Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "In line with the actual work situation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

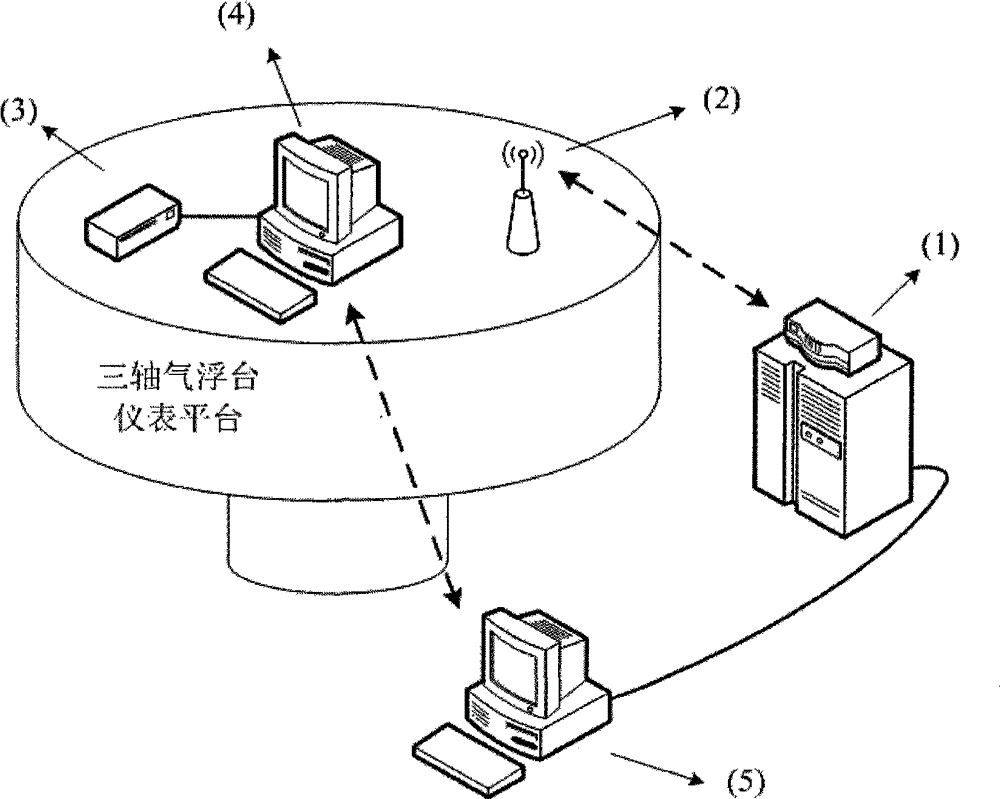

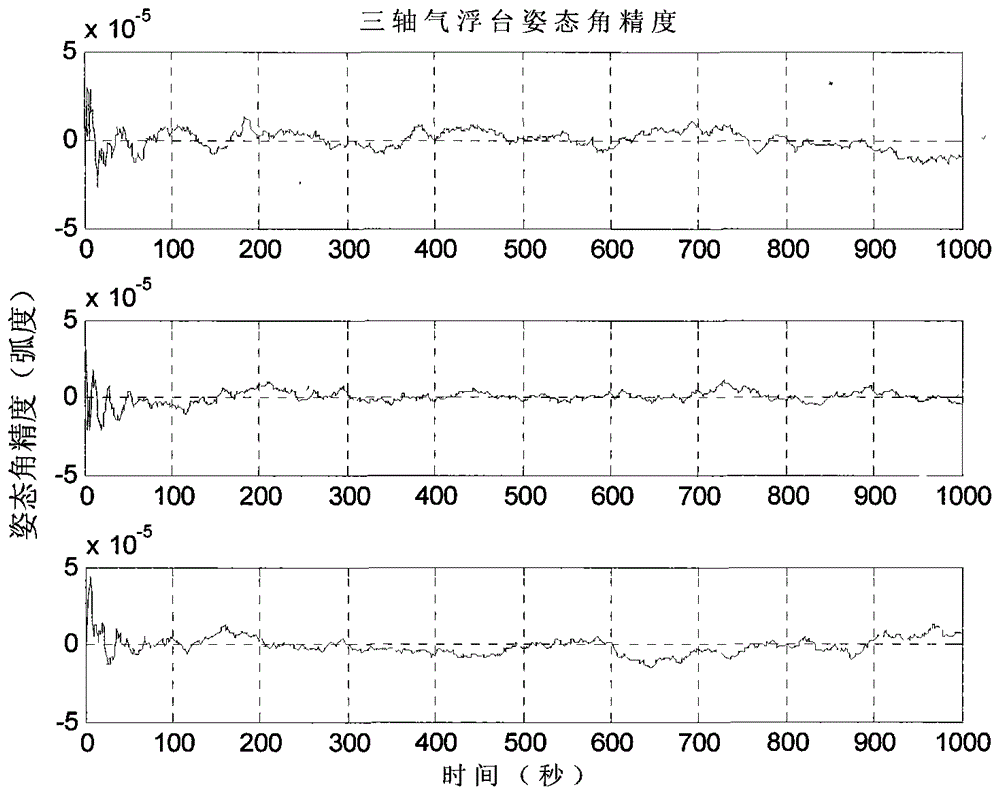

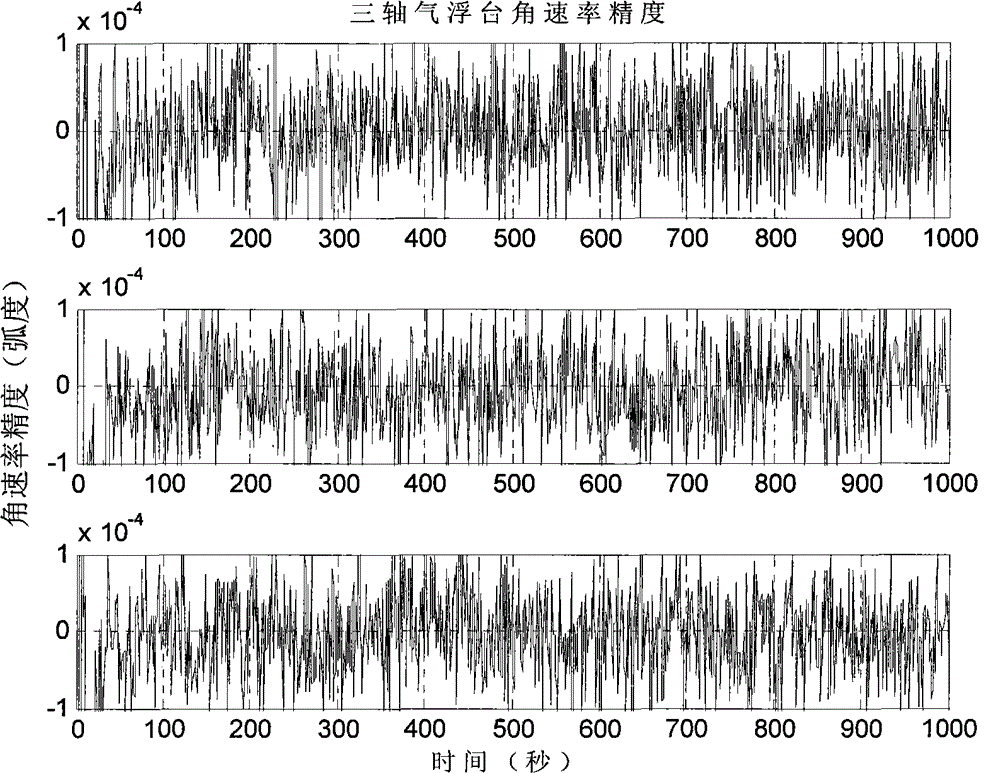

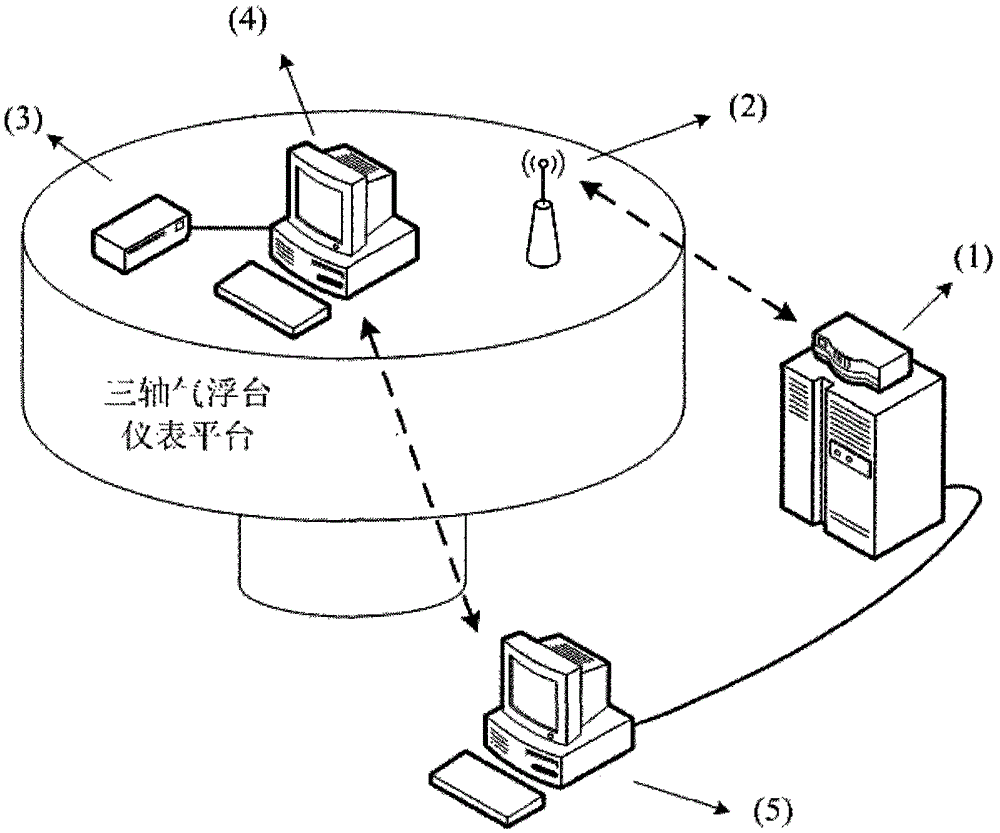

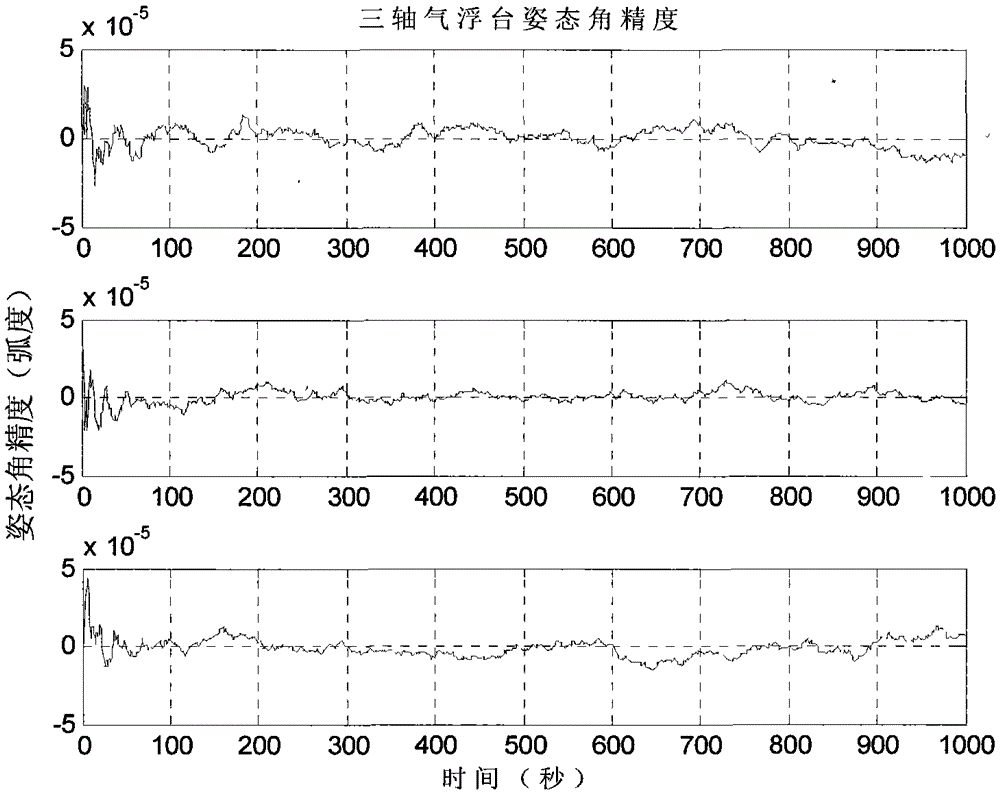

High-precision attitude determination method for spacecraft attitude motion simulation platform

ActiveCN104006787AHigh measurement accuracyEasy to installAngle measurementNavigational calculation instrumentsGyroscopeImproved method

The objective of the invention is to provide a high-precision attitude determination method for a spacecraft attitude motion simulation platform. Equipment used in the method comprises a laser tracker, an intelligent probe, a gyroscope and two industrial control computers, so a ground fully-physical simulation experimental facility is constructed. The method is an improved method for attitude determination based on extended Kalman filtering, acquires attitude information of the spacecraft attitude motion simulation platform by carrying out data-fusion filtering on output information of the laser tracker and the gyroscope, better accords with actual working conditions and has high instantaneity. Measurement equipment used in the invention is easy to install, has high measurement precision and can realize dynamic contactless measurement of the attitude angle and angular rate information of the spacecraft attitude motion simulation platform.

Owner:HARBIN INST OF TECH

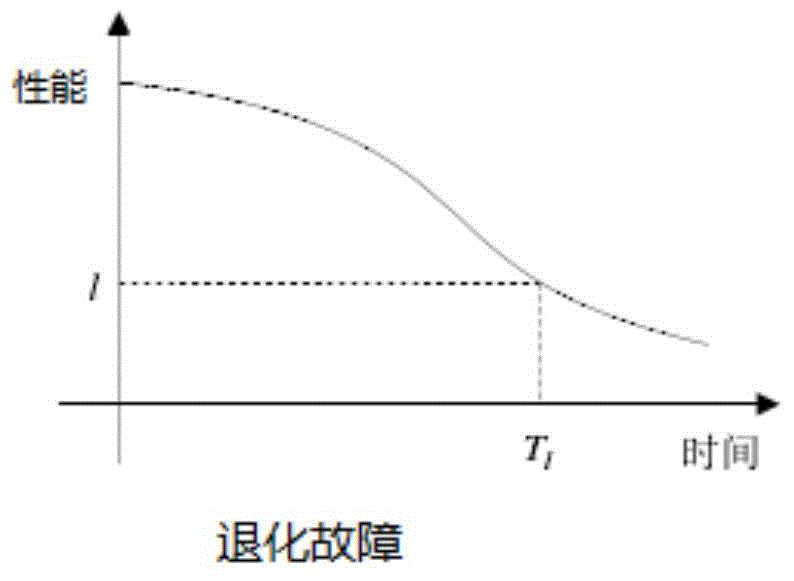

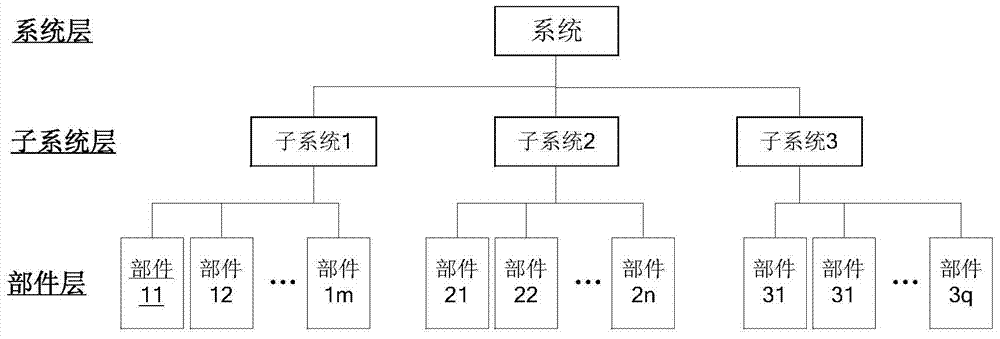

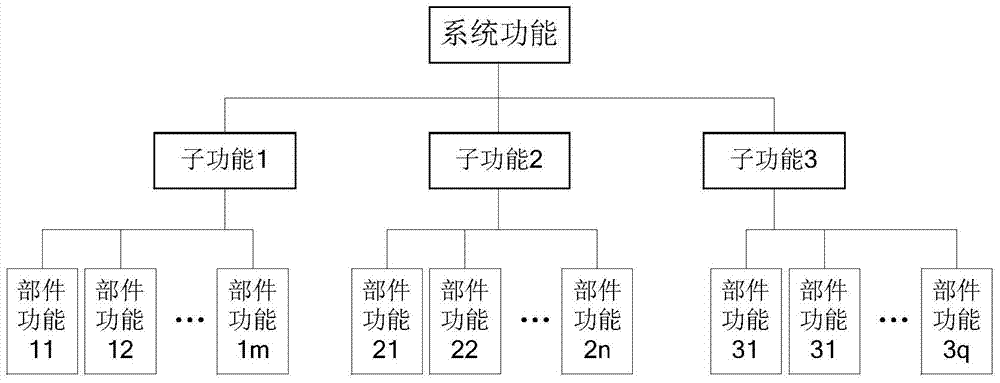

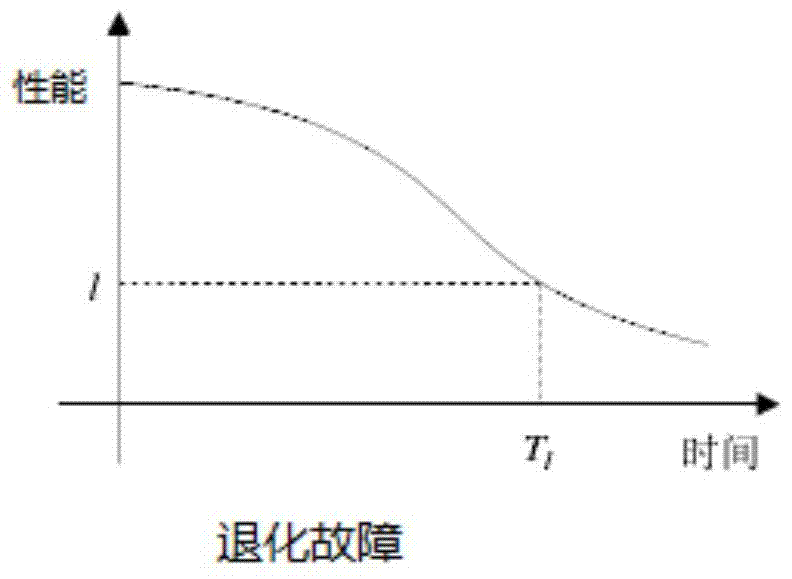

Method for reliability modeling and evaluation of dynamic cascade coupling electromechanical system

ActiveCN104537134AReliability Accurate and CrediblePerformance Response AccurateSpecial data processing applicationsCouplingNetwork model

The invention provides a method for reliability modeling and evaluation of a dynamic cascade coupling electromechanical system. The method is based on a physical background of a complex electromechanical system and is capable of carrying out research on reliability of the electromechanical system based on a dynamics response model, and an established reliability network model of the electromechanical system is capable of more accurately describing the characteristics of dynamic, cascading and coupling of the complex electromechanical system, so that reliability of the electromechanical system, which is obtained based on the network model, is more accurate and credible; meanwhile, by utilizing a method of combining dynamics analysis and uncertainty analysis, transfer of uncertain information from a bottom layer to a top layer of the network model is described, and the difficulties that an aerospace mechanism system has a response uncertainty character and system reliability information cannot be obtained through experiment measures due to large experimental expenses, long period, large technical difficulty and expensive product cost are solved.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

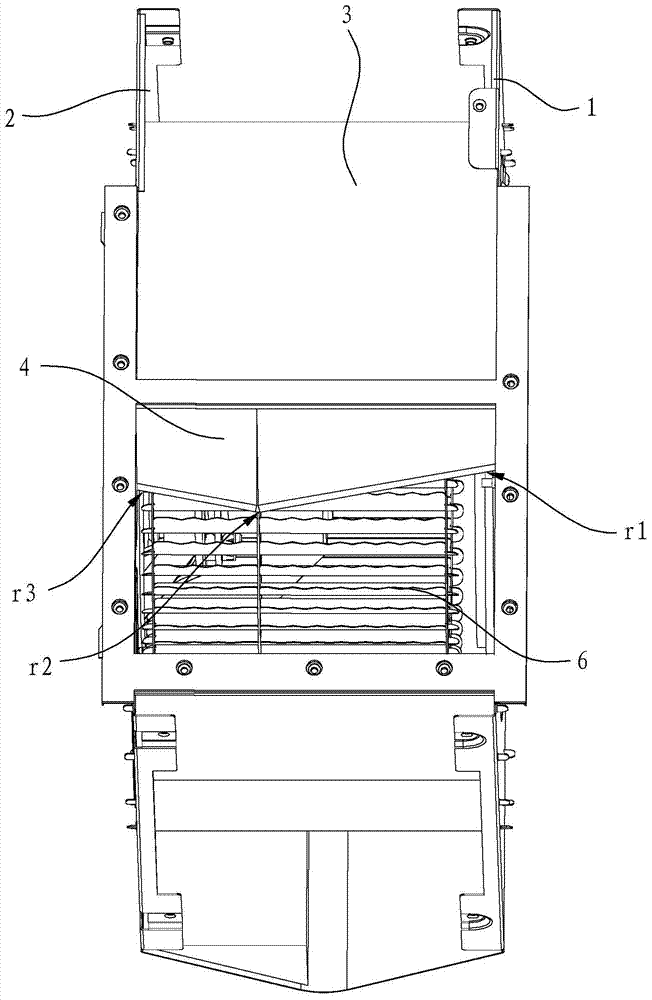

Offshore wind turbine simulation experiment device

InactiveCN103939296ARich experimental dataUnderstand clearlyEducational modelsWind motor componentsVertical vibrationTransmitted power

The invention provides an offshore wind turbine simulation experiment device. The offshore wind turbine simulation experiment device comprises a wind wheel, a power mechanism used for driving the wind wheel to rotate and a transmission mechanism used for transmitting power, wherein the transmission mechanism drives the wind wheel to rotate through a rotating shaft, and the rotating shaft is installed on a base through a supporting seat. The offshore wind turbine simulation experiment device further comprises a vibration excitation mechanism used for simulating generated environmental stress, a data collection mechanism used for collecting experimental data of each component and a data analysis mechanism used for processing the experimental data, wherein the vibration excitation mechanism comprises a horizontal vibration exciter capable of adjusting the contact distance in all directions and a vertical vibration exciter controlled by excitation signal equipment. The offshore wind turbine simulation experiment device is formed by overall decreasing an actual size according to a certain proportion, and the working state of an actual offshore wind turbine can be accurately restored. An experimental environment obtained after the combination of the horizontal vibration exciter and the vertical vibration exciter is more in accord with the complex experimental environment on the sea, and the experimental data obtained after excitation simulation are more in accord with the actual working condition of the offshore wind turbine.

