Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65results about How to "Improve work productivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

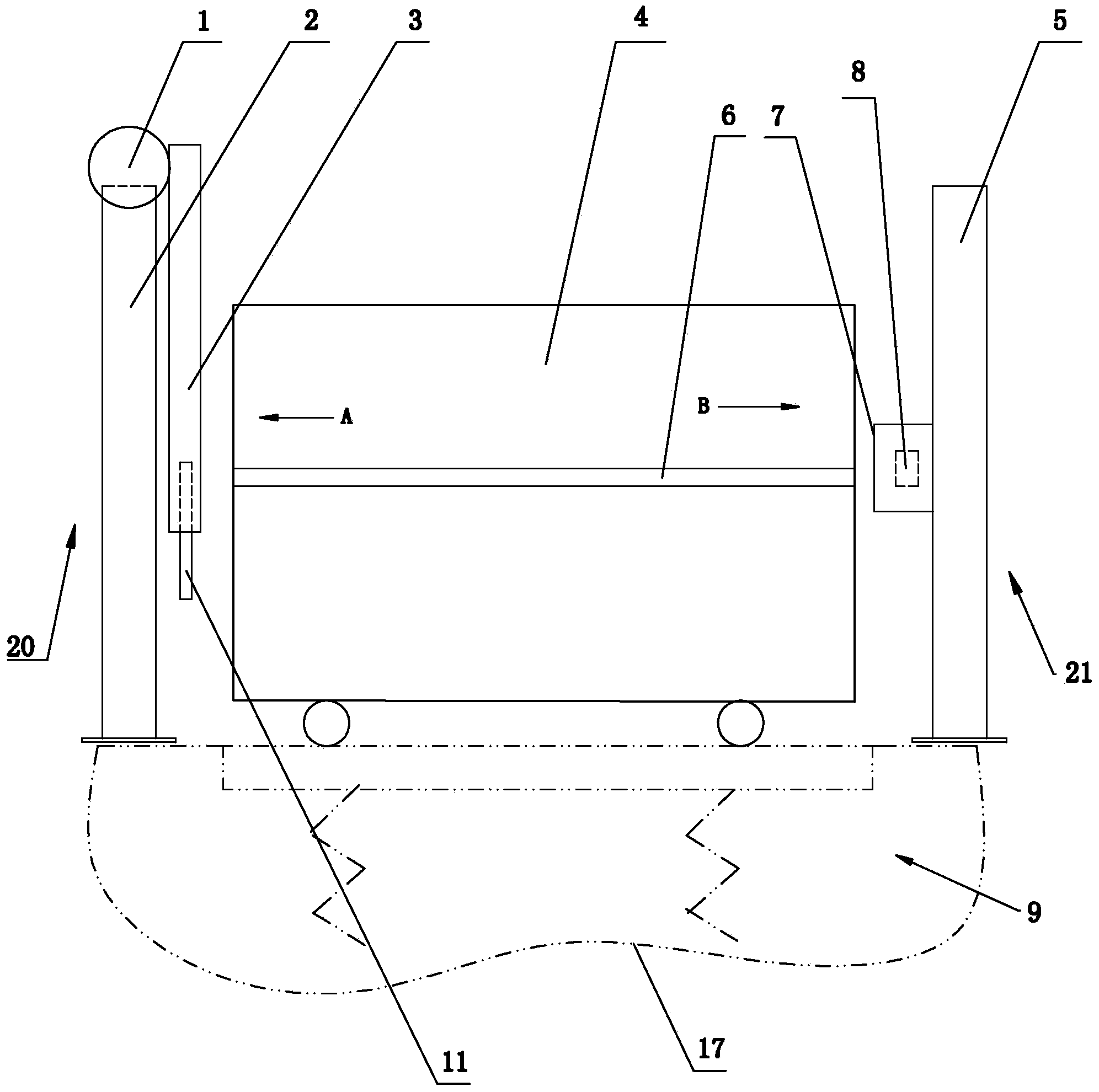

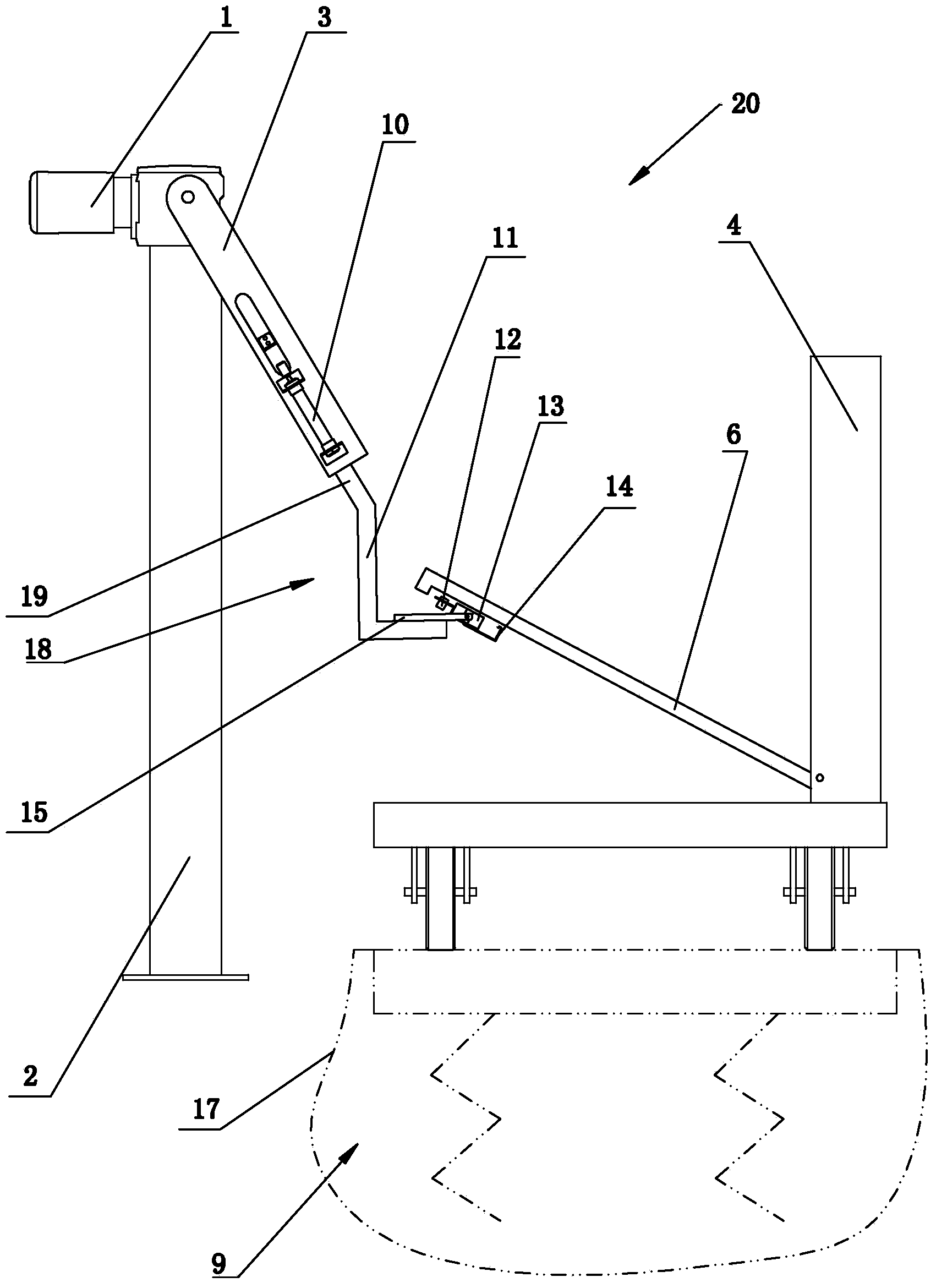

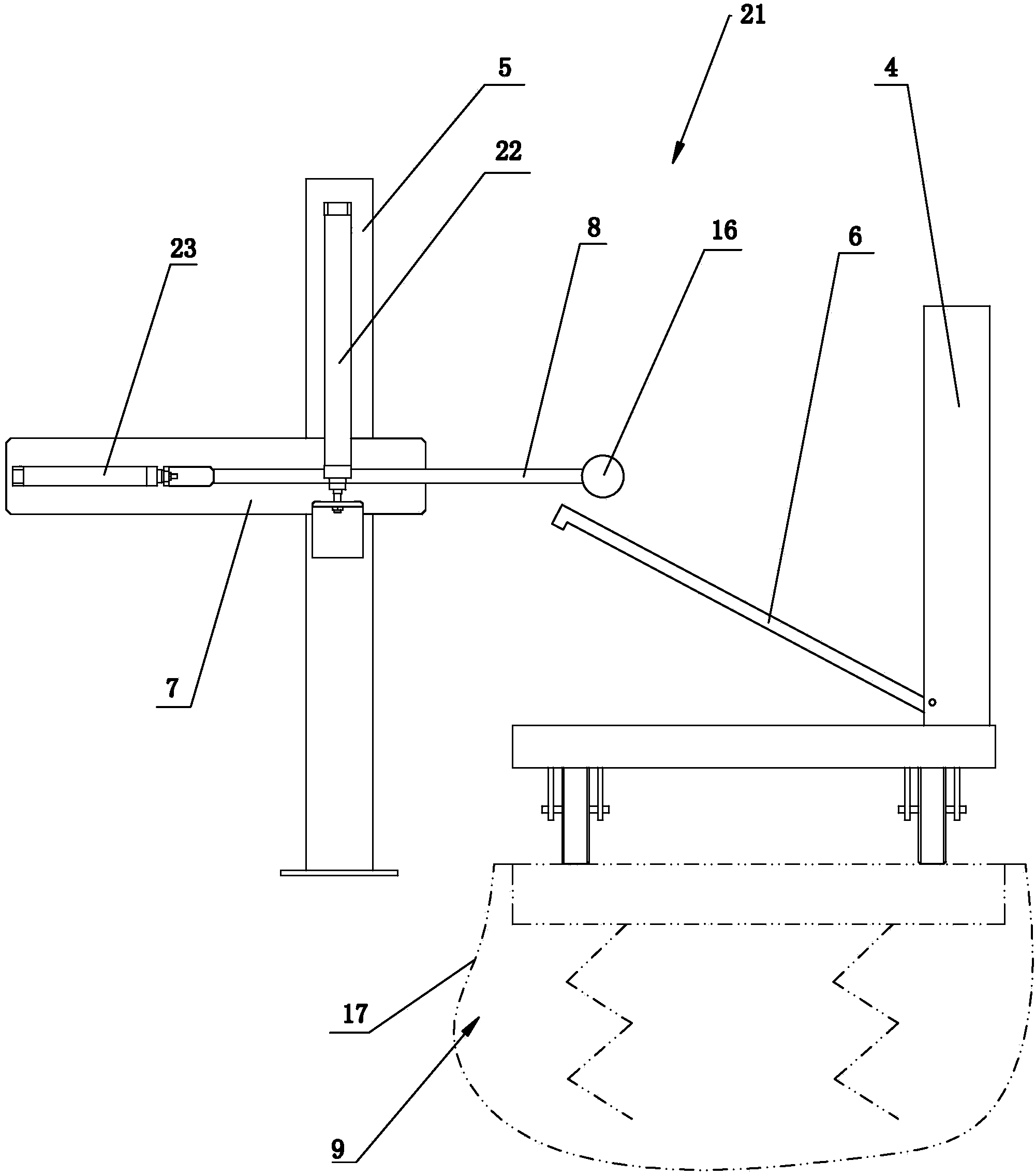

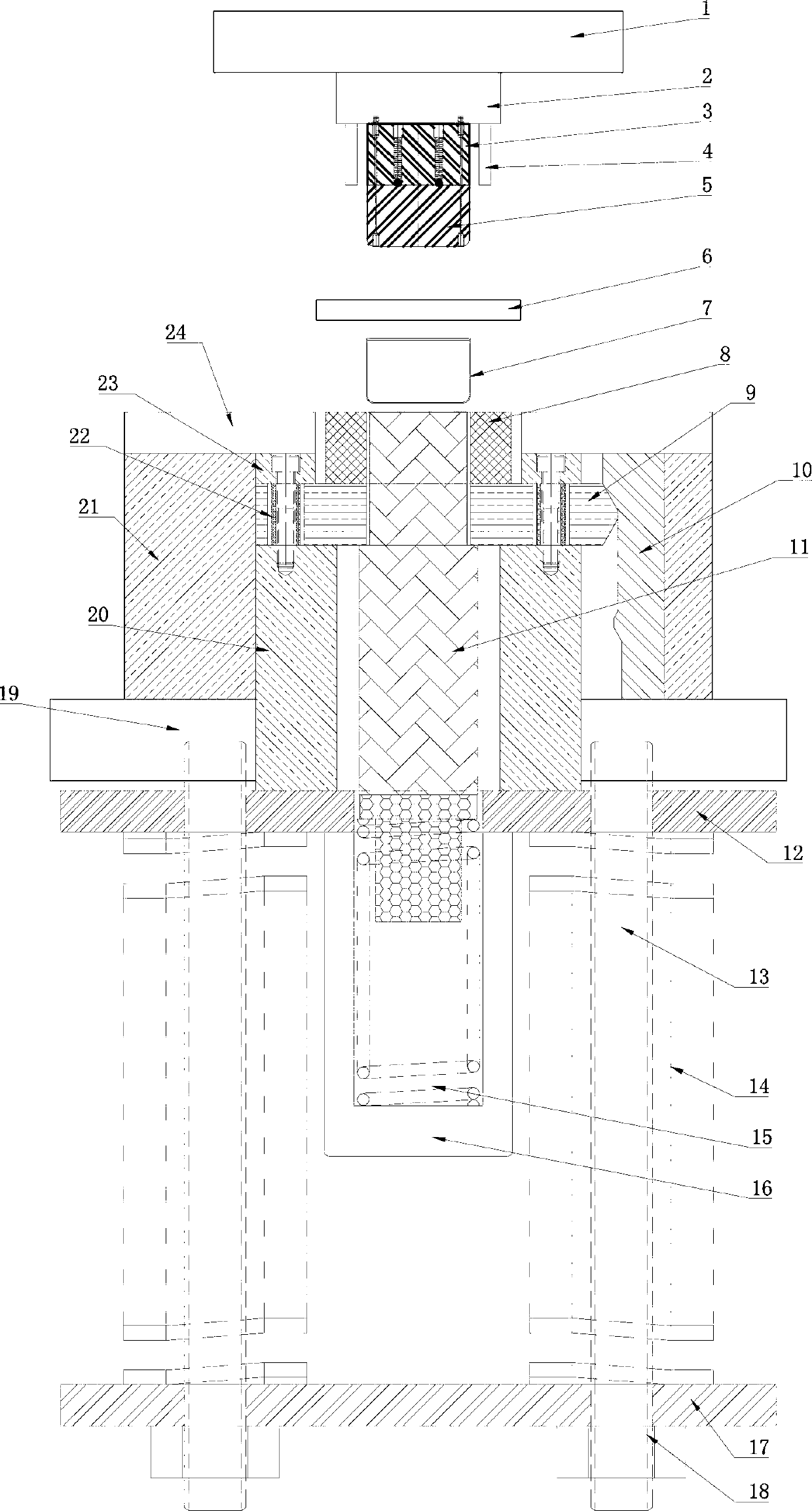

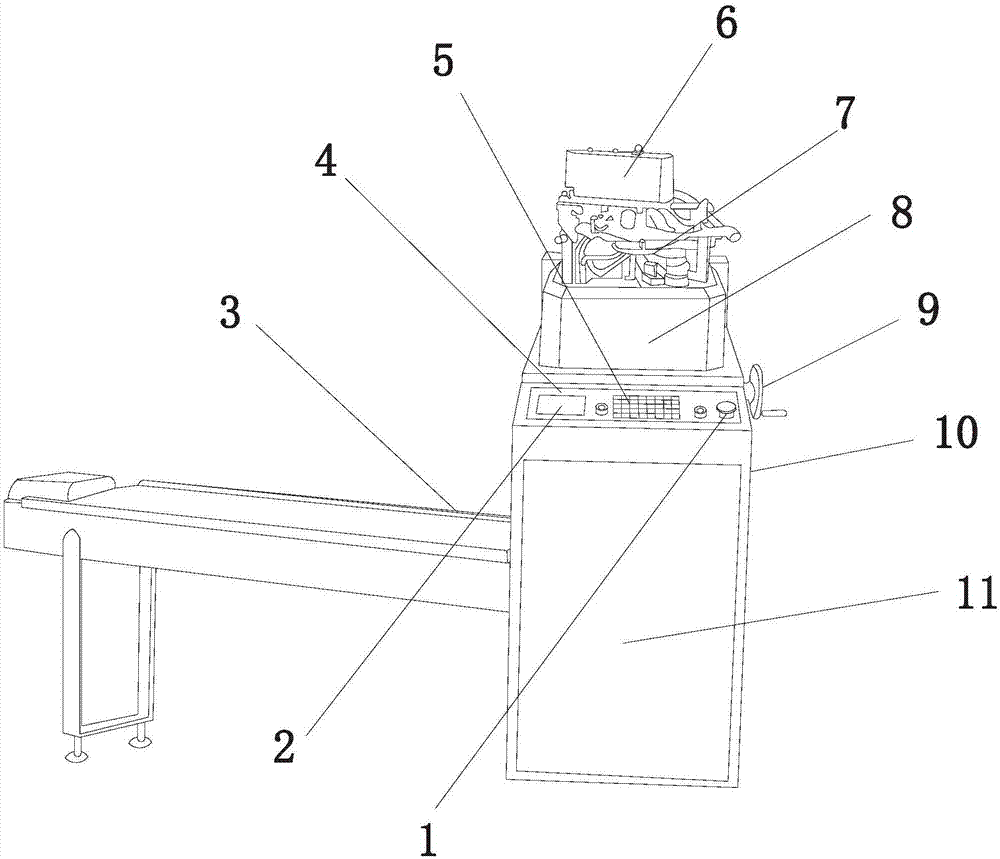

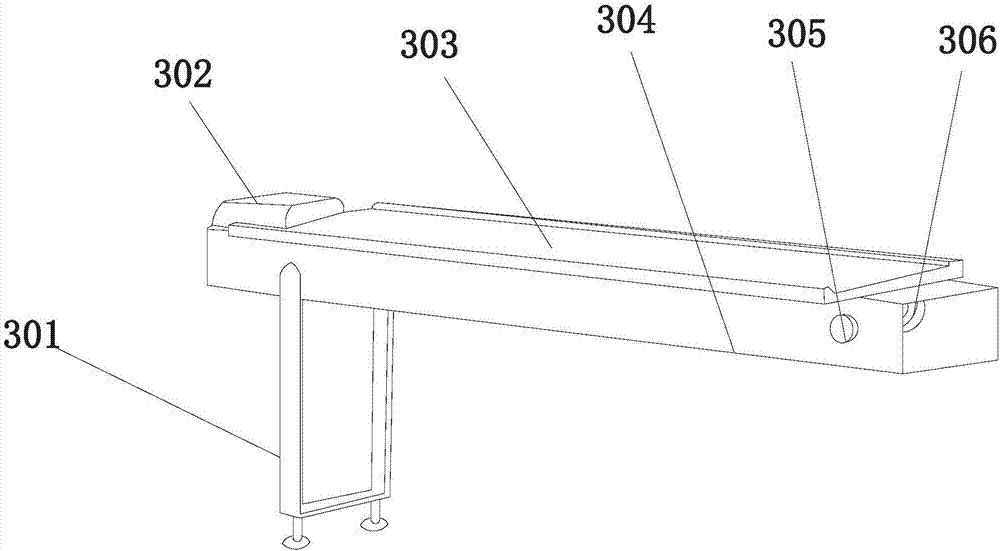

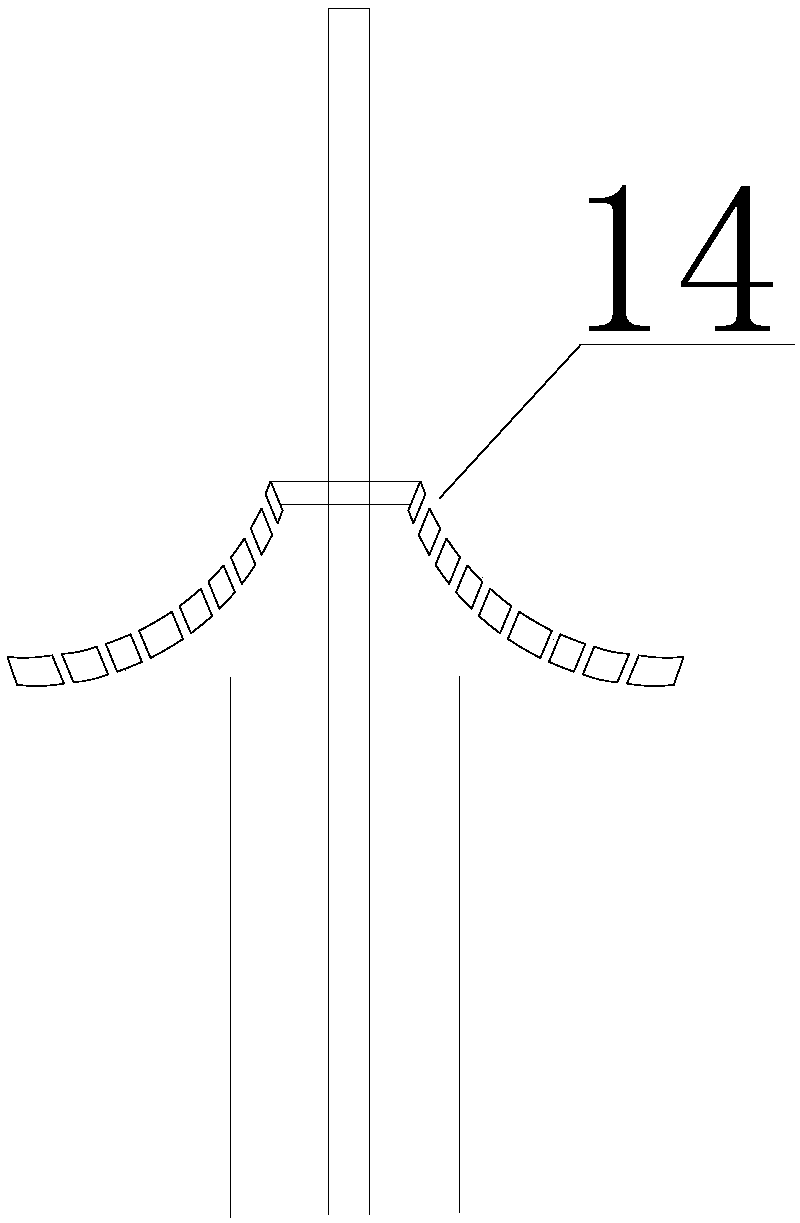

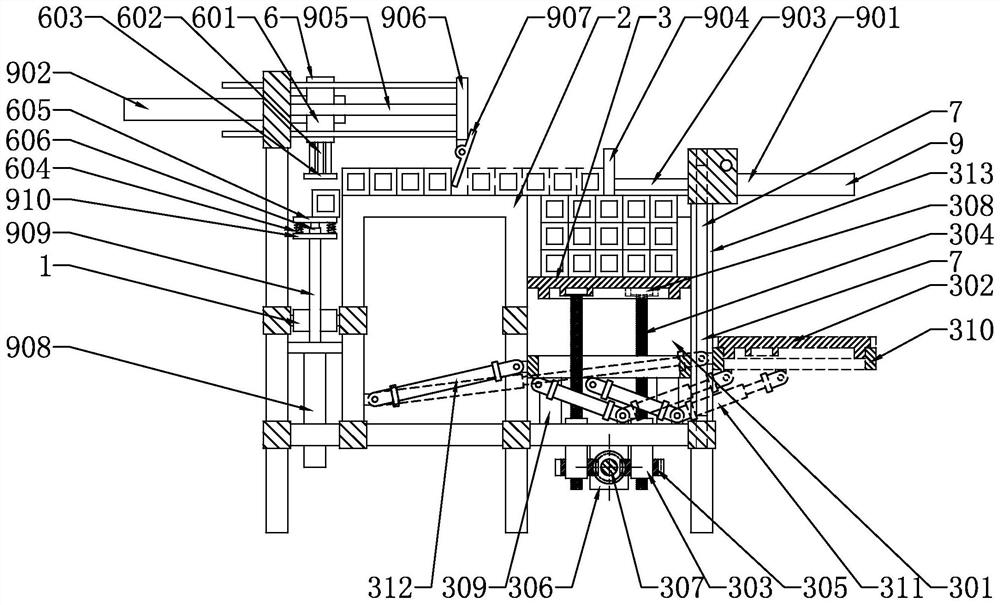

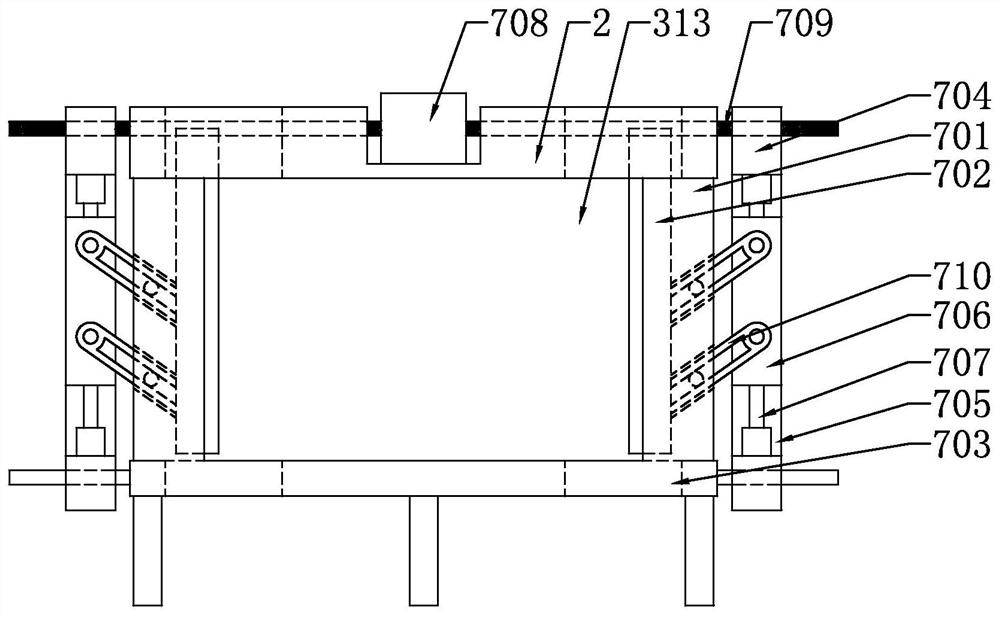

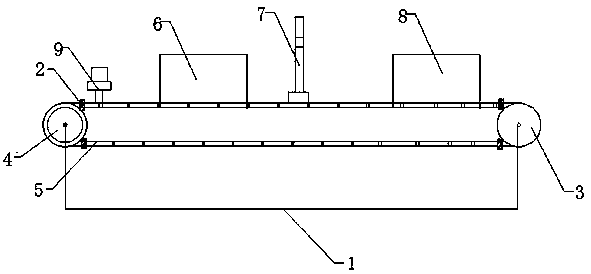

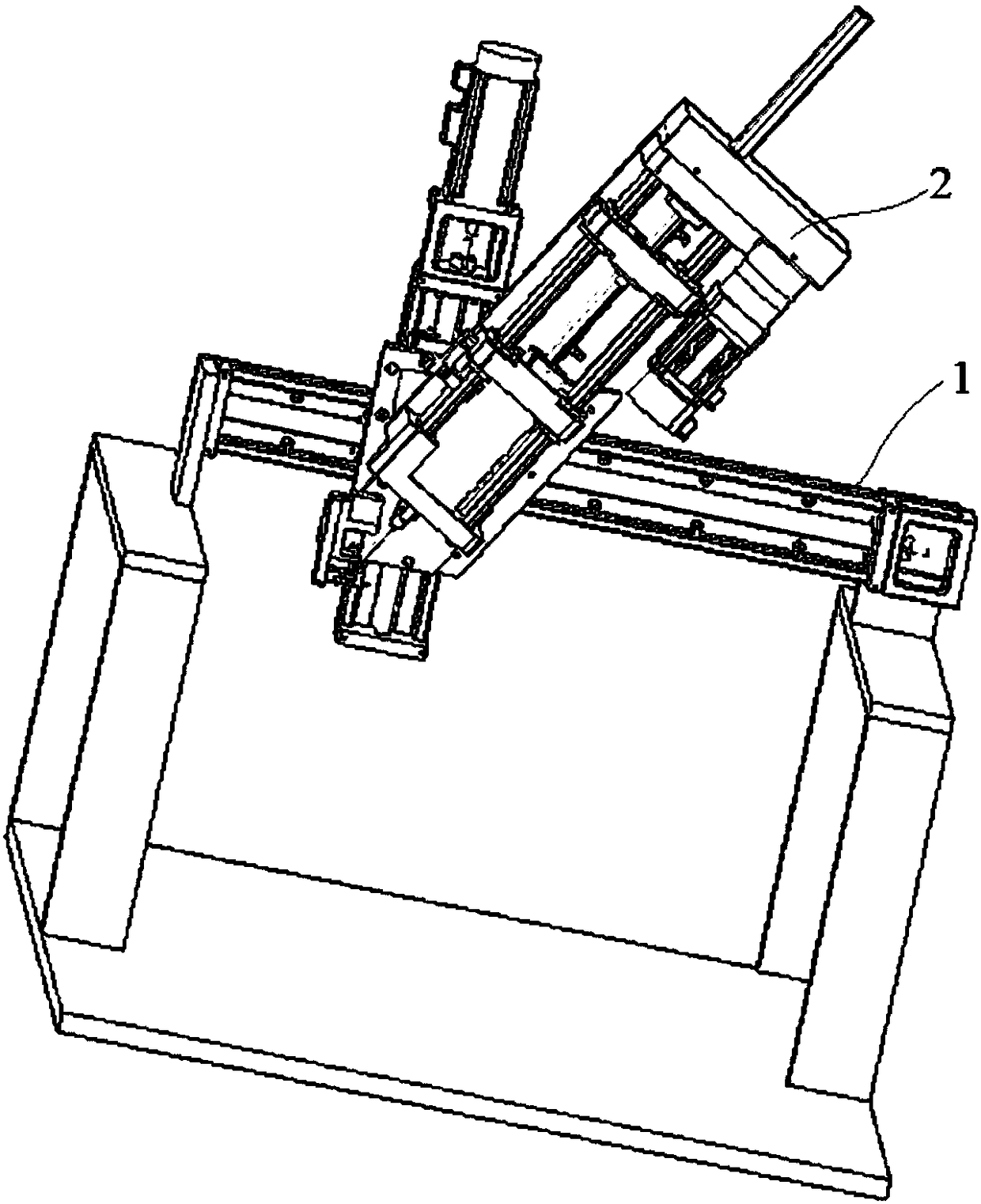

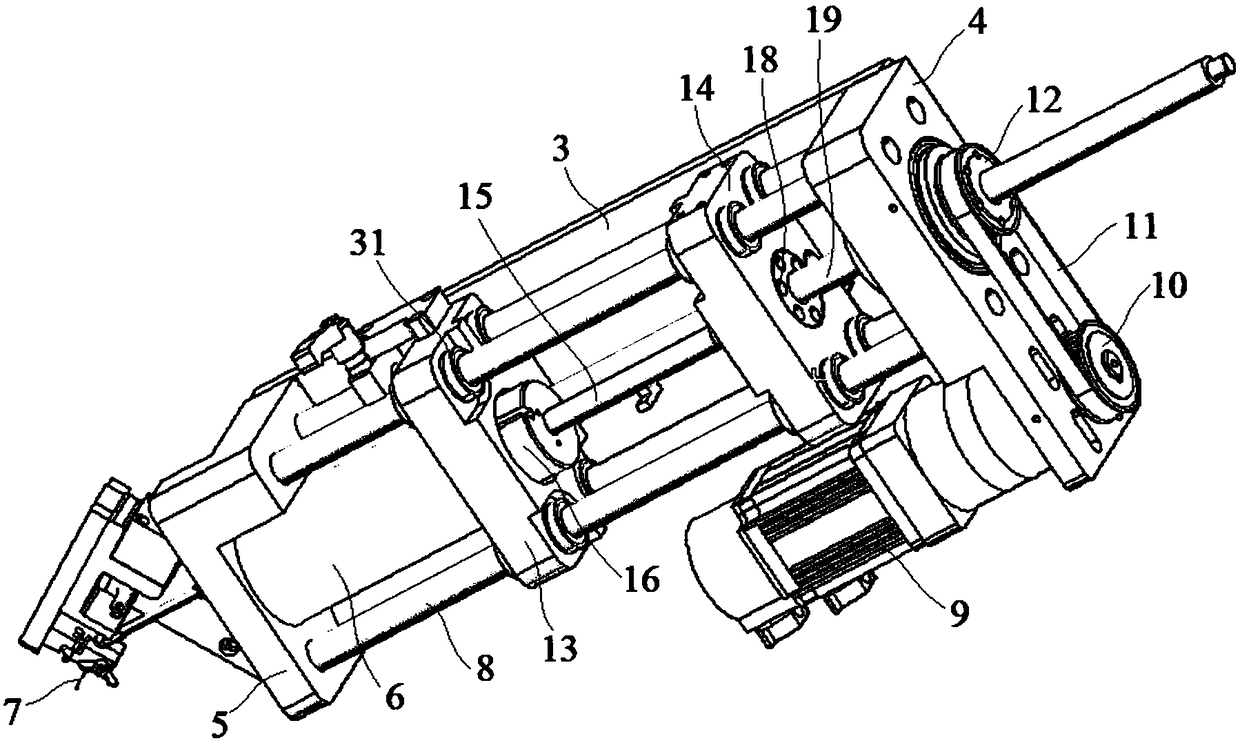

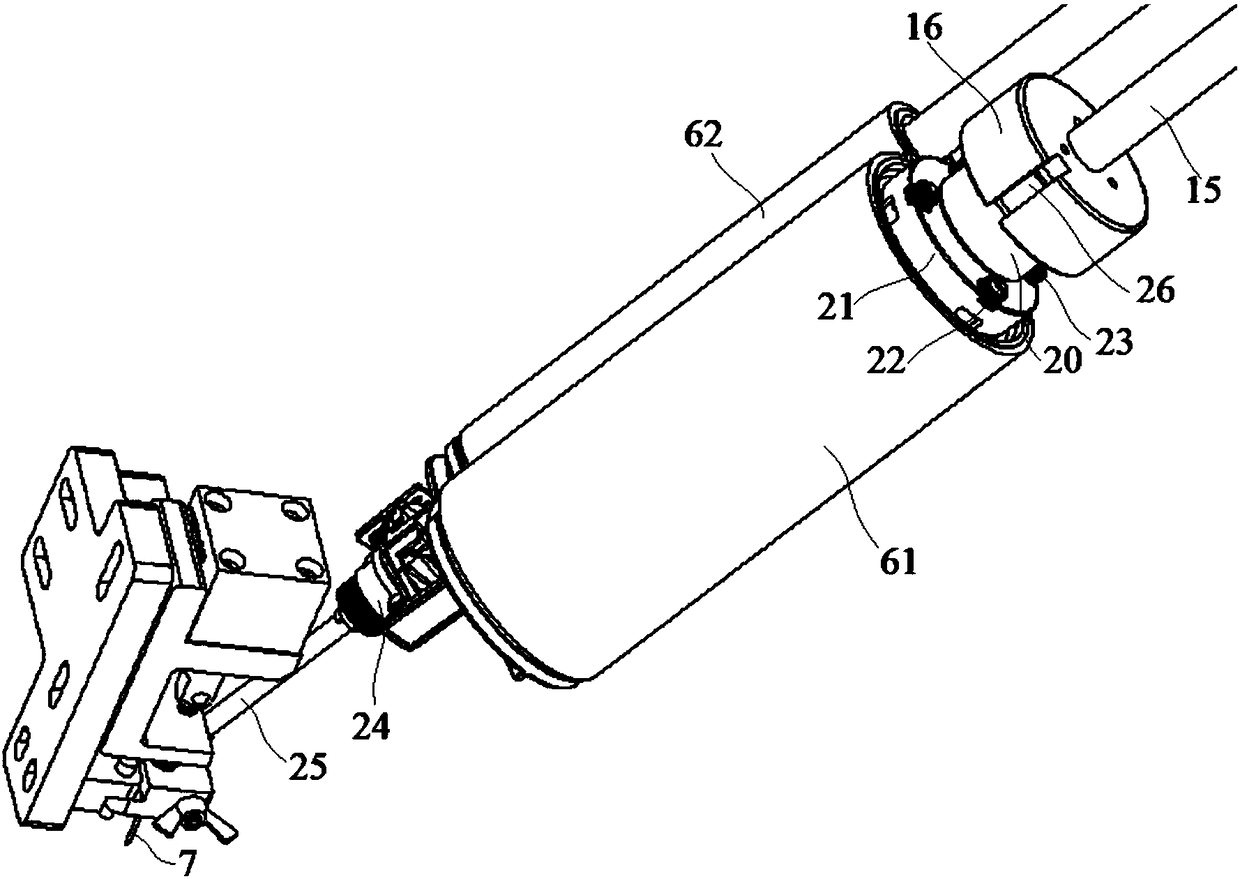

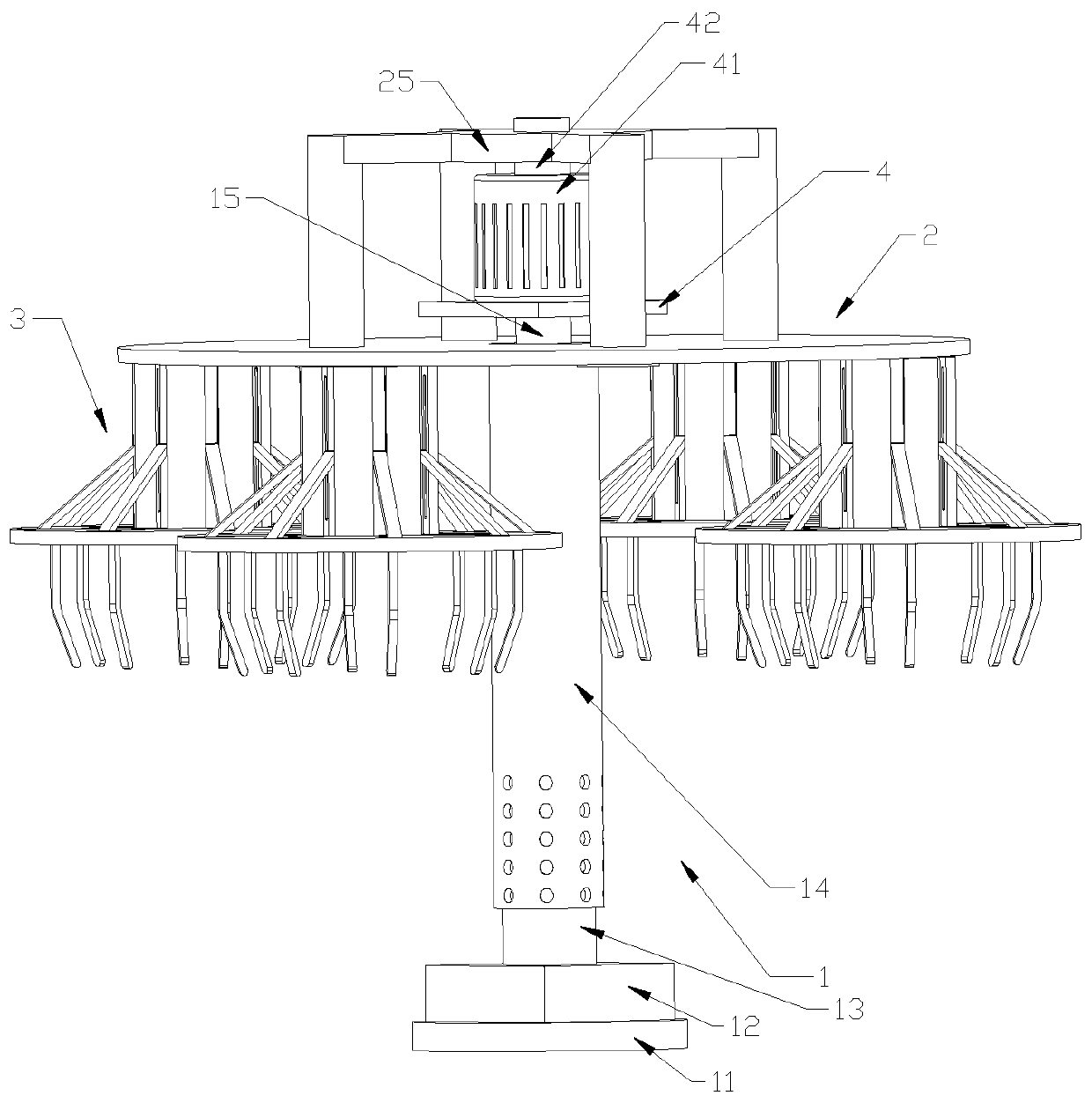

Full-automatic grafting machine

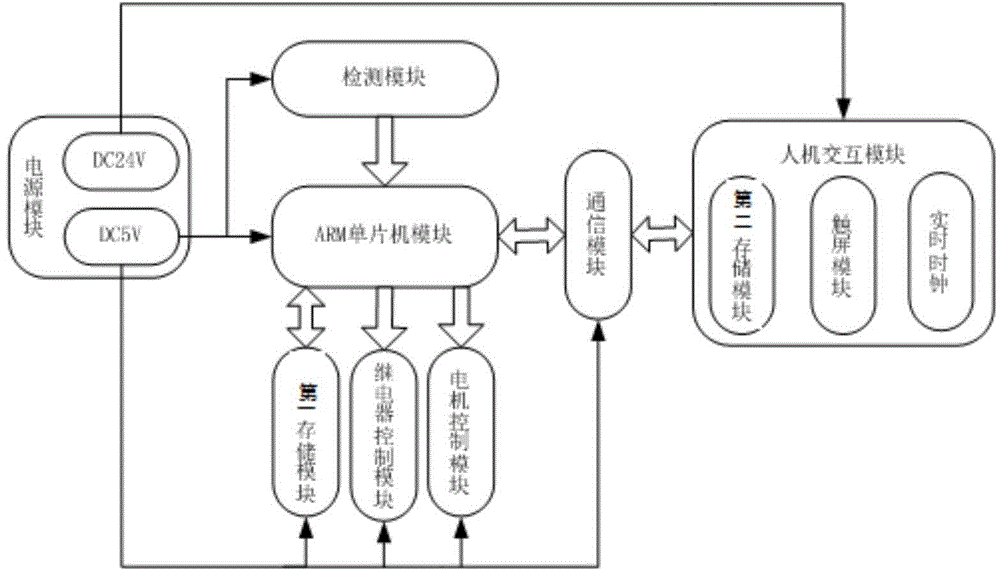

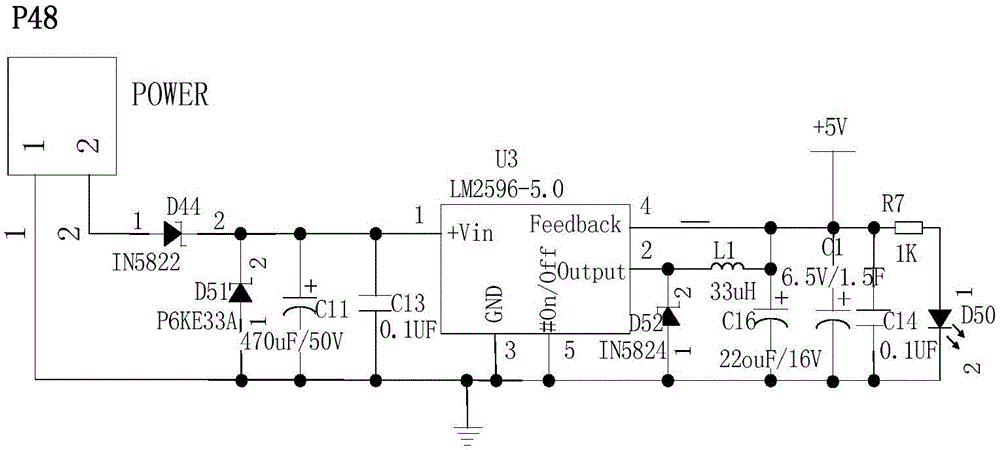

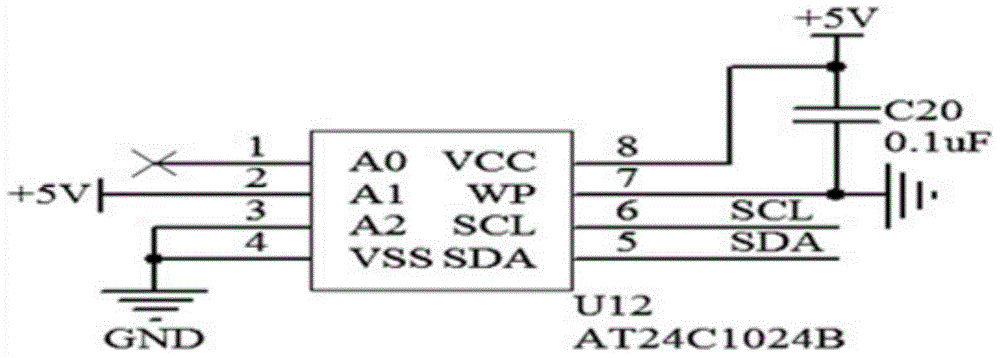

The invention discloses a full-automatic grafting machine. As long as a seedling raising plate is placed in a specified position, seedlings can be automatically taken, automatically cut and fixed in a butt-joint mode. An ARM single-chip microcomputer is used as the center of an electronic control part, and thus the full-automatic grafting machine has the advantages of being simple in structure, small in size, convenient to set and the like. A coordinate system mode is adopted for a mechanical part for accurate positioning, stock seedling grafting and scion seedling grafting are made automatic, stocks and scions are cut mechanically, the cut positions of the stocks and the cut positions of the scions are automatically aligned, and thus the seedling grafting process is fully automatic and mechanized. Because the ARM mode is adopted for control, more resources are obtained, and the complexity of the mechanical structure is effectively reduced. The working production efficiency is improved.

