Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Increased geometric surface area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

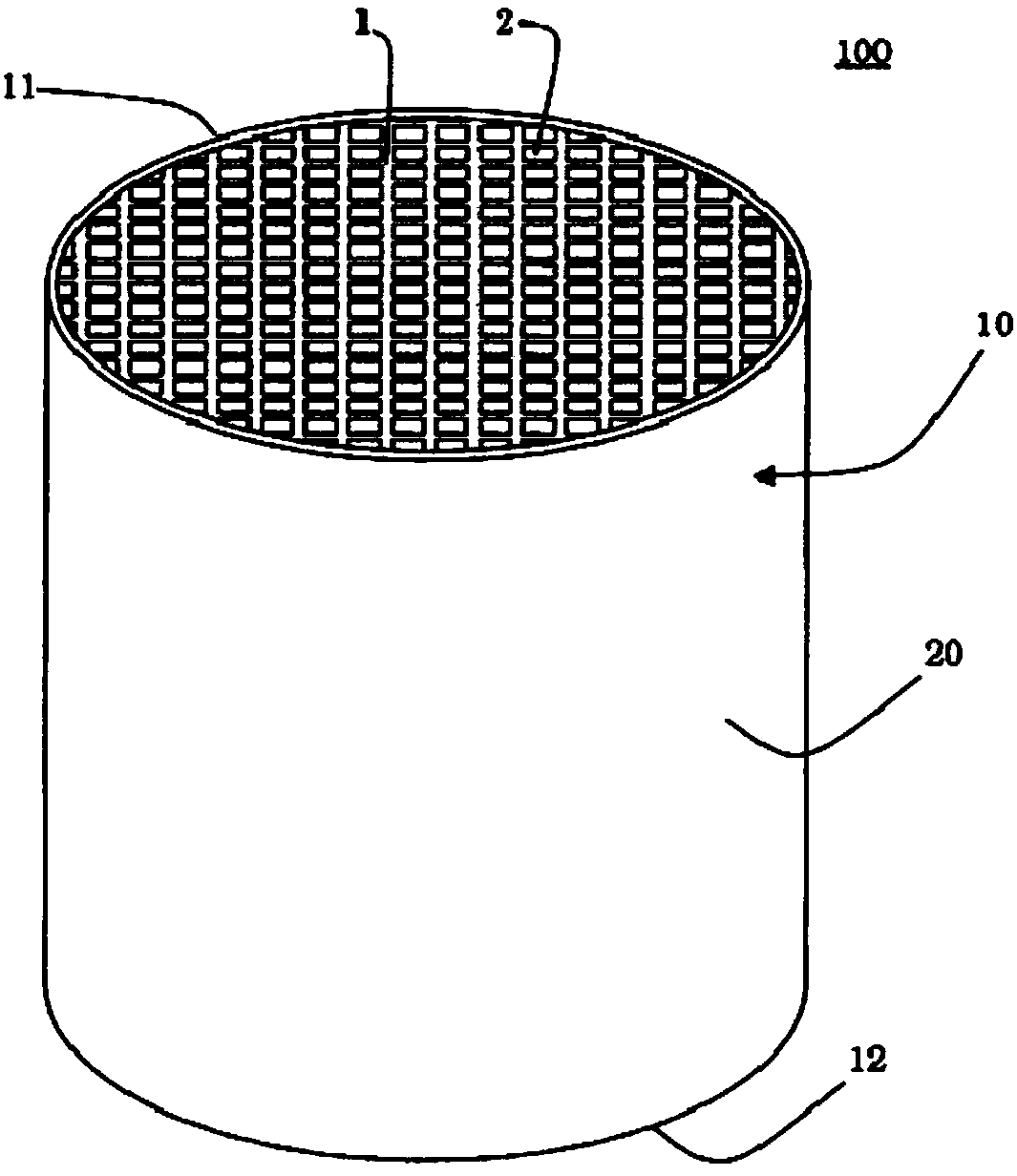

Silicon carbide porous ceramic filter and manufacturing method thereof

The invention relates to a silicon carbide porous ceramic filter and a manufacturing method thereof, in particular to a filter material for high-temperature liquid or gaseous fluid. The ideal silicon carbide porous ceramic filter has the advantages of gradient pore structure, low sintering temperature, high use temperature, high porosity factor, low pressure drop, large geometric surface area, zigzag flow path, high intensity, long service life, low production cost, easy regeneration and repeated use. Moreover, the filter is formed by compounding and sintering a plurality of layers of ceramic materials of different pore structures, and comprises a main body billet layer, a transition compound film layer and a surface compound film layer. Therefore, the filter is suitable for filtration and purification of various high-temperature and low-temperature fluids such as molten metal, high-temperature flue gas, coking gas and automobile exhaust.

Owner:淄博鑫拓耐火材料有限公司

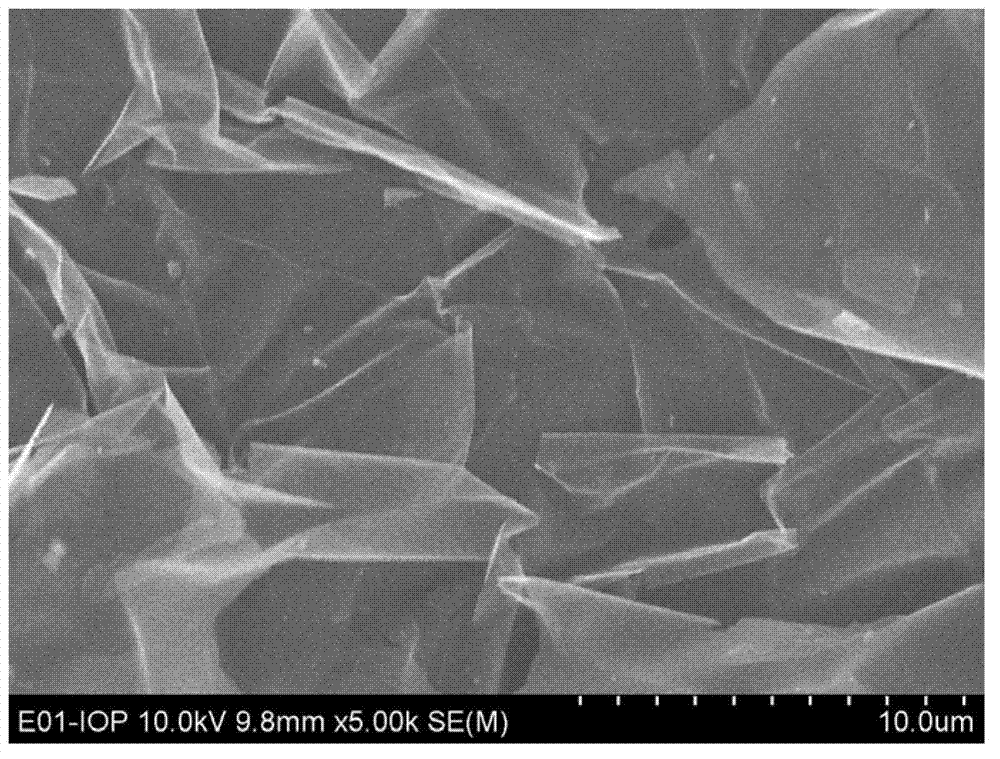

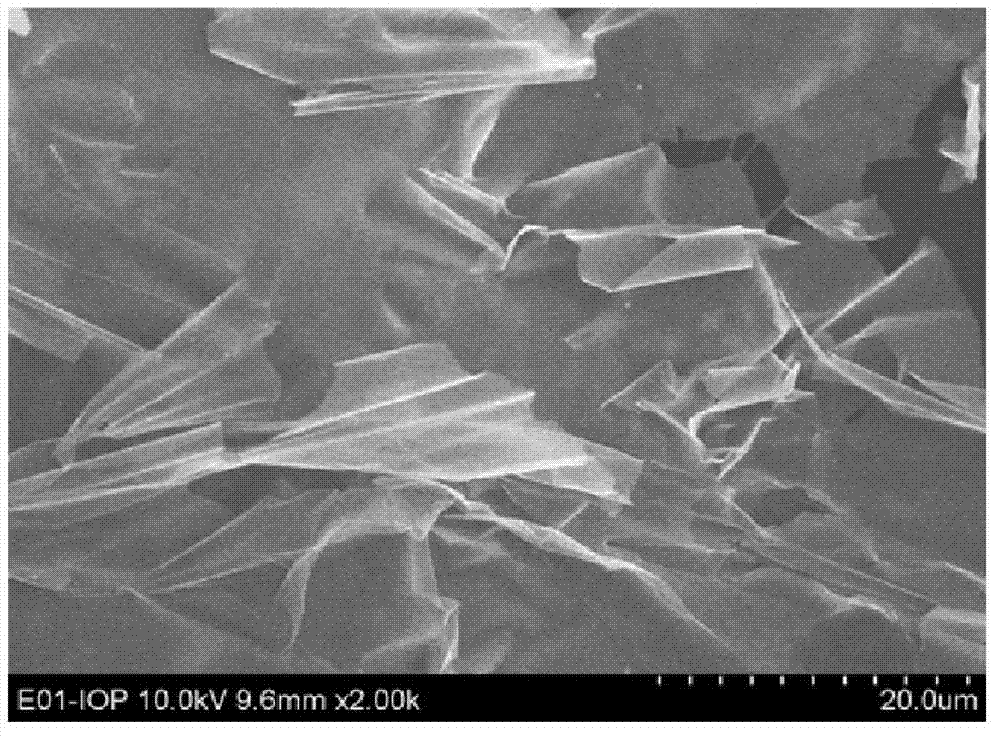

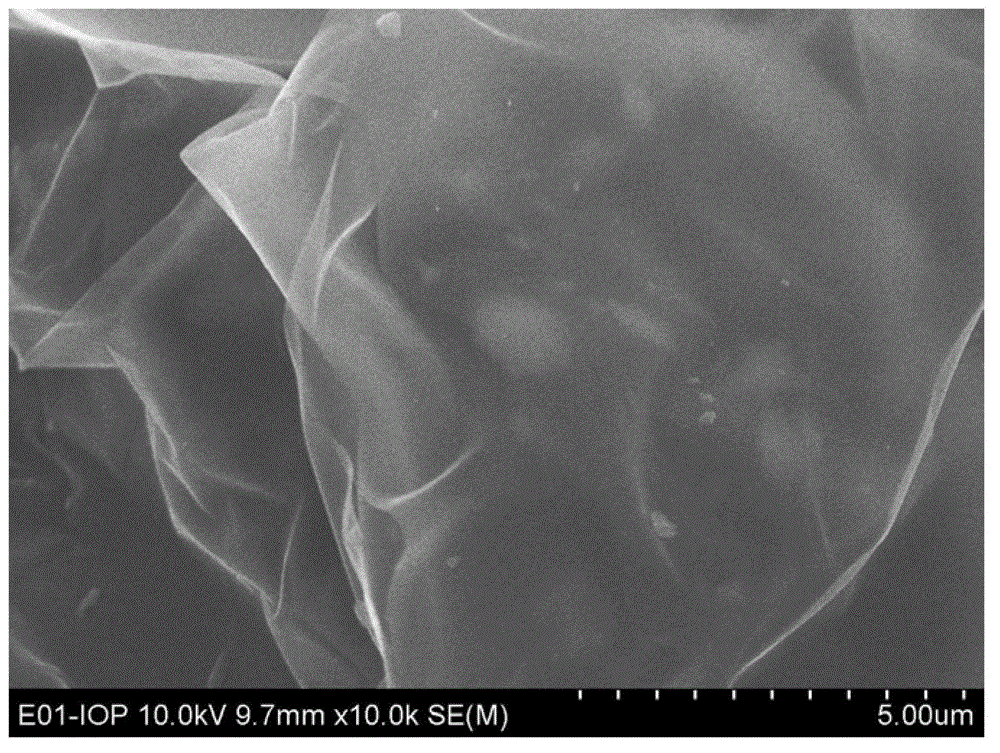

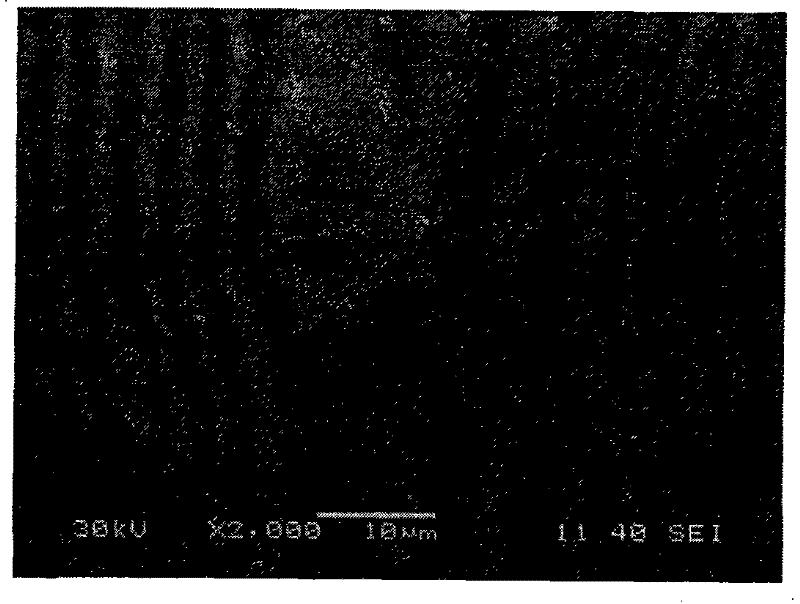

Pyrolytic hard charcoal material and preparation method and use thereof

ActiveCN102956876AIncreased geometric surface areaImprove performanceElectrolytic capacitorsCell electrodesSorbentToxic material

The invention provides a pyrolytic hard charcoal material and a preparation method and a use thereof. The pyrolytic hard charcoal material is a two dimensional plane-similar sheeting material which is formed by pyrolysing a precursor of the hard charcoal, wherein the average thickness is 1-200nm and the geometric surface area is 10-2000 square meter / g. Micropores or mesopores exist in the pyrolytic hard charcoal material. The invention further provides a method of the pyrolytic hard charcoal material. The sheet pyrolytic hard charcoal material similar to graphene in shape is extremely wide in application and can be applied to preparing a cathode material of a lithium ion battery or a sodium ion battery, an electrode material of an electrochemical capacitor, a carrier for a fuel cell and a metal air battery electrode catalyst, a composite material with great toughness effect, a toxic material absorbent, an absorbent for special use, and a decolorising agent and a gas sensitive element in food production.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Sulfureous resistant four-effect catalyst for purifying tail gas of vehicle

InactiveCN101269335AImprove sulfur resistanceEffect of catalytic efficiencyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsEmission standardAutomotive emissions

The invention relates to an anti-sulfur four-way catalyst which is provided with optimal performance and used for purifying automobile exhaust. First, a glass coating solution is prepared, then a metal alloy carrier is repeatedly immerged into the glass coating solution for coating, drying, calcinating so as to get the glass coating on the carrier, then the glass coating is repeatedly immerged into a mixed solution composed of titanium and zirconium salts and into a precious metal catalyst solution; after being baked and calcinatied, the anti-sulfur four-way catalyst which is provided with optimal performance and used for purifying automobile exhaust and takes the alloy metal as a carrier is obtained. The four-way catalyst of the invention has the following advantages that: (1) PM and NOx are catalyzed on the same catalytic bed; (2) the catalytic efficiency is not affected if the concentration of SO2ranges from 500 to 800ppm; (3) compared with other catalysts, the catalyst has high anti-sulfur performance and takes metal as the carrier. Besides, the catalyst can ensure an engine meeting the emission of European III in a laboratory, a bench experimental testing and application to meet the requirements for emission standards above European IV.

