Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Increase coking value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphite material for continuous casting mold and preparation method thereof

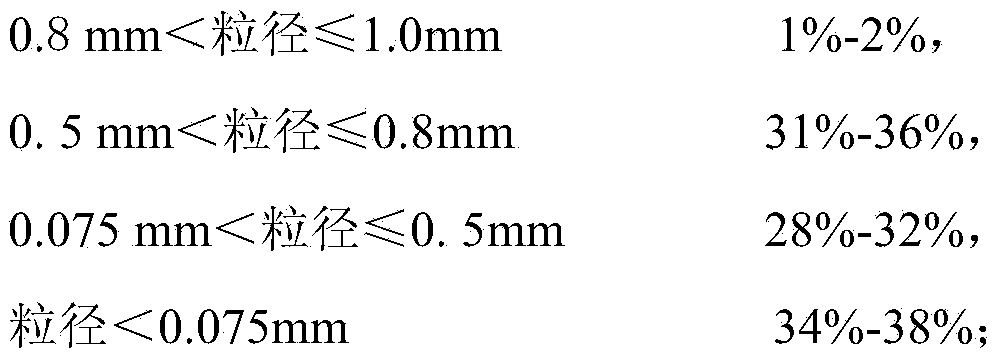

The invention relates to a preparation method of a graphite material for a continuous casting mold. The preparation method comprises the following steps: crushing, screening and burdening calcined coke, adding mid-temperature pitch, and carrying out mixing, molding, primary roasting, primary dipping, secondary roasting, secondary dipping, third roasting and graphitizing to obtain the product, wherein the particle size range and the content of the calcined coke are that the calcined coke with the particle size which is smaller than or equal to 1.0mm and greater than 0.8mm accounts for 1-2%; the calcined coke with the particle size which is smaller than or equal to 0.8mm and greater than 0.5mm accounts for 31-36%; the calcined coke with the particle size which is greater than 0.075mm and smaller than or equal to 0.5mm accounts for 28-32%; the calcined coke with the particle size which is smaller than 0.075mm accounts for 34-38%; the mixing is divided into dry blending and wet blending; the wet blending comprises the following processes: firstly heating the mid-temperature pitch to 180-230 DEG C, carrying out heat preservation and stirring for 30-60 minutes, and then adding the mid-temperature pitch to aggregate twice to knead, wherein the kneading temperature is 140-150 DEG C.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

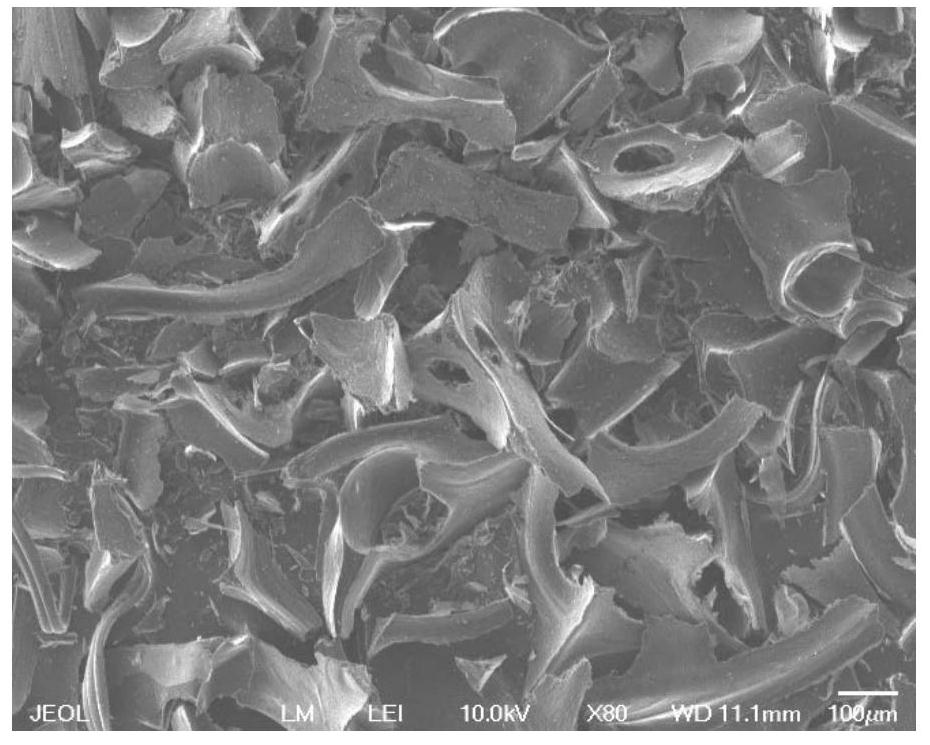

A kind of modified coal tar pitch material and its preparation method and application

InactiveCN102276997ABenzopyrene content decreasedIncrease coking valueBuilding insulationsProcess engineeringCoal

The invention discloses a modified coal pitch material as well as a preparation method and an application thereof. The modified coal pitch material is composed of the following components in parts by weight: 100 parts of raw coal pitch, 100 parts of water, 0.1-1 part of stabilizing agent and 1-20 parts of Fenton reagent. The preparation method comprises the following steps: fully freezing the rawcoal pitch at the brittleness temperature; smashing and screening to obtain coal pitch powder of which the granularity is less than 80 meshes; adding the water and the stabilizing agent; dispersing by virtue of a blender at the revolving speed of 1000-5000 rpm (revolutions per minute) to obtain a suspension, and then controlling the revolving speed at 1000-5000 rpm; dripping the Fenton reagent atconstant temperature, and reacting at room temperature for 30-90 minutes after the Fenton reagent is added to obtain the modified coal pitch. The content of carcinogen benzopyrene in the modified coal pitch prepared by the preparation method at constant temperature is greatly lowered, the coking value is higher, energy is saved, and consumption is reduced. The modified coal pitch material can be used for preparing a magnesia carbon brick binder and a road paving material after being simply processed, thereby avoiding environmental pollution. In addition, the preparation method is simple.