Owner:ZHEJIANG UNIV

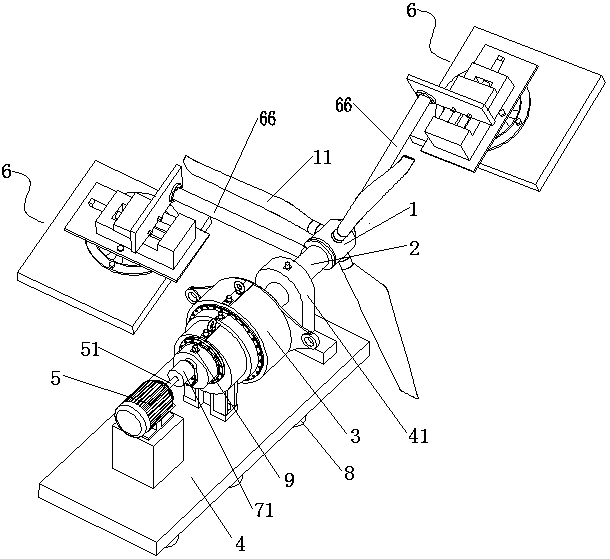

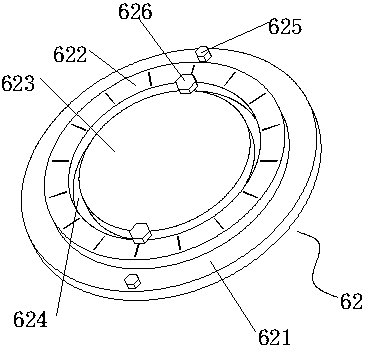

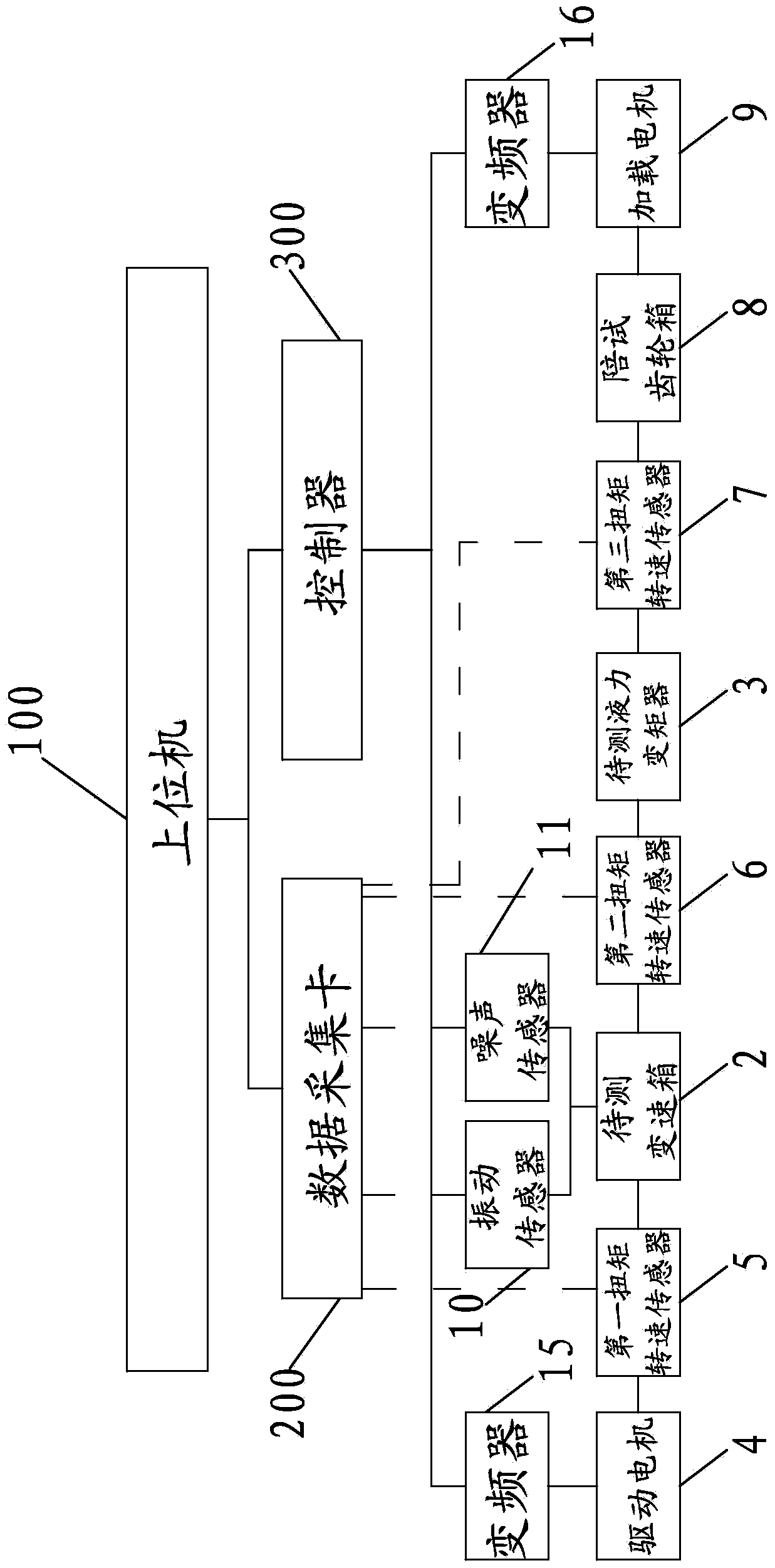

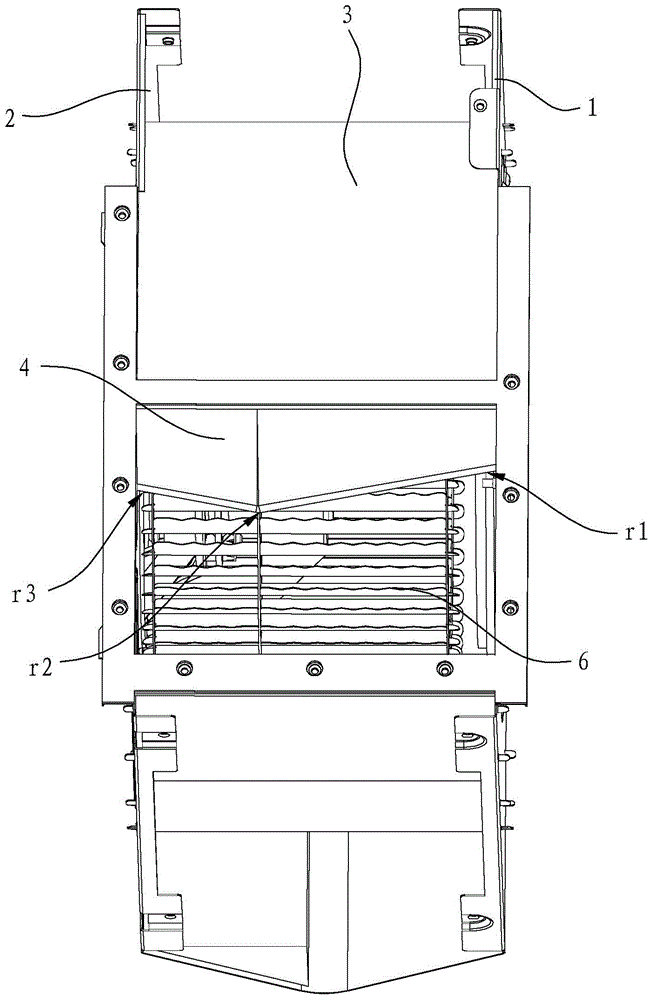

Performance detection and analysis test stand of engineering machinery transmission assembly and test method thereof

ActiveCN105372064AReduce vibrationReduce noiseMachine gearing/transmission testingElectric machineData acquisition

The present invention discloses a performance detection and analysis test stand of an engineering machinery transmission assembly. The performance detection and analysis test stand of the engineering machinery transmission assembly comprises a pedestal, a transmission to be detected, a torque converter to be detected, a driving motor, a first torque and rotational speed sensor, a second torque and rotational speed sensor, a third torque and rotational speed sensor, an accompanying gear case, a loading motor, a vibration sensor, a noise sensor, a data acquisition card, a controller and an upper computer. The driving motor, the first torque and rotational speed sensor, the transmission to be detected, the second torque and rotational speed sensor, the torque converter to be detected, the third torque and rotational speed sensor, the accompanying gear case and the loading motor are connected in turn, and the loading motor is in power supply connection with the driving motor; the first torque and rotational speed sensor, the second torque and rotational speed sensor and the third torque and rotational speed sensor are in data transmission connection with the upper computer; and the upper computer is in control connection with the driving motor and the loading motor. The performance detection and analysis test stand of an engineering machinery transmission assembly is characterized in that: a transmission and a torque converter are able to perform a performance test in the same working condition and perform a NVH detection to improve the quality of the transmission. The present invention further discloses a performance detection and analysis test method of an engineering machinery transmission assembly.

Owner:QUANZHOU INST OF EQUIP MFG +1

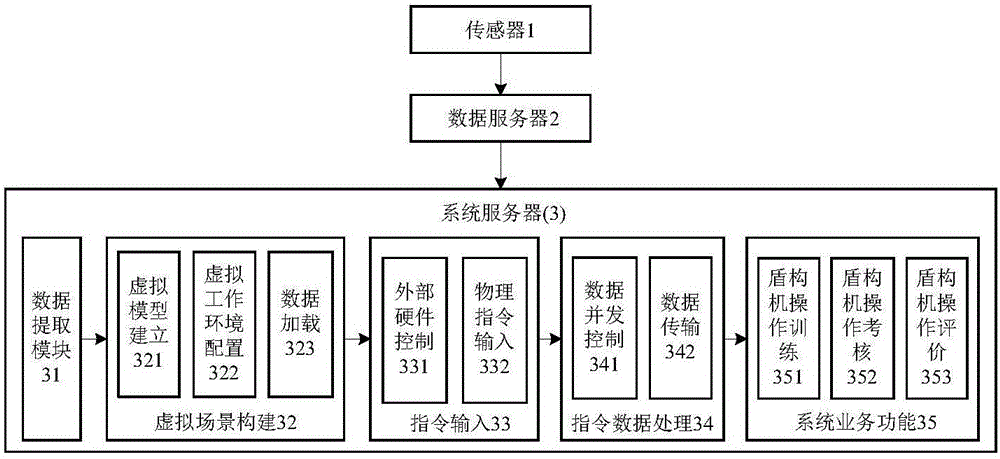

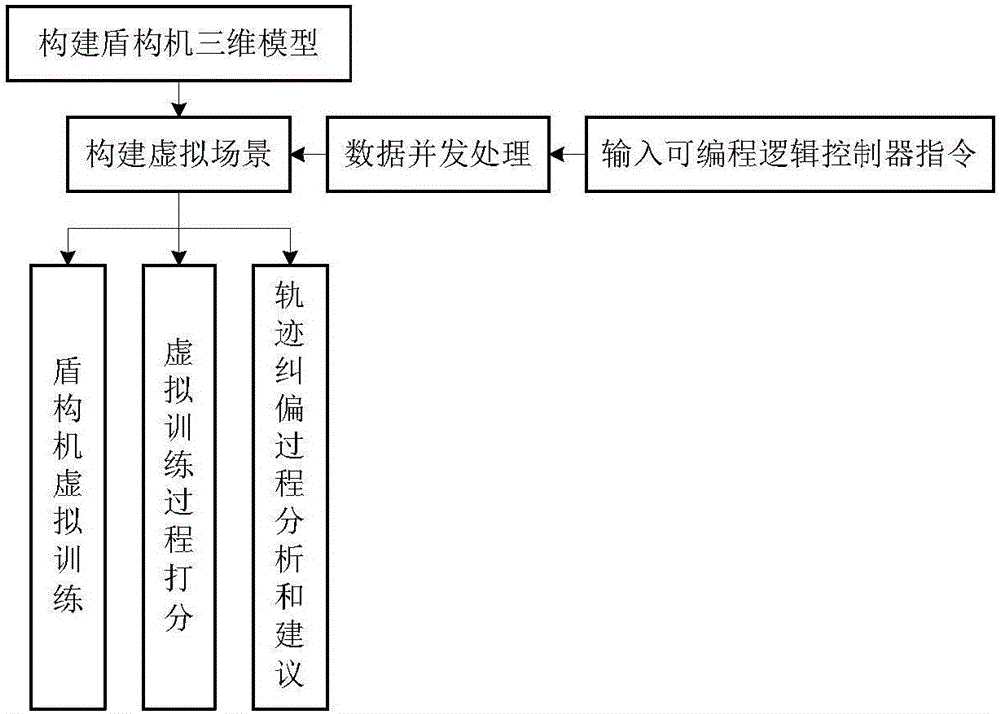

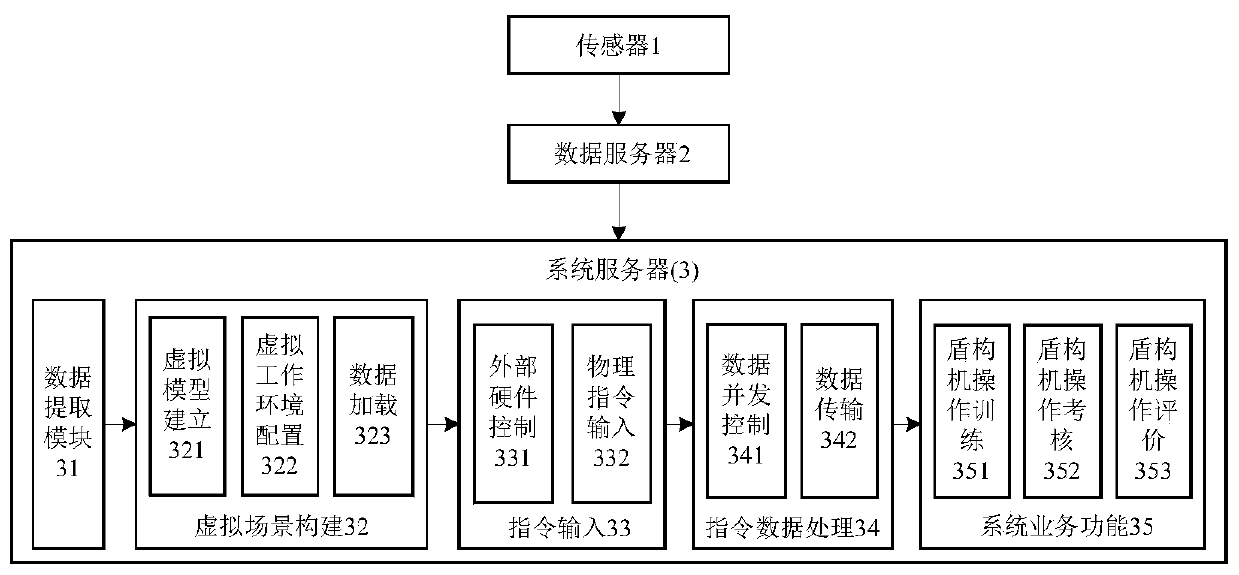

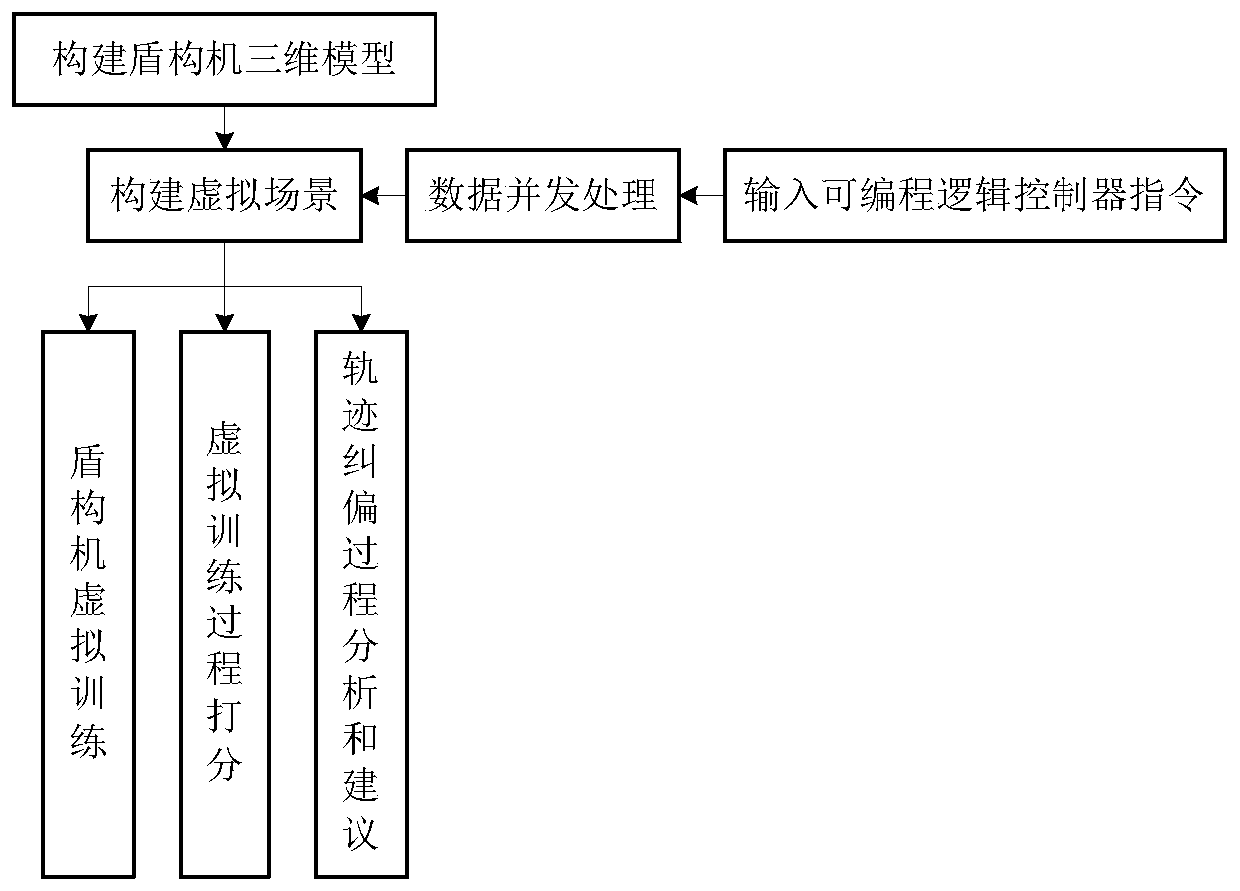

Virtual training system and method for collaborative operation of shield tunneling machine

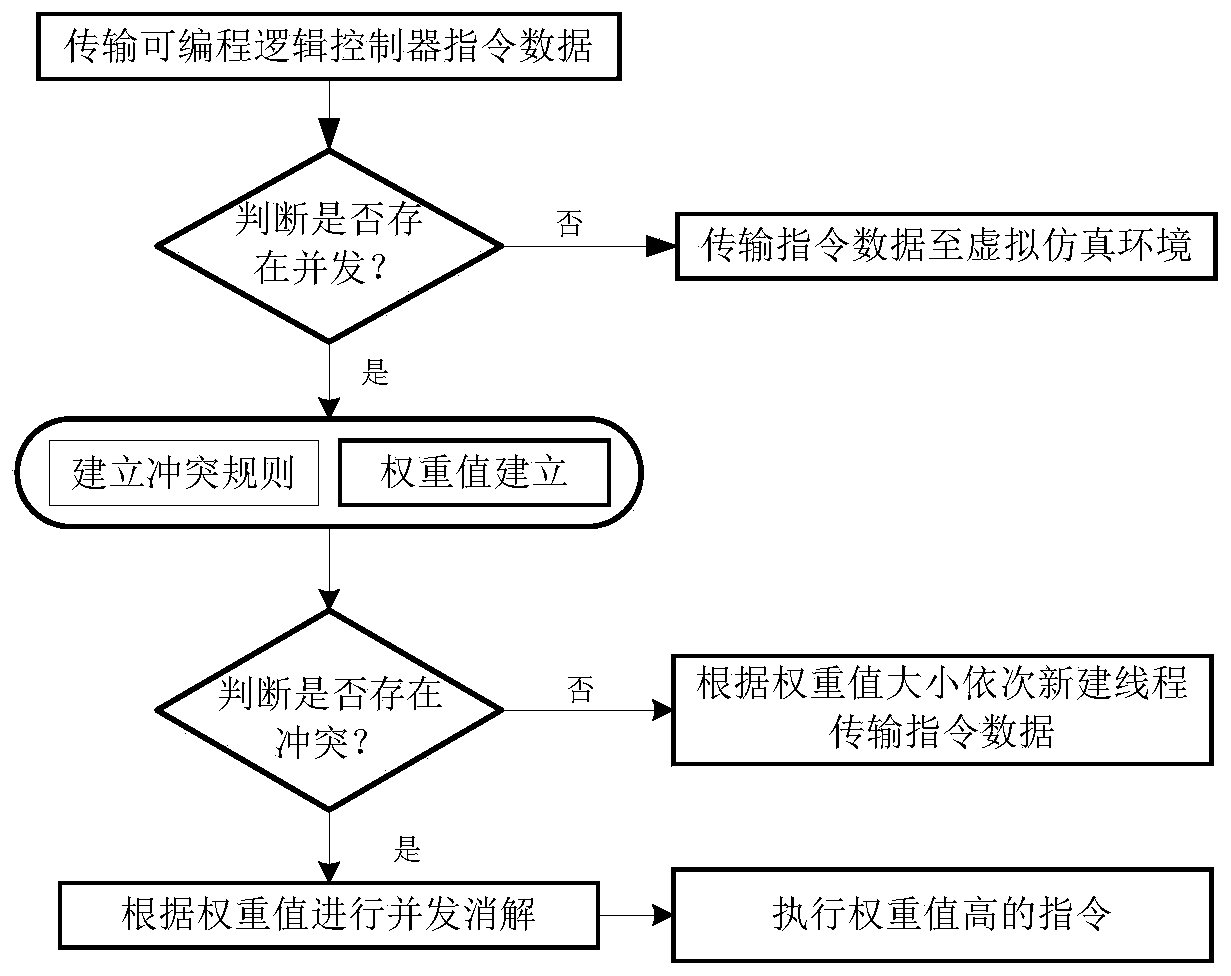

ActiveCN106652637AIncrease authenticityEnable virtual trainingCosmonautic condition simulationsSimulatorsVirtual trainingProgrammable logic controller

The invention provides a virtual training system and method for a collaborative operation of a shield tunneling machine for solving the technical problem that in the prior art, the training effect is poor as command data cannot be simultaneously controlled. The training system comprises a virtual scene construction module, a command input module, a command data processing module and a system service module. The training method comprises the following steps: a sensor acquires related data of the shield tunneling machine and transmits the same to the data server; the virtual scene construction module reads data of the data server and configures a virtual environment; the command input module transmits the command data of a programmable logic controller; the command data processing module simultaneously controls the command data; and the system service module imports the simultaneously processed command data into the virtual environment to train the shield tunneling machine and score, analyze and suggest the virtual training process. According to the system and method provided by the invention, a trainee can more directly and clearly understand the problem of his operation, so that the ability of collaboratively solving the problem by the operator is enhanced.

