Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53results about How to "Improve coating yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

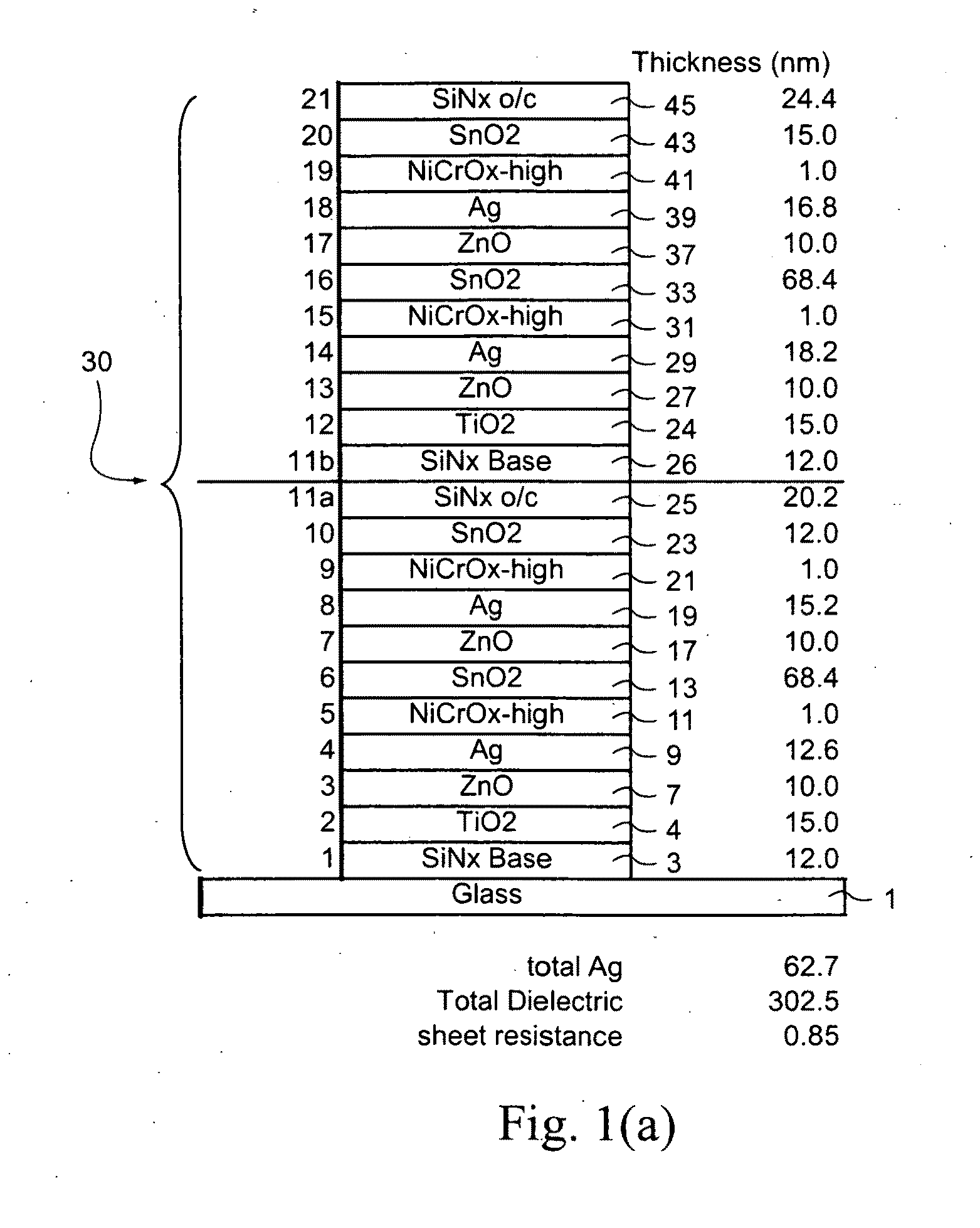

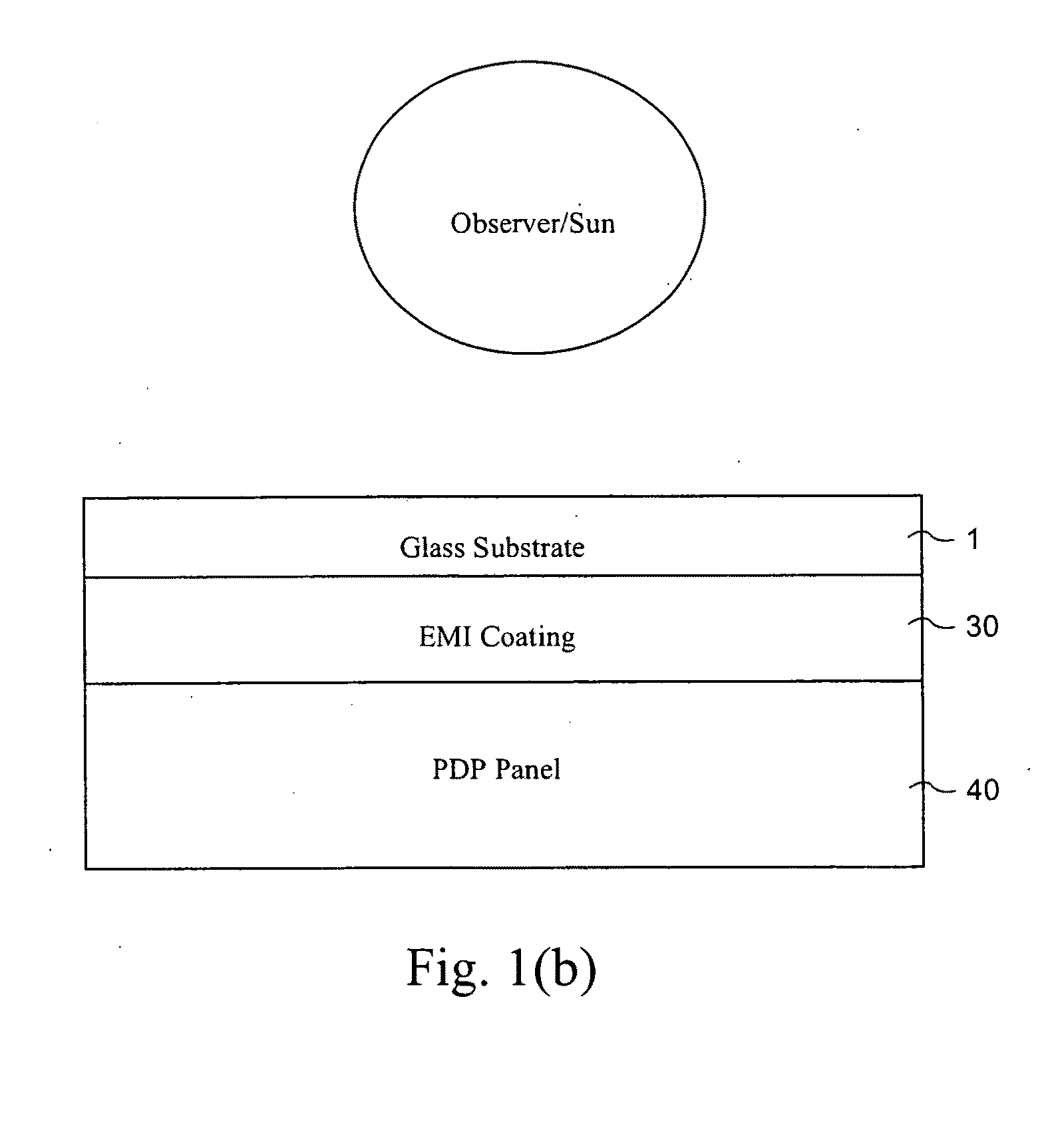

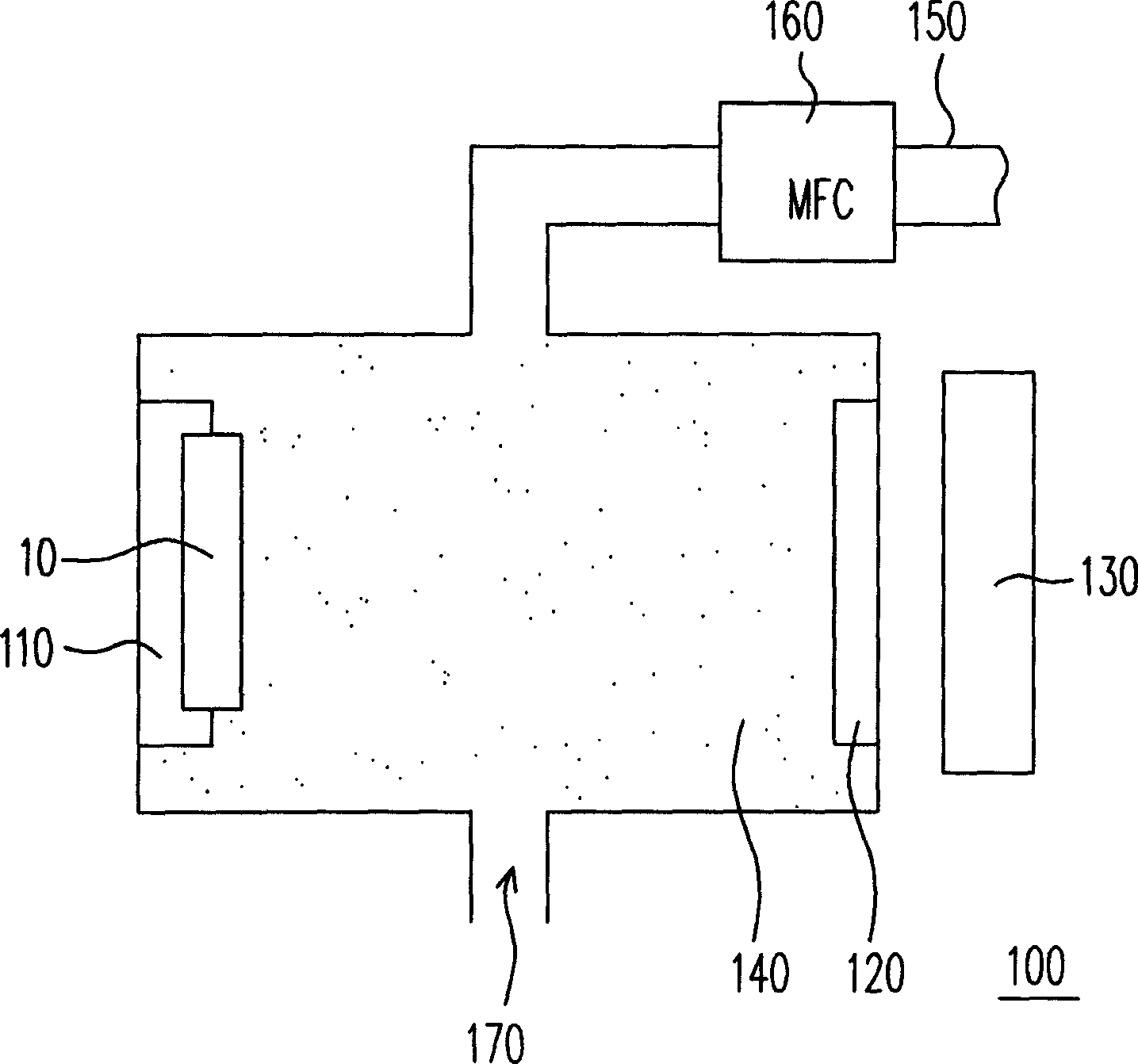

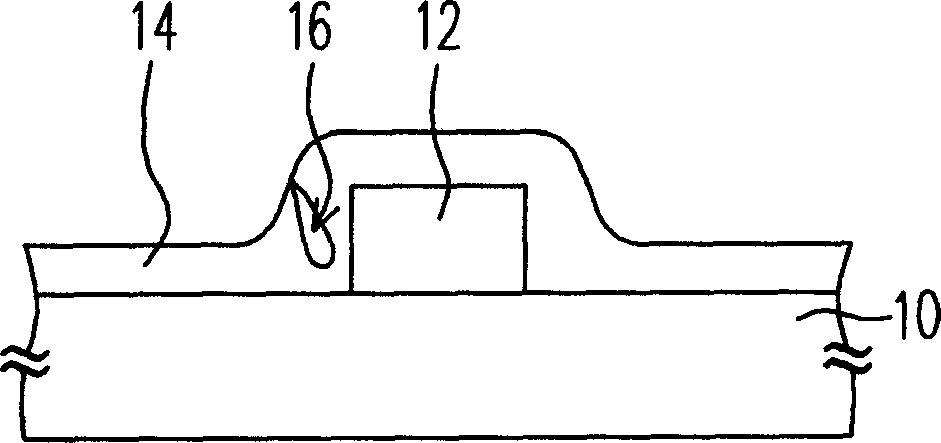

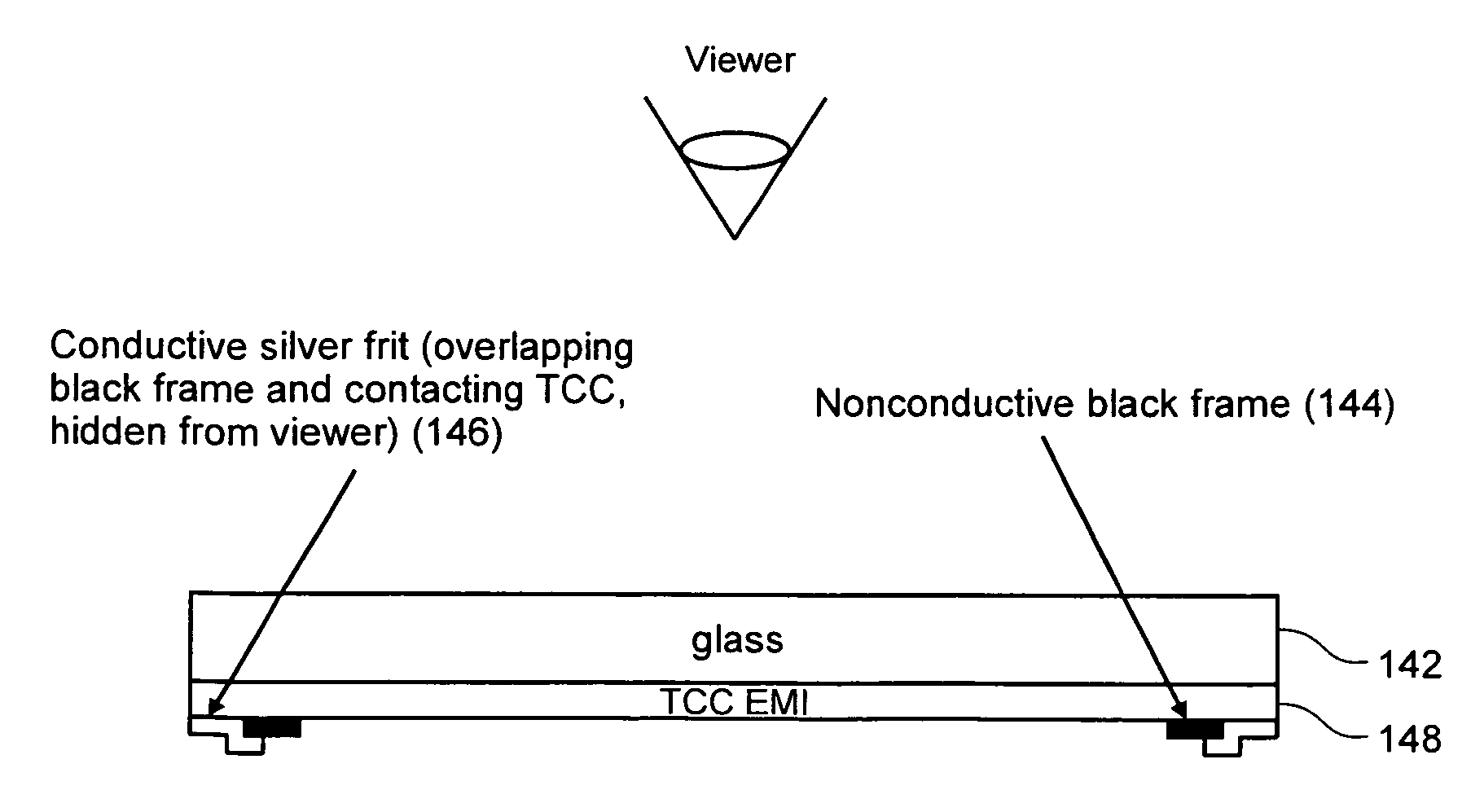

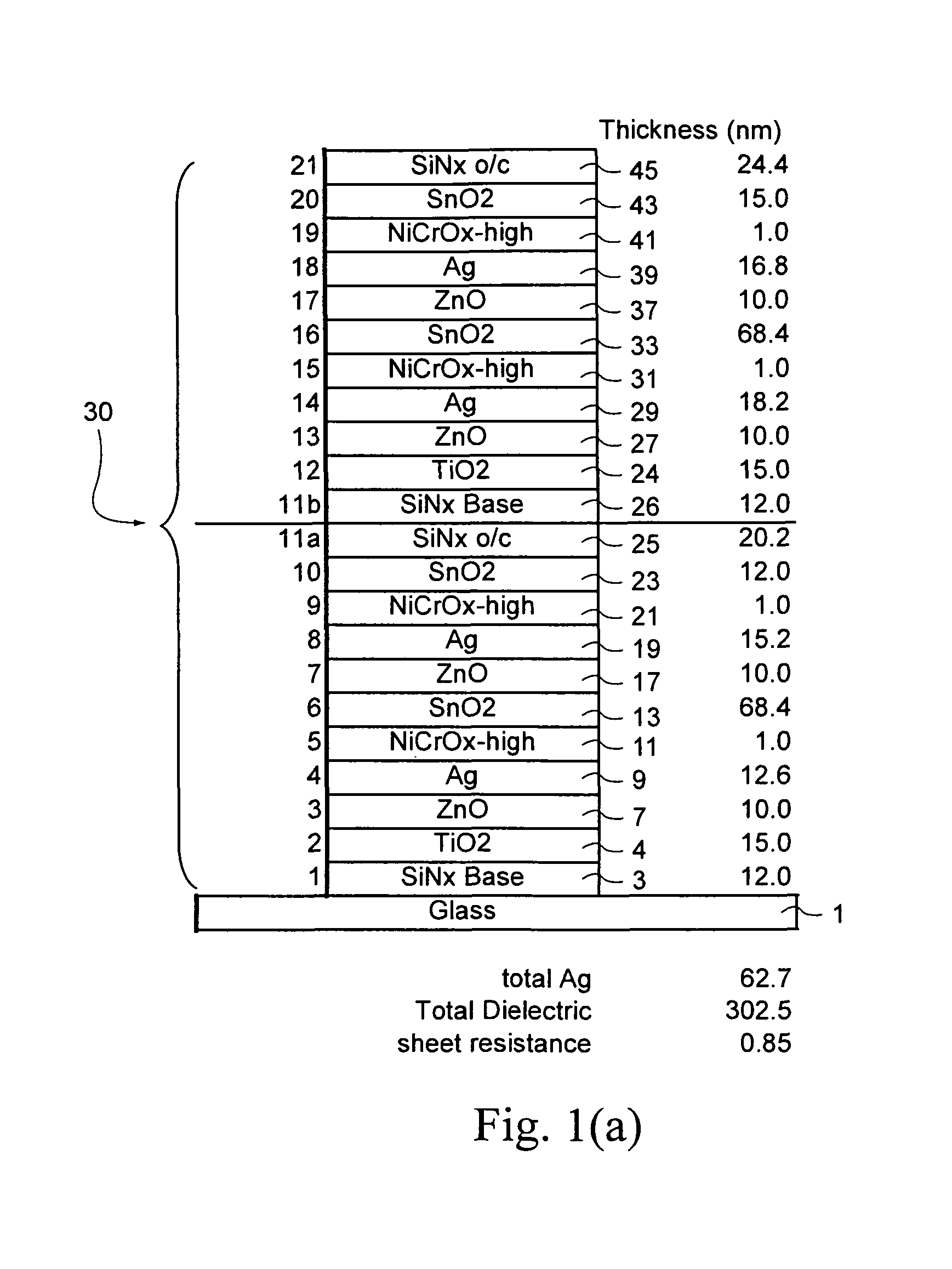

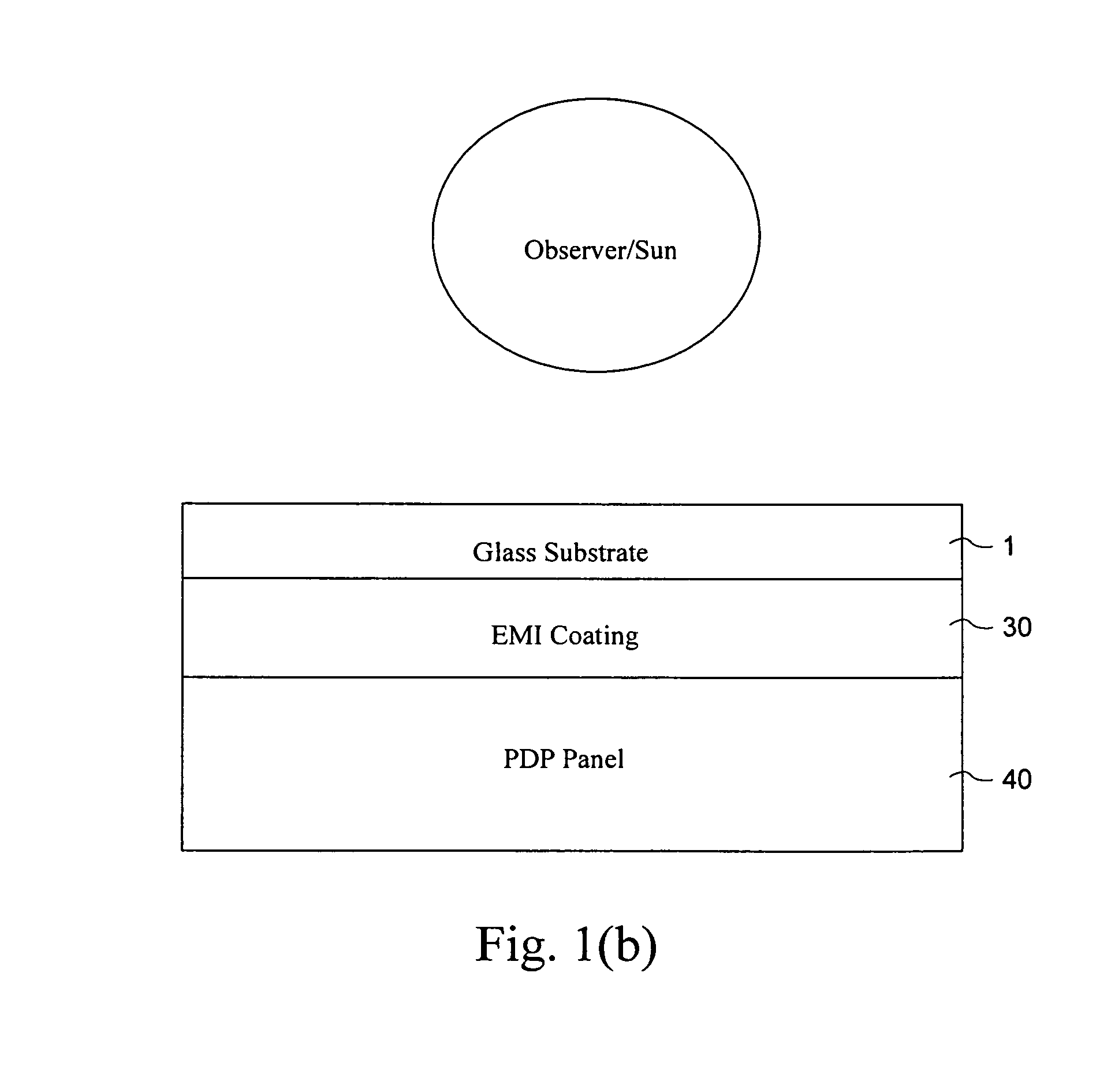

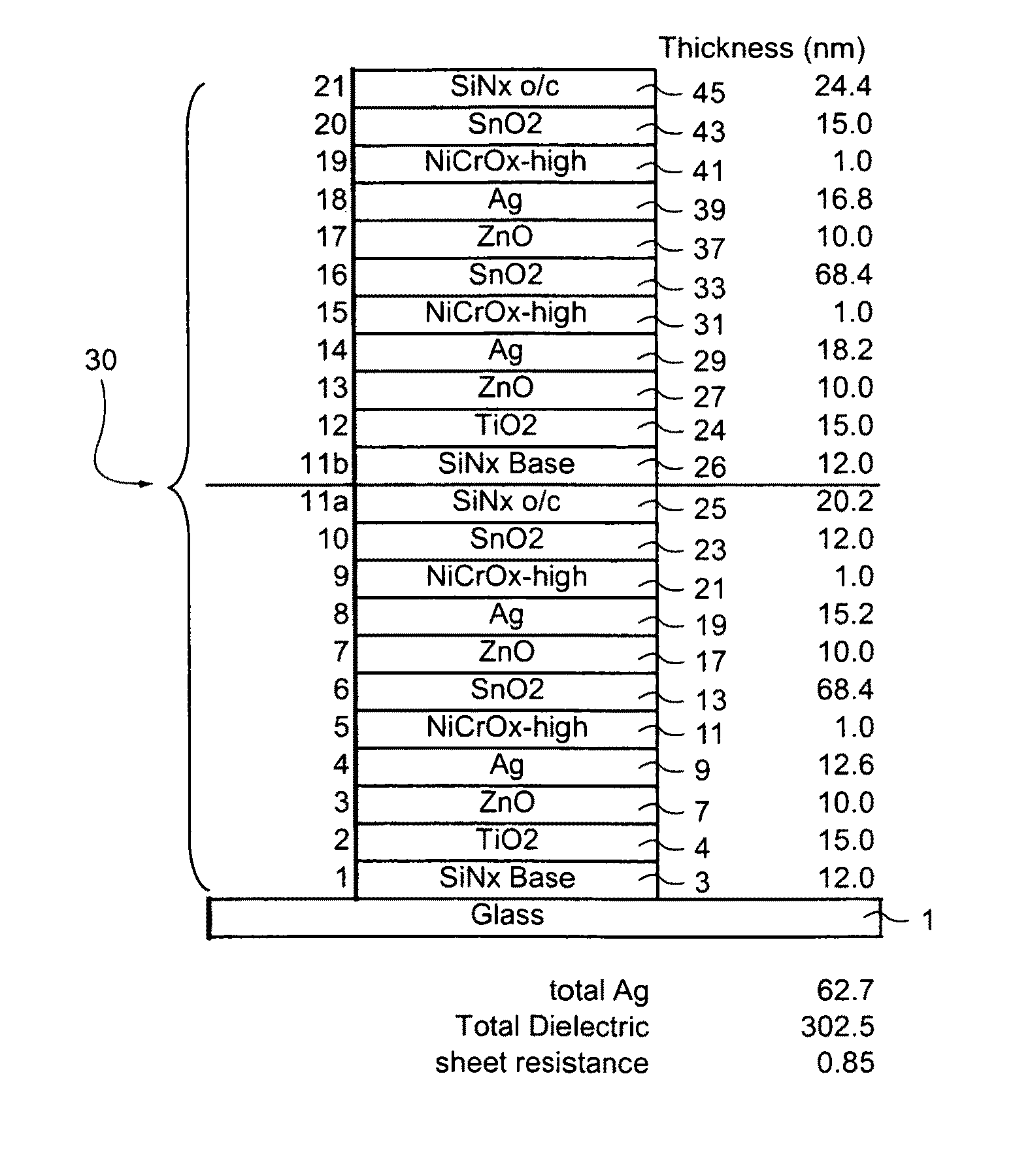

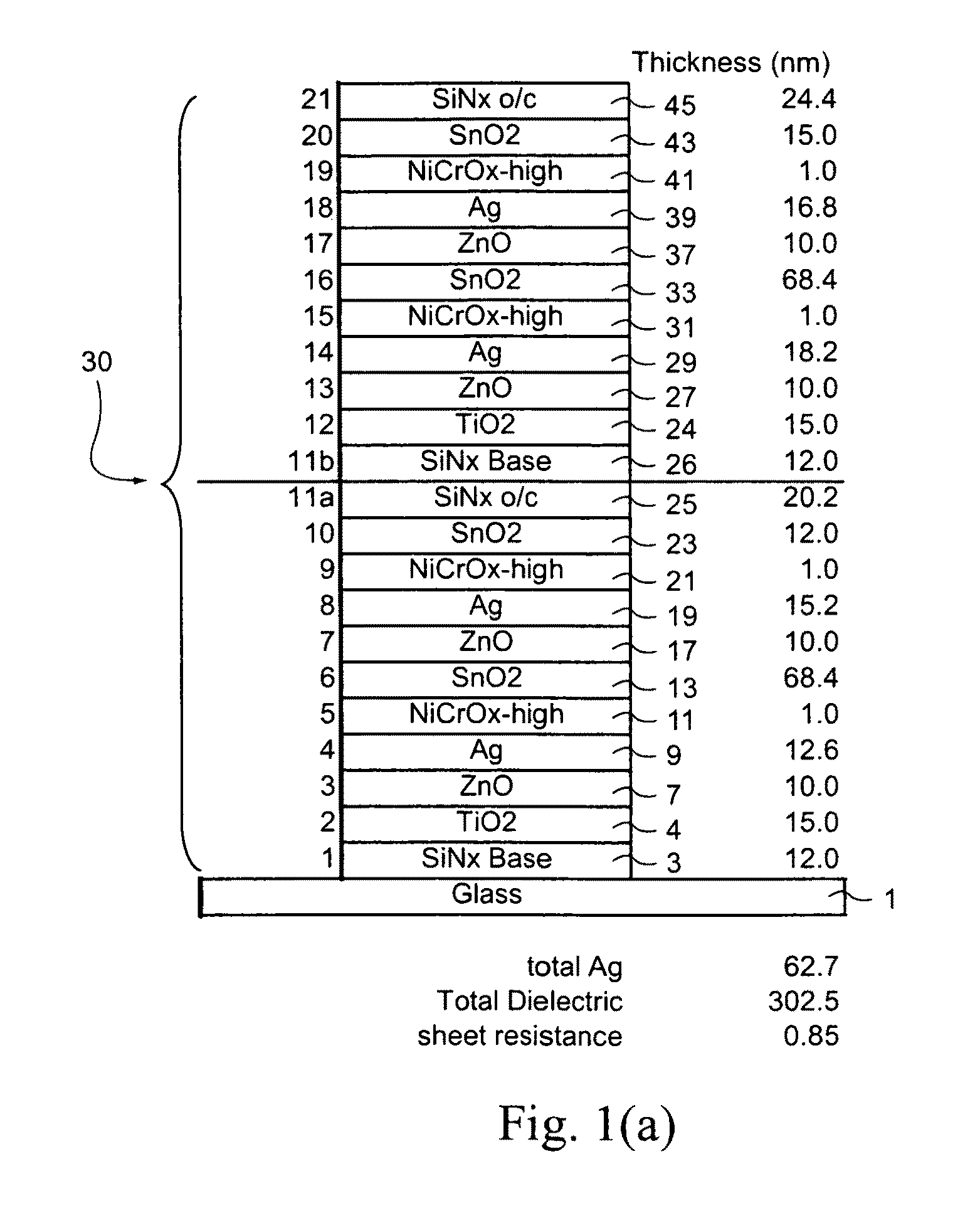

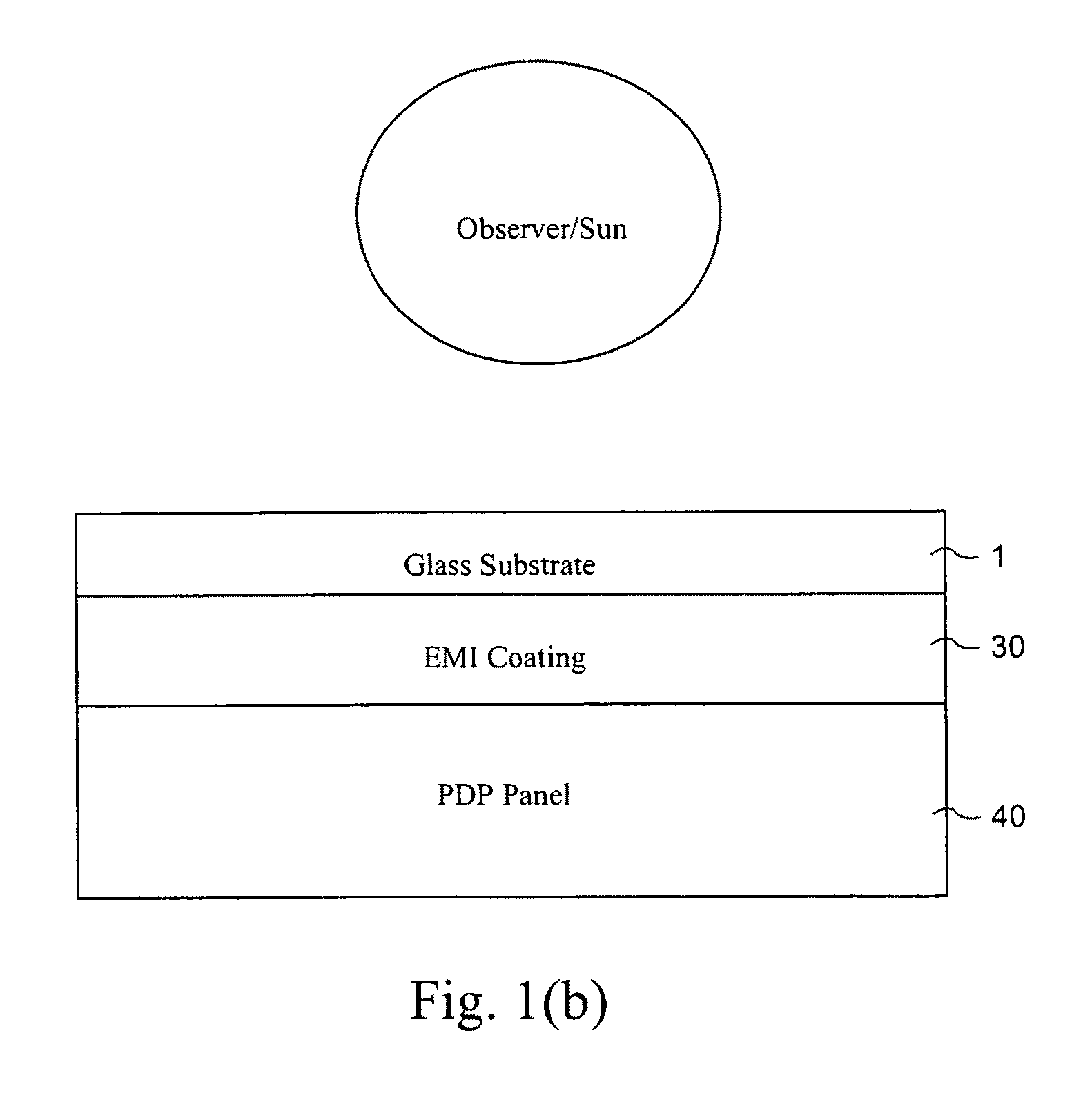

Plasma display panel including frameless EMI filter, and/or method of making the same

ActiveUS20100046191A1Easy to makeImprove display effectMagnetic/electric field screeningAlternating current plasma display panelsInfraredConductive coating