Owner:SHANGHAI INST OF TECH

Coal tar pitch binding agent and preparation method thereof

InactiveCN102976773AIncrease coking valueToxic components are reducedUnsaturated fatty acidChemistry

The invention discloses a coal tar pitch binding agent and a preparation method thereof. The coal tar pitch binding agent is composed of the following components in parts by weight: 100 parts of coal tar pitch, 10-30 parts of polyether polyol, 10-50 parts of unsaturated fatty acid, 10-30 parts of a tackifying resin, 10-30 parts of a solubilizer and 1-10 parts of a catalyst. The preparation method comprises the steps of: mixing the coal tar pitch and the solubilizer in a reaction kettle, and heating to 180 DEG C until the pitch is completely dissolved; and sequentially adding the polyether polyol, unsaturated fatty acid, the tackifying resin and the catalyst, uniformly mixing and preserving the heat for 6 hours to obtain the coal tar pitch binding agent. The coal tar pitch binding agent prepared by the invention is comparatively high in coking value, and low in toxicity and smell, and is capable of remarkably improving high-temperature bonding strength of a magnesia carbon brick.

Owner:上海柯瑞冶金炉料有限公司 +1

Impregnated pitch with low quinoline insoluble content, low softening point and high residual carbon and preparation process and application of impregnated pitch

ActiveCN102911689ALess investmentReduce energy consumptionPigmenting treatmentWorking-up pitch/asphalt/bitumen by chemical meansGraphite electrodeCarbon product

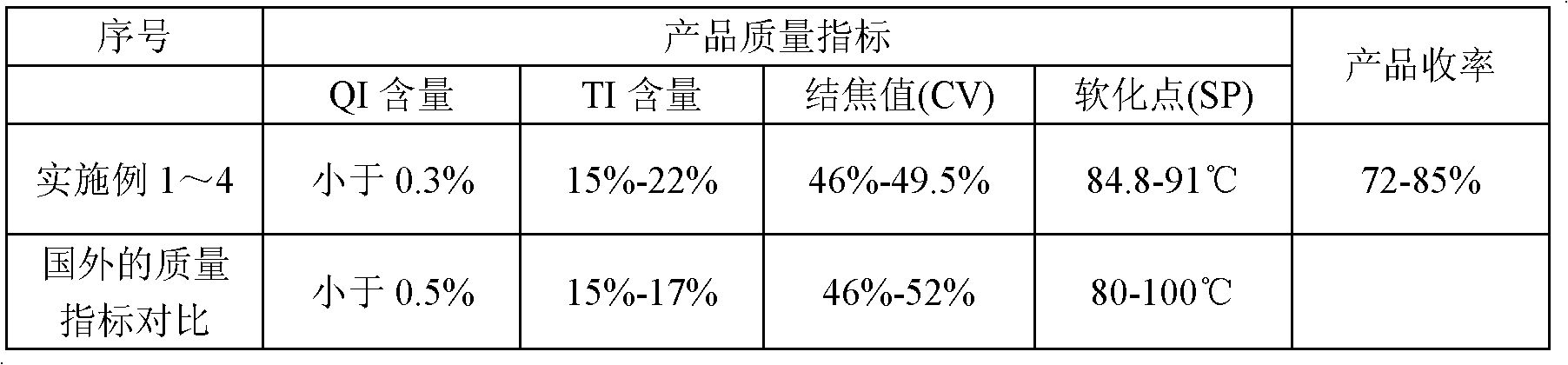

The invention relates to the field of chemical engineering and discloses a preparation process of impregnated pitch. The preparation process includes the steps: (1) adding purified earth pitch serving as raw materials into a reactor, heating the raw materials to the temperature of 375-410 DEG C with the heating rate of 6-8 DEG C / min under the condition of stirring, and carrying out constant pressure pyrocondensation polymerization reaction for 30-75min at the temperature of 375-410 DEG C; and (2) stirring and decreasing the temperature in the reactor to be lower than 300 DEG C with the cooling speed of 8-10 DEG C / min. A softening point of the prepared impregnated pitch with the low quinoline insoluble content, the low softening point and the high residual carbon ranges from 84 DEG C to 91 DEG C, the quinoline insoluble content is less than 0.3%, the coking value ranges from 46% to 49.5%, the toluene insoluble content ranges from 15% to 22%, and the impregnated pitch can be used for impregnation and densification of carbon products such as graphite electrodes.

Owner:宝钢化工湛江有限公司

Method for preparing impregnation pitch using direct coal liquefaction residue, impregnation pitch and application thereof

InactiveCN105861014ALow QI valueLow coking valueWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionBoiling pointDistillation

The invention discloses a method for preparing impregnation pitch using direct coal liquefaction residue, impregnation pitch and application thereof. The method comprises the following steps: (S1) adding an extraction solvent into the direct coal liquefaction residue, and sequentially performing hot-melting extraction, solid-liquid separation, reduced-pressure distillation and solvent recycling treatment to obtain coal liquefaction pitch; and (S2) adding heavy oil into the coal liquefaction pitch, blowing air into a reaction kettle, heating and stirring under normal pressure, and performing a heat polymerization reaction to obtain the impregnation pitch and the recycled light oil byproduct, wherein the heavy oil is anthracene oil, vacuum residue and / or catalytic cracking slurry oil with initial boiling point over 260 DEG C; and the addition volume of the heavy oil is 20-50wt% of the coal liquefaction pitch. The method disclosed by the invention has the advantages of simple technology, mild conditions, conventional equipment and easiness in enlarged production.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Graphite furnace lining used for high purity graphitization furnaces, and preparation method thereof

