Carrying device

A bearing device and bearing platform technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problem that the uniformity of the film layer cannot be guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

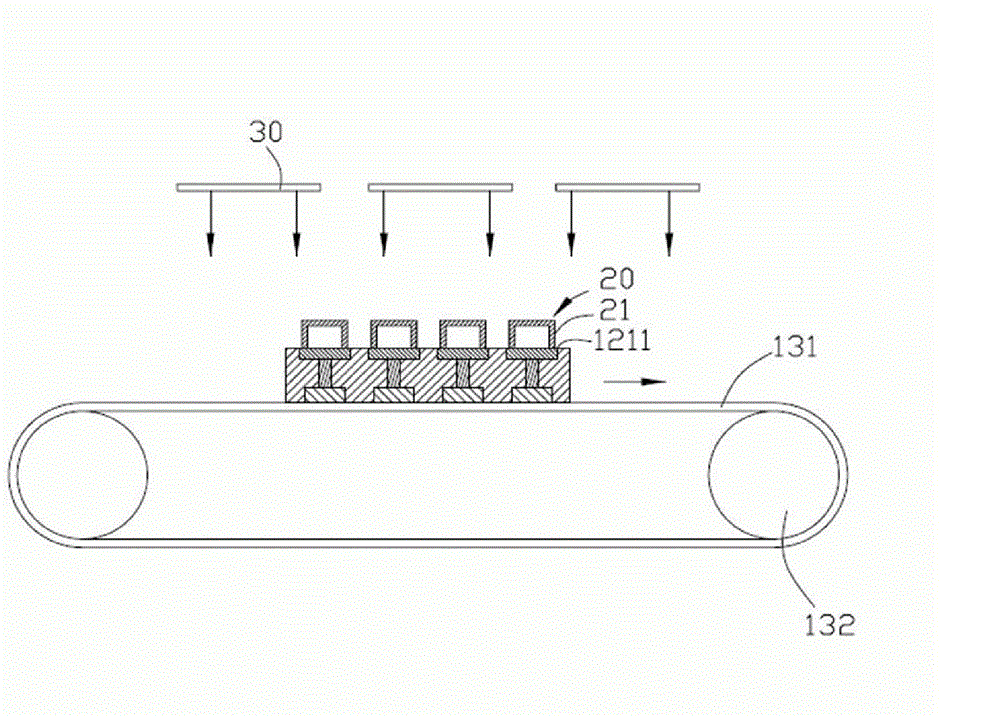

[0012] The carrying device provided by the technical solution will be further described in detail below in combination with multiple embodiments and multiple drawings.

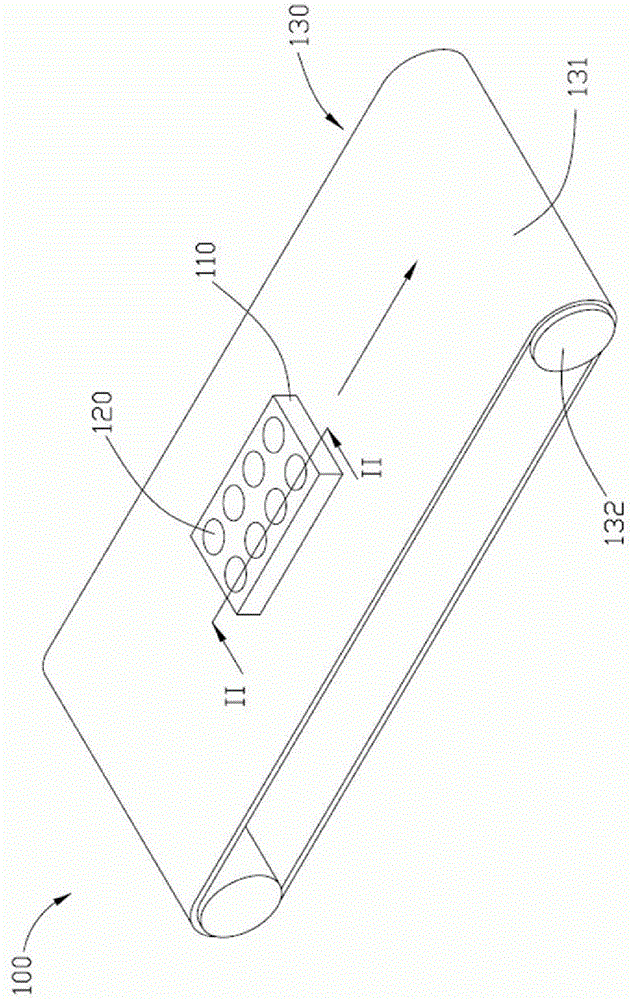

[0013] Please also refer to figure 1 and figure 2 , a bearing device 100 provided in the first embodiment of the technical solution, which includes a base 110 , a plurality of rotating bearing platforms 120 and a conveying device 130 .

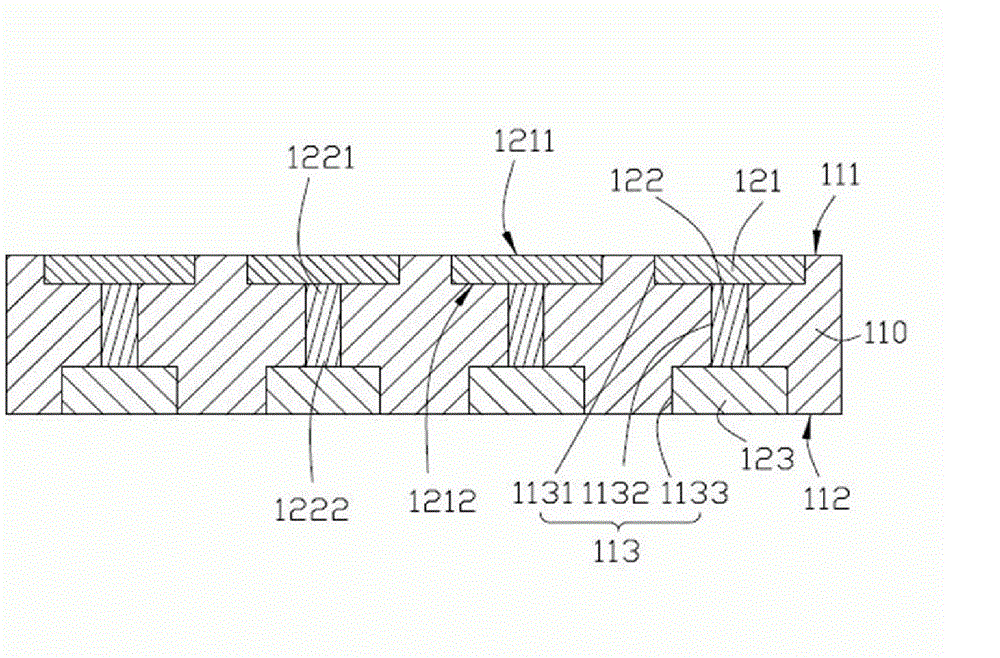

[0014] The base 110 has a plate-like structure, which can be rectangular, circular or other shapes. In this embodiment, the base 110 is in the shape of a rectangular plate, which includes a top surface 111 and a bottom surface 112 opposite to the top surface 111 . The top surface 111 and the bottom surface 112 are parallel to each other and both are planes. A plurality of receiving holes 113 are defined from the top surface 111 to the bottom surface 112 . In this embodiment, the base 110 is provided with eight receiving holes 113 , and the eight receiving holes 113 are ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com