Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

197results about How to "Good kneading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

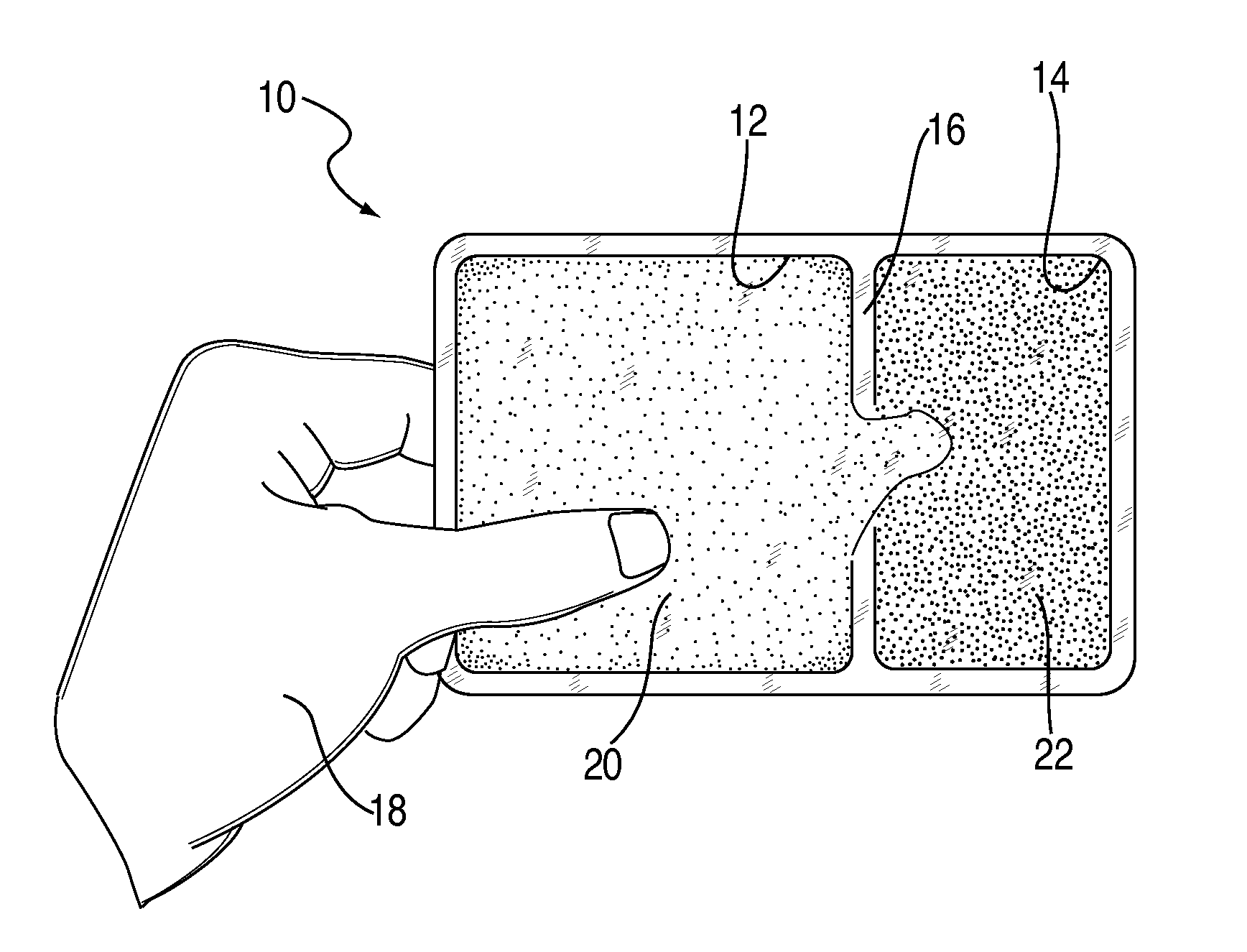

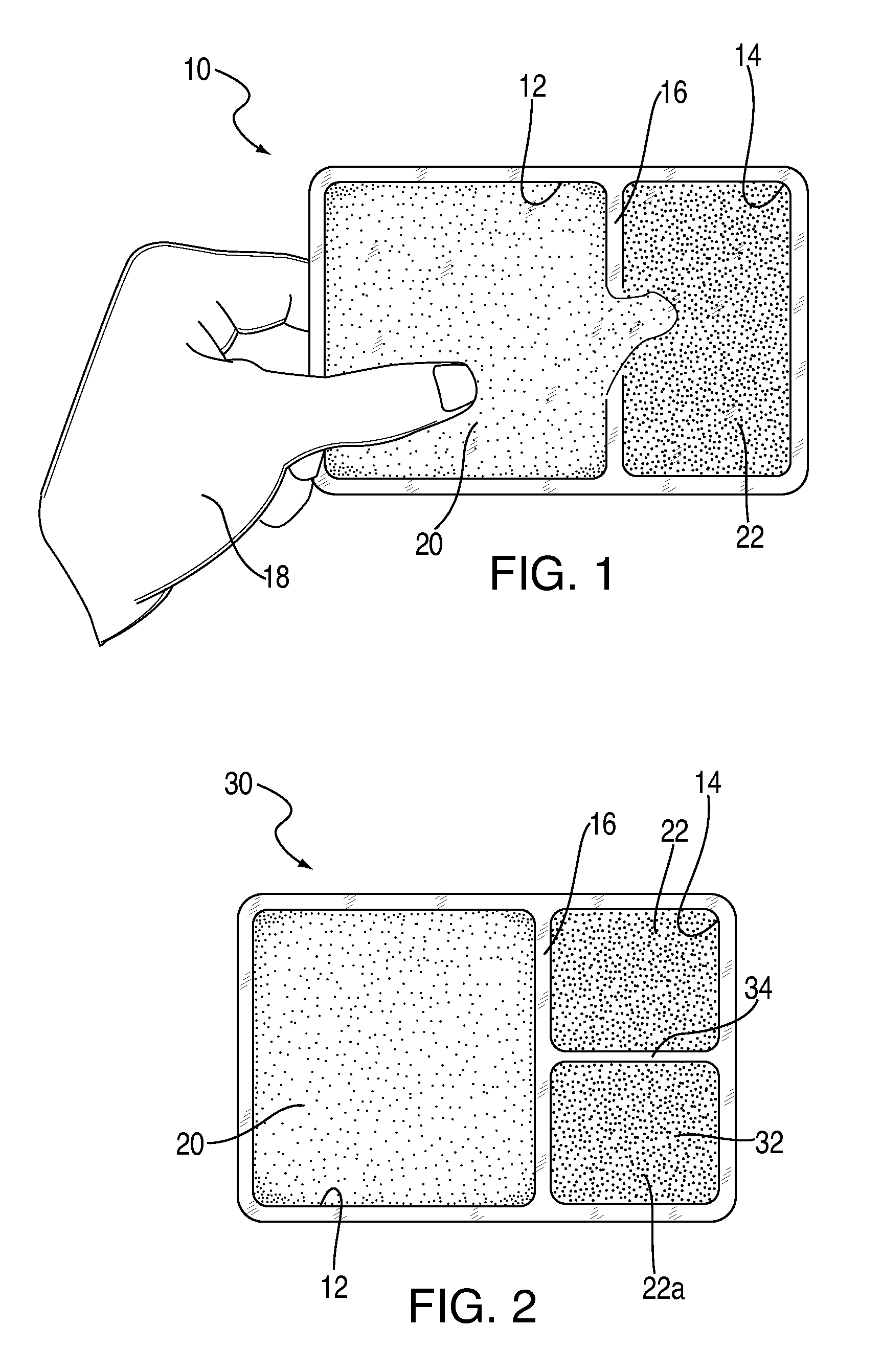

Ready mixed setting type joint compound and set initiator in chambered pouch

ActiveUS20110100844A1Extended shelf lifeReduce needRigid containersInternal fittingsMedicineJoint compound

A dosage size multi-chambered, container having separate sealed compartments is provided and includes constituent materials for forming a wallboard joint compound. The container includes a first compartment containing a first mixture including calcined gypsum, a set preventer and water, and a second compartment sealed from the first compartment with a seal and containing a second mixture including a set initiator and water, wherein upon breaking of the seal, the first and second mixtures are combinable by kneading action to provide a dose of the wallboard joint compound.

Owner:UNITED STATES GYPSUM CO

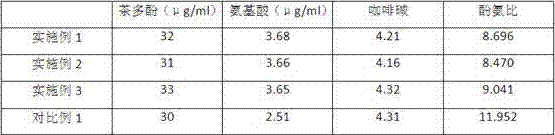

Green tea processing method for reducing bitterness of autumn tea and summer tea

ActiveCN102940053AReduce bitternessFull-bodied taste qualityPre-extraction tea treatmentGreen teaTea leaf

The invention discloses a green tea processing method for reducing bitterness of autumn tea and summer tea, comprising the following steps:1) selecting tea leaves: selecting fresh tea leaves of autumn and summer and grading; 2) withering: spreading the fresh tea leaves for withering, wherein the water content of the withered leaves is 70-75%; 3) conducting fine manipulation: carrying out fine manipulation on the withered leaves to obtain fine-manipulated leaves, wherein fine manipulation comprises rotating and cooling which are alternately and repeatedly; 4) de-enzyming: de-enzyming the fine-manipulated leaves to obtain de-enzymed leaves; 5) dampening: dampening the de-enzymed leaves; 6) rolling: rolling the dampened leaves; 7) drying: using a gross fire to dry the rolled leaves until the water content is 10-20%, then using a complete fire to dry, wherein the water content of the dried leaves is 4-6%. According to the invention, by using the fresh tea leaves and optimizing the processing method, the produced green tea can reduce the bitterness of tea, thus fragrance of green tea with natural fragrance of flower is formed, and the taste quality is thick and mellow.