Owner:西安启工数据科技有限公司

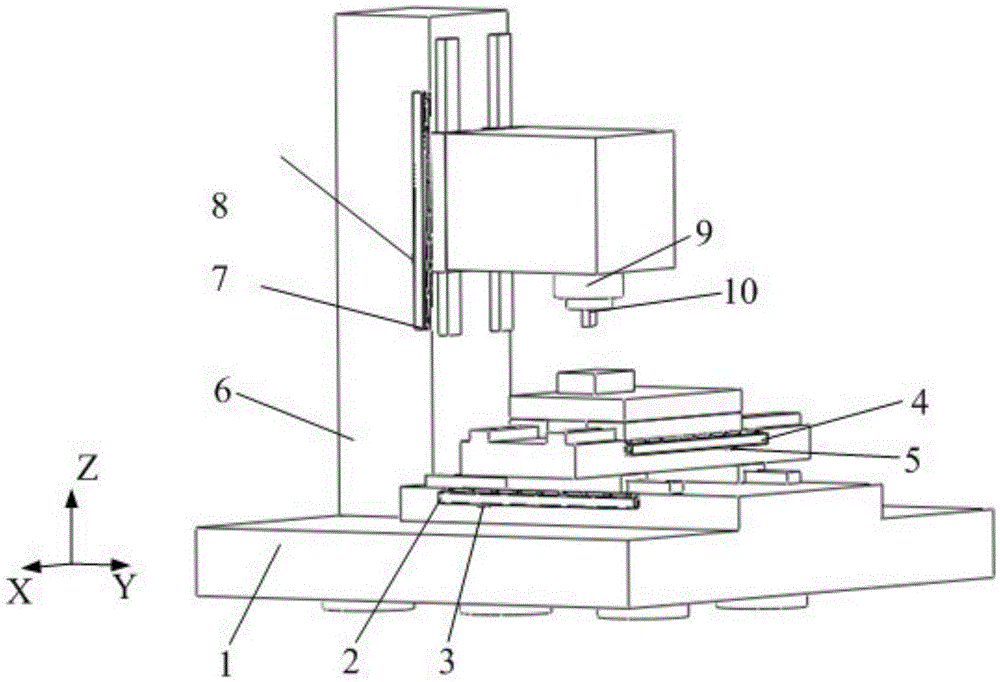

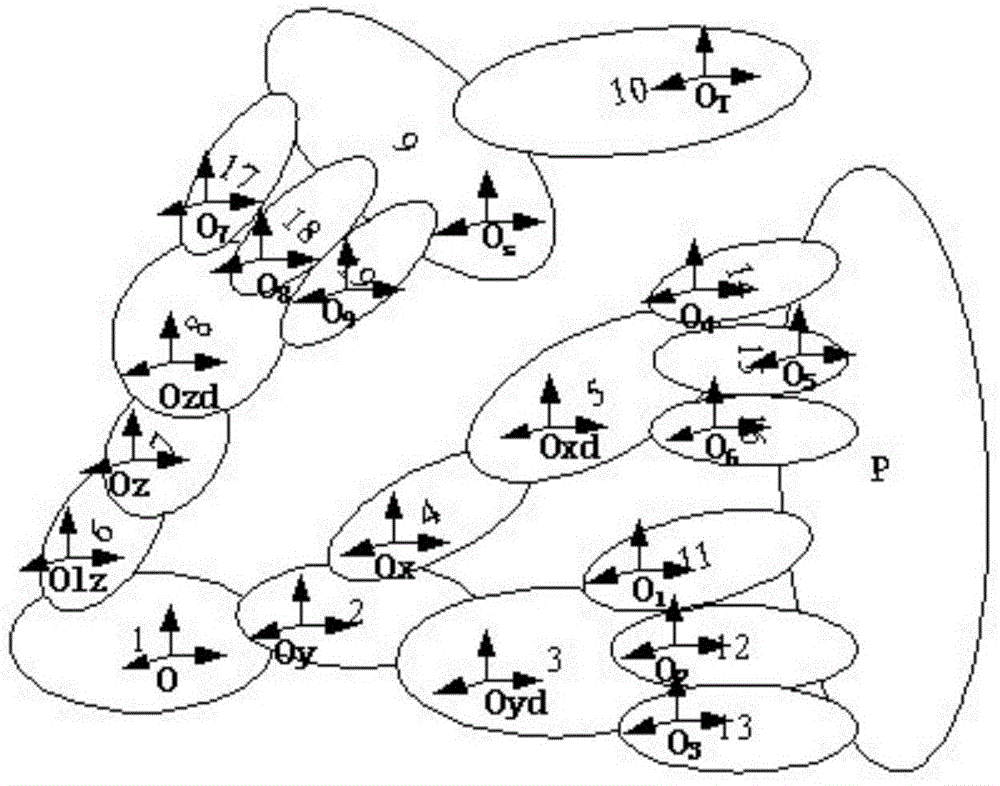

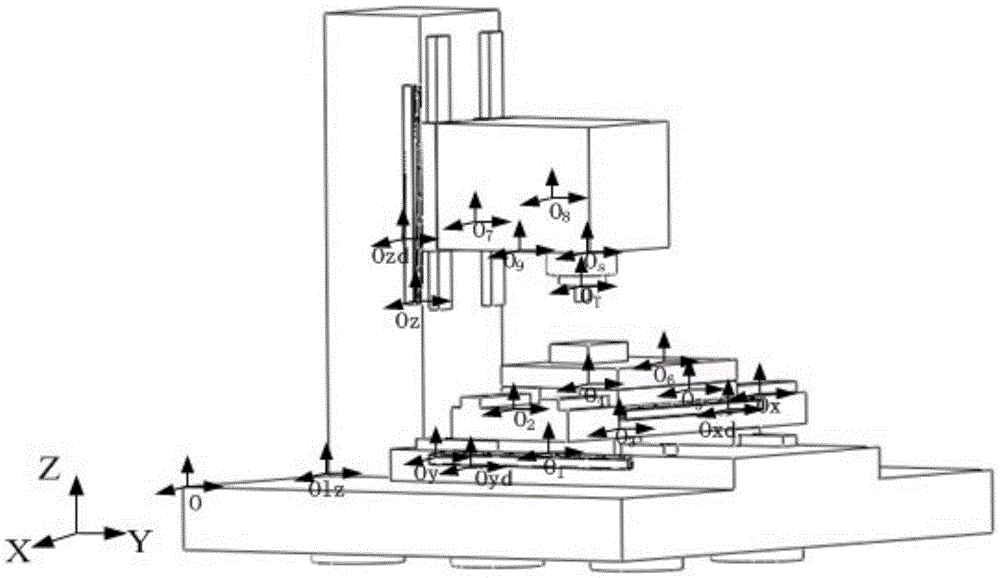

Machine tool error modeling method based on two-dimensional Abbe error and instantaneous movement center

ActiveCN105574287AIn line with the actual work situationImprove machining accuracyGeometric CADSpecial data processing applicationsNumerical controlGrating

The invention discloses a machine tool error modeling method based on a two-dimensional Abbe error and an instantaneous movement center, and relates to the technical field of machine tool error compensation. The machine tool error modeling method comprises the following steps: analyzing a deflection instantaneous center, a pitching instantaneous center and a rolling instantaneous center of an X and Y-axis guide track system of a stack working table; analyzing the deflection instantaneous center, the pitching instantaneous center and the rolling instantaneous center of a Z-axis guide track system; establishing corresponding deflection-Abbe error, pitching-Abbe error and rolling-Abbe error models. By adopting the machine tool error modeling method, the deflection instantaneous center, the pitching instantaneous center and the rolling instantaneous center of guide track systems in different motion directions can be analyzed, and the corresponding deflection-Abbe error, pitching-Abbe error and rolling-Abbe error models can be established. The zero drift error, the indication error and the guide track system Abbe error of a grating measurement system can be comprehensively considered according to the multi-body dynamic theory, a comprehensive numerically-controlled machine tool error model can be established, basis can be provided for next error compensation, and thus the processing precision of a numerically-controlled machine tool can be effectively improved.

Owner:ANHUI UNIV OF SCI & TECH

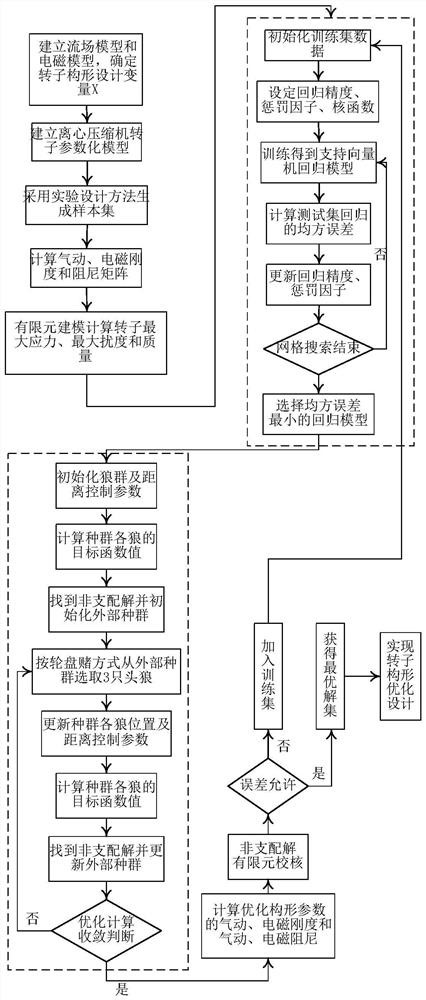

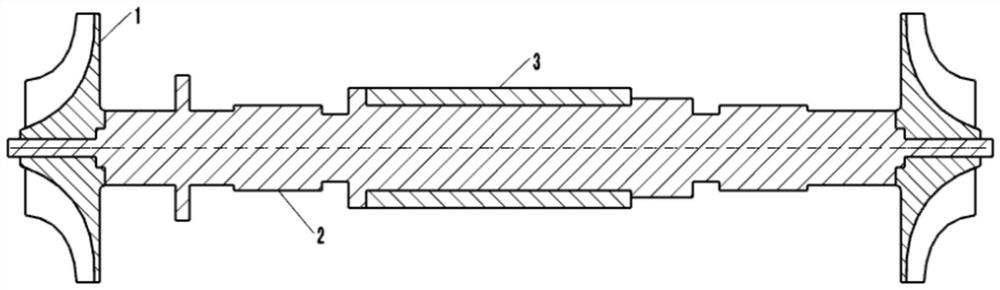

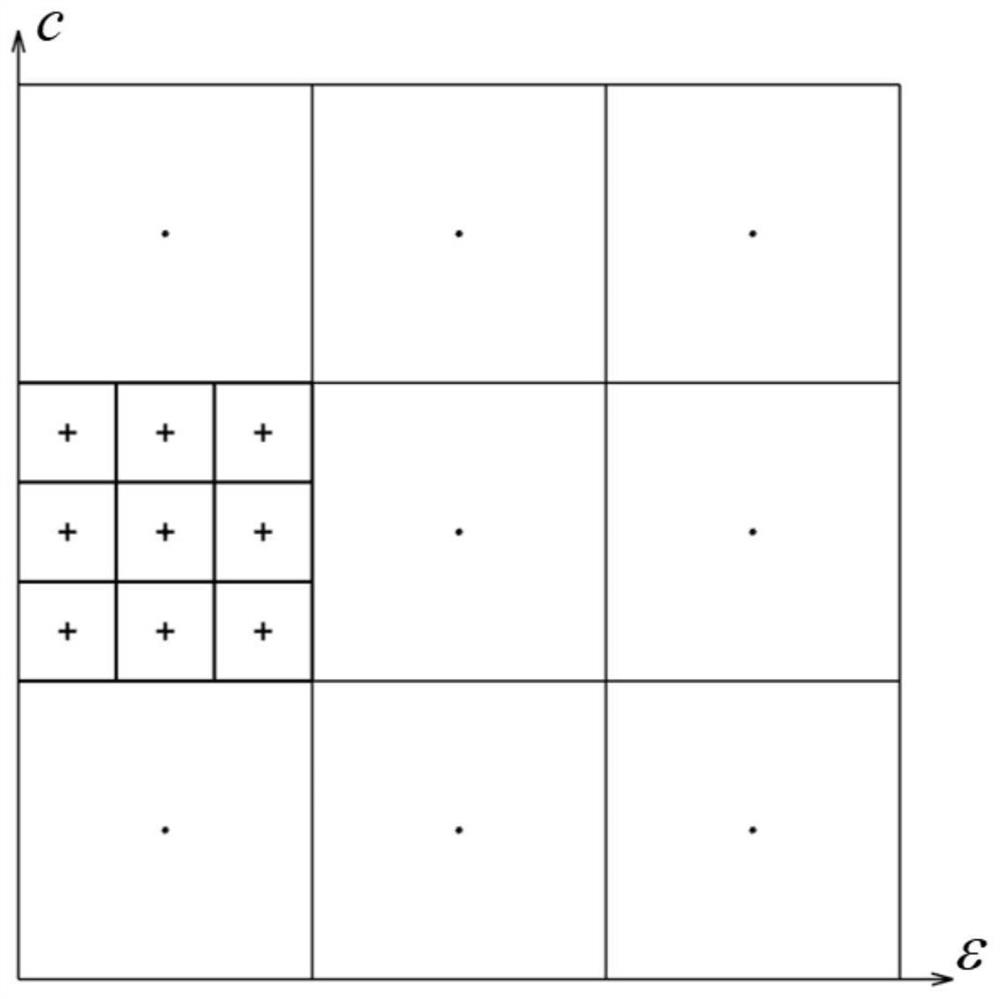

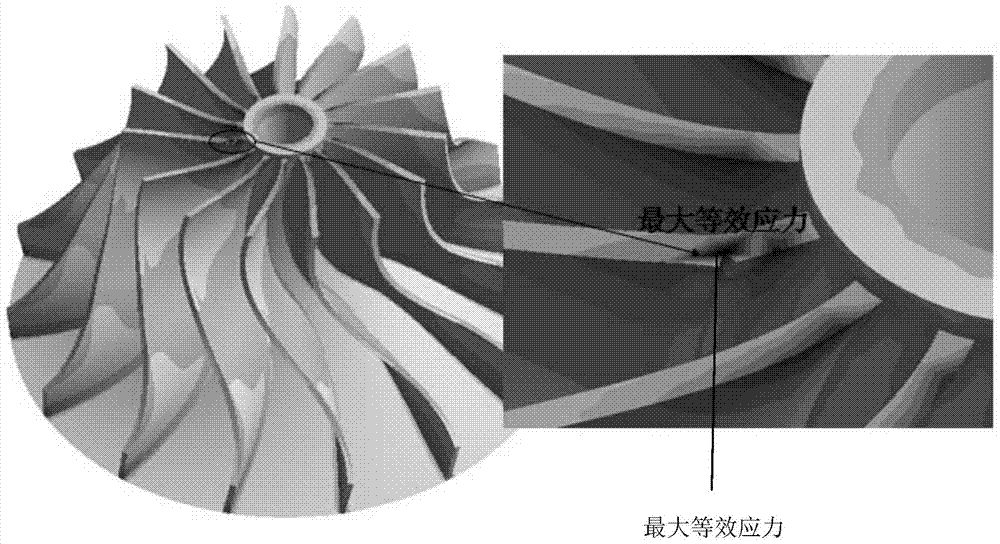

Fuel cell centrifugal compressor rotor configuration optimization design method

PendingCN111859730AAccurate shapeIn line with the actual work situationGeometric CADPump componentsFuel cellsConfiguration optimization

The invention belongs to the field of turbomachinery optimization design. The invention particularly relates to a fuel cell centrifugal compressor rotor configuration optimization design method. The method comprises the following specific steps: in the configuration optimization design process of the centrifugal compressor rotor, rotor aerodynamic stiffness, aerodynamic damping, electromagnetic stiffness and electromagnetic damping changes caused by fluid excitation of an impeller air gap, a bearing air film and sealing gas and electromagnetic excitation factors of a motor rotor are considered; and optimization calculation is performed on the rotor configuration parameters by using a support vector regression machine and an adaptive multi-target grey wolf algorithm, and thus finally obtaining uniformly distributed non-dominated solutions as the rotor configuration parameters. According to the invention, a flow field and electromagnetic excitation are included in dynamic response influence factors for a motor integrated direct drive structure and light weight requirements of the fuel cell centrifugal compressor rotor, the maximum stress and deformation of a rotor part are reduced under the condition that mass constraints are met, the structural dynamic reliability of the fuel cell centrifugal compressor is improved, and the service life of the fuel cell centrifugal compressor isprolonged.

Owner:HEFEI GENERAL MACHINERY RES INST

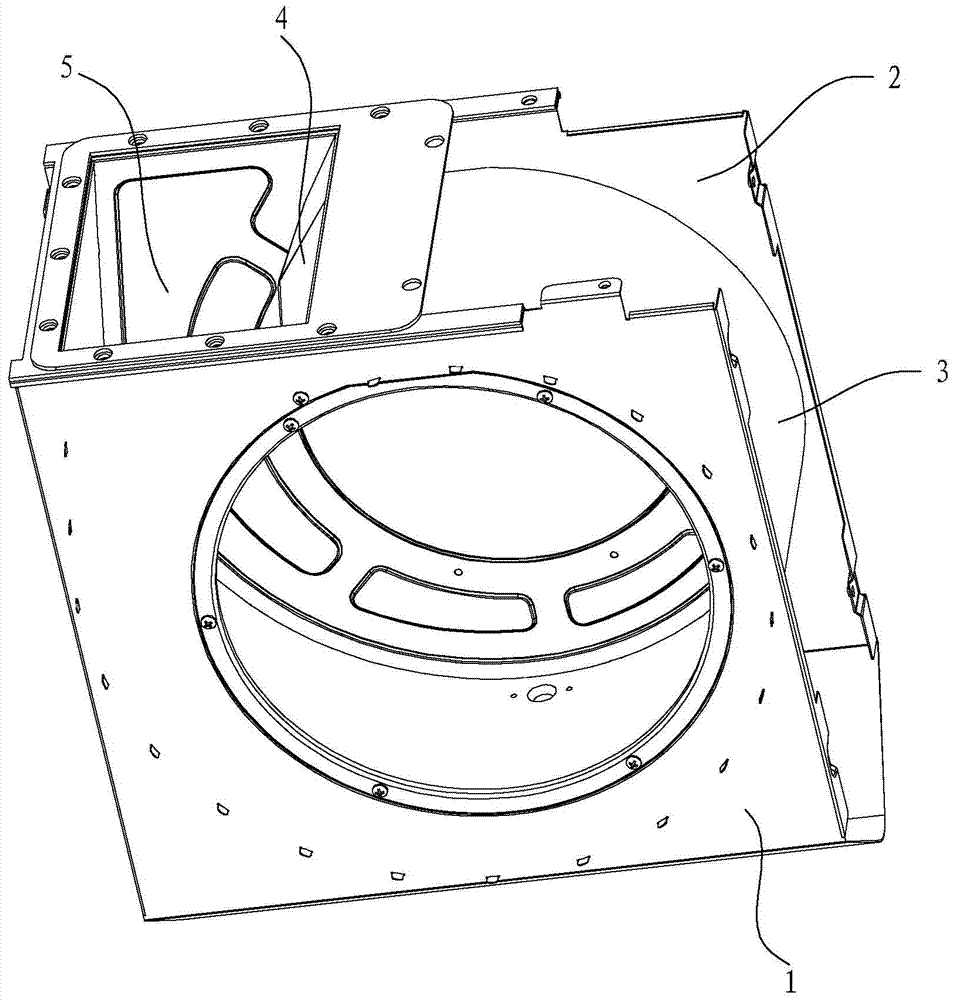

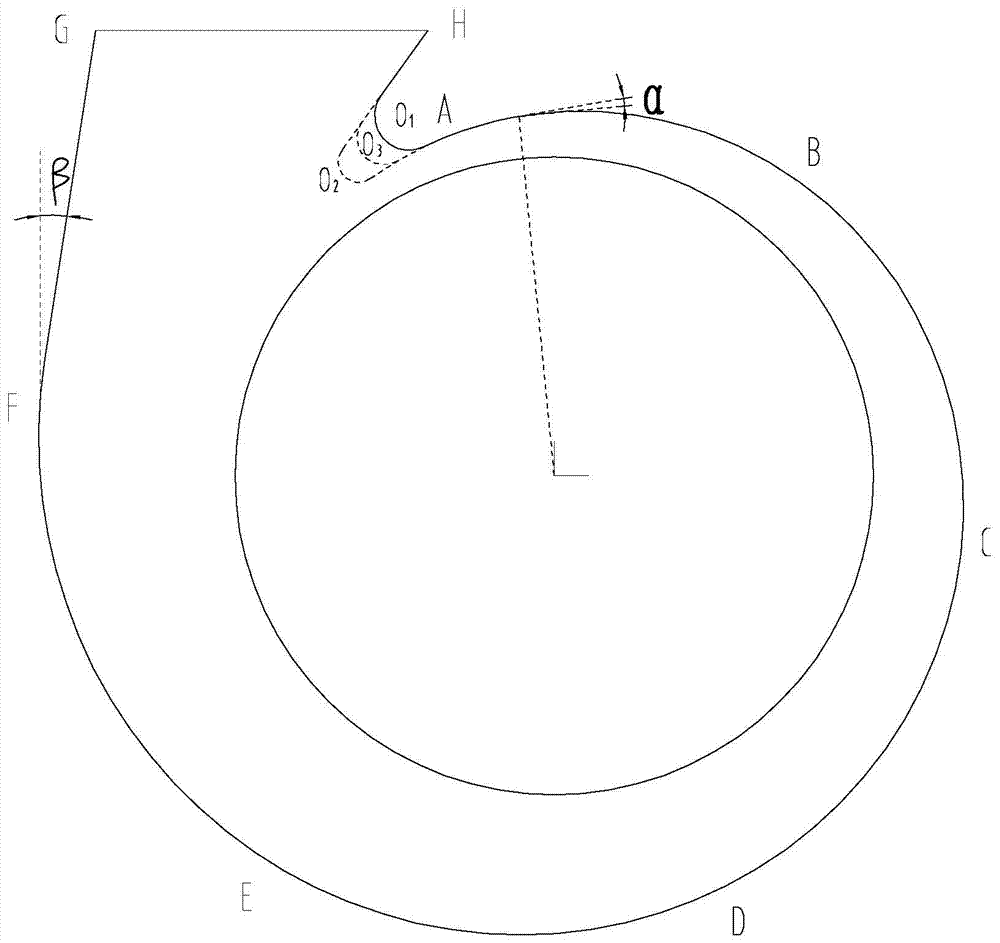

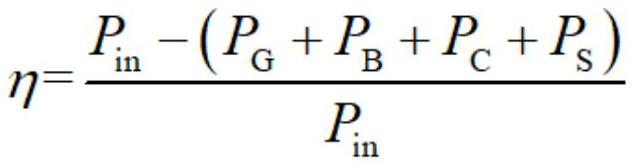

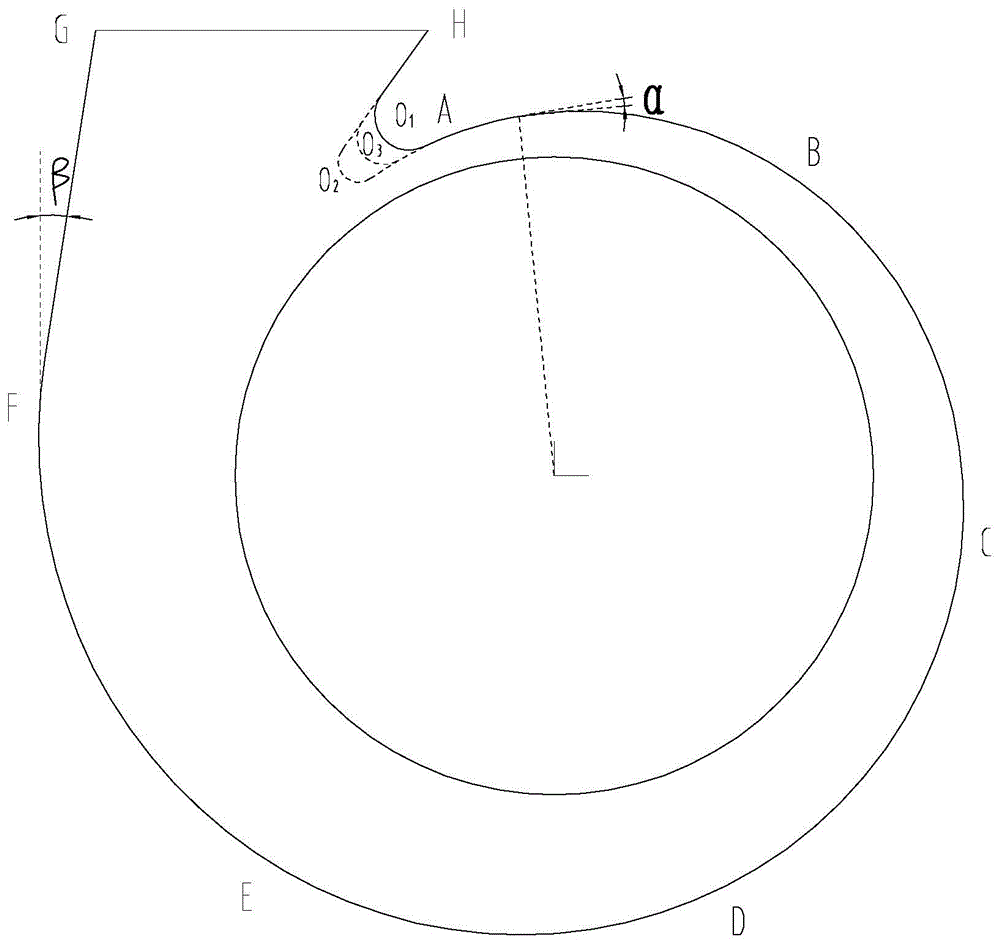

Centrifugal fan volute structure

ActiveCN104847699AIn line with the actual work situationImprove noisePump componentsPumpsAgricultural engineeringCentrifugal fan

