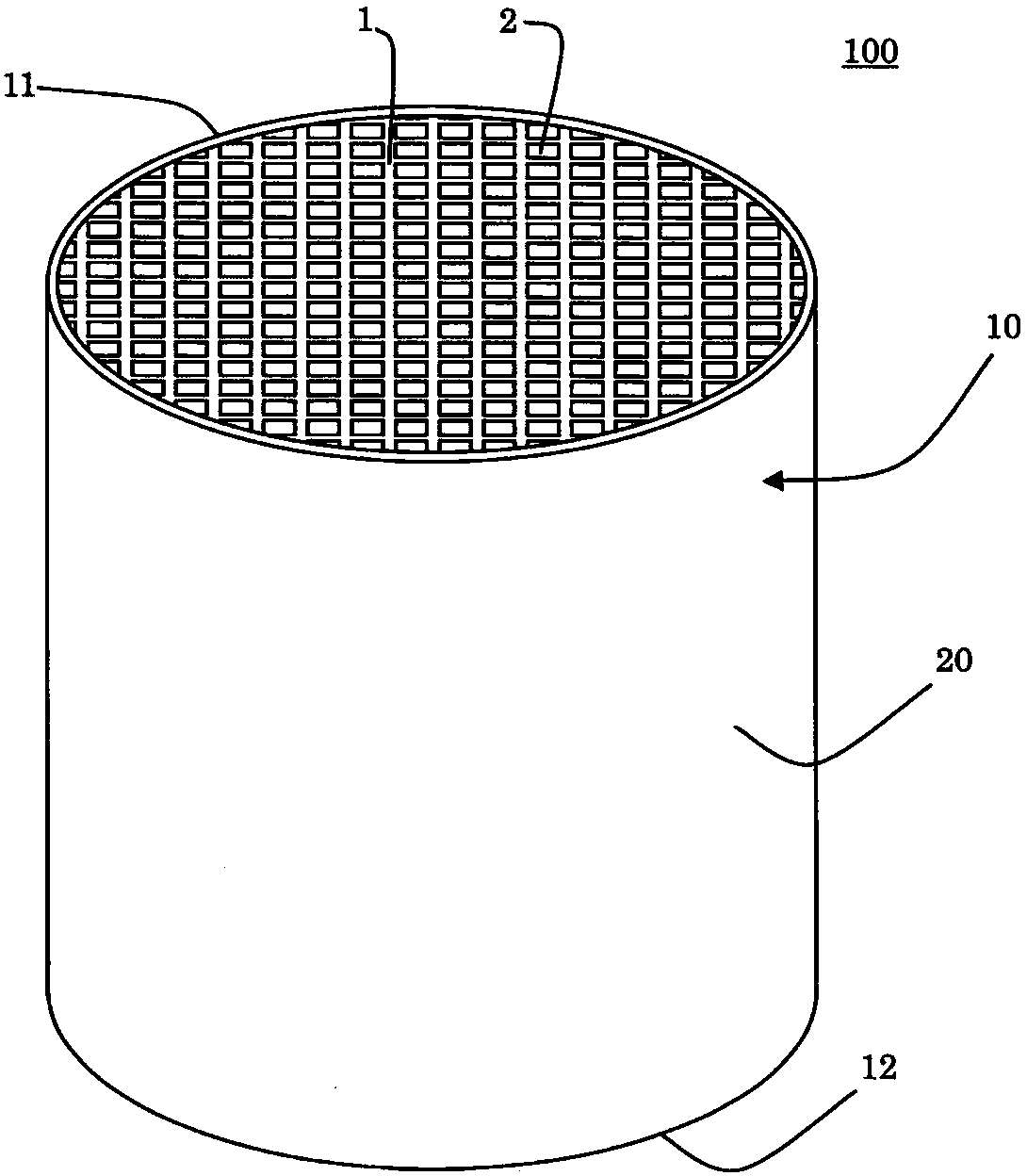

Honeycomb structure

A honeycomb structure body and technology of honeycomb structure, applied in the direction of catalyst carrier, catalyst carrier, exhaust gas treatment, etc., can solve the problems of deterioration, inability to suppress purification performance, easy stagnation of exhaust gas flow, etc., to achieve improved purification performance, less stagnation, The effect of abrasion resistance maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

