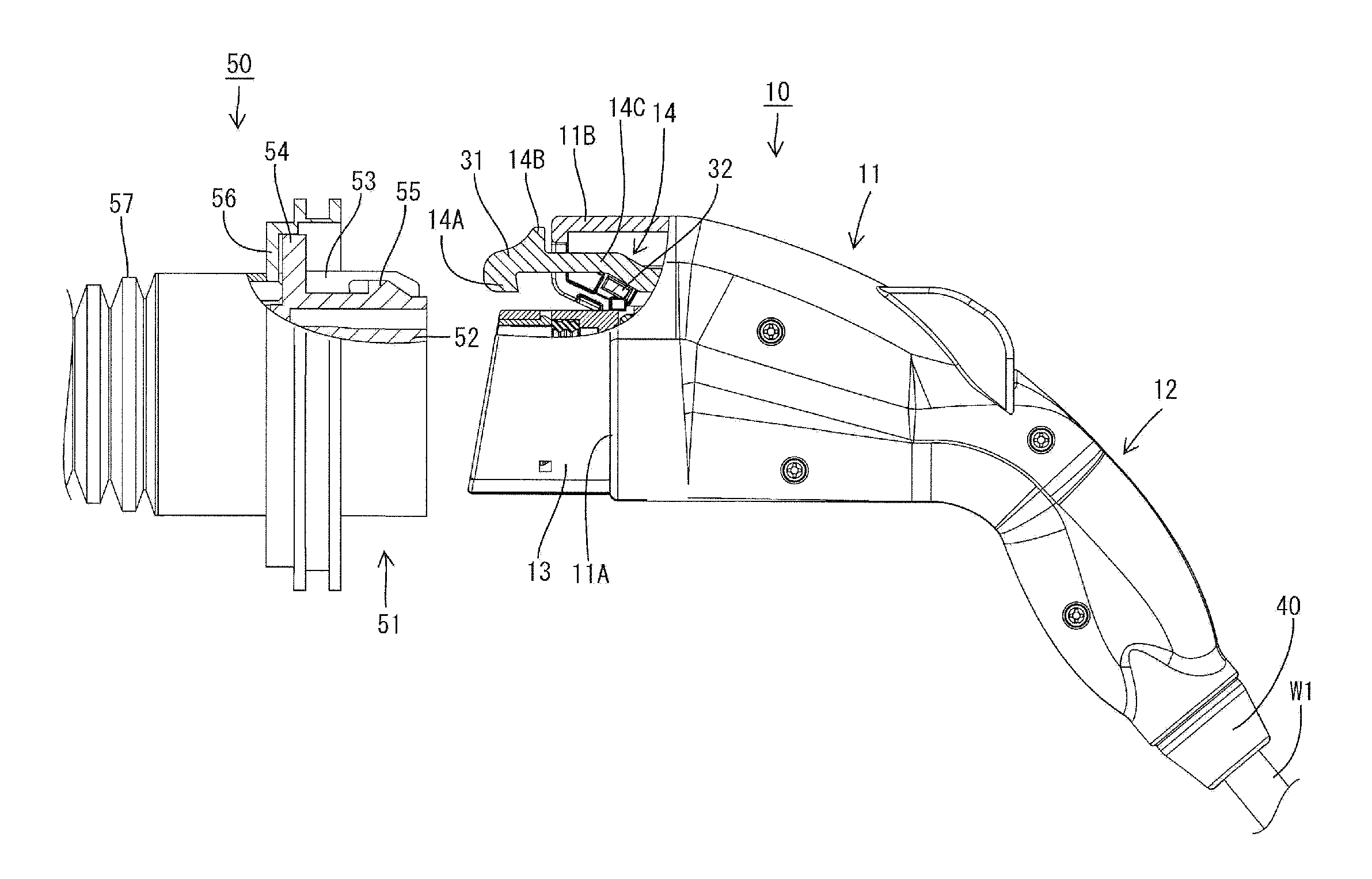

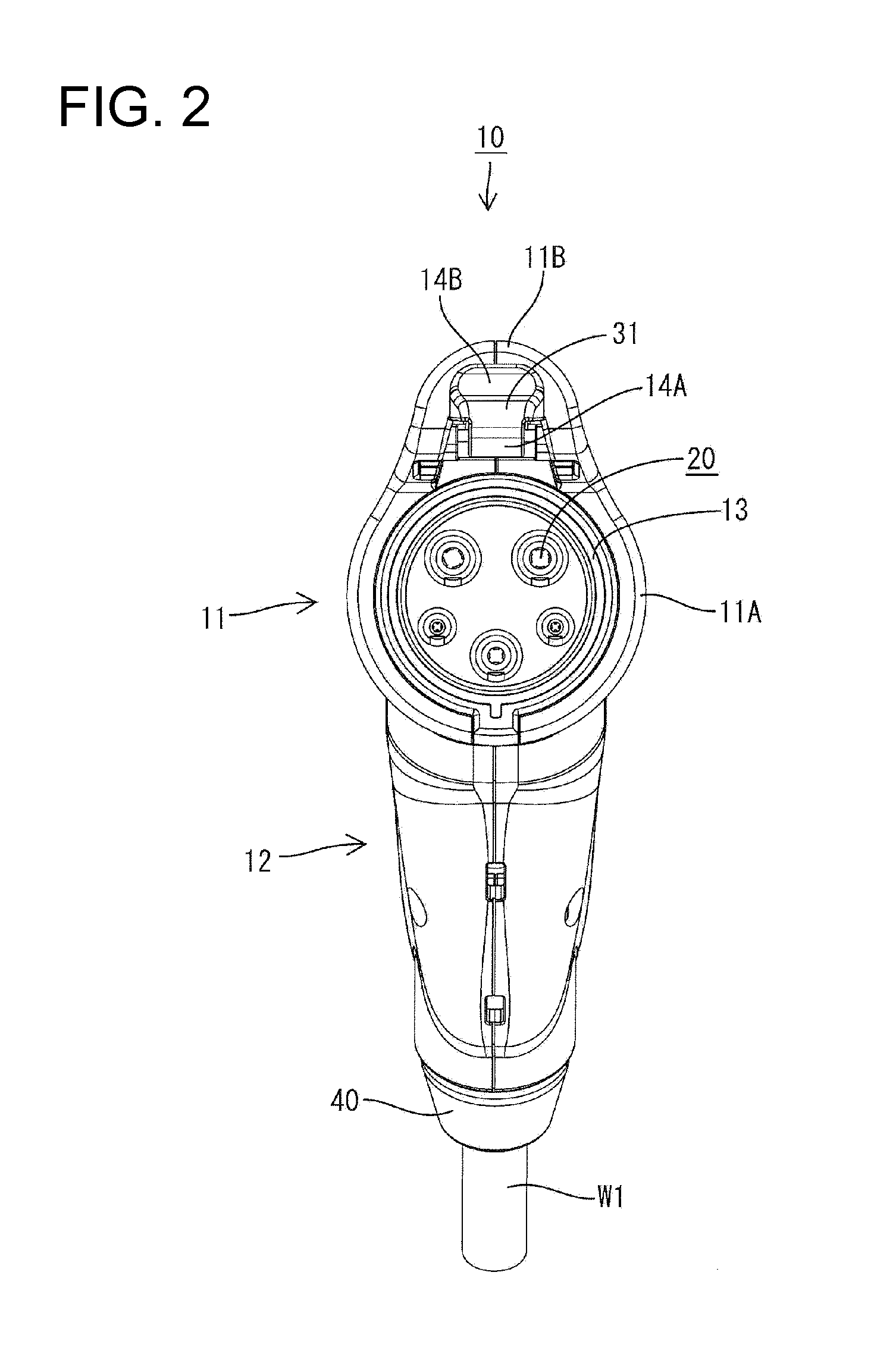

Charging connector

InactiveUS8206171B2High strengthImprove performanceVehicle connectorsCharging stationsEngineeringMechanical engineering

Owner:SUMITOMO WIRING SYST LTD

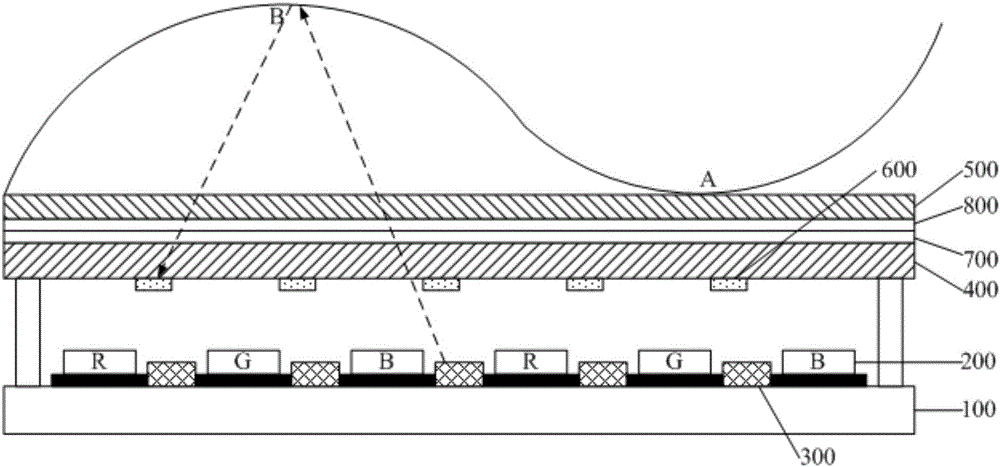

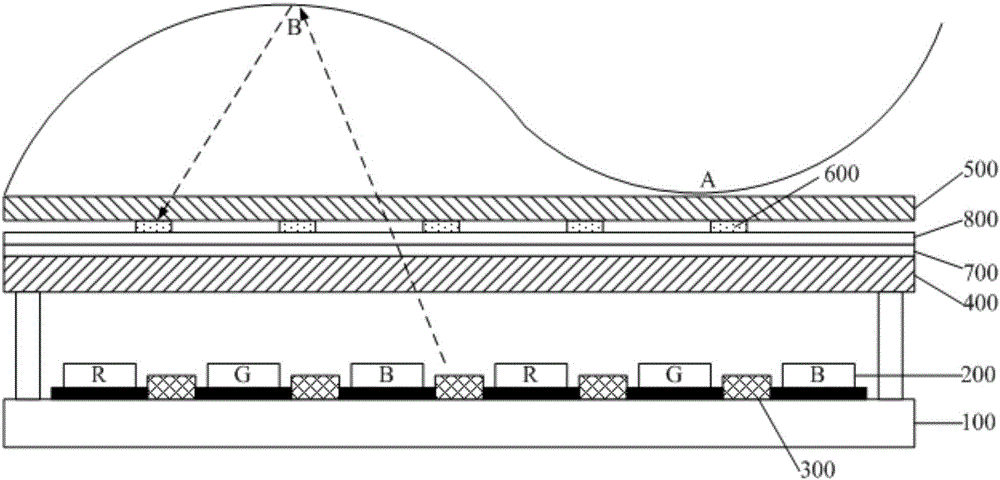

Fingerprint identification display device, manufacturing method and driving method thereof

ActiveCN106355136AQuality improvementLess likely to interfereStatic indicating devicesPrint image acquisitionDisplay deviceEngineering

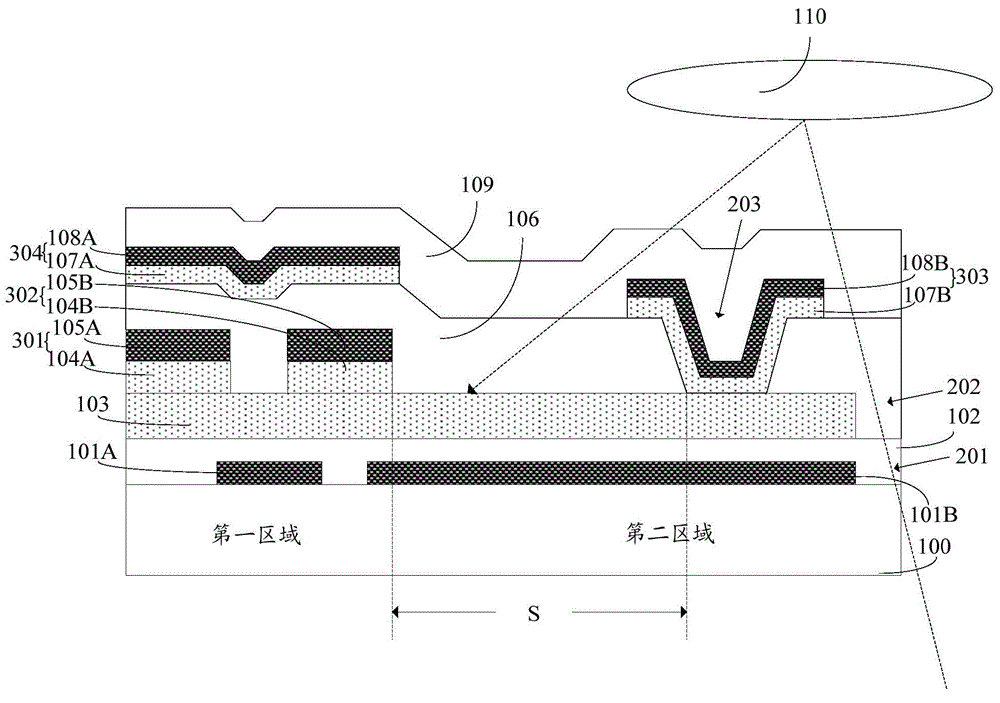

The invention discloses a fingerprint identification display device, and a manufacturing method and a drive method of the fingerprint identification display device. A plurality of photosensitive sensing units are arranged at the inner part of a display device; every photosensitive sensing unit includes a photosensitive diode used for sensing light intensity change in fingerprint pressing, and a control switch transistor for controlling the photosensitive diode to transform the light intensity change to different potential outputs; the display device further comprises a part for emitting the sensible light of the photosensitive diode. When fingers of a user close to the surface of the device, for the finger skin surface has uneven ridge and valley, the light intensity of irradiating the sensible light of the photosensitive diode sent by the display device to the ridge of the finger is different to the light intensity of the photosensitive diode reflecting valley position to the photosensitive sensing unit. The light intensity difference is transformed to be current signal difference, thus the detection of fingerprint is realized; the photosensitive sensing unit can detect the fingerprint on the basis of the photosensitive effect, and is not easy disturb internal parts of the display device, and easy to realize the high-quality fingerprint detection.