Owner:JILIN UNIV

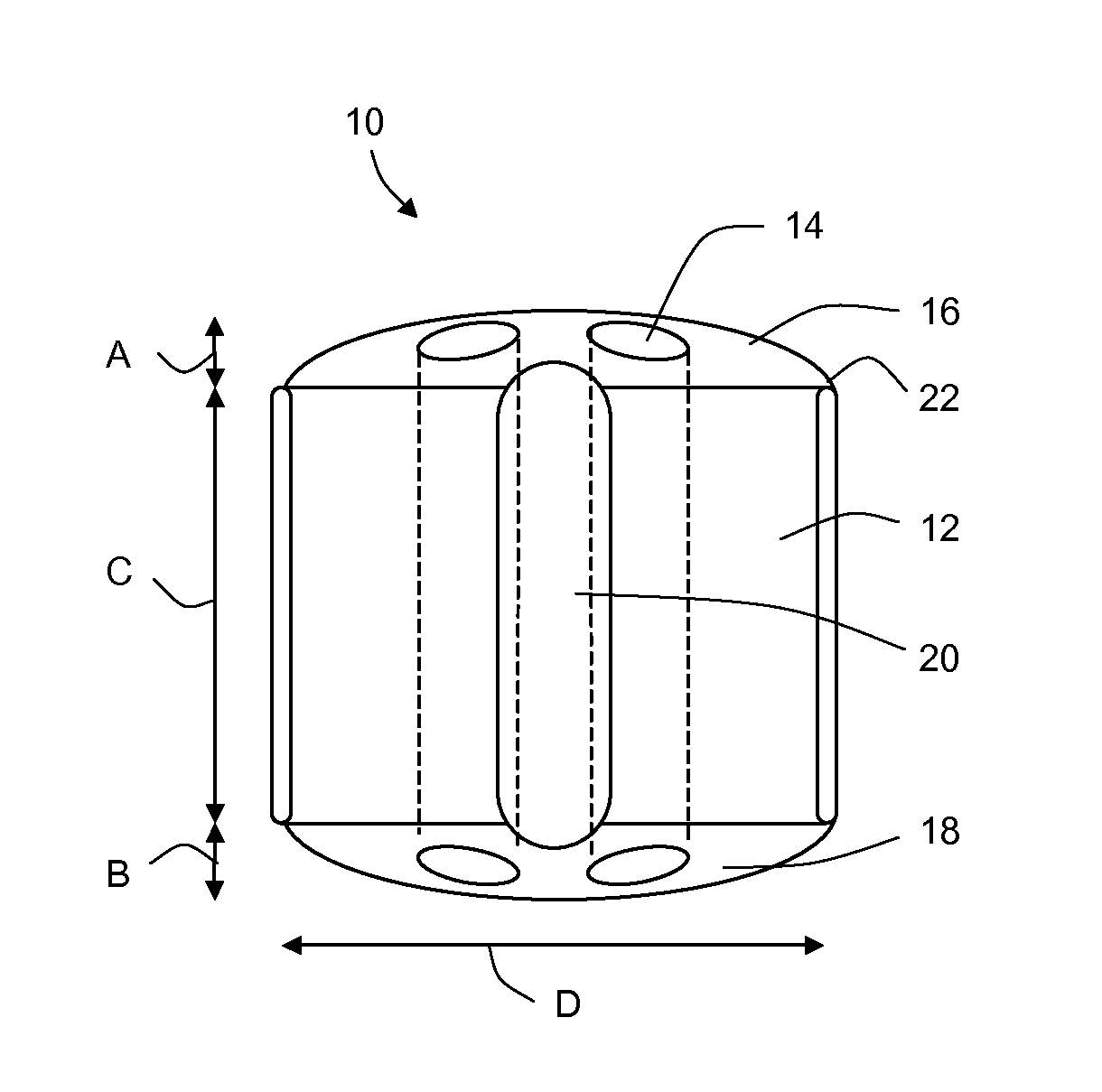

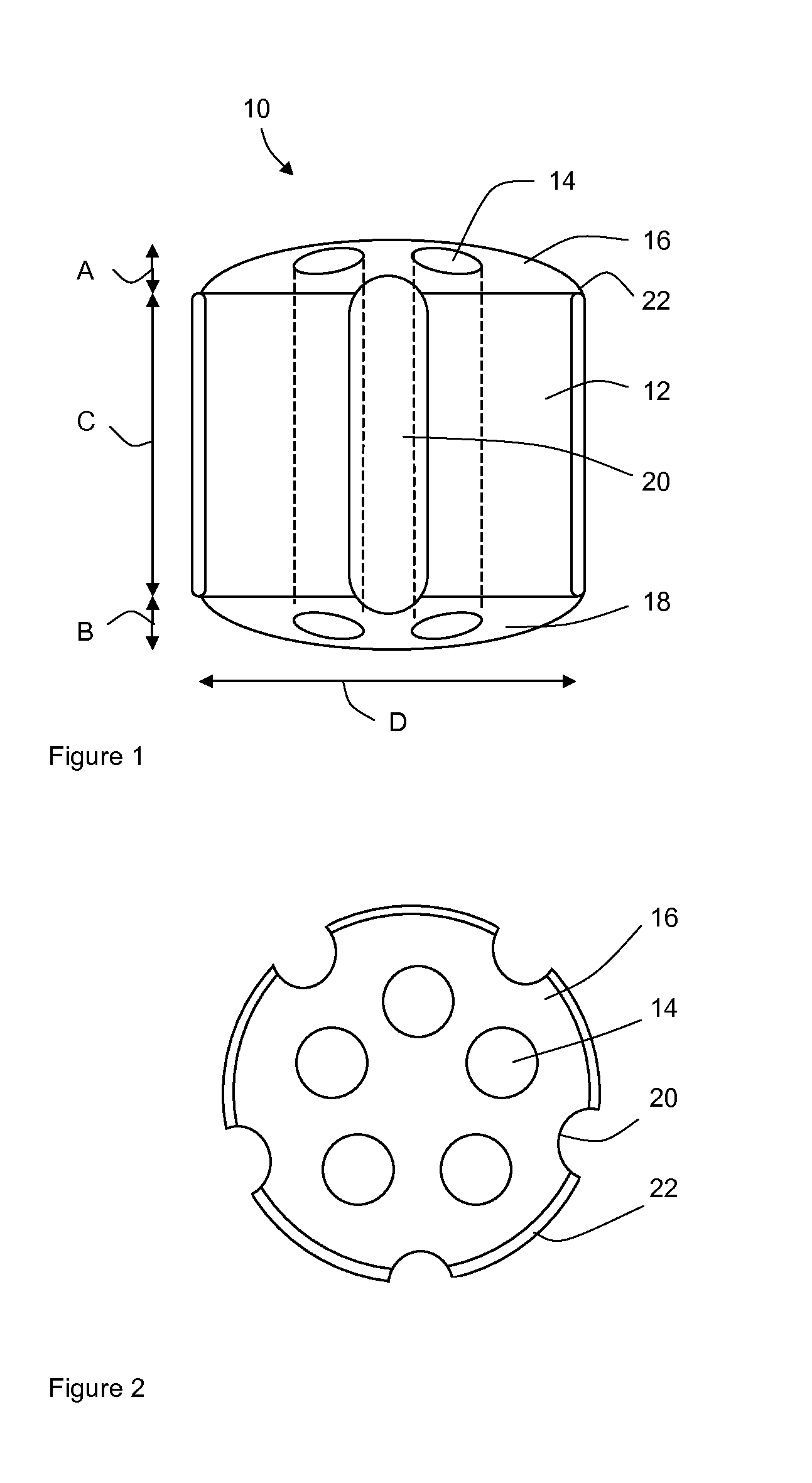

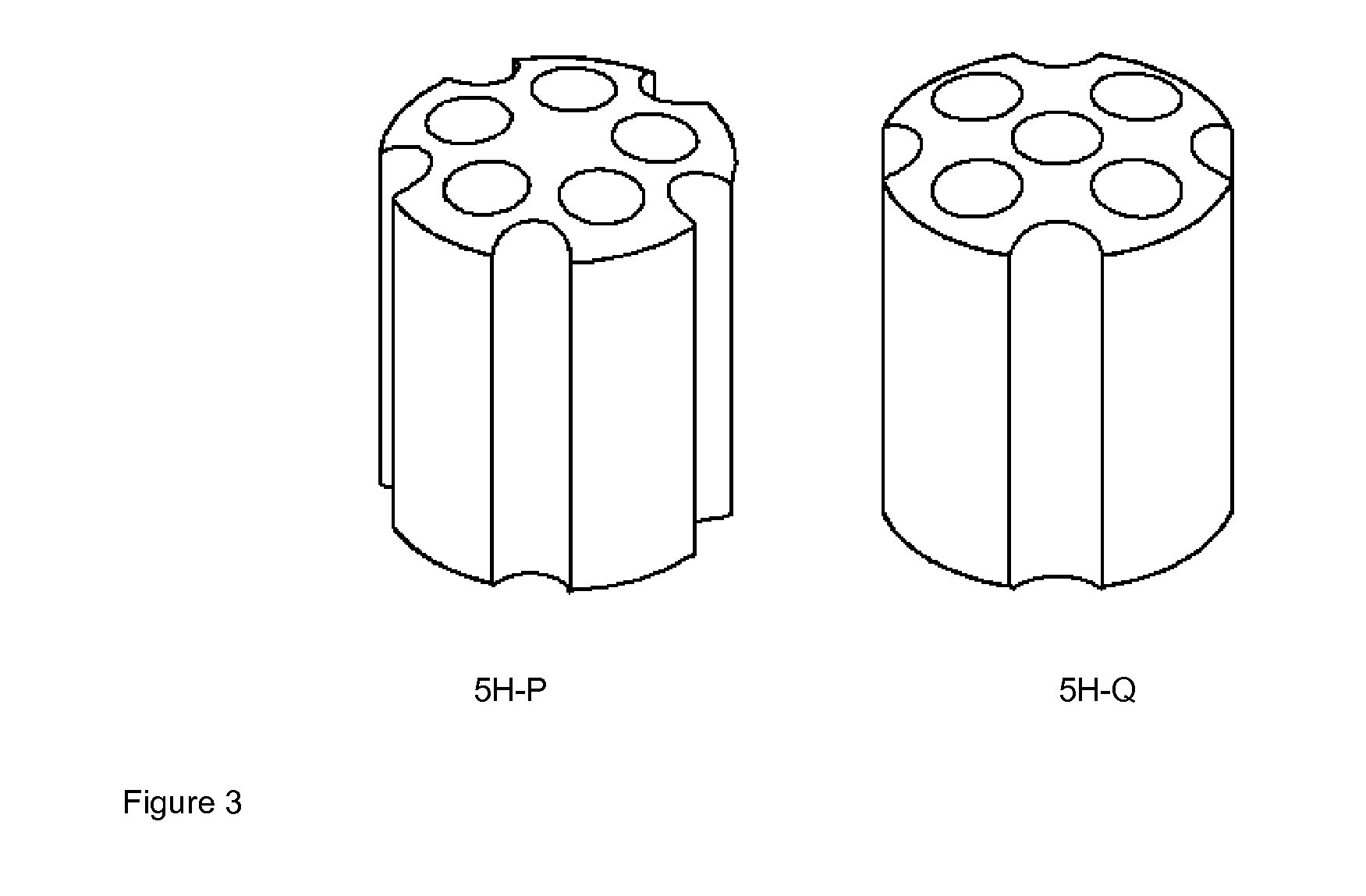

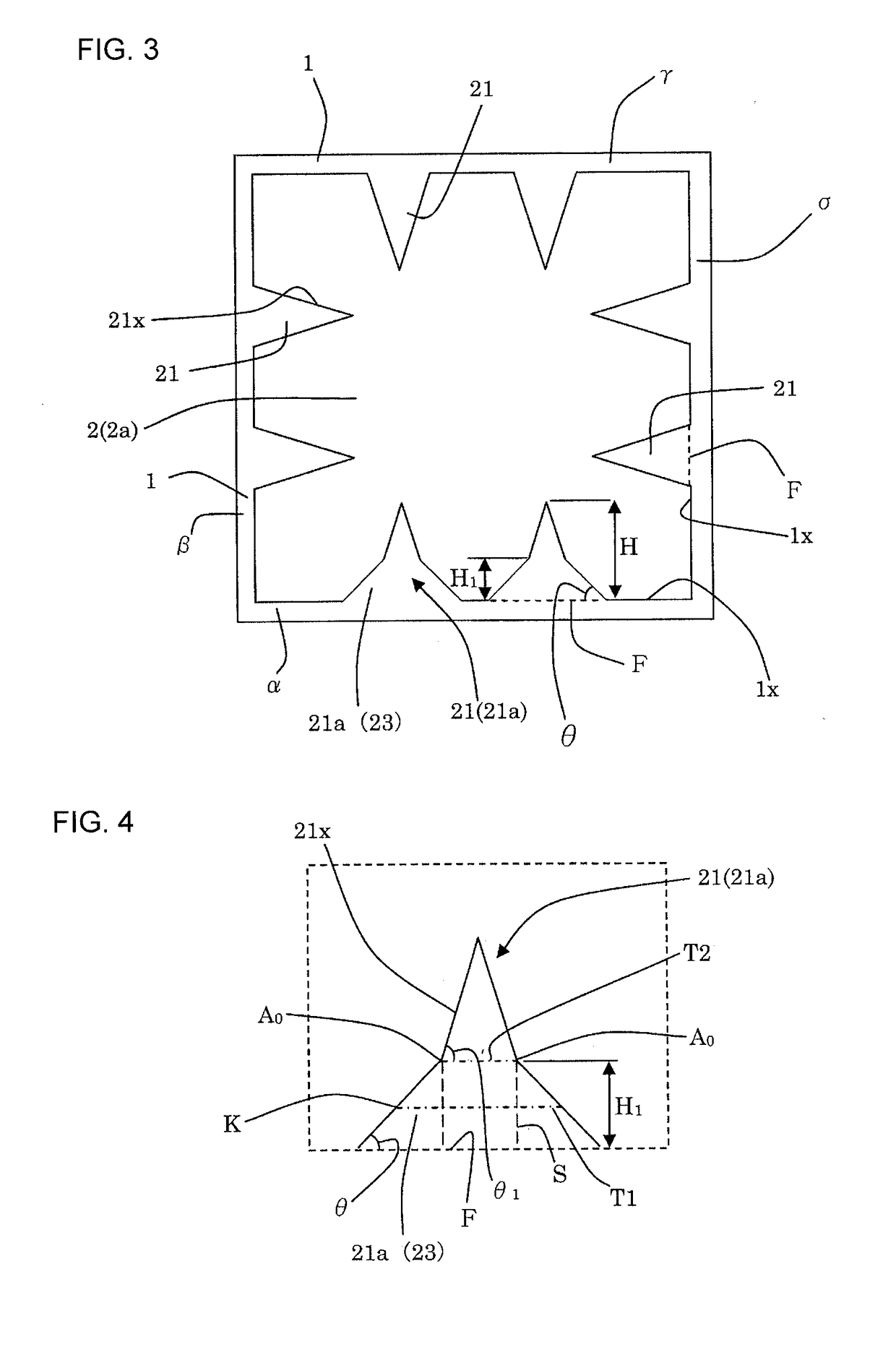

Shaped heterogeneous catalysts

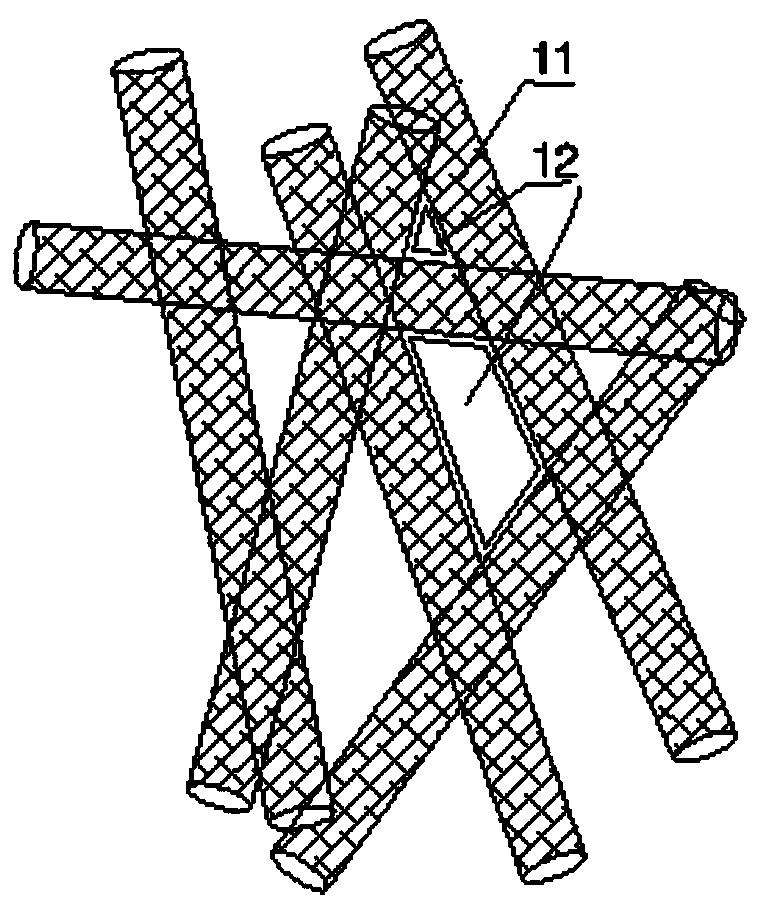

ActiveUS20110172086A1Increased geometric surface areaReduced strengthNitrogen compoundsUsing liquid separation agentFluteSteam reforming

A catalyst unit is described comprising a cylinder with a length C and a diameter D, wherein said unit has five holes arranged in a pentagonal pattern extending longitudinally therethrough, with five flutes running along the length of the unit, said flutes positioned equidistant adjacent holes of said pentagonal pattern. The catalyst may be used particularly in steam reforming reactors.

Owner:JOHNSON MATTHEY PLC

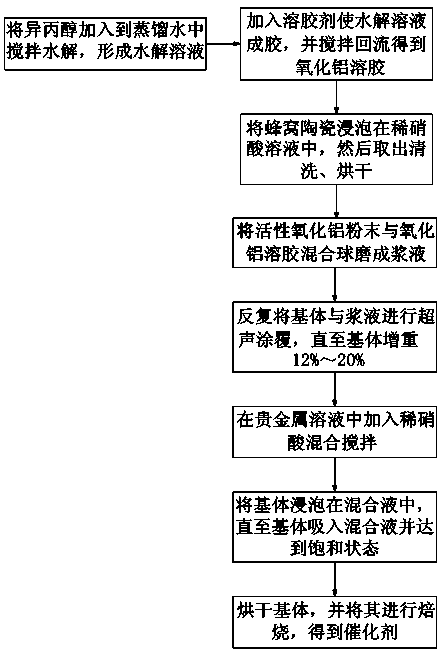

Preparation method of catalyst for removing tritium in tritium-containing air

InactiveCN104383917AReasonable workmanshipEasy to operateCatalyst carriersDispersed particle separationWeight gainingDistilled water

A disclosed preparation method of a catalyst for removing tritium in tritium-containing air comprises: (1) adding aluminium isopropoxide into distilled water and stirring for hydrolysis; (2) adding a peptizing agent to enable the hydrolysis solution to be colloidal, and performing stirring refluxing to obtain an aluminium oxide sol; (3) using honeycomb ceramic as a catalyst matrix and immersing in a diluted nitric acid solution, and then taking out, cleaning and baking; (4) mixing active aluminium oxide powder and the aluminium oxide sol, and performing ball milling to form a slurry; (5) uniformly coating the catalyst matrix with the slurry, and then baking and weighing; (6) repeating the step (5) until the weight gain of the catalyst matrix is 12%-20%; (7) adding diluted nitric acid into a noble metal solution, and mixing with stirring; and (8) immersing the catalyst matrix in the mixed solution to enable the catalyst matrix to absorb the mixed solution to reach a saturation state, and then roasting, so as to obtain the catalyst. The preparation method helps to substantially improve the processing capacity of the catalyst on gases without increasing the gas resistance of the tritium-removal system.

