Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Guaranteed production environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oil sieve tube outer wall polishing device with dust removing function

InactiveCN105290894AEffective sandingIncrease productivityGrinding carriagesRevolution surface grinding machinesMagnetPetroleum engineering

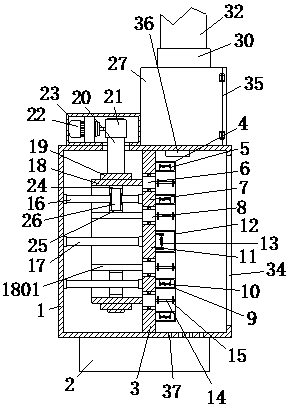

The invention relates to an oil sieve tube outer wall polishing device with the dust removing function. The polishing device is used for polishing the outer surface of an oil sieve tube. The oil sieve tube outer wall polishing device with the dust removing function comprises a bottom plate, a bracket device, a polishing device body, a fixing device, a motor device, a suction device, an air cylinder device, a cleaning device, a dust suction device and a support device. The bracket device comprises a first support rod, a first cross rod, a first bracket, a first oblique rod, a second bracket, a second support rod, a third bracket and a first positioning block. The polishing device body comprises a first air cylinder, a first push rod, a third bracket, a first fixing block, a polishing block and a first spring. The fixing device comprises a first cover plate, a second fixing block, a first fixing ring, a first vertical rod, a second cross rod, a second spring, a second vertical rod and a first magnet. The motor device comprises a motor, a revolving shaft, a first rotary plate, a first connecting rod, a third support rod, a second rotary plate and a second fixing ring. According to the oil sieve tube outer wall polishing device with the dust removing function, the oil sieve tube can be polished rapidly and effectively, the polishing efficiency is high, and the polishing effect is good.

