Compressor installing structure of outdoor unit of one-driven-many indoor unit of air conditioner

An air conditioner room and installation structure technology, applied in the directions of compressors, refrigerators, heating methods, etc., can solve the problems of sparse distribution of pipes, increased weight, and inconvenient installation, so as to reduce manufacturing costs, reduce overall structure, and reduce The effect of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

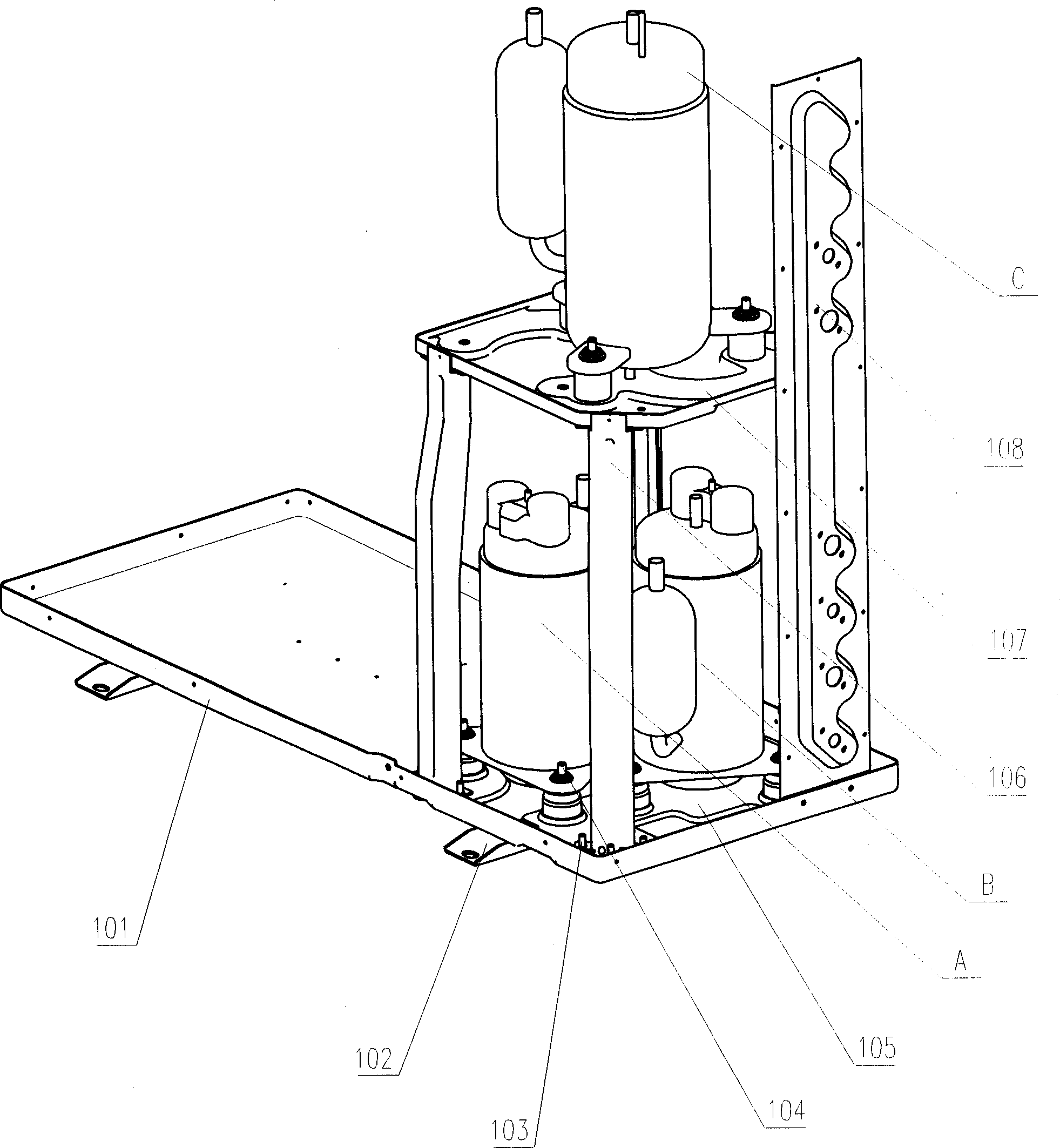

[0029] The structure diagram of the present invention is as figure 1 , 2 , 3, and 4, including bottom plate 1, several fixing screws 4, lower compressor mounting base 5, several support rods 6, upper compressor mounting base 7, several fixing screws 9, and several fixing screws 4 are fixed on the lower compression Machine mounting seat 5, the lower compressor mounting seat 5 is fixed on the bottom plate 1, the upper compressor mounting seat 7 with a number of fixing screws 9 is fixed on the support rod 6, the support rod 6 is fixed on the bottom plate 1, some upper layers Compressor A is fixed on the lower compressor mounting base 5 through nuts that cooperate with fixing screws 4 , and several lower compressors B are fixed on upper compressor mounting bases 7 through nuts that cooperate with fixing screws 9 . There are 1 to 3 upper compressors A, 1 to 3 lower compressors B, and 3 to 6 support rods 6 . In this embodiment, there are two compressors A on the upper floor and on...

Embodiment 2

[0035] The structure diagram of the present invention is as Figure 5 As shown, its structure is the same as that of Embodiment 1, except that there are two compressors A on the upper floor and two compressors B on the lower floor, which are used for one-to-four split air conditioners.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com