Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Improve product processing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrafine cemented carbide coating blade suitable for numerical control machining center and manufacturing method thereof

InactiveCN103801746AHigh hardnessImprove flexural strengthMilling cuttersTurning toolsChromium carbideNumerical control

The invention provides an ultrafine cemented carbide coating blade suitable for a numerical control machining center, the ultrafine cemented carbide coating blade is prepared from the following components by weight: 0.5-2% of tantalum carbide, 0.5-2% of chromium carbide, 0-0.5% of niobium carbide, 6-10% of cobalt and the balance of ultrafine tungsten carbide, and the invention also provides a manufacturing method of the ultrafine cemented carbide coating blade. The manufacturing method of the ultrafine cemented carbide coating blade is low in cost, and the manufactured ultrafine cemented carbide coating blade is excellent in performance, stable in quality, and suitable for the numerical control machining center, satisfies ever-growing market demands of mechanical processing industry of the numerical control machining center, and gradually replaces expensive imported products.

Owner:HUNAN RUIFENG CEMENTED CARBIDE PROD

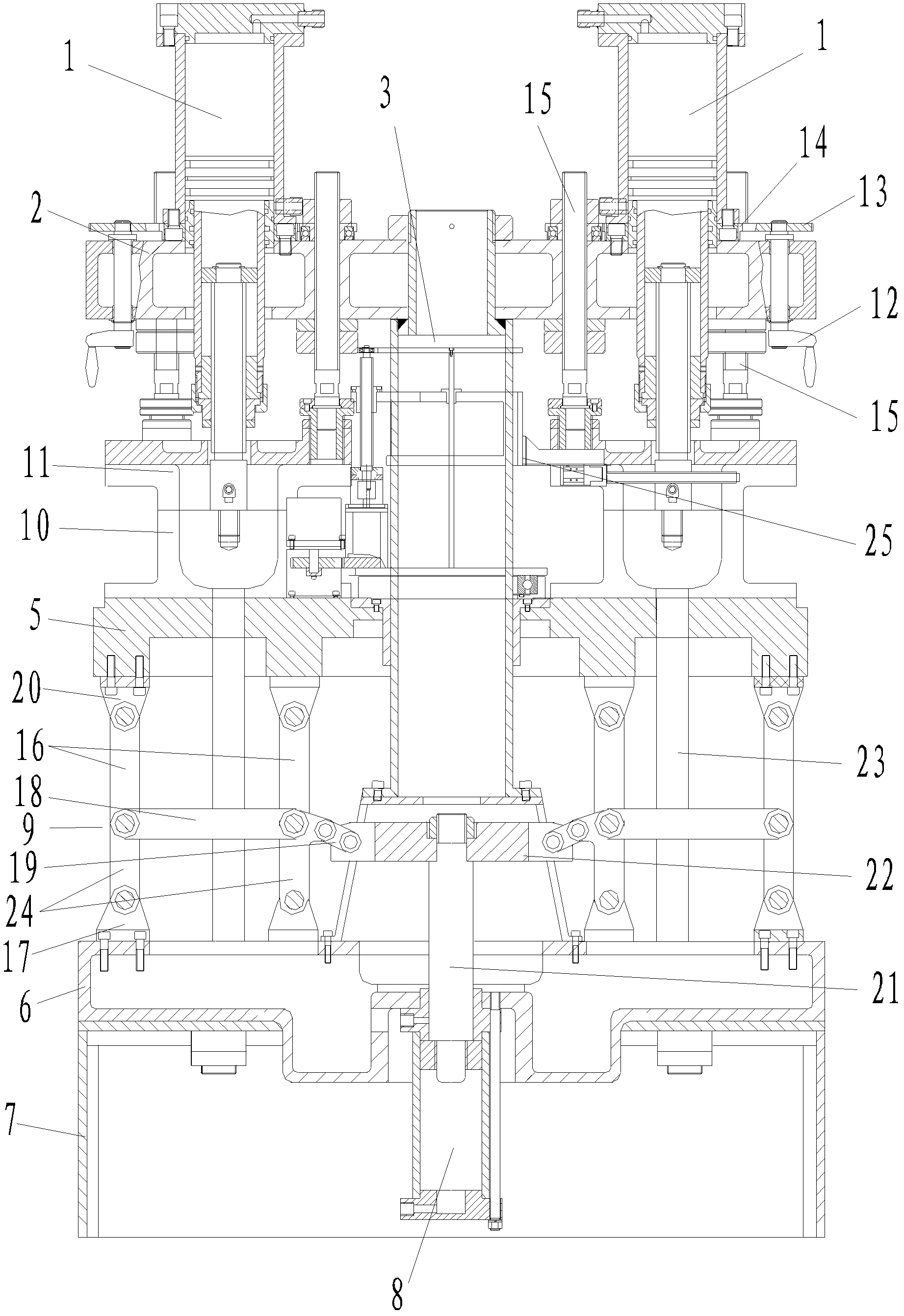

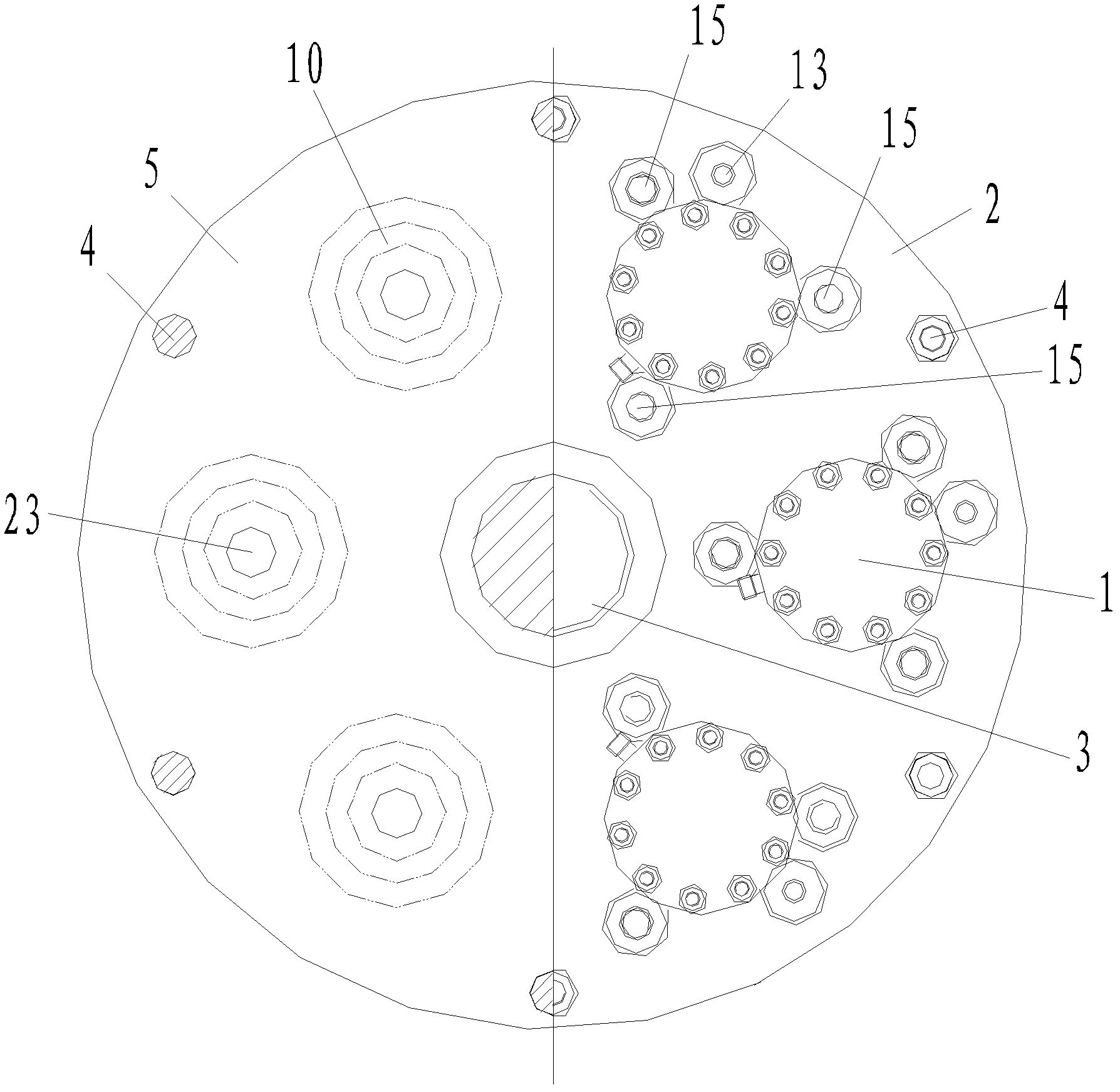

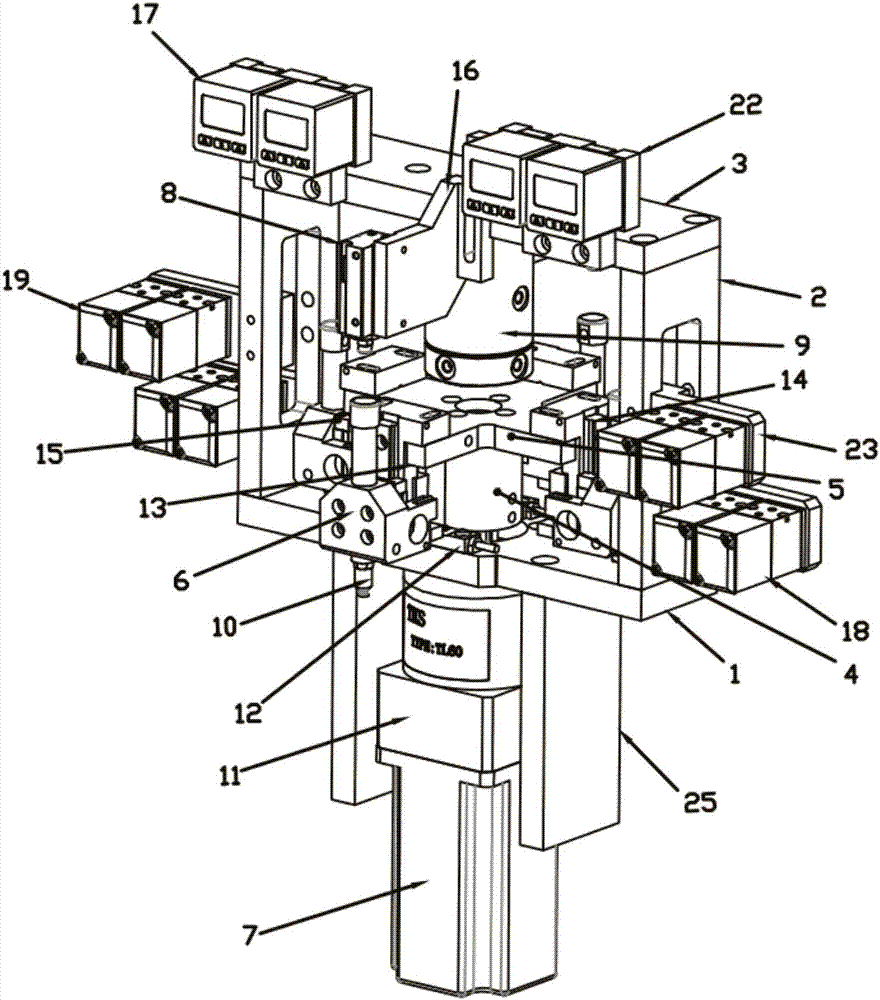

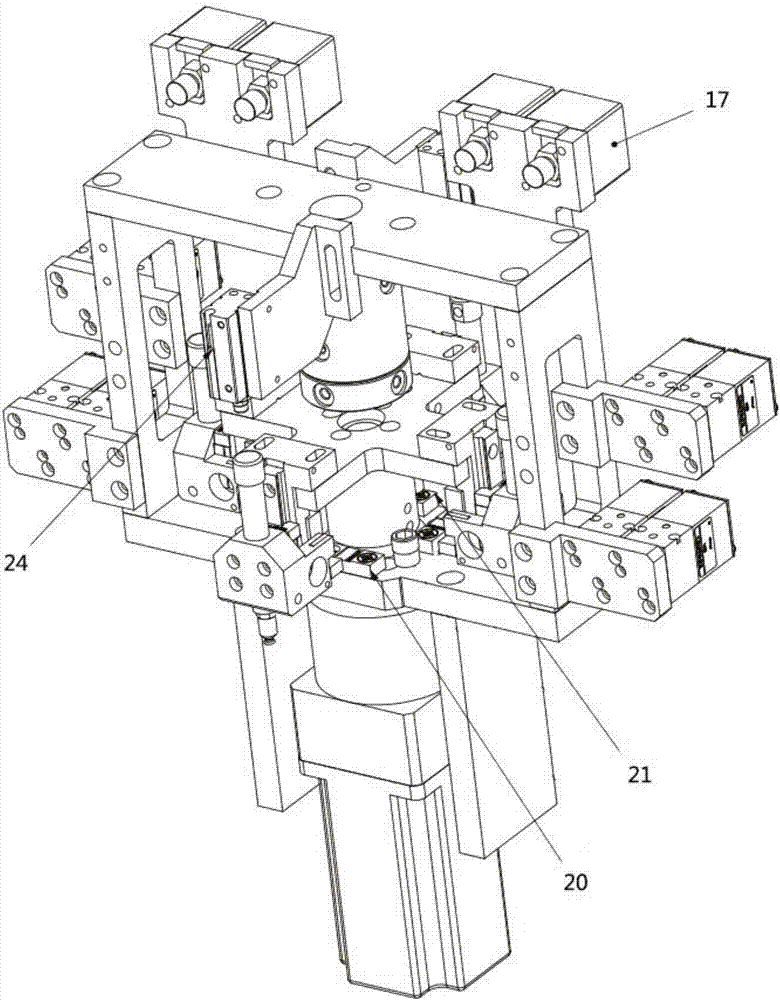

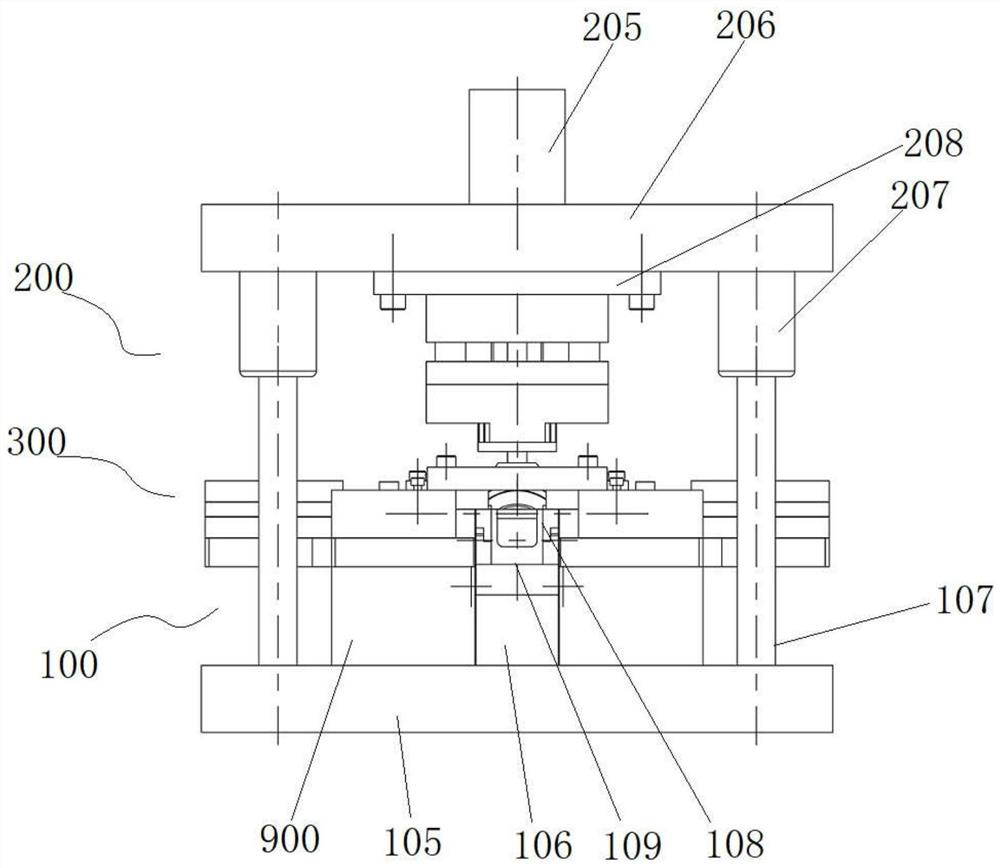

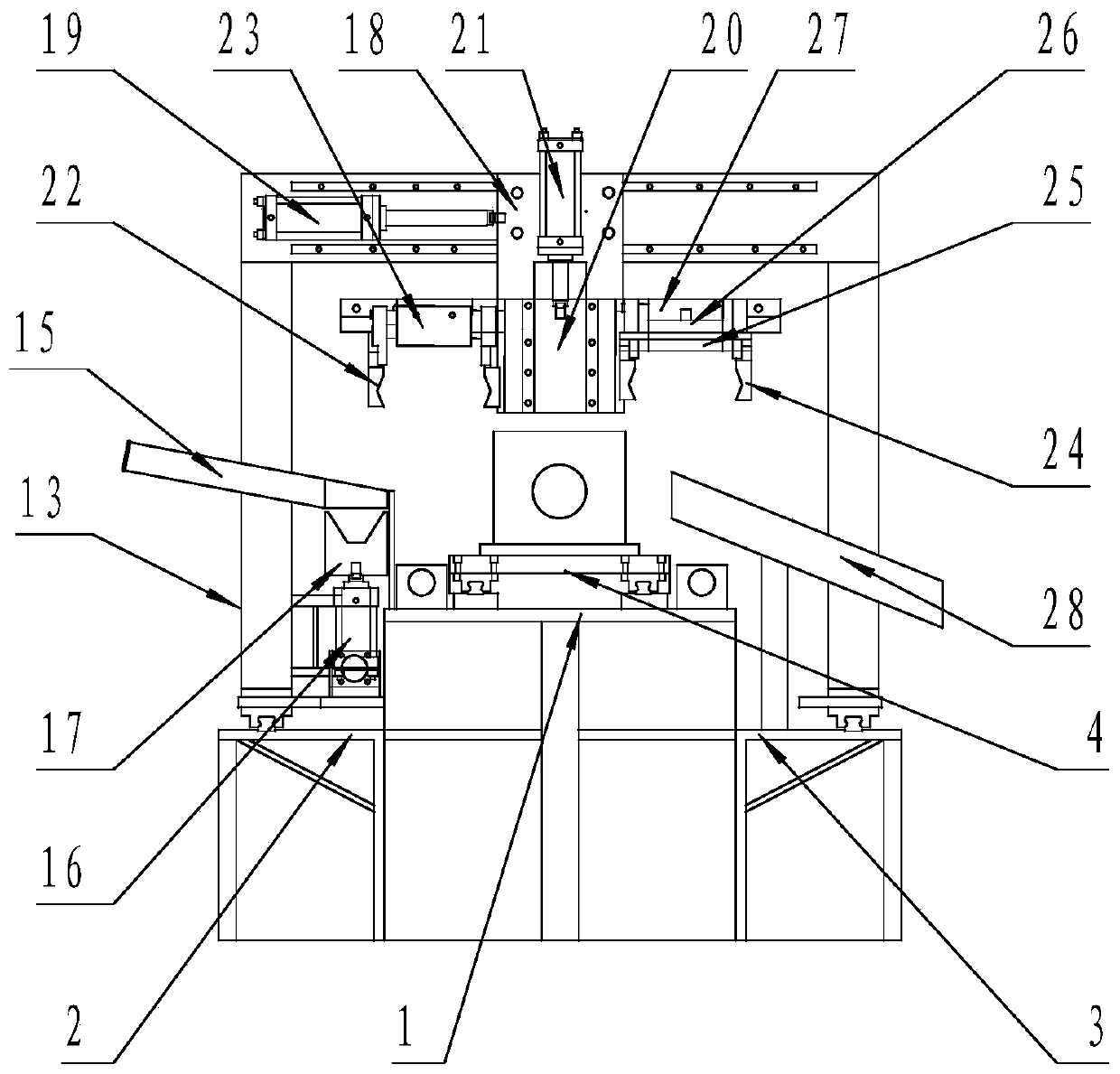

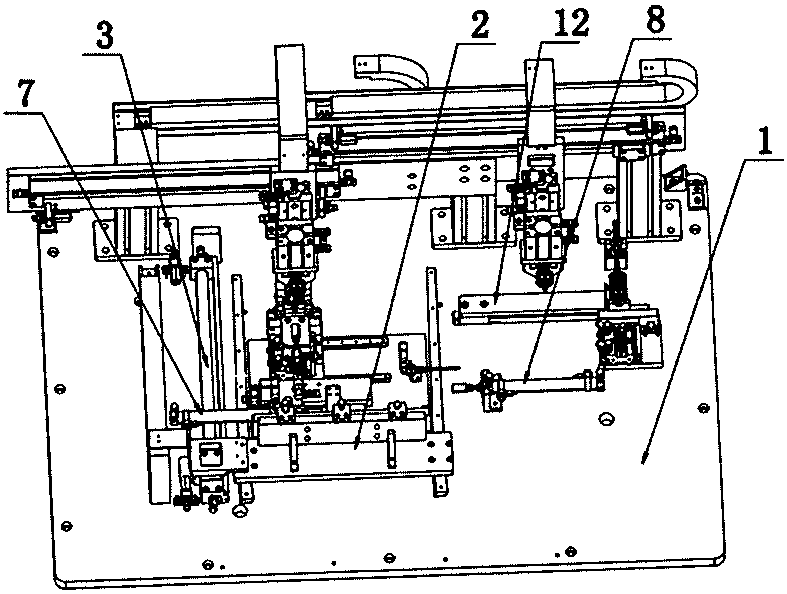

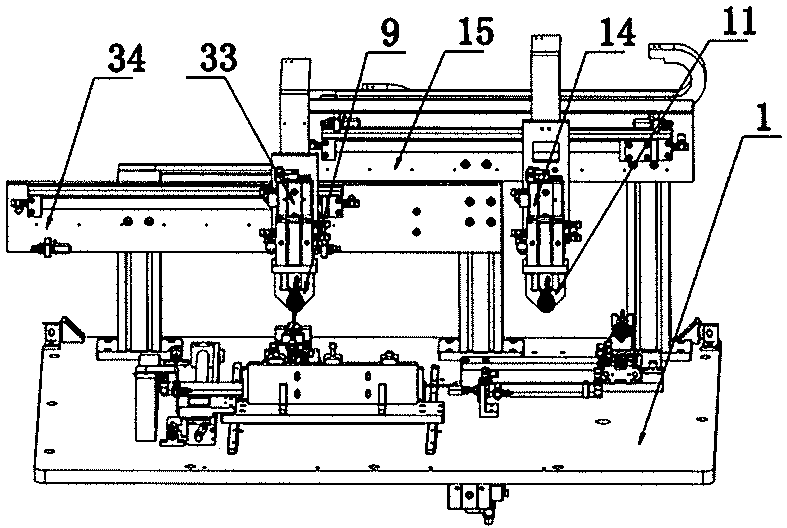

Multi-station hydraulic stretcher with transposition manipulator

InactiveCN102527807ARealize automatic ejectionImprove flexibilityProgramme-controlled manipulatorMetal-working feeding devicesHydraulic cylinderEngineering

