Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Guaranteed shape rules" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

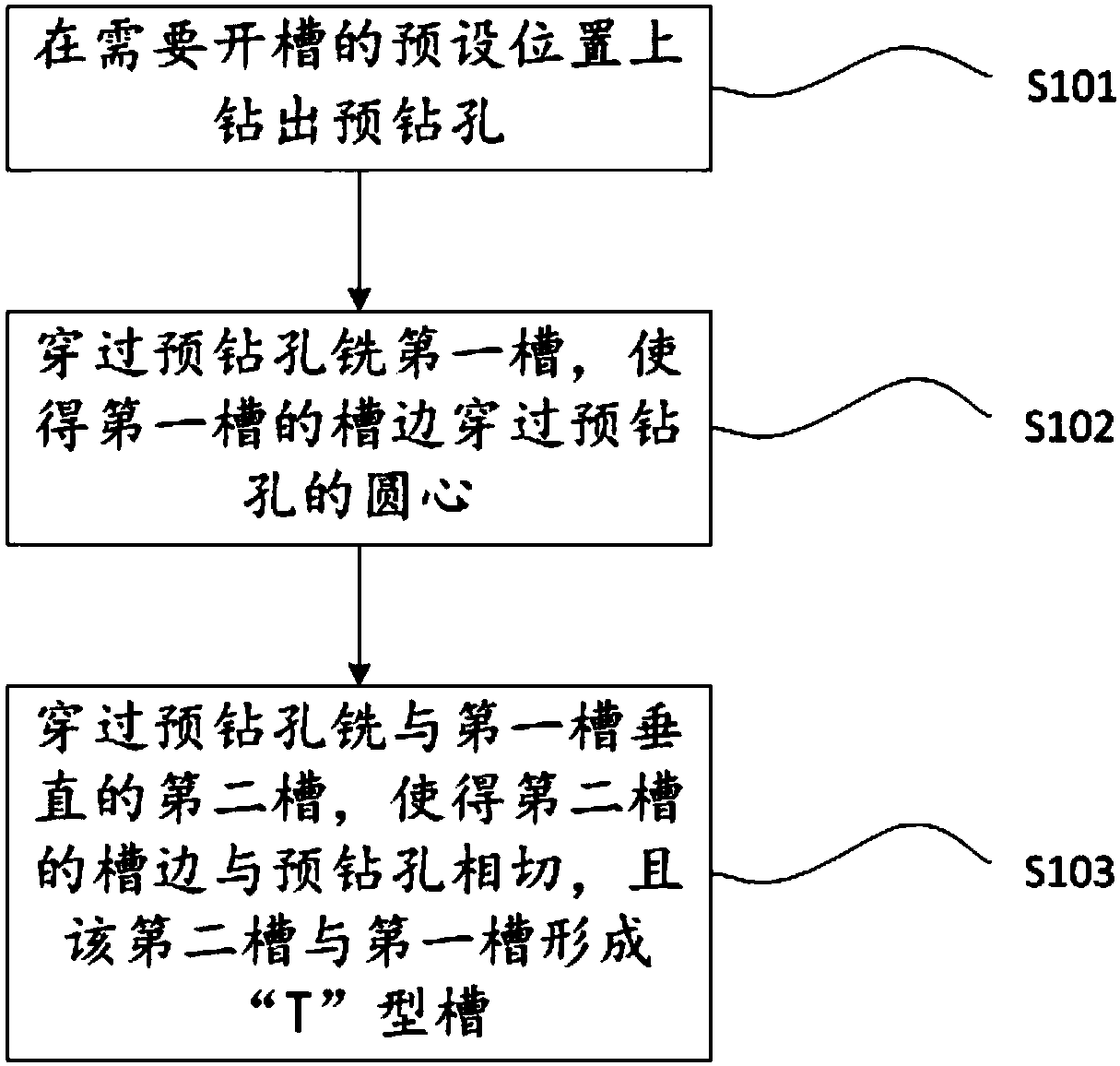

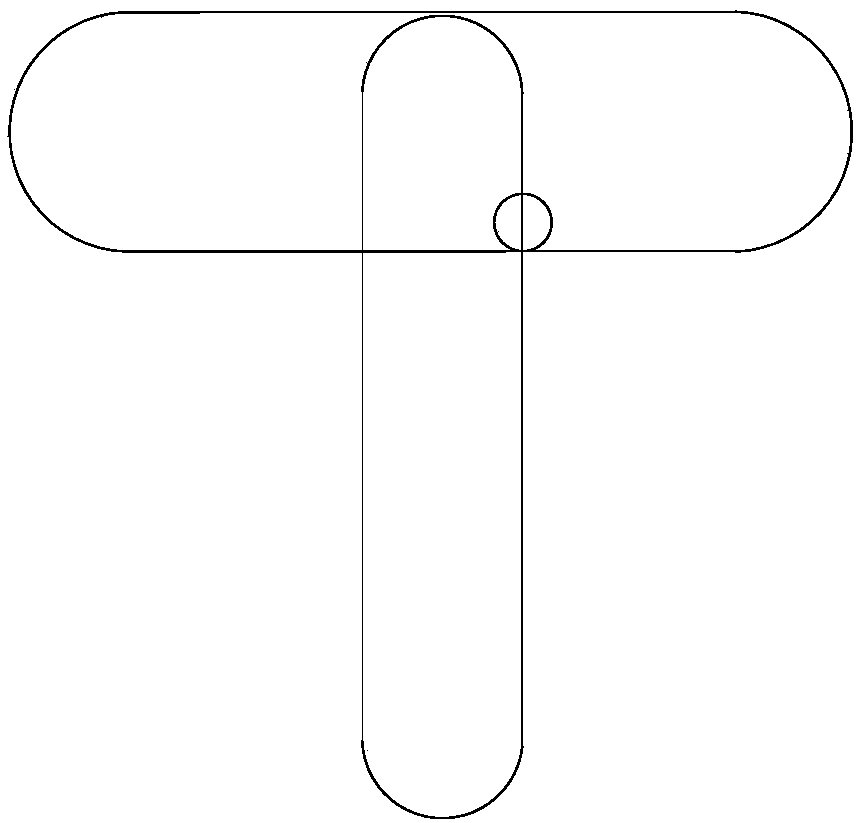

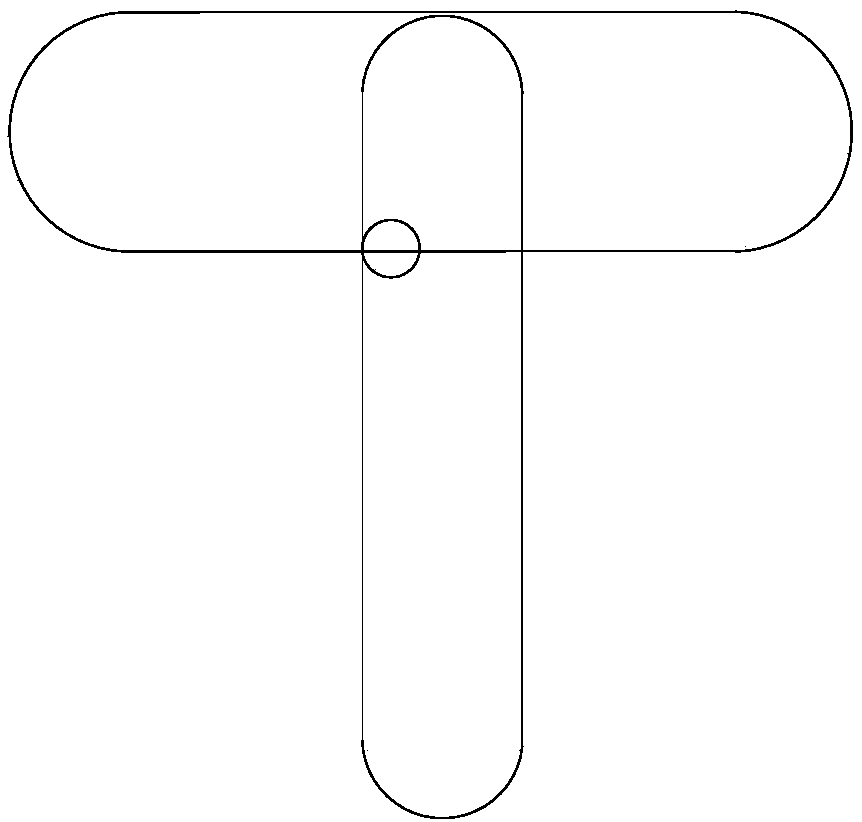

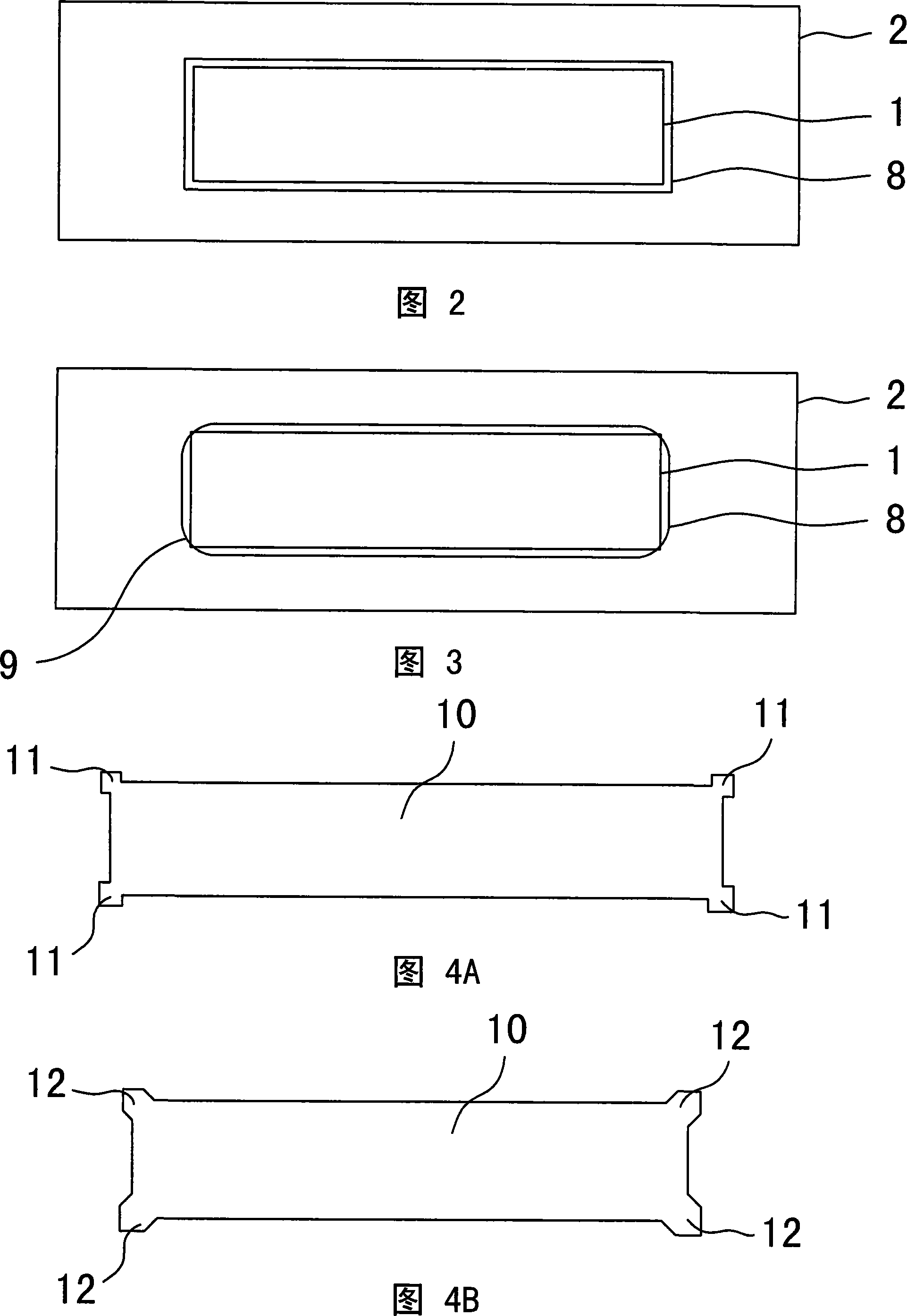

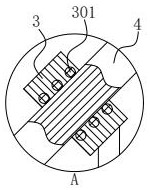

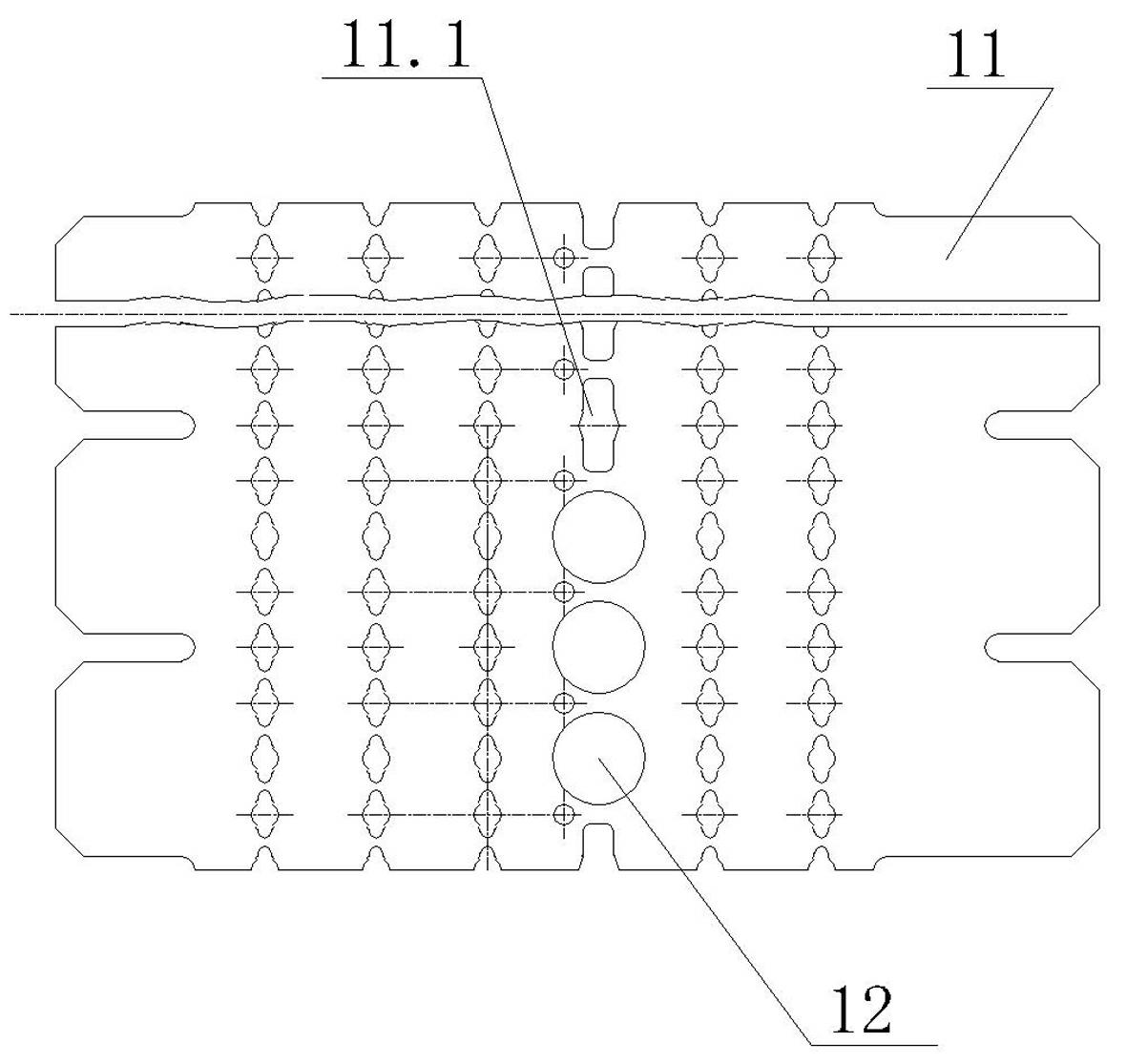

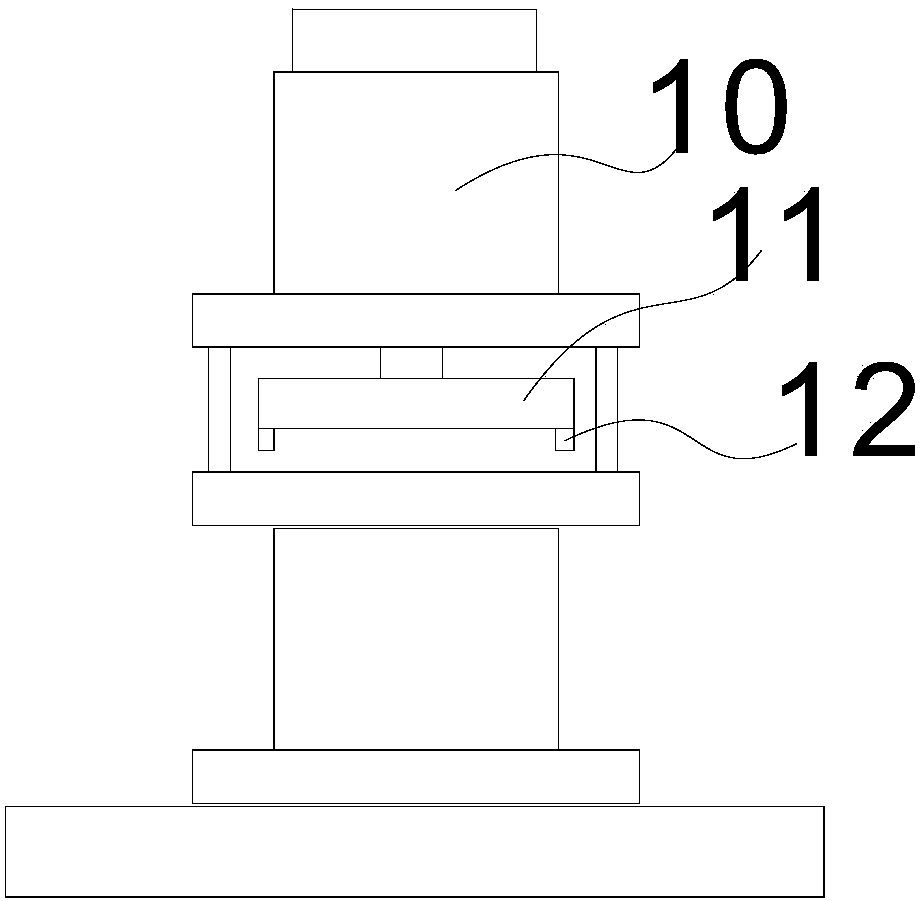

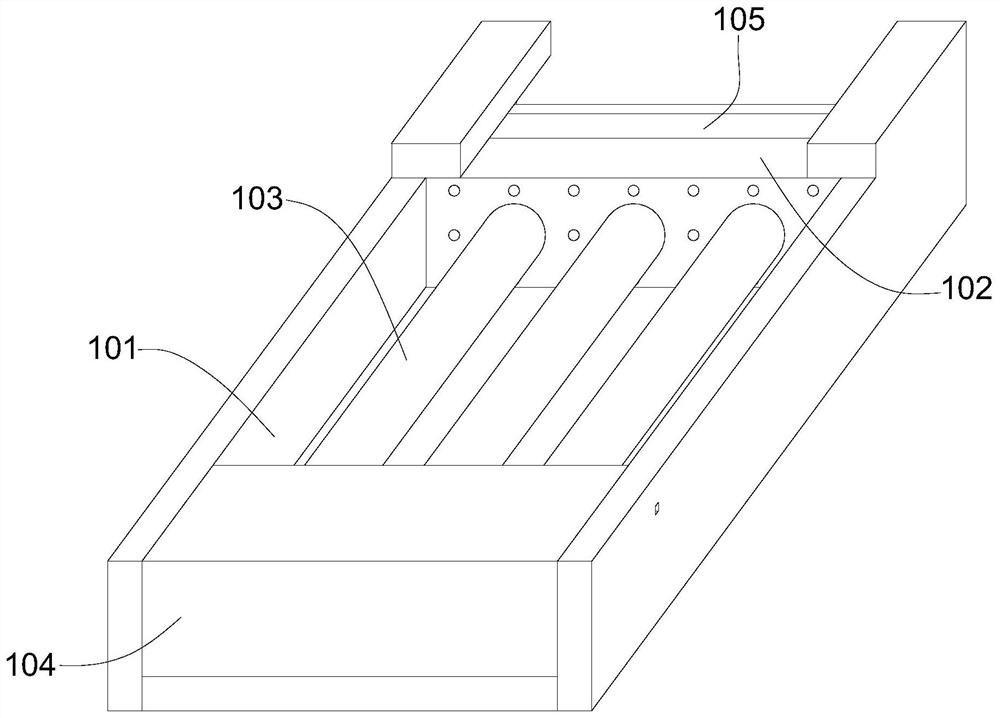

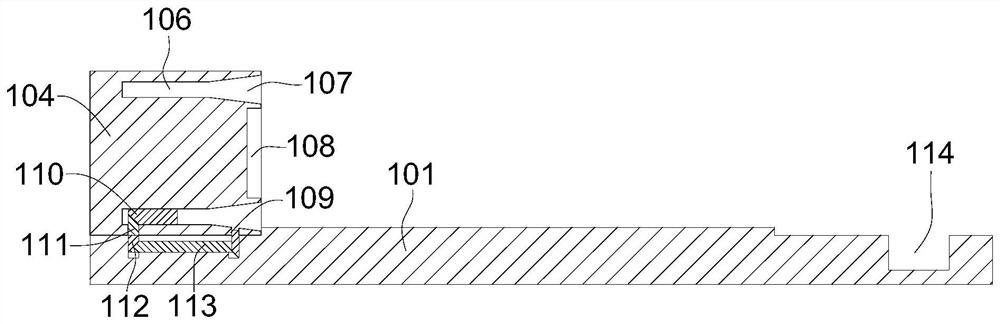

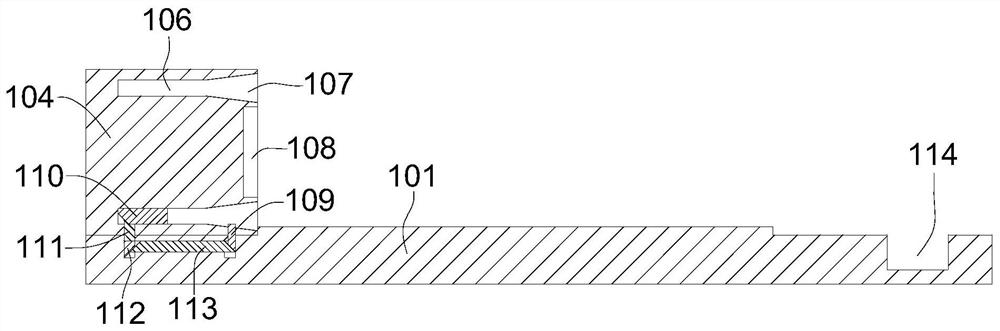

Processing method of PCB and PCB

ActiveCN107820365AGuaranteed shape rulesMeet production needsPrinted circuit manufactureEngineeringPrinted circuit board

