Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "Inhibits enzymatic oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Green tea processing method for reducing bitterness of autumn tea and summer tea

ActiveCN102940053AReduce bitternessFull-bodied taste qualityPre-extraction tea treatmentGreen teaTea leaf

The invention discloses a green tea processing method for reducing bitterness of autumn tea and summer tea, comprising the following steps:1) selecting tea leaves: selecting fresh tea leaves of autumn and summer and grading; 2) withering: spreading the fresh tea leaves for withering, wherein the water content of the withered leaves is 70-75%; 3) conducting fine manipulation: carrying out fine manipulation on the withered leaves to obtain fine-manipulated leaves, wherein fine manipulation comprises rotating and cooling which are alternately and repeatedly; 4) de-enzyming: de-enzyming the fine-manipulated leaves to obtain de-enzymed leaves; 5) dampening: dampening the de-enzymed leaves; 6) rolling: rolling the dampened leaves; 7) drying: using a gross fire to dry the rolled leaves until the water content is 10-20%, then using a complete fire to dry, wherein the water content of the dried leaves is 4-6%. According to the invention, by using the fresh tea leaves and optimizing the processing method, the produced green tea can reduce the bitterness of tea, thus fragrance of green tea with natural fragrance of flower is formed, and the taste quality is thick and mellow.

Owner:婺源县聚芳永茶业有限公司

Production method of green tea

InactiveCN105341200AInhibits enzymatic oxidationPromote formationPre-extraction tea treatmentGreen teasEngineering

The invention discloses a production method of a green tea. The production method comprises the following specific steps of withering with hot blast: uniformly spreading a thin layer of picked fresh leaves on a withering trough, wherein the leaf spreading thickness is 5cm, and the withering temperature is 60-70 DEG C, so that the fresh leaves are uniformly and consistently withered, and compared with the fresh leaves which are picked a moment ago, the mass loss of the tea leaves is 20-25% in percentage by mass; fixation with hot blast: placing the withered fresh leaves with hot blast in a roller fixation machine, wherein the roller temperature is 350-380 DEG C, the fixation time is 3-5s, 500-600kg of the leaves are put, and compared with the tea leaves which are picked a moment ago, the water loss of the tea leaves is 65-70% in percentage by mass; then, sequentially performing the following operation steps of spreading the fresh leaves after fixation for the first time so that the fresh leaves after the fixation are cooled, performing resurgence on the cooled fresh leaves, tidying tea strips, performing depilation, spreading the fresh leaves after the depilation for the second time so that the fresh leaves after the depilation are cooled, performing resurgence on the fresh leaves, shaping the tea leaves, baking the shaped tea leaves, sorting the baked tea leaves, flavor distilling and the like; and limiting the corresponding technological parameters, and improving the fragrance and the taste of the green tea. The operation step sequence is reasonably designed, and the activity of oxidase in fresh tea leaves is destroyed at high temperature and inactivated, so that the tea leaves are soft, and give out delicate fragrance, which is favorable for the formation of the fragrance of the tea leaves.

Owner:泸州市天绿茶厂

Processing method of fungus-fragrance black tea

ActiveCN107593941AQuality hasInhibits enzymatic oxidationPre-extraction tea treatmentBlack teaOxygen

The invention relates to a processing method of fungus-fragrance black tea. According to the processing method, under the basis of a conventional black tea making technology including withering, rolling, fermentation, primary drying, redrying and the like, fresh tea leaves in summer or autumn are used as raw materials of the black tea, a technological technique of forming fungus fragrance and flower fragrance is combined, namely that the processing method comprises the technological steps of performing primary withering, performing secondary withering, performing cold-rolling, performing oxygen inflation for adjusting and controlling fermentation, performing primary drying, performing redrying, mixing semi-finished tea, performing temperature-change alcoholization, performing steaming, performing pile fermentation, performing inoculating with eurotium cristatum, performing compressed shaping, enabling the eurotium cristatum to reproduce, performing drying and the like. According to themethod, in accordance with the present situations that the utilization rate of the fresh tea leaves in summer or autumn is low, the quality is poor and the tea is free from special fragrance, the technology disclosed by the invention is used, so that the made black tea has excellent qualitative characteristics of being dense in eurotium cristatum, uniform in granules, and fresh and living in color, after being brewed, the fungus -fragrance black tea is rich in fungus fragrance and has flower fragrance, the soup is reddish brown and bright in color, and fresh, mellow and rich in taste. According to the method, the organoleptic quality of the conventional black tea in summer and autumn in the respects of color, fragrance, taste and shape can be notably improved, and the condition that freshtea leaf resources in summer and autumn are wasted is reduced effectively to a certain extent.

Owner:HUNAN AGRICULTURAL UNIV +1

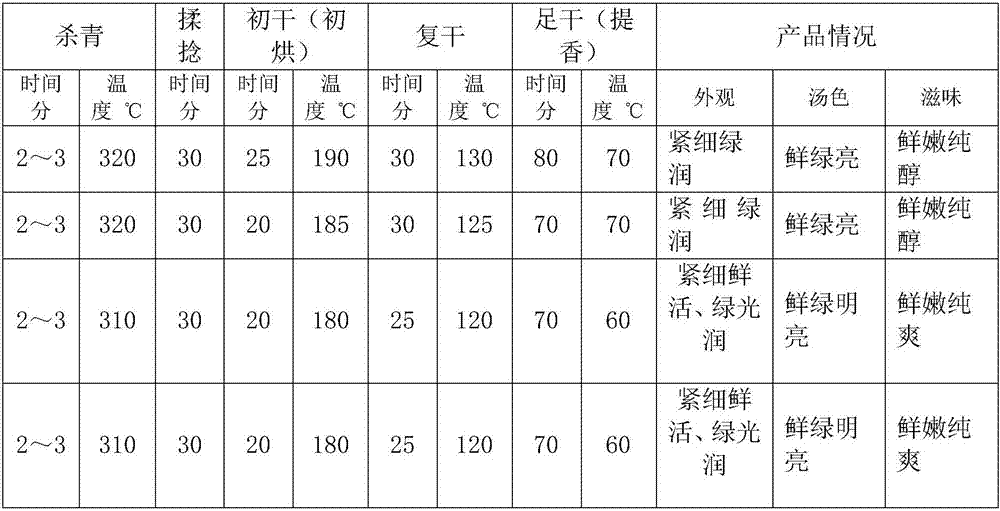

Production method of maofeng

InactiveCN105285186AAvoid Thermal Inertia ProblemsQuality improvementPre-extraction tea treatmentBiotechnologyPhenolic content in tea

The invention discloses a production method of maofeng. A specific method of operation comprises the steps of hot air withering: picked fresh leaves are uniformly and thinly spread in a withering trough, wherein the thickness of the spread leaves is not less than 10cm, the withering temperature is 60 to 70 DEG C, the withering of the fresh leaves is enabled to be uniform, compared with the picked fresh leaves, the water loss of tea is 20 to 25 percent in percentage by weight; hot air deactivating: fresh leaves treated by hot air withering are put into a cylinder deactivatingmachine, wherein the temperature of a cylinder is 350 to 380 DEG C, the deactivatingtime is 3 to 5s; then sorting, rolling, deblocking, tea strip tidying for the first time, tea strip tidying for the second time, drying for the first time, spreading and airing and drying for the second time are performed in sequence, technological parameters of production process steps are reasonably designed, and the influence on aroma and quality of taste of the maofeng is effectively avoided; the sequence of operation steps of the maofeng is reasonably designed, a hot air deactivatingstep is performed after hot air withering is treated, enzymatic oxidation of TP (tea polyphenol) and the like in the fresh leaves is inhibited, and the effect of improving maofeng tea quality is achieved.

Owner:泸州市天绿茶厂

Vegetable noodle and technology for processing same

InactiveCN105876633AEfficient sterilizationInhibits enzymatic oxidationNatural extract food ingredientsFood ingredient as mouthfeel improving agentFood additiveFlavor

The invention discloses vegetable noodle and a technology for processing the same. The vegetable noodle comprises wheat flour, purple sweet potato flour, konjac flour, table salt, dietary alkali, carrageenan, sesame oil, carrot juice, rhizoma zingiberis recens juice, asparagus lettuce juice, loofah juice, burdock juice, walnut juice, bulbus lilii juice, maca juice, honey, milk, food additives and water. The vegetable noodle and the technology have the advantages that diversified seasonal vegetables are added into the vegetable noodle, accordingly, the vegetable noodle has fresh and cool taste, diversified vitamins can be supplemented for people after people eat the vegetable noodle, and effects of reducing blood pressures and blood lipid further can be realized by the vegetable noodle; the vegetable noodle is sterilized by the aid of high-voltage pulse electric fields, fruit and vegetable juice can be effectively sterilized, enzymatic oxidation and non-enzymatic oxidation of the fruit and vegetable juice can be suppressed, and original colors, flavor, nutrition and active functions of fresh fruits and vegetables can be reserved; the technology for processing the vegetable noodle includes simple procedures and is low in cost and suitable for large-scale production and sales.

Owner:MIANYANG XIANTE RICE

Method for producing strawberry juice through HPEF (high intensity pulsed electric field) sterilization

InactiveCN103653126ASolve the problem of juicingIncrease the juice yieldFood electrical treatmentEscherichia coliLaboratory scale

The invention provides a method for producing strawberry juice through HPEF (high intensity pulsed electric field) sterilization, belongs to the technical field of deep processing of agricultural products and mainly solves the problems that strawberries are difficult to juice, the juice yield is low and the like by means of a bio-enzymatic method processing technology. Clear and transparent normal strawberry juice is obtained through low-temperature centrifugation; and an HPEF sterilization technology is used for restraining enzymatic oxidation and non-enzymatic oxidation of the strawberry juice, nutrition and active ingredients of the strawberry juice are effectively reserved, and the product storage period is prolonged. Equipment used by the method adopts bipolar positive and negative pulse OSU (Ohio State University)-4L laboratory scale pulse processor (manufactured by the OSU), and escherichia coli and pathogenic bacteria in the strawberry juice can be effectively killed, so that the product can reach a commercial aseptic condition, the prepared strawberry juice doesn't contain any preservative and has special color, flavor and nutrition of fresh strawberries, the product guarantee period can be up to more than 6 months, and the strawberry juice has a wide market development prospect.