Owner:SICHUAN INST OF MATERIALS & TECH

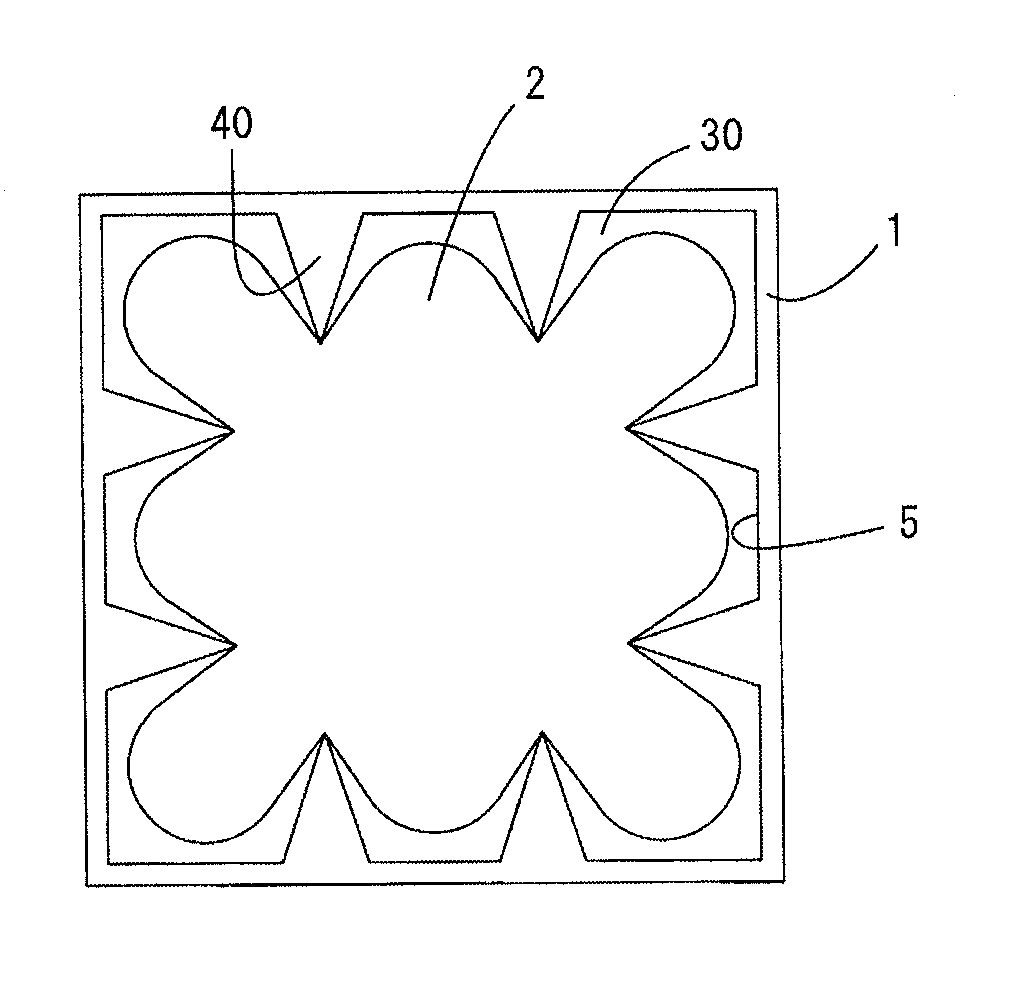

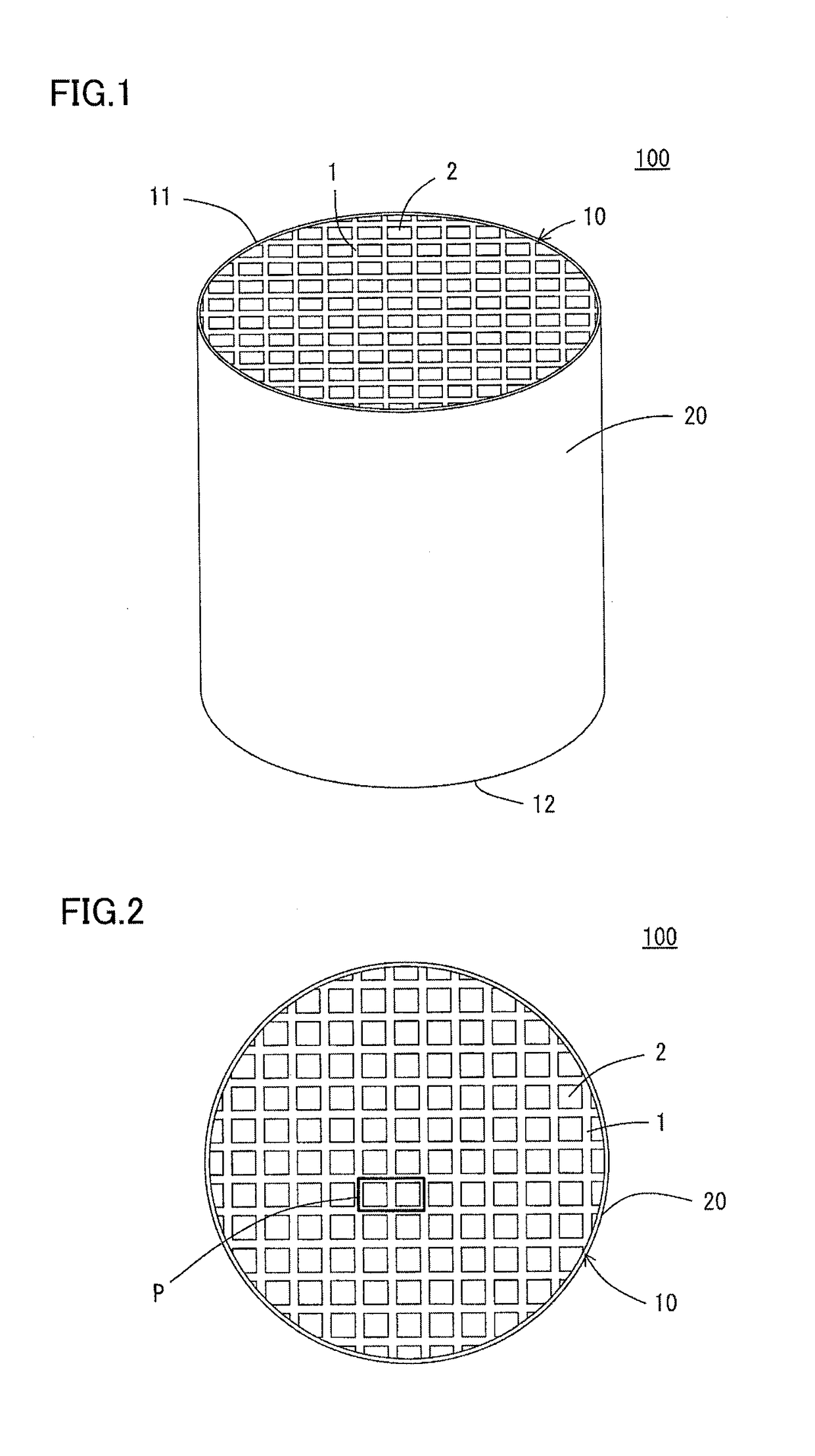

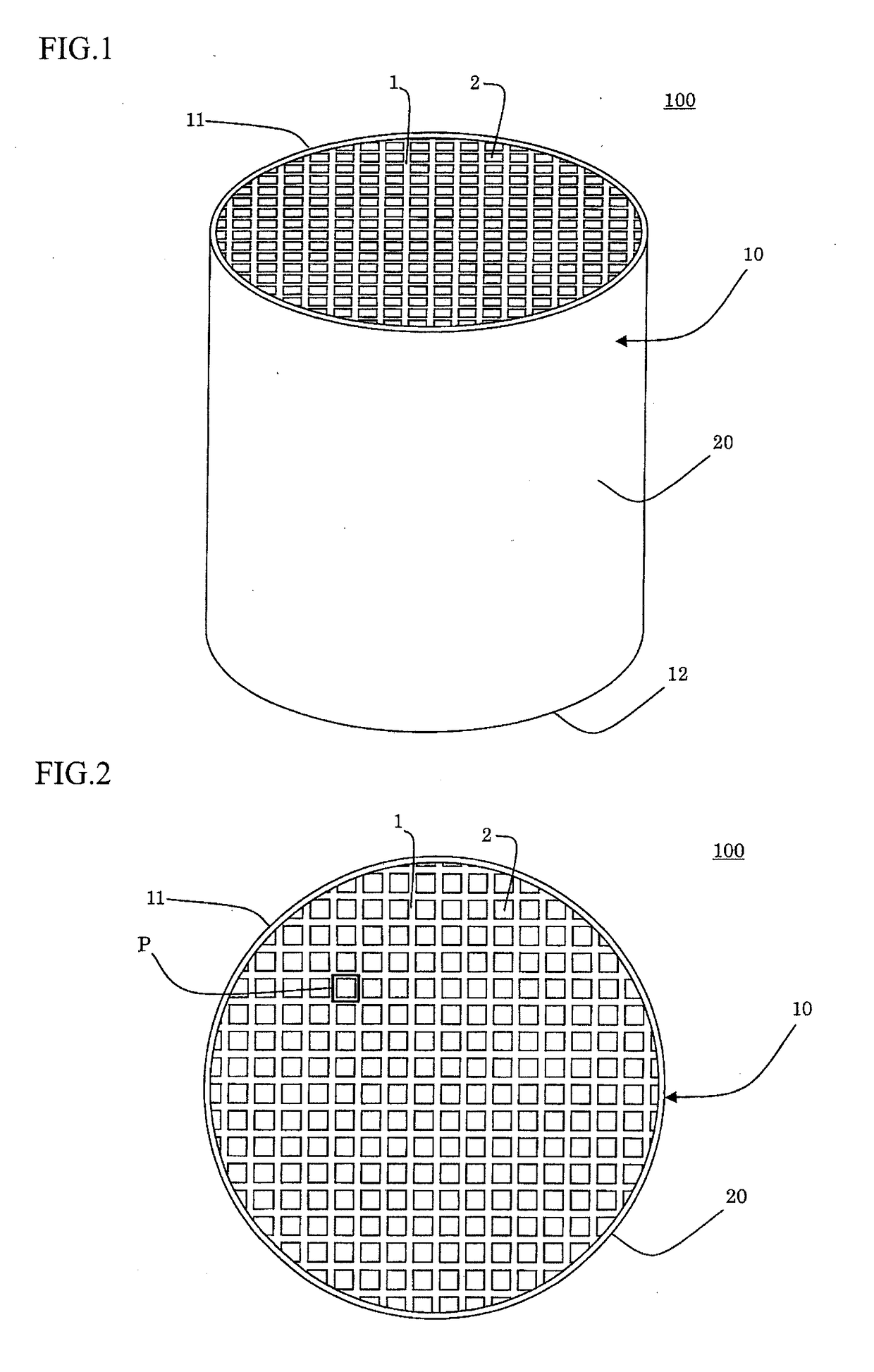

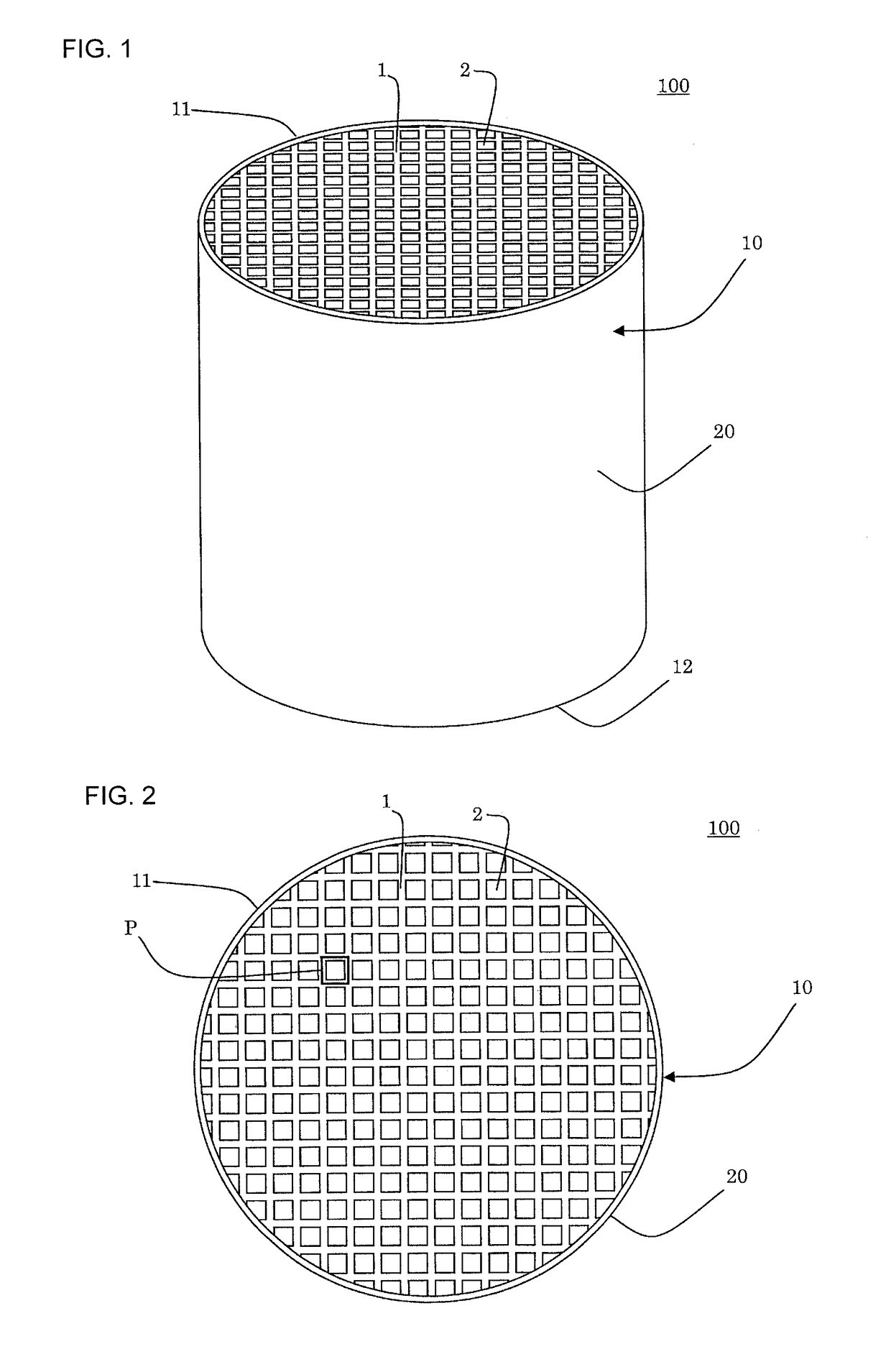

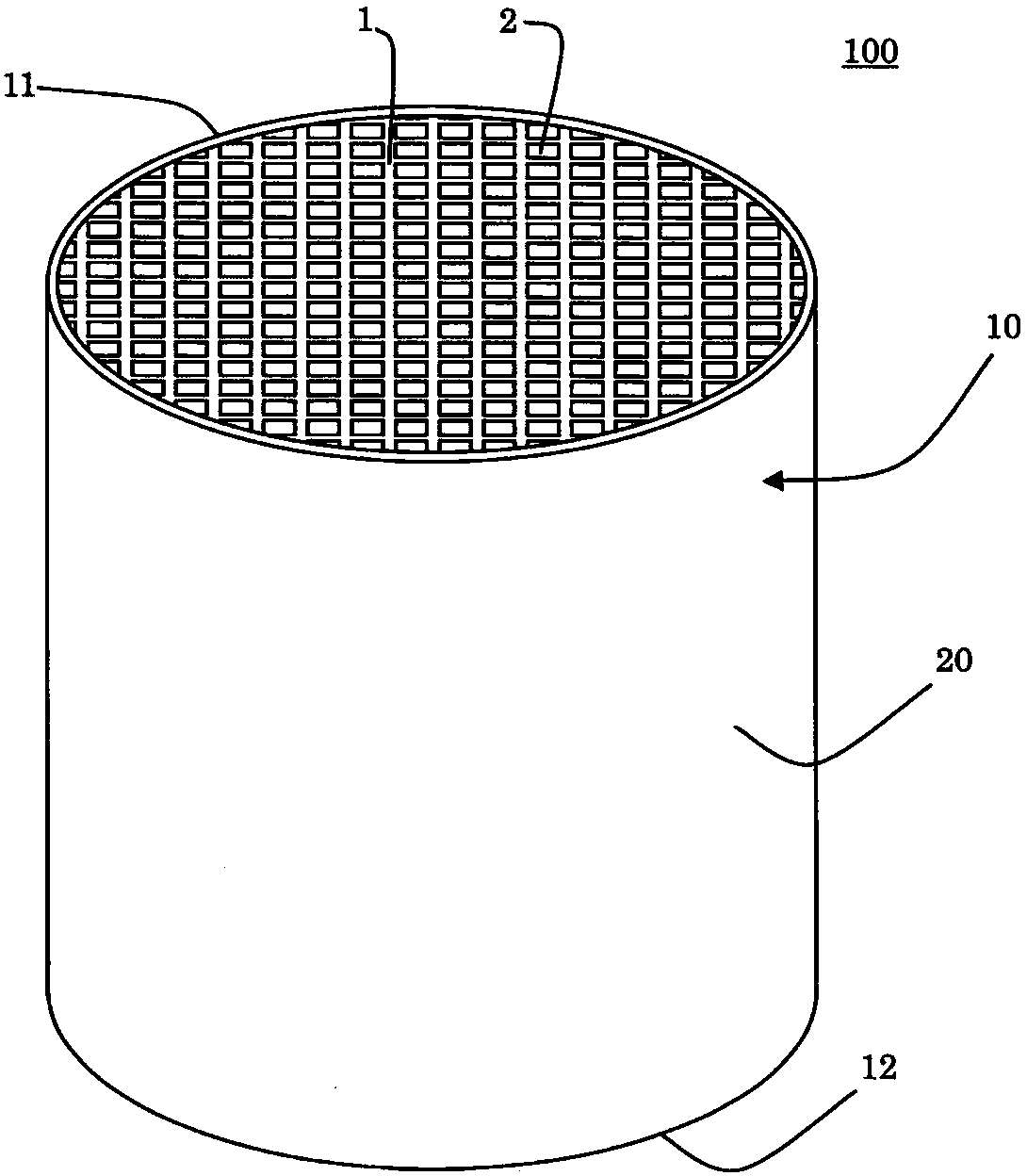

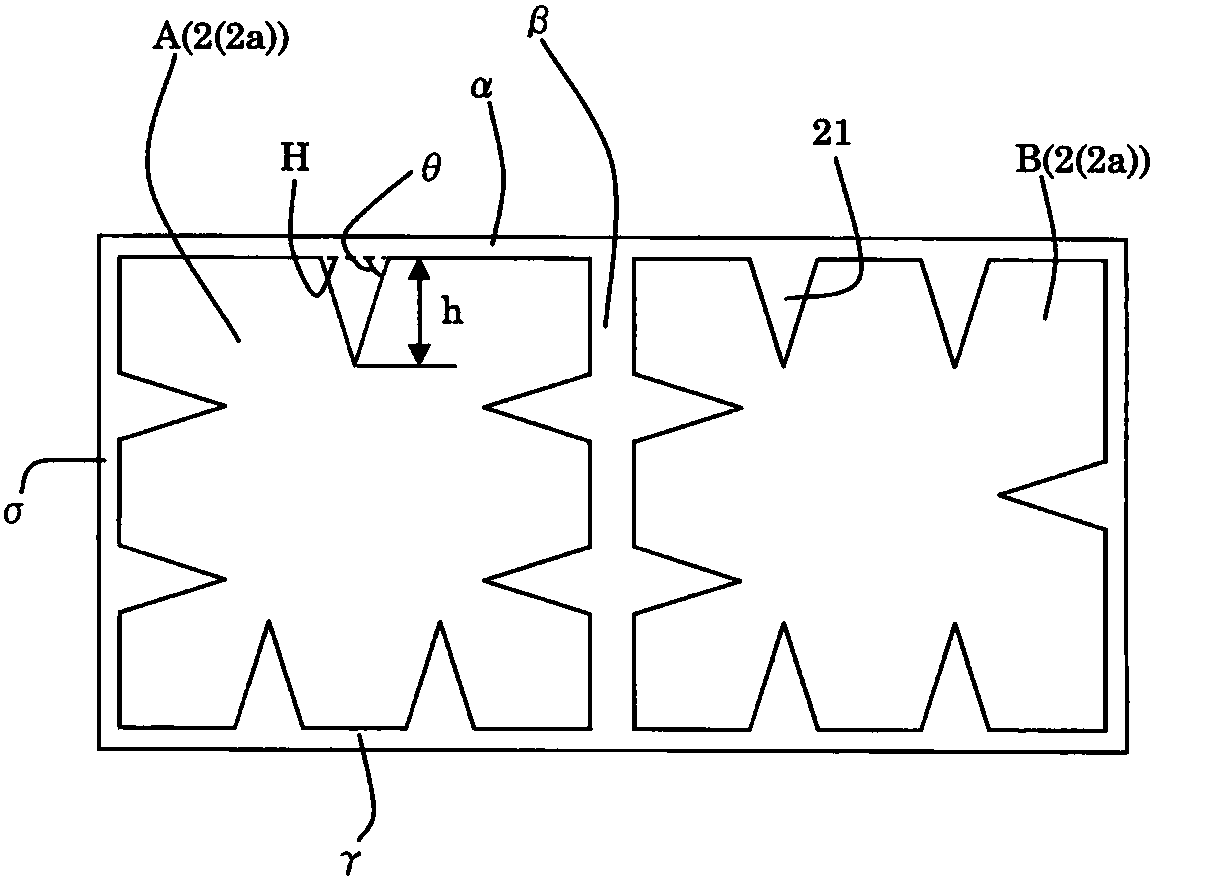

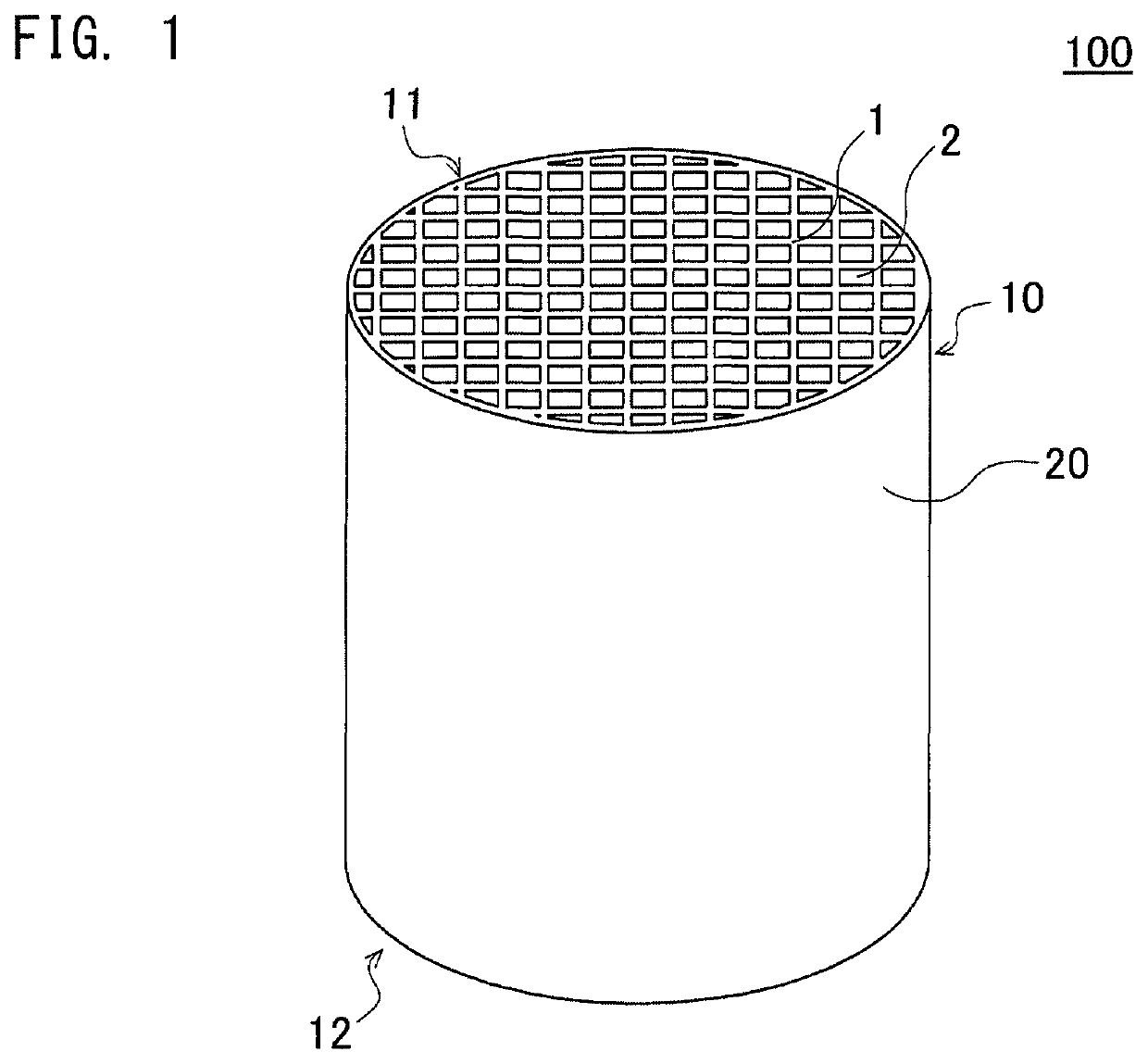