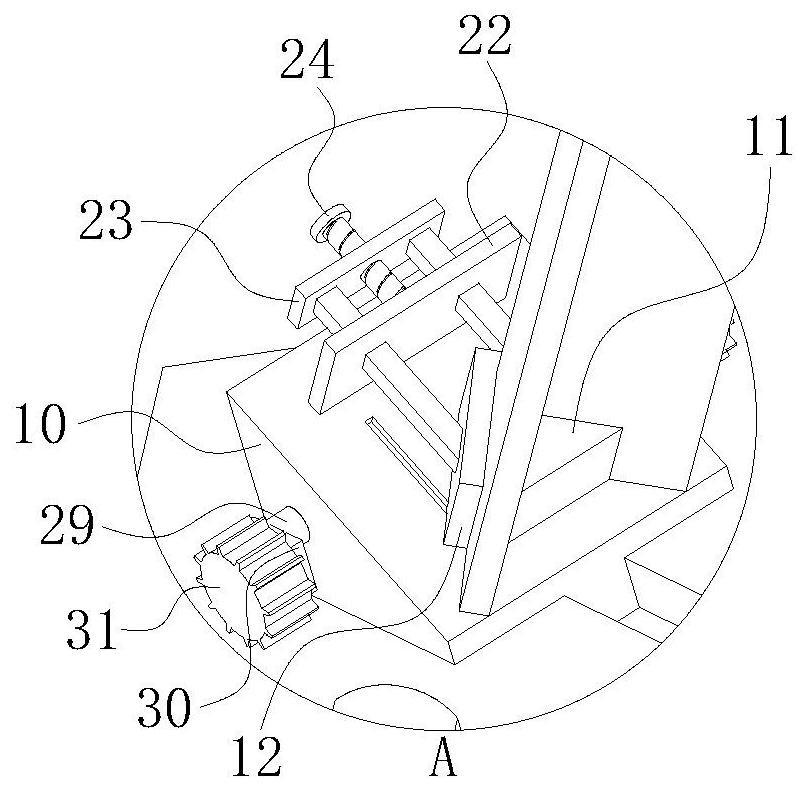

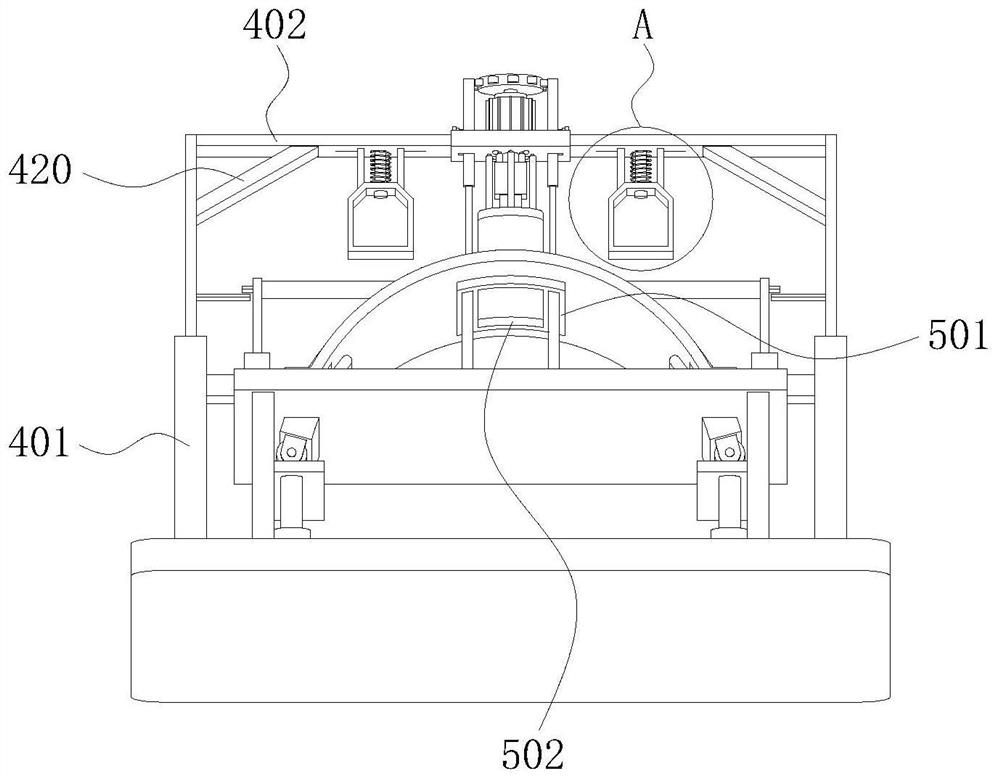

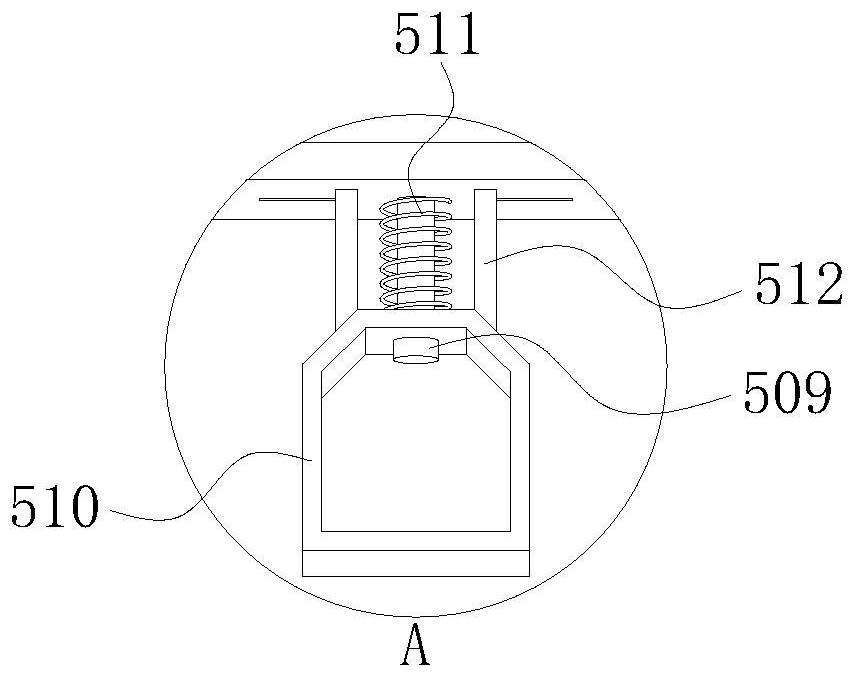

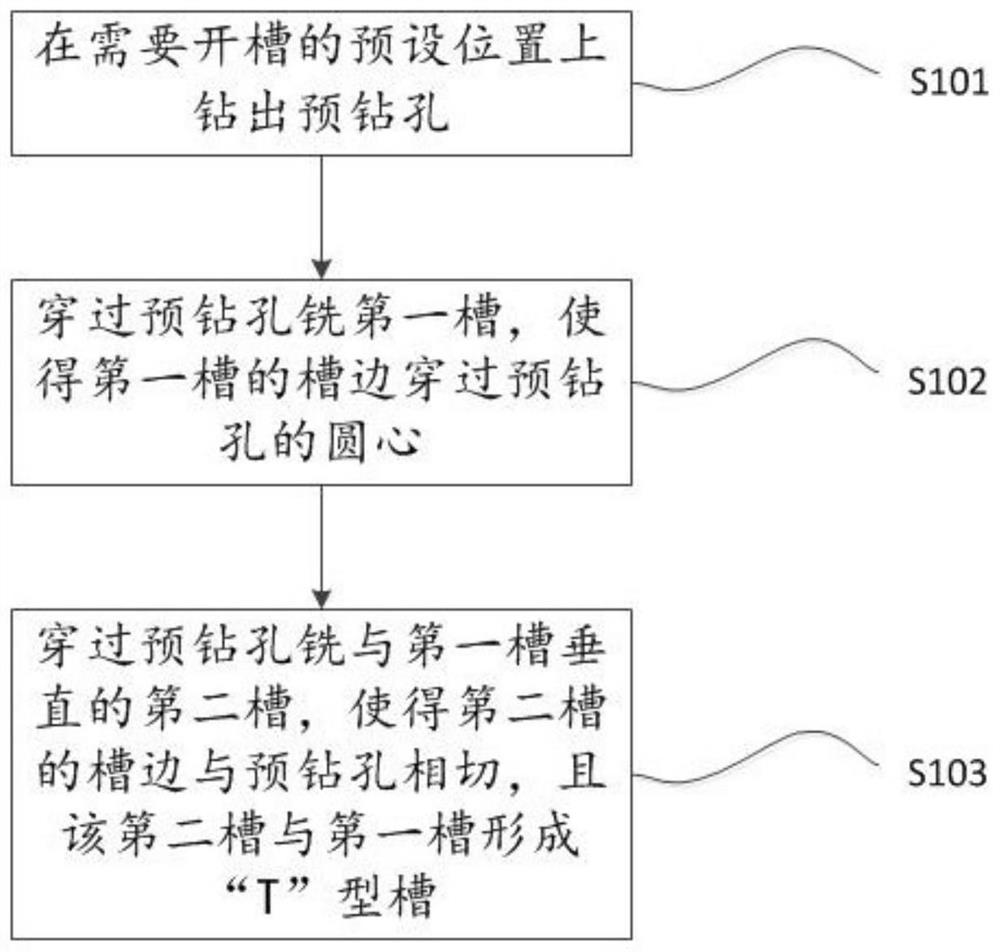

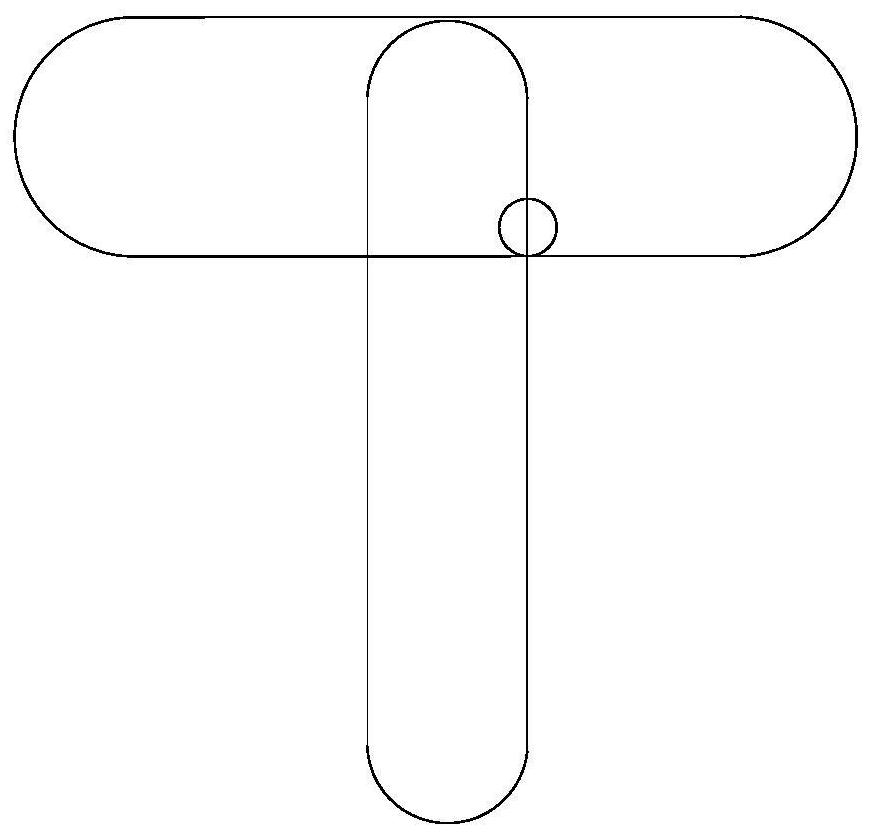

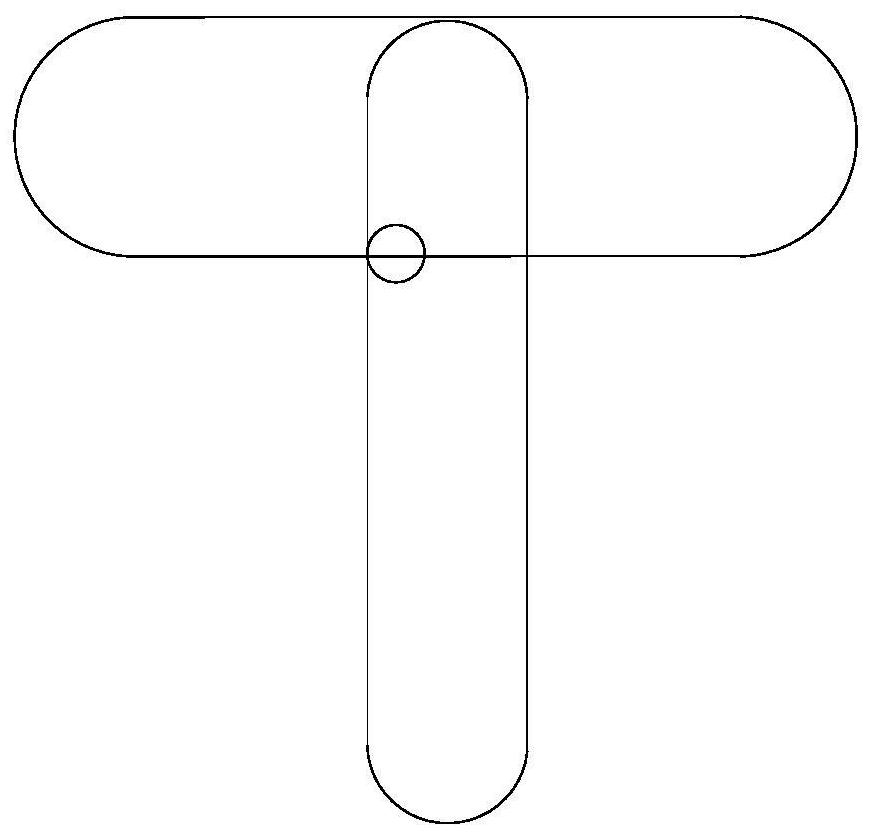

The present invention discloses a processing method of a PCB (Printed Circuit Board) and a PCB. The processing method comprises the steps of: drilling a prebored hole on a board; passing through the prebored hole to mill a first groove, wherein a groove edge of the first groove passes through the center of a circle of the prebored hole; and passing through the prebored hole to mill a second groovebeing perpendicular to the first groove, wherein a groove edge of the second groove is tangent to the prebored hole, and the second groove and the first groove form a T-shaped groove. The prebored hole is drilled in advance to determine the grooving positions and directions of the first groove and the second groove, and therefore, the manufactured T-shaped groove shape rule is ensured to satisfythe production demand.

Owner:MEIZHOU ZHIHAO ELECTRONICS TECH

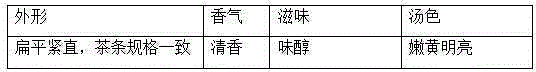

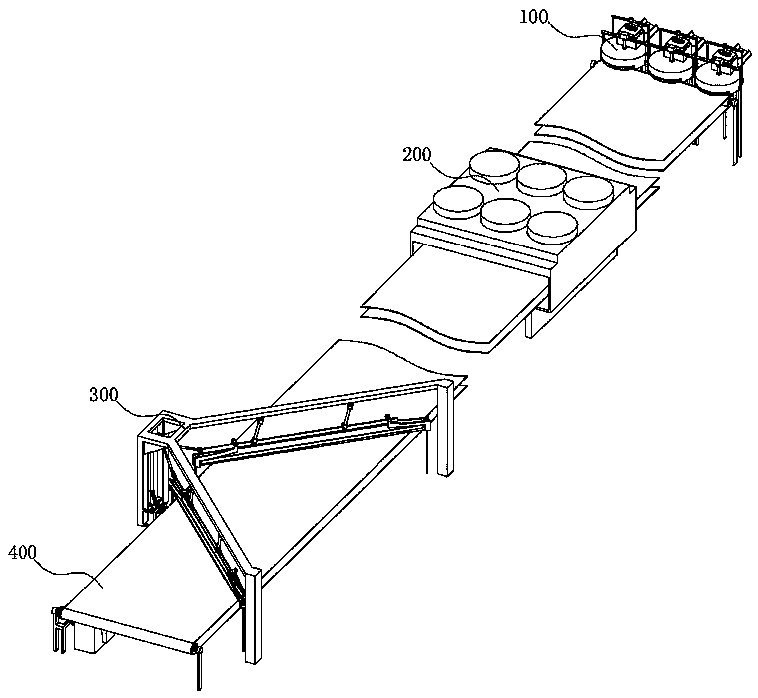

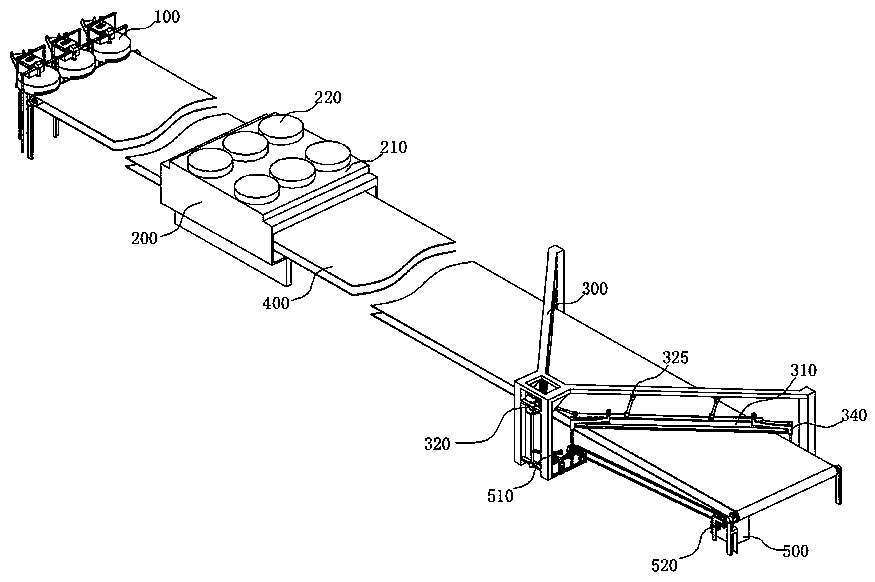

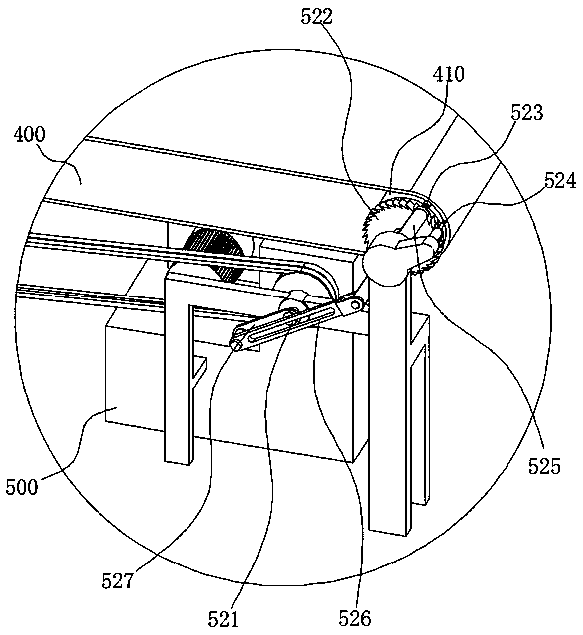

Green tea processing process

InactiveCN105076520AGuarantee the quality of selected leavesAvoid affecting the quality of finishingPre-extraction tea treatmentGreen teaImpurity

The invention discloses a green tea processing process, comprising the steps of tea leaf selection, enzyme deactivation, spreading-cooling, impurity screening, strip shaping and pressing, dividing for forming of screen bottom tea and screen surface tea, final-panning on the screen bottom tea and the screen surface tea respectively, and the like. Processed tea is enabled to be mellow and delicious in taste by strictly controlling the steps of enzyme deactivation, spreading-cooling and final-panning, and the processed tea is enabled to be uniform in size and good in forming quality by dividing different sizes of tea into the screen bottom tea and the screen surface tea, and respectively performing final-panning on the screen bottom tea and the screen surface tea respectively.