Owner:张萍

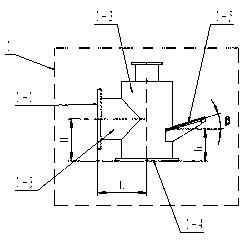

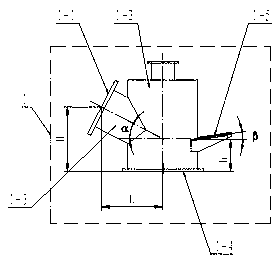

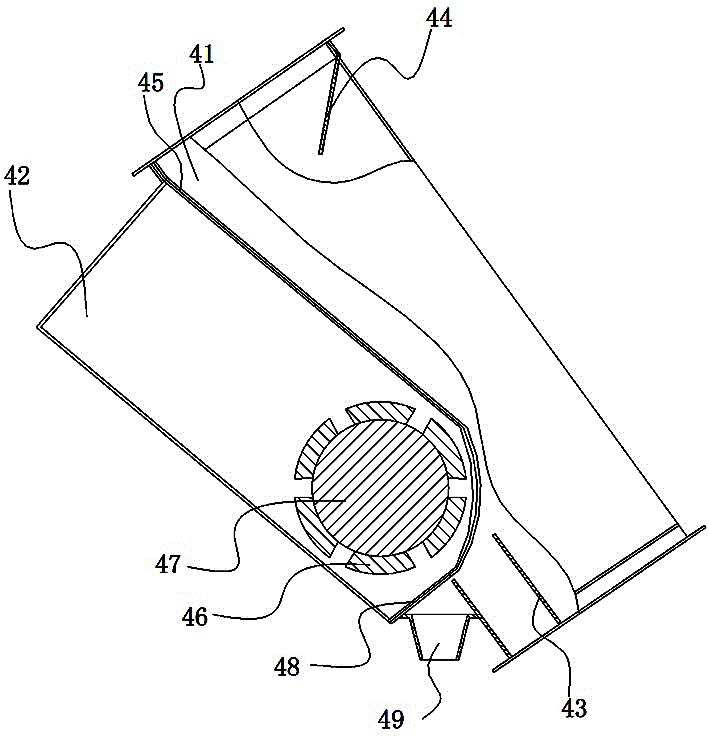

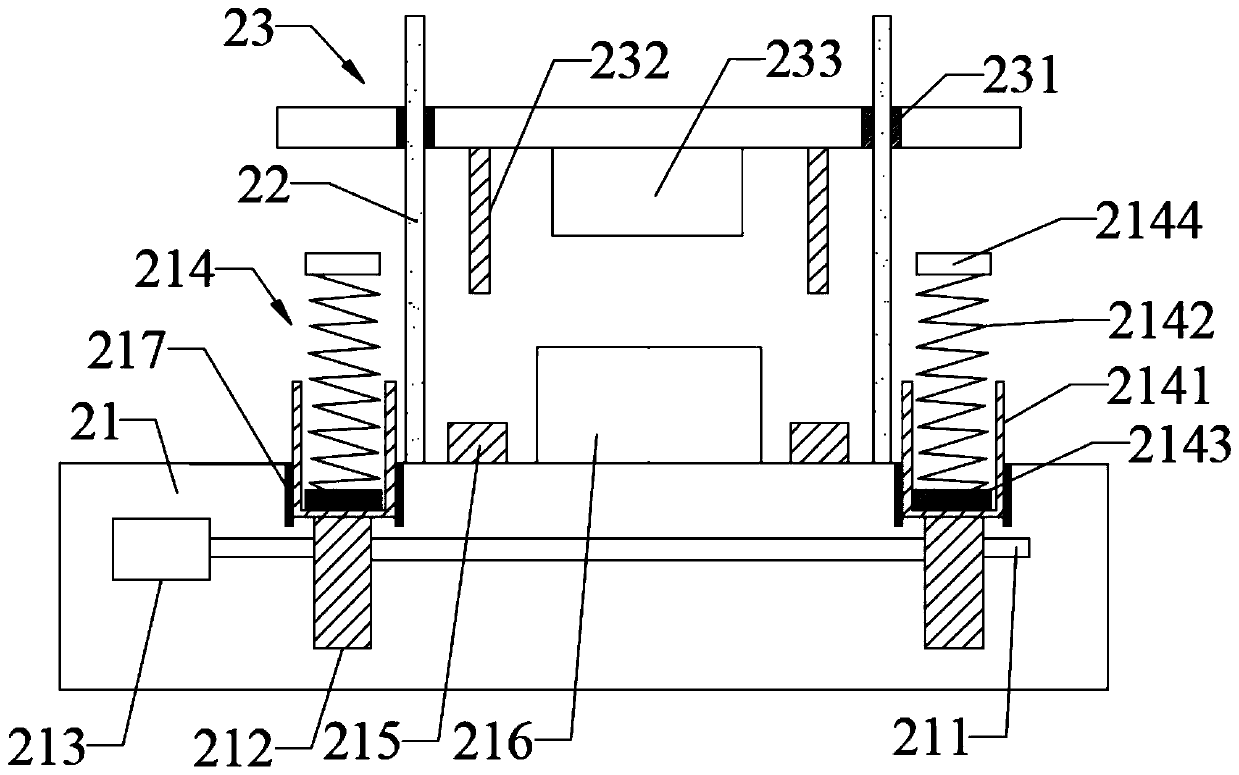

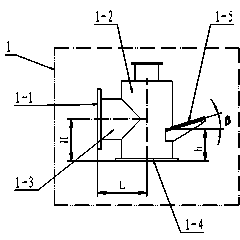

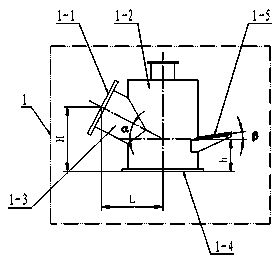

Assembly welding tool generally used for hot blast main pipe elbows

InactiveCN103302434AQuality assuranceGuaranteed cleanlinessWelding/cutting auxillary devicesAuxillary welding devicesEngineeringHot blast