Owner:婺源县聚芳永茶业有限公司

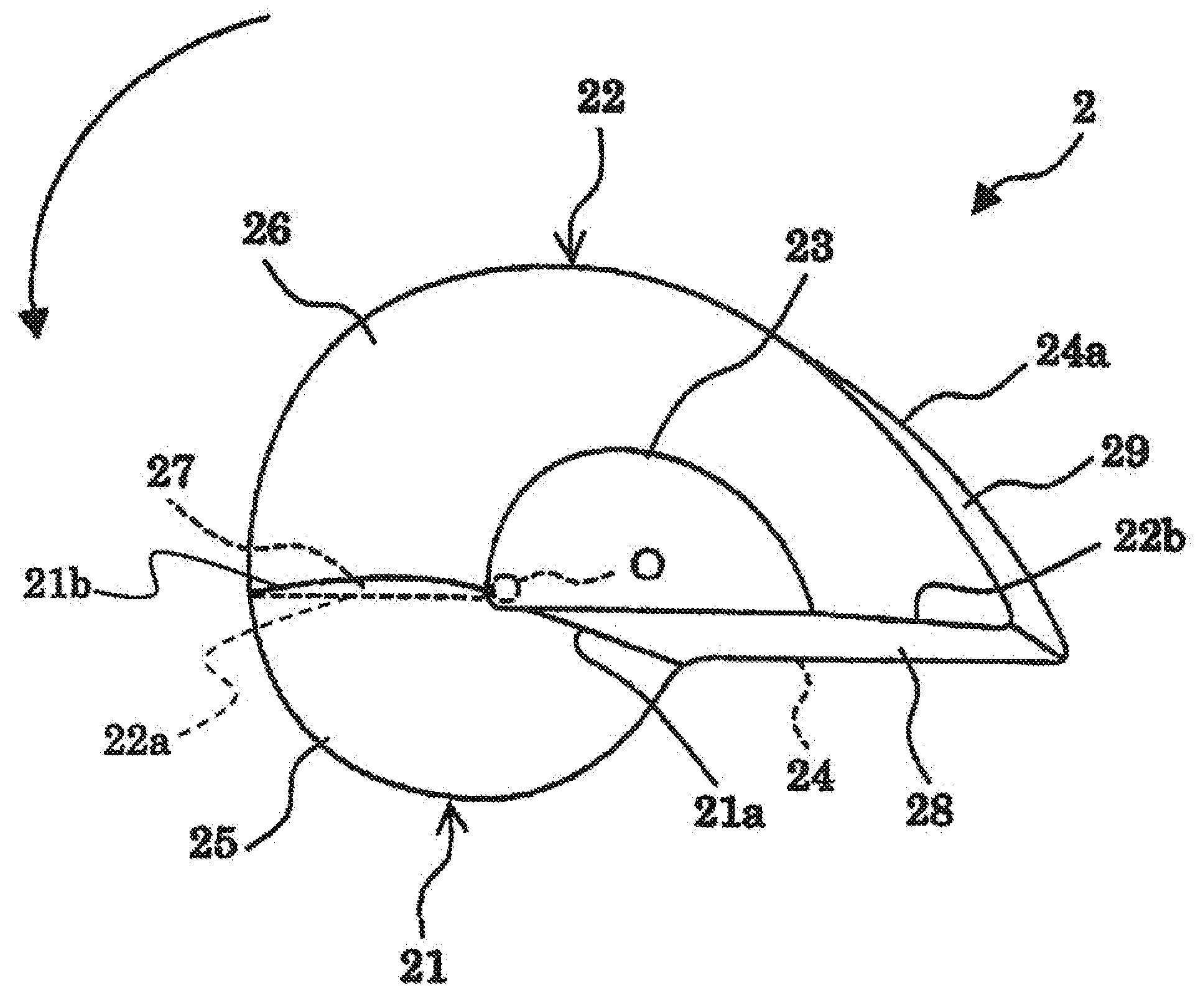

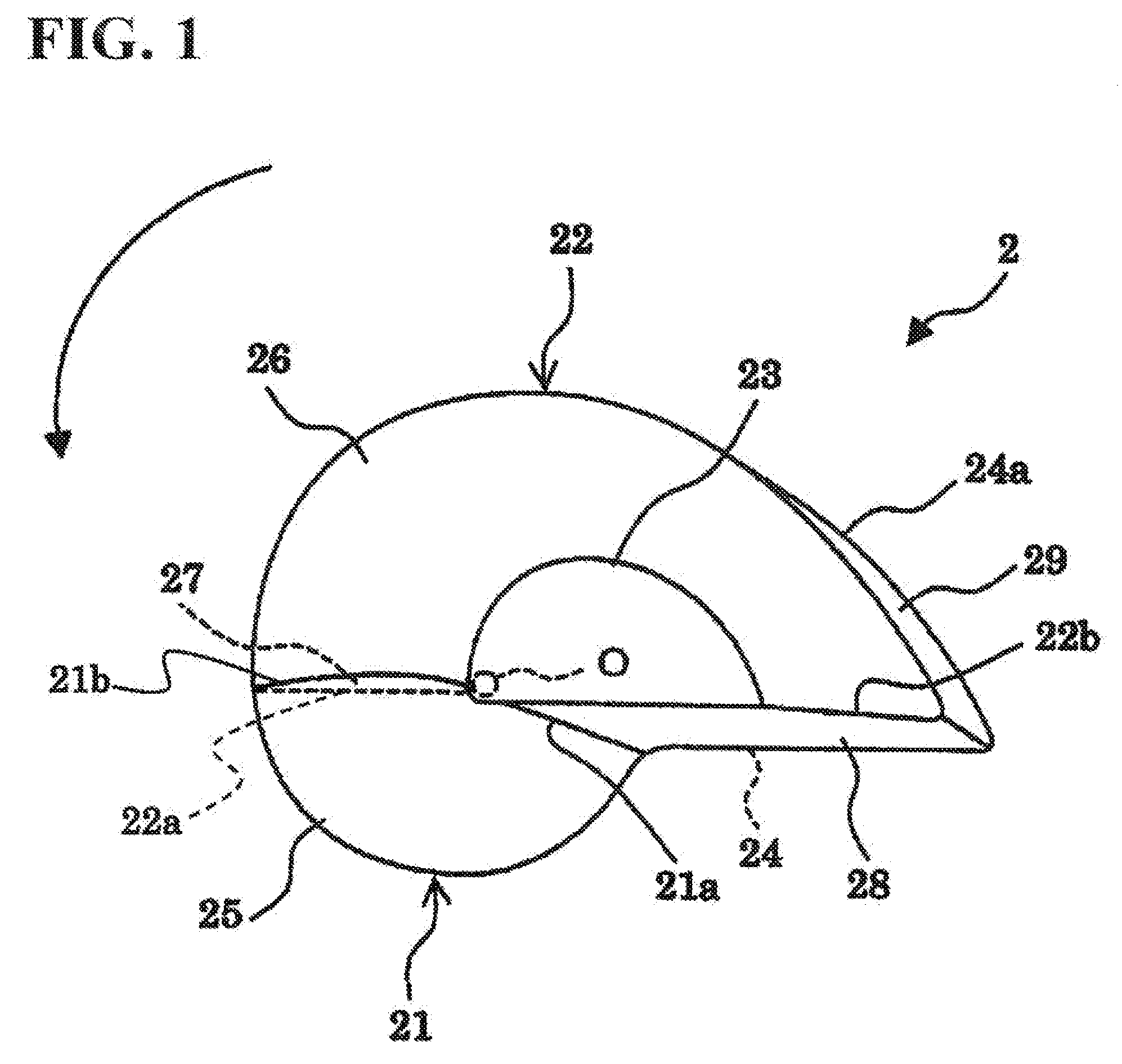

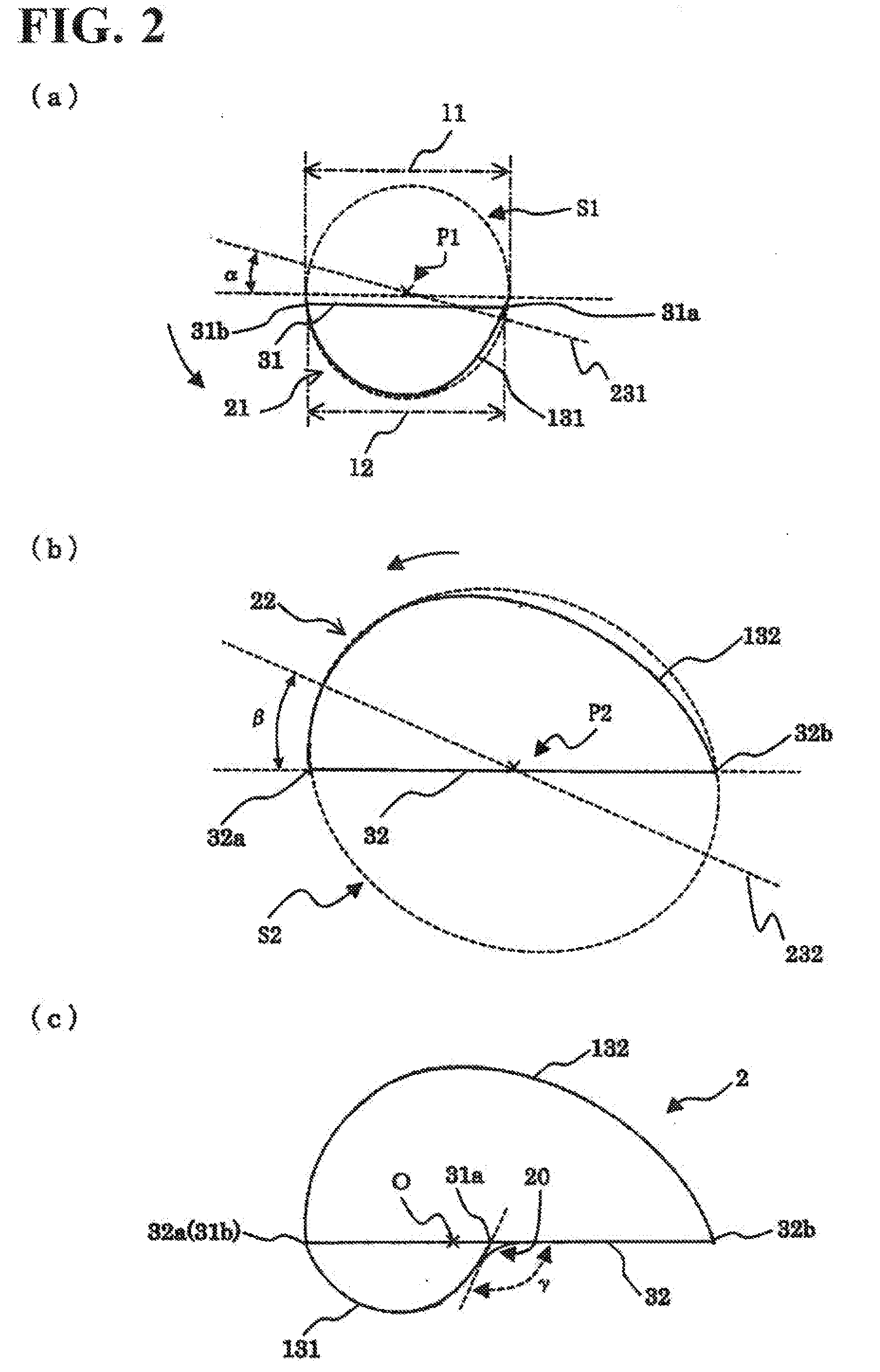

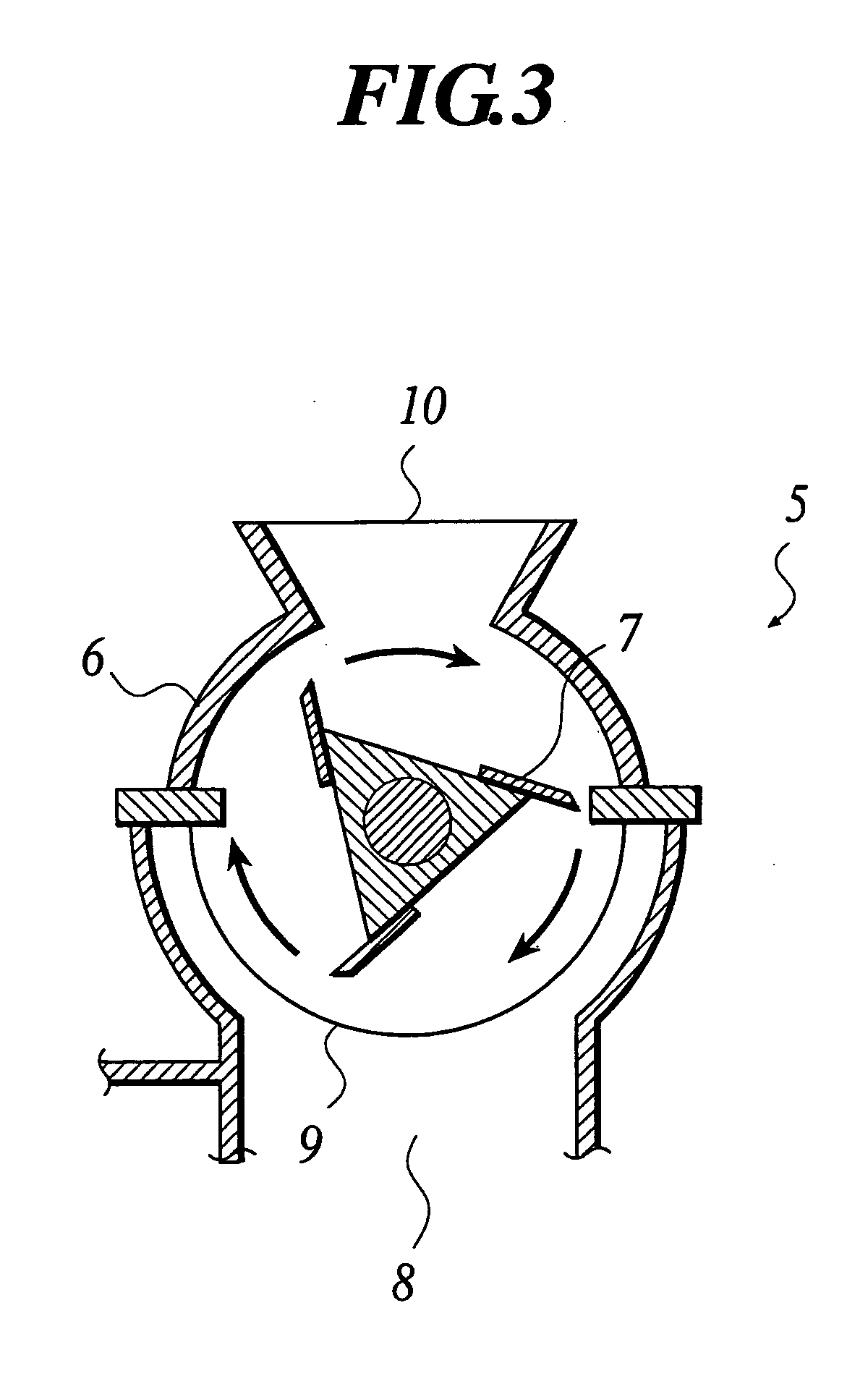

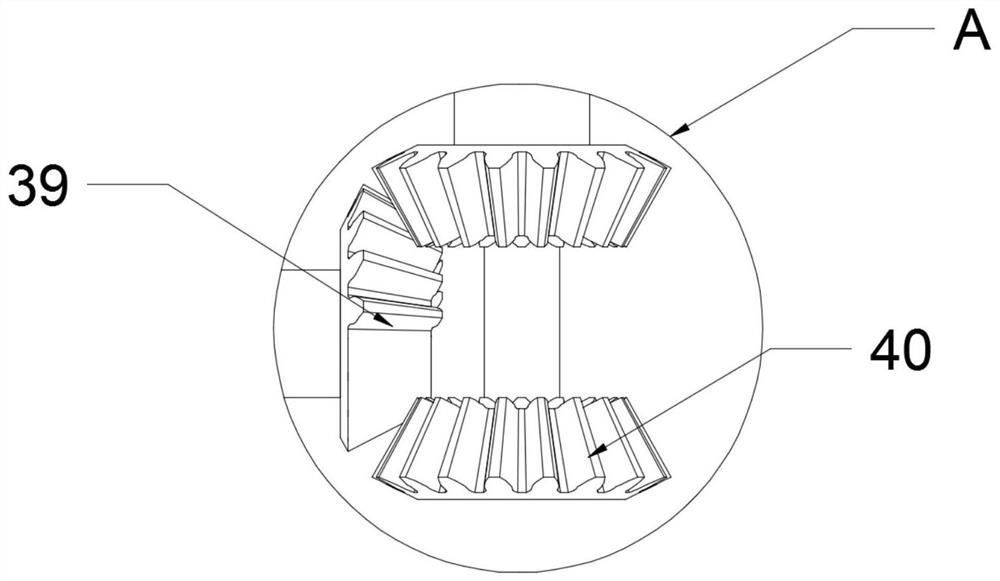

Kneading Element of Kneader, Kneader, and Bread Machine

InactiveUS20100147160A1Efficient kneadingReduce adhesionMixing/kneading structural elementsRotary stirring mixersMechanical engineeringEngineering

Owner:JAPAN KNEADER

Conjugated diene polymer conjugated diene polymer composition

InactiveUS20100056711A1Excellent kneading processabilityGood kneadingSpecial tyresHydrocarbon solventsConjugated diene

There is provided a continuous method for producing a conjugated diene polymer, comprising: polymerizing a conjugated diene, a compound of formula (I) below, and optionally other monomer in the presence of an alkali metal catalyst in a hydrocarbon solvent,wherein X1, X2, and X3 independently denote a group as defined in the specification.

Owner:SUMITOMO CHEM CO LTD

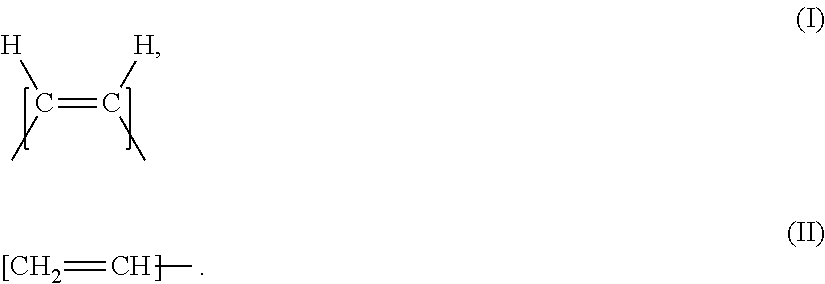

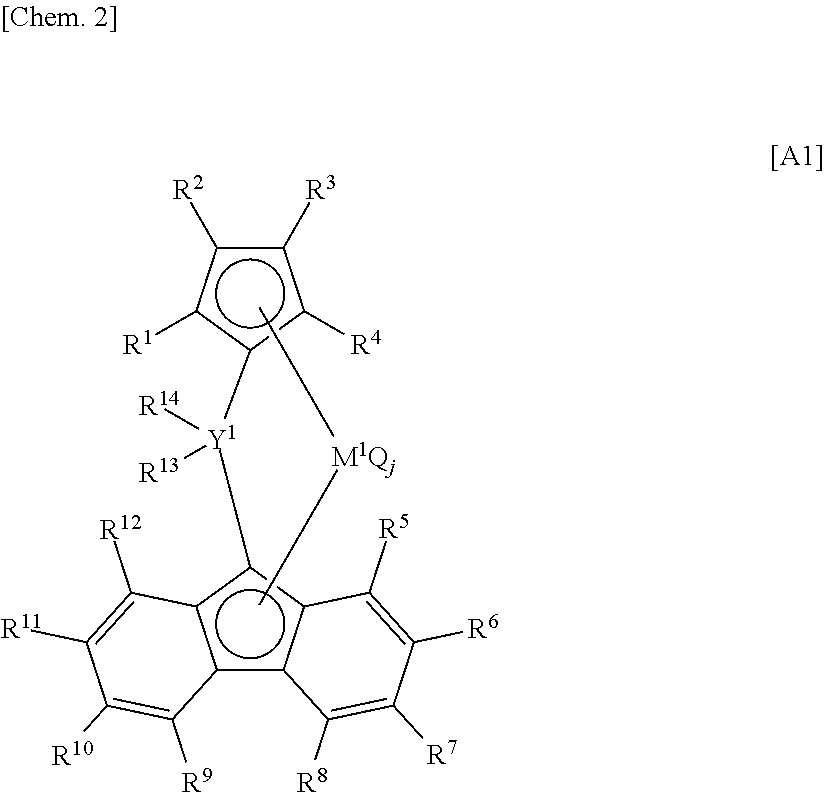

Ethylene/alpha-olefin/non-conjugated polyene copolymer, and production process and use thereof

ActiveUS20160355622A1Small long-chain branch contentExcellent curing propertyPlastic/resin/waxes insulatorsSpecial tyresChemistryStructural unit

A novel ethylene / α-olefin / non-conjugated polyene copolymer comprising structural units derived from ethylene (A), an α-olefin (B) of 3 to 20 carbon atoms, and a non-conjugated polyene (C) containing intramolecularly two or more partial structures in total selected from the group consisting of structures of Formulae (I) and (II), and having a small number of long-chain branches,The novel ethylene / α-olefin / non-conjugated polyene copolymer contains a non-conjugated polyene such as VNB as a copolymerization component and a small long-chain branch content and is excellent in curing properties in the case of crosslinking using peroxide; and a process for producing the ethylene / α-olefin / non-conjugated polyene copolymer, and a use thereof are provided.

Owner:MITSUI CHEM INC

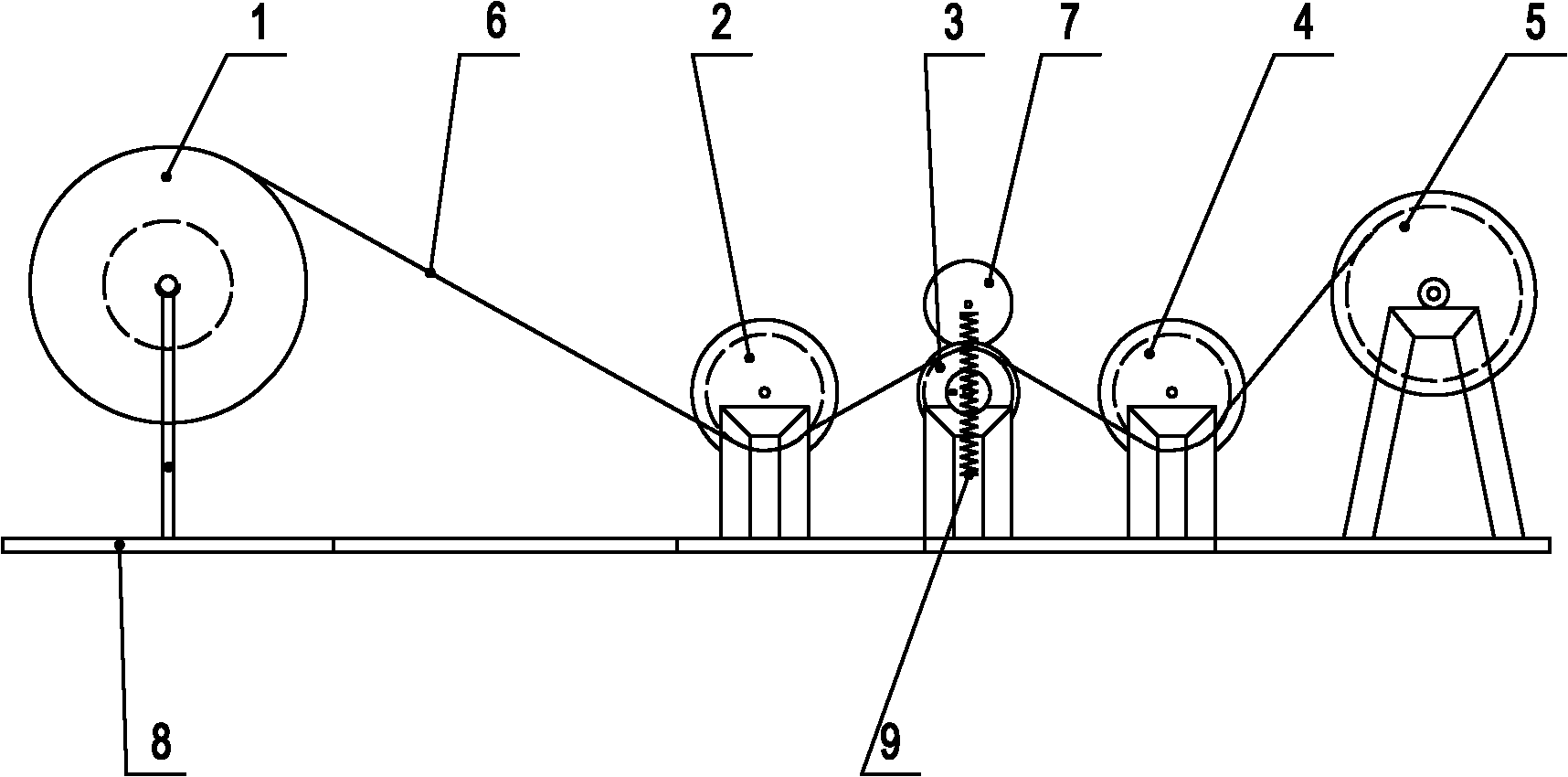

Winding steel wire machine

The invention discloses a winding steel wire machine, which is characterized by comprising a power device, a winding drum, a fixed length idler wheel, a fixed ruler detection control mechanism and a controller. A steel wire passes through the fixed length idler wheel to be wound on the winding drum, the power device is connected with the winding drum to control the winding drum to rotate, and the winding drum drives the fixed length idler wheel to rotate through the steel wire. The fixed ruler detection control mechanism is arranged on the fixed length idler wheel and used for controlling rotating length of the fixed length idler wheel, the controller is connected with the fixed ruler detection control mechanism and the power device, and the power device is controlled to stop operation through signals of the fixed ruler detection control mechanism. The winding steel wire machine uses power of the motor to pull the steel wire, can be generally used for steel wires with different diameters, has the function of setting the length and automatically stopping operation, improves work efficiency and is applicable to volume production.

Owner:江苏斯特郎电梯有限公司

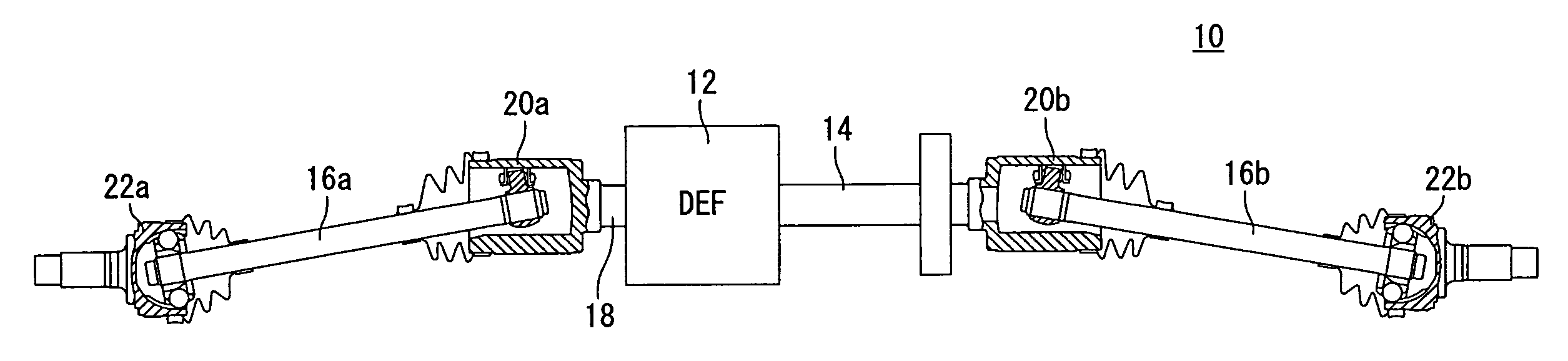

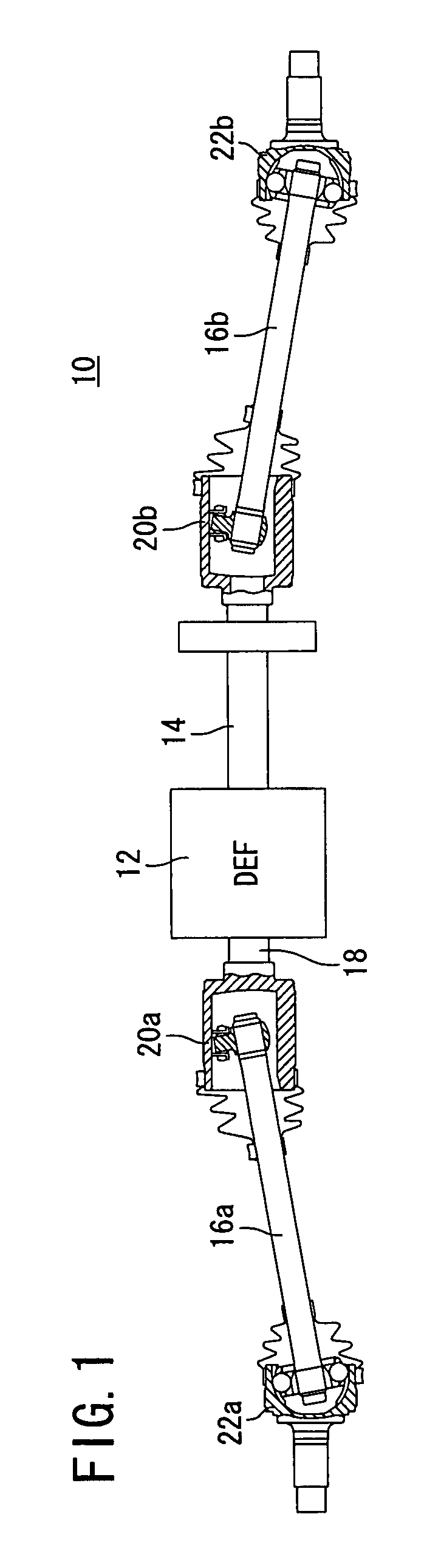

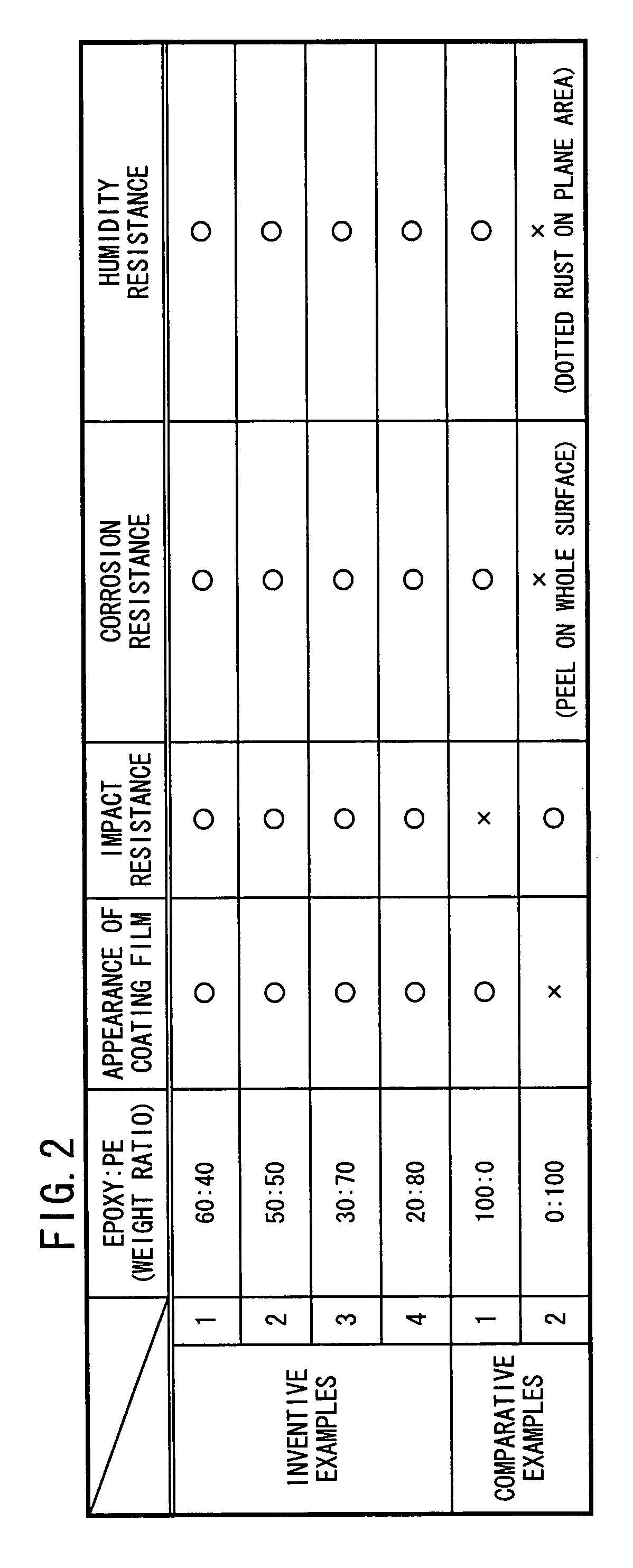

Coating Composition and Structural Member of Automotive Body

InactiveUS20080102283A1Improve propertiesImprove the immunitySynthetic resin layered productsVehicle componentsEpoxyPolyolefin

There is provided a coating film applied onto structural members of automotive body, such as drive shaft, which coating film is formed by hardening of a coating composition comprising an epoxy resin powder coating material and at least either a polyolefin resin or a modified olefin resin containing a polar group. As the polyolefin resin or modified olefin resin containing a polar group, there can be selected those of 0.1 to 80 g / 10 min melt index at 190° C. and −100° to −20° C. brittle temperature. In the coating composition, the ratio between epoxy resin powder coating material and polyolefin resin or modified olefin resin containing a polar group on a weight ratio basis is set for 1 to 70 : 99 to 30.

