Service life estimation method and device, medium, terminal and servo feeding system

A technology of life estimation and life, applied in the direction of calculation, computer-aided design, special data processing applications, etc., can solve the problem that the accuracy of transmission parts needs to be improved, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] As mentioned in the background art, the accuracy of life estimation of existing transmission components needs to be improved.

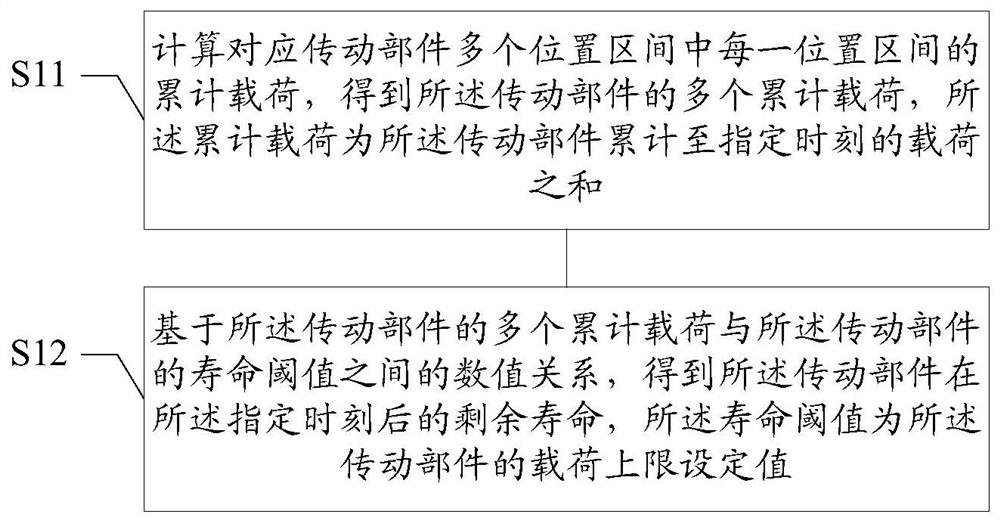

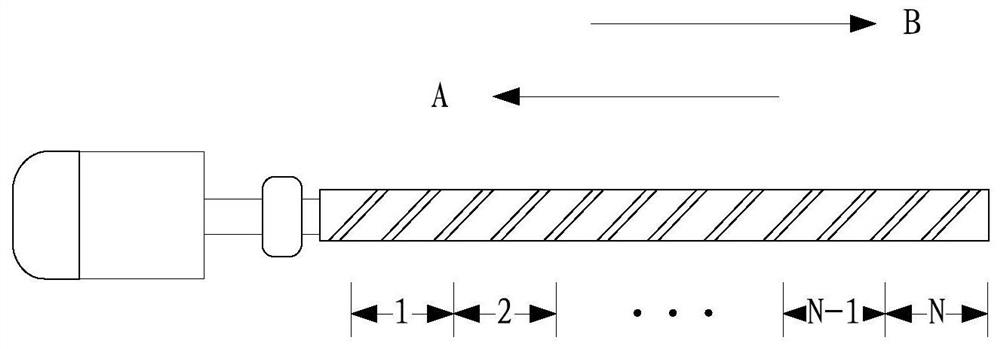

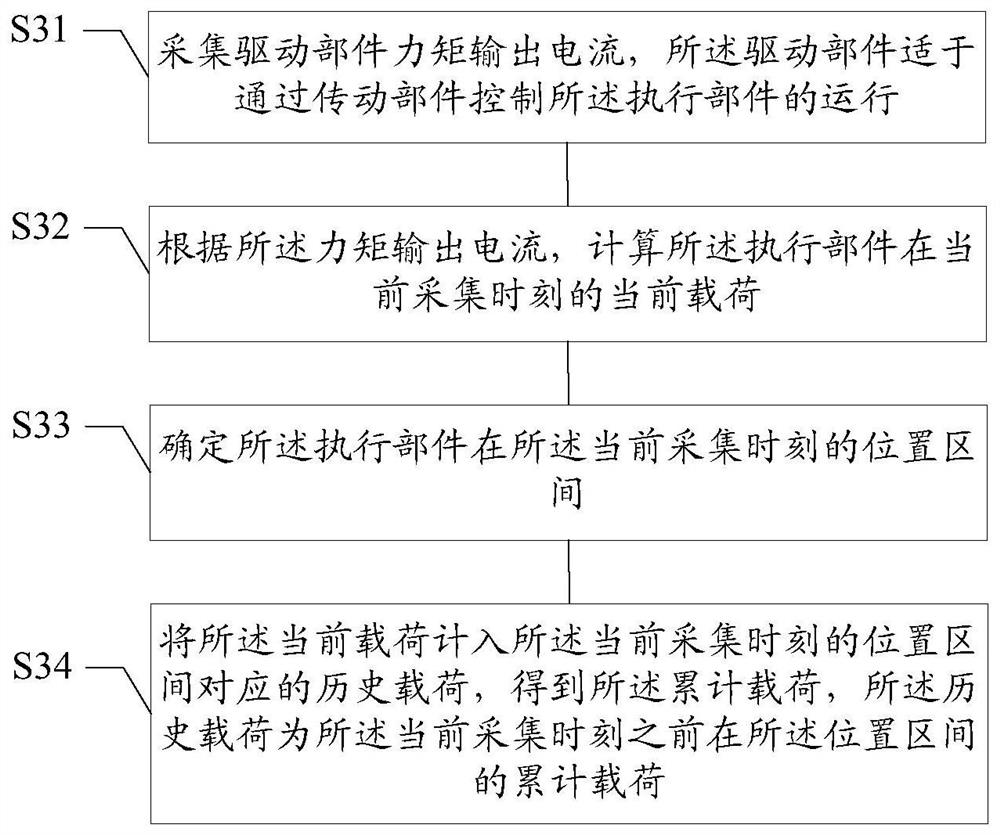

[0048] In the embodiment of the present invention, multiple cumulative loads of the transmission component are obtained by calculating the cumulative load corresponding to each position interval of the multiple position intervals of the transmission component, and the cumulative load is the cumulative load of the transmission component up to a specified time The sum of the loads; based on the numerical relationship between multiple cumulative loads of the transmission component and the life threshold of the transmission component, the remaining life of the transmission component after the specified time is obtained, and the life threshold is the Load upper limit setting value for transmission components. In this process, by calculating the multiple accumulated loads of multiple position intervals of the transmission component, the force of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com