A centrifugal fan volute structure comprises a volute top plate, a volute bottom plate and a volute surrounding plate; a volute molded line comprises a starting line HA and a finishing line FG; the centrifugal fan volute structure is characterized in that the volute molded line between the starting line HA and the finishing line FG is a spiral line; the spiral line comprises a starting spiral line AB connected with the starting line HA, a finishing spiral line EF connected with the finishing line FG and a middle spiral line connected between the starting spiral line and the finishing spiral line; spiral angles of the starting spiral line AB and the finishing spiral line EF are smaller than a spiral angle of the middle spiral line. According to the centrifugal fan volute structure, the spiral line between the starting line and the finishing line is divided into the starting spiral line AB, the finishing spiral line EF and the middle spiral line, and the spiral angles of the starting spiral line AB and the finishing spiral line EF are smaller than the spiral angle of the middle spiral line, so that the designed volute structure meet the actual working conditions; the static pressure close to the starting line is improved and the efficiency close to an optimal working condition is improved, so that the pneumatic and noise performances of a fan are better.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

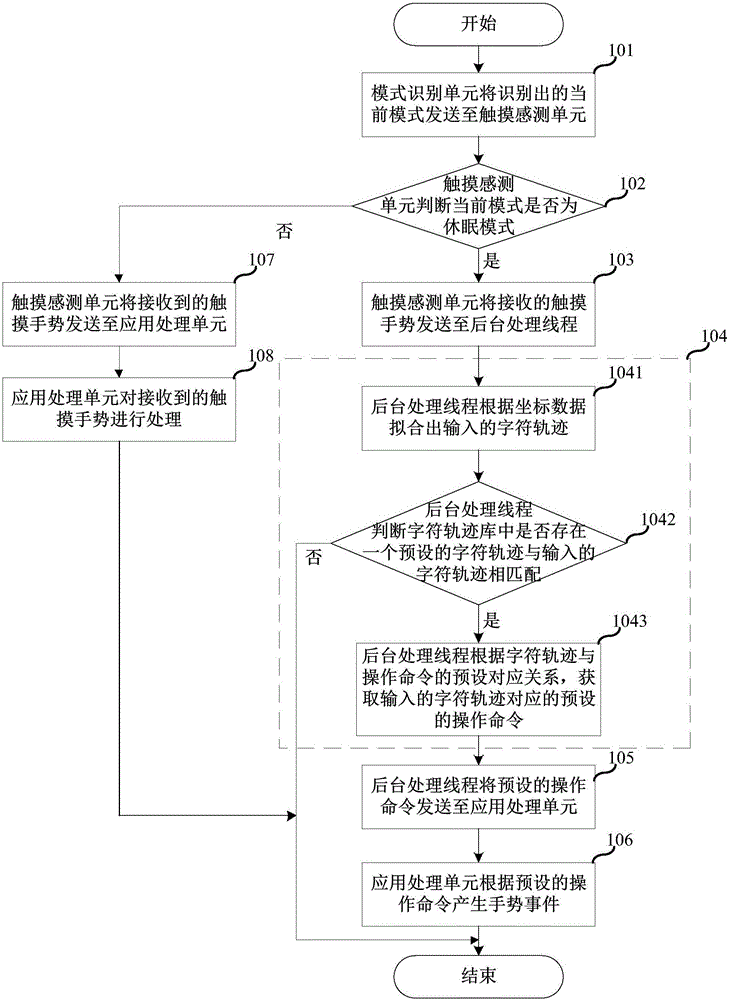

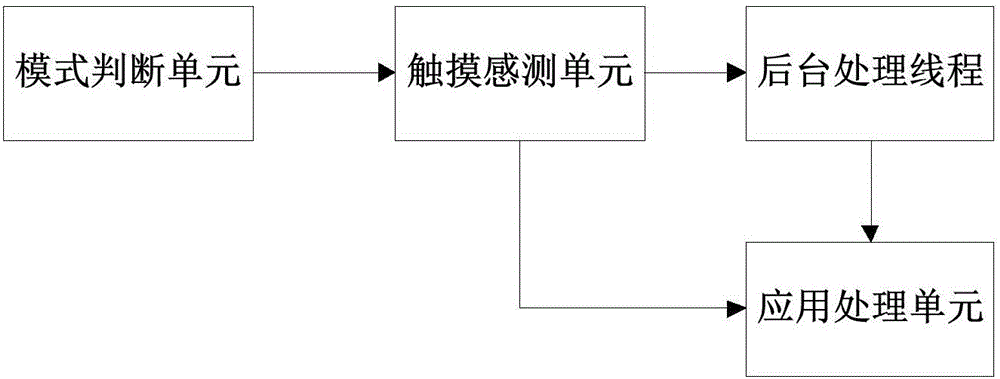

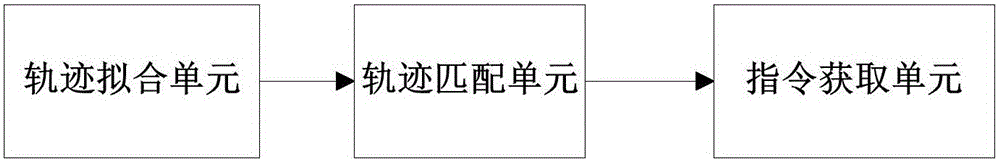

Gesture event generation method and electronic device

InactiveCN105739884AGuaranteed Low Power StatesReduce manufacturing costPower supply for data processingInput/output processes for data processingElectric equipmentCurrent mode

The invention relates to the technical field of communication, and discloses a gesture event generation method and electronic equipment. In the present invention, the method for generating the gesture event includes the following steps: the mode recognition unit sends the identified current mode of the electronic device to the touch sensing unit; if the touch sensing unit judges that the current mode is a sleep mode, then touch sensing The unit sends the received touch gesture to the background processing thread; the background processing thread judges whether the touch gesture corresponds to a preset operation command; if the touch gesture corresponds to a preset operation command, the background processing thread sends the preset operation command and sent to the application processing unit; wherein, after the application processing unit receives the preset operation command, the electronic device enters the working mode. Through the above method, the electronic device can also perform gesture recognition when it is in sleep standby mode, which not only ensures the low power consumption state of the electronic device in standby mode, but also does not increase the production cost of the electronic device.

Owner:SHANGHAI YUDE TECH CO LTD

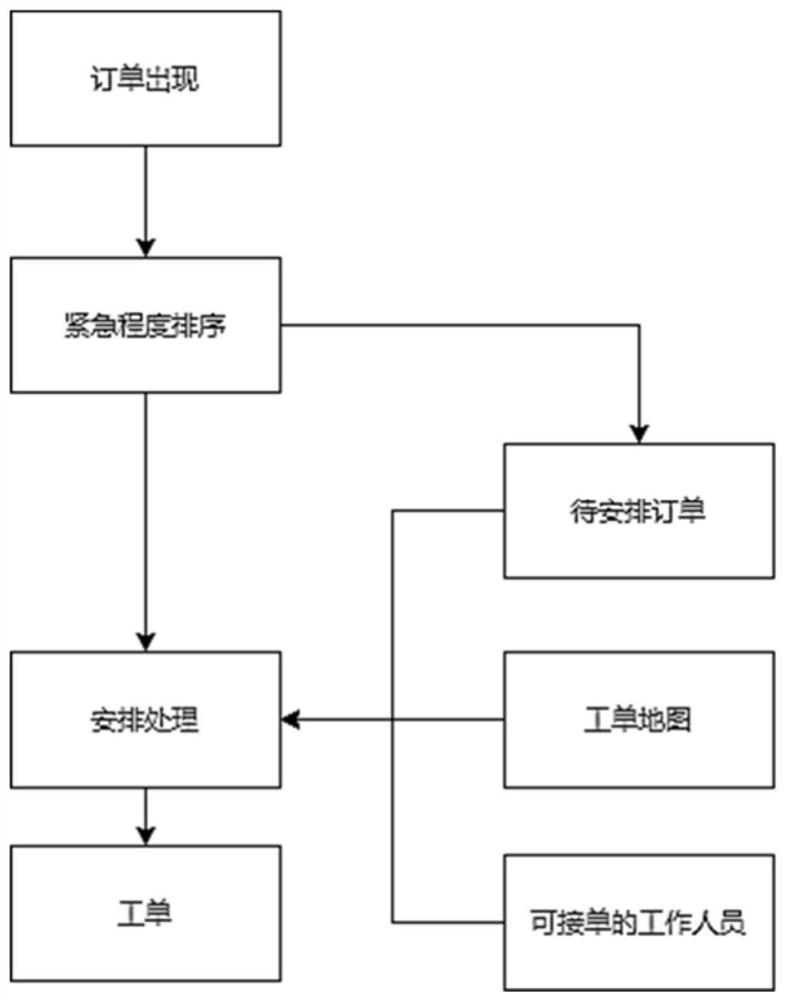

Multi-dimensional optimized electric power work order intelligent distribution method

PendingCN113298322AImprove satisfactionShort delayForecastingResourcesDistribution methodService efficiency

The invention discloses a multi-dimensional optimized electric power work order intelligent distribution method, and solves the technical problem of how to consider optimization of service cost, service quality and service efficiency. The method comprises steps of acquiring a maintenance order, and dividing the maintenance order into an emergency order and a retention order according to an order classification rule; if the order is an emergency order, immediately sending the order to a work order arrangement module; if the order is a detention order, sending the detention order to a work order distribution module within a specified time T; enabling a work order distribution module to carry out order distribution on the maintenance order; screening an optimal path on a work order map, so that a worker receives the order at each fault position, and a total path traversing the fault positions is shortest; and then, generating an electric power work order matched with a corresponding worker for each maintenance order according to the optimal path, and sending the electric power work order to the corresponding worker. Multi-dimensional optimization assignment of the electric power work order is rapidly realized, and the existing electric power work order assignment pattern is expected to be changed.

Owner:CHENGDU POWER SUPPLY COMPANY OF STATE GRID SICHUAN ELECTRIC POWER

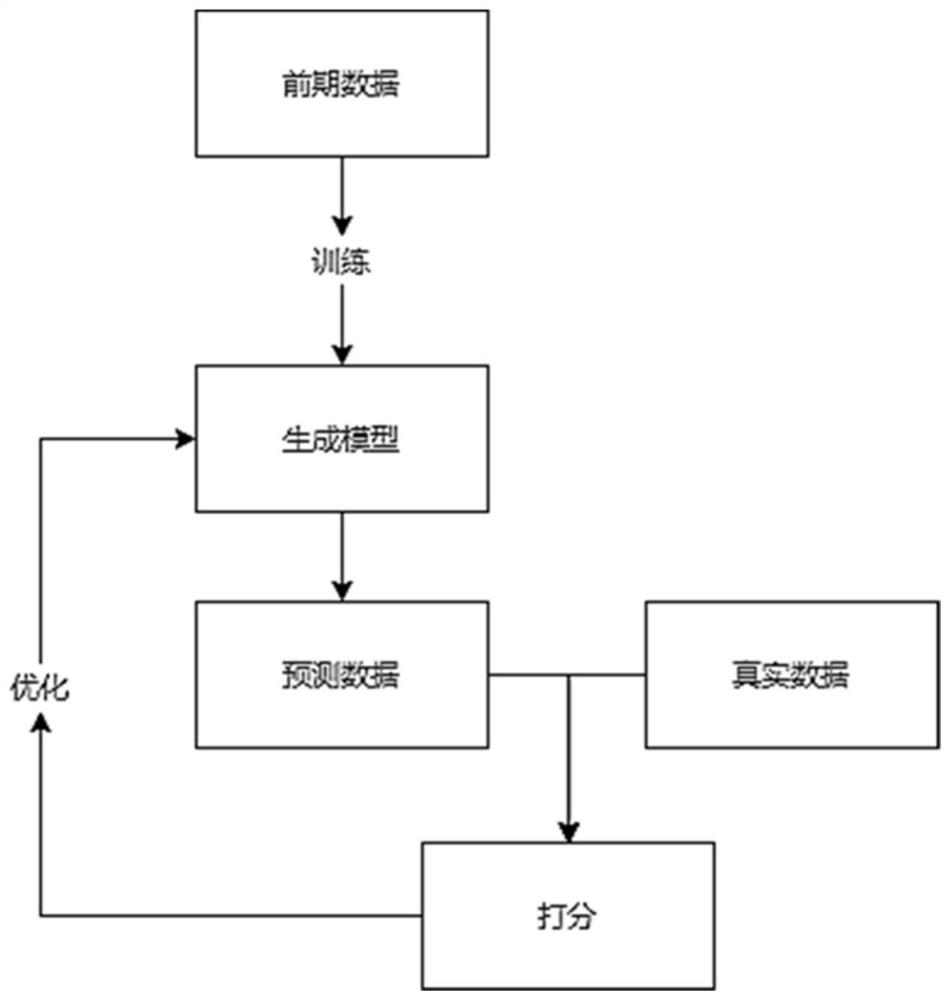

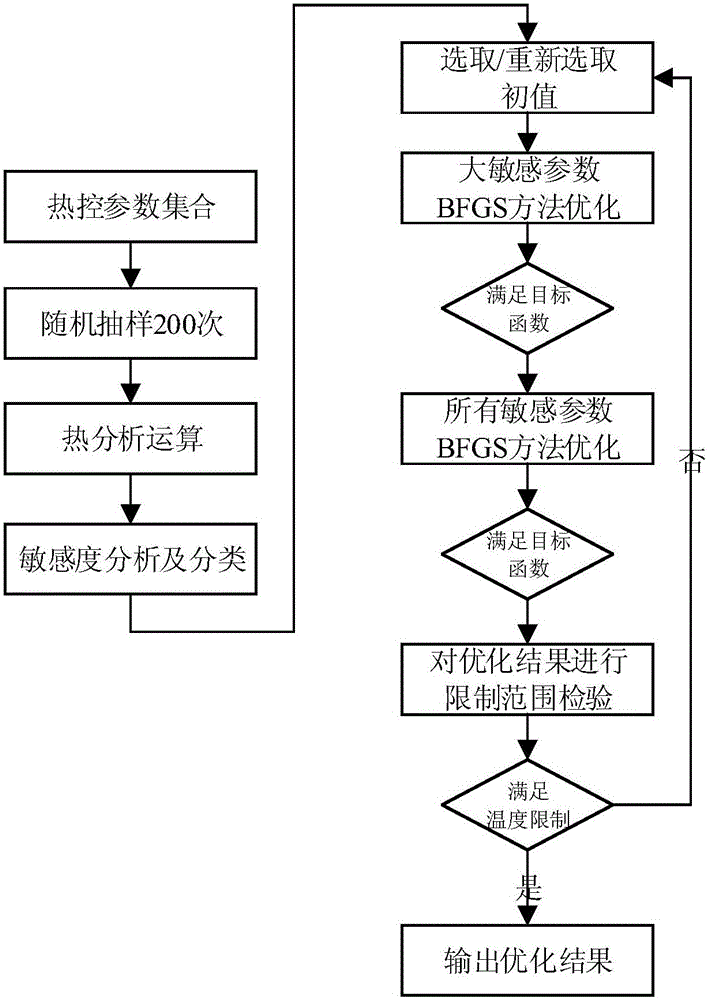

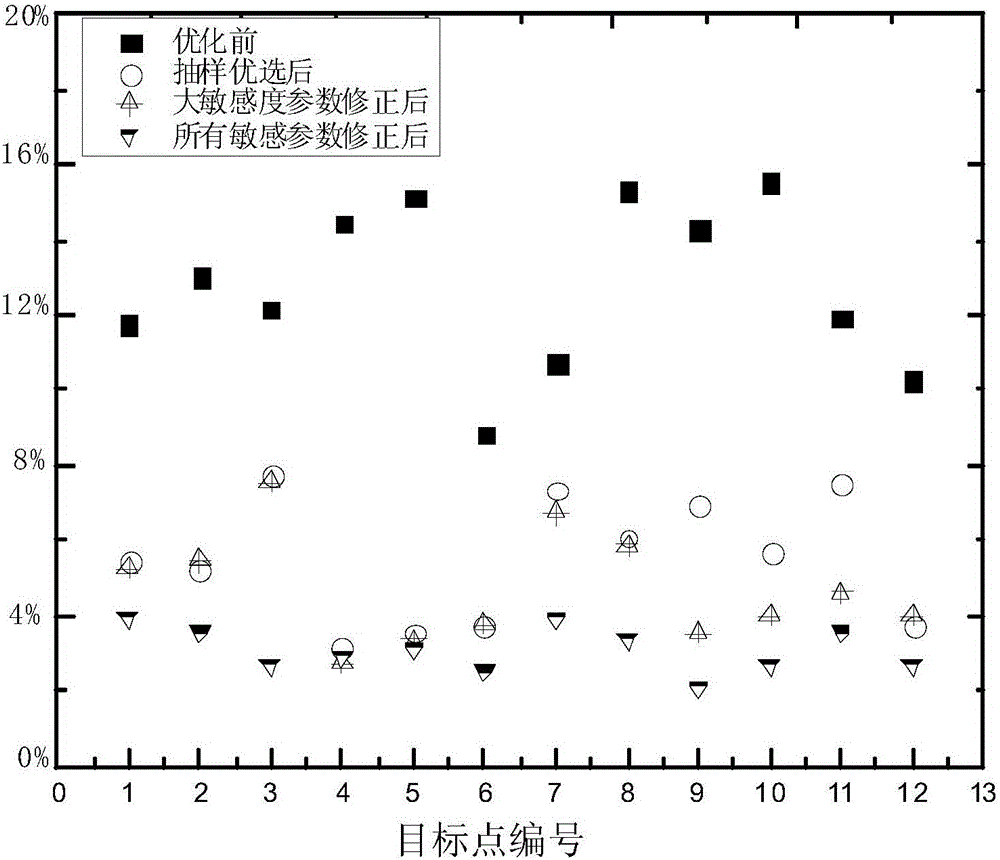

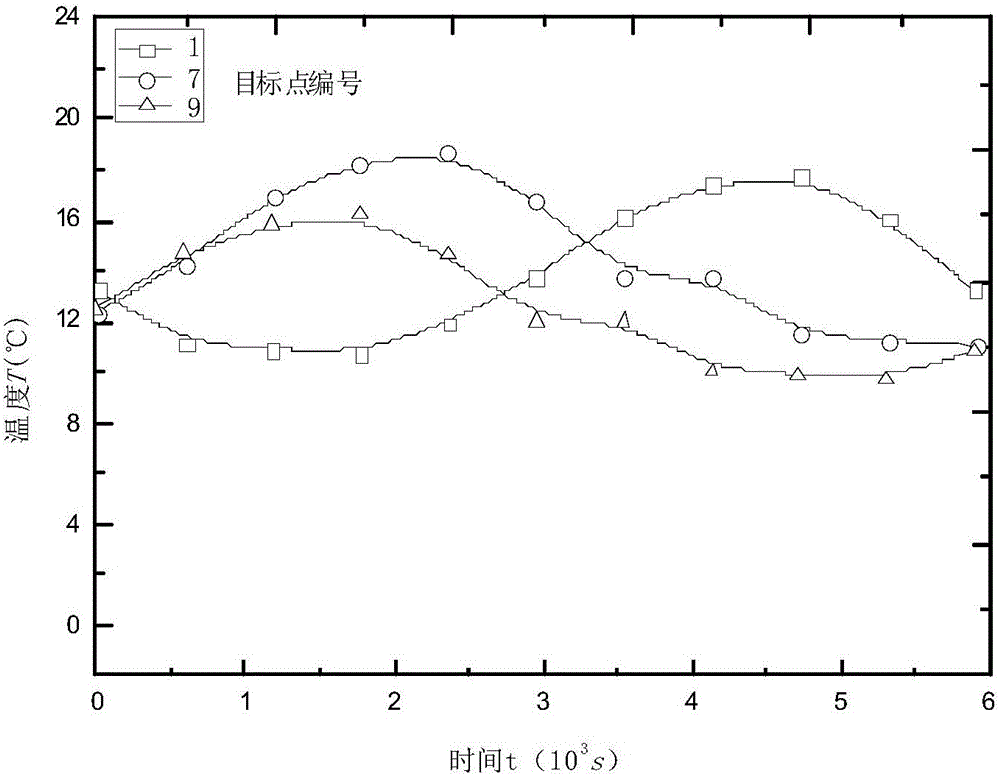

Design optimization method for spacecraft passive thermal control parameters

InactiveCN105975712AIn line with the actual work situationHigh cost-effectiveGeometric CADDesign optimisation/simulationCost effectivenessMean square