Owner:HONDA MOTOR CO LTD +1

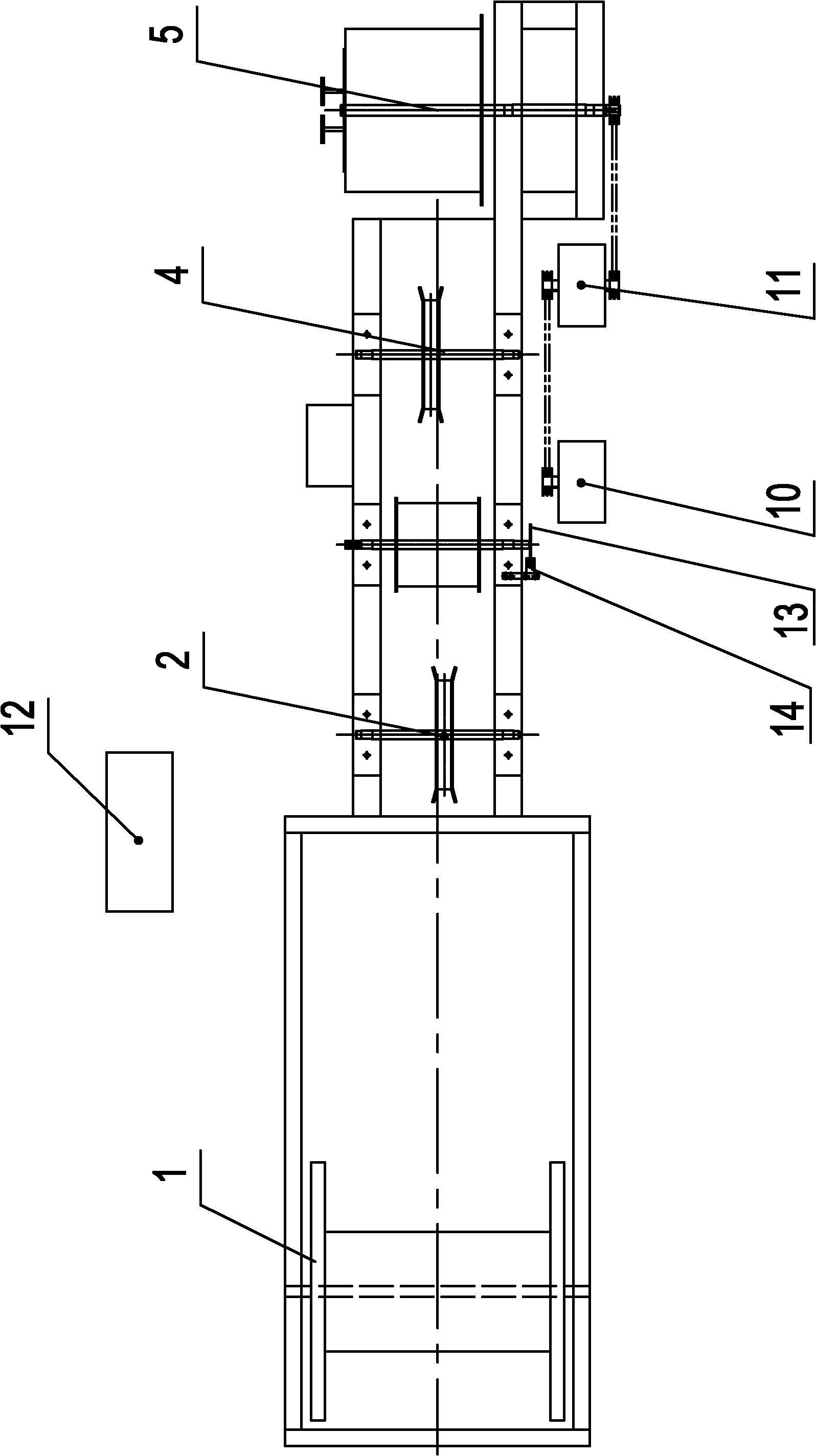

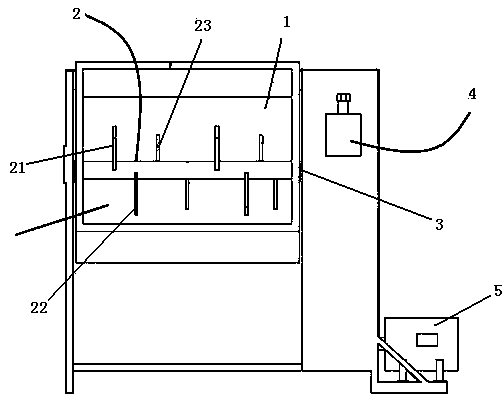

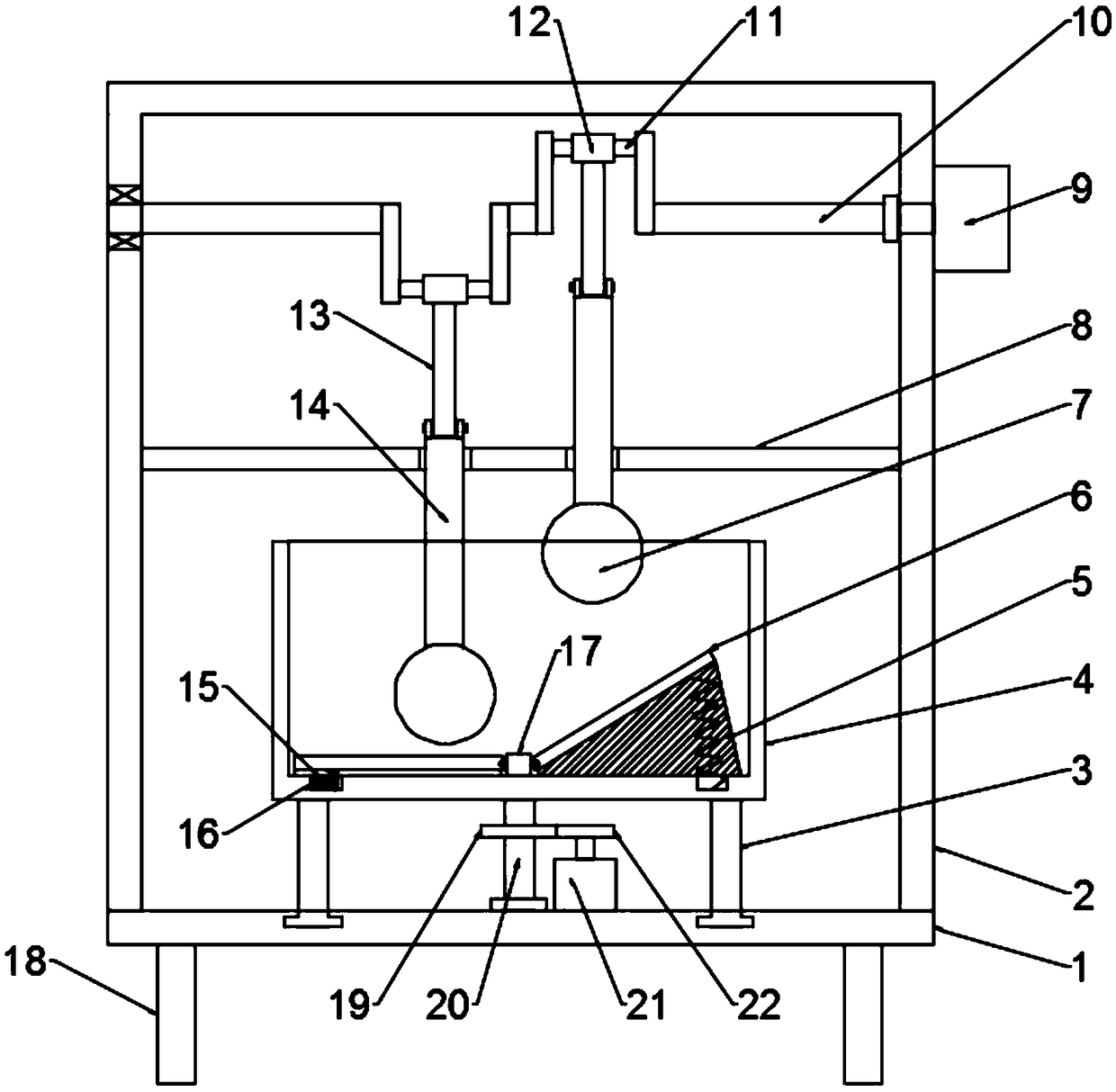

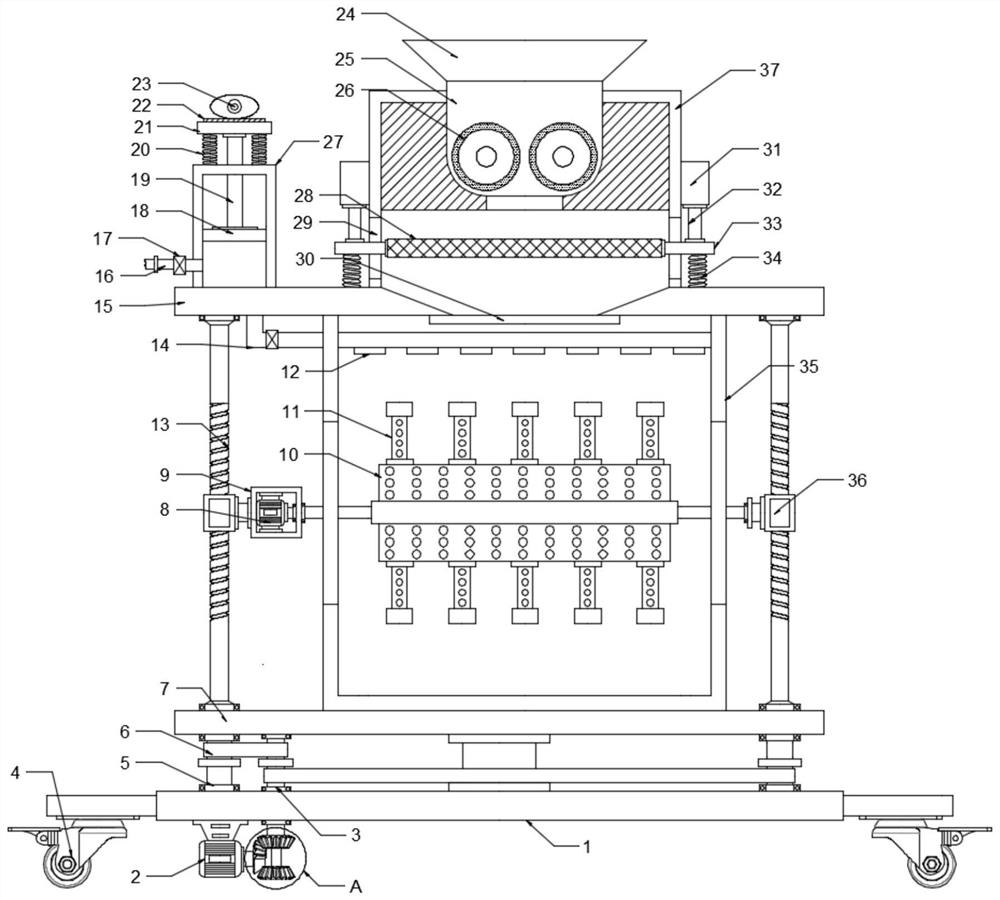

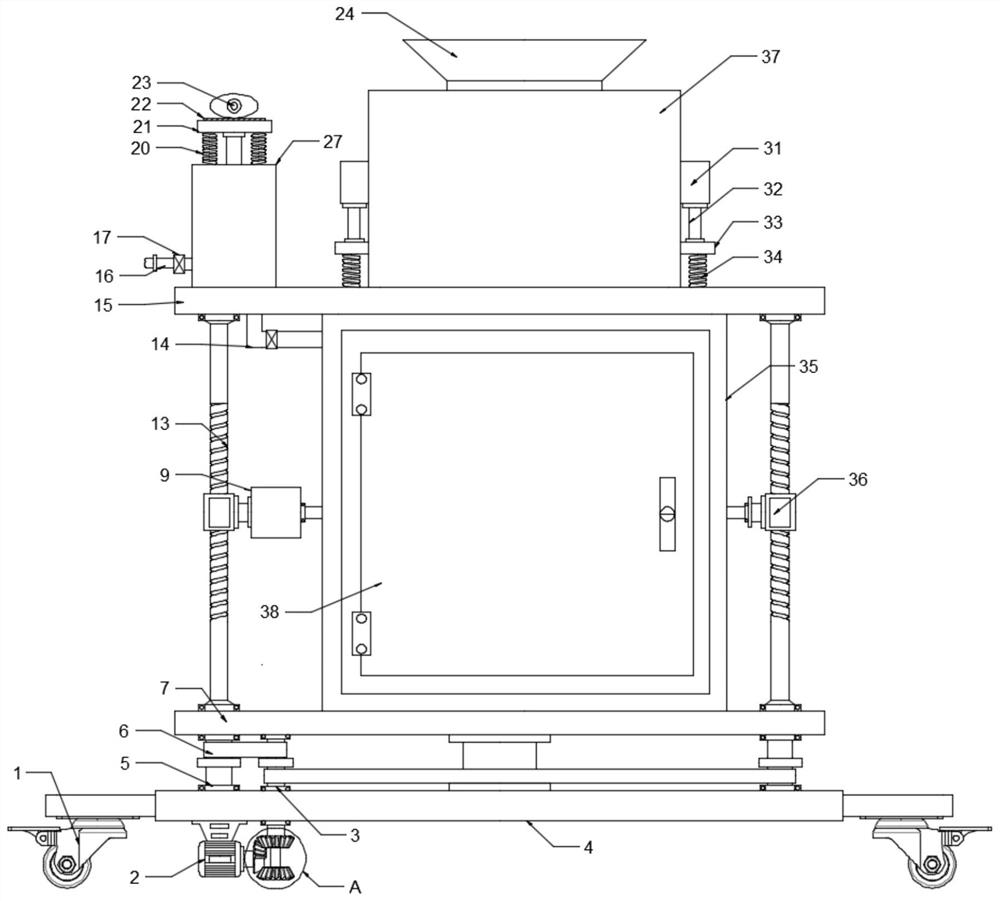

Kneading device of straw kneading machine

InactiveCN105195294AGood kneadingThe kneading device of the kneading machine has a simple structure and is easy to useCuttersGrain treatmentsFixed frameEngineering

The invention provides a kneading device of a straw kneading machine. The kneading device comprises a bottom plate, a first bracket device, a first air cylinder device, a second air cylinder device, a material collection box, a feeding device, a second bracket device, a third air cylinder device and a crushing device, wherein the bottom plate is provide with a first fixed block; the first bracket device is provided with a first bracket, a second bracket, a first inclined rod and a second inclined rod; the first air cylinder device is provided with a first air cylinder, a first pushing rod, a first pushing plate and a first slide plate; the second air cylinder device is provided with a second air cylinder, a second pushing rod, a third bracket and the like; the feeding device is provided with a feeding hopper, a material collection hopper, a material distribution block, a fixed plate and the like; the second bracket device is provided with a first fixed plate, a second fixed frame, a third inclined rod and the like; the third air cylinder device is provided with a fourth air cylinder, a fourth pushing rod, a sixth bracket and the like; the crushing device is provided with a crushing frame, a rotary wheel, crushing teeth and the like. The kneading device can be used for efficiently kneading straws and crushing the kneaded straws, so that the straws are more fine and smooth.

Owner:蔡旭东

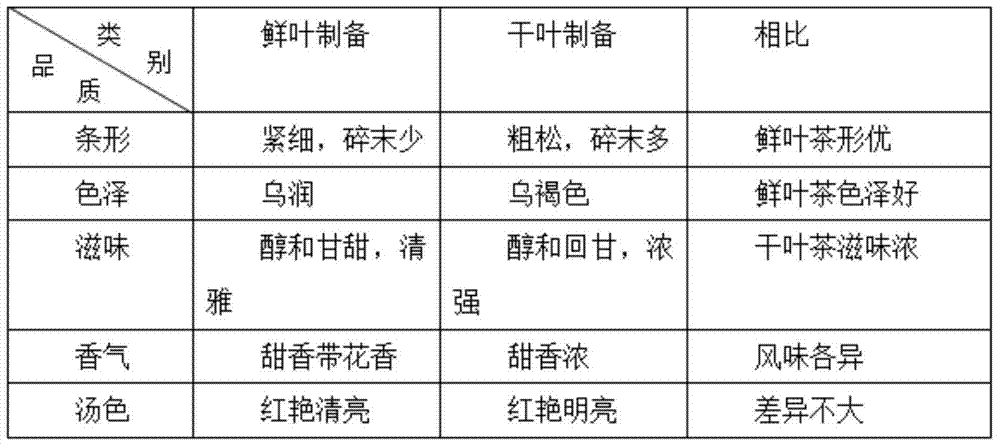

Black tea withering method

The invention discloses a black tea withering method. The black tea withering method comprises the following steps: spreading and withering, withering with hot air, and withering with cold air. Firstly, shrivelled leaf opexes caused by excessively fast withering can be effectively prevented due to spreading and withering, and then water in tea leaves can be rapidly evaporated through withering with hot air, the tension of tea cells is reduced, the toughness of buds is increased, the rolling of the tea is facilitated, the processing time is greatly reduced, the water in the tea can be enabled to be fully and uniformly distributed through the withering with cold air, and the foundation is laid for forming the high-quality black tea.

Owner:GUIZHOU FENGGANG COUNTY QIANYUZHI ECO TEA IND

Fluororesin composition process for preparing the same and cable coated with the same

ActiveUS20040254300A1Improve crack resistanceGood moldabilityPlastic/resin/waxes insulatorsFibre treatmentVinyl etherCrack resistance

Owner:DAIKIN IND LTD

Preparation method of plant beauty-maintaining black tea

ActiveCN103749774APromote formationIntelligent control of fermentation temperaturePre-extraction tea treatmentPlant nutritionBlack tea

The invention discloses a preparation method of plant beauty-maintaining black tea. The preparation method has the beneficial effects as follows: (1) the comprehensive and efficient utilization of healthcare nutrition substance resources in each raw material is enhanced, so that waste materials are changed into things of value, and high-quality natural plant composite beauty-maintaining tea is produced; (2) the beauty-maintaining black tea is prepared by using biological fermentation and enzymatic fermentation technologies, and any additive is not added to ensure the quality safety of a product; (3) through primary and fine processing of various composite plants, the product absorbs the nutritional essences of various plants to ensure that the effects of maintaining beauty and protecting skin of the tea are significant and the healthcare effect is more comprehensive.