Owner:重庆市乾丰茶业有限责任公司

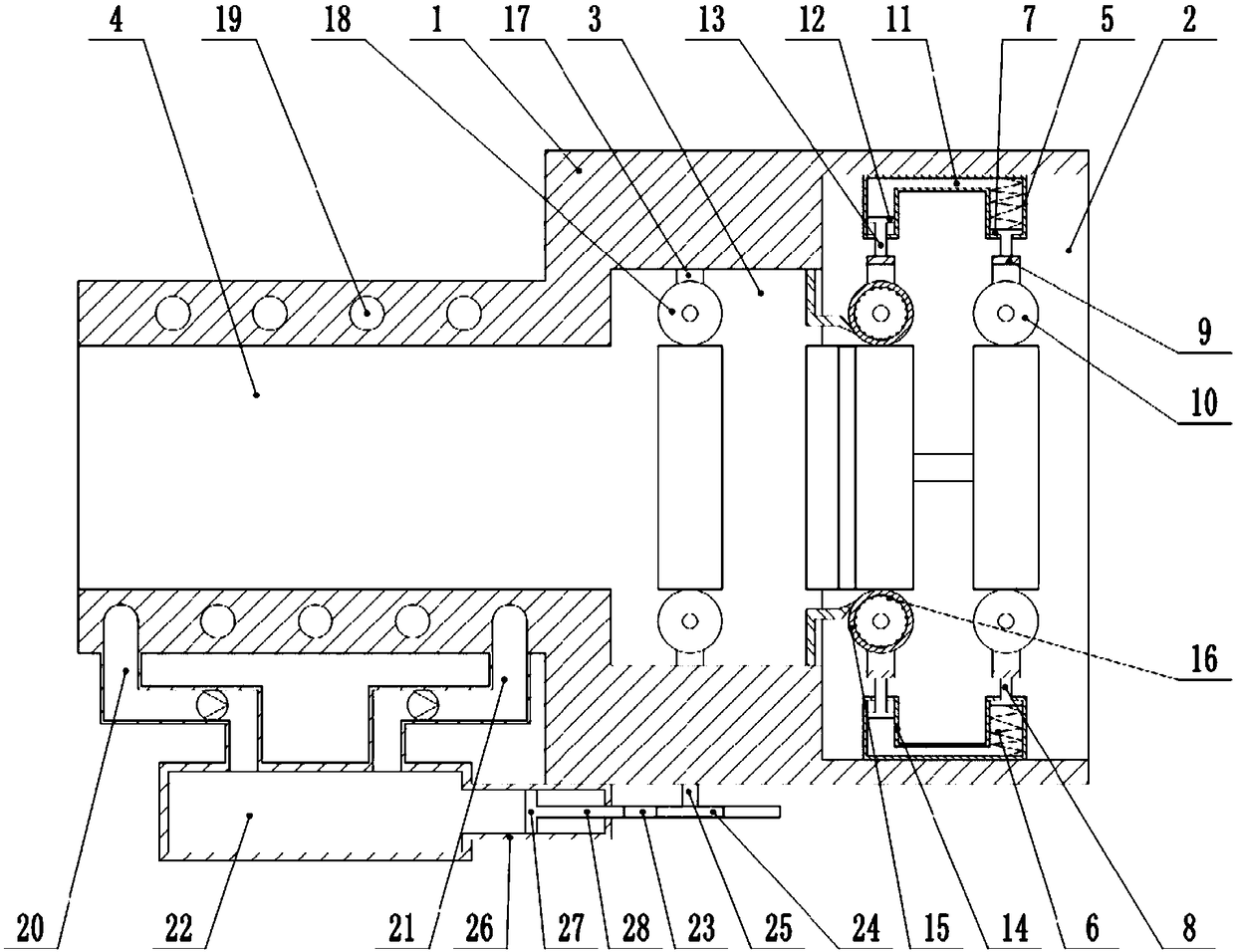

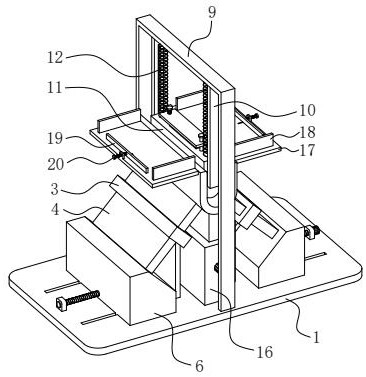

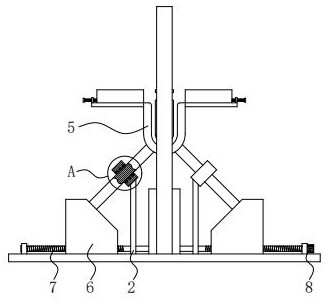

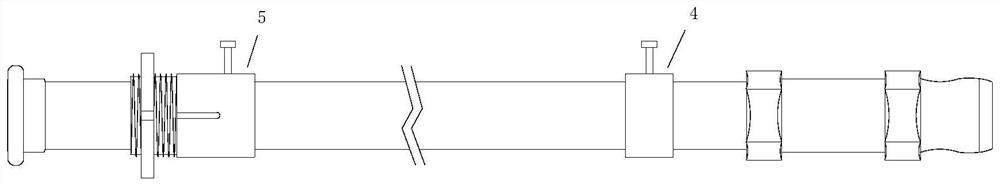

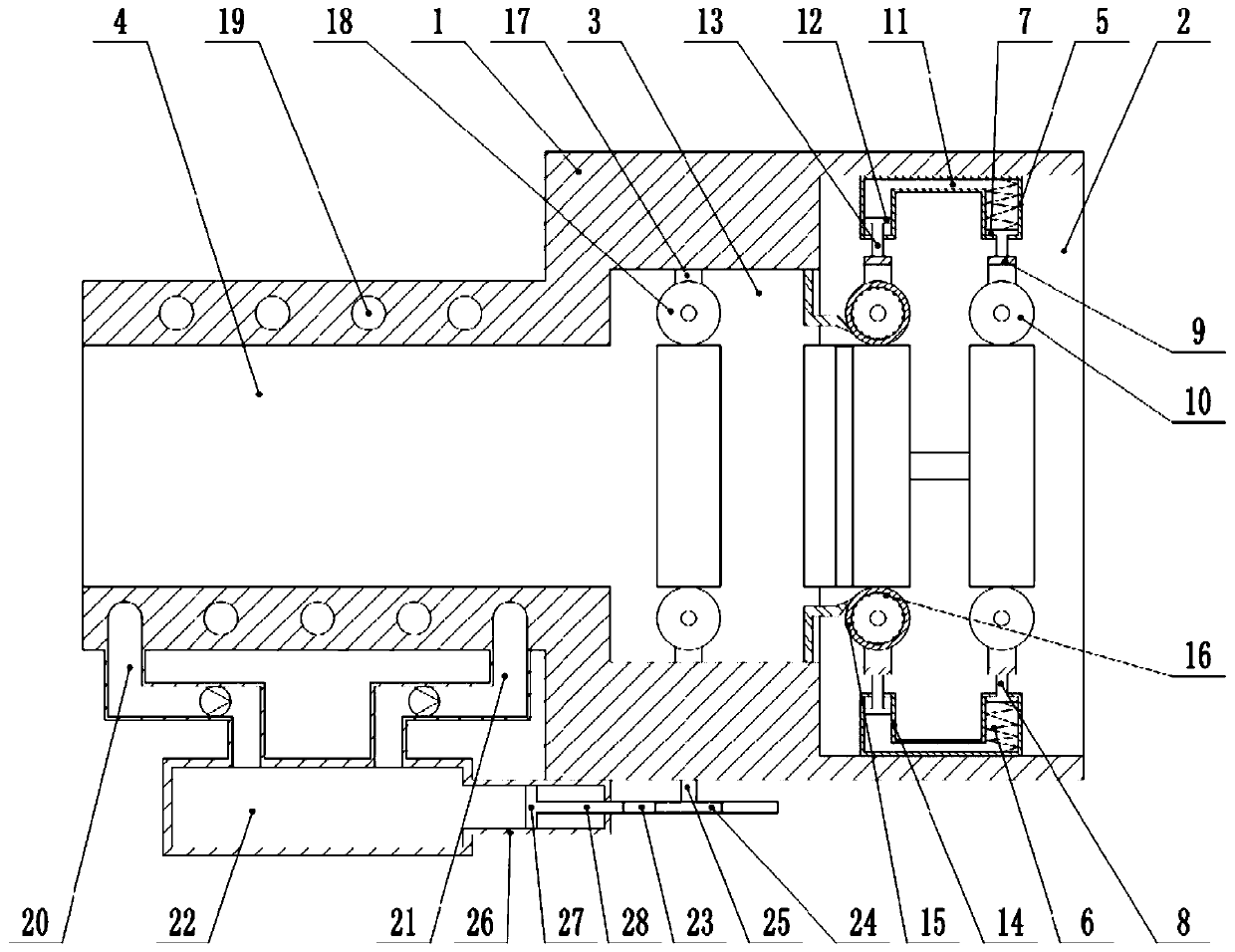

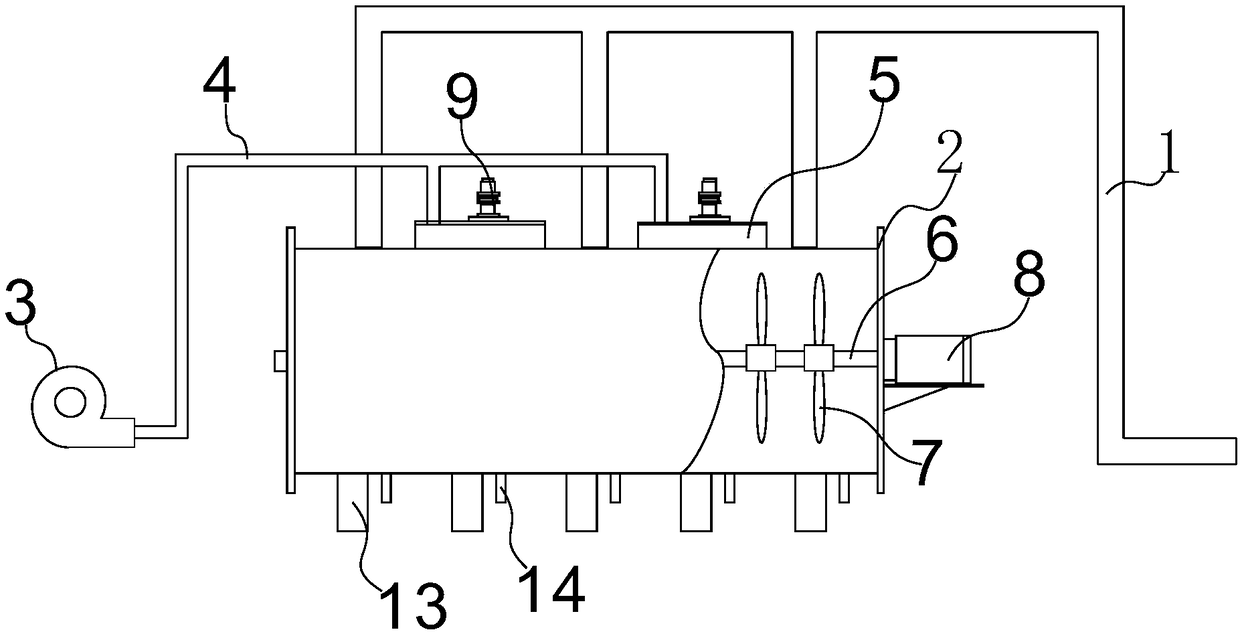

Cable production processing equipment

ActiveCN108492937ARealize repair processingWon't pushInsulating conductors/cablesInsulation layerElectrical conductor

The invention belongs to special equipment or method for manufacturing a conductor or a cable, and particularly discloses cable production processing equipment. The cable production processing equipment comprises a shell, wherein a detection hot melting cavity is formed in the shell, a detection cylinder and an extrusion cylinder are arranged on a side wall of the detection hot melting cavity, a pipeline is arranged between the detection cylinder and the extrusion cylinder and communicates with the detection cylinder and the extrusion cylinder, a detection piston plate and an extrusion pistonplate are respectively and hermetically arranged in the detection cylinder and the extrusion cylinder in a sliding way, the detection piston plate and the extrusion piston plate are respectively provided with a detection piston rod and an extrusion piston rod, one end, far away from the detection hot melting cavity, of the detection piston rod and one end, far away from the detection hot melting cavity, of the extrusion piston rod respectively extend out of the detection cylinder and the extrusion cylinder, a detection positioning rack and an extrusion positioning rack are respectively arranged at one end, far away from the detection hot melting cavity, of the detection piston rod and one end, far away from the detection hot melting cavity, of the extrusion piston rod, a detection roller and an extrusion roller are respectively and rotatably arranged on the detection positioning rack and the extrusion positioning rack, an electric heating wire is arranged in the extrusion roller, and the detection roller and the extrusion roller are encircled to form a square. By the cable production processing equipment, the problem that a square cable cannot be processed again due to air bubblesin an insulation layer during square cable manufacturing is solved.

Owner:曾广君

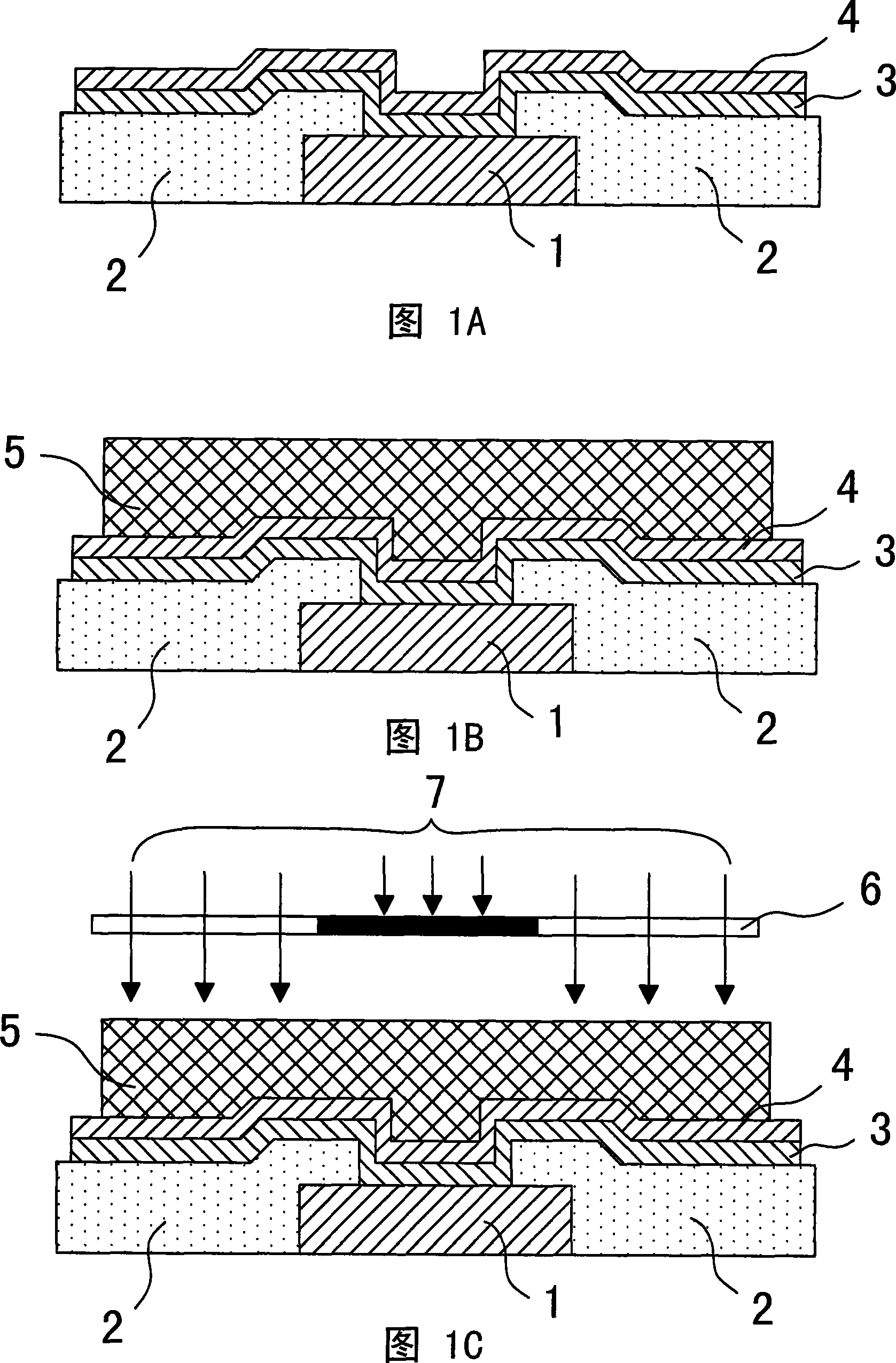

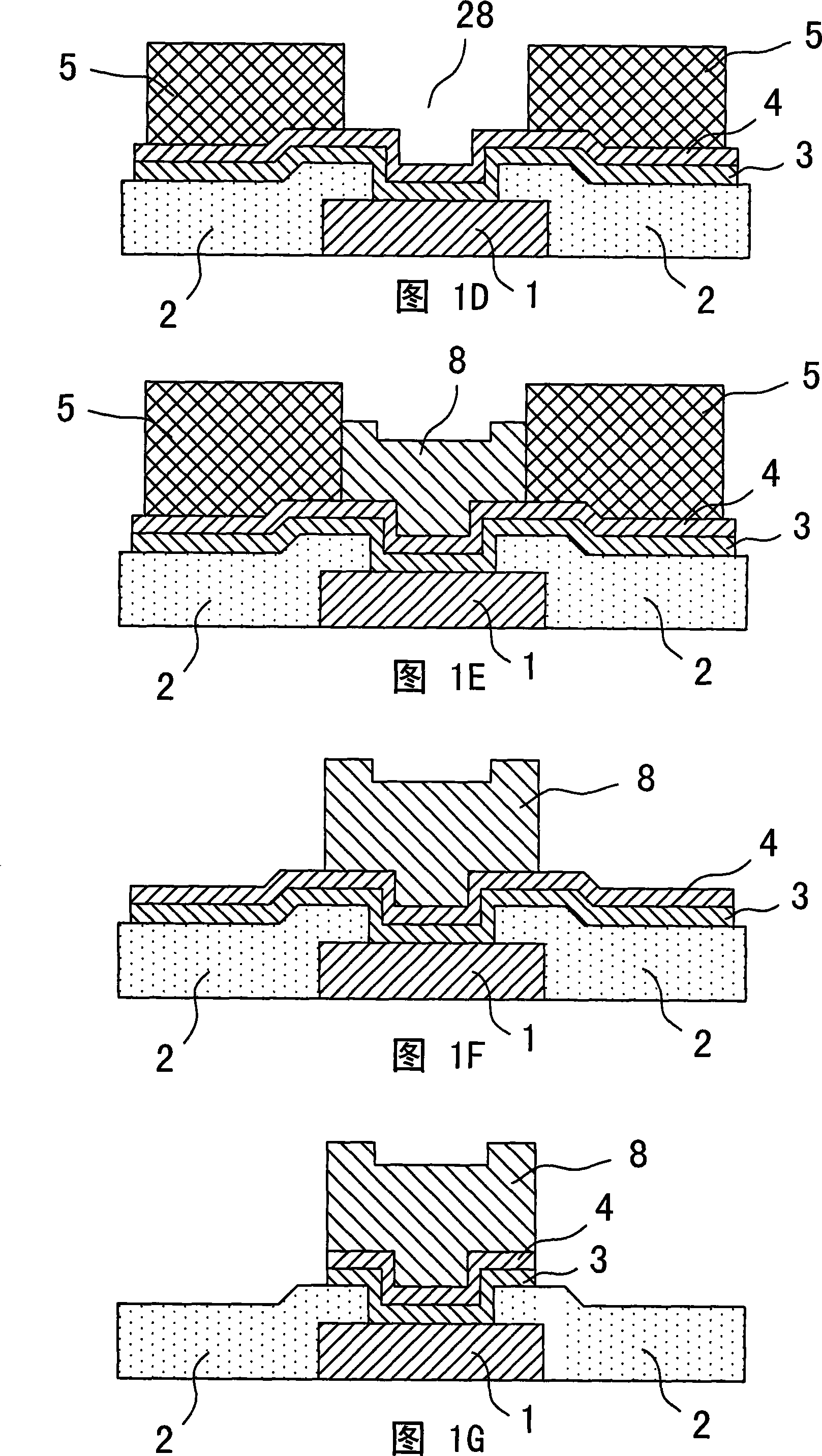

Method for compensating round angle of metal bump for semiconductor chip electric contact

InactiveCN101071782AGuaranteed shape rulesAvoid the risk of damaging the Al padSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor chipEngineering

The invention is a semiconductor chip connection point metal bump round angle compensating method, characterized by: in the course of making metal bump by combination of photoetching and plating processes, extending outward each corner theoretically designed in bump figure on photomask, increasing windowing size and compensating the inward contraction distortion of the bump figure in developing so as to assure the actually made metal bump corner consistent with the geometric shape theoretically designed. And the invention relates to the field of semiconductor IC packaging technique, solving the problem that the corner deforms into round angle in the metal bump making course, optimizing bump angular shape and improving product performance and yield.