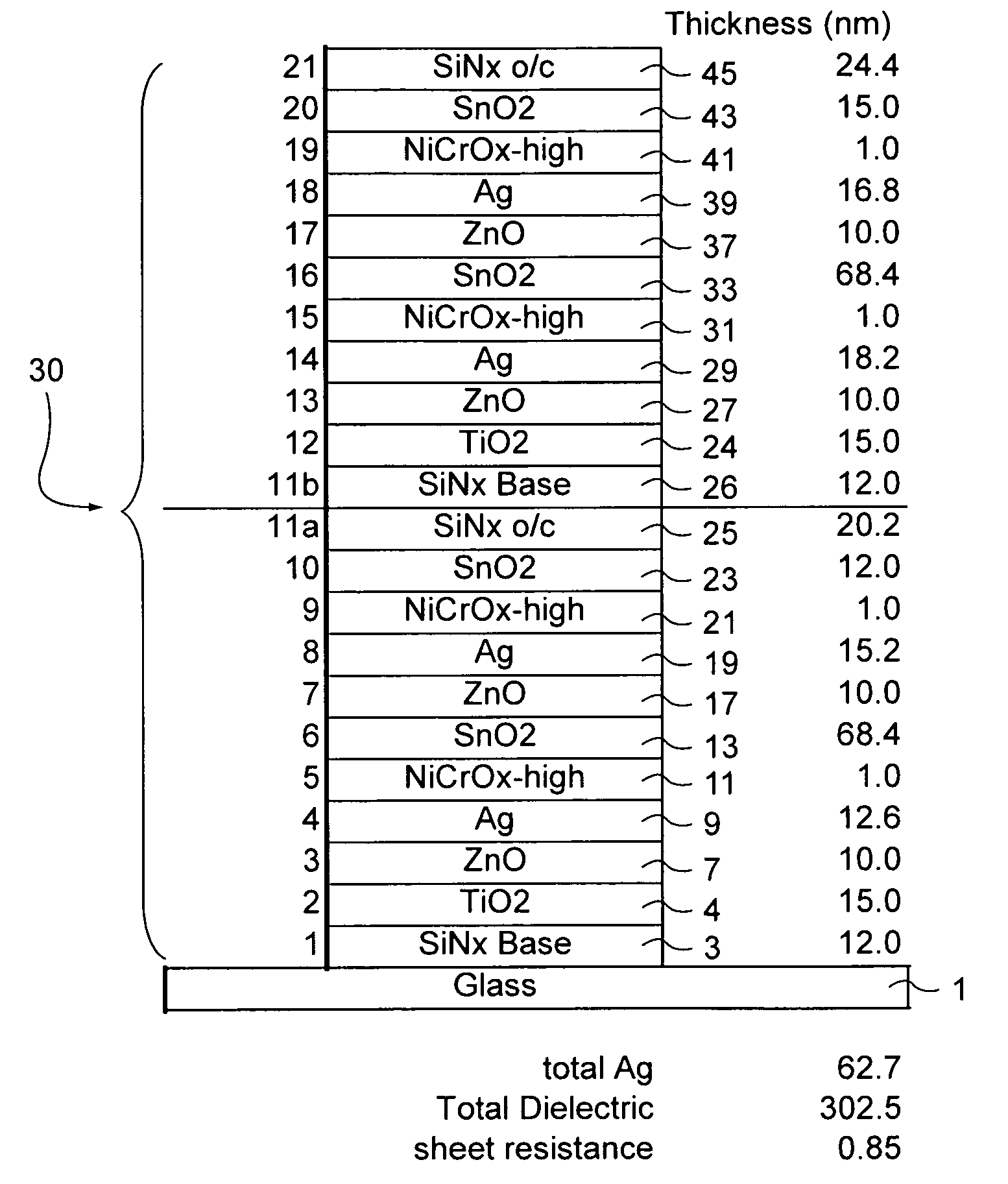

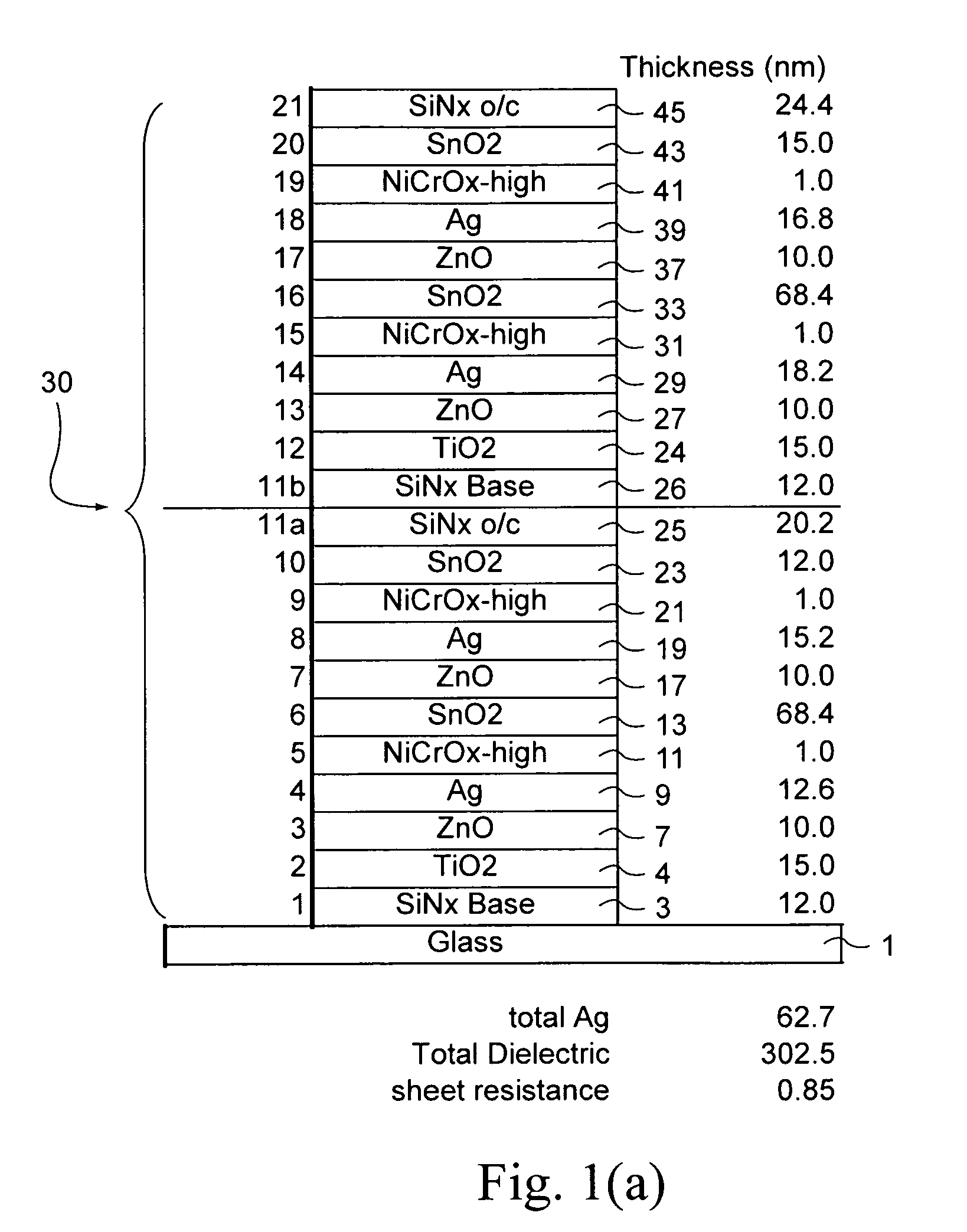

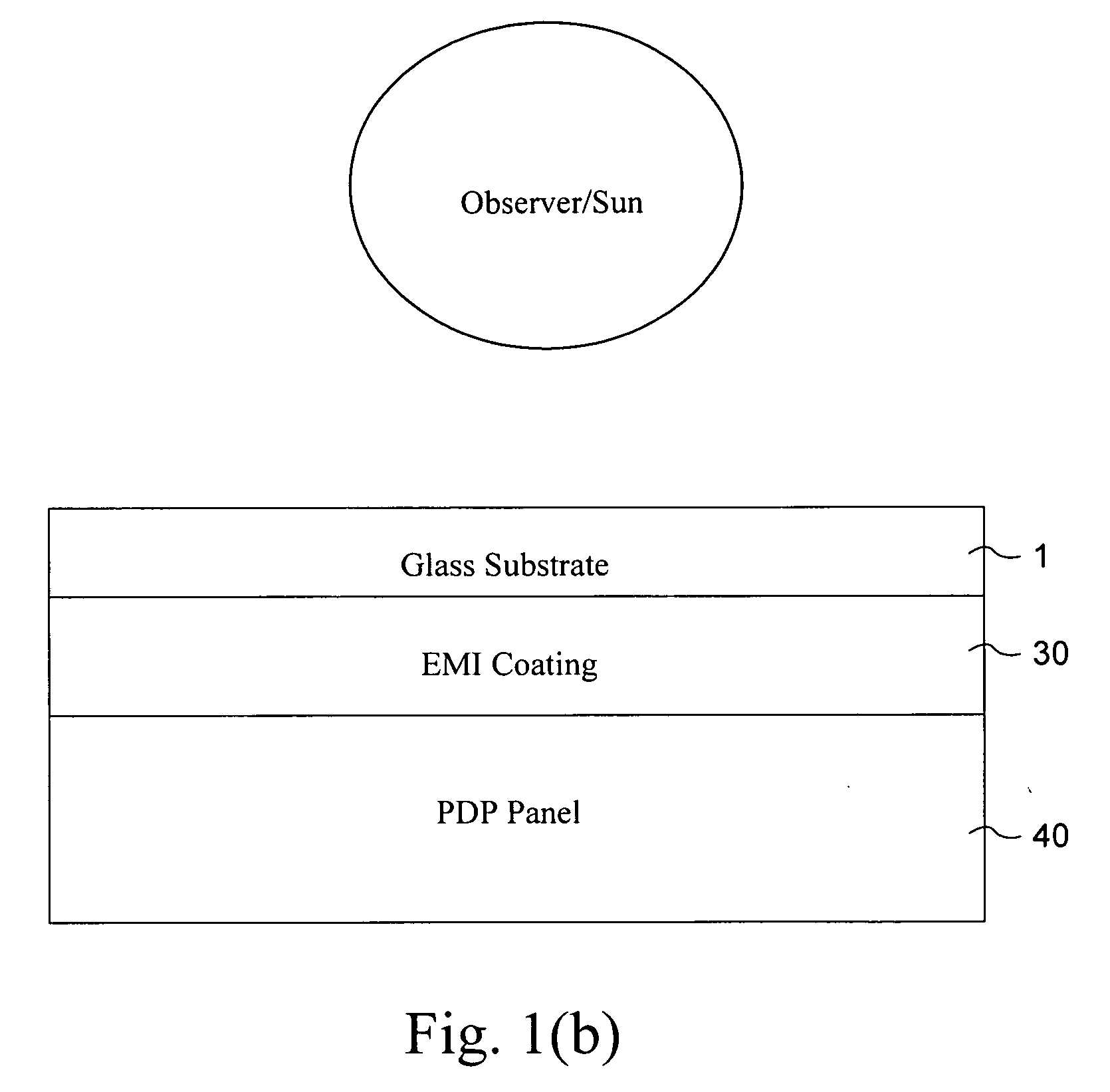

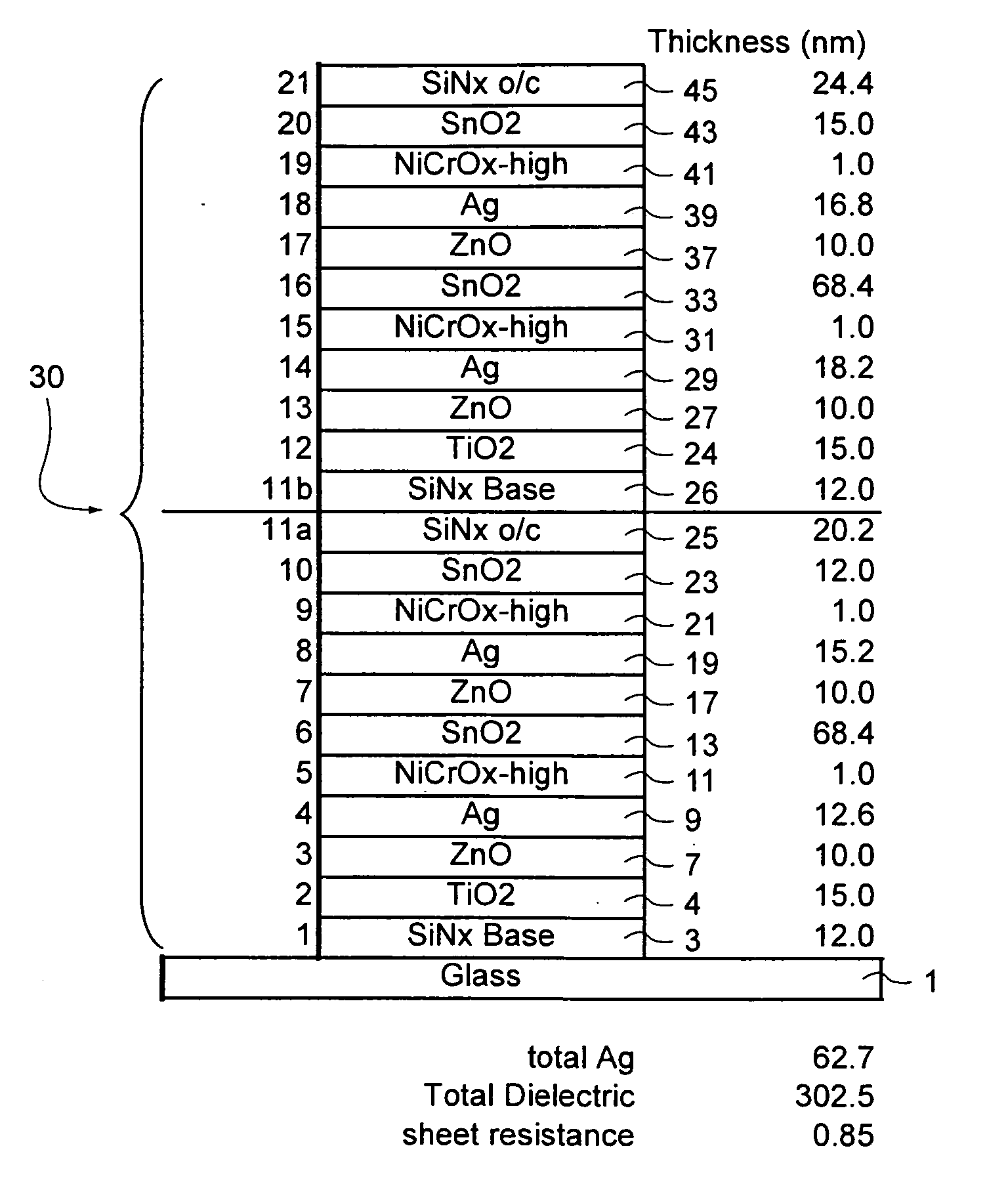

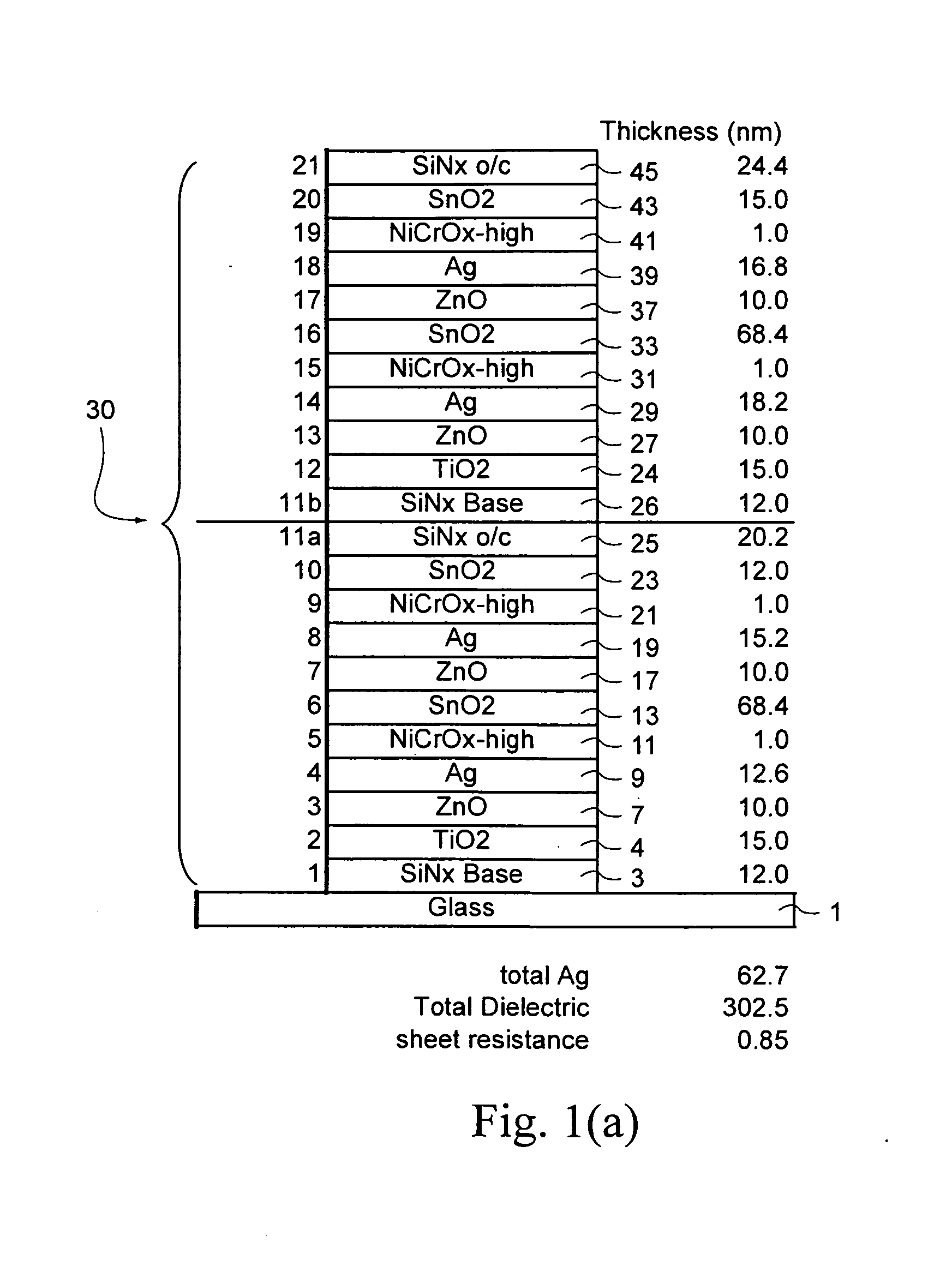

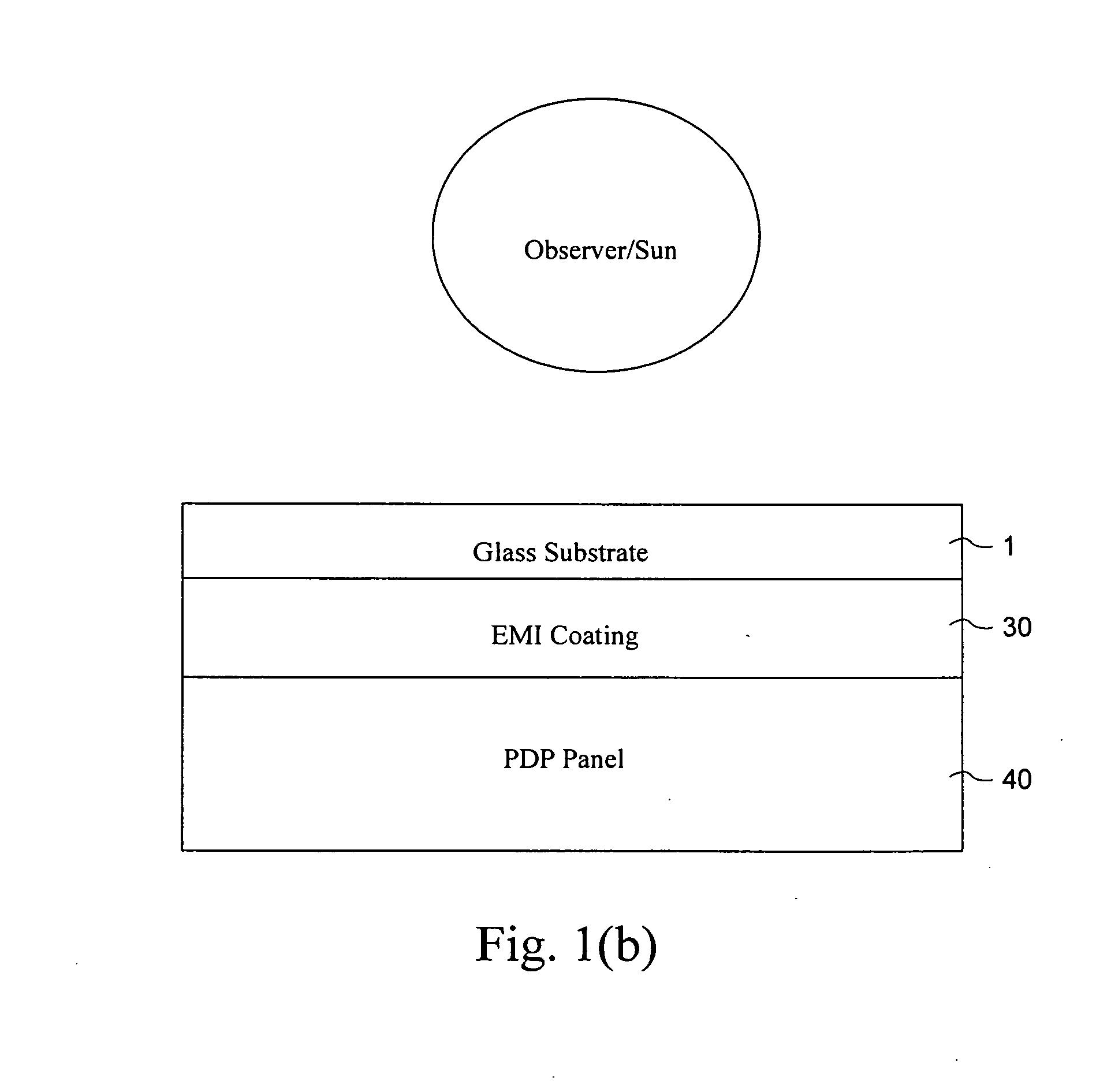

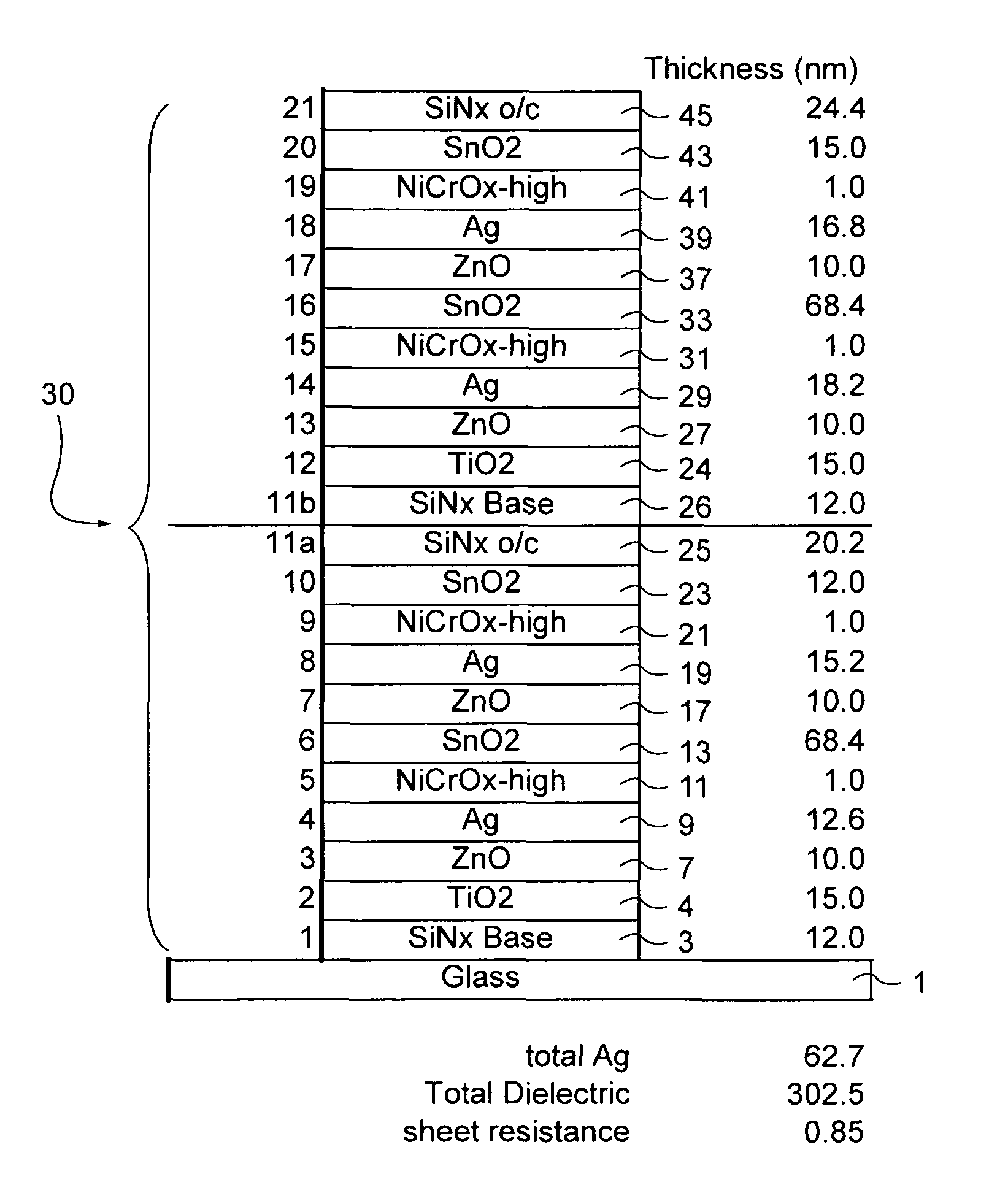

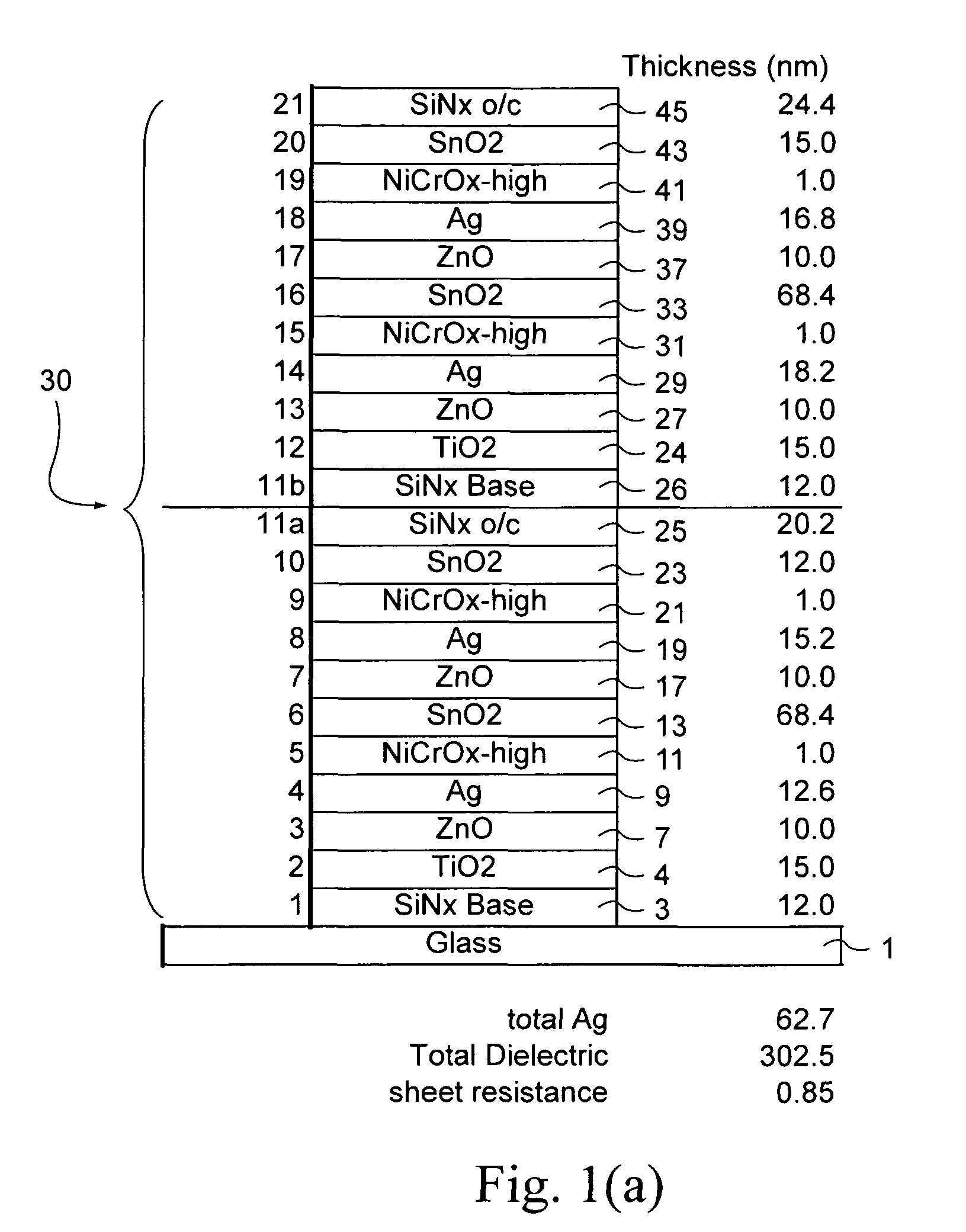

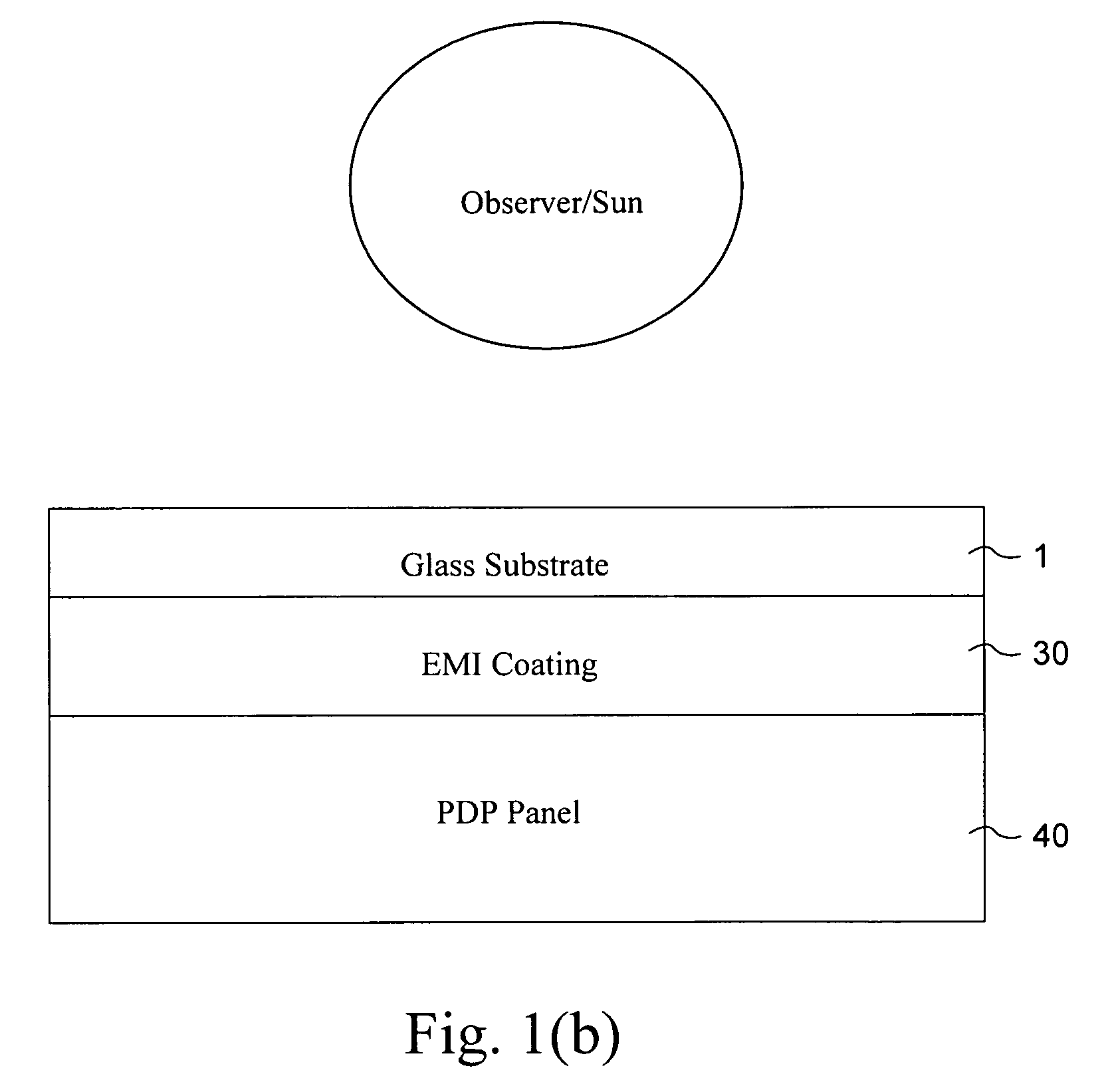

A plasma display panel (PDP) includes a frameless EMI filter supported by a glass substrate for blocking / shielding substantial amounts of electromagnetic waves, with the filter being supported by a side of the substrate opposite a viewer. In certain example embodiments, the PDP filter includes a transparent conductive coating (TCC) for electromagnetic interference (EMI) and near infrared (NIR) blocking without the need for a conductive, peripheral buss bar. Additionally, in certain example embodiments, the need for a conductive frame is reduced or eliminated. The filter has high visible transmission, and is capable of blocking / shielding electromagnetic waves.

Owner:GUARDIAN GLASS LLC

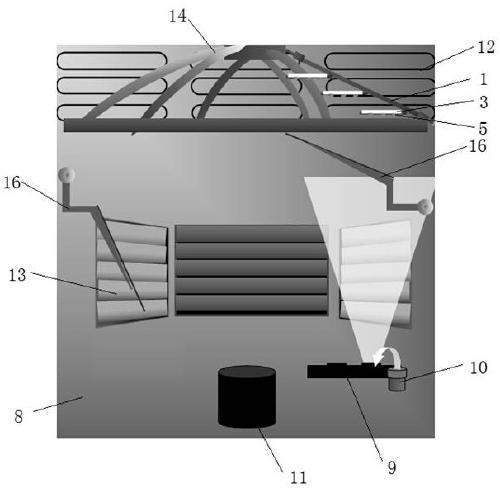

Coating system

InactiveCN102234762AOmit shipping actionAvoid pollutionLiquid surface applicatorsVacuum evaporation coatingCoating systemEngineering

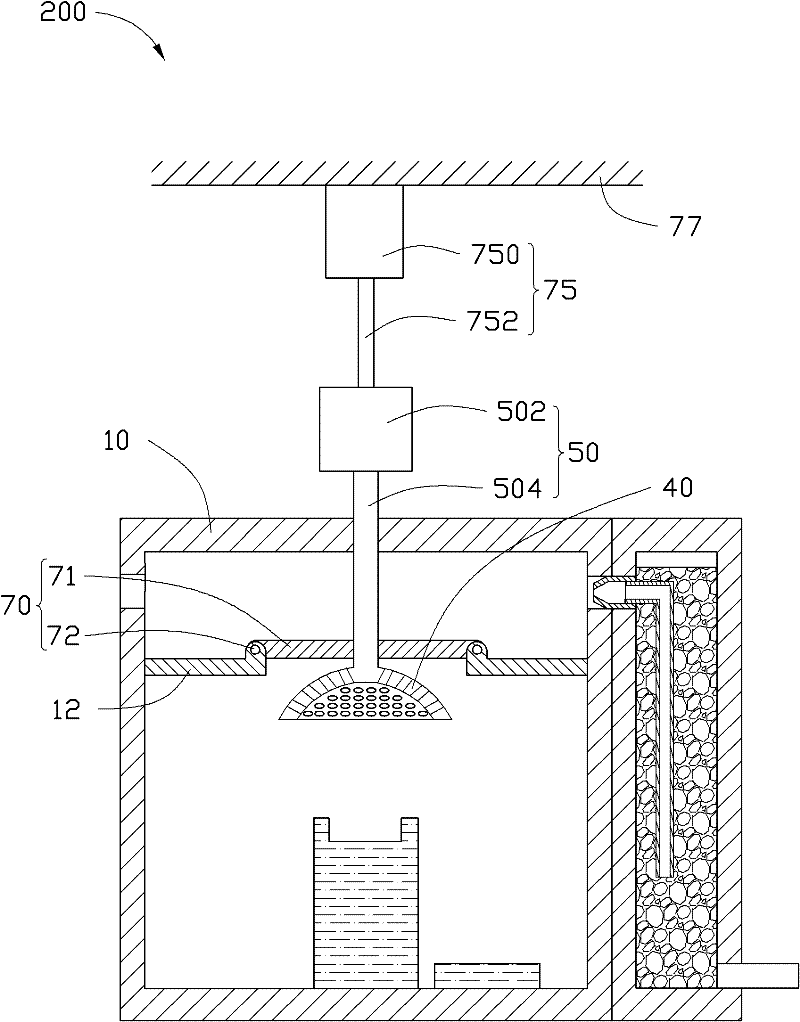

The invention discloses a coating system, which comprises a cavity, a coating umbrella frame and a rotation driving component, wherein the coating umbrella frame is used for accommodating a plurality of substrates to be coated; the rotation driving component is connected to the coating umbrella frame, and is used for driving the coating umbrella frame to rotate in the cavity; and the cavity comprises a clapboard which separates the cavity into a coating cavity and a paint spraying cavity which are separated from each other. The coating system also comprises a lifting driving component, a solvent storage chamber and an injection device, wherein the lifting driving component drives the rotation driving component to lift, so that the coating umbrella frame lifts in the coating cavity and the paint spraying cavity; the solvent storage chamber is used for storing a coating solvent, and is communicated with the paint spraying cavity; and the injection device is arranged in the solvent storage chamber and is connected to the paint spraying cavity, so that the coating solvent in the solvent storage chamber is injected to the substrates to be coated. The coating system can evaporate the substrates to be coated and also can inject a coating to the substrates to be coated.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Plasma display panel including TCC EMI filter, and/or method of making the same