Owner:黄山小罐茶业有限公司

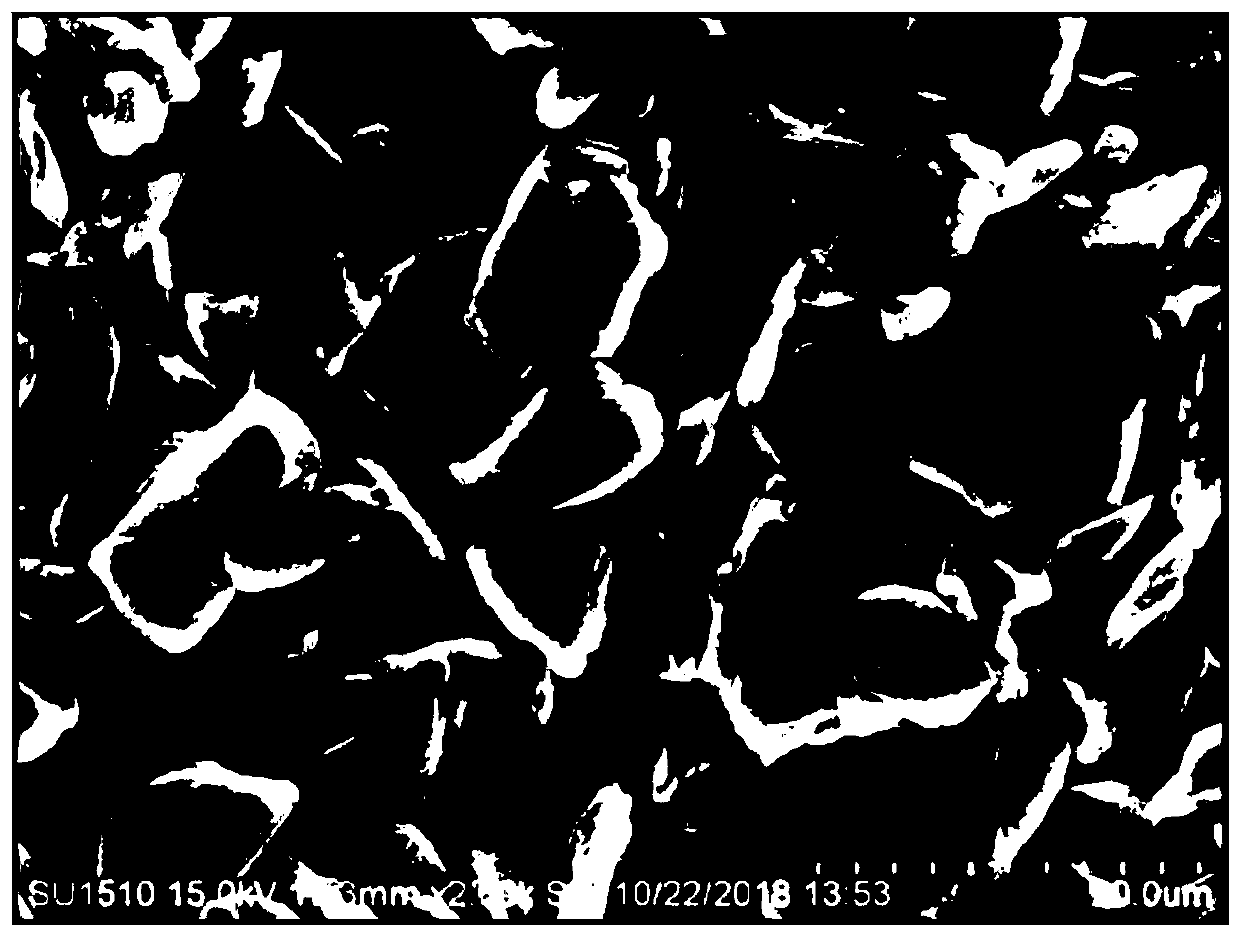

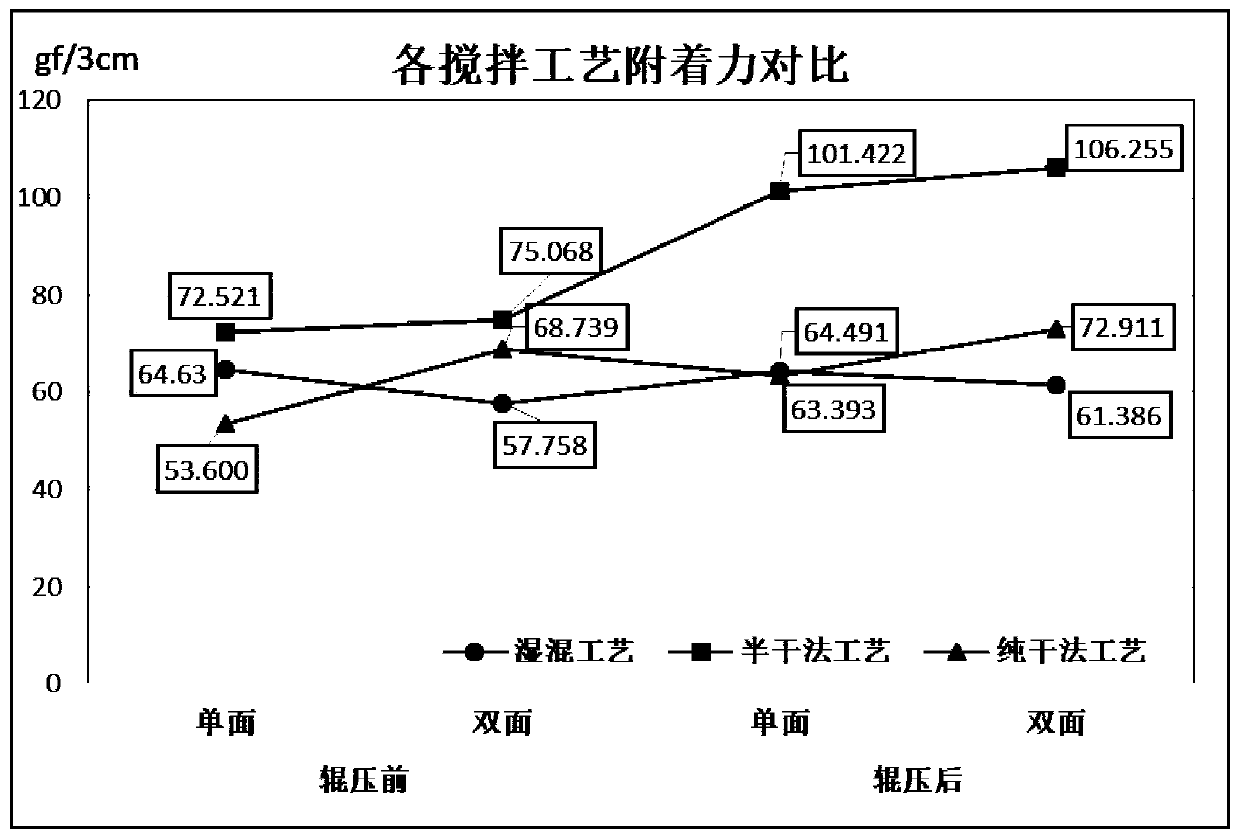

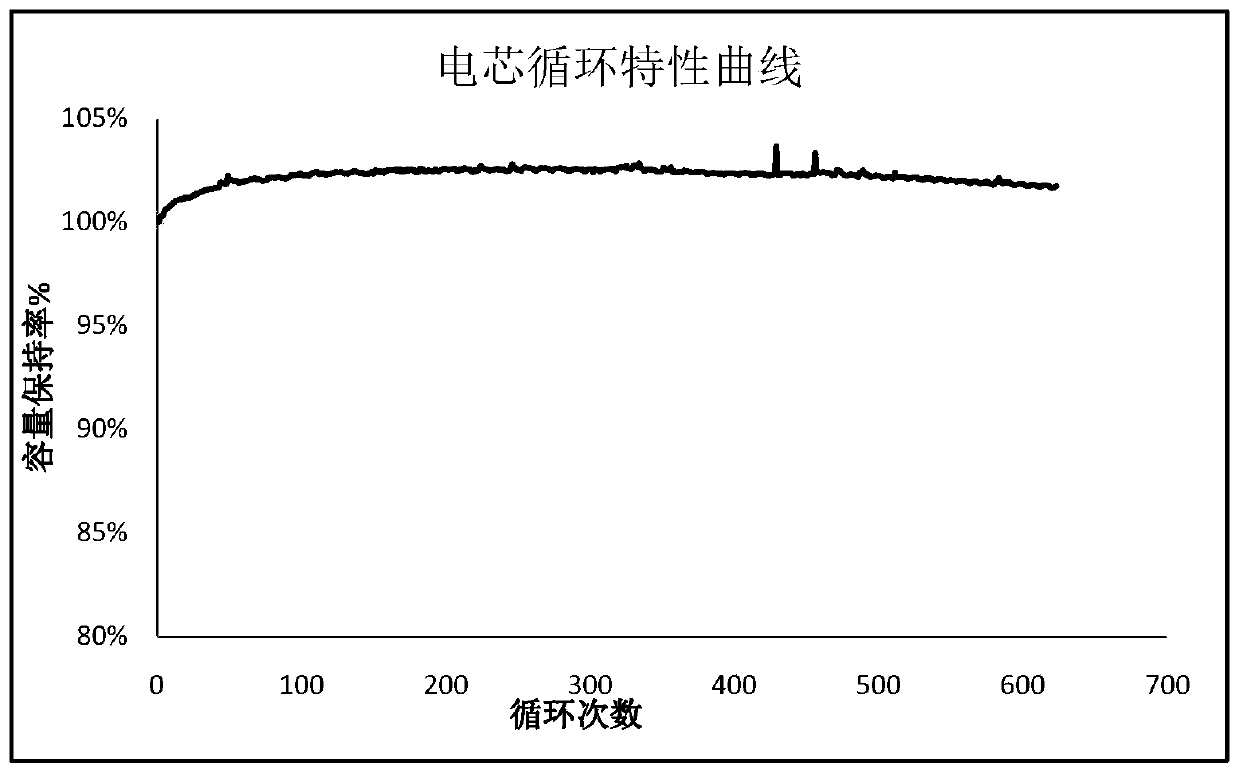

Lithium ion battery electrode paste semidry method dispensing process, lithium ion battery positive electrode sheet, lithium ion battery negative electrode sheet, and lithium ion battery

ActiveCN110600671AHigh solid contentGood dispersionElectrode manufacturing processesSecondary cellsElectrical batteryLithium-ion battery

The invention discloses a lithium ion battery electrode paste semidry method dispensing process. The electrode paste contains a binder. The required binder is added in n batches, wherein a binder powder is added in at least one batch, a binder solution is added in at least one batch, and n is an integer greater than or equal to 2. The present invention also discloses a lithium ion battery positiveelectrode sheet, a lithium ion battery negative electrode sheet, and a lithium ion battery prepared by the dispensing process. The solution provided by the invention can not only shorten the stirringtime, increase the solid content of the electrode paste and stabilize the paste viscosity, but also can reduce the equipment load and improve the dispersion performance of the paste.

Owner:恒大新能源科技集团有限公司

Low-temperature SCR denitration catalyst and preparation method thereof

InactiveCN106492790AIncrease oxygen storageImprove water and sulfur resistanceHeterogenous catalyst chemical elementsDispersed particle separationCerium nitrateTungstate

The invention provides a low-temperature SCR denitration catalyst and a preparation method thereof. The catalyst can be used for a low-temperature nitric oxide selectivity catalytic reduction reaction. The catalyst adopts manganese, cerium, vanadium and tungsten oxides as active components and adopts a coal ash and nanometer titania mixture as a compound carrier. The preparation method of the catalyst comprises the steps that coal ash is subjected to washing, drying and acid-pickling and then mixed with the nanometer titania into a quantity of deionized water, and stirring and drying are performed to obtain the composite carrier. The manganese nitrate, cerium nitrate, ammonium metavanadate and ammonium tungstate are dissolved into deionized water, the prepared composite carrier is added, and stirring, standing, drying, grinding, calcination, roasting and other processes are performed to prepare the finished catalyst. The needed raw materials are cheap and easy to obtain, the cost is obviously lowered, and the denitration performance under the low temperature condition is good.

Owner:HEBEI UNIV OF TECH

Polymer composite material and process for producing the same

InactiveUS20060255494A1Good kneadingGood dispersionLaminationLamination apparatusOrganic solventBoiling point

A polymer composite material which comprises a thermoplastic resin and a lamellar inorganic compound dispersed therein on the order of submicron to nanometer and which is excellent in mechanical properties, heat resistance, etc.; and a production process which comprises kneading a thermoplastic resin together with a lamellar inorganic compound swollen with a dispersion medium comprising water and / or an organic solvent with a shearing kneader at a temperature which is lower than the melting temperature of the thermoplastic resin and not higher than the boiling point of the dispersion medium and then kneading the resultant mixture while heating it to a temperature not lower than the boiling point of the dispersion medium. By the production process, a polymer composite material containing a lamellar inorganic compound is obtained which has the desired properties.

Owner:YAMAGATA UNIV RES INST +1

Rare earth flexible magnetic stripe for health bedding and preparation method thereof

ActiveCN103745798AReduced magnetic powder contentLow costPermanent magnetsInorganic material magnetismAntioxidantAging resistance

The invention relates to the field of magnetic materials, in particular to a rare earth flexible magnetic stripe for health bedding and a preparation method thereof. The rare earth flexible magnetic stripe for health bedding comprises the following components in parts by weight of 75-88 rare earth composite permanent magnet powder, 4-15 binder, 1-5 heat stabilizer, 0.5-2 coupling agent and 0.2-0.8 antioxidant, wherein the rare earth composite permanent magnetic powder comprises two or three of anisotropic NdFeB, NdFeN or SmFeN. The rare earth composite permanent magnetic powder is obtained through the microwave vacuum treatment with rust-preventative oil in the steps of dipping the rare earth composite permanent magnetic powder into 50-150 parts by weight of rust-preventative oil, vacuumizing to the vacuum degree of -0.02MPa to -0.001MPa, and performing microwave processing at the microwave frequency of 100MHz to 350MHz for 0.5 to 2 minutes. The preparation method comprises the treatment with rust-preventative oil, pre-magnetizing and microwave granulation, a first rolling, magnetic field orientation and a second rolling. The magnetic stripe prepared through the rare earth flexible magnetic stripe for health bedding and the preparation method thereof is good in magnetic performance and aging resistance and has improved corrosion resistance.

Owner:HEYE HEALTH TECH CO LTD

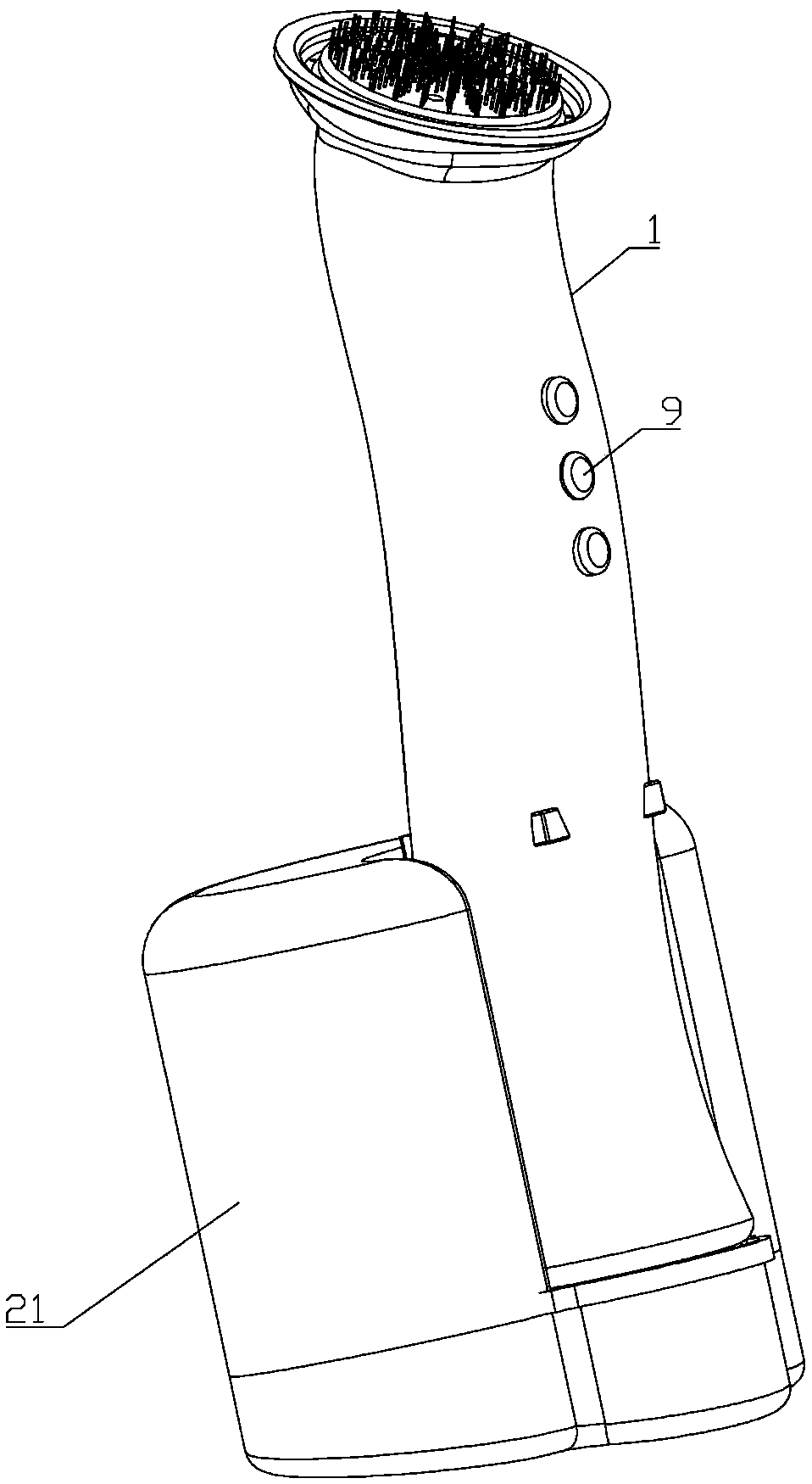

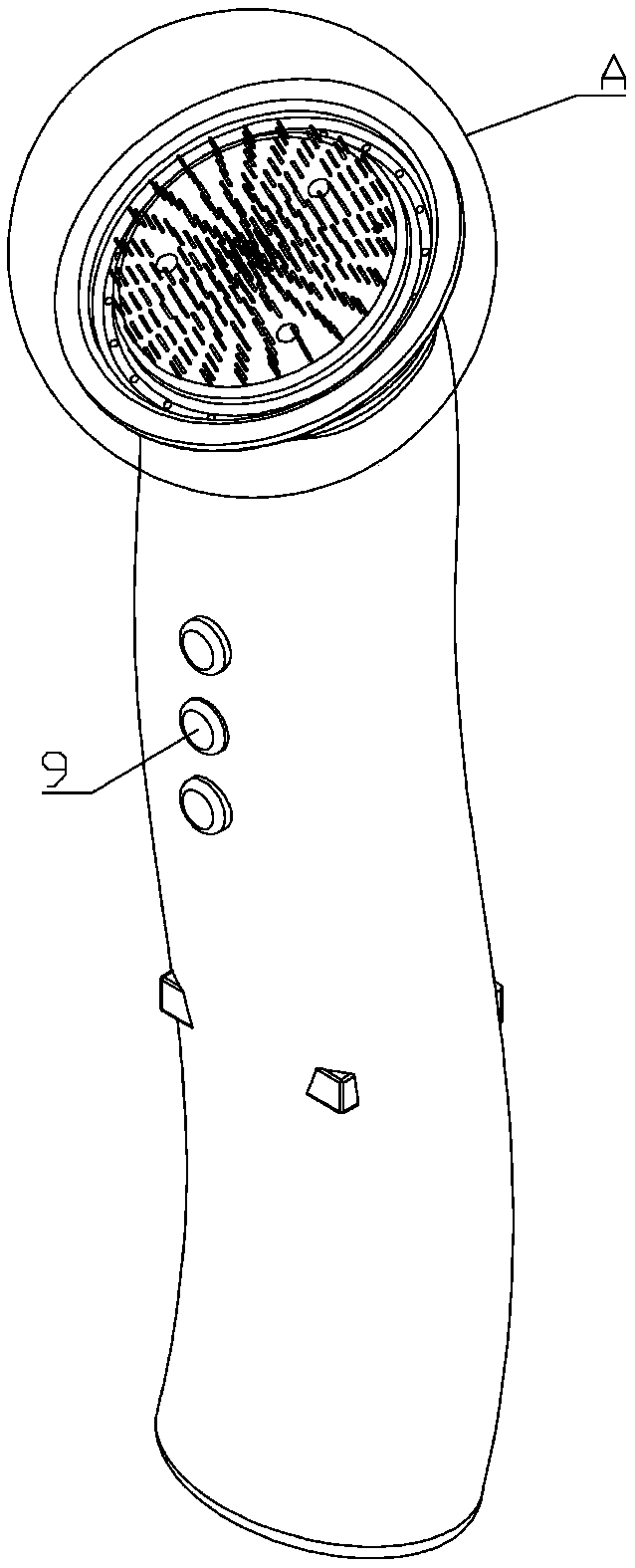

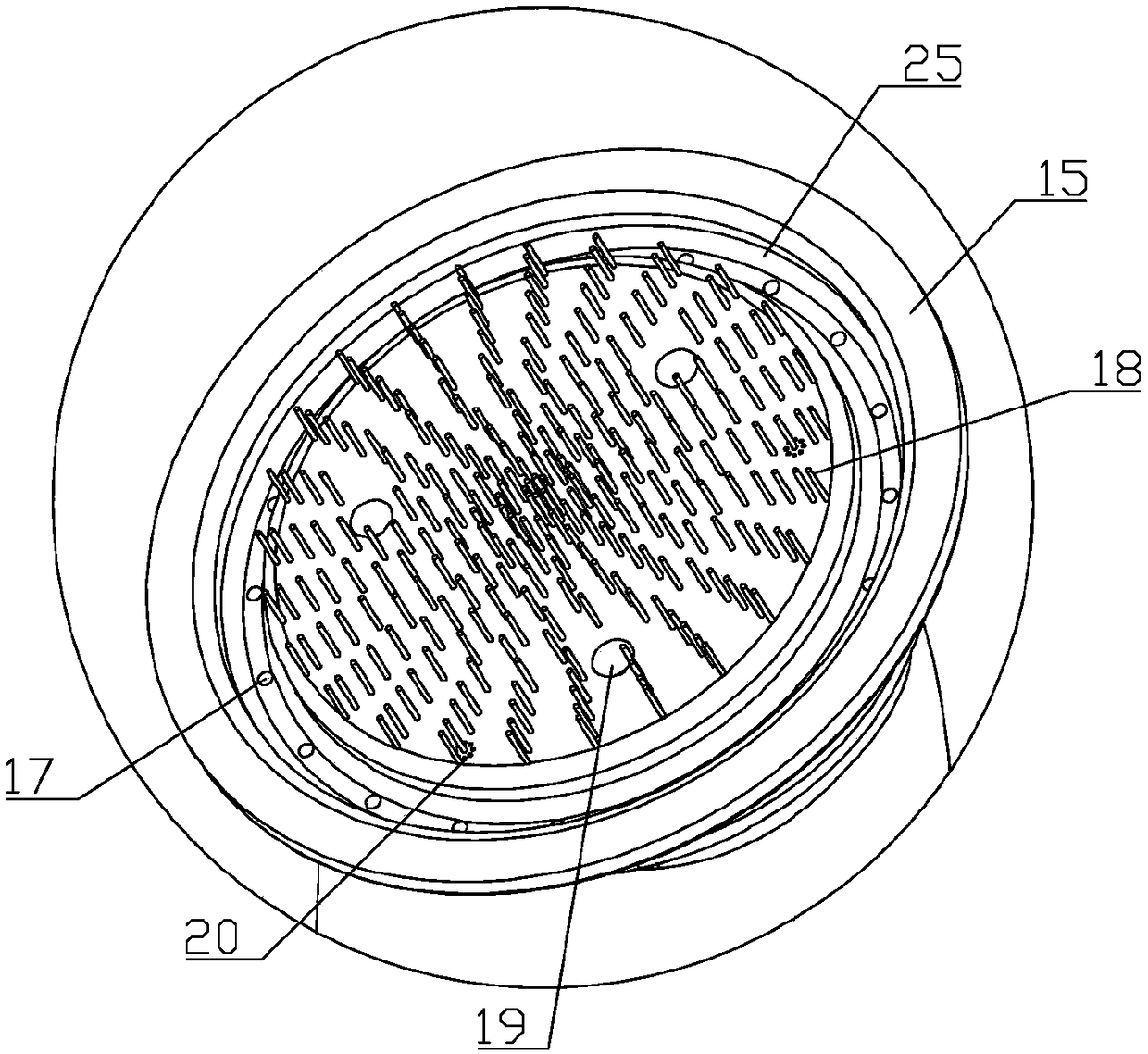

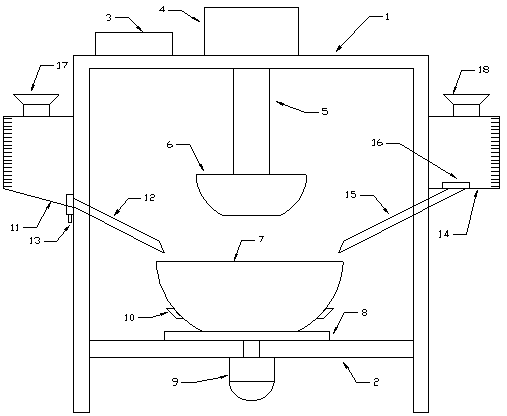

Face-cleaning instrument

PendingCN108968748AGentle and effective cleaningSoft and effective adsorptionBathroom accessoriesEngineeringLotion

The invention discloses a face-cleaning instrument. The face-cleaning instrument comprises a charging base and a face-cleaning instrument main machine body mounted on the charging base, wherein a cavity is arranged inside the face-cleaning instrument main machine body, a battery is mounted on the bottom of the cavity, a first partition plate is mounted above the battery, a water supply box, a lotion box and a recycling box are mounted on the first partition plate, a washing head is detachably mounted on the top of the face-cleaning instrument main machine body, an annular groove is arranged inthe washing head, water absorbing holes are formed in the bottom of the annular groove, first guide pipes are connected between the water absorbing holes and the recycling box, lotion holes are further formed in the washing head, second guide pipes are connected between the lotion holes and the lotion box, latex bristles uniformly distributed are further arranged on the washing head, a pluralityof water outlet holes are further formed in the washing head, the water outlet holes are uniformly distributed on the washing head, and third guide pipes are connected between the water outlet holes and the water supply box. With the face-cleaning instrument, the surface of the skin can be gently and effectively cleaned, and meanwhile, a soiling solution after face cleaning also can be effectivelyadsorbed and recycled, so that the phenomenon that the soiling solution flows to pollute clothes and other articles is avoided.