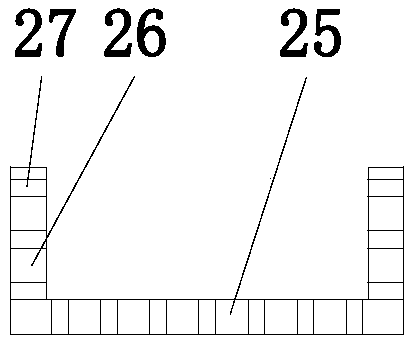

The invention provides an assembly welding tool generally used for hot blast main pipe elbows, aims to solve the problems in assembling and welding a hot blast main pipe elbow with different specifications, and comprises an assembling and welding platform base, a outlet flange positioning plate, an inlet flange center distance adjustment mechanism, an inlet flange height adjustment mechanism, an inlet flange angle adjustment mechanism, an inlet flange mounting hole center distance adjustment mechanism and a supporting frame adjusting mechanism, wherein the assembling and welding platform base is fixed on the horizontal plane, the outlet flange positioning plate and the supporting frame adjusting mechanism are mounted on the assembly welding platform base, the inlet flange center distance adjustment mechanism is mounted on one side of the assembling and welding platform base, and the inlet flange height adjustment mechanism and the inlet flange angle adjustment mechanism are fixed on the inlet flange center distance adjustment mechanism. The tool provided by the invention has the characteristics of compact structure and strong universality, guarantees the quality of products with different specifications, improves the working efficiency of welding and assembling, decreases the cost of rolled steel raw material, reduces the space occupied by equipment storage, and ensures the clean and civilized production environment of an enterprise.

Owner:QINGHUANGDAO NORTH METAL HOSE

Underground coal preparation technology adopting aqueous medium

The invention discloses an underground coal preparation technology adopting an aqueous medium and is applicable to underground coal mines. Raw coal is fed into an underground special compact jigger, clean coal is discharged, is dehydrated by the aid of a phi1-mm fixing sieve and then is screened by a phi13-mm classifying sieve, final clean coal water is dehydrated by a clean coal centrifugal dehydrator, and final clean coal and a centrifugal liquid are obtained; jigging middling coal is discharged and classified by the phi13-mm classifying sieve into lump middling coal and final middling coal,the final middling coal is dehydrated by a middling coal centrifugal dehydrator, and final middling coal and a centrifugal liquid are obtained; produced slime water is sent to an aqueous medium classifying and sorting swirler, the first section of the swirler plays a classifying role, first-section underflow enters the second section of the swirler for sorting, and second-section overflowing coarse and fine slime and underflow coarse and middling slime are obtained; the coarse and middling slime and the coarse and fine slime pass through a coarse and middling slime arc-shaped sieve I and a coarse and fine slime arc-shaped sieve J, the coarse and middling slime and the coarse and fine slime which are pre-dehydrated on the sieves are obtained, and the coarse and middling slime and the coarse and fine slime are obtained after dehydration. The technology is simple, the sorting equipment reliability is relatively high, the dynamic load is relatively low, and the sorting precision is high.

Owner:CHINA UNIV OF MINING & TECH +2

Efficient planting device for agricultural planting

InactiveCN107616031AReduce use costGuaranteed normal growthGeneral water supply conservationSnow trapsWater sourceGreenhouse

The invention discloses an efficient planting device for agricultural planting. The device comprises a greenhouse body and a greenhouse ceiling, water collection tanks are arranged at the tops of theouter sides of both the left side and the right side of the greenhouse body, filtering nets are arranged at the tops of the water collection tanks, the bottoms of the water collection tanks are both connected with water accumulation boxes through lower water pipes, the water accumulation boxes at the left side and the right side are both connected with spraying pipes located at the upper sides inside the greenhouse body through connection water pipes, and water pumping pumps are connected to the bottoms of the connection water pipes. According to the efficient planting device for agriculturalplanting, rainwater can be effectively collected and utilized to conduct irrigation, the using cost of the greenhouse is lowered, the effects of conducting ventilation and maintaining the indoor temperature and humidity to be stable can be achieved, the planting effect is improved, a fan is arranged in the channel, through a controller, a walking mechanism is controlled to move, a sunshade screenis driven to be unfolded, the temperature inside the greenhouse is lowered, and the greenhouse does not need to be manually covered with the sunshade screen, besides, salt for melting snow can be uniformly sprayed to the greenhouse ceiling in the circumferential direction, the spraying effect is good, the coverage area is large, and the snow melting effect is good.