InactiveUS20090295687A1Easy to makeImprove display effectStatic indicating devicesAlternating current plasma display panelsConductive coatingCutting glass

A plasma display panel (PDP) includes an EMI filter supported by a glass substrate for blocking / shielding substantial amounts of electromagnetic waves, with the filter being supported by a side of the substrate opposite a viewer. In certain example embodiments, a black frit and a silver frit comprise a filter frame and are supported by the filter such that the filter is closer to the glass substrate than either or both of the frits. Alternatively, in certain example embodiments, a conductive black frit comprises a filter frame and is supported by the filter such that the filter is closer to the glass substrate than the frit. The filter has high visible transmission, and is capable of blocking / shielding electromagnetic waves. Advantageously, a transparent conductive coating (TCC) can be coated on a stock, non-cut glass sheet.

Owner:GUARDIAN GLASS LLC

Plasma display panel including EMI filter, and/or method of making the same

InactiveUS20110133640A1Superior display capabilityLarge screenMagnetic/electric field screeningAlternating current plasma display panelsConductive coatingInfrared

A plasma display panel (PDP) includes a frameless EMI filter supported by a glass substrate for blocking / shielding substantial amounts of electromagnetic waves, with the filter being supported by a side of the substrate opposite a viewer. In certain example embodiments, the PDP filter includes a transparent conductive coating (TCC) for electromagnetic interference (EMI) and near infrared (NIR) blocking without the need for a conductive, peripheral buss bar. Additionally, in certain example embodiments, the need for a conductive frame is reduced or eliminated. The filter has high visible transmission, and is capable of blocking / shielding electromagnetic waves.

Owner:GUARDIAN GLASS LLC

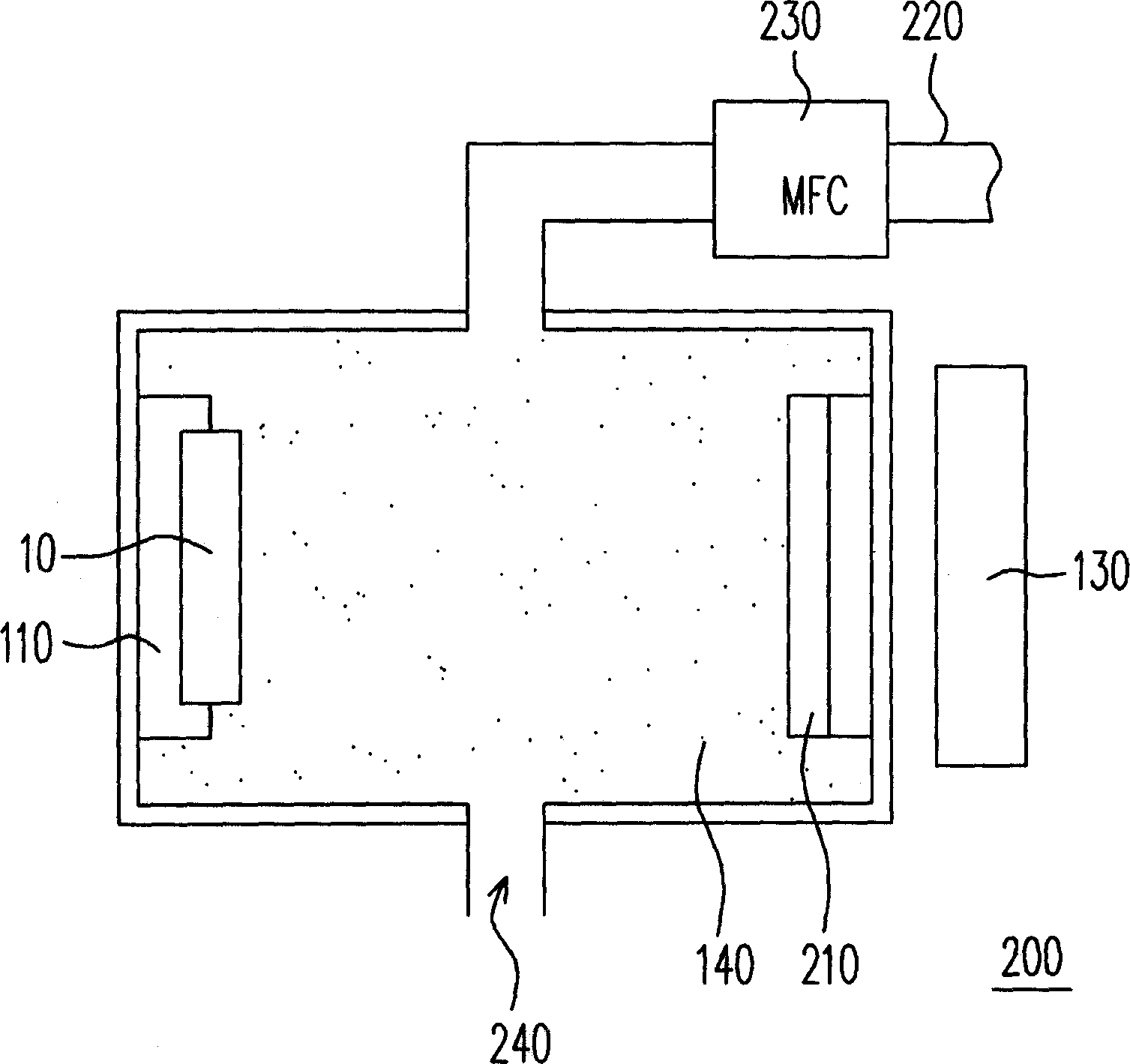

Magnetically controlled sputtering process

InactiveCN1811010AImprove coating yieldVacuum evaporation coatingSputtering coatingReaction chamberMelting point

The magnetically controlled sputtering process includes the following steps: the first providing a reaction chamber with at least base board seat, target material of aluminum, aluminum alloy or other metal of smelting point higher than that of aluminum or aluminum alloy, and magnetic controller; the subsequent transferring the base board onto the base board seat; and regulating the pressure inside the reaction chamber to 0.1-0.35 pa and sputtering to deposit film on the base board continuously. The process has high film quality.