The invention discloses a design optimization method for spacecraft passive thermal control parameters. The design optimization method comprises the following steps that firstly, statistics is carried out on a thermal control parameter set to be designed and the design scope of the thermal control parameter set, and objective temperatures and the optimum value and the limit range of the objective temperatures are determined; secondly, an objective function is established, the sensitivity of the objective function on the thermal control parameters is analyzed, and the parameters are classified according to sensitivity; then, a sampled optimal sample serves as an initial value, and step-by-step optimization is carried out on the thermal control parameters through a quasi-linear algorithm according to the sensitivity classification; finally, whether an optimized value meets the temperature limitation or not under various thermal working conditions is detected, and if not, a suboptimum sample is selected again to serve as an initial value for optimization until the optimized value meeting the temperature limitation is acquired. The establishing method for the objective function with a weight mean square error, a sensitivity analysis classifying method for multiple working condition mean square errors on the thermal control parameters, the thermal control parameter step-by-step optimizing method and the like are put forward, and the effective optimization design method is provided for improving the cost-effectiveness and reliability of a spacecraft thermal control system to meet the harsh requirements of a current spacecraft.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

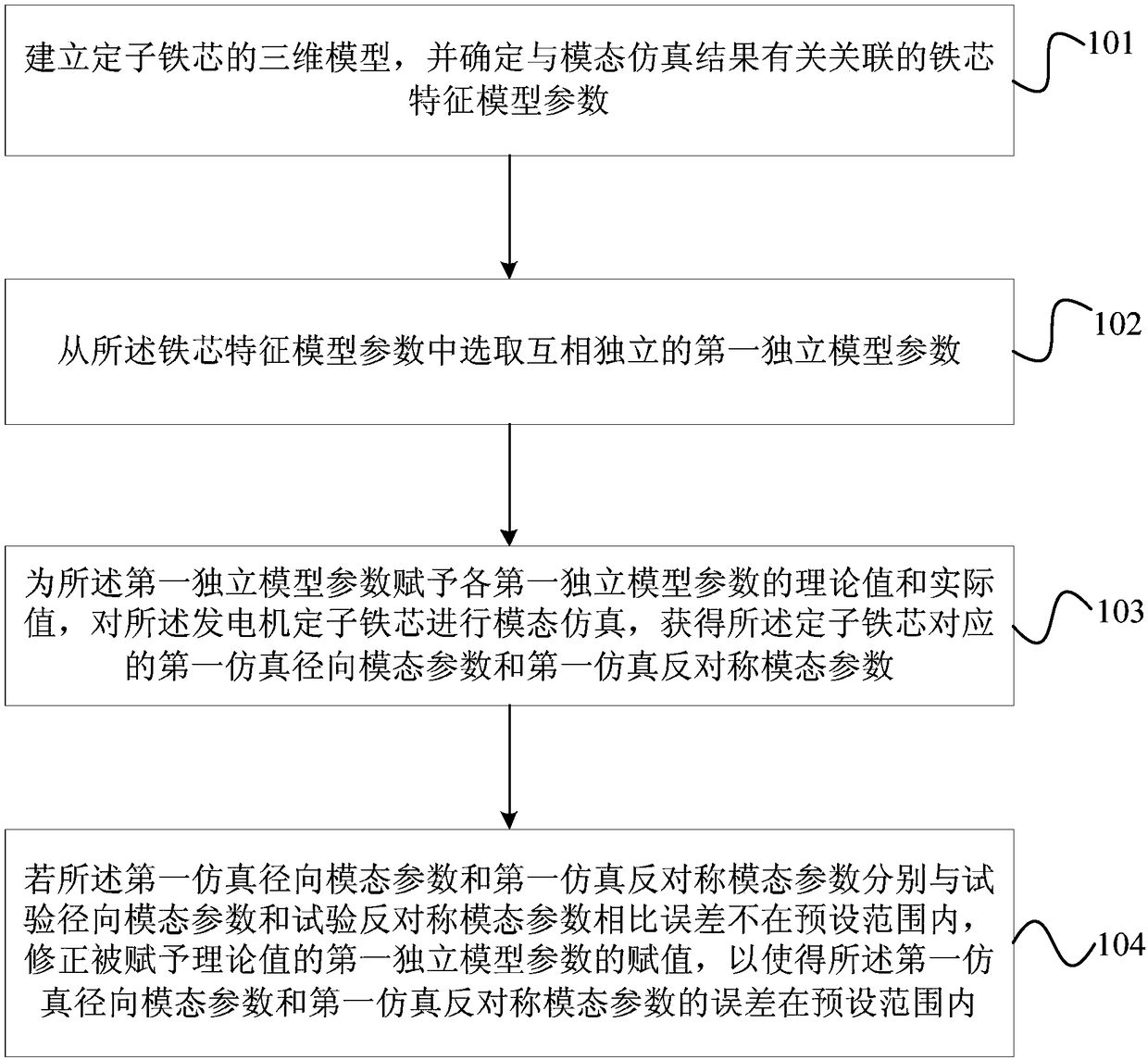

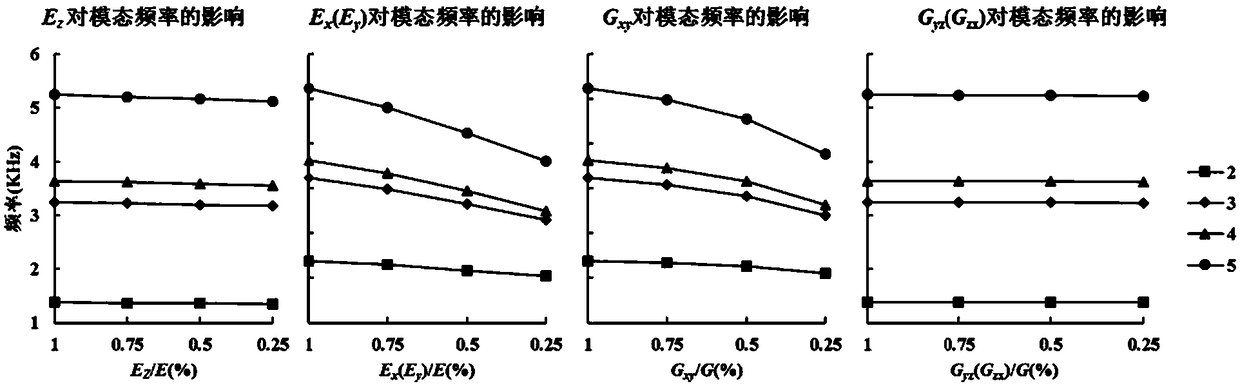

Modal simulation method and device, computing device and storage medium for generator stator

InactiveCN108416157ACorrection valueIn line with the actual work situationDesign optimisation/simulationSpecial data processing applicationsSimulationModel parameters

The embodiment of the invention discloses a modal simulation method, a device a computing device and a storage medium for a vehicle generator stator. The modal simulation method establishes a 3D modelof the stator core and determines a core characteristic model parameter associated with the modal simulation result. A first independent model parameter is selected from the stator core feature modelparameters. The theoretical value and the actual value are then assigned to the first independent model parameter and the simulated modal parameters are compared with the results of the experimentalmodal parameters. When the simulation result is inconsistent with the experimental modal result, the first independent model parameter given the theoretical value is corrected. The modal simulation isperformed again, so that the modal simulation results of the stator core are consistent with the experimental results. Thereby the theoretical value of the first independent model parameter of the stator core is corrected and the value of the stator core parameters can be more consistent with the actual working conditions.

Owner:SHANGHAI VALEO AUTOMOTIVE ELECTRICAL SYST

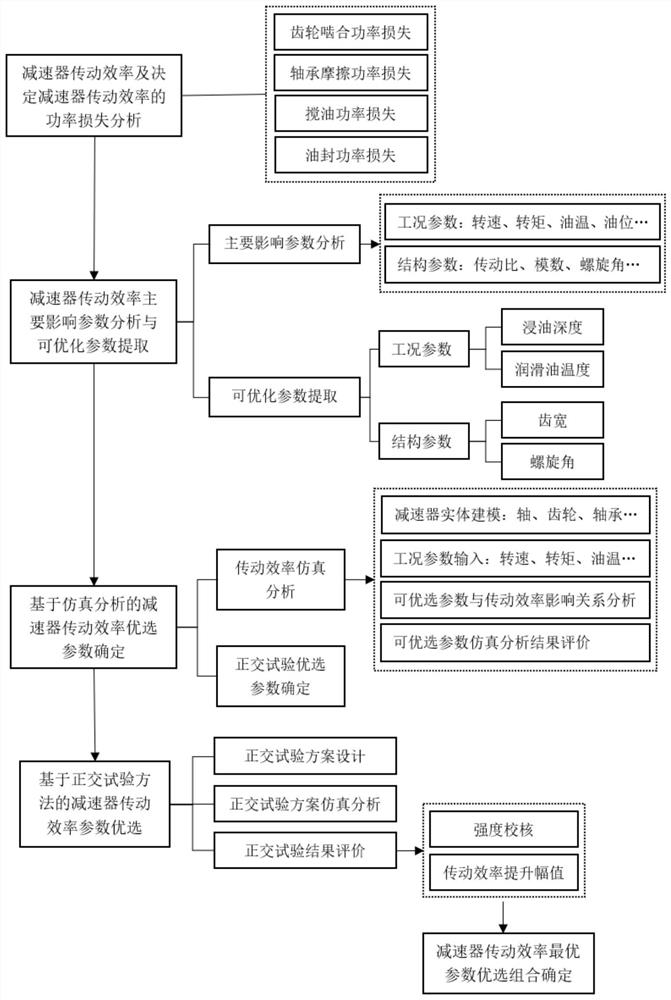

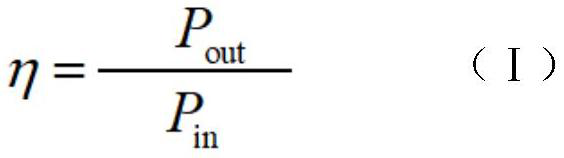

Speed reducer transmission efficiency optimization method

PendingCN114840948AConsider comprehensivelyGreat improvementGeometric CADEnergy industryAnalysis modelsPower loss

The invention relates to a method for optimizing the transmission efficiency of a speed reducer. The method comprises the following steps of: 1, proposing the transmission efficiency of the speed reducer and each power loss expression; 2, extracting structure parameters and working condition parameters which can be used for optimizing the transmission efficiency of the speed reducer; 3, establishing a speed reducer transmission efficiency simulation analysis model, analyzing the relation between the structure parameters and the working condition parameters extracted in the step 2 and the transmission efficiency, and selecting at least five parameters with the maximum influence as optimal parameters of an orthogonal test; and step 4, optimizing the transmission efficiency of the speed reducer through design of an orthogonal test scheme, simulation analysis and optimization result evaluation, and finally obtaining an optimal parameter combination meeting evaluation requirements. According to the method, influence factors are comprehensively considered in the whole optimization process, the actual operation condition is better met, the application range is wide, the method is not limited to speed reducers of specific structures, and in other words, the transmission efficiency can be greatly improved through the optimization method for speed reducers of different structures.

Owner:SHANDONG UNIV OF SCI & TECH

A centrifugal fan volute structure

ActiveCN104847699BIn line with the actual work situationImprove noisePump componentsPumpsAgricultural engineeringCentrifugal fan

A centrifugal fan volute structure comprises a volute top plate, a volute bottom plate and a volute surrounding plate; a volute molded line comprises a starting line HA and a finishing line FG; the centrifugal fan volute structure is characterized in that the volute molded line between the starting line HA and the finishing line FG is a spiral line; the spiral line comprises a starting spiral line AB connected with the starting line HA, a finishing spiral line EF connected with the finishing line FG and a middle spiral line connected between the starting spiral line and the finishing spiral line; spiral angles of the starting spiral line AB and the finishing spiral line EF are smaller than a spiral angle of the middle spiral line. According to the centrifugal fan volute structure, the spiral line between the starting line and the finishing line is divided into the starting spiral line AB, the finishing spiral line EF and the middle spiral line, and the spiral angles of the starting spiral line AB and the finishing spiral line EF are smaller than the spiral angle of the middle spiral line, so that the designed volute structure meet the actual working conditions; the static pressure close to the starting line is improved and the efficiency close to an optimal working condition is improved, so that the pneumatic and noise performances of a fan are better.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

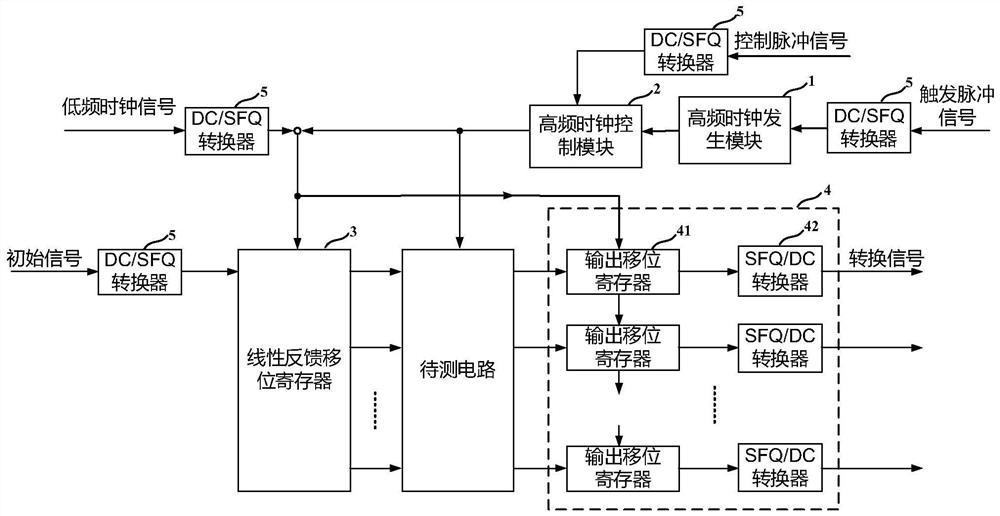

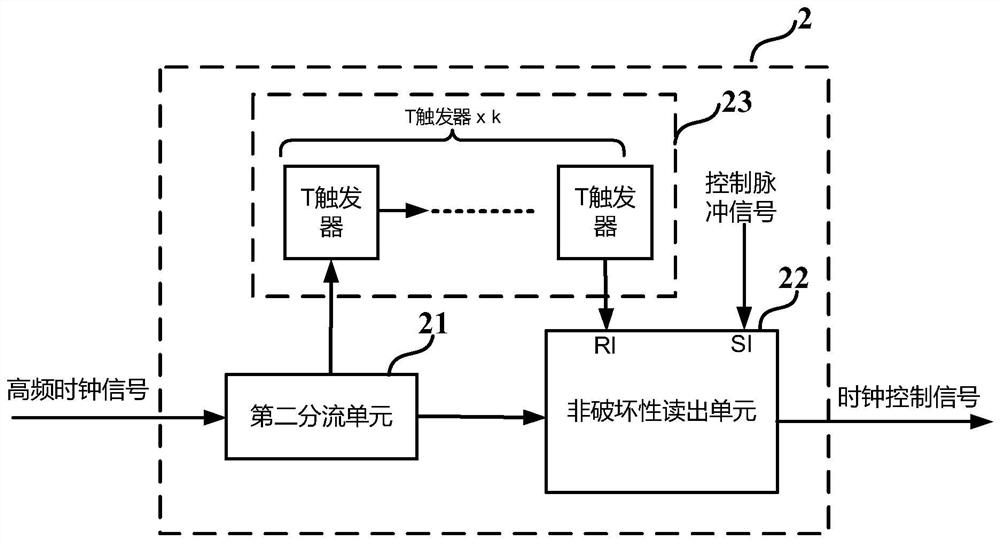

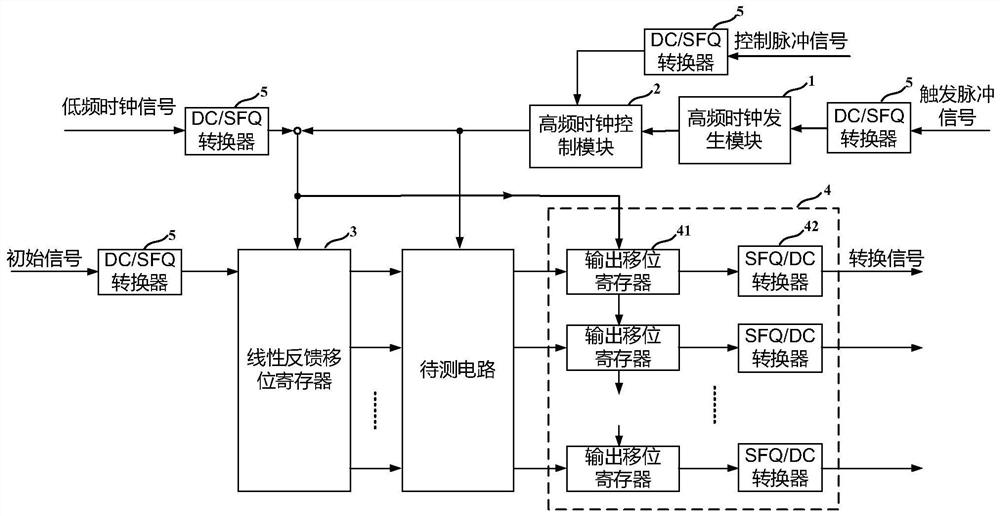

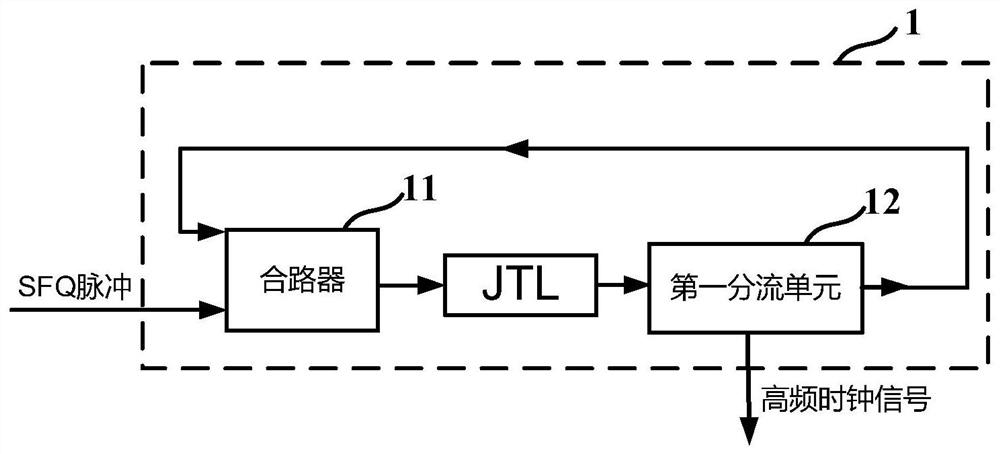

Superconducting high-frequency test system and method

ActiveCN113030709ASimple circuit structureSimple structureElectronic circuit testingEngineeringReal-time computing

The invention provides a superconducting high-frequency test system and method, and the method comprises the steps: firstly receiving a trigger pulse signal, and outputting a periodic high-frequency clock signal; controlling connection and disconnection of the high-frequency clock signal and outputting a high-frequency control clock signal is output; receiving an initial signal, setting a non-zero initial state for the linear feedback shift register, and simultaneously outputting multiple paths of periodic pseudo-random sequences with preset period lengths based on a high-frequency control clock signal; receiving, by the to-be-tested circuit, the multiple paths of pseudo-random sequences and outputting multiple paths of test signals; receiving the multi-path test signals, and outputting multi-path conversion signals based on low-frequency clock signals; comparing the multiple paths of conversion signals with an expected output result, and determining whether the circuit to be tested works normally or not. The circuit structure is relatively simple; the input signal is a pseudo-random sequence generated based on a linear feedback shift register, continuous high-frequency testing can be achieved, and the actual working condition of a circuit to be tested is better met.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

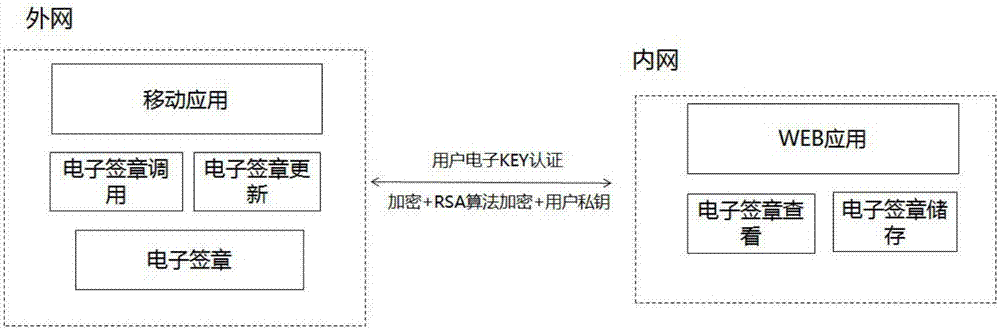

Method for receiving and delivering goods at mobile electric power materials site based on electronic signature

InactiveCN107579825ATimely processingEfficient data viewingPublic key for secure communicationUser identity/authority verificationMaterials managementElectric power

The invention provides a method for receiving and delivering goods at a mobile electric power materials site based on an electronic signature. The electronic signature, the internet and the mobile application technology are comprehensively applied; the electronic signature performs the symmetric encryption algorithm and RSA encryption algorithm to ensure the reality and the security of the identity of a signing staff, the communication of the electronic signature and the goods receiving / delivering information between the electric power intranet and extranet is realized through the mobile application and user identity electronic KEY safety authentication, thereby ensuring the immediate transmission of the information; the management targets of reducing enterprise materials management cost,optimizing a site goods receiving / delivering management mode and improving the management working efficiency are achieved.