Owner:尚许静

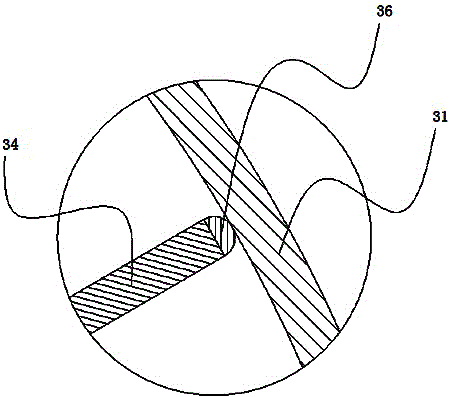

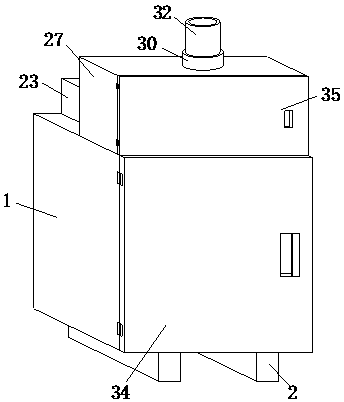

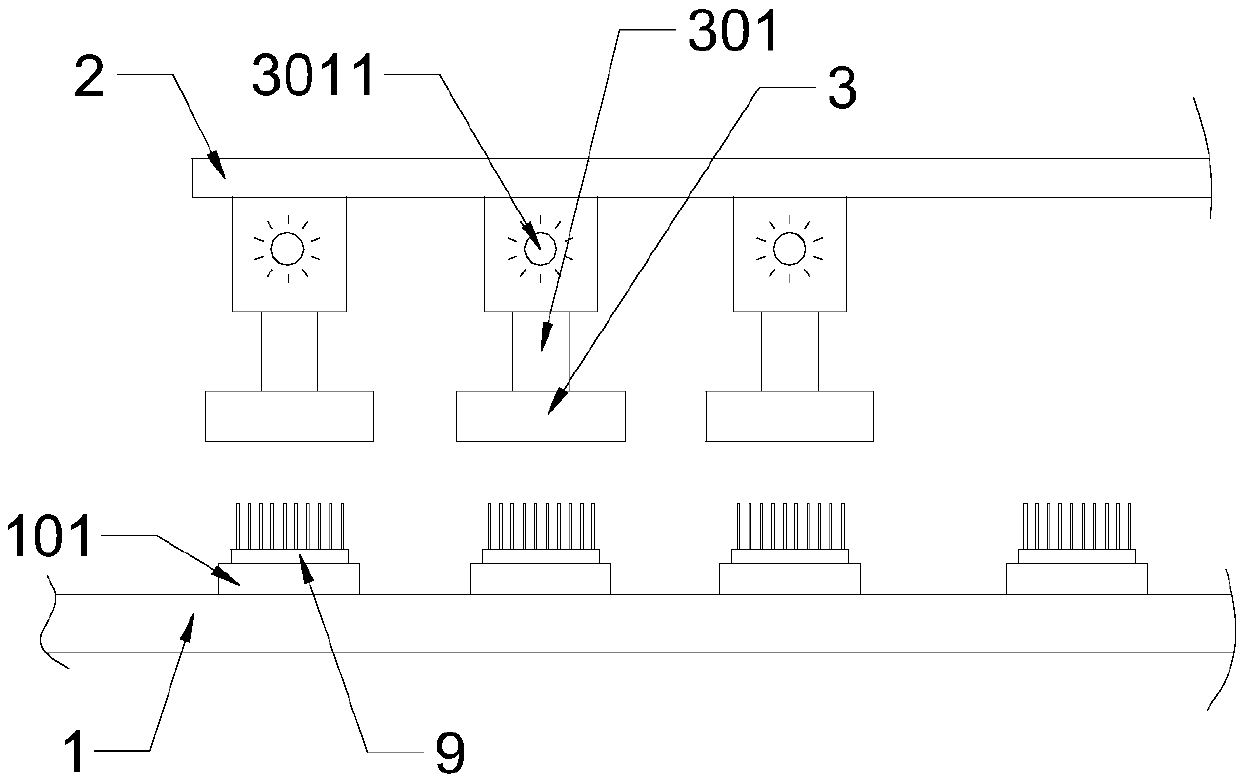

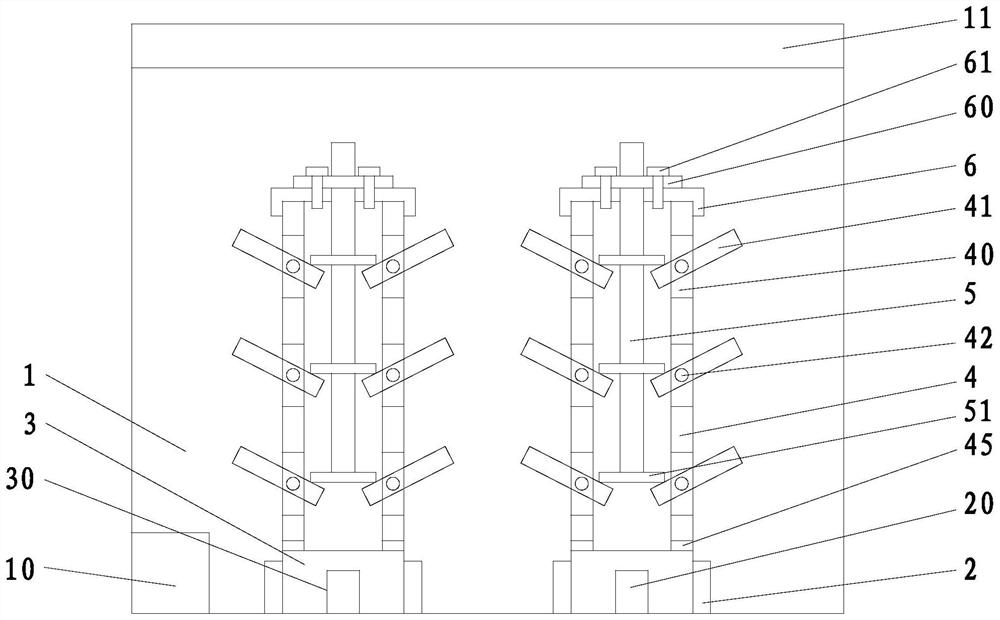

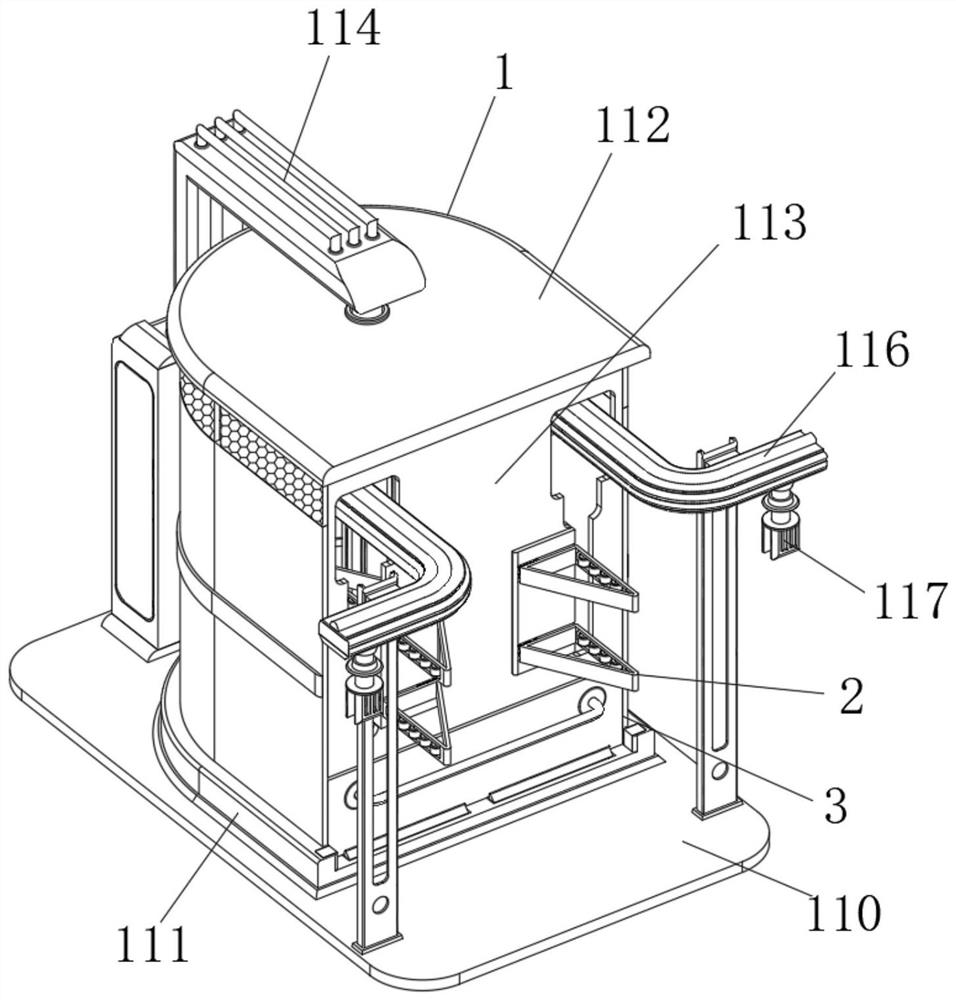

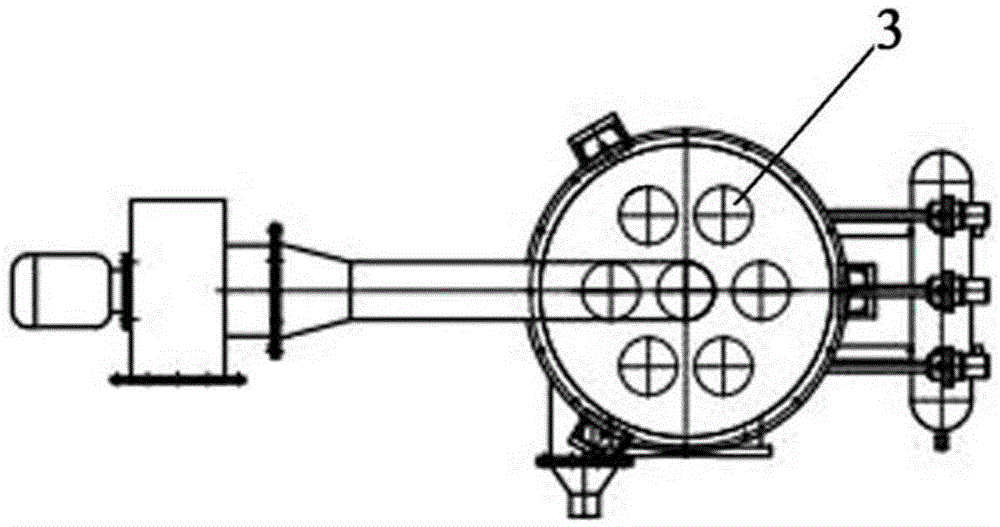

Intermittent feeding device for powder packing

ActiveCN106275599AGuaranteed production environmentGuaranteed stable packagingConveyorsLarge containersImpellerIron removal

The invention discloses an intermittent feeding device for powder packing. The intermittent feeding device for powder packing comprises a feeding bin (1), a packing machine (2), an impeller feeding device (3), a rotation stopping type level gage A (6), a rotation stopping type level gage B (7) and a pipe type iron remover (4), wherein the rotation stopping type level gage A (6) and the rotation stopping type level gage B (7) are mounted on a receiving hopper of the packing machine (2); the feeding bin (1) is connected with the packing machine (2); the impeller feeding device (3) and the pipe type iron remover (4) are successively arranged on a connecting channel for the feeding bin (1) and the packing machine (2) from top to bottom; and a plug valve (5) is further mounted on a discharging opening of the feeding bin (1) and comprises a plug board (106), a guide plate (102), a driving mechanism (103) and an elastic sealing device (105). The intermittent feeding device for powder packing has the beneficial effects of intermittent quantitative discharging, high iron removal efficiency, high packing efficiency, zero powder leakage, low powder waste rate and low production cost.