Owner:JIANGSU POLYTECHNIC COLLEGE OF AGRI & FORESTRY

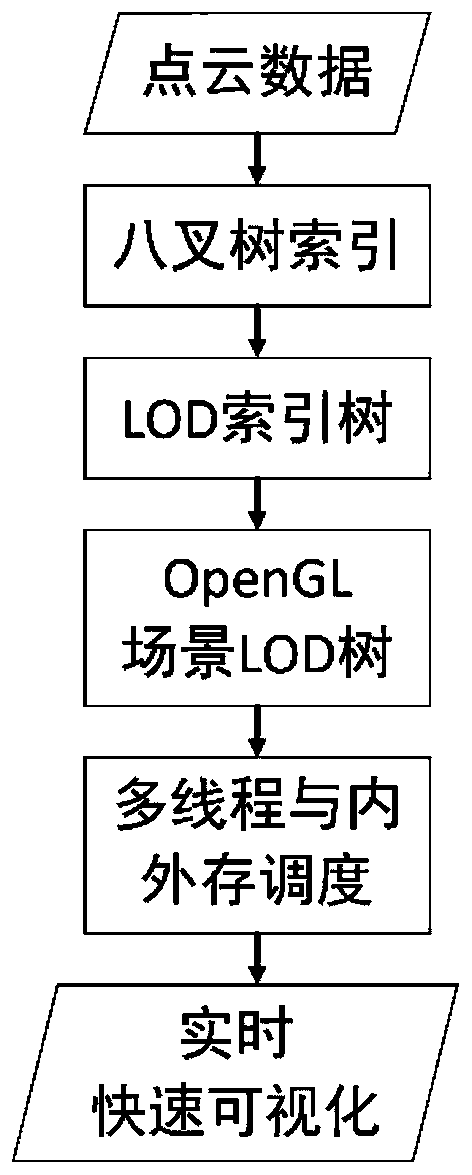

Multi-platform point cloud intelligent processing method for holographic mapping

ActiveCN110021072ARealize the organizationImplement schedulingDetails involving processing steps3D-image renderingLevel of detailMathematical model

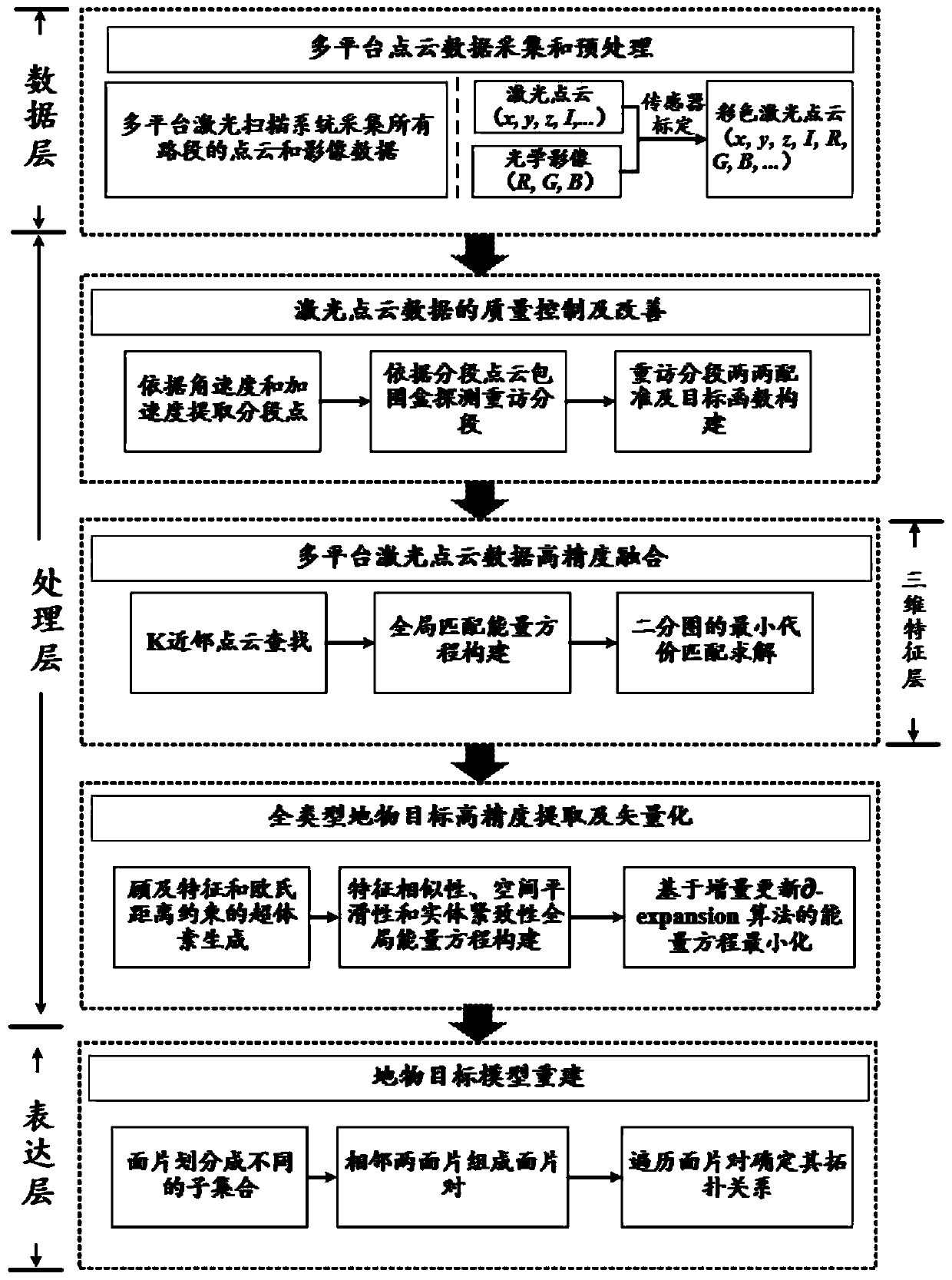

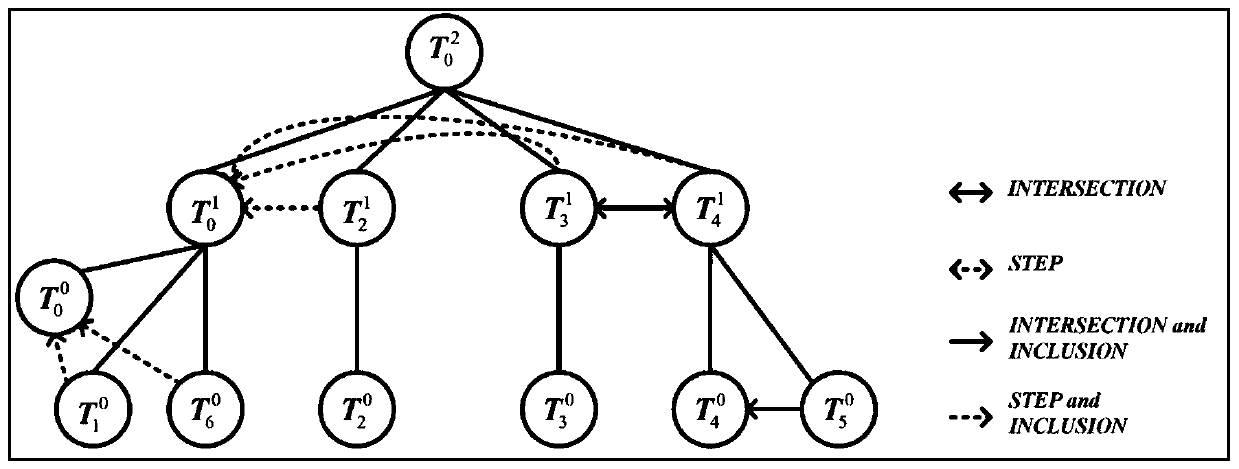

The invention relates to a multi-platform point cloud intelligent processing method for holographic mapping. The method comprises the steps of organizing and scheduling mass point cloud data; carryingout point cloud data quality control and improvement, and achieving automatic correction of point cloud position consistency under the condition of no control point; carrying out high-precision fusion of multi-platform laser point cloud data, which comprises neighbor point cloud search, global matching energy equation construction and bipartite graph minimum cost matching; automatically extracting the ground object targets, namely realizing high-precision extraction and vectorization of the full-type ground object targets through geometric semantic consistency extraction of the ground objecttargets; carrying out the ground object target multi-detail-level model reconstruction based on the Grignard law, which comprises the step of establishing a multi-detail-level three-dimensional modelof the ground object target through a Grignard mathematical model and a topological relation graph. The holographic surveying and mapping product production process based on the multi-platform point cloud data is achieved, the method is easy to operate and implement, the manual workload of data processing can be greatly reduced, the working production efficiency is improved, and the product updating period is prolonged.