Owner:CHIPMORE TECH CORP LTD

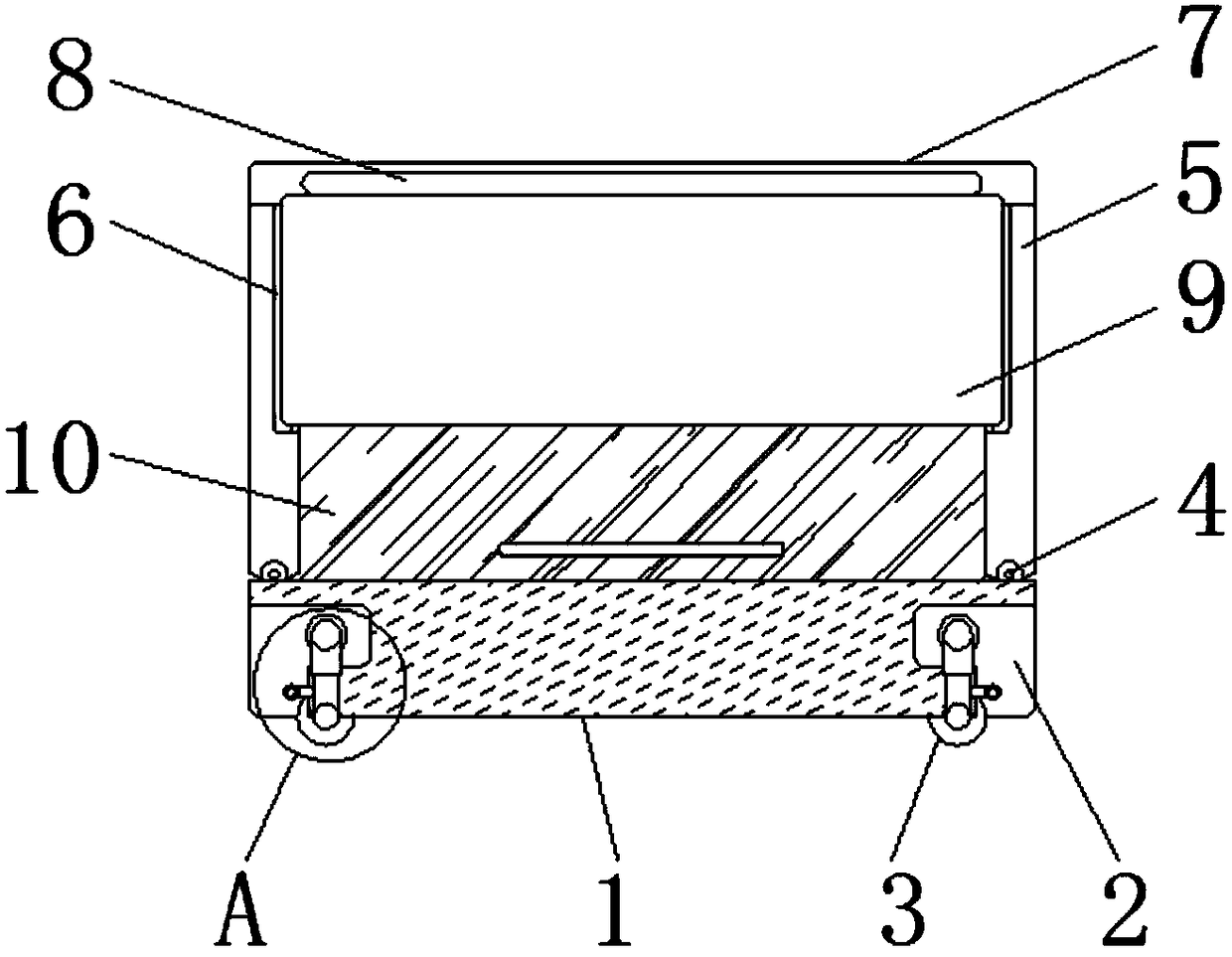

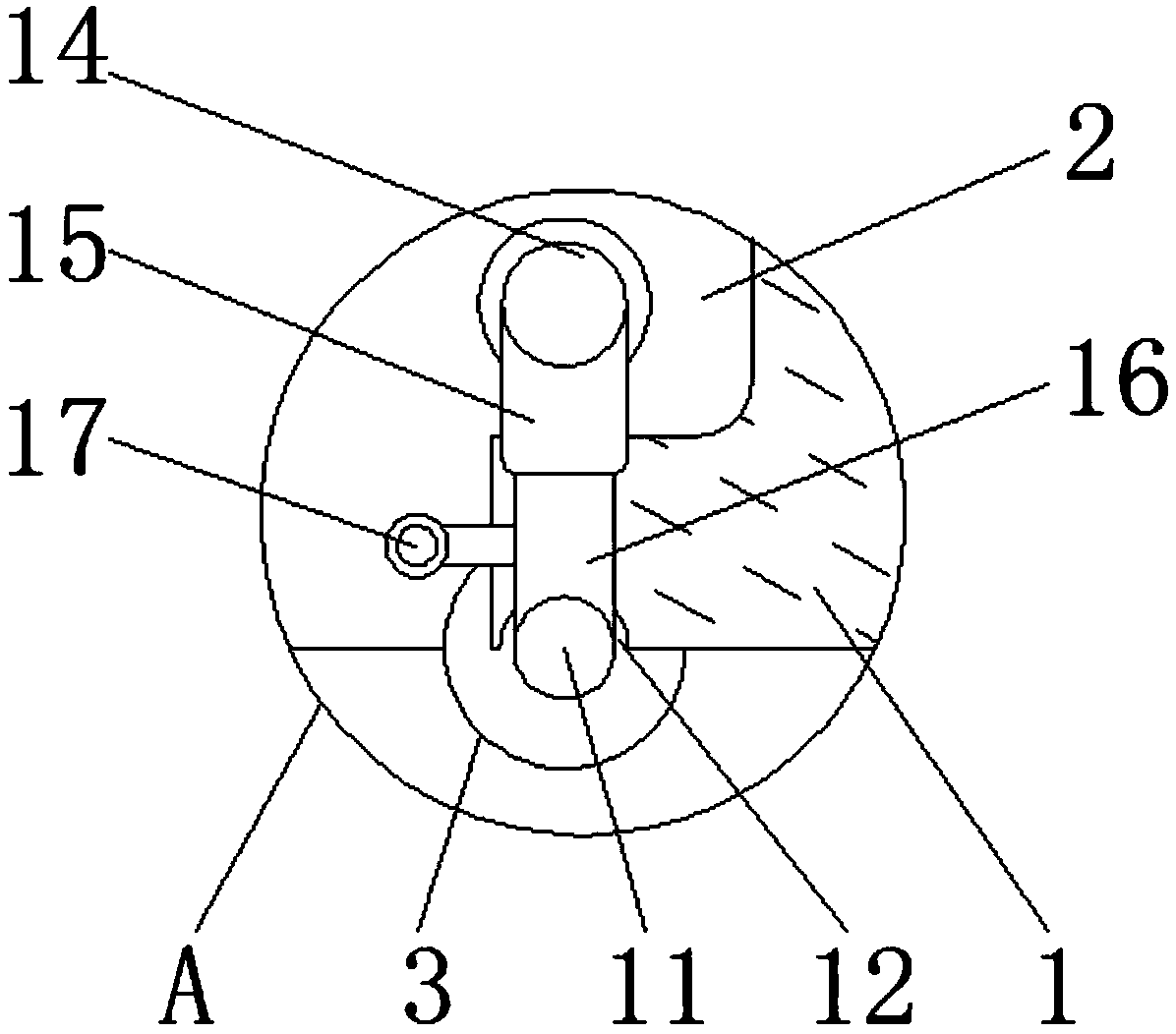

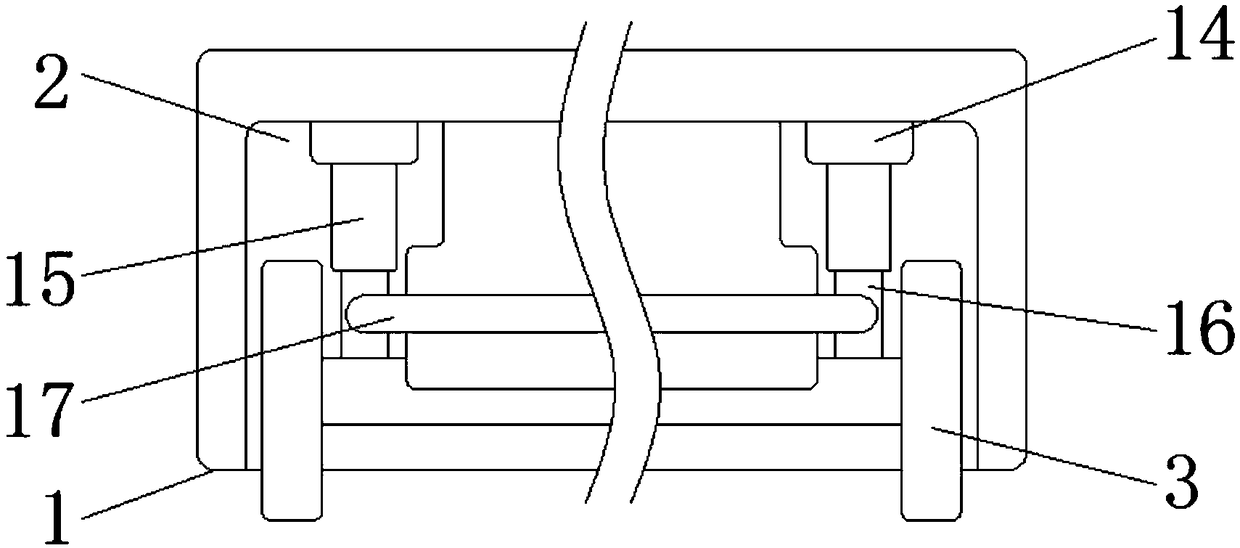

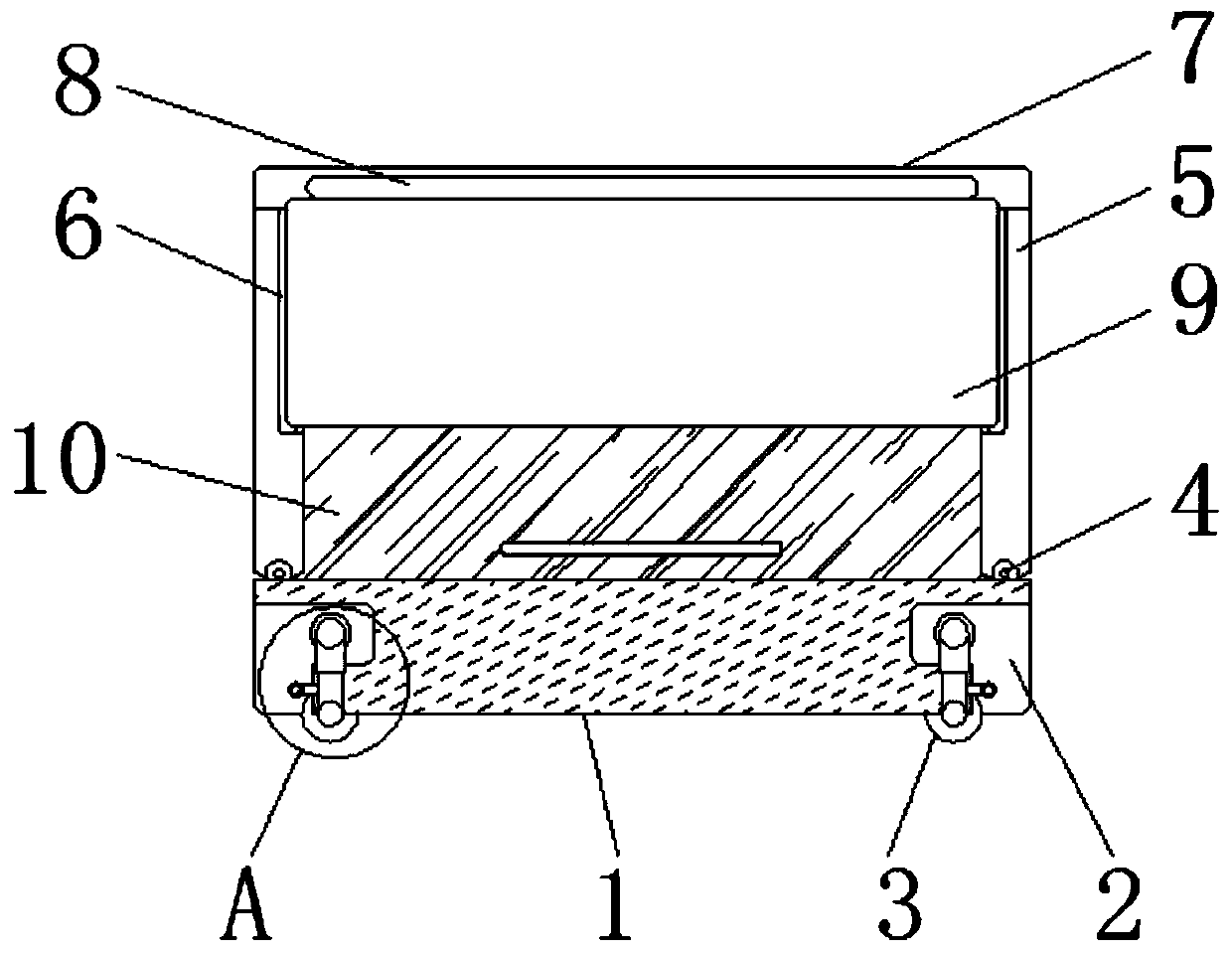

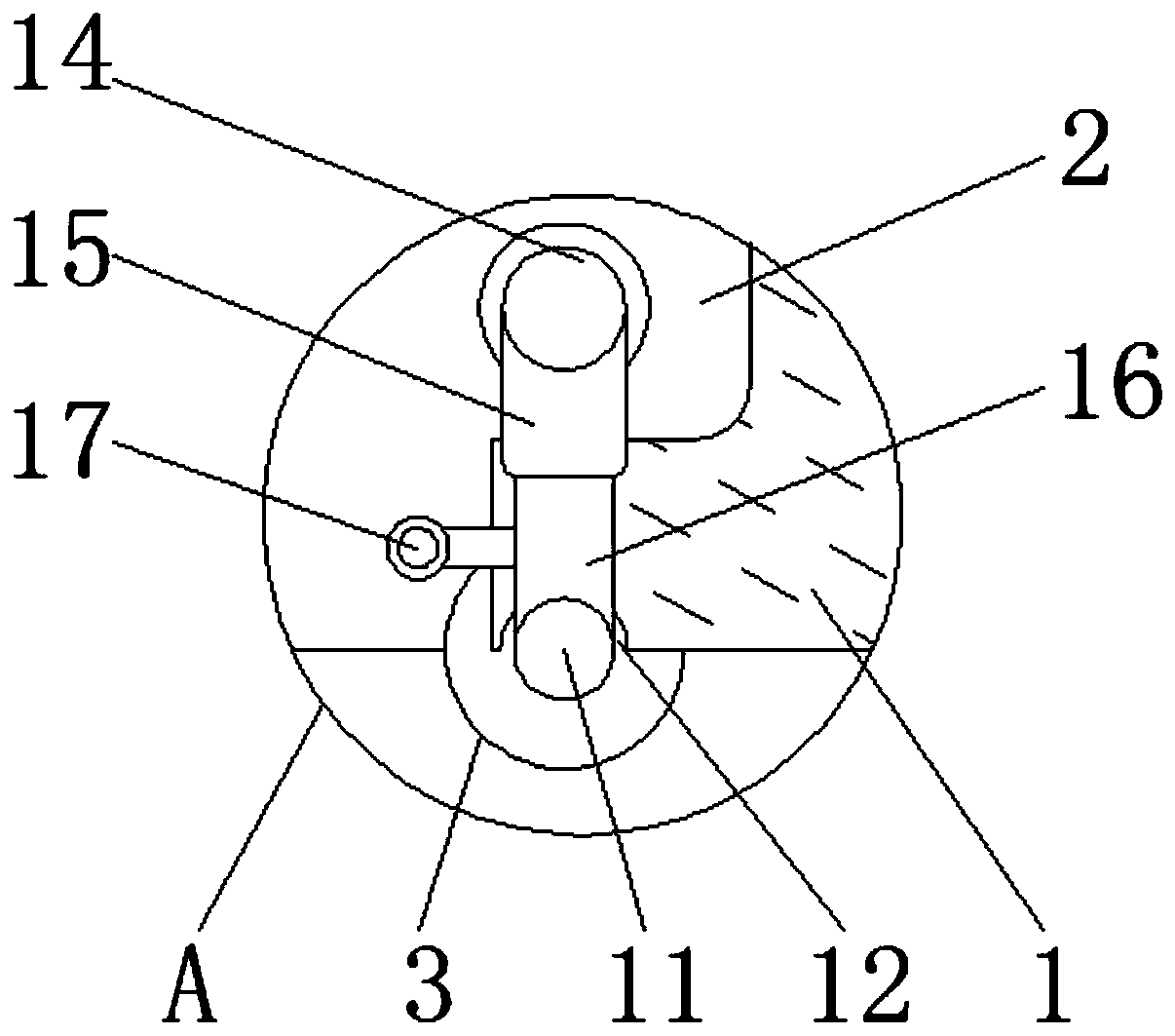

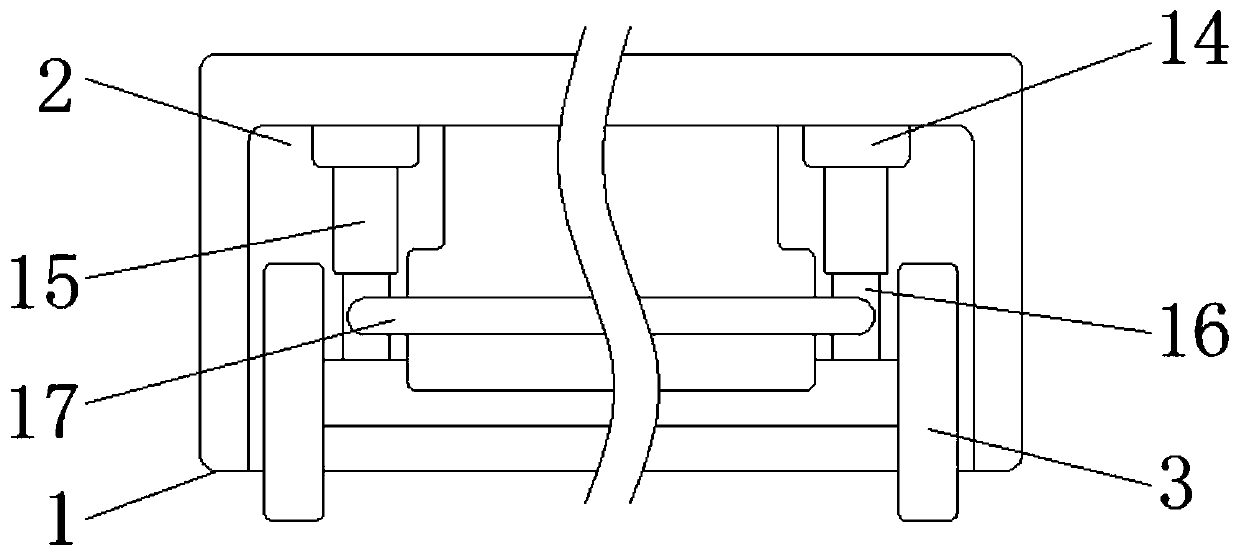

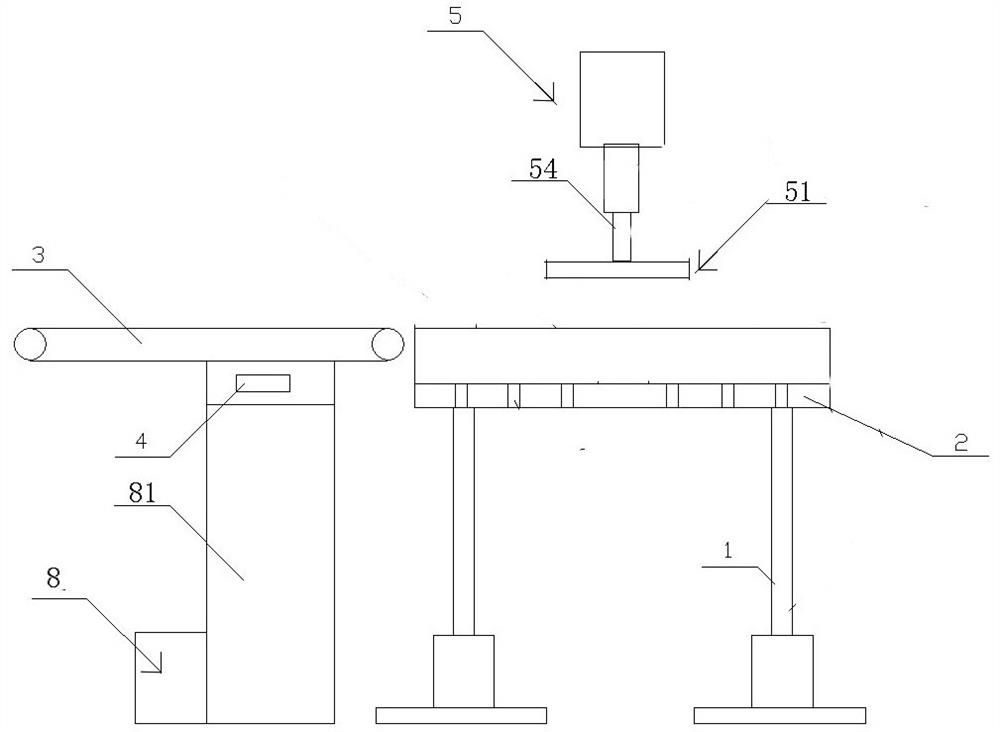

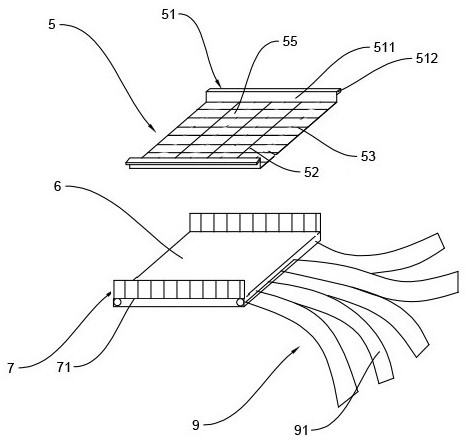

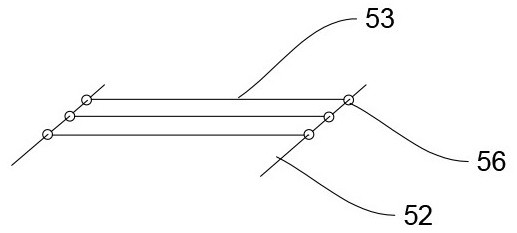

Transporting and fixing device capable of moving conveniently for selling of 3D printer

ActiveCN108438029AEasy to moveMobile 3D printer sales and transportationHand carts with multiple axesHand cart accessoriesEngineering3d printer

Owner:平邑现代中药产业园有限公司

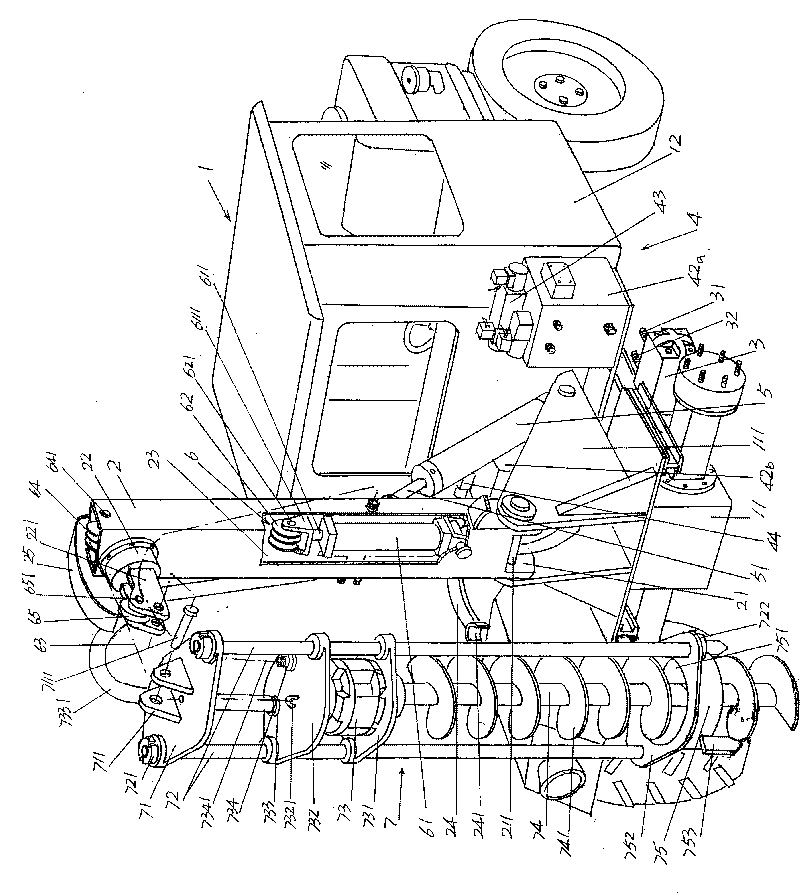

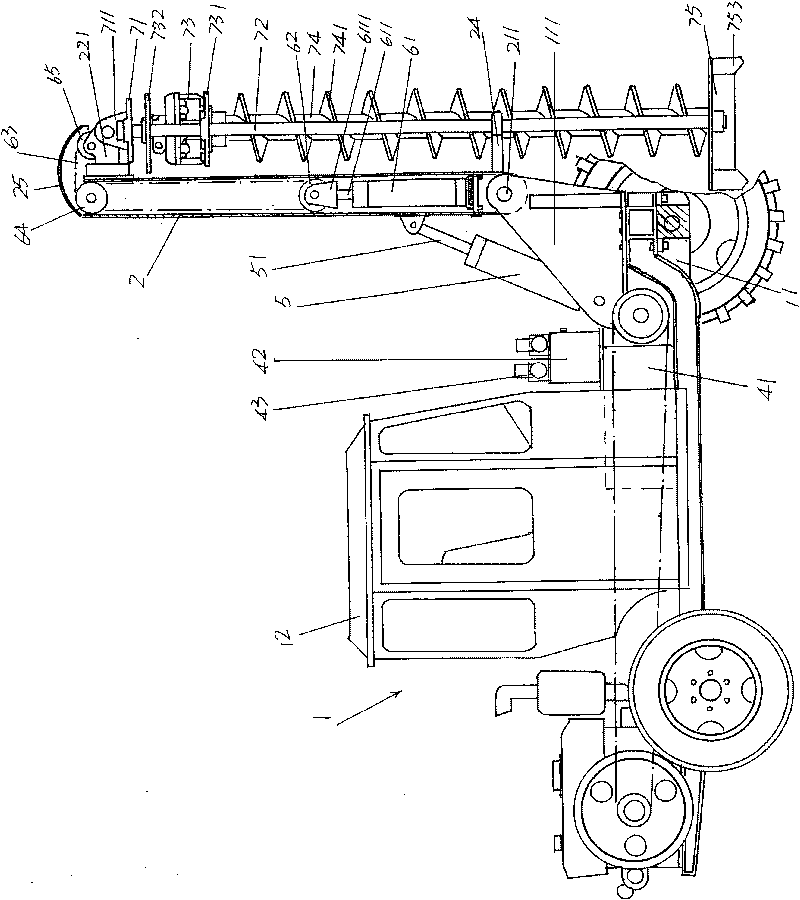

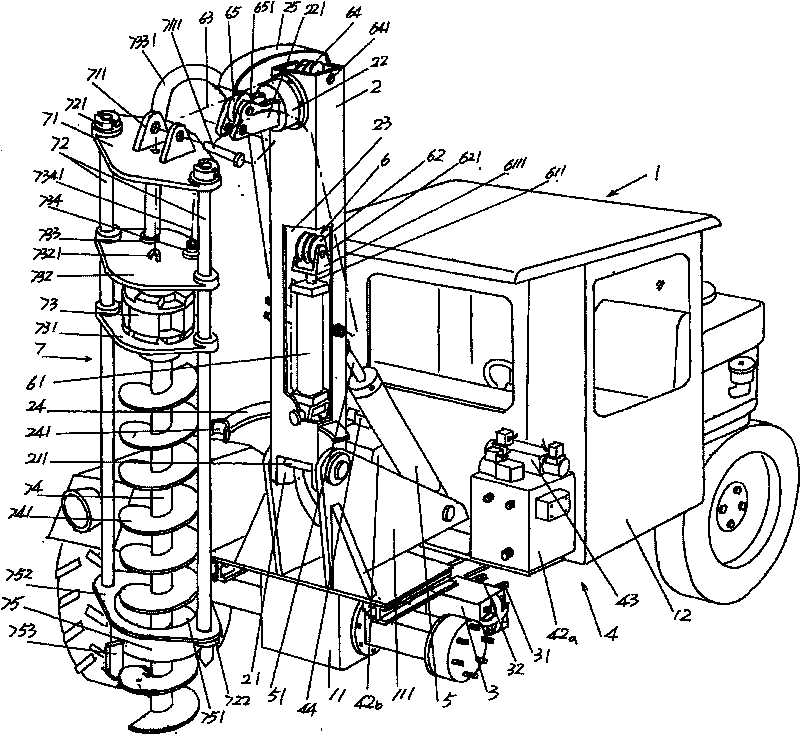

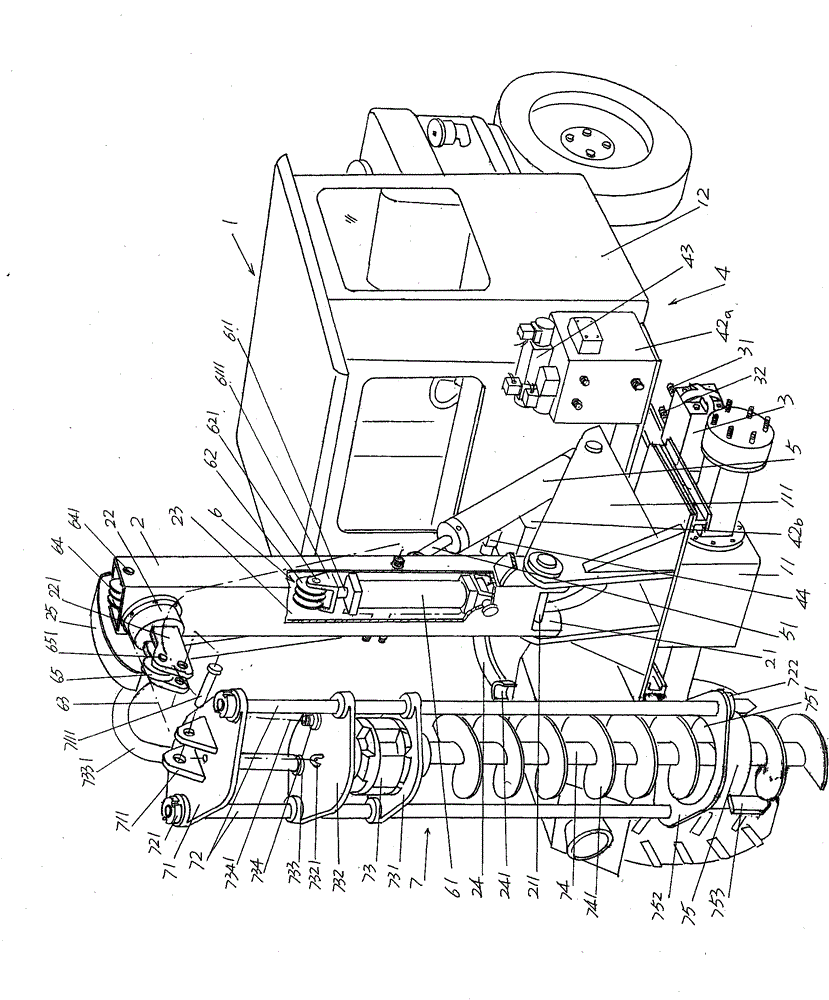

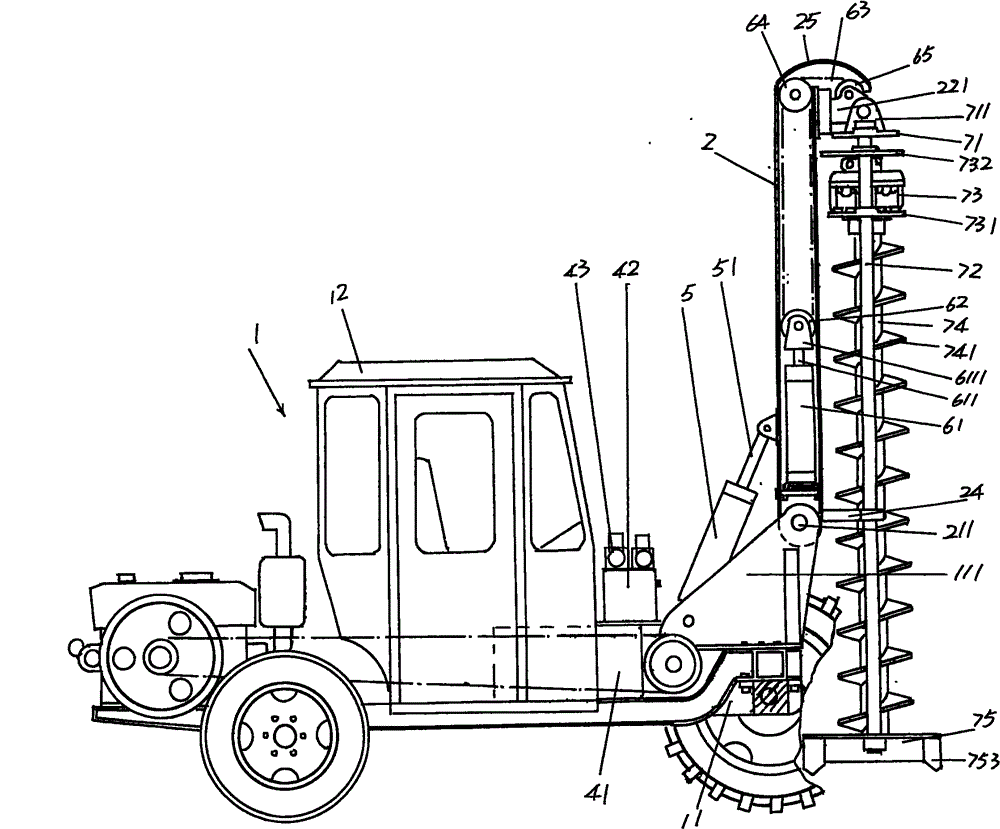

Pot hole drilling machine carried on vehicle

InactiveCN101705786AGuaranteed Shape RulesGuaranteed progressConstructionsBorehole drivesCantileverDrilling machines

The invention relates to a pot hole drilling machine carried on a vehicle, belonging to foundation engineering construction machinery. The vehicle comprises a front axle, and the pot hole drilling machine comprises a cantilever, an oil pump, a hydraulic unit, a cantilever oil cylinder, a drill lifting mechanism and a drilling mechanism, wherein the lower end of the cantilever is hinged on the front axle; the oil pump is arranged on the front axle and is in transmission connection with a power output shaft of the vehicle; the hydraulic unit is fixedly arranged on the front axle and connected with a hydraulic oil circuit of the oil pump; the cantilever oil cylinder is arranged on the front axle, hinged with the cantilever and connected with an oil circuit of the hydraulic unit; the drill lifting mechanism is arranged on the cantilever and connected with a hydraulic oil circuit of the hydraulic unit; and the drilling mechanism is arranged at the upper end of the cantilever by suspending and connected with the oil circuit of the hydraulic unit and the drill lifting mechanism. The pot hole drilling machine not only can guarantee that the shapes of drilled pot holes are regular, but also has high working efficiency so as to guarantee the progress of construction engineering, and moreover, the labor intensity of constructors can be effectively lightened.