Owner:CHUNGHWA PICTURE TUBES LTD

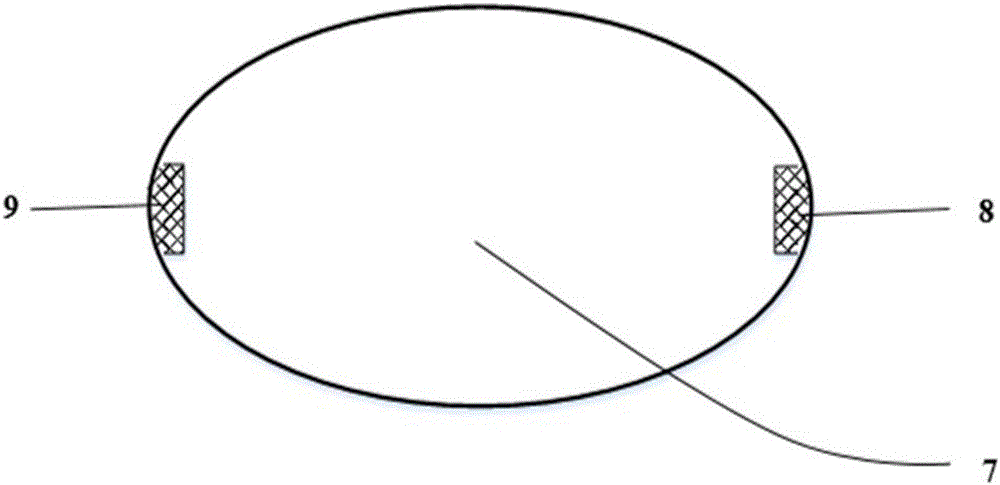

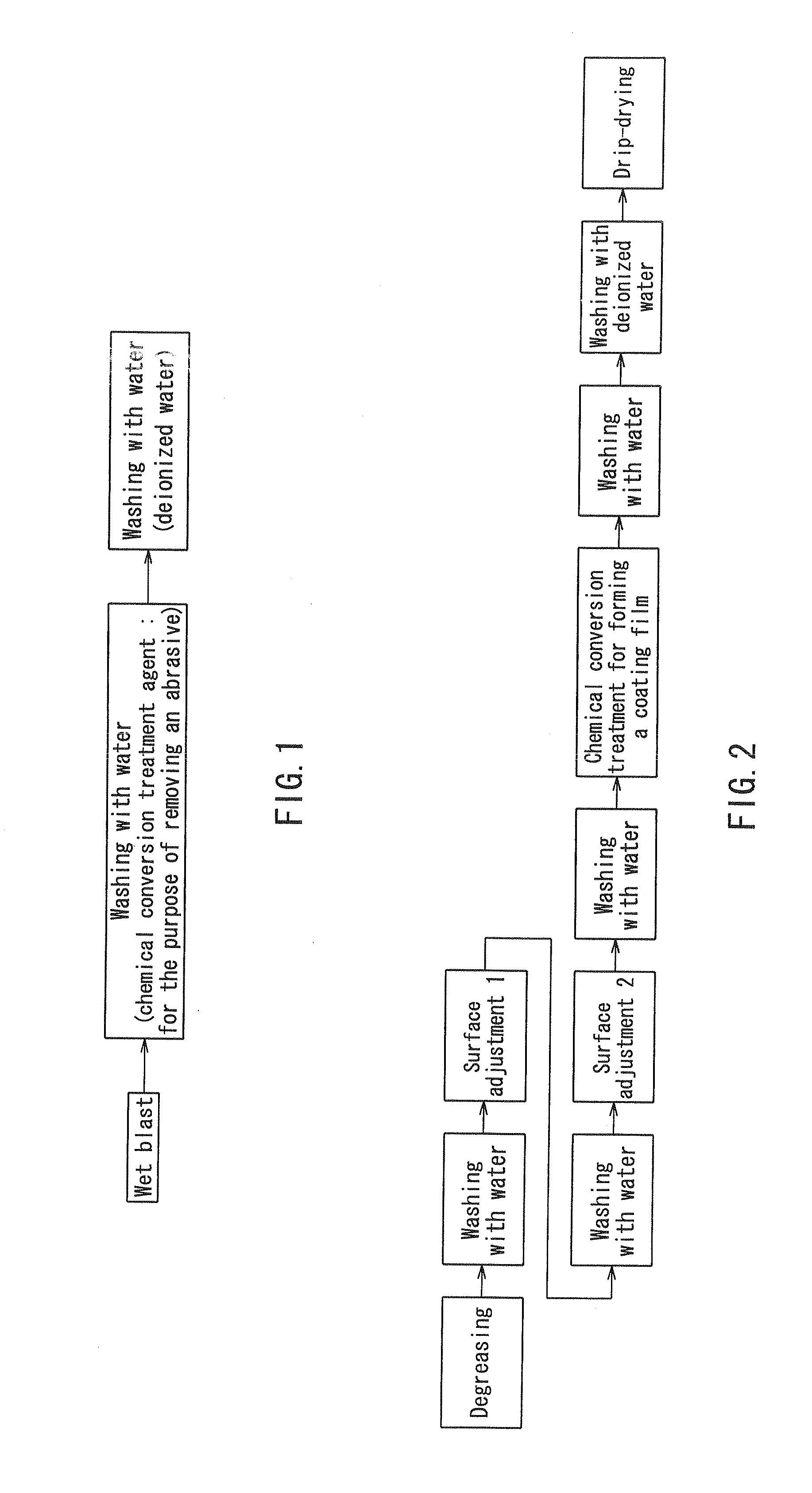

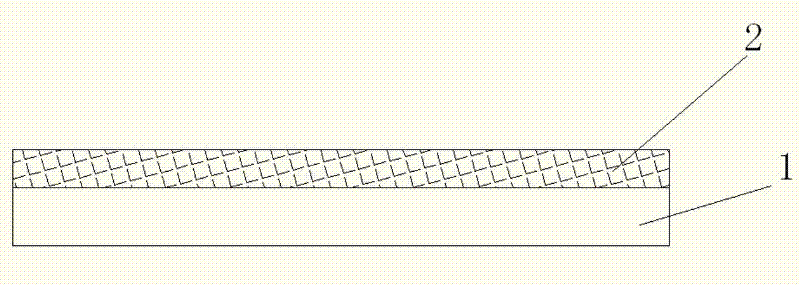

Resin eyeglass, lens anti-fog device, preparation method and applications thereof

InactiveCN106054402ALower resistanceImprove conductivityCoatingsOptical partsCamera lensSilicon monoxide

The invention discloses a resin eyeglass, a lens anti-fog device, a preparation method and applications thereof. The resin eyeglass comprises a resin substrate, a priming layer, a bedding layer, a conductive layer, an anti-oxidation layer, and a protective layer, wherein the priming layer, the bedding layer, the conductive layer, the anti-oxidation layer, and the protective layer are adhered on the resin substrate in sequence, the priming layer is a silicon monoxide film with a thickness of 10 to 20 nm; the bedding layer is a zinc oxide film, a titanium film or a nickel-chromium alloy film; the conductive layer is a conductive metal film with a thickness of 5 to 15 nm; and the anti-oxidation layer is an anti-oxidation material film with a thickness of 1 to 5 nm. The lens anti-fog device comprises one provided resin eyeglass, a positive electrode, and a negative electrode, wherein the positive electrode and the negative electrode are arranged on two ends of the resin eyeglass respectively. The provided resin eyeglass has the advantages of good electro-conductive performance, anti-reflection effect, and anti-oxidation effect, moreover, the preparation method is simple, the production efficiency is high, and the yield of plating is high. The provided lens anti-fog device can be connected to a power supply to heat the film so as to prevent water steam from forming fog on the surface of lens.

Owner:SHANGHAI COPIOUS OPTICAL S & T CO LTD

Water-based optical lens cleaning agent composition

ActiveCN102911821AEasy to cleanLow oral toxicitySurface-active non-soap compounds and soap mixture detergentsWater basedOrganic base

The invention discloses a water-based optical lens cleaning agent composition, which comprises the following raw materials in parts by weight: 5-10 parts of organic base, 3-5 parts of inorganic base, 3-5 parts of environment-friendly chelating agent, 10-15 parts of dispersing agent, 15-20 parts of penetrating agent and 40-60 parts of de-ionized water. The water-based optical lens cleaning agent composition has the advantages that 1, the composition is an ODS (Ozone Depleting Substance) cleaning liquid substitute in the optical electronic cleaning industry, 2, the composition is a highly concentrated product and is only required to be diluted in water according to a proportion of 3-5 percent to have an excellent cleaning effect, 3, the composition is made of environment-friendly raw materials, has oral toxicity, can be contacted with skin, has extremely low inhalation toxicity and is safe to human bodies and easy to biodegrade, 4, the composition is safe to a cleaned object, does not corrode a lens, has excellent compatibility, meanwhile has excellent compatibility with most of rubber and plastic, does not swell or corrode and the like, and 5, the composition has strong cleaning power, is uniform in filming on the lens after cleaning, does not produce fog or spots and has no phenomenon of bubbling, the filming yield is greatly improved, and the production efficiency is increased.

Owner:东莞市伟思化学科技有限公司

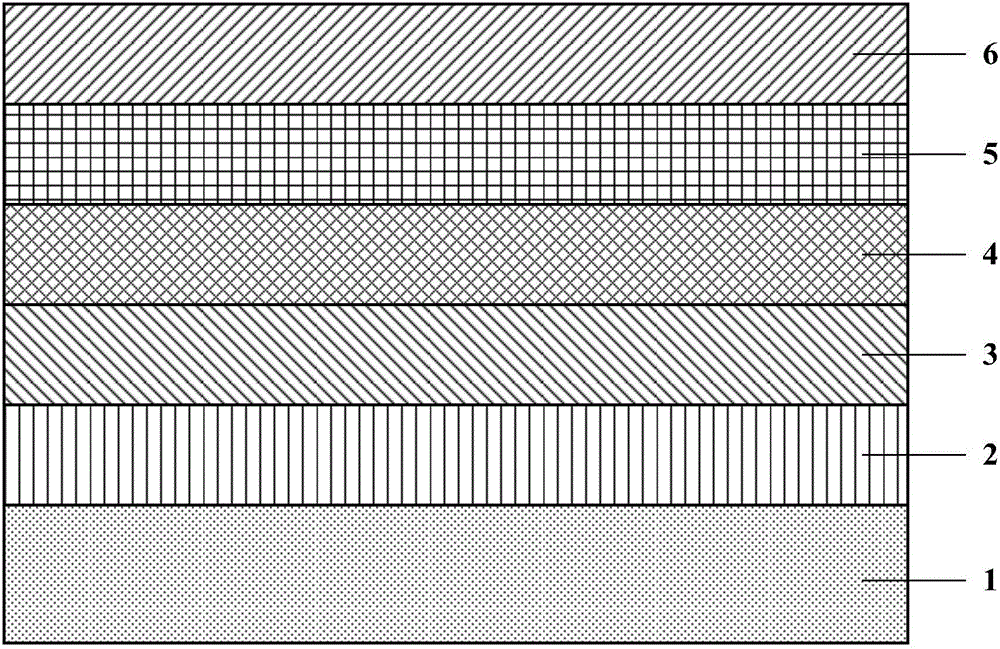

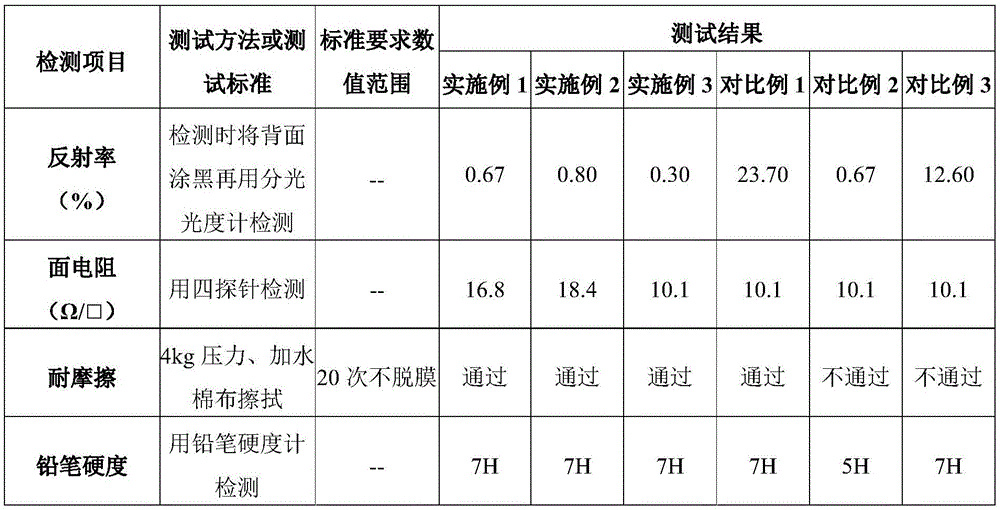

Composite conductive film and preparation method and application thereof

InactiveCN106028486ALower resistanceImprove conductivityTransparent/reflecting heating arrangementsSilicon monoxideChromium nickel

The invention discloses a composite conductive film and a preparation method and application thereof. The composite conductive film sequentially comprises a priming coating layer, an underlay layer, a conductive layer, an anti-oxidation layer, and a protection layer. The priming coating layer is a silicon monoxide film layer, and the thickness of the priming coating layer is from 10nm to 20nm. The underlay layer is a zinc oxide film layer, a titanium film layer or a nichrome alloy film layer. The conductive layer is a conductive metal film layer, and the thickness of the conductive layer is from 5nm to 15nm. The anti-oxidation layer is an anti-oxidation material film layer, and the thickness of the anti-oxidation layer is from 1nm to 5nm. The composite conductive film can be prepared through a conventional plating method, and is applied to a video glasses display screen. The composite conductive film achieves good conductivity, a good anti-reflection effect and a good anti-oxidation effect through the specified selection of the film layer materials and the thicknesses of all film layers. Moreover, the method is simple, is high in production efficiency, and is high in film plating yield.

Owner:SHANGHAI COPIOUS OPTICAL S & T CO LTD

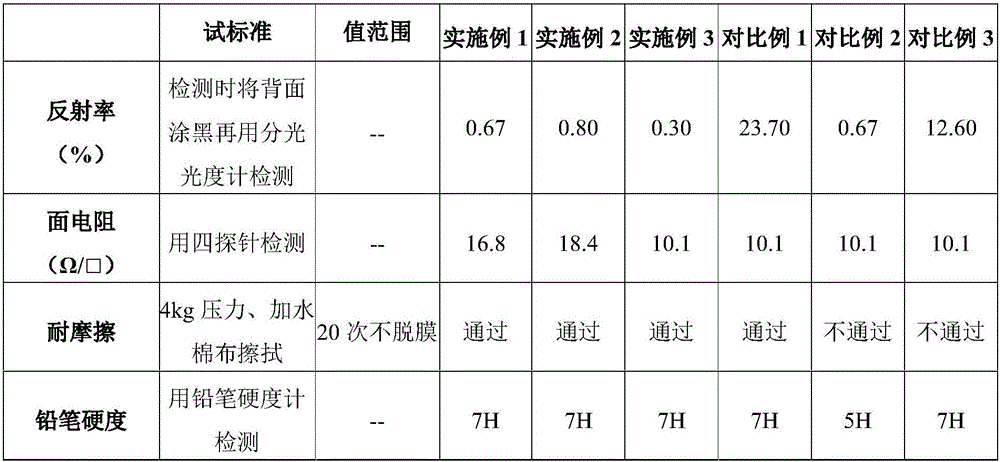

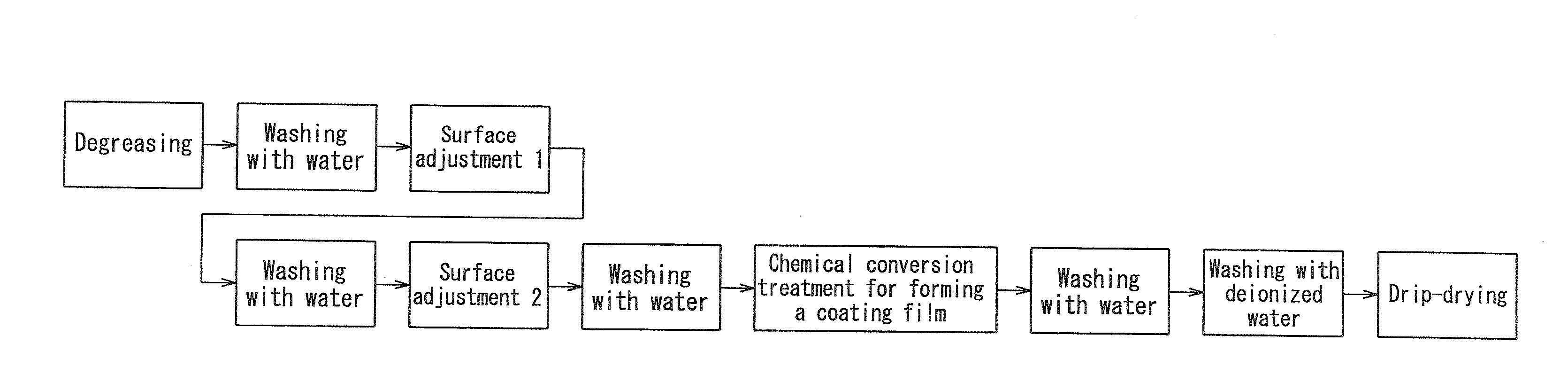

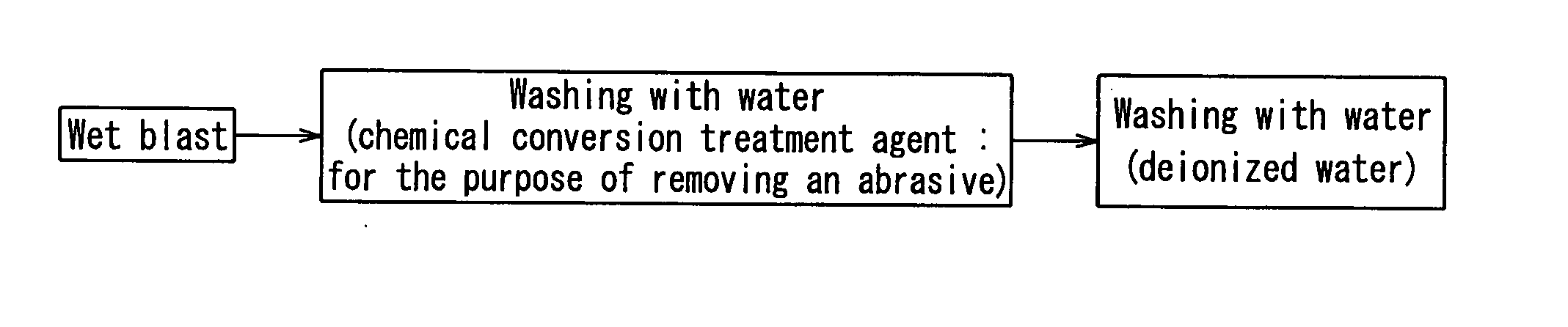

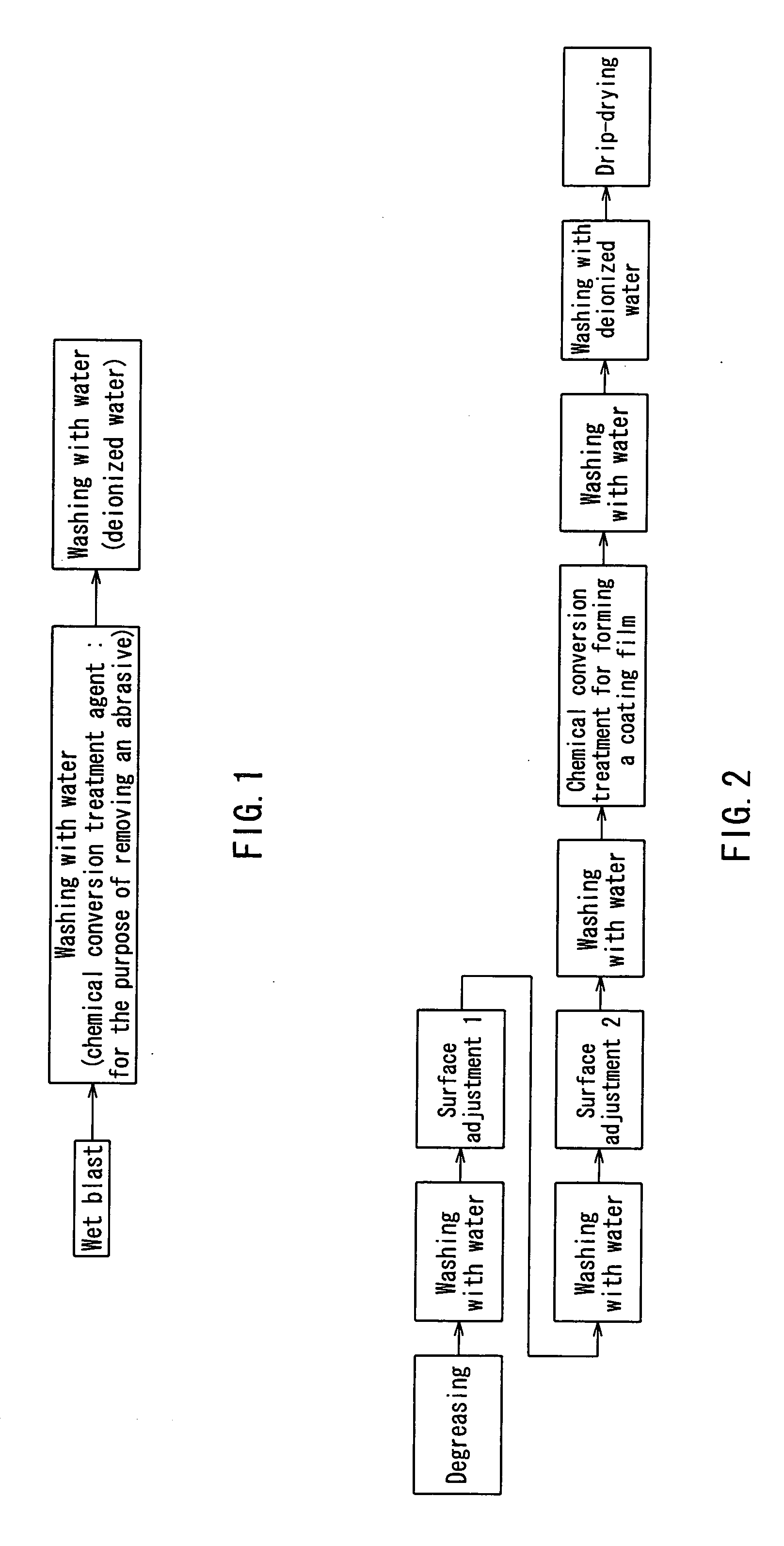

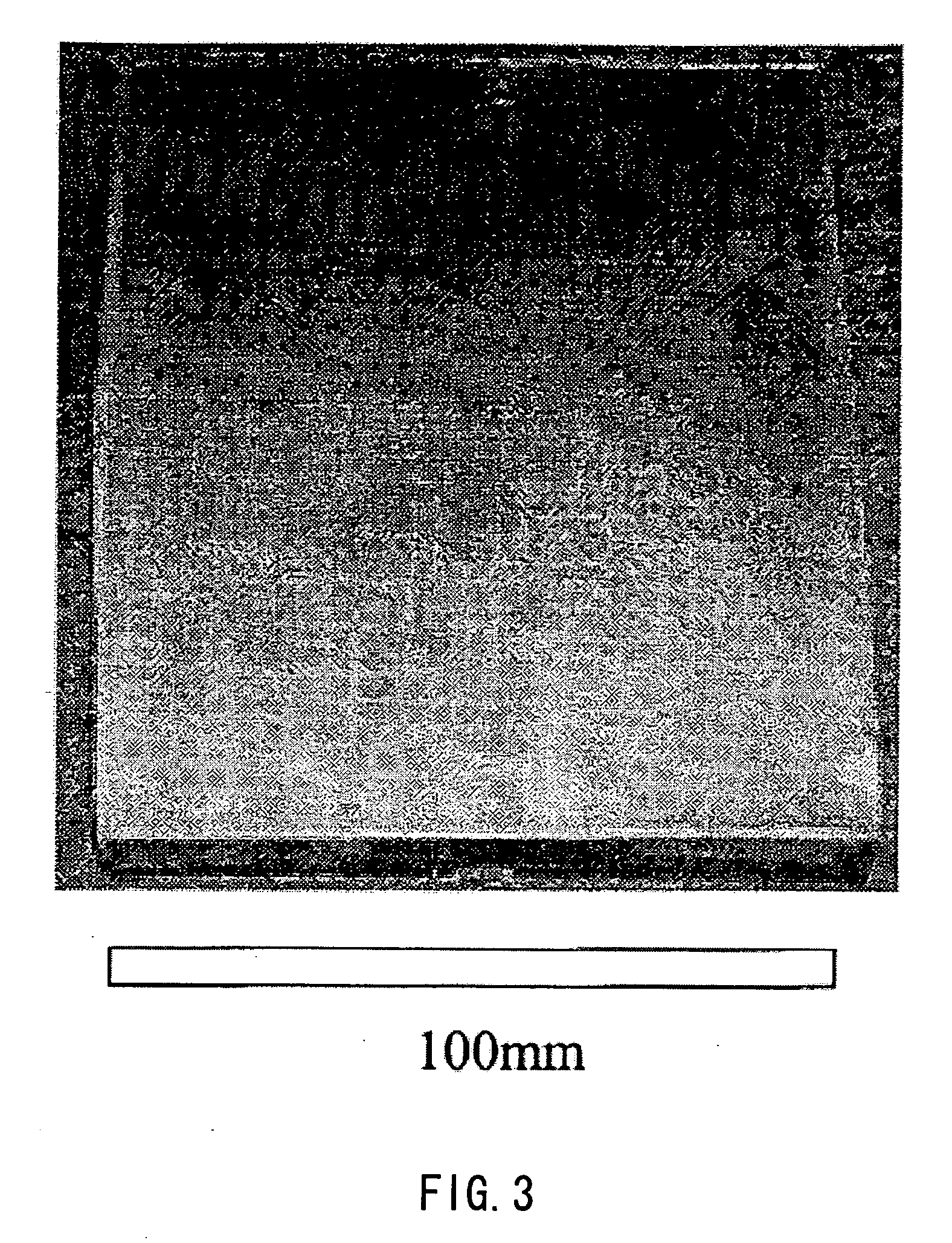

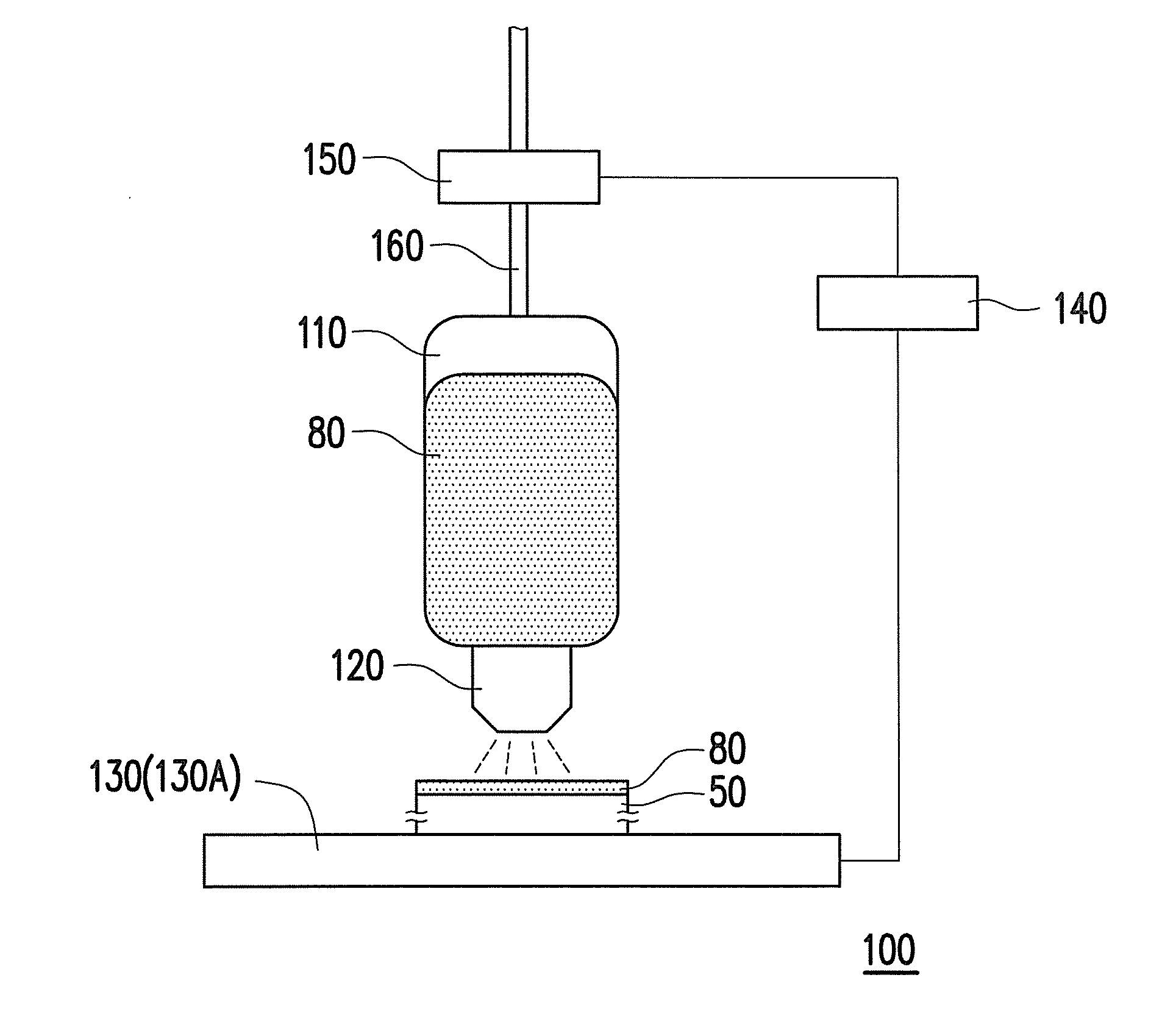

Mg or Mg-Alloy Housing and Method for Producing the Same

InactiveUS20090250142A1Reduce correctionImprove coating yieldAbrasion apparatusMetallic material coating processesAlloyMaterials science

A surface of a Mg or Mg-alloy housing of the present invention is subjected to wet blast using a mixture containing a chemical conversion treatment agent and an abrasive, whereby a chemical conversion film is formed on the surface of the Mg or Mg-alloy housing. Because of this, a chemical conversion film is formed simply on the surface of a molded product made of Mg or a Mg-alloy to reduce the correction by puttying, whereby a Mg or Mg-alloy housing is provided in which a decrease in yield and an increase in cost can be prevented.

