Residual current operated circuit breaker

A residual current and circuit breaker technology, which is applied to circuit breaker components, circuits, switches operated by ground fault current, etc., can solve the problems of increased production processes, weight increase, lack of positioning structure of springs, etc., and achieve improved positioning and coordination effects , Reduce the wiring process, improve the effect of the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

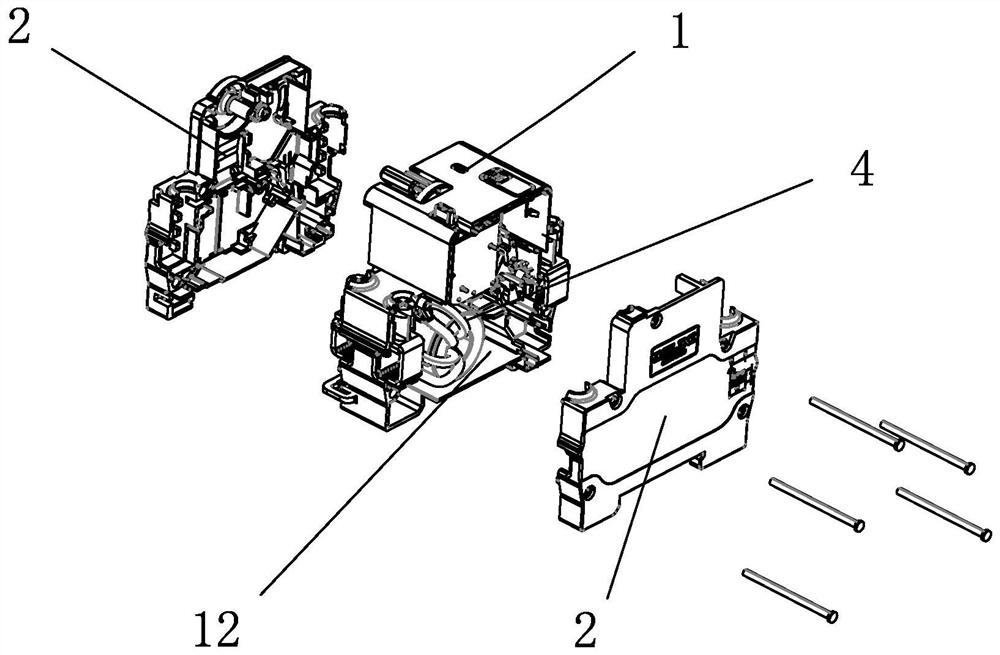

[0067] Embodiments of the residual current operated circuit breaker of the present invention are as follows Figure 1-19 As shown: it includes a base 1, a first concave cavity 11 is opened on one side of the base 1, a second concave cavity 12 is opened on the other side of the base 1, and the first concave cavity 11 and the second concave cavity 12 pass through The cover plates 2 arranged on both sides of the base 1 are closed, and the base 1 and the cover plates 2 are inserted into each other and connected through screws or rivets.

[0068] The residual current operated circuit breaker also includes a circuit breaker module 3 and a leakage protection module 4 respectively arranged in the first cavity 11 and the second cavity 12 and shielded and protected by the cover plate 2. The leakage protection module 4 includes The zero-sequence transformer 41 and the tripping mechanism, the tripping mechanism includes a tripping coil 42, the zero-sequence transformer 41 includes a magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com