Pneumatic spiral direction-converted conveyor

A conveyor and steering technology, applied in the field of direction conversion devices, can solve problems such as unbalance, surrounding sinking, adverse effects of glass plates, etc., and achieve the effect of improving the quality of processed products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

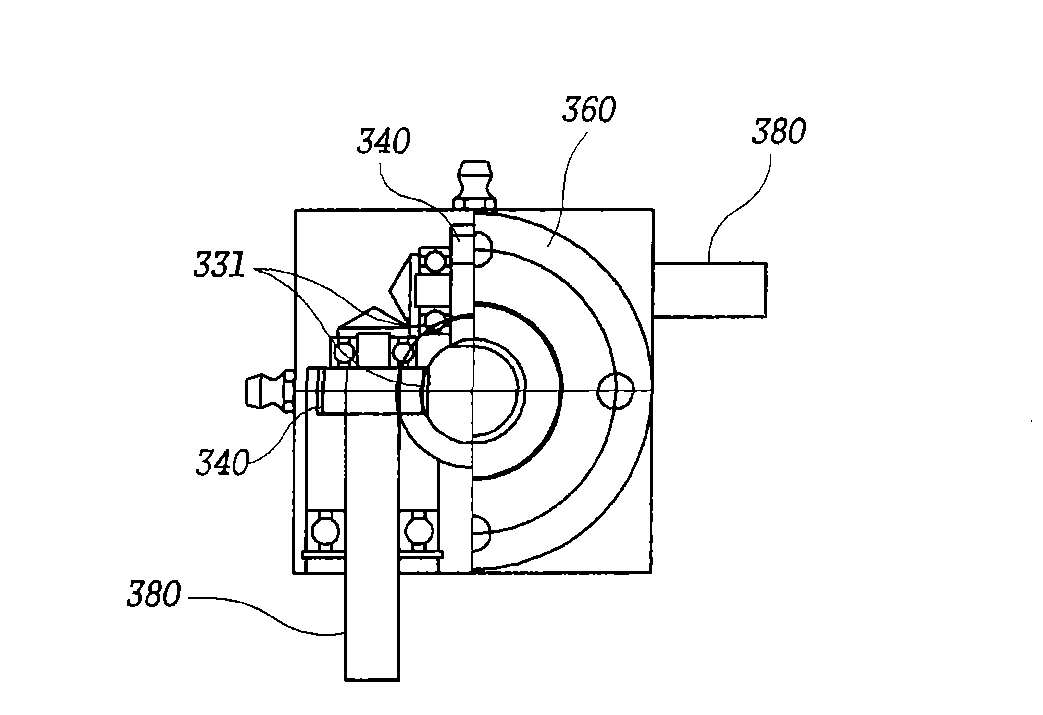

[0025] Exemplary embodiments of the present invention are described in detail in accordance with the following drawings.