Owner:WUHAN UNIV +1

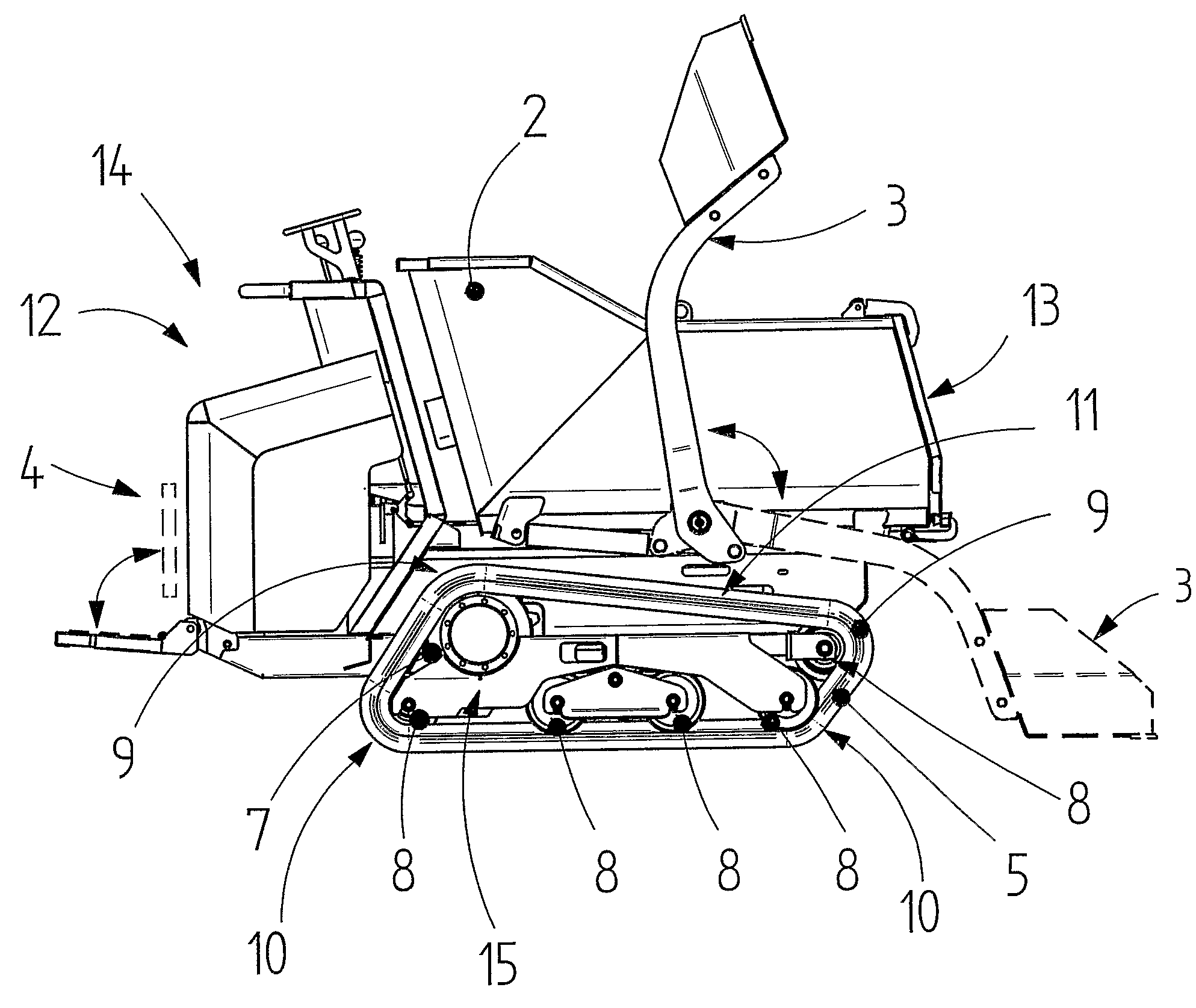

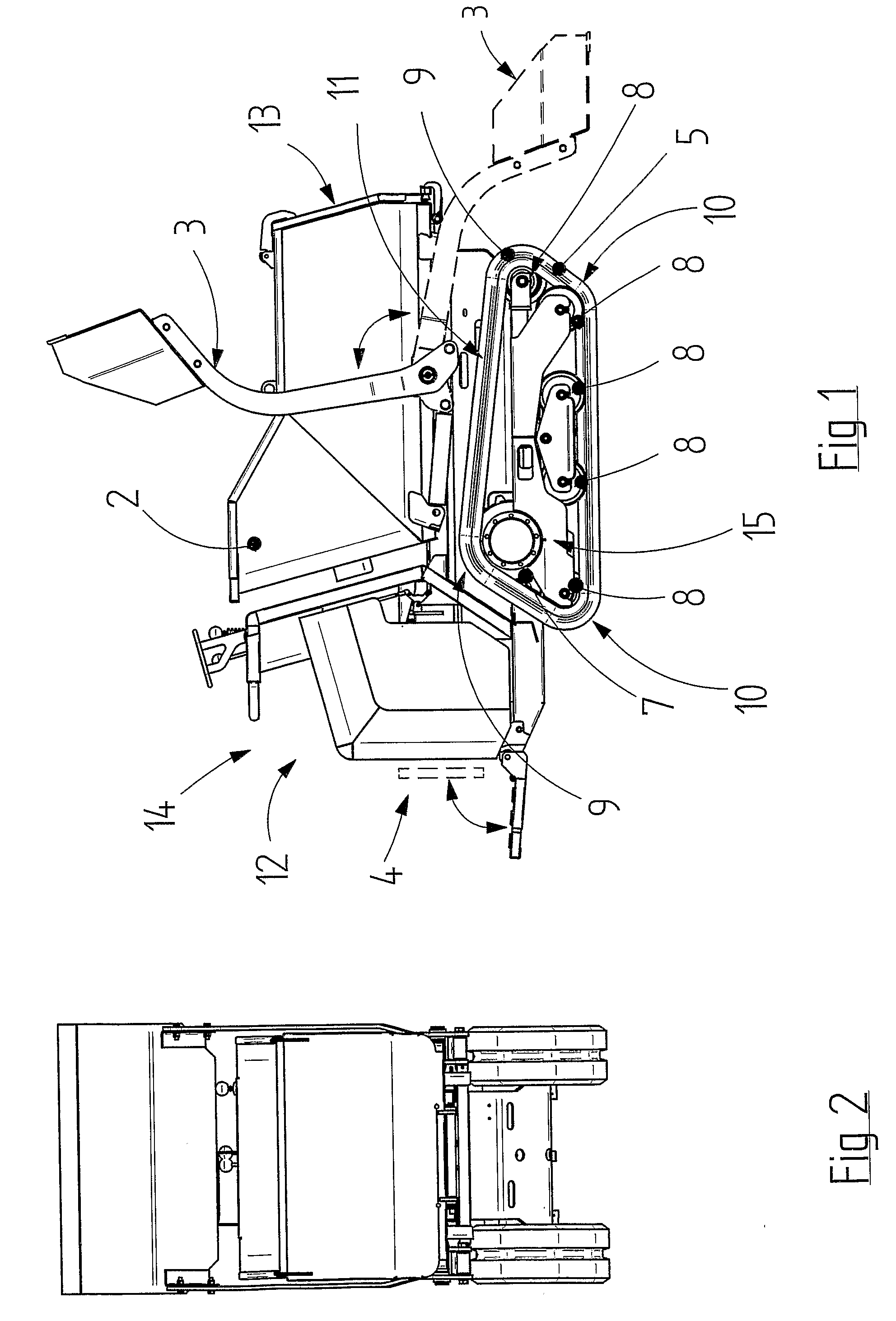

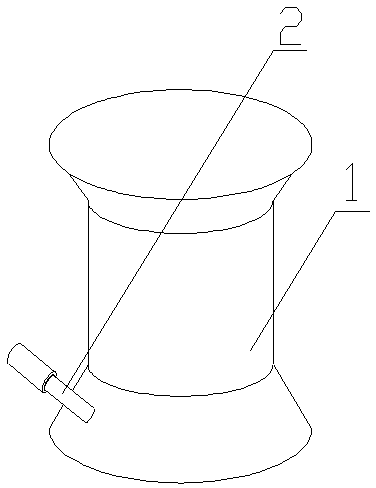

Compact tracked vehicle for transporting and self-loading material, that can be operated by a standing operator

InactiveUS20090116943A1Maximum safetyMaximum efficiency of the multi-purpose nature of the vehicleSoil-shifting machines/dredgersHand carts with one axisMotor driveEngineering

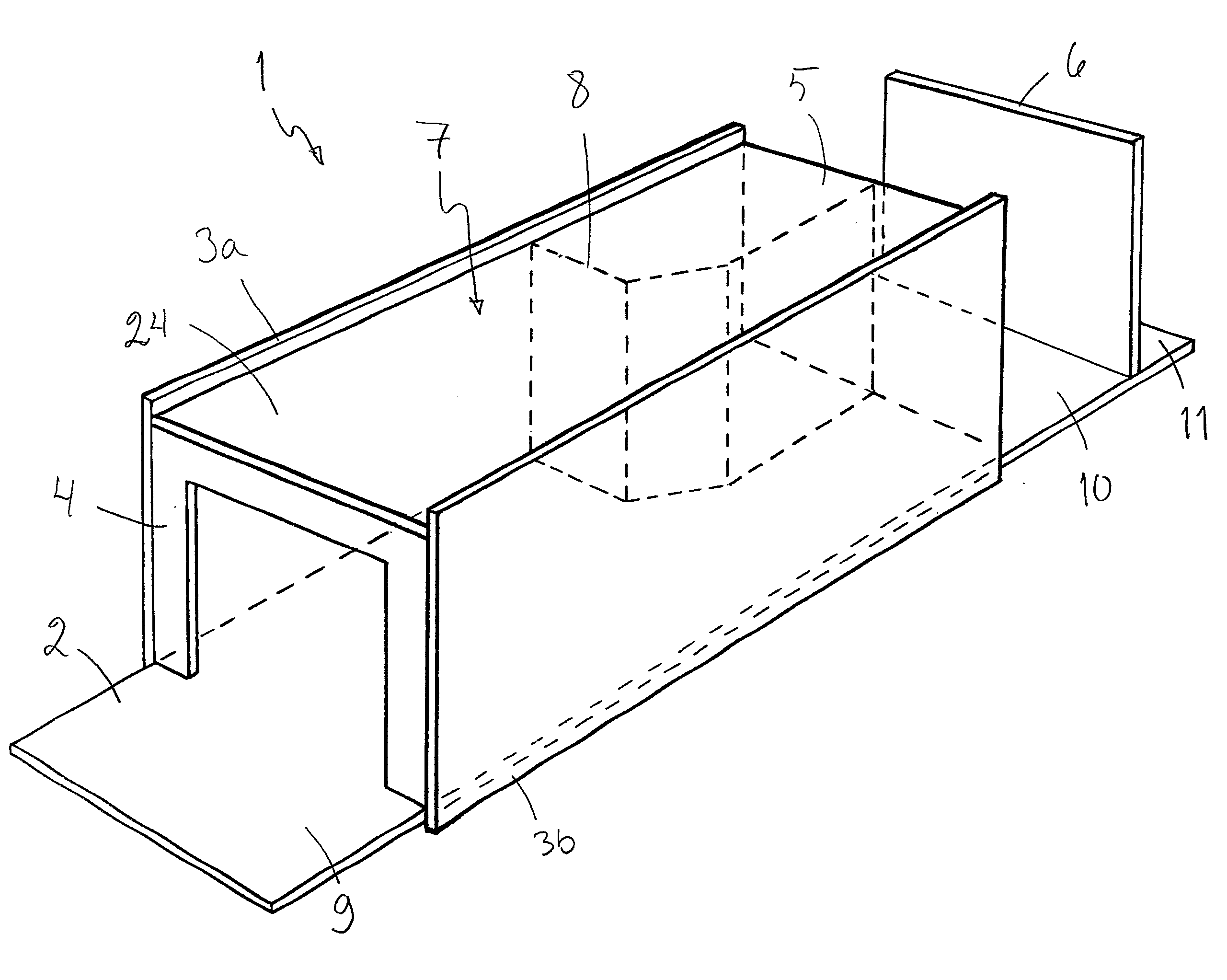

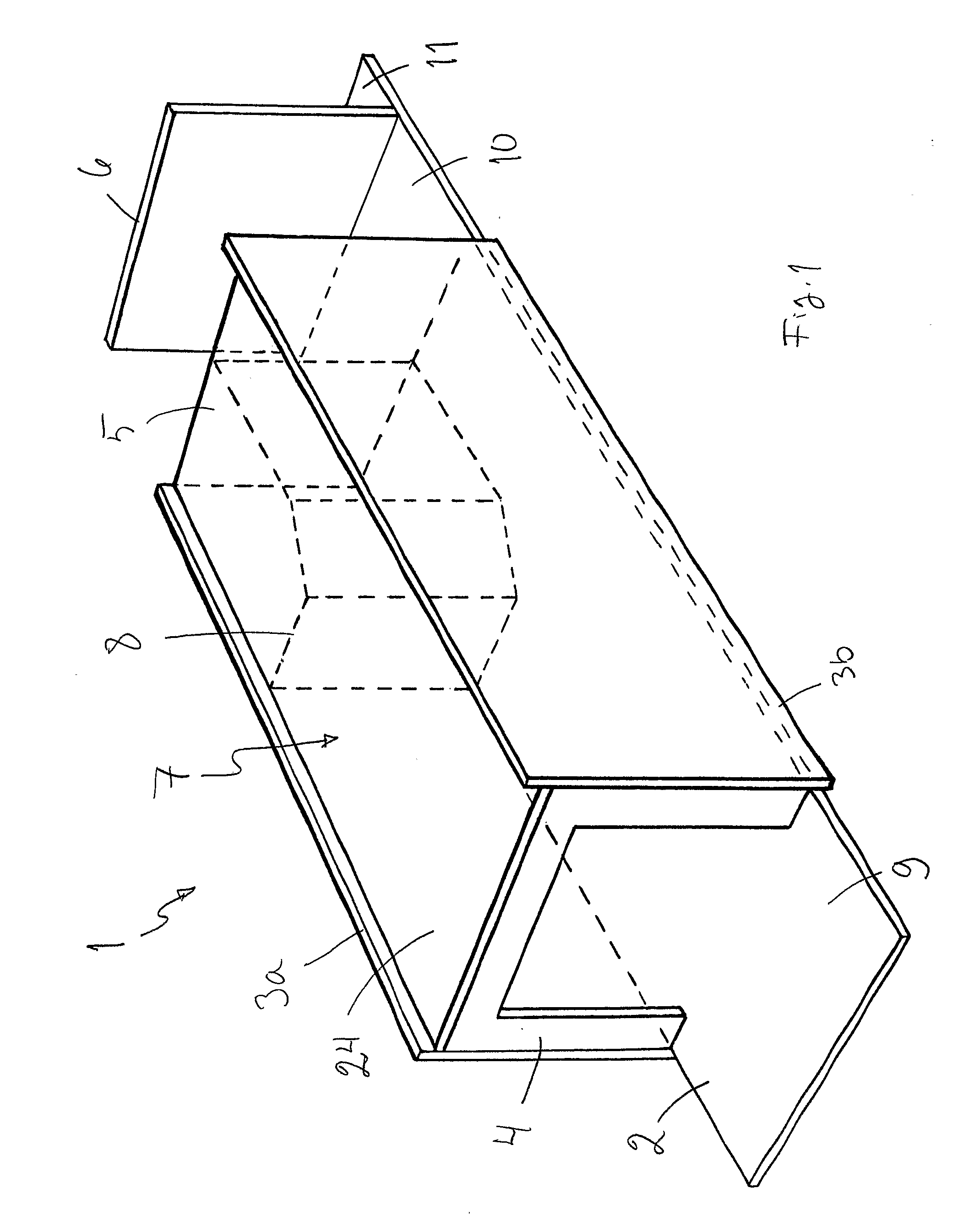

A compact tracked vehicle (1) for transporting and self-loading material, that can be operated by a standing operator, comprises in combination a body (2) for holding the material; a power shovel (3), located at the front, for body (2) self-loading; a platform (4), located at the rear, for supporting the operator; and tracks (5), wound in a loop (6). The loop (6) substantially has a parallelogram configuration around a motor-driven wheel (7) and a plurality of tension rollers (8). The parallelogram is angled in such a way that it has a pair of first vertices (9) raised off the ground and substantially translated forward relative to a pair of second vertices (10) adjacent to the ground. The motor-driven wheel (7) is associated with one of the first vertices (9) raised off the ground.

Owner:MESSERSI

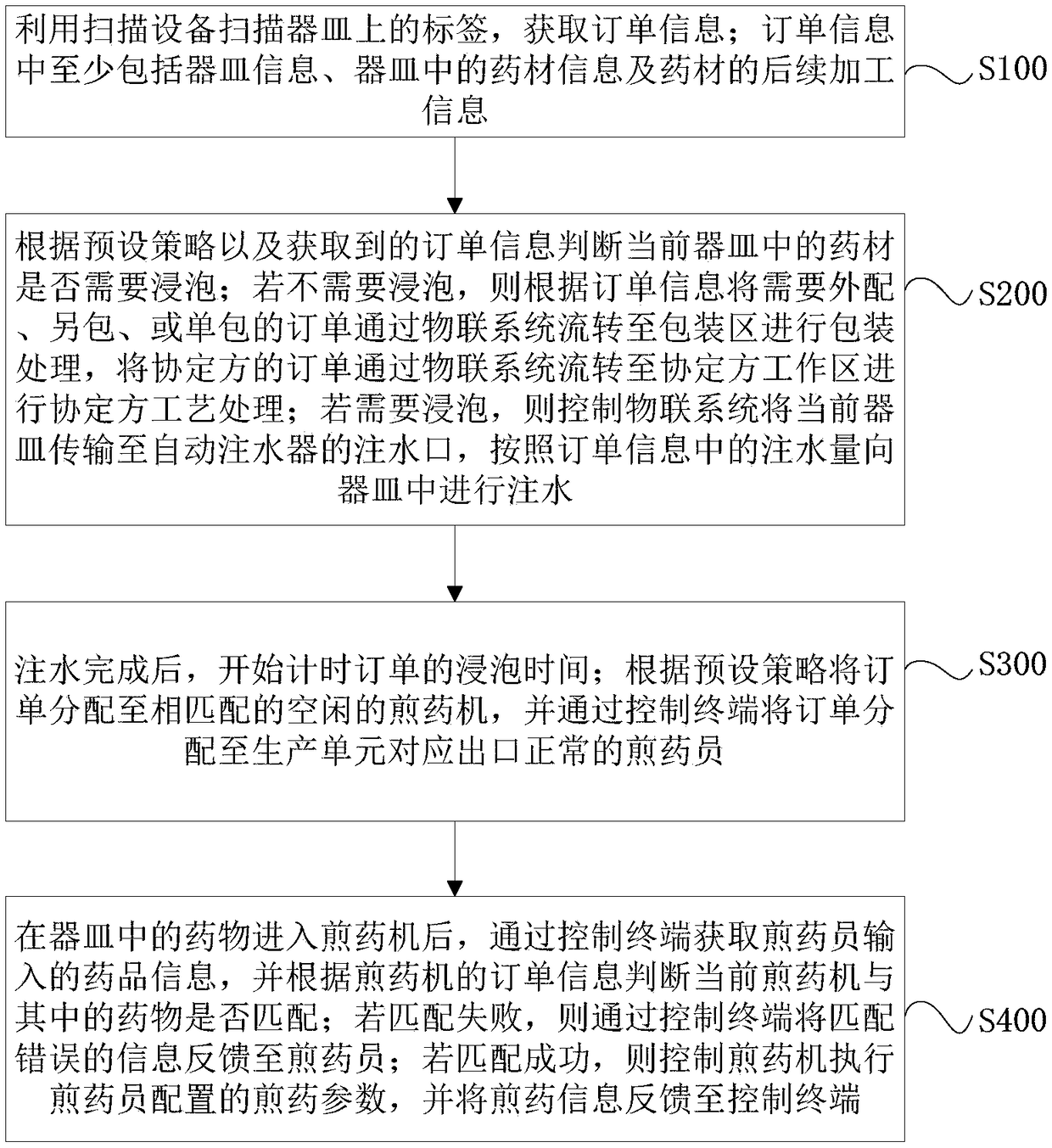

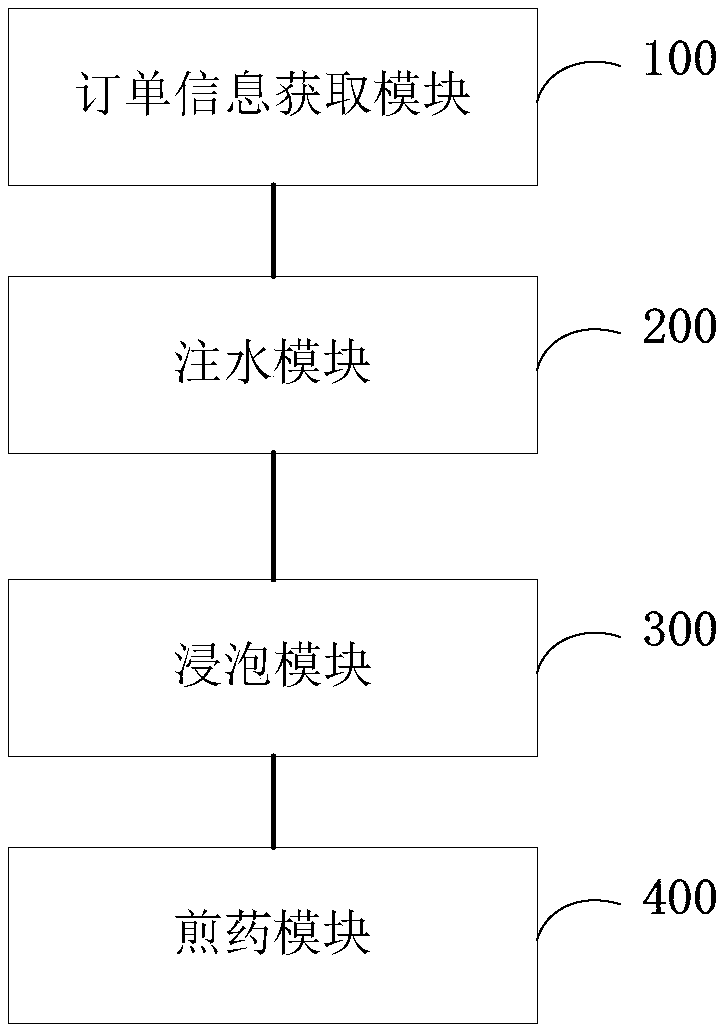

Intelligent herbal medicine decoction management method and system

InactiveCN108922596AEasy to superviseEasy to trackAlternative medicinesPharmaceutical product form changeQuality controlDecision taking

The invention discloses an intelligent herbal medicine decoction management method and system. Based on an Internet of Things system consisting of a decoction machine, an automatic printing labeling machine, an automatic water injector, a control terminal and a conveyor belt, a decoction command is issued through an intelligent decision stored in a server or the control terminal, and then devicesreceive the command and analyze a decoction plan and perform automatic parameter setting to complete automatic water injection, automatic conveying, automatic decoction and automatic printing labeling; allocation and automatic circulation of the decoction process can be realized according to the personnel availability and the device availability, and refined management and quality control of the overall decoction process can be completed. The intelligent herbal medicine decoction management method and system realizes the information flow, does not need manual signature recording, records and saves information online, and is convenient for supervision and tracking; and the whole decoction process is transparent, the decoction process is controllable, the efficiency is high, the quality is guaranteed, the labor cost is greatly reduced, and the working capacity is improved.

