Fuel cell centrifugal compressor rotor configuration optimization design method

A technology of centrifugal compressors and fuel cells, applied in liquid fuel engines, mechanical equipment, multi-objective optimization, etc., can solve problems affecting the dynamic reliability of the rotor structure, optimizing the mechanical properties of the rotor cannot meet the expected indicators, and the direction deviation of the rotor configuration optimization and other problems to achieve the effect of accelerating the convergence speed, reducing structural stress and vibration deflection, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

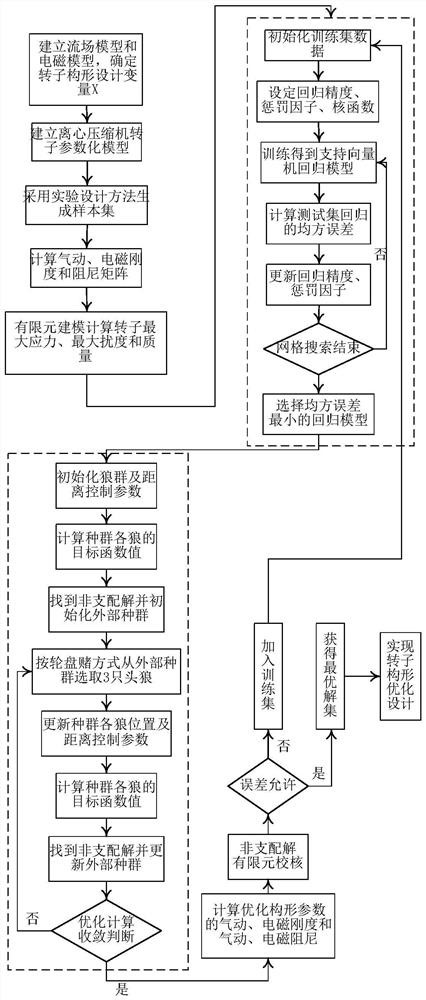

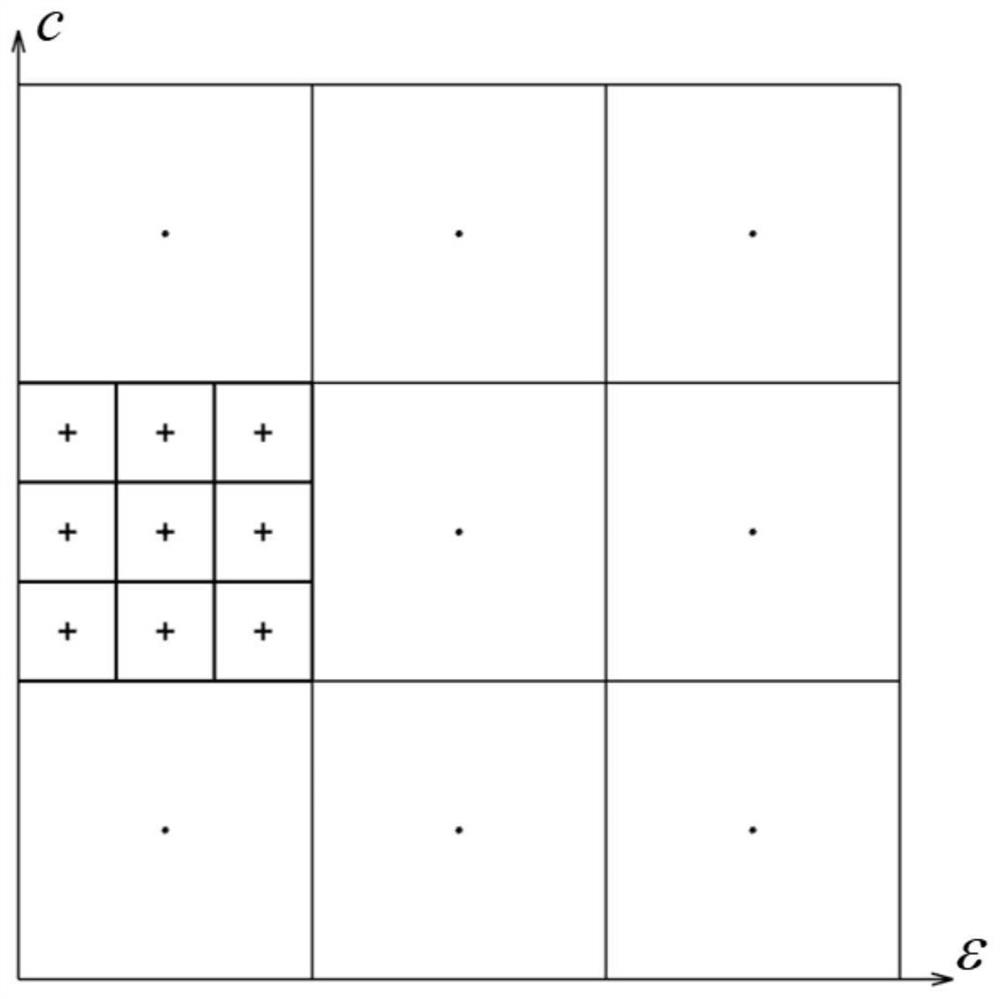

[0023] Such as Figure 1-2 As shown, a fuel cell centrifugal compressor rotor configuration optimization design method, including the following steps:

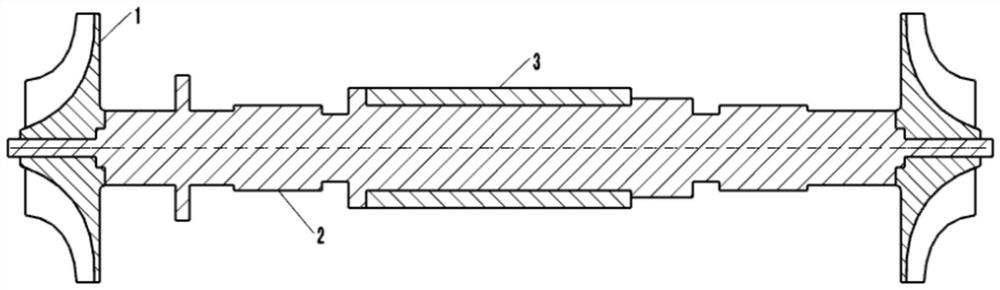

[0024] S1. Establish the flow field model of the impeller 1 air gap, bearing air film, sealing gas and the electromagnetic model of the motor winding 3, and determine the aerodynamic, electromagnetic stiffness and damping data through calculation and analysis of the fluid and electromagnetic force, and then determine the dynamic response The result affects the significant rotor configuration design variable X; the design variable X includes the position of each section of the rotor and the size of each section. Such as figure 2 As shown, the main shaft 2 of the compressor rotates in the winding 3 of the motor.

[0025] S2. Establishing a parametric model of the rotor of the centrifugal compressor according to the design variable X; establishing a parametric model of the rotor of the centrifugal compressor by using CAD means...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com