Owner:BOE TECH GRP CO LTD +1

Fingerprint identification display panel, production method thereof, driving method thereof, and display device

ActiveCN106250834AQuality improvementLess likely to interfereStatic indicating devicesPrint image acquisitionWave detectionPressure sense

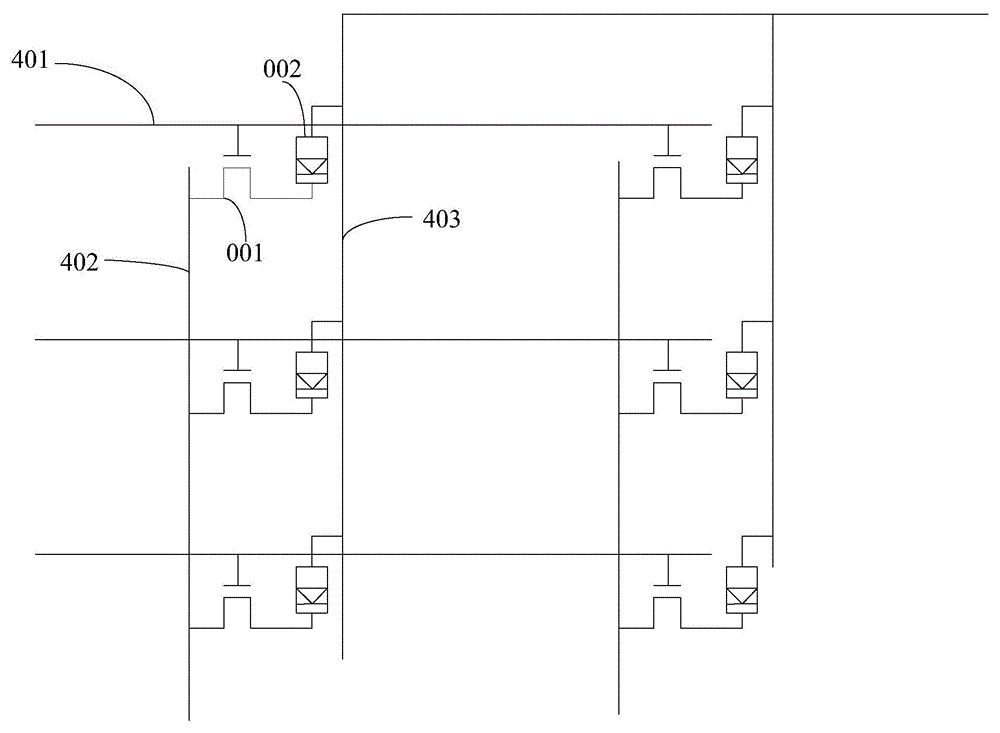

The invention discloses a fingerprint identification display panel, a production method thereof, a driving method thereof, and a display device. A plurality of ultrasonic wave detection units, a plurality of identification scanning lines, and a plurality of identification output lines are disposed in the display device. Every ultrasonic wave detection unit comprises a pressure-sensing unit used for generating ultrasonic waves and sensing the changes of the ultrasonic waves caused by pressing of fingerprints, and a control switch transistor used for controlling the pressure-sensing unit to convert the changes of the ultrasonic waves into different signals for output. When fingers of users are close to the surface of the display device, because of the uneven ridges and the uneven valleys of the skins of the fingers, the intensities of the ultrasonic waves transmitted by the pressure-sensing units reflected by the positions of the ridges and the valleys of the fingers back to the pressure-sensing units are different, and then the differences of the current signals converted by the pressure-sensing units are caused, and therefore the detection of the fingerprints is realized. The pressure-sensing unit is used for the detection of the fingerprints based on piezoelectric effect, and interferences on the internal parts in the display device are not easy to generate, and therefore high-quality fingerprint detection is easily realized.

Owner:BOE TECH GRP CO LTD

Charging connector

InactiveUS20110212645A1High strengthImprove performanceVehicle connectorsCharging stationsEngineeringMechanical engineering