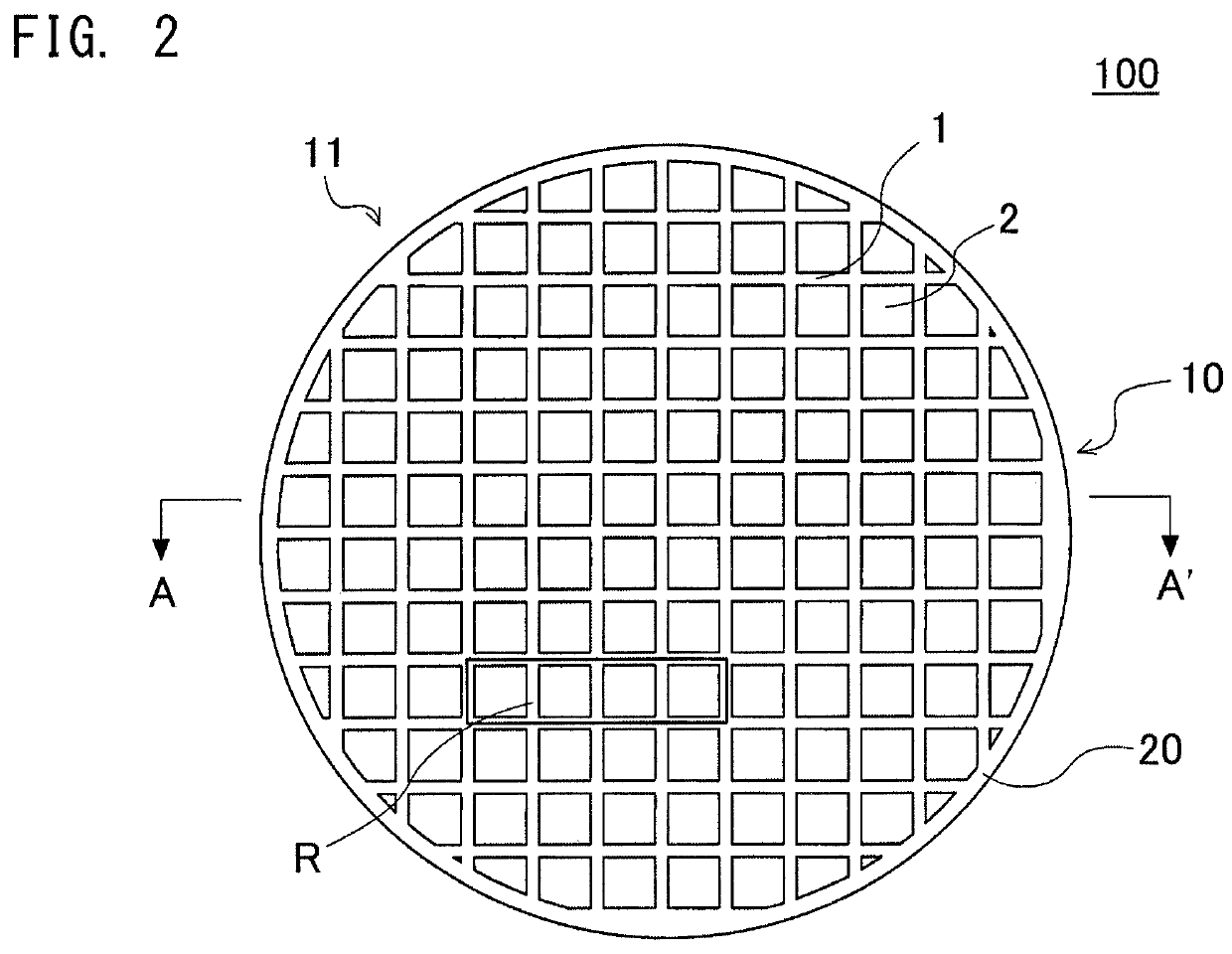

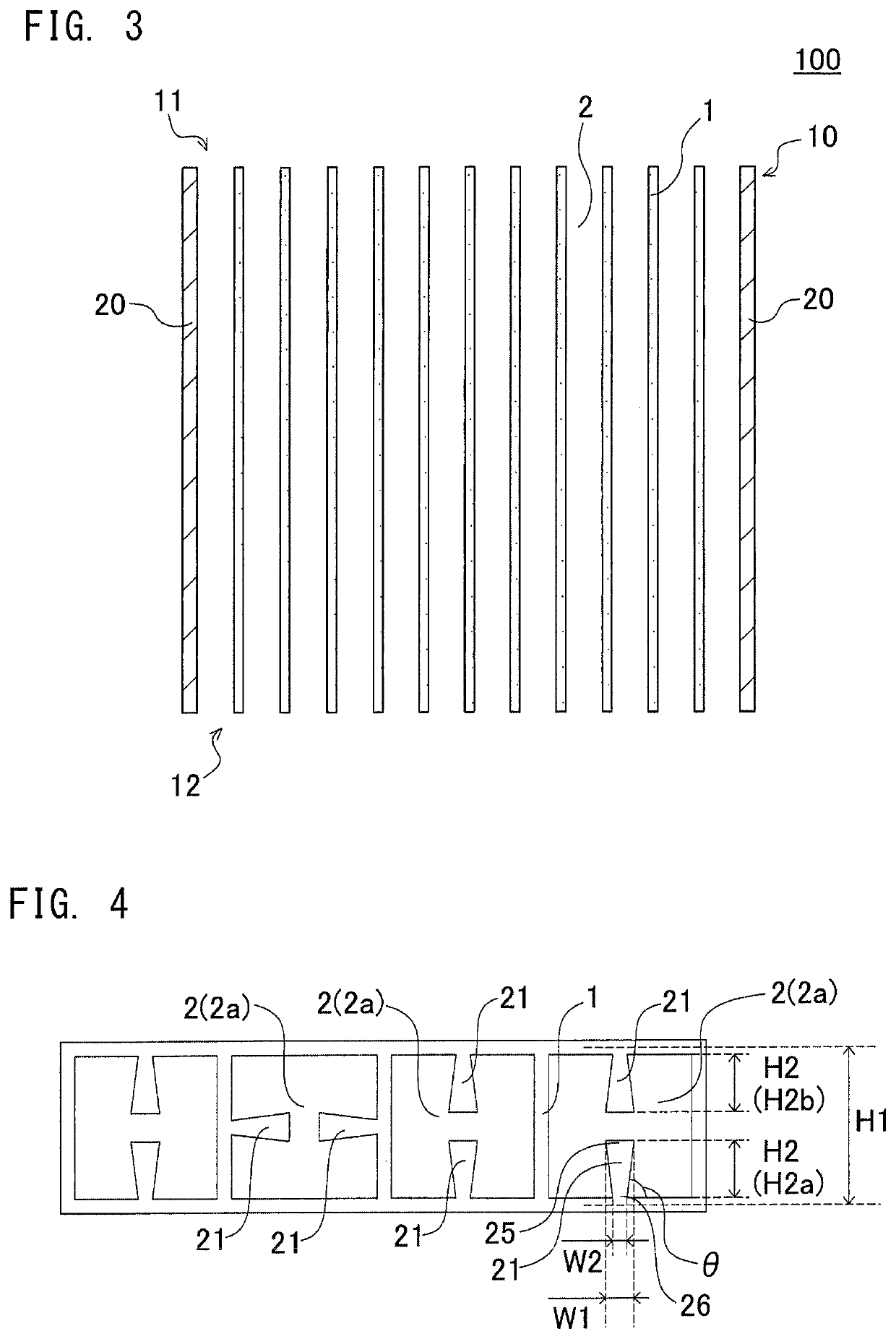

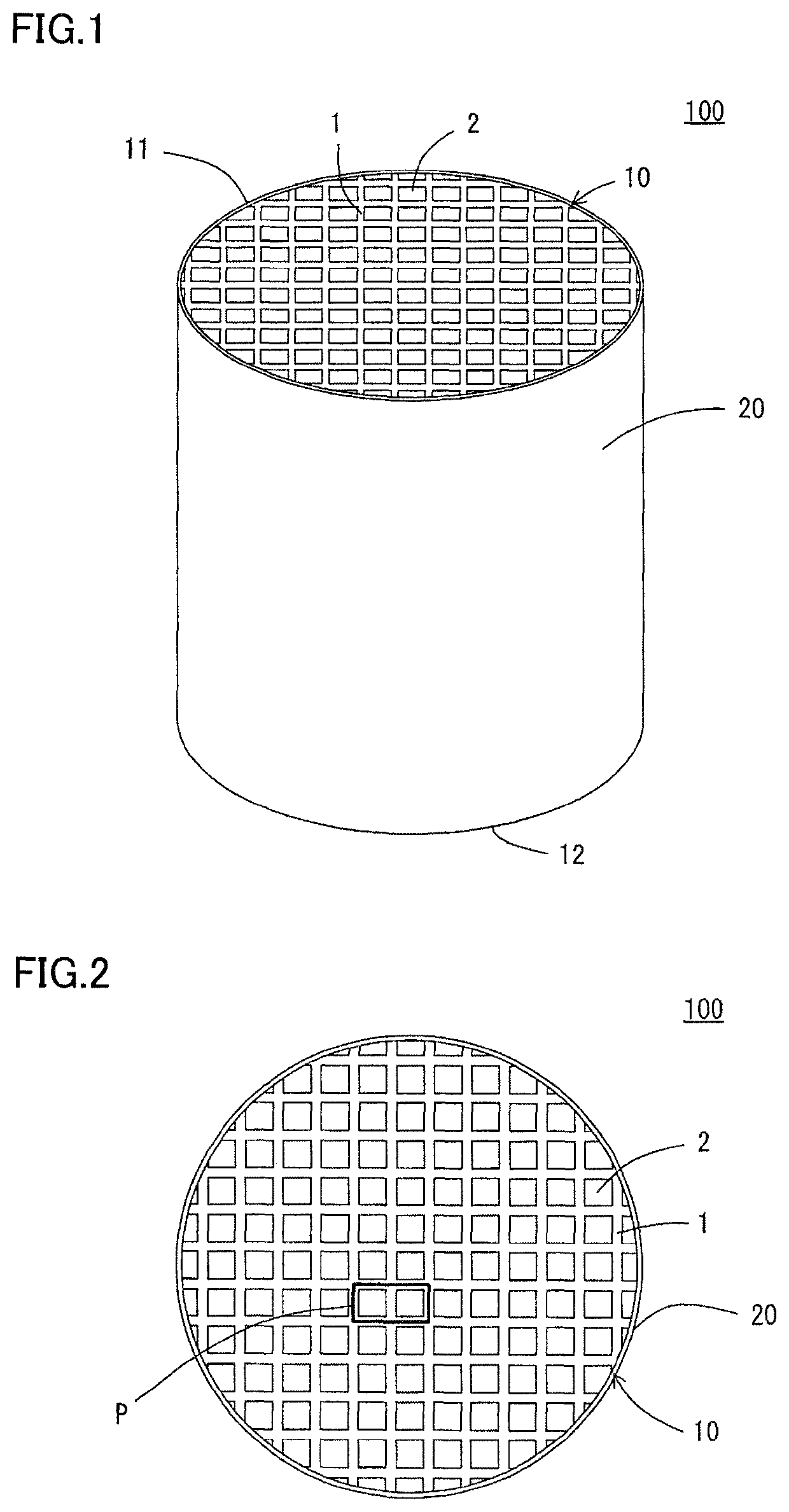

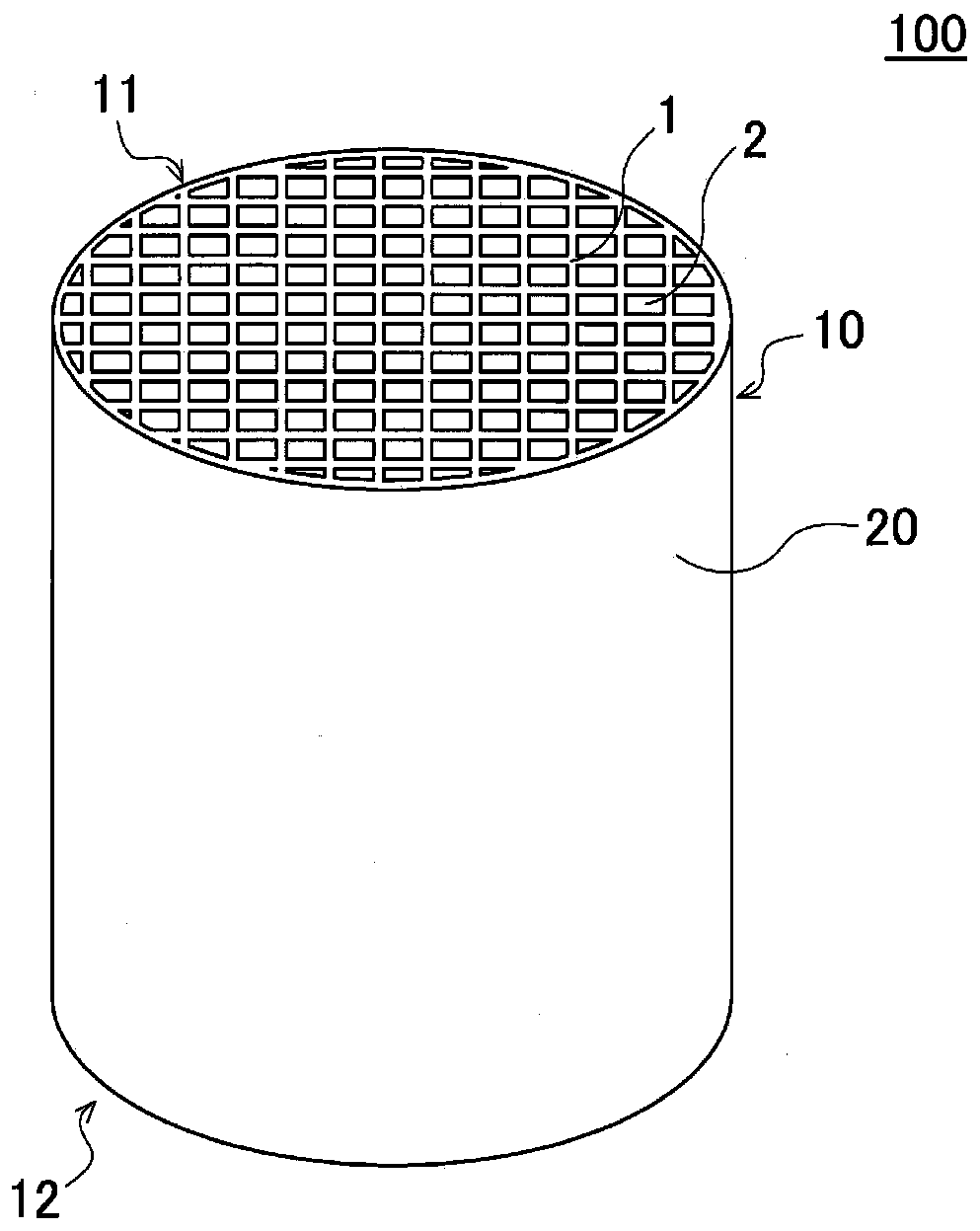

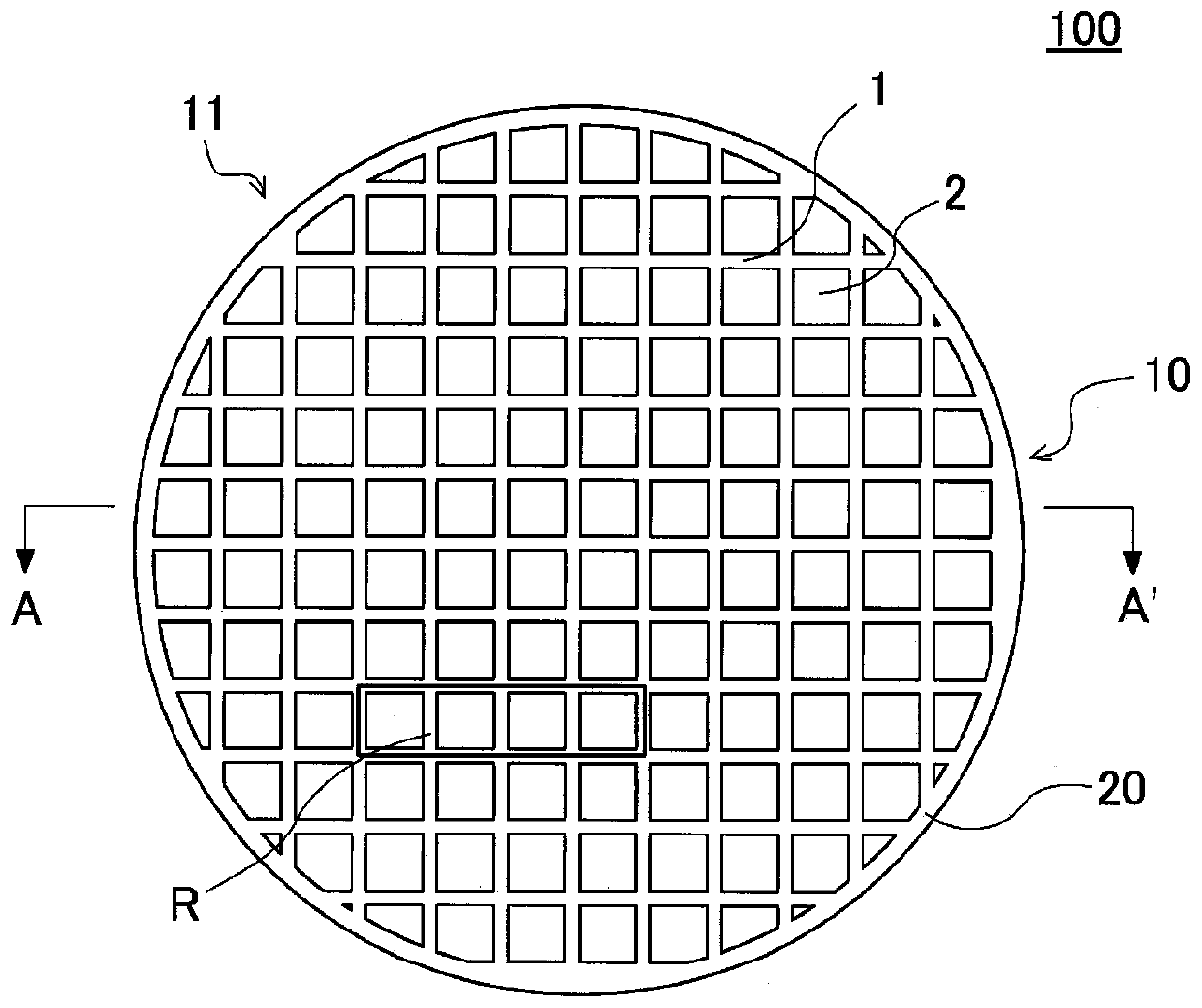

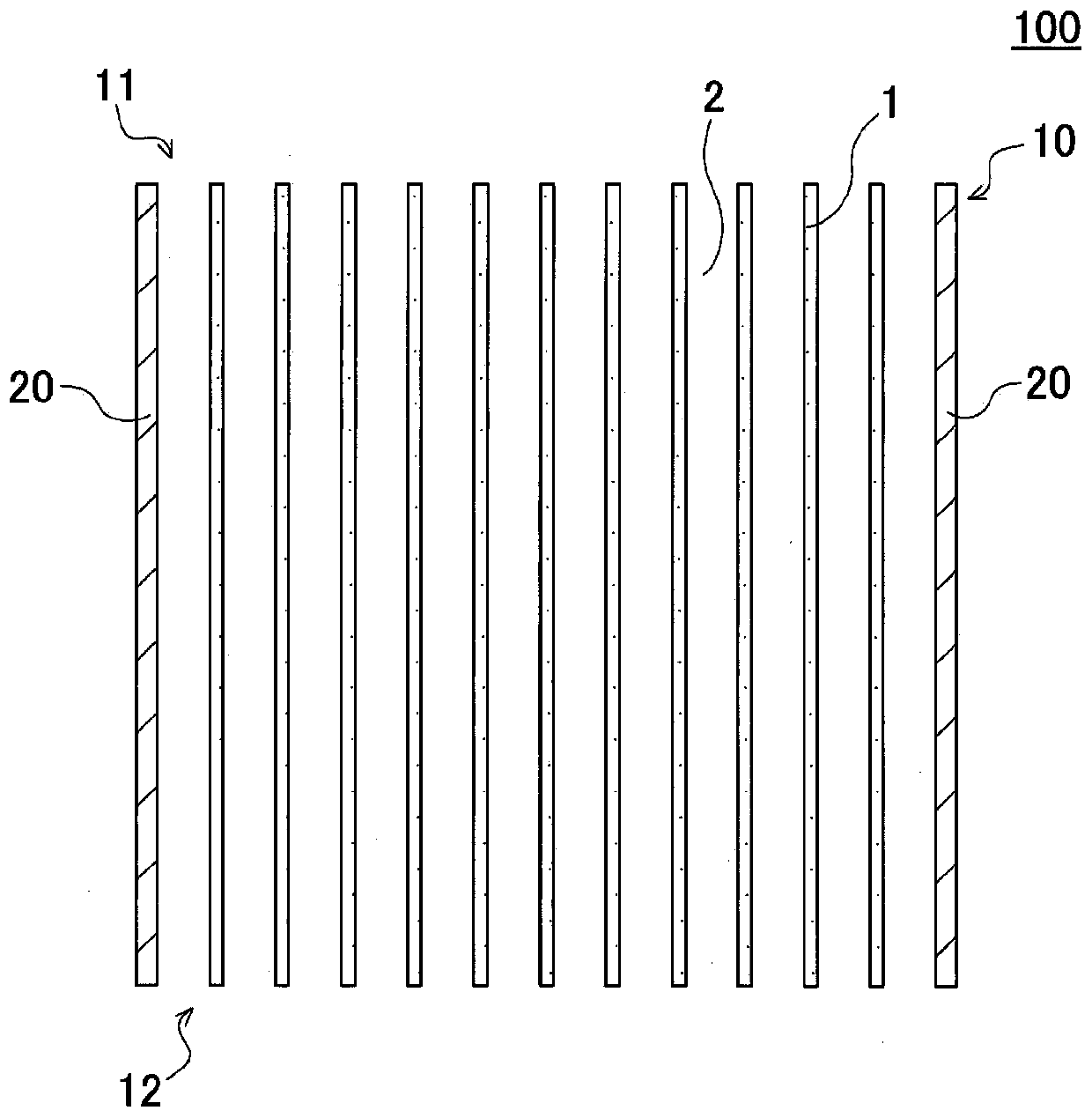

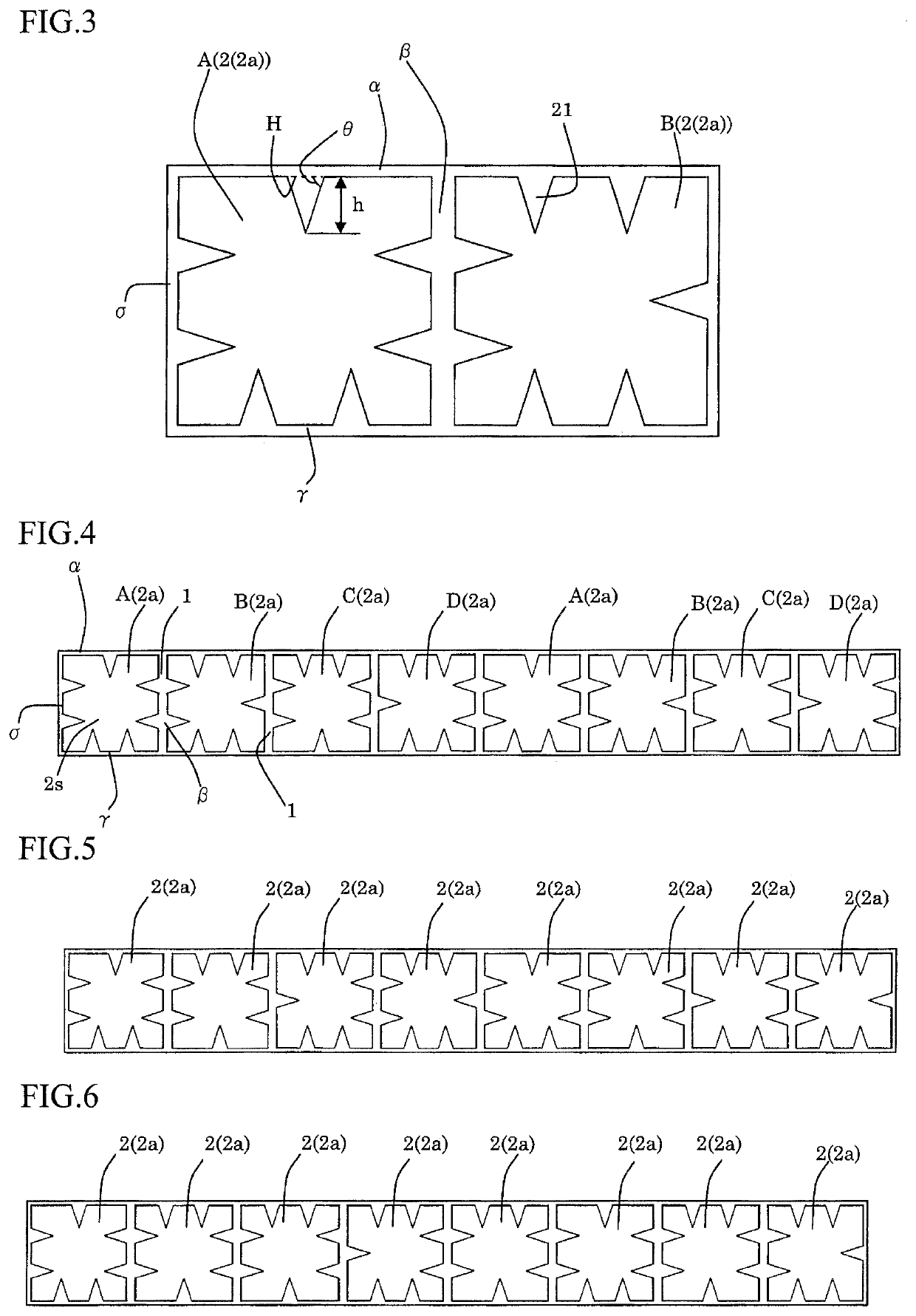

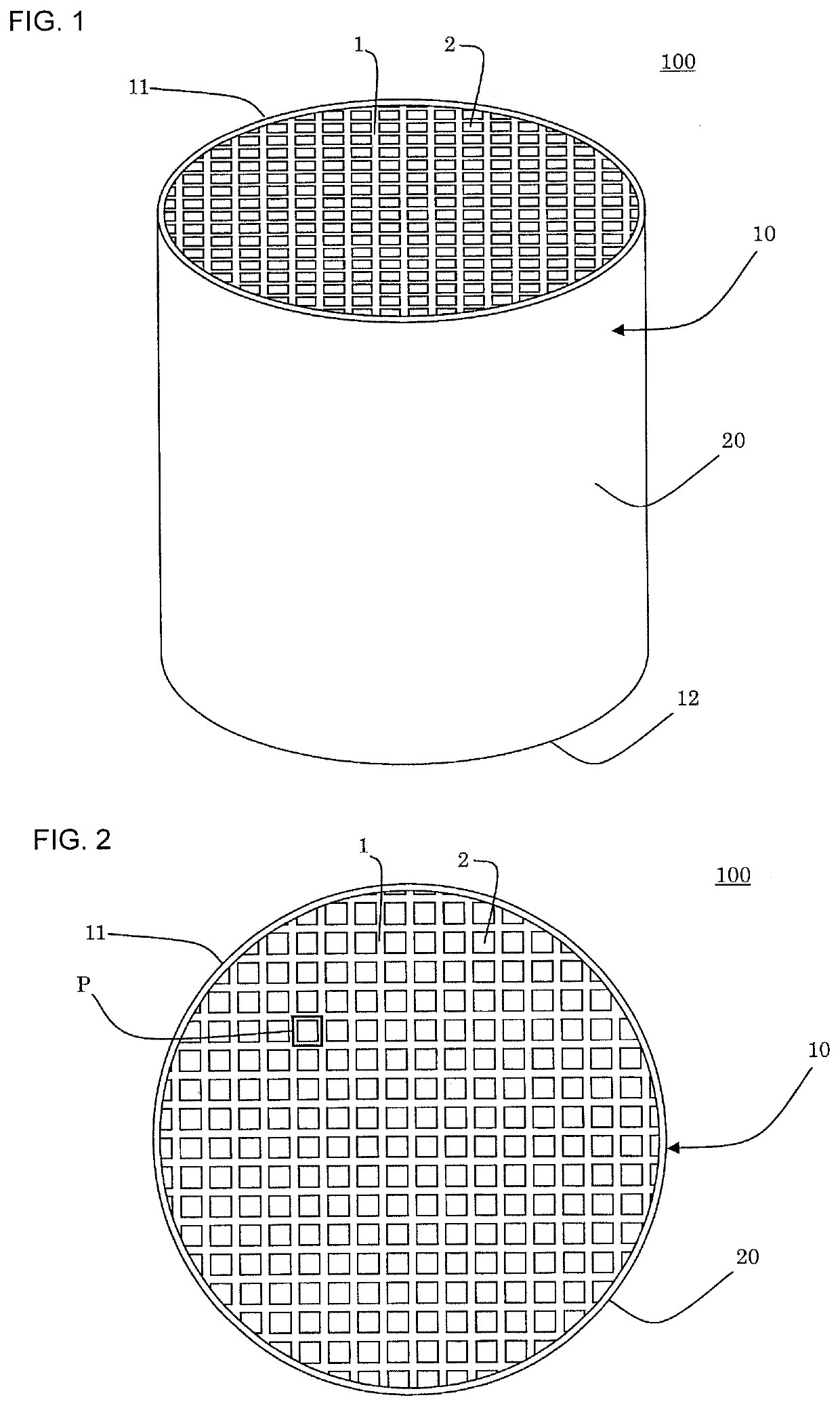

