Method for positioning and forming hidden and buried grotto in geomechanical model test

A model test and geomechanics technology, applied in underground chambers, earthwork drilling, mining equipment, etc., can solve problems such as easy formation of joints, great influence on test results, discontinuous physical and mechanical parameters, etc., to improve accuracy and Accuracy, even and dense material around the hole, and smooth inner wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

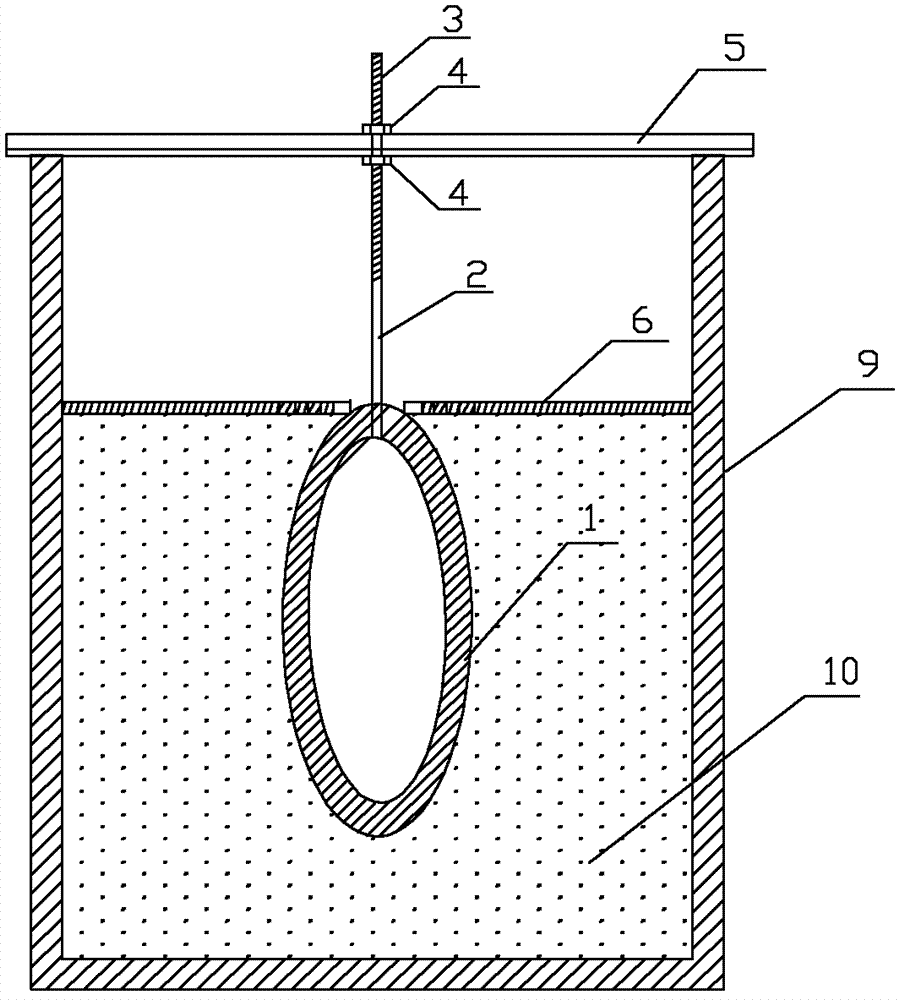

[0028] figure 1 Among them, a positioning steel rod 2 is fixed in the middle of the top of the cavity wooden formwork 1, and a precision thread 3 is tapped on the positioning steel rod 2, and the positioning steel rod 2 is connected with the steel frame set on the model frame 9 through the positioning bolt 4. Beam 5 is connected. Translating the steel beam 5 and rotating the positioning bolt 4 to move the positioning steel rod 2 up and down can realize the precise positioning of the buried cavity.

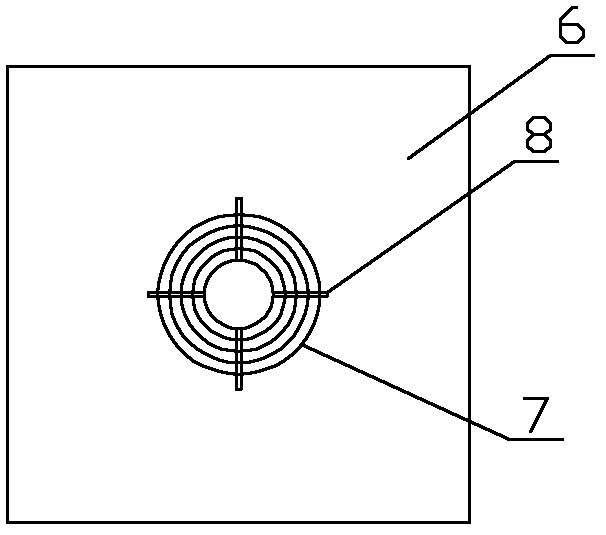

[0029] figure 2 , 3 There is a circular hole in the middle of the high-strength pressure plate 6, and a plurality of concentric and detachable steel collars 7 with different diameters are arranged on the outside of the hole. The steel collars 7 are connected together by inner hole pins 8, and the steel collars 7 is composed of several concentric rings c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com