Owner:SUMITOMO WIRING SYST LTD

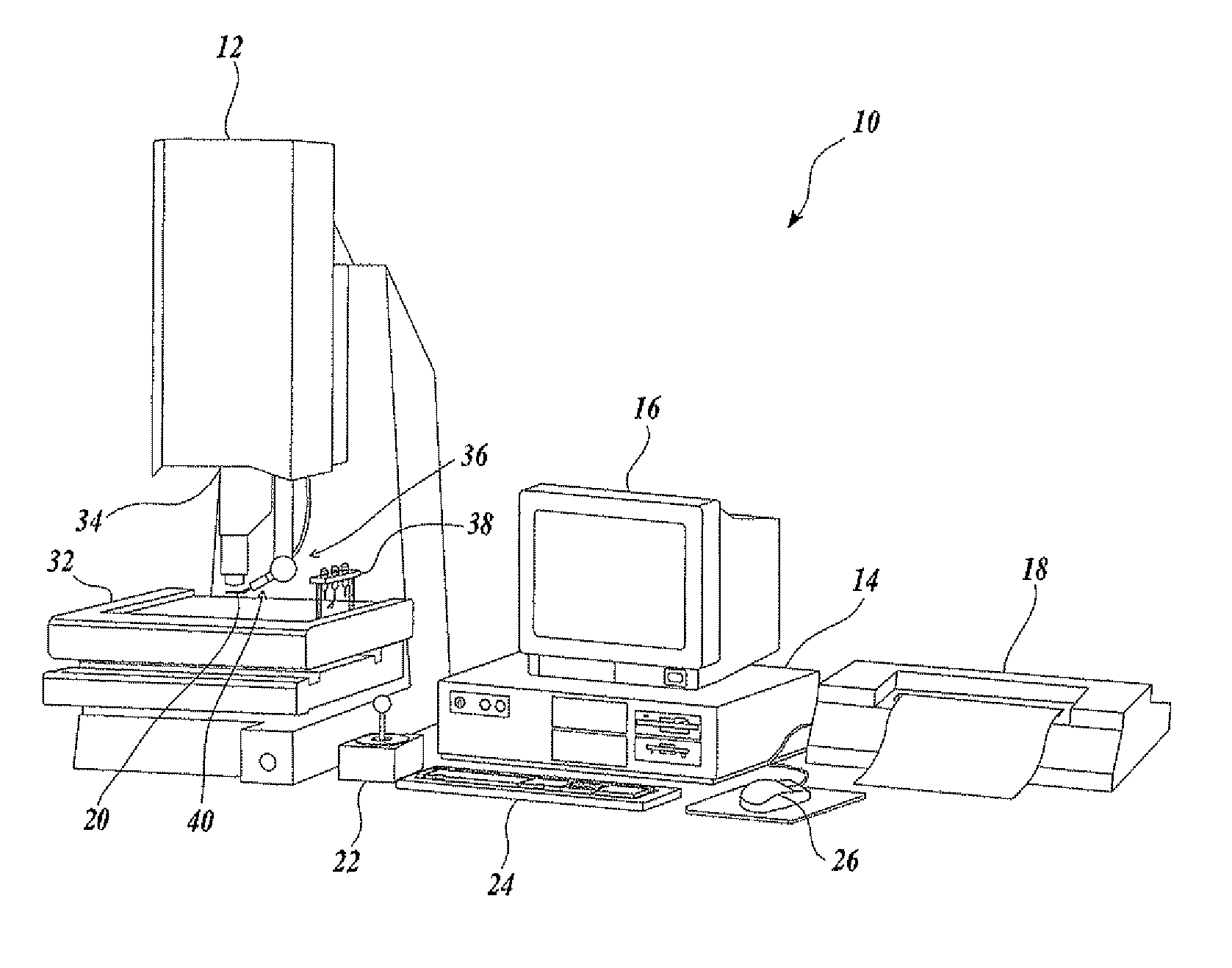

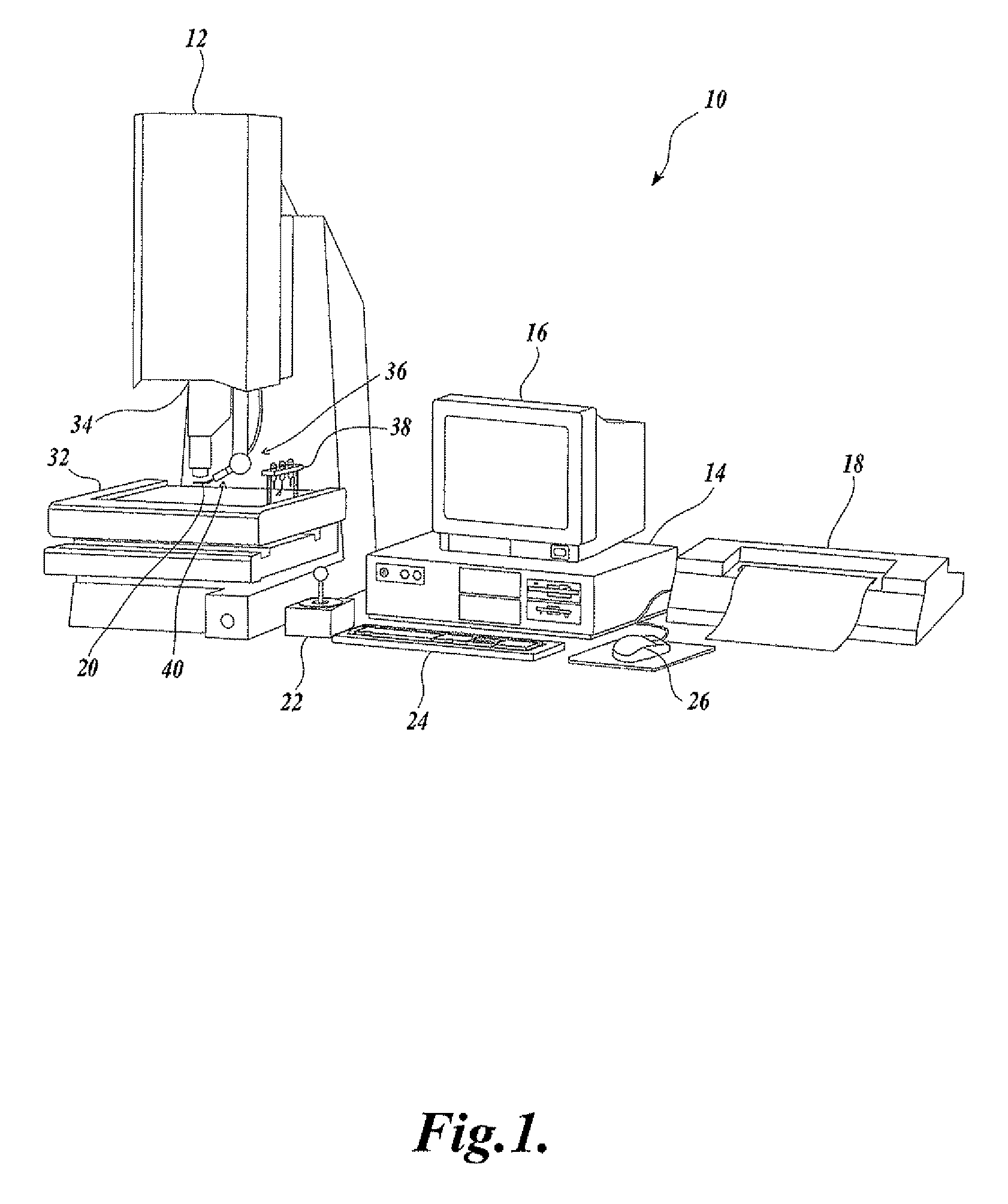

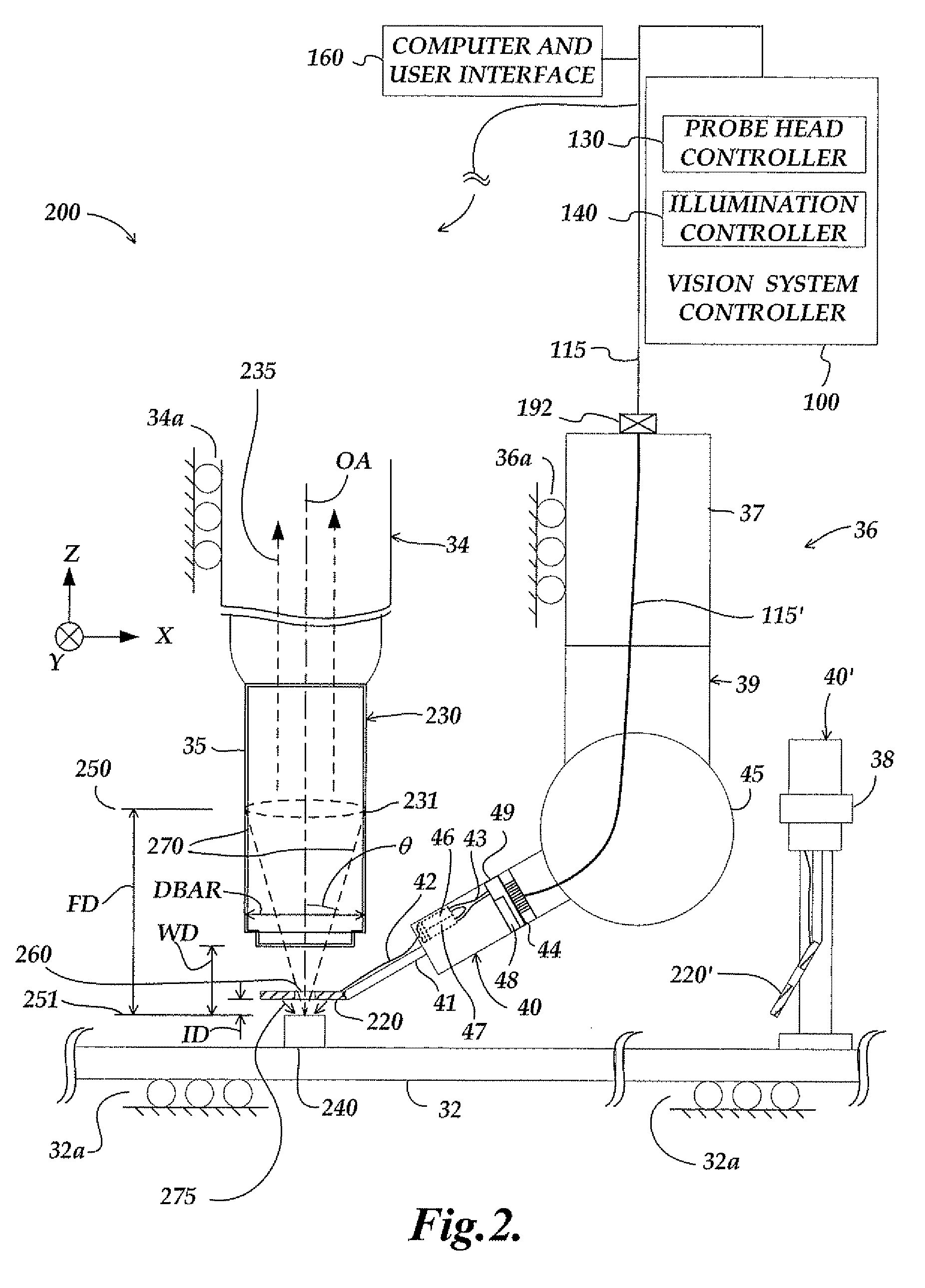

Controllable micro light assembly

ActiveUS8085295B2Increase speedChange positionTelevision system detailsWith electric batteriesMachine visionOptical axis

A micro light interface assembly for a microscopic machine vision inspection system includes a micro light assembly. The micro light assembly provides addressable light emitting elements arranged around the periphery of an aperture having an aperture dimension DAPMIN that is smaller than a barrel dimension DBAR of the inspection system objective lens. The aperture may be located along the optical axis and within the working distance of the objective lens such that the light emitting elements are closely arranged around a field of view. The micro light interface assembly may be held and operated through a connection element that may be used for the interchanging the micro light interface assembly with a touch probe, in some embodiments.

Owner:MITUTOYO CORP

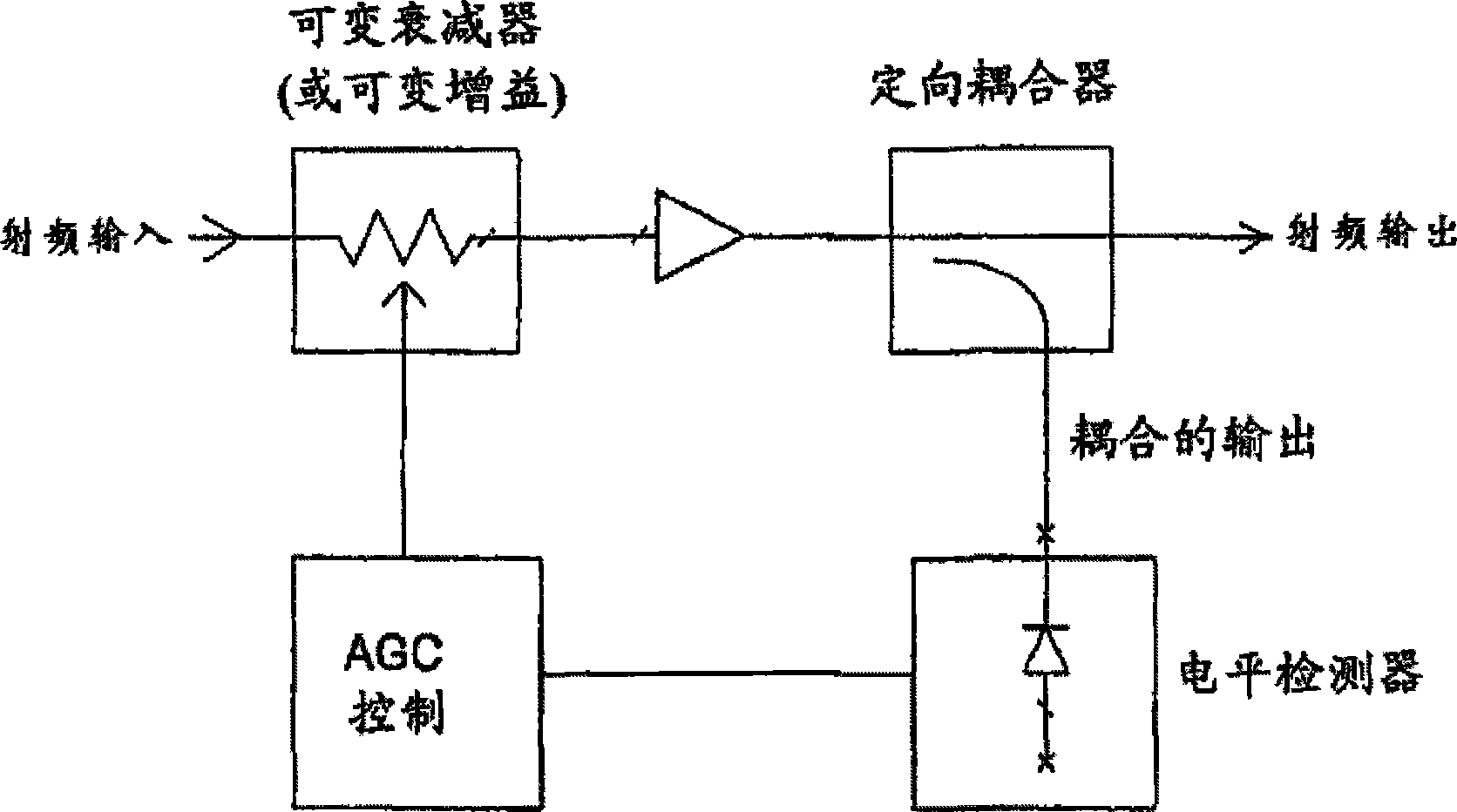

Light control automatic gain control circuit applied on cable television network optical receiver

InactiveCN101478344AEasy to design temperature compensation functionReliable controlOptical transmission adaptationsElectromagnetic transmissionElectricityOptical power

The invention relates to an optically-controlled automatic gain control circuit applied to an optical receiver of cable television network, which comprises two offset networks, a photoelectric detector and a variable attenuator. The photoelectric detector is grounded and connected with a power source via the two offset networks. The output terminal of the photoelectric detector is connected with an optical power detecting circuit, a logarithmic circuit, a phase inverting circuit, an exponential circuit, a phase proportion adjusting circuit and an adding circuit in sequence, and then is connected with the variable attenuator, thereby achieving the automatic gain control (AGC). The circuit is implemented by use of the pure analog hardware, and can control the input light power in the range above 10dB, namely, the radio-frequency output level in the range above 20dB.

Owner:SHANGHAI UNIV +1

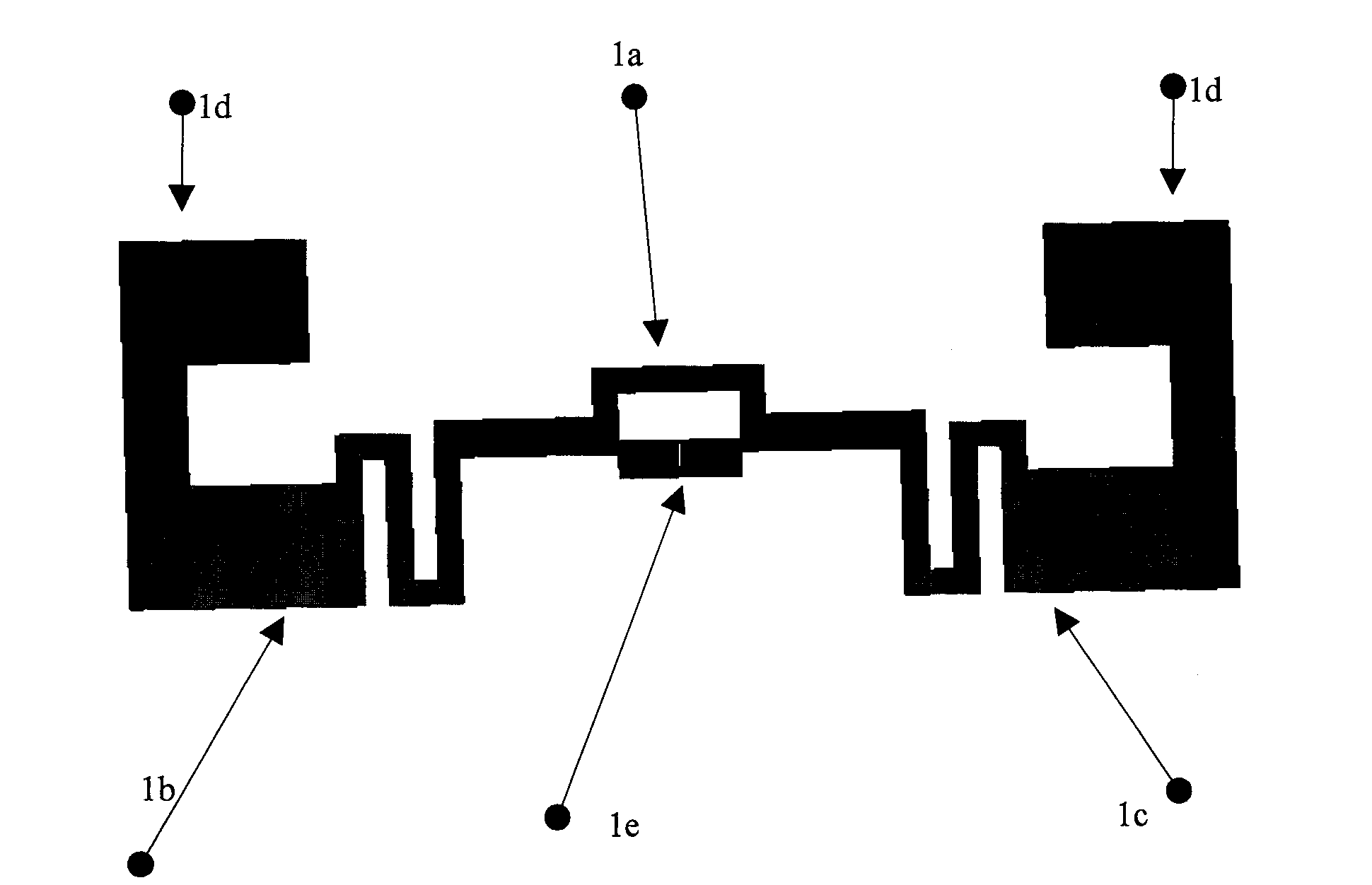

RFID antenna with asymmetric structure and design method thereof

InactiveCN101924268AImprove performanceTolerance of laxityAntenna supports/mountingsRadiating elements structural formsAntenna designNon symmetric