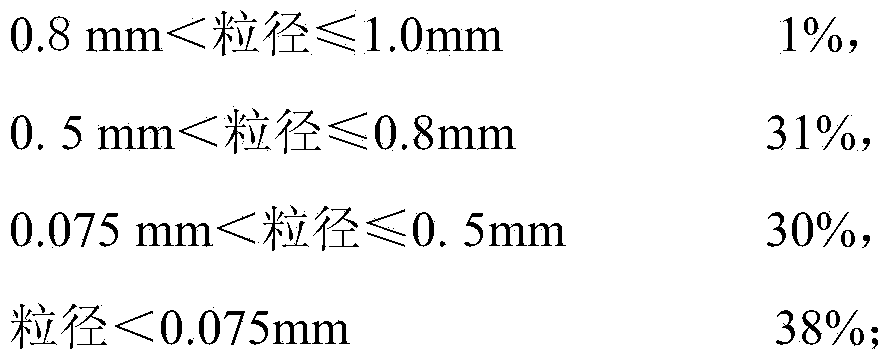

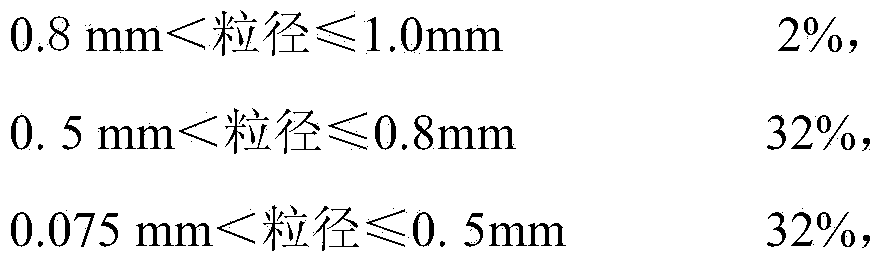

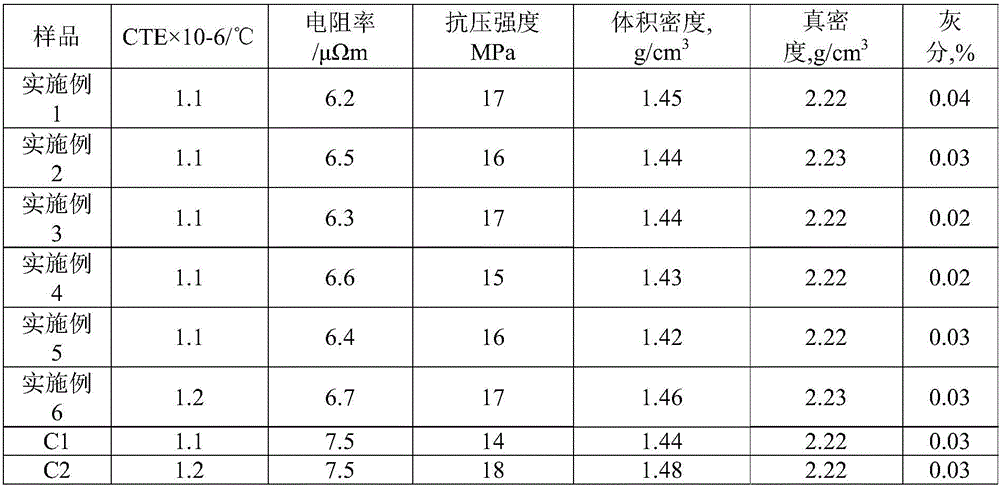

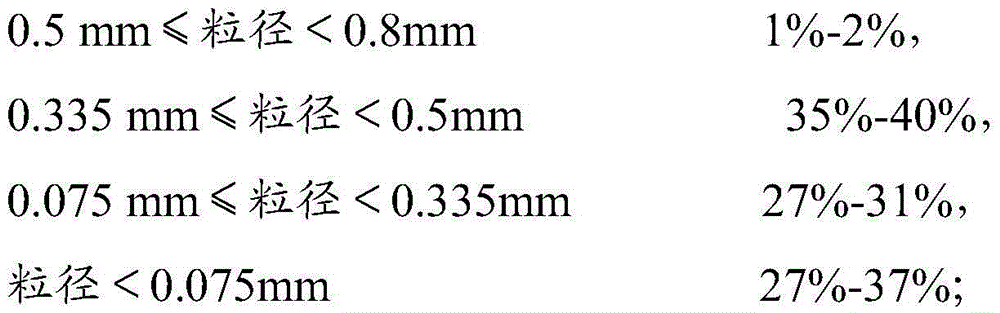

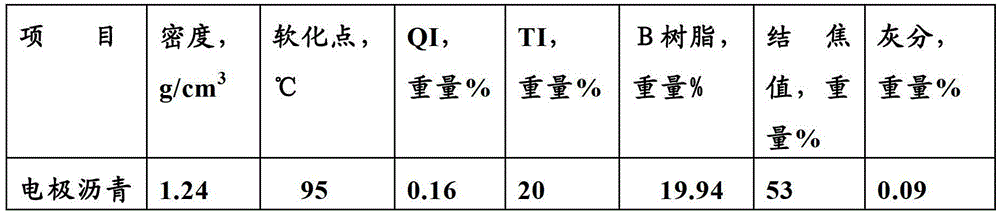

The invention discloses a graphite furnace lining used for high purity graphitization furnaces, and a preparation method thereof, and belongs to the technical field of graphite processing. The preparation method comprises steps of crushing, sieving, material preparing, dry blending, wet blending, moulding, primary roasting, primary dipping, secondary roasting, secondary dipping, tertiary roasting, and graphitization. In the raw materials of the graphite furnace lining, an aggregate is composed of calcined coke, pitch coke, and needle coke at a mass ratio of 80-82:10-15:5-8; wherein calcined coke is composed of particles with four following different particle size ranges: 0.5mm<=particle size<0.8mm, 0.335mm<=particle size <0.5mm, 0.075mm<=particle size<0.335mm, and particle size<0.075mm, and the weight amounts of the four particles account for 1 to 2%, 35 to 40%, 27 to 31%, and 27 to 37% respectively. Purity of the graphite furnace lining prepared via the preparation method is high; bulk density is large; porosity is low; ash content is low; oxidation resistance, compressive strength, and rupture strength are extremely excellent; and application requirements on high purity graphitization furnace linings are satisfied.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

Preparation method of carbon black-coal pitch composite spherical activated carbon

ActiveCN108516547AIncrease coking valueImprove non-meltingCarbon compoundsActivated carbonActive carbon

The invention relates to a preparation method of carbon black-coal pitch composite spherical activated carbon. The method comprises the following steps: performing Soxhlet extraction on medium temperature coal pitch by using a pyridine solution to obtain a pitch pyridine solution, adding carbon black, performing ultrasonic dispersion, adding the obtained solution to a polyvinyl alcohol suspension,and heating, filtering and drying the obtained solution to obtain carbon black-coal pitch composite spheres; and performing non-melting, carbonization and activation treatment on the carbon black-coal pitch composite spheres to obtain the carbon black-coal pitch composite spherical activated carbon. The method realizes the preparation of the spherical activated carbon from the medium temperaturecoal pitch, improves the coking value of the pitch and the yield after the non-melting and the carbonization, and facilitates the improvement of the specific surface area of the spherical activated carbon.