Owner:FUJITSU LTD

Plasma display panel including frameless EMI filter, and/or method of making the same

ActiveUS8147975B2Easy to makeImprove display effectMagnetic/electric field screeningGlass/slag layered productsInfraredConductive coating

A plasma display panel (PDP) includes a frameless EMI filter supported by a glass substrate for blocking / shielding substantial amounts of electromagnetic waves, with the filter being supported by a side of the substrate opposite a viewer. In certain example embodiments, the PDP filter includes a transparent conductive coating (TCC) for electromagnetic interference (EMI) and near infrared (NIR) blocking without the need for a conductive, peripheral buss bar. Additionally, in certain example embodiments, the need for a conductive frame is reduced or eliminated. The filter has high visible transmission, and is capable of blocking / shielding electromagnetic waves.

Owner:GUARDIAN GLASS LLC

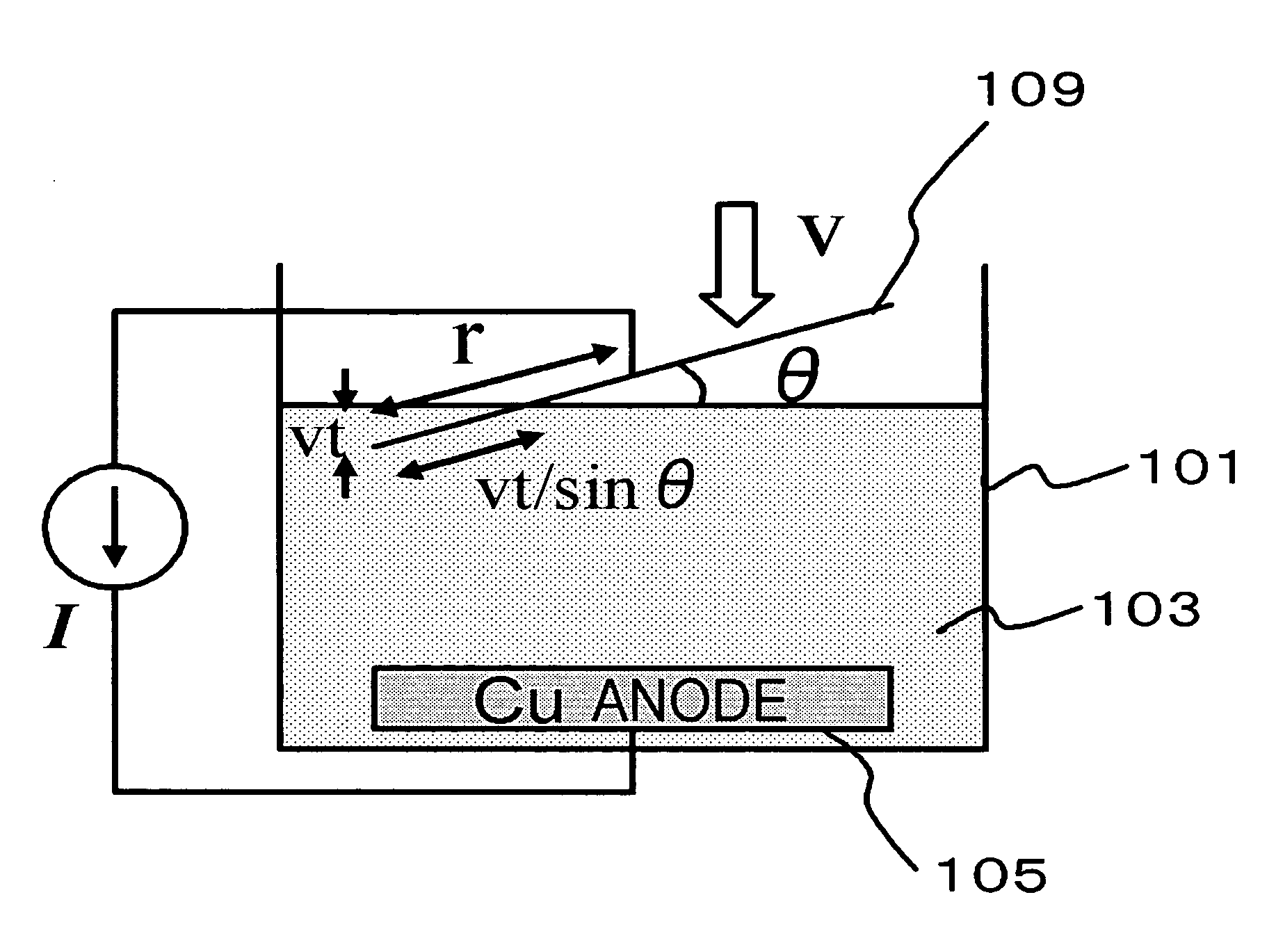

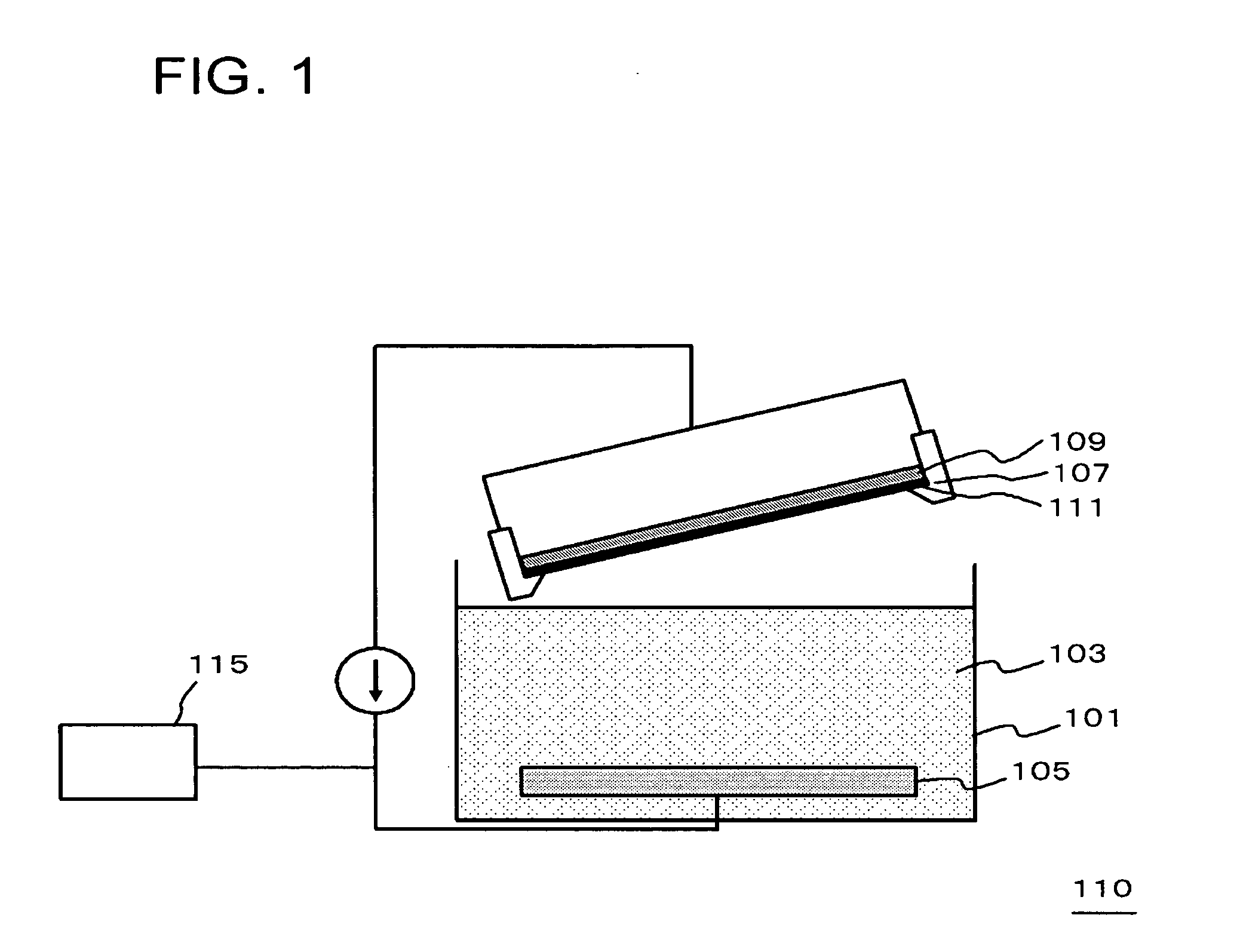

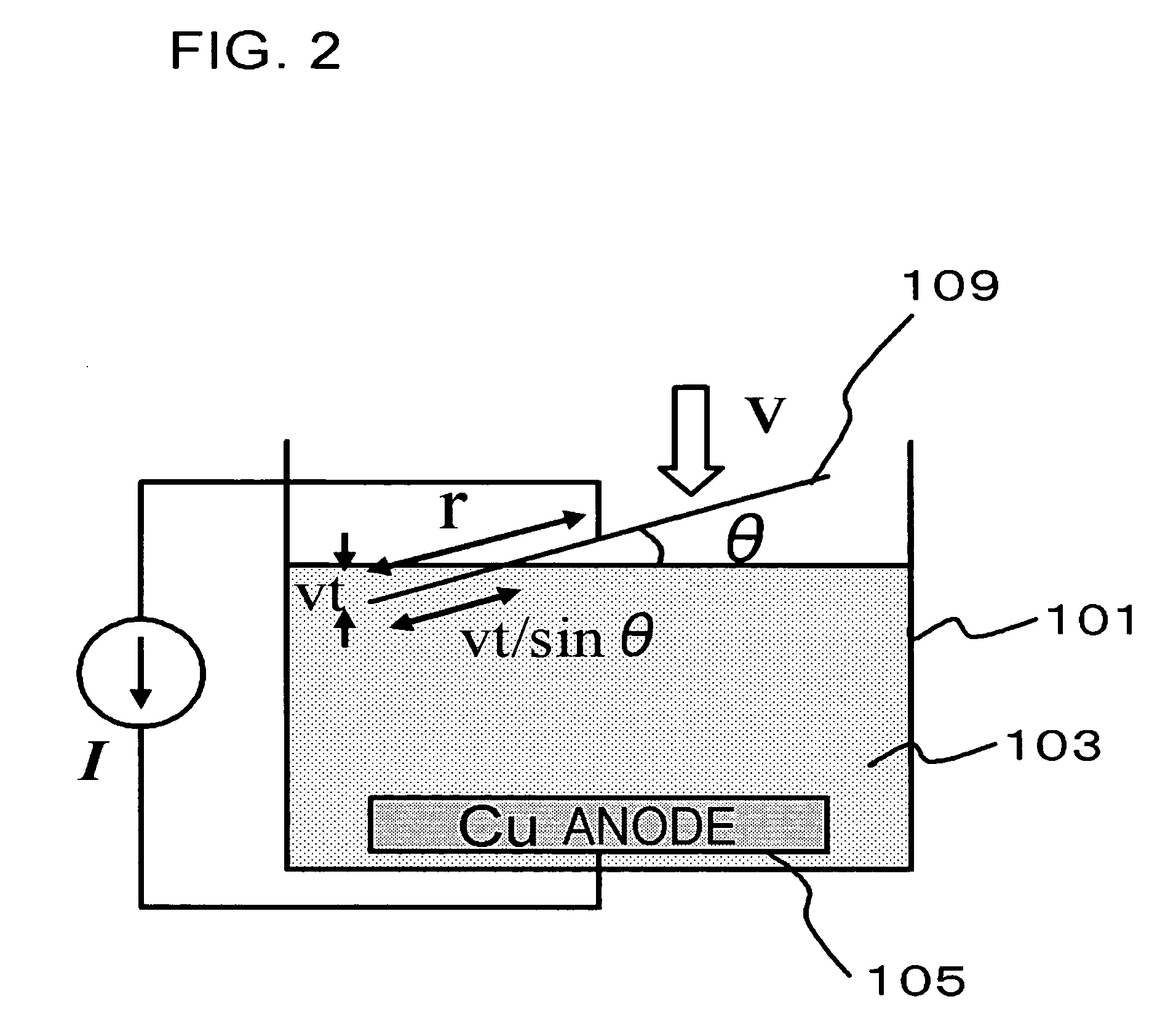

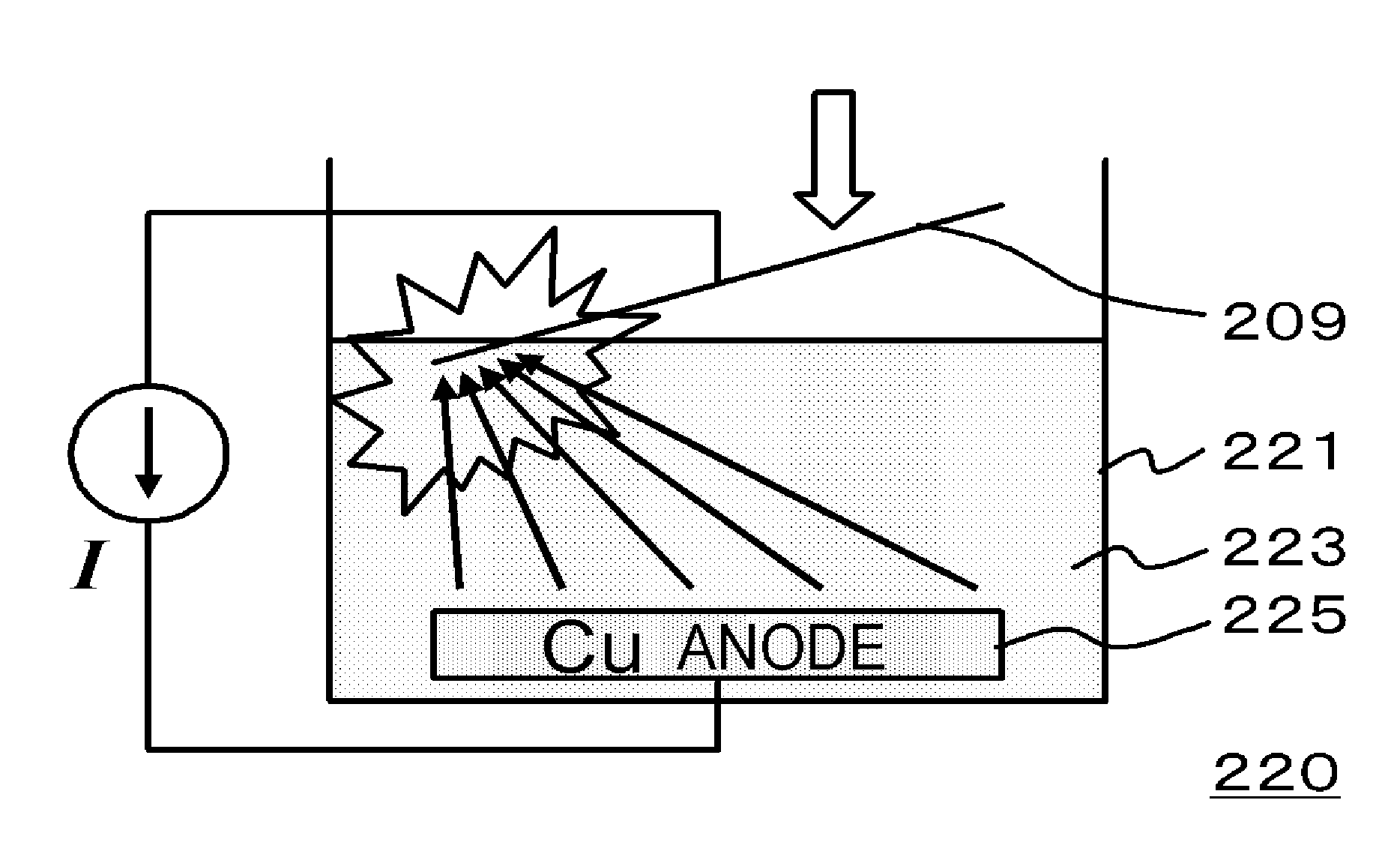

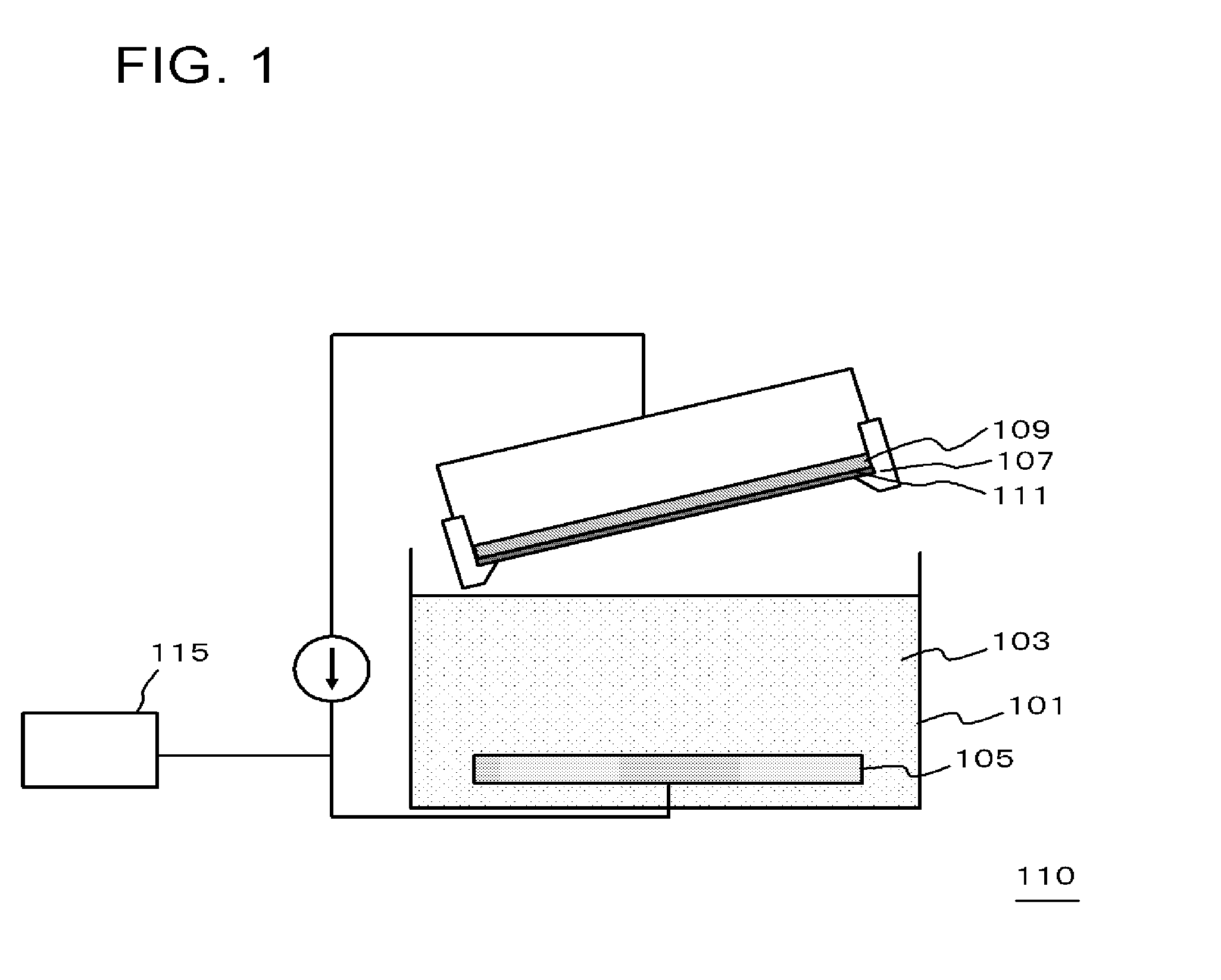

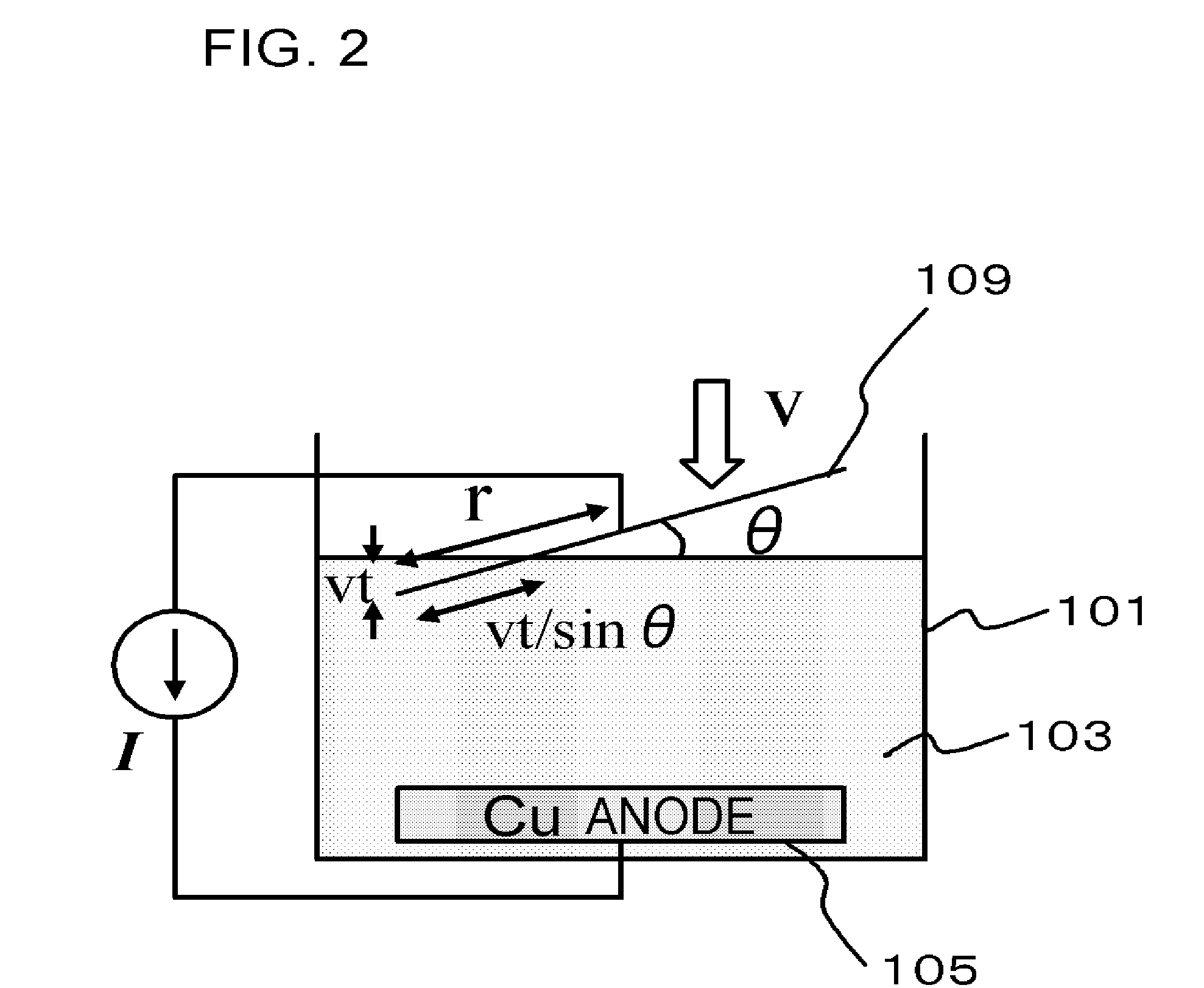

Planting process and manufacturing process for semiconductor device thereby, and plating apparatus

InactiveUS20060237319A1Inhibit currentAvoid volatilityElectrolysis componentsSemiconductor/solid-state device manufacturingManufacturing technologyDevice material

An objective of this invention is to reliably form a plating film. The following two steps are sequentially conducted: step 101 of connecting a film-formation surface of a wafer 109 to a cathode electrode 107, making the film-formation surface inclined from the surface of a plating solution 103 and immersing the wafer 109 into the plating solution 103 with applying a first current between the cathode electrode 107 and an Cu anode electrode 105 disposed in the plating solution 103, and step 103 of, after immersing the film-formation surface in the plating solution 103, applying a second current between the cathode electrode 107 and the Cu anode electrode 105 to form a metal film on the film-formation surface by electrolytic plating. In step 101, the first current is controlled on the basis of an inclination angle between the liquid surface and the film-formation surface.

Owner:RENESAS ELECTRONICS CORP

Plasma display panel including TCC EMI filter, and/or method of making the same

InactiveUS8329304B2Easy to makeImprove display effectAlternating current plasma display panelsGlass/slag layered productsCutting glassConductive coating

Owner:GUARDIAN GLASS LLC

Plasma display panel including EMI filter, and/or method of making the same

InactiveUS8592059B2Easy to makeImprove display effectMagnetic/electric field screeningAlternating current plasma display panelsInfraredConductive coating

A plasma display panel (PDP) includes a frameless EMI filter supported by a glass substrate for blocking / shielding substantial amounts of electromagnetic waves, with the filter being supported by a side of the substrate opposite a viewer. In certain example embodiments, the PDP filter includes a transparent conductive coating (TCC) for electromagnetic interference (EMI) and near infrared (NIR) blocking without the need for a conductive, peripheral buss bar. Additionally, in certain example embodiments, the need for a conductive frame is reduced or eliminated. The filter has high visible transmission, and is capable of blocking / shielding electromagnetic waves.

Owner:GUARDIAN GLASS LLC

Coating method for plastic parts

InactiveCN103341435AImprove coating yieldImprove the problem of unqualified performance experimentPretreated surfacesCoatingsSurface cleaningChemistry

The invention discloses a coating method for plastic parts. The coating method comprises the steps of assembling coating tools, cleaning the surfaces of the plastic parts, electrostatic dust removal, PRIMER and primer coating, surface coating and the like which are sequentially carried out. Under the condition of not affecting control procedures of a coating process, the coating yield can be increased or the problem of disqualification in performance experiments can be improved by coating the PRIMER. A production process is easy and convenient to operate, and can be used for greatly reducing the production cost.

