Preparation method of environment-friendly high-softening-point asphalt

A high softening point asphalt, softening point technology, applied in the processing of tar pitch/petroleum pitch/natural pitch, processing tar pitch/petroleum pitch/natural pitch by chemical methods, processing tar pitch/petroleum pitch/natural pitch through mixed fractions Equal direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

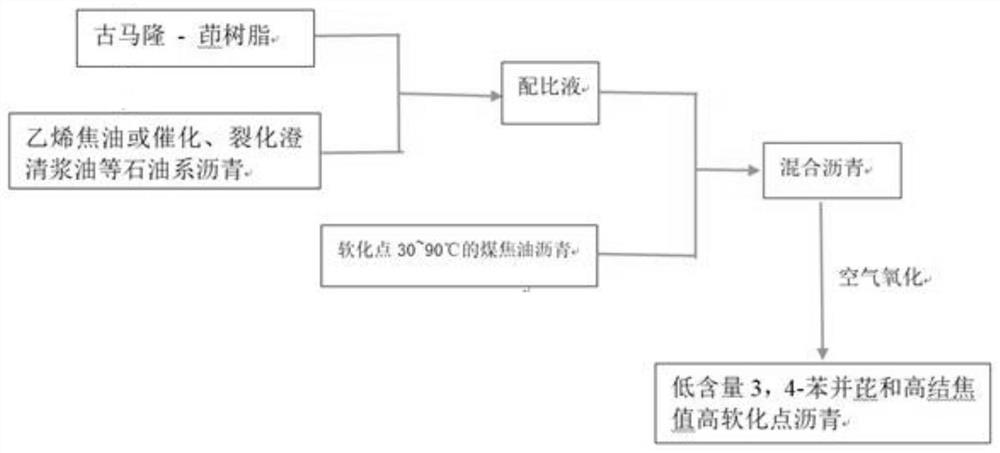

[0020] A kind of preparation method of environment-friendly high softening point asphalt provided by the present embodiment, such as figure 1 As shown, it specifically includes the following steps:

[0021] Add 15kg of ethylene tar and add 5kg of coumarone-indene resin to mix uniformly to form a proportioning solution, then add 80kg of softening point and be 75°C, and the content of quinoline insolubles is 0.02% coal tar pitch to obtain mixed pitch, and mix the pitch at 325 ℃ for air oxidation to obtain pitch with a softening point of 281°C, a coking value of 82%, and a 3,4-benzopyrene content of 150 ppm, which can be used as spinning pitch.

Embodiment 2

[0023] The preparation method of a kind of environment-friendly high softening point asphalt provided in this embodiment specifically comprises the following steps:

[0024] Adopt catalysis, cracking clarified slurry oil 20kg to add 4kg coumarone-indene resin and mix uniformly to form proportioning liquid, then add 76kg softening point and be 80 ℃, the coal tar pitch that quinoline insoluble matter content is 0.03%, obtain mixed pitch, will The mixed asphalt is air oxidized at 330°C to obtain asphalt with a softening point of 276°C, a coking value of 81%, and a 3,4-benzopyrene content of 200ppm, which can be used as coated asphalt.

Embodiment 3

[0026] The preparation method of a kind of environment-friendly high softening point asphalt provided in this embodiment specifically comprises the following steps:

[0027] Adopting ethylene tar and catalysis, the mixture 10kg of cracking slurry oil adds 6kg coumarone-indene resin and mixes uniformly to form proportioning liquid, then adds 84kg softening point and is 64 ℃, and the coal tar pitch that quinoline insoluble matter content is 5%, obtains Mixed asphalt, the mixed asphalt is air oxidized at 325°C to obtain asphalt with a softening point of 256°C, a coking value of 78.2%, and a 3,4-benzopyrene content of 120ppm, which can be used for refractory binder asphalt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com