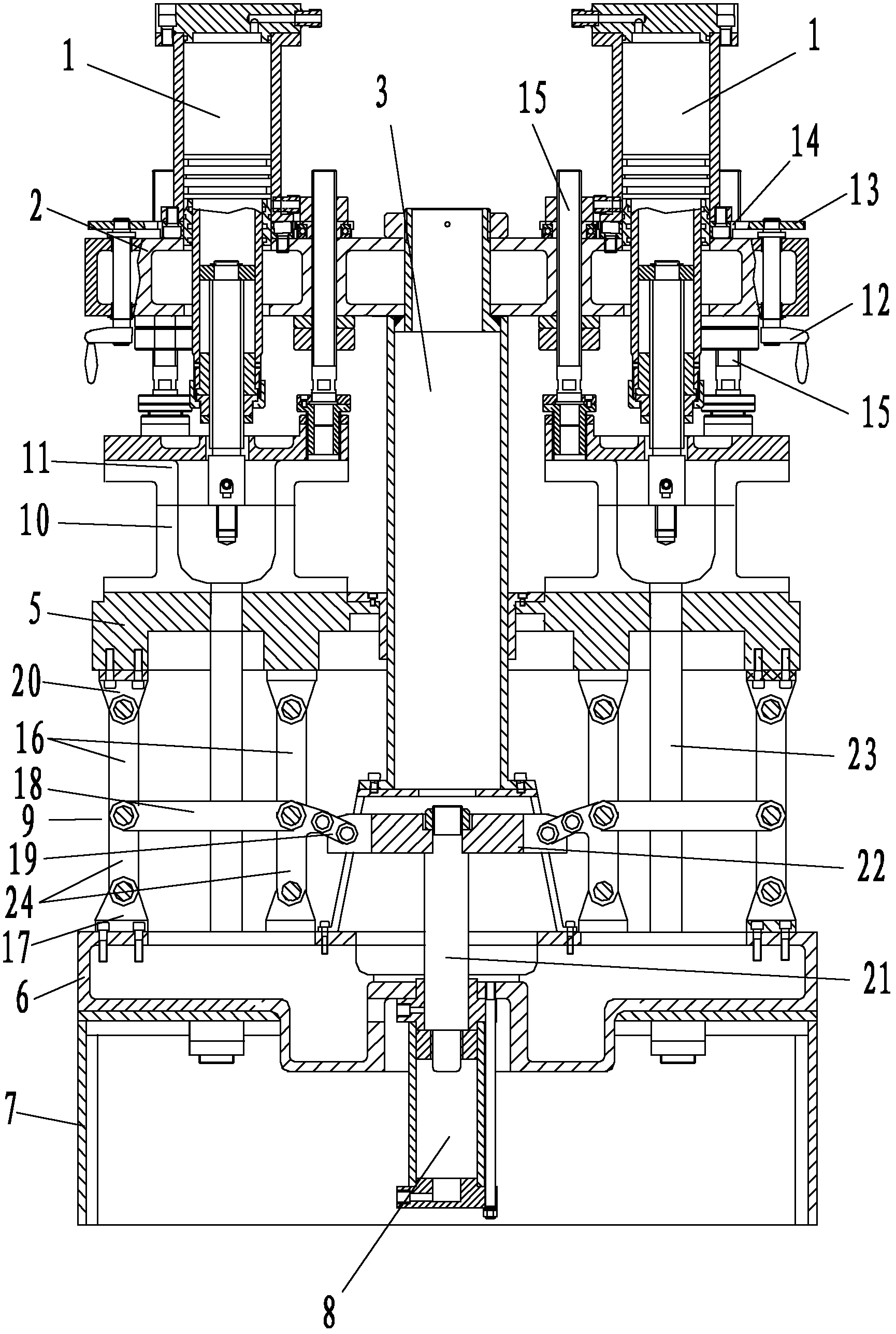

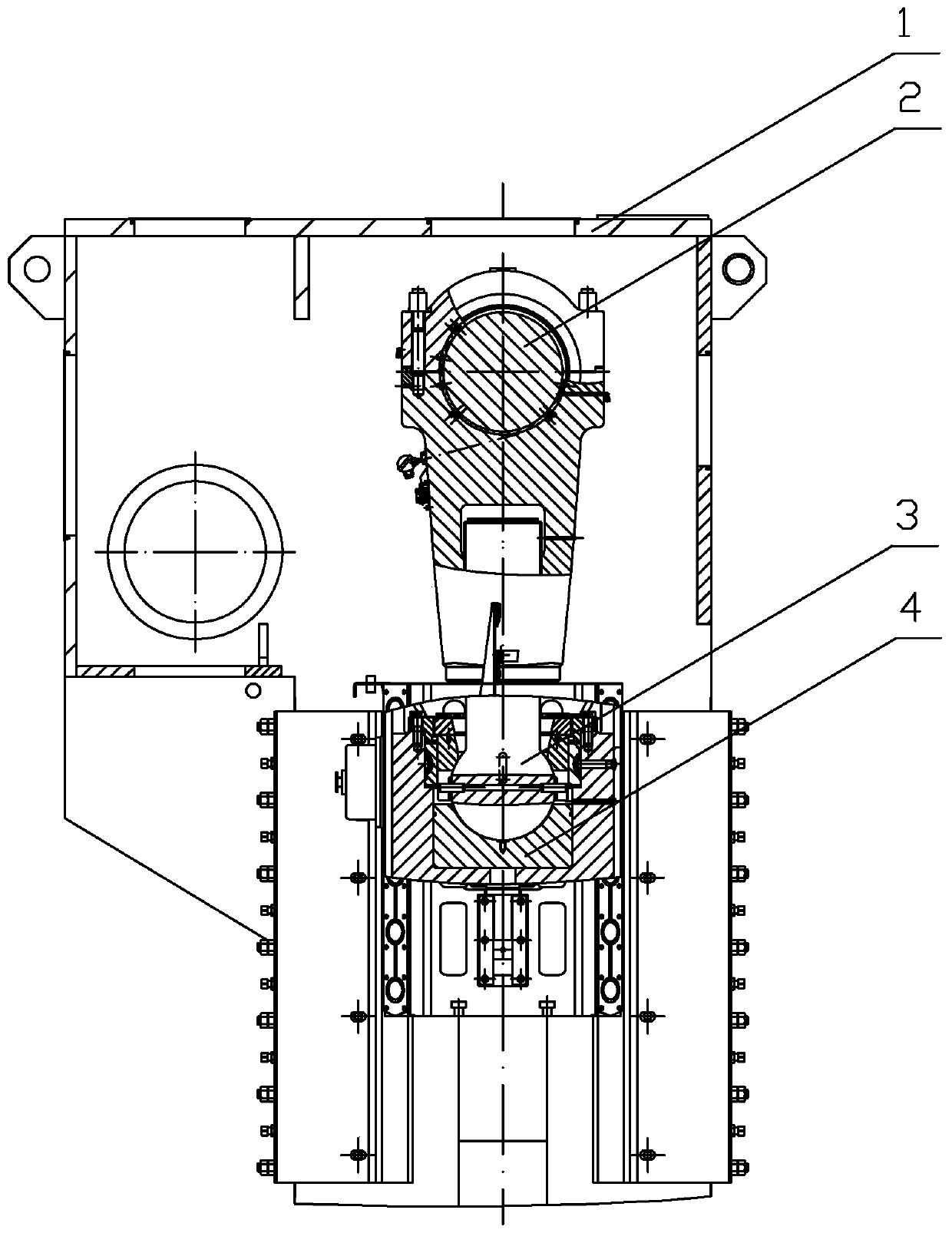

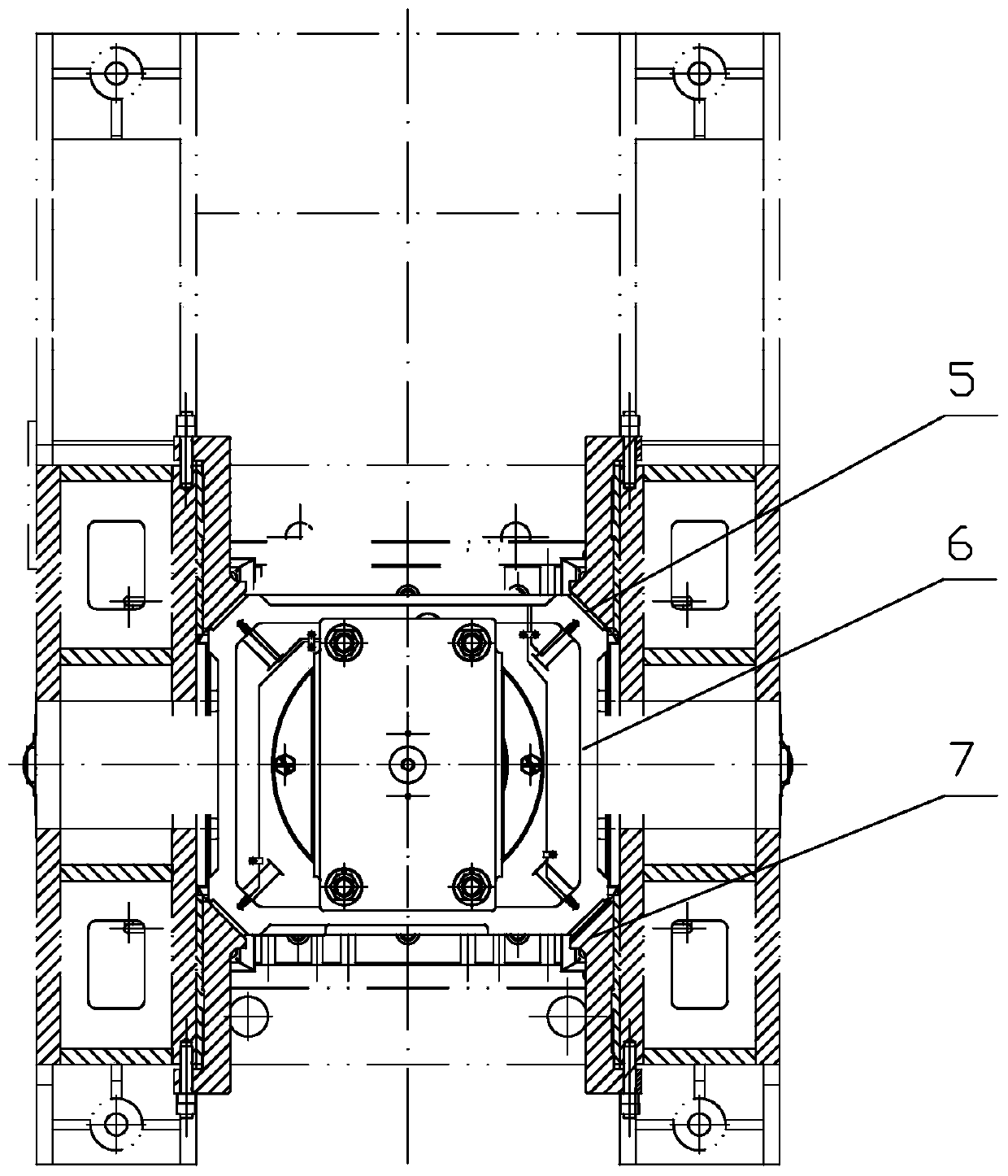

The invention relates to a multi-station hydraulic stretcher with a transposition manipulator, which comprises a base, a bed bedplate, an upper oil cylinder bedplate, a middle upright, a peripheral upright and the transposition manipulator. The base is fixed on the ground; the bed bedplate is fixed on the base; the middle upright and the peripheral upright support the upper oil cylinder bedplate and a working bedplate between the upper oil cylinder bedplate and the bed bedplate; a plurality of upper hydraulic cylinders are distributed on the upper oil cylinder bedplate in the peripheral direction; a crankshaft mechanism is arranged between the bed bedplate and the working bedplate; the working bedplate is driven to move up and down by the crankshaft mechanism; the positions on the working bedplate, which correspond to the upper hydraulic cylinders, are provided with die stations; the transposition manipulator is arranged on the working bedplate and can rotate left and right to clamp and put down a workpiece; according to the invention, a plurality of independent die stations are arranged on the stretcher, so that the repeated stretching process on the same product on the same stretcher can be implemented; and meanwhile, the transposition manipulator can be used for carrying out automatic transposition on the workpiece.

Owner:SUZHOU YUEHAI STRETCHING MACHINERY

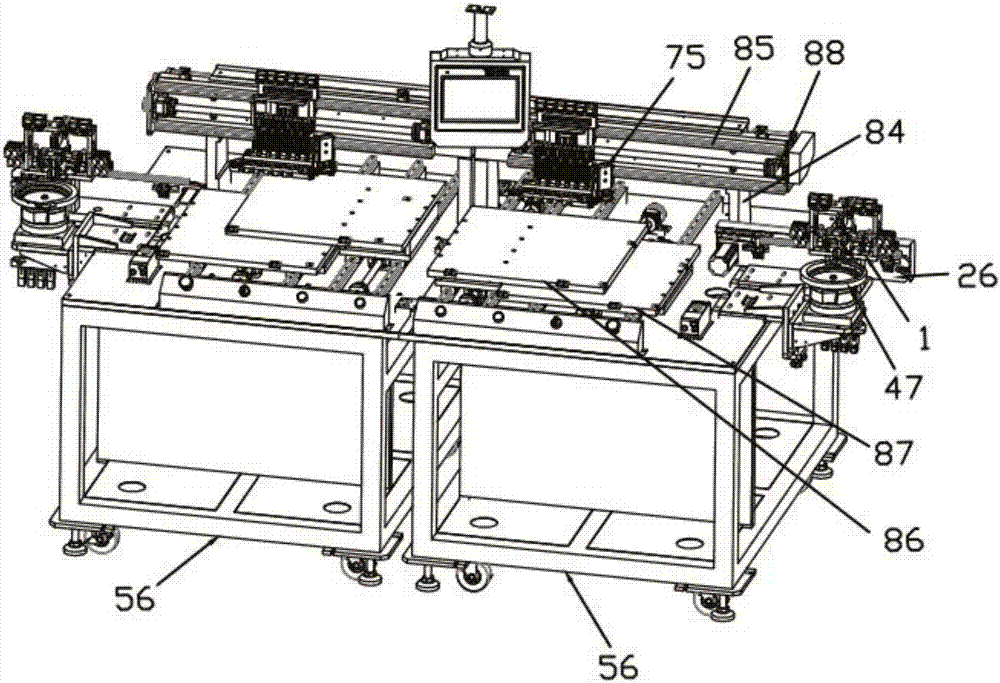

Multifunctional high-rate chip setting machine

ActiveCN107161651AImprove work efficiencyReduce the probability of breakageConveyorsConveyor partsTransfer mechanismHigh rate

The invention discloses a multifunctional high-rate chip setting machine, comprising a support, a vibrating disk, a rotating mechanism, a transfer mechanism, a carrying mechanism, a correcting mechanism and a working mobile platform, wherein the vibrating disk is arranged on the support, the rotating mechanism is arranged on the support and is used for picking up chips in the vibrating disk, the transfer mechanism is arranged on the support and is used for collecting the chips in the rotating mechanism, the carrying mechanism is arranged on the support and is used for carrying the chips in the transfer mechanism to a processing plate, the correcting mechanism is arranged on the carrying mechanism and is used for correcting directions and positions of the chips, and the working mobile platform is arranged on the support and is used for setting the processing plate. According to the multifunctional high-rate chip setting machine disclosed by the invention, the problem that the frequency of existing round trip operation is solved, and the work efficiency is increased.

Owner:深圳市智领芯科技有限公司

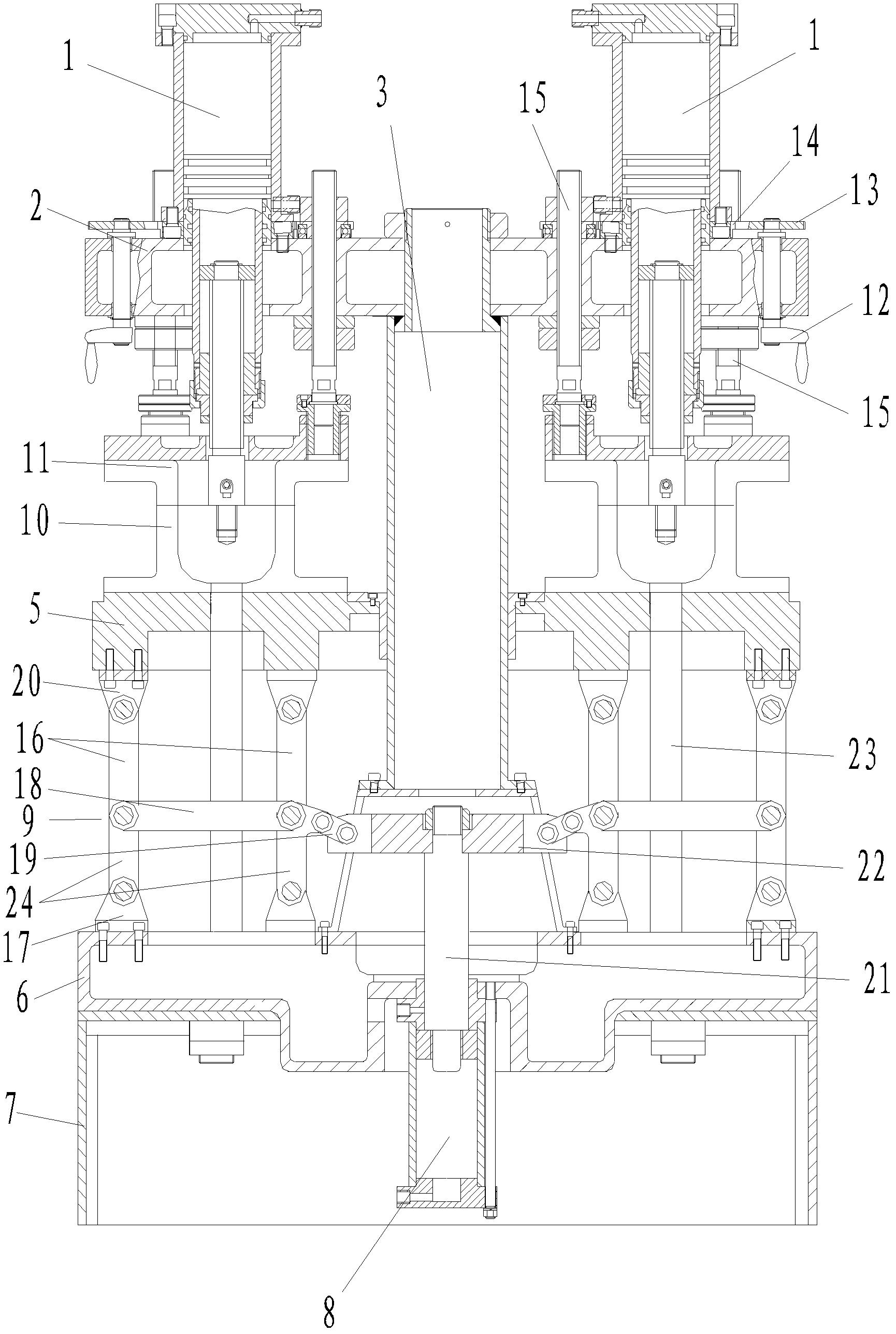

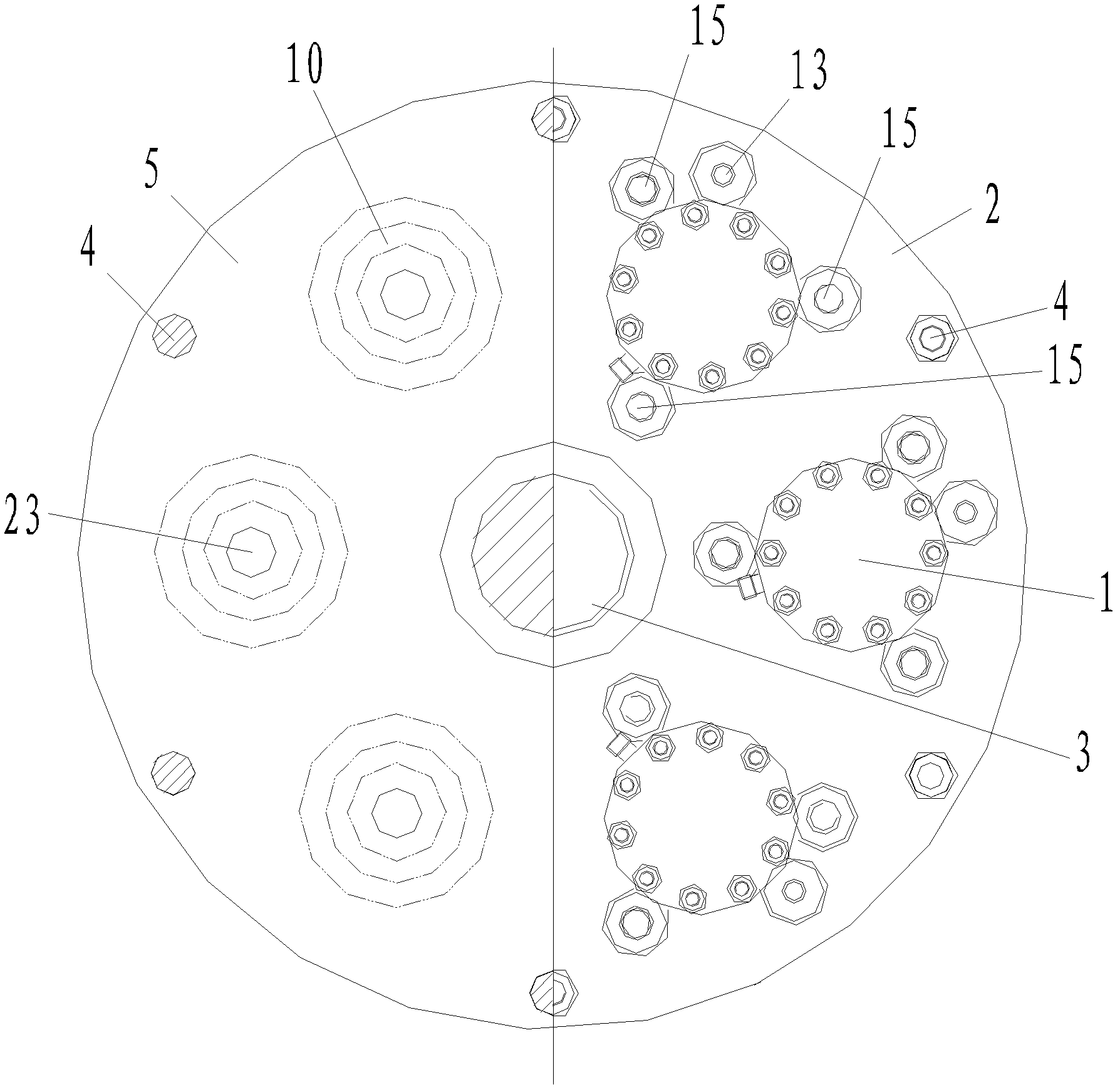

Multi-station hydraulic drawing machine

InactiveCN102554006AImprove flexibilityRealize automatic ejectionHydraulic cylinderPulp and paper industry

The invention relates to a hydraulic drawing device, in particular to a multi-station hydraulic drawing machine which comprises a base, a machine base bedplate, an upper oil cylinder bedplate, a middle column and columns, wherein the base is fixedly arranged on the ground, and the machine base bedplate is fixedly arranged on the base; the upper oil cylinder bedplate is supported between the upper oil cylinder bedplate and the machine base bedplate by the middle column and the columns, and a plurality of hydraulic cylinders are distributed on the upper oil cylinder bedplate in the circumferential direction; and a crank mechanism is arranged between the machine base bedplate and a working bedplate, and drives the working bedplate to move up and down, and mould stations are arranged on the working bedplate corresponding to the upper hydraulic cylinders. By arranging a plurality of independent mould stations on the drawing machine, the multiple drawing processes on the same product can be realized on the same drawing machine, so that the machining efficiency is improved.

Owner:SUZHOU YUEHAI STRETCHING MACHINERY

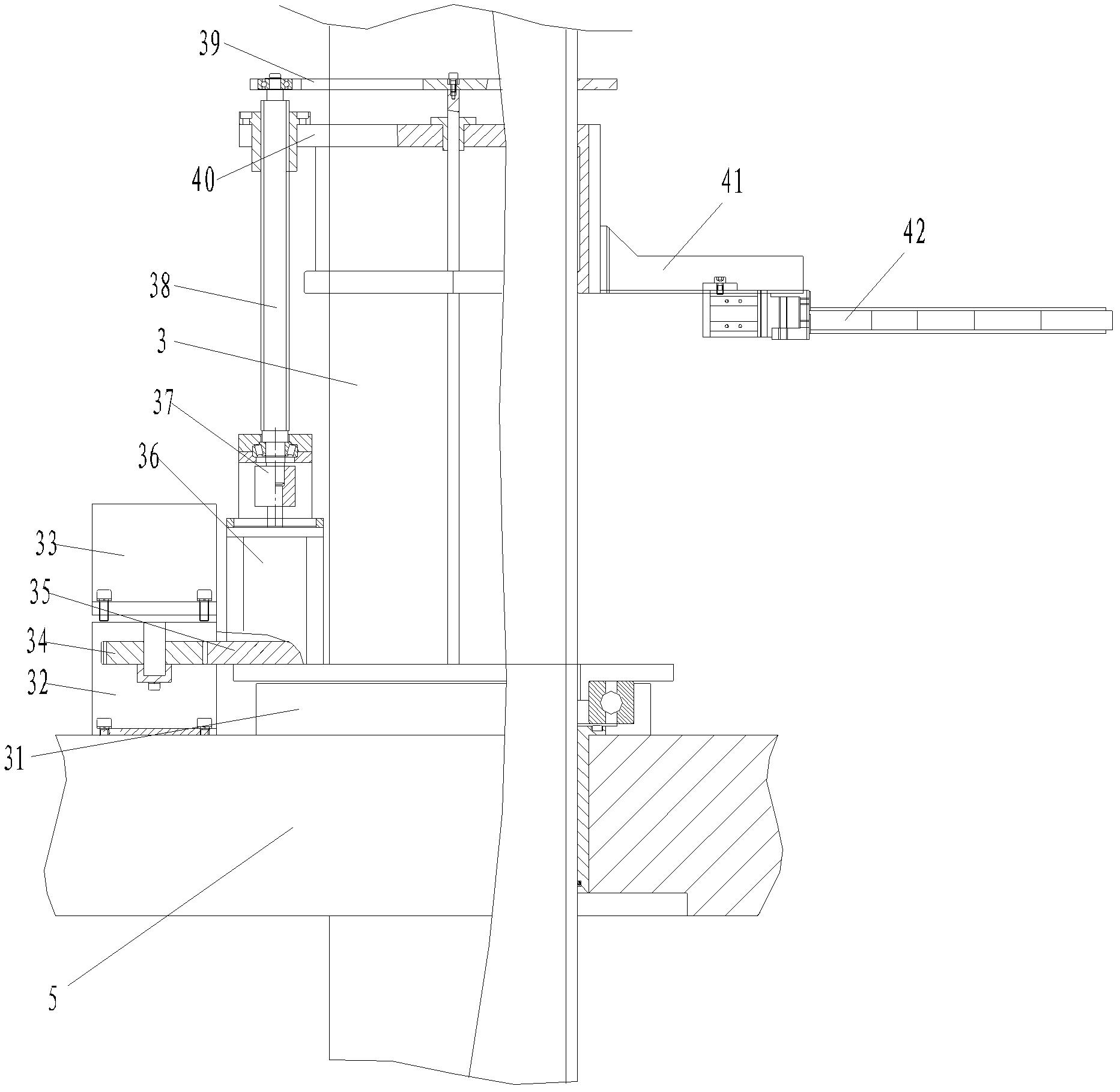

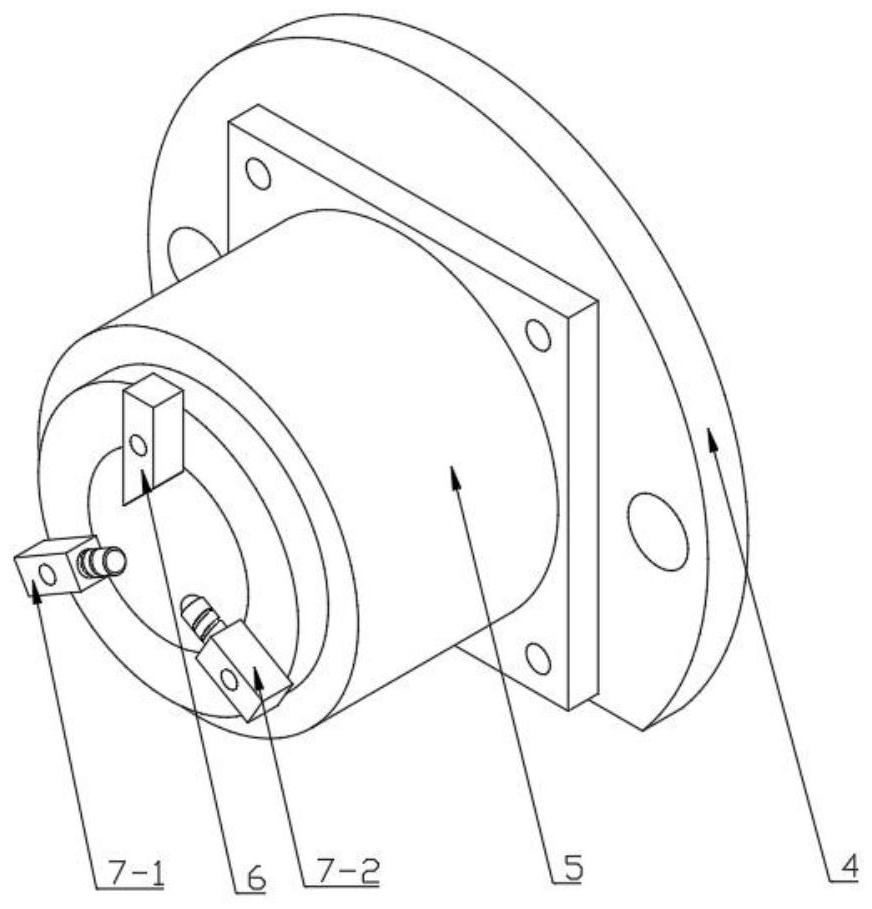

Temperature control precision improving device of forging mechanical press

ActiveCN110538956AStable accuracyImprove overall accuracyForging press drivesHeating/cooling devicesMachine pressWear resistant

The invention discloses a temperature control precision improving device of a forging mechanical press. The device comprises a crankshaft bearing bush and eccentric body bush temperature control device, and further comprises a sliding block guide rail temperature control device and a ball head temperature control device; the sliding block guide rail temperature control device comprises temperaturecontrol channels arranged at the front left side, the front right side, the rear left side and the rear right side of a sliding block, the temperature control channels are arranged at the position, provided with a guide rail plate, in the sliding block, and each temperature control channel is provided with an air inlet and an air outlet; and the ball head temperature control device comprises a wear-resistant copper pad arranged in a ball head seat, a ball head screw rod doses relative movement in the wear-resistant copper pad, the wear-resistant copper pad is connected with the ball head seatthrough a screw, a seal ring is arranged between the wear-resistant copper pad and the ball head seat, and a spiral temperature control channel is arranged on the fitting surface of the ball head seat and the interior of wear-resistant copper pad. According to the device, the temperature of the guide rail plate is controlled to be stable, the guide rail plate can not be expanded due to heating temperature rise, the precision of a sliding block guide rail is kept stable, the stability of the ball head screw rod and the ball head seat is guaranteed, and the overall precision, production efficiency and machined product quality of the forging mechanical press are improved.

Owner:RONGCHENG HUADONG METAL FORMING MACHINERY +1

Device for improving temperature control precision of hot die forging press

InactiveCN110538955AGuaranteed to operate independentlyAvoid precision changesForging press drivesHeating/cooling devicesTemperature controlEngineering

A device for improving temperature control precision of a hot die forging press comprises a worktable temperature control device and a sliding block temperature control device, wherein the worktable temperature control device includes a first temperature control channel arranged at the bottom part of a worktable and on the contact surface of a device body, the first temperature control channel isprovided with an air inlet and an air outlet, the air inlet of the first temperature control channel is connected with a cool-air system through a pipeline, and a temperature sensor is arranged in each of temperature measuring holes in the worktable; the sliding block temperature control device includes a second temperature channel arranged in a sliding block and on the contact surfaces of slidingblock guide plates at the front part and the rear part of the sliding block, and the second temperature control channel is provided with an air inlet and an air outlet. The temperature of the slidingblock and the temperature of the worktable are each controlled to be at a stable level, and deformation caused by temperature rise due to heating cannot be generated; meanwhile, continued conductionof the heat of a high temperature forged part is blocked, so that the phenomenon that the precision of other moving parts is changed due to heat conduction is avoided, and the overall precision, the production efficiency and the processed product quality of the hot die forging press are improved.

