Physical extraction method of tea pigment by taking aged tea as raw material

An extraction method and a technology for tea pigments are applied in the field of physical extraction of tea pigments using cooked tea as a raw material, which can solve the problems of many impurities, high labor intensity and high production cost, achieve simple process flow, improve extraction rate and high safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

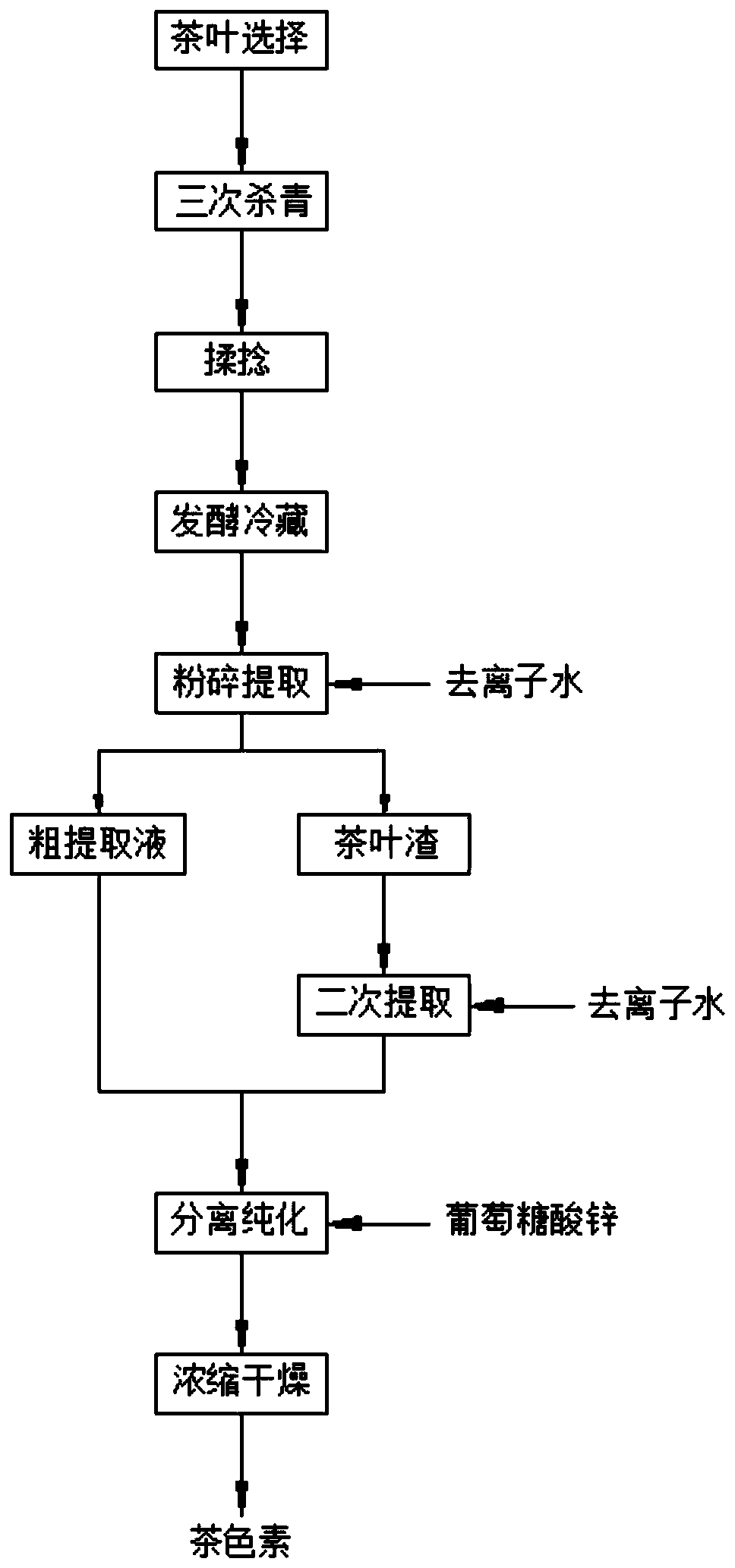

Image

Examples

Embodiment 1

[0025] A kind of physical extraction method using cooked tea as raw material tea pigment according to the present invention comprises the following steps:

[0026] Step 1, tea selection: choose fresh organic green tea leaves with one bud and one leaf or one bud and two leaves, remove the old leaves, wash with fresh water, remove impurities and dust on the leaves, and place them in a cool place to dry naturally for later use;

[0027] Step 2, tea maturation: select 1000g of dried tea leaves and add them to the de-greening machine for three times, then transfer them to the fine twister for reciprocating kneading, until the tea leaves are curled into strips, take them out of the fine-kneader, and let them dry naturally Put it in the fermentation box for 1 day of fermentation, then put it in the refrigerator for refrigerated aging for 15 days, then transfer it to the freezer for quick freezing, and set aside;

[0028] Among them, after each finish, it needs to be cooled before the...

Embodiment 2

[0036] A kind of physical extraction method using cooked tea as raw material tea pigment according to the present invention comprises the following steps:

[0037] Step 1, tea selection: choose fresh organic green tea leaves with one bud and one leaf or one bud and two leaves, remove the old leaves, wash with fresh water, remove impurities and dust on the leaves, and place them in a cool place to dry naturally for later use;

[0038] Step 2, tea maturation: select 1000g of dried tea leaves and add them to the de-greening machine for three times, then transfer them to the fine twister for reciprocating kneading, until the tea leaves are curled into strips, take them out of the fine-kneader, and let them dry naturally Put it in the fermentation box for 1.5 days of fermentation, then put it in the refrigerator for refrigerating and aging for 17 days, then transfer it to the freezer for quick freezing, and set aside;

[0039] Among them, after each finish, it needs to be cooled be...

Embodiment 3

[0047] A kind of physical extraction method using cooked tea as raw material tea pigment according to the present invention comprises the following steps:

[0048] Step 1, tea selection: choose fresh organic green tea leaves with one bud and one leaf or one bud and two leaves, remove the old leaves, wash with fresh water, remove impurities and dust on the leaves, and place them in a cool place to dry naturally for later use;

[0049] Step 2, tea maturation: select 1000g of dried tea leaves and add them to the de-greening machine for three times, then transfer them to the fine twister for reciprocating kneading, until the tea leaves are curled into strips, take them out of the fine-kneader, and let them dry naturally Put it in the fermentation box for 2 days of fermentation, then put it in the refrigerator for refrigerating and aging for 20 days, then transfer it to the freezer for quick freezing, and set aside;

[0050] Among them, after each finish, it needs to be cooled befo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com