Owner:DONGMING XINGYE SCI TECH CO LTD

Plating process and manufacturing process for semiconductor device thereby

InactiveUS20110155578A1Inhibit currentAvoid volatilityCellsMachining electric circuitsEngineeringElectroplating

An objective of this invention is to reliably form a plating film. The following two steps are sequentially conducted: step 101 of connecting a film-formation surface of a wafer 109 to a cathode electrode 107, making the film-formation surface inclined from the surface of a plating solution 103 and immersing the wafer 109 into the plating solution 103 with applying a first current between the cathode electrode 107 and an Cu anode electrode 105 disposed in the plating solution 103, and step 103 of, after immersing the film-formation surface in the plating solution 103, applying a second current between the cathode electrode 107 and the Cu anode electrode 105 to form a metal film on the film-formation surface by electrolytic plating. In step 101, the first current is controlled on the basis of an inclination angle between the liquid surface and the film-formation surface.

Owner:RENESAS ELECTRONICS CORP

Mg or Mg-alloy housing and method for producing the same

InactiveUS20060054249A1Reduce correctionImprove coating yieldMetallic material coating processesAbrasion apparatusAlloyMaterials science

A surface of a Mg or Mg-alloy housing of the present invention is subjected to wet blast using a mixture containing a chemical conversion treatment agent and an abrasive, whereby a chemical conversion film is formed on the surface of the Mg or Mg-alloy housing. Because of this, a chemical conversion film is formed simply on the surface of a molded product made of Mg or a Mg-alloy to reduce the correction by puttying, whereby a Mg or Mg-alloy housing is provided in which a decrease in yield and an increase in cost can be prevented.

Owner:FUJITSU LTD

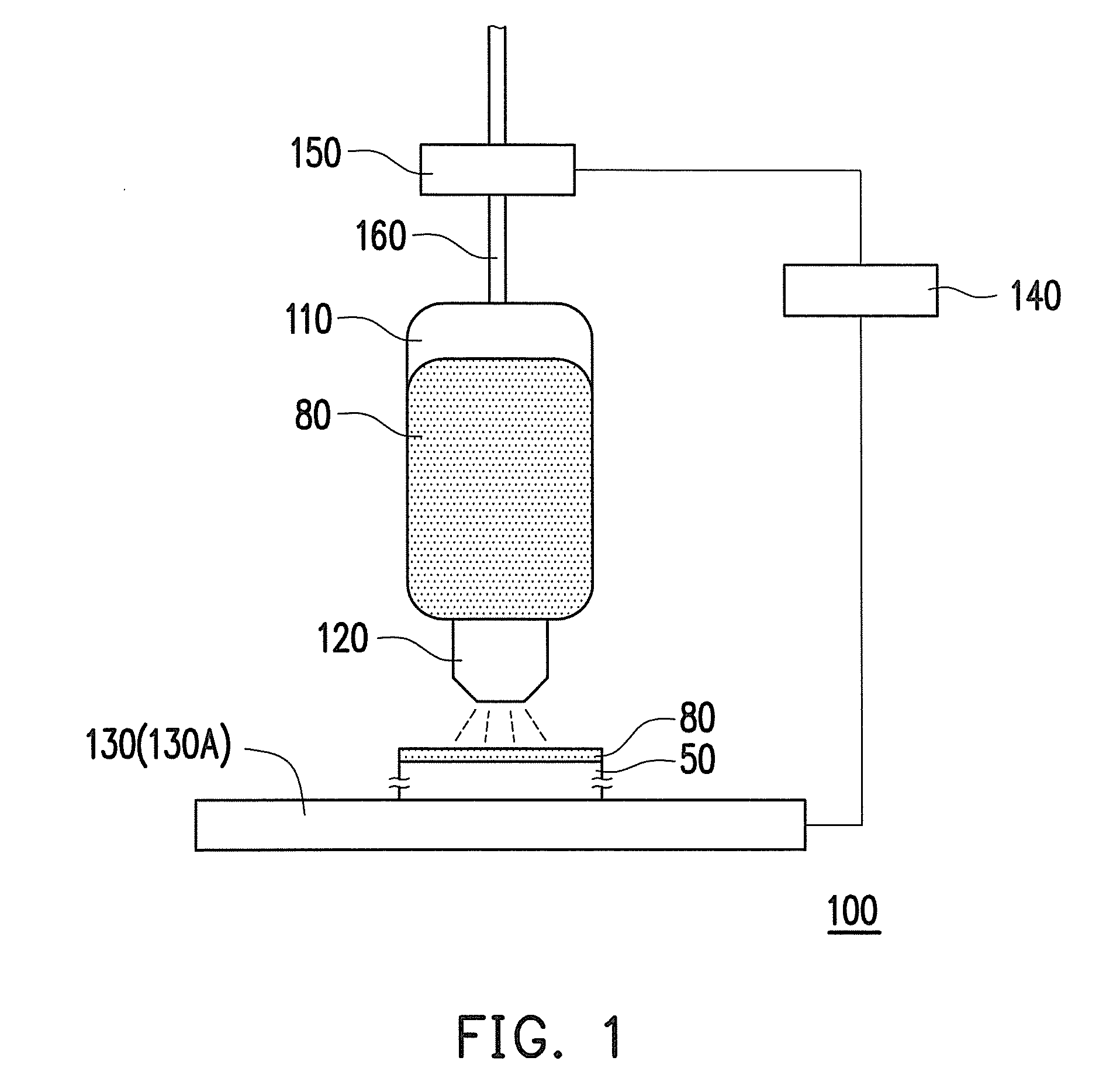

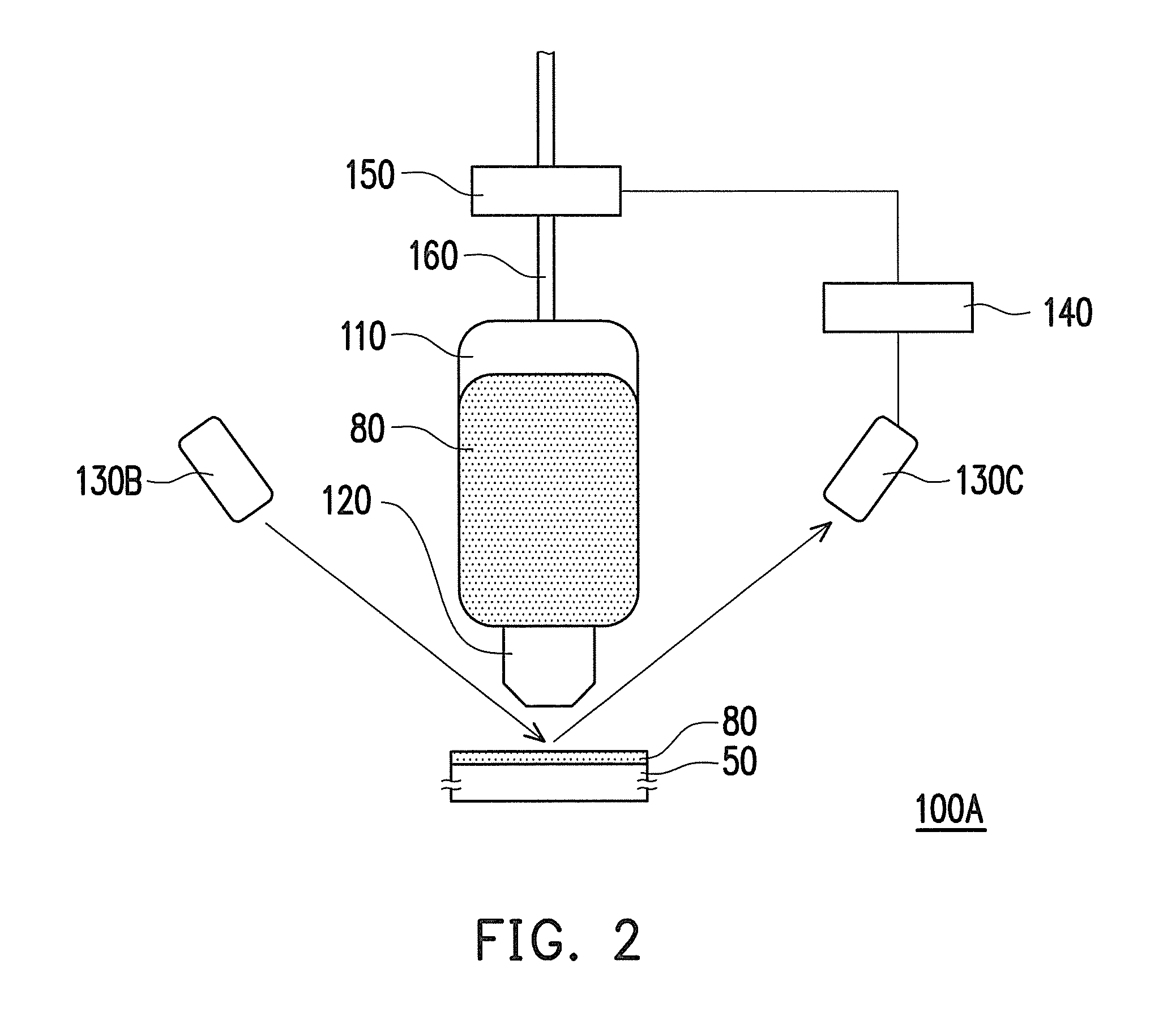

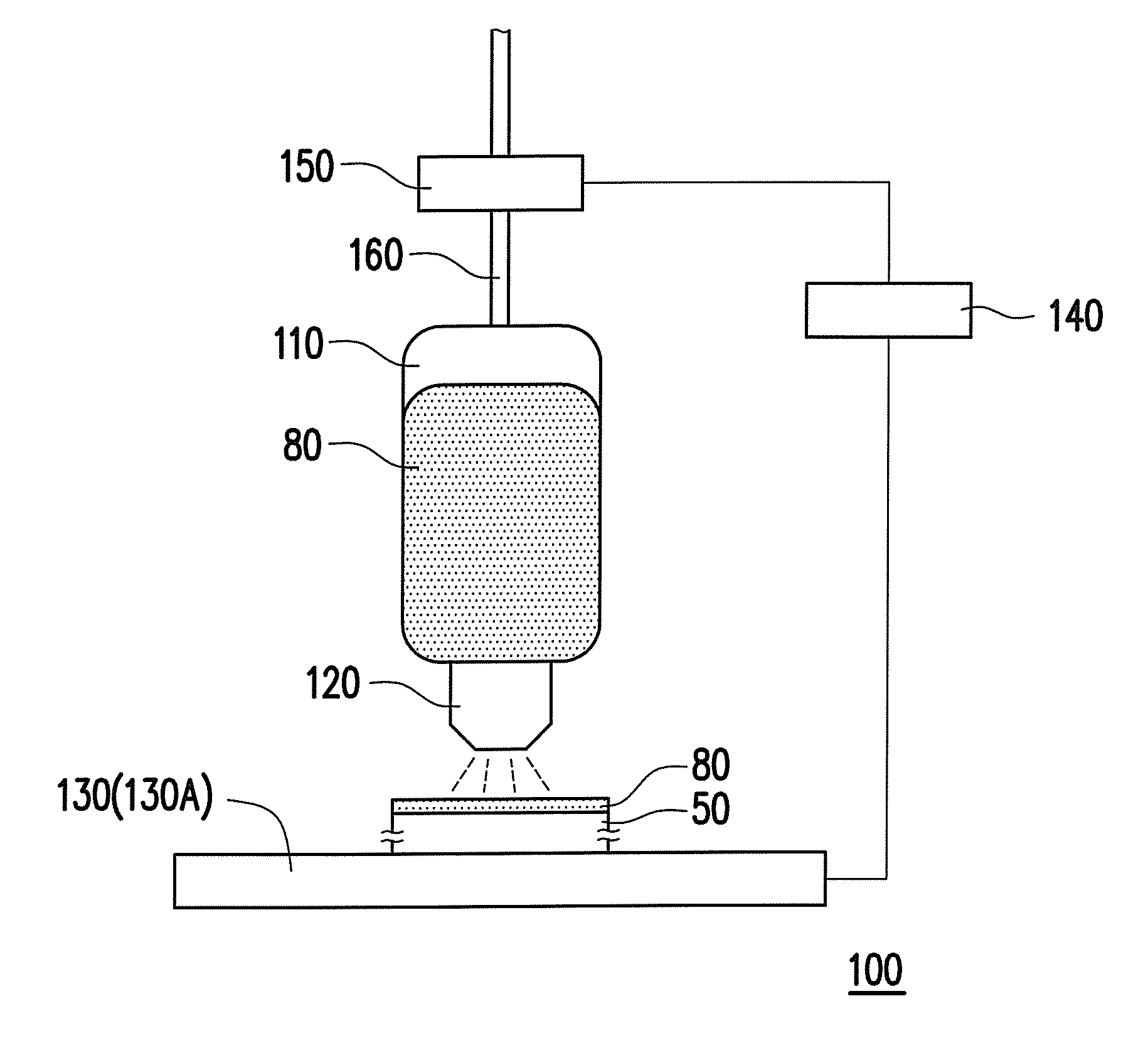

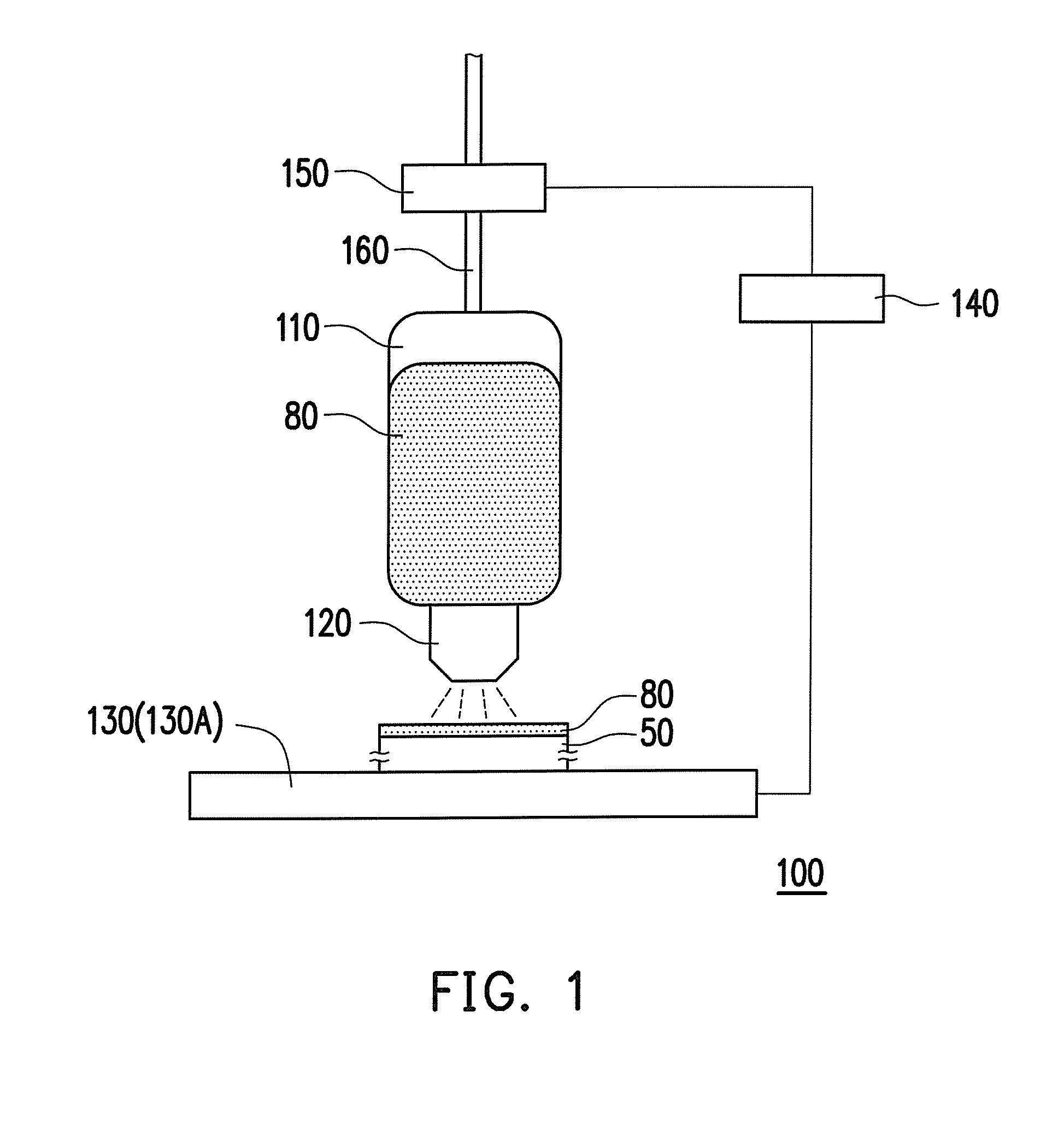

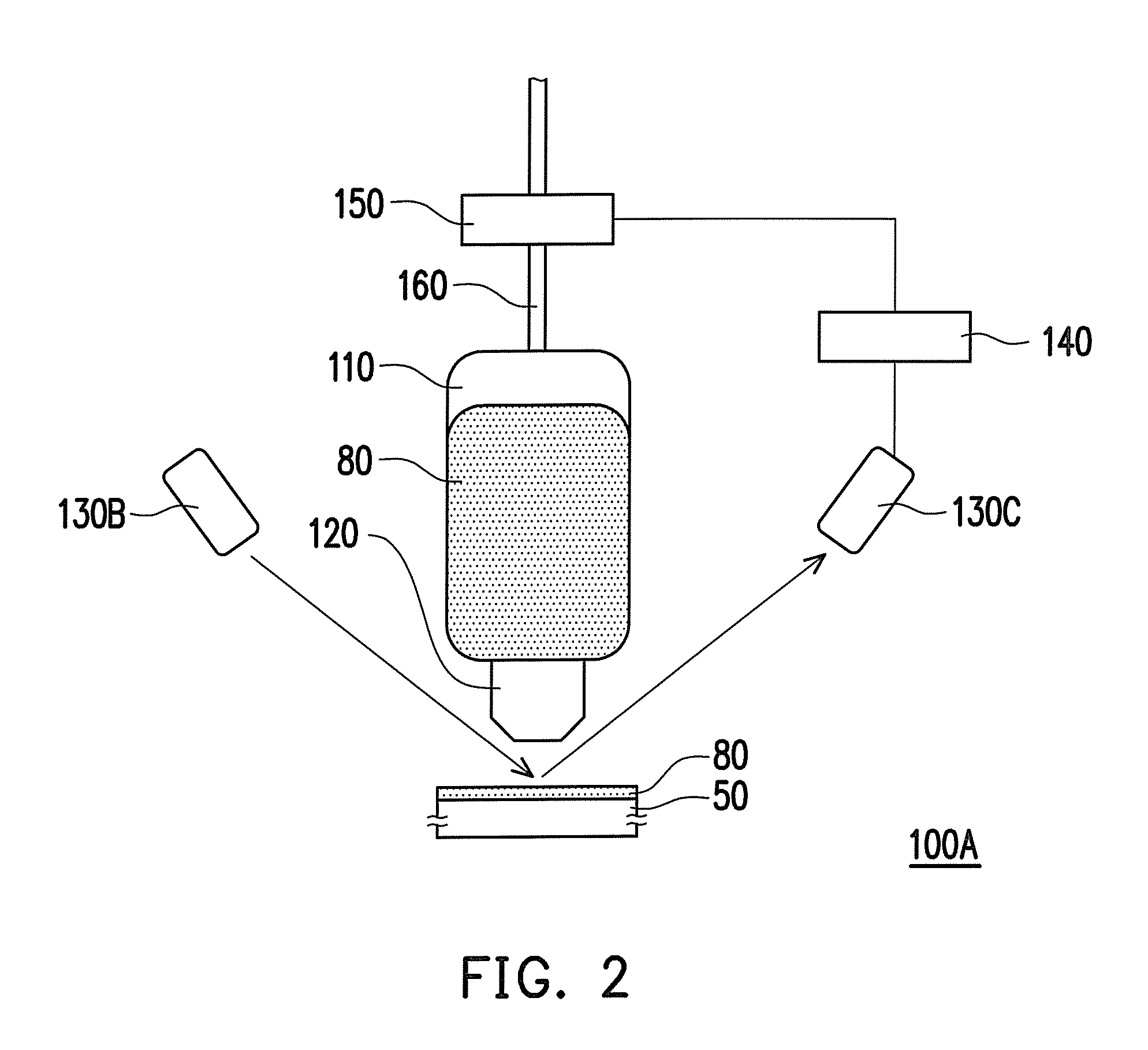

Spray coating apparatus

InactiveUS20140252118A1Improve coating yieldAvoid inconsistenciesLiquid surface applicatorsSpraying apparatusSpray coatingSpray nozzle

A spray coating apparatus including a containing tank, a spray nozzle, and a detection unit is provided. The containing tank contains a glue. The spray nozzle is connected to the containing tank to spray and coat the glue on a work piece. The detection unit detects specification data of the glue on the work piece.

Owner:GENESIS PHOTONICS

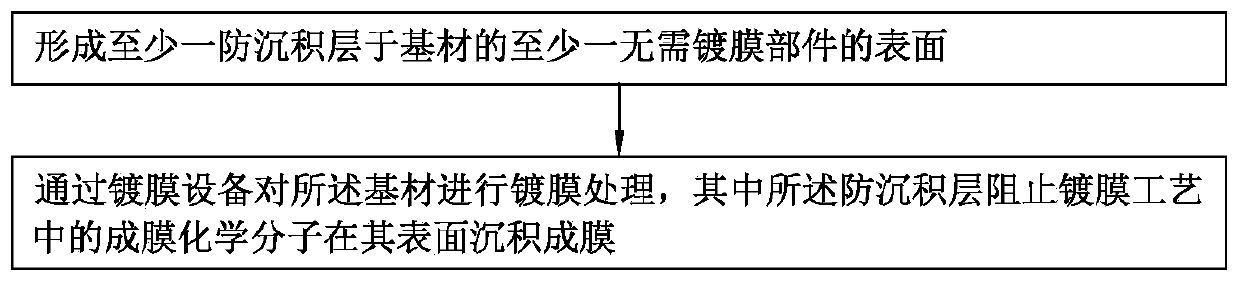

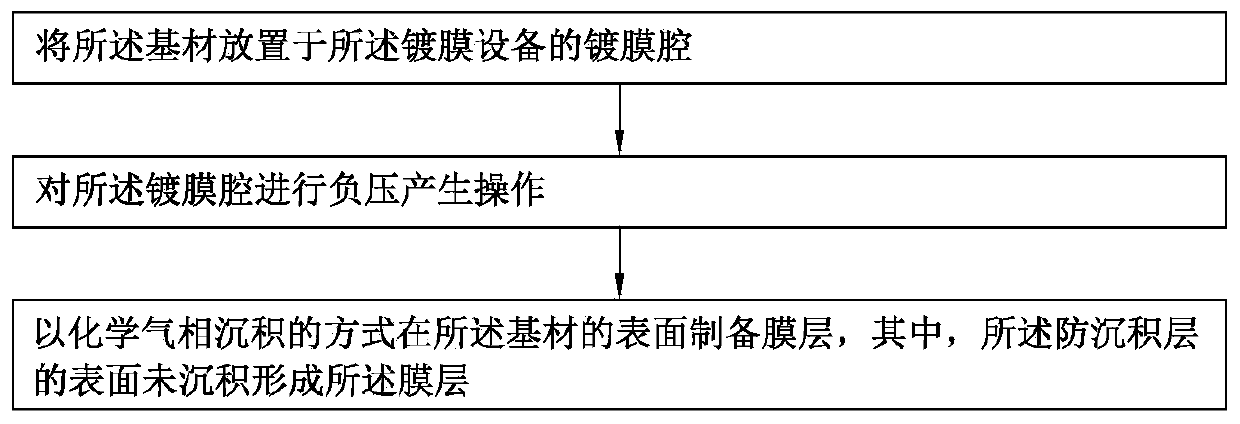

Film coating method and protective layer

PendingCN111424256ALow costImprove coating yieldChemical vapor deposition coatingFilm coatingFilm-coated tablet

The invention provides a film coating method and a protective layer. The film coating method comprises the following steps: A, at least one surface of an anti-deposition layer is formed on at least one surface of a substrate without a film coating component; and B, film coating treatment is performed on the substrate by a film coating device, wherein the anti-deposition layer prevents film-formingchemical molecules in the film coating process from being deposited on the surface of the anti-deposition layer to form a film.

Owner:JIANGSU FAVORED NANOTECHNOLOGY CO LTD

Low-dust fall vacuum magneto-controlled sputter coating equipment

InactiveCN102409312AReduce maintenance frequencyIncrease contact areaVacuum evaporation coatingSputtering coatingMetallurgyDust fall

The invention discloses low-dust fall vacuum magneto-controlled sputter coating equipment, which is provided with a sputtering region, wherein a target and an assembly of a magneto-controlled sputtering cathode are arranged in the sputtering region. The low-dust fall vacuum magneto-controlled sputter coating equipment is characterized in that: a shield of the magneto-controlled sputtering cathode is provided with a stainless steel net. During coating of glass with a vacuum magneto-controlled sputter coating method, a cathode shield is provided with the stainless steel net, so that the contact area and adsorption force between ions not sputtered onto a substrate and the cathode shield are increased, the probability of the production of dust fall on coated glass is lowered effectively, the yield of coated products is increased greatly, and the maintenance frequency of the coating equipment is lowered.