Owner:浙江雅锐斯智能科技有限公司

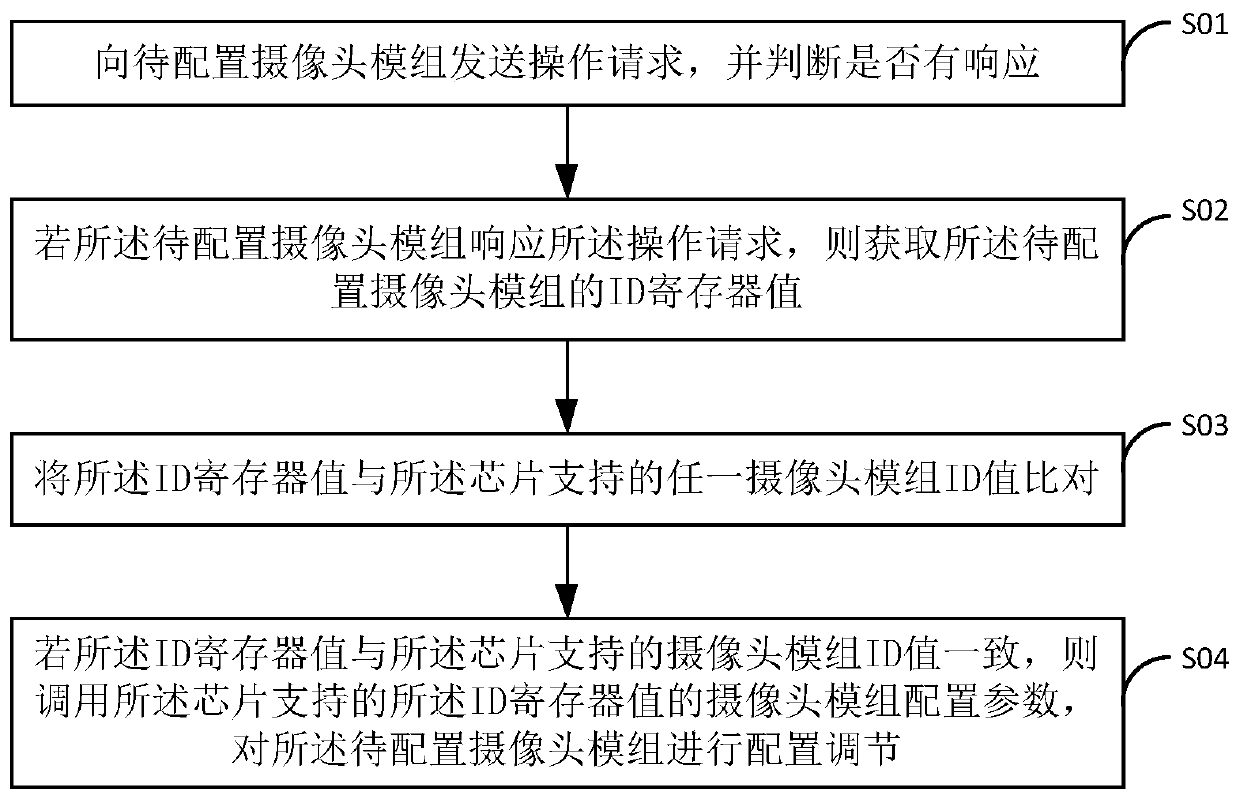

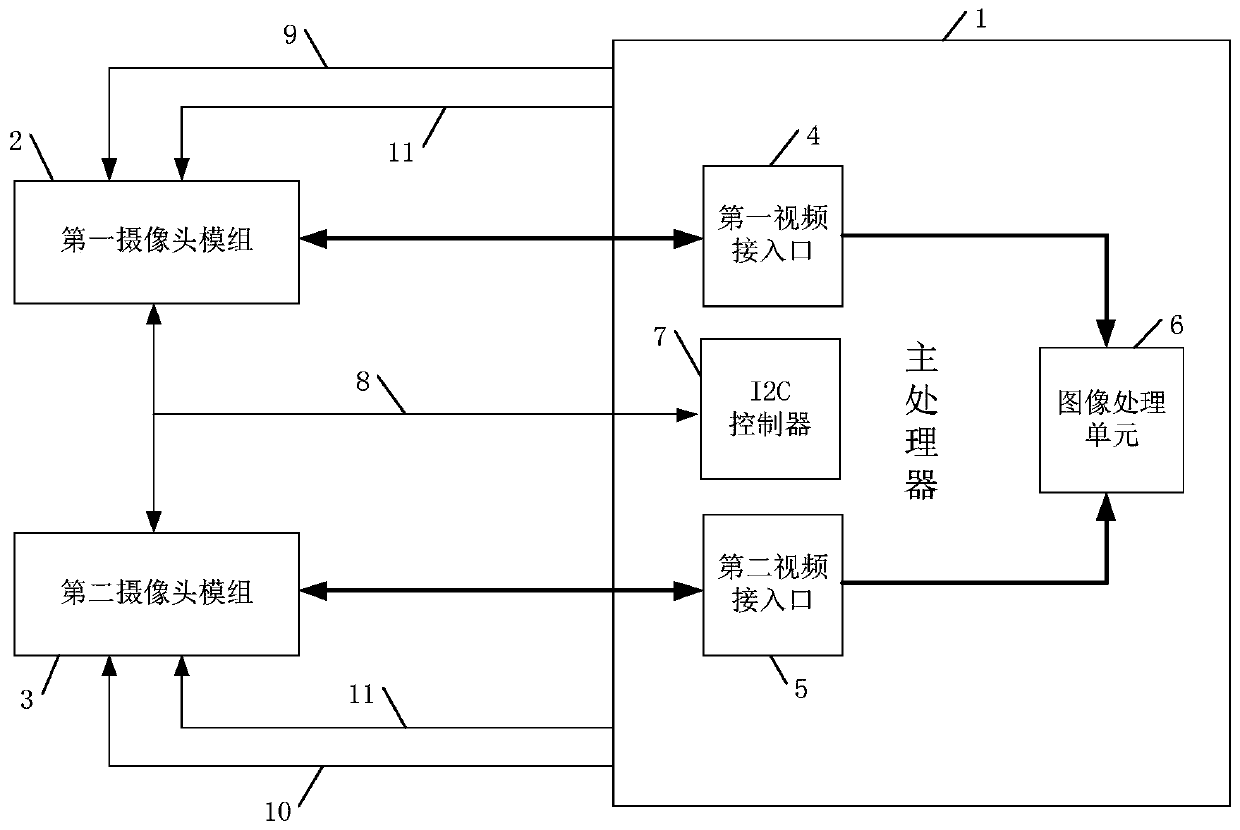

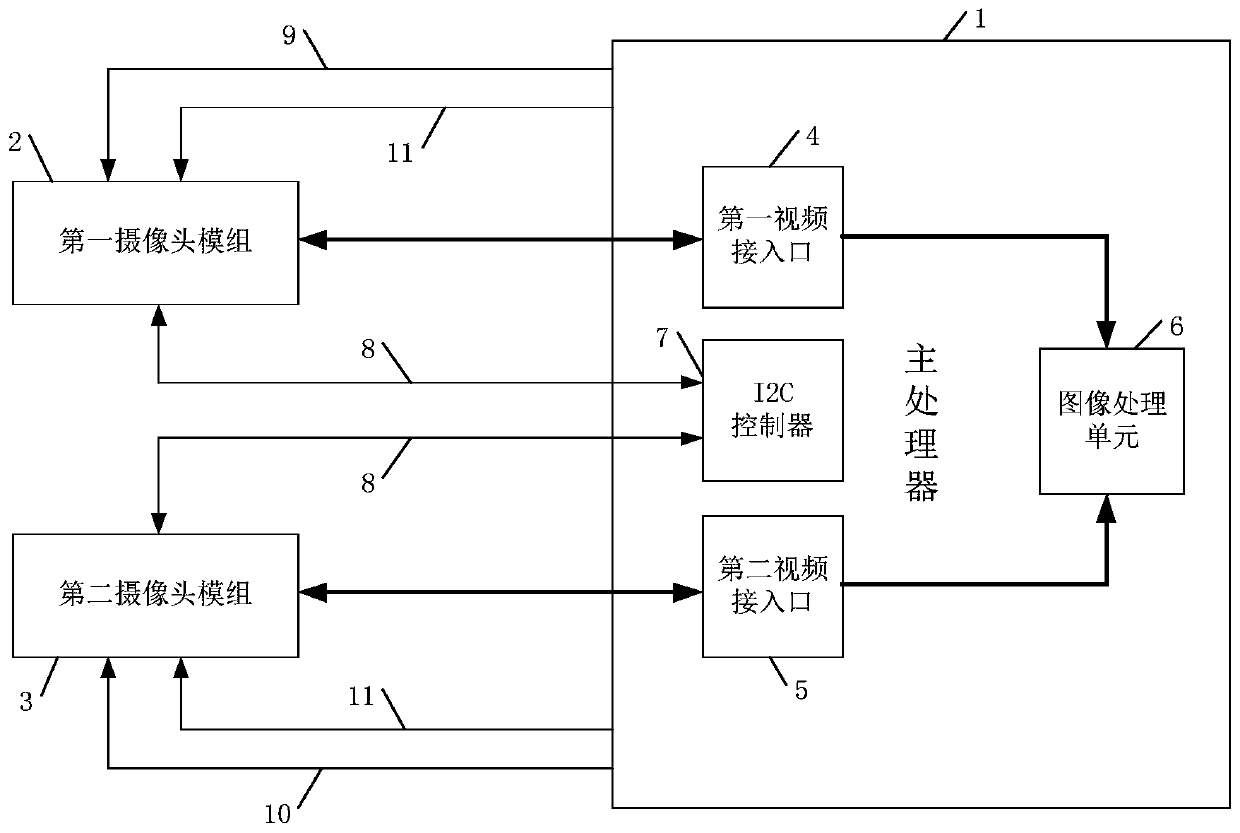

An automatic detection method and system for a camera module

ActiveCN109874010AReduce error rateImprove work productivityTelevision systemsCamera moduleEmbedded system

The invention discloses an automatic detection method and system for a camera module, wherein the configuration parameters of the types of all camera modules supported by a chip software driver are preset in the chip software driver. The method comprises the steps of sending an operation request to a to-be-configured camera module, and judging whether a response exists or not; If the to-be-configured camera module responds to the operation request, obtaining an ID register value of the to-be-configured camera module; comparing the ID register value with the ID value of any camera module supported by the chip; and if the ID register value is consistent with the ID value of the camera module supported by the chip, calling a camera module configuration parameter of the ID register value supported by the chip, and carrying out configuration adjustment on the to-be-configured camera module. According to the method and the device, the type of the camera module accessed to the camera input system can be automatically identified, more camera modules are supported, and meanwhile, the preset configuration parameters are called for configuration, so that the error rate is reduced, and the working production efficiency is improved.

Owner:CHENGDU GUOKE MICROELECTRONICS CO LTD

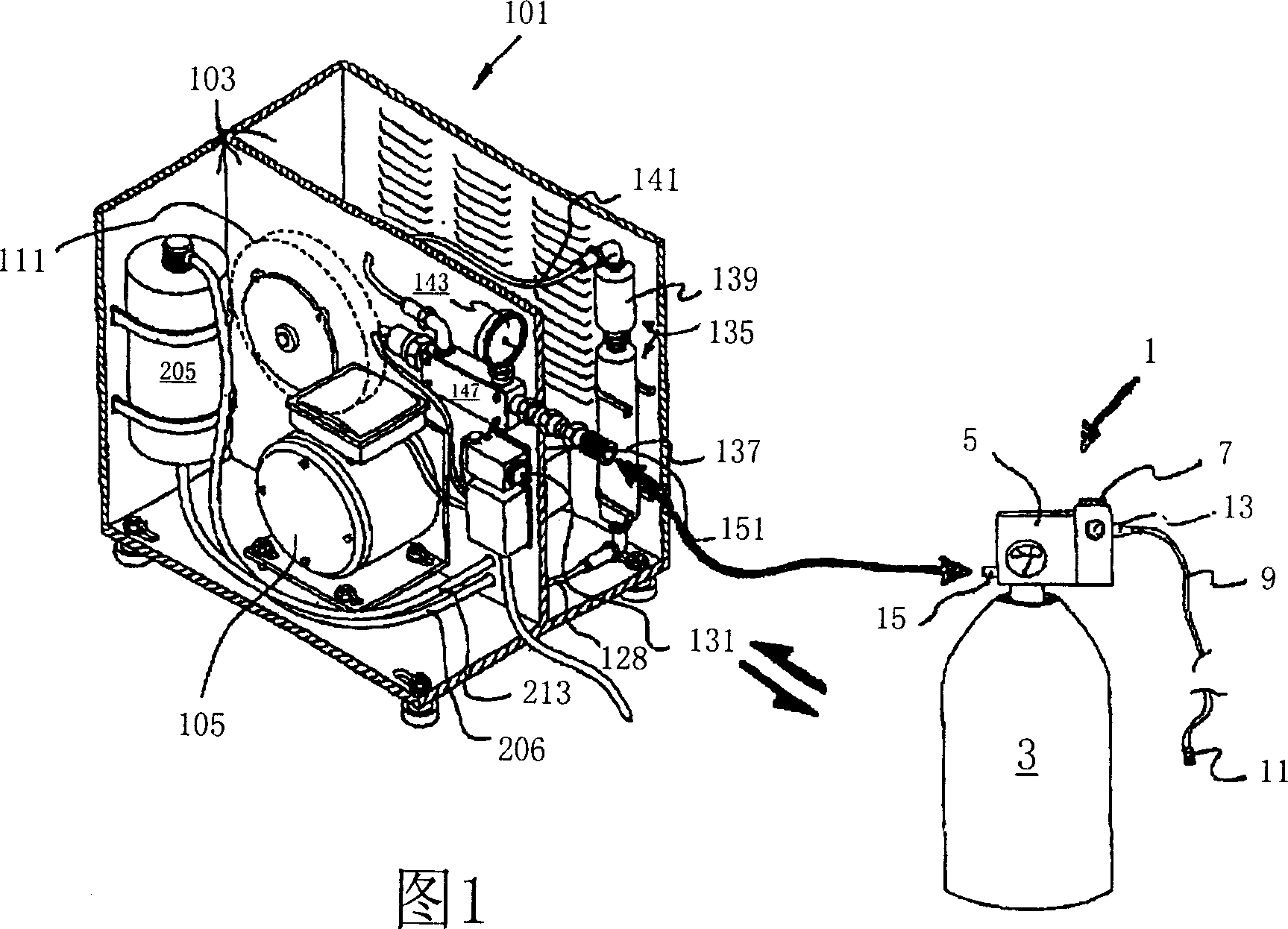

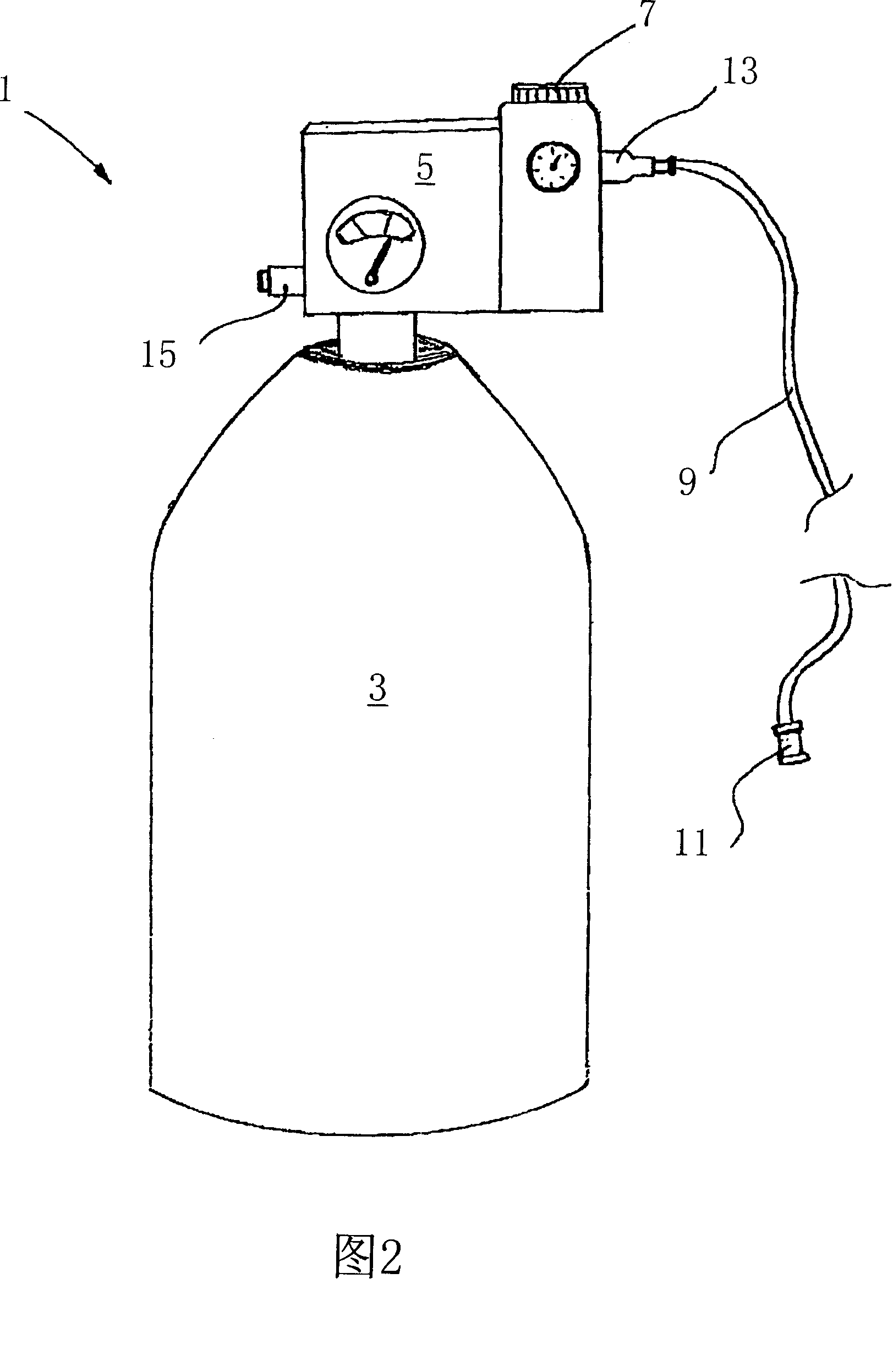

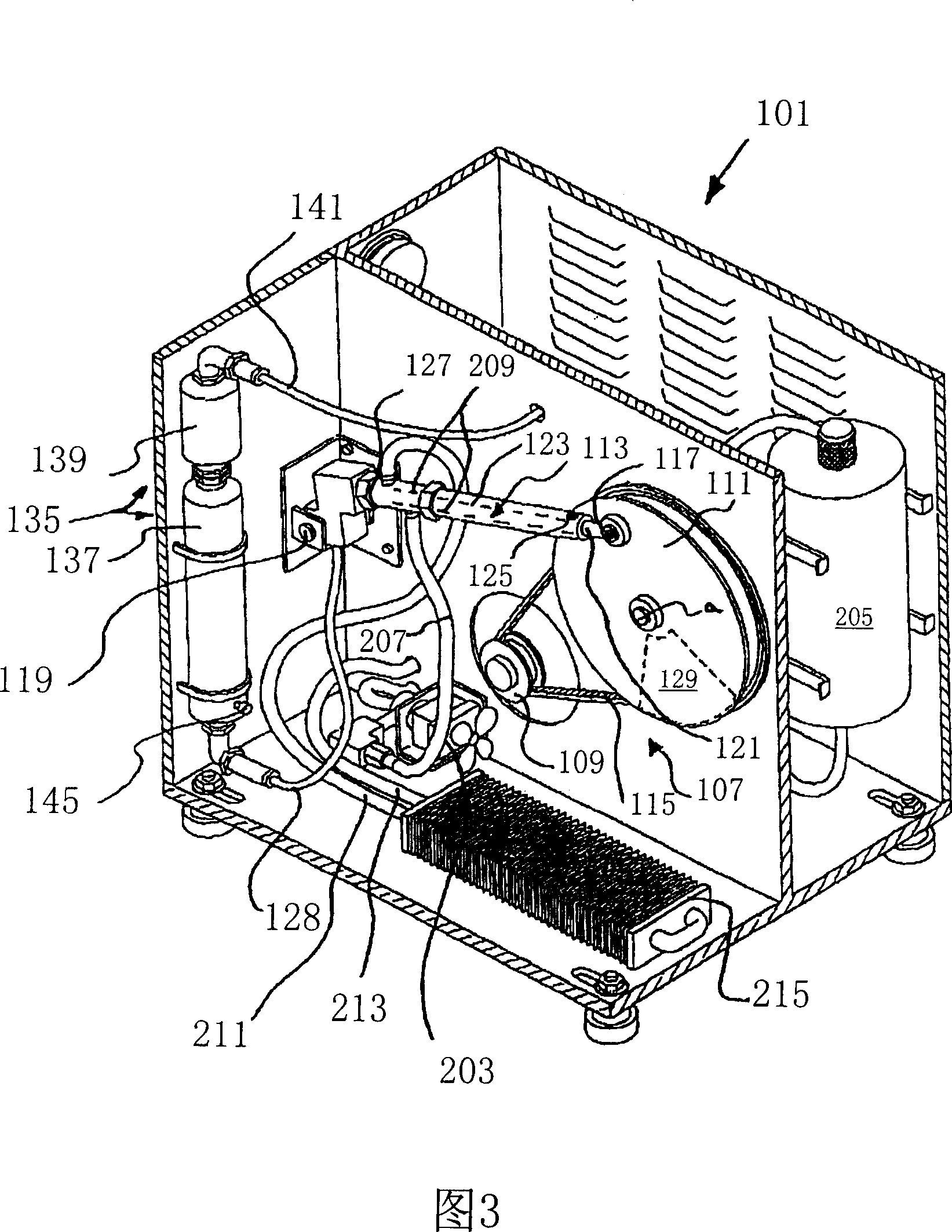

A system comprising a compressor and a portable pneumatic pressure reservoir

InactiveCN101033825AImprove work productivityReduce labor costsPositive displacement pump componentsPipeline systemsGas compressorAtmospheric air

Owner:R·L·小图兰

Polyurethane grinding wheel

InactiveCN106938446ALower sintering temperatureHigh energyAbrasion apparatusGrinding devicesMixed materialsGrinding wheel

The invention discloses a polyurethane grinding wheel and a production process thereof. According to the polyurethane grinding wheel, abrasive materials in raw materials are carborundum, and polyurethane is adopted as a binding agent; and the polyurethane comprises a polyurethane material A and a polyurethane material B. The production process includes the steps that material mixing is firstly carried out, wherein the carborundum and the polyurethane material A are put into a material mixing machine to be mixed, and the polyurethane material B and auxiliary materials are sequentially added to be evenly mixed; then a mixed material is screened to be placed into a die to be subject to pressing molding; and finally, a green body is sintered for 8 h to 24 h at the temperature ranging from 125 DEG C to 165 DEG C, and is cooled to be discharged out of a furnace. According to the production process, the polyurethane serves as the binding agent to produce the grinding wheel, the auxiliary materials in an existing grinding wheel recipe can be applied to the method according to the production requirement, and the manufactured grinding wheel has the beneficial effects that the sintering temperature is low, saved energy resources are many, pollution is avoided, the molding density is large, the grinding wheel balance is good, the rotating speed is high, the grinding performance is high, and the production period is short, and the quality of products in the machine tool industry, the bearing industry, the bent axle industry, the engine industry and the steel rolling industry is improved.

Owner:龙口东润砂轮有限公司

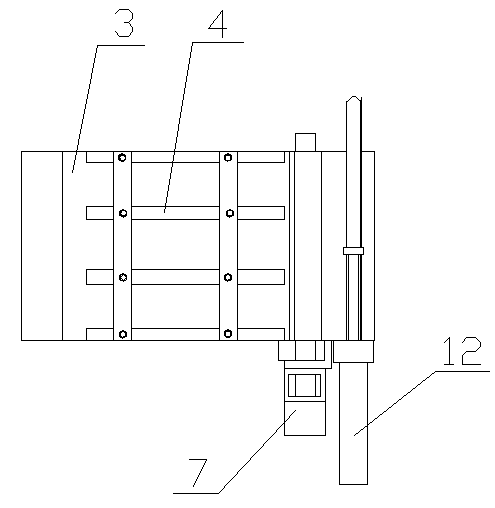

Turning device for tread storage book truck

The invention discloses a turning device for a tread storage book truck, and belongs to the technical field of tire manufacturing equipment. The turning device for the tread storage book truck comprises a first vertical column and a second vertical column, wherein the first vertical column and the second vertical column are oppositely arranged on two sides of the book truck; the first vertical column is provided with a sucking mechanism which is used for turning louver plates at a vertical position of the book truck at an angle; and the second vertical column is provided with a pressing mechanism which is used for pressing the louver plates turned at an angle to a horizontal position. The louver plates can be turned into a horizontal state from a vertical state by matching operation of the sucking mechanism and the pressing mechanism, a whole work procedure can be automatic without any manual operation, the labor intensity of an operator is greatly reduced, the production efficiency is effectively improved, and the danger accidents which are easily caused during manual operation are avoided.