The invention discloses a design method for an RFID antenna with an asymmetric structure. The method comprises the following steps of: determining target impedance of the antenna according to the use of the antenna and a chip; designing a first antenna with a symmetric structure, which meets the target impedance, namely designing an annular structure of the antenna, designing a folded structure with two symmetric folded patterns and designing a receiver on the outermost part; designing a second antenna with a symmetric structure, which meets the target impedance, by using the same mode, wherein the folded patterns of the second antenna are different from those of the first antenna and the annular structure and the receiver of the second antenna are the same as those of the first antenna; combining the designed symmetric antennas to form the antenna with the asymmetric structure in a mode that the two folded patterns in the folded structure of the antenna use the folded patterns of the first and second antennas respectively and the annular structure uses the common structure of the first and second antennas; and performing structural fine adjustment on the obtained antenna with the asymmetric structure. The method has good universality, and provides a guide for the design of the asymmetric structural antennas.

Owner:AEROSPACE INFORMATION

Lazy arm protruded four-link steel wire rope telescoping mechanism

The invention provides a lazy arm protruded four-link steel wire rope telescoping mechanism which comprises a large arm, a bi-arm, a tri-arm and a small arm, wherein one tri-arm protruded steel wire rope is wound on a four-link pulley, a tri-arm double-layer half-moon pulley arranged below the tail part of the tri-arm, a piston rod head half-moon pulley on a piston rod and a bi-link steel wire rope pulling plate, so as to finally form a four-link steel wire rope used for driving a telescopic arm. The lazy arm protruded four-link steel wire rope telescoping mechanism provided by the invention has the following advantages: 1, one steel wire rope is utilized to form the four-link steel wire rope according to a certain winding method, so that the steel wire rope is uniformly stressed, and the safety factor of the service life of the steel wire rope is improved; 2, two layers of half-moon pulleys are arranged below the tri-arm, so that the occupied space of the telescoping mechanism is saved to a greater extent; and 3, the four-link steel wire rope in the telescoping mechanism adopts one steel wire rope, so that the telescoping mechanism has increased telescopic oil cylinder movement space and less possibility of generating interference compared with the prior art.

Owner:CHANGDE HANFENG HYDRAULIC MACHINERY

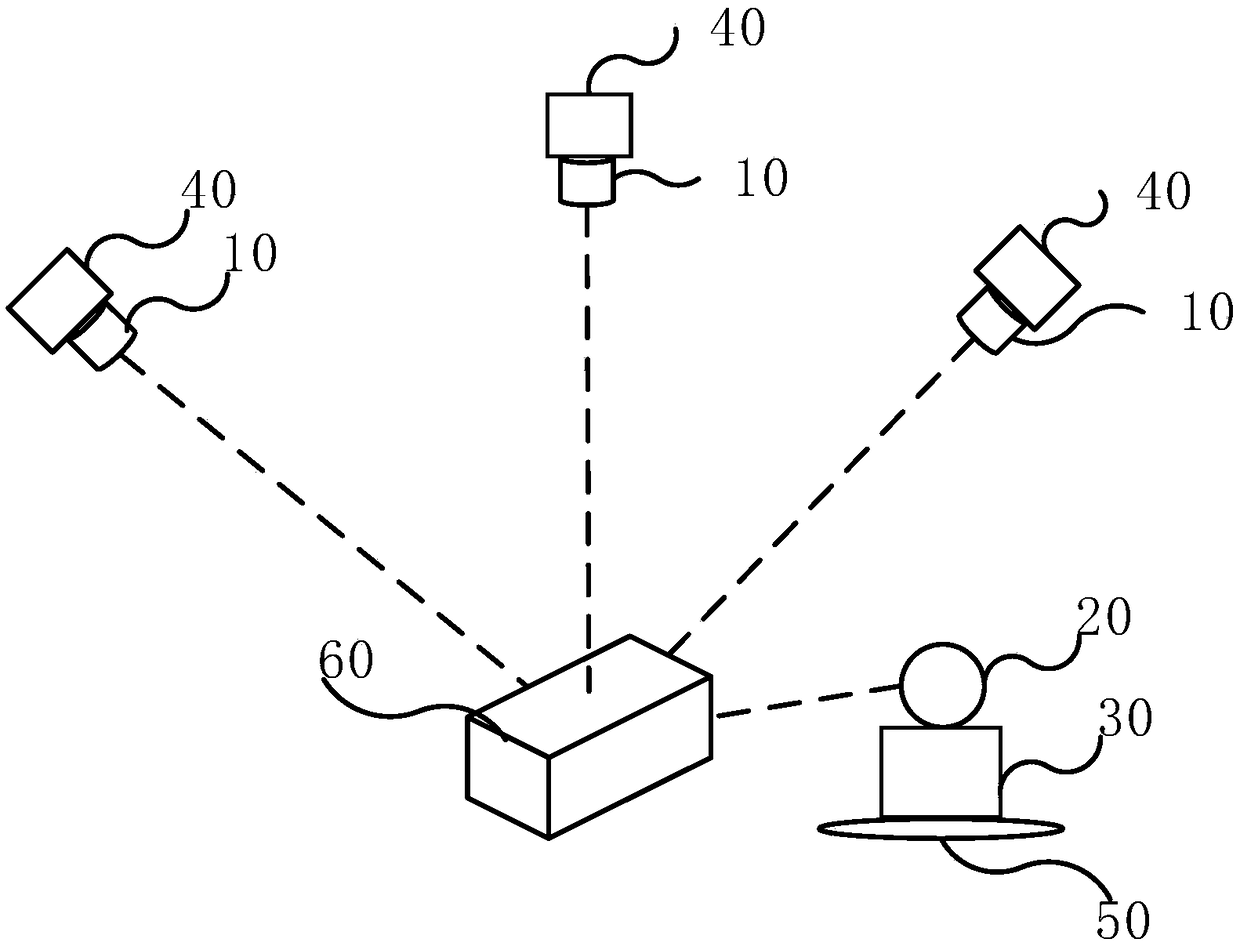

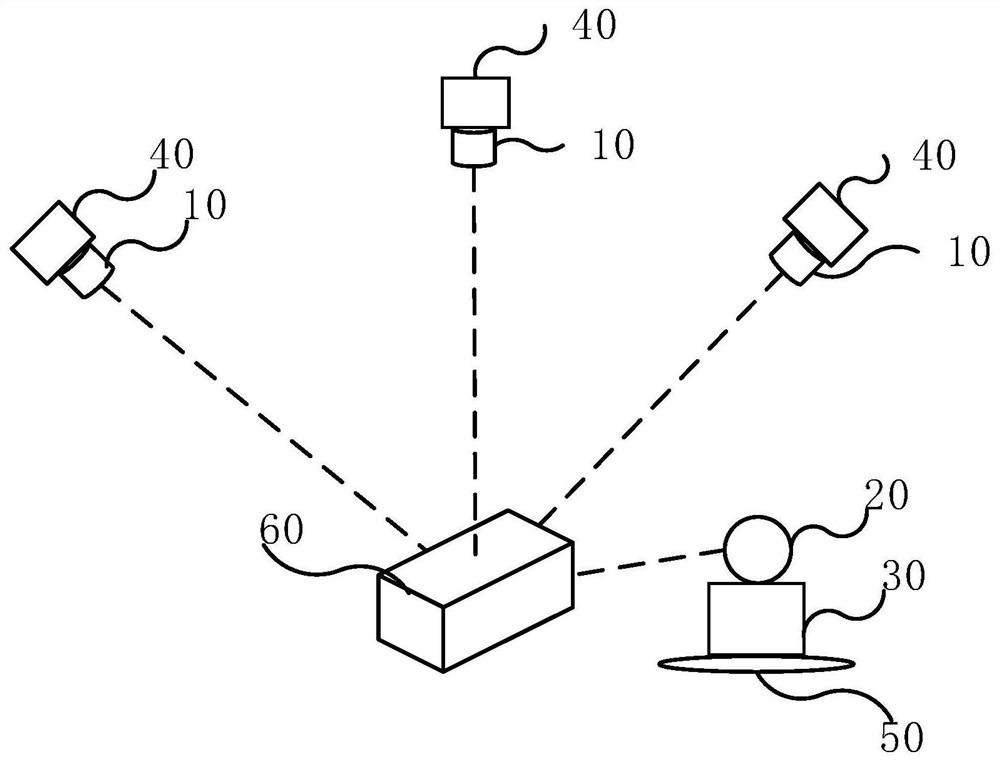

Three-dimensional scanning method and system

The present invention relates to a three-dimensional scanning system for acquiring three-dimensional data of an object. The system comprises a projector and a scanner. The projector is used for projecting a feature image of a first wave band to a scanned object, the feature image comprises a plurality of key features. The scanner comprises a projection module for emitting scanning light of a second wave band to the surface of the scanned object, a first acquisition module used for collecting a feature image projected to the scanned object and obtaining key feature three-dimensional data projected to the surface of the scanned object, a second acquisition module used for collecting scanning light of a second wave band reflected by the scanned object and obtaining dense three-dimensional point cloud data of the surface of the scanned object, wherein, the first wave band and the second wave band do not interfere with each other. According to the three-dimensional scanning system providedby the invention, the collection of the feature image of the first wave band and the collection of the reflected scanning light of the second wave band do not interfere with each other, and the collected three-dimensional data is more accurate.

Owner:SHINING 3D TECH CO LTD

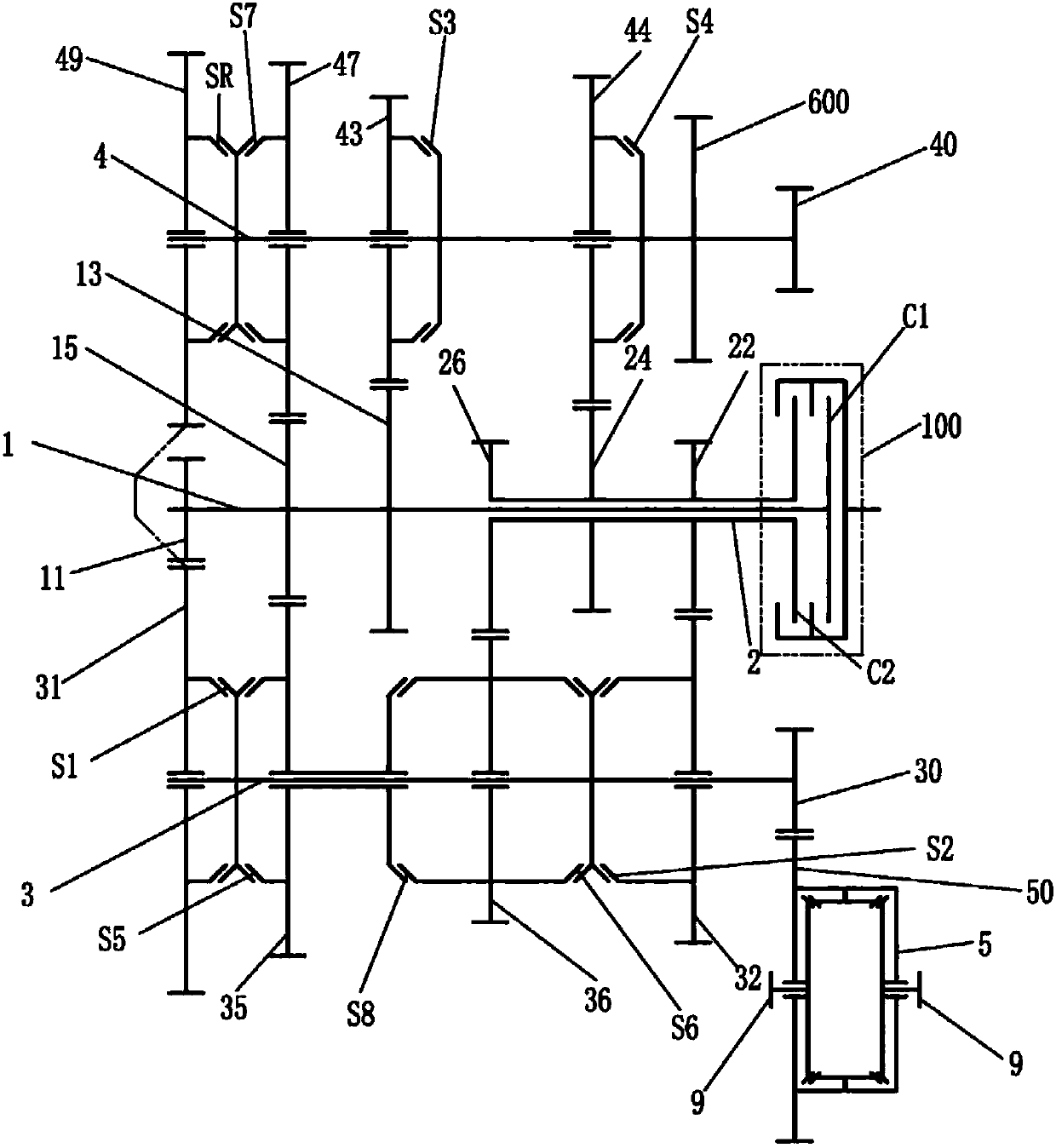

Eight-speed double-clutch automatic transmission

PendingCN107917167AShorten the axial lengthShorten radial lengthToothed gearingsTransmission elementsGear driveAutomatic transmission