Owner:侯成

Profile extrusion molding resin composition and profile extrusion resin molded product

InactiveUS20130023618A1Improve kneading effectNice appearanceAlkaline-earth metal silicatesHeat resistanceShell molding

The present invention provides a profile extrusion molding resin composition capable of forming a profile extrusion resin molded product which is excellent in strength, impact resistance, heat resistance, scratch resistance, surface appearance and shaping property. The profile extrusion molding resin composition of the present invention comprises an aromatic vinyl-based resin component which comprises a rubber-reinforced aromatic vinyl-based resin (A) having the following definition (1) and an ultrahigh molecular weight aromatic vinyl-based resin (B) having the following definition (2) at specific proportions, said resin composition further comprising a lubricant (C) and an inorganic filler (D) in specific amounts based on the aromatic vinyl-based resin component: (1) A resin which is constituted from a graft polymer (a1) obtained by graft-polymerizing an aromatic vinyl compound in the presence of a rubber polymer and, if required, a polymer (a2) obtained by polymerizing an aromatic vinyl compound (with the proviso that a content of the component (a2) is not more than 90% by mass based on a total amount of the components (a1) and (a2)), and which has an acetone-soluble component having a weight-average molecular weight of not more than 1,000,000; and (2) a resin which is obtained by polymerizing a monomer component comprising an aromatic vinyl compound, and which has an acetone-soluble component having a weight-average molecular weight of not less than 2,000,000.

Owner:TECHNO POLYMER CO LTD

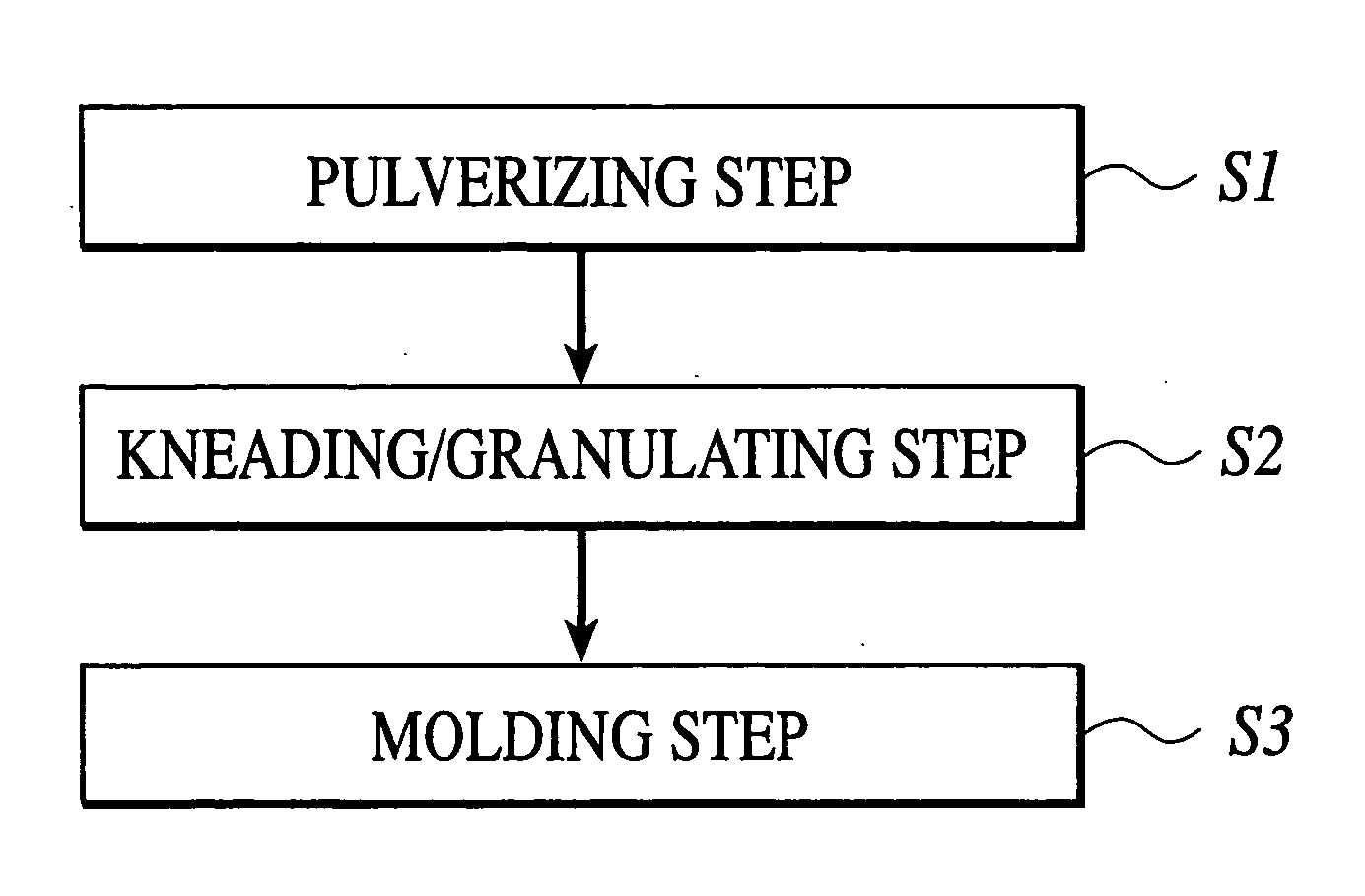

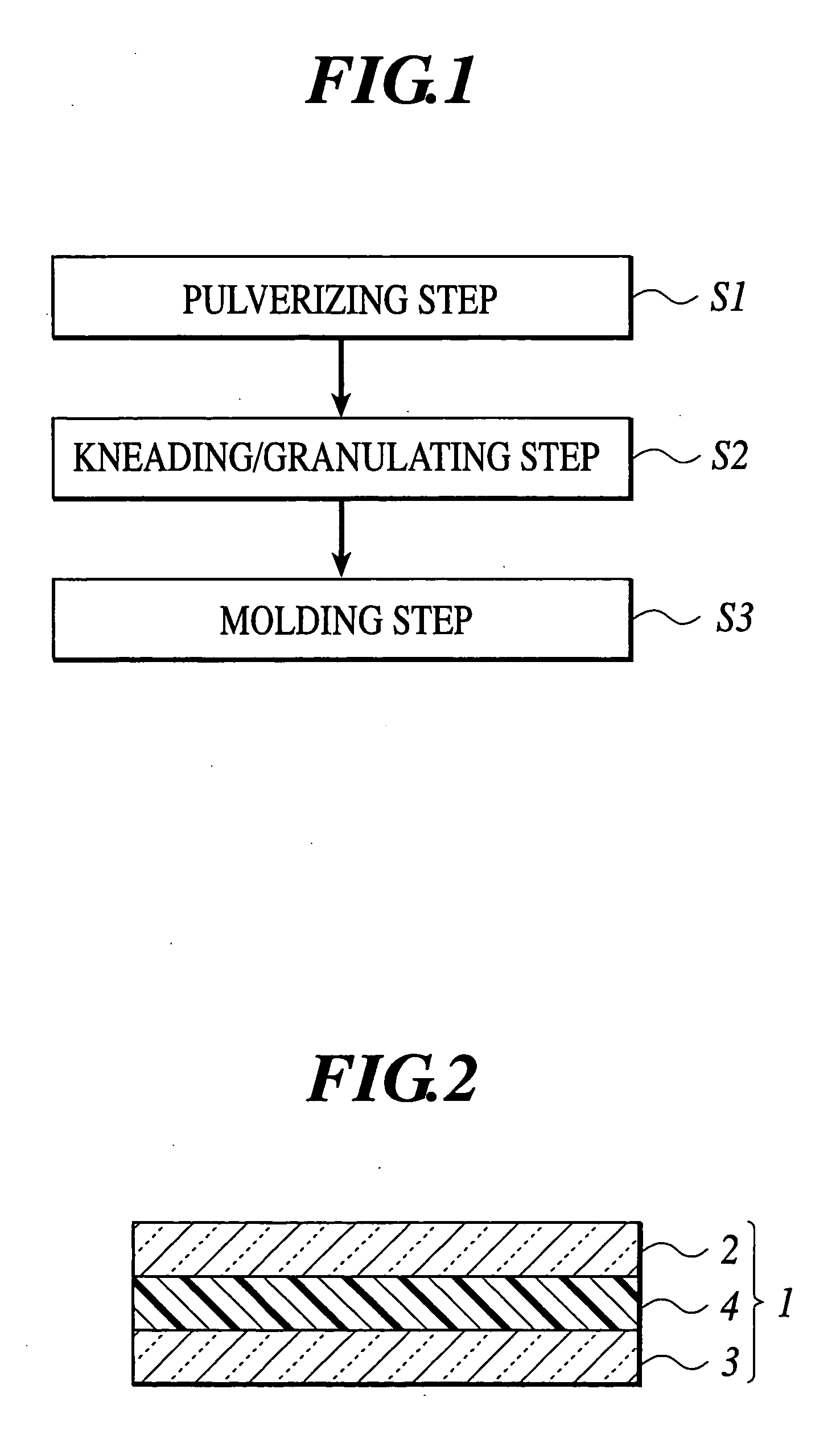

Methods for molding and processing polyvinyl butyral resin, and method for reusing laminated glass

InactiveUS20050146074A1Low costShort timeSolid waste disposalPlastic recyclingPolymer chemistryPolyvinyl butyral resin

A method for molding a polyvinyl butyral resin, including: kneading and granulating a polyvinyl butyral resin with a filler; and molding into a molded product by melting a mixture of the polyvinyl butyral resin and the filler, wherein the mixture being obtained in the step of kneading and granulating.

Owner:SUBARU CORP +1

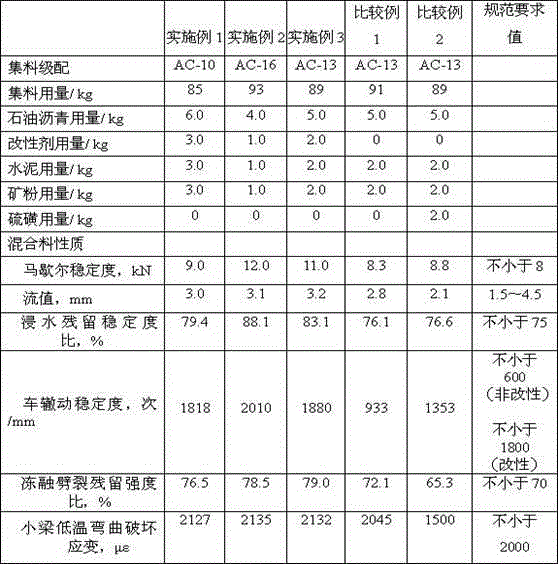

Anti-rutting asphalt mixture and preparation method thereof

The invention discloses an anti-rutting asphalt mixture and a preparation method thereof. The anti-rutting asphalt mixture disclosed by the invention comprises the following components in percentage by weight: 1.0-3.0% of an anti-rutting modifying agent, 4.0-6.0% of petroleum asphalt, 1.0-3.0% of cement, 1.0-3.0% of a mineral powder, and 85.0-93% of aggregates. The preparation method of the anti-rutting asphalt mixture comprises the following steps: heating a stirring kettle and the aggregates to be at a temperature of 125-150 DEG C for standby application, simultaneously adding molten petroleum asphalt, the aggregates, the cement, the mineral powder and anti-rutting modifying agent particles in the stirring kettle, and uniformly stirring the mixture so as to obtain the anti-rutting asphalt mixture. The specially-made anti-rutting modifying agent is added in the anti-rutting asphalt mixture, so that the dynamic rutting stability of a mixture vehicle is greatly improved, the anti-rutting performance of asphalt pavements can be obviously improved, and the anti-rutting asphalt mixture is particularly suitable for asphalt highways with heavy traffics and asphalt highways where rutting is easy to occur in high-temperature regions in the South of China.