Owner:山东三江智能装备有限公司

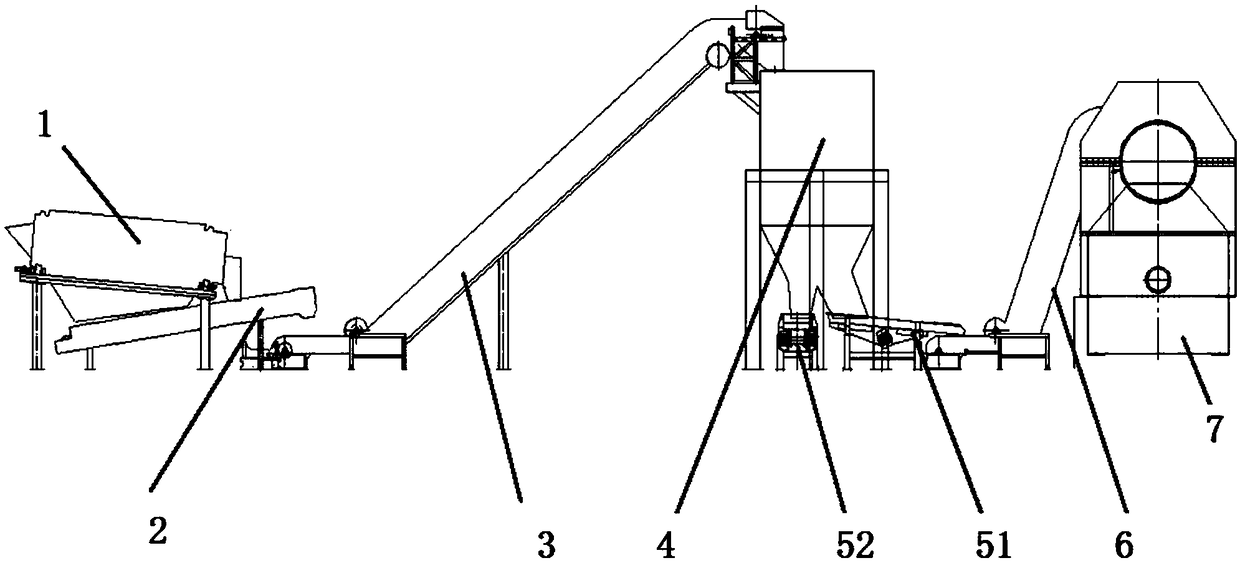

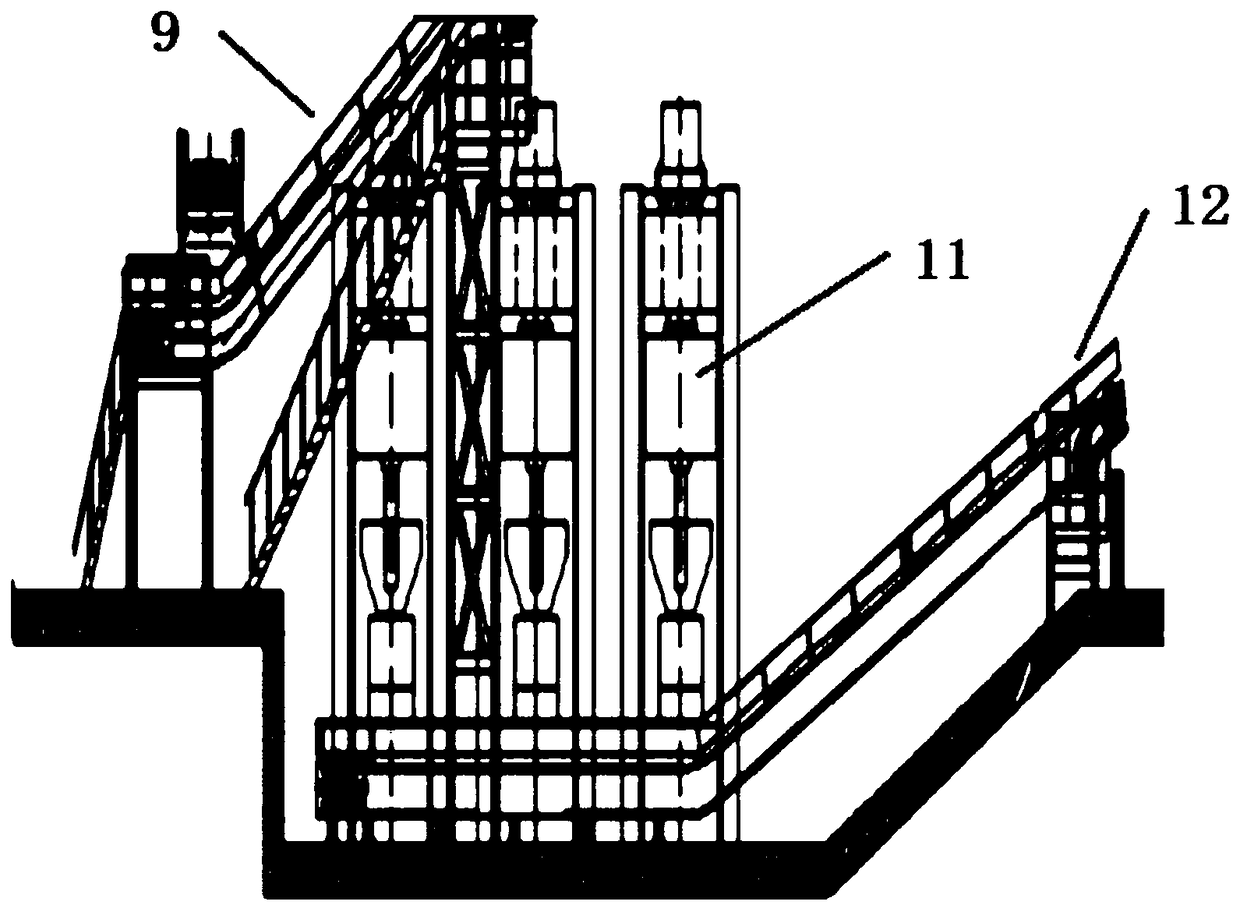

Crushing material hot-pressing forming line

Owner:JIANGSU HUAHONG TECH STOCK

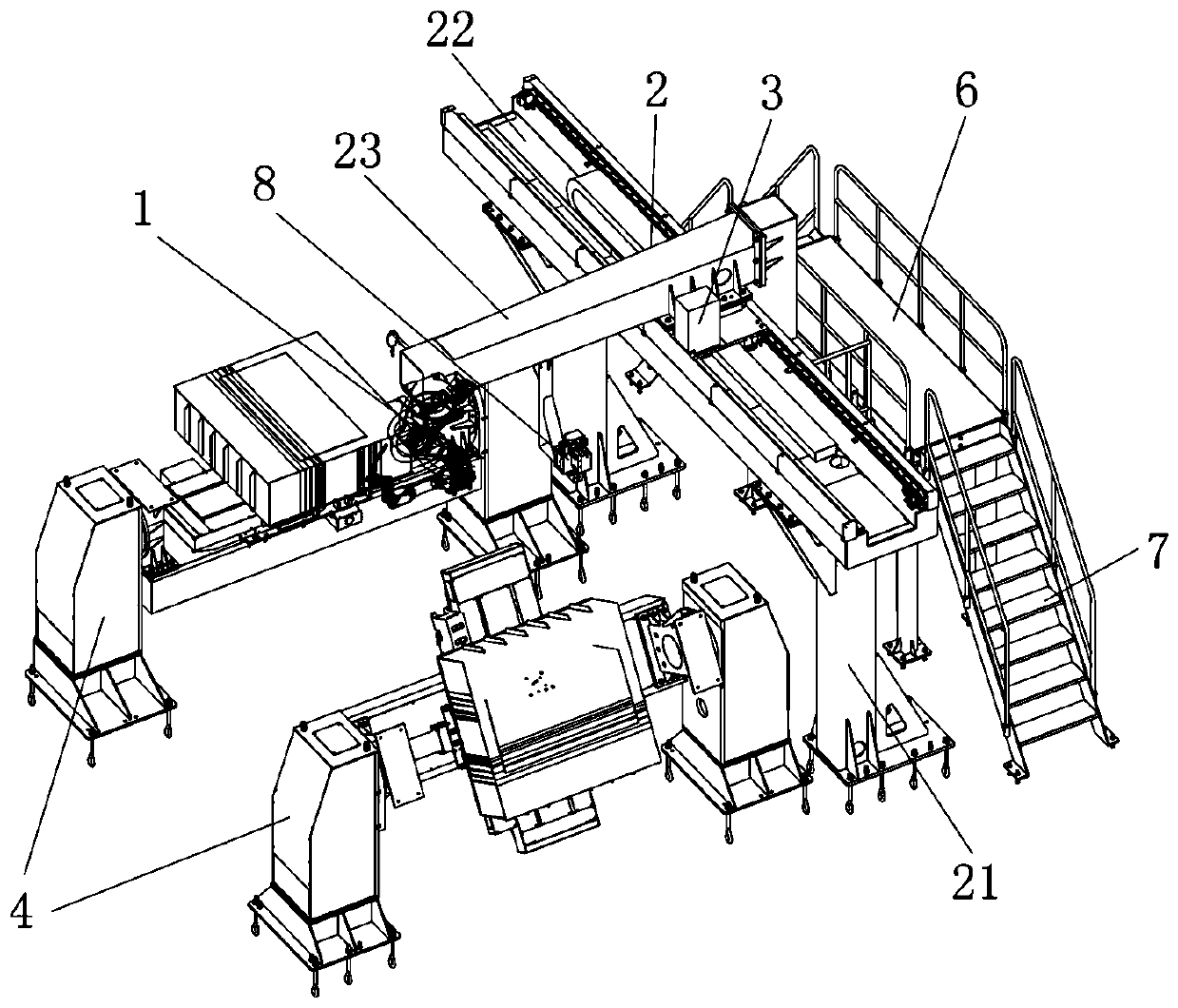

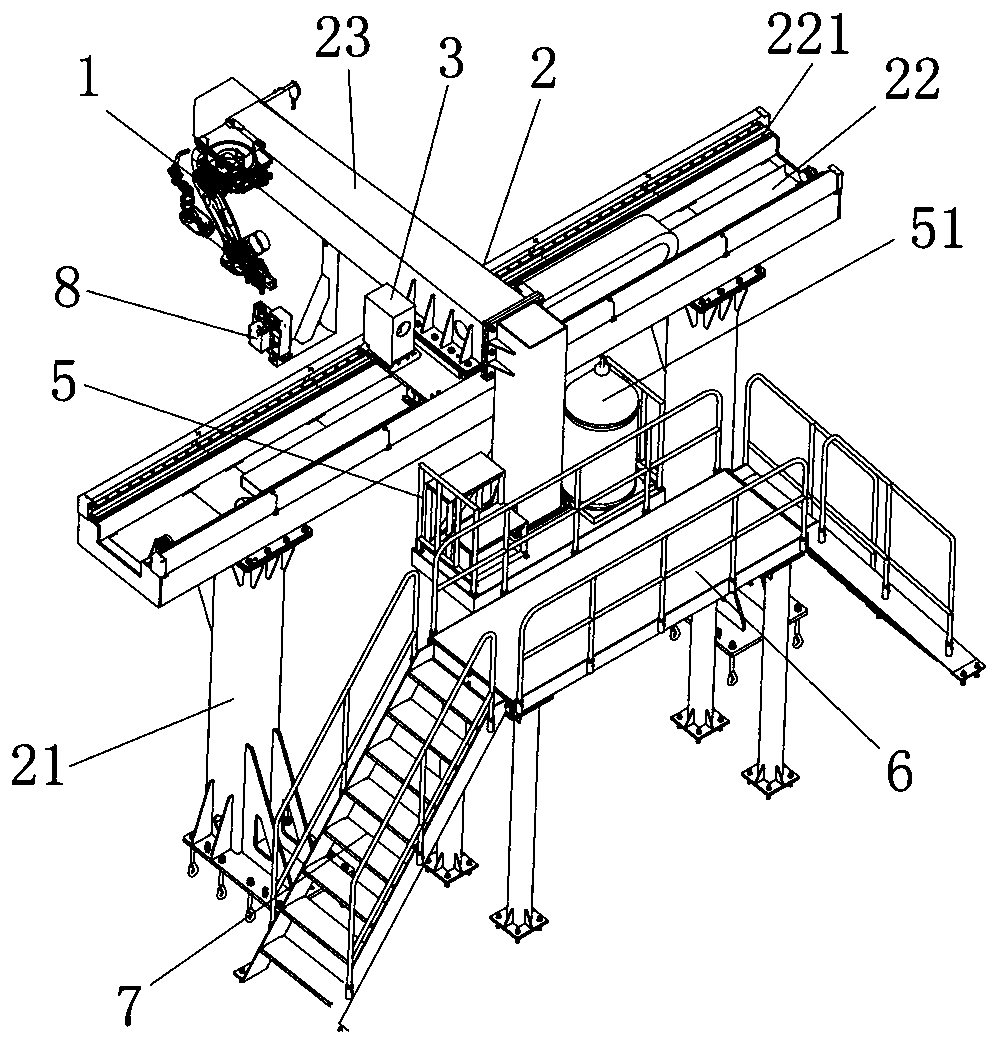

Double-workstation welding device for box parts automatic welding flow production line

InactiveCN107755940AIncrease profitImprove work productivityWelding/cutting auxillary devicesAuxillary welding devicesProduction lineEngineering

The invention discloses a double-workstation welding device for a box parts automatic welding flow production line. The double-workstation welding device comprises a welding robot for welding a workpiece and a traveling mechanism enabling the welding robot to reciprocatingly travel between two workstations, the traveling mechanism comprises a portal frame, a traveling rail and a longitudinal beamfor realizing traveling of the welding robot along the traveling rail, the traveling rail is arranged on a top crossbeam of the portal frame, and one end of the longitudinal beam is fixedly connectedwith the welding robot while the other end of the same is arranged on the traveling rail and can travel and move along the same. The double-workstation welding device does not need to stop and wait, so that working efficiency of equipment can be improved substantially, investment of the equipment is reduced, and utilization rate of the equipment is increased.

Owner:ZHUZHOU TIANYI AUTOWELDING SYST CO LTD

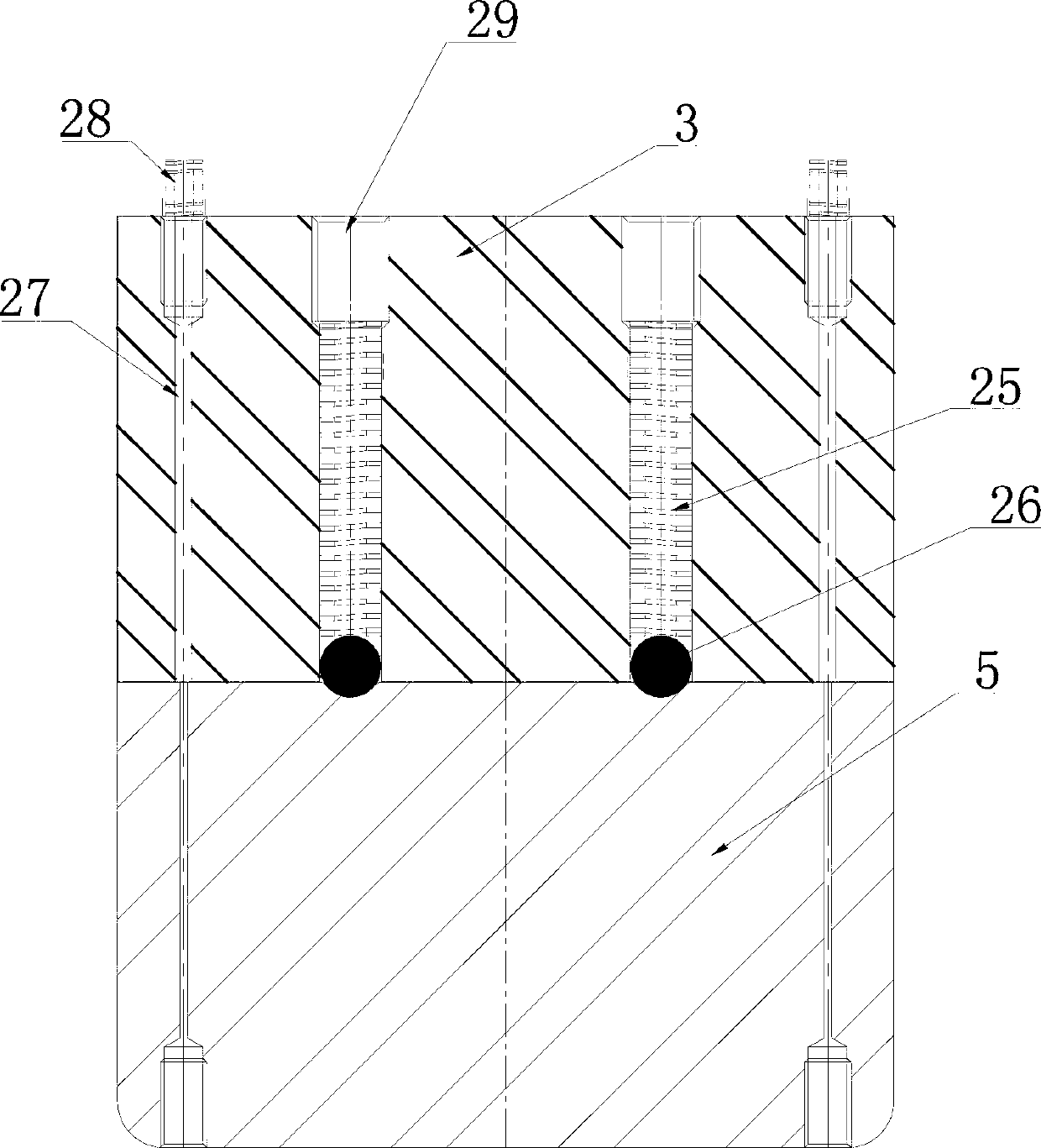

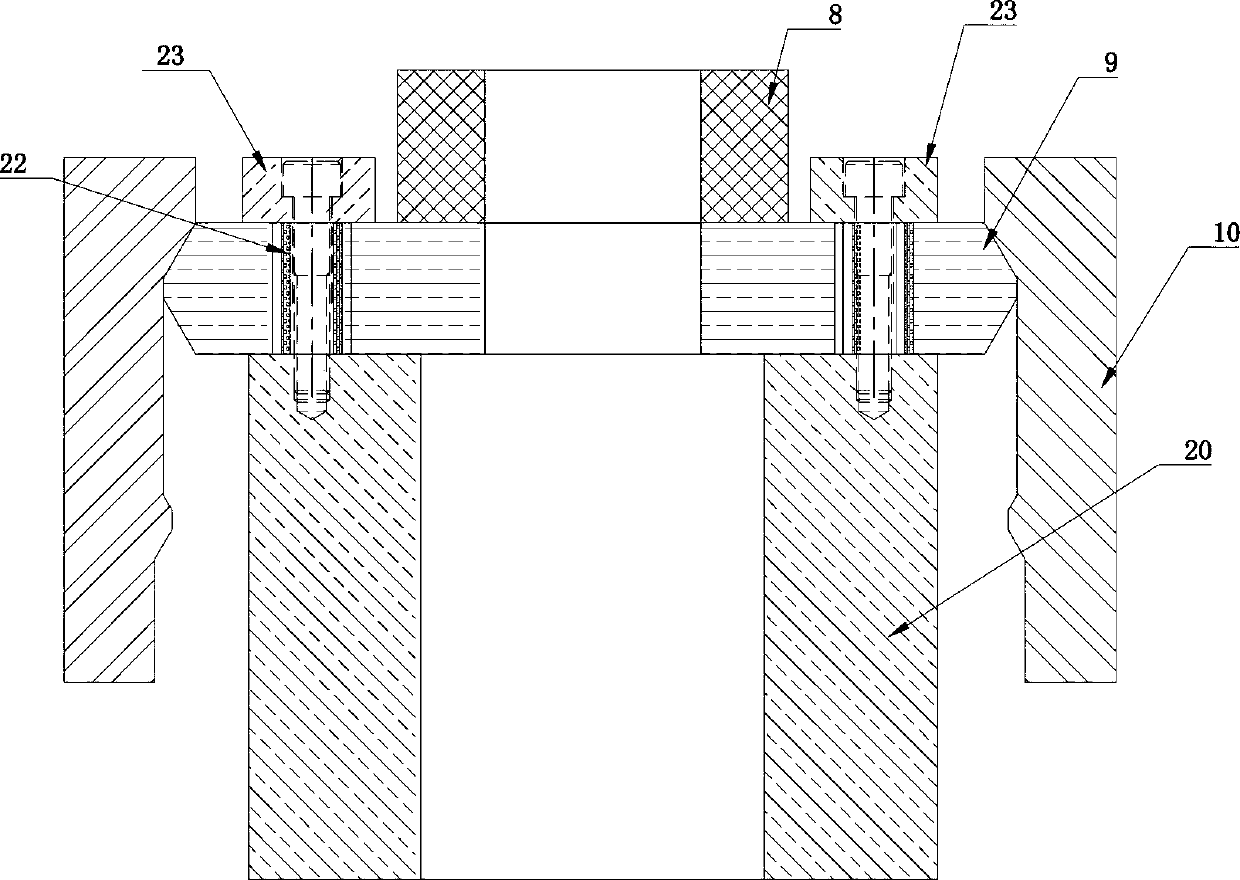

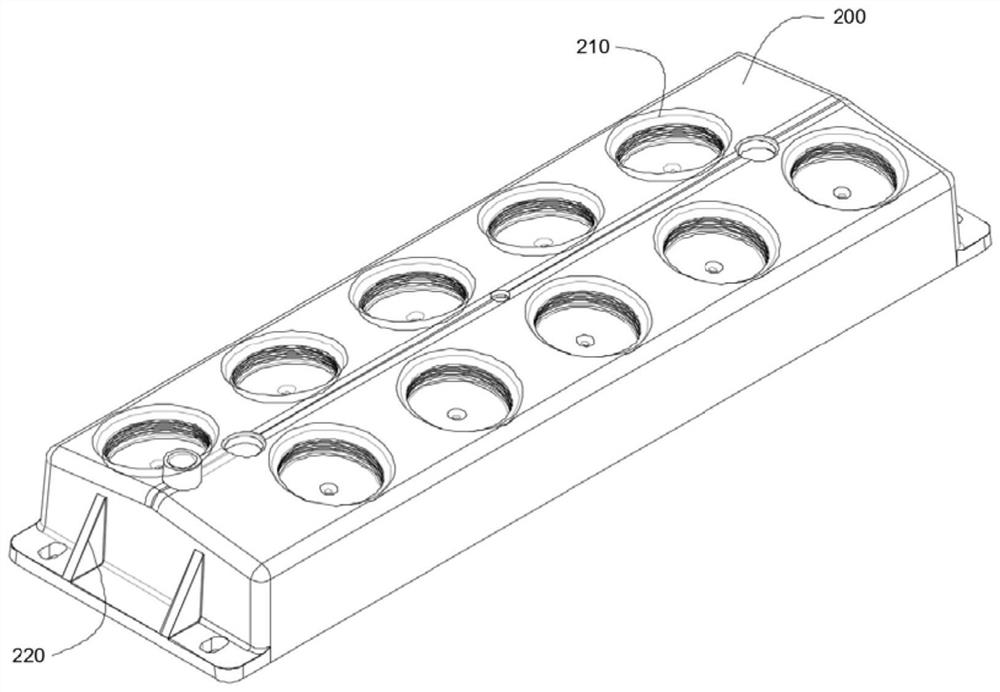

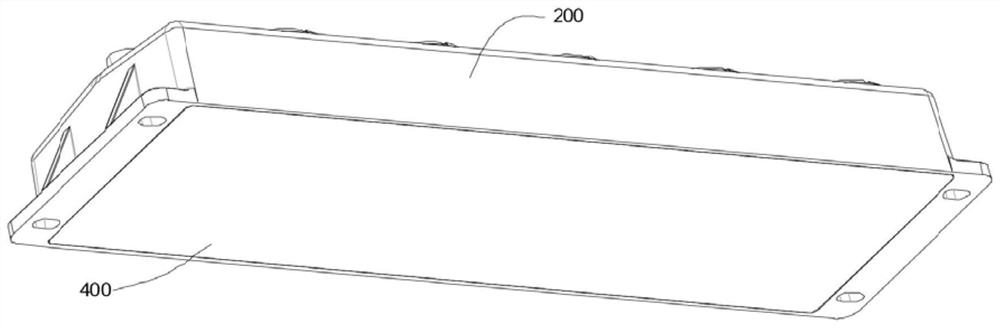

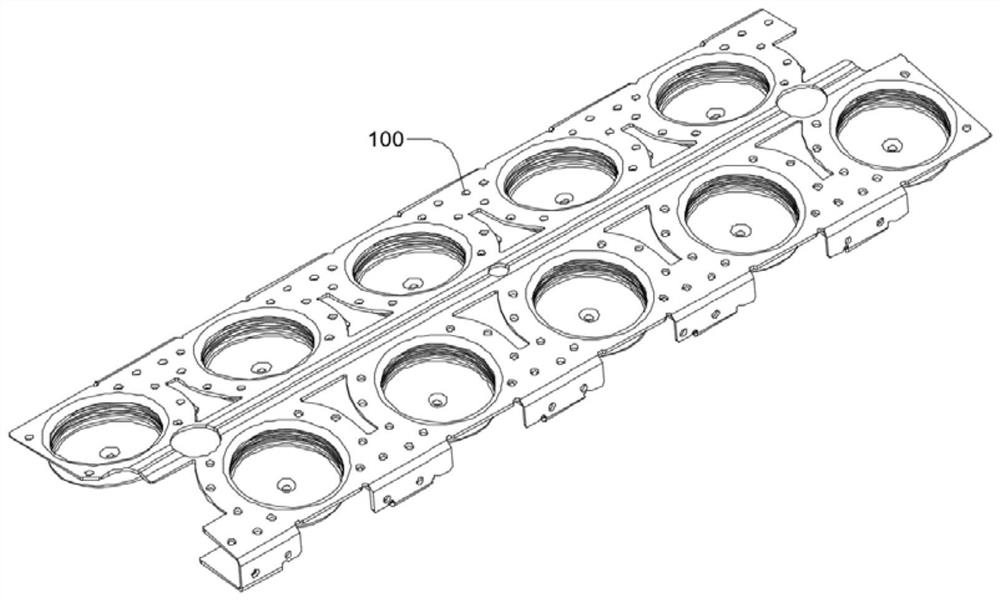

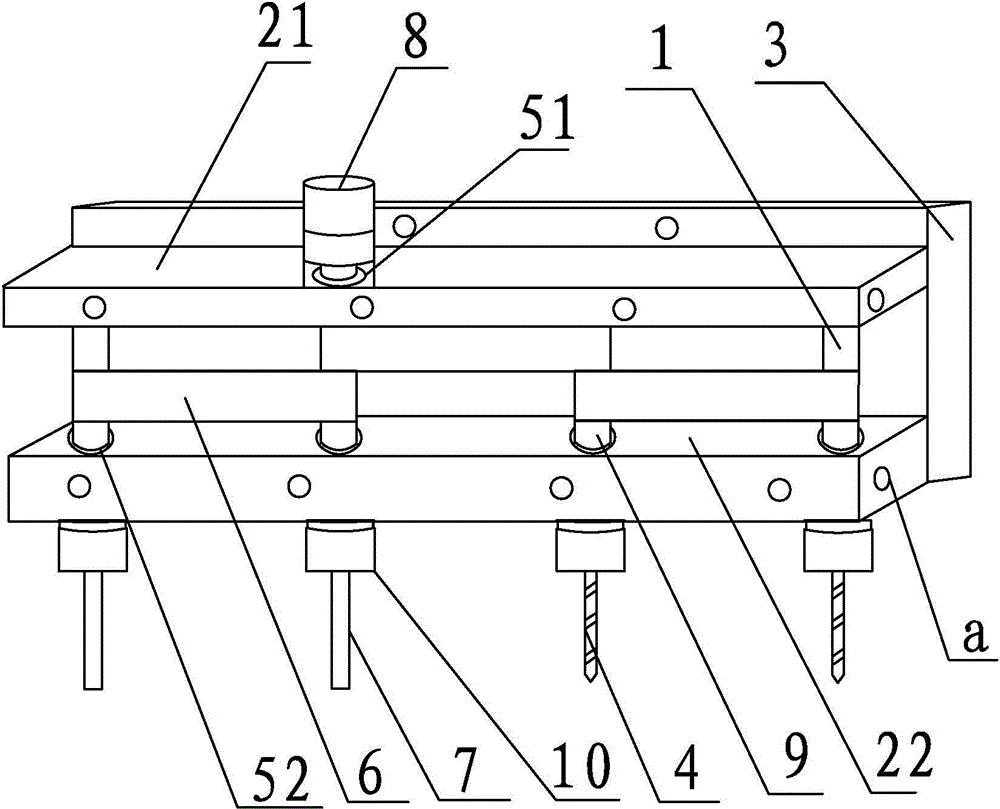

Battery shell automatic notching die

InactiveCN103341550ANo tiltingTranslation stabilizationShaping toolsStructural engineeringMechanical engineering

A battery shell automatic notching die comprises an upper die and a lower die. The upper die comprises an upper die plate, a notching male die fixing plate is fixedly connected with the lower face of the upper die plate, the lower face of the notching female die fixing plate is fixedly connected with a notching male die and locating rods, the locating rods are located around the notching male die, and locating cores are movably connected with the lower face of the notching male die in a front-and-back and left-and-right mode. The lower die comprises a lower die plate, a lower die seat is fixedly connected with the upper face of the lower die plate, female die cover plates are fixedly connected with the upper face of the lower die seat, and penetrating holes are formed in the middle of the female die cover plates. The middle part of the lower die seat and the middle part of the lower die plate are movably connected with a lower locating seat together in an up-and-down mode, guiding sliding blocks are arranged on the upper face of the lower locating seat, upper locating rings are arranged on the upper faces of the guiding sliding blocks, the upper locating rings, the guiding sliding blocks and the lower locating seat are fixedly connected through equal-altitude sleeves, guiding sliding rails are arranged between the lower die seat and the lower locating seat, the guiding sliding rails are fixedly installed inside the lower die seat and the upper face of the lower die plate, the guiding sliding blocks correspond to the guiding sliding rails, and the guiding sliding blocks are connected with the guiding sliding rails in an up-and-down sliding mode.