The invention discloses an eight-speed double-clutch automatic transmission which comprises double clutches, a first input shaft, a second input shaft, a first output shaft, a second output shaft anda differential mechanism. The first input shaft is coaxially sleeved with the second input shaft. The first input shaft is fixedly provided with a first-reverse-gear drive gear, a fifth-seventh-gear drive gear and a third-gear drive gear. The second input shaft is fixedly provided with a sixth-gear drive gear, a fourth-gear drive gear and a second-gear drive gear. The first output shaft is sleevedwith a first-gear driven gear, a fifth-gear driven gear, a sixth-gear driven gear and a second-gear driven gear. The second output shaft is sleeved with a reverse-gear driven gear, a seventh-gear driven gear, a third-gear driven gear and a fourth-gear driven gear. The first output shaft is provided with a first-gear synchronizer, a fifth-gear synchronizer, a second-gear synchronizer and a sixth-gear synchronizer. The second output shaft is provided with a reverse-gear synchronizer, a seventh-gear synchronizer, a third-gear synchronizer and a fourth-gear synchronizer, and an eighth-gear synchronizer is fixed to the fifth-gear driven gear. The first output shaft and the second output shaft are connected with the differential mechanism through a first main speed reduction drive gear, a second main speed reduction drive gear and a main speed reduction gear. By means of the eight-speed double-clutch automatic transmission, the axial length and the radial length of the transmission are effectively shortened, and the structure is simplified.

