Automatic Grabbing Spreading Device

A spreading and automatic technology, applied in the direction of transportation and packaging, thin material handling, conveyor objects, etc., can solve problems such as unsmooth pulling and easy interference of cloth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

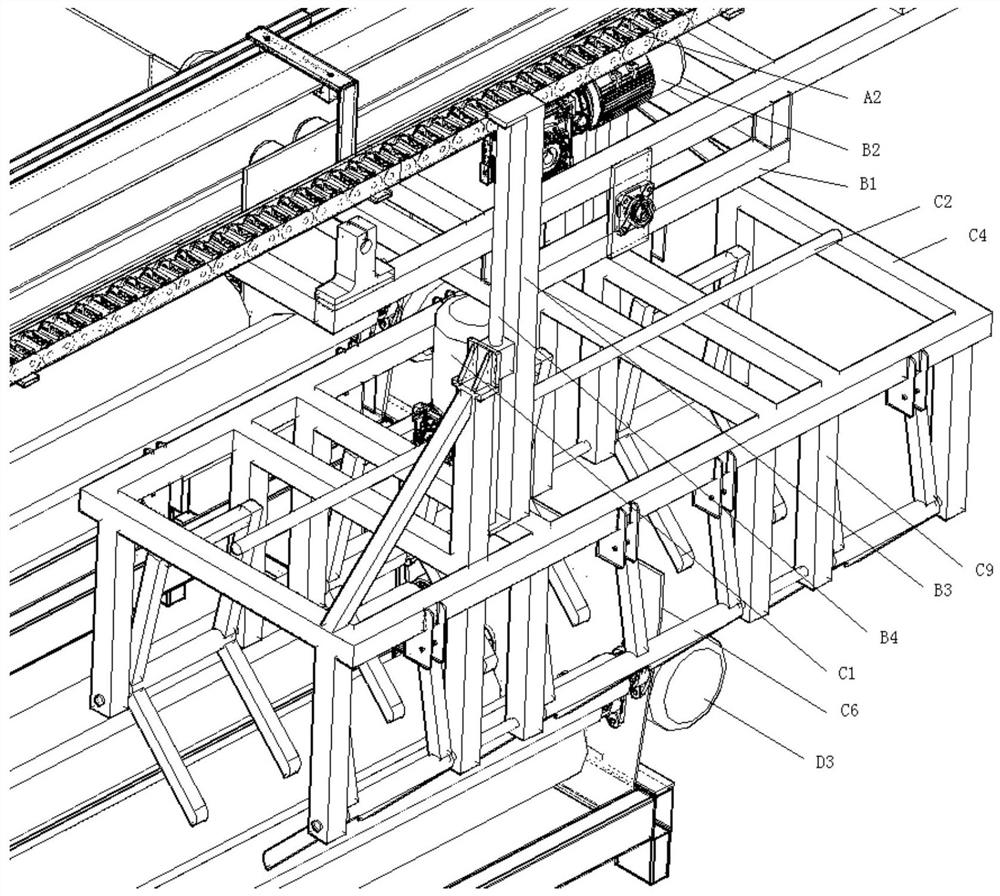

[0022] An automatic grab and spread device (see attached figure 1 to the attached Figure 5), including portal mounting bracket A1 and several sets of spreading equipment, each set of spreading equipment includes a cloth placing mechanism, a spreading mechanism and a grabbing mechanism, and the grabbing mechanism includes a portal mounting bracket , the upper connecting frame B1 and the grabbing hand connecting frame, the connecting bar of the portal mounting bracket is located above the entrance of the cloth placing mechanism and the spreading mechanism, and the portal mounting bracket is along the connecting bar. A transmission chain A2 is configured, the upper connecting frame is a rectangular frame as a whole, and two lateral moving connecting plates A3 symmetrically arranged along the center of the upper connecting frame are fixed above the upper connecting frame, and each lateral moving connecting plate is fixed with a A traverse motor A4, the driving end of the travers...

Embodiment 2

[0028] This embodiment is basically the same as Embodiment 1, the difference is that, in this embodiment, the traverse motor, the gripping hand drive motor, and the upper drive motor are all equipped with position photoelectric encoder disks, and the traverse motor, gripper The hand drive motor and the upper drive motor are both electrically connected with the on-site control device, a proximity sensor is fixed on the side of the vertical connecting rod, and the n-shaped driving square tube is filled with a permanent magnet for triggering corresponding to the position of the proximity sensor. A proximity sensor is also fixed on the extension rod, and a permanent magnet for triggering is filled on the connecting pipe corresponding to the position of the proximity sensor. The setting of the photoelectric encoder plate can locate the output of the traverse motor, the grasping hand drive motor and the upper drive motor, and the further design of the proximity sensor, the electrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com