Owner:YUNNAN POWER GRID +1

A shield machine cooperative operation virtual training system and method

ActiveCN106652637BIncrease authenticityEnable virtual trainingCosmonautic condition simulationsSimulatorsVirtual trainingConcurrency control

Owner:西安启工数据科技有限公司

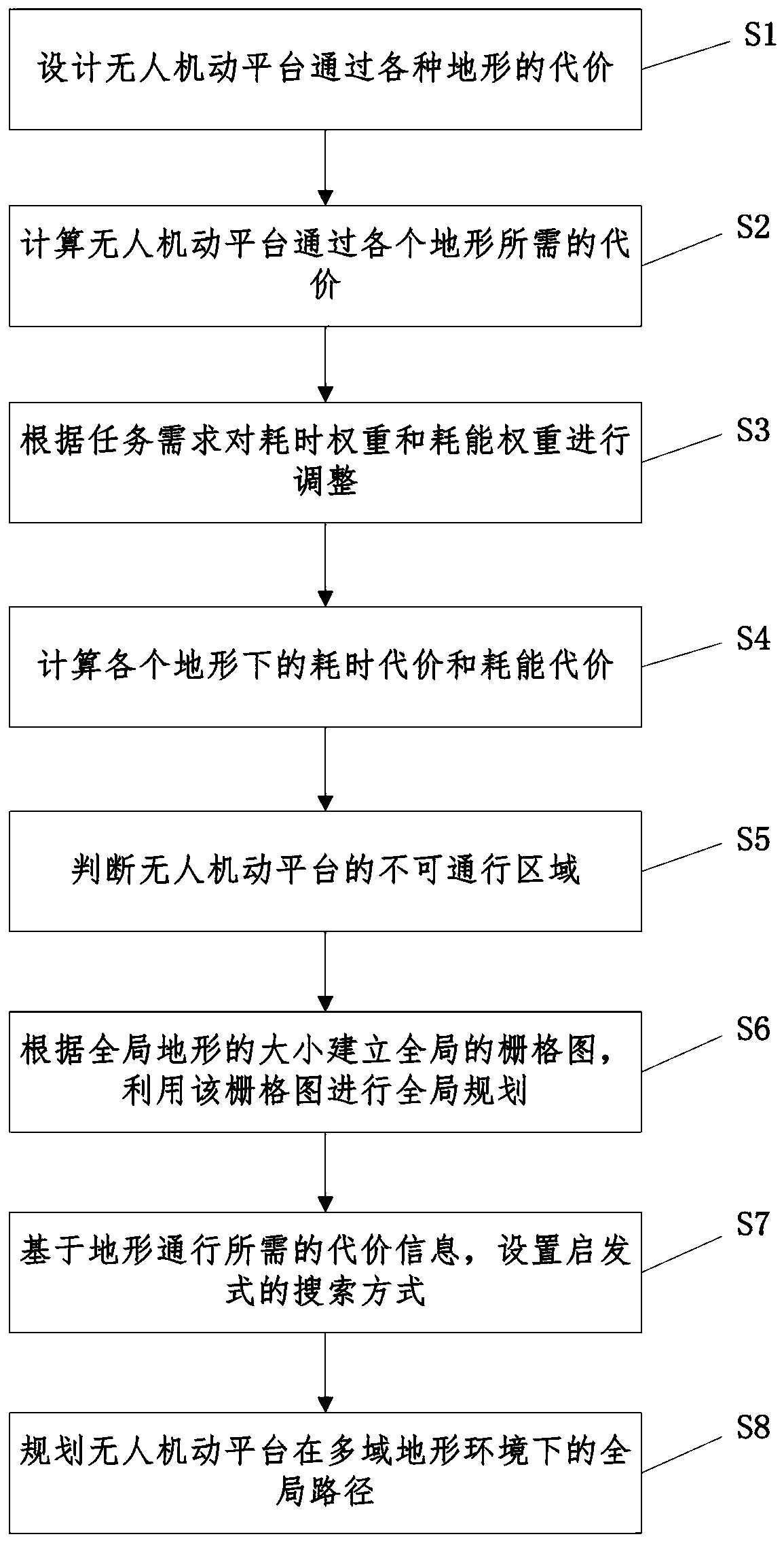

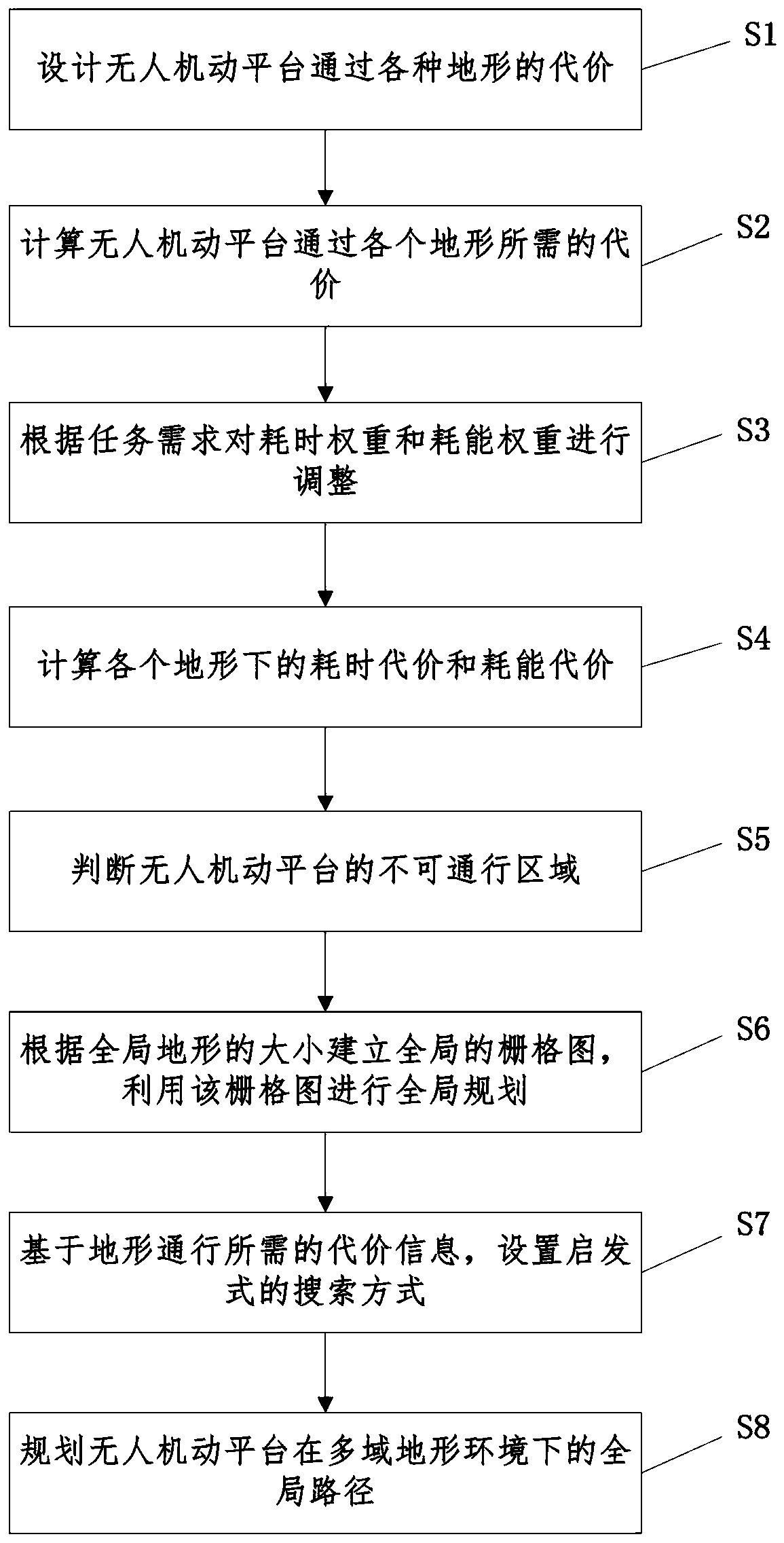

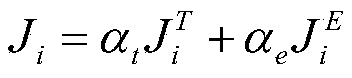

Global path planning method of unmanned aerial vehicle moving platform in multi-domain terrain environment

ActiveCN111176273AIn line with the actual work situationPosition/course control in two dimensionsVehiclesSimulationUncrewed vehicle

The invention provides a global path planning method of an unmanned aerial vehicle moving platform in a multi-domain terrain environment. The global path planning method comprises a calculation methodfor the passing cost of the multi-domain terrain environment with a pavement pavement, a soft pavement, a wading pavement, a ramp, a ditch and a cliff and a path planning method based on the cost calculation method. The cost calculation considers the speed and the energy consumption of task execution of the platform, the time consumption cost and the energy consumption cost are included, and respective weight values are given to the time consumption cost and the energy consumption cost; the calculation of the time consumption cost and the energy consumption cost is combined with the obstaclecrossing capability of the platform and topographic environment factors, and a parameterized function relational expression of the passage cost of the maneuvering platform and the type and the size oftopographic obstacles is established; and the cost calculation method is combined with a traditional path planning method to realize a global path planning function of the maneuvering platform in a multi-domain terrain environment.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

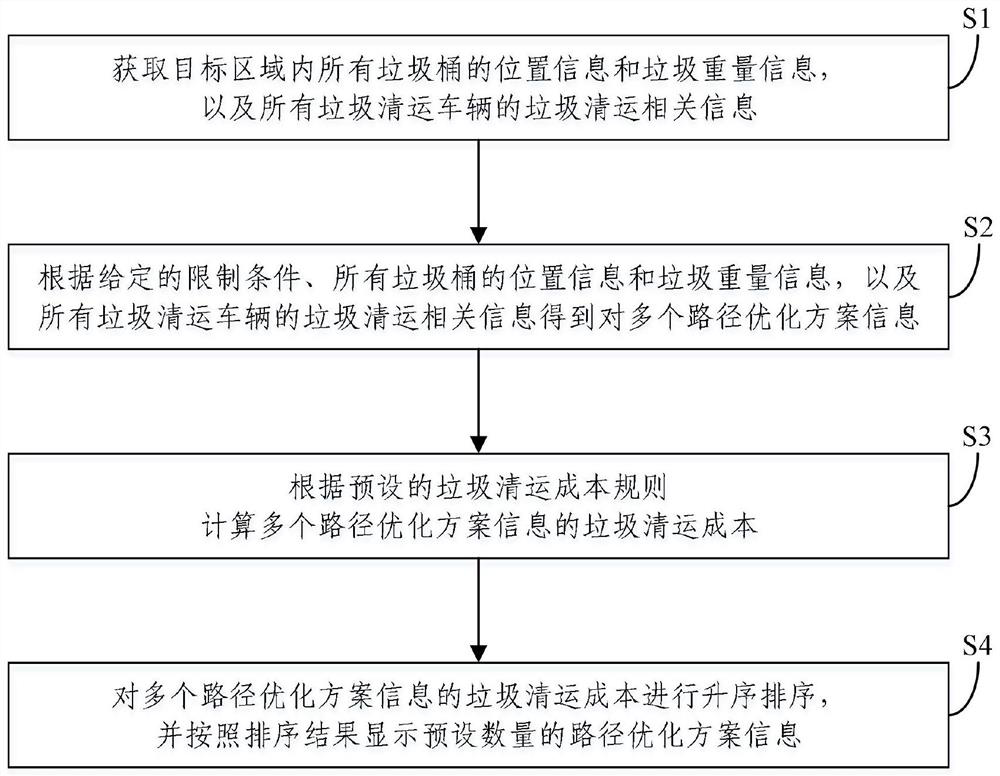

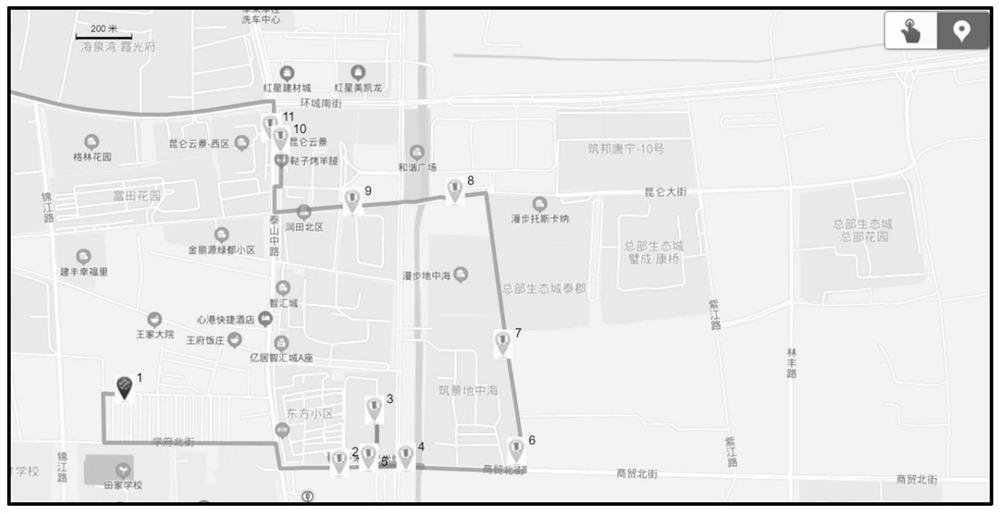

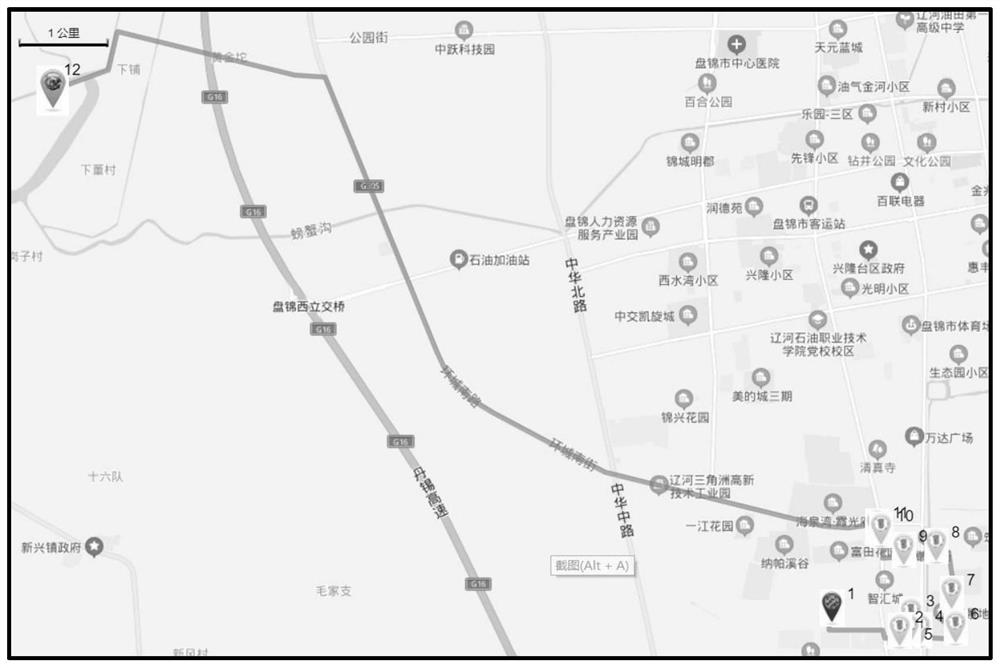

Path optimization system and method for garbage collection and transportation

PendingCN112365032AReduce operating costsIn line with the actual work situationInstruments for road network navigationForecastingGarbage collectionComputer science

The embodiment of the invention discloses a path optimization method and system for garbage collection and transportation. The method comprises the steps of acquiring the position information and garbage weight information of all garbage cans in a target area and garbage collection and transportation related information of all garbage collection and transportation vehicles; obtaining a plurality of pieces of path optimization scheme information according to given limiting conditions, the position information and the garbage weight information of all the garbage cans and the related garbage collection information of all the garbage collection vehicles; calculating the garbage clearing cost of the multiple pieces of path optimization scheme information according to a preset garbage clearingcost rule; and performing the ascending sorting on the garbage collection costs of the multiple pieces of path optimization scheme information, and a preset number of pieces of path optimization scheme information are displayed according to the sorting. According to the path optimization method, the operation cost of the garbage collection vehicle is considered according to an algorithm, and the operation cost of the sanitation vehicle can be effectively reduced.

Owner:BEIJING ENVIRONMENT ENG TECH CO LTD

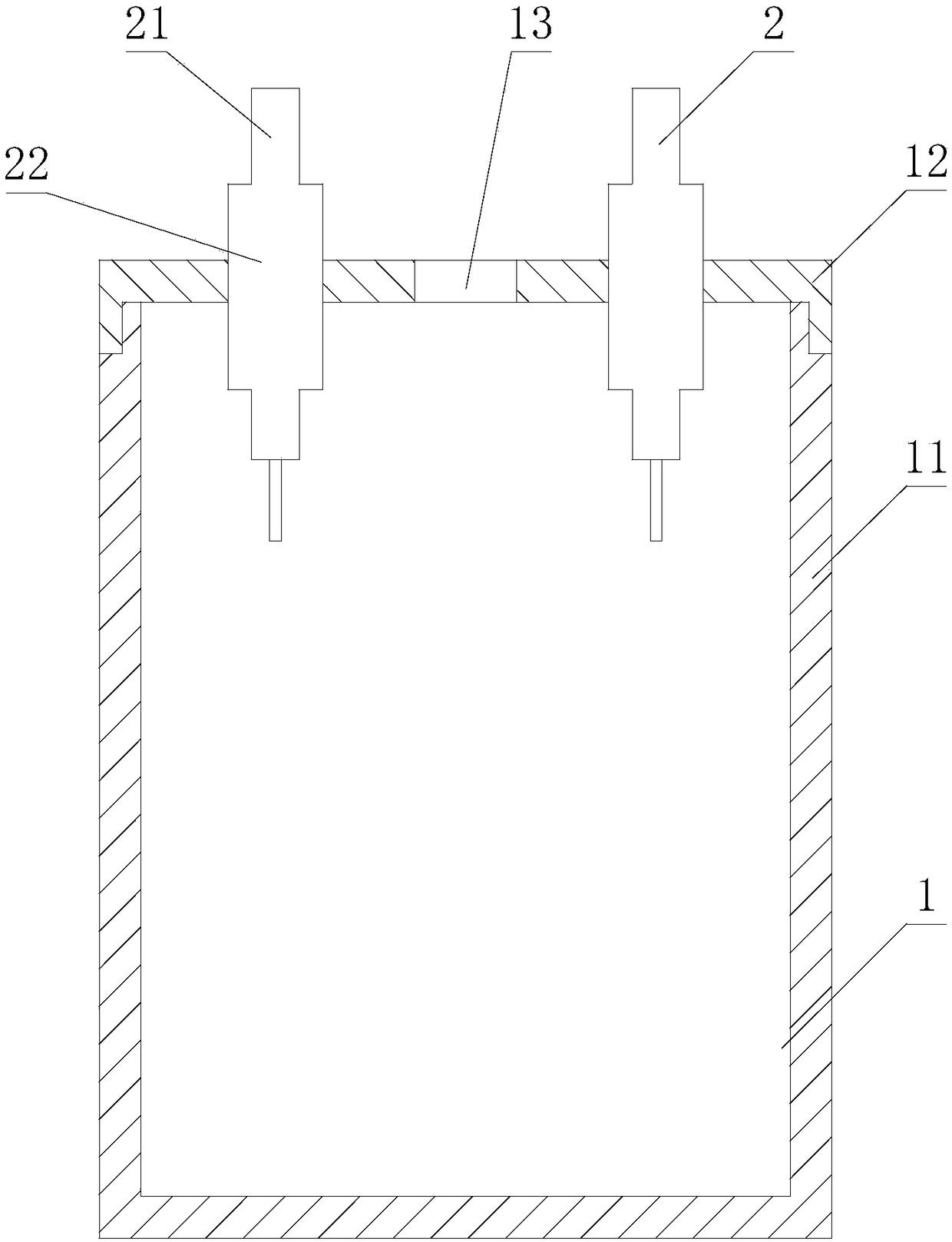

Method and device for testing electrochemical corrosion resistance of pole sealant

PendingCN108088790AIn line with the actual work situationApplicable Choice EvaluationWeather/light/corrosion resistanceElectrical batteryEngineering

The invention provides a device for testing the electrochemical corrosion resistance of pole sealant and a method for testing the electrochemical corrosion resistance of the pole sealant by the aid ofthe device. The device comprises a battery jar and positive and negative terminals. The battery jar comprises a shell and a cover, pole holes are formed in the cover, the positive and negative terminals include a positive lead terminal and a negative lead terminal, and sealant poles are arranged in the middle of the positive lead terminal and the middle of the negative lead terminal and are fixedinto the pole holes. The device and the method have the advantages that practical working principles of batteries are simulated by the aid of the method, a novel evaluation process is established, the corrosion resistance of the sealant and sealing binding force of the sealant and lead poles can be visually reflected by the corroded lengths of the lead poles in the sealant poles, accordingly, thedevice and the method conform to practical working conditions of the storage batteries and are suitable for selecting and evaluating the sealant, and accurate results can be obtained by the aid of the device and the method.