Owner:常熟市飞达汽车保养工具设备有限公司

Red ink powder and preparation method thereof

The invention relates to a red ink powder and a preparation method thereof. The preparation method comprises the following steps: heating 30-90 parts of resin, 5-10 parts of red pigment, 0.1-5 parts of charge control agent and 1-30 parts of polypropylene wax to melt, stirring the molten materials to disperse evenly, performing spray granulation with an atomizer, cooling to obtain ink powder particles, adding flowable agent for modification and finally obtaining the ink powder product through air classification. The ink powder particles prepared by the invention has uniform particles, good low-temperature fixing effect, more than 90% of transfer printing rate small processing equipment investment, simple process operation, short flow, low production cost, and no effluent or exhaust gas emission which can pollute the environment in preparation process, and ultrafine and ultracoarse ink powder particles can be recycled to a melting kettle for reuse, thus making the most use of the raw materials.

Owner:山东富美科技有限公司

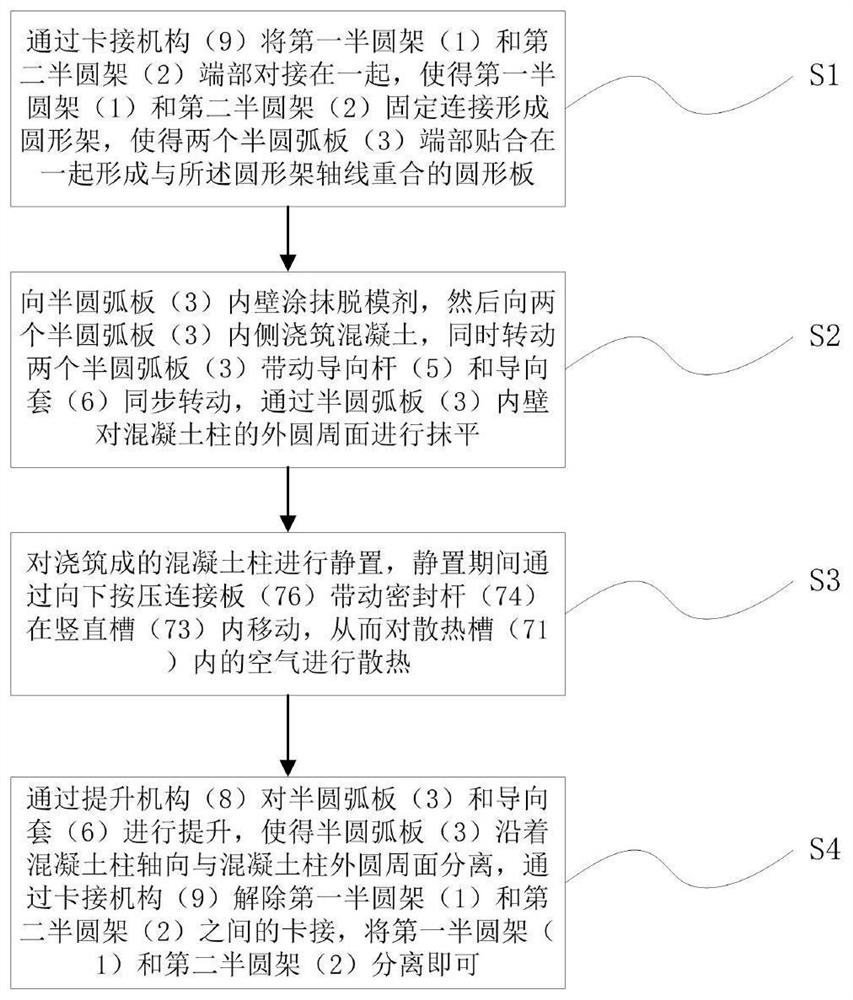

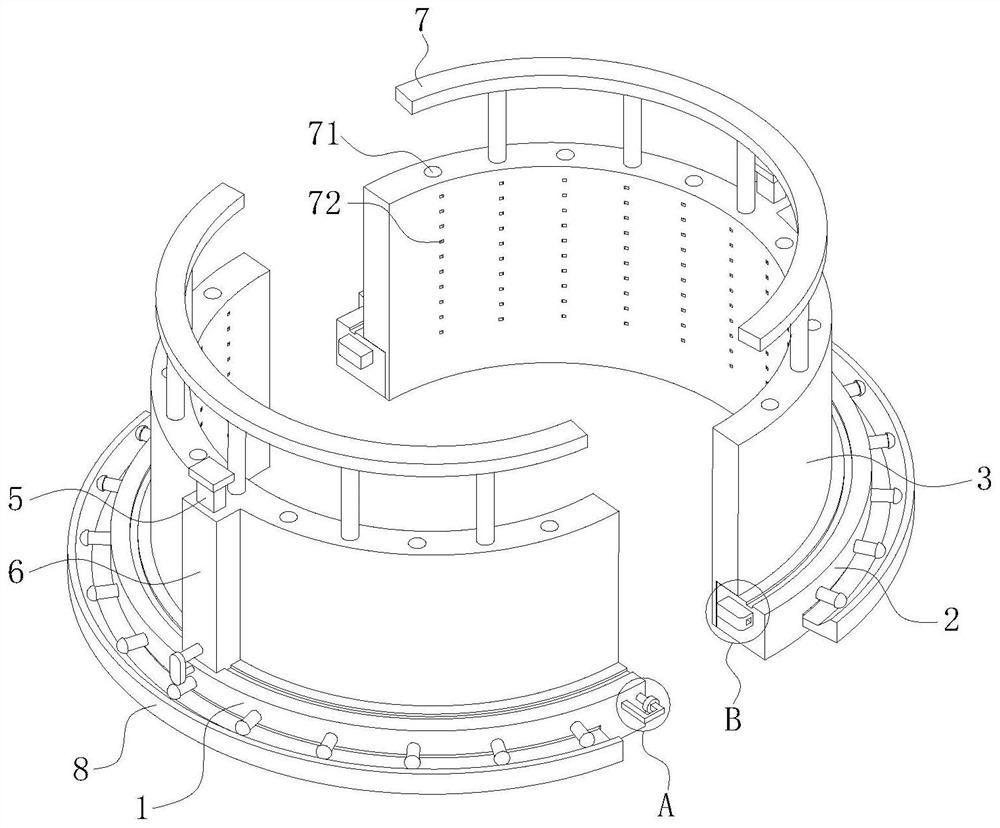

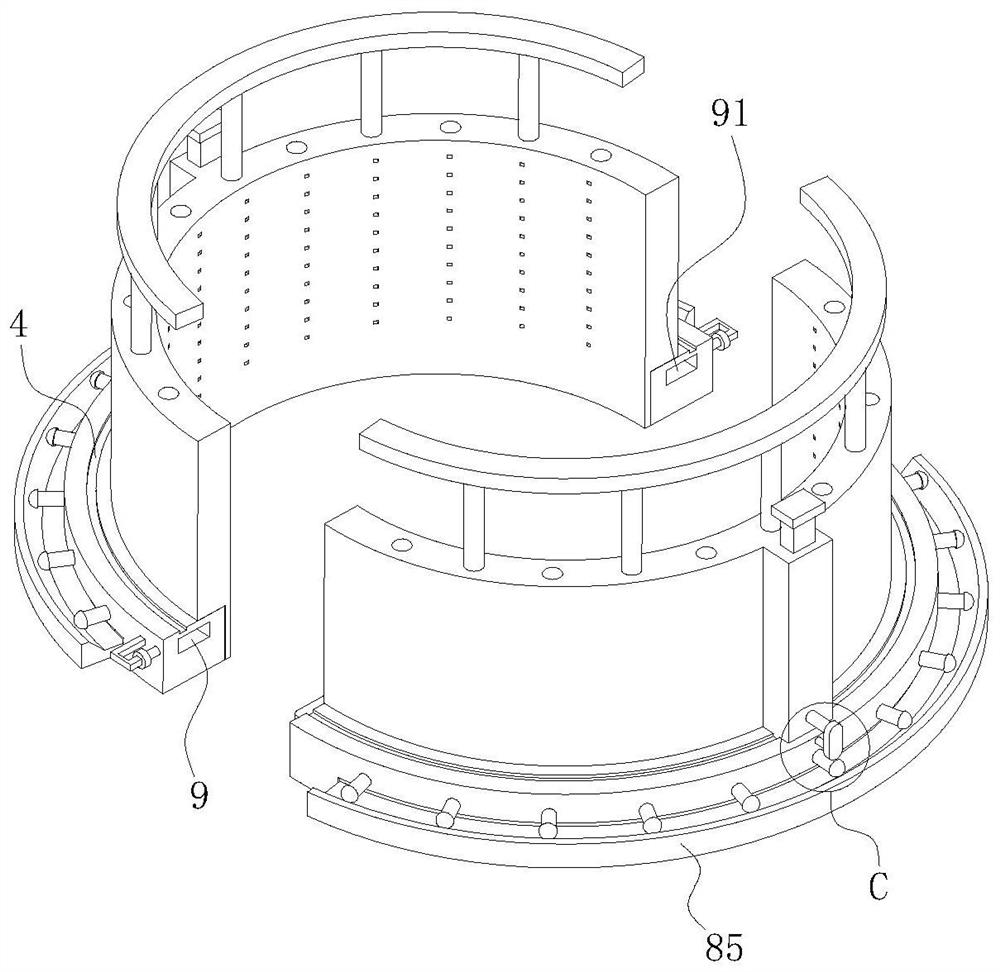

High-strength building concrete column pouring construction method

InactiveCN113152789AEfficient removalAvoid crackingStrutsForms/shuttering/falseworksButt jointArchitectural engineering

The invention belongs to the technical field of building construction, and particularly relates to a high-strength building concrete column pouring construction method. The high-strength building concrete column pouring construction method is completed through cooperation of a high-strength building concrete column pouring construction device and comprises the following steps of 1, butt joint fixing; 2, pouring and trowelling; 3, standing for heat dissipation; and 4, mold removal and separation. In the pouring construction process of a concrete column, heat generated in the hydration process of the concrete column is effectively dissipated, and the situation that the edge of the concrete column is prevented from being damaged in the process of dismantling a semi-arc plate, and the circumferential surface of the concrete column is scratched are avoided; the shape of the circumferential surface of the concrete column is ensured to be regular, and the pouring quality of the concrete column is improved.

Owner:郭良红

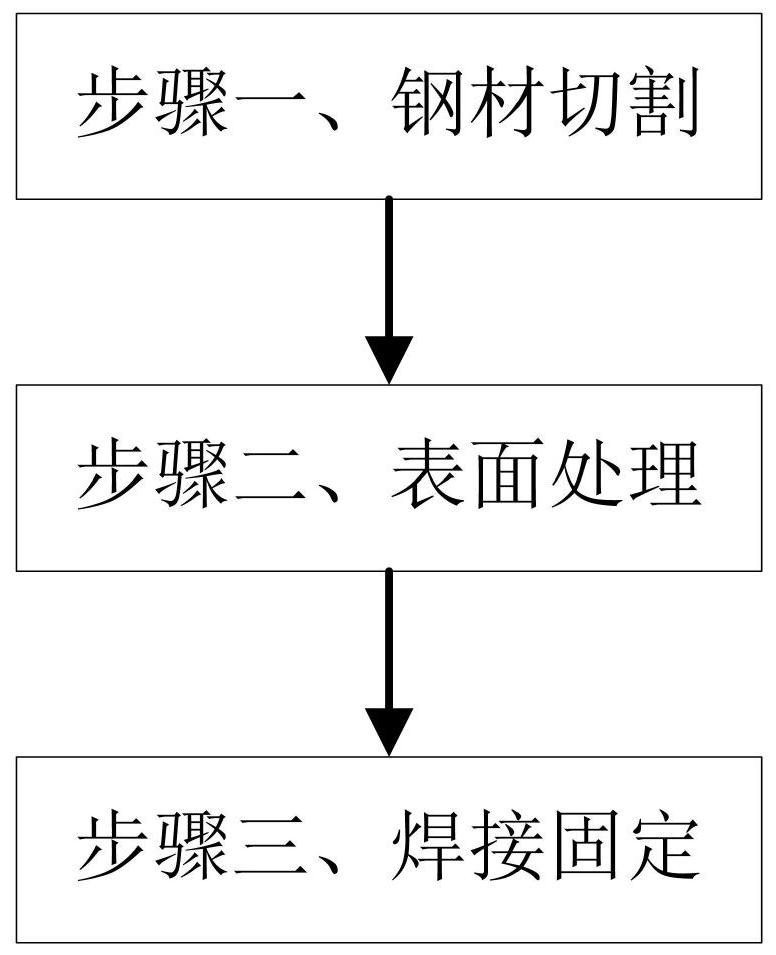

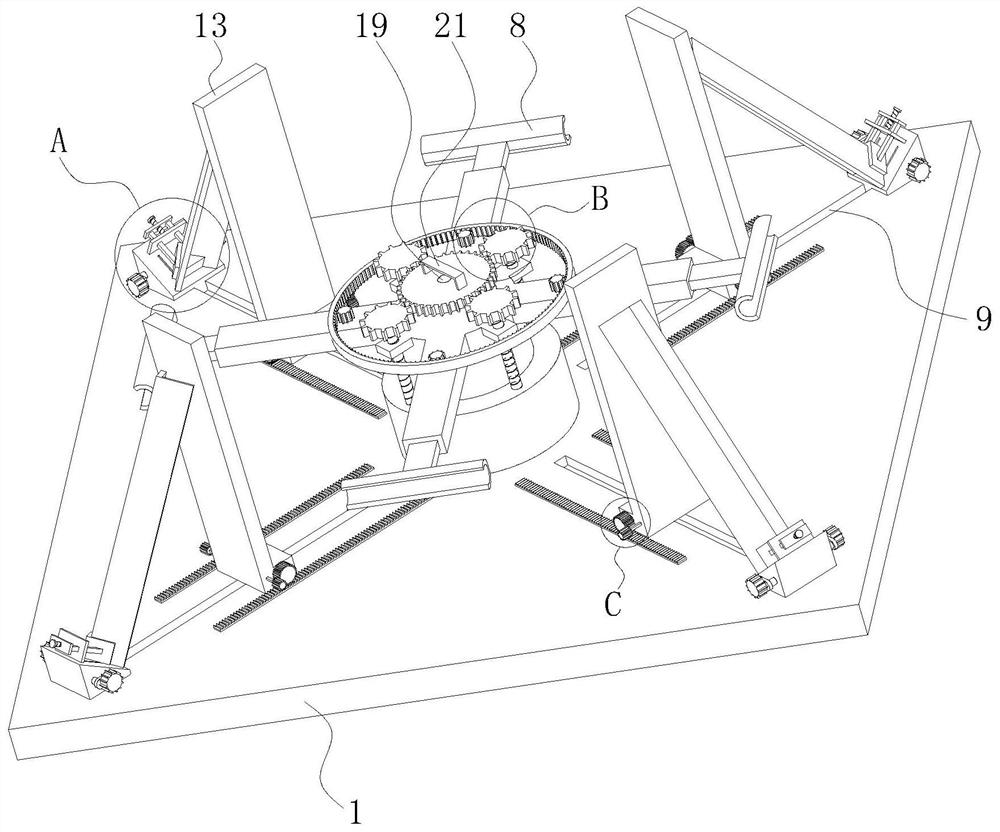

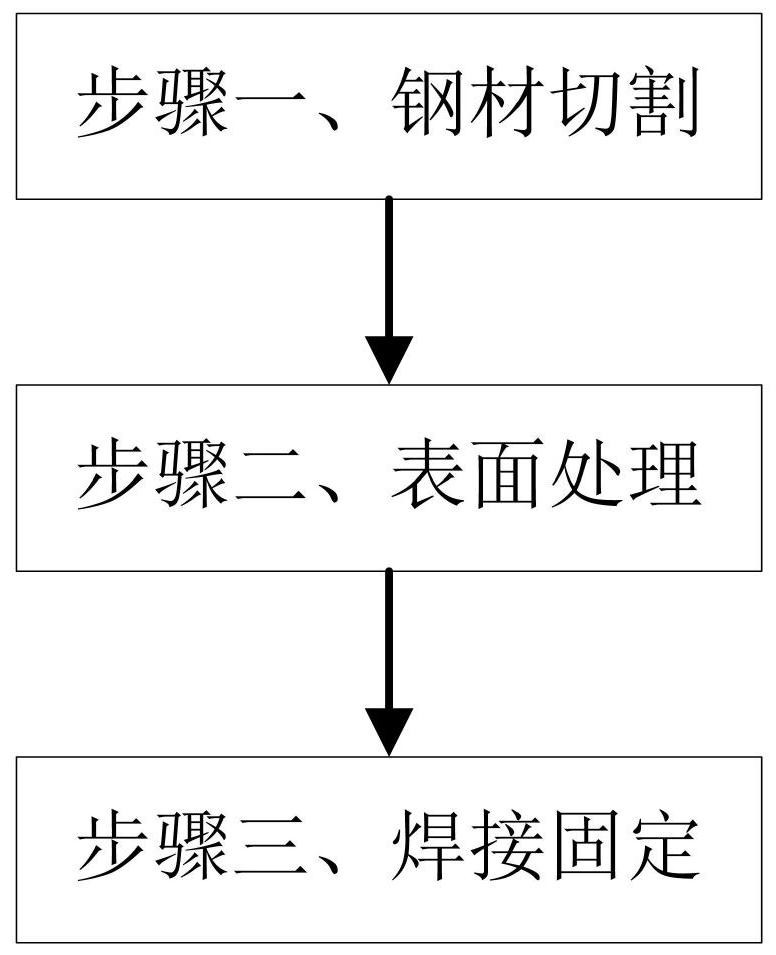

Manufacturing and machining method for communication iron tower building assembly type steel structure

The invention belongs to the technical field of communication equipment, and particularly relates to a manufacturing and machining method for a communication iron tower building assembly type steel structure. The manufacturing and machining method comprises the following steps of 1, steel cutting, specifically, angle steel is cut into four main rods with the same length, and a round pipe is cut into four auxiliary rods with the same length; 2, surface treatment, specifically, hot galvanizing anti-corrosion treatment is conducted on the surfaces of the main rods and the auxiliary rods; and 3, welding and fixing, specifically, the main rods and the auxiliary rods which are subjected to surface treatment are welded together to obtain a single-layer steel structure, wherein the third step is completed through cooperation of a manufacturing and machining device for the communication iron tower building assembly type steel structure. According to the manufacturing and machining method for the communication iron tower building assembly type steel structure, it is guaranteed that the inclination angles of the main rods in the to-be-welded state are the same, and the four main rods incline towards the axis of a guide cylinder; and it is guaranteed that the ends of the main rods in the two adjacent single-layer steel structures can be accurately connected together in a butt-joint mode.

Owner:湖南省通信建设有限公司

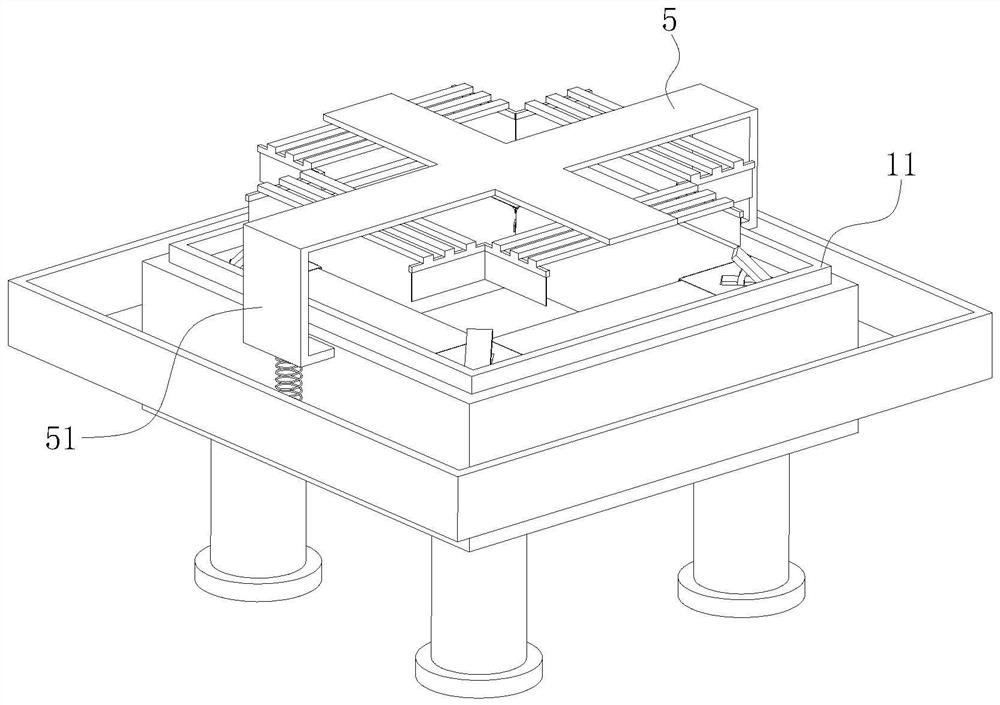

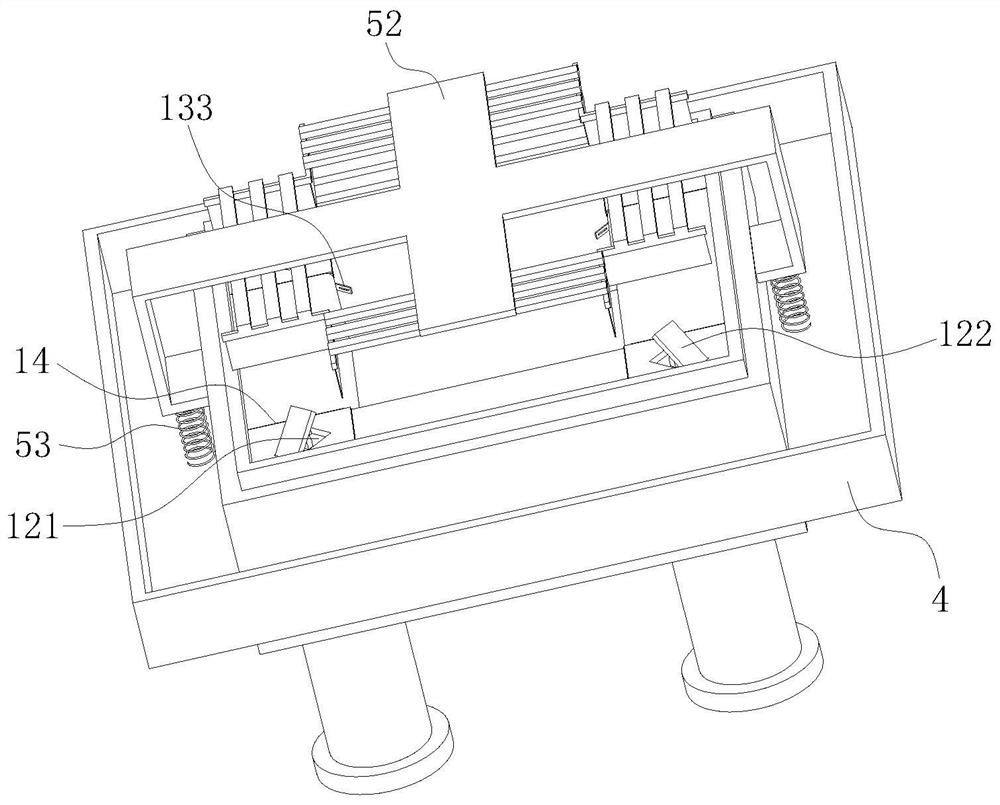

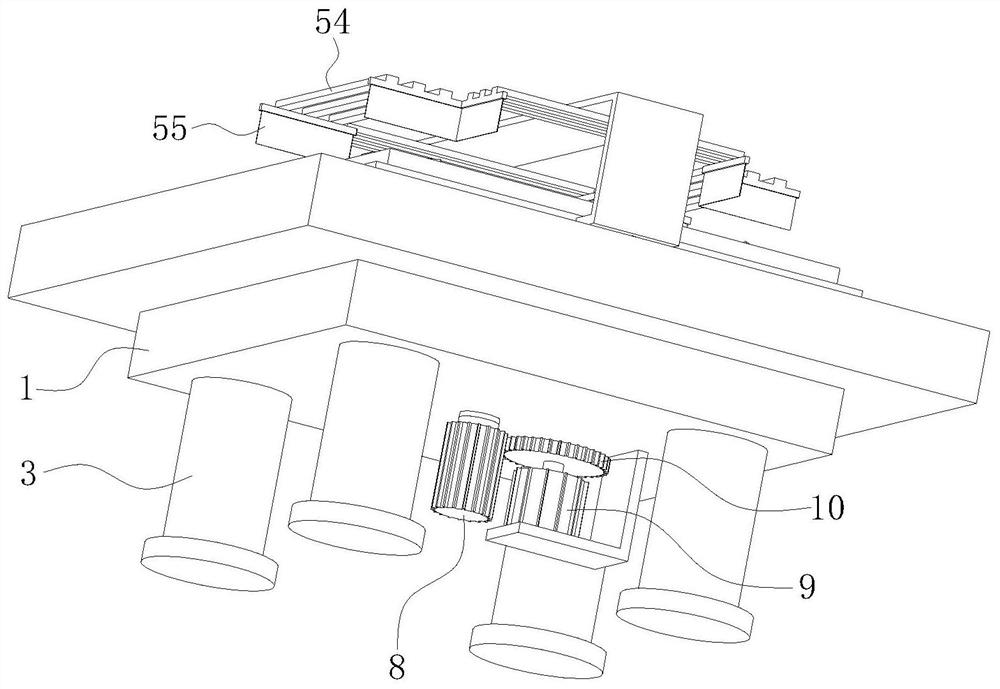

Punching calibration device for outer wall of furnace shell of intermediate frequency furnace

PendingCN114130888AConsistent wearGuaranteed punching effectMetal-working feeding devicesGrinding machinesPunchingIntermediate frequency

The invention belongs to the technical field of power equipment, and particularly relates to a punching calibration device for the outer wall of a furnace shell of an intermediate frequency furnace, the punching calibration device comprises a horizontal bottom plate, supporting columns are uniformly and fixedly mounted on the upper surface of the bottom plate, and a horizontal machining table is jointly and fixedly mounted at the tops of the uniformly arranged supporting columns; a clamping mechanism and a punching mechanism are mounted on the bottom plate; when the outer wall of the furnace shell of the intermediate frequency furnace is punched through the punching device, it is guaranteed that the abrasion degrees of all the cutting blocks are consistent, and therefore material waste is reduced; and after trepanning is finished, the grinding wheel horizontally moves in the rotating state to calibrate the two side walls of the kidney-shaped hole, it is guaranteed that the two side walls of the kidney-shaped groove are flush, and it is further guaranteed that the shape of the kidney-shaped hole is regular.