Owner:昆山德拉特兰传动科技有限公司

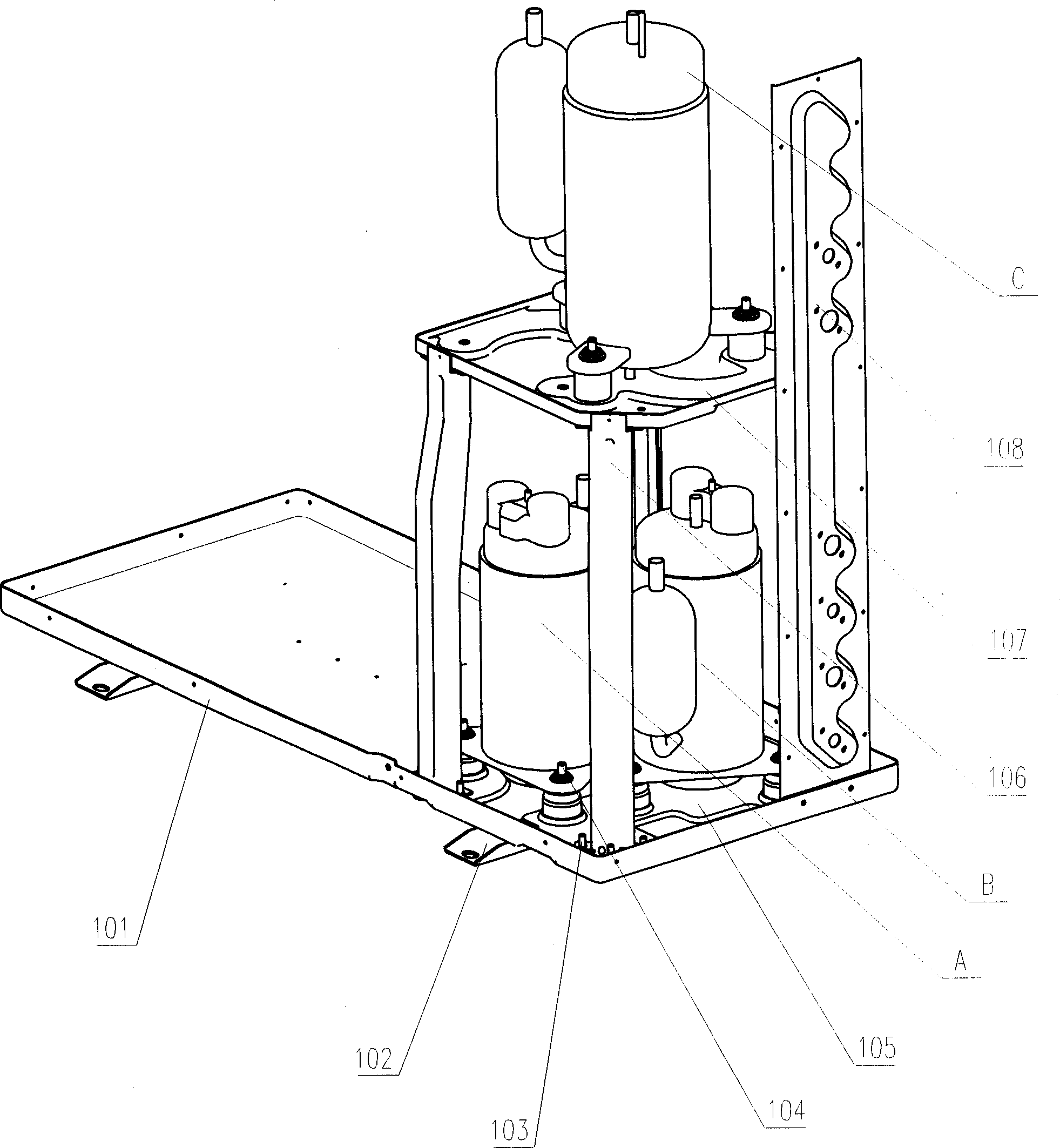

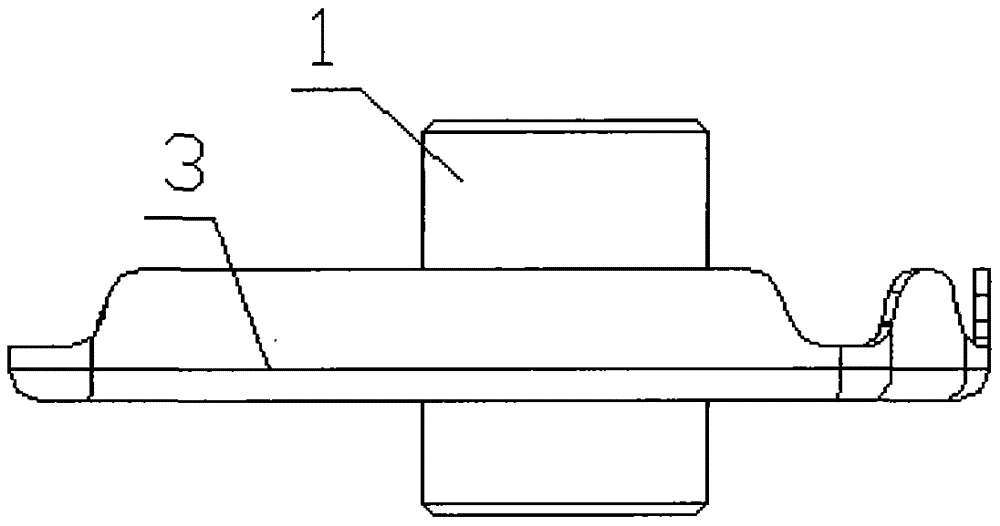

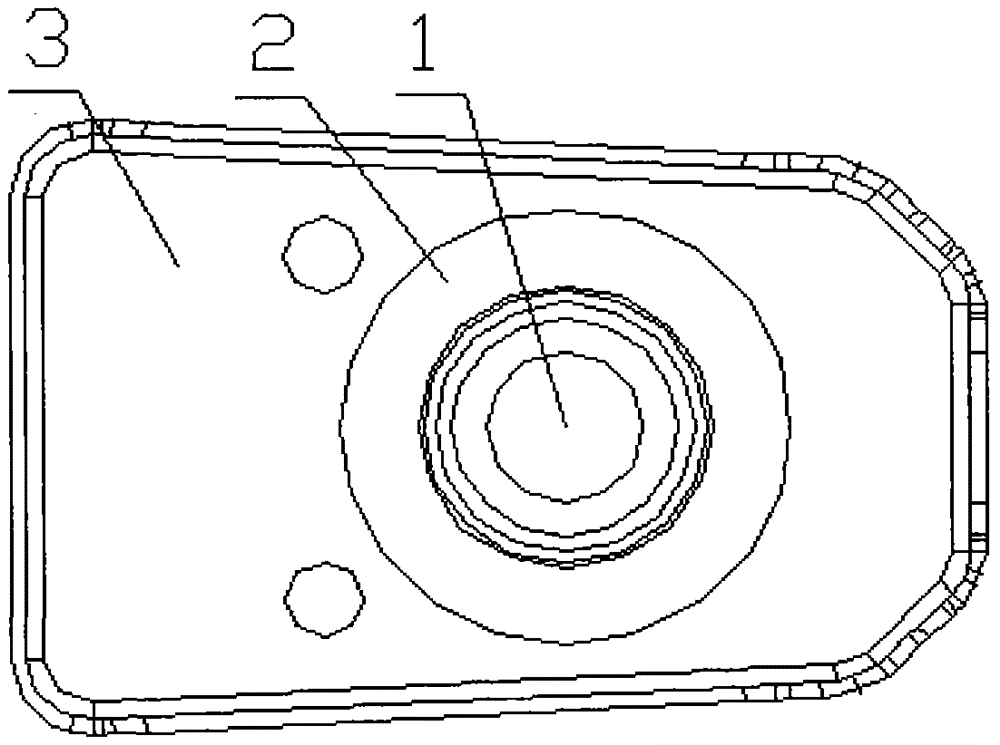

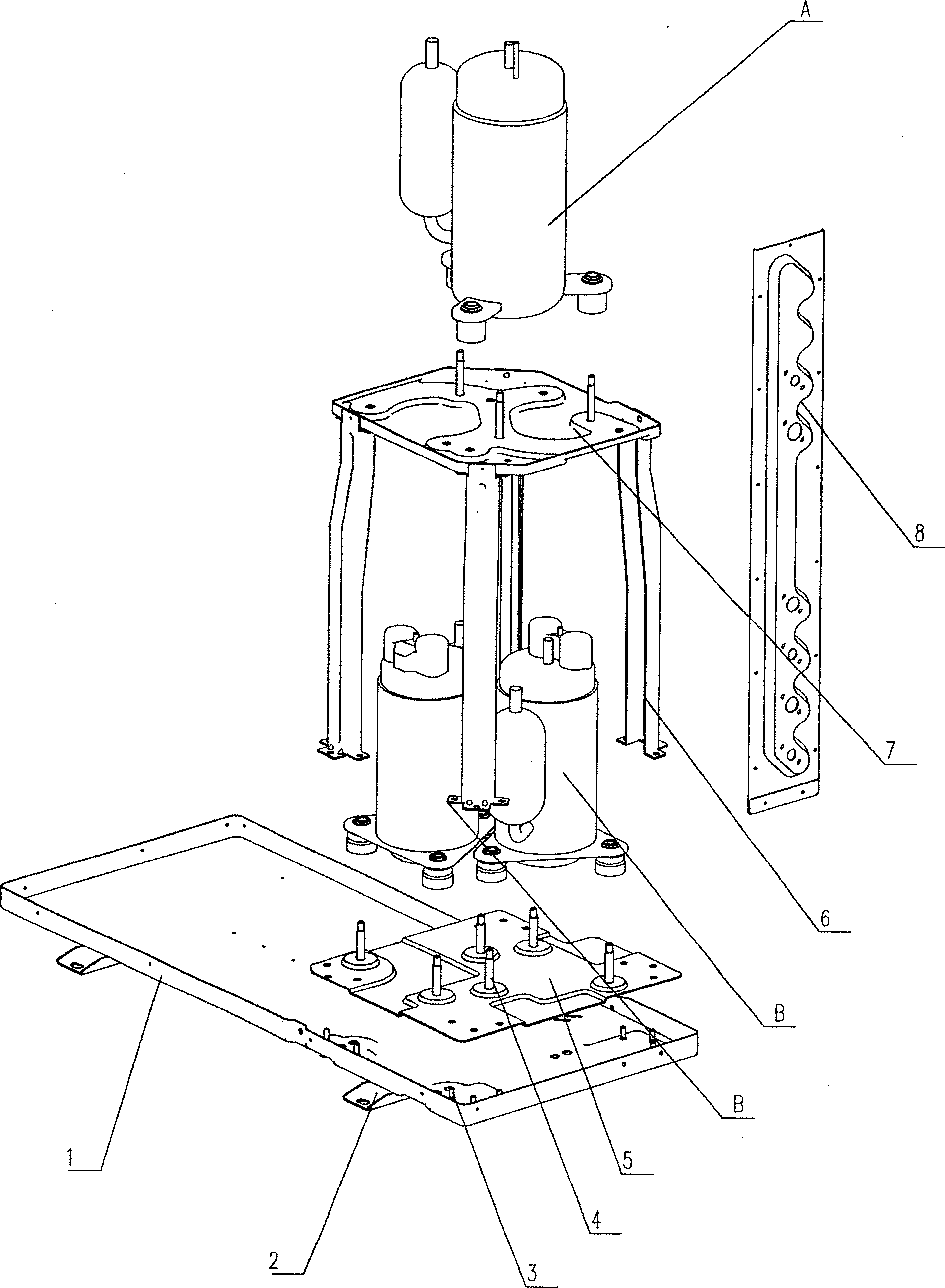

Compressor installing structure of outdoor unit of one-driven-many indoor unit of air conditioner

InactiveCN1693807ASmall footprintSmall structureCompressorSpace heating and ventilation detailsGas compressorEngineering

Owner:HISENSE HOME APPLIANCES GRP CO LTD

Novel magnetorheological damper

ActiveCN107120378AReduce dosageIncrease dampingSpringsNon-rotating vibration suppressionBall bearingClosed chamber

The invention discloses a novel magnetorheological damper comprising an outer cylinder, a rotor cylinder located in the outer cylinder and a ball lead screw located in the rotor cylinder. One end of the ball lead screw stretches out of the outer cylinder, and a compression buffering block and a connecting screw rod are installed at the end of the ball lead screw, and meanwhile, the ball lead screw is further sleeved with a ball nut and a nut seat; the nut seat is fixedly connected with the top end of the rotor cylinder; the bottom end of the rotor cylinder penetrates through an upper partitioning plate, an outer stator and an inner stator and is connected with a rotor; the rotor cylinder and the rotor are supported on a pair of angular contact ball bearings to conduct rotating motion; the upper partitioning plate, the outer stator, the inner stator and the rotor form a closed chamber; the chamber is filled with magnetorheological fluids; two annular grooves are formed in the inner stator; coils are wound in the two annular grooves correspondingly; and two magnetic fields are produced after the coils are electrified. The novel magnetorheological damper has performance that the magnetorheological fluids are small in using amount, the damping is high , and the high damping is achieved even at a low frequency, the smoothness of a vehicle can be improved, and the control stability of the vehicle can be also controlled.

Owner:NANJING FORESTRY UNIV

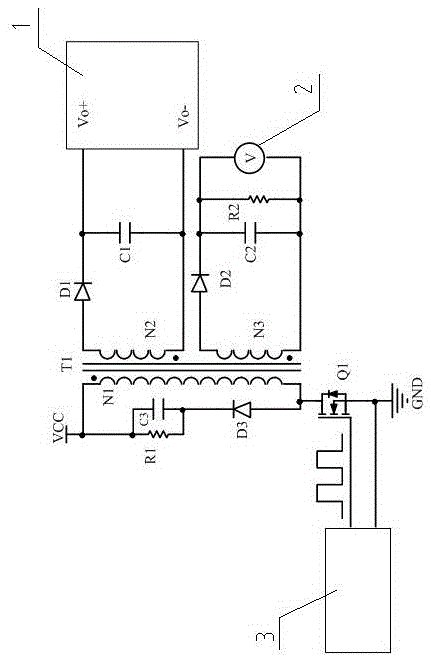

DC high voltage isolation detection method

The invention provides a DC high voltage isolation detection method. A flyback transformer is arranged, and the flyback transformer is composed of a primary excitation winding, a secondary detection winding and a sampling winding. One end of the primary excitation winding is connected with a DC power supply, and the other end is connected with a main switching tube which is connected with a pulse driving unit. DC voltage is converted into pulse voltage by the main switching tube through chopping so that coupling of the flyback transformer is realized. The two ends of the primary excitation winding are provided with a primary clamp circuit used for a clamp transformer secondary reflected voltage protection main switching tube. The two ends of the secondary detection winding are provided with a secondary detection circuit which is composed of a diode D1 and a capacitor C1. The two ends of the sampling winding are provided with a secondary rectification filtering circuit which is composed of a diode D2, a capacitor C2 and a resistor R2. The flyback transformer is arranged, and isolation, high-precision detection and low cost can be realized through winding of the flyback transformer and selection of the low-voltage-drop diodes.

Owner:SHANGHAI JARI INFORAMTION SCI & TECH

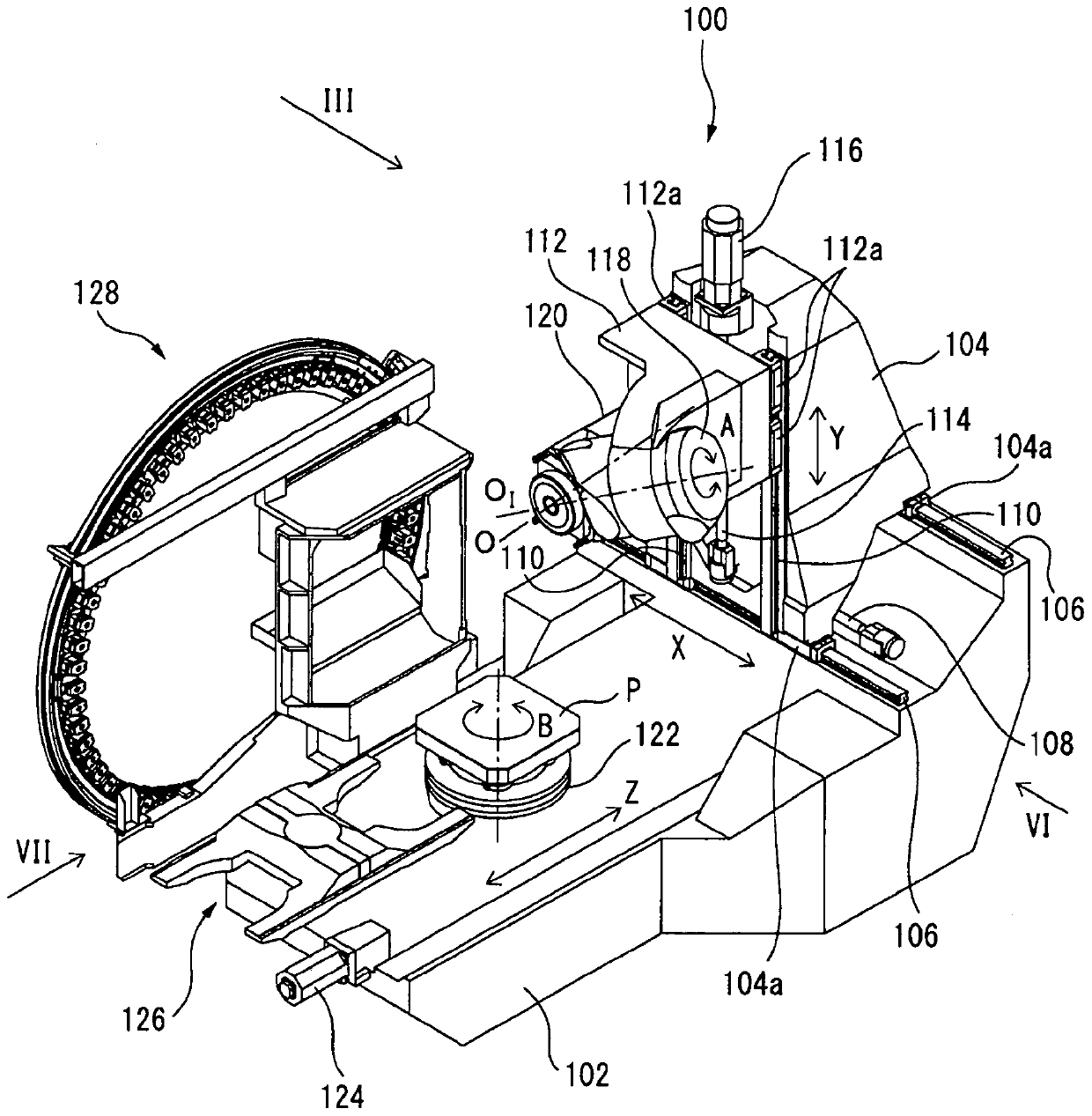

Machine tool

InactiveCN110325321AHigh synthesisLess likely to interfereMachine tool componentsMilling machinesRotational axisMachine tool

A machine tool (100) has a main shaft (152) having a tool (T) mounted on the tip thereof; a main shaft head (120) that rotatably supports the main shaft; orthogonal triaxial linear feed shafts that move the main shaft and a table (122), on which a workpiece is mounted, relative to one another; and a rotational feed shaft that is capable of changing the orientation of the rotational axis (O) of themain shaft. The machine tool (100) is provided with: a rotational feed shaft device (118) that is not parallel to any of the linear feed shafts and that rotates the main shaft head around an inclinedaxis (OI) that intersects the rotational axis of the main shaft; and a main shaft head base (112) that rotatably supports the main shaft head so that the point of intersection between the rotationalaxis and the inclined axis of the main shaft coincides with a defined reference point (PR) at the tip side of the main shaft.

Owner:MAKINO MILLING MASCH CO LTD

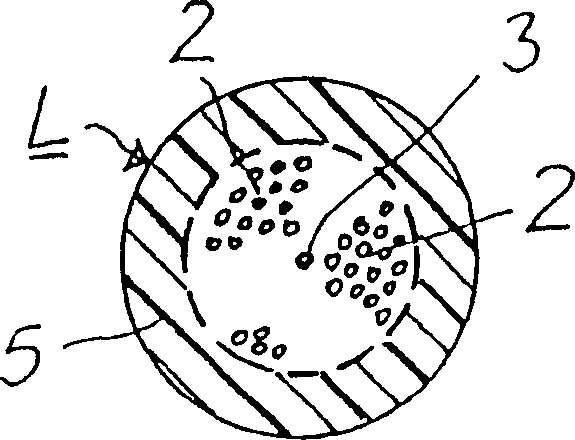

Flexible electric wire

InactiveCN1290122CGreat Alternating Bending StrengthDeformation does not preventDetails of conductive coresFlexible cablesElectricityFiber

The invention relates to a flexible electrical line (L) having at least one electrical conductor (1). The conductor is comprised of a non-metallic element, which is resistant to tensile forces, and of a multitude of metallic wires (2), which are arranged around the same and made of a material that conducts electricity well. In order to obtain the flexibility and to prevent ruptures, particularly in the event of intense vibrations, a loose combination consisting of a large number of aramide fibers (4) is used as the element (3) that is resistant to tensile forces. The cross-section of the loose combination corresponds to the cross-section of a single metallic wire (2). In addition, the conductor (1) is surrounded by an insulation (5).