Owner:NANJING FEIMA FOOD

Process for making green tee

InactiveCN105104599AInhibits enzymatic oxidationAccelerate evaporationPre-extraction tea treatmentWater contentSizing

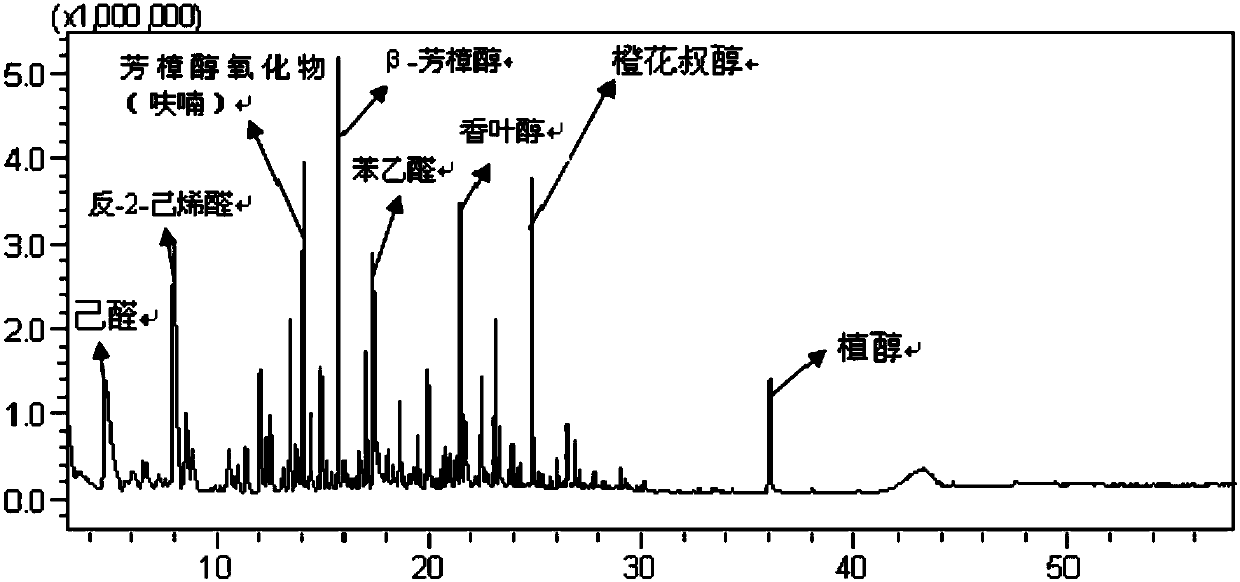

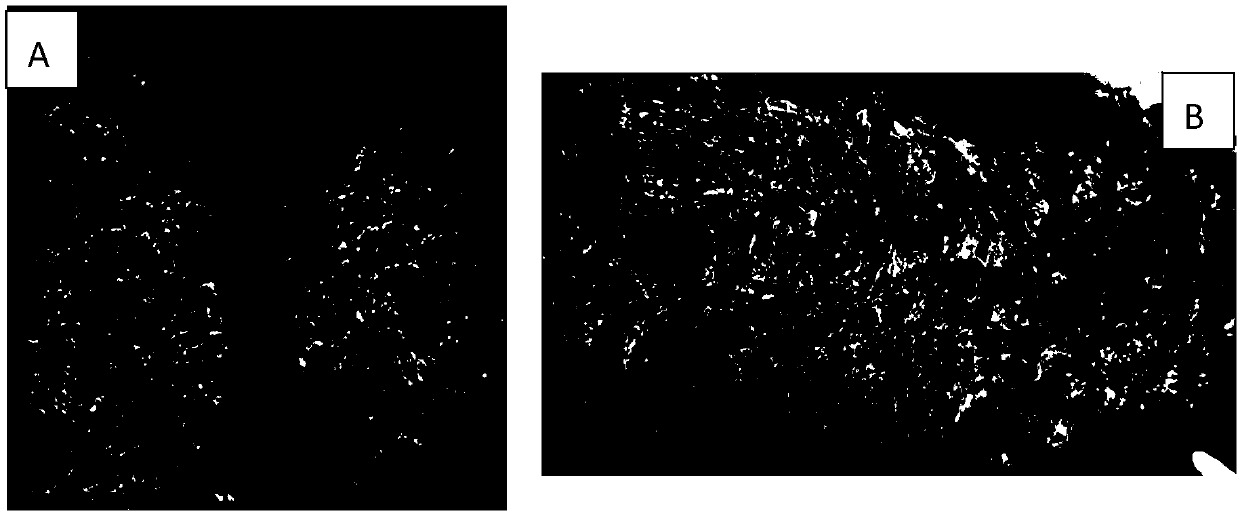

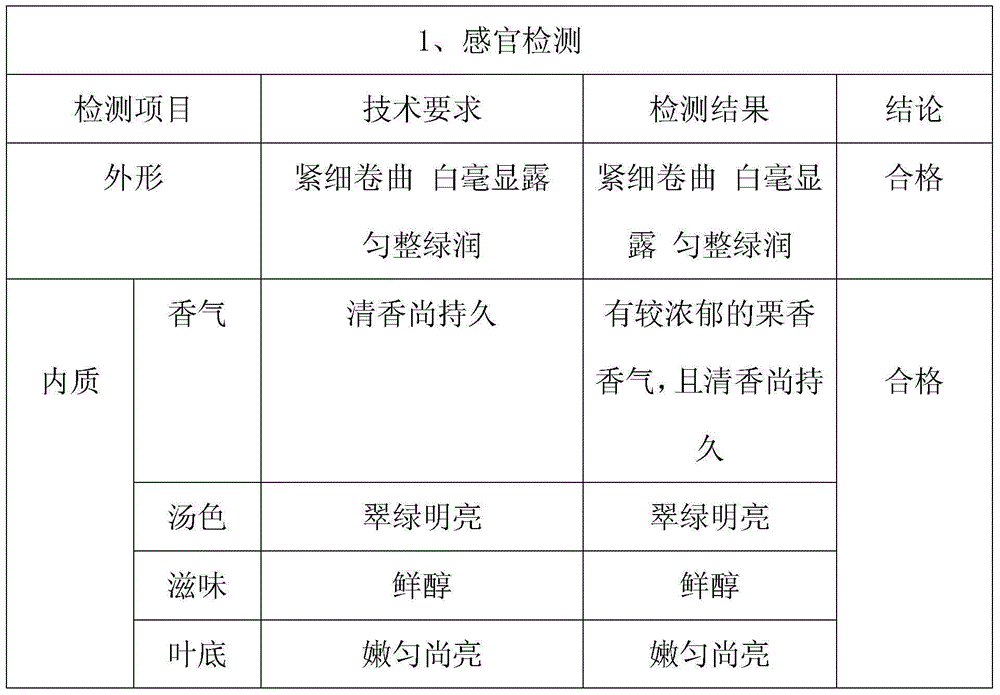

The invention discloses a process for making green tee, which comprises steps: 1 deterioration; 2 de-enzyming; 3 cool sharing; 4 softening; 5 rolling; 6 secondary de-enzyming; 7 first baking; 8 secondary cool sharing; 8 secondary baking; 9 sizing; and 10 packaging warehousing. Green tee which is prepared through the process for making the green tee is strong in chestnut aroma, long in duration time of aroma, is below 5% in water content of tea, low in water content, long in retention time, verdant in color, uniform and tidy in shape, revealed in pekoes, crimp in trabs and excellent in quality of tee, fresh and pure in taste, sweet, clear in liquor color, light, green and bright in infused leaves, and can achieve grades above one or more.

Owner:GUIDING YIFENG TEA IND CO LTD

Green tea processing method

ActiveCN104146084APrevent discoloration from fermentationPromote biochemical reactionsPre-extraction tea treatmentFlavorGreen tea

The present invention relates to a green tea processing method, which comprises the following steps: grading fresh tea leaves, fine manipulation of green tea leaves, deactivation of enzymes, rolling to fix shape, primarily drying with gross fire;, and improving aroma with complete fire. Wherein, the step of fine manipulation of green tea leaves comprises rocking of green leaves and standing process, the rocking process is carried out immediately after the grading of fresh tea leaves in factory, a long roller continuous enzyme deactivation machine is adopted, and the temperature of hot air in the barrel is controlled at 45-55 DEG C to perform rocking for 1.5-2.5 minutes; the standing process follows the rocking process; the standing process is carried indoors at a temperature of 10-25 DEG C, the thickness of the tea leaves in standing process is 5-15 centimeters, and the duration time is 40-80 minutes. The tea leaves processed with the present invention retain the external characteristics of green tea, have the intrinsic mellow, pleasant and fragrant taste and flavor at the same time, and are suitable for people with different physical characteristics to drink.