Owner:倪志华

Silicon rod sticking improving process

InactiveCN104195643AShort curing timeImprove work productivityAfter-treatment detailsFine working devicesSilver pasteAir bubble

The invention relates to a silicon rod sticking improving process belonging to the technical field of silicon rod cutting. The silicon rod sticking improving process comprises the steps of uniformly smearing glue (epoxy glue) on the surface of a crystal rod, and then, pressing ground glass on the crystal rod to ensure that whether air bubbles are generated on the glass can be directly seen after the glass is stuck; if no air bubbles are generated, continuing to stick the glass to a workpiece plate; and if air bubbles are generated, directly separating in water with the high temperature of 100 DEG C. By using the silicon rod sticking improving process, the time consumed by using the traditional sticking process is shortened, the quality problem of edge breakage caused when the silicon rod is processed is reduced, and the risks of overhigh single battery piece cost caused by silver paste leakage from an edge breakage position when silicon wafers are put into production of battery pieces and relatively short service life of silk screen printing equipment are also reduced.

Owner:无锡尚品太阳能电力科技有限公司

Synchronous transfer device for hosiery machine

The invention discloses a synchronous transfer device for a hosiery machine. The structure comprises: an emergency stop button, a display screen, a transmission seat, a control panel, a control button, a transmission shaft box, a textile main body, a workbench, a turntable, and a device casing , motor cabin, support frame, baffle plate, transmission track, transmission casing, transmission shaft, transmission gear, the beneficial effect of the present invention: after using the upper transmission seat on the hosiery machine, the staff can be allowed to sit on both sides, The socks can be inspected along the way, so that the staff can detect the thread ends of the socks and trim them when the socks are driven, without picking up and sending out the socks for inspection, which can improve the efficiency of work and production.

Owner:李歆怡

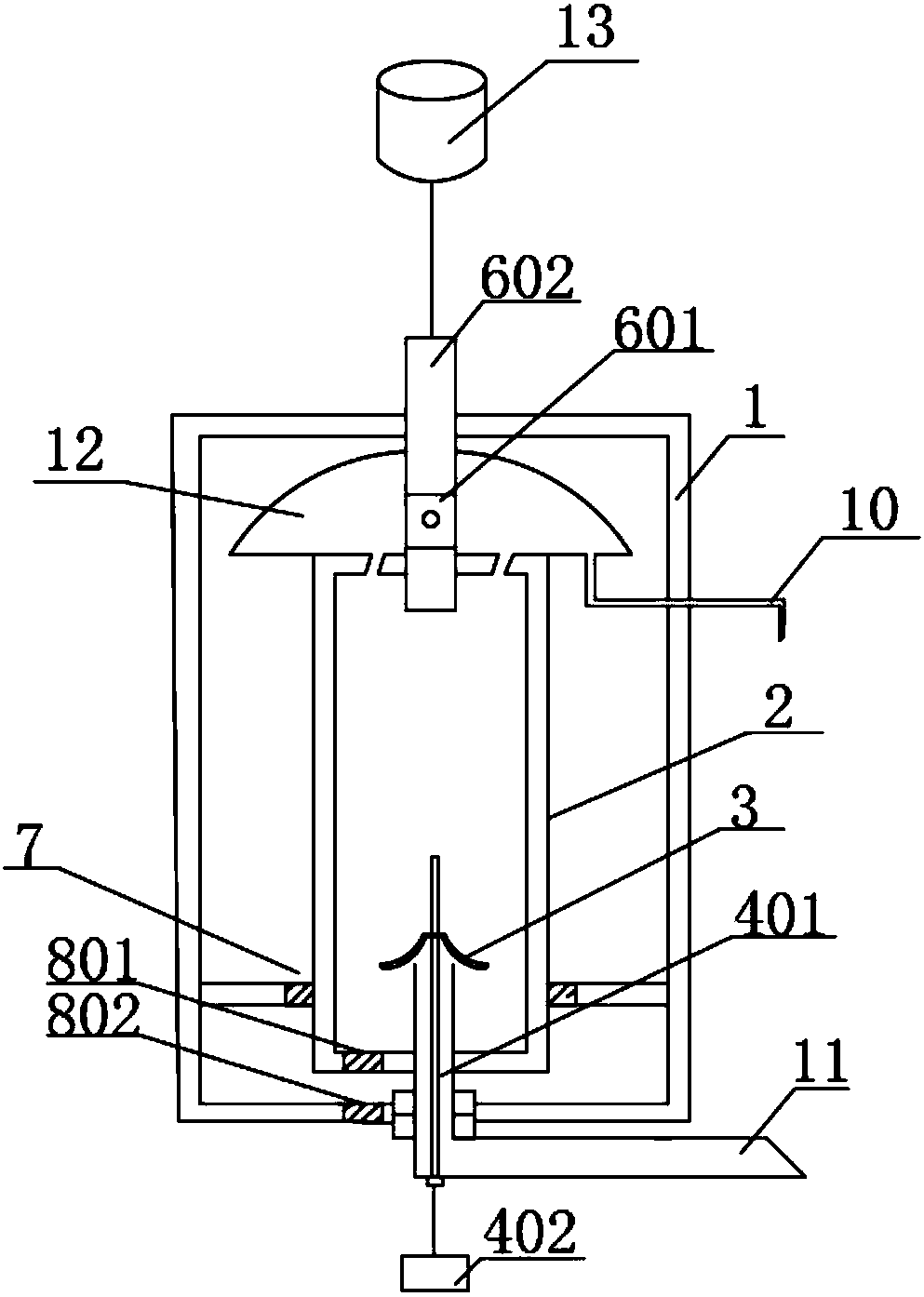

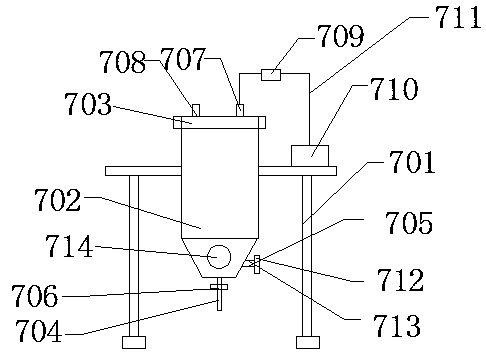

Tubular type centrifuge

The invention discloses a tubular type centrifuge. The tubular type centrifuge comprises a barrel, a rotary drum, a liquid collecting plate, a feeding tube and a liquid draining tube, wherein the rotary drum is coaxially mounted in the barrel; the upper end of the rotary drum is connected with a driving shaft through a coupler; the bottom of the rotary drum communicates with the feeding tube; an annular slide way is arranged between a side of the rotary drum and the barrel, so that the rotary drum rotates stably; through holes are formed in the upper end of the rotary drum; the liquid collecting plate is coaxially mounted at the upper end of the rotary drum; during high-speed running of the rotary drum, separated liquid flows to the liquid collecting plate via the through holes; the liquiddraining tube is arranged on the bottom of the liquid collecting plate; and an ultrasonic waveguide rod is coaxially arranged on a vertical portion of the feeding tube, and is electrically connectedwith a peripheral ultrasonic generation source. According to the tubular type centrifuge, the rotary drum which does not need to be taken out can be automatically and thoroughly cleaned.

Owner:武汉正天成生物科技有限公司

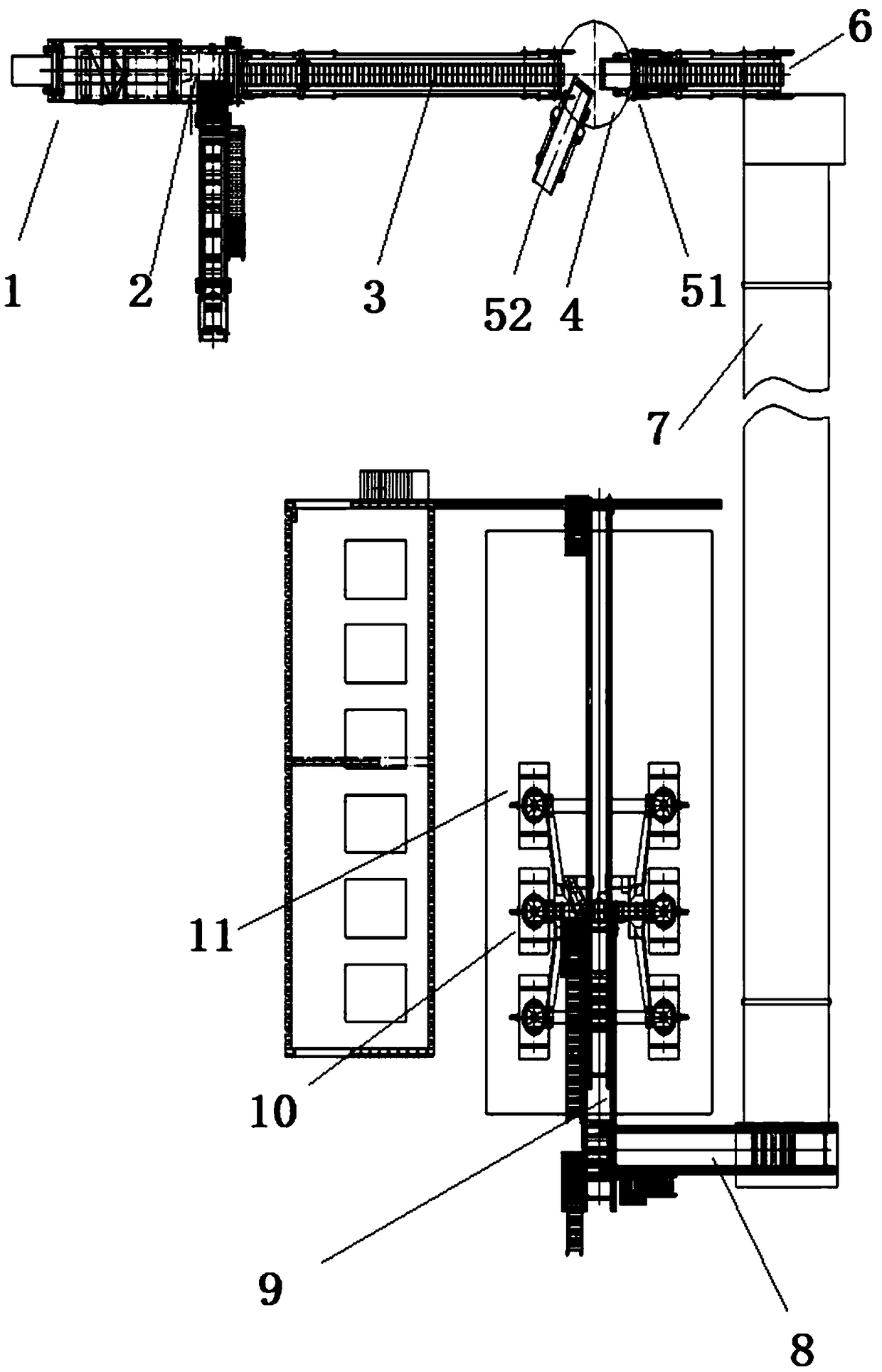

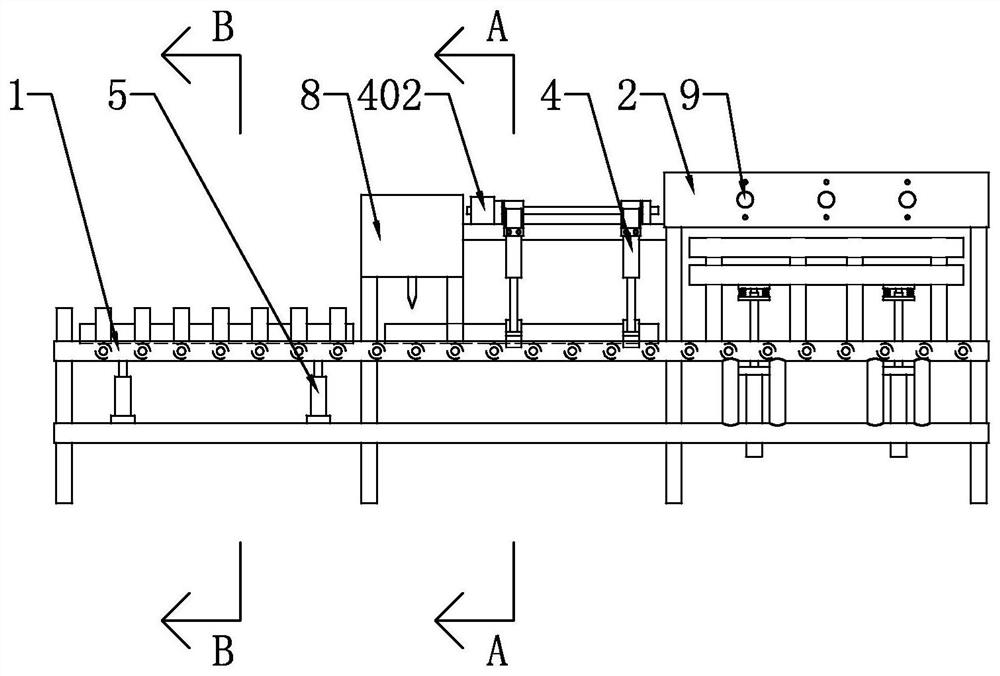

Automatic bundled pipe feeding device for circular sawing machine and feeding method thereof

PendingCN113182605AReduce labor intensityImprove work productivityMetal sawing devicesCircular sawIndustrial engineering

The invention relates to an automatic bundled pipe feeding device for a circular sawing machine and a feeding method thereof. The automatic bundled pipe feeding device comprises a rack with a sawing roller way, wherein a lifting device used for lifting a pipe, a material distributing device installed on the rack and used for feeding the pipe into a saw cutting roller way, a saw cutting clamping device installed on the rack and used for clamping and lifting the pipe on the saw cutting roller way to be cut by cutting equipment and a discharging device installed on the rack and used for discharging the pipe cut by the cutting equipment out of the saw cutting roller way are installed on the rack. A worker lifts the bundled pipes to the lifting device through a crane, the lifting device is started, the bundled pipes are lifted to the working position of the material distributing device, the material distributing device is started, the bundled pipes are separated into independent pipes one by one, the pipes are sequentially fed into the saw cutting roller way, the saw cutting clamping device clamps the pipes and moves the pipes to the cutting equipment for cutting, then the pipes sawn by the cutting equipment are put back to the saw cutting roller way, and the discharging device is started to discharge the pipes out of the saw cutting roller way.

Owner:卢成奔

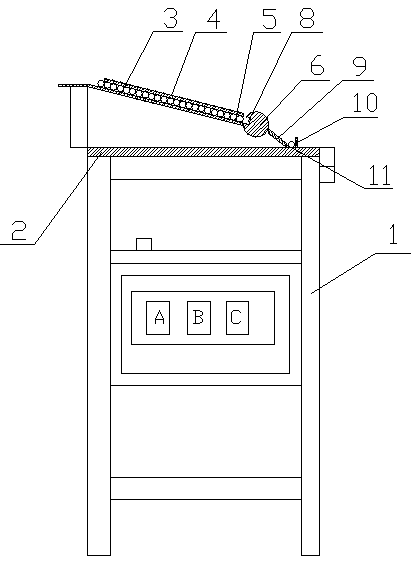

Automatic feeder for core-free grinding machine

InactiveCN103203668AArranged in orderEasy to useRevolution surface grinding machinesAgricultural engineeringEngineering

The invention discloses an automatic feeder for a coreless grinding machine and relates to the field of machinery. The automatic feeder comprises a machine frame, wherein an operation platform is fixedly connected with the upper end of the machine frame; an inclined material plate is arranged on the operation platform; a material-pressing inclined plate parallel to the material plate is arranged above the material plate; a clearance is formed between the material-pressing inclined plate and the material plate; a rotary pulling rod is arranged on the right lower side of the material plate; a material-pulling cylinder is fixedly connected with one end of the rotary pulling rod; an axial groove is formed in the rotary pulling rod; an inclined material-guiding plate is fixedly connected to the operation platform and is arranged on the right lower side of the rotary pulling rod; a vertically-arranged material baffle plate is fixedly arranged on the operation platform and is arranged on the right side of the material-guiding plate; a clearance is formed between the material-guiding plate and the material baffle plate; a material-pushing cylinder is arranged on one side of the operation platform; and the free end of the material-pushing cylinder is correspondingly arranged in the clearance between the material-guiding plate and the material baffle plate. The automatic feeder for the coreless grinding machine is simple in structure, convenient to use and high in production efficiency. Accidental injury caused by a human operation error can be avoided.

Owner:YIZHENG RUNYANG MACHINERY

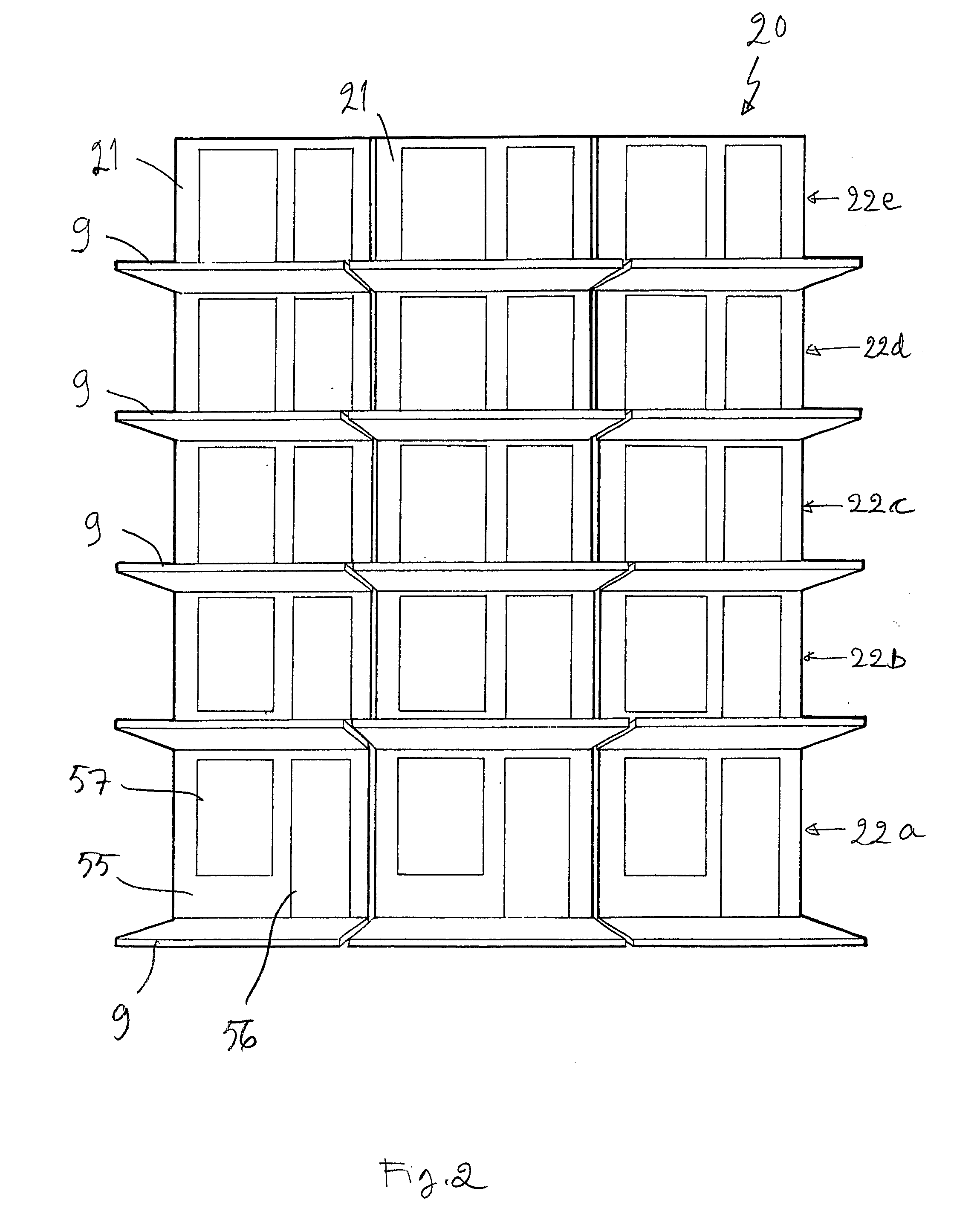

Room Arrangement, Ship, Building and Method for Constructing a Room Arrangement

Owner:STX FINLAND OY +1

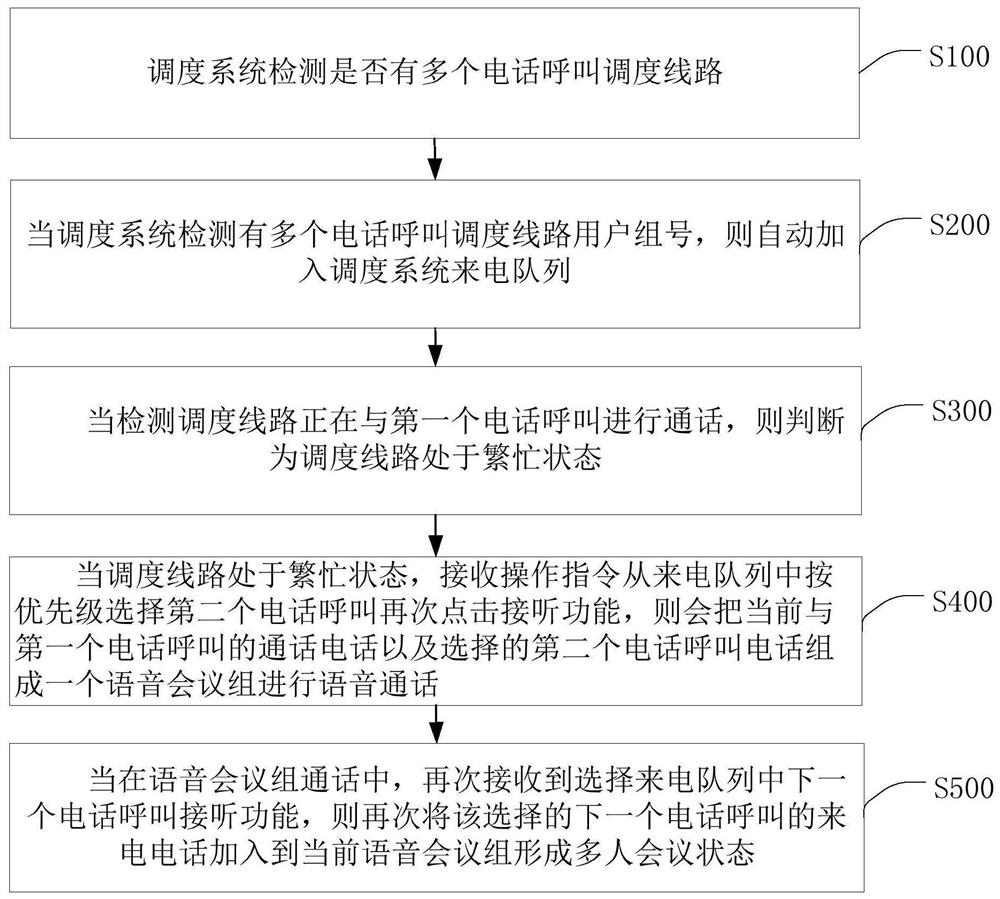

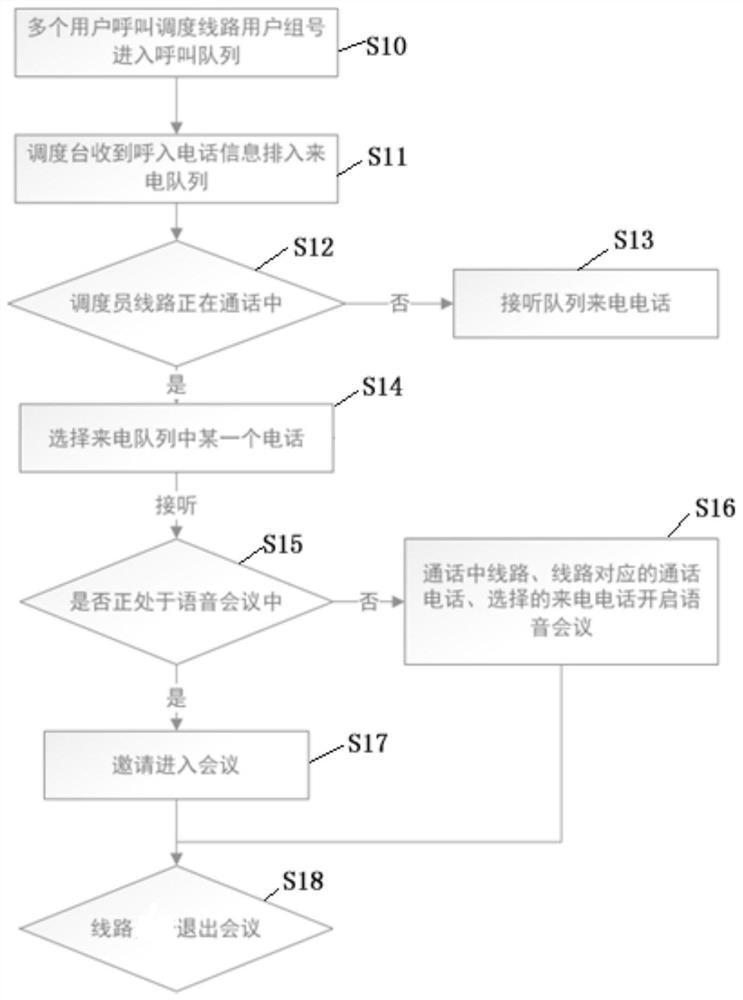

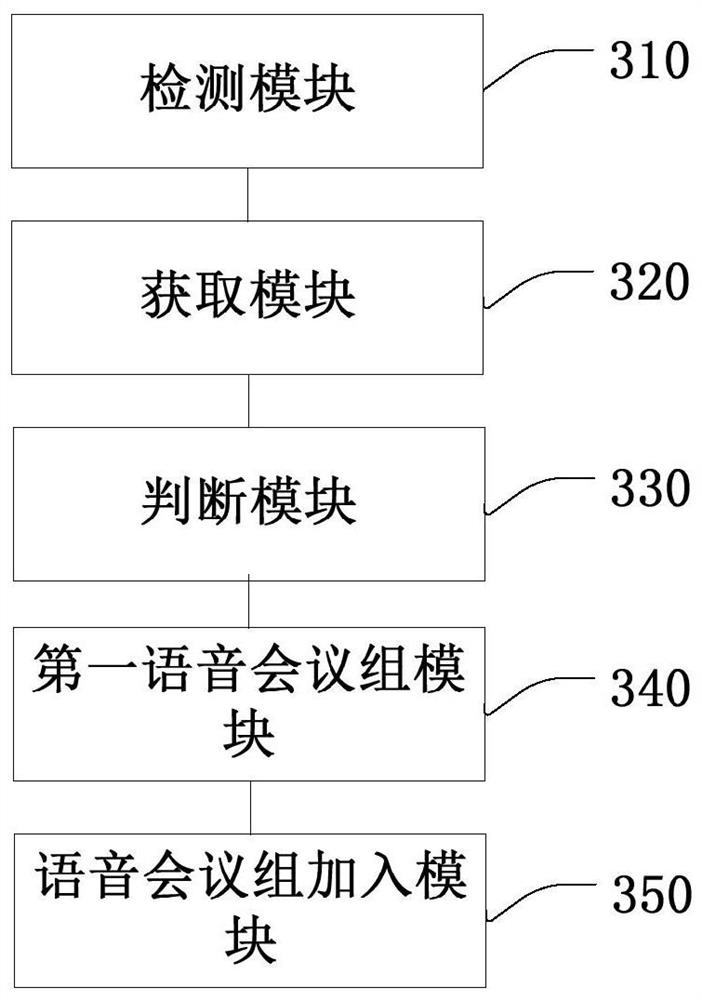

Incoming call queue call answering processing method and device, terminal and medium

PendingCN113596269AReduce waiting timeImprove work productivityAutomatic exchangesReal-time computingUser group

The invention discloses an incoming call queue call answering processing method and device, a terminal and a medium. The method comprises the following steps: calling a scheduling line user group number by a plurality of telephone users to enter a scheduling system incoming call queue; when the scheduling line is in a busy state, receiving an operation instruction, selecting a second telephone call from the incoming call queue according to the priority, clicking the answering function again, and forming a voice conference group by a call call of the current call with the first telephone call and the selected call of the second telephone call for voice call; and adding the incoming call of the selected next telephone call into the current voice conference group to form a multi-person conference state when the next telephone call answering function in the selected incoming call queue is received again in the voice conference group call. The invention provides a scheme for quickly answering the call in the incoming call queue in the busy line state, so that the call waiting time of the user is reduced, and the working production efficiency is improved.