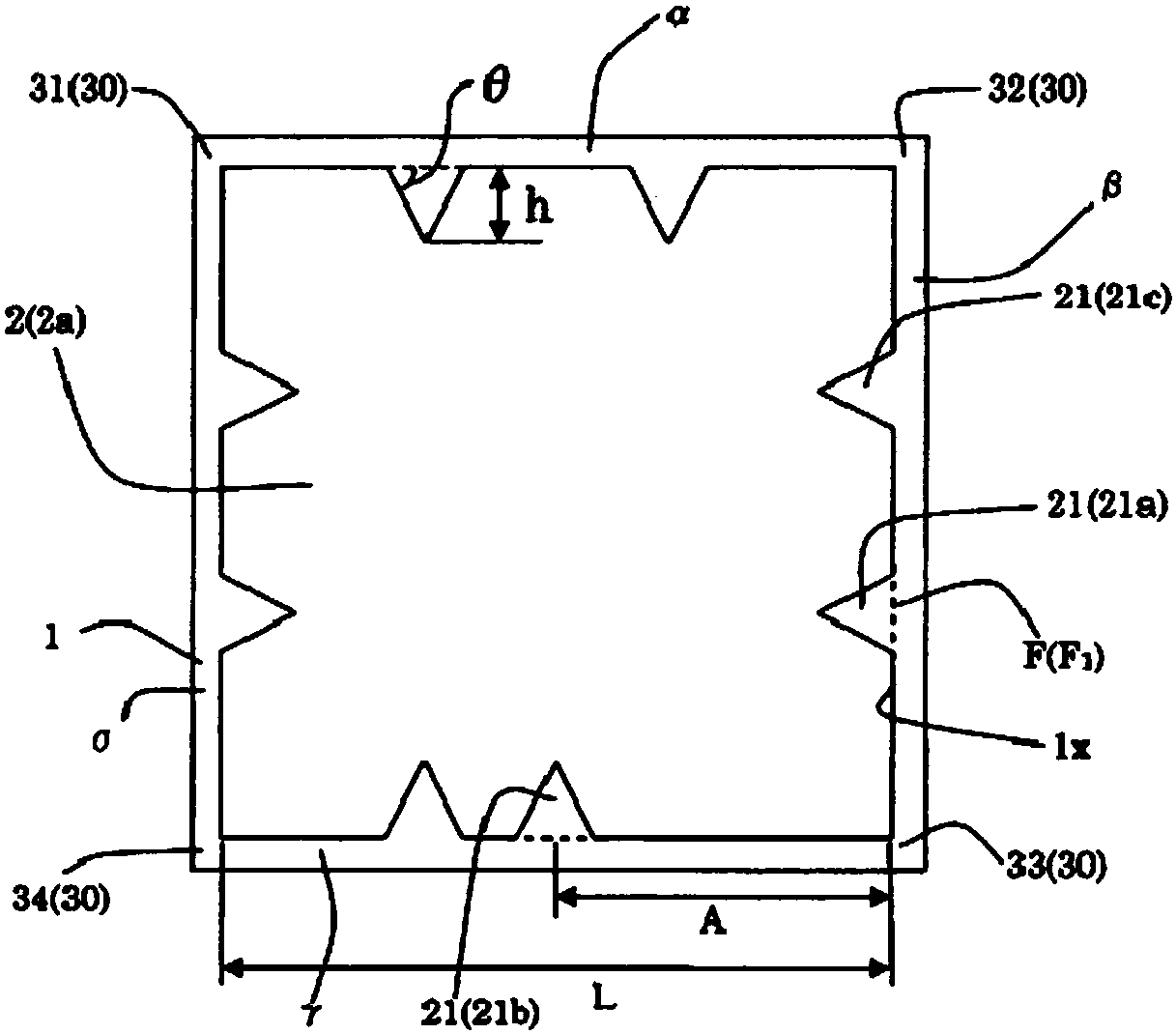

Honeycomb structure

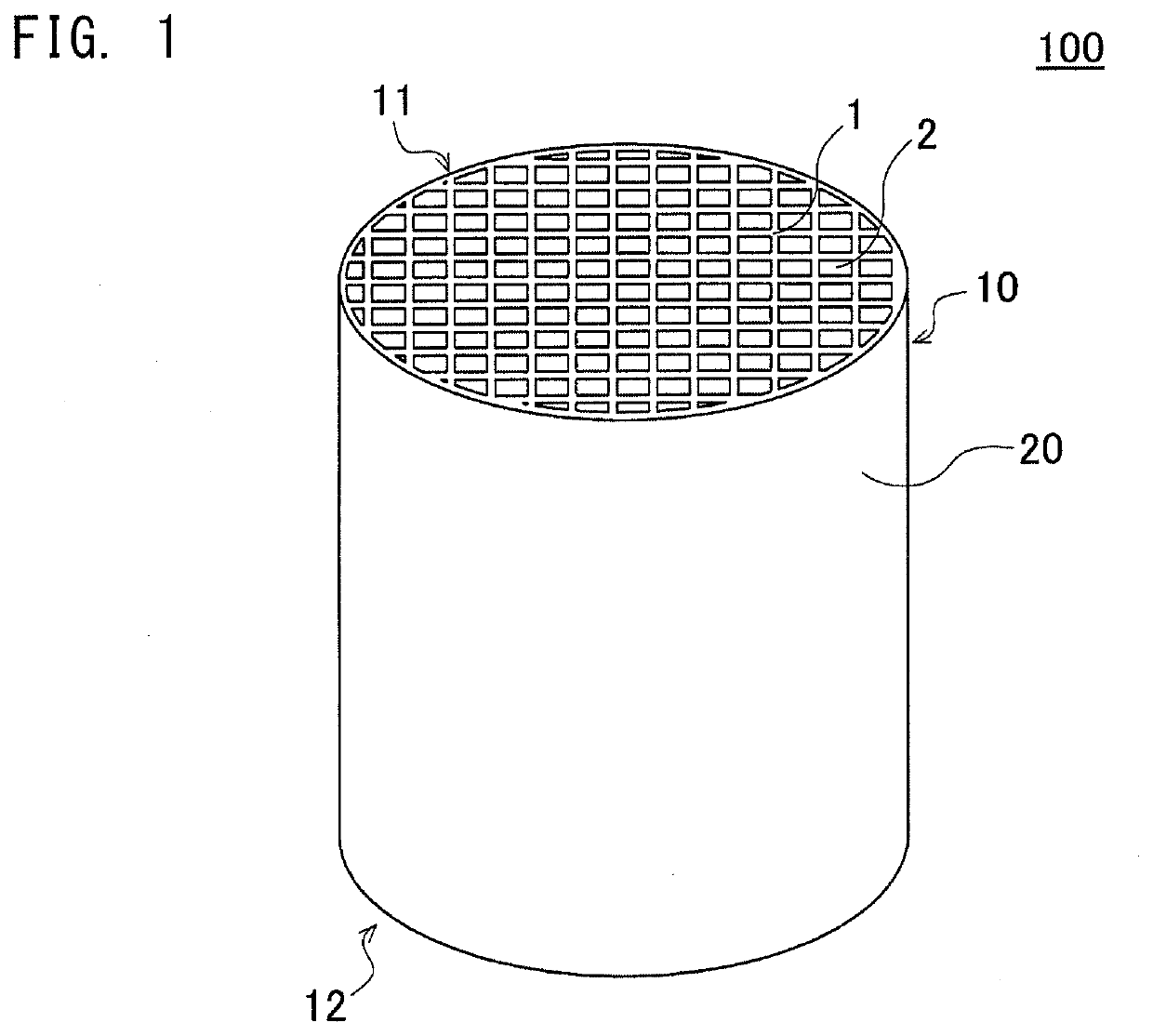

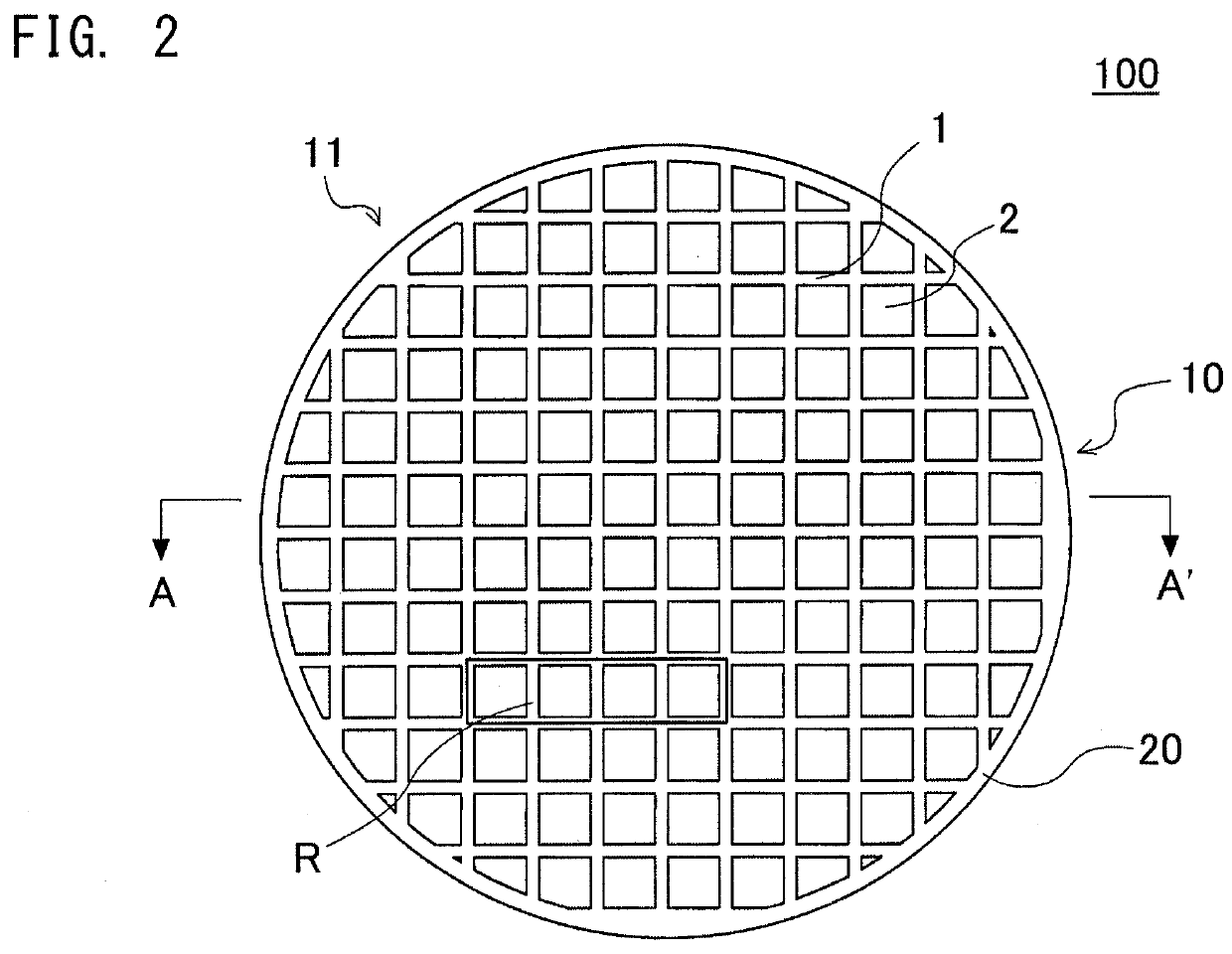

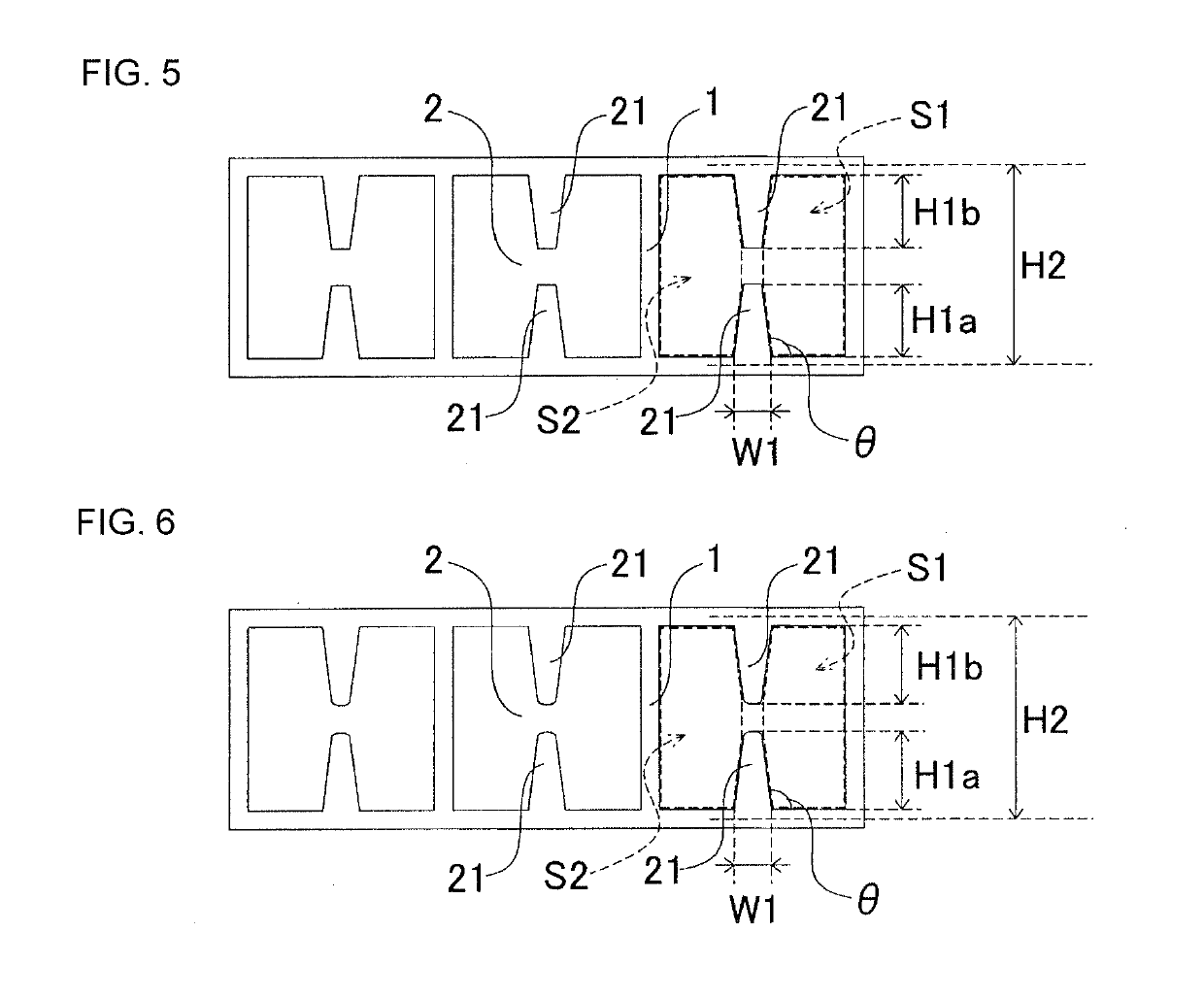

ActiveUS20180280962A1Reduce total pressure lossIncrease surface areaPhysical/chemical process catalystsDispersed particle filtrationEngineeringHoneycomb structure

