Production method of cutting die

A production method and technology of die-cutting knives, which are applied in metal processing, other household appliances, household components, etc., can solve problems affecting product quality, poor durability, poor die-cutting accuracy, and skewed incision sections, so as to improve the quality of processed products , improve product quality, improve the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

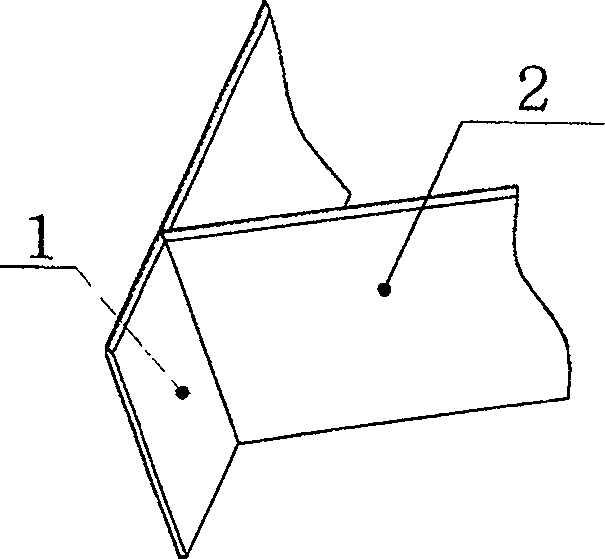

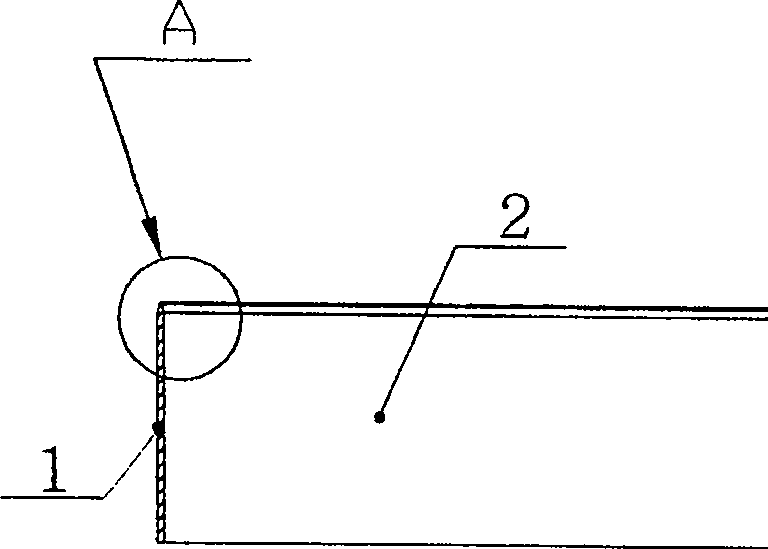

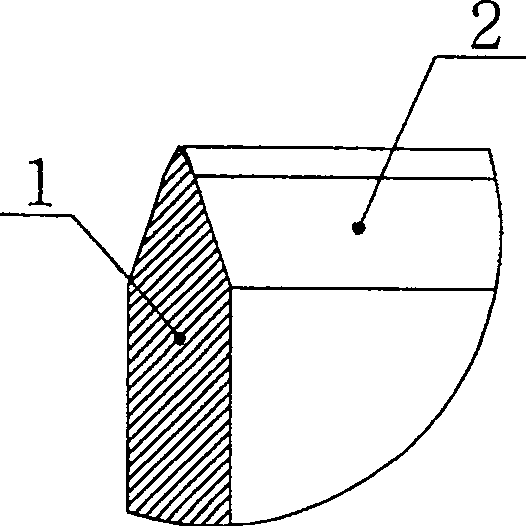

[0032] Such as figure 1 As shown, the connection of the die-cutting blade of the die-cutting die is to install the blade 2 on the side of a straight blade 1 . Such as figure 2 and image 3 As shown, the blade 2 and the blade 1 are in the shape of a cantilever with a gap after being connected. During the die-cutting process, they are subjected to tens of thousands of times of force, and often break and damage, which affects the quality, cost and production cycle of the produced product. . In order to ensure that the material is cut, it is necessary to make the blade 2 coincide with the side of the blade 1 to achieve the best effect. Therefore, the requirements for the connection angle of the blade are higher, and the related equipment and molds are also higher. However, this does not mean easy to do.

[0033] Such as Figure 4 , Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com