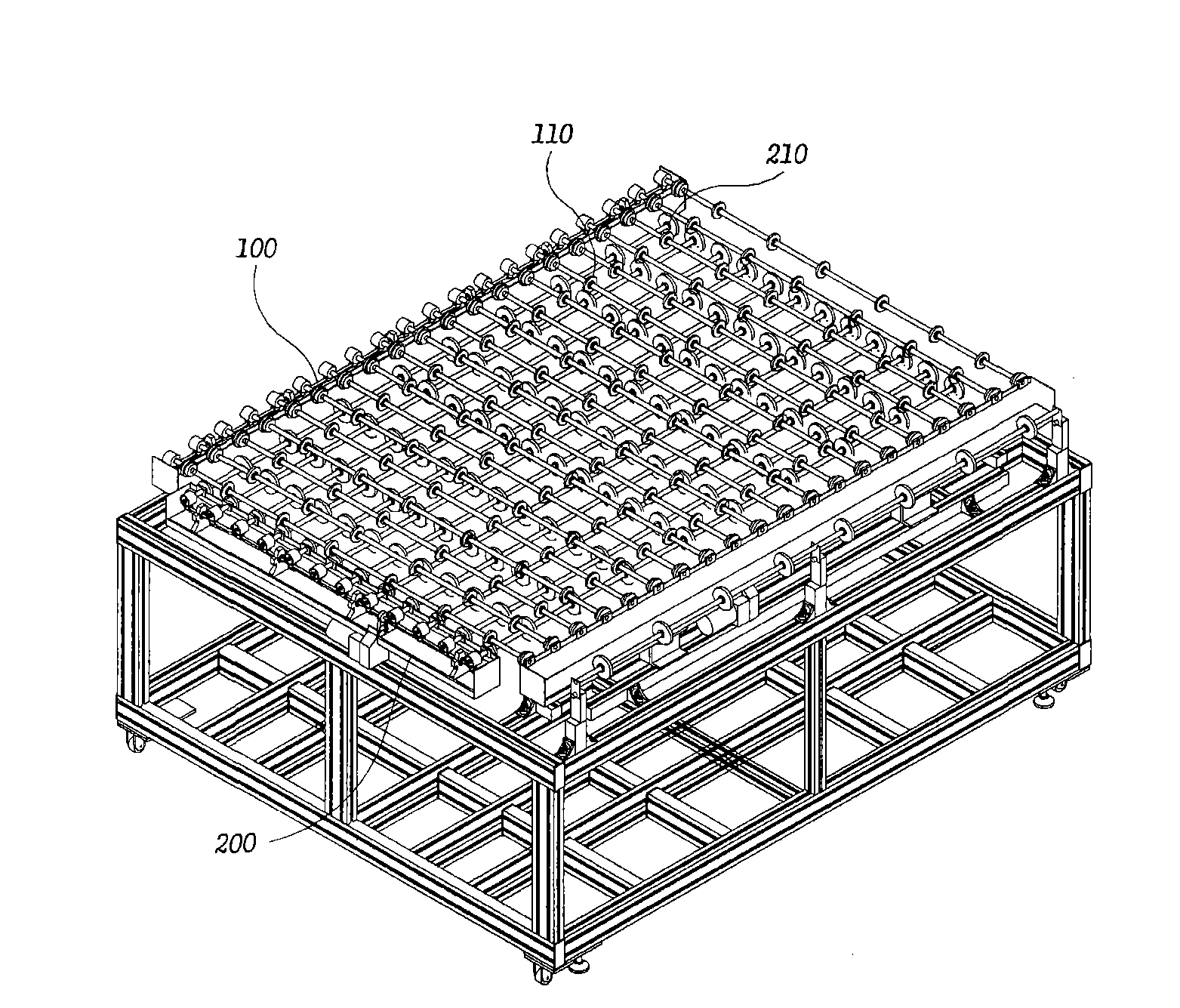

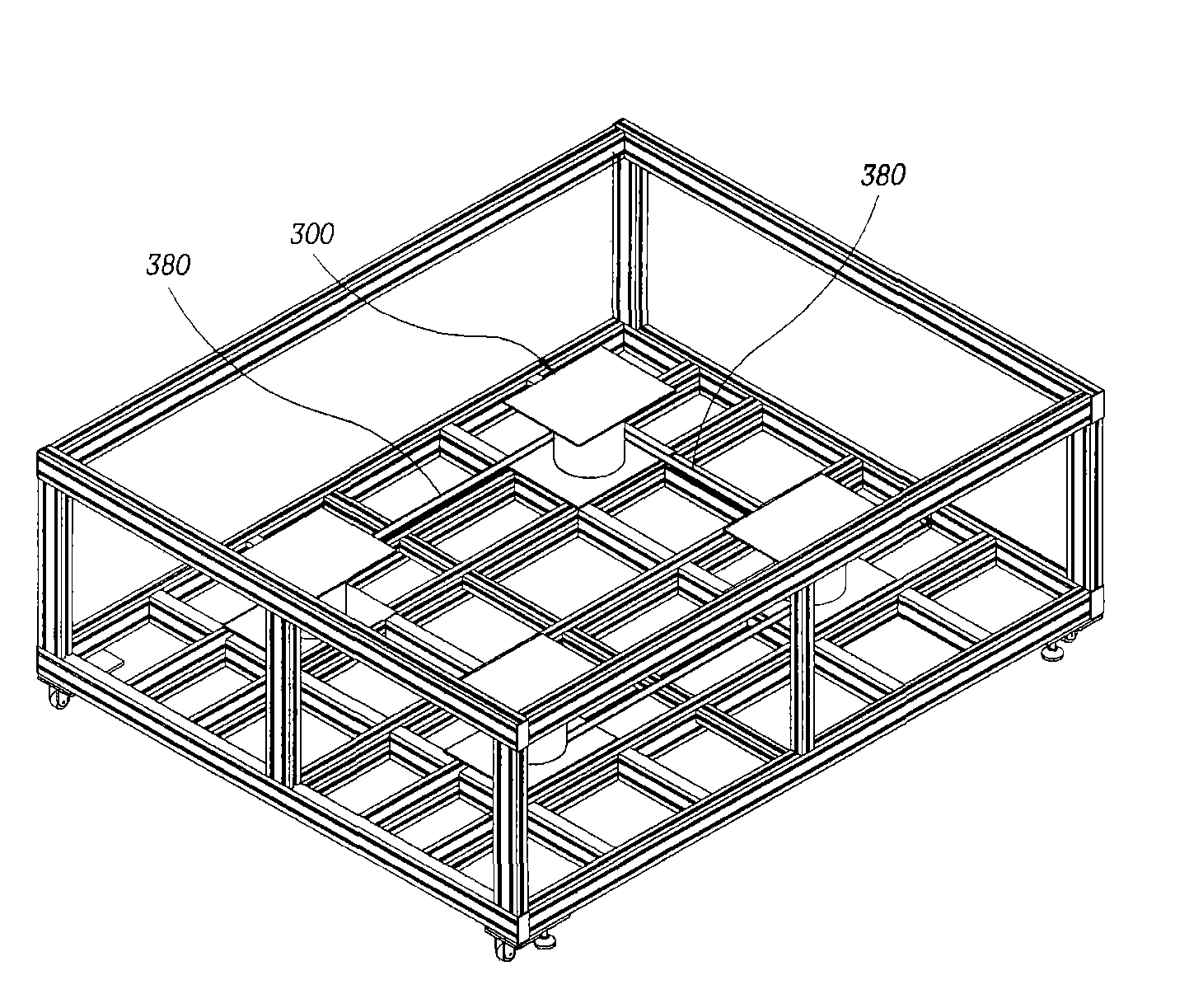

[0026] figure 1 is a perspective view showing the structure of the implementation case of the present invention; figure 2 is a perspective view showing the structure of the operating part of the present invention; FIG. 3 is a partial cross-sectional view showing the internal structure of the pneumatic spiral at the core of the present invention, Figure 3a is a plane cross-sectional view, Figure 3b is a frontal cross-sectional view; Figure 4 Yes figure 1 the floor plan;

[0027] The present invention is composed of a lower frame 100, an upper frame 200 and a plurality of pneumatic screws 300. The upper frame 200 plays a lifting role relative to the above-mentioned lower frame 100 at a certain height, and the plurality of pneumatic screws and the above-mentioned upper frame 200 keep balance , can realize the lifting effect.

[0028] The above-menti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com