Owner:绩溪县上庄茶叶专业合作社 +3

Manufacture method of stomach nourishing rose flower tea

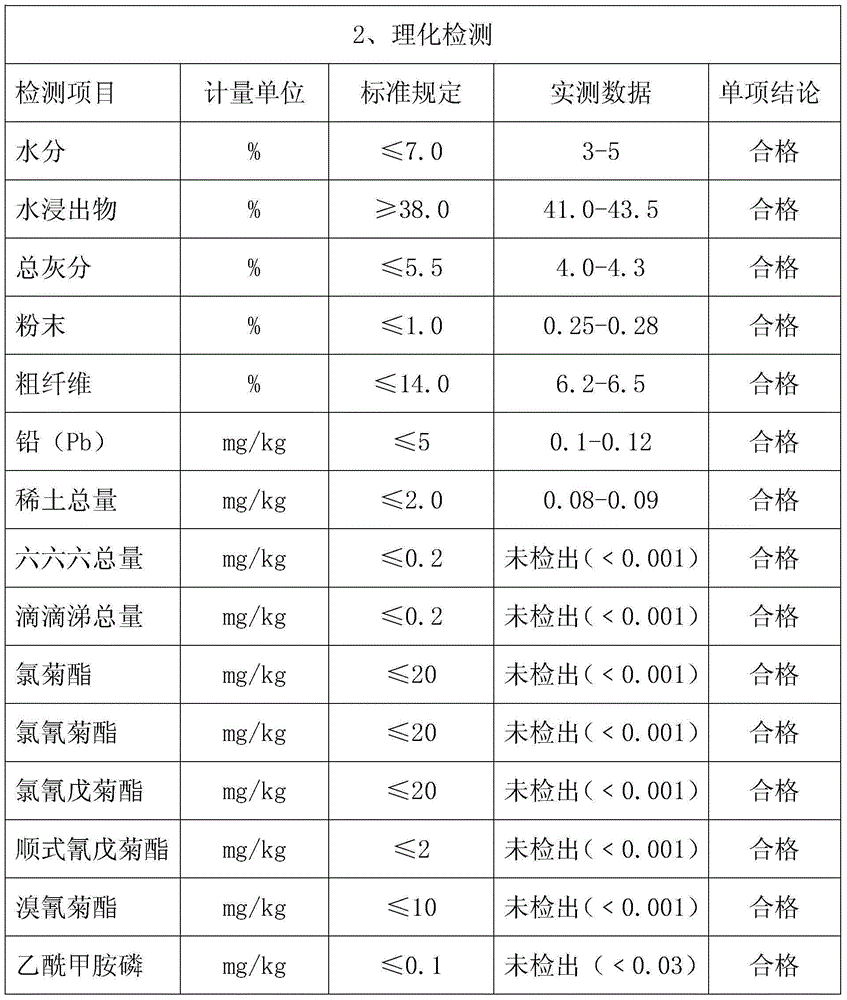

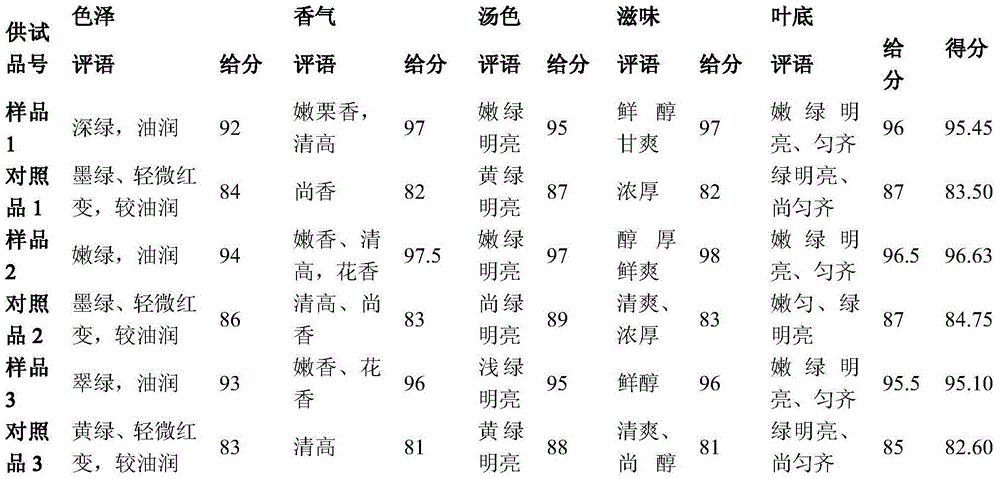

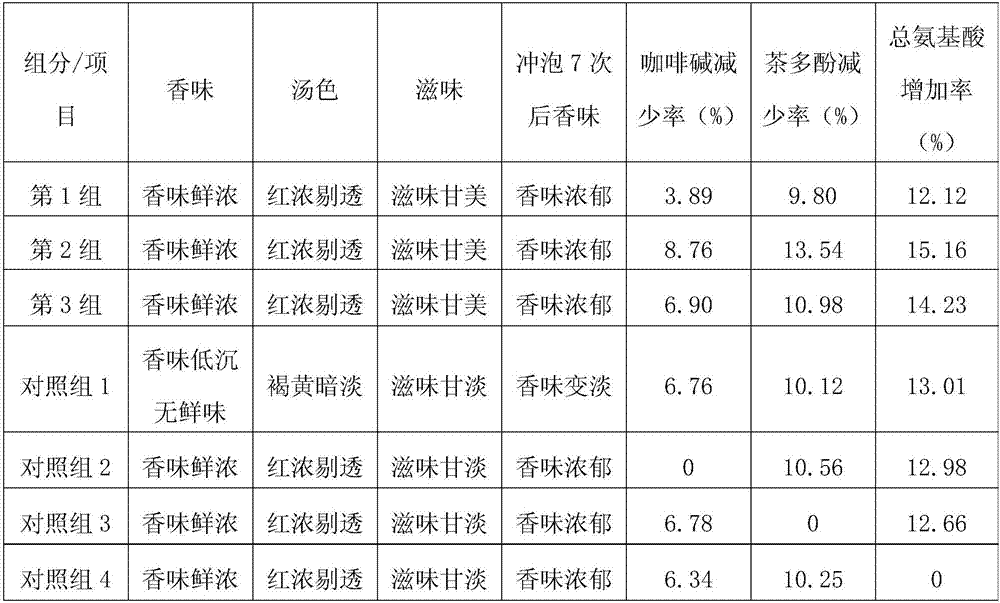

InactiveCN107125360AReduce contentIncrease varietyPre-extraction tea treatmentDigestive systemPresent methodTotal amino acids

The present method discloses a manufacture method of stomach nourishing rose flower tea and relates to the field of flower tea manufacturing and processing. The manufacture method of the stomach nourishing rose flower tea comprises the following steps: rose flower picking, rose flower pretreating, tea base pretreating, scenting, rose flower fermenting, drying and packaging. The manufacture method of the stomach nourishing rose flower tea reduces content of caffeine and tea polyphenols in the tea by fermenting the rose flowers and tea bases, improves content of total amino acids, extends freshness of the fragrance of the flower petals and improves a fragrance dispersing ability of the flower petals, so that the prepared stomach nourishing rose flower tea is fresh, mellow, lasting, and mellow and mild in mouthfeel, also has effects of nourishing the stomach, and is suitable for patients with gastrointestinal diseases to drink.

Owner:广西凌云县绿贵茶业有限公司

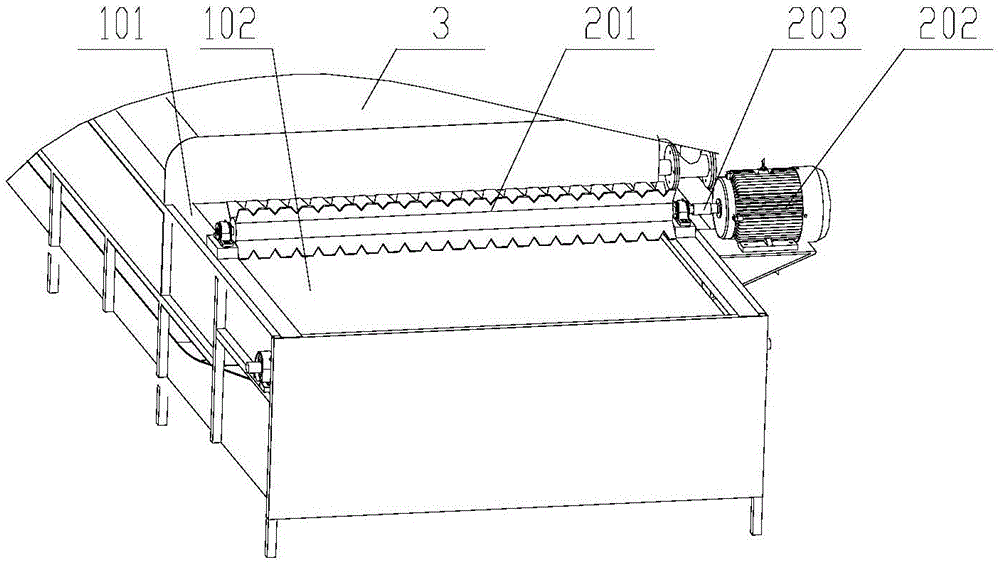

Vegetable drying process line

ActiveCN106577999AGuaranteed temperatureDestroys and inactivates oxidase activityFruits/vegetable preservation by dehydrationWater vaporSuperheated steam

The invention discloses a vegetable drying process line comprising an incoming material arranging device, a dewatering device and drying device which are arranged sequentially on a material conveying system. The material conveying system comprises an air-permeable conveying belt, the incoming material arranging device levels materials accumulated on the conveying belt, the dewatering device comprising a dewatering chamber arranged on the material conveying system and mixes and dewaters vegetables through superheated vapor and water vapor, and the drying device comprises a drying chamber arranged on the material conveying system and circularly dries the vegetables entering the drying chamber through circulating hot air different in direction. The vegetable drying process line realizes streamlined automatic production of vegetable drying, has the advantages of low labor intensity and higher production efficiency, is wider in application range, can realize dewatering of various melon and fruit vegetables and is higher in stability of production process and product processing quality.

Owner:湖南新发食品有限公司

Water removing device for production of chrysanthemum scented tea

InactiveCN110301491AFast deliveryFinishing job is goodPre-extraction tea treatmentTea substituesEngineeringConveyor belt

The invention discloses a water removing device for the production of chrysanthemum scented tea and belongs to the technical field of scented tea preparation. The water removing device comprises a feeding mechanism, a water removing mechanism and a drying mechanism, the output end of the feeding mechanism extends to the water removing mechanism, one end of the drying mechanism extends to the waterremoving mechanism, the water removing mechanism includes a water removing cabinet, a holding assembly and a water removing assembly, the holding assembly is located in the water removing cabinet, one end of the water removing assembly is located directly under the holding assembly, and the other end of the water removing assembly is placed outside the water removing cabinet to be fixedly connected with the water removing cabinet. The chrysanthemum on a first conveyor belt and a second conveyor belt are separated on the first conveyor belt or the second conveyor belt through a plurality of separation blocks so as to be concentrated in an orderly manner, a wavy baffle can block the upper layer of the stacked chrysanthemum and pull the same over to tile the chrysanthemum on the first conveyor belt or the second conveyor belt, and the chrysanthemum tiled on the first conveyor belt and the second conveyor belt can facilitate water removal.