Owner:RONGCHENG HUADONG METAL FORMING MACHINERY +2

Online camshaft measuring and machining process

InactiveCN102179729AEasy to operateGuaranteed machining accuracyAutomatic control devicesMeasurement/indication equipmentsEngineeringWaste product

The invention relates to the technical field of camshafts, in particular to an online camshaft measuring and machining process which comprises the following steps: 1. measuring and positioning during installing and clamping: carrying out axial and circumferential measuring and positioning on a blank camshaft; 2. improving precision by measuring abrasion of a compensation cutter: automatically measuring the abrasion of the compensation cutter through rough turning, half-fine turning and measuring programs so as to ensure machining precision; and 3. improving precision by measuring practical positions of compensation holes: measuring the practical position coordinates of the compensation holes so as to improve the displacement of the holes. The online camshaft measuring and machining process is simple to operate, carries out positioning by a probe during installing and clamping, automatically measures the abrasion of the compensation cutter through rough turning, half-fine turning and measuring programs so as to ensure machining precision, measures the practical positions of the compensation holes so as to improve the precision, so that the operation program not only can improve machining efficiency, but also can greatly improve the quality of produced products, and avoid generation of waste products after being off-line.

Owner:CRRC QISHUYAN CO LTD

Sheath blowing machine

The invention discloses a sheath blowing machine, and belongs to the technical field of vehicle body part machining. The machine comprises a machining platform, an expansion cylinder seat, a main cabinet and an air cylinder; the expansion cylinder seat, the main cabinet and the air cylinder are all arranged on the upper surface of the machining platform, the air cylinder and the expansion cylinderseat are distributed from left to right and are axially aligned, and the main cabinet is adjacently arranged at the rear end of the expansion cylinder seat; an inner pipe is arranged in the middle ofthe inner side of the expansion cylinder seat in a penetrating mode, a strain gauge is annularly arranged in the middle of the outer side of the inner pipe, and the four corners of the surface of thestrain gauge are connected with probes in series; and connecting cables are inserted into the upper end of the expansion cylinder seat, and the input ends of the connecting cables are electrically connected with the output ends of the probes. According to the machine, sheaths are successively subjected to sealing, air inflating, and inhaul cable inserting through a machining mechanism controlledby a host system, combined mounting on the inhaul cable sheaths is completed by the machine through the automatically-controlled machining mechanism, and compared with a traditional manual productionmode, the machine has the beneficial effects that the machining efficiency is improved, and the machined product quality of the inhaul cable sheaths is guaranteed through the machine.

Owner:余姚市镒万金属软管有限公司

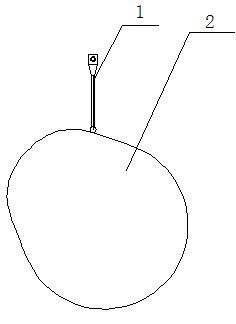

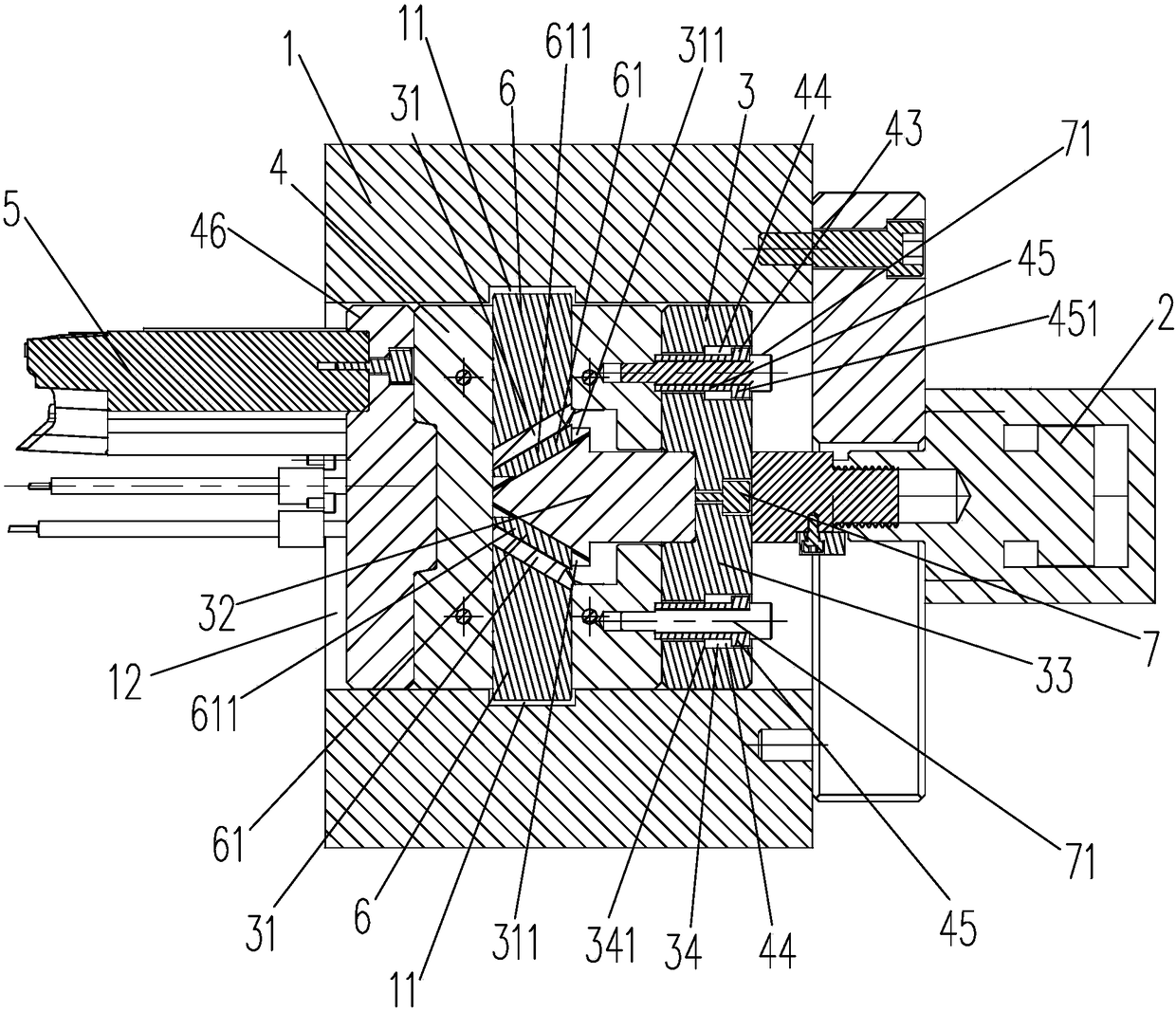

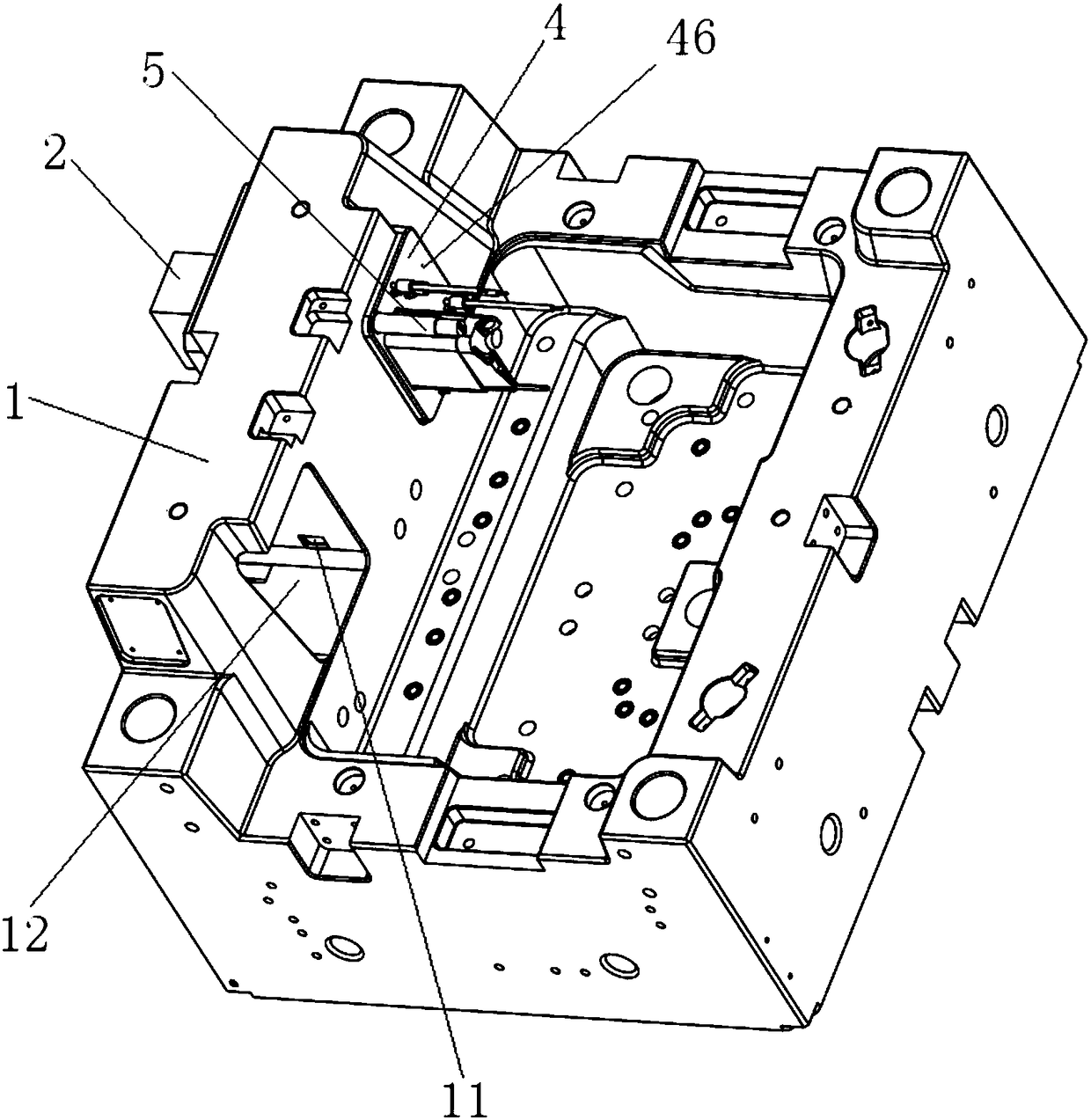

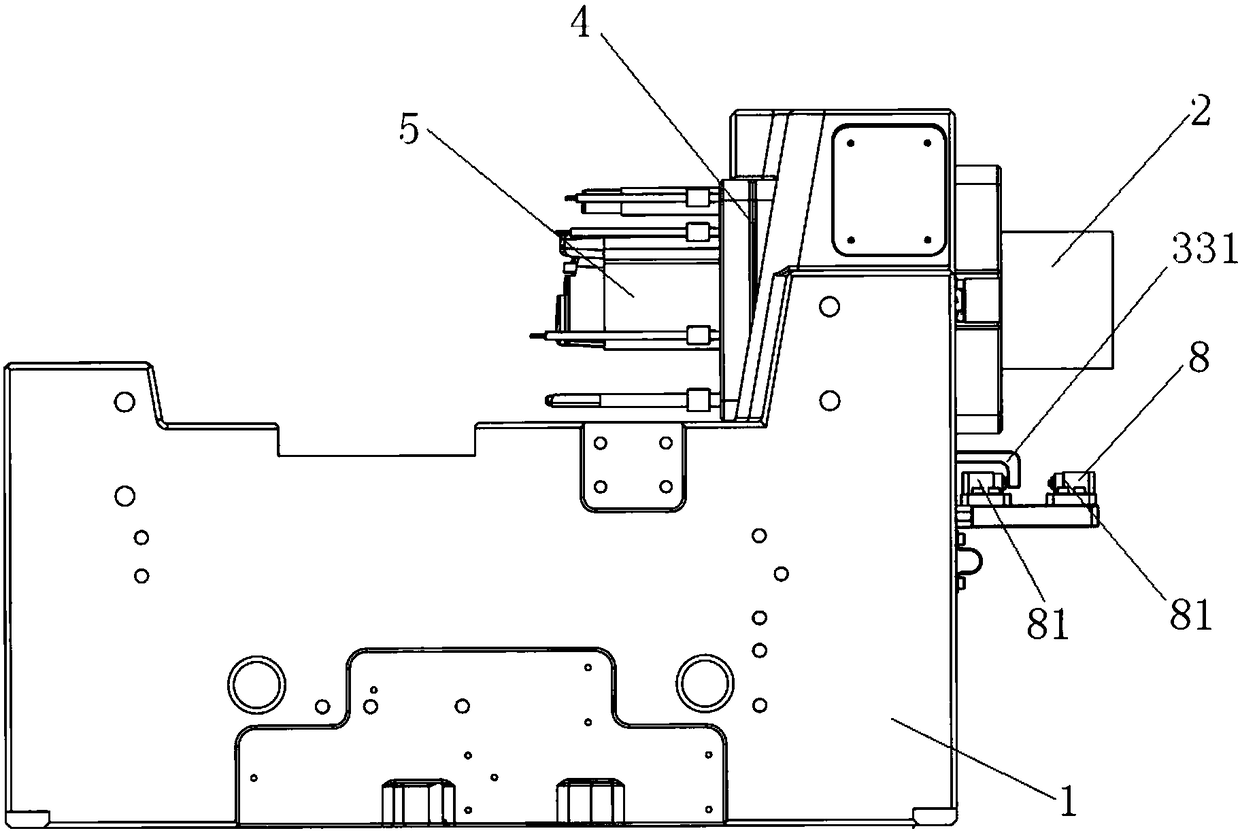

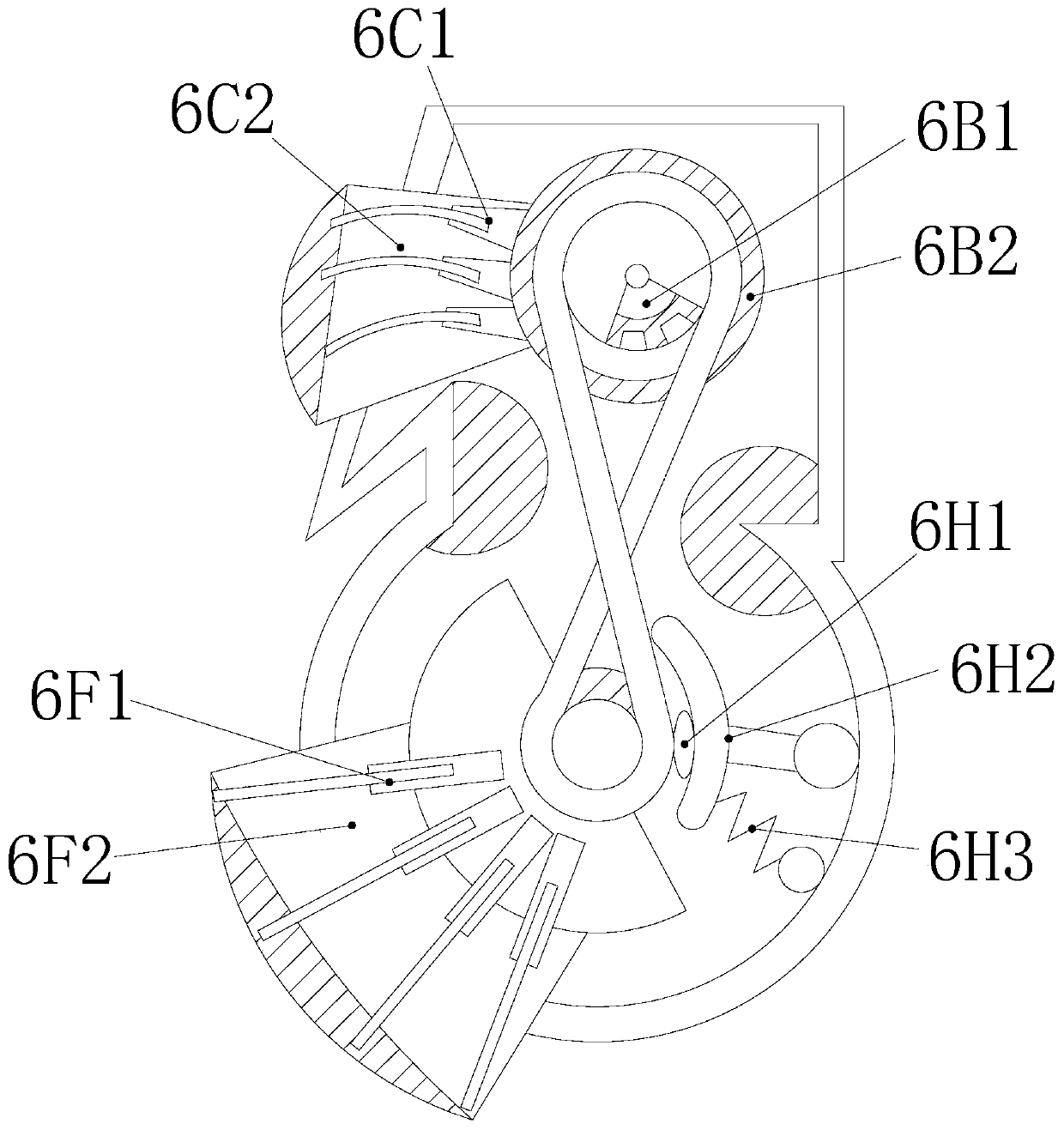

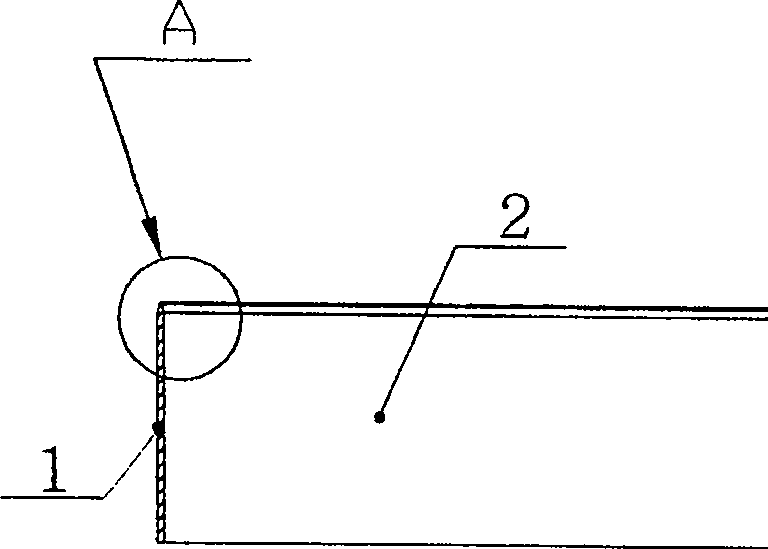

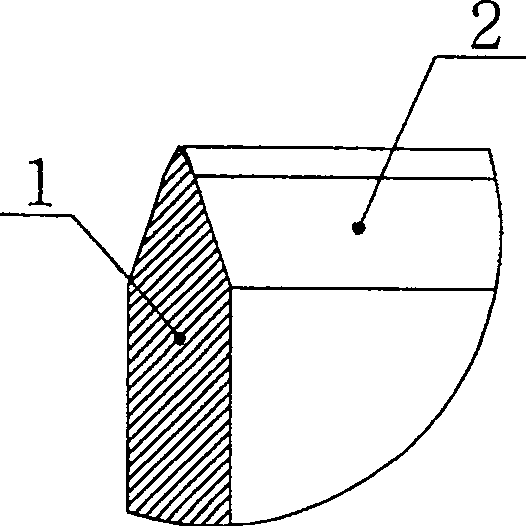

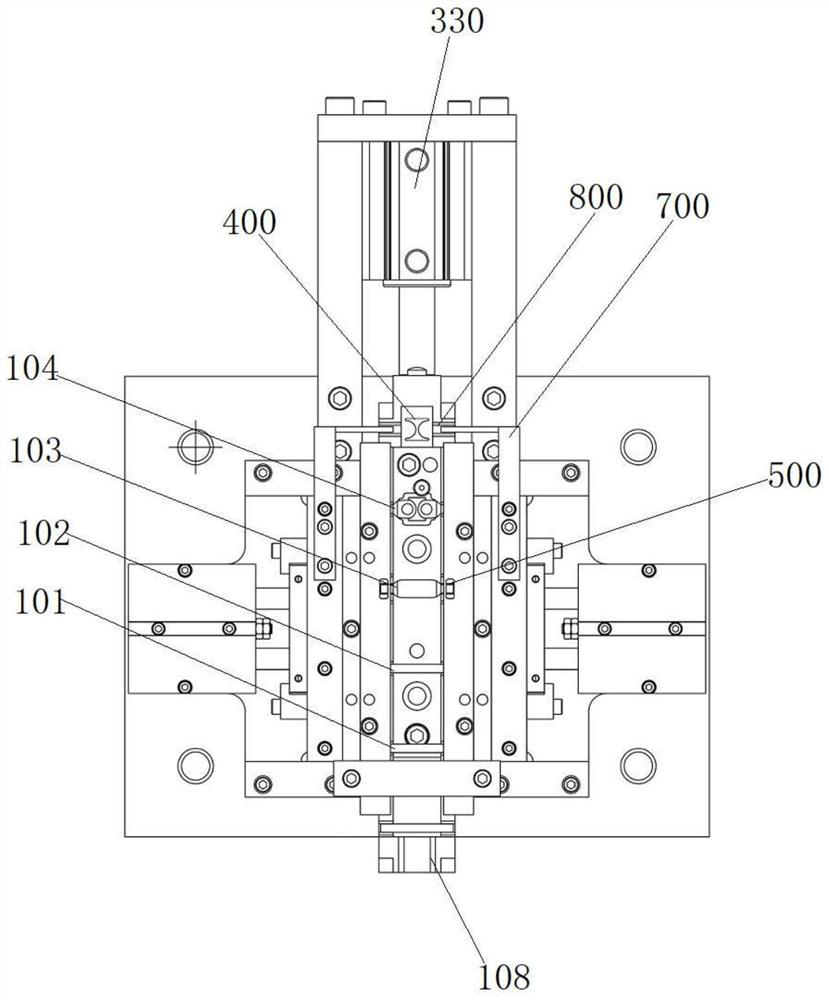

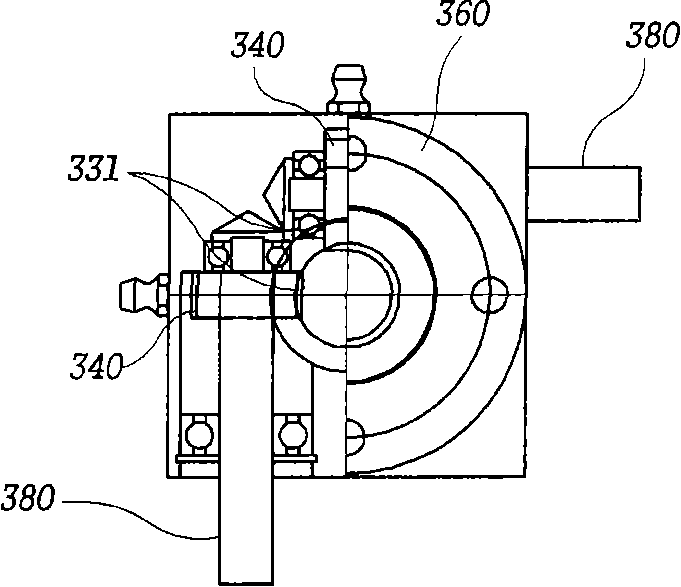

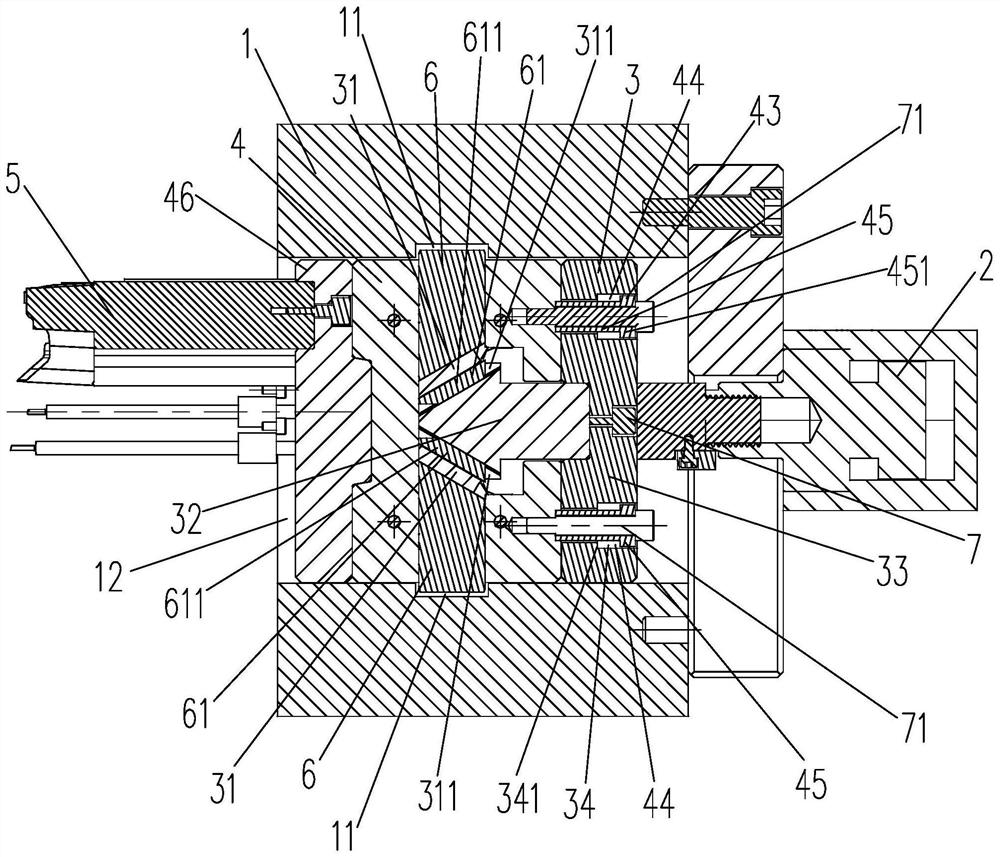

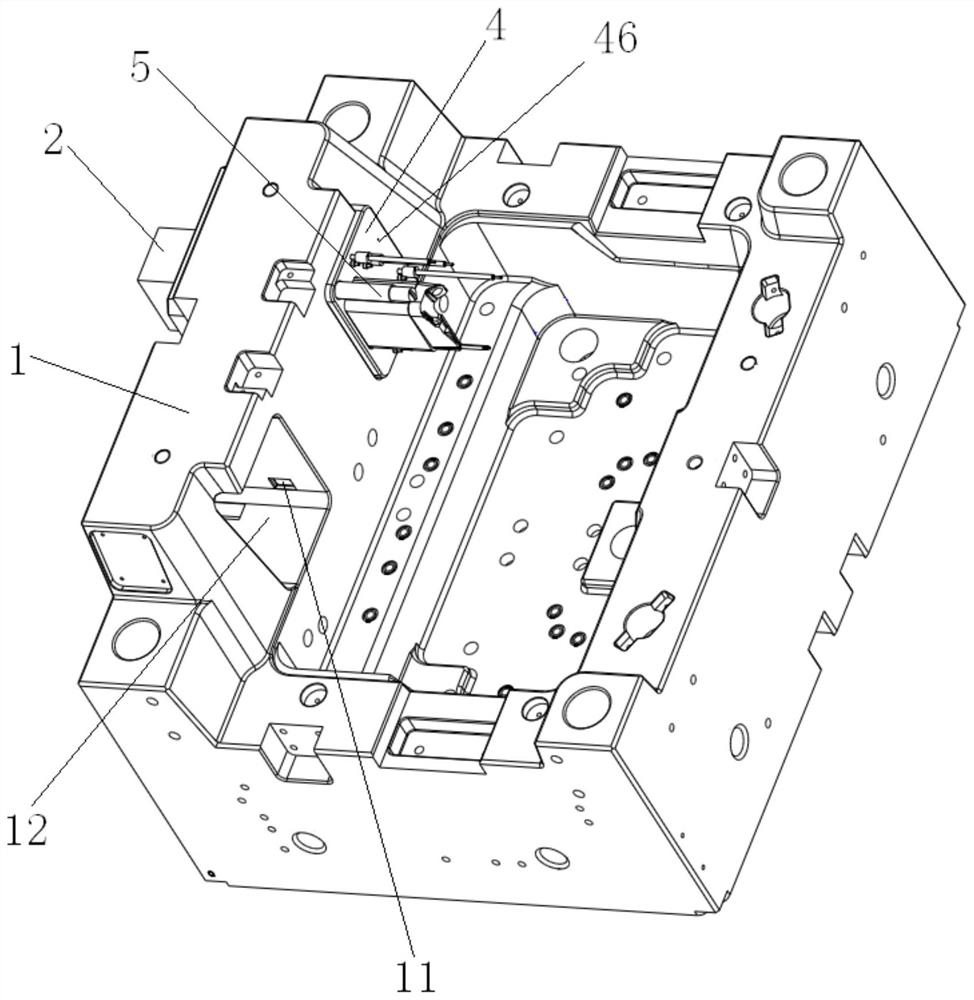

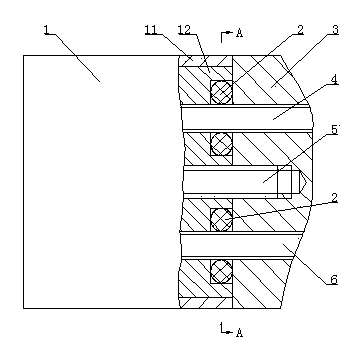

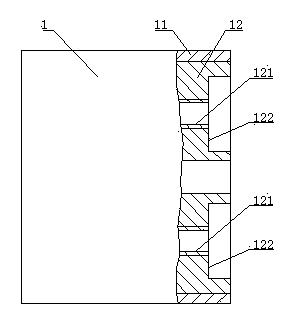

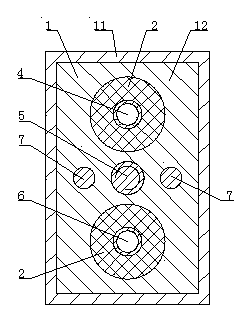

Retreat-preventing mechanism for core loosing of die, and die

ActiveCN108454032AFeatures that prevent fallbacksQuality improvementEngineeringMechanical engineering

The invention provides a retreat-preventing mechanism for core loosing of a die. The retreat-preventing mechanism comprises a die body, a drive unit mounted on the die body, a driving member connectedwith the output terminal of the drive unit, an internal drawing fixed block, an internal drawing arranged on the internal drawing fixed block and a retreat-preventing block, wherein a guide groove extending along an interior-to-exterior direction is arranged in the internal drawing fixed block; the retreat-preventing block is embedded in a guiding groove; the driving member is provided with an active part; the retreat-preventing block is provided with a passive part mating with the active part; and a spacing groove is arranged on the die body. When the drive unit pushes the driving member tomove forward, the driving member pushes the retreat-preventing block, the internal drawing fixed block and the internal drawing head to move forward, and the driving member also pushes the retreat-preventing block to extend outward and then to be embedded into the spacing groove in the die body; and when the drive unit pulls the driving member to move backward, the driving member pulls the retreat-preventing block to contract inwardly and retreat from the spacing groove, and the driving member pulls the retreat-preventing block, the internal drawing fixed block and the internal drawing head tomove backward.