Owner:CHAOWEI POWER CO LTD

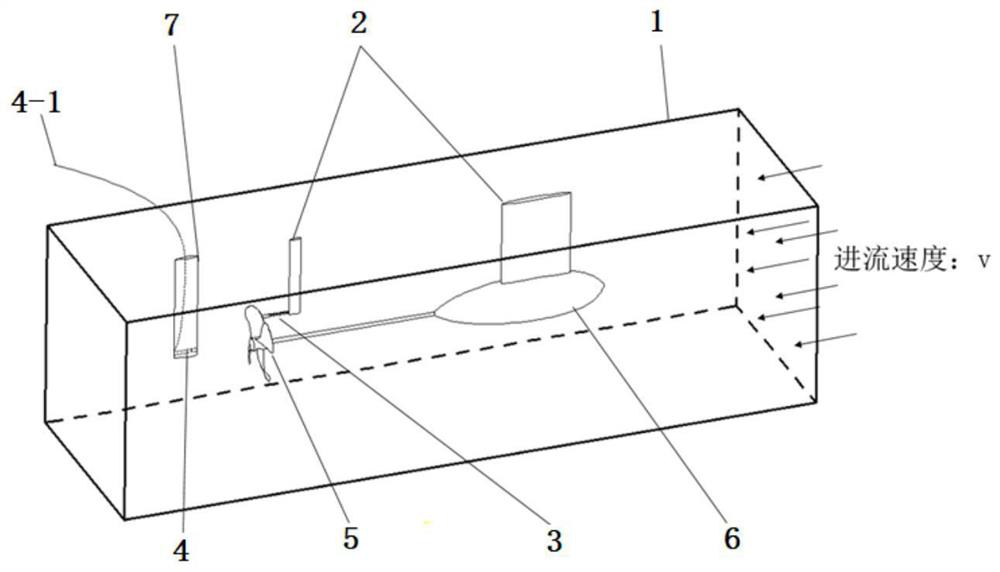

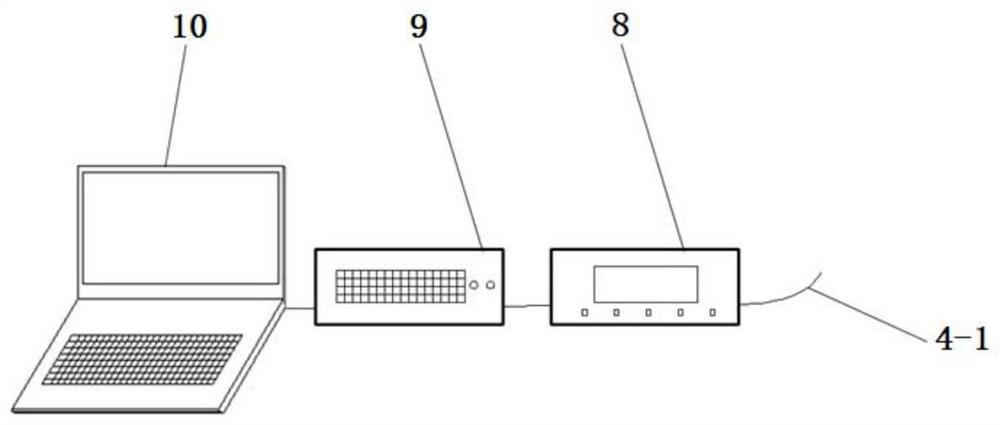

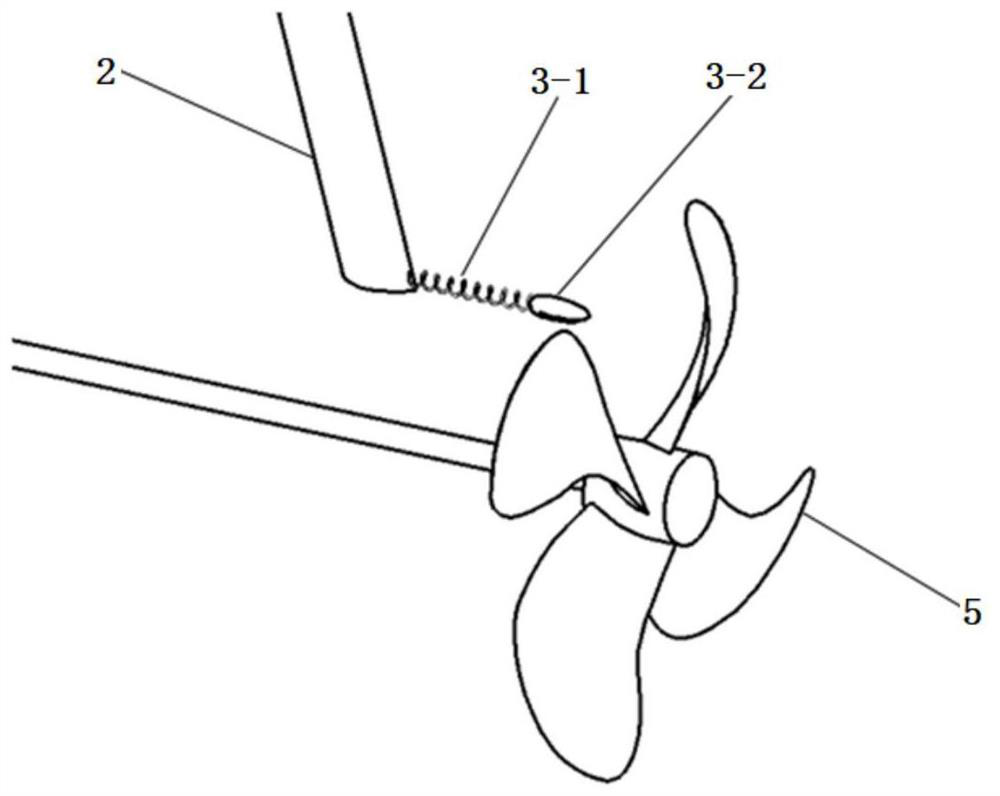

Method for testing and measuring modal parameters of ship propeller rotor under real prestress

ActiveCN113306675AIn line with the actual work situationModal parameters are accurately obtainedSustainable transportationVessel designingClassical mechanicsMechanics

The invention relates to a method for testing and measuring modal parameters of a ship propeller rotor under real prestress. The method comprises the following steps: designing a whole test flow, namely deducing a test principle, selecting and arranging test facilities and instruments, arranging the test flow, processing test data and the like, and finally, the purpose of measuring the modal parameters of the ship propeller rotor under the real prestress is achieved. According to the method provided by the invention, with the help of test facilities such as a circulating water tank or a towing tank commonly used in the ship and ocean engineering field, the rotor is enabled to be in a stress state the same as that in a real working state by setting the inflow speed and the rotation speed of the rotor of the propeller in a flow field, and meanwhile, modal parameters are measured, so that the modal parameters of the rotor in a real stress state can be accurately obtained. Compared with a common marine propeller rotor modal parameter test at present, the measurement method provided by the invention better conforms to the actual working condition of the rotor, and the measurement result has higher accuracy and practicability.

Owner:708TH RES INST OF CSSC

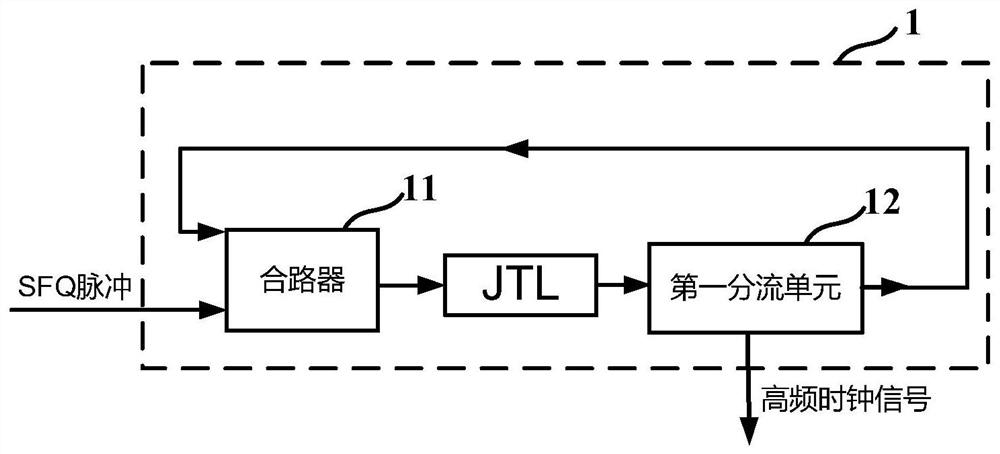

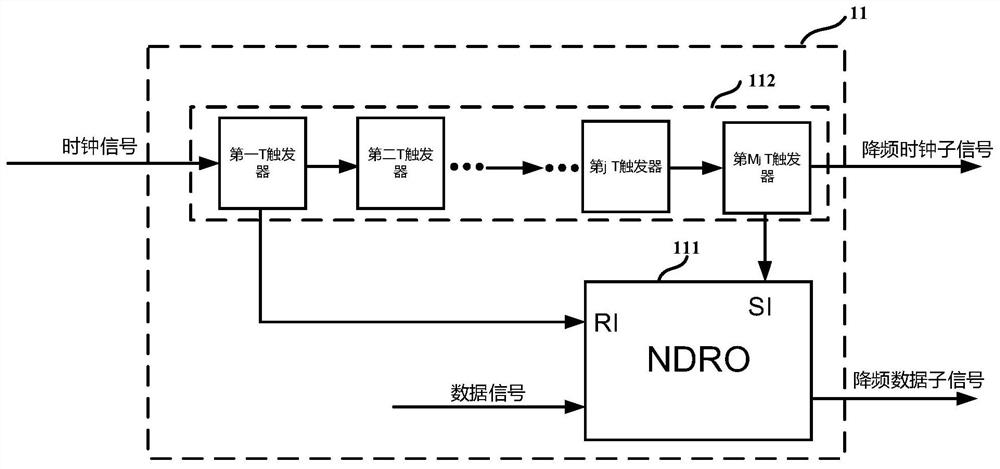

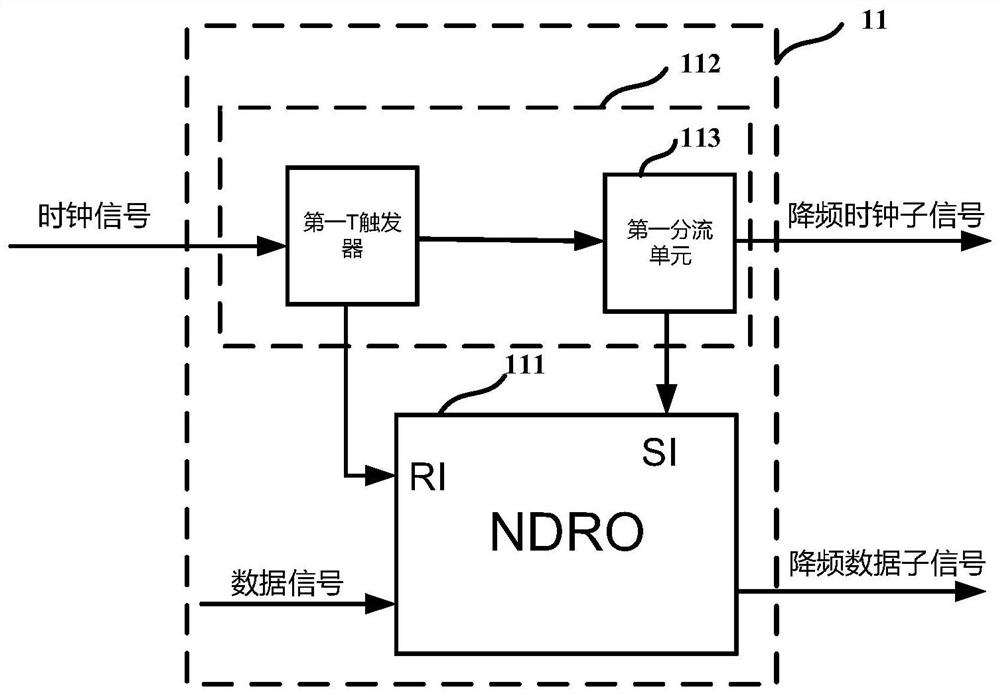

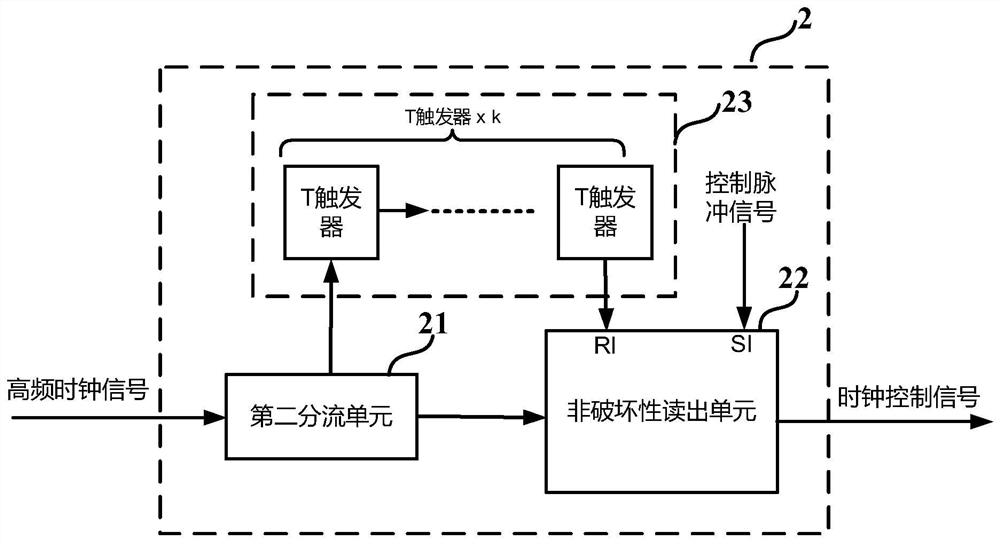

Superconducting high-frequency underclocking module and method and superconducting high-frequency testing system and method

PendingCN113098435ASimple circuit structureSimple test systemImpedence networksElectrical testingEngineeringUnderclocking

The invention provides a superconducting high-frequency underclocking module and method, and the method comprises the steps: receiving a high-frequency clock signal, converting the high-frequency clock signal into an underclocking clock sub-signal and a double clock signal, carrying out the resetting based on the double clock signal, carrying out the periodic selection sampling of a test signal, and converting the test signal into an underclocking test signal. The invention further provides a superconducting high-frequency test system and method based on the linear feedback shift register. The circuit structure is simpler; the continuous high-frequency test can be realized, and the actual working condition of the circuit to be tested is better met; and the data frequency reduction system reduces the frequency to the KHz level by performing frequency reduction processing on the output GHz-level high-frequency signal, so that the signal can be directly output, and the whole test system is simplified.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

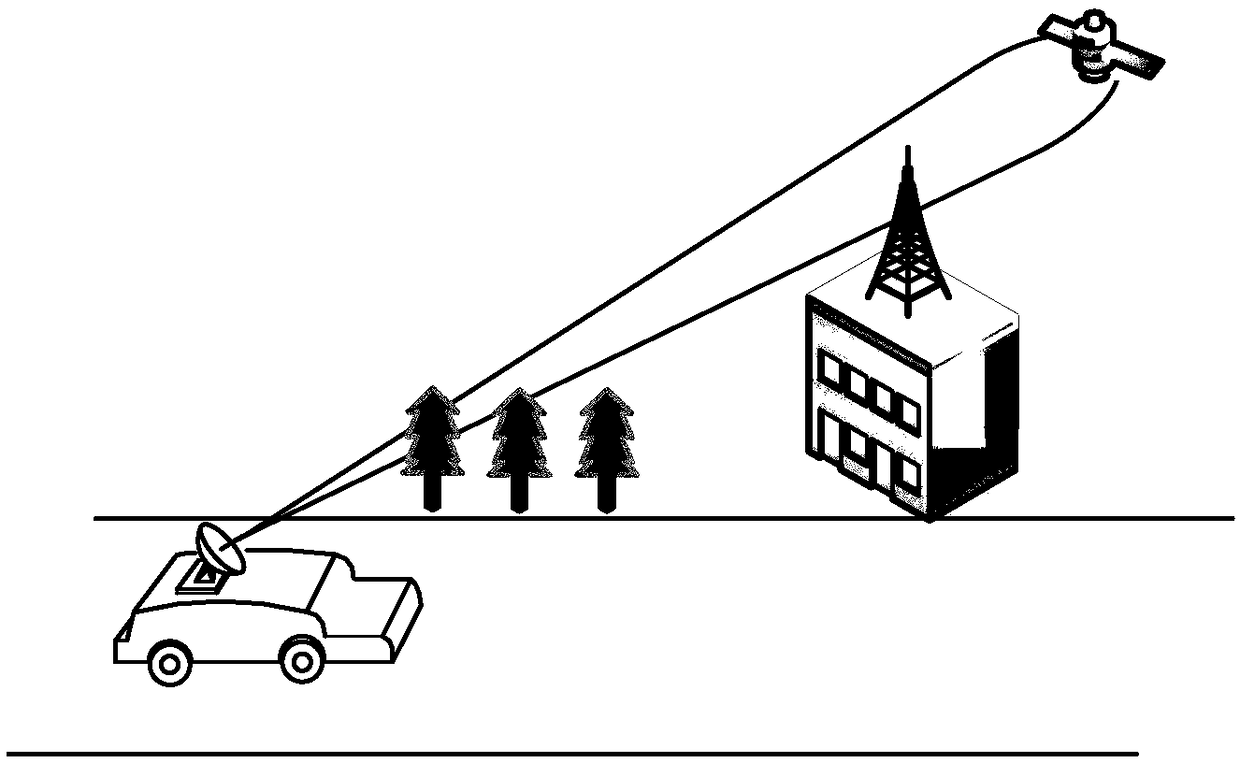

A shadow occlusion detection method for satellite mobile communication

ActiveCN106357354BEliminate the time-consuming problem of pointing and rotating 360°High speedTransmission monitoringRadio transmissionOcclusion detectionComputer science

The invention discloses a method for detecting shadow shade in mobile satellite communication. The method comprises the following steps: 1) a satellite communication in motion beam is aligned with a target satellite; 2) when shade is absent and alignment is realized, the maximum strength value M of a receipt signal is counted and analyzed, and then the strength threshold value Tn and Tr of the receipt signal are set; 3) the strength value of the receipt signal acquired at the moment t is Vt; 4) when Vt is smaller than Tn, the target satellite is completely shaded, otherwise, operation turns to step 5); 5) when a carrier of an antenna enters a shade region, a timer is started, the antenna is stopped from tracking the satellite, and orientation of a current beam of the antenna is maintained, when the carrier of the antenna does not enter the shadow shade region, the antenna continues to track the satellite, and the antenna is restarted to track the satellite when the carrier of the antenna travels out of the shadow shade region; when P3 is smaller than or equal to eta, the carrier of the antenna is located in the shadow shade region. With the adoption of the method, whether satellite communication is shaded by a shadow can be detected rapidly and accurately.