Owner:王远志

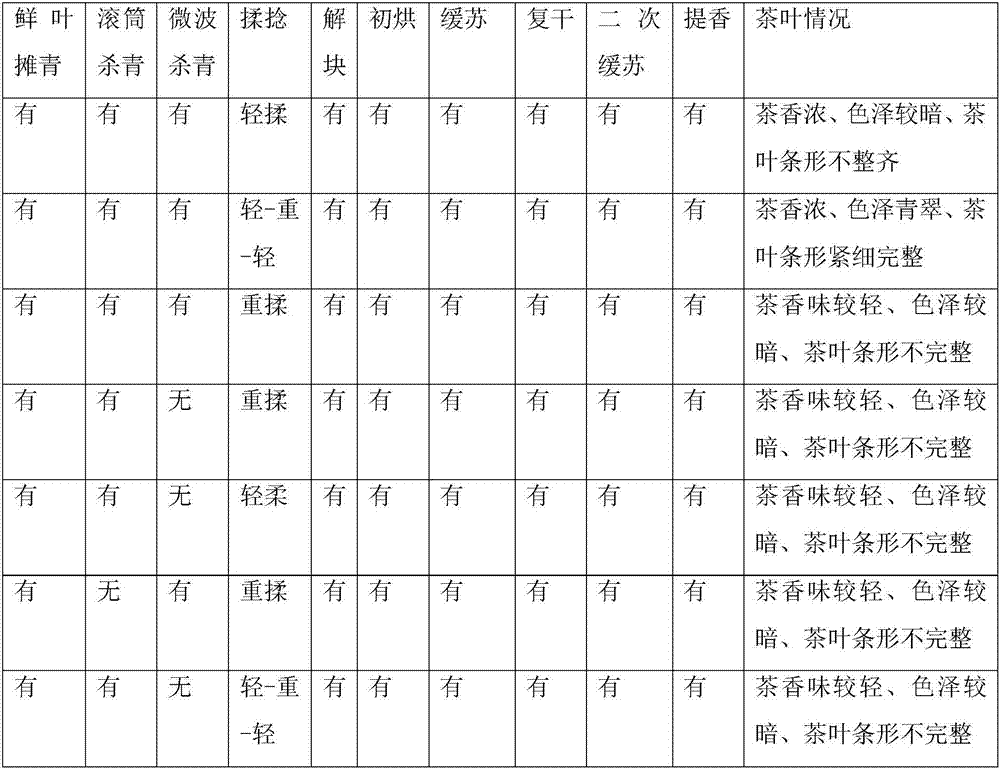

Combined enzyme-deactivating method for tea leaves

InactiveCN106490211AInhibits enzymatic oxidationEasy to shapePre-extraction tea treatmentEnzymeFlavor

The invention discloses a combined enzyme-deactivating method for tea leaves. The method comprises the steps of cleaning fresh leaves and removing water, spreading, deactivating enzymes with rollers, carrying out supplementary deactivation with microwaves, rolling, settling and drying, and the like. According to the invention, the tea leaves, which are primarily treated according to the processes, including storing and spreading, are deactivated, two sections of rollers are utilized to deactivate enzymes in an enzyme-deactivating process, and wet heat air is emitted in the continuous conveying process between the two rollers, so that the problems of yellowing, red stalks and red leaves of a large number of tea leaves in the rollers caused by difficulty in wet air discharging and incomplete enzyme deactivating are avoided; and through supplementary deactivation with microwaves, the oxidase activity in the fresh leaves can be quickly damaged and passivated, and the enzymatic oxidation of tea polyphenols can be restrained. According to the method disclosed by the invention, the problems of uneven enzyme deactivation and poor enzyme deactivation effect of the present enzyme-deactivating method for tea leaves can be solved, and meanwhile, the taste and flavor of the tea leaves are guaranteed.

Owner:雅安市友谊茶叶有限公司

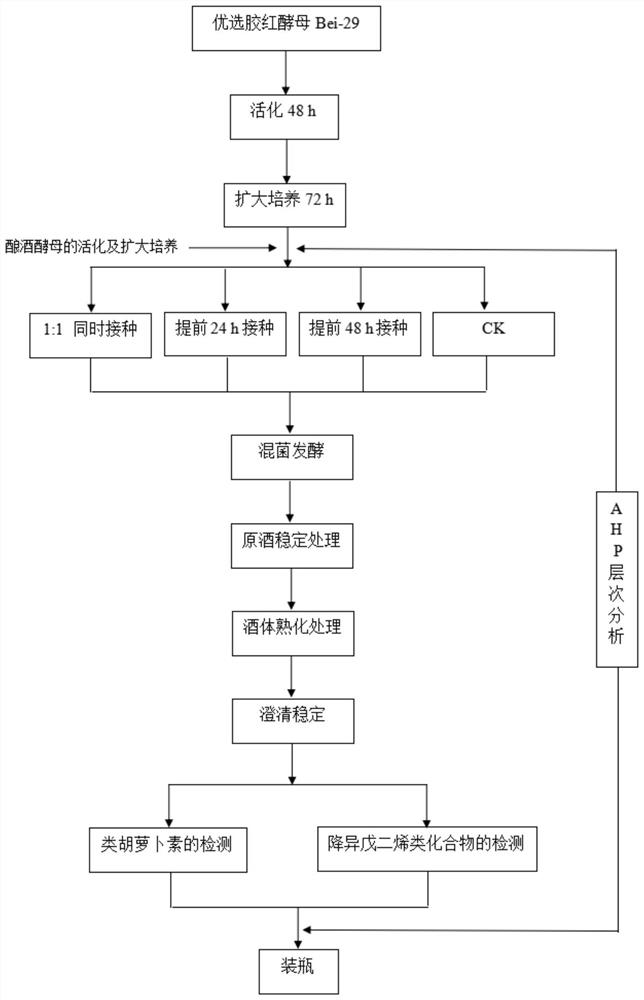

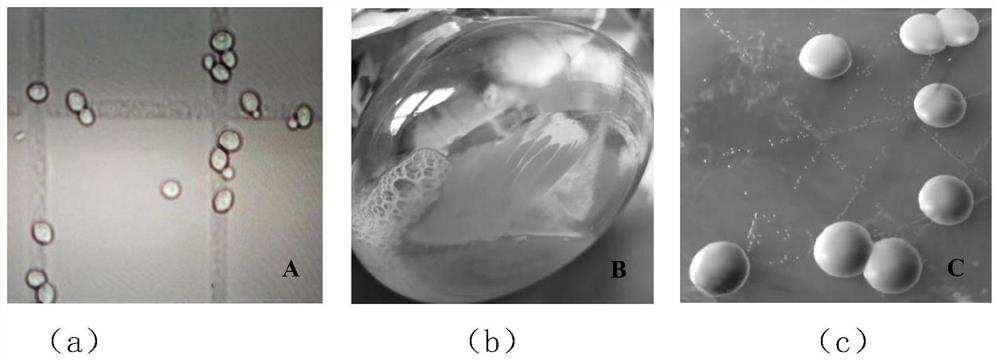

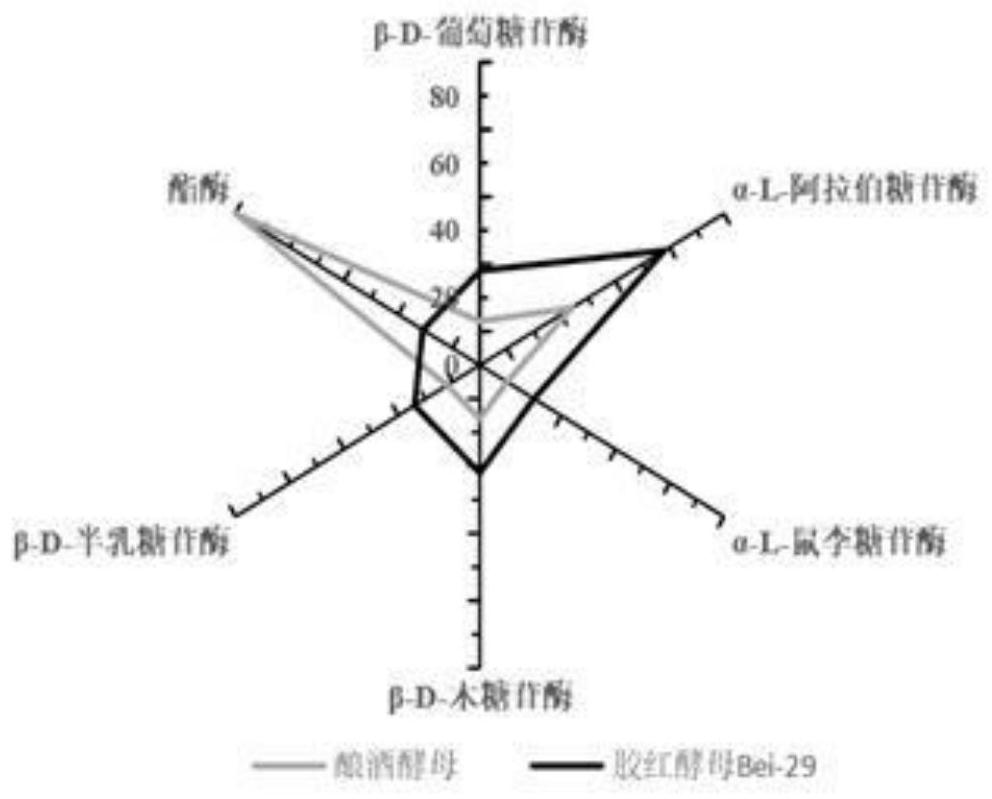

Preparation method and detection method of healthy nutritional fruit wine for brewing yeast Bei-29

PendingCN112226376AFacilitated releaseMinimize the time difference between sample immersion and extractionFungiComponent separationAroma compoundSaccharomyces cerevisiae

The invention relates to the technical field of wine and fruit wine brewing, in particular to a preparation method and detection method of healthy nutritional type fruit wine for brewing yeast Bei-29.Optimal rhodotorula mucilaginosa and saccharomyces cerevisiae are subjected to mixed fermentation, so that the content of carotenoids (astaxanthin, beta-carotene, zeaxanthine and lycopene) in fermented raw wine is increased, and the components and content of norisoprene, terpene aroma substances and fruity ester substances are increased. The method provided by the invention comprises the steps of1) performing activation culture on optimized rhodotorula mucilaginosa Bei-29; 2) performing amplification culture on the rhodotorula mucilaginosa Bei-29 subjected to activation culture; 3) performing mixed fermentation on the rhodotorula mucilaginosa Bei-29 subjected to amplification culture and the saccharomyces cerevisiae, and then detecting the carotenoids and norisoprene aroma compounds.