Owner:SICHUAN YIXIN NEW MATERIAL CO LTD

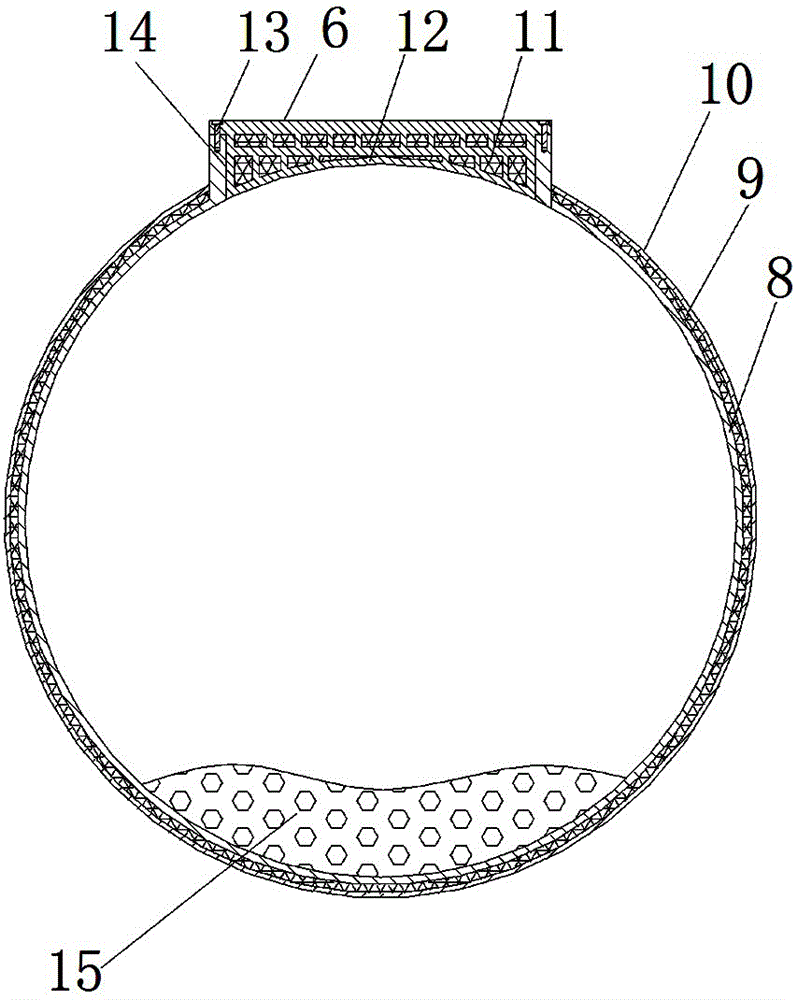

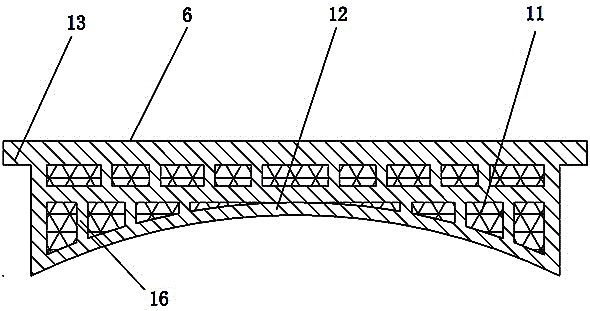

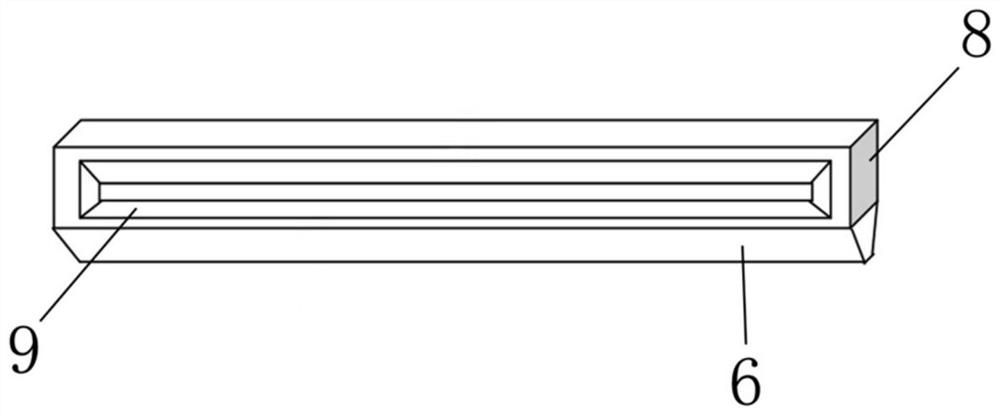

Rapid treatment device for surface of steel plate

InactiveCN106141888AImprove processing efficiencyIncrease surface areaEdge grinding machinesPolishing machinesInsulation layerSheet steel