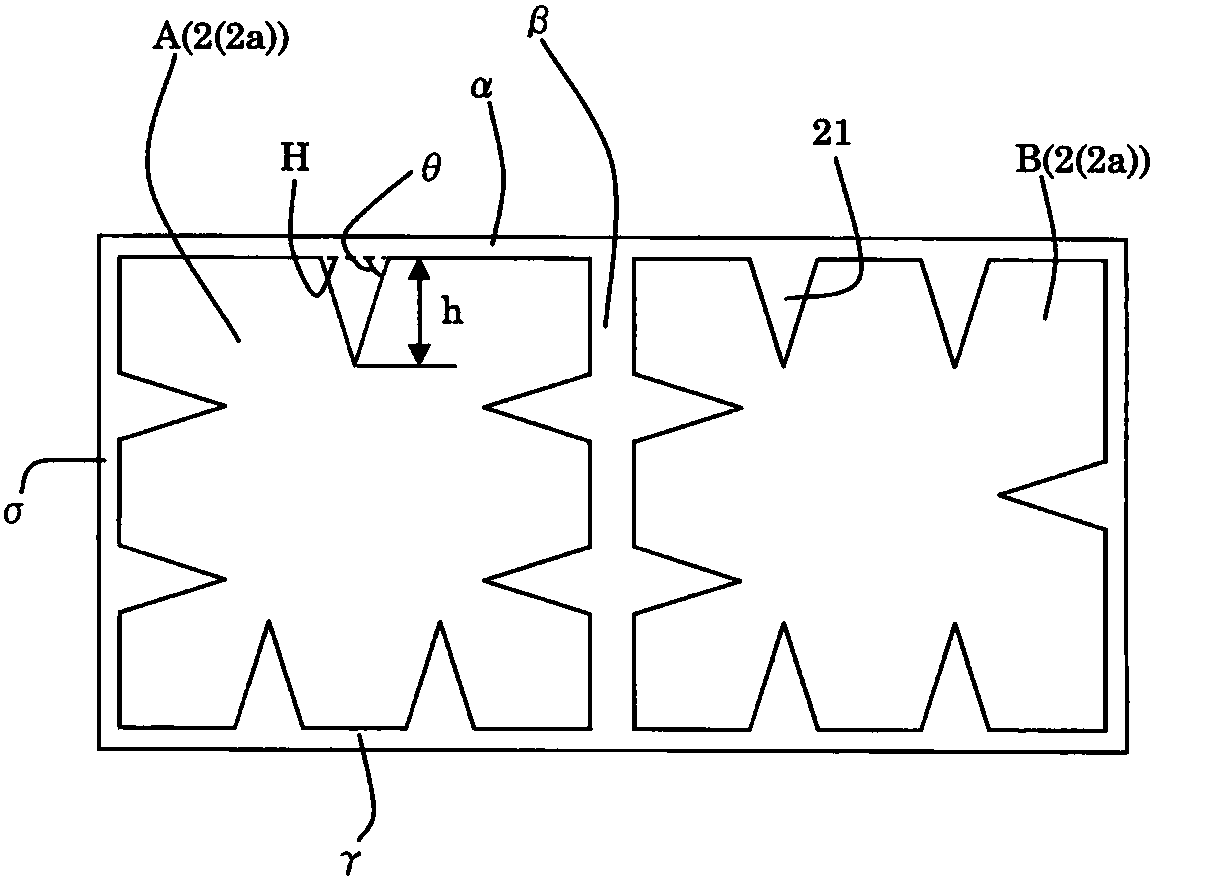

[0086] In Example 1, first, a molding material for producing a honeycomb structure was prepared. Specifically, a binder, a surfactant, a pore-forming material, and water are added to a ceramic raw material to form a molding raw material. It should be noted that kaolin, talc, and alumina, which are cordierite-forming raw materials, were used as ceramic raw materials.

[0087] Next, the obtained molding raw materials are kneaded with a kneader, and then kneaded with a vacuum mud mill to form a green body. Next, the obtained green body is extruded using a nozzle to produce a honeycomb molded body. The change in the arrangement direction of the nozzle using the shape of the cell including the protrusion is Figure 4 The nozzle shown "the compartment shape of one specific compartment is 4 times symmetric to the compartment shape of other specific compartments adjacent to one specific compartment". After the honeycomb molded body is fired, the thickness of the partition wall is 3...

Embodiment 2~18、 comparative example 1~7

[0122] A honeycomb structure was produced in the same manner as in Example 1, except that the predetermined number of protrusions and the arrangement direction of the shape of cells including the protrusions were changed as shown in Table 1 and Table 3.

[0123] For the honeycomb structures of Examples 2 to 18 and Comparative Examples 1 to 7, the thickness of the partition wall (mm), the porosity (%) of the partition wall, and the cell density (cell / cm 2 ), carry out LA-4 test, erosion test, and evaluation of pressure loss. The results are shown in Tables 1 to 4.

[0124] table 3

[0125]

[0126] Table 4

[0127]

[0128] (result)

[0129]As shown in Table 2 and Table 4, it can be seen that the honeycomb structures of Examples 1 to 18 include specific cells, so that compared with the honeycomb structures of Comparative Examples 1, 3, 5, and 6 that do not have specific cells, The purification performance of the exhaust gas after the catalyst is supported is high.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com