Owner:上海信羽电子科技有限公司

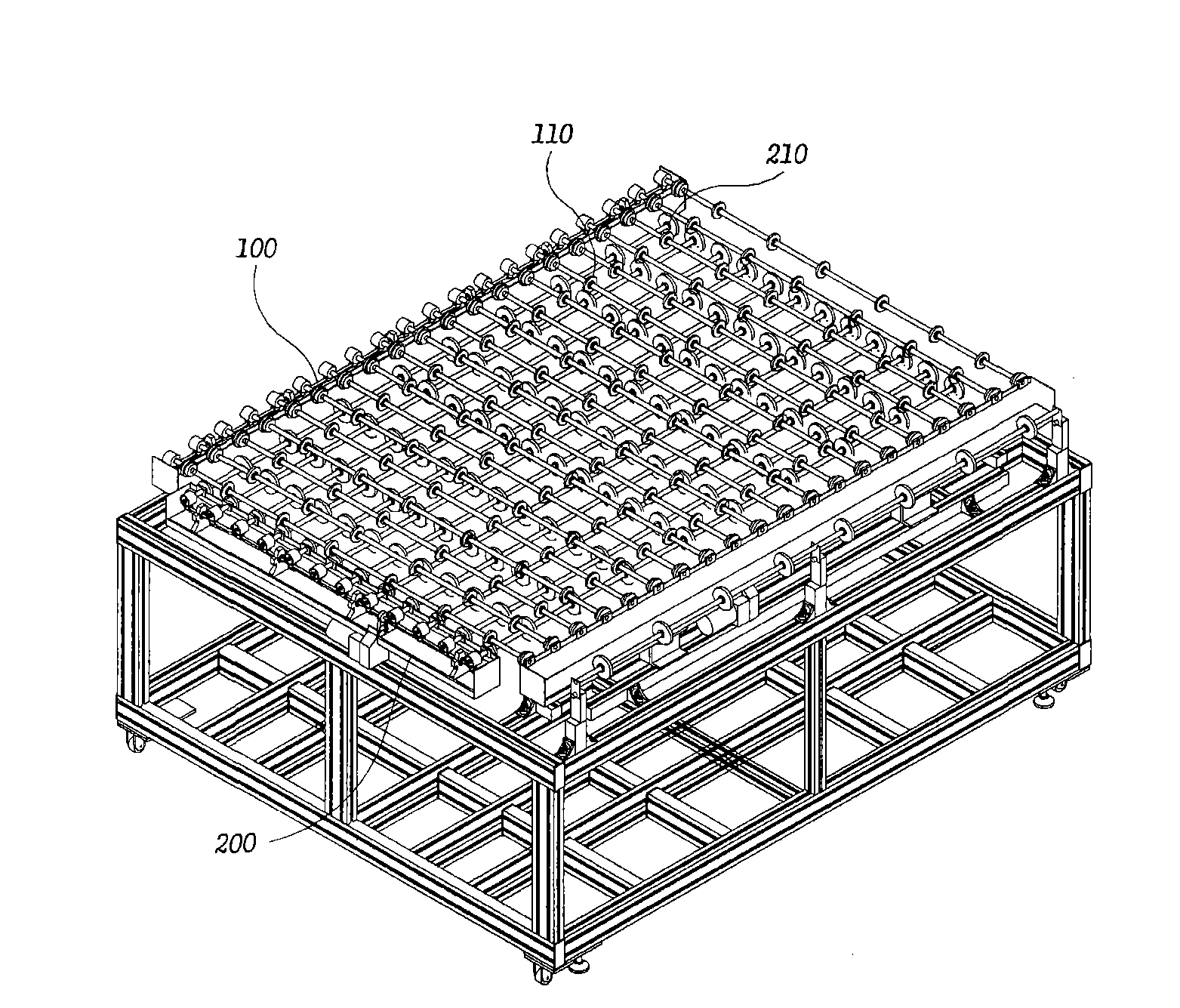

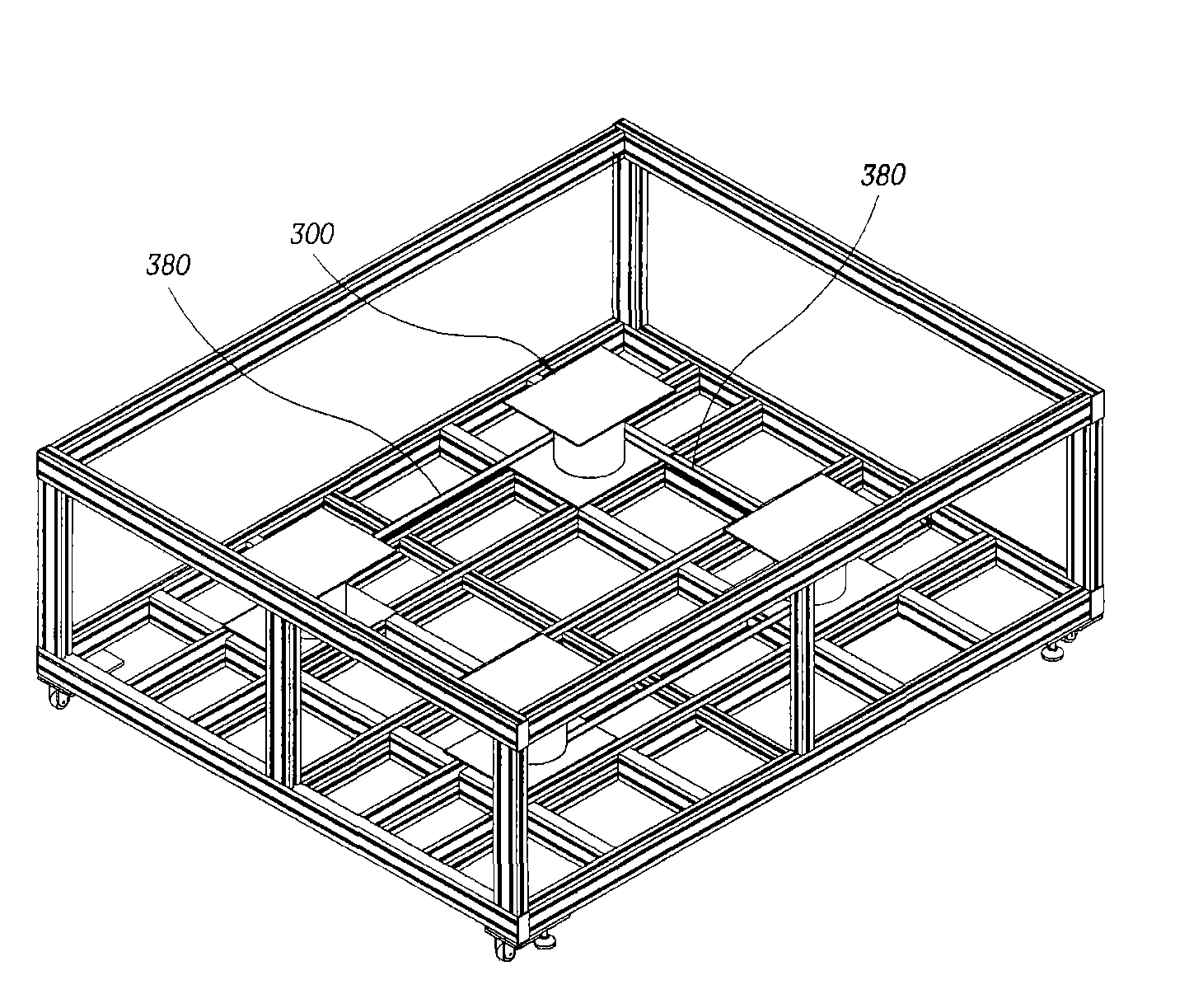

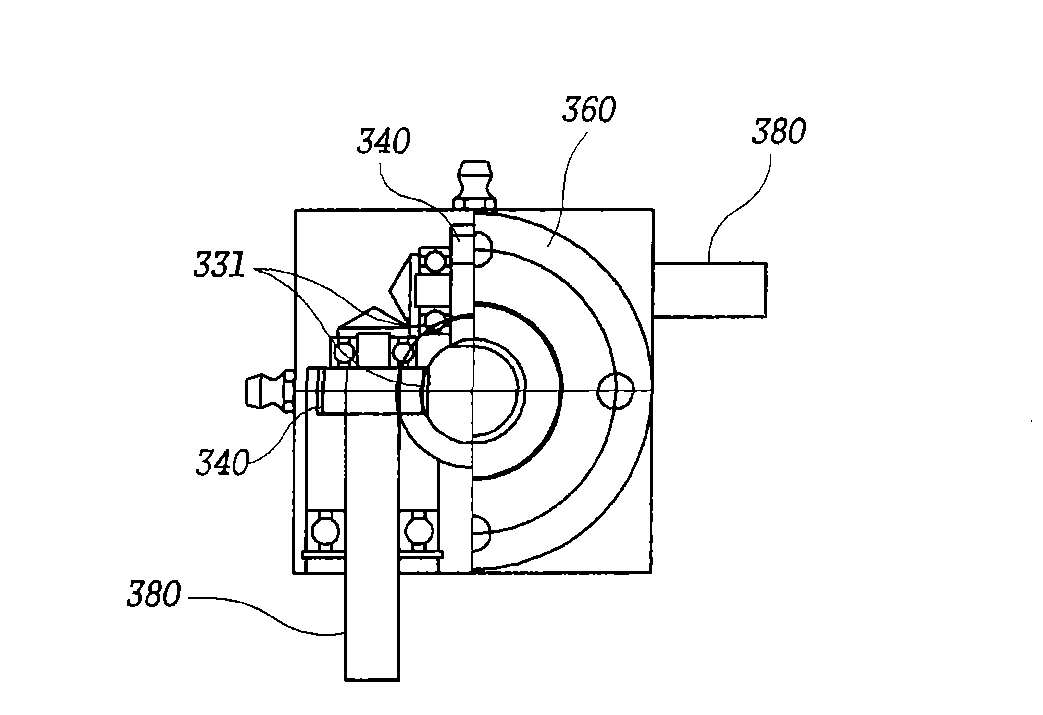

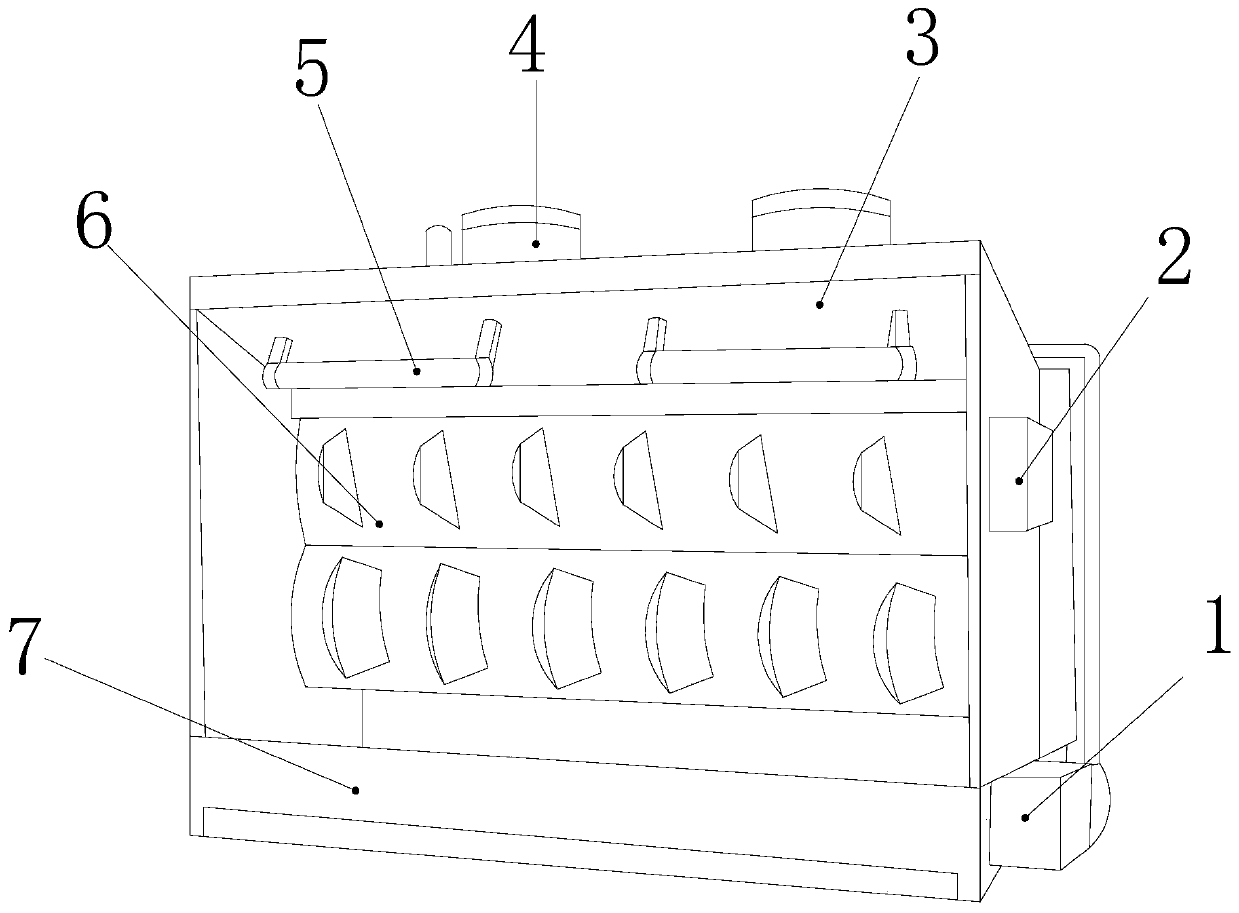

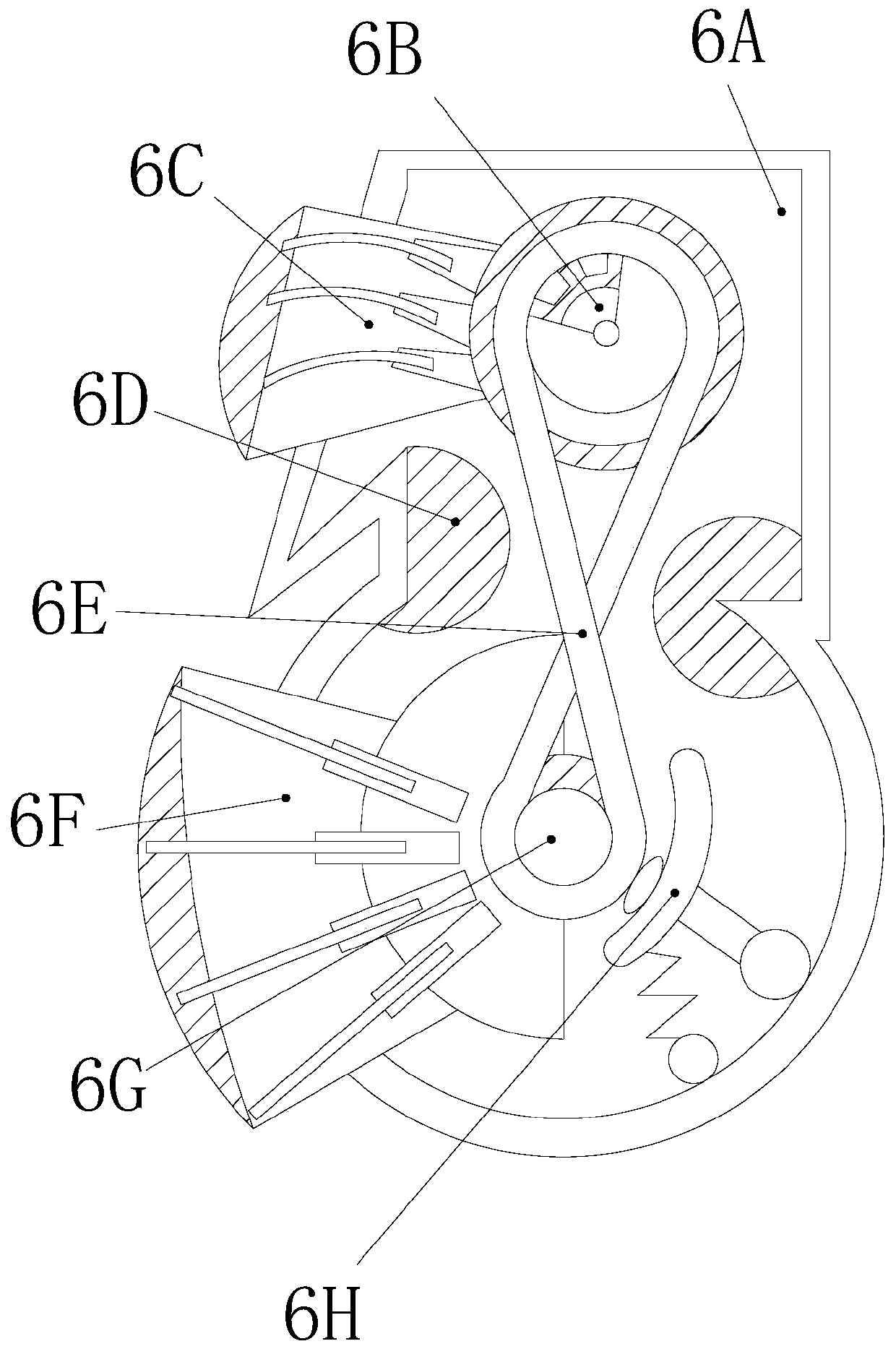

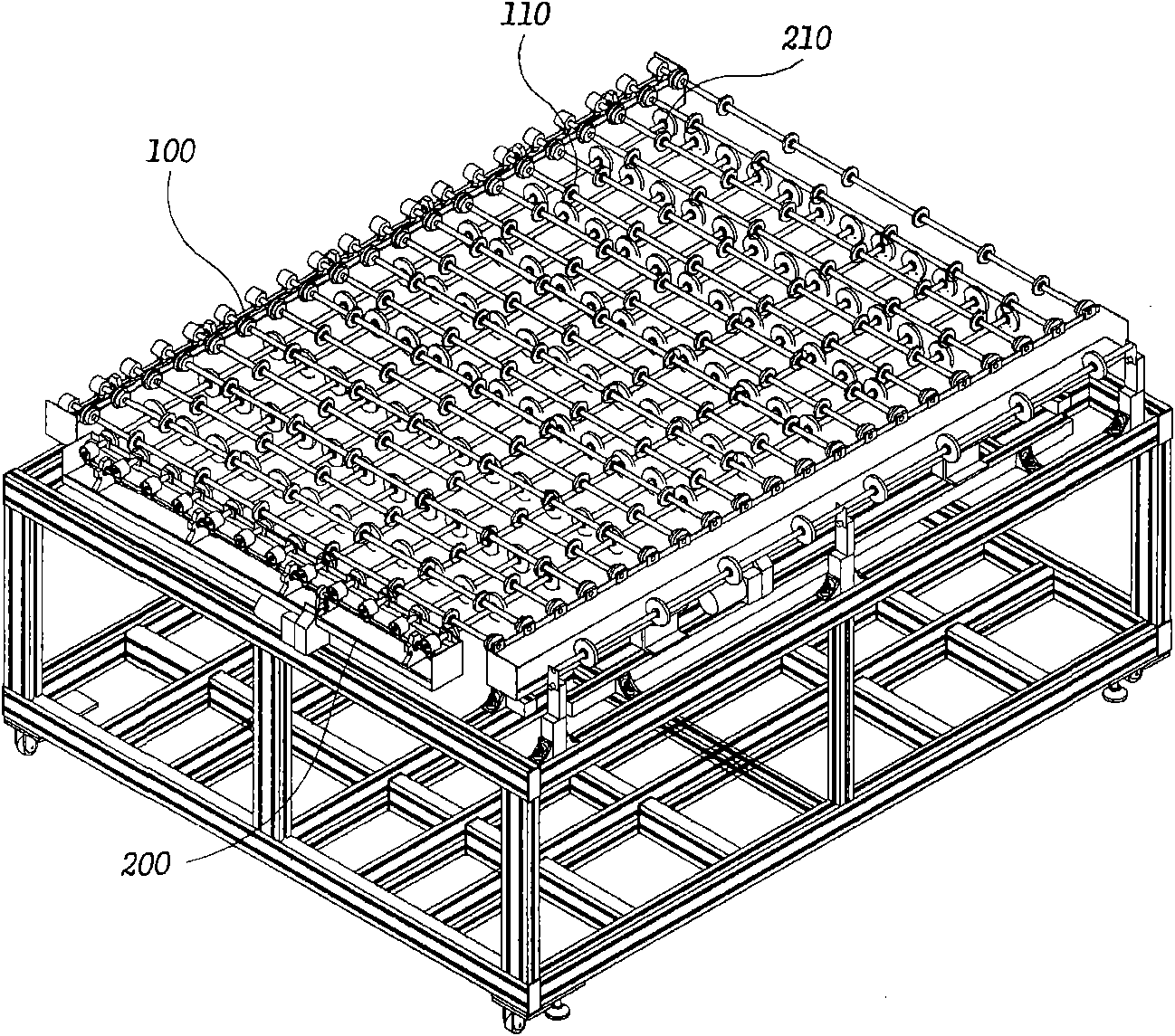

Pneumatic spiral direction-converted conveyor

InactiveCN102101584AImprove product processing qualityCharge manipulationConveyor partsLiquid-crystal displayEngineering

The invention relates to a technology of a direction conversion device of a manufacturing engineering conveyor line of a glass plate for a liquid crystal display device, in particular to a pneumatic spiral direction-converted conveyor. In order to more stably convert the conveying direction of a heavy-weight large-size glass plate, a balanced level state is integrally kept by uniformly dispersingpower in the ascending / descending action process of an upper stand provided with trip rollers in an arraying way so that partial subsidence is not generated, therefore bad influence is ensured not tobe caused on the glass plate and the quality of processed products is also enhanced when the direction of the large-size glass plate is converted.