Owner:林嘉宏

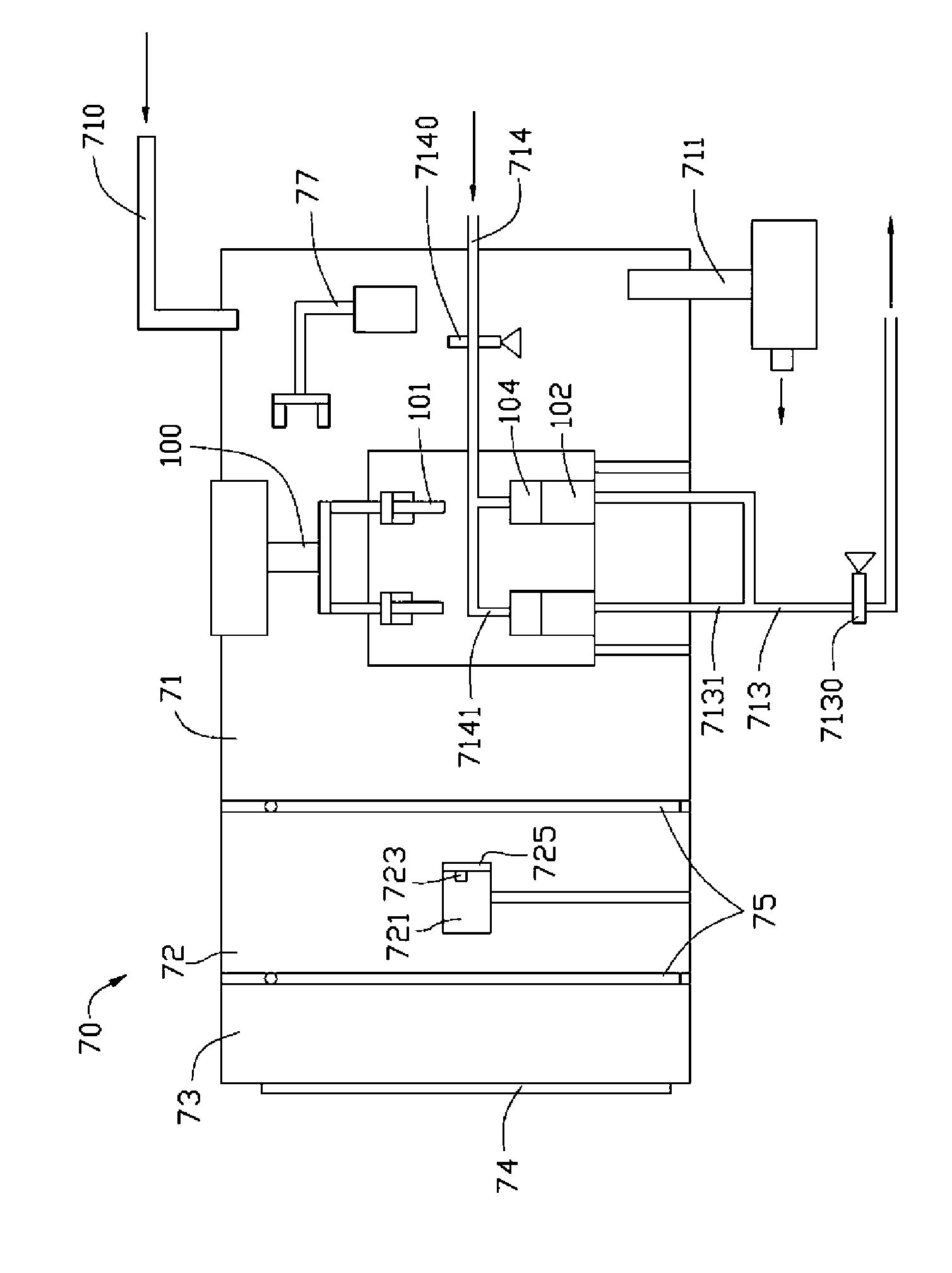

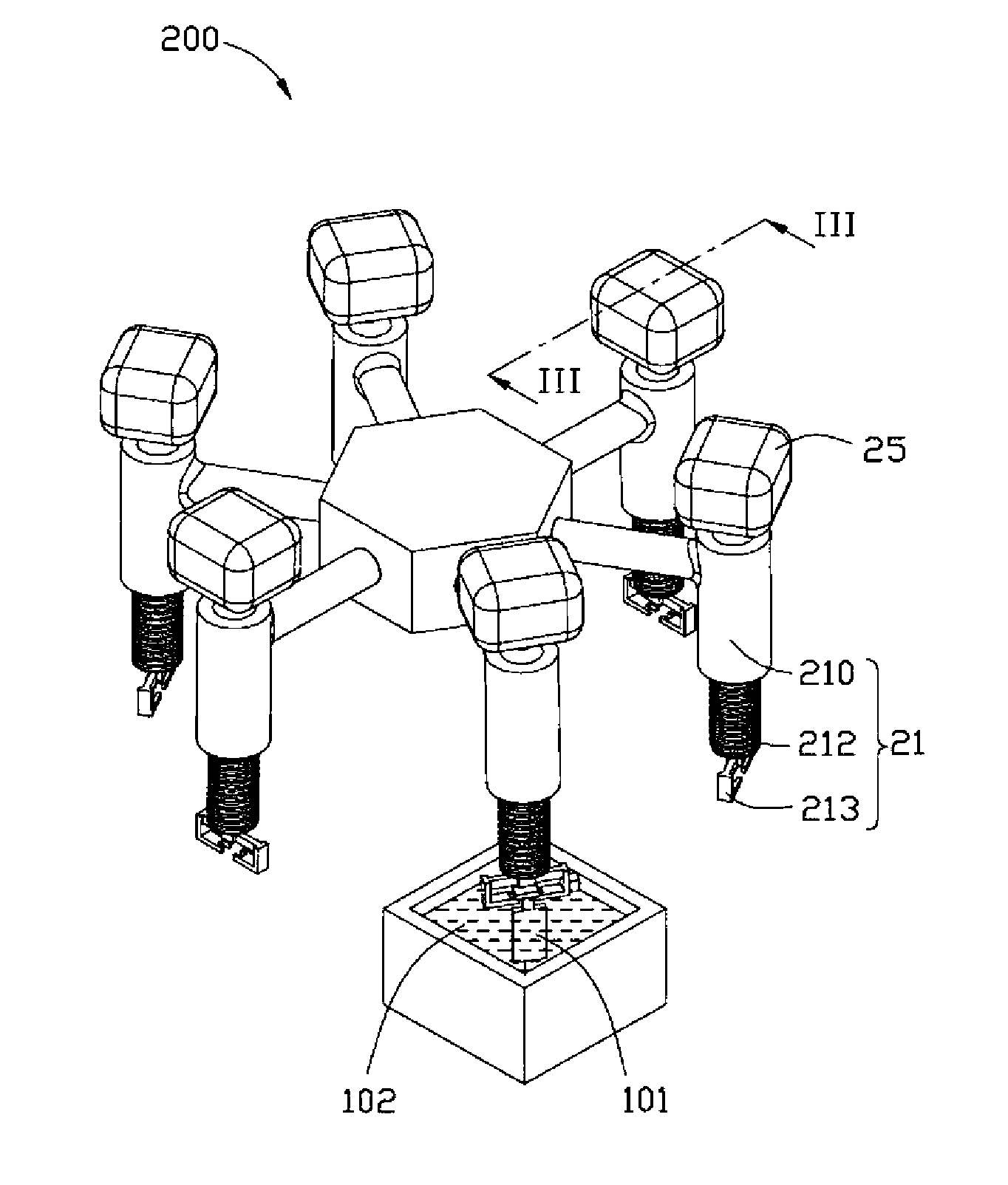

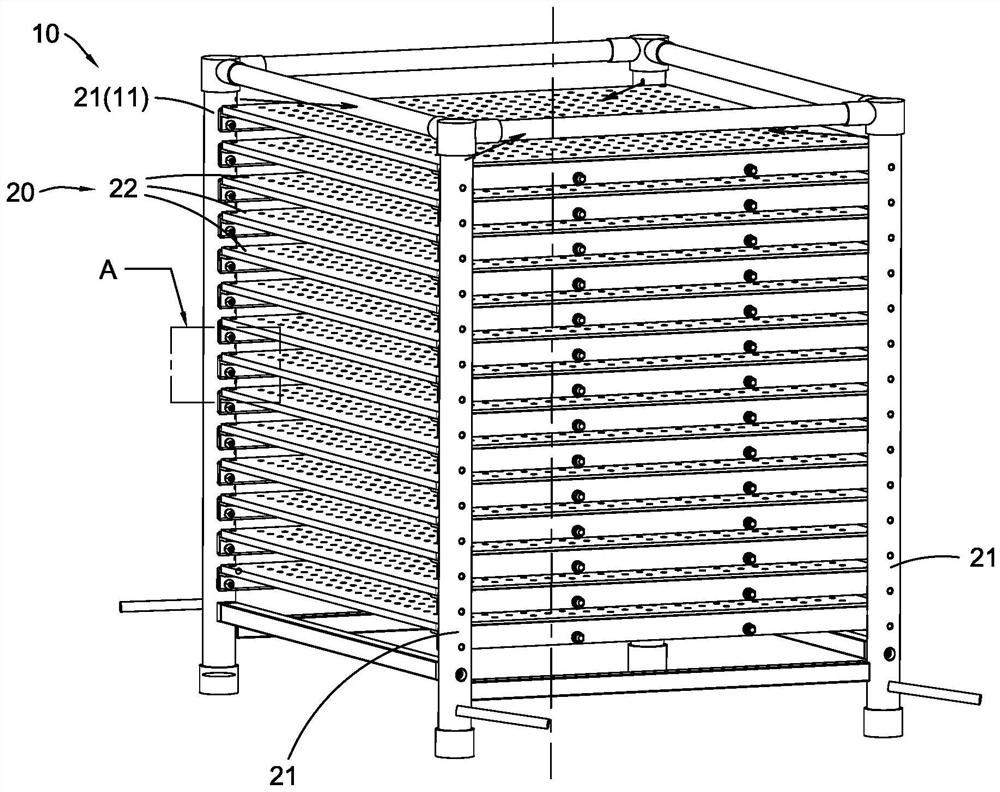

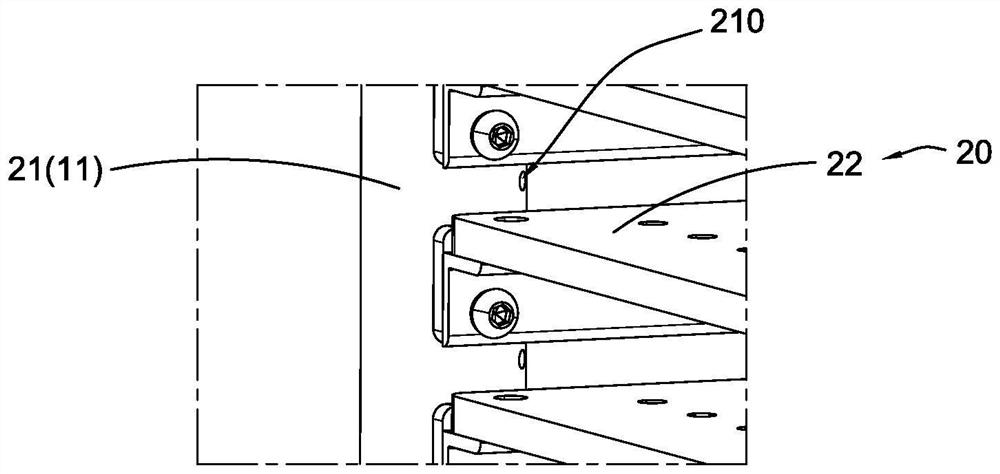

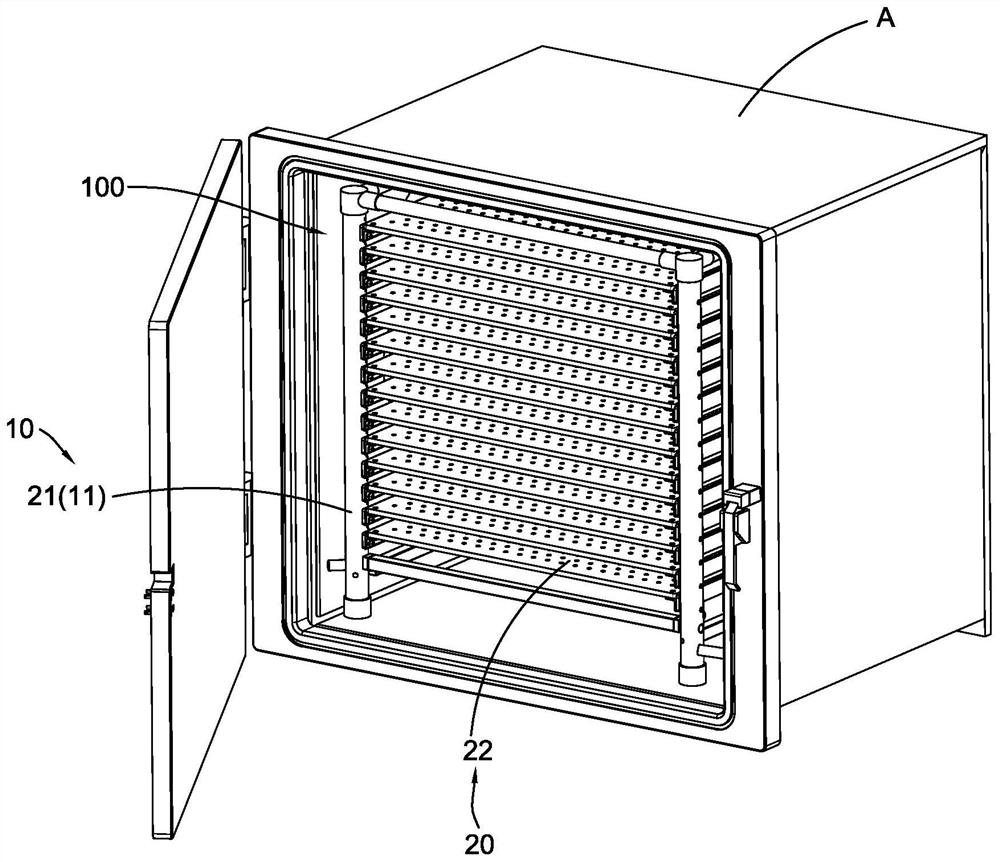

Wet film-coating system

ActiveCN101988193ASolve Oxidation ProblemsImprove coating yieldLiquid surface applicatorsSemiconductor/solid-state device manufacturingMetallurgyFilm-coated tablet

The invention relates to a wet film-coating system which comprises a film-coating chamber, an annealing chamber and a cavity door arranged on the annealing chamber which are optionally and mutually communicated, wherein, the film-coating chamber comprises a wet film coating device and a clamping arm, the film coating is carried out on at least one substrate to be coated by the wet film coating device, the clamping arm clamps and drives the wet film coating device to move freely in the film-coating chamber and the annealing chamber, and loading and unloading of at least one substrate to be coated on the wet film coating device are carried out by the cavity door in the annealing chamber; and the annealing chamber comprises a heating device for heating the coated substrate generated by the wet film coating device, and the heated substrate is cooled in the annealing chamber. By film coating and heating in the film-coating chamber and the annealing chamber which are mutually communicated, the wet film-coating system avoids the oxidation problem caused by movement of the coated substrate in air and improves film-coating yield rate.

Owner:QIDONG OCEAN CABLE CO LTD

Process for preparing flame-retardant adhesive

The invention discloses a process for preparing a flame-retardant adhesive. The flame-retardant adhesive is prepared by the following steps: 1) selectively adding a powdery flame retardant and a solvent corresponding to the powdery flame retardant into an adhesive, immersing the powdery flame retardant in the solvent for 12h, wherein the volume ratio of the powdery flame retardant to the solvent is (1:3)-(1:5); 2) placing the resulting product obtained in step 1) in a horizontal sand mill, adjusting the pressure of horizontal sand mill to 4-6kg, grinding for five times to obtain a product having a fineness of 2-5mum; 3) filtering the resultant product obtained in step 2) by a filter screen having 150-400 meshes, and adding the filtered product to the adhesive while stirring; 4) injecting the stirred adhesive containing the powdery flame retardant into an online stirring device, installing pump exhausting pipes at the bottommost part of the online stirring device to pump glue output. The coating yield ratio of the flame-retardant adhesive is improved by the preparation method of flame-retardant adhesive provided by the invention.

Owner:SUZHOU SIDIKE NEW MATERIALS SCI & TECH

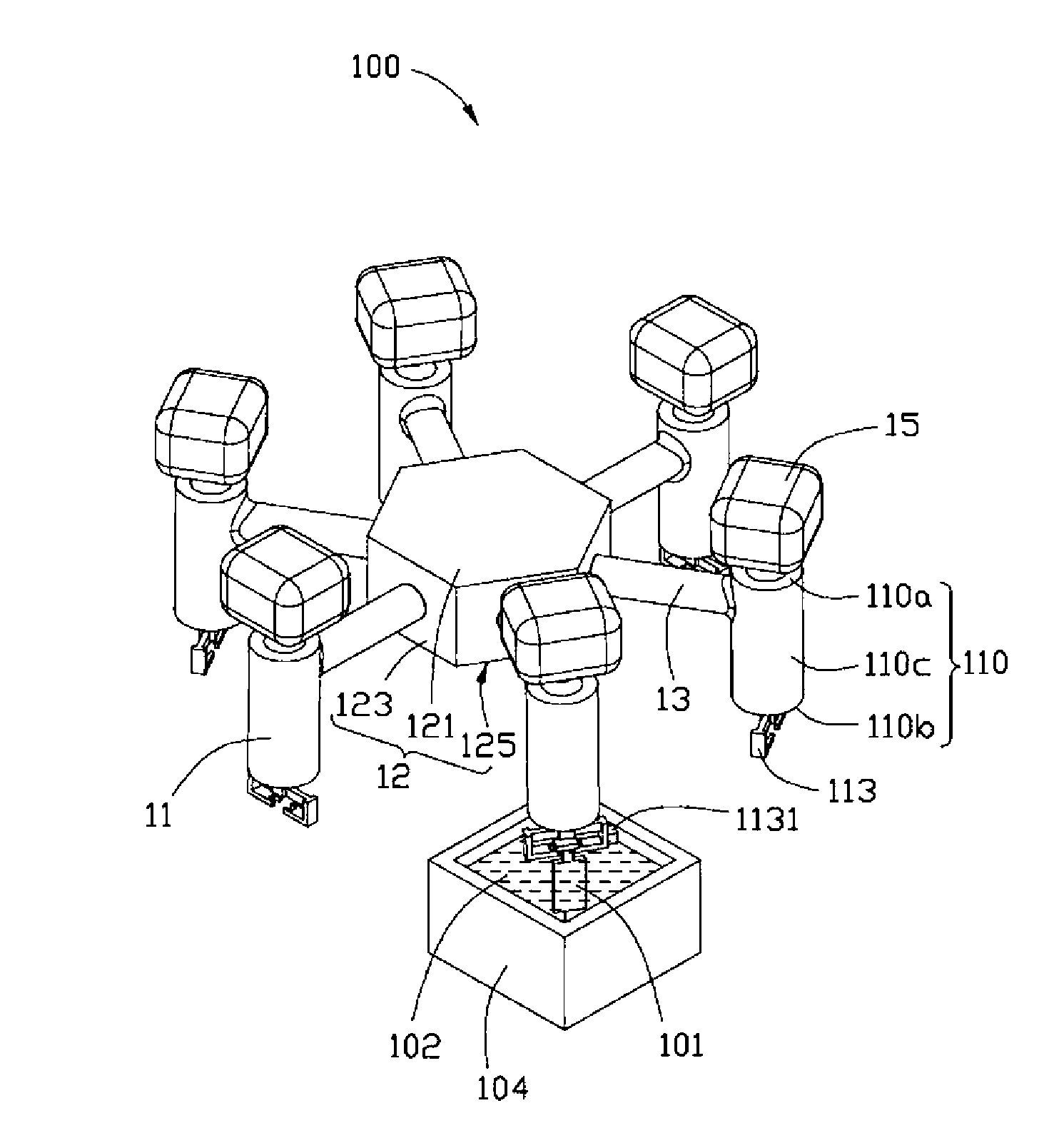

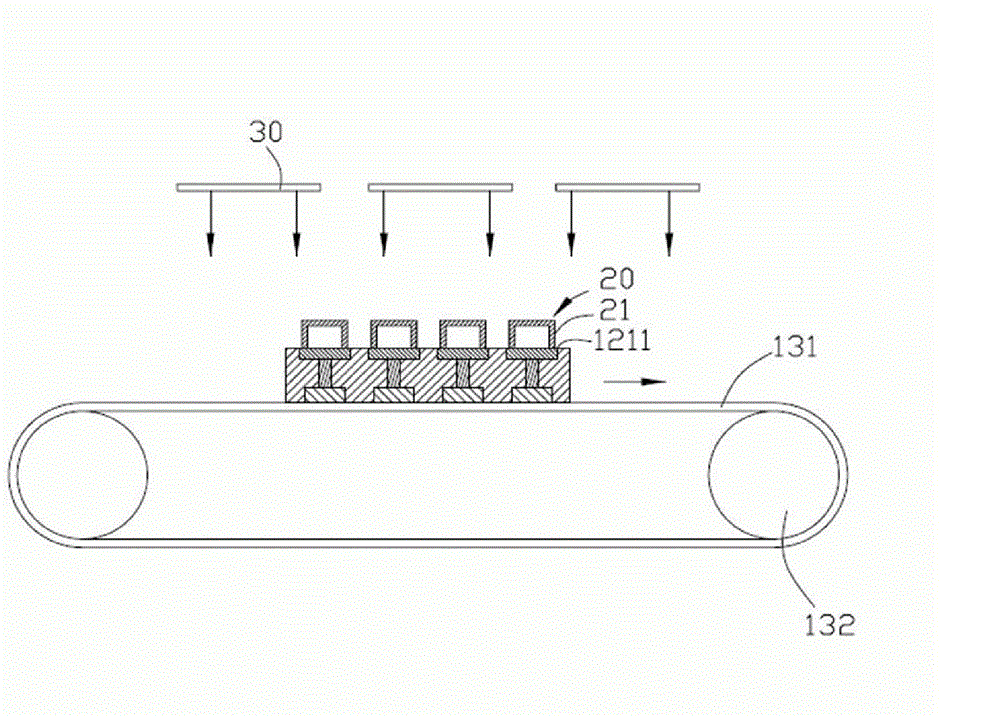

Carrying device

InactiveCN101921992BImprove coating yieldImprove yieldVacuum evaporation coatingSputtering coatingSputteringMechanical engineering

The invention provides a carrying device which is used for carrying out continuous sputtering on a workpiece. The carrying device comprises a plurality of rotary carrying platforms, a base and a conveying device, wherein the rotary carrying platforms are installed on the base; each rotary carrying platform is provided with a carrying surface for carrying the workpiece and driving the workpiece placed on the carrying surface to rotate relative to the base around an axis which is perpendicular to the carrying surface; and the base is arranged at the conveying device, and the conveying device is used for driving the base and the rotary carrying platforms to move.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

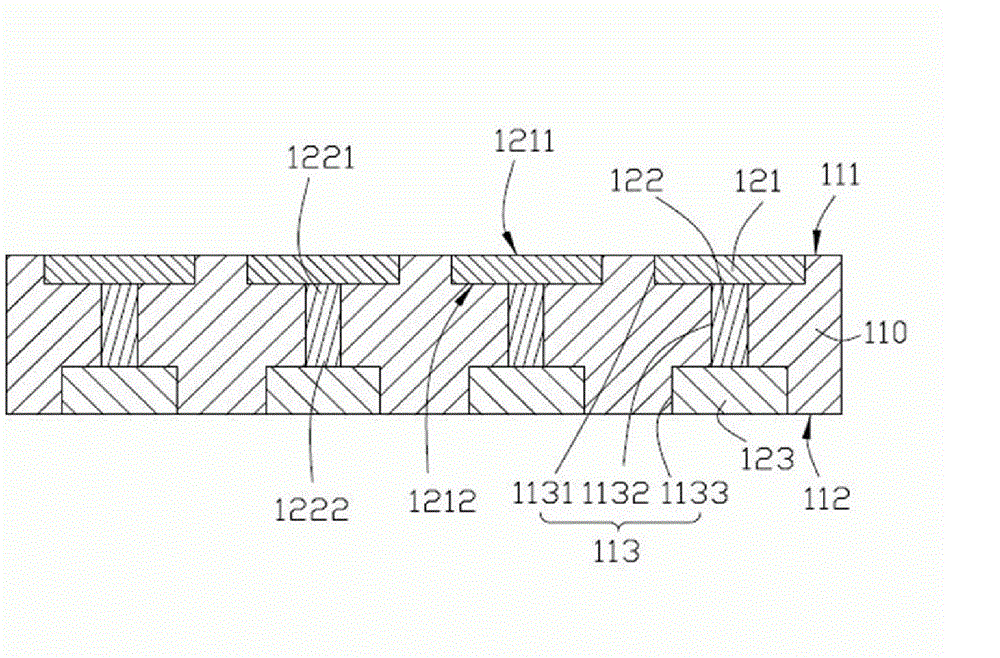

Manufacturing method of electrode plate and electrode plate

InactiveCN108199004AImprove pass rateImprove electrical performanceCell electrodesConductive pasteWork in process

The invention provides a manufacturing method of an electrode plate. The manufacturing method comprises the following steps of providing a current collector; providing graphene, an aqueous binding agent and water, and uniformly mixing the graphene, the aqueous binding agent and the water to form conductive glue; coating the conductive glue on a surface of the current collector to obtain a conductive glue layer combined with a surface of the current collector; providing an electrode active substance, the aqueous binding agent and the water, and uniformly mixing the electrode active substance, the aqueous binding agent and the water to form conductive paste; coating the conductive paste on the conductive glue layer to obtain an electrode material layer; baking the current collector combinedwith the conductive glue layer and the electrode material layer under a baking temperature for a certain time so that water in the conductive glue layer and the electrode material layer is evaporatedto obtain a half-finished product of the electrode plate; and grinding the half-finished product of the electrode plate to obtain the electrode plate. Moreover, the invention also provides the electrode plate obtained by employing the manufacturing method of the electrode plate.

Owner:SHENZHEN MOTTCELL NEW ENERGY TECH CO LTD

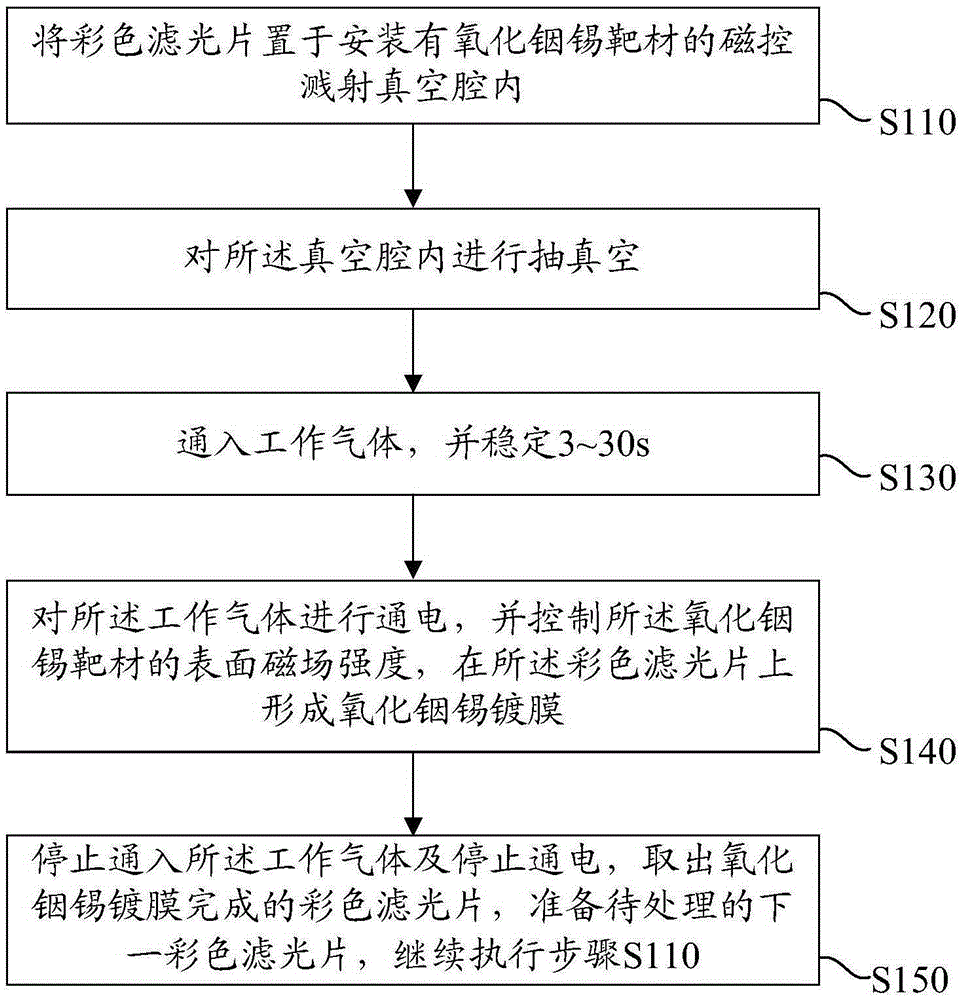

Indium tin oxide coating method

InactiveCN105331929ASolve the phenomenon of excessive resistanceImprove cleanlinessVacuum evaporation coatingSputtering coatingElectrical resistance and conductanceMetallurgy

An indium tin oxide coating method comprises the following steps that S110, a color filter is arranged in a magnetron sputtering vacuum cavity provided with an indium tin oxide target; S120, the vacuum cavity is vacuumized; S130, work gas is introduced and stabilized for 3-30 s; S140, the work gas is electrified, the surface magnetic field strength of the indium tin oxide target is controlled, and an indium tin oxide coating is formed on the color filter; and S150, introduction of work gas and electrification are stopped, the color filter coated with the indium tin oxide coating is taken out, a to-be-processed next color filter is prepared, and the step S110 continues to be executed. By means of the indium tin oxide coating method, the cleanliness of the vacuum cavity can be guaranteed, the influences of impurities on the coating process are avoided, and therefore the phenomenon that the resistance of the color filter coated with the indium tin oxide coating exceeds the standard can be effectively avoided, and the coating yield is improved.