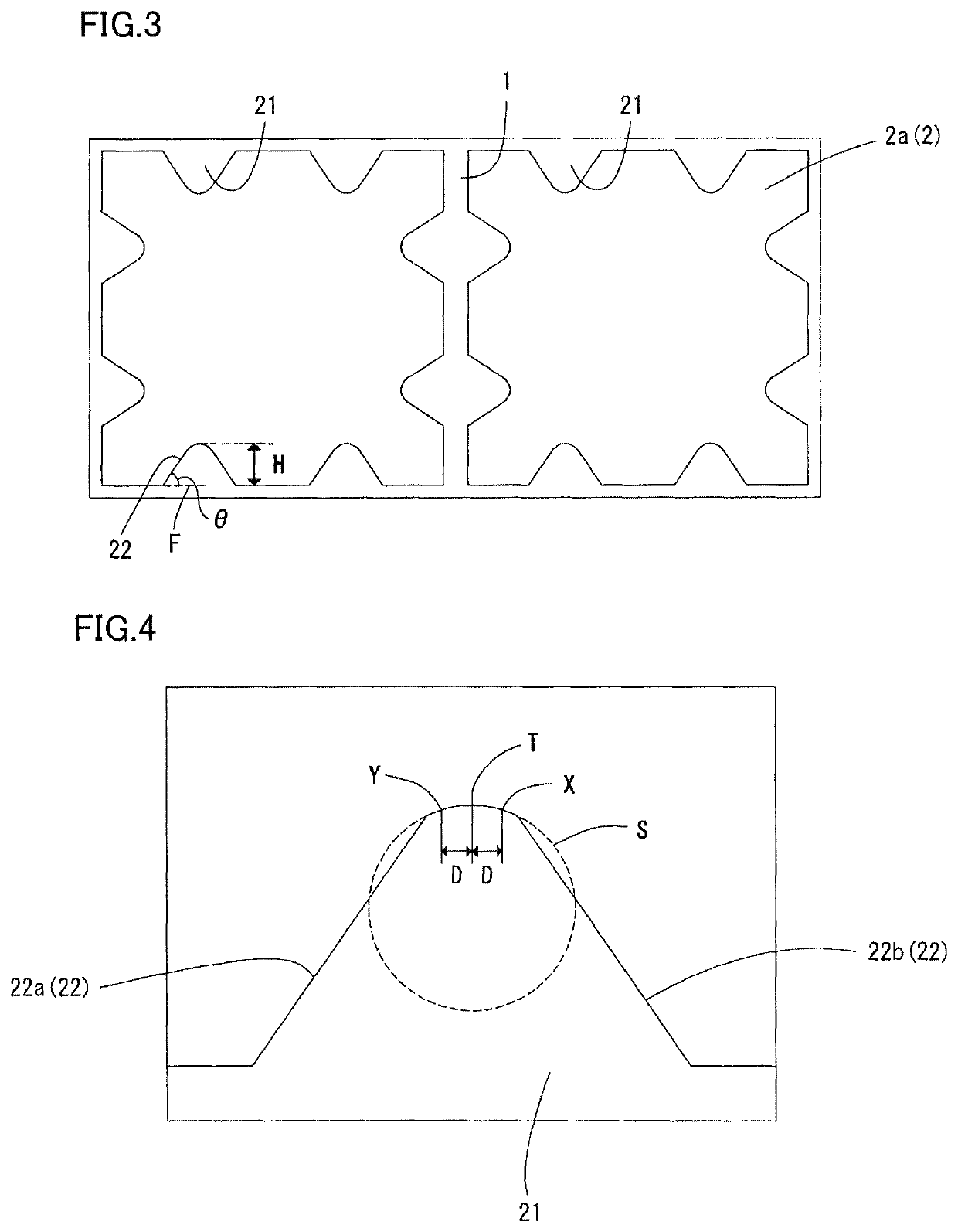

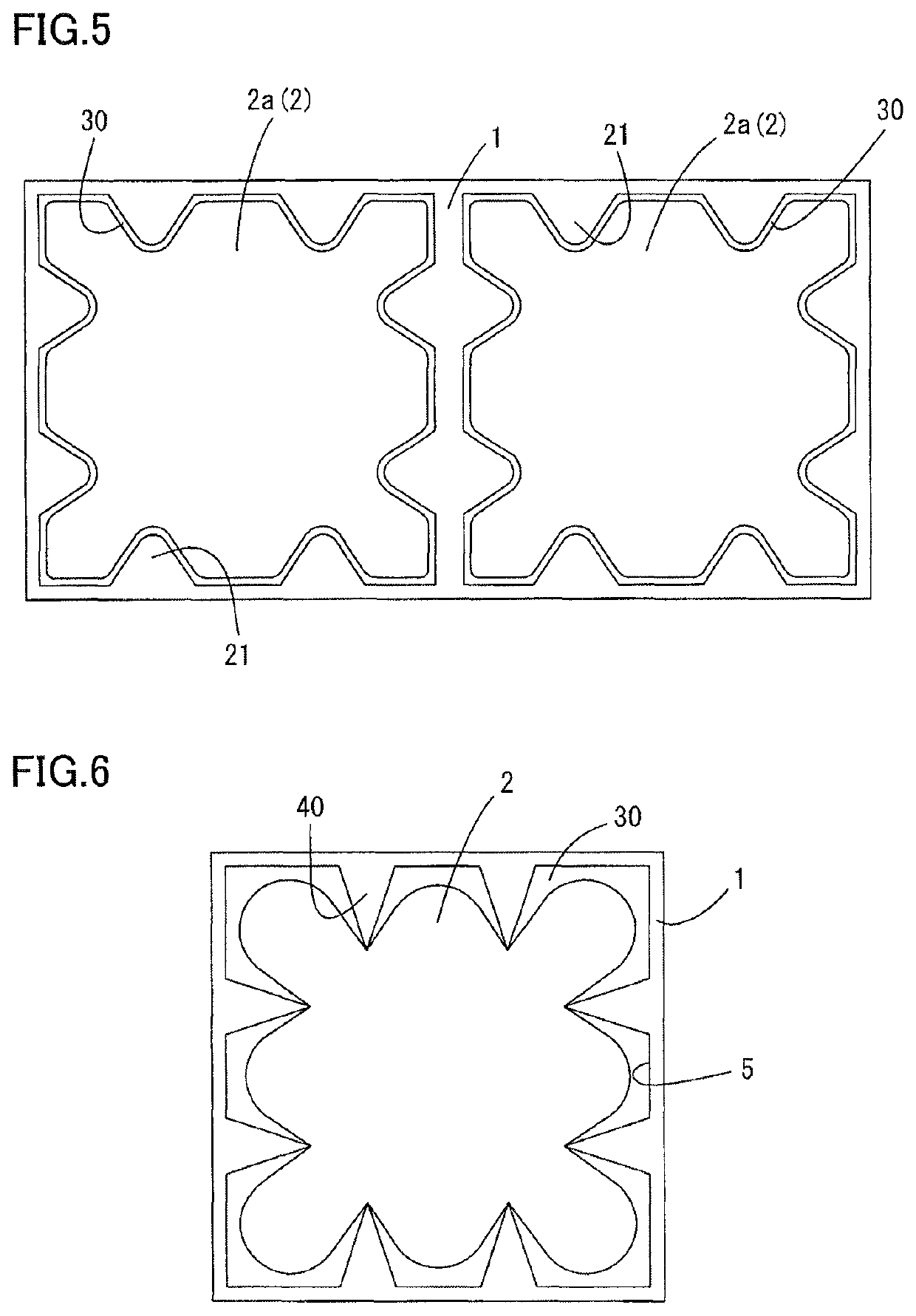

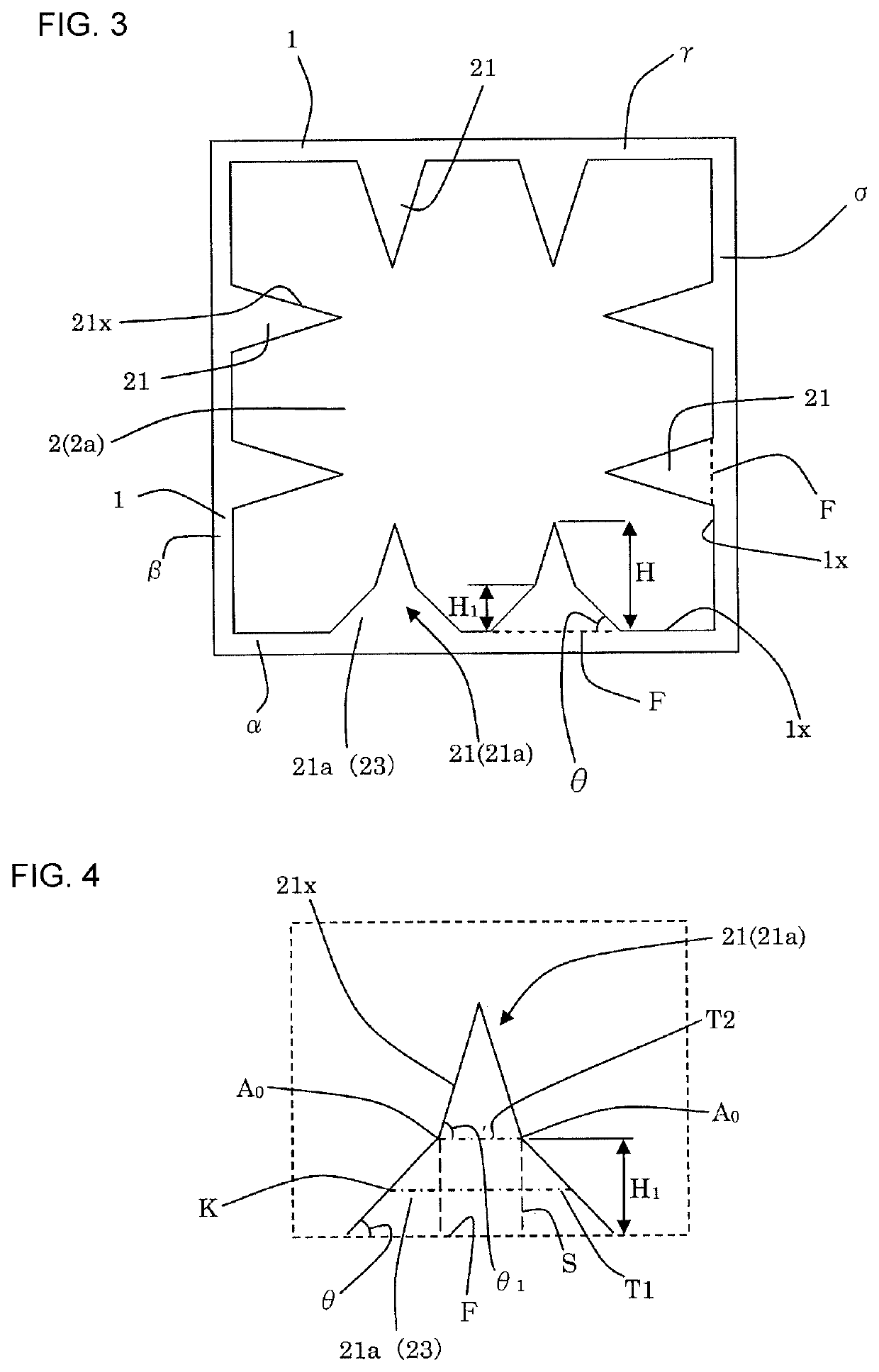

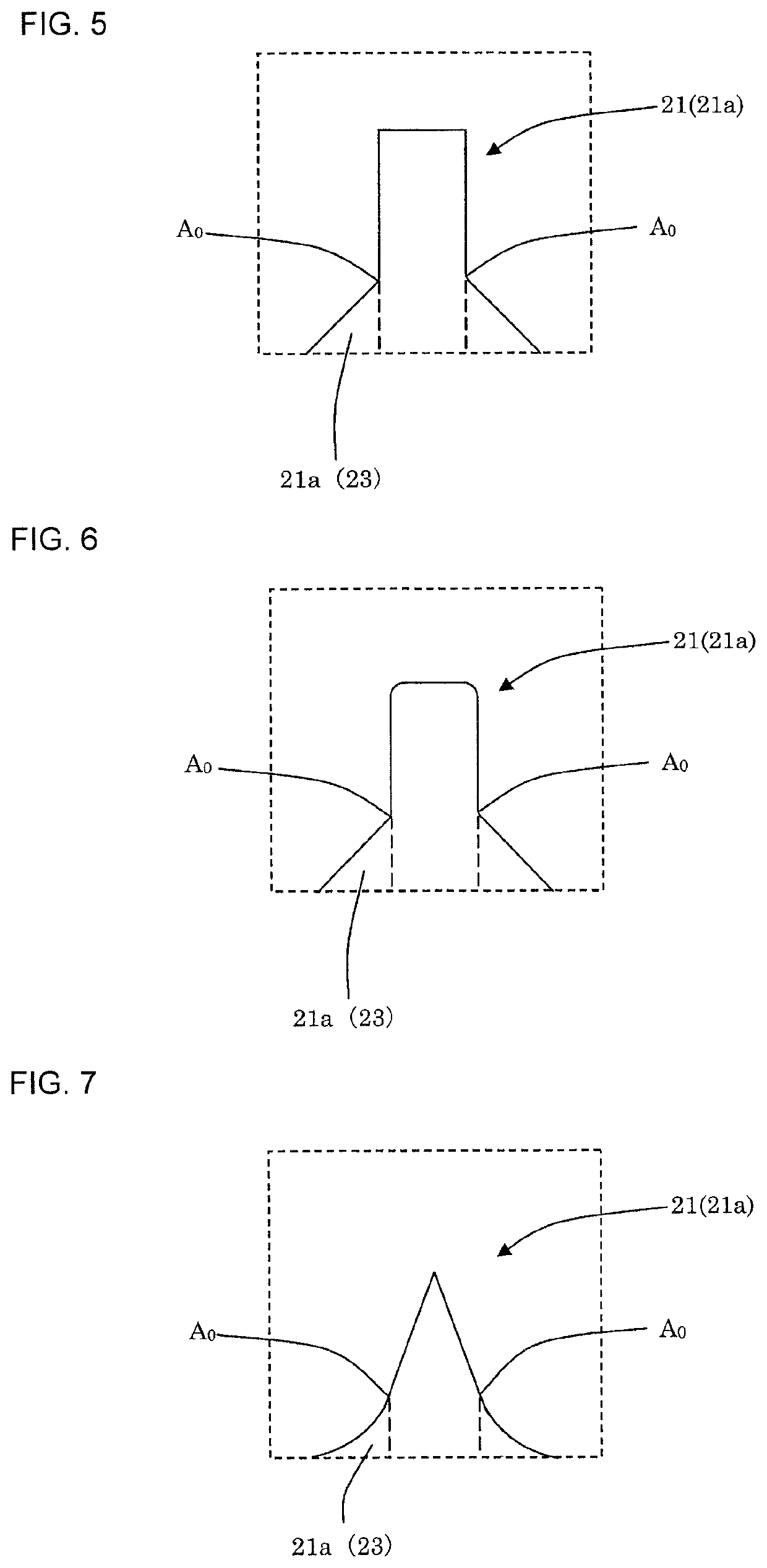

A honeycomb structure includes a pillar-shaped honeycomb structure body having porous partition walls, wherein the partition walls have projecting portions,in the cells of 10% or more of the plurality of cells, the projecting portions project into the cells, a tip curvature radius R of an apex of each of the projecting portions is from 0.01 to 0.1 mm, side surfaces of the projecting portions are inclined to the surfaces of the partition walls at an inclination angle of 40 to 70°, and a relation of 0.04≤H / A≤0.4 is satisfied.

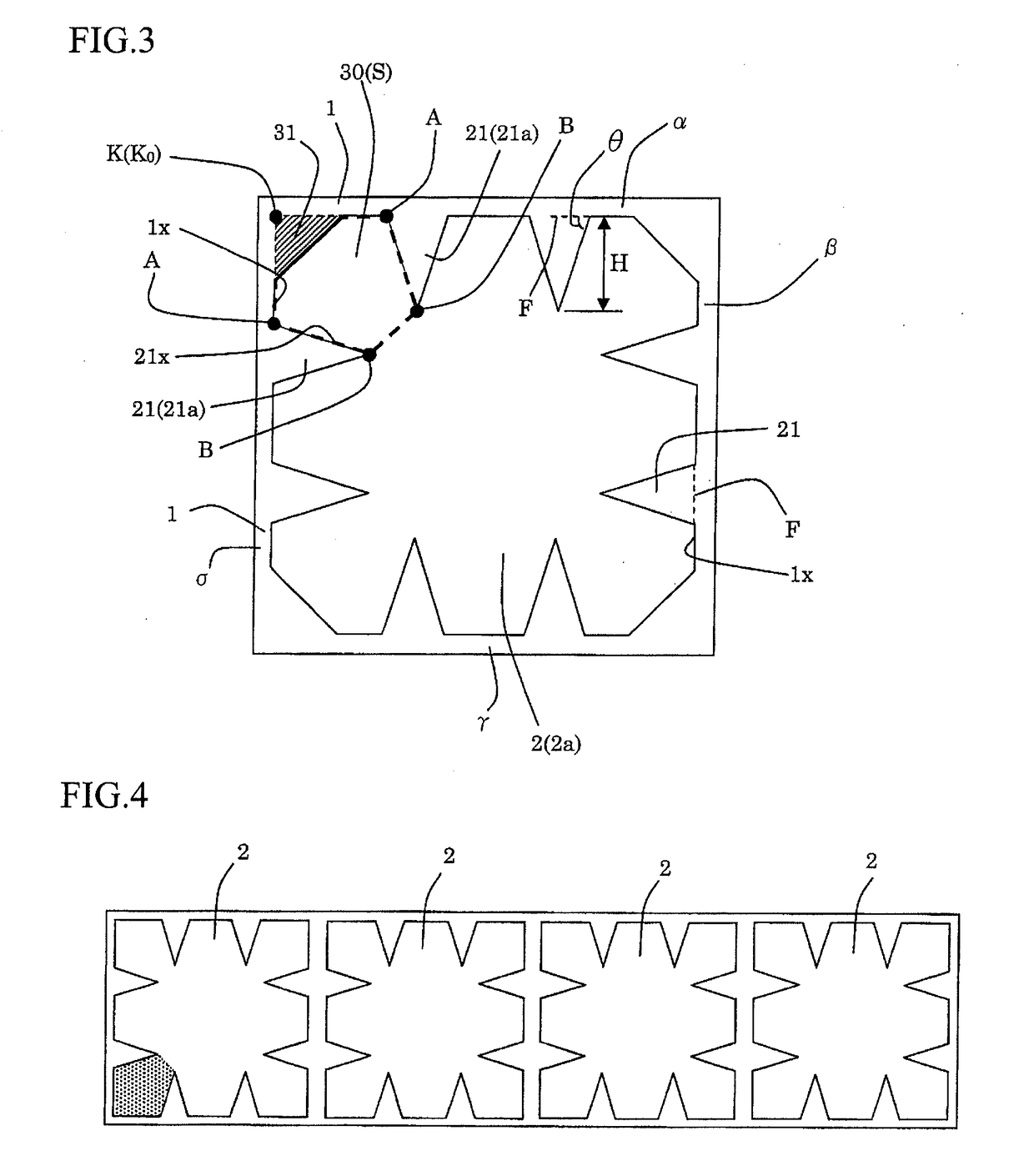

Honeycomb structure

ActiveUS20180280961A1Improve purification effectIncrease surface areaPhysical/chemical process catalystsDispersed particle filtrationEngineeringMechanical engineering

A honeycomb structure including: a honeycomb structure body having porous partition walls which are disposed to surround a plurality of cells and a circumferential wall, wherein the partition walls are provided with protrusions, at least one of the plurality of cells includes a specific cell configured so that the protrusions protrude into the cell from the respective partition walls, and the specific cell is provided with a porous material made of the same material as the partition walls in a range of 5 to 50% including an intersection with respect to a pentagonal area which is formed by connecting the intersection when two partition walls configuring the peripheral edge of the specific cell extend and two points of bottom parts and top parts, respectively, of the respective protrusions disposed on the two partition walls, in the cross section orthogonal to the extending direction of the cells.

Owner:NGK INSULATORS LTD

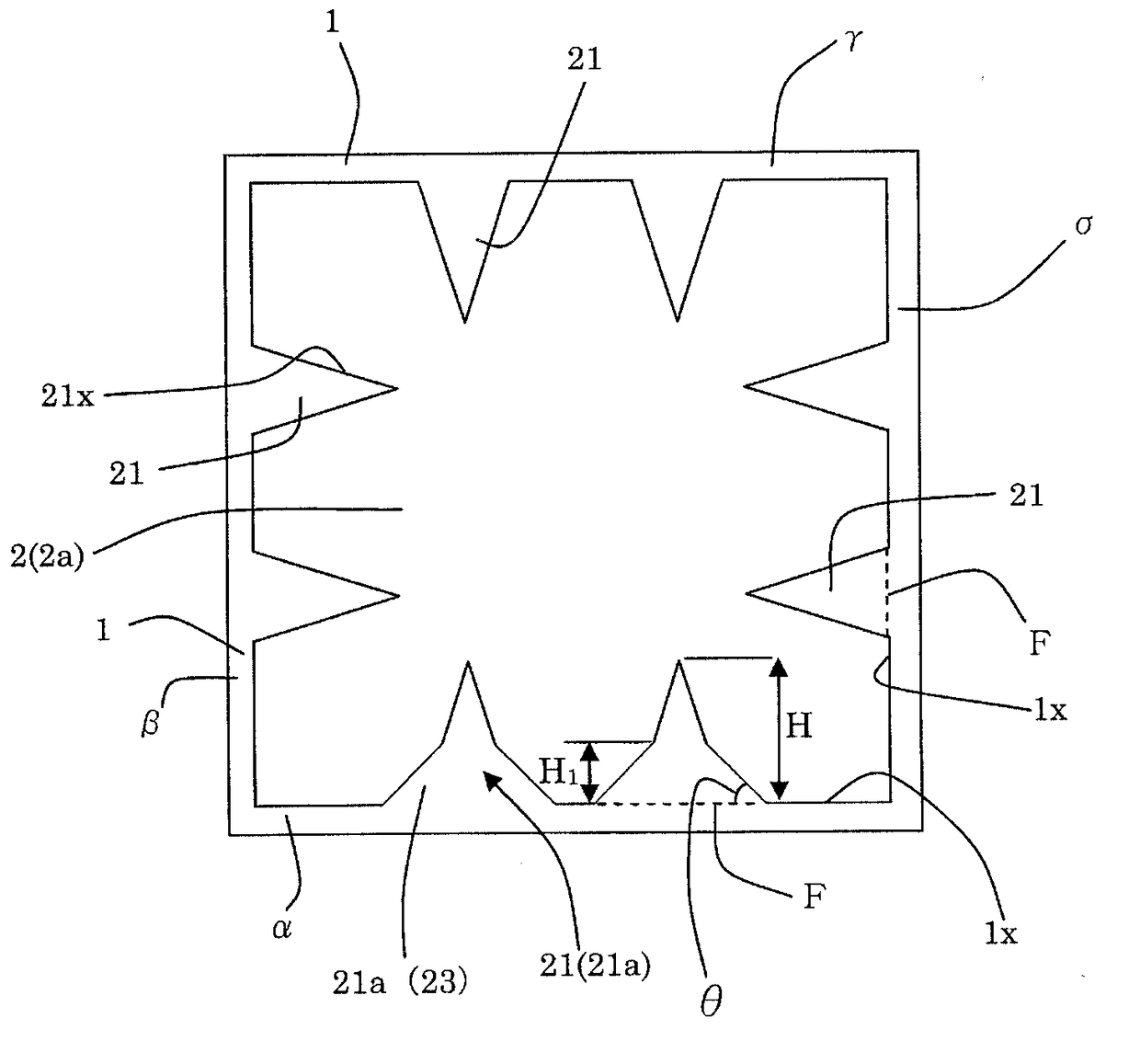

Honeycomb structure

ActiveUS20180280958A1Suitable purification performanceIncrease surface areaCatalyst carriersDispersed particle filtrationMechanical engineeringHoneycomb structure

A honeycomb structure includes a pillar-shaped honeycomb structure body having porous partition walls, wherein the partition walls have projecting portions, the projecting portions include specific projecting portions in which side surfaces have a divergent shape inclined at an inclination angle of 40 to 70°, a relation of 0.04≤H / A≤0.40 is satisfied, a relation of 0.04≤H1 / A≤0.38 is satisfied, the height H of the specific projecting portion and the height H1 of the hem satisfy a relation of H1<H, and a ratio of a total number of the specific projecting portions is 2.5% or more.