Owner:TAE SUNG ENG

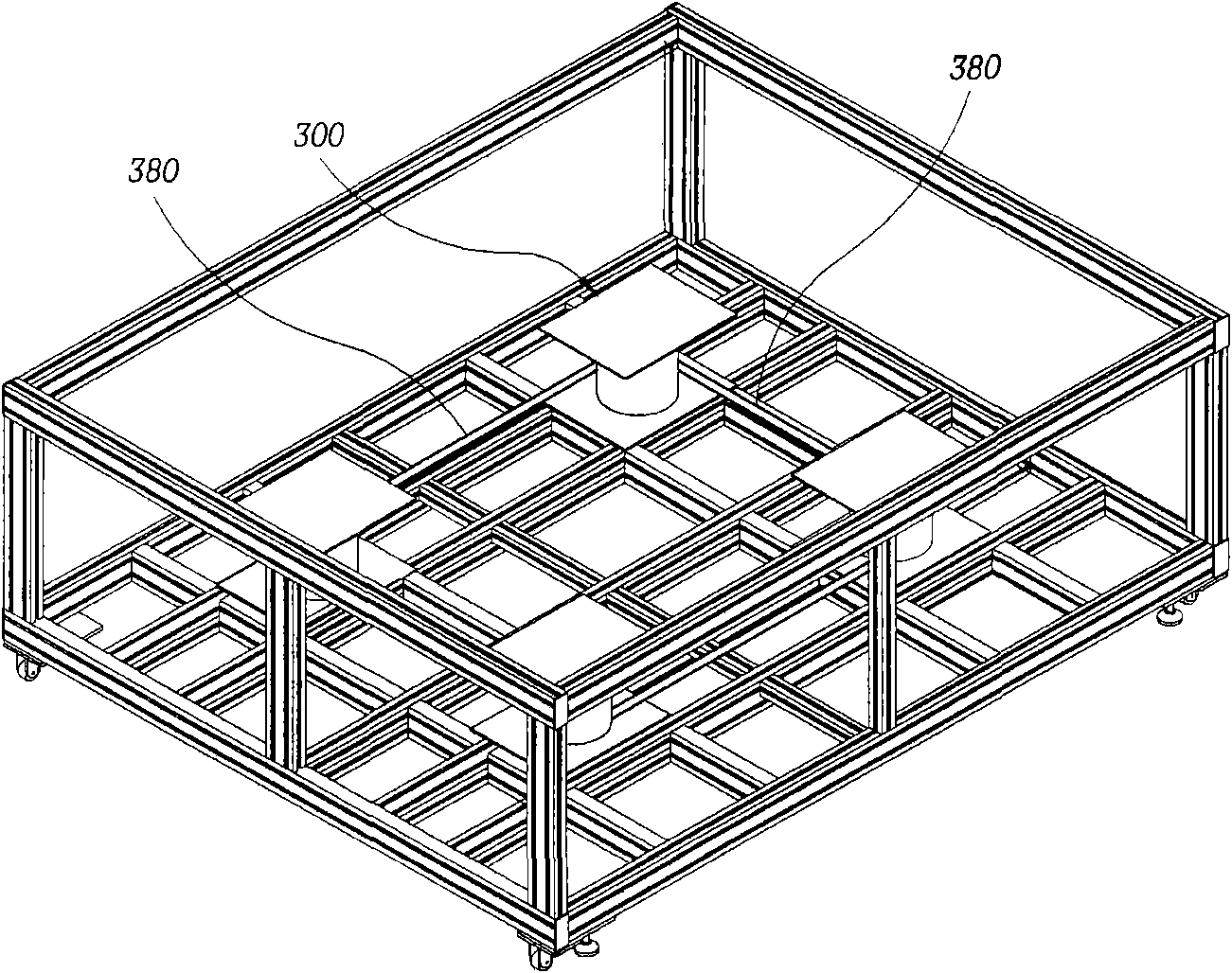

Micro-casting and Rolling Additive Manufacture for Large Special-shaped Pipes

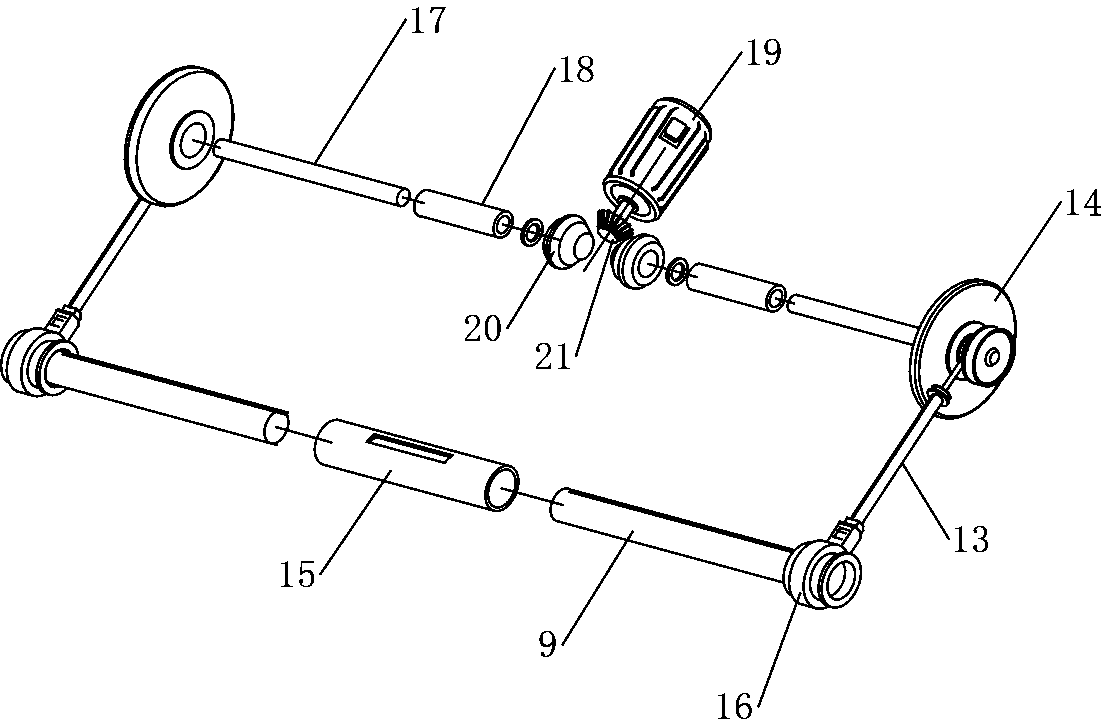

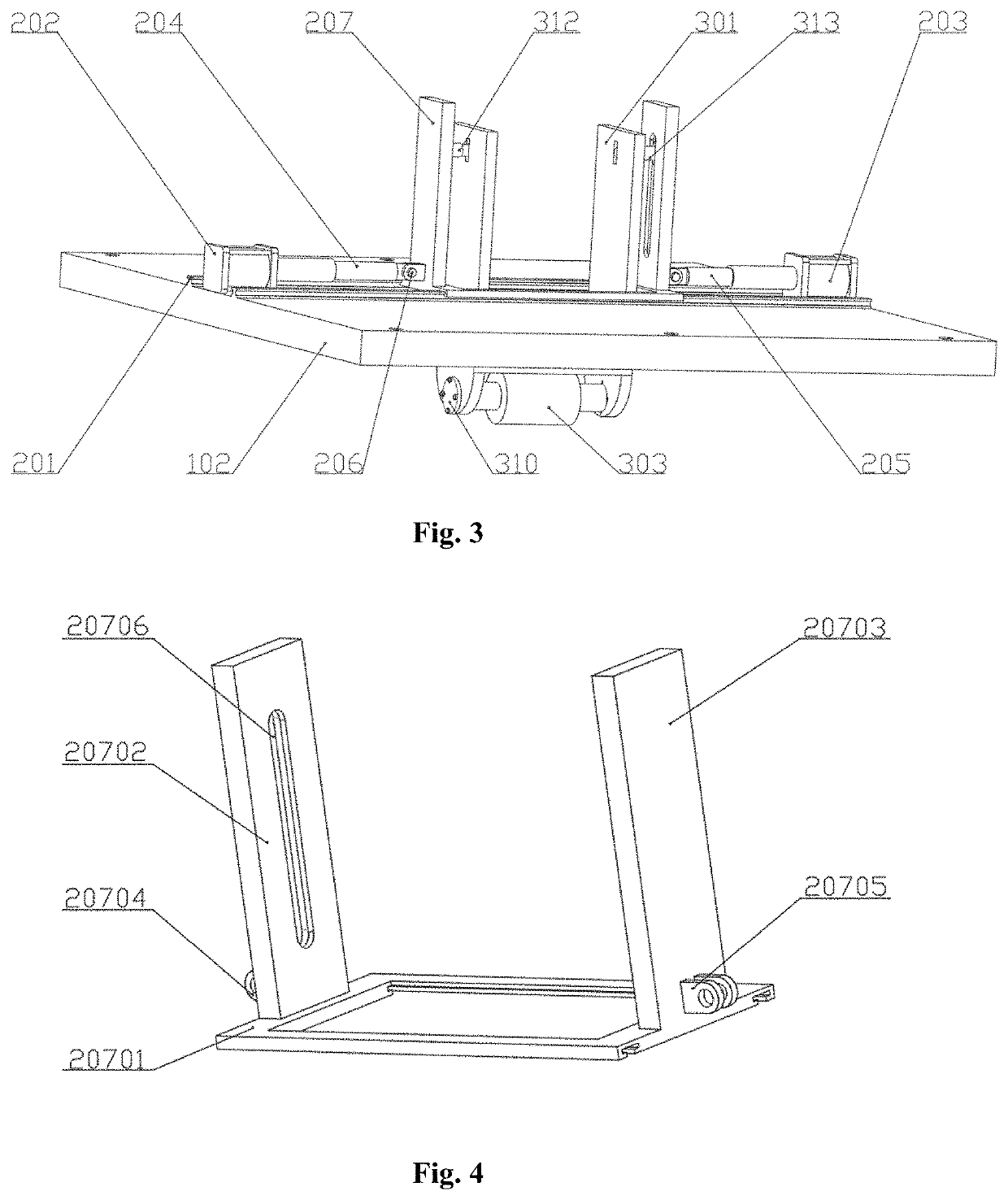

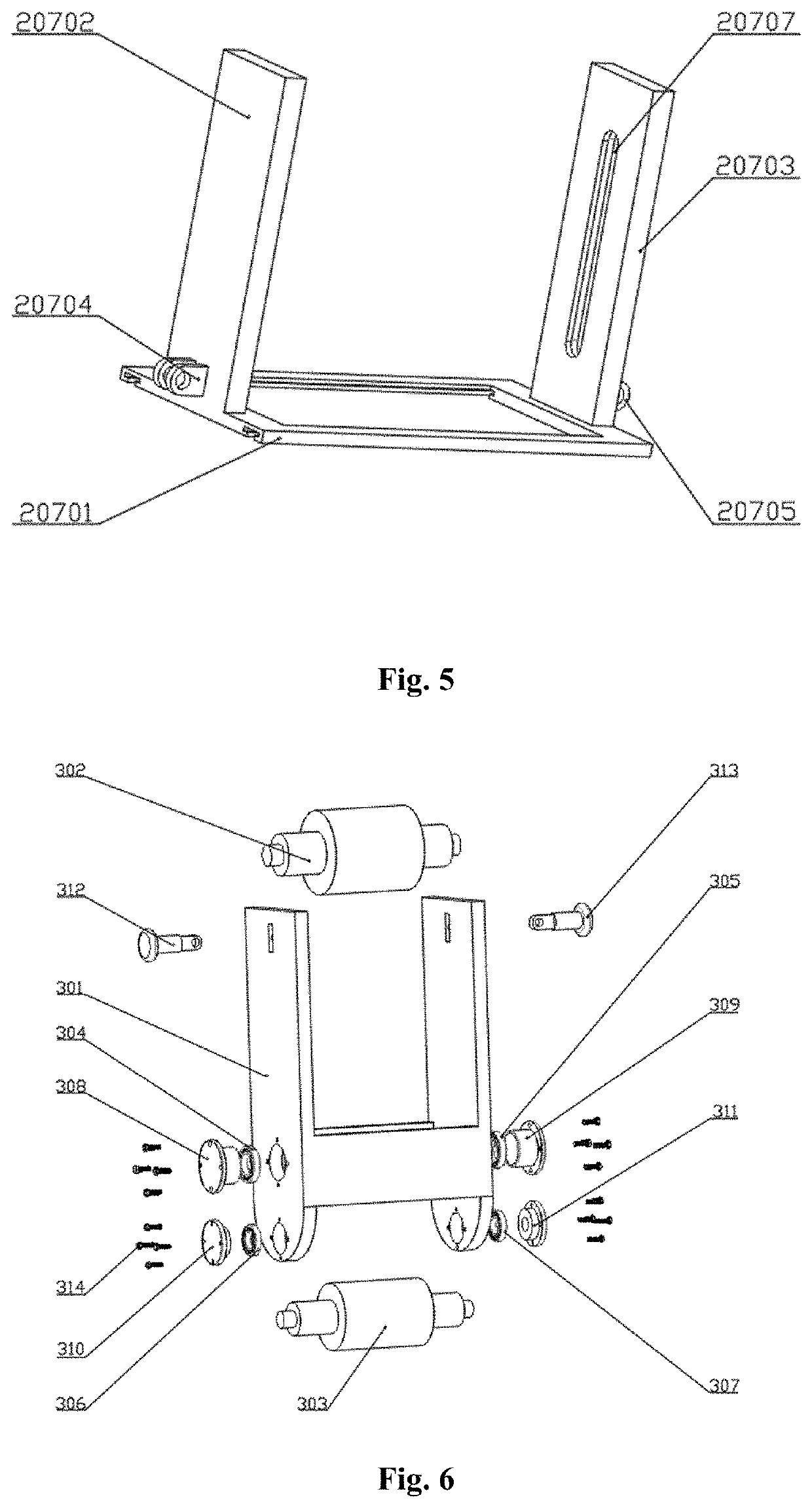

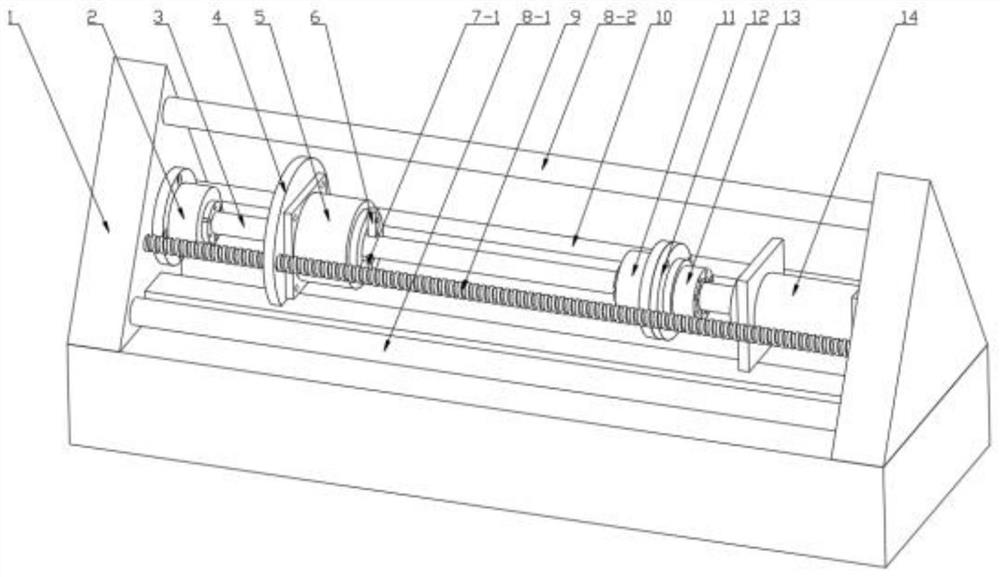

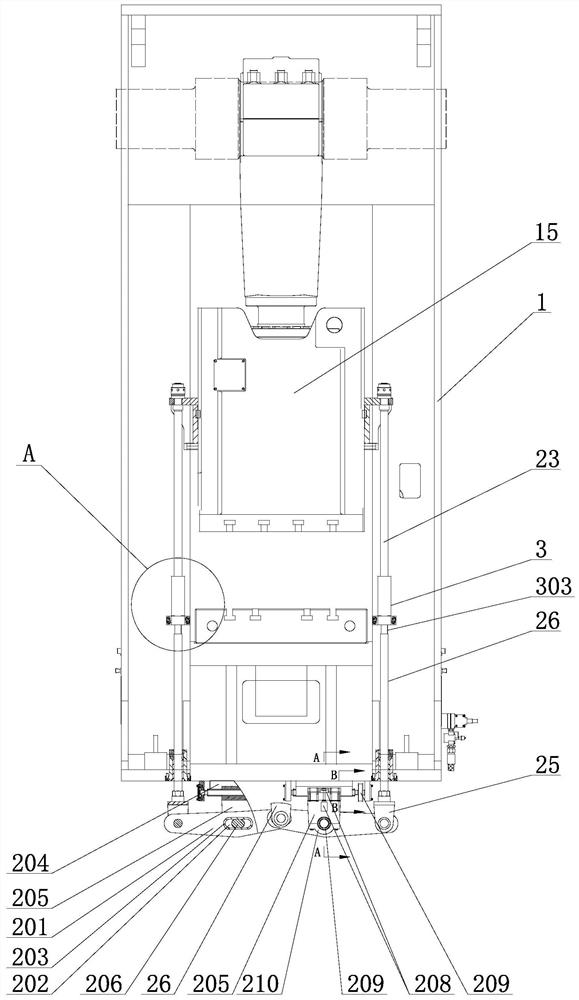

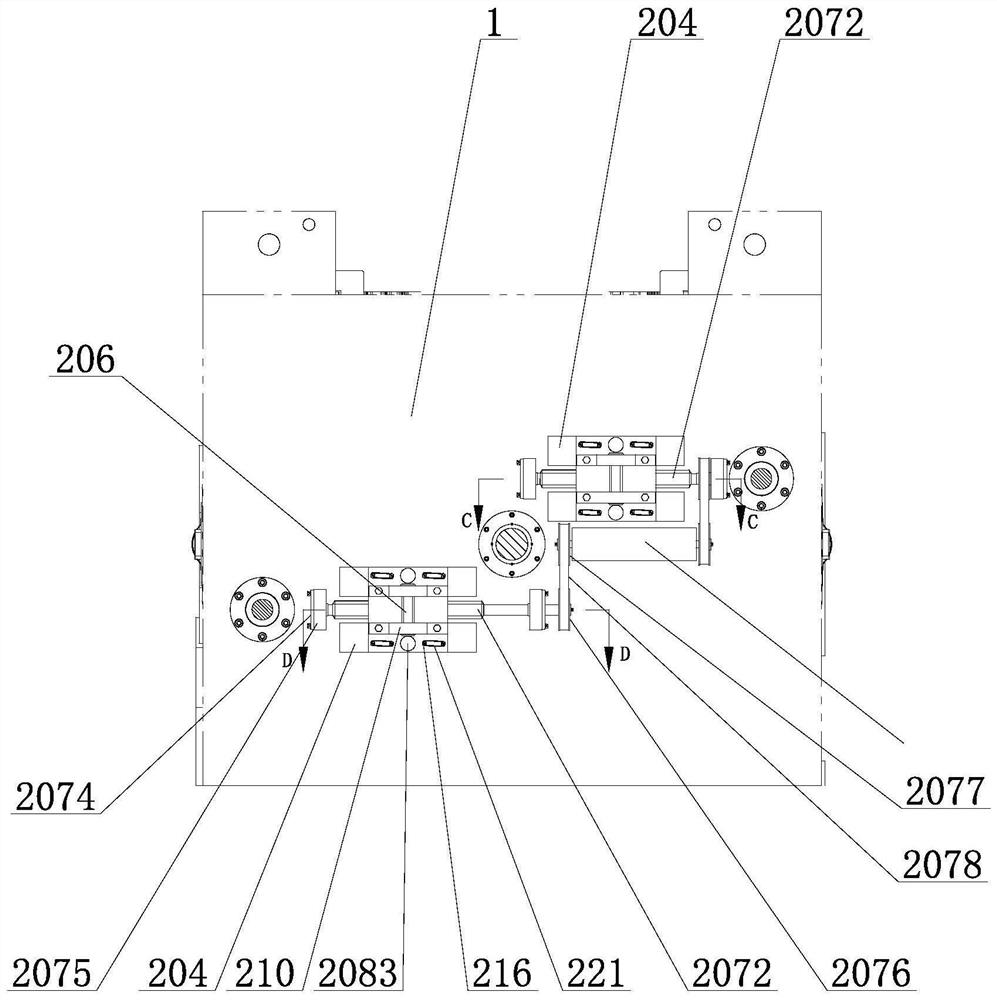

ActiveUS20210197458A1Improve product processing qualityReduction procedureAdditive manufacturing apparatusMetal rolling stand detailsHydraulic cylinderClassical mechanics

The present invention discloses a roll forming device for micro-casting and rolling additive manufacture for large special-shaped pipes, comprises a supporting assembly, a sliding assembly, and a roller system assembly. The sliding assembly includes a guide rail, hydraulic cylinders, hydraulic push rods and a guide rail sliding frame. Two ends of the guide rail are respectively fixedly connected with the centers of two ends of the frame plate in a width direction, the lower surface of the sliding plate of the guide raid sliding frame is slidably connected with the guide rail, housings of the hydraulic cylinders are respectively fixedly connected to the centers at both ends of the frame plate in the width direction. The invention adopts the structures of the guide rail, the hydraulic cylinder and the steering hinge rod to expand the working range of the device and the working types of workable parts.

Owner:YANSHAN UNIV

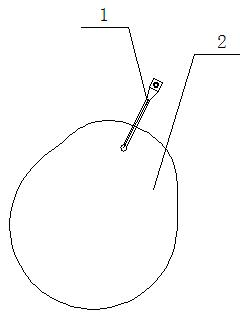

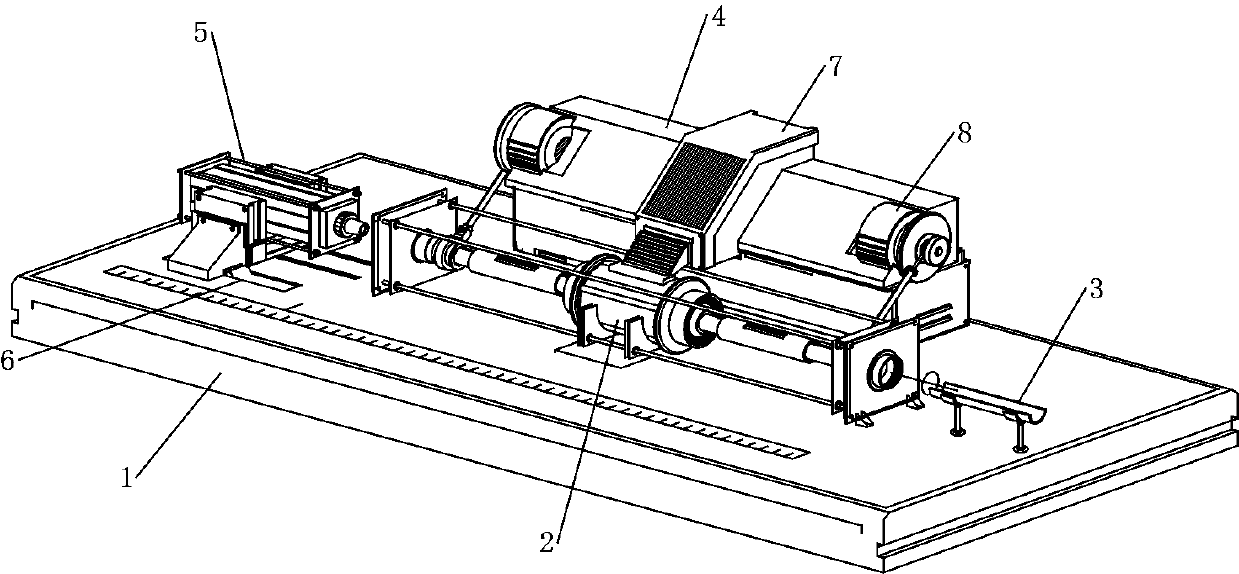

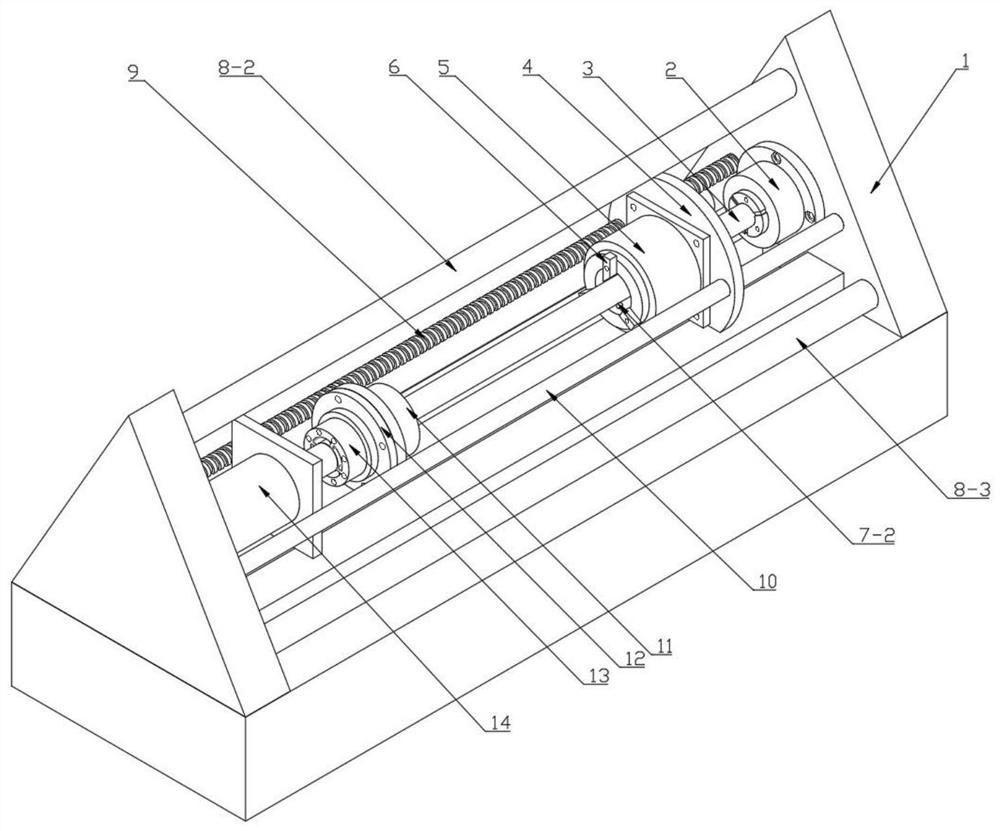

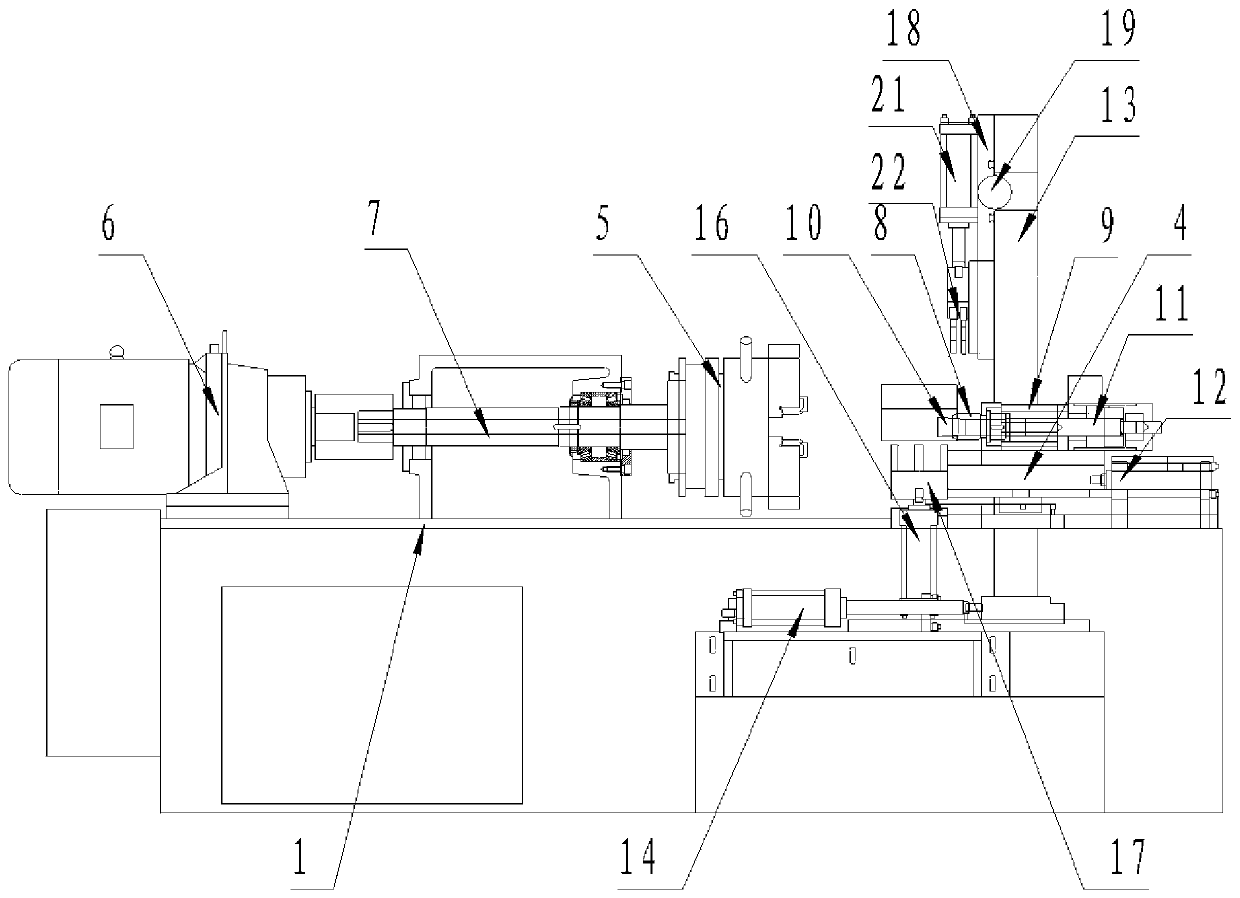

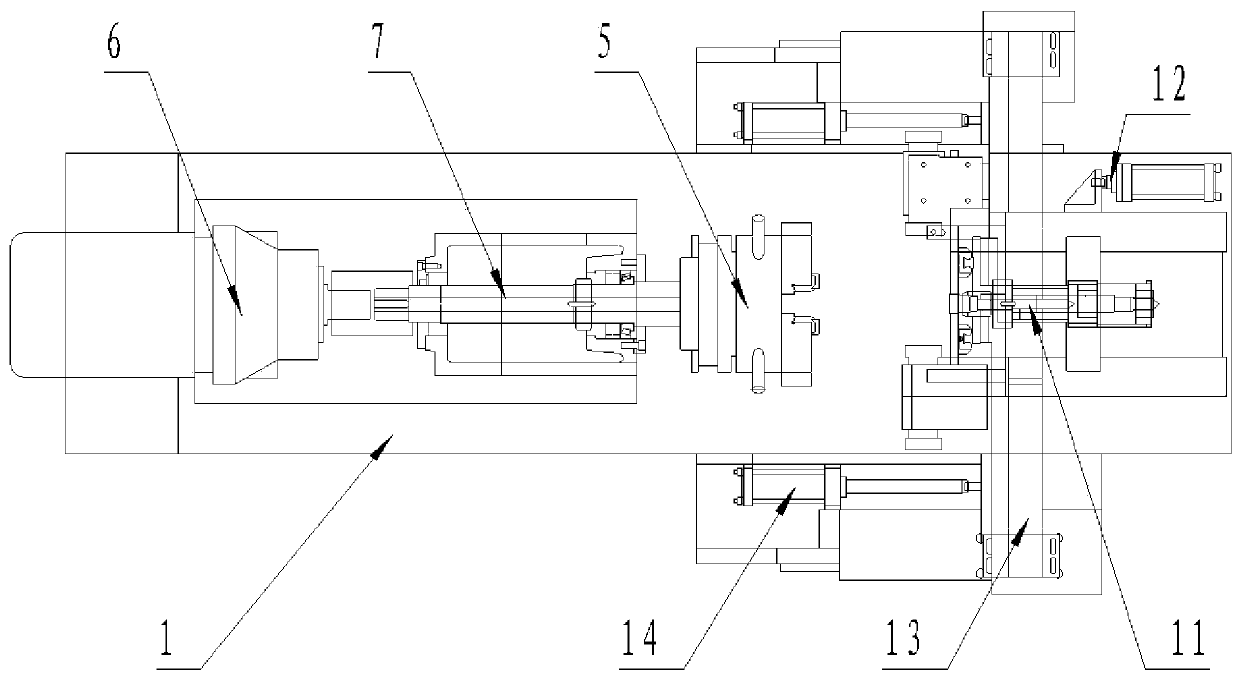

Axial stretching machining equipment for thin-wall slender shaft parts and method

The invention discloses axial stretching machining equipment for thin-wall slender shaft parts and a method. The axial stretching machining equipment comprises a base, a left hydraulic chuck is fixed to the inner side of the left supporting face of the base, the left hydraulic chuck and a right hydraulic chuck clamp the thin-wall slender shaft parts, the right hydraulic chuck is installed on a sensor connecting piece, the sensor connecting piece is connected with a hydraulic cylinder through an installation tension and compression sensor, and the hydraulic cylinder is fixed on the right supporting surface of the base; and a ball screw and a driven shaft are connected between the left supporting face and the right supporting face of the base, a motor fixing base is connected to the ball screw and the driven shaft, a disc type motor is installed on the motor fixing base, turning tools, first supporting idler wheels and second supporting idler wheels which are in contact with the thin-wall slender shaft parts are evenly distributed and installed on a rotating disc of the disc type motor, head balls of the two supporting idler wheels can rotate freely, and radial feeding is achieved through threads. The method adopts a route of pre-stretching, rough machining, pre-stretching, semi-finish machining, pre-stretching and finish machining. The cutting performance is improved, and machining deformation is effectively prevented.