Owner:NEXANS +1

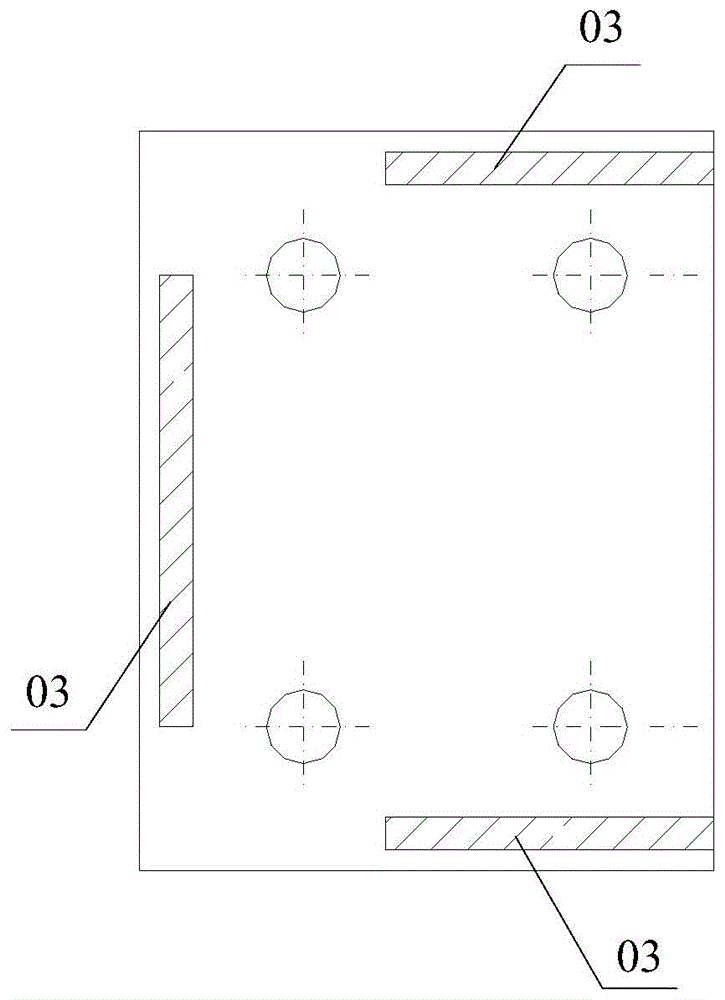

Elevator and its guide shoe mounting seat

The invention discloses a guide shoe mounting base. The guide shoe mounting base comprises a top plate and a bottom plate, wherein the top plate is fixedly connected with a guide shoe, the bottom plate is fixedly connected with a car, the top plate is provided with slotted holes, and the bottom plate is provided with bolt holes. The guide shoe mounting base further comprises at least three rib plates and a side plate, the rib plates are fixedly connected between the top plate and the bottom plate, one of the rib plates is longitudinally arranged along the slotted holes, the other two rib plates are arranged at two ends of the longitudinally arranged rib plate and perpendicular to the same, the slotted holes are distributed in two sides of the longitudinally arranged rib plate, and the bolt holes are distributed in two sides of the longitudinally arranged rib plate; the side plate is fixedly connected with the top plate and perpendicular to the top plate, and at least two bolts are mounted on the side plate. By the aid of the guide shoe mounting base, longitudinal play of the guide shoe mounting base after working fatigue is effectively avoided, and the bolts are convenient to fasten and demount. The invention further discloses an elevator comprising the above guide shoe mounting base.

Owner:CHONGQING FUJI ELEVATOR

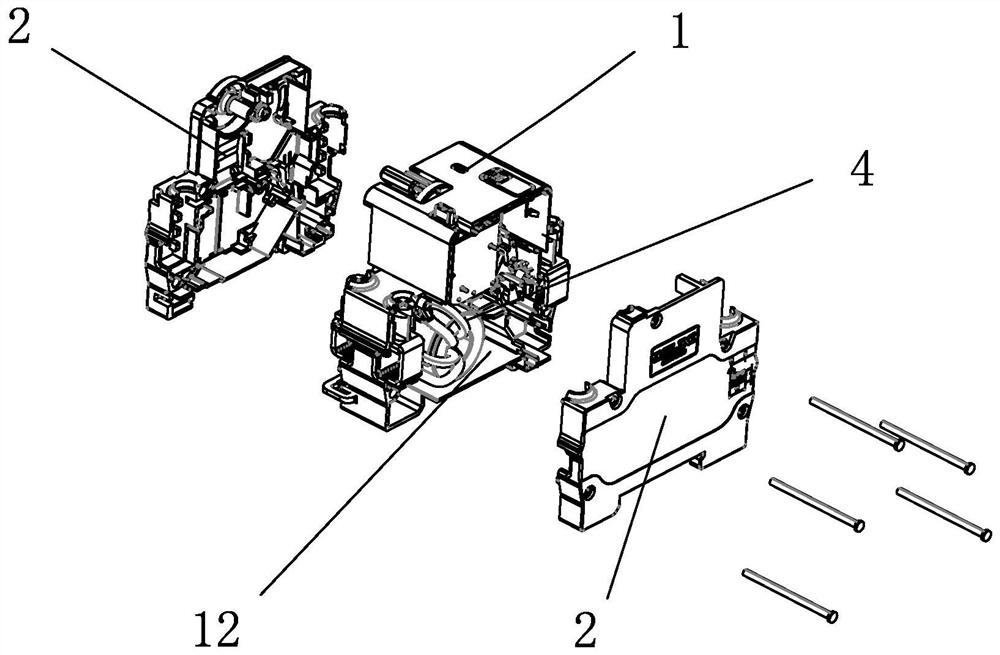

Residual current operated circuit breaker

PendingCN111785576ARaise the induced potentialReduce volumeSwitch operated by current/voltage unbalanceSwitch operated by earth fault currentsEngineeringInductor

The invention discloses a residual current operated circuit breaker, which comprises a base and a cover plate. A concave cavity is formed in one side of the base; the electric leakage protection module comprises a zero sequence mutual inductor and a tripping mechanism. The tripping mechanism comprises a tripping coil, the zero sequence mutual inductor comprises a magnetic ring and a secondary winding. A first wire and a second wire are further included and matched with the magnetic ring in a penetrating mode. The tripping coil comprises a coil framework and a coil winding; a circuit board is connected between the secondary winding and the tripping coil; the first wire and the second wire are both wound on the zero sequence mutual inductor and penetrate through an inner hole of the zero sequence mutual inductor at least twice, a plurality of discrete components used for achieving filtering of output signals of the mutual inductor and switching devices are arranged on the circuit board,and the secondary winding and the tripping coil are electrically connected through the discrete components. The device is convenient to install, the existing product structure can be simplified, and the product weight and the production cost are reduced.

Owner:DELIXI ELECTRIC

A fingerprint identification display device, its manufacturing method and driving method

ActiveCN106355136BQuality improvementLess likely to interfereStatic indicating devicesPrint image acquisitionLight irradiationDisplay device

The invention discloses a fingerprint identification display device, a manufacturing method and a driving method thereof. A plurality of photosensitive units are arranged inside the display device, and each photosensitive unit includes: a photosensitive unit for sensing changes in light intensity when a fingerprint is pressed. Diodes, and control switch transistors used to control the photodiode to convert light intensity changes into different potential outputs; the display device also has a component that emits light that can be sensed by the photodiode. When the user's finger is close to the surface of the display device, due to the uneven ridges and valleys on the skin surface of the finger, the photodiode emitted by the display device can sense the light intensity of the light irradiated on the ridges and valleys of the finger and reflected to the photodiode of the photosensitive unit Differently, the light intensity difference is converted into the current signal difference to realize the fingerprint detection. The photosensitive unit detects the fingerprint based on the photosensitive effect, which is not easy to interfere with the internal components of the display device, and it is easy to realize high-quality fingerprint detection.

Owner:BOE TECH GRP CO LTD +1

Current transformer assembly

PendingCN111430098ASimplify the assembly processPrevent axial wobbleTransformers/reacts mounting/support/suspensionTransformers/inductances casingsElectrically conductiveStructural engineering

The invention discloses a current transformer assembly which comprises an annular current transformer, a shell used for containing the current transformer, a plurality of current-carrying components and wire holders correspondingly connected with the current-carrying components respectively. Supporting components are also installed and fixed in a way of being cooperated with the current transformer. The current-carrying components are made of rigid conductive materials, and the current-carrying components are matched with the supporting components to be fixedly arranged in the inner hole of the current transformer in a penetrating manner. The assembly process is simple and operation is more stable.

Owner:DELIXI ELECTRIC

A DC high voltage isolation detection method

The invention provides a DC high voltage isolation detection method. A flyback transformer is arranged, and the flyback transformer is composed of a primary excitation winding, a secondary detection winding and a sampling winding. One end of the primary excitation winding is connected with a DC power supply, and the other end is connected with a main switching tube which is connected with a pulse driving unit. DC voltage is converted into pulse voltage by the main switching tube through chopping so that coupling of the flyback transformer is realized. The two ends of the primary excitation winding are provided with a primary clamp circuit used for a clamp transformer secondary reflected voltage protection main switching tube. The two ends of the secondary detection winding are provided with a secondary detection circuit which is composed of a diode D1 and a capacitor C1. The two ends of the sampling winding are provided with a secondary rectification filtering circuit which is composed of a diode D2, a capacitor C2 and a resistor R2. The flyback transformer is arranged, and isolation, high-precision detection and low cost can be realized through winding of the flyback transformer and selection of the low-voltage-drop diodes.

Owner:SHANGHAI JARI INFORAMTION SCI & TECH

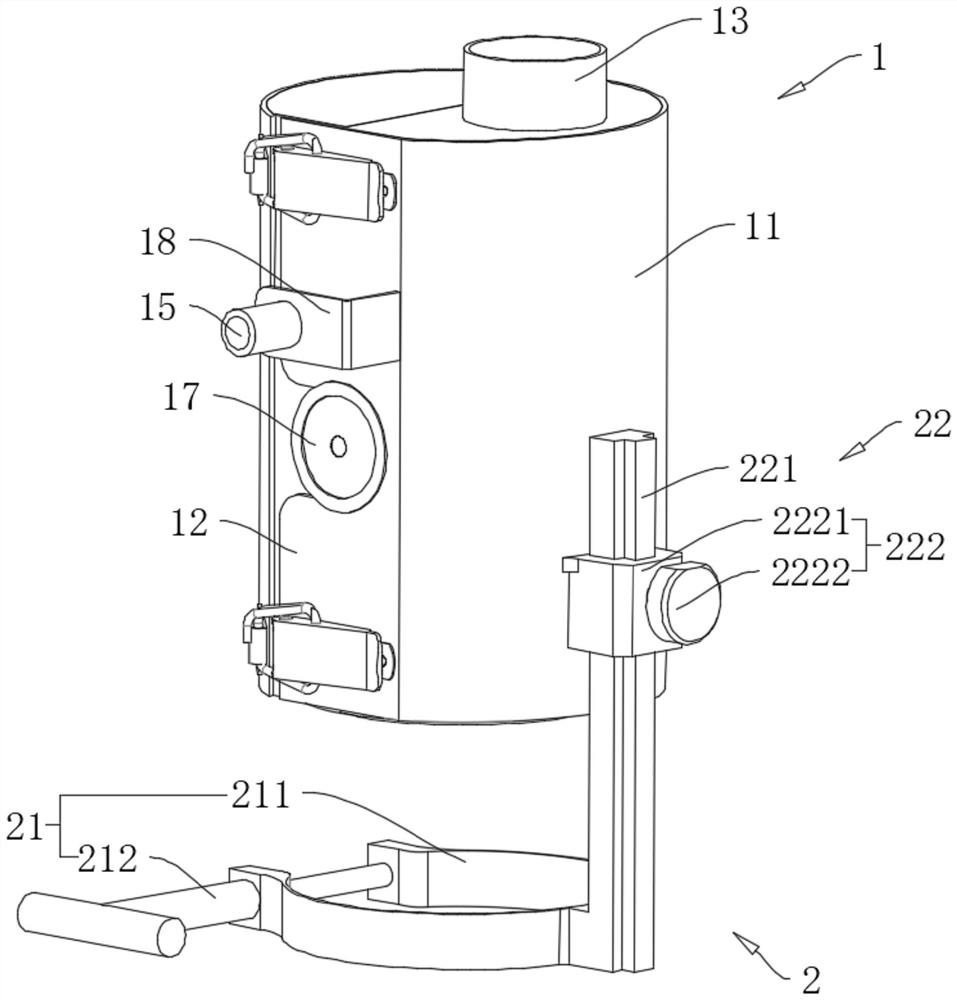

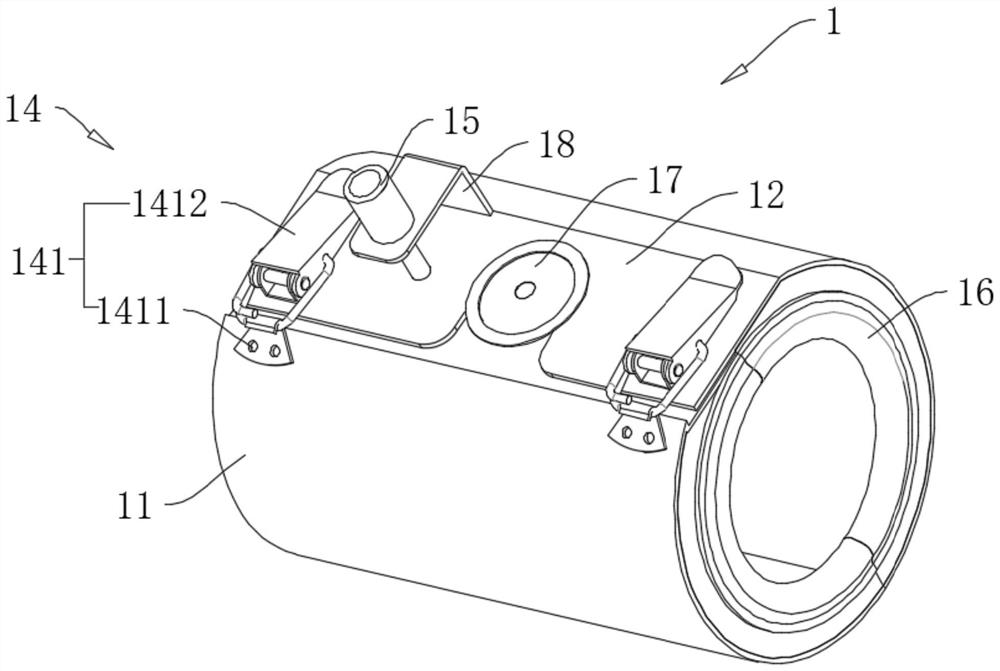

Novel high-safety air draft device for steel cylinder

ActiveCN114017668AEasy to open and closeEnsure safetyVessel mounting detailsContainer filling methodsStructural engineeringMechanical engineering