Owner:CHINA PETROLEUM & CHEM CORP +1

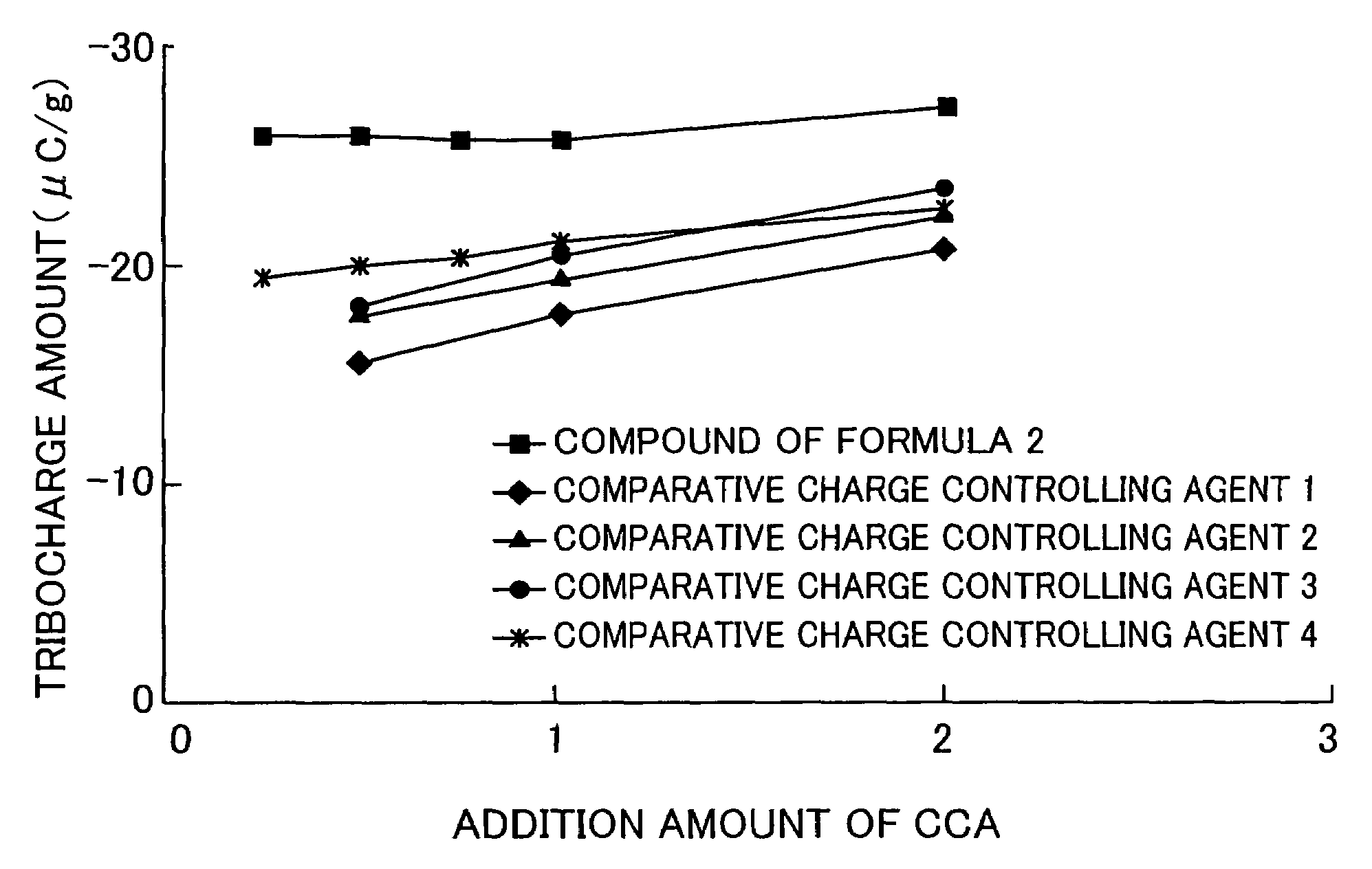

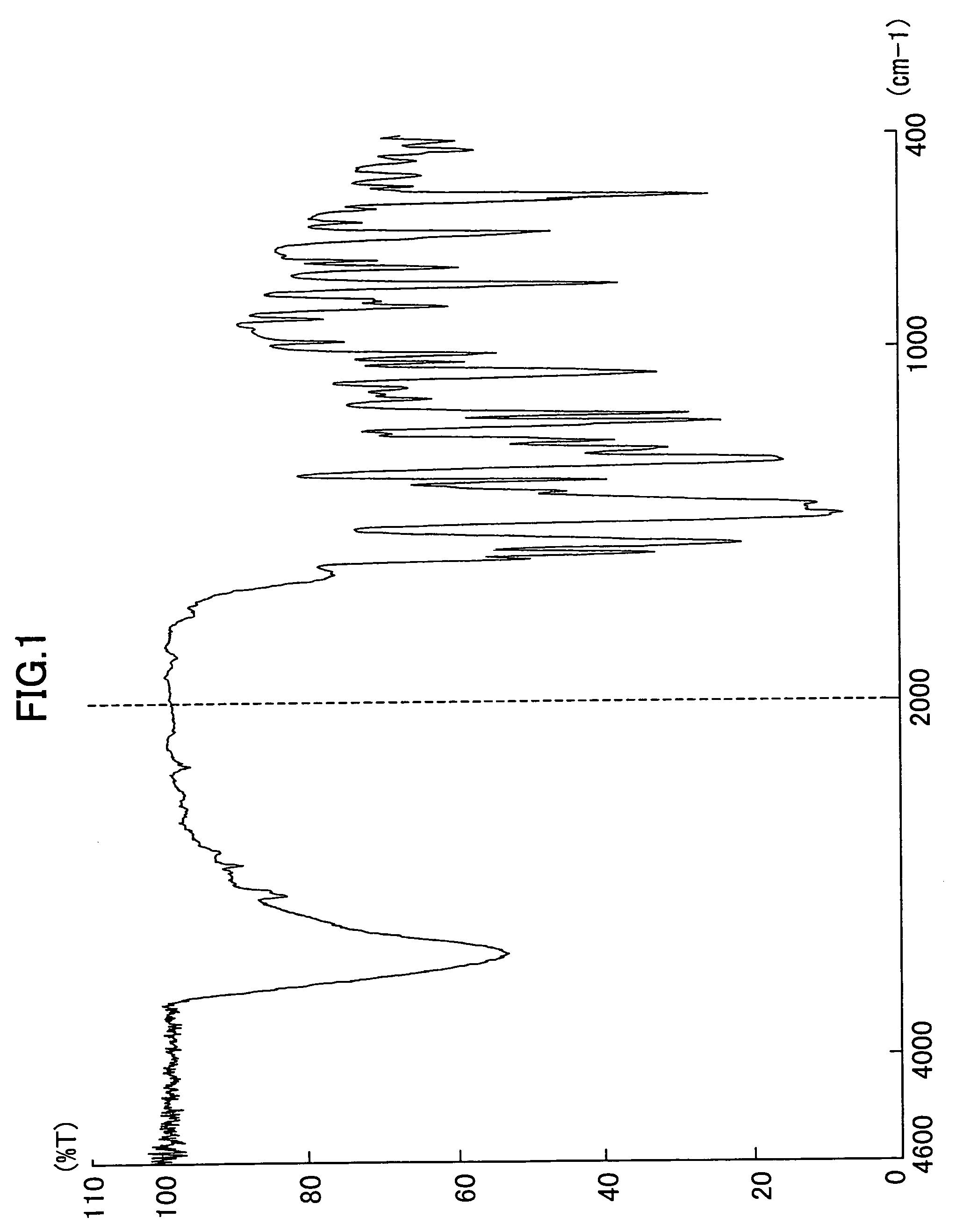

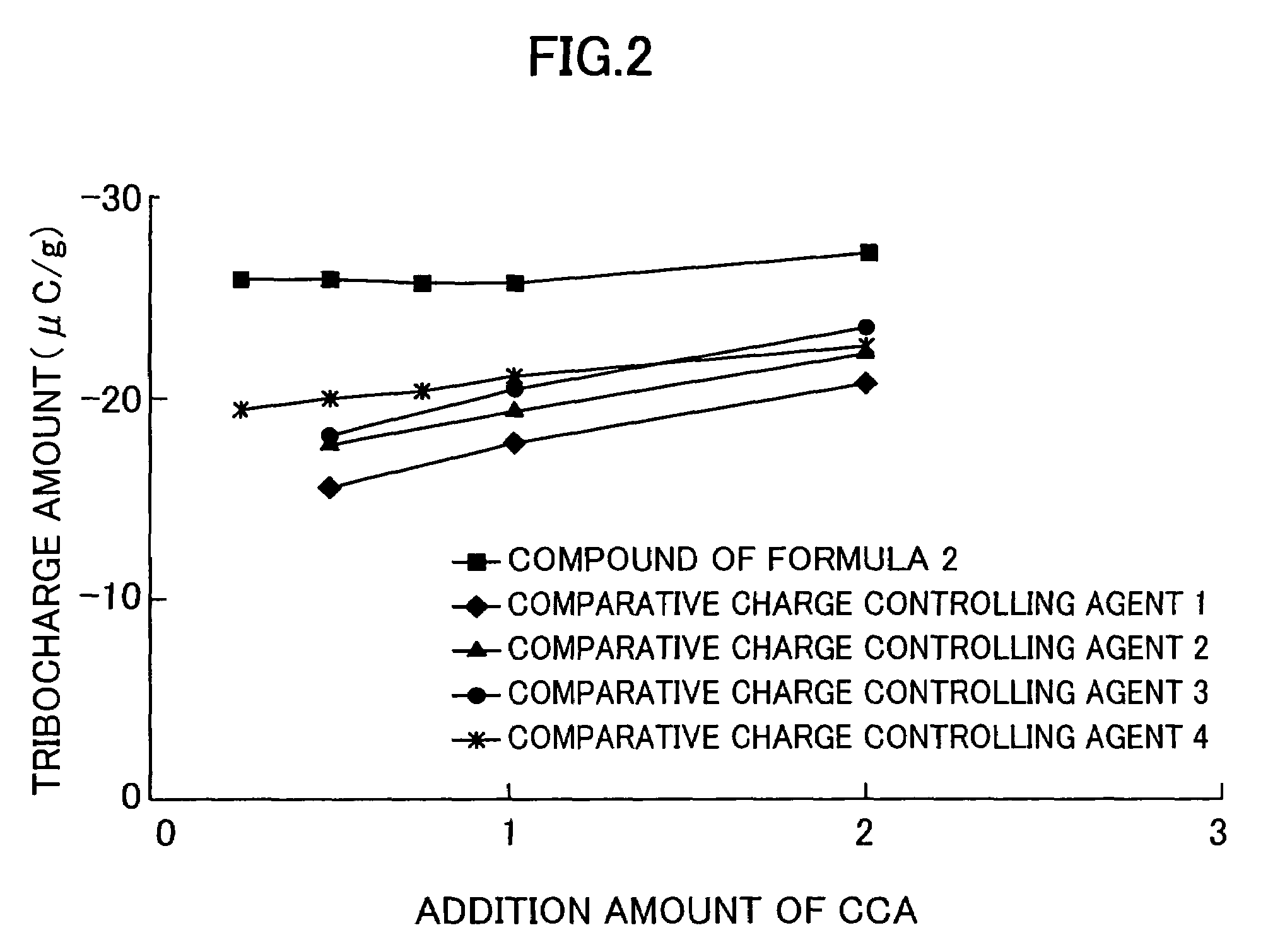

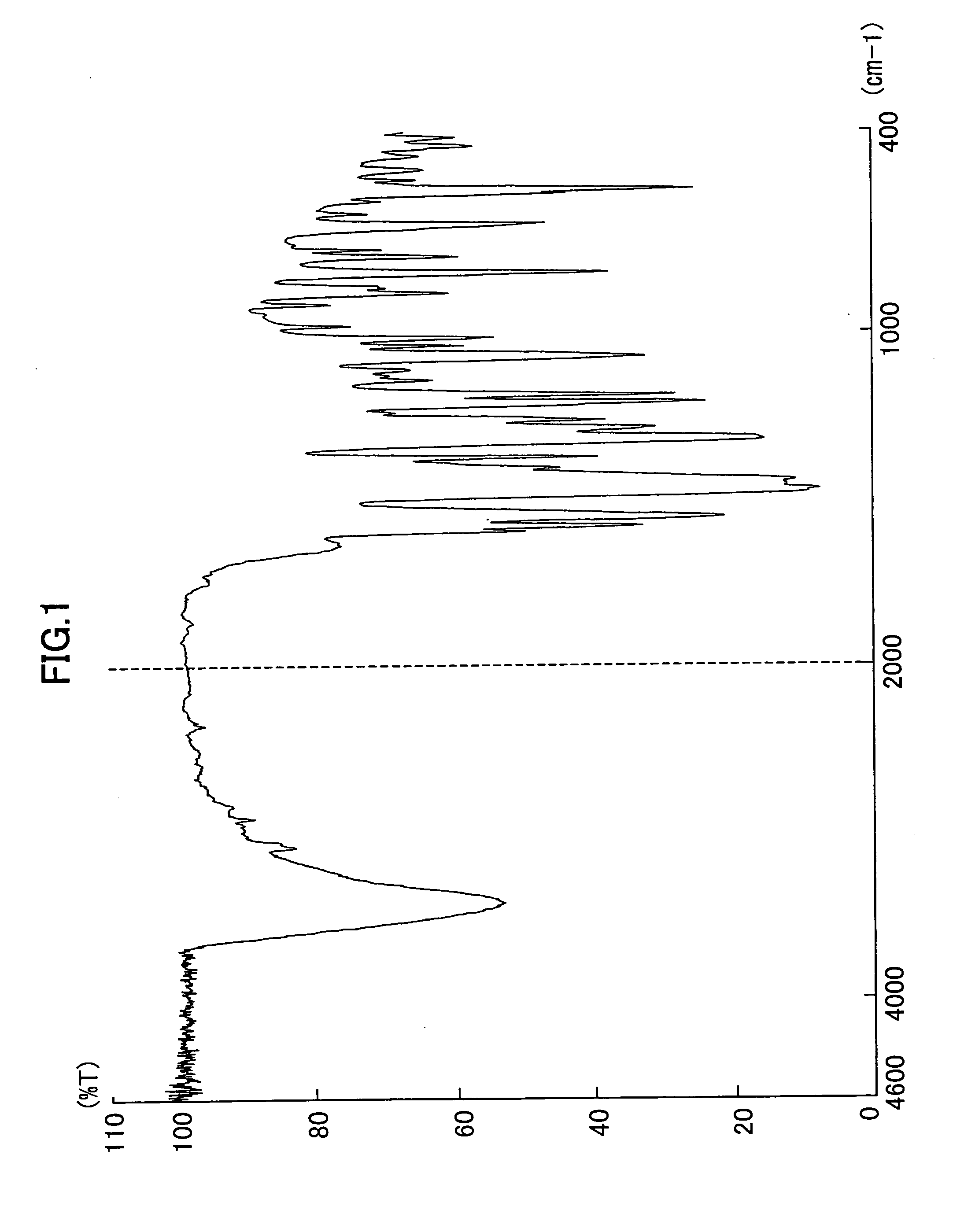

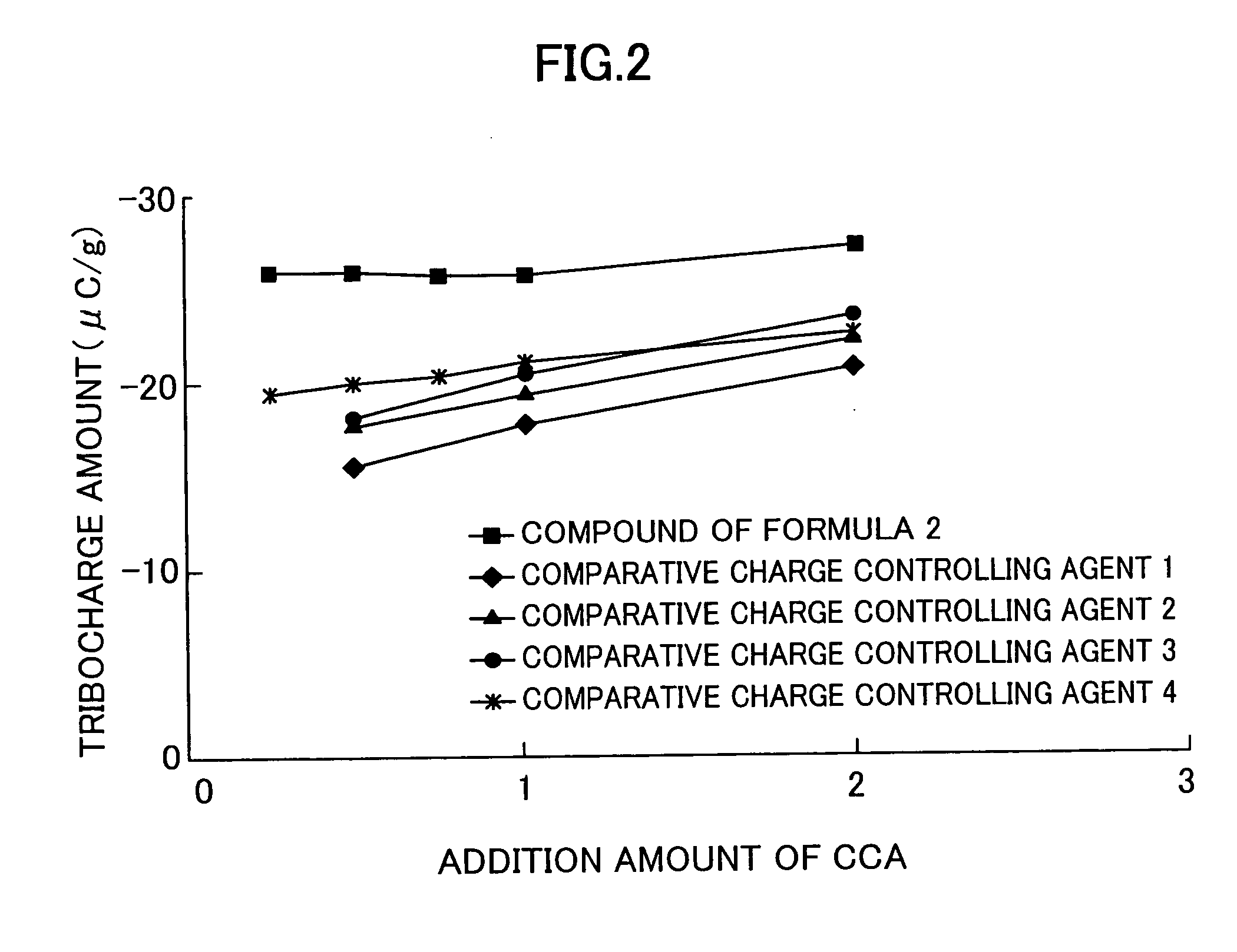

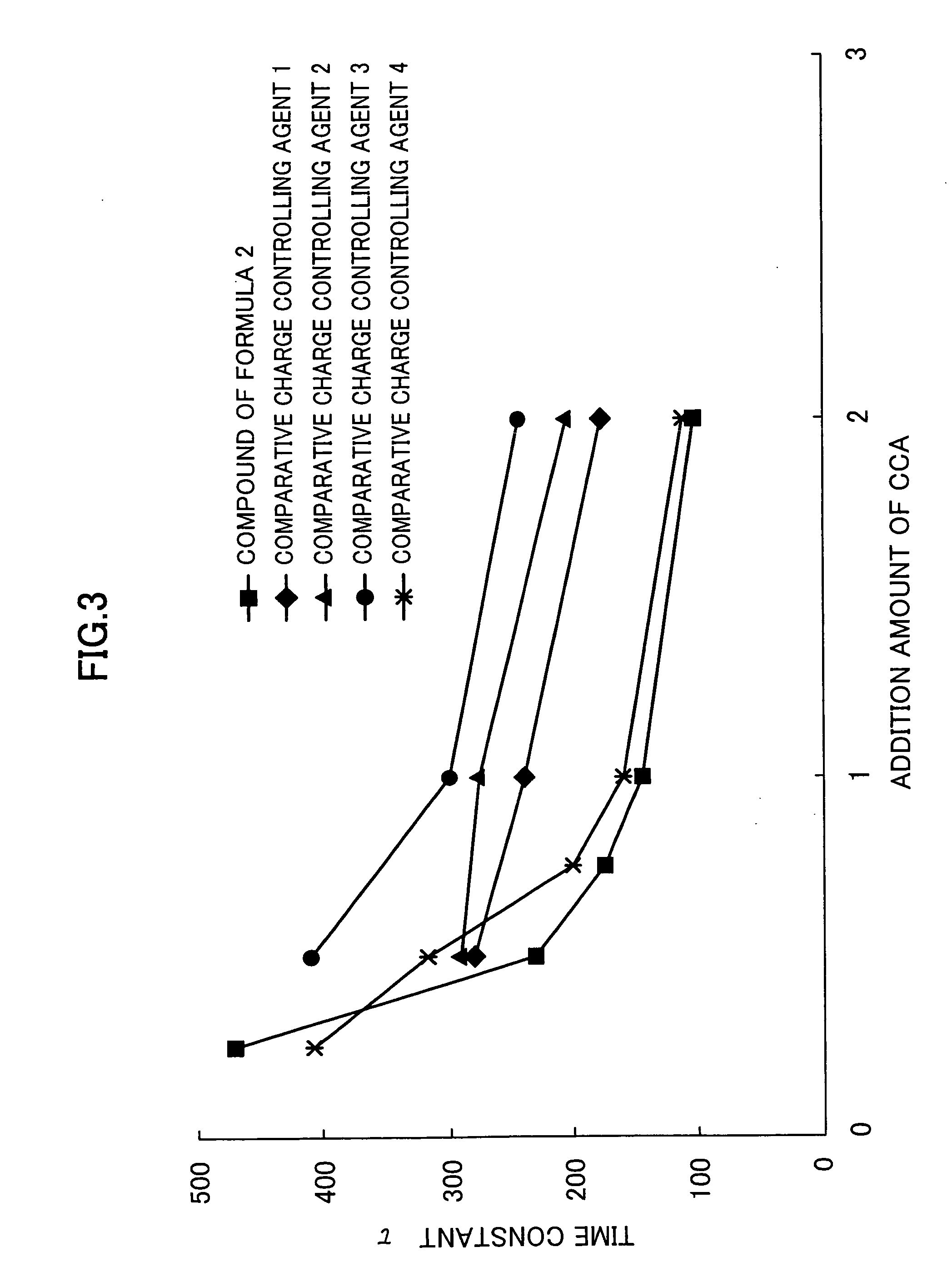

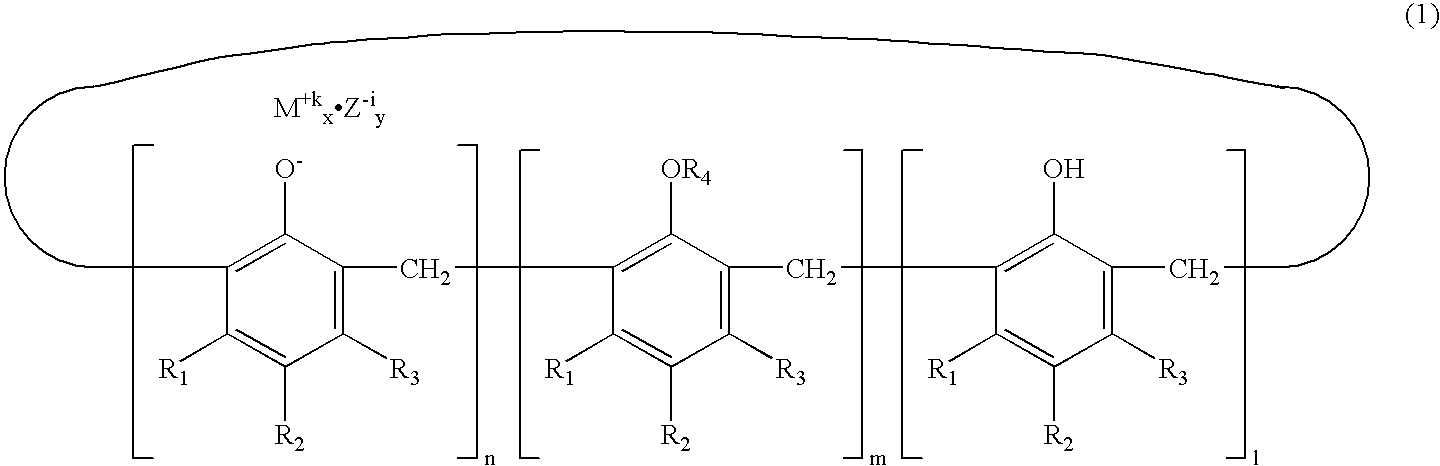

Mono azo iron complex compound, and charge controlling agent and toner using the same

ActiveUS7402369B2Easy to chargeReduce consumptionOrganic chemistryCoupling reaction in azo dyesCharge controlAlkali metal

The present invention is to provide a charge controlling agent and negatively chargeable toner that do not contain any toxic metal, are essentially free from the risk of evoking ignition or explosion, and can exhibit a high charge amount and rapid initial increase in charging.The charge controlling agent is a mono azo iron complex compound represented by Formula (1):wherein J represents H, alkali metal, ammonium, or alkyl ammonium, or two or more of those elements in combination.

Owner:HODOGOYA CHEMICAL CO LTD

Mono azo iron complex compound, and charge controlling agent and toner using the same

ActiveUS20070020547A1Easy to chargeReduce consumptionCoupling reaction in azo dyesOnium based azo dyesCharge controlAlkali metal

The present invention is to provide a charge controlling agent and negatively chargeable toner that do not contain any toxic metal, are essentially free from the risk of evoking ignition or explosion, and can exhibit a high charge amount and rapid initial increase in charging. The charge controlling agent is a mono azo iron complex compound represented by Formula (1): wherein J represents H, alkali metal, ammonium, or alkyl ammonium, or two or more of those elements in combination.