Owner:TRULY HUIZHOU SMART DISPLAY

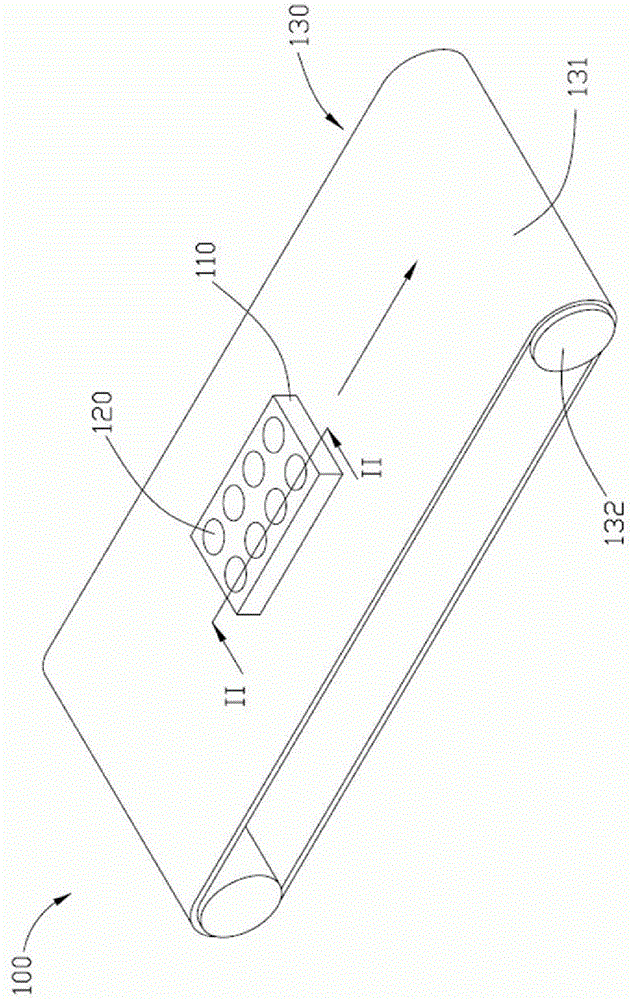

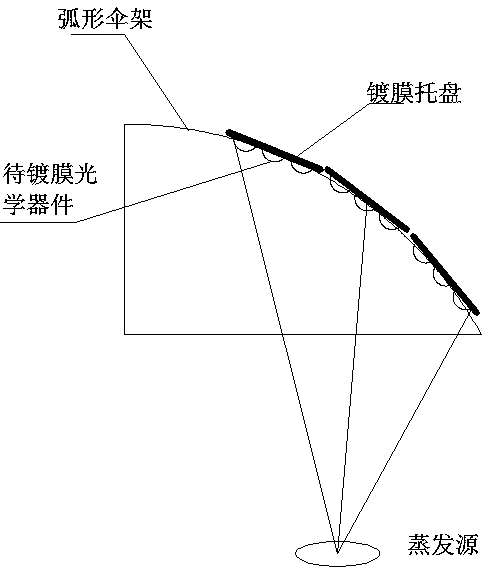

Optical coating multi-angle umbrella frame and coating machine comprising same

PendingCN110230034AConsistent slopeReduce filmVacuum evaporation coatingSputtering coatingCoated surfaceOptical coating

The invention relates to the field of optical coating, and discloses an optical coating multi-angle umbrella frame and a coating machine comprising the umbrella frame. The umbrella frame is of an umbrella-shaped structure formed by fixing a plurality of fan-shaped umbrella pieces on umbrella ribs, and each umbrella piece comprises a fan-shaped support (1) and at least one support plate (3) used for containing a coating tray (2), each support plate (3) is parallel to each other, one end of each support plate (3) is rotationally connected to one side of a support (1), and is limited and fixed byan angle limiting mechanism (4), and the other end of each support plate (3) is a free end; and during evaporation, the to-be-coated surface of an optical device (5) to be coated on the coating tray(2) is perpendicular to an evaporation source. According to the umbrella frame, the to-be-coated surfaces of the optical devices to be coated fixed on the umbrella frame and the evaporation source below the umbrella frame are in vertical relation, so that the defects of under-film or film deviation during evaporation can be effectively avoided, and the product yield is improved.

Owner:江苏光腾光学有限公司

Method of forming a layer of glue on a work piece

InactiveUS20160067728A1Improve coating yieldAvoid inconsistenciesLiquid surface applicatorsSpraying apparatusEngineeringMechanical engineering

Owner:GENESIS PHOTONICS

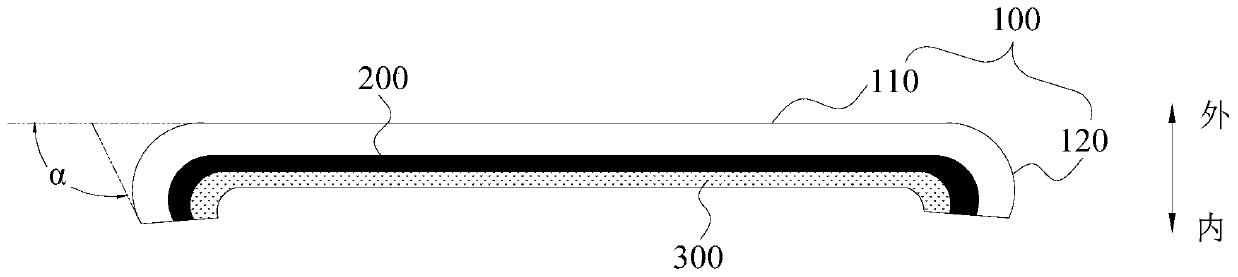

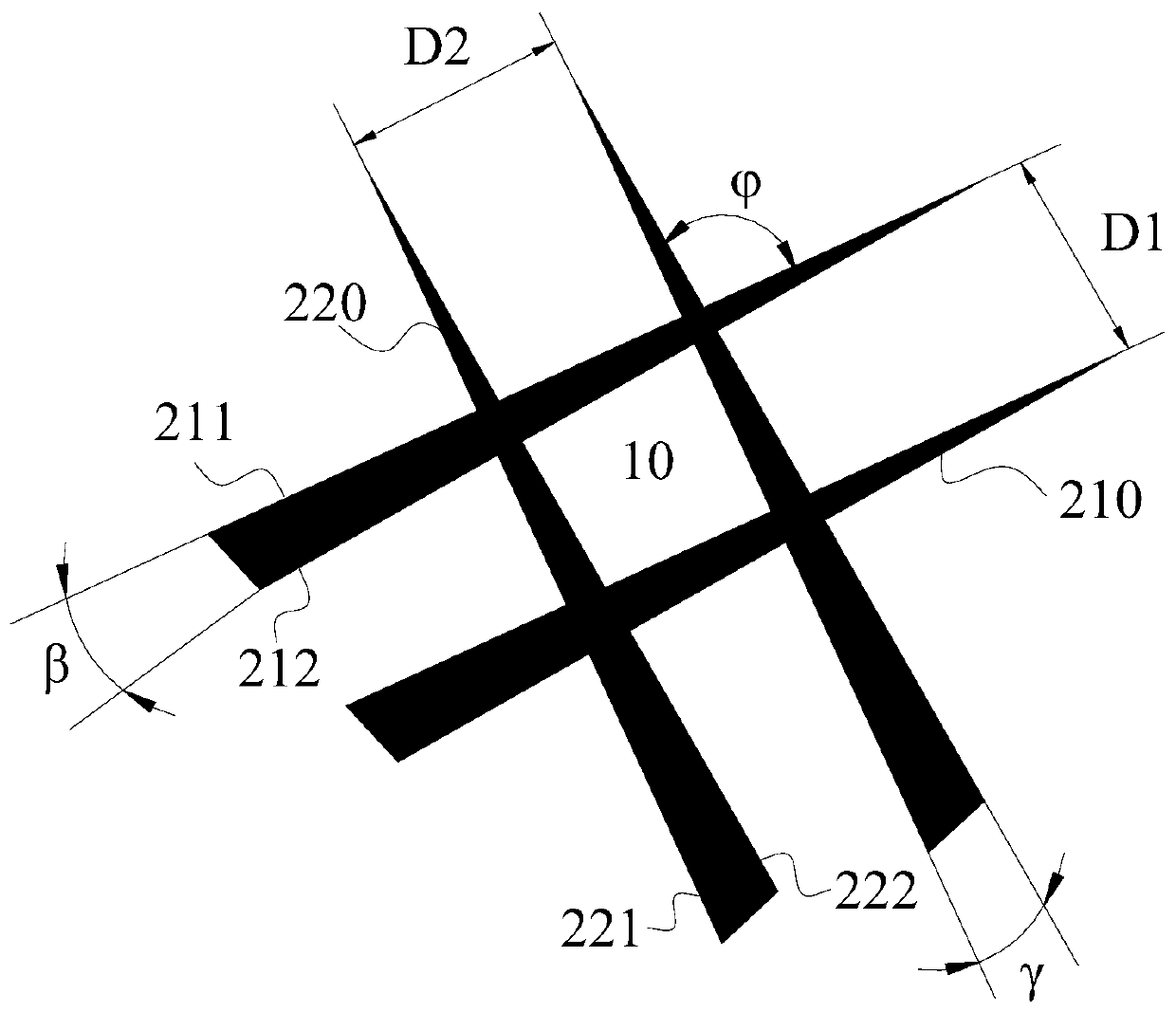

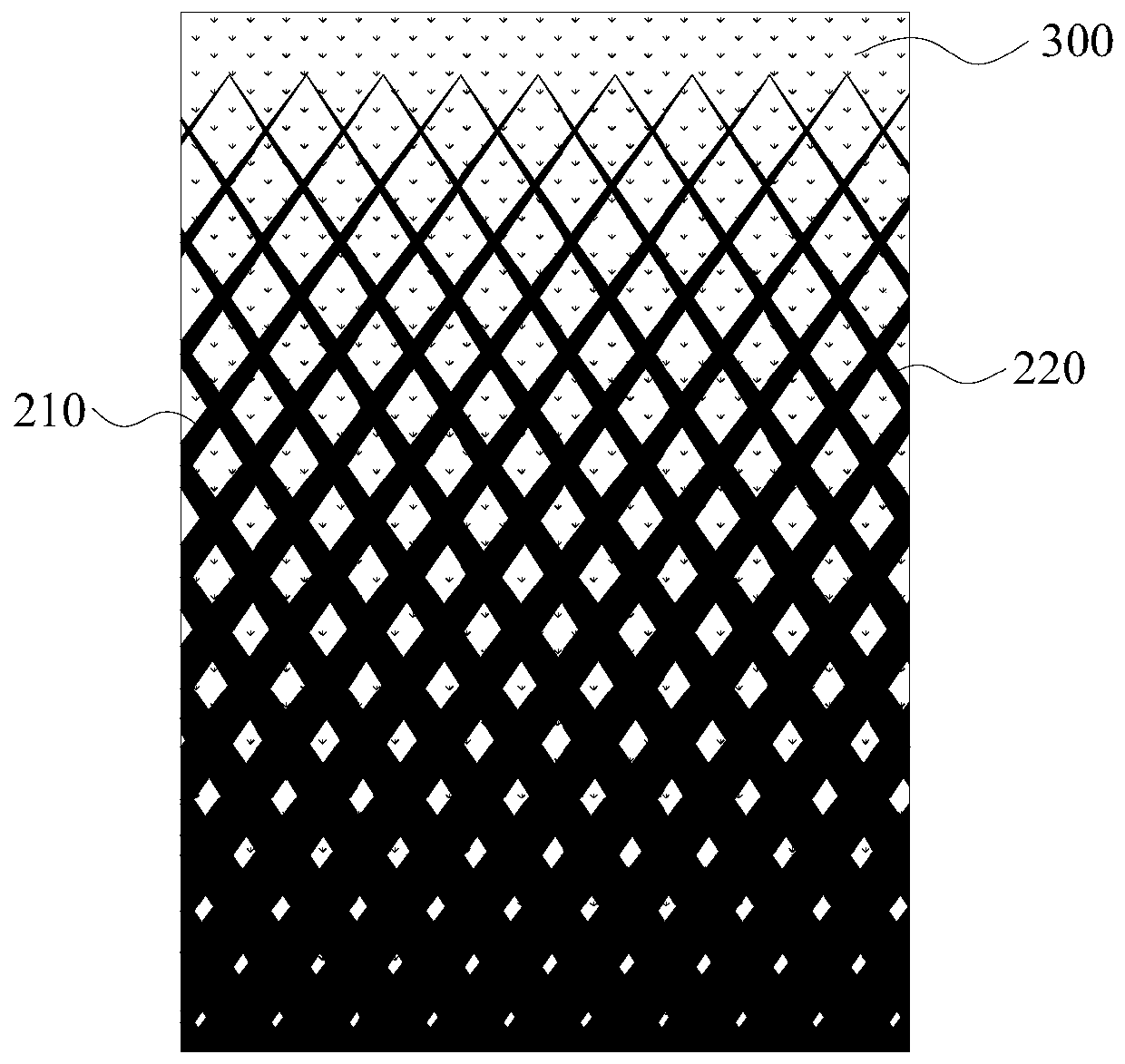

Shell, preparation method and electronic equipment

ActiveCN110740598ALow coating yieldHigh priceCasings/cabinets/drawers detailsOther printing apparatusComposite materialEngineering

The invention discloses a shell, a preparation method and electronic equipment. The shell comprises a glass substrate, a first ink layer and a second ink layer; a bending angle between the side wall and main body surface of the glass substrate is greater than 70 degrees; the first ink layer is arranged on the inner surface of the glass substrate; the first ink layer comprises a plurality of firstcolor strip parts which are arranged in parallel and a plurality of second color strip parts which are arranged in parallel; the width of the first color strip parts and the width of the second colorstrip parts are gradually increased in respective extending directions; the first color strip parts and the second color strip parts are arranged in a staggered mode and define a hollow area; and thefirst color strip parts and the second color strip parts cover part of the surface of the main body surface and part of the surface of the side wall respectively; the second ink layer is located on the side, away from the glass substrate, of the first ink layer; the second ink layer at least covers the hollowed-out area; and the second ink layer and the first ink layer have different colors. Therefore, the shell has a good gradient color appearance and is low in cost.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

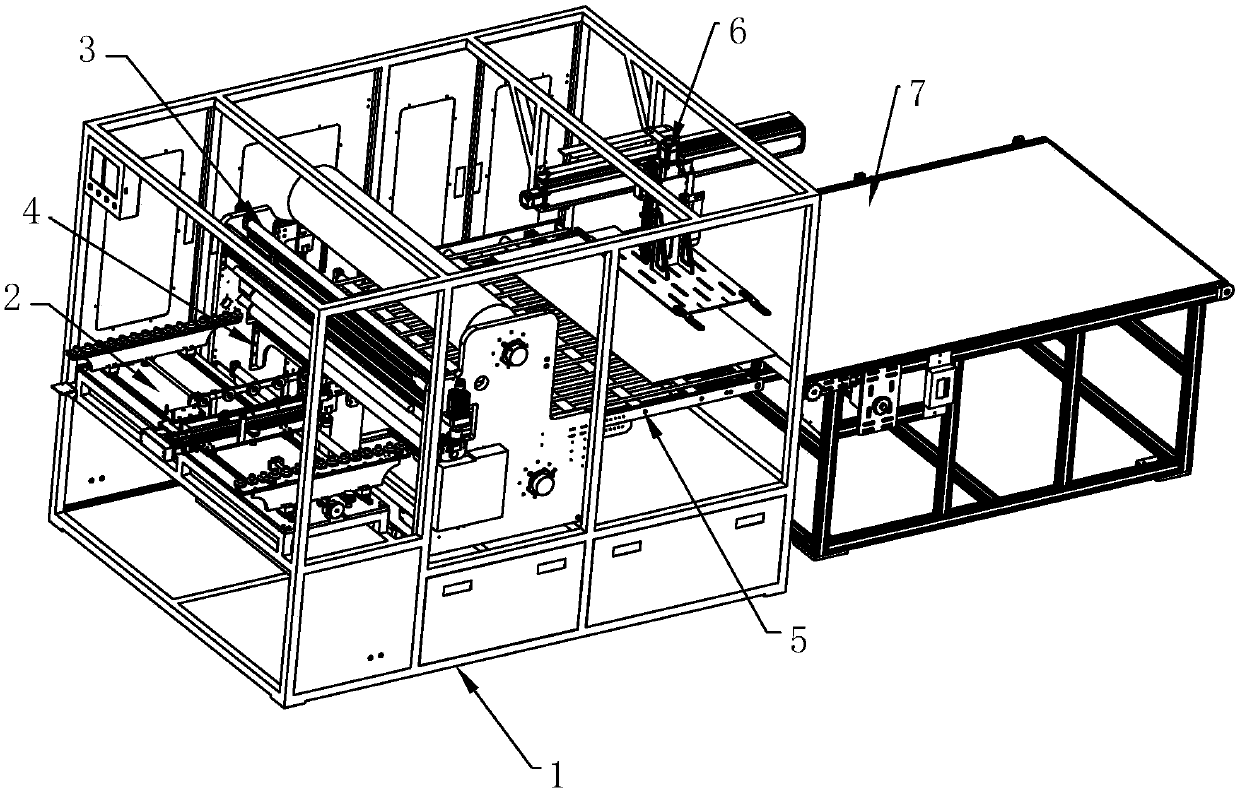

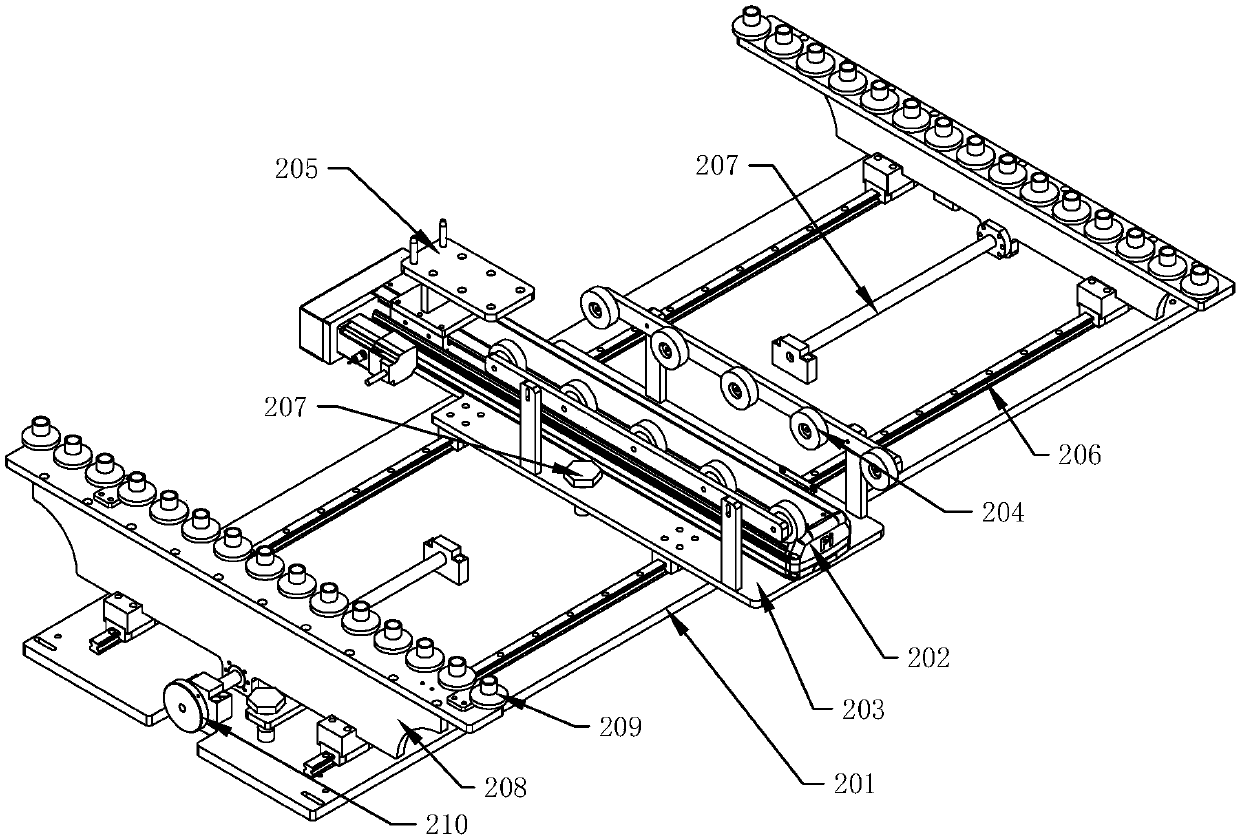

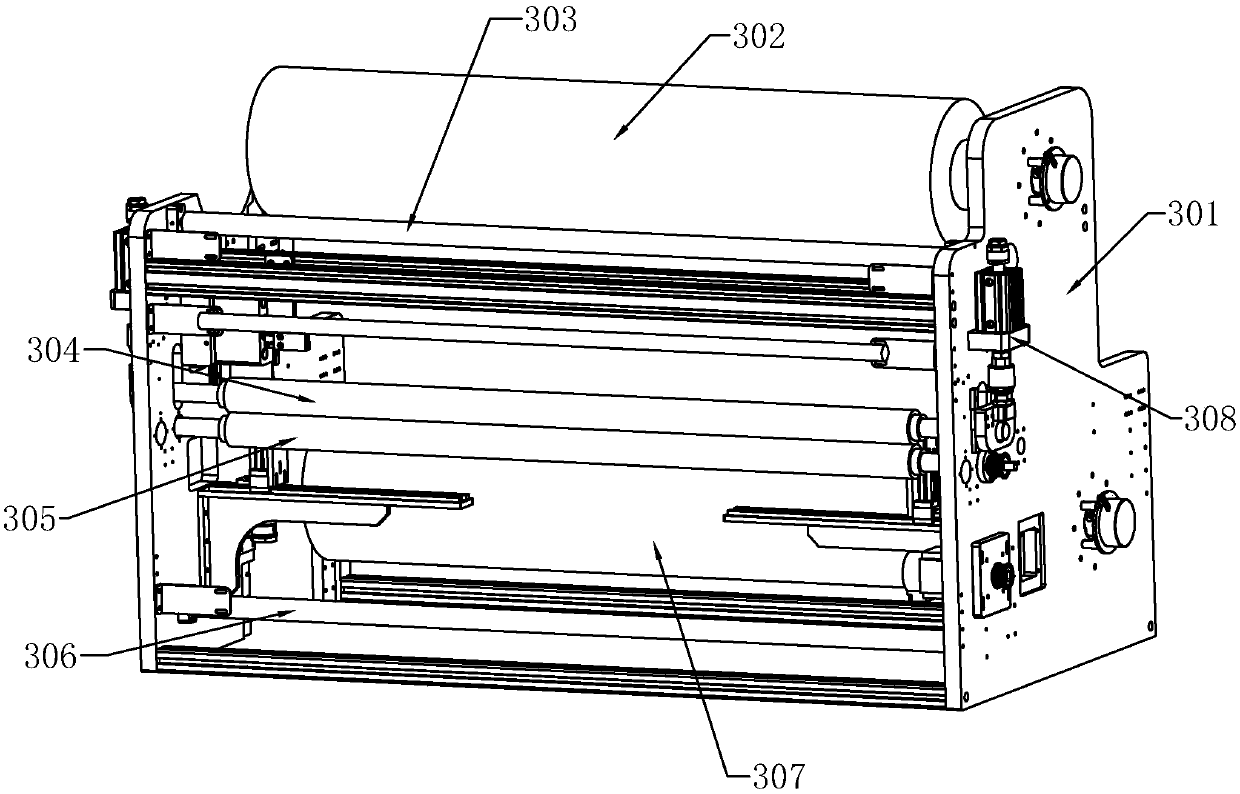

High-precision film laminating system

ActiveCN109940970ASolve the problem of low positioning accuracy of feedingHigh lamination accuracyLamination ancillary operationsLaminationEngineeringPulley

The invention relates to a high-precision film laminating system. The high-precision film laminating system comprises a frame body, wherein a loading mechanism, a film laminating mechanism, a film cutting mechanism, a discharging conveying belt and an unloading mechanism are sequentially arranged in the frame body, and a stacked material conveying belt is arranged at one end part of the unloadingmechanism; the loading mechanism comprises a loading base plate, an adjusting sliding rail is arranged at the top of the loading base plate, a loading support plate is arranged in the middle of the adjusting sliding rail, positioning brackets are arranged on two sides of the loading support plate, and the loading support plate and the positioning bracket are connected with the adjusting sliding rail in a sliding manner; positioning bolts and a linear sliding table are arranged on the loading support plate, loading pulley blocks are arranged on the loading support plate on two sides of the linear sliding table, and a material pushing claw is arranged on a sliding block of the linear sliding table; and positioning rollers are uniformly arranged at the tops of the positioning brackets, the bottoms of the positioning brackets are cooperatively connected with an adjusting lead screw at the top of the loading base plate, and an adjusting rotating disc is arranged at the end part of the adjusting lead screw.

Owner:苏州凌文机电科技有限公司

A kind of preparation technology of flame retardant adhesive

The invention discloses a process for preparing a flame-retardant adhesive. The flame-retardant adhesive is prepared by the following steps: 1) selectively adding a powdery flame retardant and a solvent corresponding to the powdery flame retardant into an adhesive, immersing the powdery flame retardant in the solvent for 12h, wherein the volume ratio of the powdery flame retardant to the solvent is (1:3)-(1:5); 2) placing the resulting product obtained in step 1) in a horizontal sand mill, adjusting the pressure of horizontal sand mill to 4-6kg, grinding for five times to obtain a product having a fineness of 2-5mum; 3) filtering the resultant product obtained in step 2) by a filter screen having 150-400 meshes, and adding the filtered product to the adhesive while stirring; 4) injecting the stirred adhesive containing the powdery flame retardant into an online stirring device, installing pump exhausting pipes at the bottommost part of the online stirring device to pump glue output. The coating yield ratio of the flame-retardant adhesive is improved by the preparation method of flame-retardant adhesive provided by the invention.

Owner:JIANGSU SIDIKE NEW MATERIALS SCI & TECH CO LTD

Gas inlet system of coating device

ActiveCN112899656AAvoid the problem of uneven surface coatingImprove coating qualityChemical vapor deposition coatingDiamondCoating

The invention mainly provides a gas inlet system of a coating device. The gas inlet system is used for the coating device to provide coating gas for at least one product to be coated, the coating device is used for carrying out diamond-like coating on the product to be coated, and the gas inlet system of the coating device comprises at least one stand column, and the coating device provides coating gas for the surface of the product to be coated through the stand column.

Owner:JIANGSU FAVORED NANOTECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com