Owner:西安震有信通科技有限公司

Adhesive pouring device of LED (light emitting diode) lamp

InactiveCN108311349AAvoid wastingQuantitativeLiquid surface applicatorsCoatingsDrive shaftEngineering

The invention relates to an adhesive pouring device of an LED (light emitting diode) lamp. The adhesive pouring device comprises a machine frame, wherein a transmission shaft with a chain wheel is arranged at both ends of side frames of the machine frame; two parallel chains are arranged on the chain wheel; a transmission gear is arranged at the transmission shaft at one end and is connected witha power mechanism; the part, starting from one end of the transmission gear, of the machine frame is sequentially provided with a preheating area, an adhesive pouring area and a curing area; lamp positioning devices are uniformly arranged on each chain; the adhesive pouring area comprises a support base and an adhesive pouring tank, and a metering valve and a liquid level sensor are arranged on the adhesive pouring tank. The adhesive pouring device has the advantages that the structure is simple, the continuity is strong, the automation degree is high, and the production efficiency is effectively improved.

Owner:成都众鑫聚合科技有限公司

Preparation method of high-performance dry-mixed mortar

The invention provides a preparation method of high-performance dry-mixed mortar, which comprises the following steps: providing machine-made sand, and drying; conveying the dried machine-made sand toa probability sieve using a belt conveyor and an elevator, sieving the machine-made sand into coarse, medium and fine sand with different specifications, and storing the sand; selecting sand of different specifications according to different requirements for manufacturing mortar; by weight, feeding 100 to 130 parts of PO42.5 cement, 70-90 parts of stone powder, 800-820 parts of sand and 0.4-0.6 part of an admixture into a stirrer to be mixed and stirred for longer than 3 minutes; and after stirring, conveying obtained mortar into a special mortar tank on a construction site through a transport vehicle to be continuously stirred for later use. The beneficial effects are that: the mortar can be used while being mixed, the quality is reliable, the construction performance is improved, the characteristics of water retention, modification and consistency of the admixture are fully utilized, the workability and operability of mortar are improved, and the working and production efficiency ofconstructors is improved.

Owner:怀化明达建材有限公司

Spool with wire clamp

InactiveCN103318714ANot easy to fall offImprove work productivityStructural engineeringMechanical engineering

The invention discloses a spool with a wire clamp. The spool is characterized in that the spool is an I-shaped spool, the wire clamp is disposed on the spool and comprises an outer cylinder and an inner post, one end of the inner post is fixedly connected to the inner side of one end of the spool, the outer cylinder is in a cylinder shape having an opening at one end, the inner post is also cylindrical, the diameter of an inner cavity of the outer cylinder is larger than that of the inner post, and the outer cylinder is sleeved on the inner post. The spool has the advantages that after a wire is tightly wound, the wire end is wound on the inner post before the inner post is sleeved with the outer cylinder; accordingly, the wire end is tightly clamped and rarely drops, and work efficiency and production efficiency are improved.

Owner:WUXI TONGXIN PLASTIC PROD

Processing device for stamping part of upper cover of high-precision notebook computer

PendingCN108405263ARealize fully automatic operationPrevents Dispensing Efficiency LossLiquid surface applicatorsCoatingsAdhesiveEngineering

The invention discloses a processing device for a stamping part of an upper cover of a high-precision notebook computer. The processing device comprises a three-axis machine frame and an adhesive dispensing mechanism, wherein the adhesive dispensing mechanism is movably arranged on the three-axis machine frame through an installation plate, and further comprises a strip plate, an upper installation plate, a lower installation plate, an adhesive bucket and an adhesive dispensing head; a push block is arranged between a fixed block and the upper installation plate, and is movably arranged on a guide column; a lock block is fixedly connected with the side surface of the fixed block through a connecting plate, and is provided with an opening part; a spiral column penetrates through both sidesof the opening part, and is locked and fixed by a wrench part; the lower ends of a first auxiliary adhesive bucket and a second auxiliary adhesive bucket are provided with a connector, and the connector is respectively communicated with the first auxiliary adhesive bucket and the second auxiliary adhesive bucket; the lower part of the connector is connected with a mixing pipe; the mixing pipe is communicated and connected with the adhesive dispensing head. The processing device has the advantages that the adhesive pushing pressure is maintained within the stable pressure range, so as to avoidthe connector falling off and the like due to overlarge pressure; the continuity of adhesive dispensing is maintained, and the working efficiency is improved.

Owner:苏州丰川电子科技有限公司

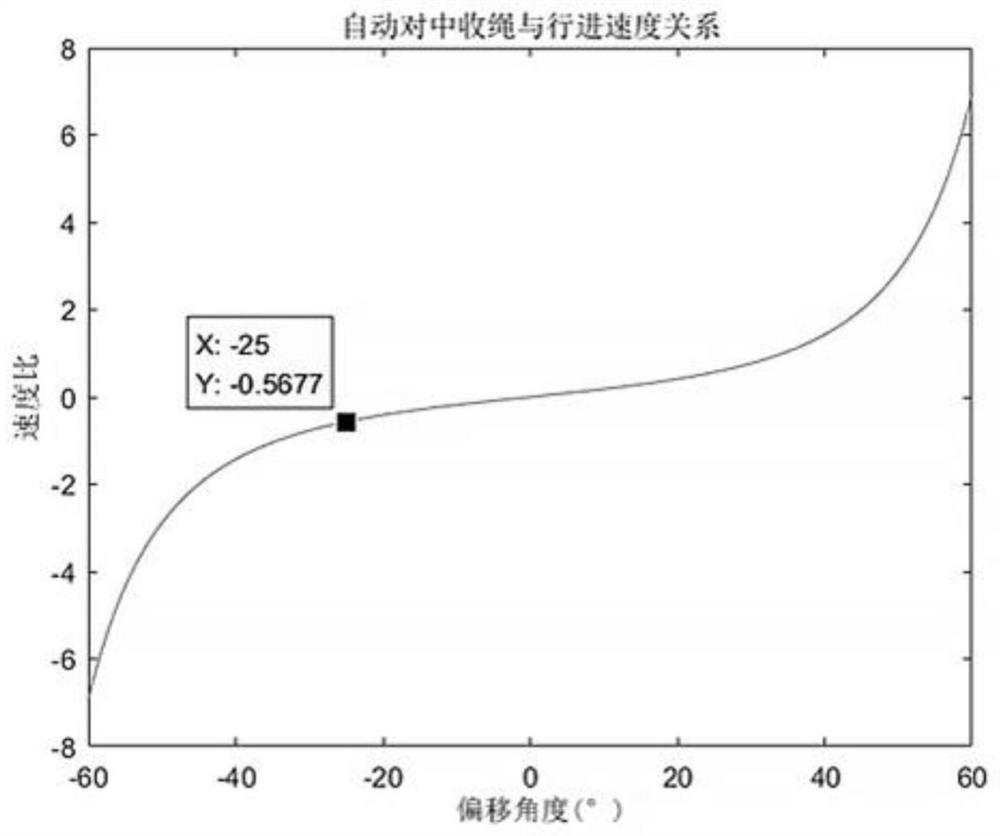

Under-actuated hoisting equipment control system and method thereof

ActiveCN113896111ARealize anti-skewing and inclined hangingImprove stabilityDesign optimisation/simulationComplex mathematical operationsControl systemControl engineering

The invention discloses an under-actuated hoisting equipment control system and a method thereof. The system comprises a hoisting scene information obtaining module, a swing angle obtaining module, a height obtaining module and a control module, and the hoisting scene information obtaining module, the swing angle obtaining module and the height obtaining module are all connected with the control module; and the control module controls a hoisting mechanism of hoisting equipment to act. When the system and the method are used, the three-prevention functions of inclined pulling and hoisting prevention, swinging prevention and collision prevention of the gantry crane hoisting equipment in the hoisting process can be achieved, so that the stability, the safety, the working efficiency and the controllability of production and transportation operation are improved, and the system and the method have the characteristics of being high in stability, safety, working efficiency and controllability.

Owner:ROCKET FORCE UNIV OF ENG

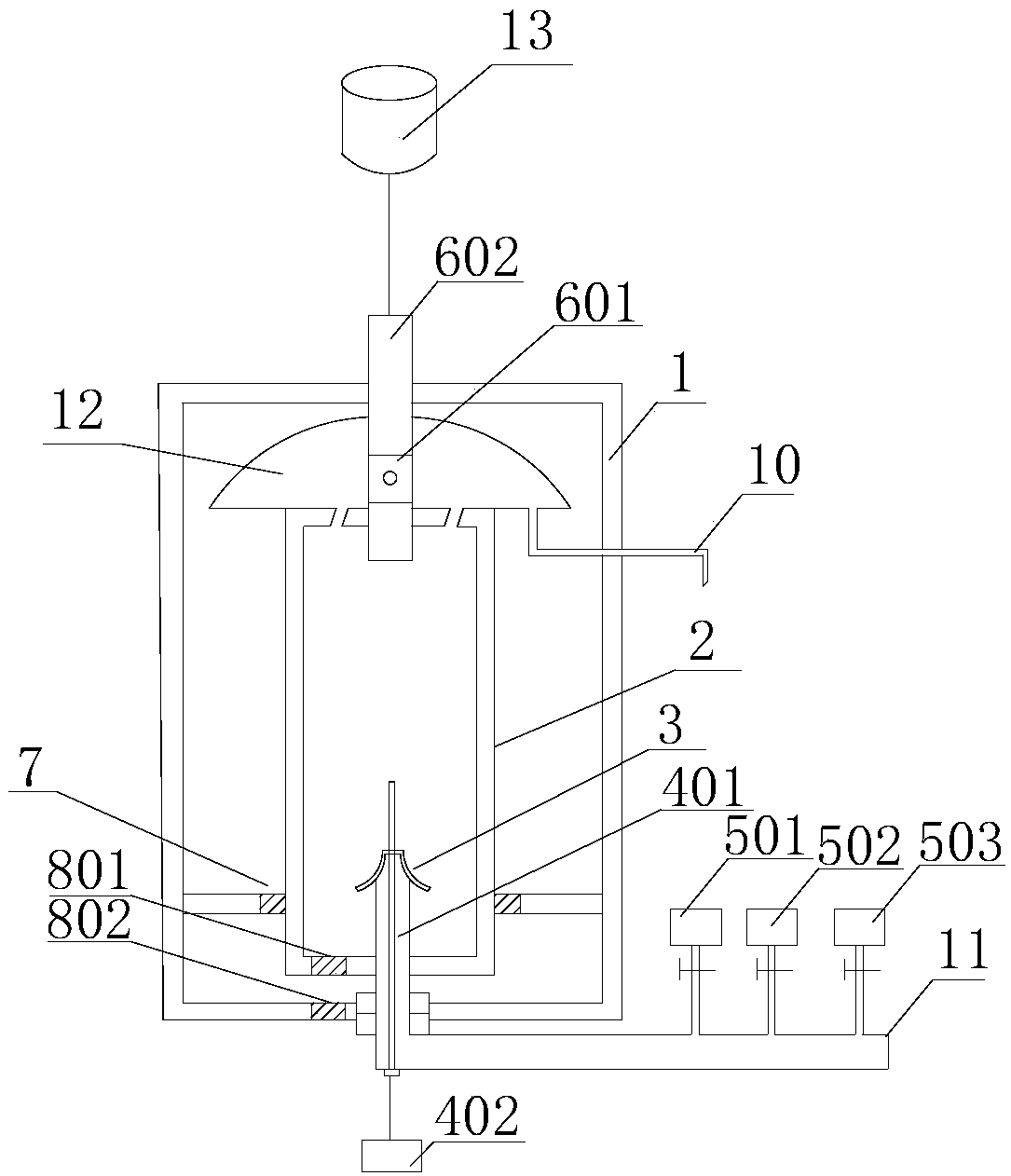

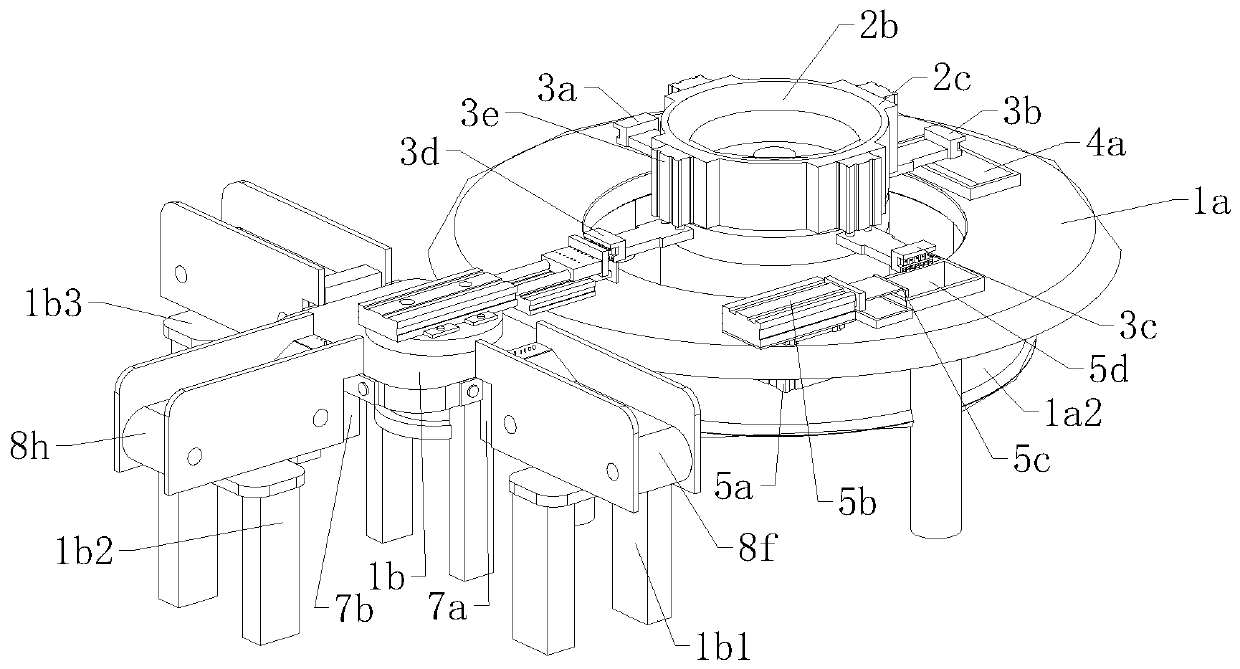

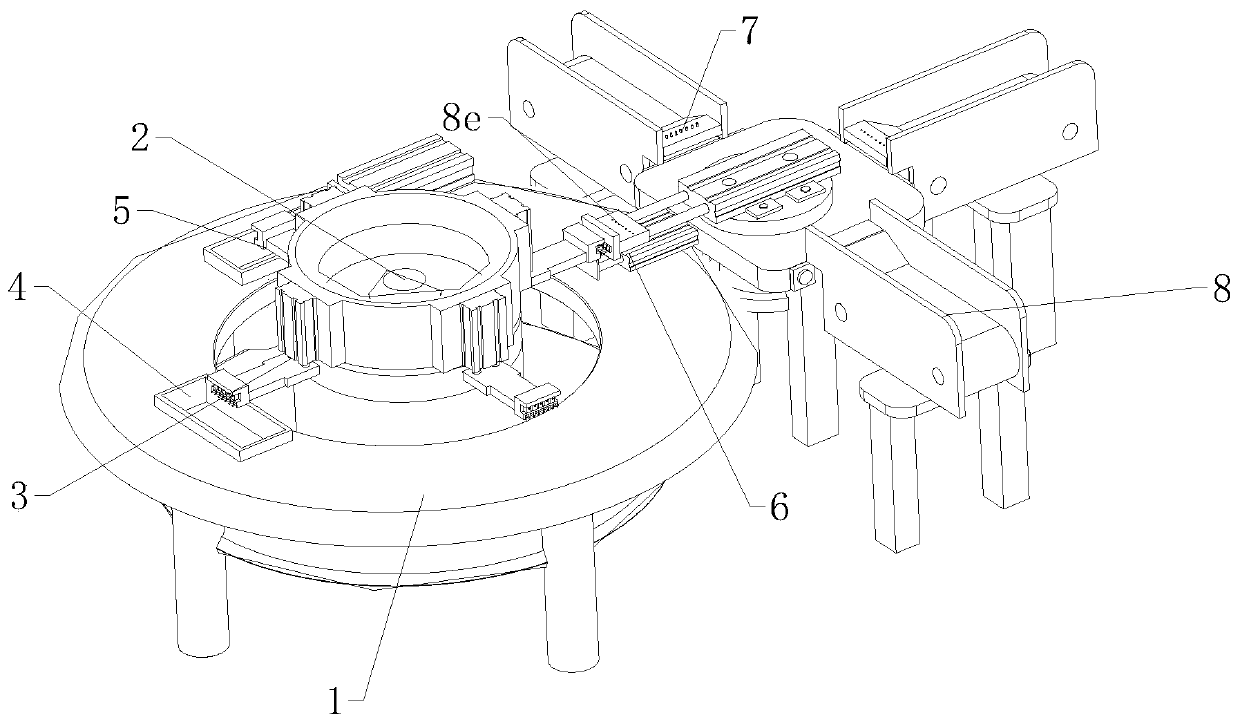

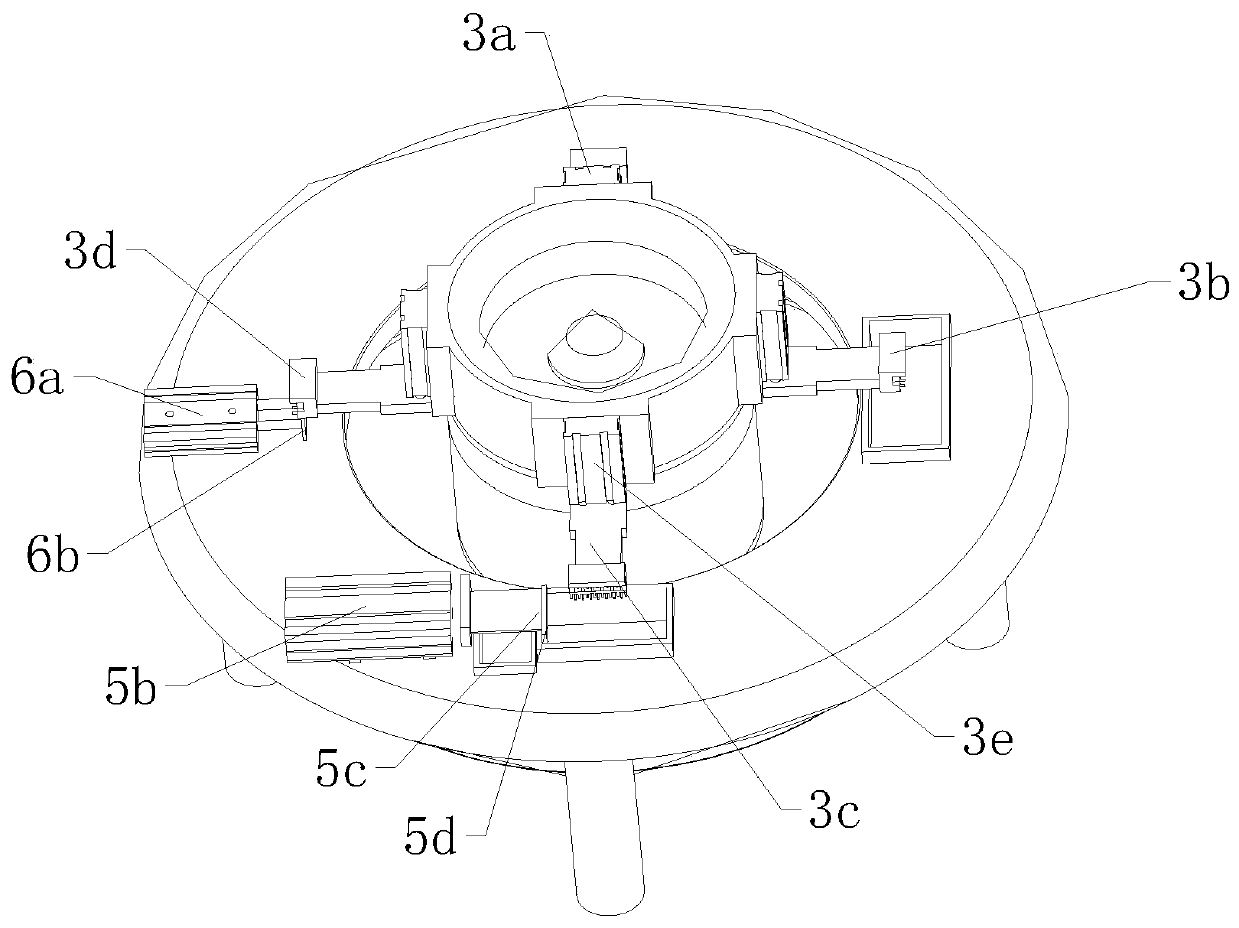

Tinning and detecting device for relay terminal

ActiveCN110137034AEasy to detectSimple working processTesting dielectric strengthRelaysTinningEngineering

The invention relates to the field of relay terminal production equipment and particularly relates to a tinning and detecting device for a relay terminal. The device comprises a supporting mechanism,a rotating mechanism, a fixed mechanism, a welding aiding mechanism, a tinning mechanism, a discharging mechanism, a detecting mechanism and a sorting mechanism. The supporting mechanism is verticallyarranged, the tinning mechanism is fixedly connected to the supporting mechanism, the discharging mechanism is fixedly connected to the supporting mechanism, and the detecting mechanism is fixedly connected to a side wall of the supporting mechanism. The tinning mechanism comprises a first cylinder, a second cylinder, a tin scraping block and a tin liquid pool. The detecting mechanism comprises athird cylinder, a fourth cylinder, a first detecting head and a second detecting head. According to the tinning and detecting device for the relay terminal, the automatic tinning of the relay terminal is carried out, at the same time, the relay terminal is automatically taken down, the relay terminal is detected, relay terminals of different problems are classified, the workflow is simplified, the work and production efficiency are improved, the relay terminal is convenient to tin and detect, the dependence on persons is reduced, and the automatic integrated production is achieved.