Owner:NORTHWEST A & F UNIV

Sweet potato leaf fermented beverage and preparation method thereof

InactiveCN104814501ADestructive activityPrevent enzymatic oxidationFood ingredient functionsFood preparationCooking & bakingAdditive ingredient

The invention discloses a sweet potato leaf fermented beverage and a preparation method thereof. The sweet potato leaf fermented beverage comprises the following raw materials in percentage by weight: 20 to 40 percent of sweet potato leaf fermented liquid, 1 to 2 percent of honey, 4 to 6 parts of white granulated sugar, 0.05 to 0.15 percent of edible essence, and 0.015 to 0.03 percent of D-sodium erythorbate; then, water is added to make up the volume to 100 percent. According to the preparation method, fresh sweet potato leaves are dried in the sun and are subjected to high-temperature baking processing, so that the activity of enzyme in the sweet potato leaves is broken, and polyphenol compounds are prevented from enzymatic oxidation, so that the taste is guaranteed; in addition, the original taste in the sweet potato leaves can be removed, the baking fragrance is improved, and the taste is enhanced. The sweet potato leaves are fermented by utilizing traditional black tea fungi, so that nutritional ingredients of the fermented liquid are improved; the beverage prepared by using the fermented liquid has a plurality of effects of resisting cancer, nourishing the stomach and the like.