Owner:HODOGOYA CHEMICAL CO LTD

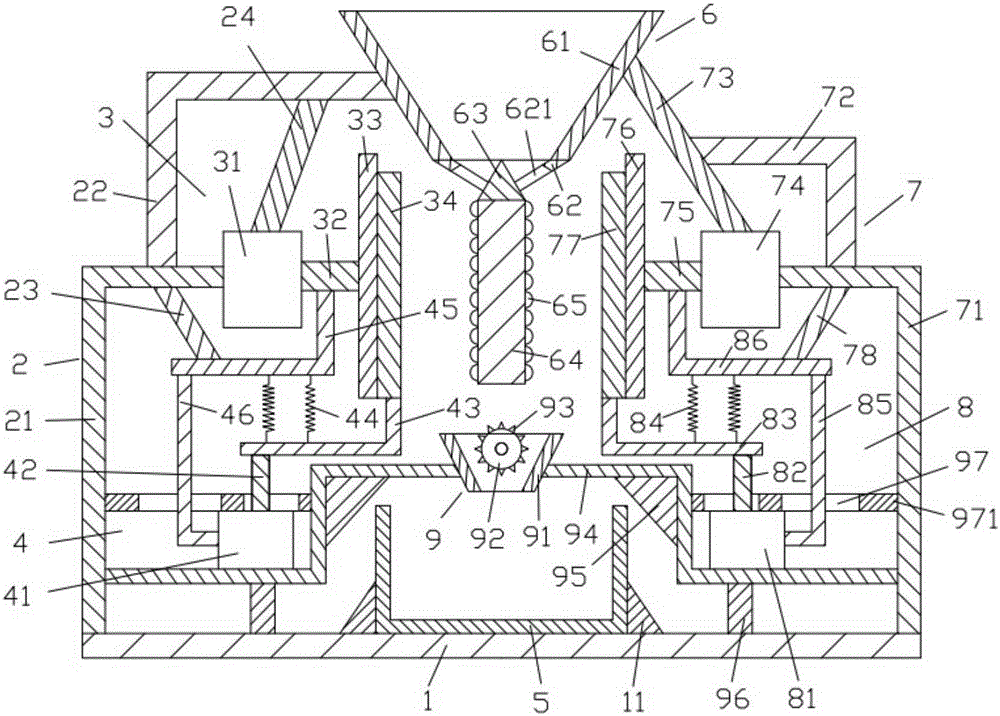

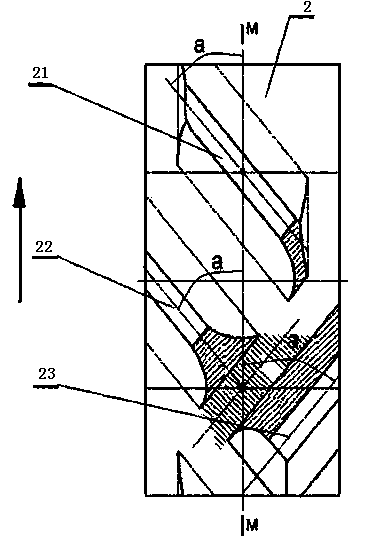

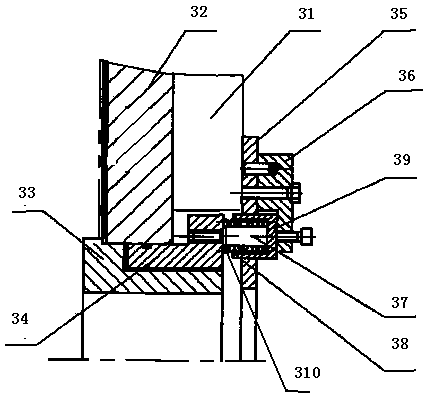

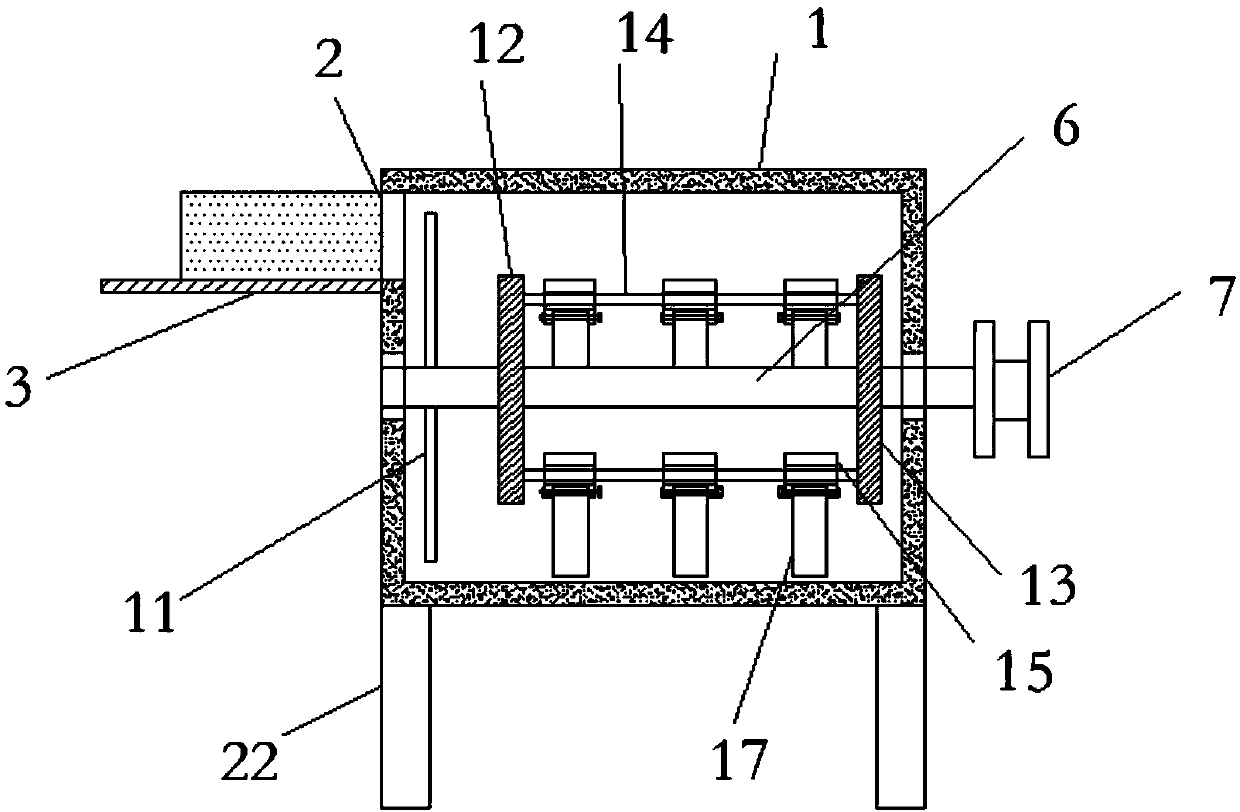

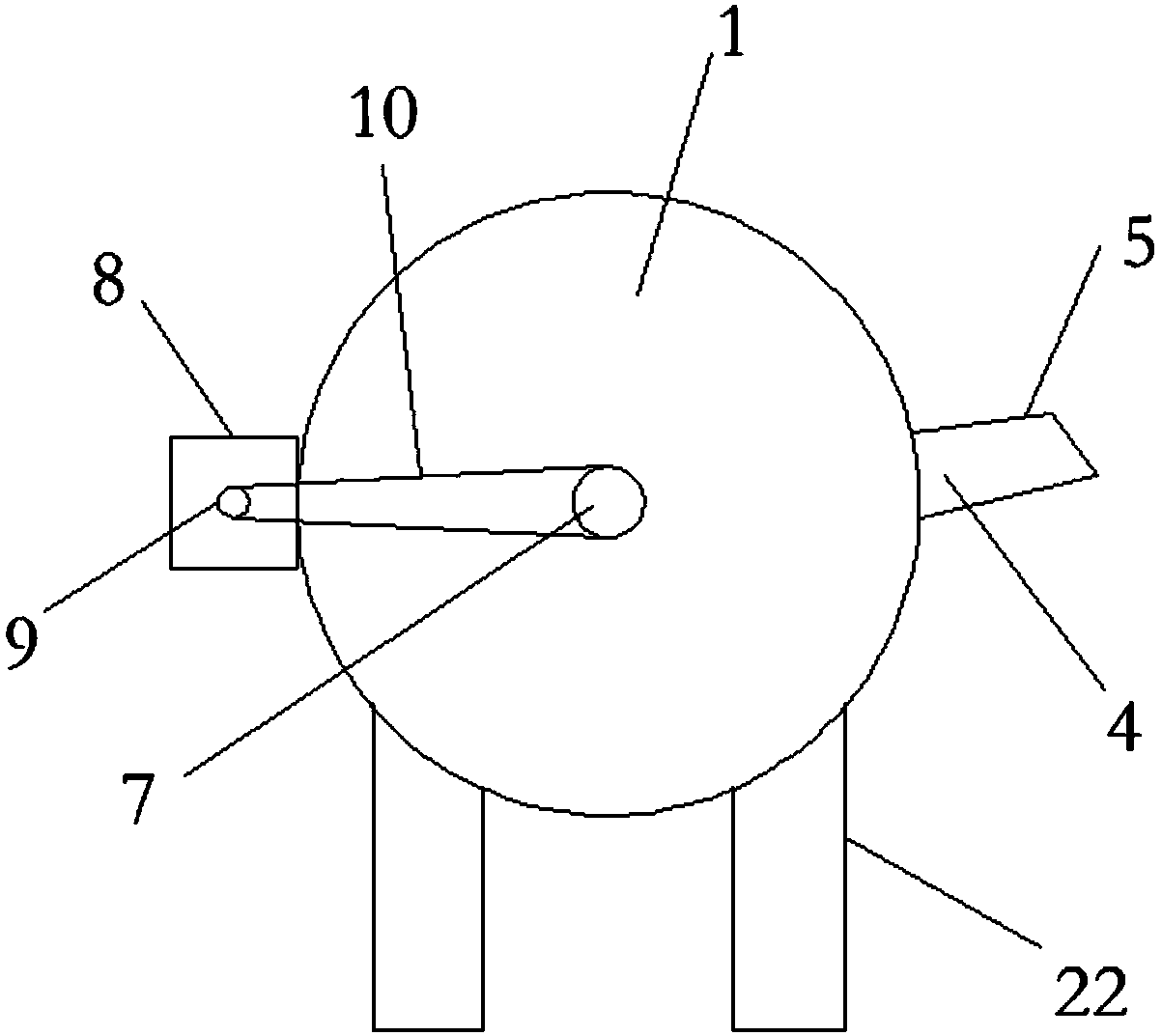

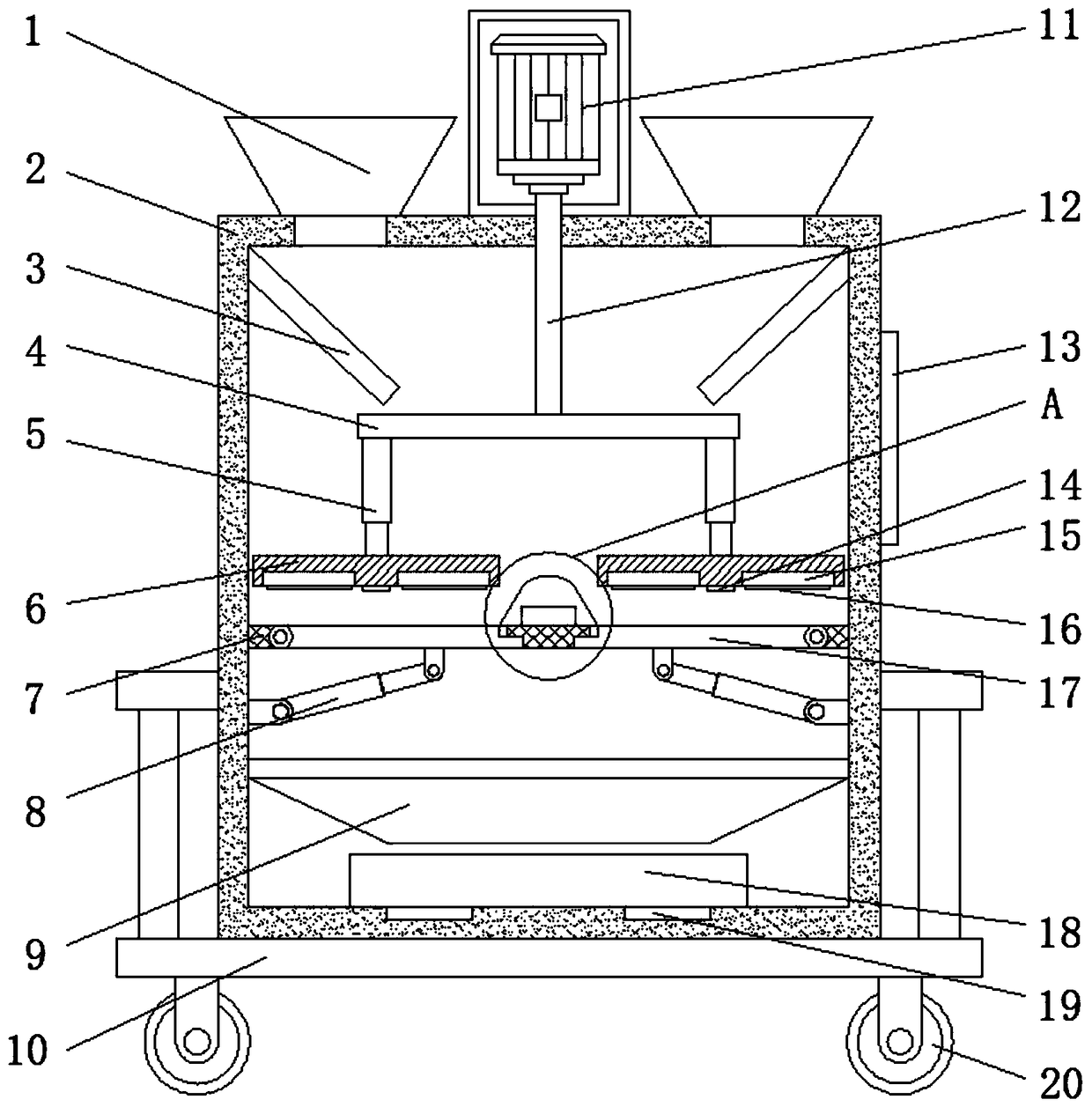

Crank type continuous dough kneading device for flour processing

InactiveCN108967459AImprove kneading efficiencyGood kneadingMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsGear wheelEngineering

The invention discloses a crank type continuous dough kneading device for flour processing. The crank type continuous dough kneading device comprises a bottom plate, a dough kneading frame, an installation frame, a rotary shaft, a gear, an incomplete gear, a first motor, an installation rod, fan-shaped collecting plates, springs, a second motor, a crank, a rod journal, a sleeve, a connection rod,a movable rod and two dough kneading balls. The crank type continuous dough kneading device is provided with the second motor, the crank, the rod journal, the sleeve, the movable rod, the dough kneading balls and the fan-shaped collecting plate, the two dough kneading balls knead dough continuously, the dough kneading efficiency is high, when the dough kneading balls move upwards, the corresponding fan-shaped collecting plates rotate upwards under the effects of springs, the dough is collected, so that dough kneading for the next time is facilitated, the dough can be further kneaded more sufficiently and uniformly, the dough kneading efficiency is improved, the first motor, the incomplete gear and the gear are arranged to intermittently drive the dough kneading frame to rotate a certain angle, so that the dough kneading balls can knead and press the different parts of the dough, thus dough kneading is more sufficient, and the dough kneading speed is increased.

Owner:CHANGSHA FENGYING MACHINERY TECH CO LTD

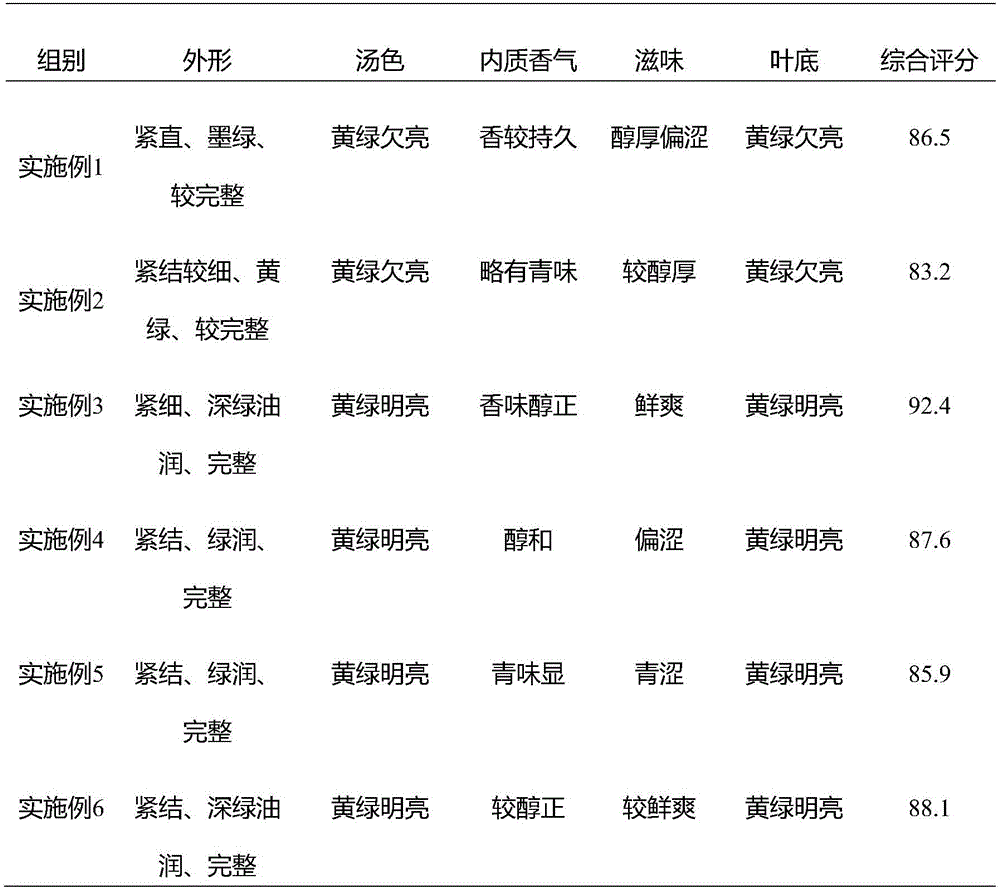

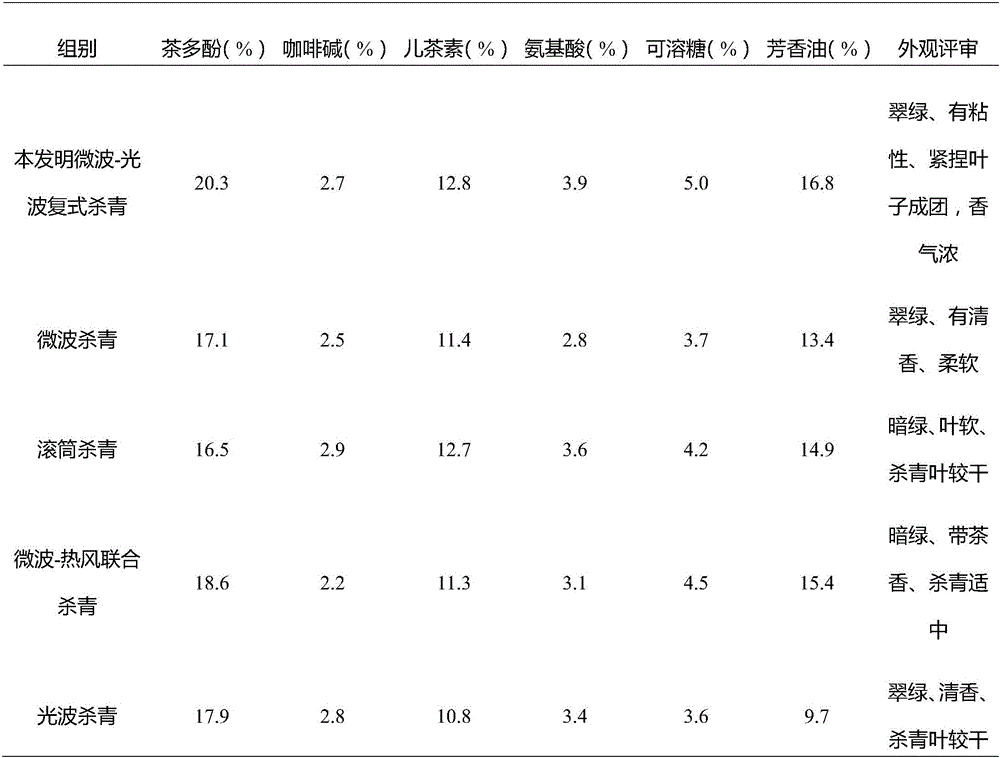

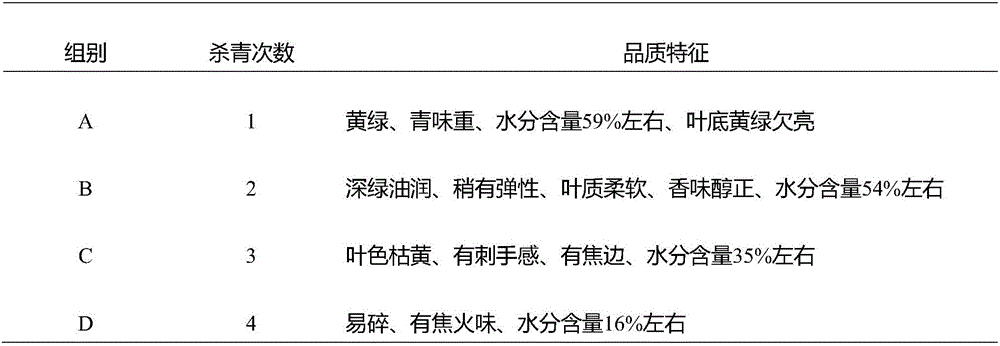

Microwave and light wave compound de-enzyme process

The invention relates to the technical field of tea processing and in particular relates to a microwave and light wave compound de-enzyme process. The microwave and light wave compound de-enzyme process comprises five processing procedures of tedding of fresh leaves, de-enzyming, twisting, secondary de-enzyming and secondary twisting; a prepared tea product has the advantages of high quality, high nutrition, fragrant flavor and delicious taste; in addition, a de-enzyme process has the advantages of high working efficiency, low energy consumption and easiness in operation.

Owner:贵州安顺春来茶业有限公司

Black tea making process

The invention discloses a black tea making process, belonging to the technical field of tea leaf processing. The black tea making process comprises the following steps: picking tea leaves, performing withering fermentation, performing primary drying, kneading, performing secondary kneading, inspecting, and delivering from a warehouse, wherein black tea to be withered is put into a withering chamber of a machine body in the withering fermentation step; the withered black tea is put into a fermentation chamber of the machine body; a variable frequency motor is powered on; a first fan and a second fan are driven to rotate by the variable frequency motor through a rotating shaft; when the fist fan is rotated, negative pressure can be formed at a rotation center; under the action of the negative pressure in the fermentation chamber, the air inside the fermentation chamber is fed into a flue and is discharged out from an air discharge hole under the action of a one-way valve; the humidity of the air inside the fermentation chamber inside the machine body is 85-95%. By adopting the scheme, the moisture of the black tea is evaporated to form high-humidity air which is conveyed into the fermentation chamber, so that no extra humidification equipment is needed in the scheme, and meanwhile the moisture of fresh black tea leaves can be effectively utilized.

Owner:GUIZHOU PROVINCE MEITAN COUNTY XINHUI TEA IND CO LTD

Straw silk rubbing machine

The invention relates to a straw silk rubbing machine. The machine comprises a silk rubbing cavity, supporting columns, a feeding port, a feed hopper, a discharge port and a discharge hopper. The supporting columns are fixed to the bottom of the silk rubbing cavity, the feeding port is formed in one side of the silk rubbing cavity, and the feeding hopper is arranged at the outer side of the feeding port; the top of the feeding hopper is fixedly connected with the outer wall of the silk rubbing cavity, the discharge port is formed in the side, perpendicular to the feeding port, of the silk rubbing cavity, and the discharge hopper is arranged at the outer side of the discharge port; the top of the discharge hopper is fixedly connected with the outer wall of the silk rubbing cavity, a rotation motor is fixed to the side, away from the discharge port, of the silk rubbing cavity, and an output end of the rotation motor is fixedly connected with a second belt plate; a rotor is arranged in the silk rubbing cavity, two ends of the rotor are rotatably connected with the silk rubbing cavity through bearings, and the end, away from the feeding port, of the rotor penetrates through the silk rubbing cavity and is fixedly connected with a first belt plate. According to the straw silk rubbing machine, straw which enters the feeding port is divided into straw segments of equal length through across blade, and the straw is subjected to silk rubbing conveniently.