Owner:UNIV OF SCI & TECH LIAONING

Preparation method of impregnant asphalt

InactiveCN101967388AIncrease powerImprove solubilityWorking-up pitch/asphalt/bitumen by selective extractionKeroseneQuinoline

The invention belongs to the technical field of asphalt further processing, in particular to a preparation method of impregnant asphalt, aiming at providing a preparation method of the impregnant asphalt, which can be used for obtaining impregnant asphalt products with low QI (Quinoline Insoluble) content and high coking value. The preparation method comprises the following steps of: A, mixing kerosene and absorber oil into a mixed solvent in the weight ratio of 0.85-1.15:0.85-1.15; B, mixing the mixed solvent and asphalt with the coking value of 54%-58% in the weight ratio of 0.8-1.2:0.8-1.2, and stirring evenly at 250-300 DEG C; and C, precipitating the mixture obtained in the step B at 250-300 DEG C, filtering residuals and recycling the solvent of filter liquor to get the impregnant asphalt. The quinoline insoluble content in the impregnant asphalt got by using the method is 0.1%-0.5%, the softening point is 80-90 DEG C, and the coking value is 50%-54%, so the impregnant asphalt can meet the requirements for manufacturing high-power or ultrahigh-power electrodes, especially for manufacturing electrode joints.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

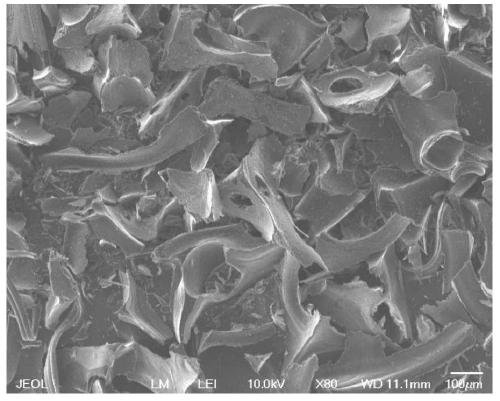

Method for preparing high-softening-point asphalt for general grade asphalt carbon fiber from coal tar pitch

ActiveCN103952168AHigh melting pointReduce anisotropyWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by chemical meansFiberCarbon fibers

The invention relates to a method for preparing an isotropic high-softening-point asphalt, the isotropic high-softening-point asphalt prepared by the method, application of the isotropic high-softening-point asphalt to the preparation of carbon fiber and a method for preparing carbon fiber by using the isotropic high-softening-point asphalt. The preparation process is a continuous production process, has wide raw material sources, good controllability, easiness for operation and no environmental pollution, and is suitable for industrialized production.

Owner:ZHANJIANG JUXIN NEW ENERGY +1

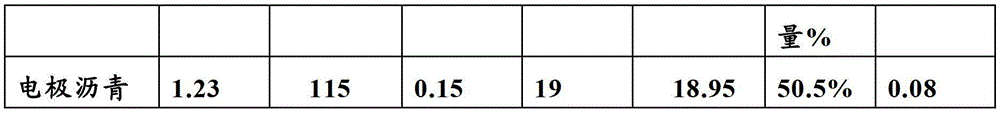

Electrode pitch and preparation method thereof

ActiveCN104031669ALow softening pointLow QI contentTar working-up by solvent extractionTar working-up by thermal treatmentOrganic solventAtmosphere

The invention provides a method for preparing an electrode pitch by using direct coal liquefaction residues as a raw material. The method comprises the following steps: 1, extracting the direct coal liquefaction residues by using an organic solvent to obtain extracted pitch; and 2, processing the extracted pitch in inert atmosphere at 350-420DEG C to obtain the electrode pitch. The softening point of the electrode pitch is 90-120DEG C, the QI content of the electrode pitch is lower than 0.2%, and the coking value of the electrode pitch is greater than 50%. The invention provides the cheap electrode pitch prepared by using the cheap direct coal liquefaction residues as a raw material, and the preparation method thereof.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Method for preparing prebaked anode with high-sulfur coke

InactiveCN103031573AHigh bulk densityEliminate defects with high porosityVolumetric Mass DensityCalcination

The present invention discloses a method for preparing a prebaked anode with high-sulfur coke. The high-sulfur coke is calcinated independently and grinded into powder in the prebaked anode formulation. The method comprises the following steps: A, calcinating the high sulfur coke with a sulfur content of 3-5% at 1250-1350 DEG C in a rotary kiln independently, then storing in a high-sulfur coke dedicated rear-calcination cabin; B, preparing the high-sulfur coke after calcination into powder; and C, dosing the powder with a sulfur content of 3-5% according to a normal production process, wherein the weight ratio of S / Ca in the raw material is (36-62):1. An embodiment of the invention can solve the problems that the molding raw block is low in density and the products are easy to crack in calcinations through calcinating the high sulfur coke independently, storing independently and making into the powder as an anode material; and can improve the oxidation resistance of the anode and reduce the environmental pollution caused by the high sulfur coke in the prior art.