Owner:娄尤来

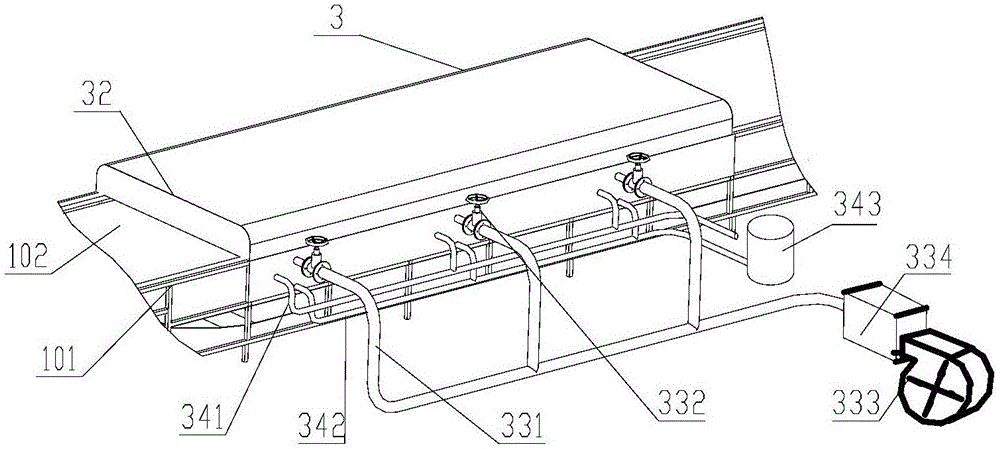

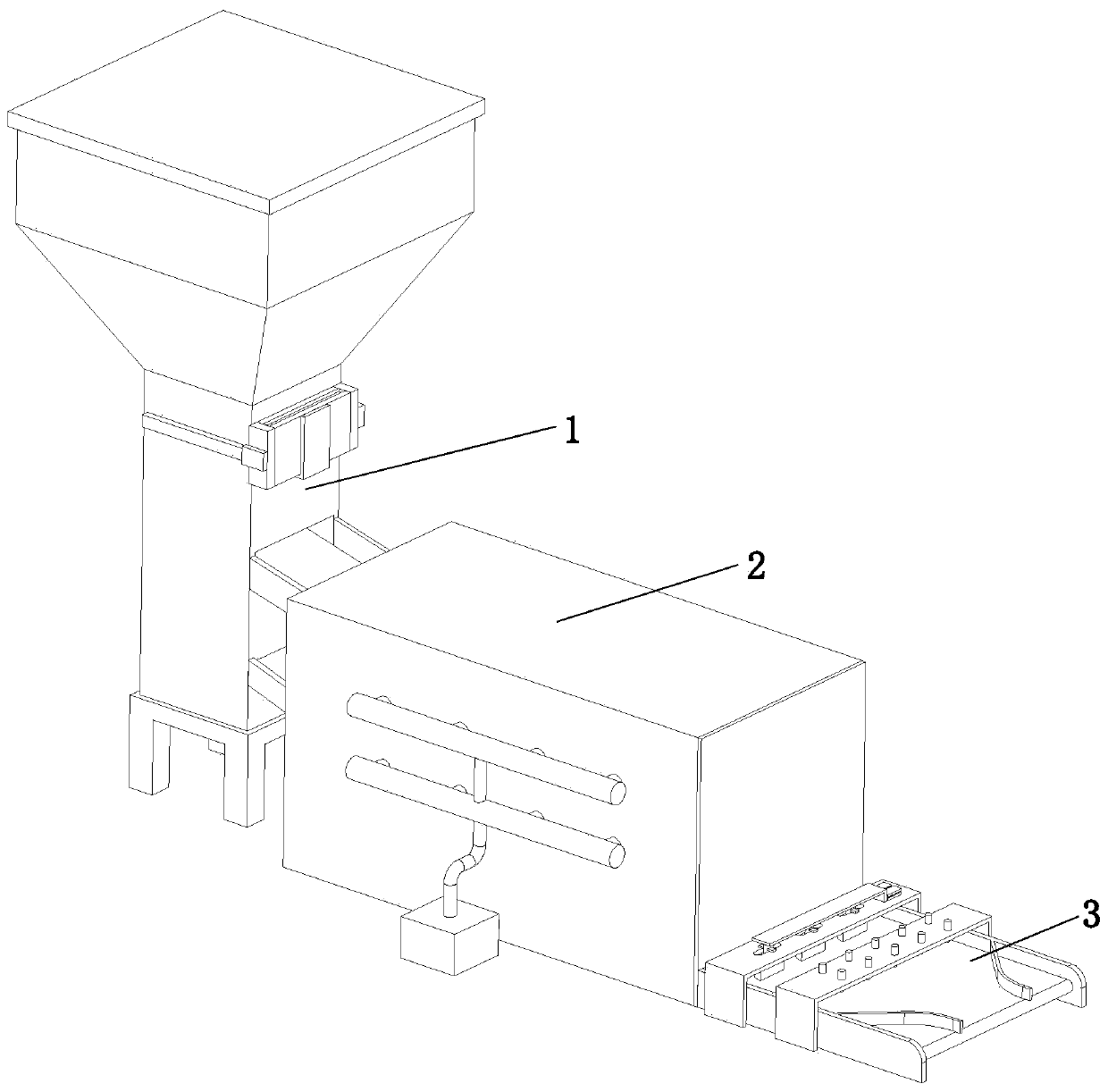

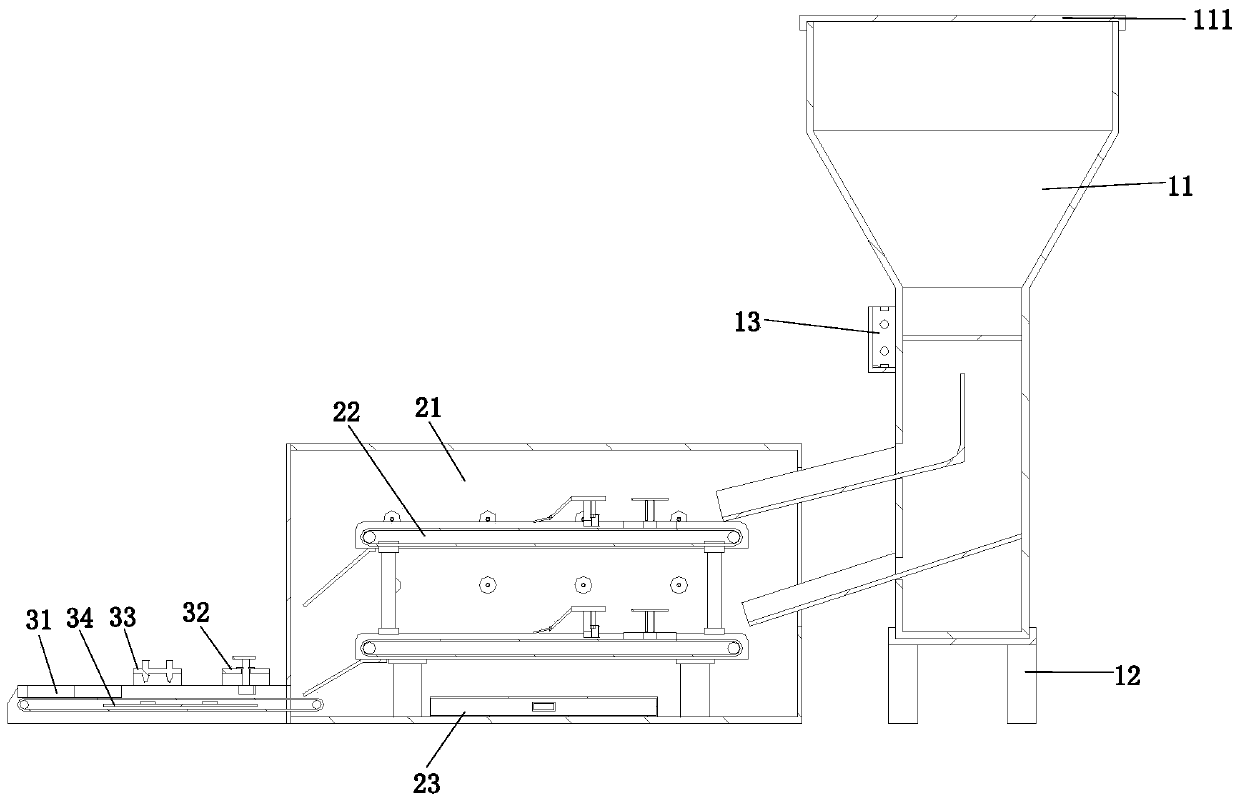

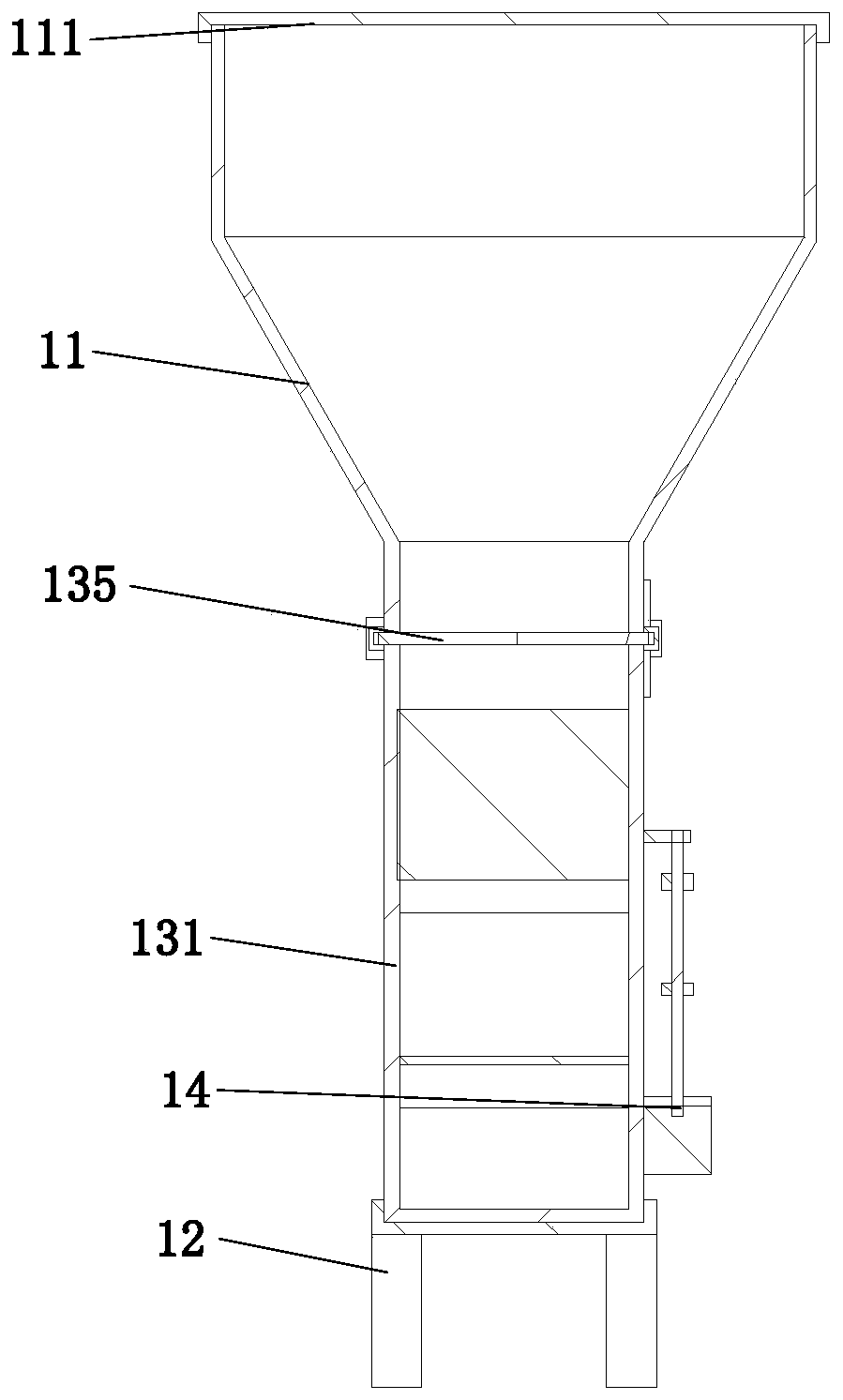

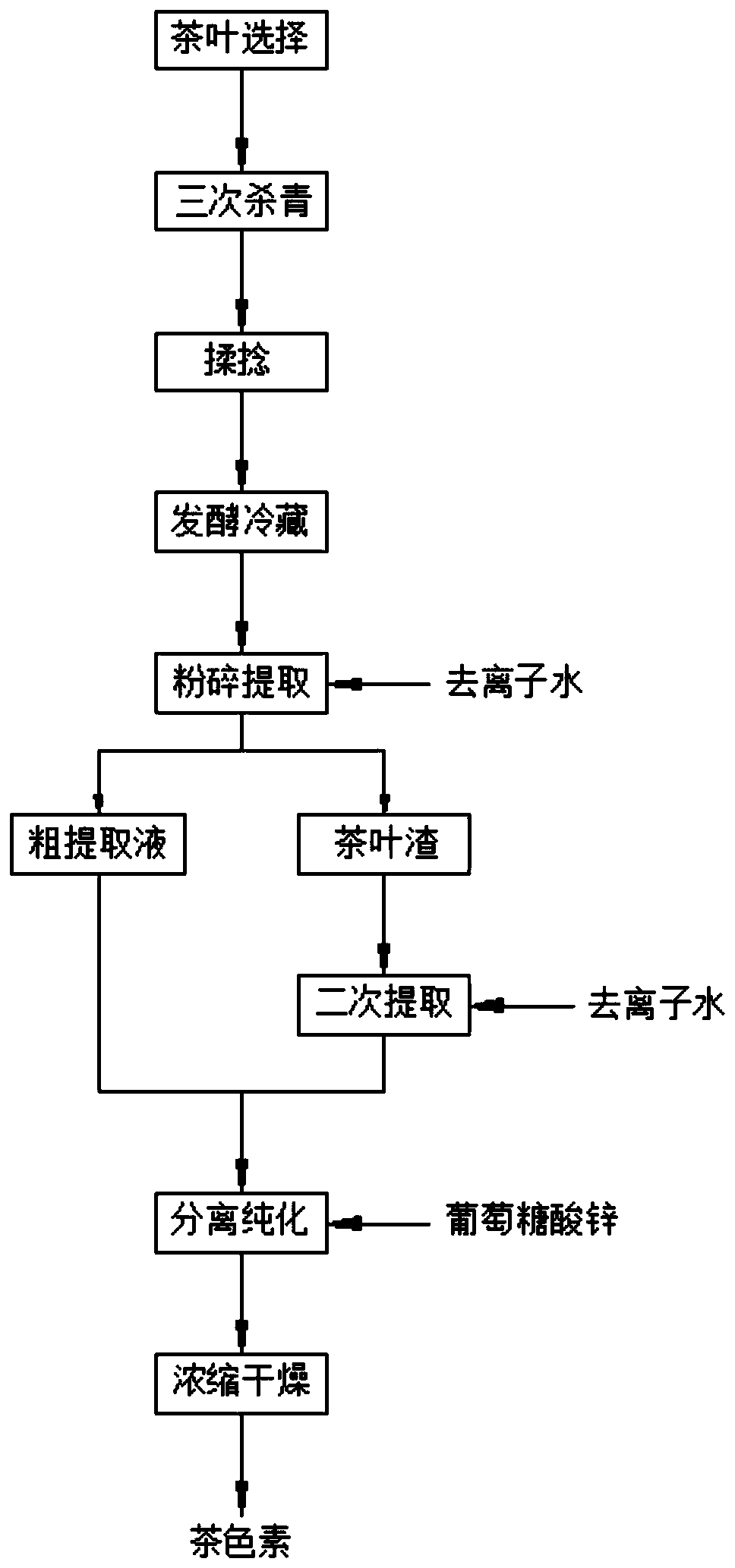

High-purity separation method and equipment for physically extracting tea pigment

PendingCN113604070AHigh extraction rateInhibits enzymatic oxidationTransportation and packagingMixersPhysical chemistryEngineering

The invention discloses a high-purity separation method for physically extracting tea pigment. S1, raw material pretreatment; s2, tea pigment extraction; s3, separation and purification; and s4, concentrating and drying; the invention further discloses high-purity separation equipment for physically extracting the tea pigment, the high-purity separation equipment comprises a tea leaf crusher, an ultrasonic extraction tank, a central control box and a safety valve arranged on the ultrasonic extraction tank, and a discharge port in the lower end of the ultrasonic extraction tank is communicated with the negative pressure generator through a connecting pipe. The outlet end of the tea leaf crusher is communicated with a feeding hole of the ultrasonic extraction tank; and a plurality of groups of temperature sensing belts are annularly arranged on the side wall of a tank body of the ultrasonic extraction tank, and an electric heating element is arranged in an area close to each temperature sensing belt. According to the method, the material-to-liquid ratio, the ultrasonic extraction temperature and the ultrasonic extraction time are refined, so that the extraction rate of the tea pigment is increased, and the equipment can ensure that the temperature of the extracting solution in the tank body uniformly rises to the set temperature, so that the extraction efficiency is ensured.

Owner:方竹生物科技清远有限公司

Production method of Tieguanyin tea leaves high in amino acid content

InactiveCN105875914AIncrease the content of amino acidsUnique tastePre-extraction tea treatmentCelluloseArginine

The present invention discloses a production method of Tieguanyin tea leaves high in amino acid content. The production method comprises the following steps: cystine, tyrosine, aspartic acids, valine, alanine, glycine, proline, arginine and lysine are mixed evenly, and the mixture is added into water to be mixed evenly to obtain material A; and fresh Tieguanyin leaves are weighed, the material A is sprayed on the Tieguanyin leaves, the Tieguanyin leaves are air-spread, the air-spread Tieguanyin leaves are placed under gentle sunlight at 4-5 pm for 30-50 min, protease and cellulose are added, the treated Tieguanyin leaves are subjected to rocking and cooling alternately, the rocked and cooled Tieguanyin leaves are rolled, the material A is sprayed on the rolled Tieguanyin leaves, the treated Tieguanyin leaves are put into a sealed fermentation tank to conduct fermentation until 75-80% of the materials turn red, the fermented materials are air-spread to a room temperature, then the air-spread materials are sent into a green tea roasting machine to conduct enzyme deactivating, the remaining material A is added into the enzyme deactivated materials to be mixed evenly, the treated materials are dried to the moisture content of 5-8wt%, the dried materials are baked, and the baked materials are cooled to a room temperature to obtain the Tieguanyin tea leaves. The Tieguanyin tea leaves are high in amino acid content, unique in taste, simple in technology, and low in costs.

Owner:FUJIAN FUYUAN TEA IND CO LTD

Method suitable for preservation preparation of south Xinjiang hippophae rhamnoides leaf tea nutritional ingredients

The invention discloses a method suitable for preservation preparation of south Xinjiang hippophae rhamnoides leaf tea nutritional ingredients. According to the method, picking period of hippophae rhamnoides leaf is determined to be September every year; microwave technology is adopted for fresh leaf enzyme deactivation, and microwave sterilization and drying setting are adopted; microwave enzyme deactivation effect is the best when leaf adding amount is controlled to be 40g, enzyme deactivation time is controlled to be 90s, and microwave powder is controlled to be 60%; POD relative enzymatic activity is controlled to be 1.690% or less, tea polyphenol content is controlled to be 16.981% or less, flavones dissolving-out amount is controlled to be 2.340mg / g; hippophae rhamnoides leaf tea is obtained via rolling, drying, and water content controlling. Research is carried out based on south Xinjiang dry inland climate so as to determine appropariate picking period of hippophae rhamnoides leaf and appropriate technology used for preserving the hippophae rhamnoides leaf tea nutritional ingredients. The effective method used for preserving south Xinjiang hippophae rhamnoides leaf tea nutritional ingredients is obtained; and application value is high.

