Multifunctional high-rate chip setting machine

A multi-functional, high-speed technology, applied to conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as high defective rate, low production efficiency, smashed chips, etc., to improve the quality of processed products and improve work efficiency , the effect of reducing the probability of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

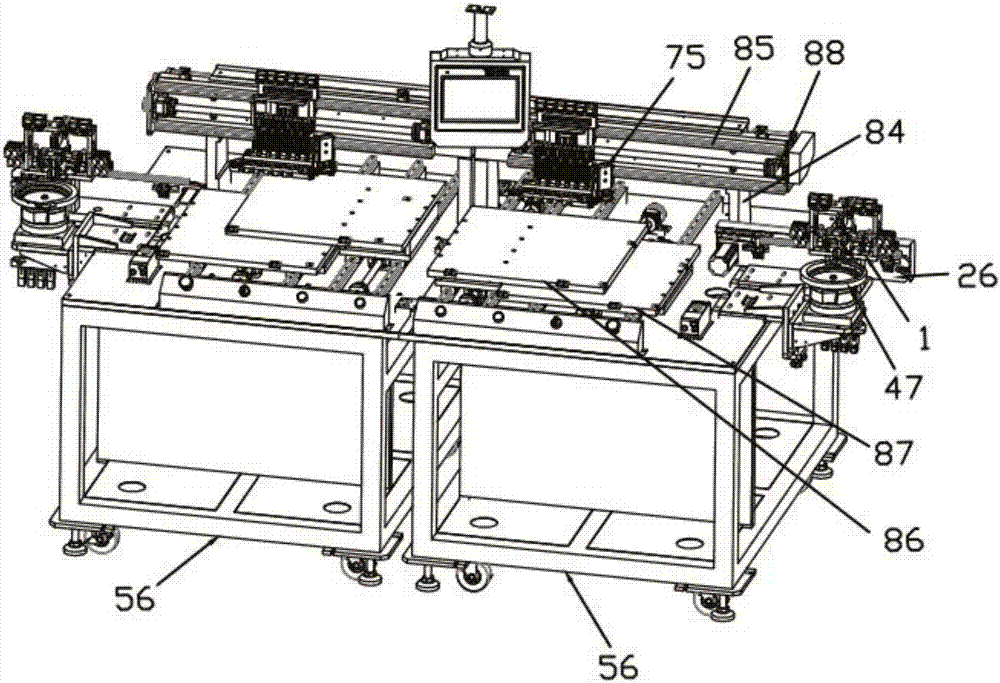

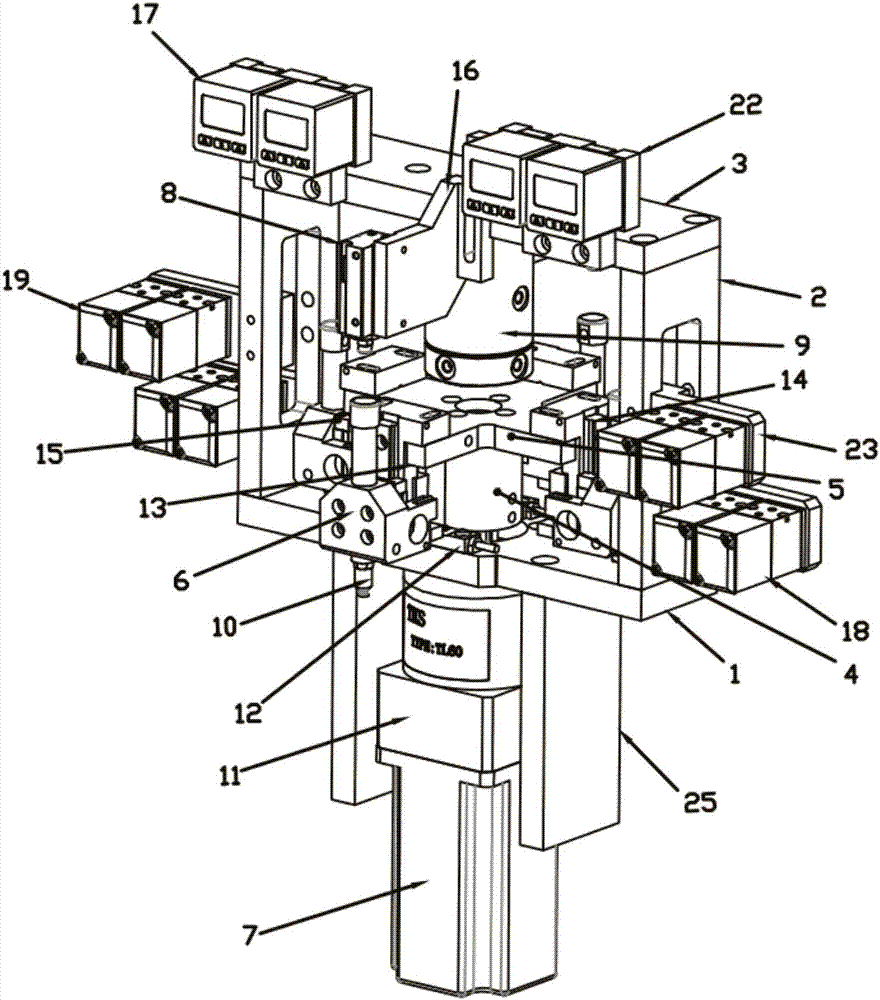

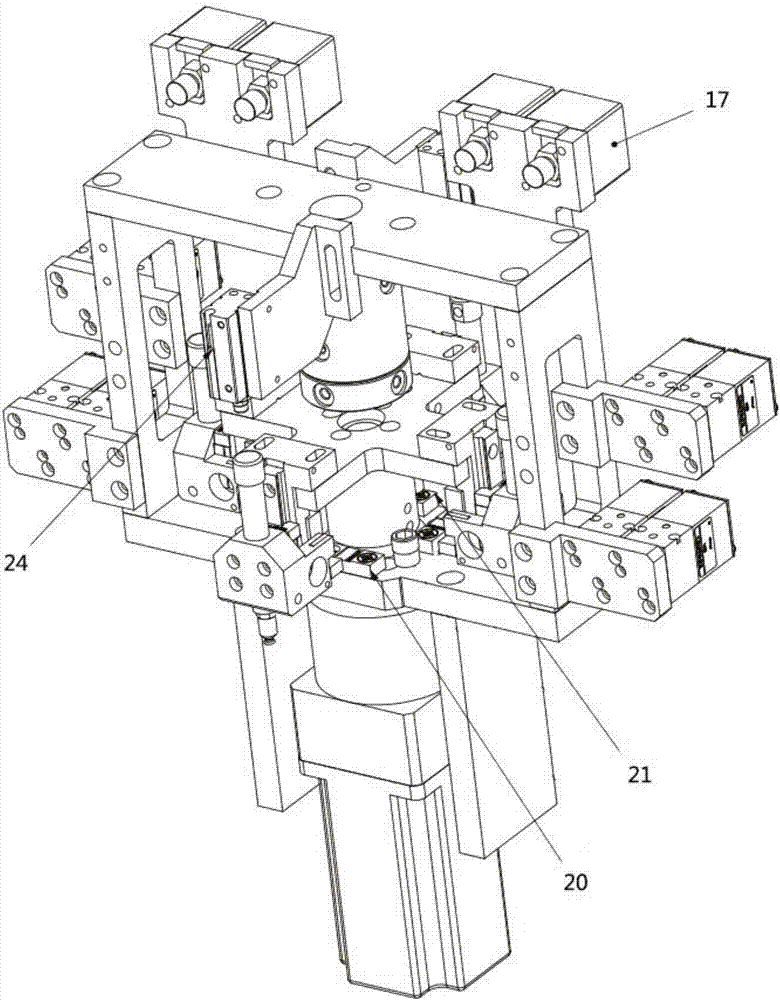

[0029] Such as figure 1 , 2 1. As shown in 3, a multifunctional high-speed film swing machine includes a support 56, a vibration plate arranged on the support, a transfer mechanism, and a rotation mechanism that is arranged on the support and transfers the chips in the vibration plate to the transfer mechanism; The rotating mechanism includes a mounting plate 1, a support vertical plate 2 arranged at both ends of the mounting plate, and a top plate 3 arranged on the top of the supporting vertical plate; a rotating connection shaft 4 is arranged above the mounting plate, and a The rotating mounting block 5 is provided with a suction rod fixing member 6 slidingly connected with the rotating mounting block on the side of the rotating mounting block; a rotating servo motor 7 for driving a rotating connecting shaft is provided below the mounting plate; The suction rod cylinder 8 that pushes the suction rod fixing part to move downward; the vacuum rotary connector 9 located above t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com