Owner:HUNAN CHUANGYUAN NEW MATERIALS

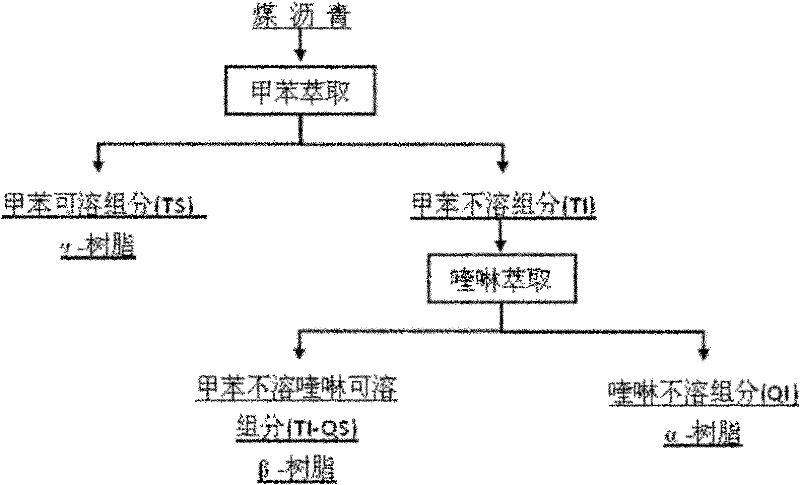

Medium temperature coal pitch modification method and product

InactiveCN105238428AHigh softening pointIncrease coking valueWorking-up pitch/asphalt/bitumen by chemical meansVacuum dryingChar

A medium temperature coal pitch modification method includes the following steps: (1) mixing anhydrous AlCl3 and medium temperature coal pitch which is crushed to the particle size of 0.1 mm or less according to the weight ratio of (2-12):100 in a V-shaped mixer, and then sending into a reaction kettle; (2) introducing N2 to exclude air in the reaction kettle, heating up to 100 DEG C, carrying out heat preservation for 25-35 min, then heating up to 200-320 DEG C, carrying out a reaction for 1-5 h, cooling, and then taking out; and (3) crushing the material obtained after reaction in the step (2), then washing with dilute hydrochloric acid, filtering, carrying out vacuum drying, removing the modifier AlCl3, and thus obtaining the modified medium temperature coal pitch. Compared with raw material pitch, the modified medium temperature coal pitch obtained from modification by the method has higher softening point and coking value, and especially has the QI and beta resin greatly improved; and with the modified medium temperature coal pitch as a binder, a carbon material with excellent structure and properties can be prepared.

Owner:HUNAN UNIV

Blend asphalt for coating graphite anode material

ActiveCN106675054AEffective meltingLow volatileCell electrodesBuilding insulationsGranularityGraphite

The invention discloses blend asphalt for coating a graphite anode material. The blend asphalt is prepared from the following components in percentage by weight: 50%-80% of coal asphalt and 20%-50% of petroleum asphalt, the softening point is at the temperature of 110-140 DEG C, the volatile matter is smaller than or equal to 60%, and the coking value is larger than or equal to 40%. The blend asphalt can reduce the volatile matter, increases the coking value and is easy to operate. Meanwhile, by means of the blend asphalt, the qualified rate of granularity of the coated graphite anode material can be increased by 5% or higher, the tap density can be increased by 5%-10%, and the comprehensive performance of the graphite anode material is improved finally.

Owner:赣州市瑞富特科技有限公司

Method for preparing high-strength formed coke through cold press molding

ActiveCN111154278ARealize cold press formingIncrease cold strengthBuilding insulationsMetallurgyEthyl acetate

The invention relates to a formed coke forming process, and discloses a method for preparing high-strength formed coke through cold press forming. A used binder is prepared from the following components in parts by mass: 0 to 20 parts of corn starch, 60 to 80 parts of asphalt, 0 to 5 parts of artificial graphite or a boron compound, 0 to 10 parts of cement or magnesium oxide, 0 to 20 parts of ethyl acetate and 0 to 2 parts of sodium hydroxide. The binder accounts for 8.6%-10.7% of the mass of the coke powder. The mixed binder and coke powder (metallurgical coke or petroleum coke) are premixeduniformly, a certain amount of water is added, and the formed coke is obtained through normal-temperature cold press molding. The formed coke prepared by the method has the excellent characteristics of high cold and hot strength, good thermal stability, high forming rate, low cost and the like.

Owner:孝义诚远环保科技有限公司

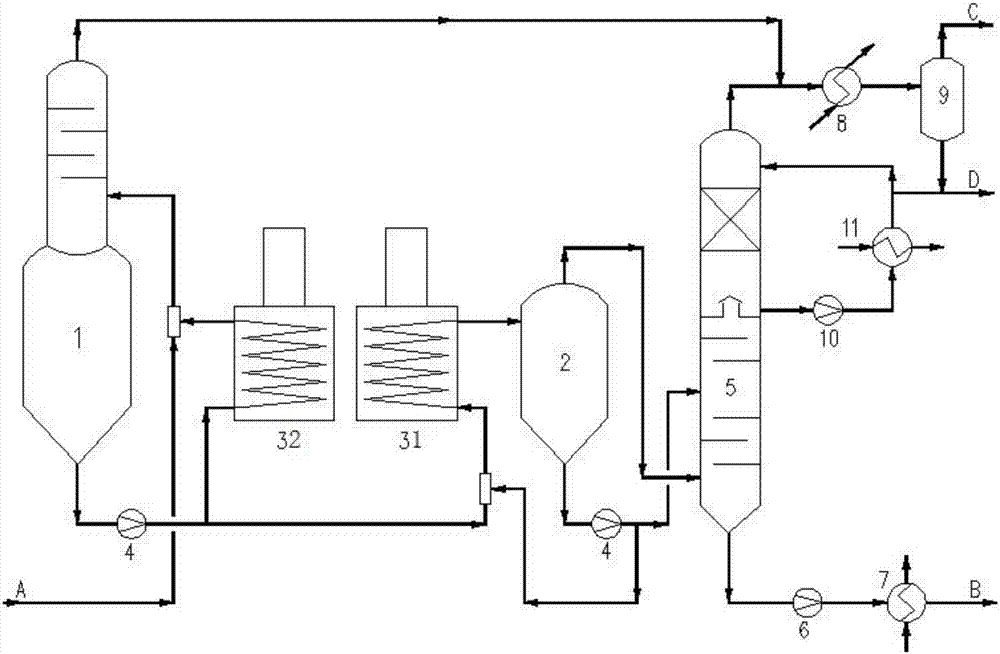

Modified pitch production device

ActiveCN107057740AShort processReduces the possibility of cokingWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by chemical meansProcess engineeringTower

