Flexible electric wire

A wire and flexible technology, applied in the field of flexible wires, to achieve the effect of large alternating bending strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

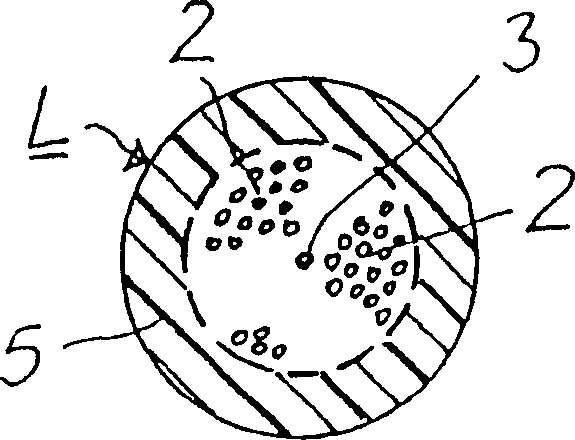

[0013] figure 1 and figure 2 The cable L shown has an electrical conductor 1 consisting of a number of metal wires 2 with good electrical conductivity and a tensile element 3 . The metal wire 2 is preferably a copper wire. The tensile element 3 is a bulk combination of many very thin but tensile aramid filaments 4 . One suitable material is known under the trade name "Kevlar". This loose combination is soft and easily deformable in the radial direction, so that the tensile element 3 is soft. A layer of insulating skin 5 is wrapped around the conductor 1 . This insulating skin is made, for example, of polyurethane.

[0014] The electrical conductor 1 has a plurality of wires 2 which are bundled together with the tensile element 3 to form the complete electrical conductor 1 . The entire cross-section of the tensile element corresponds to a single wire 2 . The above-mentioned bundle combination process itself can be accomplished in any manner. Suitable methods are twisti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com