Owner:中国人民解放军火箭军工程大学

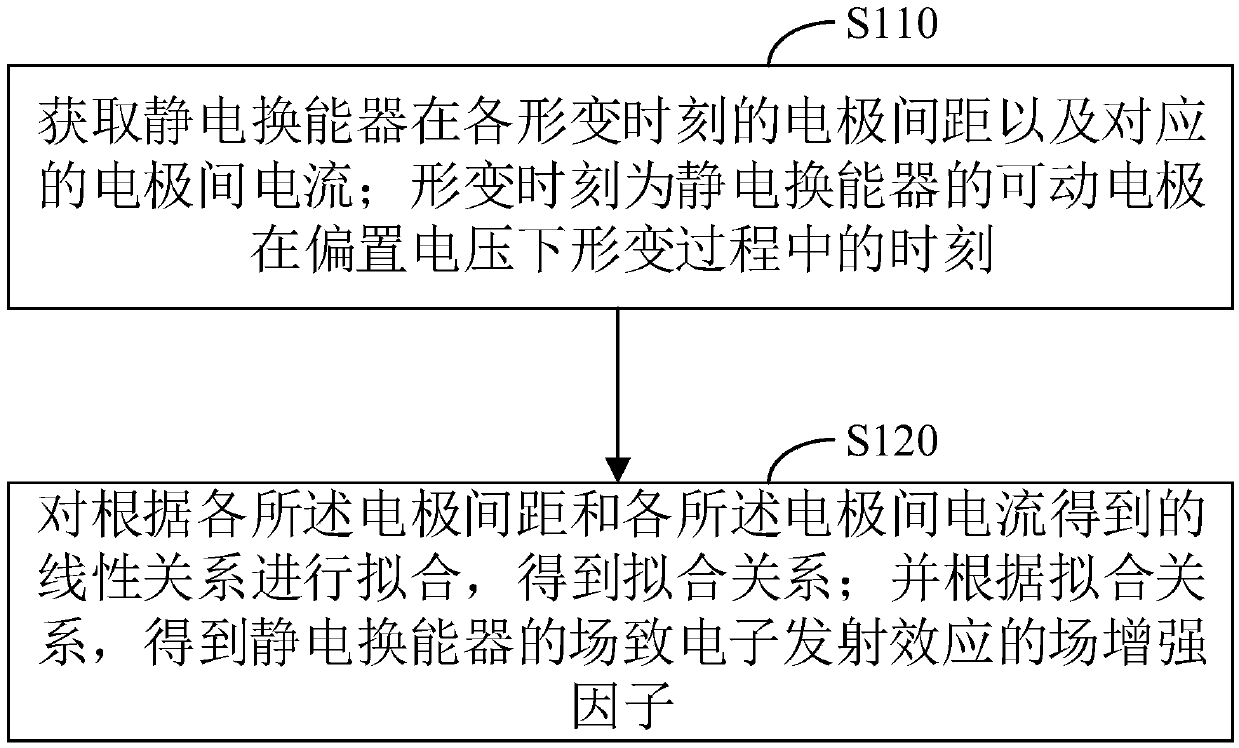

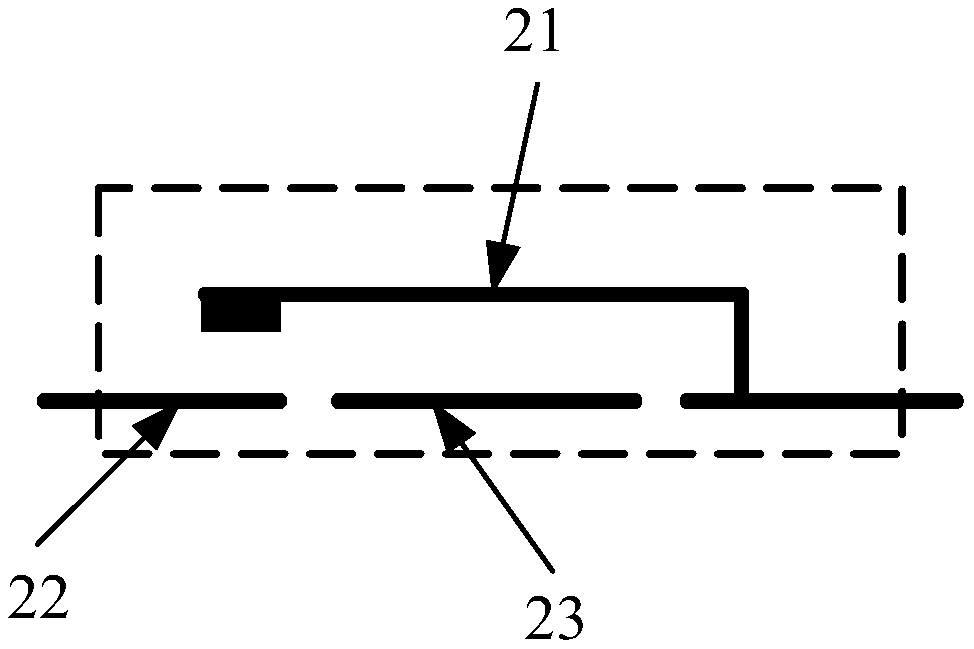

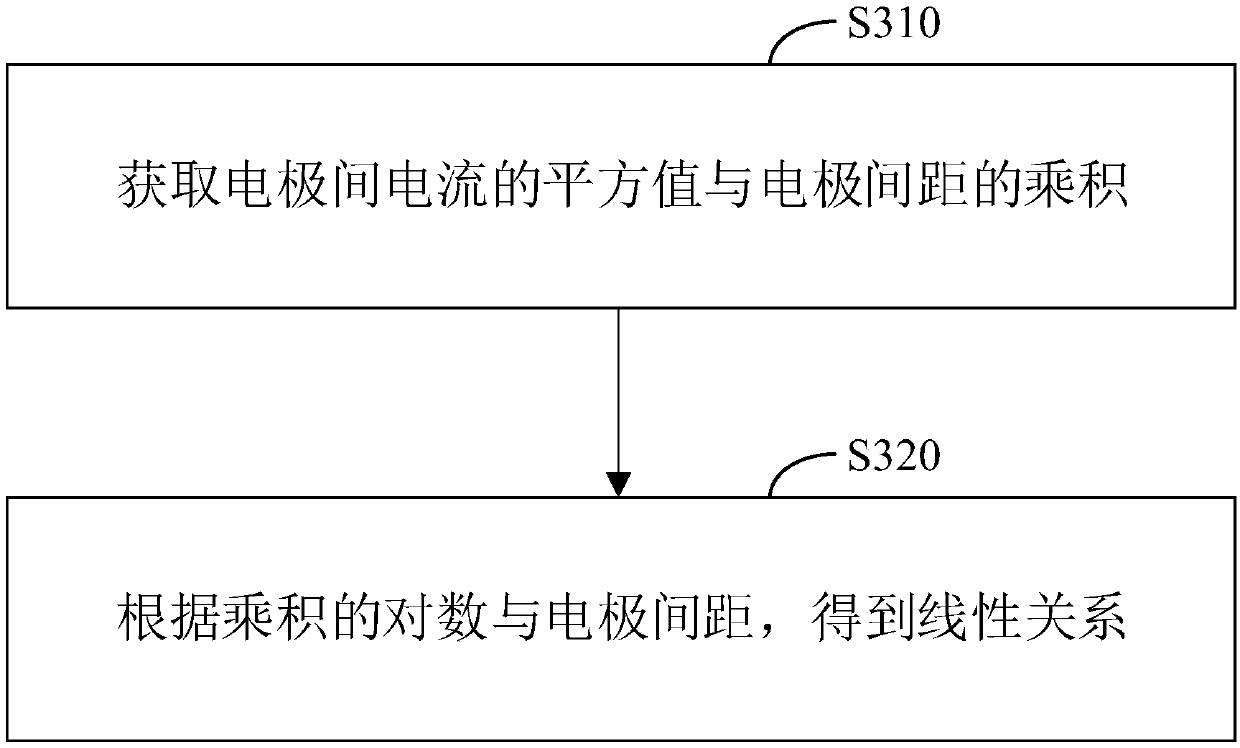

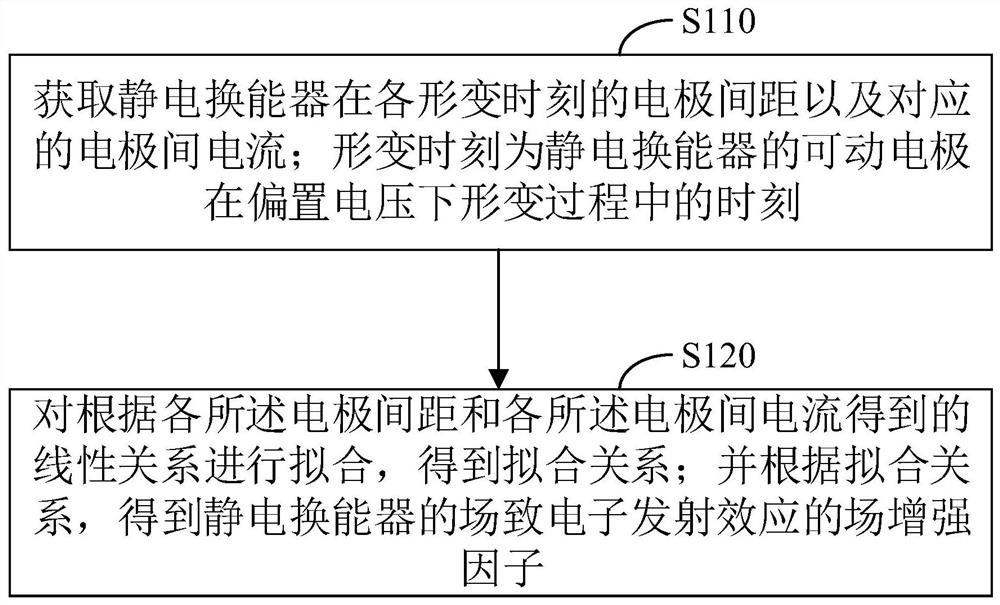

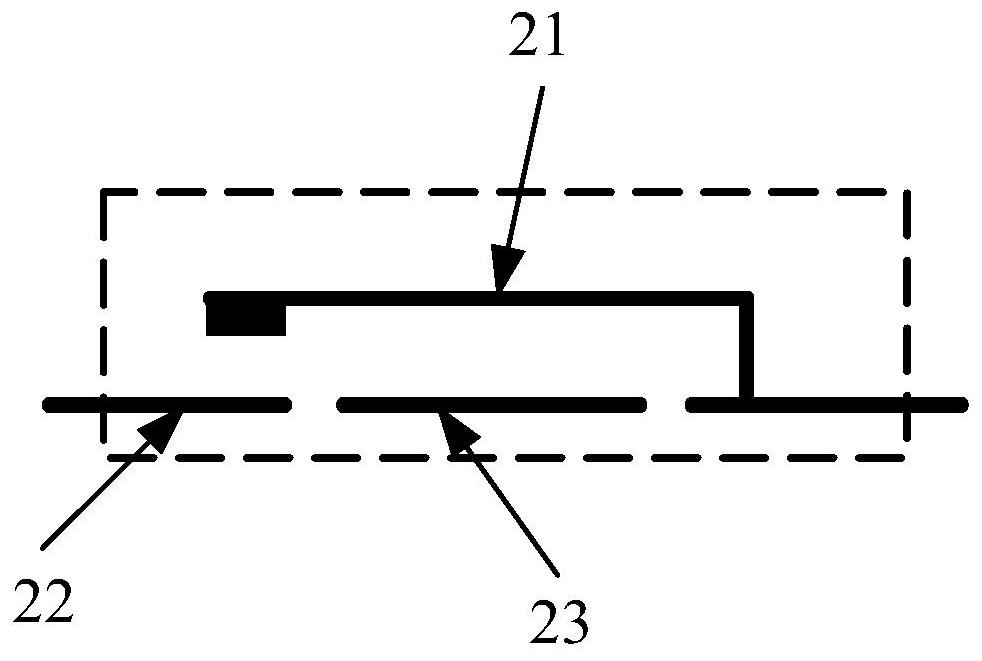

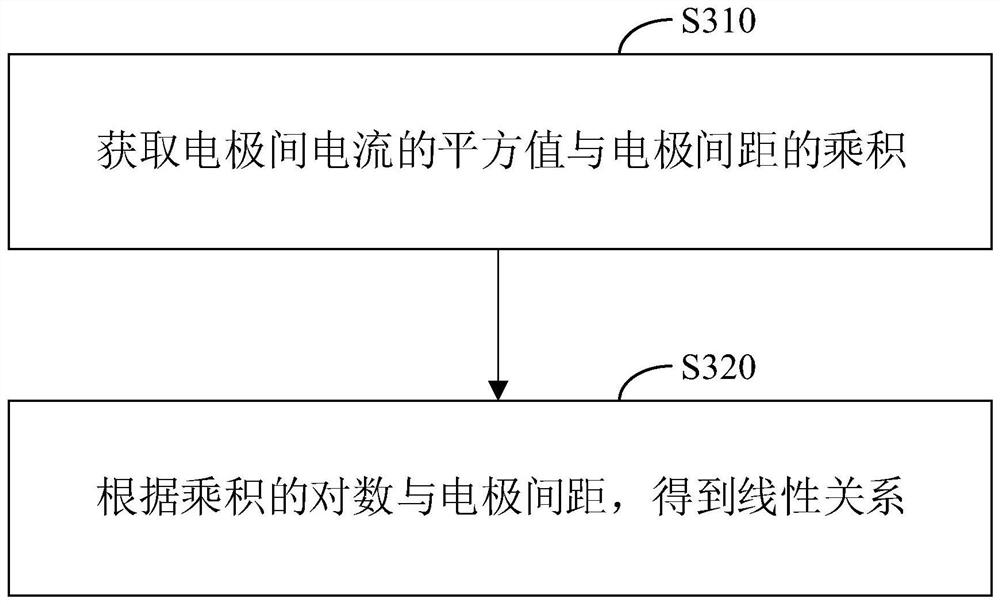

Method, apparatus, system, and storage medium for extracting field enhancement factor

ActiveCN109596896AIn line with the actual work situationImprove accuracyTelevision system detailsImpedence networksField electron emissionLinearity

The present application relates to a method, an apparatus, a system, and a storage medium for extracting a field enhancement factor. The method comprises: collecting an electrode spacing of an electrostatic transducer and the corresponding current between the electrodes at each deformation time, wherein the deformation time is a moment during deformation of the movable electrodes of the electrostatic transducer under a bias voltage; and fitting a linear relation obtained according to each electrode spacing and each current between the electrodes to obtain a fitting relation, and obtaining thefield enhancement factor of a field electron emission effect of the electrostatic transducer according to the fitting relation. According to the method for extracting the field enhancement factor, itcan be fully considered that after the bias voltage is applied, the electrodes of the electrostatic transducer will be deformed and each electrode spacing will gradually become smaller during the deformation, so that the error caused by each electrode spacing is regarded as a fixed value is avoided. The field enhancement factor obtained by the method is more consistent with the actual working condition of the electrostatic transducer, thereby improving the accuracy of acquiring the field enhancement factor.

Owner:CHINA ELECTRONICS PROD RELIABILITY & ENVIRONMENTAL TESTING RES INST

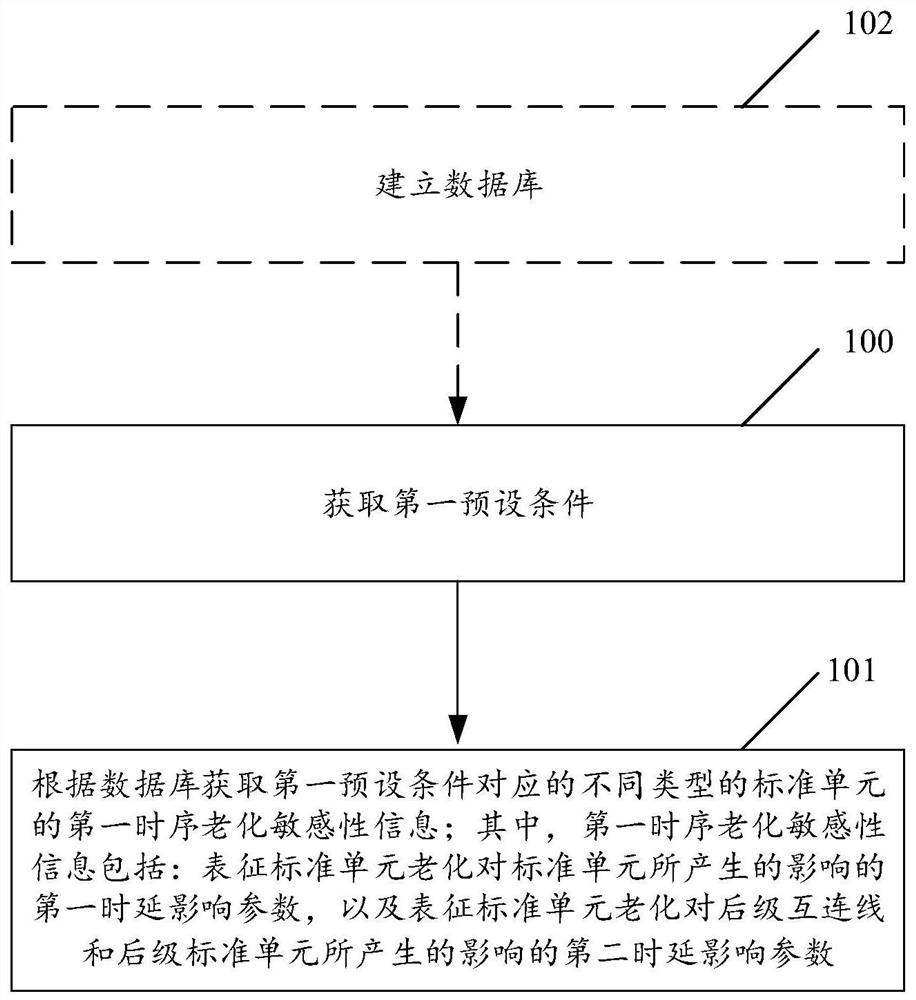

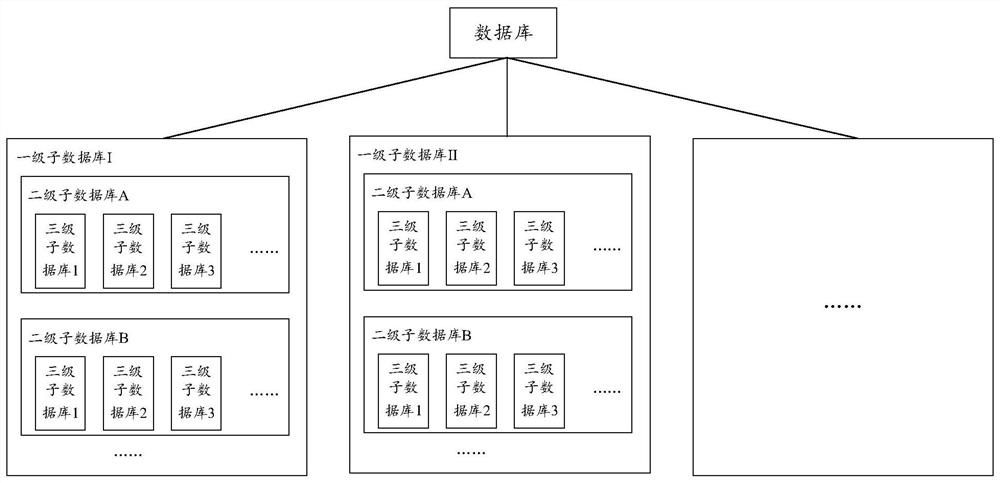

Method and device for acquiring time sequence aging sensitivity information, electronic equipment and medium

PendingCN114330203AImprove reliabilityIn line with the actual work situationComputer aided designSpecial data processing applicationsTime delaysEquipment computers

The invention provides a method and device for obtaining time sequence aging sensitivity information, electronic equipment and a computer readable storage medium. The method for obtaining the time sequence aging sensitivity information comprises the steps that a first preset condition is obtained; obtaining first time sequence aging sensitivity information of different types of standard units corresponding to a first preset condition according to a database; wherein the first time sequence aging sensitivity information comprises a first time delay influence parameter representing the influence of the aging of the standard unit on the standard unit, and a second time delay influence parameter representing the influence of the aging of the standard unit on a post-stage interconnection line and a post-stage standard unit.

Owner:SANECHIPS TECH CO LTD

Field enhancement factor extraction method, device, system and storage medium

ActiveCN109596896BIn line with the actual work situationImprove accuracyTelevision system detailsImpedence networksField electron emissionElectrostatic transducer

The present application relates to a method, an apparatus, a system, and a storage medium for extracting a field enhancement factor. The method comprises: collecting an electrode spacing of an electrostatic transducer and the corresponding current between the electrodes at each deformation time, wherein the deformation time is a moment during deformation of the movable electrodes of the electrostatic transducer under a bias voltage; and fitting a linear relation obtained according to each electrode spacing and each current between the electrodes to obtain a fitting relation, and obtaining thefield enhancement factor of a field electron emission effect of the electrostatic transducer according to the fitting relation. According to the method for extracting the field enhancement factor, itcan be fully considered that after the bias voltage is applied, the electrodes of the electrostatic transducer will be deformed and each electrode spacing will gradually become smaller during the deformation, so that the error caused by each electrode spacing is regarded as a fixed value is avoided. The field enhancement factor obtained by the method is more consistent with the actual working condition of the electrostatic transducer, thereby improving the accuracy of acquiring the field enhancement factor.

Owner:CHINA ELECTRONICS PROD RELIABILITY & ENVIRONMENTAL TESTING RES INST

Superconducting high-frequency testing system and method

ActiveCN113030709BSimple structureIn line with the actual work situationElectronic circuit testingCircuit under testHemt circuits

The present invention provides a superconducting high-frequency testing system and method, which firstly receives a trigger pulse signal, outputs a periodic high-frequency clock signal; controls the continuity of the high-frequency clock signal, and outputs a high-frequency control clock signal; receives the initial The signal is a linear feedback shift register with a non-zero initial state, and based on the high-frequency control clock signal, multiple periodic pseudo-random sequences with preset cycle lengths are simultaneously output; the circuit to be tested receives multiple pseudo-random sequences and outputs multiple test signals ; receiving the multi-channel test signal, and outputting a multiplexed signal based on a low-frequency clock signal; comparing the multiplexed signal with an expected output result to determine whether the circuit to be tested works normally. The circuit structure of the invention is relatively simple; the input signal is a pseudo-random sequence generated based on a linear feedback shift register, which can realize continuous high-frequency testing and is more in line with the actual working conditions of the circuit to be tested.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

A high-precision attitude determination method for a space vehicle attitude motion simulation platform

ActiveCN104006787BHigh measurement accuracyEasy to installAngle measurementNavigational calculation instrumentsGyroscopeFlight vehicle

The objective of the invention is to provide a high-precision attitude determination method for a spacecraft attitude motion simulation platform. Equipment used in the method comprises a laser tracker, an intelligent probe, a gyroscope and two industrial control computers, so a ground fully-physical simulation experimental facility is constructed. The method is an improved method for attitude determination based on extended Kalman filtering, acquires attitude information of the spacecraft attitude motion simulation platform by carrying out data-fusion filtering on output information of the laser tracker and the gyroscope, better accords with actual working conditions and has high instantaneity. Measurement equipment used in the invention is easy to install, has high measurement precision and can realize dynamic contactless measurement of the attitude angle and angular rate information of the spacecraft attitude motion simulation platform.

Owner:HARBIN INST OF TECH

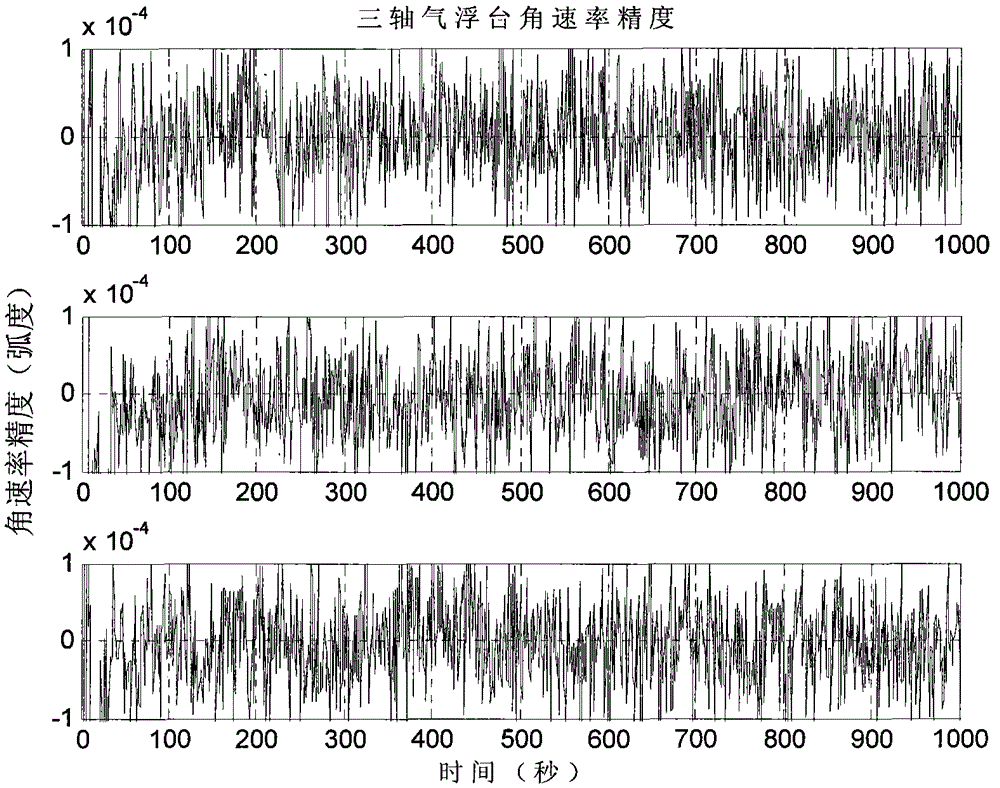

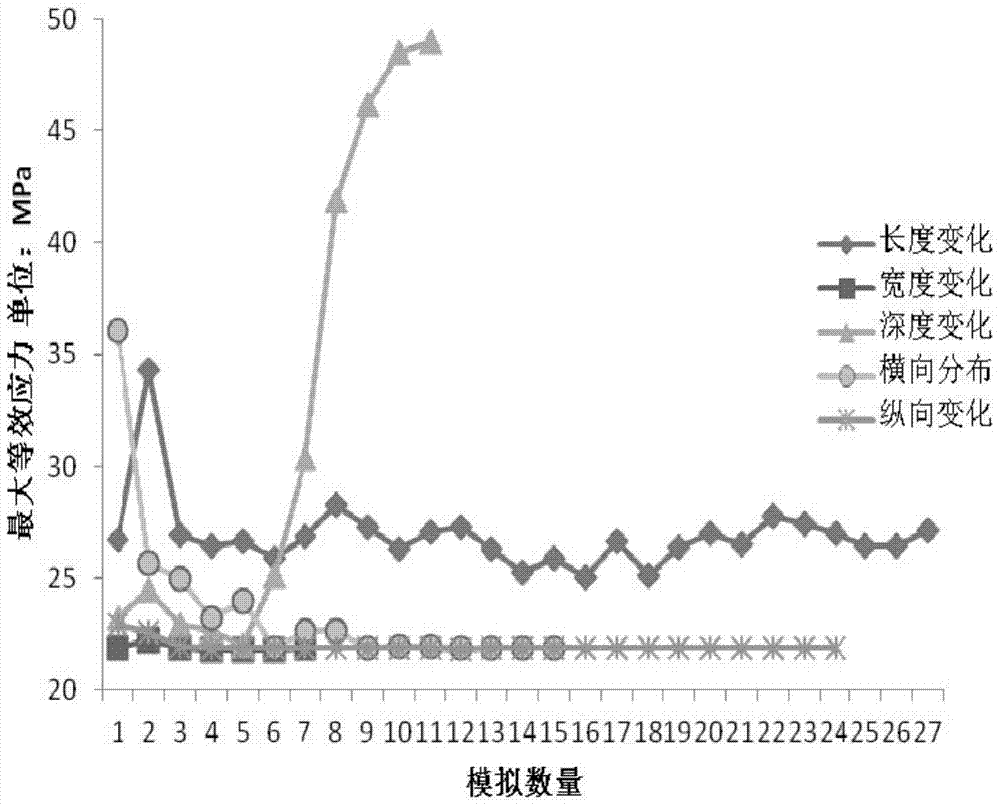

Optimal Design Method of Impeller Blade Structure of Large Turboexpander Considering Defects

InactiveCN104331553BReduce weightExtend working lifeSpecial data processing applicationsStress concentrationImpeller

The invention aims at the impeller of a turboexpander in a large-scale air separation equipment, and in particular relates to a structural optimization design method of a blade of a large turboexpander considering defects. On the basis of the original impeller stress analysis, the present invention adds defect factors, uses the generalized regression neural network and the multi-objective optimization algorithm based on the genetic algorithm to perform genetic optimization operations on the impeller parameters, and finally obtains evenly distributed Pareto optimal solutions as the impeller blade optimization parameters , the optimization process integrates the actual working characteristics of the impeller, the overall strength and structural rigidity of the impeller are high, and the practicability is strong. Under the condition of satisfying the strength requirement of the impeller, the method reduces the stress concentration under the action of defects, improves the working life of the impeller, reduces the weight and moment of inertia of the impeller, and saves materials.

Owner:ZHEJIANG UNIV

A Reliability Modeling and Evaluation Method for Dynamic Cascaded Coupled Electromechanical Systems

ActiveCN104537134BReliability Accurate and CrediblePerformance Response AccurateSpecial data processing applicationsCouplingNetwork model

The invention provides a method for reliability modeling and evaluation of a dynamic cascade coupling electromechanical system. The method is based on a physical background of a complex electromechanical system and is capable of carrying out research on reliability of the electromechanical system based on a dynamics response model, and an established reliability network model of the electromechanical system is capable of more accurately describing the characteristics of dynamic, cascading and coupling of the complex electromechanical system, so that reliability of the electromechanical system, which is obtained based on the network model, is more accurate and credible; meanwhile, by utilizing a method of combining dynamics analysis and uncertainty analysis, transfer of uncertain information from a bottom layer to a top layer of the network model is described, and the difficulties that an aerospace mechanism system has a response uncertainty character and system reliability information cannot be obtained through experiment measures due to large experimental expenses, long period, large technical difficulty and expensive product cost are solved.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com