Pressure sensor package structure and package method

A pressure sensor and packaging structure technology, applied in microstructure devices, manufacturing microstructure devices, microstructure technology, etc., can solve the problem of affecting pressure transmission, uneven contact between flexible colloid and cavity, and inability to effectively maintain product shape. Chip protection and other issues, to achieve excellent performance and ensure the effect of surface flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

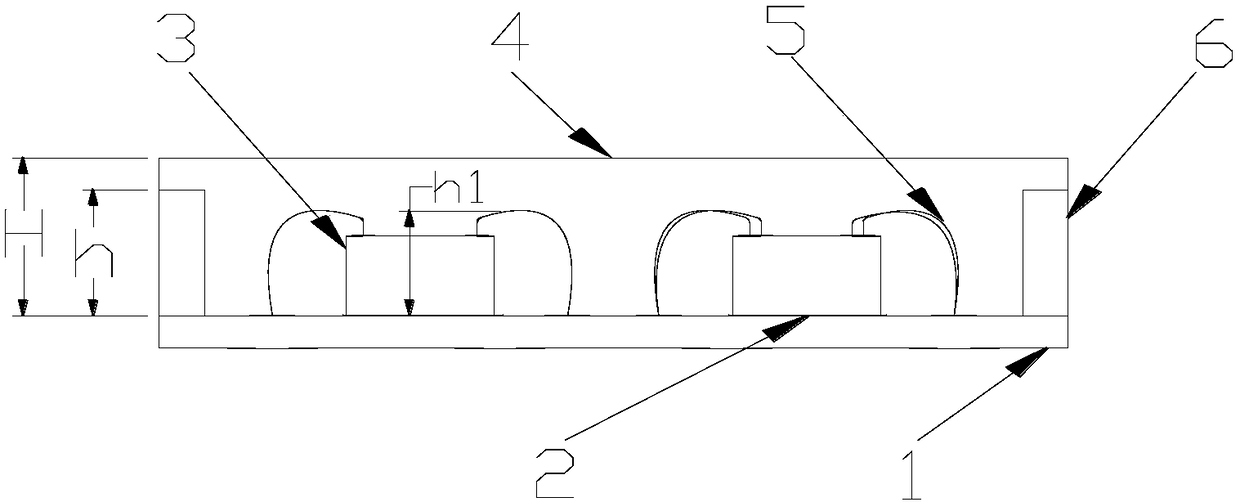

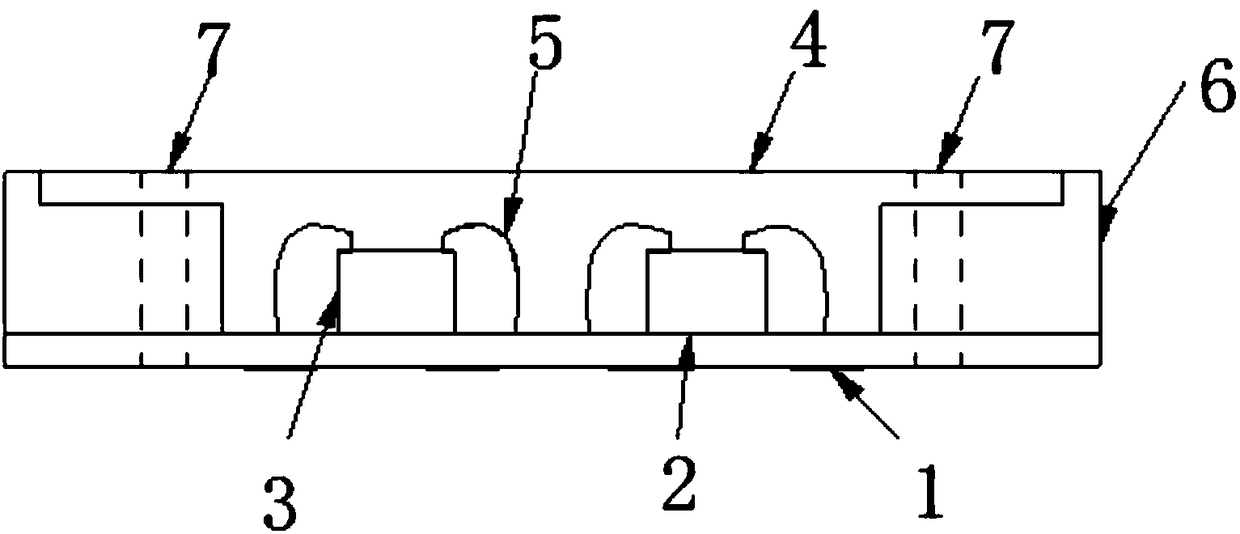

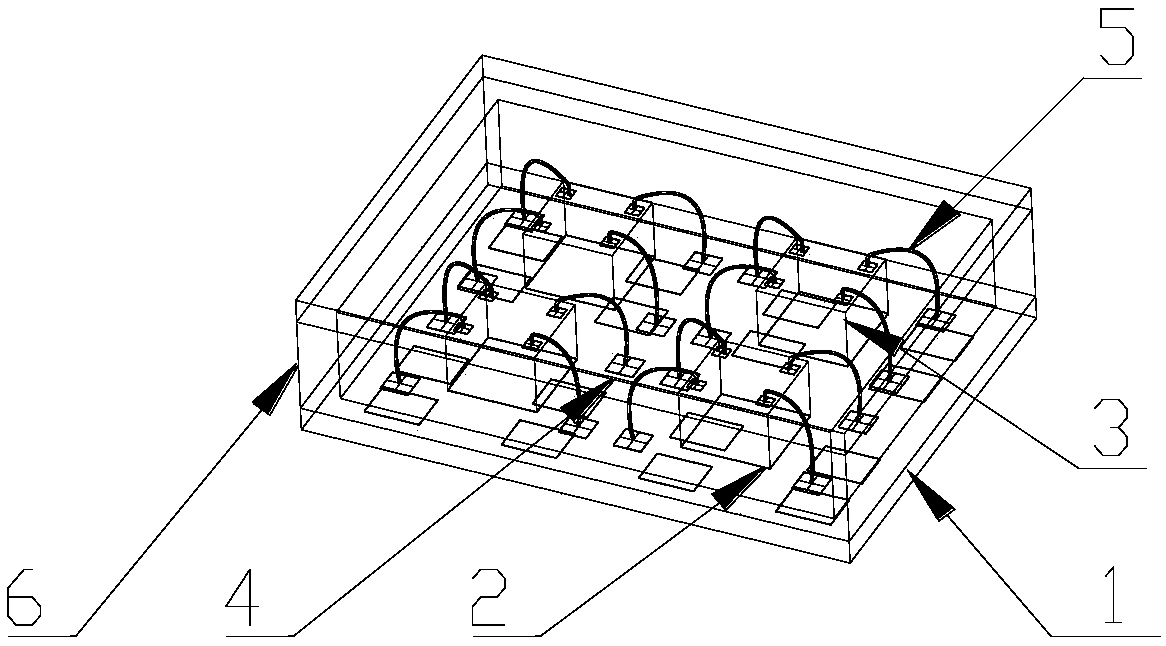

[0027] like figure 1 As shown, a pressure sensor packaging structure, the pressure sensor in this embodiment is a pressure sensor for pulse measurement, including a packaging substrate 1, including a rigid colloid 6 on the packaging substrate, and the rigid colloid 6 is arranged around the packaging substrate 1 , enclosing a cavity, the cavity is provided with a chip 3, the chip is pasted on the package substrate through the adhesive 2, the pad of the chip is connected with the pad of the package substrate through the gold wire 5, and the gold wire forms an arc shape; the cavity and the upper surface of the rigid colloid are filled with flexible colloid 4.

[0028] The distance from the top surface of the flexible colloid to the packaging substrate is H, the distance from the top surface of the rigid colloid to the packaging substrate is h, the distanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com