Low-temperature SCR catalytic module and preparation method and application thereof

An SCR catalyst and low-temperature technology, which is applied in the field of low-temperature SCR catalytic modules and its preparation, can solve problems such as high solid content of slurry, easy cracking of coating, and reduced yield, and achieve simplified process steps, large reaction surface, and improved yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

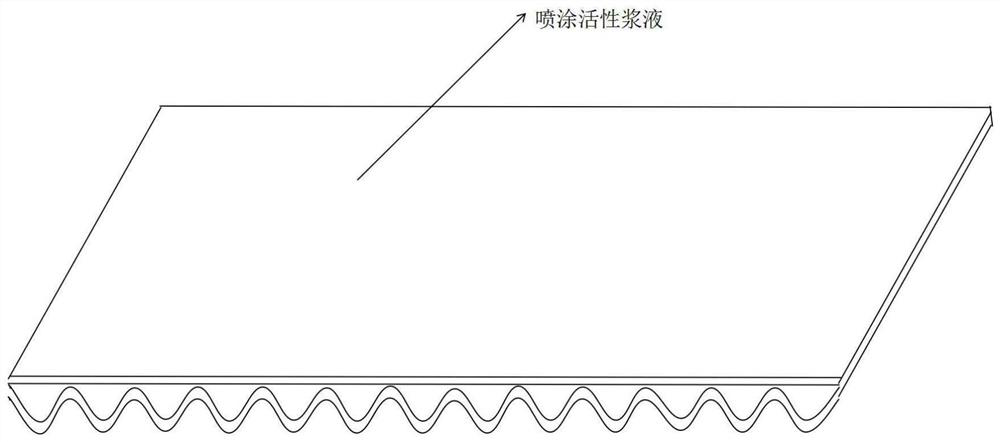

[0032] 1. Preparation of catalyst carrier

[0033] S11. Add 10.4kg vanadyl oxalate to 289kg deionized water, then add 6.6kg ammonium molybdate, 54kg silica sol, stir and mix evenly, add 90kg TiO 2 , sonicate for 2 hours under stirring conditions, and prepare a low-temperature SCR catalyst active slurry with a solid content of 20%; when the corrugated refractory fiber paper sheet is bonded to the flat glass fiber paper substrate, the low-temperature SCR catalyst active slurry is evenly sprayed, dried and collected. volume ready for use;

[0034] S12. Laying and cutting the refractory fiber paper into 500mm*500mm*500mm cubes and placing them in the mould;

[0035] S13, immersing the carrier obtained in S12 in 20% low-temperature SCR catalyst active slurry for 5 minutes, vacuum purging, microwave drying at 80°C, and roasting in air at 450°C for 3 hours;

[0036] 2. Catalytic module coating

[0037] S21. Add 5.2kg of vanadyl oxalate to 167kg of deionized water, then add 3.3kg o...

Embodiment 2

[0046] 1. Preparation of catalyst carrier

[0047] S11. Add 10.4kg vanadyl oxalate to 439kg deionized water, then add 6.6kg ammonium molybdate, 54kg silica sol, stir and mix evenly, add 90kg TiO 2, under stirring conditions, ultrasonic 2h, the preparation of low-temperature SCR catalyst active slurry with a solid content of 15%; when the corrugated refractory fiber paper sheet is bonded to the flat glass fiber paper backing, the low-temperature SCR catalyst active slurry is evenly sprayed, dried and rolled stand-by;

[0048] S12. Laying and cutting the refractory fiber paper into 500mm*500mm*500mm cubes and placing them in the mould;

[0049] S13, immersing the carrier obtained in S12 in 15% low-temperature SCR catalyst active slurry for 5 minutes, vacuum purging, microwave drying at 100°C, and roasting in air at 400°C for 4 hours;

[0050] 2. Catalytic module coating

[0051] S21. Add 5.2kg vanadyl oxalate to 167kg deionized water, then add 4.9kg ammonium molybdate, 18kg s...

Embodiment 3

[0057] 1. Preparation of catalyst carrier

[0058] S11. Add 5.2kg of vanadyl oxalate to 820kg of deionized water, then add 3.3kg of ammonium molybdate and 27kg of silica sol, stir and mix evenly, add 45kg of TiO 2 , under stirring conditions, ultrasonic 2h, prepared low-temperature SCR catalyst active slurry with a solid content of 5%; when the corrugated refractory fiber paper sheet is bonded to the flat glass fiber paper backing, evenly spray the low-temperature SCR catalyst active slurry, dry and rewind stand-by;

[0059] S12. Laying and cutting the refractory fiber paper into 500mm*500mm*500mm cubes and placing them in the mould;

[0060] S13. Add 5.2kg vanadyl oxalate to 370kg deionized water, then add 3.3kg ammonium molybdate, 27kg silica sol, stir and mix evenly, add 45kg TiO 2 10% low-temperature SCR catalyst active slurry was obtained by ultrasonication for 2 hours under stirring conditions, and the carrier obtained in S12 was immersed in the 10% low-temperature SCR...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com