Owner:建始惠万农生物科技有限公司

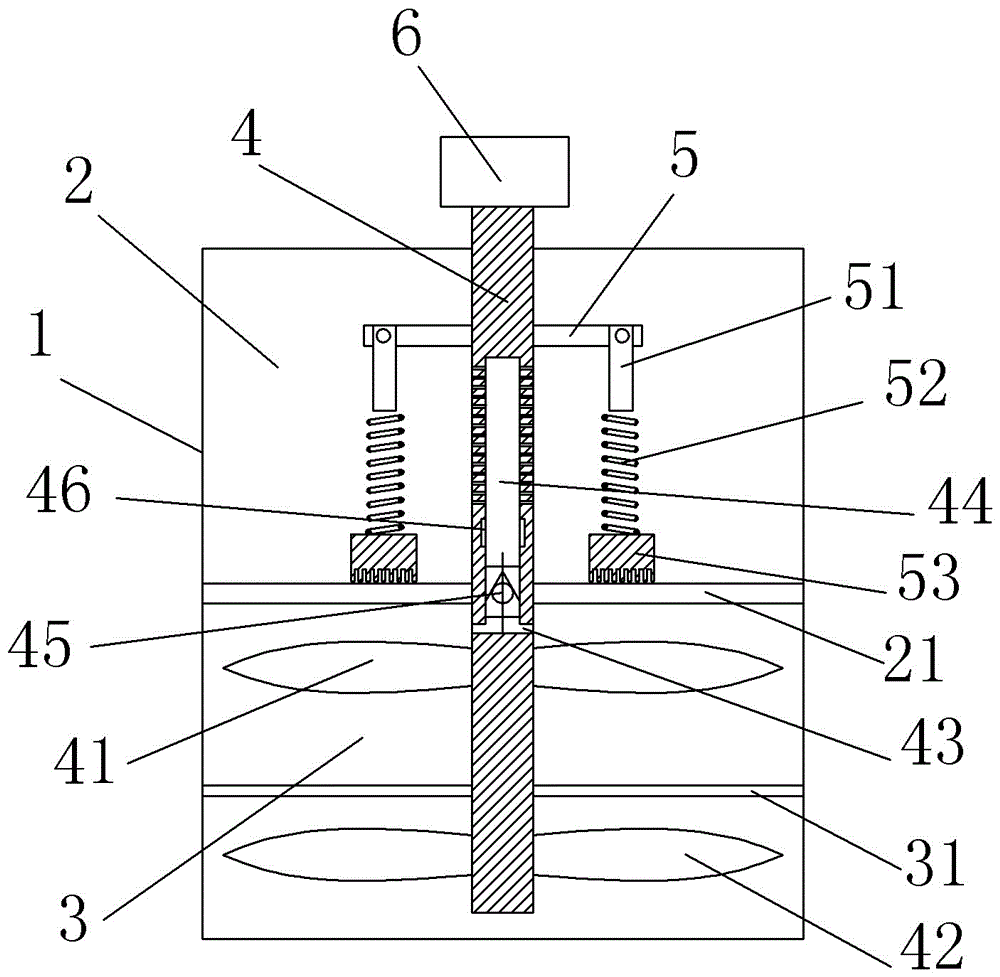

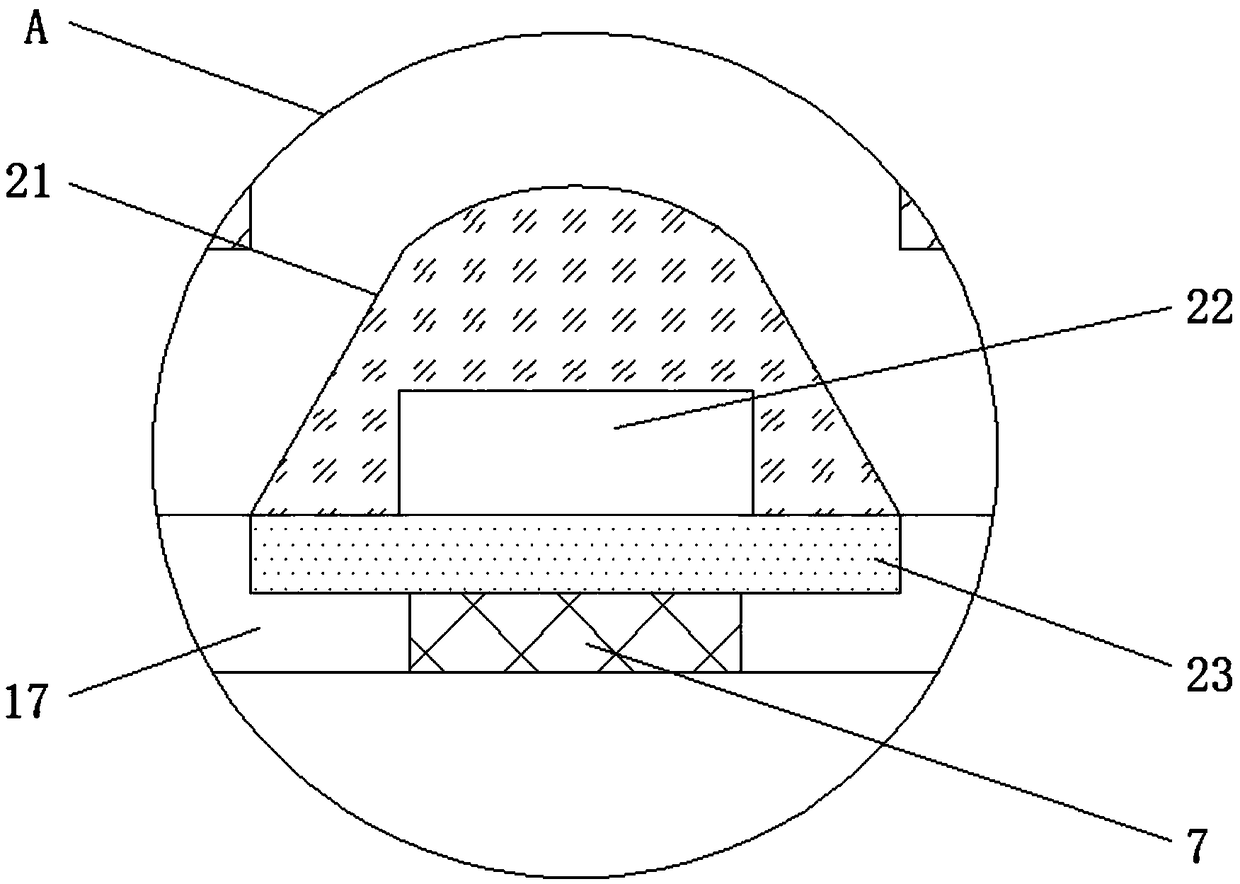

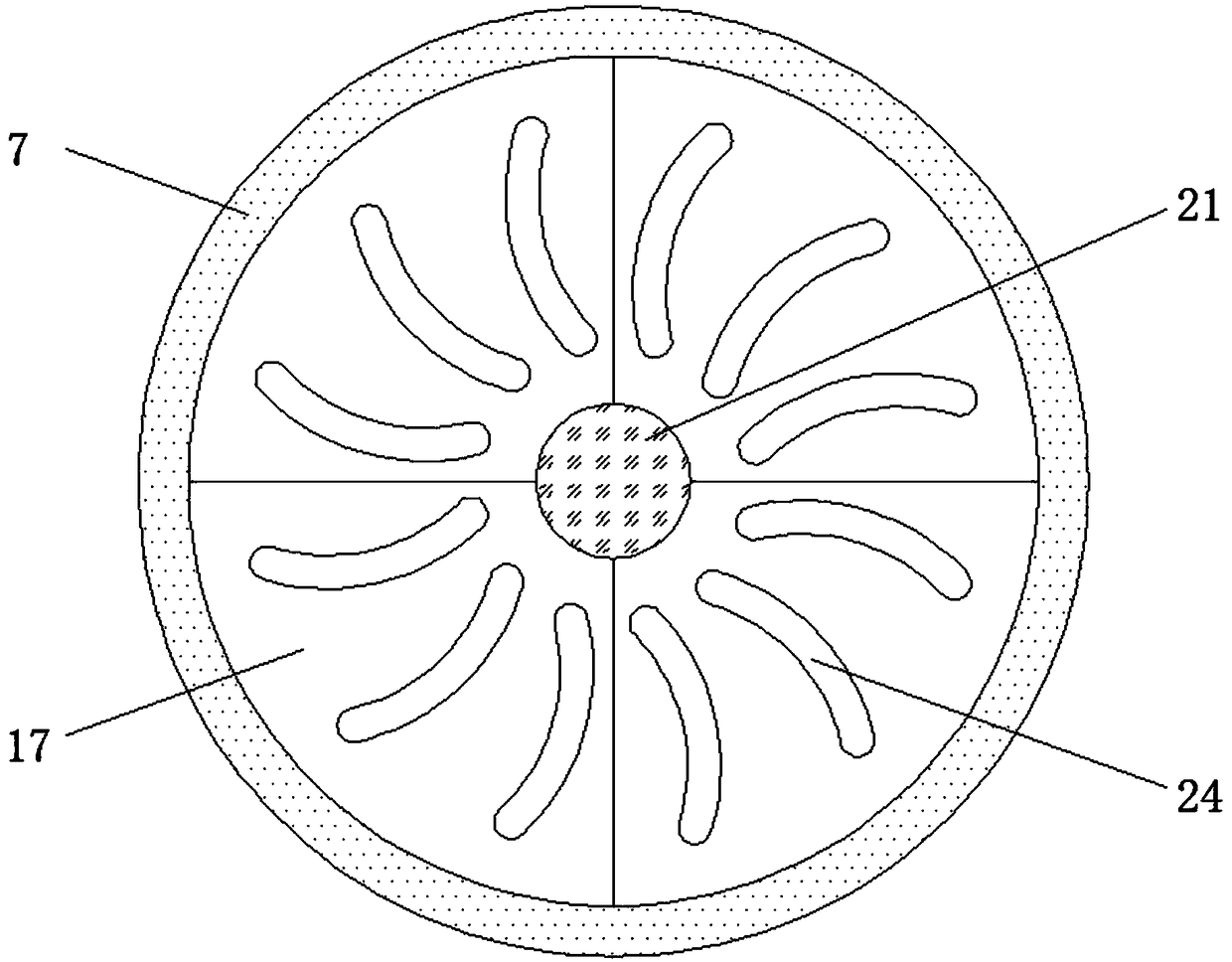

Rolling equipment for tea production

InactiveCN109221505AGood kneadingIncrease the use heightPre-extraction tea treatmentEngineeringRolling disk

The invention discloses rolling equipment for tea production. The rolling equipment comprises filling hoppers, a processing box and a fixed frame; the top of the fixed frame is provided with the processing box, and the top of the processing box is provided with the filling hoppers; a servo motor is mounted between the filling hoppers, and the output end of the servo motor extends to the inside ofthe processing box and is provided with a rotating shaft; one end of the rotating shaft is provided with a fixed rod; each of two ends of the bottom of the fixed rod is provided with a first electrictelescopic rod; the output end of the first electric telescopic rod is provided with a rolling seat; the center of the inside of the processing box is provided with a rolling disk below which a collecting hopper is mounted; and a collecting box is mounted below the collecting hopper. The rolling equipment is provided with the filling hoppers, the processing box and the fixed frame, and the bottomend of the inside of each rolling seat above first rolling teeth is uniformly provided with heating blocks, so that the heating blocks are convenient to electrify to heat and roll tea, and increase ofthe rolling way of the device and improvement of the applicability of the device are facilitated.

Owner:湖北孟宗生态茶叶有限公司

Processing method of green tea

The invention discloses a processing method of green tea in the field of tea processing. The processing method of the green tea comprises the following steps: 1, selecting materials: selecting tea with a single bud or one bud and one leaf; 2, drying: drying the picked tea by a microwave vacuum drying technology until the water content is 45 to 48 percent, wherein the vacuum degree is 0.085 to 0.1 Mpa and the microwave power is 1 to 2 kw; 3, rolling: spraying coconut juice on the surface of the dried tea uniformly, putting the tea into a rolling machine to roll, and during rolling, rolling the tea by a heavy rolling mode for 4 to 5 minutes, spraying the coconut juice on the surface of the tea for the second time and then rolling the tea by a light rolling mode for 8 to 10 minutes; 4, drying: drying the rolled tea until the water content is 40 to 42 percent; 5, enhancing fragrance: putting the dried tea into a fragrance enhancing machine and enhancing fragrance until the water content is 7 to 8 percent, wherein the fragrance enhancing temperature is 220 to 230 DEG C. According to the scheme, the processing process is optimized, so that the prepared green tea has rich taste, and the bitterness is reduced.

Owner:务川自治县雾青茶业有限公司

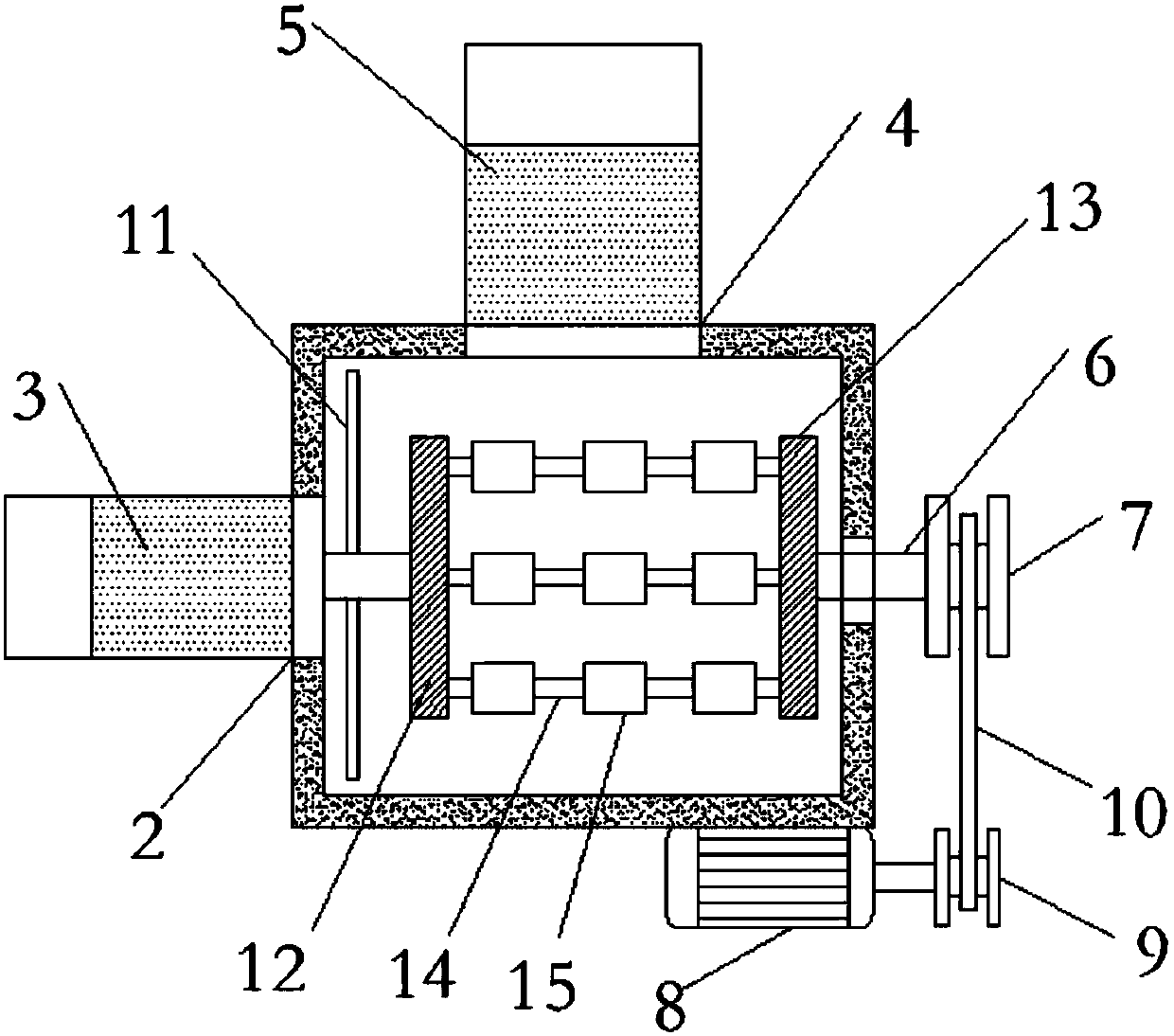

Novel multifunctional dough kneading machine

InactiveCN108522574AImprove the effect of kneadingImprove kneading efficiencyMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsHydraulic cylinderWater storage tank

The invention discloses a novel multifunctional dough kneading machine. The dough kneading machine comprises a rack, a supporting plate and an electric hydraulic cylinder, wherein the output end of the electric hydraulic cylinder is connected with a dough hammer through a connecting rod; a dough kneading tank is formed right under the dough hammer; a rotating plate is arranged on the supporting plate, and the dough kneading tank is fixedly arranged on the rotating plate; a heat device is arranged on the outer wall of the lower part of the dough kneading tank; and a material storage tank with ascale is arranged on one side of the rack, and a discharge pipe is connected with the bottom of the material storage tank and is arranged in an inclined manner; a water storage tank with a scale is arranged on one side of the rack, and a water outlet pipe is connected with the bottom of the water storage tank and is arranged in an inclined manner. The novel multifunctional dough kneading machinecan realize operation of automatic water adding and automatic flour adding in the dough kneading process, can perform automatic heating in the dough kneading process according to requirements, does not need more labor force, can perform quantitative flour and water adding to facilitate dough kneading operation, and is simple in structure, convenient to operate and high in practicality.

Owner:SICHUAN XIONGJIAN IND

Dough kneading device for bread processing

InactiveCN112042689AQuality improvementEasy to kneadMixing/kneading structural elementsMixing/kneading with horizontally-mounted toolsBiotechnologyReciprocating motion

The invention discloses a dough kneading device for bread processing, and relates to the technical field of food processing devices. The device comprises a supporting base and a dough kneading box, wherein a supporting plate is fixedly arranged above the dough kneading box, a grinding box is arranged on the upper surface of the supporting plate, a grinding groove is formed in the grinding box, grinding rollers are arranged in the grinding groove, a screen is arranged below the grinding groove, screw rods are arranged on the upper surface of a bottom plate, nuts are arranged on the surfaces ofthe screw rods, the nuts are fixedly connected with a second driving motor, the second driving motor is connected with a rotating rod, and stirring blades are symmetrically arranged on the upper sideand the lower side of the rotating rod. According to the method, the grinding rollers rotate inwards at the same time to grind flour, so that solid particles bonded in the flour are fully scattered; apiston cylinder conveys water to a water conveying pipe and a spray head through a water inlet pipe, and the spray head sprays the water into the dough kneading box; the nuts drive the rotating rod to do reciprocating motion in the dough kneading box in the vertical direction, and the rotating rod drives the stirring blades and stirring rods to rotate; and the automation degree is high, and the dough kneading quality is improved by pre-grinding the flour.

Owner:GANZHOU LIANGHUA FEIER SNOW FOOD CO LTD

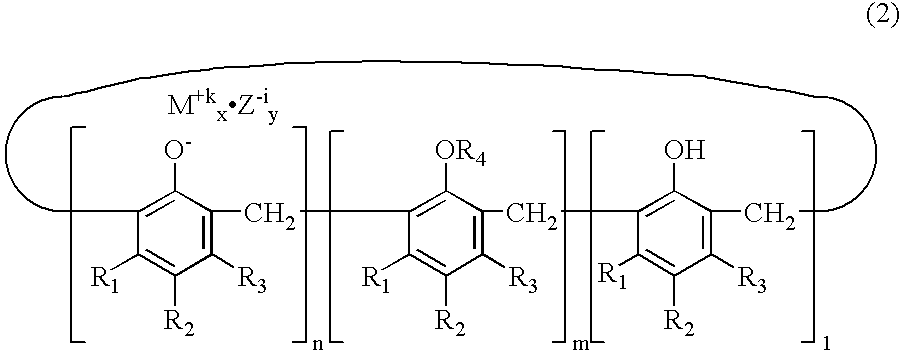

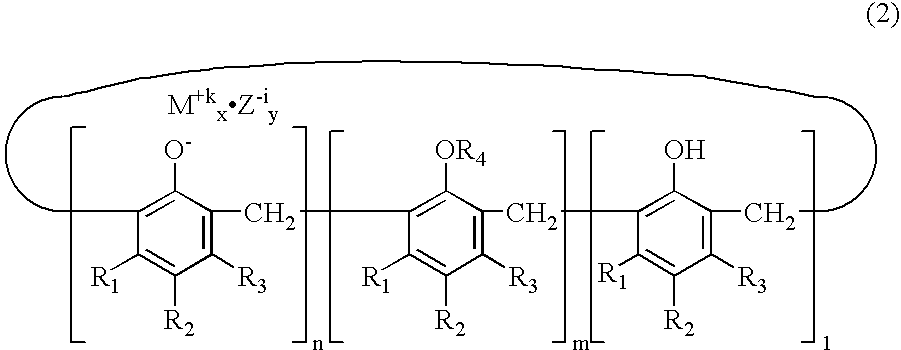

Resin additive composition and process for producing the same

InactiveUS7052630B2Control contentGood kneadingOther chemical processesMixing methodsPolyolefinWater soluble

In this application is disclosed a resin additive composition which can by produced by precipitating a calix(n+m+l)arene represented by the following general formula (2) and in a dissolved state together with or at the same time at least one functional ingredient selected from the group consisting of various water-soluble or hydrophilic resin flam-retardants, resin thermal stabilizers and resin curing agents, and in a dissolved or suspended state.This resin additive composition has a good affinity for organic polymers such as polyolefin and the like, which allows the functional ingredient(s) to be dispersed homogeneously in the resin. Therefore are provided high-performance resin compositions comprising various functional ingredient(s).

Owner:AJINOMOTO CO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com