Owner:泰州市科健电炉电器有限公司

A kind of processing method of pcb and pcb

ActiveCN107820365BGuaranteed shape rulesMeet production needsPrinted circuit manufactureStructural engineeringMechanical engineering

The present invention discloses a processing method of a PCB (Printed Circuit Board) and a PCB. The processing method comprises the steps of: drilling a prebored hole on a board; passing through the prebored hole to mill a first groove, wherein a groove edge of the first groove passes through the center of a circle of the prebored hole; and passing through the prebored hole to mill a second groovebeing perpendicular to the first groove, wherein a groove edge of the second groove is tangent to the prebored hole, and the second groove and the first groove form a T-shaped groove. The prebored hole is drilled in advance to determine the grooving positions and directions of the first groove and the second groove, and therefore, the manufactured T-shaped groove shape rule is ensured to satisfythe production demand.

Owner:MEIZHOU ZHIHAO ELECTRONICS TECH

A metal furniture curved panel stamping forming machine

ActiveCN113333553BGuaranteed static statePrevent slidingMetal-working feeding devicesPositioning devicesSheet metal stampingMaterials science

The invention belongs to the technical field of furniture, and specifically relates to a stamping and forming machine for metal furniture curved panels, including a horizontal bottom plate, a guide sleeve is installed on the bottom plate through a bracket, an inclined plate is installed inside the guide sleeve, and a pressure block is installed on the top surface of the inclined plate; A wedge-shaped block is installed on the bottom plate, and a U-shaped frame is installed on the upper surface of the bottom plate. Two guide plates are installed on the bottom surface of the horizontal section of the U-shaped frame. A stamping block is slidingly installed between the two guide plates. The level of the stamping block and the U-shaped frame The sections are connected by return springs; the present invention uses two mutually independent pressure-bearing blocks to support and shape the sheet metal. After stamping is completed, the two pressure-bearing blocks are separated from the metal sheet along the inclined path, and the pressure is applied during the separation process. There is no relative sliding between the block and the metal plate, which avoids damage to the surface of the plate.

Owner:睢宁志磊家具有限公司

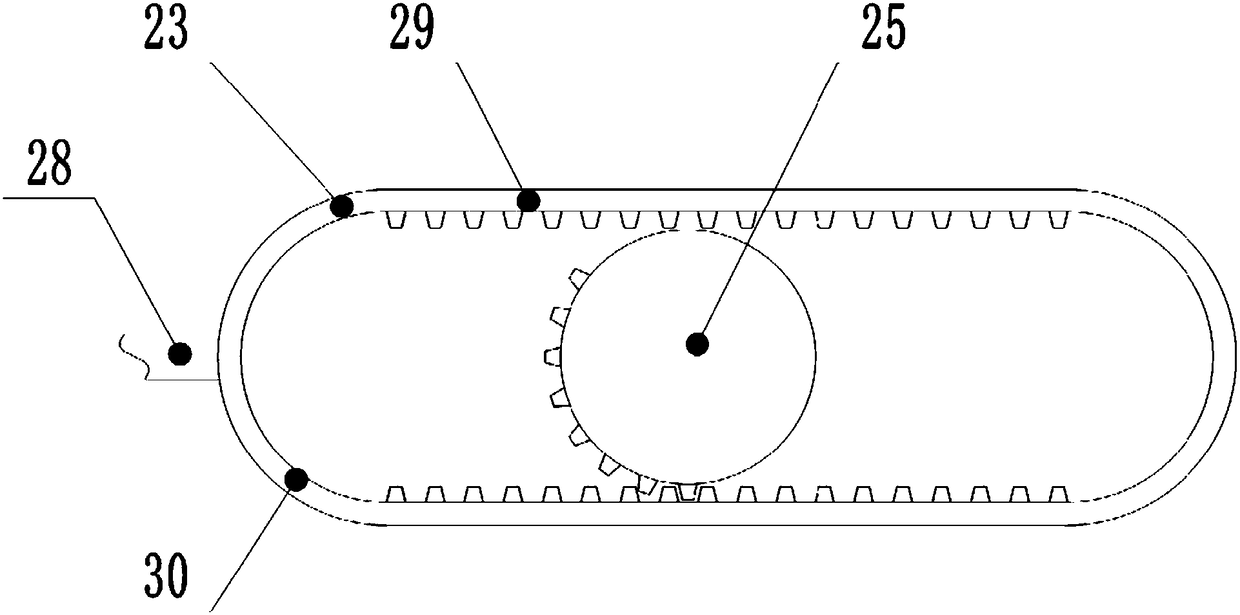

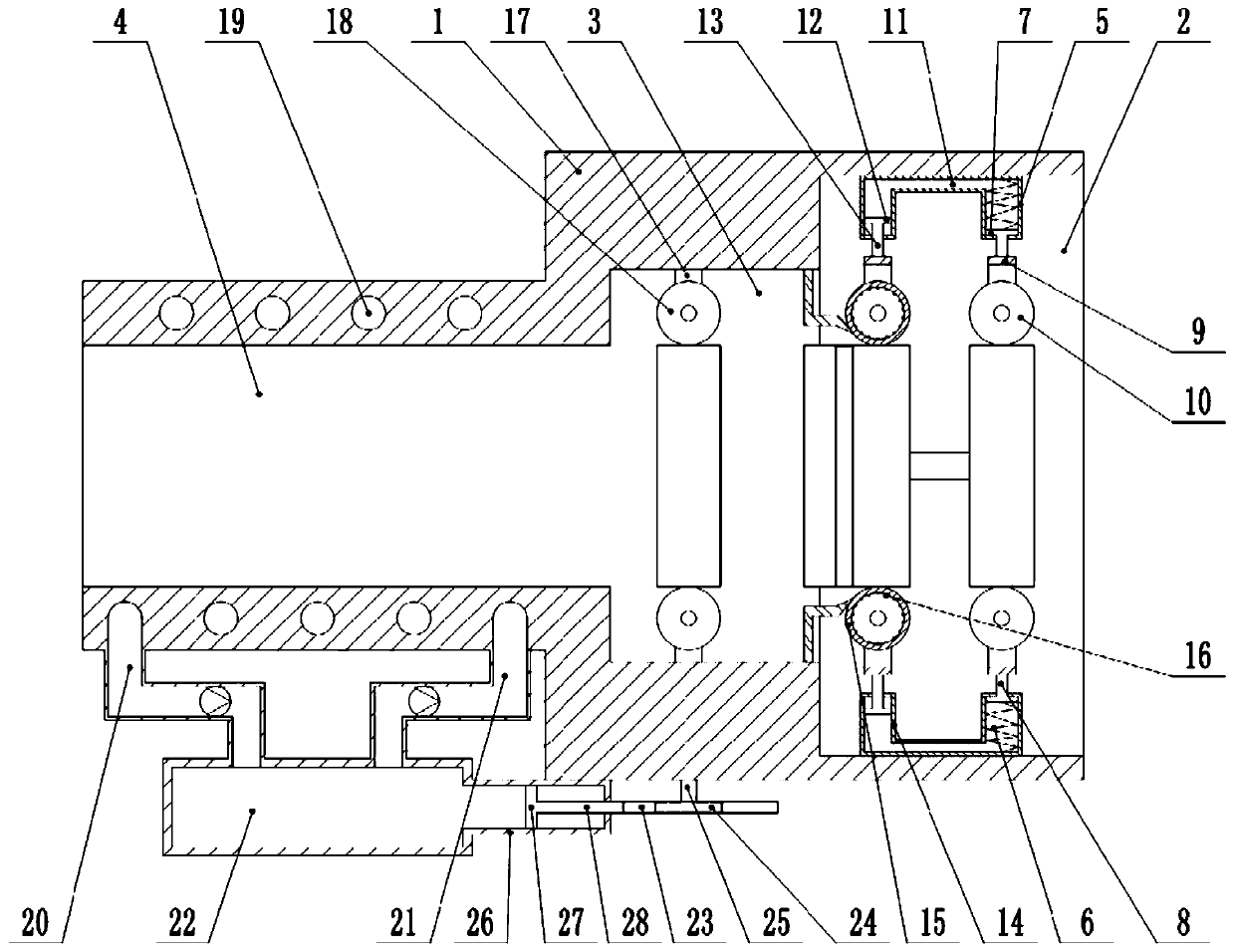

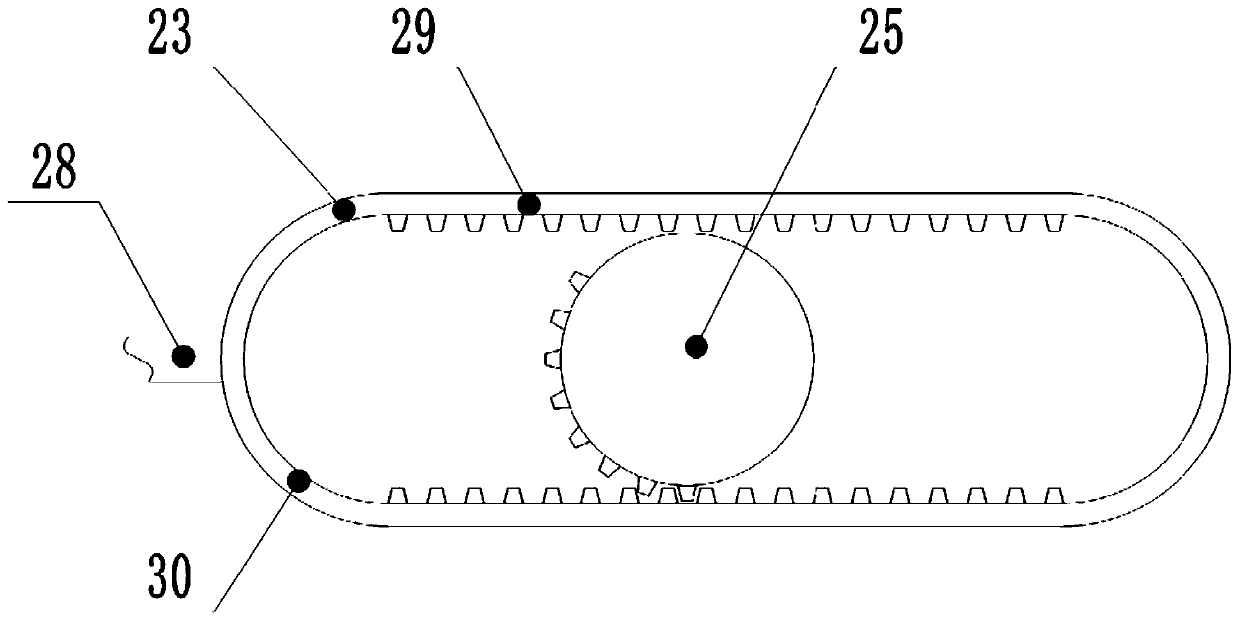

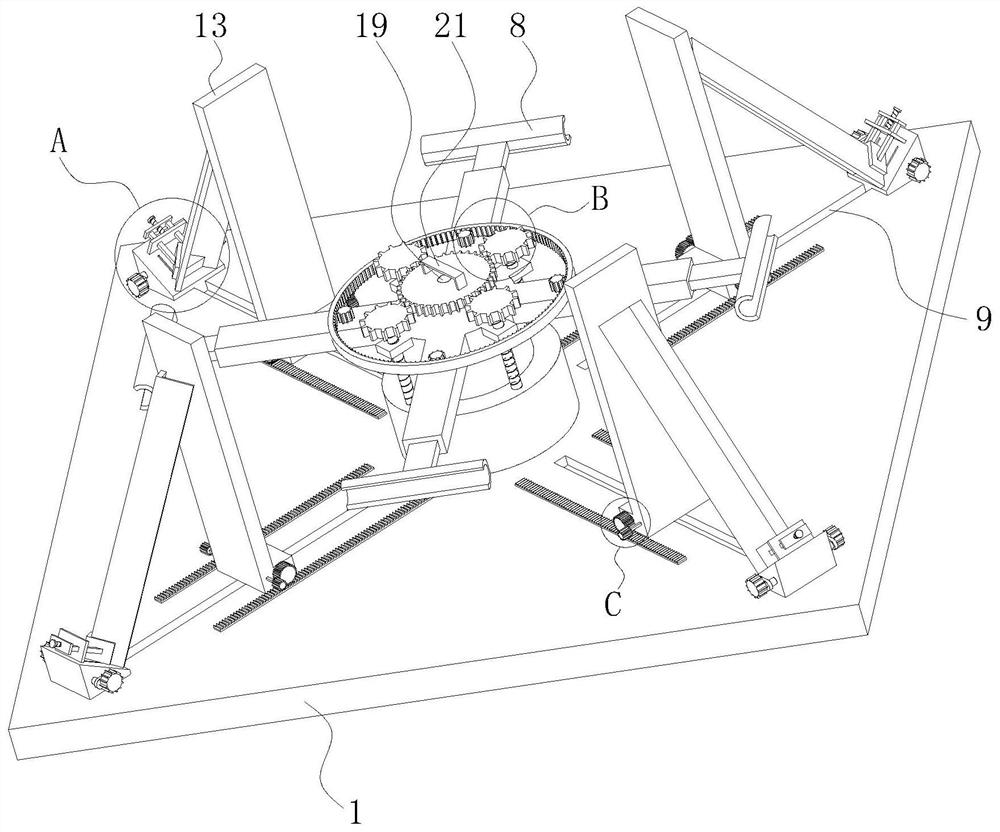

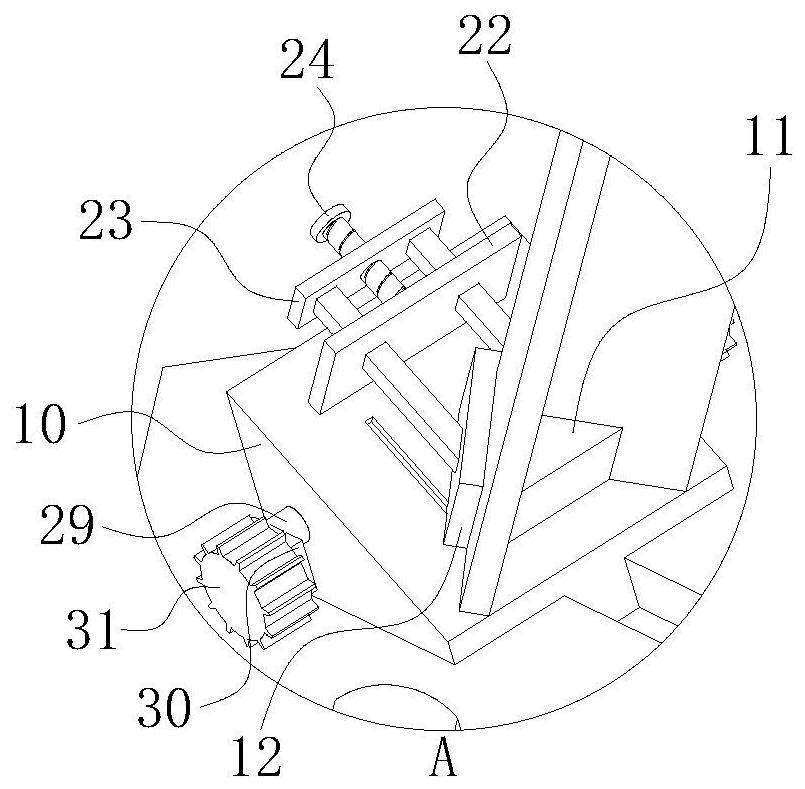

A carton board cutting and folding processing machine and processing method

ActiveCN112454990BReduce processing efficiencyGuaranteed shape rulesPaper-makingBox making operationsGear wheelCarton

The invention belongs to the technical field of carton manufacturing, and specifically relates to a carton board cutting and hemming processing machine and a processing method. The carton board cutting and hemming processing machine includes a base, the top surface of the base is provided with a square groove; the outer wall of the base A receiving frame is installed on the top; a cutting mechanism is installed above the receiving frame; the inner wall of the square groove slides vertically with a sealing plate; the bottom surface of the base is rotated and installed with a threaded column; the bottom of the threaded column is vertically fixed and installed with a gear column; A reciprocating motor is installed on the surface, and gears are installed on the output shaft of the reciprocating motor; a limit frame that cooperates with the edge of the carton board is fixed and fixed horizontally on the upper surface of the base; four unloading mechanisms are uniformly arranged on the base. The present invention can ensure that the side walls of the folded carton are in a vertical state, and ensure the regular shape of the carton after bonding; the present invention does not need to manually collect cutting waste materials, and is easy to operate and high in processing efficiency.

Owner:WUHAN YADU CHAODA PACKAGING PRINTING

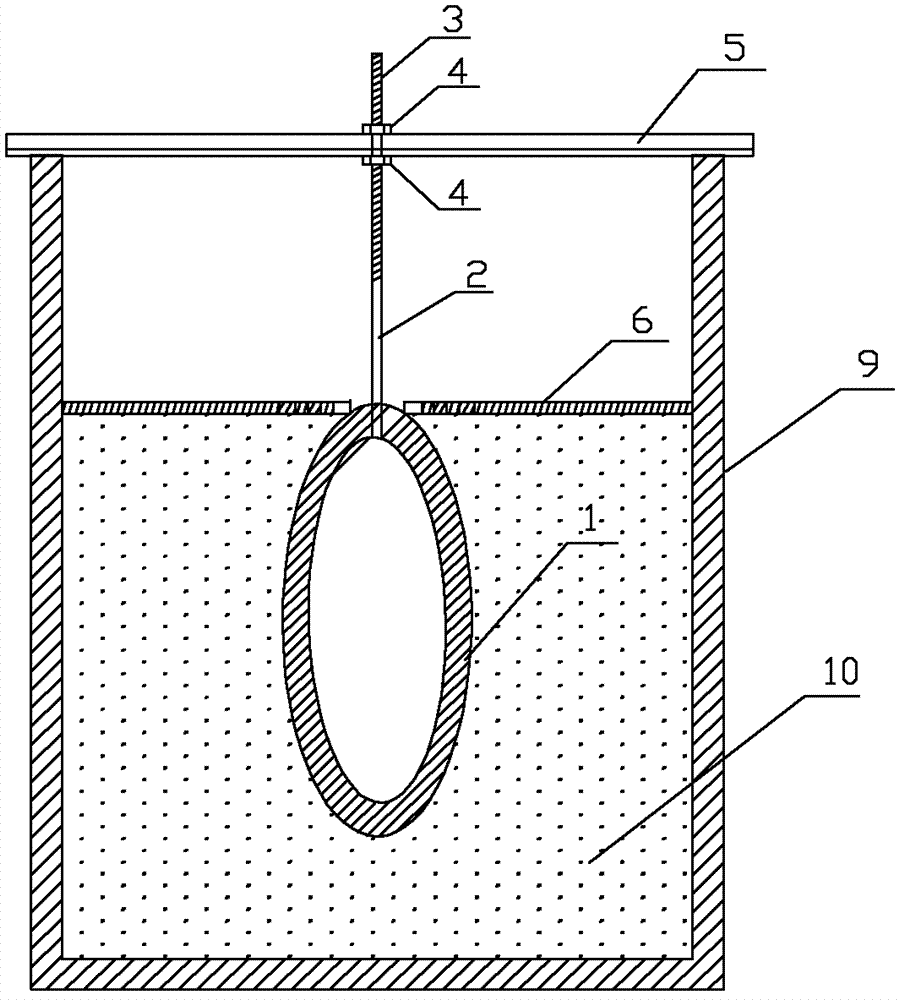

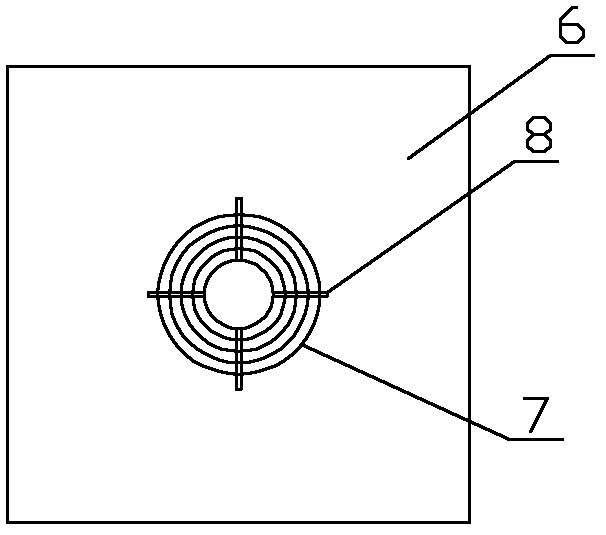

Method for positioning and forming hidden and buried grotto in geomechanical model test

The invention relates to a method for positioning and forming a hidden and buried grotto in a geomechanical model test. The method comprises the following steps of: 1) manufacturing a wooden mould which has the same shape as the grotto, fixing a positioning steel rod in the middle at the top of the wooden mould of the grotto, connecting the positioning steel rod with a steel cross beam on a model frame through a positioning bolt, and moving the positioning steel rod up and down by translating the steel cross beam and rotating the positioning bolt to position the hidden and buried grotto precisely; 2) according to the spatial shape of the wooden mould of the grotto, manufacturing a high-strength pressing plate with steel lantern rings which are concentric and have different diameters, and compacting a model material layer by layer by using the high-strength pressing plate; and 3) moving the positioning steel rod up by rotating the positioning bolt, and pulling out the wooden mould to form a modeled hidden and buried grotto. By adopting the method, the modeled hidden and buried grottoes with different shapes and different diameters can be manufactured; the spatial precise positioning of the hidden and buried grotto can be realized; the interference of the model material on the periphery of the grotto in the grotto forming process is reduced; and standard shape, smooth inner wall and uniform and compact peripheral material of the grotto are effectively ensured.