Owner:XI AN JIAOTONG UNIV +1

Forging machinery press temperature control accuracy improvement device

ActiveCN110538956BGuaranteed to operate independentlyImprove accuracyForging press drivesHeating/cooling devicesTemperature controlEngineering

Owner:RONGCHENG HUADONG METAL FORMING MACHINERY +1

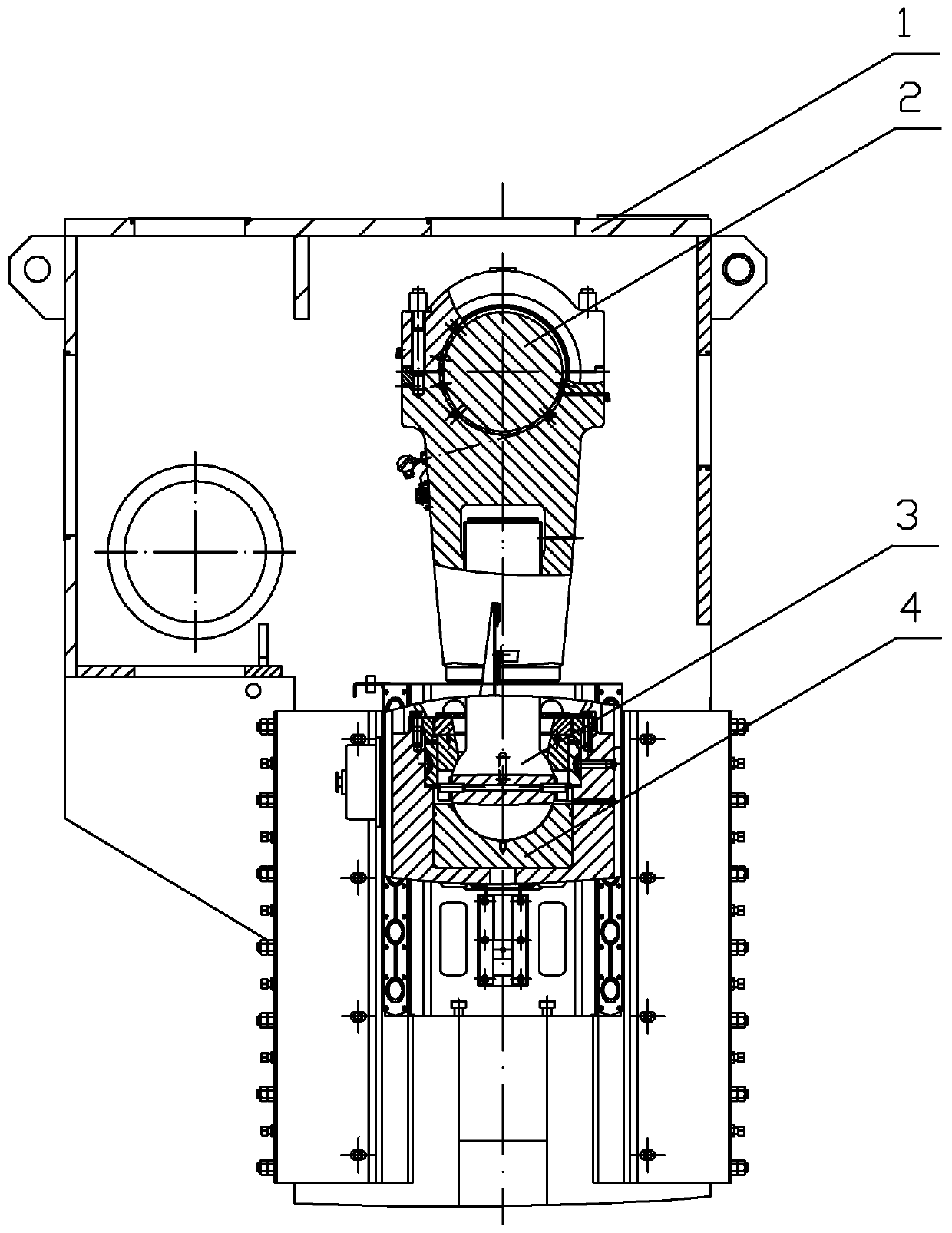

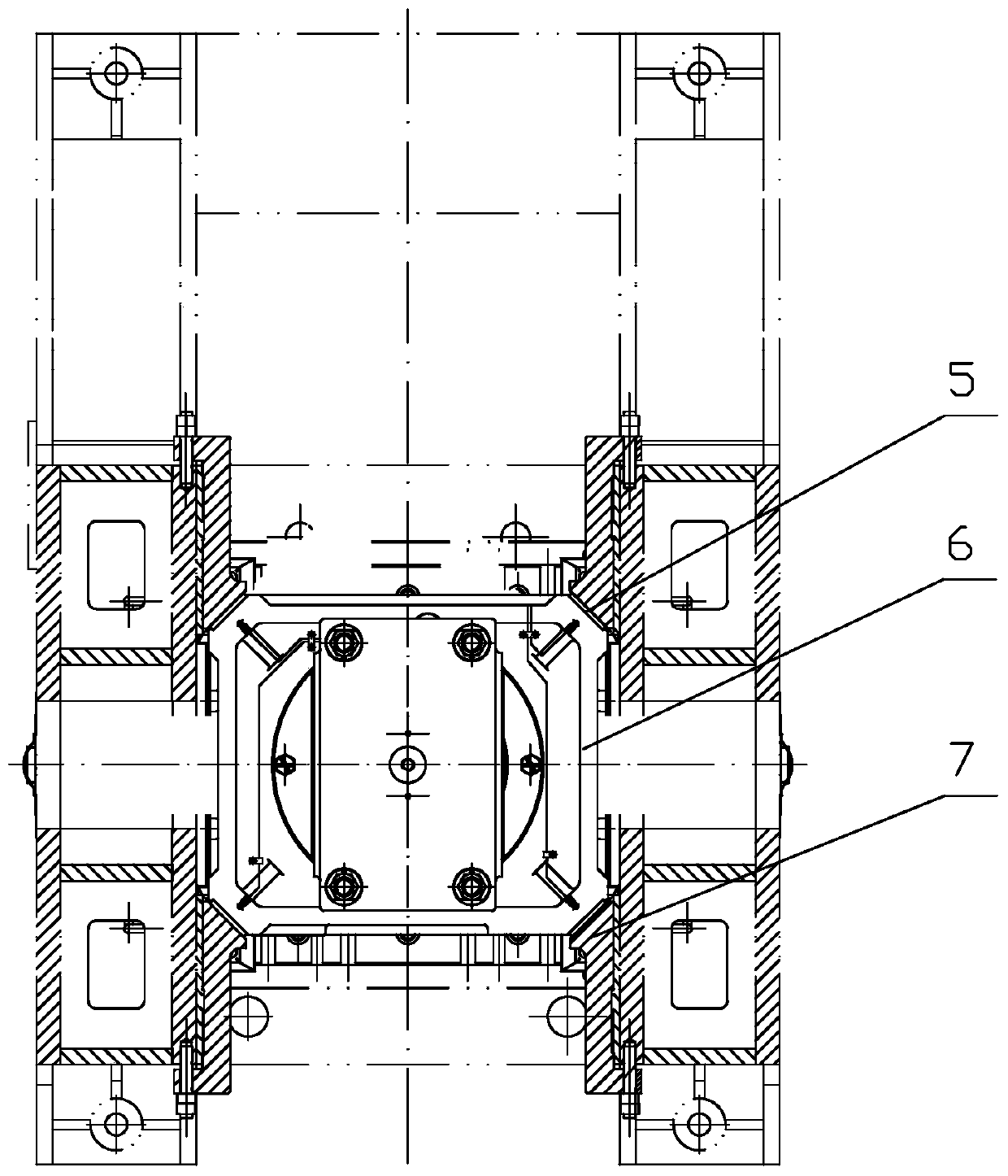

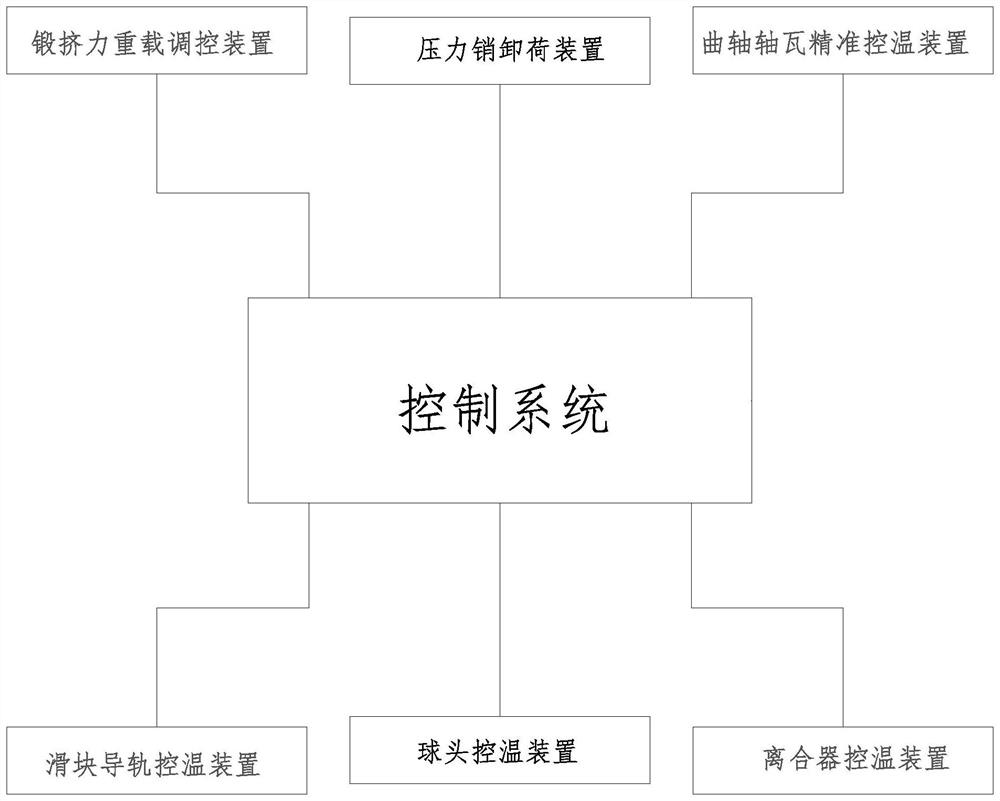

Precise and efficient hot die forging press

ActiveCN113245490AImprove the ability to resist heavy loadExtended service lifeUpsetting pressesSwagging pressesClutchAutomatic control

The invention relates to the field of high-end equipment manufacturing industry, in particular to a precise and efficient hot die forging press. The precise and efficient hot die forging press comprises a rack, wherein a forging extrusion force heavy load regulation and control device, a pressure pin unloading device, a crankshaft bearing bush temperature control device, a sliding block guide rail temperature control device, a ball head temperature control device and a clutch temperature control device which are connected with a control system are arranged on the rack respectively. The forging extrusion force heavy load regulation and control device can automatically and accurately regulate and control the magnitude of forging extrusion force under the heavy load condition, and the pressure pin unloading device can float a pressure pin upwards, so that the rotating torque and resistance in the transmission link are reduced; the crankshaft bearing bush temperature control device is adopted for accurately controlling the temperature of a bearing bush, and meanwhile efficient sealing thin oil lubrication is conducted; the clutch temperature control device is adopted to realize accurate and efficient temperature control of a clutch; and the sliding block guide rail temperature control device and the ball head temperature control device are adopted for conducting cold air temperature control on a friction pair, so that the transmission precision, efficiency and reliability of equipment and the product quality are effectively improved, and intelligent operation and maintenance and automatic control wiring are achieved.

Owner:RONGCHENG HUADONG METAL FORMING MACHINERY

Rapid paint sprayer for atomizing and removing flow falling orange peel of hardware plate disc type fin

The invention discloses a rapid paint sprayer for atomizing and removing flow falling orange peel of a hardware plate disc type fin. The structure comprises a liquid collection backflow box, an electric control box, a square inner groove, a paint tank barrel, a plate hanging bracket, a fin paint spraying device and a filtering base. In the invention, the plate hanging bracket is cooperated with the fin paint spraying device so as to form a stamping spray effect; a paint liquid is atomized and covered in a water curtain manner so that comprehensive wrapping performance of a hardware plate is high, a thickness of a paint surface is reduced, and air permeability of the plate is increased; compactness of a bottom rotary compaction paint surface is guaranteed through a film pressure needle suction plate, and a flow falling orange peel phenomenon caused by paint surface loosening is avoided; and the film pressure needle suction plate is also used for preventing water and color fading of thepaint surface of the hardware plate to form a thin film pressure evacuation treatment effect, reverse suction operation of a spray needle tube is used for achieving, longitudinal butterfly fin atomization of a longitudinal cross section of the hardware plate is also covered and homogenized from top to bottom, a paint surface material utilization rate is high, a protection effect is obvious, and plate stacking gap density is small.

Owner:滨州富创科技服务有限公司

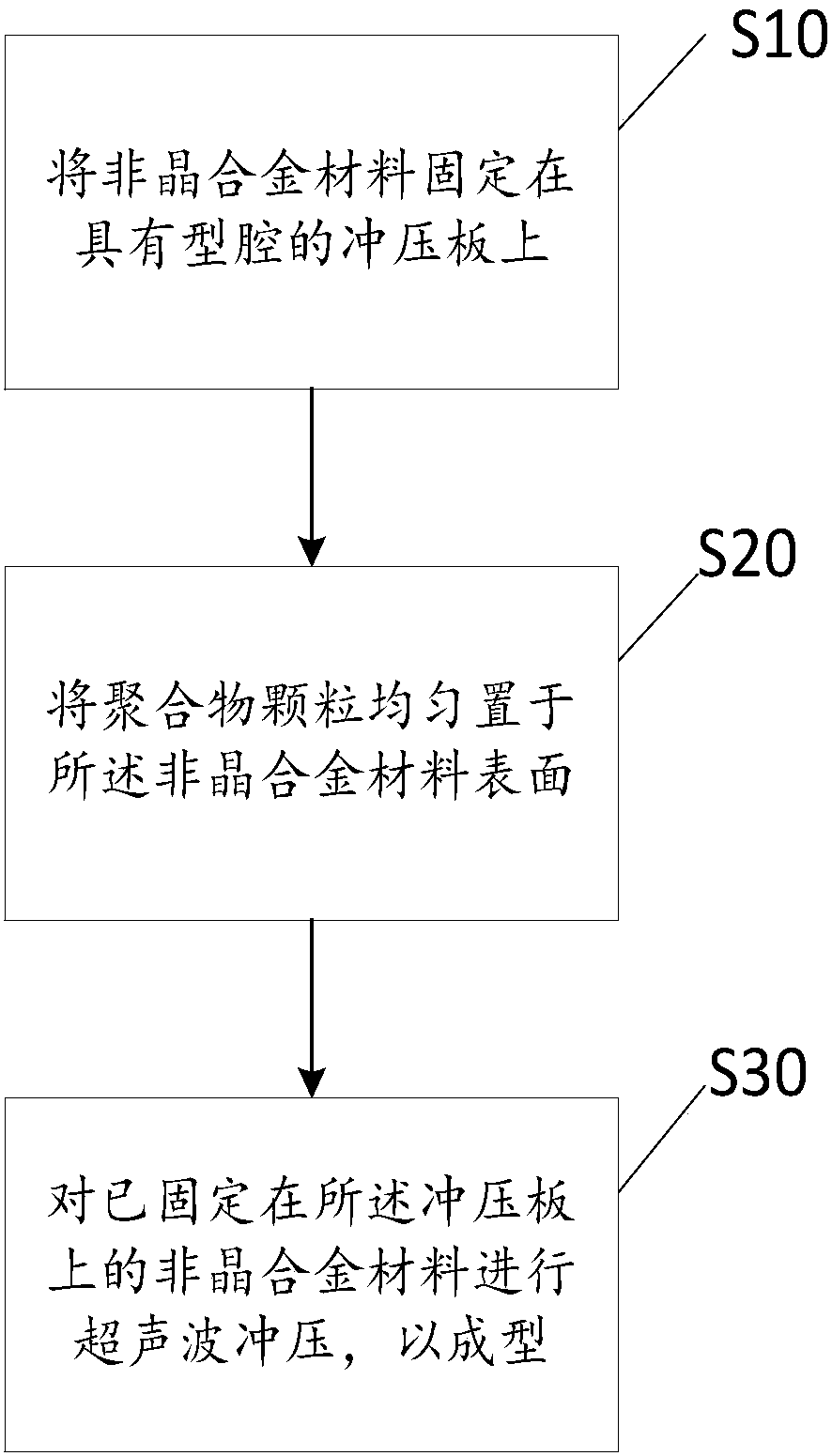

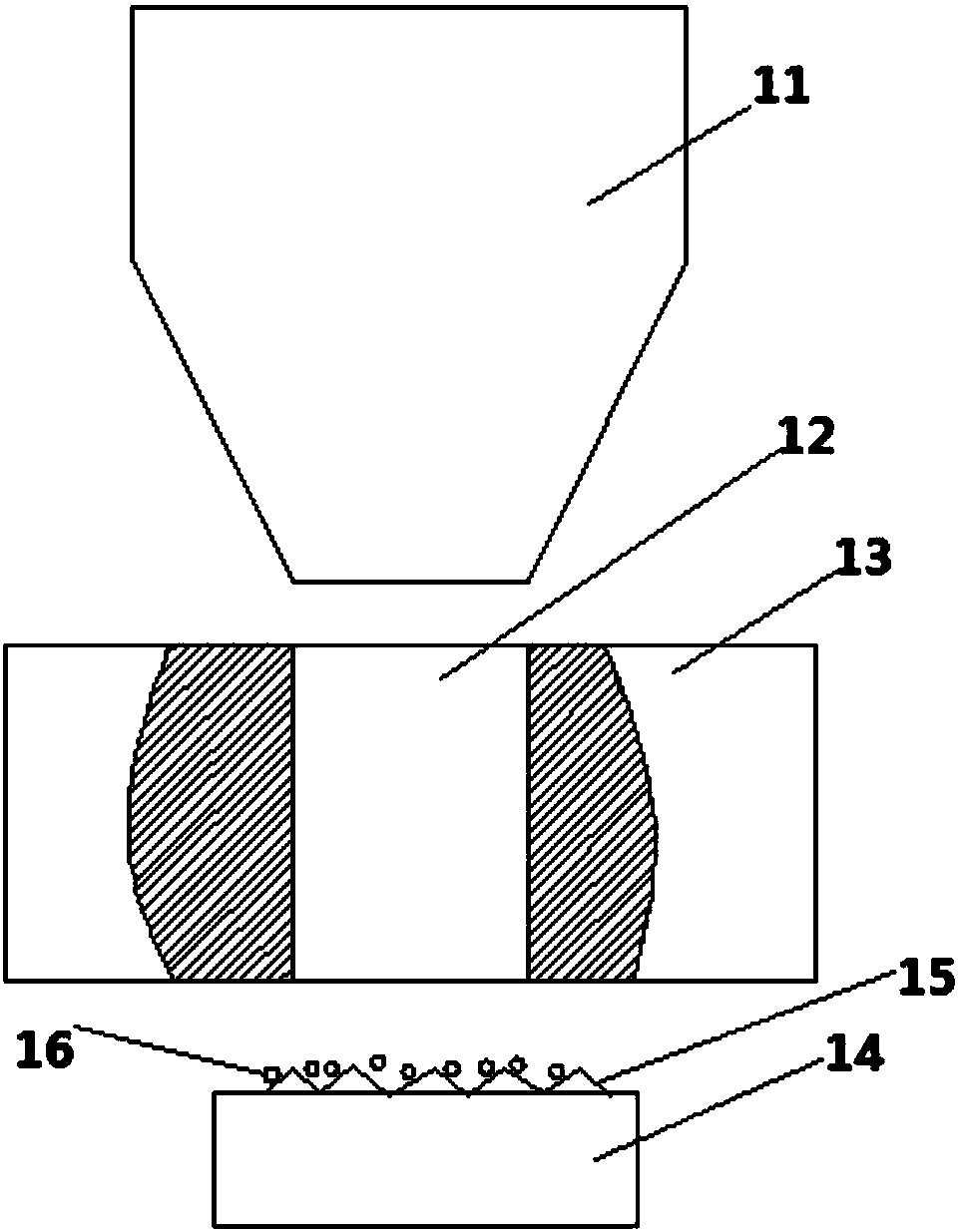

Ultrasonic-assisted amorphous alloy blanking molding method

ActiveCN108246861AImprove stamping stabilityImprove product processing qualityUltrasonic assistedPunching

The invention discloses an ultrasonic-assisted amorphous alloy blanking molding method. The method includes the following steps that S10, an amorphous alloy material is fixed to a punching plate witha cavity; S20, polymer particles are evenly arranged on the surface of the amorphous alloy material; and S30, the amorphous alloy material fixed to the punching plate is subject to ultrasonic punchingfor molding. According to the ultrasonic-assisted amorphous alloy blanking molding method, blanking of the amorphous alloy material is soft blanking under ultrasonic assistance, and the technical problem that in the amorphous alloy punching molding process in the prior art, stamping force borne by the amorphous alloy surface is not even is solved.

Owner:SHENZHEN UNIV +1

Production method of cutting die

InactiveCN100480007CAvoid deformationHigh strengthDomestic articlesMetal working apparatusEngineeringMachining

Owner:汕头和兴隆激光刀模有限公司

Nut machining process

ActiveCN109623288AImprove product processing qualityStable processingNutsPre treatmentMachining process

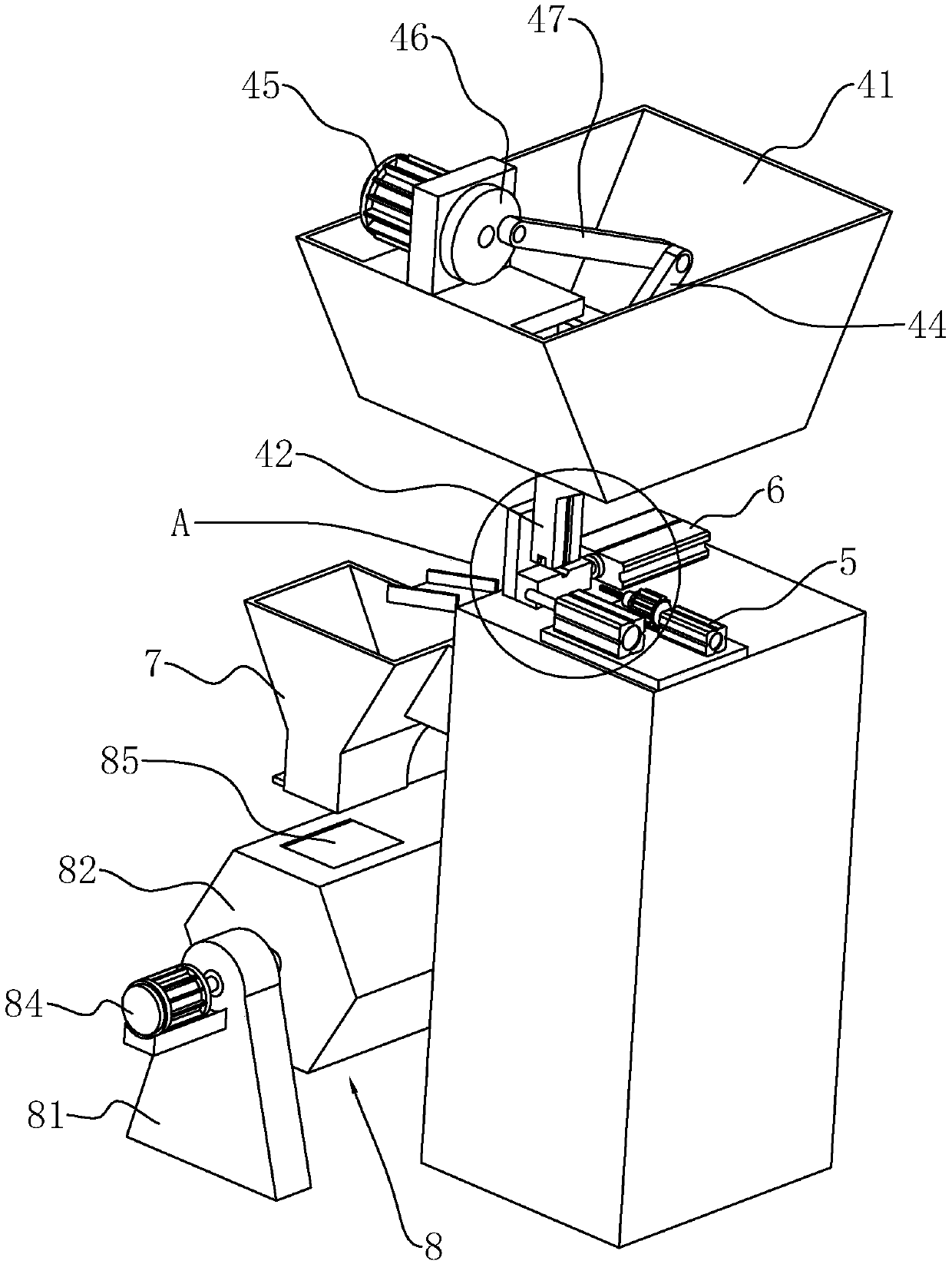

The invention discloses a nut machining process, and relates to the technical field of nut machining. The nut machining process comprises the following steps: pretreatment, forming and machining, deoiling treatment, tapping, cleaning treatment and surface treatment. Nut bodies which are collected by an unloading device are placed in a collecting hopper, a discharging opening of the collecting hopper is connected with a conveying flow channel for conveying the nut bodies, conveying plates are arranged below the conveying flow channel at interval, a tapping device for tapping the nut bodies between the conveying flow channel and each conveying plate is arranged on one side of the conveying plate, a pushing device which is used for pushing out the tapped nut bodies to the other side of the conveying plate is arranged at one end of each conveying plate, and a collecting device for receiving the tapped nut bodies is arranged on the side, which is away from the corresponding pushing device,of each conveying plate. The nut machining process has the effects of stable machining, capability of improving the quality of nut machined products and high efficiency.

