Foaming material multi-specification slitting equipment

A foam material, multi-specification technology, applied in the field of foam material multi-specification slitting equipment, can solve the problems affecting cutting accuracy, foam material deformation, single shape, etc., to achieve convenient packaging, prevent tilting, and regular shape. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

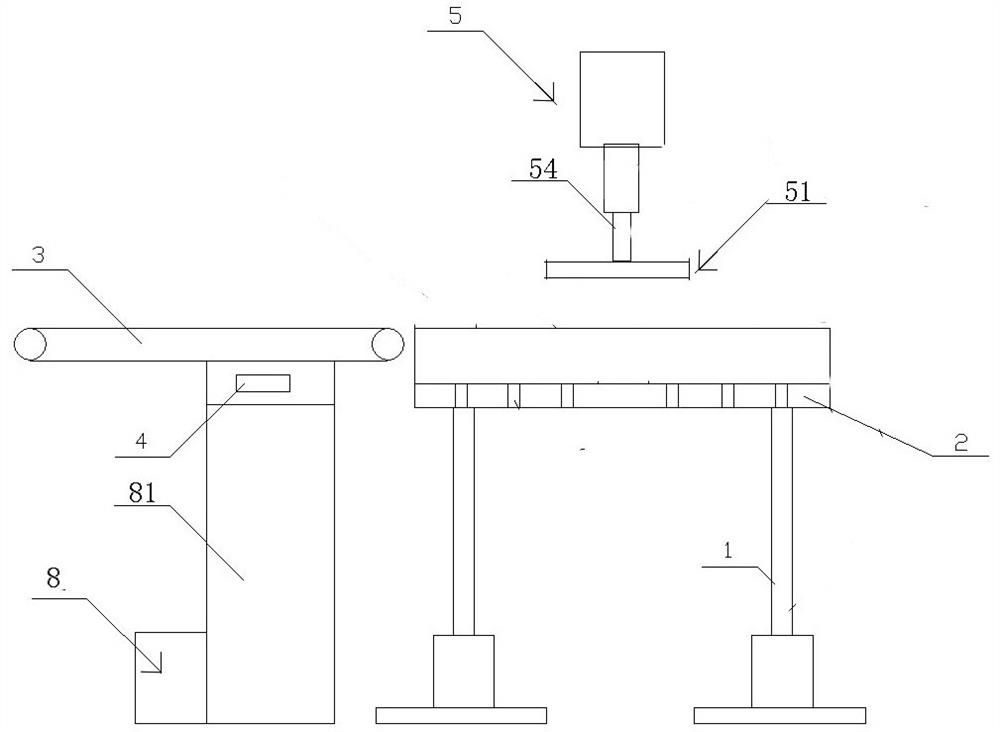

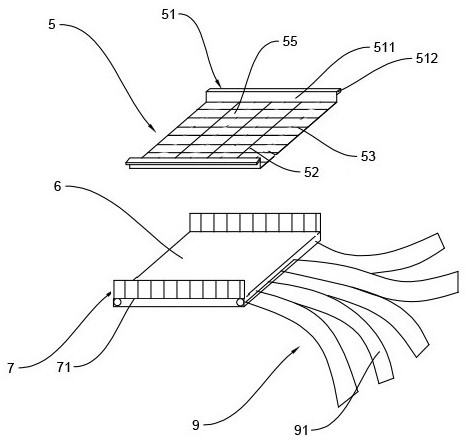

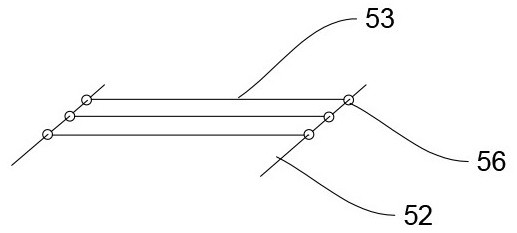

[0034] see Figure 1 to Figure 3 , is a kind of foaming material multi-standard cutting equipment, including a host frame 1, a workbench 2 is arranged on the host frame 1, and a transmission device 3 is arranged at one end of the host frame 1, and abuts against the workbench 2 Then, the transmission device 3 is provided with a stop device 4, and the top of the workbench 2 is provided with a cutting device 5; the workbench 2 is used to place foam material blocks, and the workbench 2 is provided with a conveyor belt 6 , both sides of the conveyor belt 6 are provided with stabilizing plates 7, and the stabilizing plates 7 are provided with a plurality of parallel limiting grooves 71; the cutting device 5 includes two fixed sides 51 parallel to each other, and a plurality of two ends are The first cutting line 52 fixed on the fixed side 51, the second cutting line 53 crossing the first cutting line 52, the hydraulic rod 54 affixed to the fixed side 51, the first cutting line 52 ,...

Embodiment 2

[0041] see figure 1 , Figure 4 , Figure 5 , the present embodiment is a multi-standard cutting equipment for foam materials, comprising a main machine frame 1, a workbench 2 is arranged on the main machine frame 1, and a transmission device 3 is arranged at one end of the main machine frame 1, and is connected with the working machine frame 1. The table 2 abuts, the transmission device 3 is provided with a stop device 4, and the top of the workbench 2 is provided with a cutting device 5; the workbench 2 is used to place foam material blocks, and the workbench 2 The conveyor belt 6 is set, and the both sides of the conveyor belt 6 are provided with a stabilizing plate 7, and the stabilizing plate 7 is provided with a plurality of parallel limiting grooves 71; the cutting device 5 includes two fixed sides 51 parallel to each other, a plurality of Both ends are respectively fixed to the first cutting line 52 of the fixed side 51, the second cutting line 53 intersecting with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com