Owner:SHANDONG UNIV

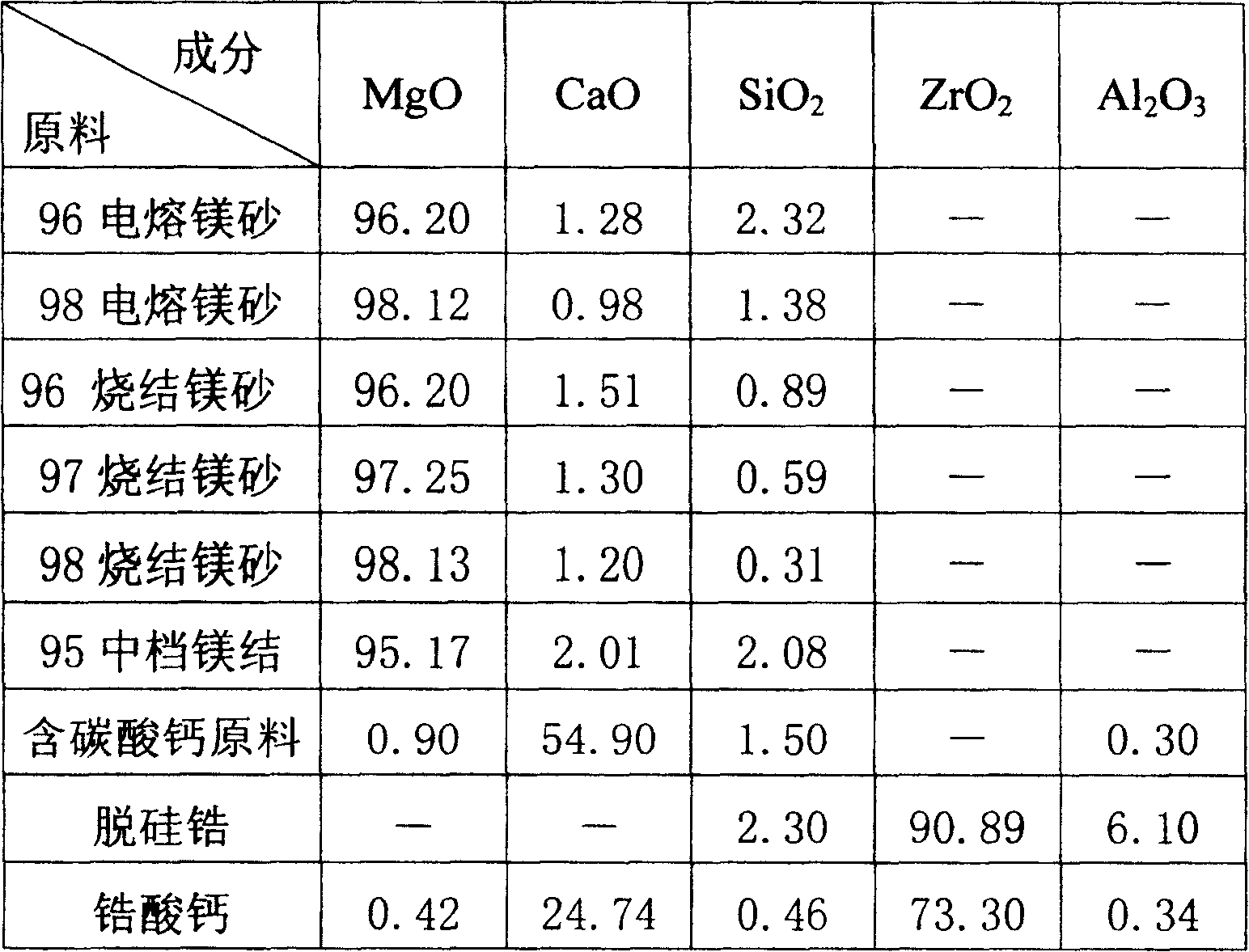

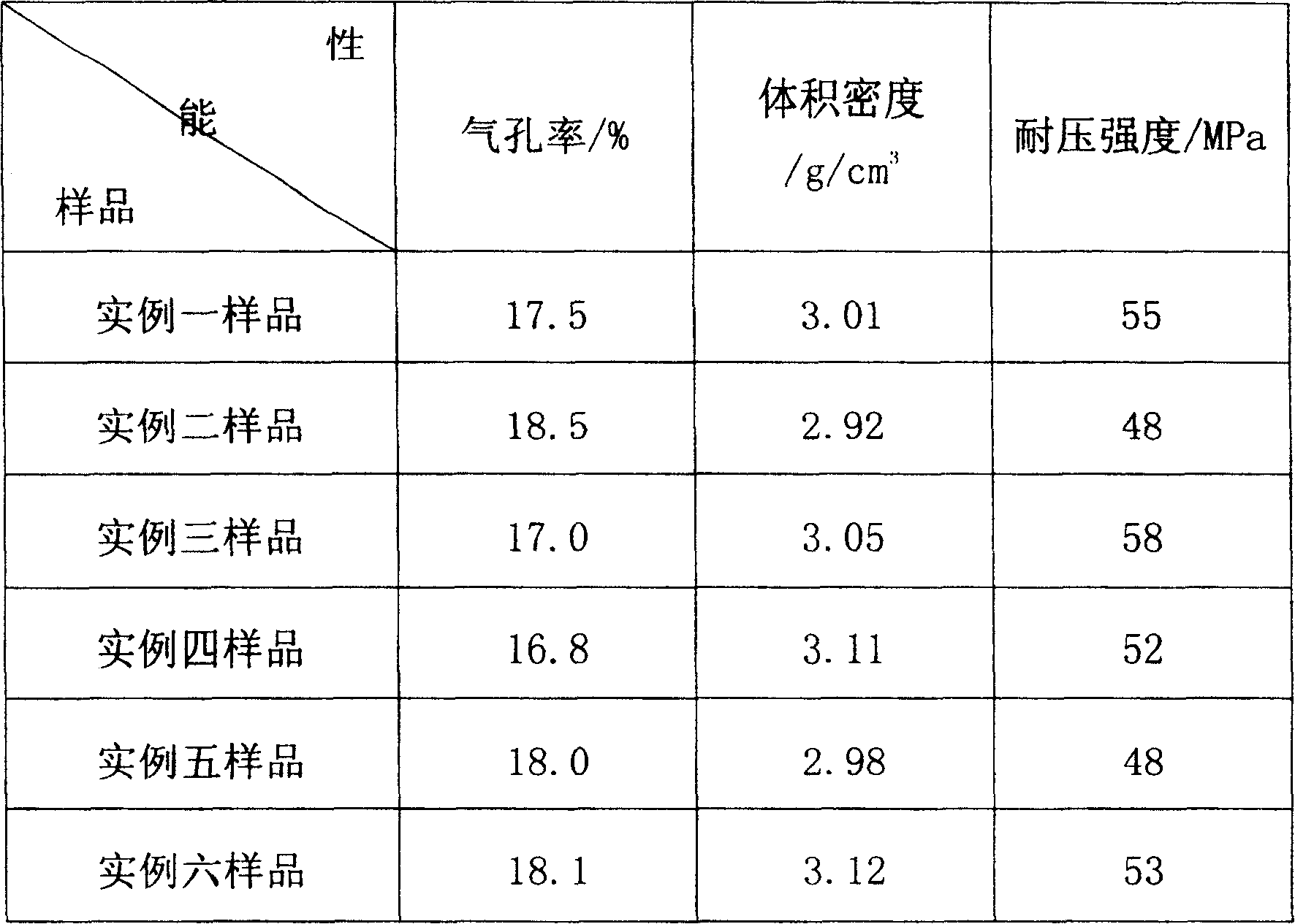

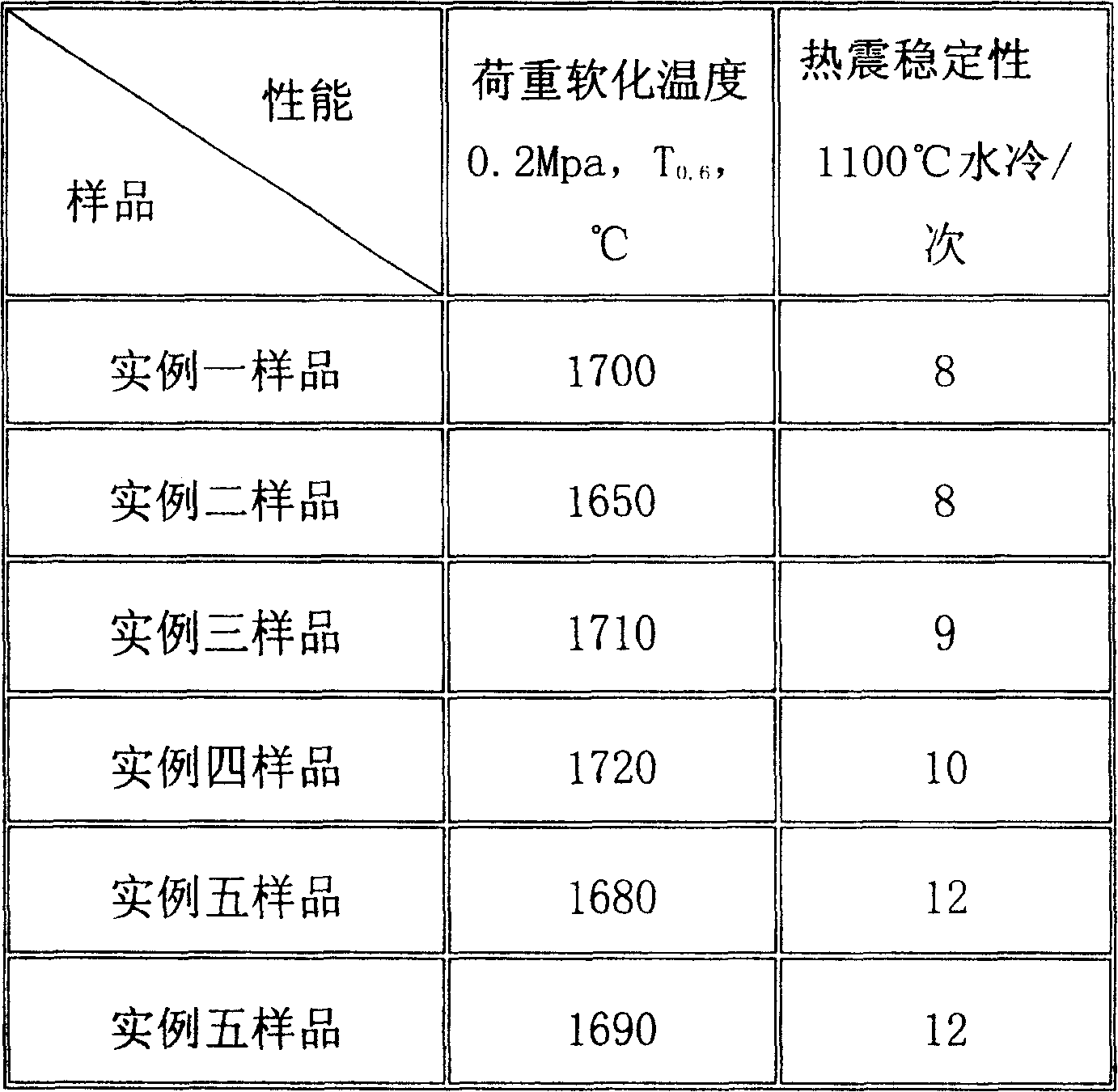

MgO-CaO-ZrO2 brick for cement kiln high-temperature zone and its preparation method

The invention discloses MgO-CaO-ZrO2 bricks for cement kiln hot zones, wherein the components include magnesite clinker or fused magnesia sand containing 94-99% of magnesium oxide 75-85%, light calcium carbonate 3-13%, zirconium dioxide 2-10% or calcium zirconate 2-6%, iron-oxide red as addition agent 1-4%, and balancing sulfite black liquor as binder bonding agent. The invention also discloses a process for making the MgO-CaO-ZrO2 bricks.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

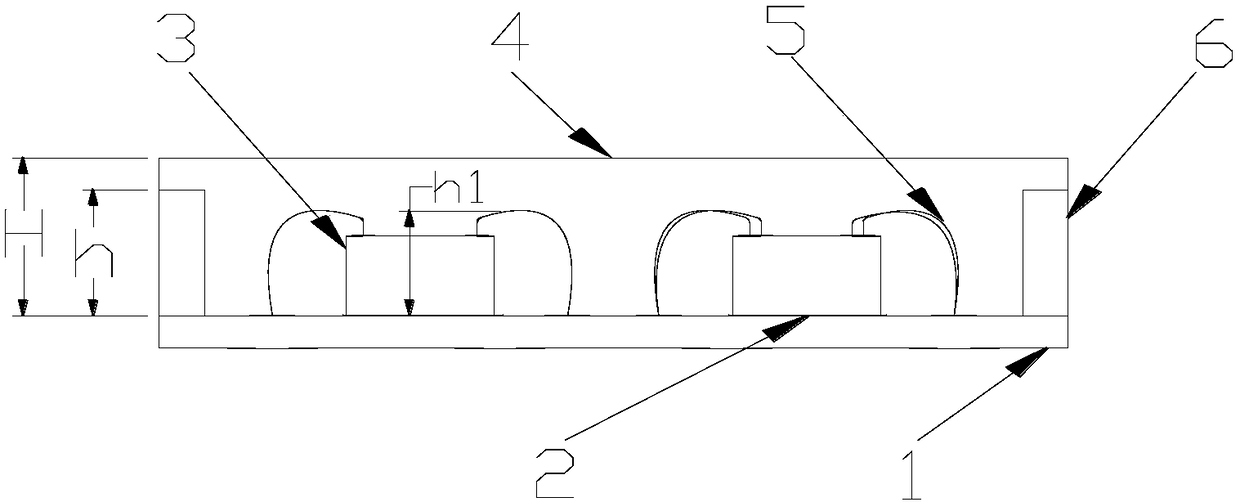

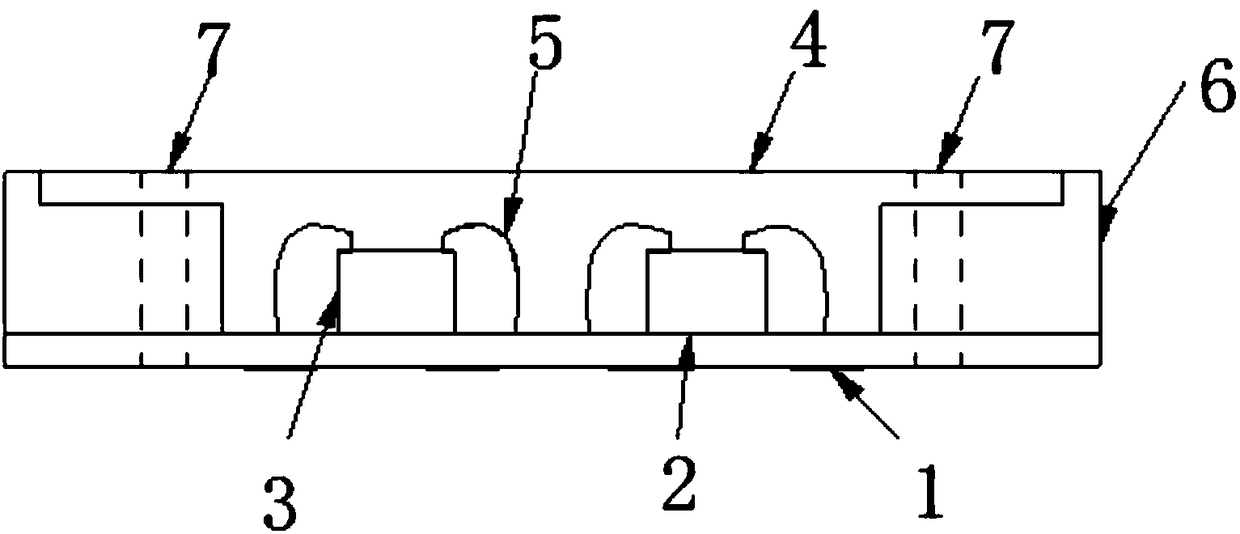

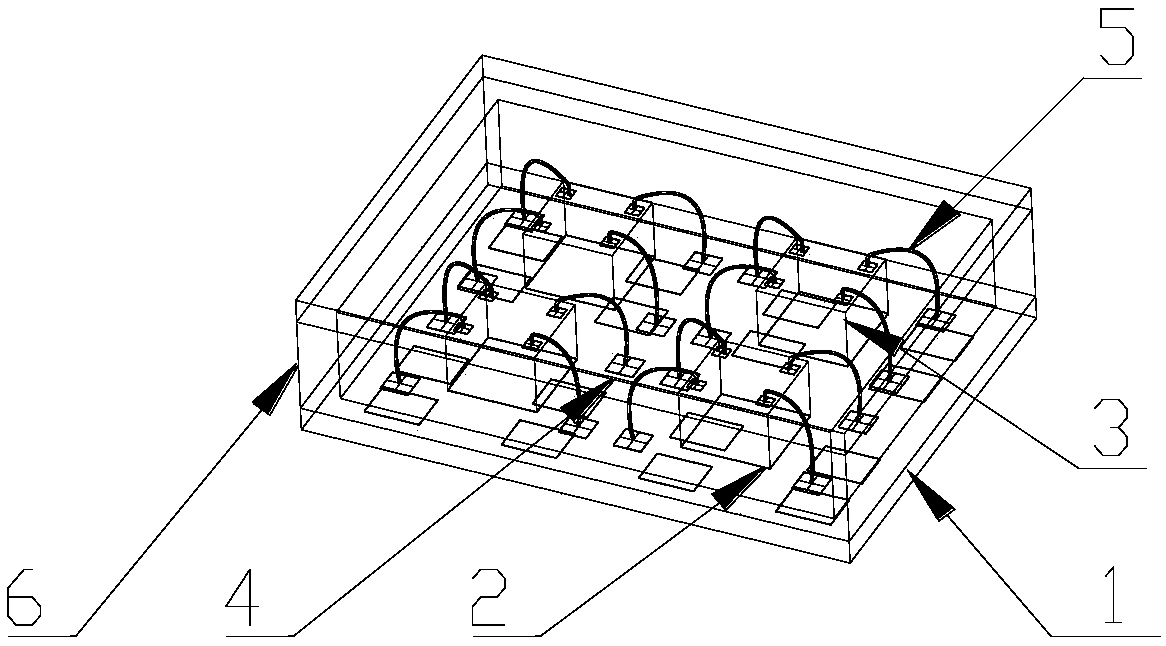

Pressure sensor package structure and package method

PendingCN108328562AGuaranteed surface flatnessImprove performanceDecorative surface effectsCatheterColloidForce sensor

The invention discloses a pressure sensor package structure and package method. The structure comprises a package substrate, the edge of the package substrate is provided with a circle of rigid colloid, a hollow cavity is formed in the rigid colloid, a chip is arranged in the hollow cavity, a bonding pad of the chip is connected to the bonding pad of the package substrate through a gold wire, andthe gold wire is curved; the interior of the hollow cavity and the upper surface of the rigid colloid are filled with the flexible colloid; the distance from the top surface of the flexible colloid tothe package substrate is H, the distance from the top surface of the rigid colloid to the package substrate is h, the distance from the vertex of the gold wire to the package substrate is h1, and H>h>h1 is satisfied. The chip is pasted onto the package substrate by adhesive bonding. The pressure sensor package structure disclosed by the invention not only ensures the shape regularity of the product but also has the rigidity to achieve the purpose of protecting the chip and the gold wire in the case of ensuring the excellent performance of the pressure sensor, and the surface flatness of the potting colloid is ensured by a process method.

Owner:山东盛芯电子科技有限公司

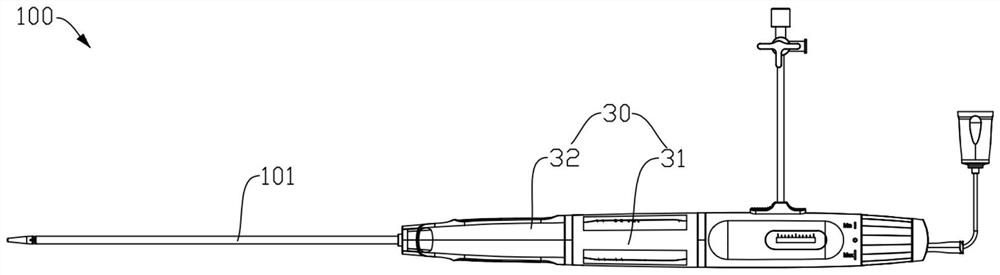

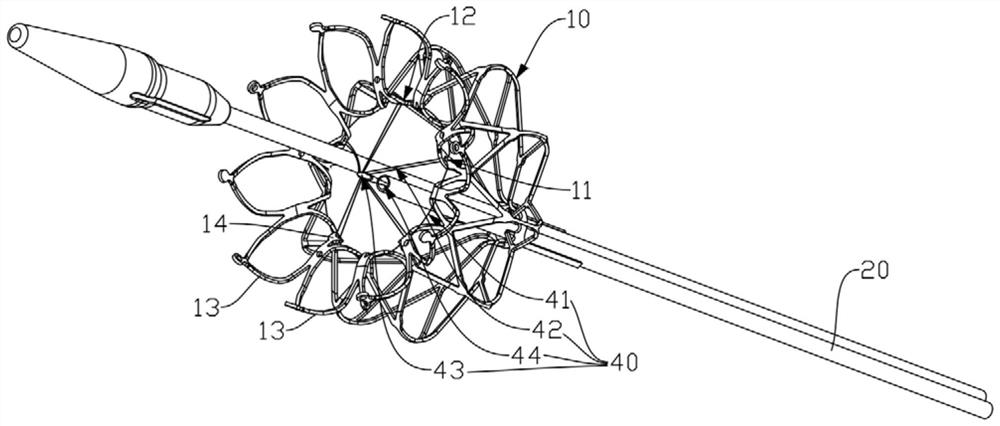

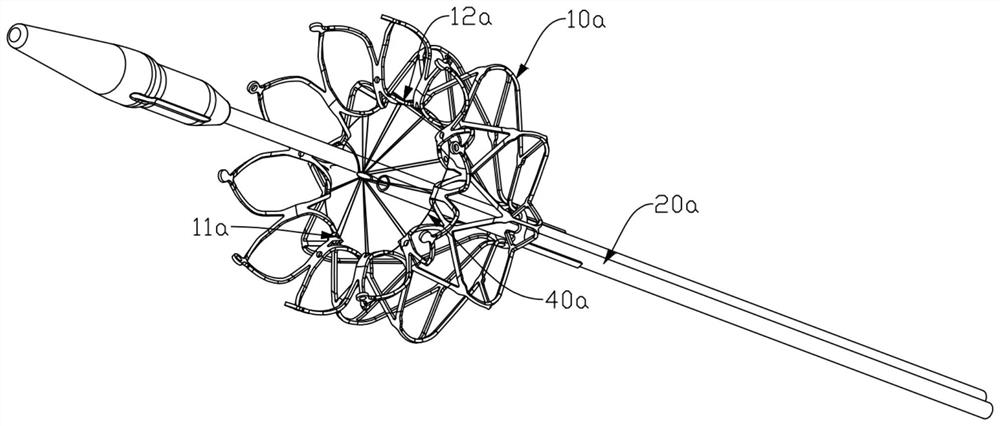

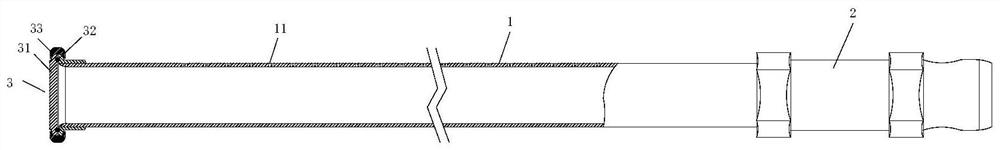

Atrial septal stoma device

PendingCN114052889AReduce in quantitySmall diameterSurgical instruments for heatingAtrial septumMutual influence

The invention provides an atrial septal stoma device. The atrial septal stoma device comprises an elastic supporting frame, a handle and at least one diameter adjusting line. The waist part of the elastic supporting frame is provided with an electrode for ablating target tissues, and the waist part of the elastic supporting frame is also provided with a plurality of threading holes along the circumferential direction. The diameter adjusting lines are wound among the threading holes and are connected with the handle, the handle pulls the diameter adjusting lines so as to change the diameter of the waist part, and one diameter adjusting line penetrates through at least three threading holes. According to the atrial septal stoma device, the number of the diameter adjusting lines is reduced, the winding mode of the diameter adjusting lines on the elastic supporting frame is simplified, and the smoothness of pulling the diameter adjusting lines is improved. And after the number of the diameter adjusting lines is reduced, mutual influence is weak in the size condition process, the elastic supporting frame is stressed more uniformly, and it can be guaranteed that the shape of a flow dividing channel is regular.

Owner:HANGZHOU NOYA MEDTECH CO LTD

Honeycomb paperboard composite gluing device, gluing method and honeycomb board and honeycomb paperboard tray prepared by using honeycomb paperboard composite gluing device

PendingCN112718383AGuaranteed uniformityGuaranteed accuracyLiquid surface applicatorsLaminationHoneycombManufacturing engineering

The invention discloses a honeycomb paperboard composite gluing device, a gluing method and a honeycomb board and a honeycomb paperboard tray prepared by using the device. The honeycomb paperboard composite gluing device comprises a glue spraying pipe with two through ends; a plurality of groups of paired glue spraying holes are arranged on the glue spraying pipe at equal intervals; one end of the glue spraying pipe is connected with a glue inlet joint for glue inlet of an external glue pipe; and the other end of the glue spraying pipe is connected with an end socket for plugging. According to the honeycomb paperboard composite gluing device provided by the invention, a glue spraying mode is adopted, gluing is uniform, positioning is convenient, and the glue spraying accuracy can be guaranteed; and the honeycomb paperboard, an upper composite paper (board) and a lower composite paper (board) are all made of double-sided Cobb paper, so that the paper cost is greatly reduced, and meanwhile, the processing and the preparation are convenient.