Owner:诸暨市科讯电子科技有限公司

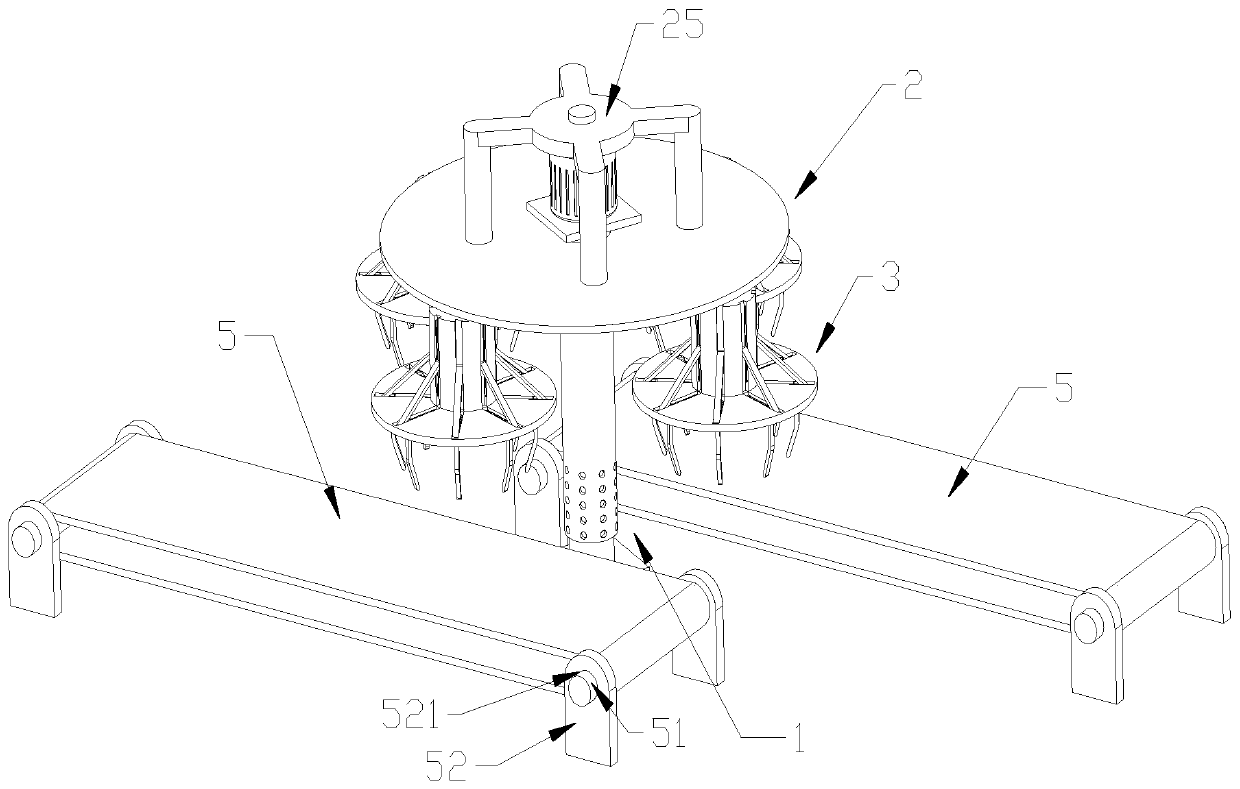

Rotary cargo converting mechanism used for rotary packaging assembly line

The invention discloses a rotary cargo converting mechanism used for a rotary packaging assembly line. The mechanism comprises a lifting column, a rotary disc is arranged on the upper portion of the lifting column, mechanical claw discs which are distributed in an arrayed mode in the axial direction are arranged under the rotary disc, a motor base is arranged on the rotary disc, a servo motor is arranged on the motor base, and a driving shaft is arranged on the servo motor. The rotary disc comprises a rotary disc body, a first bearing hole is formed in the center of the rotary disc body, firstfixing columns which are arranged in an arrayed mode in the axial direction are arranged under the rotary disc body, and fixing plates which are arranged in an arrayed mode in the axial direction arefurther arranged at the lower end of the rotary disc body. Third supporting columns penetrating through the rotary disc body are arranged on the fixing plates correspondingly, extending rods are arranged on the third supporting columns correspondingly, and a positioning plate is arranged in the center of a space among the extending rods jointly. A positioning hole is formed in the center of the positioning plate, the driving shaft is inserted into the positioning hole, and the mechanical claw discs are arranged on the first fixing columns which are distributed under the rotary disc body in the arrayed mode in the axial direction correspondingly. The rotary cargo converting mechanism is large in mechanical grapping range and wide in application cargo range, cargo grabbing and cargo placingare performed at the same time, and the working production efficiency can be improved easily.

Owner:安徽省华民食品有限公司

Atomizing structure and atomizer

PendingCN112474162AQuick assembly workImprove work productivityLiquid spraying apparatusEngineeringMechanical engineering

The invention provides an atomizing structure and an atomizer, and relates to the technical field atomizers. The atomizing structure comprises an integrated heat dissipation base for bearing an atomizing sheet and an integrated type shell, wherein the heat dissipation base is fixedly connected to the shell; a plurality of through holes for exposing the atomizing sheet are formed in the shell; a bottom plate for bearing a circuit board is arranged on the bottom of the shell; and the bottom plate is connected to the shell. The atomizer comprises the atomizing structure. The atomizing structure achieves the technical effect of high assembly and work efficiency.

Owner:DONGGUAN TENGTENG ELECTRONICS CO LTD

Multi-shaft synchronous torque transmission head

InactiveCN104889740AOvercoming transmission gapAchieve precisionOther manufacturing equipments/toolsTorque transmissionEngineering

The invention discloses a multi-shaft synchronous torque transmission head. The multi-shaft synchronous torque transmission head comprises a spindle head arranged at the Z axis of a drilling machine, the spindle head comprises four rotation main shafts arranged in the same horizontal line with equal intervals, two horizontal support frames arranged in parallel, a vertical fixing plate, and four transmission heads, the two support frames are both provided with penetrating holes penetrating through the four rotation main shafts, a bearing matched with the rotation main shaft is arranged in each penetrating hole, side edges of the two horizontal support frames are both fixedly arranged on the surface of the vertical fixing plate via screws, the four transmission heads are fixedly arranged at the bottom ends of the four rotation main shafts via hexagon nuts, a synchronous belt and a synchronous wheel matched with the synchronous belt are arranged on each two adjacent rotation main shafts positioned between the two horizontal support frames in a sleeved manner, the number of the synchronous wheels is six, and the synchronous wheels are all arranged on the rotation main shafts. According to the multi-shaft synchronous torque transmission head, the transmission is realized via the synchronous wheels and the synchronous belts, the transmission precision is reached, and noises are reduced.

Owner:SUZHOU DARUIKE PRECISION MACHINERY CO LTD

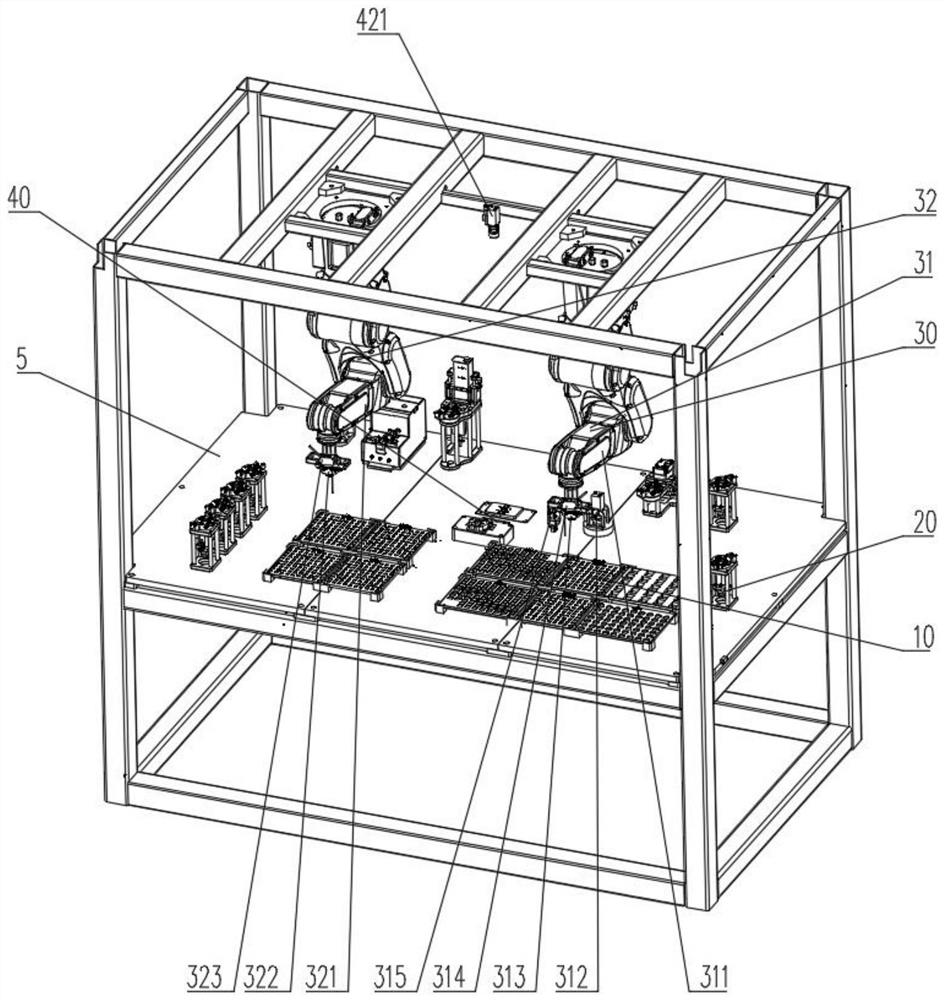

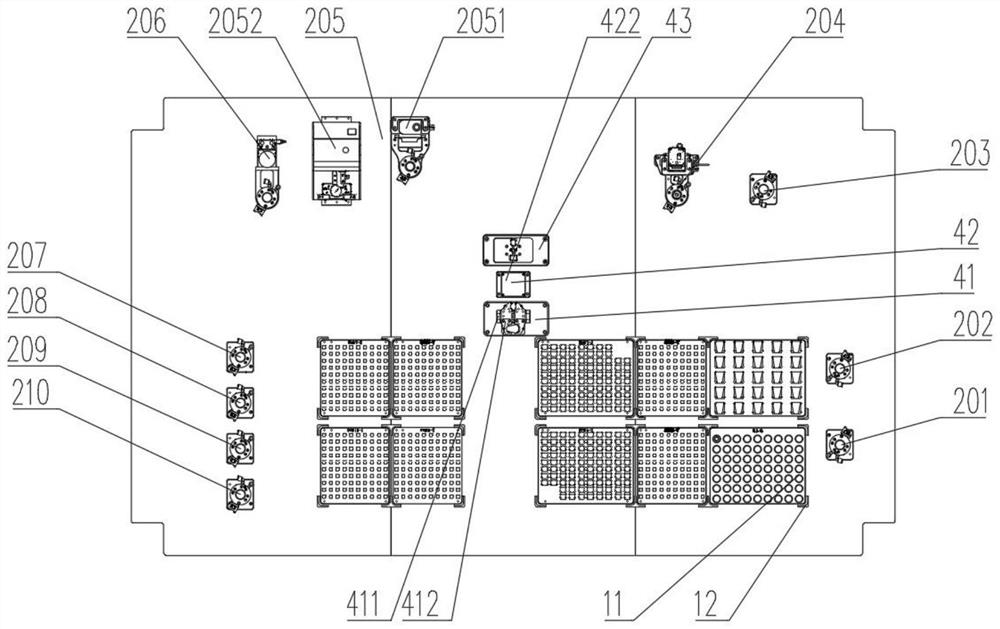

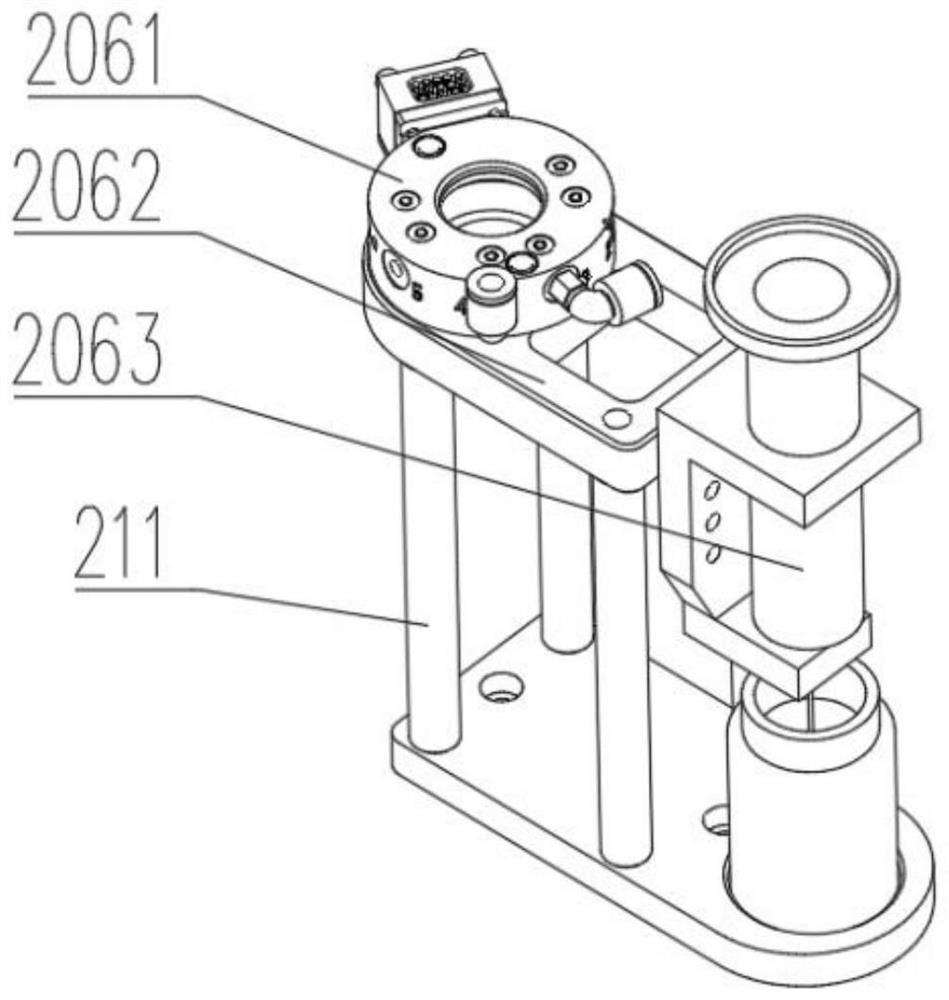

Automatic assembling equipment for optical assembly

ActiveCN114226172AQuality assuranceHigh degree of automationLiquid surface applicatorsCoatingsEngineeringClip device

The invention provides automatic assembly equipment for an optical assembly, and the equipment comprises a part feeding device which is used for placing different parts of the optical assembly; the tool slave disc material taking device comprises a plurality of assembly slave discs, and the assembly slave discs are used for adsorbing different parts or glue liquid storage devices respectively; the flexible assembly system comprises a plurality of assembly mechanical arms, and the assembly mechanical arms are used for being connected with the assembly slave discs and carrying, dispensing and assembling parts through the assembly slave discs or independently completing carrying and assembling of the parts; the positioning and clamping device is used for positioning and fixing the parts, so that the assembling mechanical arm completes dispensing and assembling of the parts on the positioning and clamping device; the part feeding device, the tool slave disc material taking device and the positioning and clamping device are all arranged on the assembling table, and the flexible assembling system is arranged above the assembling table. The equipment can realize automatic assembly of the optical assembly.

Owner:SHANGHAI RADIO EQUIP RES INST

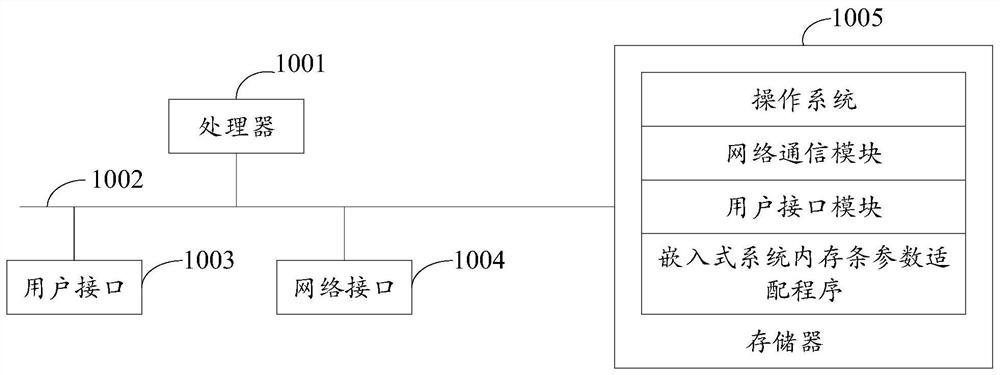

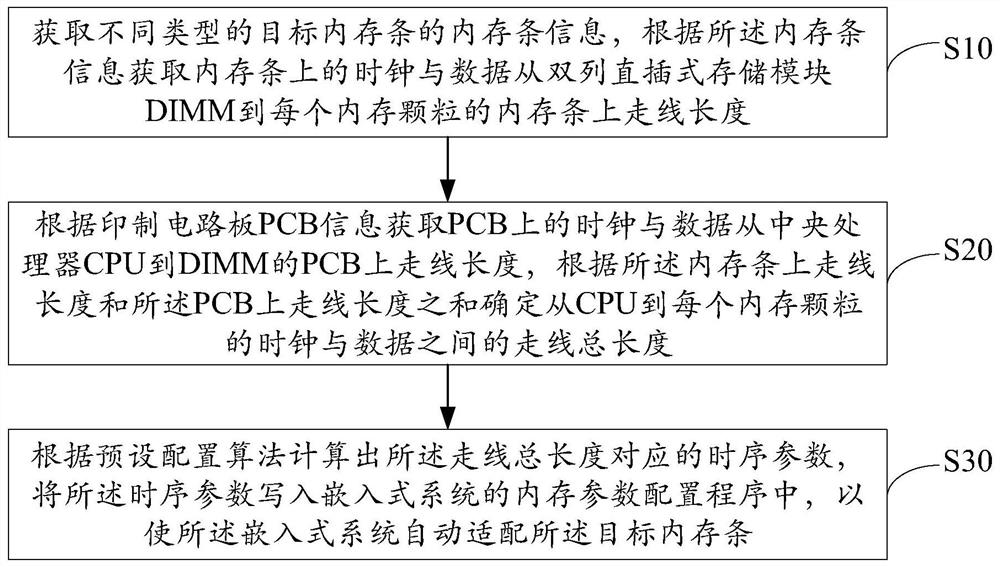

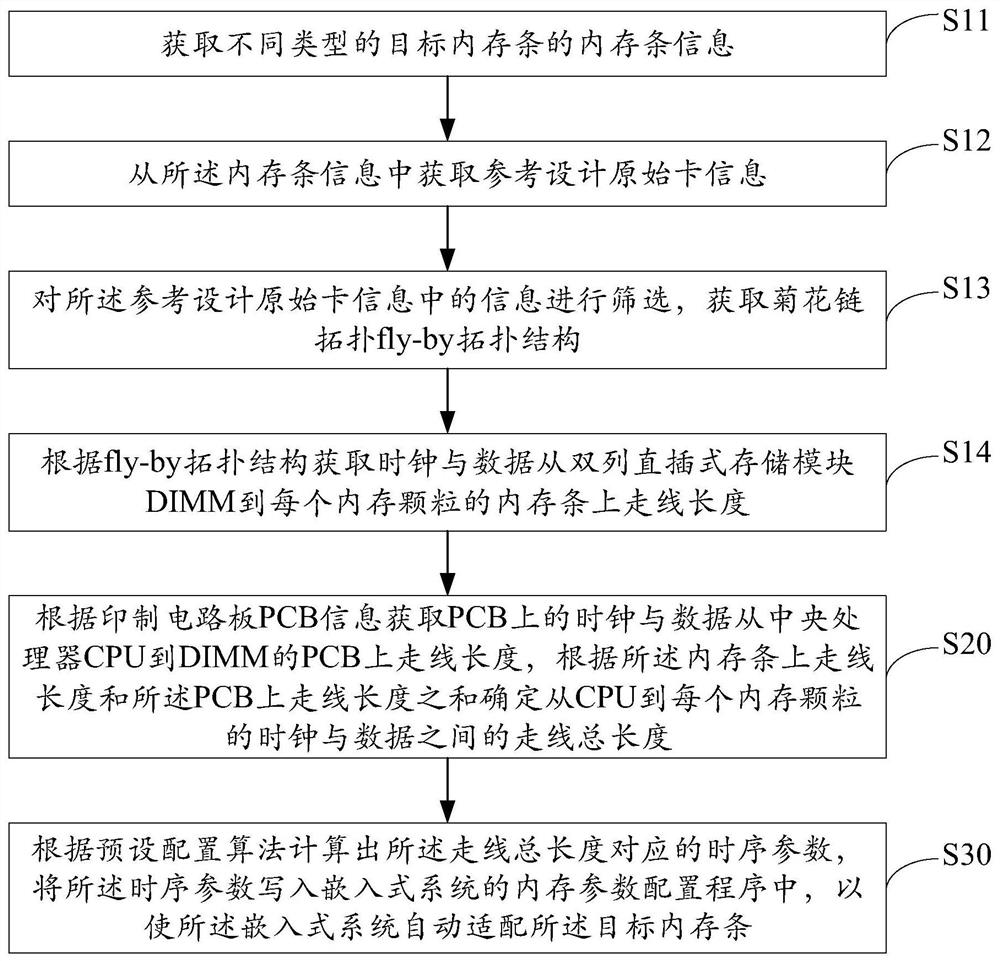

Memory bank parameter adaptation method and device for embedded system, equipment and storage medium

ActiveCN112052043AQuick fitImprove stabilityBootstrappingArchitecture with single central processing unitComputer hardwareDIMM

The invention discloses an memory bank parameter adaptation method and device for embedded system, equipment and a storage medium, and the method comprises the steps: obtaining memory bank informationof different types of target memory banks, and obtaining routing length of a clock and data on a memory bank from a DIMM to the memory bank of each memory particle according to the memory bank information; according to the PCB information, obtaining the PCB routing length of the clock and the data on the PCB from a CPU to the DIMM, wherein the sum of the routing length on the memory bank and therouting length on the PCB is the total routing length between the clock and the data from the CPU to each memory particle; calculating a time sequence parameter corresponding to the total wiring length according to a preset configuration algorithm, and enabling the embedded system to automatically adapt to the target memory bank according to the time sequence parameter; The embedded system can beautomatically adaptive to different types of memory banks, the stability of the system is improved, the memory bank range adaptive to the system is enlarged, the flexibility of memory adaptation of the system is improved, and the working and production efficiency is improved.

Owner:FENGHUO COMM SCI & TECH CO LTD

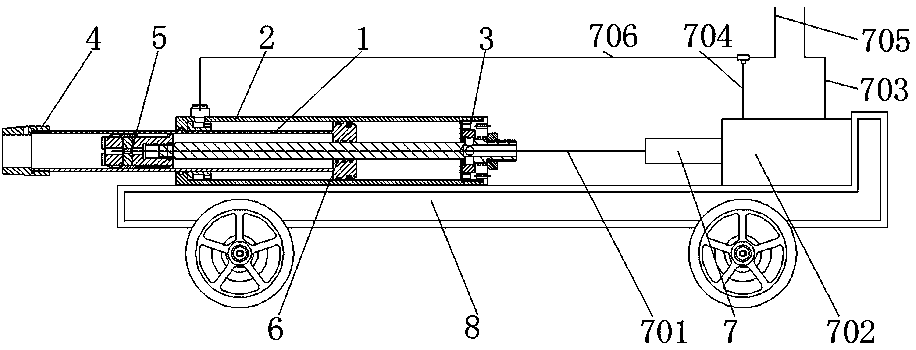

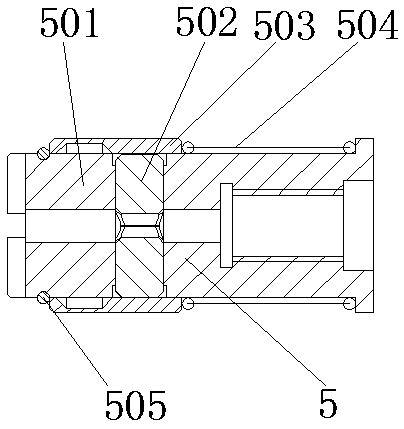

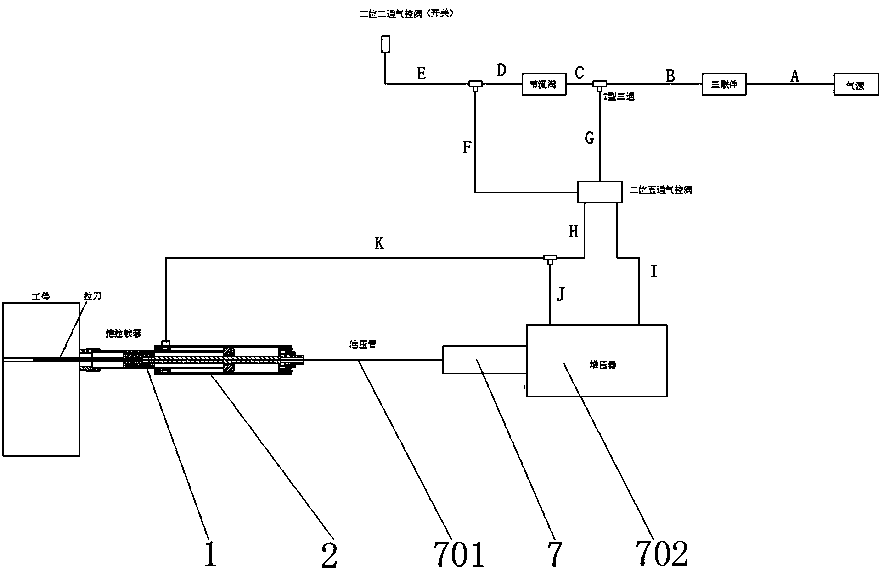

Broaching reaming vehicle

The invention discloses a broaching reaming vehicle. The broaching reaming vehicle comprises a piston rod, a cylinder cover, a spring and a steel cable baffle ring for a shaft, and is characterized inthat a cylinder body is installed on the outer side of the piston rod, an outer blind nut is arranged on the left side of the piston rod, and the cylinder cover is installed on the right side of thecylinder body; a working head assembly is connected in the piston rod, a broaching head is arranged in the working head assembly, a clamping jaw is installed on the right side of the broaching head, alock sleeve is arranged on the outer side of the clamping jaw, and the spring is installed on the right side of the lock sleeve; the steel cable baffle ring for the shaft is arranged above the broaching head, sealing rings are installed on the upper side and the lower side of the piston rod, and the right side of the cylinder body is connected with a gas circuit assembly; and an oil-pressure pipeis arranged in the gas circuit assembly, a pressurizer is installed on the right side of the oil-pressure pipe, and a pressurizer access route I is connected to the upper side of the pressurizer. Thebroaching reaming vehicle is provided with the sealing rings, thereby being capable of achieving more uniform broaching force, large machining depth, high working efficiency and convenient movement.

Owner:QINGDAO QIANSHAO PNEUMATIC TOOLS MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com