Owner:温州博力浩实业有限公司

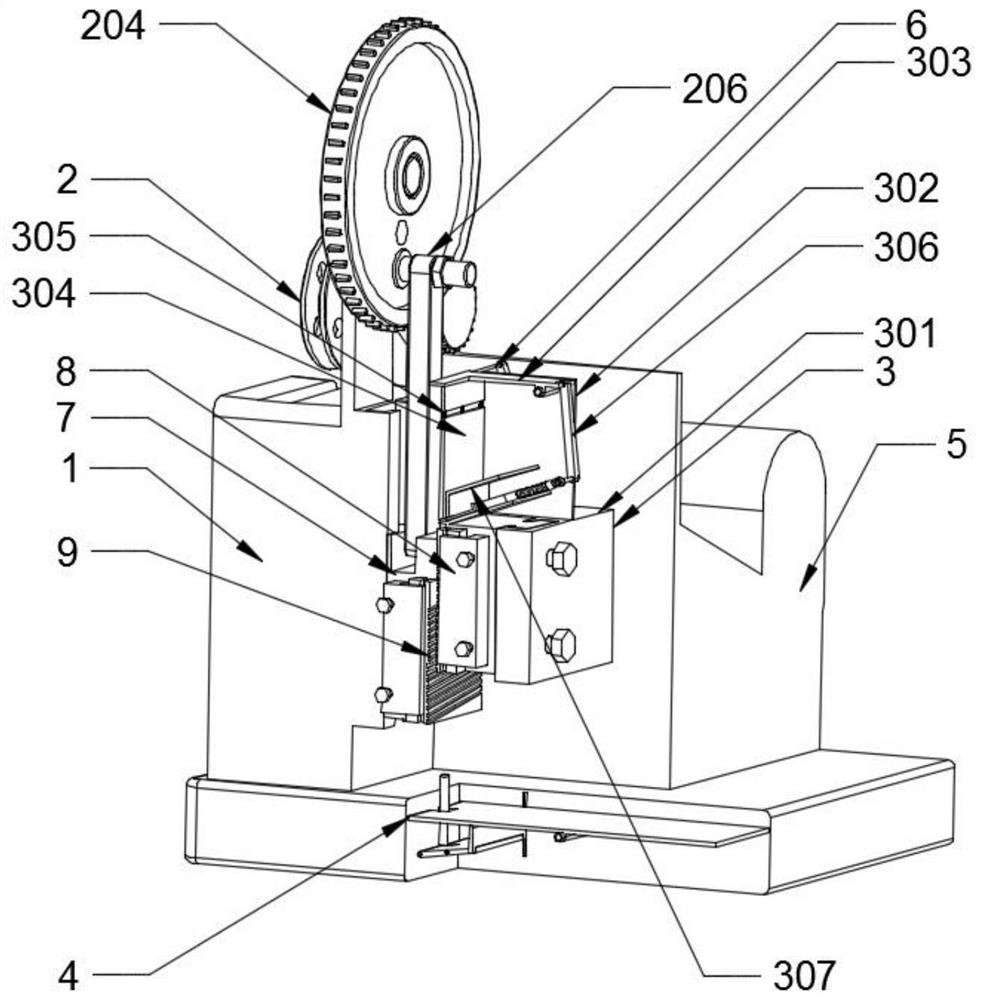

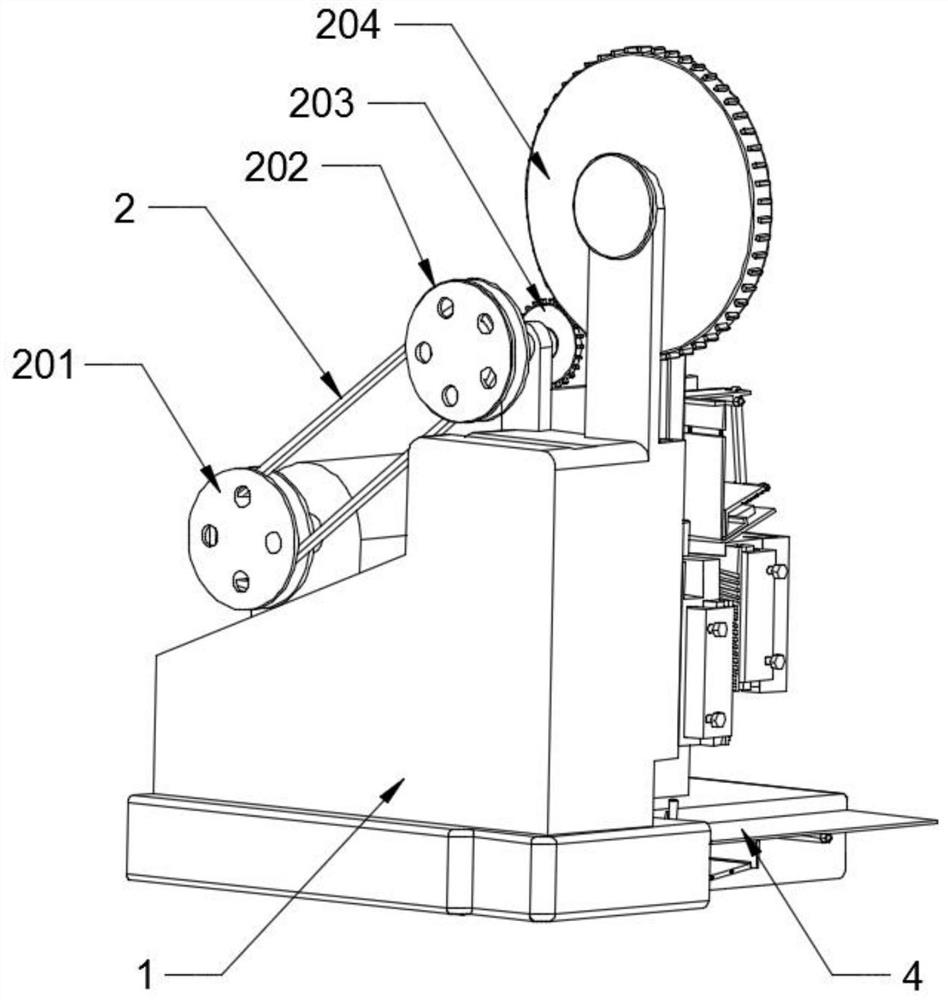

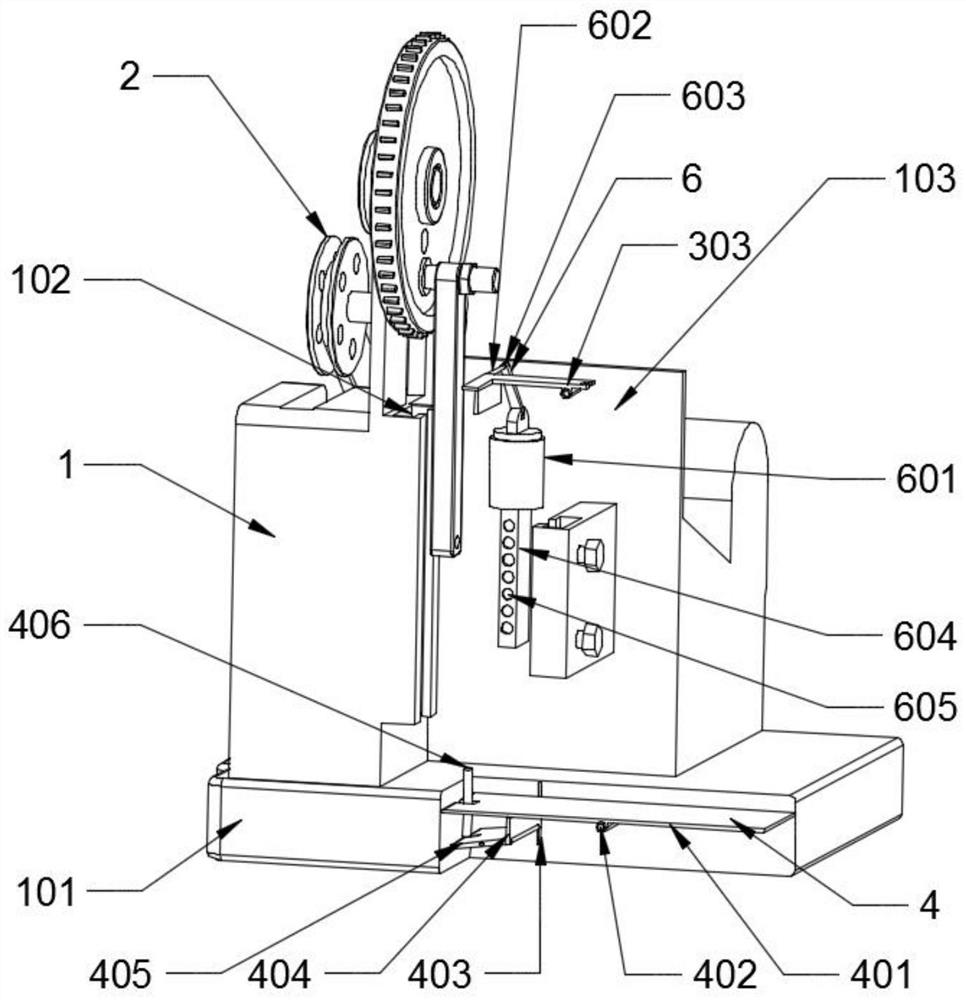

Transmission mechanism for automatic thread rolling machine

InactiveCN112792270AImprove product processing qualityEasy to useGearingScrew-threads articlesProcess engineeringControl engineering

The invention discloses a transmission mechanism for an automatic thread rolling machine. The transmission mechanism comprises a supporting mechanism, a power mechanism and a machine body, wherein the power mechanism is fixedly installed at the top end of the supporting mechanism, the machine body is arranged on the side, close to the power mechanism, of the supporting mechanism, a cleaning mechanism is fixedly installed on the portion, on the side face of the machine body, of the supporting mechanism, a sliding mechanism is slidably connected to the side face of the supporting mechanism, a switching mechanism is fixedly welded to the side, close to the machine body, of the supporting mechanism, a fixing mechanism is fixedly installed on the side face of the switching mechanism, a material guiding mechanism is arranged at the position, under the sliding mechanism and the fixing mechanism, of the bottom end of the supporting mechanism, and thread rolling plates are fixedly connected to the side faces of the sliding mechanism and the fixing mechanism in a clamped mode. When the transmission mechanism is used, the transmission mechanism is linked with other parts in the thread rolling process, more effects are achieved, the product machining quality of the device is improved, the device is easier to use, and the part machining efficiency is higher.

Owner:南通振馨芫纺织品有限公司

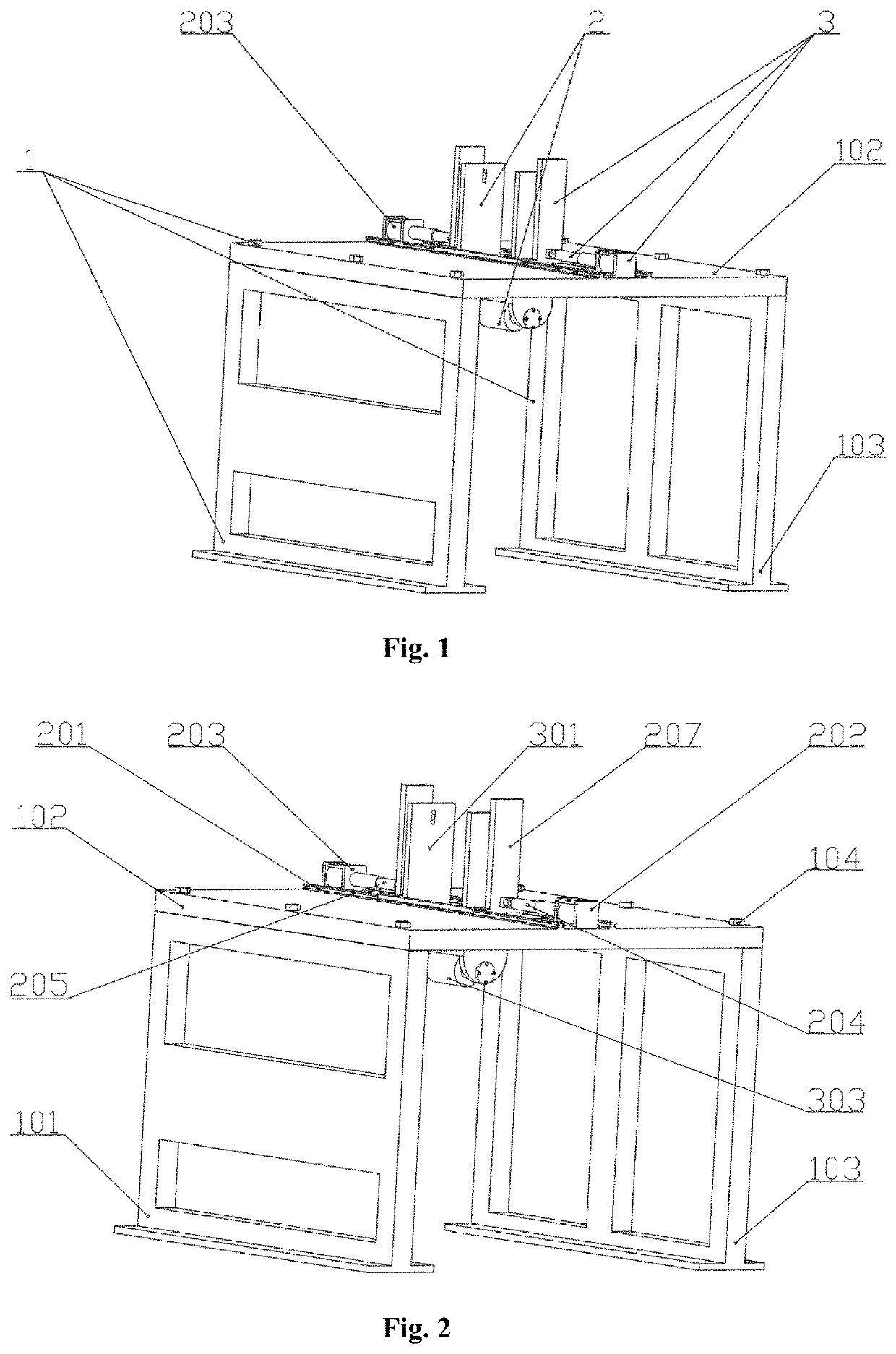

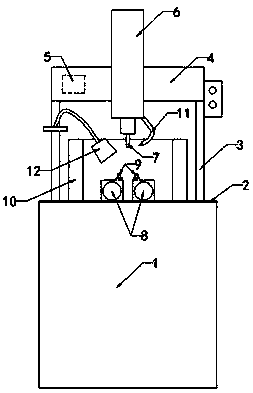

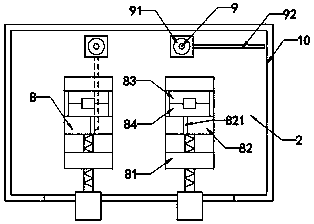

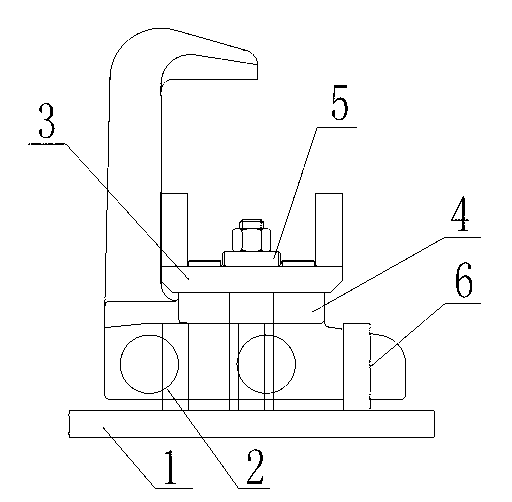

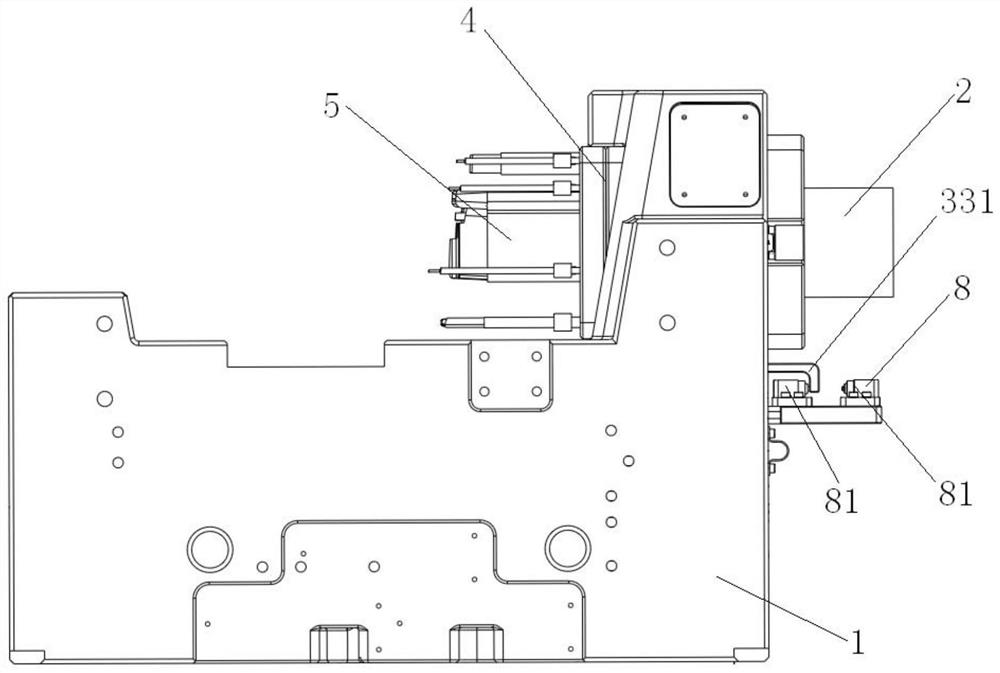

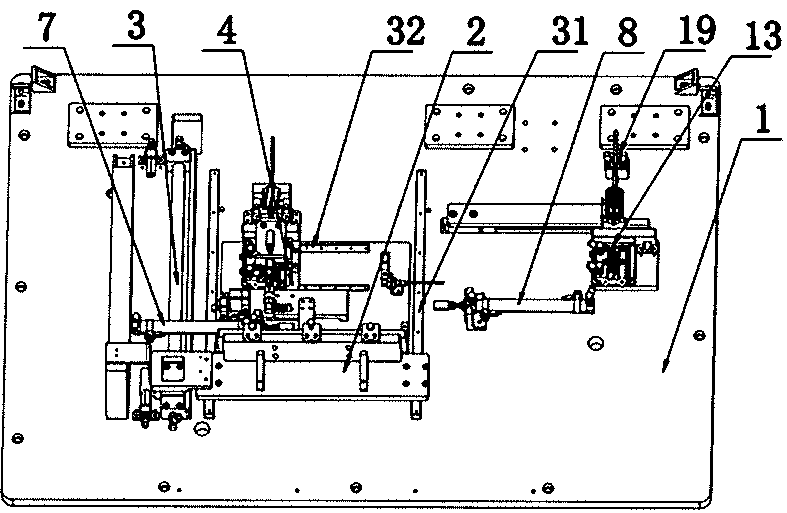

Drilling device for communication connector

InactiveCN109382667ASimple structureIncrease productivityLarge fixed membersPositioning apparatusElectric machineryDrive motor

The invention provides a drilling device for a communication connector. A rack (1) is provided with a working table (2), two supporting plates (3) are arranged on the working table (2), a cross beam (4) is connected between the supporting plates (3), the cross beam (4) is connected with a transverse moving arm (6), and a drilling knife (7) which is driven to rotate by a driving motor is arranged in the transverse moving arm (6). The drilling device for the communication connector is characterized in that two symmetric clamping mechanisms (8) are further arranged on the working table (2) and positioned below the transverse moving arm (6), and a workpiece positioning and examination mechanism (9) is arranged at the top end of each clamping mechanism (8); and each clamping mechanism (8) consists of a base (81), a clamping block adjusting component (82) arranged on the base (81) as well as a clamping block I (83) and a clamping block II (84) which are placed on the base (81). The drillingdevice is simple in structure, two machining stations are provided simultaneously, the drilling device does not need to stop for taking and mounting workpieces in a machining process, and the production efficiency is greatly improved.

Owner:丹阳市宏泰金属制品有限公司

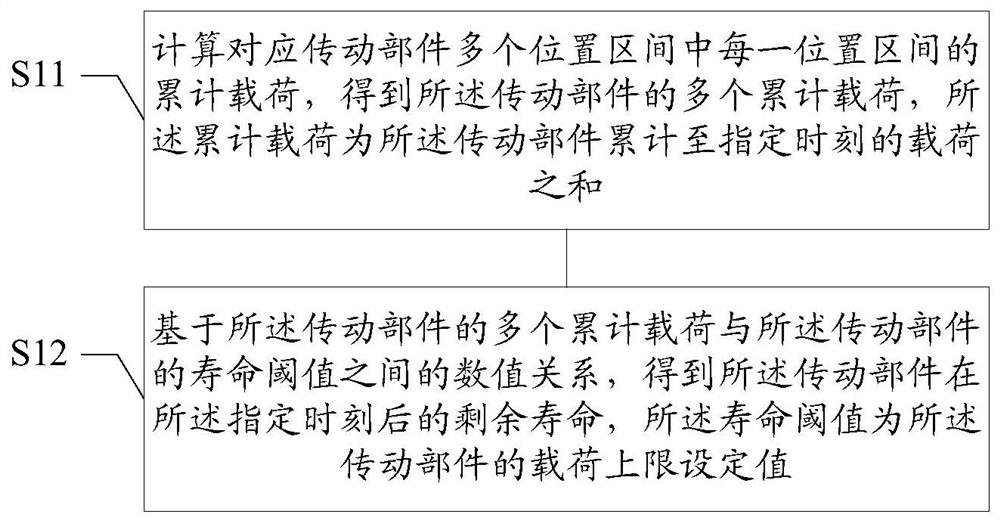

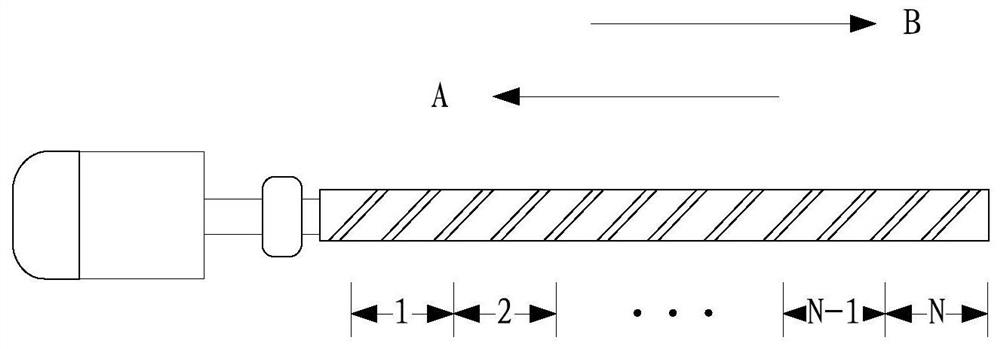

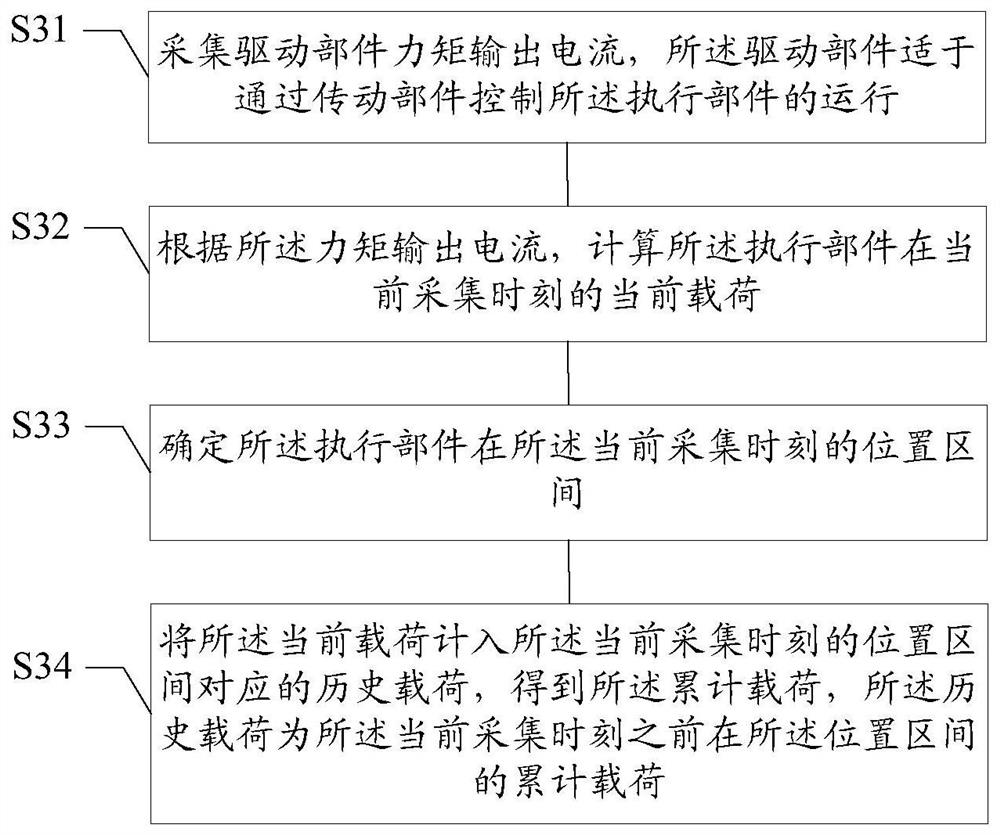

Service life estimation method and device, medium, terminal and servo feeding system

PendingCN113704953AImprove accuracyMaster usageDesign optimisation/simulationSpecial data processing applicationsComputer scienceIndustrial engineering

The embodiment of the invention discloses a service life estimation method and device, a medium, a terminal and a servo feeding system, and the method comprises the steps: calculating the cumulative load of each position interval in a plurality of position intervals of a corresponding transmission part, and obtaining a plurality of cumulative loads of the transmission part, wherein the cumulative load is the sum of loads accumulated to a specified moment by the transmission part; and based on the numerical relationship between the multiple accumulated loads of the transmission part and a life threshold value of the transmission part, obtaining the remaining life of the transmission part after the specified moment is obtained, wherein the life threshold value is a load upper limit set value of the transmission part. According to the technical scheme, the accuracy of estimating the service life of the transmission part can be improved.