Owner:NGK INSULATORS LTD

Shaped heterogeneous catalysts

ActiveUS8563460B2Increased geometric surface areaReduced strengthNitrogen compoundsCeramic shaping apparatusSteam reformingEngineering

Owner:JOHNSON MATTHEY PLC

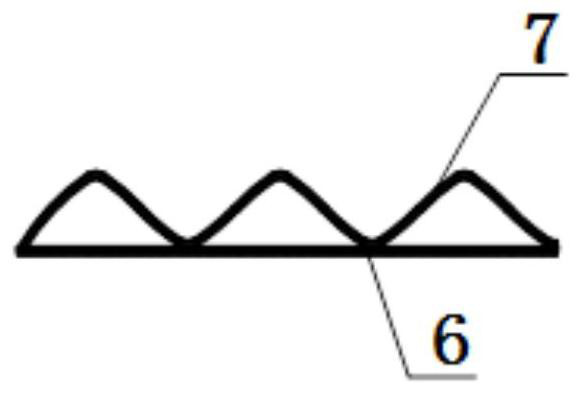

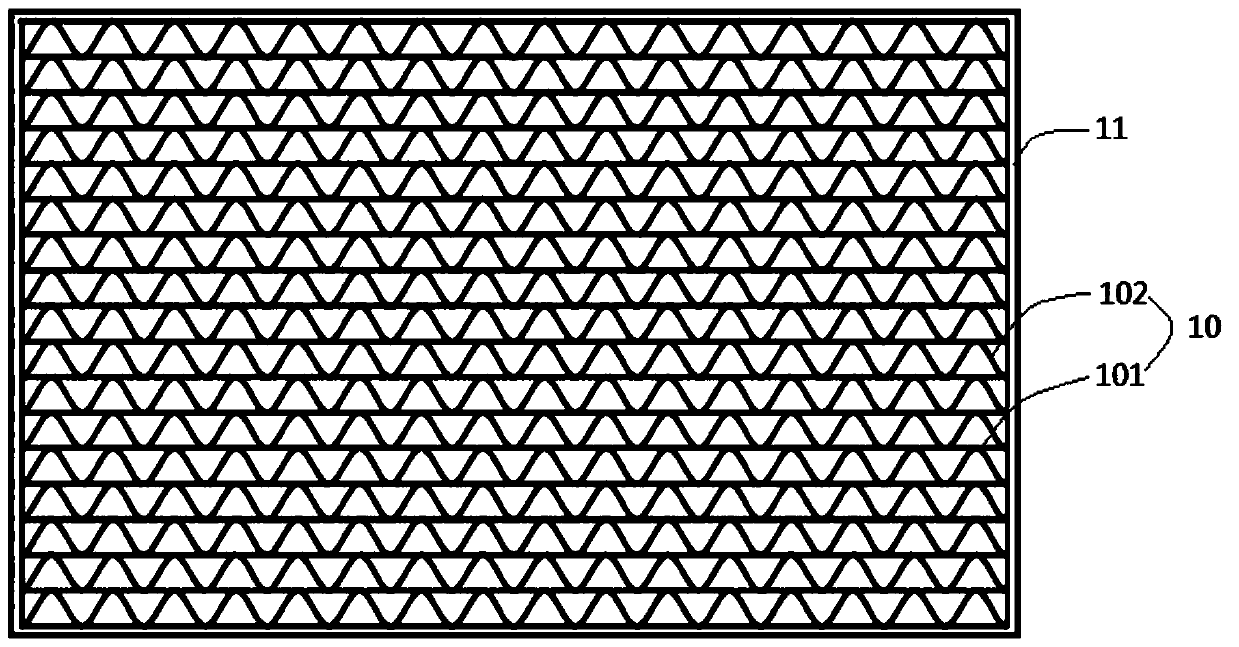

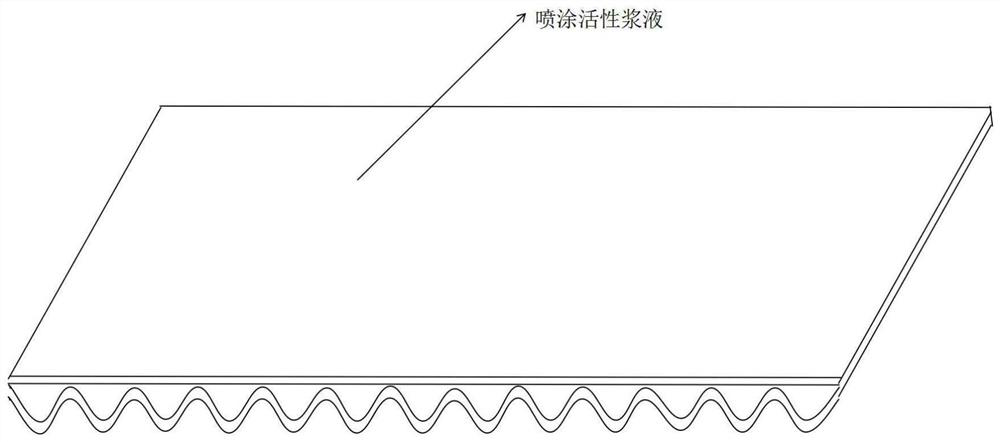

Fiber-based carrier, waste gas treatment module and preparation method

InactiveCN111871196AEasy to prepareEasy to industrializeCatalyst carriersDispersed particle separationFiberProcess engineering

The invention provides a fiber-based carrier, a waste gas treatment module and a preparation method. Planar refractory fiber paper at a first path of feeding unit sequentially passes through a first path of feeding tensioning unit and a first path of feeding guide unit to enter a sizing unit for sizing; planar refractory fiber paper at the second path of feeding unit enters the corrugated pressingunit through the second path of feeding tensioning unit and the second path of feeding guide unit in sequence, is pressed into corrugated refractory fiber paper by the corrugated pressing unit and then enters the compounding unit to be gathered with the sized planar refractory fiber paper; the two materials are pressed for adhesion and lamination to form a carrier module; then the carrier modulecomposite base material passes through the guide unit and then enters the winding unit to be collected into a roll shape for later use; then the collected carrier module composite base material is processed into a cylinder, a fan-shaped body or a cubic module; and strengthening treatment is carried out on the processed and molded carrier module composite base material, and drying and roasting arecarried out to obtain the carrier module. Industrialized batch production is achieved, and the service life of the module is prolonged.

Owner:QINGDAO HSJ ENVIRONMENTAL PROTECTION TECH CO LTD +1

Pyrolysis hard carbon material and preparation method and use thereof

ActiveCN102956876BIncreased geometric surface areaImprove performanceElectrolytic capacitorsCell electrodesPtru catalystElectrical battery

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

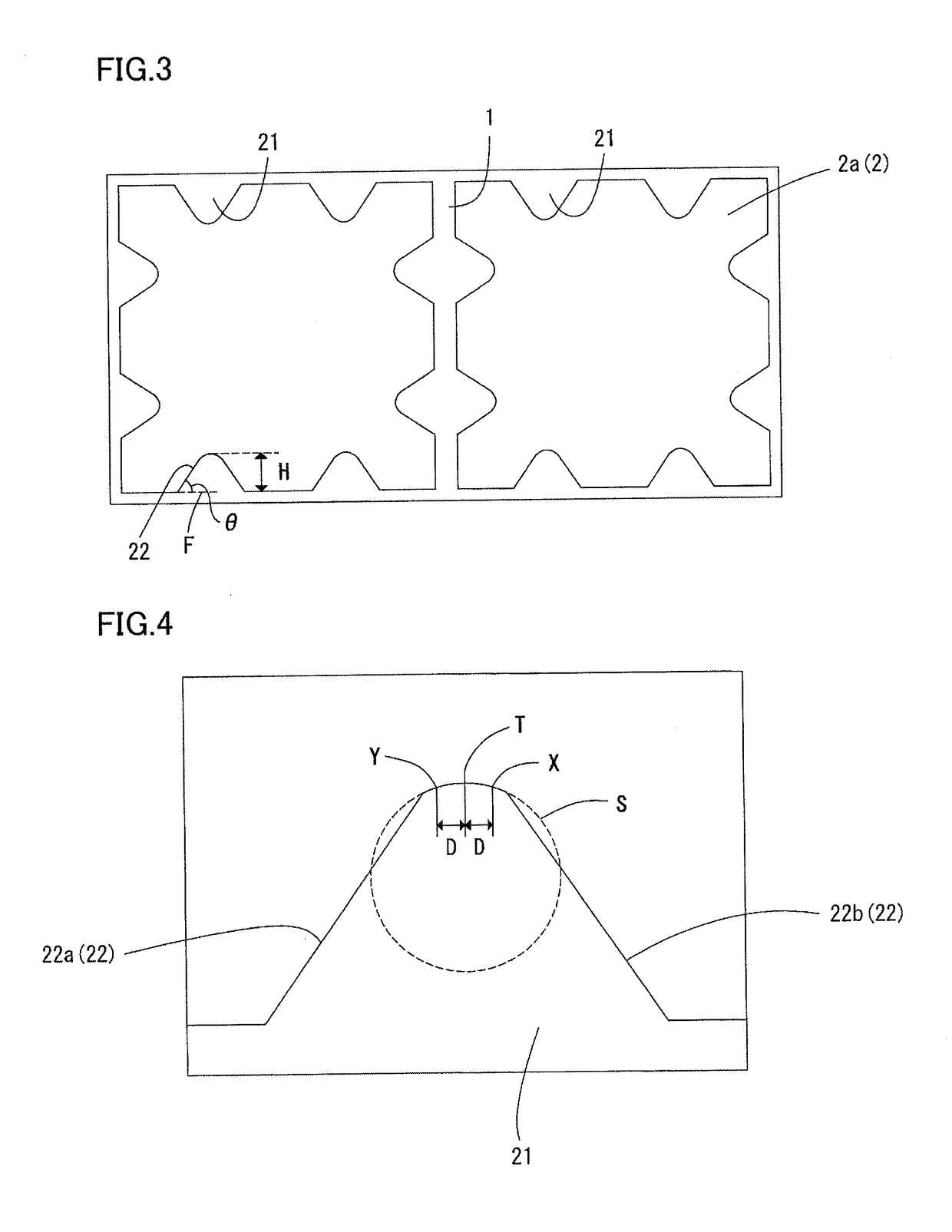

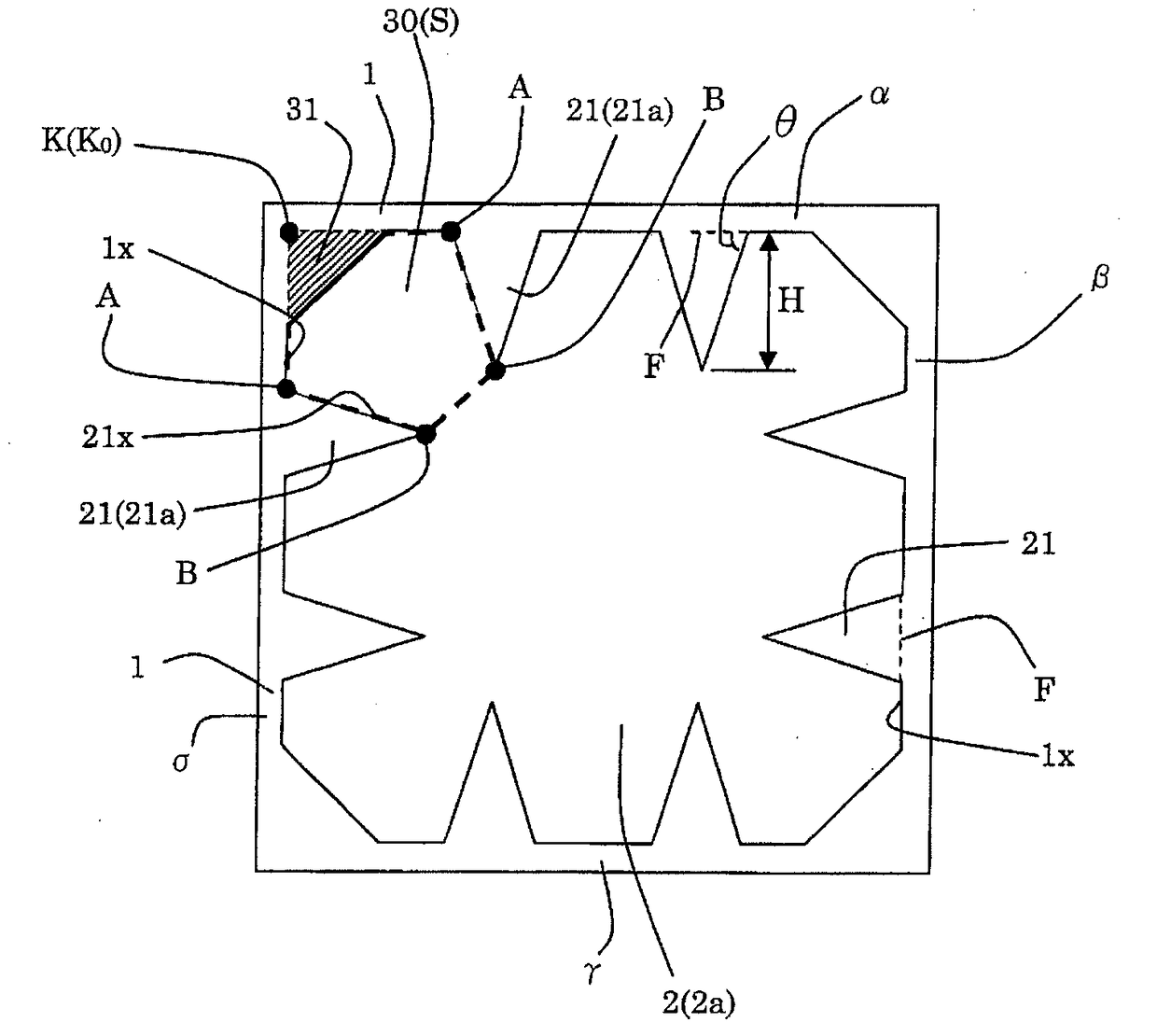

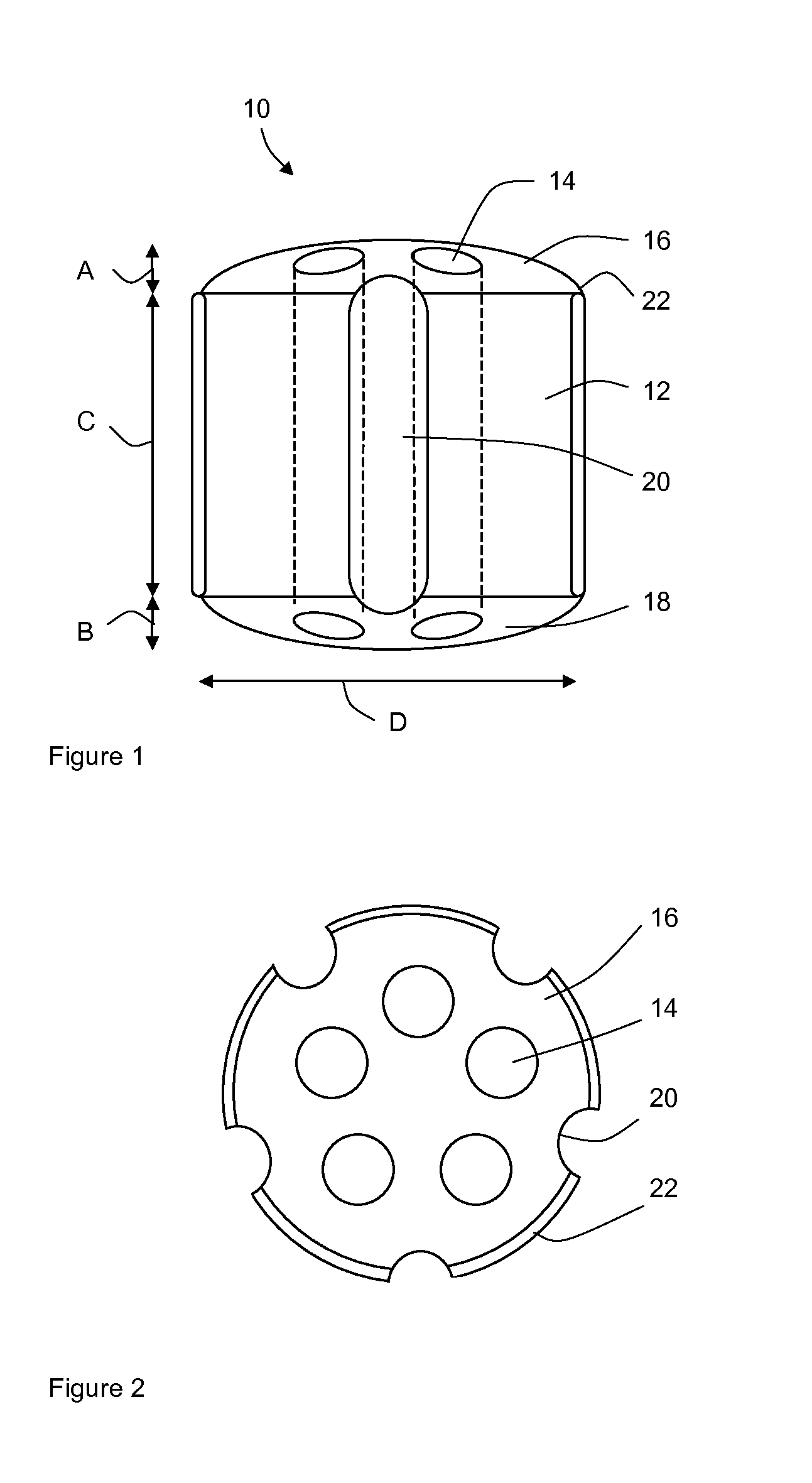

Honeycomb structure

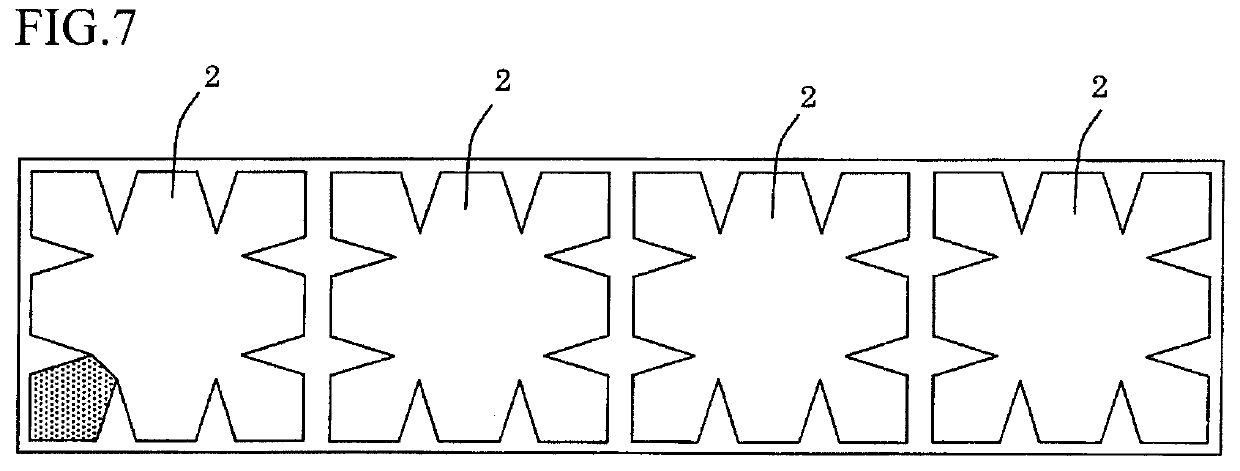

ActiveCN108686508AGuaranteed wear resistanceNot easy to stagnateCatalyst carriersDispersed particle filtrationPtru catalystMechanical engineering

The invention provides a honeycomb structure which enhances the purification performance during high exhaust flow and maintains the wear resistance in the condition of carrying a catalyst. The honeycomb structure includes a honeycomb structure body having porous partition walls which are disposed in region to define a plurality of cells (2) extending from a first end surface to a second end surface and forming a fluid channel of fluid and a circumferential wall arranged around the partition walls, wherein the partition walls are provided with protrusions (21) which protrude to extend into thecells and are continuously disposed in an extending direction of the cells, the cells have a polygonal shape in a cross section orthogonal to the extending direction of the cells, the plurality of cells include a plurality of specific cells (2a) having at least one place where two sides each of which is provided with a different number of protrusions intersect each other, and in the cross sectionorthogonal to the extending direction of the cells, disposition directions of the shapes of the cells including the protrusions in the specific cells are different in one specific cell and other specific cells other than the one specific cell.

Owner:NGK INSULATORS LTD

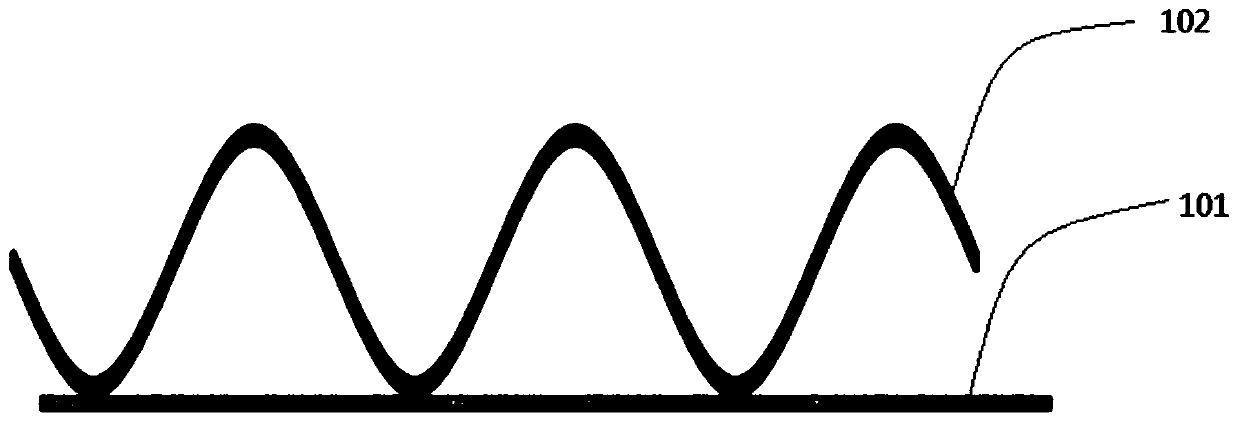

Honeycomb structure

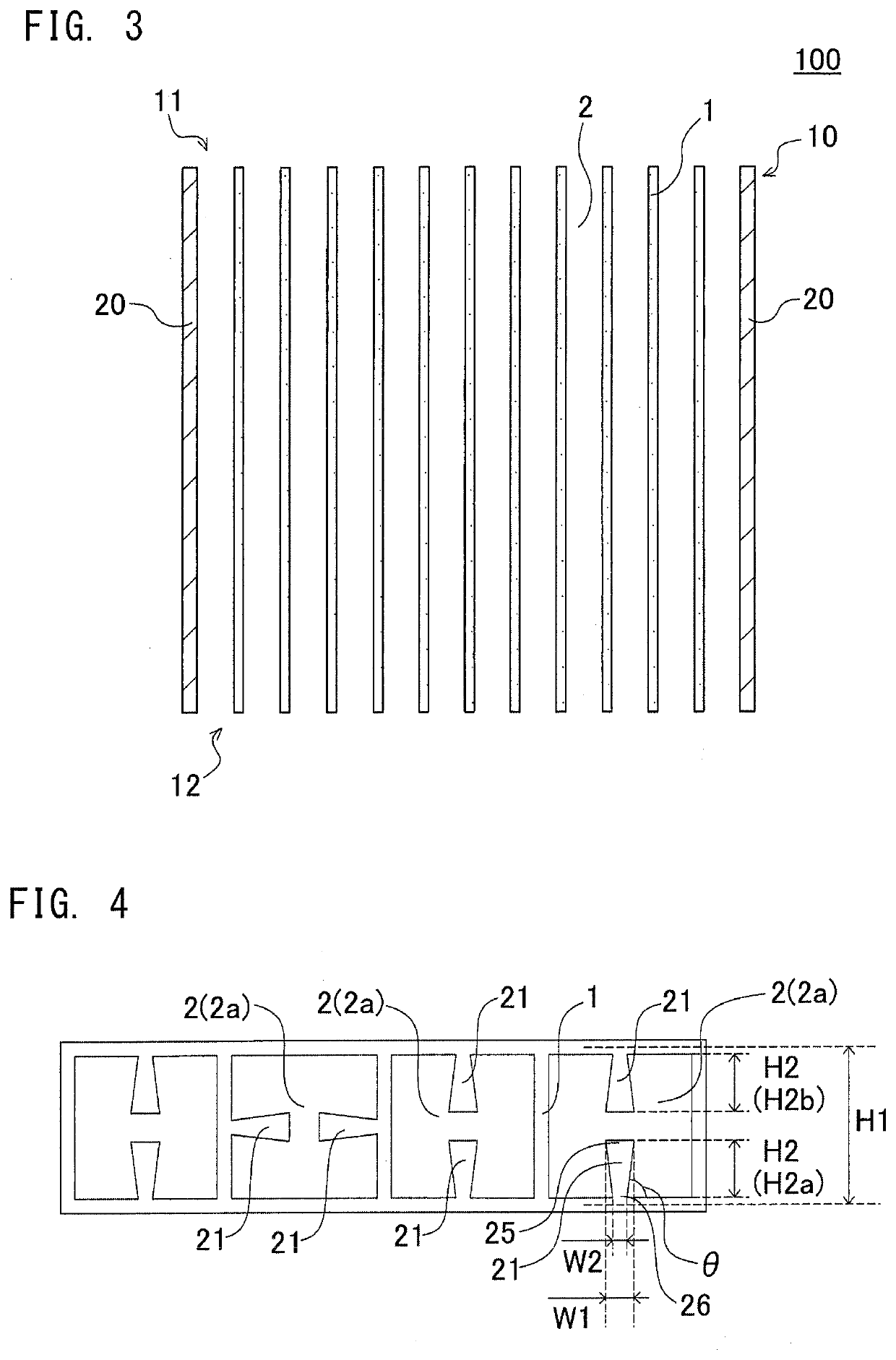

ActiveUS11020733B2Suppress worsening of emissionImprove performancePhysical/chemical process catalystsDispersed particle filtrationEngineeringMechanical engineering

A honeycomb structure includes a pillar-shaped honeycomb structure body having porous partition walls surrounding a plurality of cells which extend from a first to a second end face and which form flow channels of a fluid, and a circumferential wall enclosing the partition walls, wherein, specific cell of the cells is provided with a pair of projection which projects into the cell from the partition wall, the projection projects, in at least a pair of opposed partition walls among the partition walls constituting the cell, into the cell from a first and a second side, and which is provided continuously in a direction the cell extends, and in the case where the width of a top part of the projection is denoted by W1, and the width of a bottom part of the projection is denoted by W2, W1>W2 holds, and W2 / W1 is 0.5 to 0.9.