The invention relates to a modified pitch production device. A pitch inlet of a flash column on the upper portion of a flash modification reaction still is connected with a raw material pitch conveying pipeline, and an oil gas mining opening of the flash column is connected with an oil gas condenser cooler. A pitch outlet of a lower reaction kettle is connected with a furnace tube inlet of a first tubular heating furnace, and a furnace tube outlet of the first tubular heating furnace is connected with a pitch inlet of a secondary modification reaction still. One path of a pitch outlet of the secondary modification reaction still is connected with a first pitch conveying pipeline on the upstream portion of the first tubular heating furnace, and the other path of the pitch outlet is connected with a pitch inlet of a fractionating tower. An oil gas mining opening of the secondary modification reaction still is connected with an oil gas inlet in the lower portion of the fractionating tower. An oil gas mining opening of the fractionating tower is connected with the oil gas condenser cooler, and a modified pitch mining opening of the fractionating tower is connected with a modified pitch outwards-conveying pipeline. A double-still two-step reaction method is adopted, the generation quantity of an alpha-component and a beta-component can be effectively controlled, and the product quality is controllable. The process is simple and easy to carry out, and the modified pitch production device saves energy, and is environmentally friendly and suitable for various pitch raw materials.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Method for modifying silicon-carbon composite negative electrode by asphalt modification process derivative

ActiveCN111342035ALow light contentReduce escapeMaterial nanotechnologyCell electrodesCarbon compositesCarbon layer

The invention relates to the technical field of lithium battery materials. The invention particularly relates to a method for modifying a silicon-carbon composite negative electrode by an asphalt modification process derivative. The content of light components of the modified asphalt is low, the relative molecular mass is high, and the hydrocarbon ratio is greater than 1.5. The molecular decomposition polymerization reaction is gentle in the carbonization process, and volatile gas escape is greatly reduced, so that a higher coking value is achieved after carbonization, a compact asphalt nano-coated carbon layer with low pore defect degree is formed on the surfaces of nano-silicon and graphite, excessive active lithium ion consumption is avoided in the charging and discharging process of the modified asphalt coated silicon-carbon composite negative electrode material, and the first coulombic efficiency of the battery is remarkably improved. Besides, the compact asphalt nano-coated carbon layer with low pore defect degree can also play an effective role in buffering the volume expansion of the inner-layer silicon, so that the diving condition of the battery is obviously delayed, andthe coulombic efficiency and the cycle retention rate of the material are improved.

Owner:西安英纳吉科技有限公司

Low-temperature carbonization method of directly heating formed coke

ActiveCN102757806ACompact structureReduce the number of poresCoking carbonaceous materialsMetallurgyNitrogen

The invention discloses a low-temperature carbonization method of directly heating formed coke. The low-temperature carbonization method comprises the steps of: performing advanced co-grinding treatment on asphalt and a certain amount of powder material (the powder material is coke powder or pulverized coal); then adding the mixture into the coke powder to be mixed uniformly; then adding a certain amount of water and a dimethylbenzene activator in the uniformly mixed material; performing normal-temperature briquetting forming and volatilization treatment; and finally directly heating the formed coke to realize low-temperature carbonization of the formed coke, thereby obtaining the carbonized formed coke. Through the measures, the low-temperature carbonization and solidification of the formed coke is realized through direct heating on the premise that the quality of the formed coke is guaranteed. Only by pre-treating the raw materials, can the formed coke be carbonized at low temperature by direct heating under an air, nitrogen or carbon dioxide atmosphere; therefore, the low-temperature carbonization method of directly heating the formed coke, disclosed by the invention, has the advantages of simplifying the subsequent process flow, reducing the production cost and breaking the limitation that the formed coke in the traditional formed coke process must be indirectly heated to a high temperature for the carbonization under a sealing condition.

Owner:CENT SOUTH UNIV

Coal tar pitch binding agent and preparation method thereof

InactiveCN102976773BIncrease coking valueImprove low temperature bond strengthPolyesterPolymer science

Owner:上海柯瑞冶金炉料有限公司 +1

A kind of preparation method of high softening point pitch for producing general-purpose pitch carbon fiber with coal tar pitch

ActiveCN103952168BHigh melting pointReduce anisotropyWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by chemical meansFiberGeneral purpose

The invention relates to a method for preparing an isotropic high-softening-point asphalt, the isotropic high-softening-point asphalt prepared by the method, application of the isotropic high-softening-point asphalt to the preparation of carbon fiber and a method for preparing carbon fiber by using the isotropic high-softening-point asphalt. The preparation process is a continuous production process, has wide raw material sources, good controllability, easiness for operation and no environmental pollution, and is suitable for industrialized production.

Owner:ZHANJIANG JUXIN NEW ENERGY +1

Preparation method of petroleum-based high softening point spinning pitch

ActiveCN102776014BHigh softening pointIncrease coking valueWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by chemical meansTarVaporization

The invention discloses a preparation method of petroleum-based high softening point spinning pitch and belongs to the technical field of spinning pitch. The preparation method includes the steps of preheating ethylene tar, performing wiped film vaporization to remove light components at the temperature of 220-280 DEG C under the vacuum degree of 80-120Pa so as to obtain ethylene tar pitch, transferring the ethylene tar pitch into a reactor, heating to 330-360 DEG C, performing constant-temperature thermal polycondensation to obtain ethylene tar pitch softening at 200-225 DEG C, performing wiped film vaporization to the ethylene tar pitch to remove part of the light components at the temperature of 340-370 DEG C under the vacuum degree of 80-120Pa so as to finally obtain spinning pitch which softens at 270-285 DEG C. The preparation method has the advantages of continuity in operation, simplicity in process flow, high controllability and suitability for industrial production. The prepared spinning pitch is high in coking value, excellent in spinning performance, and available for continuous spinning more than 10000m in length.

