Composite conductive film and preparation method and application thereof

A technology of composite conductive film and conductive metal film, applied in the field of composite conductive film and its preparation, can solve the problems of poor anti-fog effect, unsuitable for video glasses, etc., and achieve low overall resistance, good anti-reflection effect, coating yield and high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

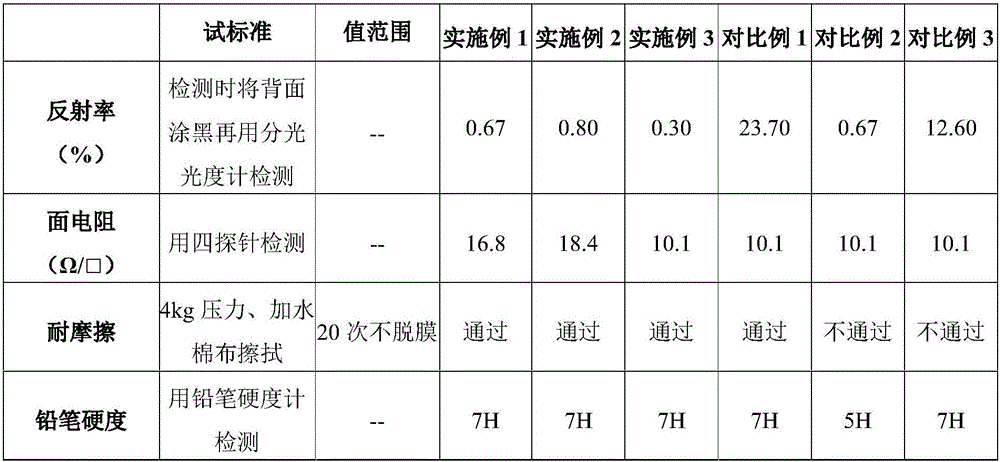

Embodiment 1

[0038] A kind of composite conductive film, its cross-sectional structure schematic diagram is as figure 1 As shown, the composite conductive film includes a primer layer 1, a bedding layer 2, a conductive layer 3, an anti-oxidation layer 4 and a protective layer 5 from bottom to top; wherein, the primer layer is a SiO film layer, and the film layer The thickness is 10nm; the bedding layer is ZnO film, the film thickness is 27.1nm; the conductive layer is Ag film, the film thickness is 6nm; the anti-oxidation layer is Ti film, the film thickness is 1nm; the protective layer is Si 3 N 4 The thickness of the film layer is 49.9nm.

[0039] The composite conductive film is prepared by the following steps:

[0040] (1) After the PMMA / PC resin substrate is cleaned with plasma, it is placed in a magnetron sputtering coating machine, and a pure Si target is fed into oxygen and inert gas for reactive sputtering, and the PMMA / PC composite resin substrate is coated SiO film layer, the...

Embodiment 2

[0046] A kind of composite conductive film, its cross-sectional structure schematic diagram is as figure 1 As shown, the composite conductive film includes a primer layer 1, a bedding layer 2, a conductive layer 3, an anti-oxidation layer 4 and a protective layer 5 from bottom to top; wherein, the primer layer is a SiO film layer, and the film layer The thickness is 12.3nm; the bedding layer is ZnO film, the film thickness is 25.6nm; the conductive layer is Ag film, the film thickness is 5nm; the anti-oxidation layer is Ti film, the film thickness is 1nm; the protective layer is Si 3 N 4 The thickness of the film layer is 67.7nm.

[0047] The composite conductive film is prepared by the following steps:

[0048] (1) After the PMMA / PC resin substrate is cleaned with plasma, it is placed in a magnetron sputtering coating machine, and a pure Si target is fed into oxygen and inert gas for reactive sputtering, and the PMMA / PC composite resin substrate is coated SiO film layer, t...

Embodiment 3

[0054] A kind of composite conductive film, its cross-sectional structure schematic diagram is as figure 1 As shown, the composite conductive film includes a primer layer 1, a bedding layer 2, a conductive layer 3, an anti-oxidation layer 4 and a protective layer 5 from bottom to top; wherein, the primer layer is a SiO film layer, and the film layer The thickness is 12nm; the bedding layer is ZnO film, the film thickness is 27.1nm; the conductive layer is Ag film, the film thickness is 10nm; the anti-oxidation layer is Ti film, the film thickness is 3nm; the protective layer is Si 3 N 4 The thickness of the film layer is 57.8nm.

[0055] The composite conductive film is prepared by the following steps:

[0056] (1) After the PMMA / PC resin substrate is cleaned with plasma, it is placed in a magnetron sputtering coating machine, and a pure Si target is fed into oxygen and inert gas for reactive sputtering, and the PMMA / PC composite resin substrate is coated SiO film layer, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com