Owner:海宁市华升包装有限公司

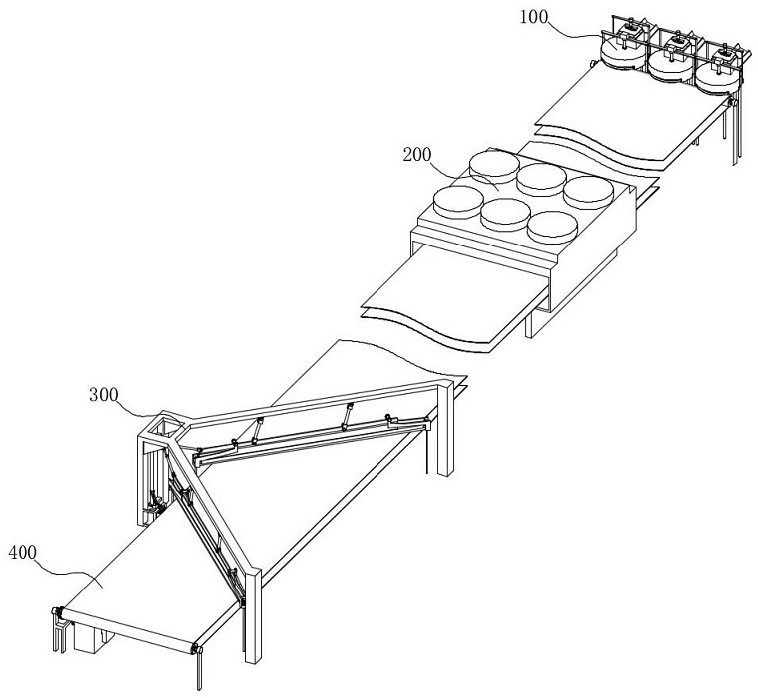

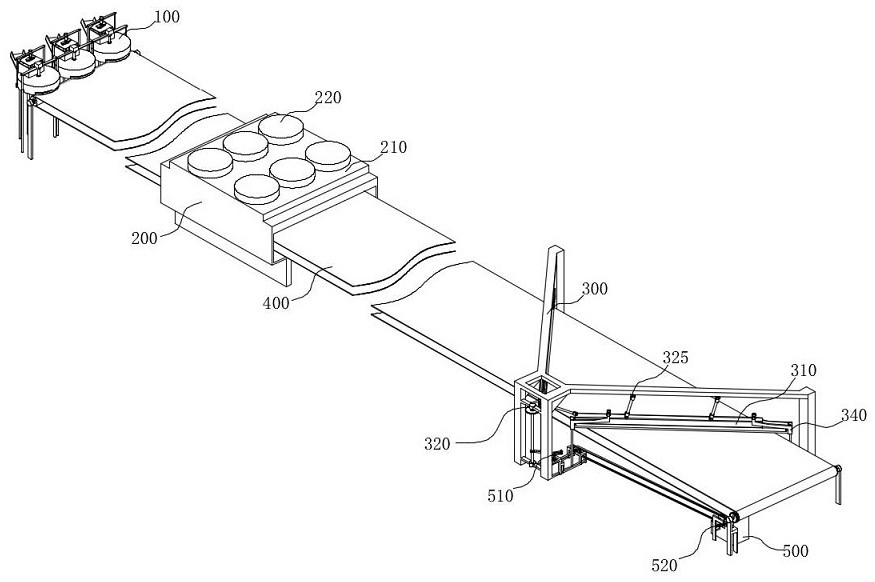

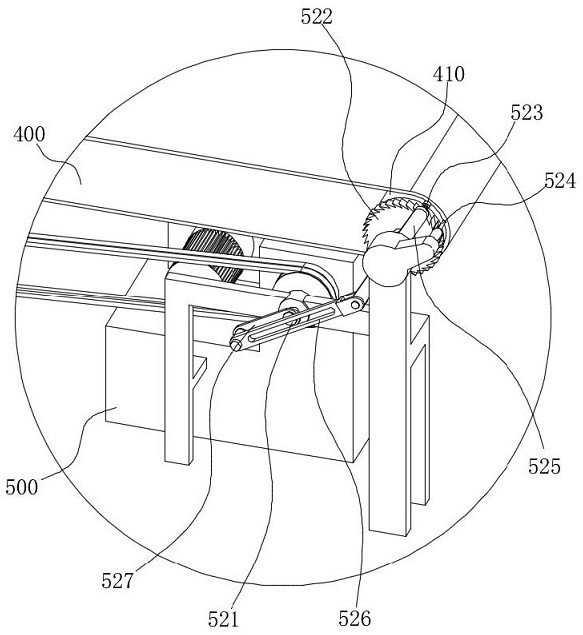

Traditional Chinese medicine raw material dicing device capable of reducing breakage rate

The invention relates to a traditional Chinese medicine raw material dicing device capable of reducing breakage rate. The traditional Chinese medicine raw material dicing device capable of reducing the breakage rate comprises a machine frame, wherein a conveying belt is installed on the machine frame, two dicing cutters distributed in a right angle shape are arranged on the conveying belt, cutterfaces of the dicing cutters are perpendicular to the belt face of the conveying belt, the dicing cutters are connected with an adjustment mechanism A, the adjustment mechanism A is used for adjustingthe two dicing cutters to respectively advance to cut flaky medicine materials in corresponding cutting directions, and the cutting direction of each dicing cutter is parallel to the cutter face of each dicing cutter, and inclines down and points to the direction of the conveying belt. The traditional Chinese medicine raw material dicing device capable of reducing the breakage rate is stable in structure, reasonable in layout, stable in running, capable of achieving continuous dicing processing for traditional Chinese medicine raw materials, and capable of effectively reducing the dicing breakage rate, and meets current use requirements.

Owner:岳西神农氏农业科技有限公司

An easy-to-move transport fixture for selling 3D printers

ActiveCN108438029BEasy to moveMobile 3D printer sales and transportationHand carts with multiple axesHand cart accessoriesEngineeringIdler-wheel

Owner:平邑现代中药产业园有限公司

A traditional Chinese medicine raw material dicing device that reduces the broken rate

ActiveCN110465984BWon't crushReduce breakage rateMetal working apparatusMedicinal herbsBreakage rate

The invention relates to a traditional Chinese medicine raw material dicing device capable of reducing breakage rate. The traditional Chinese medicine raw material dicing device capable of reducing the breakage rate comprises a machine frame, wherein a conveying belt is installed on the machine frame, two dicing cutters distributed in a right angle shape are arranged on the conveying belt, cutterfaces of the dicing cutters are perpendicular to the belt face of the conveying belt, the dicing cutters are connected with an adjustment mechanism A, the adjustment mechanism A is used for adjustingthe two dicing cutters to respectively advance to cut flaky medicine materials in corresponding cutting directions, and the cutting direction of each dicing cutter is parallel to the cutter face of each dicing cutter, and inclines down and points to the direction of the conveying belt. The traditional Chinese medicine raw material dicing device capable of reducing the breakage rate is stable in structure, reasonable in layout, stable in running, capable of achieving continuous dicing processing for traditional Chinese medicine raw materials, and capable of effectively reducing the dicing breakage rate, and meets current use requirements.

Owner:岳西神农氏农业科技有限公司

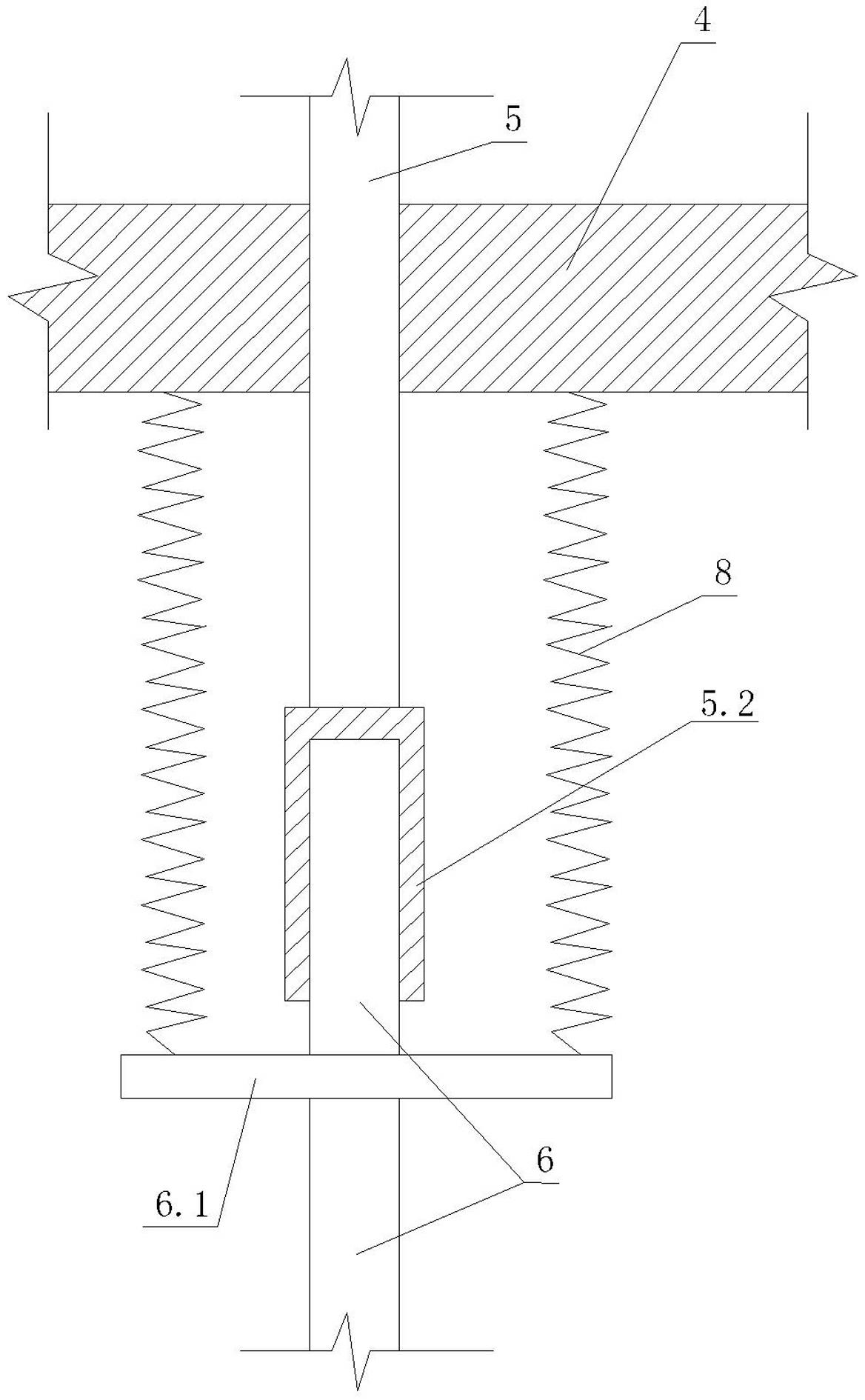

Tool for adding alloy fusible core to fuse link

The invention discloses a tool for adding an alloy fusible core to a fuse link, which comprises a fused liquid tank (1) with a liquid outlet nozzle (1.4), an air pump (2),a travel switch (3), a workbench (4), a slide bar (5) and a guide bar (6) for touching the travel switch (3), wherein an opening (1.1) and an air-suction inlet (1.2) are formed at the upper end of the fused liquid tank (1), a sealing cover (1.3) is arranged on the opening (1.1), the air-suction inlet (1.2) is communicated with the air pump (2), the fused liquid tank (1) is connected with the slide bar (5), a chute (7) matched with the slide bar (5) is arranged on the workbench (4), the lower end of the slide bar (5) is movably sleeved with the guide bar (6), a tension spring is arranged between the guide bar (6) and the workbench (4), a backing plate (10) is arranged on the workbench (4), and a pit (10.1) just opposite to the liquid outlet nozzle (1.4) is formed on the backing plate (10). The tool is convenient, efficient, and accurate.

Owner:宁波莱堡智能电气科技有限公司

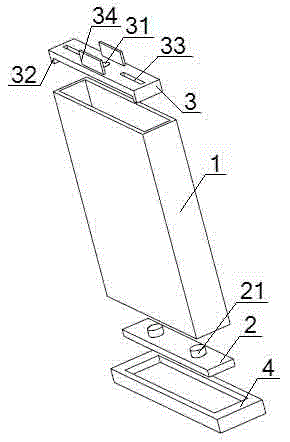

A kind of soft package lithium-ion battery shape injection molding device and using method thereof

The invention provides a soft package lithium-ion battery shape injection molding device, comprising a fixture, a lower cover and an upper cover, wherein a square structure with openings at two ends is adopted as the fixture; the inner side of the top part and the inner side of the bottom part of the fixture are hermetically matched with the upper cover and the lower cover respectively; a base is sleeved outside the bottom part of the fixture; a handle is arranged on the top part of the upper cover; two ends of the bottom part of the upper cover are provided with corner pads; a glue injection hole and a polar lug hole are also formed in the upper cover; a support pillar is arranged on the top part of the lower cover; the materials of the fixture, the lower cover and the upper cover are all die steels; the material of the base is rubber; in use, de-molding agent is evenly sprayed to the bottom part of the upper cover, the inner wall of the fixture and the top part of the lower cover firstly, and drying; then assembling the upper cover, the fixture and the lower cover; and then injecting glue into the injection molding device and curing the injected glue; finally, disassembling the upper cover, the fixture and the lower cover. Due to the adoption of the device, the shape of the monomer battery is completely protected, the regular shape of the injected monomer battery is guaranteed, and furthermore the service life of the injection molding device is prolonged.

Owner:DONGFENG COMML VEHICLE CO LTD

A kind of cable production and processing equipment

ActiveCN108492937BRealize repair processingWon't pushInsulating conductors/cablesElectrical conductorInsulation layer

The invention belongs to special equipment or method for manufacturing a conductor or a cable, and particularly discloses cable production processing equipment. The cable production processing equipment comprises a shell, wherein a detection hot melting cavity is formed in the shell, a detection cylinder and an extrusion cylinder are arranged on a side wall of the detection hot melting cavity, a pipeline is arranged between the detection cylinder and the extrusion cylinder and communicates with the detection cylinder and the extrusion cylinder, a detection piston plate and an extrusion pistonplate are respectively and hermetically arranged in the detection cylinder and the extrusion cylinder in a sliding way, the detection piston plate and the extrusion piston plate are respectively provided with a detection piston rod and an extrusion piston rod, one end, far away from the detection hot melting cavity, of the detection piston rod and one end, far away from the detection hot melting cavity, of the extrusion piston rod respectively extend out of the detection cylinder and the extrusion cylinder, a detection positioning rack and an extrusion positioning rack are respectively arranged at one end, far away from the detection hot melting cavity, of the detection piston rod and one end, far away from the detection hot melting cavity, of the extrusion piston rod, a detection roller and an extrusion roller are respectively and rotatably arranged on the detection positioning rack and the extrusion positioning rack, an electric heating wire is arranged in the extrusion roller, and the detection roller and the extrusion roller are encircled to form a square. By the cable production processing equipment, the problem that a square cable cannot be processed again due to air bubblesin an insulation layer during square cable manufacturing is solved.

Owner:曾广君

Foaming material multi-specification slitting equipment

PendingCN113733171AAvoid leaningGuaranteed shape rulesMetal working apparatusProduct processingEngineering

The invention provides foaming material multi-specification slitting equipment, and belongs to the technical field of bean product processing. The foaming material multi-specification slitting equipment comprises a workbench, a conveying belt is arranged on the workbench, stabilizing plates are arranged on the two sides of the conveying belt, and limiting grooves are formed in the stabilizing plates; a cutting device comprises two parallel fixing edges, a first cutting line, a second cutting line intersecting with the first cutting line and a hydraulic rod fixedly connected with the fixing edges, and the first cutting line and the second cutting line form a cutting hole. According to the foaming material multi-specification slitting equipment, during cutting, the area of the cutting holes can be adjusted and controlled by adjusting the distance between the second cutting lines and the inclination degree, so that the quality and the shape of a cut finished foaming material are controlled, the shapes of the cutting holes can be different, and foaming materials of different shapes and weights can be cut at the same time; and the stabilizing plate is arranged, so that inclination of the foaming material in the cutting process can be effectively prevented, and it can be guaranteed that the shape of the cut foaming material is regular.

Owner:ZHEJIANG RUNYANG NEW MATERIAL TECH

Foam sheet machine pre-storage material device capable of effectively preventing particle damage

The invention relates to the field of production of thermal insulation sheets, and in particular, relates to a foam sheet machine pre-storage material device capable of effectively preventing particledamage, wherein the device includes a feeding pipe, a pre-storage hopper having the top communicating with the feeding pipe, and a fan feeding mechanism. According to the device, a material is suckedby negative pressure, so a fan does not directly make contact with particles, the shape of the particles is prevented from being damaged, the regular shape of the particles after foaming molding is ensured, and the performance of thermal insulation sheets is ensured.

Owner:天津宇屹新材料科技发展有限公司

mold for prefabricated concrete

ActiveCN111844388BGuaranteed flatnessEffectively fixedMouldsMould auxillary partsRebarMechanical engineering

The application discloses a concrete prefabricated component mold, which includes a main body, a first slider, a second slider, an auxiliary connecting piece, a fixing block and a plurality of connecting rods, the main body includes a bottom plate and two opposite side plates, the first The slider is slidably connected with the bottom plate, the first slider is provided with a plurality of first installation holes, and the plurality of connecting rods are installed on the first slider, the second slider is slidably connected with the side plate, and the second slider is provided with The second mounting hole and the connecting hole, the second mounting hole is set corresponding to the first mounting hole, the connecting hole is set corresponding to the end of the connecting rod away from the first slider, the auxiliary connecting piece is provided with an auxiliary hole, and the fixing block is located at the first receiving groove. At one end, the steel bar is located in the corresponding first installation hole, limit hole and second installation hole. The concrete prefabricated component mold disclosed by the invention has simple structure and convenient operation, can quickly complete the installation and fixing of steel bars, and can easily separate the prefabricated component from the concrete prefabricated component mold.

Owner:SHAANXI CONSTR ENG GRP CO LTD THE FIRST BUILDING

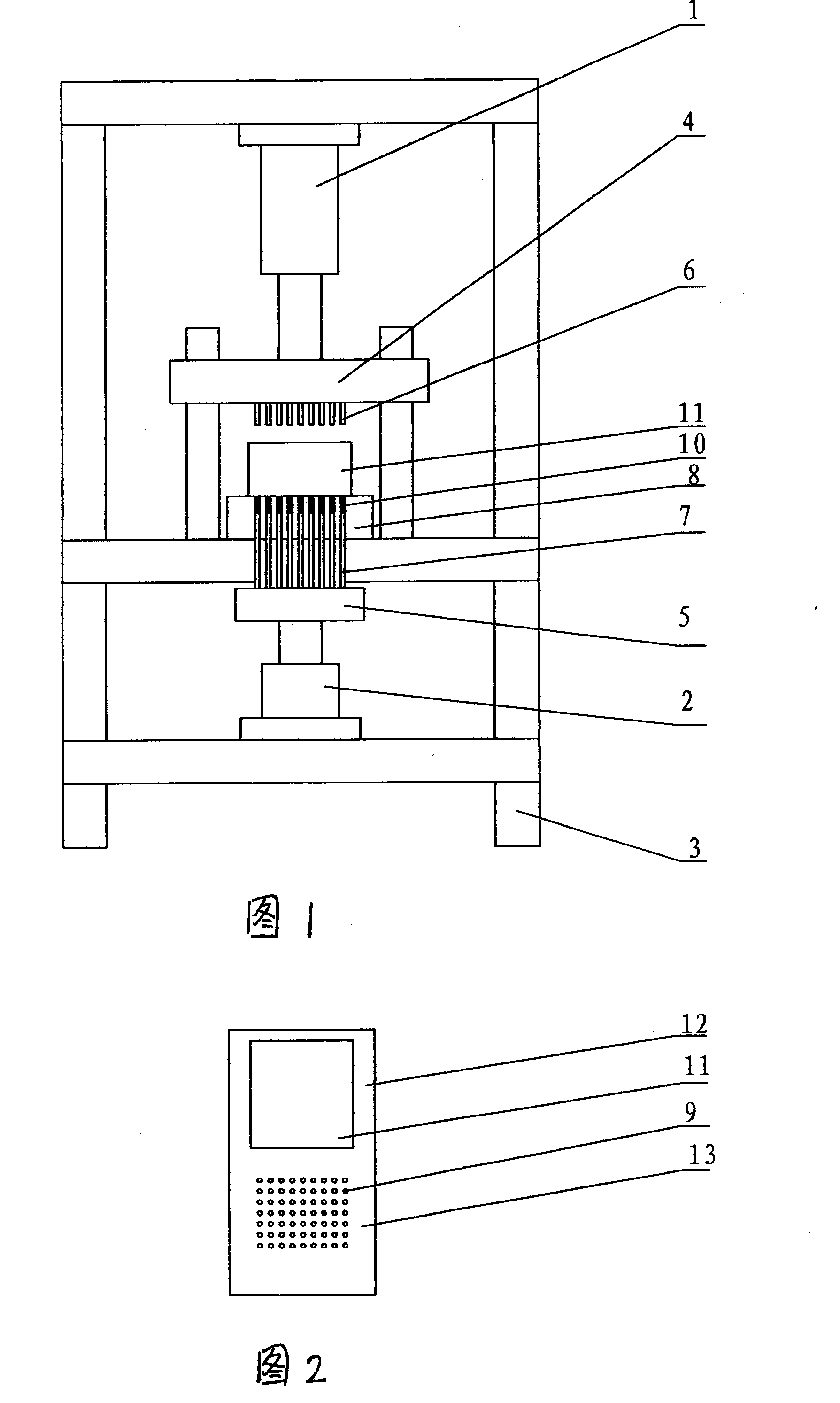

Equipment and method for preparing columnar amalgam in use for fluorescent lamp

InactiveCN101093780AEnsure consistencyGuaranteed shape rulesElectric discharge tubesGas discharge lamp detailsPunchingNose

The equipment for preparing columned amalgam includes following parts: punching oil cylinder; up going oil cylinder and stand; up molding board installed on the punching oil cylinder; low molding board installed on the up going oil cylinder; punching needle being fixed on the up molding board; nose spike fixed on the low molding board; die hole set up on the bottom die. Top part of the nose spike is inside the die hole of the bottom die. Using press equipment and molding press method to produce columned amalgam, the invention guarantees consistent diameter and regular shape of amalgam so as to meet both requirements of technique and performance of fluorescent lamp.

Owner:程亚军

Pot hole drilling machine carried on vehicle

InactiveCN101705786BGuaranteed shape rulesGuaranteed progressConstructionsBorehole drivesFoundation engineeringCantilever

The invention relates to a pot hole drilling machine carried on a vehicle, belonging to foundation engineering construction machinery. The vehicle comprises a front axle, and the pot hole drilling machine comprises a cantilever, an oil pump, a hydraulic unit, a cantilever oil cylinder, a drill lifting mechanism and a drilling mechanism, wherein the lower end of the cantilever is hinged on the front axle; the oil pump is arranged on the front axle and is in transmission connection with a power output shaft of the vehicle; the hydraulic unit is fixedly arranged on the front axle and connected with a hydraulic oil circuit of the oil pump; the cantilever oil cylinder is arranged on the front axle, hinged with the cantilever and connected with an oil circuit of the hydraulic unit; the drill lifting mechanism is arranged on the cantilever and connected with a hydraulic oil circuit of the hydraulic unit; and the drilling mechanism is arranged at the upper end of the cantilever by suspending and connected with the oil circuit of the hydraulic unit and the drill lifting mechanism. The pot hole drilling machine not only can guarantee that the shapes of drilled pot holes are regular, but also has high working efficiency so as to guarantee the progress of construction engineering, and moreover, the labor intensity of constructors can be effectively lightened.

Owner:常熟市飞达汽车保养工具设备有限公司

A method for manufacturing and processing an assembled steel structure of a communication tower

The invention belongs to the technical field of communication equipment, and in particular relates to a method for manufacturing and processing an assembled steel structure of a communication tower, comprising the following steps: Step 1, cutting steel: cutting the angle steel into four main rods of equal length, and cutting the round pipe into four auxiliary rods of equal length; step 2, surface treatment: carry out hot-dip galvanized anticorrosion treatment on the surface of the main rod and auxiliary rod; step 3, welding and fixing: welding the main rod and auxiliary rod after surface treatment together to obtain Single-layer steel structure; wherein, Step 3 is completed with the cooperation of a communication tower to build an assembled steel structure manufacturing and processing device. The invention ensures that the inclination angles of the main rods are the same in the state to be welded, and that the four main rods are all inclined toward the axis of the guide cylinder; the invention ensures that the ends of the main rods in two adjacent single-layer steel structures can be accurately butt together.

Owner:湖南省通信建设有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com