Owner:TIANJIN UNIV +1

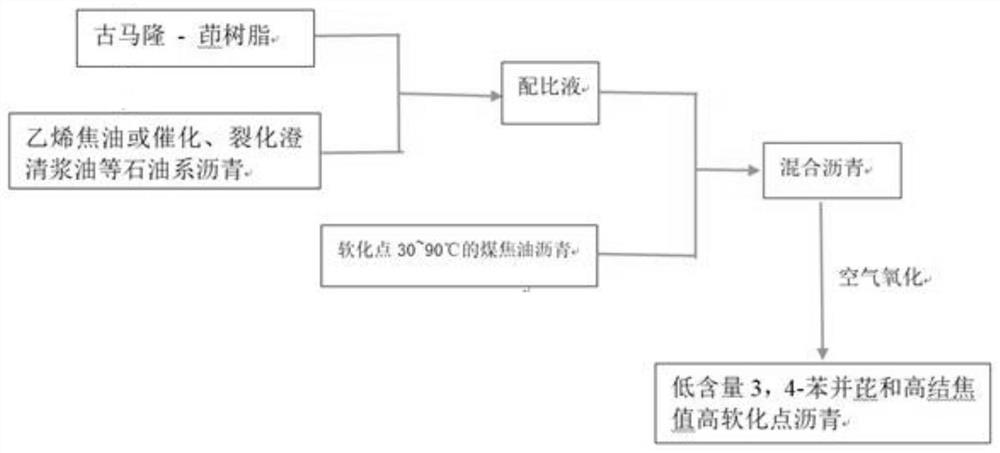

Preparation method of environment-friendly high-softening-point asphalt

ActiveCN113621397AWell mixedIncrease coking valueWorking-up pitch/asphalt/bitumen by mixing fractionsWorking-up pitch/asphalt/bitumen by chemical meansAsphaltCoal tar product

The invention relates to a preparation method of environment-friendly high-softening-point asphalt, which comprises the following steps of: adding coumarone-indene resin into ethylene tar or petroleum asphalt to obtain a proportioning solution; well mixing the proportioning solution with coal tar pitch with the softening point of 30-90 DEG C to obtain mixed asphalt; and oxidizing the mixed asphalt at the temperature of 320-340 DEG C to obtain the environment-friendly high-softening-point asphalt. The method has the following beneficial effects: (1) the coumarone-indene resin and the petroleum asphalt such as ethylene tar or catalytic and cracked clarified slurry oil are more easily and uniformly mixed, and the obtained proportioning solution is also more easily and uniformly mixed with coal tar asphalt with the softening point of 30-90 DEG C; (2) the softening point of the prepared low-content 3, 4-benzopyrene and high-coking-value and high-softening-point asphalt is controlled to be 190-285 DEG C according to requirements, the content of the 3, 4-benzopyrene is 0-300 ppm, and the coking value is 65-85%; and (3) the coking value is increased by 3-5% compared with that of asphalt with the same softening point, the content of 3, 4-benzopyrene is reduced by about 50% compared with similar products, and the asphalt is more environment-friendly.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

A method for preparing prebaked anode with high sulfur coke

InactiveCN103031573BHigh bulk densityEliminate defects with high porosityVolumetric Mass DensityCalcination

The present invention discloses a method for preparing a prebaked anode with high-sulfur coke. The high-sulfur coke is calcinated independently and grinded into powder in the prebaked anode formulation. The method comprises the following steps: A, calcinating the high sulfur coke with a sulfur content of 3-5% at 1250-1350 DEG C in a rotary kiln independently, then storing in a high-sulfur coke dedicated rear-calcination cabin; B, preparing the high-sulfur coke after calcination into powder; and C, dosing the powder with a sulfur content of 3-5% according to a normal production process, wherein the weight ratio of S / Ca in the raw material is (36-62):1. An embodiment of the invention can solve the problems that the molding raw block is low in density and the products are easy to crack in calcinations through calcinating the high sulfur coke independently, storing independently and making into the powder as an anode material; and can improve the oxidation resistance of the anode and reduce the environmental pollution caused by the high sulfur coke in the prior art.

Owner:HUNAN CHUANGYUAN NEW MATERIALS

Tempering Adhesive

The invention relates to a tempering adhesive, which belongs to the graphite electrode pitch adhesive. A tempering adhesive is composed of the following components by weight percentage: 20%-50% of medium-temperature asphalt, and 80%-50% of modified asphalt. It improves the coking value of the binder pitch, increases the yield of raw products after roasting by 1.5-4%, increases the density and strength of products by 1.5-3%, and reduces the labor intensity of operators.

Owner:SICHUAN GUANGHAN SHIDA CARBON

Impregnated pitch with low quinoline insoluble content, low softening point and high residual carbon and preparation process and application of impregnated pitch

ActiveCN102911689BLess investmentReduce energy consumptionPigmenting treatmentWorking-up pitch/asphalt/bitumen by chemical meansGraphite electrodeQuinoline

The invention relates to the field of chemical engineering and discloses a preparation process of impregnated pitch. The preparation process includes the steps: (1) adding purified earth pitch serving as raw materials into a reactor, heating the raw materials to the temperature of 375-410 DEG C with the heating rate of 6-8 DEG C / min under the condition of stirring, and carrying out constant pressure pyrocondensation polymerization reaction for 30-75min at the temperature of 375-410 DEG C; and (2) stirring and decreasing the temperature in the reactor to be lower than 300 DEG C with the cooling speed of 8-10 DEG C / min. A softening point of the prepared impregnated pitch with the low quinoline insoluble content, the low softening point and the high residual carbon ranges from 84 DEG C to 91 DEG C, the quinoline insoluble content is less than 0.3%, the coking value ranges from 46% to 49.5%, the toluene insoluble content ranges from 15% to 22%, and the impregnated pitch can be used for impregnation and densification of carbon products such as graphite electrodes.

Owner:宝钢化工湛江有限公司

Production method of high-quality impregnated asphalt

The invention relates to the field of coal chemical industry, and particularly provides a production method of high-quality impregnated asphalt. Tar reaches a certain temperature through secondary heat exchange, so that the tar reaches low viscosity and good fluidity, the density of the tar is reduced, separation is performed through a disc centrifuge with a high separation factor, and slag phase has good fluidity and is prevented from blocking a disc and a slag cavity due to the setting of regular slag discharge and intermittent slag discharge of the centrifuge. The centrifugally purified tar is distilled, and parameters are properly controlled, so that the requirements for softening point, toluene insoluble, quinoline insoluble, coking value, ash content and the like of the high-quality impregnated asphalt are met.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

A method for modifying silicon-carbon composite negative electrode with asphalt modified process derivatives

ActiveCN111342035BLow light contentReduce escapeMaterial nanotechnologyCell electrodesCarbon compositesCarbon layer

Owner:西安英纳吉科技有限公司

A kind of blended pitch for coating graphite negative electrode material

The invention discloses blend asphalt for coating a graphite anode material. The blend asphalt is prepared from the following components in percentage by weight: 50%-80% of coal asphalt and 20%-50% of petroleum asphalt, the softening point is at the temperature of 110-140 DEG C, the volatile matter is smaller than or equal to 60%, and the coking value is larger than or equal to 40%. The blend asphalt can reduce the volatile matter, increases the coking value and is easy to operate. Meanwhile, by means of the blend asphalt, the qualified rate of granularity of the coated graphite anode material can be increased by 5% or higher, the tap density can be increased by 5%-10%, and the comprehensive performance of the graphite anode material is improved finally.