Owner:UQTURFAN COUNTY YANSHAN FRUIT IND CO LTD

Aquilaria sinensis leaf tea drink and preparation technology thereof

The invention relates to the technical field of tea drink, and concretely relates to aquilaria sinensis leaf tea drink and a preparation technology thereof. The aquilaria sinensis leaf tea drink comprises the following raw materials in parts by weight: 0.1-3 parts of aquilaria sinensis leaf tea, 0.5-10 parts of a sweetener, 0.01-1 part of a stabilizing agent, and 100 parts of water. The aquilaria sinensis leaf tea is prepared by performing fresh-leaf acquisition, combined deactivating of enzymes, rolling, piling fermentation, baking and tea warming. The aquilaria sinensis leaf tea drink is prepared from the above raw materials by performing raw material preparation, crushing, extraction, blending, homogenizing, sterilization and canning. The aquilaria sinensis leaf tea drink has no compositions for compatibility, has the unique flavor of the aquilaria sinensis leaf tea, also contains abundant trace elements and flavonoids, has both nutrition efficacy and health-care efficacy, and is good in mouthfeel. The preparation technology is capable of improving the mouthfeel of the drink and fully giving play to the unique effects of the aquilaria sinensis leaf tea, and is simple and low in cost.

Owner:东莞市莞香园艺科技有限公司

Aquilaria sinensis flower tea drink and preparation technology thereof

ActiveCN104206581AGive full play to natural performanceSoup color goldenTea substituesBiotechnologyAquilaria sinensis

The invention relates to the technical field of tea drink, and concretely relates to aquilaria sinensis flower tea drink and a preparation technology thereof. The aquilaria sinensis flower tea drink comprises the following raw materials in parts by weight: 0.1-3 parts of aquilaria sinensis flower tea, 0.5-10 parts of a sweetener, 0.01-1 part of a stabilizing agent, and 100 parts of water. The aquilaria sinensis flower tea is prepared by performing acquisition and winnowing on aquilaria sinensis flower, combined deactivating of enzymes, spreading and cooling, first baking and secondary baking. The aquilaria sinensis flower tea drink is prepared from the above raw materials by performing raw material preparation, crushing, extraction, blending, homogenizing, sterilization and canning. The aquilaria sinensis flower tea drink has no compositions for compatibility, has the unique flavor of the aquilaria sinensis flower tea, also contains abundant trace elements and flavonoids, has both nutrition efficacy and health-care efficacy, and is good in mouthfeel. The preparation technology is capable of improving the mouthfeel of the drink and fully giving play to the unique effects of the aquilaria sinensis flower tea, and is simple and low in cost.

Owner:东莞市莞香园艺科技有限公司

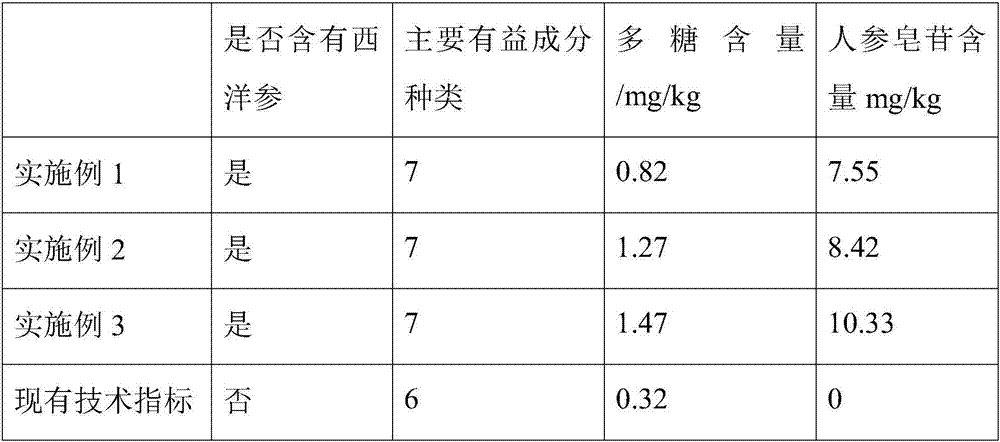

Ginseng leaf and acanthopanax complex fermentation dark tea

The invention discloses ginseng leaf and acanthopanax complex fermentation dark tea, and belongs to the field of preparation of fermentation dark tea. Fresh ginseng leaves, fresh acanthopanax leaves and fresh wild clove flowers are selected as raw materials, and the steps of enzyme deactivation, rolling, pile fermentation, re-rolling, drying and the like are performed to prepare the ginseng leaf and acanthopanax complex fermentation dark tea. As the enzyme deactivation conditions, rolling conditions and pile fermentation conditions of the preparation process of the ginseng leaf and acanthopanax complex fermentation dark tea are systematically optimized, the prepared ginseng leaf and acanthopanax complex fermentation dark tea is in an oil black color and contains plentiful panaxoside, hyperoside, tea polyphenol and free amino acid. By means of the method, precipitation of nutrient substances in the raw materials is effectively promoted, the nutrient ingredients can be absorbed by the human body more easily, and the utilization rate of the raw materials is increased; besides, a beneficial deep processing mode is provided for the ginseng leaves, the acanthopanax leaves and the wild clove flowers.

Owner:丁政然

Aquilaria sinensis pillow and manufacturing technology of Aquilaria sinensis pillow

ActiveCN104207564AGive full play to natural performanceIncrease loopPillowsEssential-oils/perfumesEngineeringOrganic chemistry

The invention relates to the technical field of pillows, in particular to an Aquilaria sinensis pillow and a manufacturing technology of the Aquilaria sinensis pillow. The manufacturing technology includes the steps of preparing raw materials which include, by weight, 10 parts to 80 parts of Aquilaria sinensis leaves, 2 parts to 20 parts of Aquilaria sinensis flowers and 1 part to 5 parts of Aquilaria sinensis wood, wherein the Aquilaria sinensis leaves are prepared through the steps of withering, water removing, drying and aroma extracting, the Aquilaria sinensis flowers are prepared through the steps of collecting, drying and aroma extracting, and the Aquilaria sinensis wood is prepared through the steps of material selecting, smashing or slicing after bark removing, filtering and frying aroma extracting; evenly stirring the raw materials in proportion to prepare pillow inner fillers, then placing the fillers into a pillow bag for packaging, and obtaining a pillow inner; placing the pillow inner into a pillowcase to obtain the Aquilaria sinensis pillow. The pillow inner of the Aquilaria sinensis pillow keeps the special health care effects of the Aquilaria sinensis leaves, the Aquilaria sinensis flowers and the Aquilaria sinensis wood according to the raw material compatibility of the all-natural Aquilaria sinensis leaves, the all-natural Aquilaria sinensis flowers and the all-natural Aquilaria sinensis wood, the smell is aromatic and refreshing, and the manufactured Aquilaria sinensis pillow is aromatic in smell and has the brain fitness effect, the refreshment effect and the nerve soothing and health maintenance effects.

Owner:东莞市莞香园艺科技有限公司

Tea leaf processing technique

InactiveCN107080007AQuality improvementImprove qualityPre-extraction tea treatmentClimate change adaptationOxygenase activityBud

The invention discloses a tea leaf processing technique, comprising the following steps: selecting and picking fresh, tender and strong three leaves with one bud; spreading the picked tea leaves uniformly on a bamboo sieve for cooling; standing the cooled tea leaves indoors; pouring the stood tea leaves into a bamboo rocking machine for rocking; killing the rocked tea leaves in a killing pot; rolling the killed tea leaves in a rolling machine, lightly rolling for 10-12 minutes, heavily rolling for 5-8 minutes, and then lightly rolling again for 18-20 minutes; shaping the rolled tea leaves in a tea leaf shaper; drying the shaped tea leaves in a dryer; disinfecting the dried tea leaves; and packaging the tea leaves in a vacuum condition. According to the tea leaf processing technique, the killing environment is scientifically and reasonably improved, the activity of oxidase in fresh tea leaves is better destroyed and passivated, enzymatic oxidation of tea polyphenols and the like in fresh leaves are inhibited, and partial moisture in fresh leaves is evaporated, so the tea leaves are softened and convenient for rolling and shaping, formation of good aroma is promoted, and the processing quality of tea leaves is improved.

Owner:贵州博联茶业股份有限公司

Processing technology of American ginseng-black tea beverage

InactiveCN107397009AImprove health benefitsStrong and stable structurePre-extraction tea treatmentChemical reactionAdditive ingredient

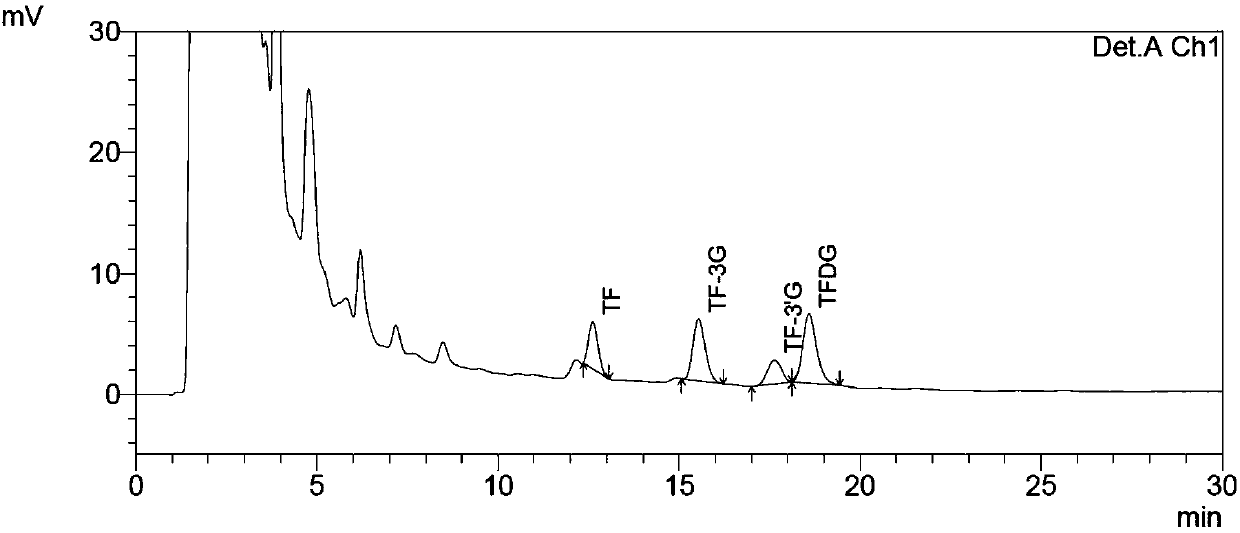

The invention discloses a processing technology of an American ginseng-black tea beverage. The processing technology comprises the steps of preparing raw materials, preprocessing raw materials, rolling, fermenting, washing, concentrating and preparing the beverage. The American ginseng has the health care functions of strengthening the function of the central nervous system, protecting the cardiovascular system, improving the immunity, promoting the blood activity, curing diabetes, tonifying the lung and reducing internal heat, and nourishing the stomach to improve the production of body fluid; the black tea contains multiple nutrient elements, in the fermentation process of the black tea, chemical components in fresh leaves are changed greatly due to the chemical reaction of polyphenols, theaflavin, thearubigins and other ingredients can be generated, and the fragrance is thickened compared with the fragrance of the fresh leaves, so that the specific color, fragrance and taste of the black tea are formed, and the beverage prepared by the black tea is very popular. According to the processing technology of the American ginseng-black tea beverage, the tea leaves and the American ginseng can be effectively combined, the prepared beverage not only has the basic taste value, and also the health-care efficiency is promoted.