The invention discloses a novel high-safety air draft device for a steel cylinder; the device comprises an air draft cover shell and a fixing hoop, the air draft cover shell is used for extracting gas leaked from a steel cylinder connector, and the fixing hoop is used for fixing the air draft cover shell to a steel cylinder; the air draft cover shell comprises two shell bodies, the fixing hoop is connected with one shell body, the two shell bodies are connected in a hinged mode, fixing faces are arranged on the sides, away from the hinged end, of the two shell bodies, through holes are formed in the two fixing faces, openings are formed in the two through holes, the through holes in the two fixing faces can form a closed through hole, the shell bodies are connected with exhaust pipes, and the exhaust pipe are communicated with the inner cavities of the shell bodies. a locking mechanism is arranged on each shell body and is used for tightly fixing the two shell bodies together; a pneumatic lock is arranged on one shell body and is in signal connection with a control terminal. The novel high-safety air draft device for the steel cylinder can prevent the staff from opening the air draft cover shell by mistake, so that the safety is improved, and meanwhile, the novel high-safety air draft device for the steel cylinder is simple in overall structure, convenient to operate and high in mounting efficiency.

Owner:上海至纯系统集成有限公司

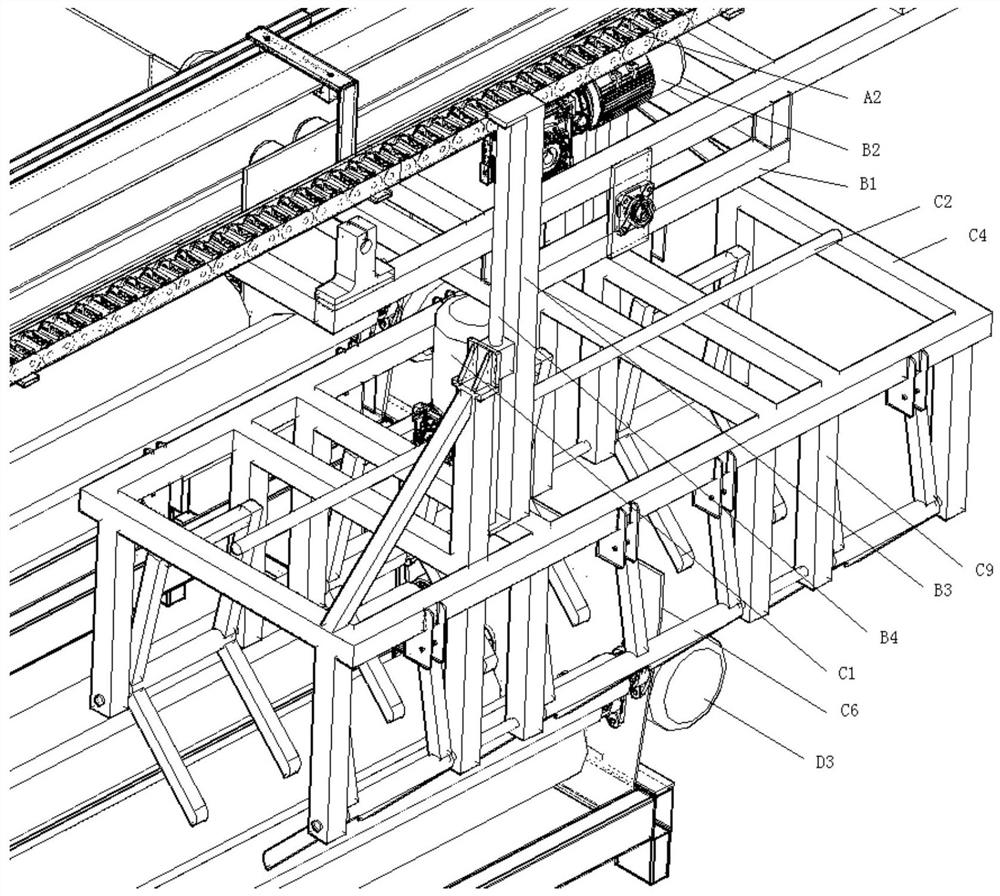

Automatic Grabbing Spreading Device

ActiveCN111747104BHigh degree of automationLess likely to interfereConveyor partsWebs handlingElectric machineryDrive motor

The invention relates to an automatic grabbing and spreading device. The invention solves the problems in the prior art. The key point of the technical solution is that it includes a door-type mounting bracket and several groups of spreading equipment, and each group of spreading equipment includes a mechanism, a spreading mechanism and a grabbing mechanism, the grabbing mechanism includes a portal mounting bracket, an upper connecting frame and a grabbing hand connecting frame, and the grabbing frame includes a rectangular grabbing main frame, all The lower sections of the vertical connecting rods located on the same side of the grasping main frame are connected by a circular connecting rod, and several rotating tubes are set on the circular connecting rod, and all the rotating tubes are connected along the upper connecting frame. The central axis of the grab is arranged symmetrically, a grab hand driving motor is fixed on the grab main frame, and several grab hand connecting wheels are fixed on the output shaft of the grab hand drive motor and are connected to the rotating tube through a steel wire rope. .

Owner:圣山集团有限公司

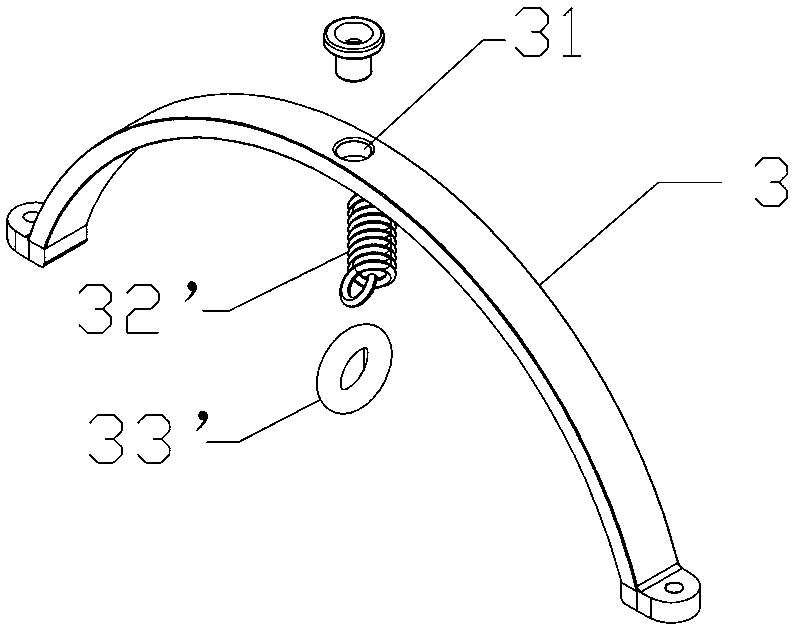

Non-interference and high-stability ribbon loom weft insertion device

The invention provides a non-interference and high-stability ribbon loom weft insertion device. The non-interference and high-stability ribbon loom weft insertion device comprises a shuttle body, andfurther comprises a weft yarn leading-out assembly connected to the shuttle body and a weft yarn pulling-back assembly which is matched with the weft yarn leading-out assembly to commonly lead yarn movement; the shuttle body is internally provided with two mounting channels; at least one mounting channel is arranged at each of two sides of the shuttle body; the weft yarn pulling-back assembly is arranged in the mounting channels; a mounting cavity is mounted in the shuttle body; the mounting cavity is internally and detachably provided with a quill fixing assembly; a communicated weft yarn passing path is arranged between the mounting cavity and the weft yarn leading-out assembly. The non-interference and high-stability ribbon loom weft insertion device provided by the invention is simplein structure and convenient to use; the assemblies are relatively easy and convenient to dismount and adjust; yarn movement and a corresponding structure design are optimized and the device is easy toproduce and manufacture; in a movement process of weft yarns, interference does not easily occur and the movement is smooth; friction abrasion is not easy to occur and the quality of ribbons and theservice life of the device are effectively improved.

Owner:HUZHOU HYUNDAI TEXTILE MACHINERY

Pneumatic tire

PendingCN114761258AImprove driving stabilityIncreased durabilityPneumatic tyre reinforcementsTyre beadsTire beadEngineering

The present application provides a pneumatic tire capable of ensuring the communication of a transponder and improving the driving stability and durability of the tire. In a pneumatic tire in which a carcass layer (4) has a structure in which the carcass layer (4) is rolled up around a bead core (5) from the inside to the outside of the tire, the end (4e) of a rolled-up part (4B) of the carcass layer (4) is disposed between a main body part (4A) of the carcass layer (4) and a belt layer (7), and a transponder (20) extending in the circumferential direction of the tire is embedded between the rolled-up part (4B) of the carcass layer (4) and a rubber layer. The rubber layer is disposed on the outer side of the carcass layer (4) in the sidewall portion, and the transponder (20) is disposed between a position (P1) 15 mm outward in the tire radial direction from the upper end (5e) of the bead core (5) and a position (P2) 5 mm inward in the tire radial direction from the tip (7e) of the belt layer (7).

Owner:YOKOHAMA RUBBER CO LTD

Three-dimensional scanning method and system

ActiveCN109141289BLess likely to interfereImage enhancementImage analysisComputer graphics (images)Cloud data

The invention relates to a three-dimensional scanning system for acquiring three-dimensional data of an object, comprising: a projector for projecting a feature image of a first wave band to the scanned object, the feature image including a plurality of key features. The scanner includes a projection module for emitting the scanning light of the second waveband to the surface of the scanned object, and the first waveband and the second waveband do not interfere with each other; The characteristic image of the object, to obtain the three-dimensional data of the key features projected on the surface of the scanned object; the second acquisition module is used to collect the scanning light reflected by the scanned object in the second wave band, and obtain the dense three-dimensional points on the surface of the scanned object cloud data. The present invention provides a three-dimensional scanning system that collects characteristic images of the first waveband and scanning light reflected by the second waveband, which is less prone to interference, so that the collected three-dimensional data is more accurate.

Owner:SHINING 3D TECH CO LTD

Back anti-collision beam welding assembly

The invention relates to the field of a vehicle part, in particular to a back anti-collision beam welding assembly. The back anti-collision beam welding assembly comprises a protecting plate, wherein a towing hook fixing plate and a towing hook nut are arranged in the middle of the protecting plate; the towing hook fixing plate is welded to the protecting plate; the towing hook nut is welded to the towing hook fixing plate; a bent side is also arranged on the towing hook fixing plate; the towing hook fixing plate and the towing hook nut are concentric. In use, the towing hook nut is welded to the towing hook fixing plate, so that the towing hook nut is prevented from rotating; the towing hook fixing plate is a round plate concentric to the towing hook nut, the towing hook fixing plate and the towing hook nut are uniformly welded, and during welding, the towing hook fixing plate does not interfere with the turning side of the protecting plate, so that the back anti-collision beam welding assembly is suitable for mass production.

Owner:李少华

Compressor installing structure of outdoor unit of one-driven-many indoor unit of air conditioner

InactiveCN100501262CSmall footprintSmall structureCompressorSpace heating and ventilation detailsGas compressorEngineering

Owner:HISENSE HOME APPLIANCES GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com