Pyrolysis hard carbon material and preparation method and use thereof

A technology for pyrolyzing hard carbon and hard carbon, which is applied in the direction of electrolytic capacitors, electrical components, battery electrodes, etc., to achieve the effects of easy control, simple process and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

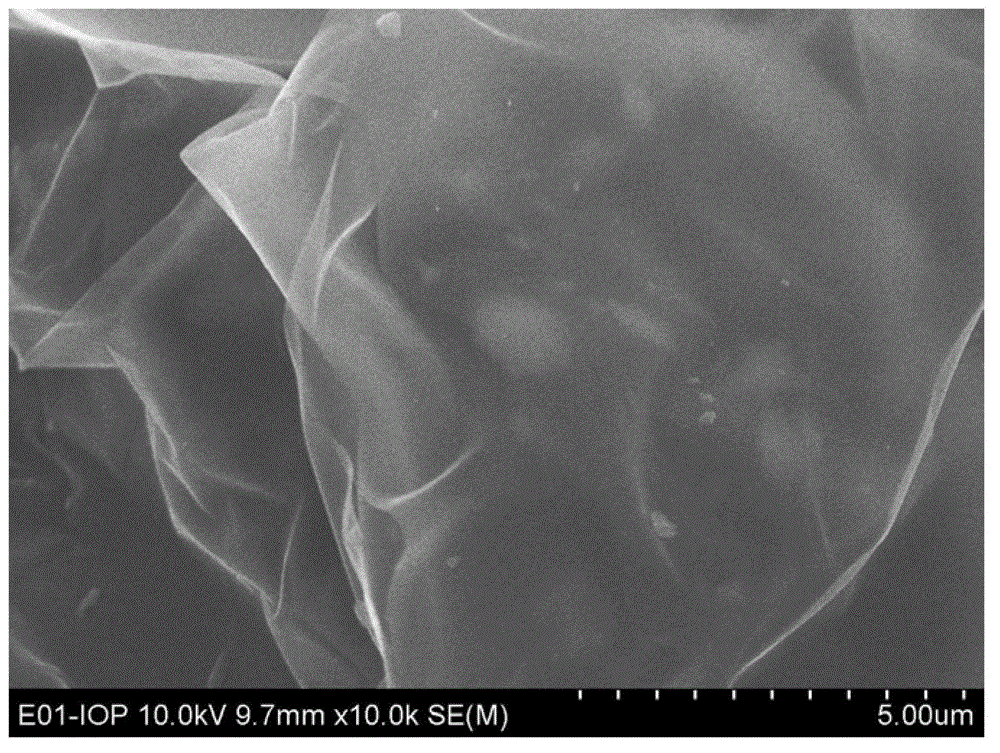

[0055] After washing, drying, and ball milling, 10 g of glucose was placed in a pyrolysis reactor, and Ar-8%H 2 (H 2 accounted for Ar-H 2 The volume percentage of the mixed gas is 8%), and the temperature in the reactor is raised to 750°C at a rate of 2°C / min, and after maintaining a constant temperature for 15 hours, it is naturally cooled to room temperature to obtain an average thickness of about 3nm and a geometric surface area of about 623m 2 / g, the smallest pore diameter is about 0.7nm, and the ratio of the smallest radial dimension to the average thickness is about 5200:1.

[0056] The SEM photos of the flake-like material at magnifications of 5K and 10K are shown in Figure 1(a) and Figure 1(b), from which it can be clearly seen that the pyrolytic hardening The morphology of the carbon material is mainly flake.

[0057] X-ray diffraction pattern as Figure 8 shown, d 002 =3.72; Raman spectrum such as Figure 9 Shown, L a =23nm.

[0058] Electron diffraction s...

Embodiment 2

[0061] Except for Ar-1%H 2 (H 2 accounted for Ar-H 2 The volume percentage of the mixed gas is 1%) to replace Ar-8%H 2 Except, all the other obtain flake-shaped pyrolytic hard carbon materials according to the same method as in Example 1, with an average thickness of about 5nm and a geometric surface area of about 405m 2 / g, the smallest pore diameter is about 0.7nm, and the obtained flake material has a ratio of the smallest radial dimension to the average thickness of about 3200:1.

[0062] The SEM photo of the flake-like material at a magnification of 2K is as follows figure 2 As shown, it can be clearly seen from the SEM image that the pyrolysis hard carbon material produced by the above preparation method is in the form of a large number of flakes, and the hard carbon material that is mainly thin flakes can be obtained after proper separation.

[0063] According to the X-ray diffraction pattern, d 002 =3.72; Raman spectrum, L a =20nm.

Embodiment 3

[0065] Except for Ar-0.5%H 2 (H 2 accounted for Ar-H 2 The volume percentage of the mixed gas is 0.5%) to replace Ar-8%H 2 Except, all the other obtain the pyrolytic hard carbon material according to the same method as in Example 1, and get the flake product therein to detect, and its average thickness is about 8nm, and the geometrical surface area is about 280m 2 / g, the smallest pore diameter is about 0.7nm, and the ratio of the smallest radial dimension to the average thickness is about 1000:1.

[0066] The SEM photo of the flake-like material at a magnification of 1K is as follows image 3 As shown, it can be clearly seen from the SEM image that the pyrolytic hard carbon material produced by the above preparation method presents a certain amount of thin flakes, which are difficult to separate and collect.

[0067] According to the X-ray diffraction pattern, d 002 =3.72; Raman spectrum, L a =20nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com