Owner:赣州市瑞富特科技有限公司

A process for upgrading asphalt by flashing and maintaining pressure combined with electric tracing heating and maintaining temperature in retention tower

ActiveCN104694146BImprove energy savingImprove adhesionWorking-up pitch/asphalt/bitumen by thermal meansTube furnaceEngineering

The invention relates to a flashing and pressure holding combined retention tower electric tracing heating temperature holding modified pitch production technology. The production technology is a single-heat production technology, only one tube furnace is adopted for heating in the process, energy-saving effect is remarkable, and flashing separation and continuous heating temperature holding thermal polymerization are combined. Flashing separation is conducted firstly on pitch, then oxidization thermal polymerization is conducted by controlling electric heating temperature holding accurately, an obtained target product meets the requirement of the carbon industry for pitch better, cohesiveness is excellent during mixed kneading of a carbon element mixture, and coking value is higher after roasting.

Owner:HENAN KAITAN NEW MATERIAL +1

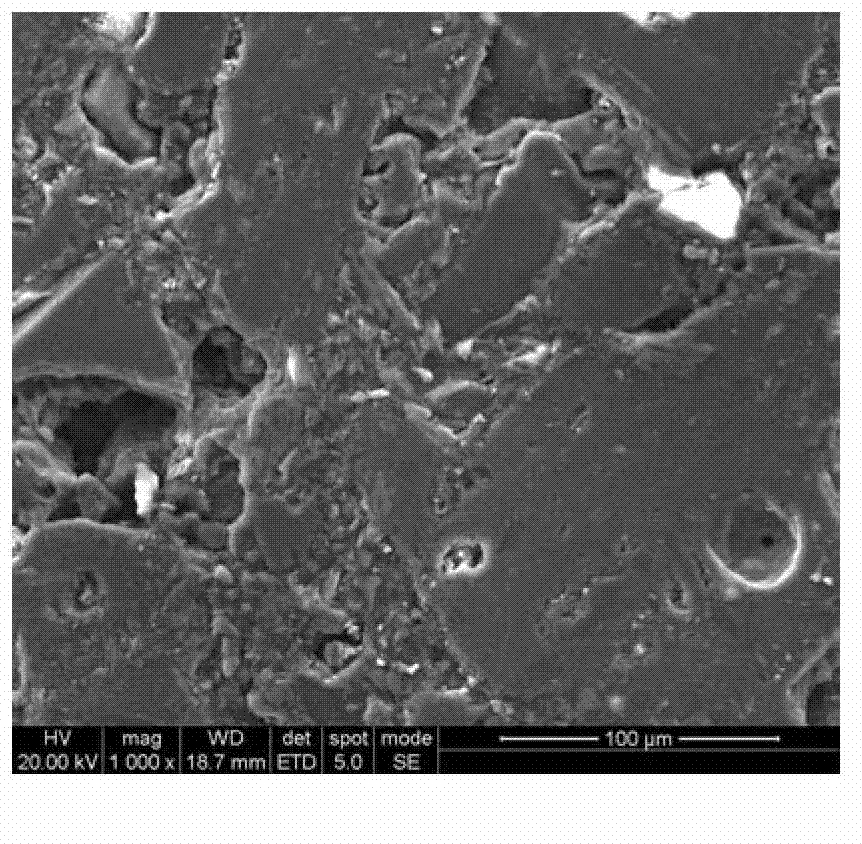

Inorganic modified coal pitch and preparation method thereof

InactiveCN102051060BAccelerate thermal polymerization reactionHigh bulk densityBuilding insulationsAluminium electrolysisComposite cathode

The invention discloses an inorganic modified coal pitch and a preparation method thereof. The preparation method of the inorganic modified coal pitch comprises the following steps of: 1, mixing: mixing 80-95 percent by mass of original coal pitch and 5-20 percent by mass of inorganic particles; and 2, modified heat treatment: putting the mixture obtained in the step 1 to a reaction vessel, heating the reaction vessel to the modified temperature of 150-300 DEG C, stirring and modifying for 1.0-6.0h to obtain the inorganic modified coal pitch. The TI, QI and Beta resin contents and the coking value of the inorganic modified coal pitch are all remarkably improved. The volume density, the compression strength, the bending strength, the oxidation resistance and the electrolysis expansiveness resistance performance of a carbon electrode for aluminium electrolysis and a TiB2 / C composite cathode material, which are prepared from the inorganic modified coal pitch, are remarkably improved.

Owner:CENT SOUTH UNIV

A method for preparing high-strength molded coke by cold pressing

ActiveCN111154278BRealize cold press formingIncrease cold strengthBuilding insulationsPhysical chemistryHigh intensity

The invention relates to a form coke forming process, and discloses a method for preparing high-strength form coke by cold pressing. The mass ratio of the binder used is: 0-20 parts of corn starch, 60-80 parts of asphalt, 0-5 parts of artificial graphite or boron compound, 0-10 parts of cement or magnesium oxide, 0-20 parts of ethyl acetate, 0-2 parts of sodium hydroxide. The total ratio of the binder is 8.6%-10.7% of the coke powder mass. Pre-mix the mixed binder and coke powder (metallurgical coke or petroleum coke), then add a certain amount of water, and often warm and cold press to obtain molded coke. The form coke prepared by the invention has excellent characteristics such as high cold and hot strength, good thermal stability, high molding rate and low cost.

Owner:孝义诚远环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com