Owner:ANHUI XINXUTANG TEA CO LTD

Processing method of green tea

InactiveCN105124020AAvoid yellowingAvoid undercookedPre-extraction tea treatmentGreen teasProcess engineering

The invention discloses a processing method of green tea. The processing method comprises the following steps: removing green; spreading for cooling; frying for drying, namely frying tea leaves for drying by a flat-tea frying machine, wherein the temperature is controlled at 330-350 DEG C and frying time is 20-25 seconds; further frying and lowering the temperature by 10 DEG C every other minute until the temperature is 260 DEG C; further frying until the degree of dryness of the tea leaves reaches 80-85%, suddenly raising the temperature to 310-320 DEG C, continuously frying for 15-20 seconds then taking the tea leaves out from the pan; spreading for cooling; distilling fragrance, namely uniformly laying the tea leaves at the top of a roaster which is plaited by bamboo and is triangular at the top, wherein the laying thickness is 1cm; heating the roaster by Qinggang charcoal placed under the roaster, wherein the heating temperature is 90-100 DEG C and the heating time is 30-40 minutes; spreading for cooling; and removing tea siftings and tea fragments to obtain the green tea. The processing method is capable of making the green tea product heavy in refreshing fragrance, good in taste and lasting in sweet aftertaste.

Owner:ANLONGXIAHEPING TEA

Green tea processing method for reducing bitterness of autumn tea and summer tea

ActiveCN102940053BReduce bitternessFull-bodied taste qualityPre-extraction tea treatmentGreen teaWater content

The invention discloses a green tea processing method for reducing bitterness of autumn tea and summer tea, comprising the following steps:1) selecting tea leaves: selecting fresh tea leaves of autumn and summer and grading; 2) withering: spreading the fresh tea leaves for withering, wherein the water content of the withered leaves is 70-75%; 3) conducting fine manipulation: carrying out fine manipulation on the withered leaves to obtain fine-manipulated leaves, wherein fine manipulation comprises rotating and cooling which are alternately and repeatedly; 4) de-enzyming: de-enzyming the fine-manipulated leaves to obtain de-enzymed leaves; 5) dampening: dampening the de-enzymed leaves; 6) rolling: rolling the dampened leaves; 7) drying: using a gross fire to dry the rolled leaves until the water content is 10-20%, then using a complete fire to dry, wherein the water content of the dried leaves is 4-6%. According to the invention, by using the fresh tea leaves and optimizing the processing method, the produced green tea can reduce the bitterness of tea, thus fragrance of green tea with natural fragrance of flower is formed, and the taste quality is thick and mellow.

Owner:婺源县聚芳永茶业有限公司

Method for drying roses and rose product prepared by method

ActiveCN109282579AFragrance is smallLittle nutrient lossPre-extraction tea treatmentDrying solid materials with heatMicrowaveDesiccant

The invention provides a method for drying roses and a rose product prepared by the method. The method for drying the roses comprises the steps that the roses are subjected to microwave or far infrared radiation, and first treatment roses are obtained; food desiccants are laid on a bottom layer, and the first treatment roses are spread on the food desiccants in a monolayer; after hot air circulation, warm-keeping and drying under 25-45 DEG C, second treatment roses are obtained; and the dried second treated roses are separated from the desiccants to obtain dried roses. According to the methodfor drying roses, the roses in the rose product are prepared; the water removing process has the characteristics of high efficiency, low energy consumption, and low aroma and nutrient loss; the dryingprocess is uniform and low in loss of rose color; and the rose products prepared by the method have the characteristics of rich flavor, good color and good shape.

Owner:甘肃铭启洋生物科技有限公司

Production method of roasted green tea

InactiveCN107125346AInhibits enzymatic oxidationEasy to kneadPre-extraction tea treatmentChemistryEpigallo-catechin gallate

The invention discloses a production method of roasted green tea. The production method comprises the following steps: spreading fresh leaves: spreading fresh tea leaves into a shady, cool and ventilated environment: carrying out fixation: carrying out the fixation through a high-temperature hot air roller fixation manner; rolling: rolling the tea leaves subjected to the fixation; unblocking: putting the rolled tea leaves into an unblocking machine for unblocking; primarily drying: putting the unblocked tea leaves into a chain plate machine and drying; tempering: naturally cooling the tea leaves which are primarily dried; drying again: frying and drying the tempered tea leaves; carrying out secondary tempering: naturally cooling the fried and dried tea leaves again; improving aroma: improving the aroma of the tea leaves subjected to the secondary tempering; refining, sorting and packaging: eliminating impurities in the tea leaves through refining and sorting and packaging. According to the production method of the roasted green tea, disclosed by the invention, the green tea has fine and fresh color and luster, is bright green, smooth and bright and has a bright green and pure taste and full tea aroma.

Owner:SHAANXI DONGYU BIO TECH

Preparation method for anoectochilus roxburghii semi-fermented tea

ActiveCN104798924AFully retain the flavorPreserve the flavorPre-extraction tea treatmentAnoectochilus roxburghiiTea leaf

The invention discloses a preparation method for anoectochilus roxburghii semi-fermented tea. The preparation method comprises the following steps: (1) air-curing and withering: conducting air-curing and withering on anoectochilus roxburghii whole herbs which are sorted and cleaned up; converting to temperature control withering after about 5-7% of water is lost; (2) temperature control withering: carrying out warm-air heating and automatic humiture control to enable the water content to be 65-70%; (3) primary rocking and drying of green leaves: spreading the completely withered anoectochilus roxburghii whole herbs in a green leaves rocking machine for primary rocking; carrying out primary drying after the primary rocking; (4) secondary rocking and drying of green leaves: spreading the primarily dried anoectochilus roxburghii whole herbs for secondary rocking; carrying out secondary drying after the secondary rocking; (5) microwave deactivation of enzymes; (6) soft pressing and rolling: rolling secondarily dried anoectochilus roxburghii tea leaves by adopting a rolling machine; drying the rolled anoectochilus roxburghii tea leaves after the rolling is finished; (7) microwave drying: instantly drying the rolled anoectochilus roxburghii tea leaves to obtain a finished product, namely the anoectochilus roxburghii semi-fermented tea. The preparation method has the advantages that the astringency of anoectochilus roxburghii semi-fermented tea can be vanish; the fragrance is appropriate; the dense mellow degree is improved; the anoectochilus roxburghii semi-fermented tea is dense in soup, mellow in taste, appropriate in fragrance, and brewing resisting.

Owner:厦门乐莲乐生物科技有限公司

Physical extraction method of tea pigment by taking aged tea as raw material

InactiveCN111471318ANo pollution in the processNo recycling issuesNatural dyesFood scienceBiotechnologyMicrowave oven

The invention relates to the technical field of tea processing, and particularly discloses a physical extraction method of tea pigment by taking aged tea as a raw material. The physical extraction method comprises the following steps: selecting fresh green tea leaves, adding the tea leaves into a fixation machine, performing fixation for three times, performing reciprocating rolling, naturally airing, fermenting, and refrigerating aging; putting the tea leaves into a microwave oven to be quickly dissolved, transferring the tea leaves into a heatable crushing device, adding deionized water, andcontinuously crushing the tea leaves under a heating condition; drying tea residues, further crushing, supplementing a proper amount of deionized water, carrying out secondary extraction in ultrasonic waves, and filtering to obtain a secondary extracting solution; adding zinc gluconate into extracting solution, stirring, mixing and cooking, and then carrying out microfiltration and ultrafiltration to obtain an essence; and carrying out low-temperature vacuum concentration, and carrying out spray drying to obtain the tea pigment. The defects in the prior art are overcome, the tea pigment is extracted by adopting a physical extraction method after the tea leaves are aged, the extraction condition is mild, the extraction efficiency is high, and the cost is relatively low.

Owner:浙江中禄松波生物工程有限公司

Combined green-fixing method of tea leaves

InactiveCN108782799AInhibits enzymatic oxidationEasy to shapePre-extraction tea treatmentFlavorProduct gas

The invention discloses a combined green-fixing method of tea leaves. The method comprises the steps of fresh leaf washing and draining, spreading, green-fixing in a cylinder, remedial green-fixing with microwave, rolling, tea strip tidying, drying and the like. According to the method, green-fixing is performed on tea leaves which are subjected to primary treatment including green leaf storage and other processes, two-stage cylinder green-fixing is utilized in the green-fixing process, humid and hot air is emitted during continuous delivery between the two cylinders, so that the problem thata great number of tea leaves are yellow and have red stalks or leaves due to the fact that humid air in the cylinder is difficult to emit and green-fixing is not performed sufficiently can be avoided;and remedial green-fixing with microwave can be used for quickly destroying and passivating the activity of oxidase in fresh leaves and inhibiting enzymatic oxidation of tea polyphenol and the like.The method can solve the problems of uneven green-fixing and poor green-fixing effect in an existing tea leaf green-fixing method, and ensures the taste and flavor of tea leaves.

Owner:付世平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com