Owner:NGK INSULATORS LTD

Fiber-based corrugated photocatalytic module and preparation method thereof

InactiveCN111167304ASmall bulk densityLight in massGas treatmentDispersed particle separationNano catalystFiber

The invention provides a fiber-based corrugated photocatalytic module and a preparation method thereof. The photocatalytic module is mainly used for photocatalytic degradation of pollutants. Accordingto the preparation method of the fiber-based corrugated photocatalysis module in the invention, the photocatalytic module is composed of a plurality of catalyst units which are stacked in sequence and a module shell; the plurality of the catalyst units which are stacked in sequence are packaged in the module shell; each catalyst unit comprises a carrier and a nanometer TiO2 catalyst layer which is embedded into the carrier and is uniformly distributed on the surface of the carrier; the carrier is formed by bonding and compounding corrugated refractory fiber paper and planar refractory fiber paper; and the corrugated refractory fiber paper is prepared by processing the planar refractory fiber paper. The photocatalysis module has the characteristics of high activity, strong impact resistance, free assembling of specifications and sizes and the like.

Owner:QINGDAO HSJ ENVIRONMENTAL PROTECTION TECH CO LTD +1

Method for preparing butyl acetate by using molecular sieve immobilized catalyst

ActiveCN105820052BNo pollutionAvoid churnMolecular sieve catalystsOrganic compound preparationAcetic acidChemical synthesis

The invention belongs to the field of chemical synthesis processes, and particularly relates to a method for preparing n-butyl acetate from a molecular sieve immobilized catalyst. Butanol, acetic acid and water are added to an esterification reaction still according to the proportion of (2-5 L):1L:3L, the molecular sieve immobilized catalyst accounting for 5% to 30% of the total proportion of the volume of the reaction system is added, reacting is carried out for 15 min to 30 min at the temperature of 80 DEG C to 115 DEG C, then condensation is carried out, and n-butyl acetate is obtained through rectification and recovery. N-butyl acetate is prepared through the catalytic action of the molecular sieve immobilized catalyst, the acetic acid conversion rate reaches 98% or above, the yield of n-butyl acetate is 99.5% or above, and the obtained esterification product is high in purity; the molecular sieve immobilized catalyst can be reused 6-8 times, so that the production cost is greatly reduced.

Owner:GUANGXI XINTIANDE ENERGY +2

Honeycomb structure

ActiveUS10828631B2Improve performanceIncreased geometric surface areaPhysical/chemical process catalystsDispersed particle filtrationMechanical engineeringHoneycomb structure

A honeycomb structure includes a pillar-shaped honeycomb structure body having porous partition walls, wherein the partition walls have projecting portions,in the cells of 10% or more of the plurality of cells, the projecting portions project into the cells, a tip curvature radius R of an apex of each of the projecting portions is from 0.01 to 0.1 mm, side surfaces of the projecting portions are inclined to the surfaces of the partition walls at an inclination angle of 40 to 70°, and a relation of 0.04≤H / A≤0.4 is satisfied.

Owner:NGK INSULATORS LTD

Composite porous metal catalyst distillation construction member and preparing method thereof

InactiveCN1241664CImprove conversion rateHigh selectivityCatalyst activation/preparationDistillation separationCeramic coatingActive component

The present invention discloses a composite porous metal catalytic distillation structure component and its preparation method. Said structure component is formed from base body, modifying layer and active layer. It is characterized by that it uses the porous metal regular packing with micropore structure as base body, uses the ceramic coating layer formed after the surface of the base body is treated as modifying layer and uses the catalyst active component covering on the modifying layer as active layer. Said invented catalytic distillation structure component integrates the distillation packing and catalyst into one body so as to raise its reaction and separation effect, and is easily suitable for industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

Honeycomb structure

PendingCN111468194AImprove heating effectSmall heat capacityCatalyst carriersDispersed particle filtrationMechanical engineeringHoneycomb structure

Provided is a honeycomb structure in which an increase in pressure loss can be suppressed and an improvement in temperature increase can be expected. The honeycomb structure includes a pillar-shaped honeycomb structure body having porous partition walls 1 surrounding a plurality of cells 2 which extend from a first to a second end face and which form flow channels of a fluid, and a circumferentialwall enclosing the partition walls, wherein, specific cell of the cells is provided with a pair of projection which projects into the cell from the partition wall, the projection projects, in at least a pair of opposed partition walls among the partition walls 1 constituting the cell, into the cell from a first and a second side, and which is provided continuously in a direction the cell extends,and in the case where the width of a top part 25 of the projection 21 is denoted by W1, and the width of a bottom part 26 of the projection 21 is denoted by W2, W1>W2 holds, and W2 / W1 is 0.5 to 0.9.

Owner:NGK INSULATORS LTD

Silicon carbide porous ceramic filter and manufacturing method thereof

Owner:淄博鑫拓耐火材料有限公司

Sulfureous resistant four-effect catalyst for purifying tail gas of vehicle

InactiveCN101269335BImprove sulfur resistanceEffect of catalytic efficiencyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsEmission standardAutomotive emissions

The present invention relates to an anti-sulfur four-way catalyst which is provided with optimal performance and used for purifying automobile exhaust. First, a glass coating solution is prepared, then a metal alloy carrier is repeatedly immerged into the glass coating solution for coating, drying, calcinating so as to get the glass coating on the carrier, then the glass coating is repeatedly immerged into a mixed solution composed of titanium and zirconium salts and into a precious metal catalyst solution; after being baked and calcinated, the anti-sulfur four-way catalyst which is provided with optimal performance and used for purifying automobile exhaust and takes the alloy metal as a carrier is obtained. The four-way catalyst of the present invention has the following advantages that: (1) PM and NOxare catalyzed on the same catalytic bed; (2) the catalytic efficiency is not affected if the concentration of SO2 ranges from 500 to 800ppm; (3) compared with other catalysts, the catalyst has high anti-sulfur performance and takes metal as the carrier. Besides, the catalyst can ensure an engine meeting the emission of European III in a laboratory, a bench experimental testing and application to meet the requirements for emission standards above European IV.

Owner:JILIN UNIV

Honeycomb structure

ActiveUS10953394B2Increase surface areaPurification performance can not be suppressedCatalyst carriersDispersed particle filtrationEngineeringMechanical engineering

Owner:NGK INSULATORS LTD

Honeycomb structure

ActiveUS20200230588A1Increase widthReduce weightPhysical/chemical process catalystsDispersed particle filtrationEngineeringMechanical engineering

A honeycomb structure includes a pillar-shaped honeycomb structure body having porous partition walls surrounding a plurality of cells which extend from a first to a second end face and which form flow channels of a fluid, and a circumferential wall enclosing the partition walls, wherein, specific cell of the cells is provided with a pair of projection which projects into the cell from the partition wall, the projection projects, in at least a pair of opposed partition walls among the partition walls constituting the cell, into the cell from a first and a second side, and which is provided continuously in a direction the cell extends, and in the case where the width of a top part of the projection is denoted by W1, and the width of a bottom part of the projection is denoted by W2, W1>W2 holds, and W2 / W1 is 0.5 to 0.9.

Owner:NGK INSULATORS LTD

Honeycomb structure

ActiveUS20190299203A1Increased geometric surface areaInhibit deteriorationGas treatmentDispersed particle separationEngineeringHoneycomb structure

A honeycomb structure includes a pillar-shaped honeycomb structure body which has porous partition walls disposed to surround a plurality of cells Among the partition walls surrounding one of the cells, each of the partition walls constituting two opposite sides of the cell sandwiched therebetween is provided with a projection which project to extend into the cell and which is continuously provided in a direction in which the cell extends, and the area S1 of one region of the cell divided by a virtual line that virtually connects distal ends of the two projections in a section of the honeycomb structure body, and the area S2 of the other region (S1≤S2) of the cell satisfy 70%≤S1 / S2×100%.

Owner:NGK INSULATORS LTD

Honeycomb structure

ActiveUS10722877B2Increase blockingSuitable purification performanceCatalyst carriersDispersed particle filtrationStructural engineeringMechanical engineering

A honeycomb structure includes a pillar-shaped honeycomb structure body having porous partition walls, wherein the partition walls have projecting portions, the projecting portions include specific projecting portions in which side surfaces have a divergent shape inclined at an inclination angle of 40 to 70°, a relation of 0.04≤H / A≤0.40 is satisfied, a relation of 0.04≤H1 / A≤0.38 is satisfied, the height H of the specific projecting portion and the height H1 of the hem satisfy a relation of H1<H, and a ratio of a total number of the specific projecting portions is 2.5% or more.

Owner:NGK INSULATORS LTD

Thin-wall and high-specific-surface-area honeycomb porous ceramic and preparation method thereof

InactiveCN108706985AIncreased geometric surface areaImprove thermal shock resistanceCeramicwareHydrated aluminaKaolin clay

The invention discloses thin-wall and high-specific-surface-area honeycomb porous ceramic and a preparation method thereof. The thin-wall and high-specific-surface-area honeycomb porous ceramic is prepared from, by weight, 35-45% of high-purity flaky talcum powder, 1-5% of hydrated alumina micro powder, 5-10% of washed kaolin powder, 5-10% of calcined kaolin powder, 20-30% of 99-grade alpha-alumina powder, 10-15% of quartz flaky micro powder, 3-5% of cordierite raw powder, 2-3% of liquid surfactant, 0.5-2% of powder surfactant, 2-3% of elasticizer, 1.8-2.3% of internal lubricant, 1.8-2.3% of external lubricant and 22-28% of high purity water. The honeycomb porous ceramic greatly increases the geometric surface area of a carrier and improves thermal shock resistance, and the honeycomb porous ceramic prepared through the preparation method can effectively improve the production efficiency and improve the product performance.

Owner:安徽中鼎美达环保科技有限公司

Honeycomb structure

ActiveCN108691618ANot easy to stagnateIncreased geometric surface areaPhysical/chemical process catalystsDispersed particle filtrationStructural engineeringMechanical engineering

The present invention provides a honeycomb structure including a honeycomb structure portion having a partition wall partitioning a compartment; a compartment is provided with protrusions on both sides extending from a corner of the compartment; a protrusion disposed at a shorter distance from the one corner portion to the protrusion portion from a corner extending from a corner portion and located at a position closest to the corner portion as a first protrusion portion; a protrusion disposed at a longer distance from the one corner portion to the protrusion portion from a corner extending from a corner portion and located at a position closest to the corner portion as a second protrusion portion; the length of one side on which the second protrusion is provided is L, the distance from the corner portion to the bottom center position of the second protrusion is A, and the number of protrusions on the side on which the second protrusion is provided is N,the relationship of the formula(1): 1 / (N+1) < A / L is satisfied. The ratio of the total number of corners formed to satisfy the relationship of the formula (1) to the total number of corners of all the cells in the honeycomb structure portion is 2.5% or more.

Owner:NGK INSULATORS LTD

Method for utilizing molecular sieve supported catalyst to prepare acetic ether

InactiveCN105753691AGood effectNo pollutionMolecular sieve catalystsOrganic compound preparationMolecular sieveAcetic acid

The invention belongs to the field of chemical synthesis processes and particularly relates to a method for utilizing a molecular sieve supported catalyst to prepare acetic ether.Ethanol, acetic acid and water are vaporized according to the volume ratio of 3-8 L to 2-3 L to 3 L, then a vaporization product is led into an esterification reaction kettle, the molecular sieve supported catalyst accounting for 5-30% of the total volume percentage of a reaction system is added, reaction is performed at the temperature of 110-115 DEG C for 15-30 minutes, condensation is performed, and the acetic ether is obtained through distillation recovery.The method utilizes the catalytic action of the molecular sieve supported catalyst to prepare the acetic ether, the acetic acid conversion rate is up to 98% or above, the acetic ether yield is 99.5% or above, an obtained esterification product is high in purity, the molecular sieve supported catalyst can be repeatedly used for 6-8 times, and the production costs are greatly reduced.

Owner:GUANGXI XINTIANDE ENERGY

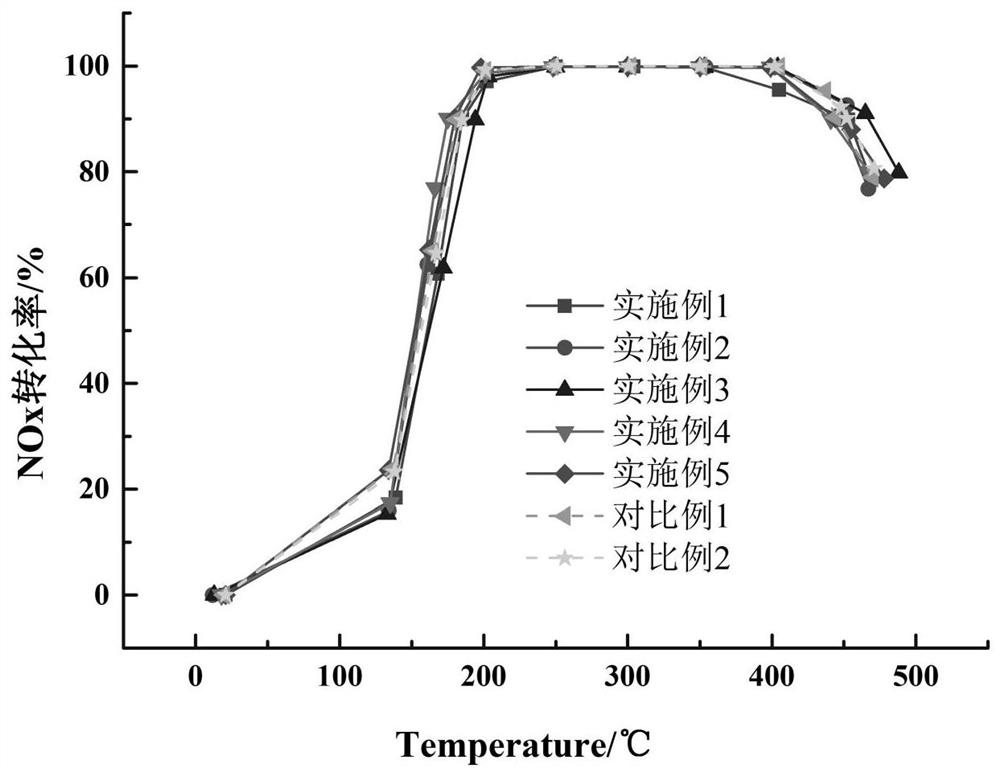

Low-temperature SCR catalytic module and preparation method and application thereof

InactiveCN111871197ALow densityHigh strengthGas treatmentDispersed particle separationFiberPtru catalyst

The invention relates to the technical field of air pollution control and environmental catalytic materials, in particular to a low-temperature SCR catalytic module and a preparation method and application thereof, wherein the obtained SCR catalytic module is mainly used for removing and purifying NOx in low-temperature flue gas. The preparation method of the low-temperature SCR catalytic module can reduce the coating frequency of the catalytic module, so that energy consumption is reduced, and the product performance is improved. In the forming process of the corrugated refractory fiber papersheet and the planar refractory fiber paper bottom lining, the low-temperature SCR catalyst active slurry is optimally used for the inorganic strength enhancer, the reinforced refractory fiber papersheet is processed into a carrier with a fixed size, and the carrier is bonded by utilizing the low-temperature SCR catalyst active slurry, so that the strength of the refractory fiber paper sheet isimproved. The roasted carrier module pre-coated with the catalyst is further coated with the catalyst, wherein the coating amount of the catalyst is increased; meanwhile, the catalyst is used for filling, so that the effect between the refractory fiber and the catalyst coating is enhanced.

Owner:QINGDAO HSJ ENVIRONMENTAL PROTECTION TECH CO LTD +1

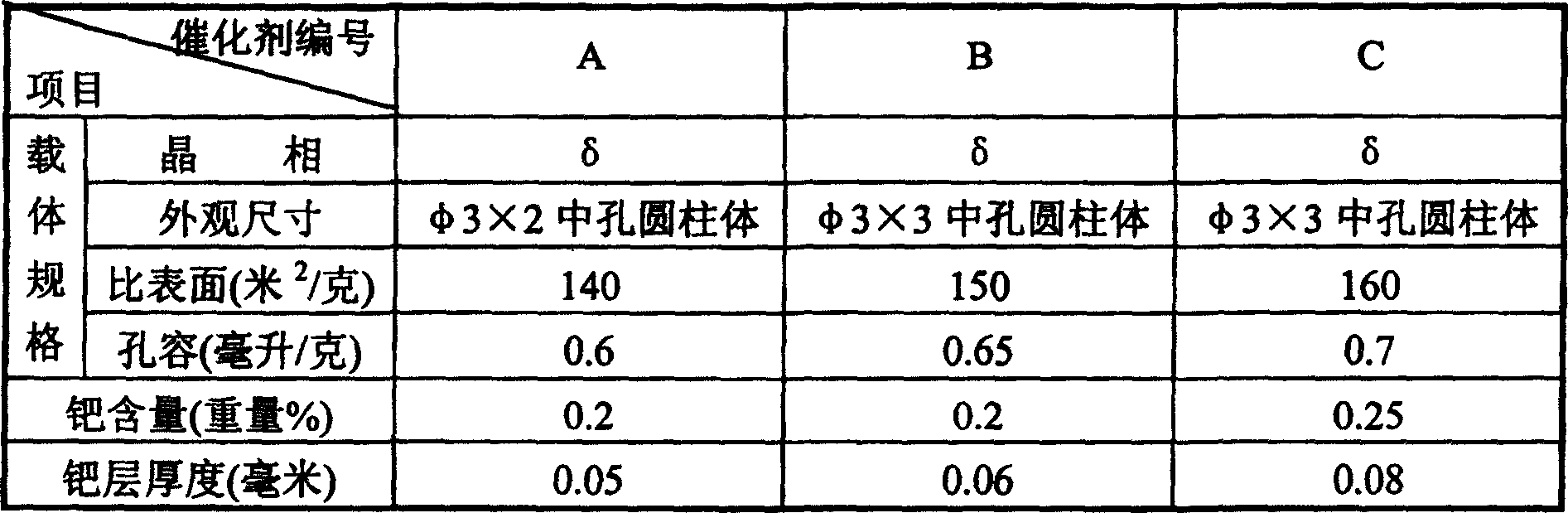

First-stage selective hydrogenation catalyst for pyrolysis gasoline

InactiveCN1218020CSmall pressure dropPressure drop can reduceRefining to eliminate hetero atomsPalladiumPyrolysis gasoline

The present invention relates to a catalyst for pyrolysis gasoline one-stage selective hydrogenation. Said invention utilizes the adoption of loading palladium on delta-phase alumina carrier, in which the pore volume of the carrier is 0.6-0.9 ml / g, specific surface area is 140-170 sq.m / g and the thickness of catalyst shell layer is 0.03-0.09 mm.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic distillation tower member and its manufacture

InactiveCN1193820CImprove conversion rateHigh selectivityChemical/physical/physico-chemical processesGas phaseCatalytic distillation

The catalytic distillation tower member consists of base body, modified layer and activating layer and features the base body made of regular porous ceramic stuffing, the modified layer being coating formed through surface treatment of the base body with alpha-alumina, and the activating layer comprising active catalyst component coated to the modified layer. The catalyst distillation tower member integrates the distilling stuffing and catalyst; has high efficiency, enough gas-liquid contact area, efficient mass transfer between the gas phase and the liquid phase, and excellent reaction and separation effect; and is convenient in assembling and disassembling and suitable for industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com