Owner:SYMG SHANGHAI INTELLIGENCE SYST CO LTD

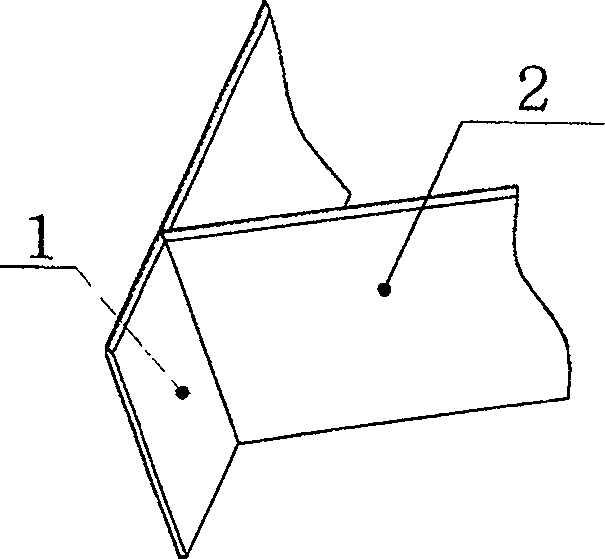

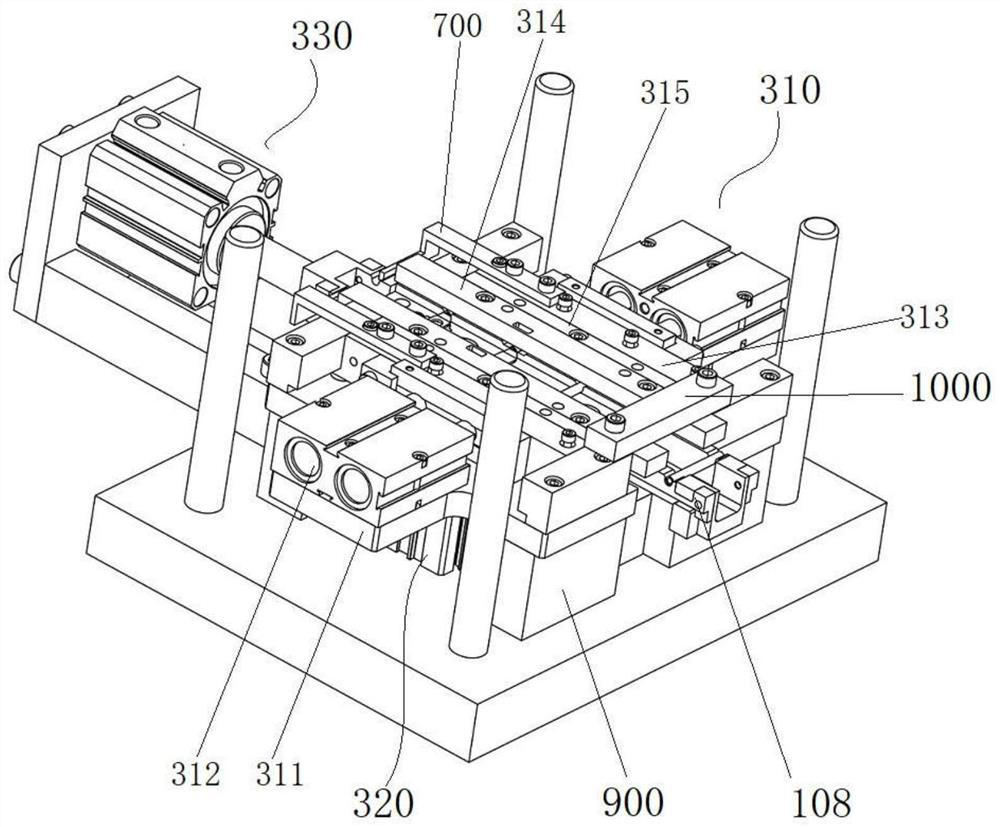

Steel plate spring support drilling tool

InactiveCN103008719AImprove machining accuracyReduce setup timePositioning apparatusMetal-working holdersMechanical engineeringPositioning system

The invention discloses a steel plate spring support drilling tool. The steel plate spring support drilling tool comprises a pedestal assembly (1), a positioning device (2), a drilling and positioning device (3), a positioning and guiding device (4) and a positioning post (6), wherein two holes are formed in the two sides of the drilling and positioning device (3); the positioning and guiding device (4) is arranged on the pedestal assembly (1); and the positioning post (6) is matched with the two holes formed in the drilling and positioning device (3) to position. The steel plate spring support drilling tool has the characteristics of good structure, convenience in use, high machined product quality, high precision, safety, reliability, practicability and high efficiency, and the product quality can be greatly improved in mass production.

Owner:QINGTE GRP

Automatic mould for SC wiring terminal

PendingCN114160677AAchieve deburringIngenious structural designEdge grinding machinesShaping toolsControl systemElectric machinery

The invention discloses an automatic die for an SC wiring terminal. Forming such as pressing and splitting is carried out through a lower die and an upper die. The two transverse adjusting mechanisms are symmetrically arranged on the two sides of the lower die, the vertical adjusting mechanisms are arranged on the lower portions of the transverse adjusting mechanisms, and the front-back adjusting mechanism is arranged at the front end of the lower die. An air cylinder device is arranged at the corresponding position of the moving mechanism, a magnetic travel switch is installed on an air cylinder, the magnetic switch is controlled through a PLC control system on automation equipment so that the moving mechanism can complete circulating motion, and therefore the purpose of automatic production is achieved. And the fourth insert pin clamps the wire pressing part of the SC wiring terminal, a rotating motor on the fourth insert pin drives the SC wiring terminal to rotate and rub with the polishing block, and deburring of the connecting part of the SC wiring terminal is achieved. Reversing of air outlet and air inlet of the miniature air pump is achieved through the reversing valve, so that the inner air bag is deflated to be separated from the wire pressing part of the SC wiring terminal, and the SC wiring terminal is blown off by inflating the inner positioning pipe. The device is ingenious in structural design, convenient and efficient to use and high in quality of machined products.

Owner:乐清市嘉韵电器有限公司

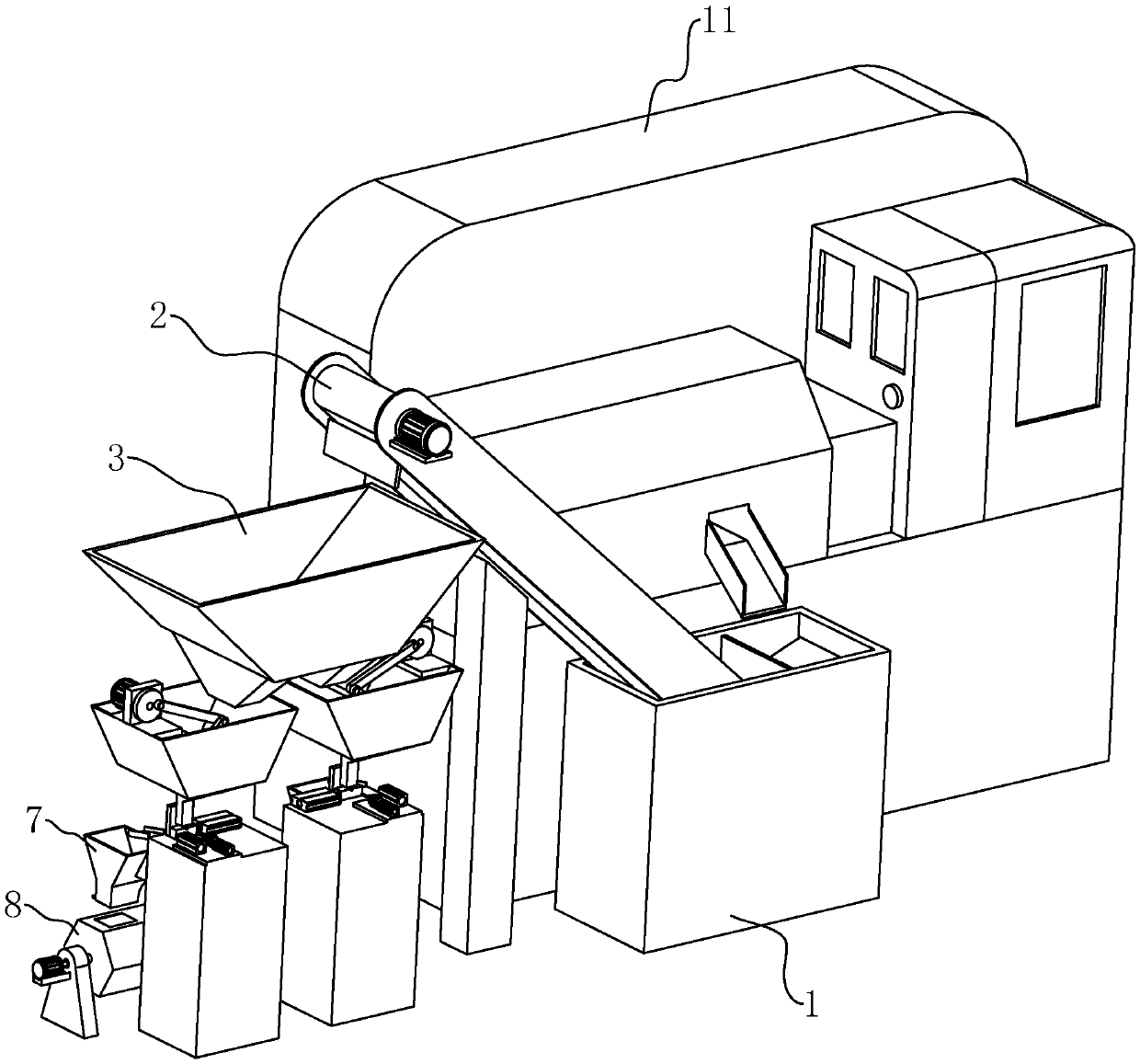

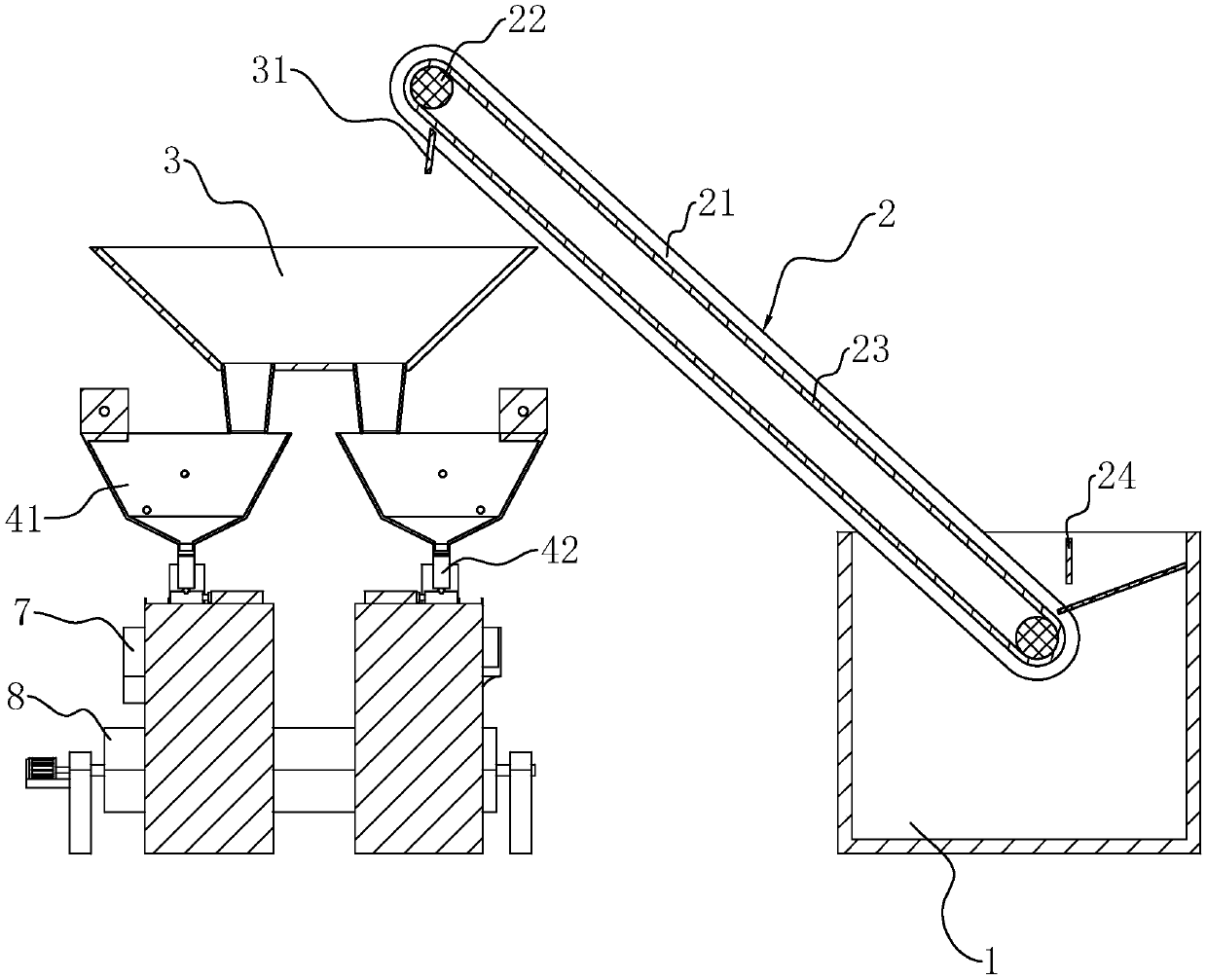

Automatic threading machining device for large-opening-diameter steel pipe joint

PendingCN111360341AReduce labor intensityRealize automatic feeding processThread cutting machinesSteel tubePush and pull

The invention discloses an automatic threading machining device for a large-opening-diameter steel pipe joint. The automatic threading machining device for the large-opening-diameter steel pipe jointcomprises a large-opening-diameter steel pipe joint threading machining and power device, a sliding base, a large-opening-diameter steel pipe joint clamping and fixing device fixedly mounted on the top face of the sliding base, a push and pull device for pushing the sliding base and the large-opening-diameter steel pipe joint clamping and fixing device on the top face of the sliding base to move along the center line of the right side of the top face of a main strip-shaped worktable, a large-opening-diameter steel pipe joint feeding device for feeding for the large-opening-diameter steel pipejoint clamping and fixing device, and a large-opening-diameter steel pipe joint threading machining product discharging device. Automatic loading and automatic machining of large-opening-diameter steel pipe joint threading can be achieved, labor intensity of operation workers can be reduced, safety hidden danger is reduced, the large-opening-diameter steel pipe joint threading machining product quality is improved, and a large-opening-diameter steel pipe joint threading machining product yield and work efficiency can be improved.

Owner:济南迈科管道科技有限公司

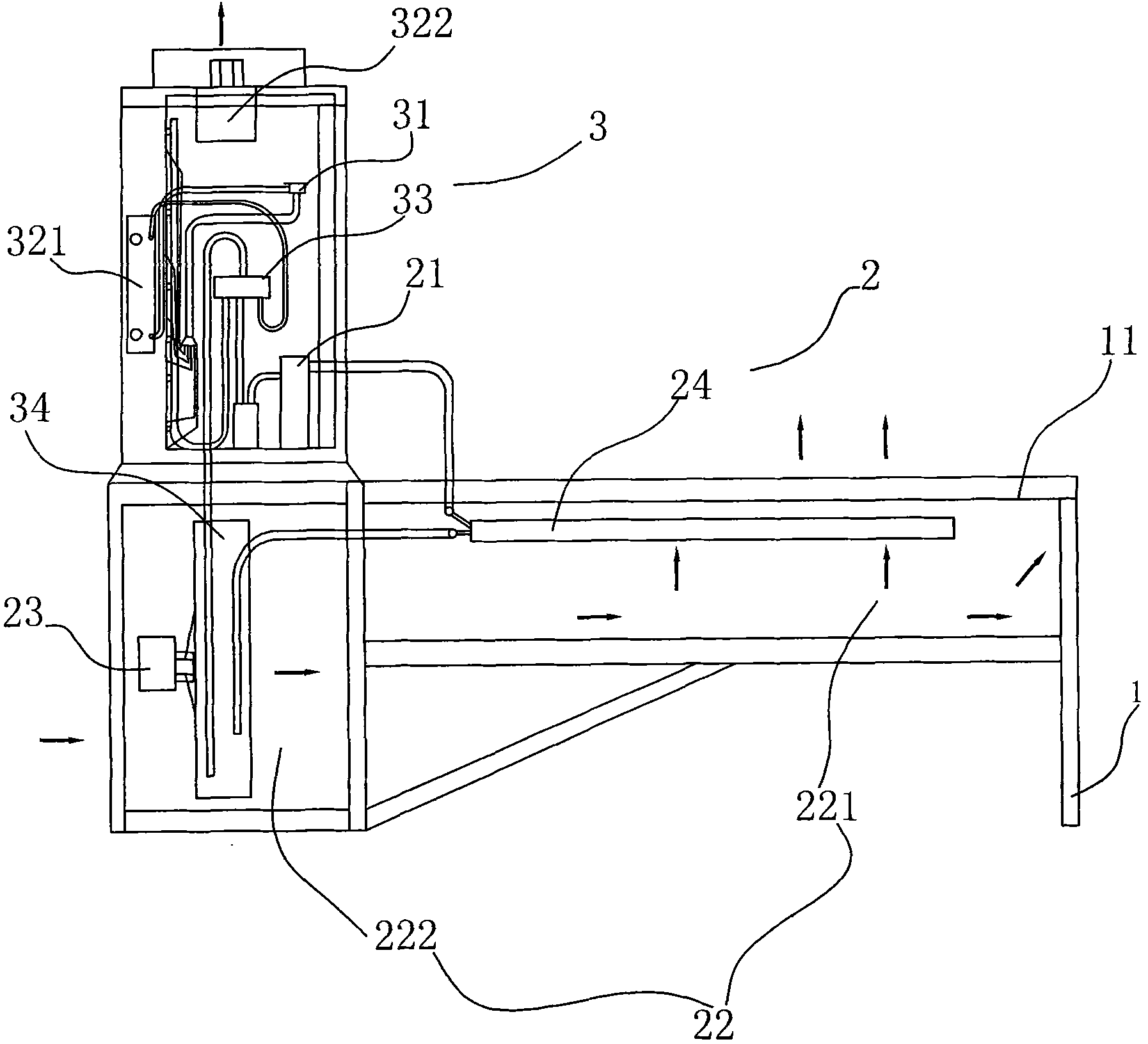

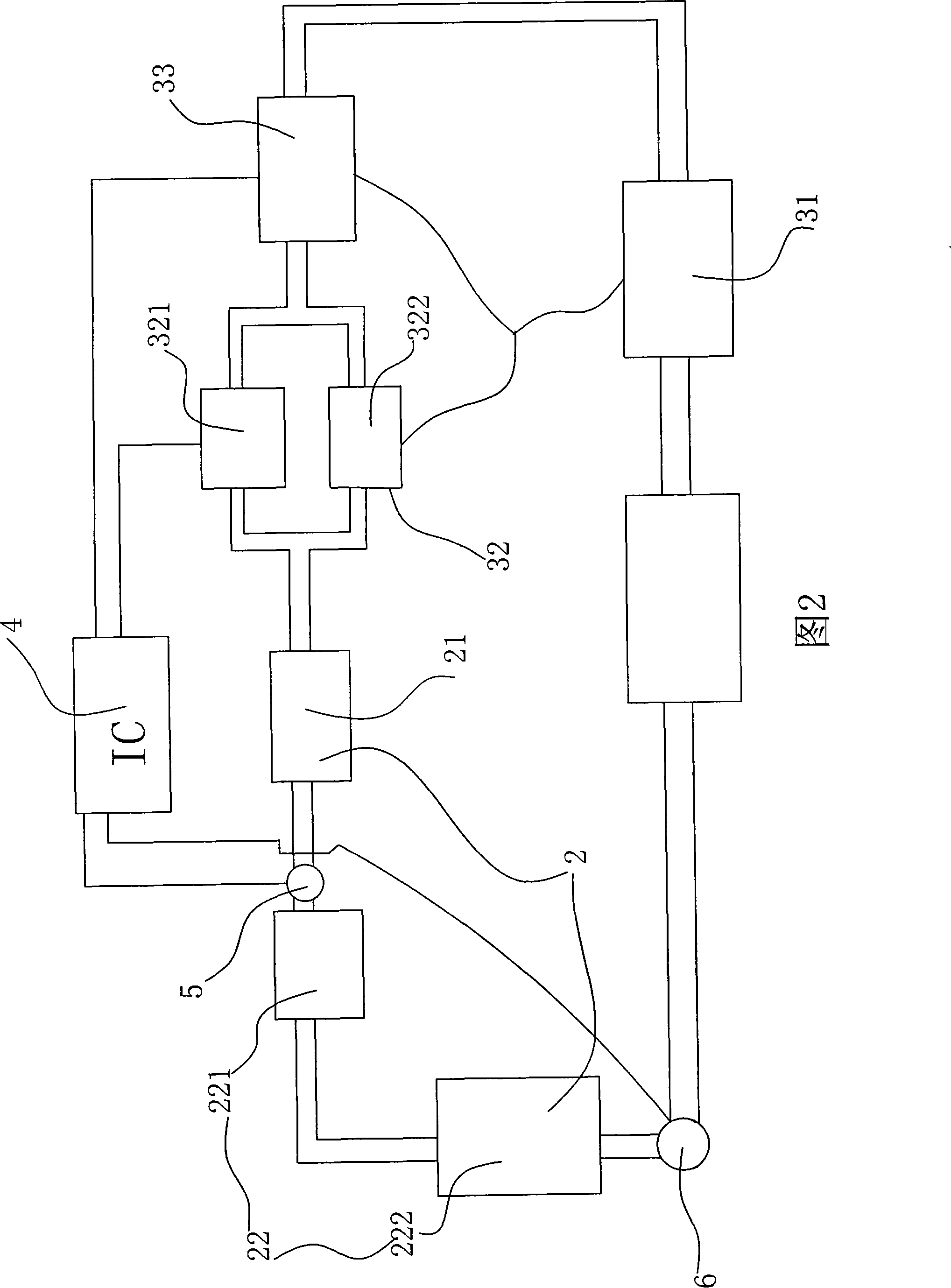

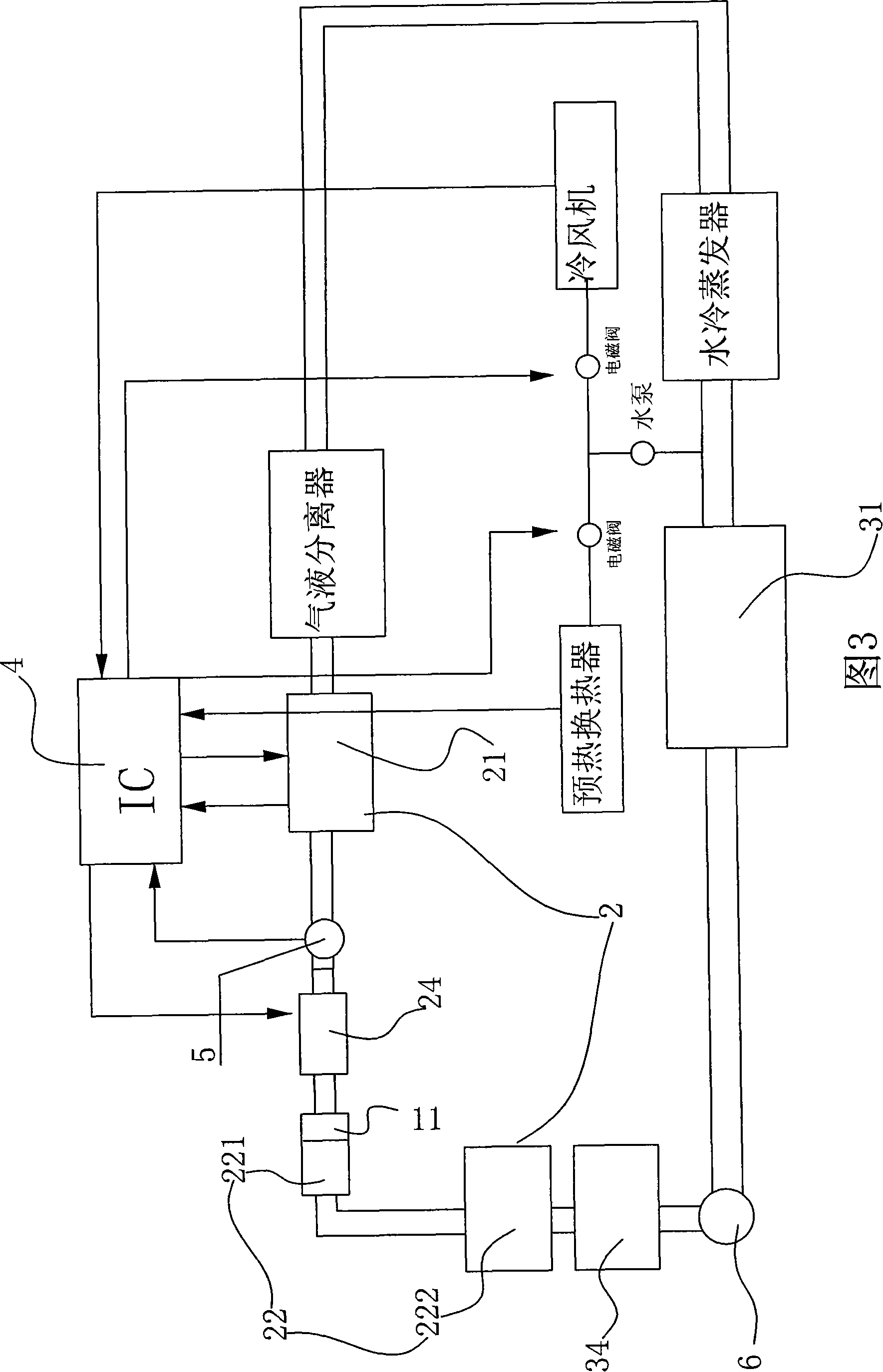

Environmental protective energy saving drying apparatus

InactiveCN101093134BImprove securityFast dehumidification performanceDrying solid materials with heatHearth type furnacesWaste heat recovery unitThermal energy

This invention discloses an environmental protection and energy-saving drier including a bracket, a baking unit and a cooling unit connected with the baking unit, in which the baking unit includes a compressor and a condenser connected with it and a heat exchanger in between, the cooling unit includes an expansion valve, an evaporator and a four-way valve, one end of the expansion valve is connected with the condenser, the other end is connected with the evaporator by the four-way valve, the other end of the evaporator is connected with the compressor, the baking unit and the cooling unit areset in the bracket, which can recover and utilize waste heat of cold water set and turn heat of low quality to that of high quality to realize waste heat recovery and environmental protection.

Owner:深圳市汇腾热能设备有限公司

Precise and efficient hot die forging press

ActiveCN113245490BImprove movement guidance accuracyImprove mechanical conversion efficiencyUpsetting pressesSwagging pressesTemperature controlAutomatic control

Owner:RONGCHENG HUADONG METAL FORMING MACHINERY

Pneumatic spiral direction-converted conveyor

InactiveCN102101584BImprove product processing qualityCharge manipulationConveyor partsLiquid-crystal displayEngineering

The invention relates to a technology of a direction conversion device of a manufacturing engineering conveyor line of a glass plate for a liquid crystal display device, in particular to a pneumatic spiral direction-converted conveyor. In order to more stably convert the conveying direction of a heavy-weight large-size glass plate, a balanced level state is integrally kept by uniformly dispersingpower in the ascending / descending action process of an upper stand provided with trip rollers in an arraying way so that partial subsidence is not generated, therefore bad influence is ensured not tobe caused on the glass plate and the quality of processed products is also enhanced when the direction of the large-size glass plate is converted.

Owner:TAE SUNG ENG

Mold core pulling anti-back mechanism and mold

ActiveCN108454032BFeatures that prevent fallbacksQuality improvementMechanical engineeringElectrical and Electronics engineering

Owner:上海信羽电子科技有限公司

Mandril-cooling device of wood-plastic extrusion die

The invention discloses a mandril-cooling device of a wood-plastic extrusion die. The mandril-cooling device comprises a tail mandril, a front mandril, a water inlet pipe, screws, a water outlet pipe and a positioning pin, wherein the tail mandril comprises an outer cylinder, an inner mandril; and the inner mandril is arranged in the outer cylinder. The mandril-cooling device also comprises two sealing rings; the inner mandril is provided with two threaded holes; the right end of the inner mandril is provided with two concave circular truncated cones; the threaded holes are formed in the middle of the mandril; one sealing ring is arranged in each concave circular truncated cone; the water inlet pipe passes through an inner hole of each sealing ring and is connected with the threaded hole in a position close to the upper part of the inner mandril; the water outlet pipe passes through the inner hole of each sealing ring and is connected with the threaded hole formed in a position close to the lower part of the inner mandril; and the tail mandril is connected with the front mandril through the screws. The mandril-cooling device can be disassembled and assembled rapidly, has good sealing property and is free of leakage; water scale can be removed easily; and a machined product has high quality.

Owner:湖北高新明辉模具有限公司

An automatic car lift motor rotor shaft knurling feeding device

ActiveCN111299960BImprove work efficiencyImprove product processing qualityElectric machineryKnurling

The invention provides an automatic car lifting motor rotor shaft knurling feeding device, which includes a worktable, a material shifting mechanism and a feeding mechanism installed on the workbench; the material moving mechanism includes a sliding table and a main cylinder, and a clamp is installed on the sliding table The material table, the first stopper and the second stopper are fixed on the clamping table, the first driving cylinder is installed on the sliding table, the second driving cylinder and the first jaw are installed on the working table; when working, the first clamping The claws clamp the workpiece to the clamping table, the main cylinder drives the workpiece to the external knurling machine for processing and returns to its position, and the first driving cylinder pushes the clamping table to the unloading mechanism for unloading. The present invention is an automatic car lifting motor rotor shaft knurling feeding device. The workpiece is automatically knurled through the sliding table and the main cylinder. After the processing is completed, the horizontal feeding and homing of the clamping table can be realized by driving the cylinder. The device's High work efficiency and high quality processed products.

Owner:宁波丞达精机股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com