The invention discloses a rapid treatment device for the surface of a steel plate. The rapid treatment device comprises a mounting seat (1), a driving device and a roller (7); the roller (7) is located at one side of the mounting seat (1); and the driving device which drives the roller (7) to rotate is mounted on the mounting seat (1). The rapid treatment device is characterized in that a feeding hole (14) is formed in the roller (7) and is connected with a cover plate (6) in a sealing way; a plurality of small steel balls (15) are placed in the roller (7) composed of an outer shell (10), a sound insulation layer (9) and an inner shell (8); an opening radially extending to form the feeding hole (14) is formed in the inner shell (8); the outer shell (10) is located at the outer side of the inner shell (8); and the sound insulation layer (9) is located in a cavity between the outer shell (10) and the inner shell (8). The rapid treatment device has the beneficial effects of high deburring efficiency, high rust removal efficiency and good rust removal effect.

Owner:MEISHAN DEXIN AVIATION EQUIP

Rubber production technology

The invention discloses a rubber production technology and relates to the field of rubber production. According to the rubber production technology, EPDMs (ethylene propylene diene monomers), carbon black, regenerated rubber, a softening agent, an activating agent and an aid are extracted to be mixed, subjected to high-temperature and high-pressure desulfurization, smelted coarsely and then refined. The rubber production technology has the advantages as follows: the rubber production process is simple and convenient, produced rubber is high in oxidation resistance, corrosion resistance and wear resistance, mutual effects of all components are avoided, the production effectiveness and safety are guaranteed, the temperature range is strictly controlled in a calendering technology, draping of a framework material with the rubber is guaranteed, the density of cords is uniform, and the uniformity of the thickness of the rubber on two sides of the cords is improved.

Owner:ANHUI MEIXIANG IND

Polyimide enameled wire drying device and using method thereof

InactiveCN111151428AEasy to dryPrevent situations that reduce productivityDispersed particle filtrationPretreated surfacesActivated carbon filtrationGear wheel

The invention discloses a polyimide enameled wire drying device and a using method thereof. The polyimide enameled wire drying device comprises a drying box, landing legs, a partition plate, a first ring box, a first heating wire, a first rotating ring, a fixed ring, a second rotating ring, a second ring box, a second heating wire, a fixed plate, a box body, a third heating wire, threaded rods, alimit disc, a first fixing column, a second fixing column, a first transmission cylinder, a second transmission cylinder, a driven pulley, a transmission belt, a driving pulley, a stepper motor, a chassis, a driving gear, a driven gear, a transmission gear, a purification box, a frame, an activated carbon filter plate, a fixed cylinder, a fan, an exhaust pipe, an air hole, a discharge door, a cleaning door, a temperature control switch and an air inlet. According to the polyimide enameled wire drying device, an enameled wire is fixed to the surfaces of the threaded rods to be quickly dried effectively, the production efficiency is prevented from being reduced due to the long drying time of the enameled wire; and the stepper motor drives the multiple threaded rods to rotate, so that the enameled wire is heated evenly, and the drying effect is accordingly improved.

Owner:江苏龙创新材料科技有限公司

Water saving type nut cleaning device

PendingCN109499969ANot easy to spillDissolves and softens quicklyCleaning using liquidsWater savingMechanical engineering

The invention discloses a water saving type nut cleaning device. A cleaning box, a plate chain, a driving rolling column, a driven rolling column, a partition plate, a steam pipe, a gas sucking channel and a water spraying pipe are included; the two sides of the cleaning box are provided with the driving rolling column and the driven rolling column correspondingly; the driving rolling column and the driven rolling column are sleeved with the plate chain; the two side walls of the cleaning box are provided with a feeding port and a discharging port correspondingly; the plate chain penetrates into the cleaning box from the feeding port and penetrates out of the discharging port; a material falling device is arranged above the feeding end of the plate chain; and the vertically arranged partition plate is arranged in the cleaning box. According to the water saving type nut cleaning device, due to the fact that the steam pipe is matched with the gas sucking channel, oil dirt on a nut can befast dissolved and softened, and can effectively drip, the amount of water for use is effectively saved, and the later water spraying pipe is used in cooperation so that the nut can be cleaned completely.

Owner:嘉兴光明科技股份有限公司

Process for producing automobile tyre

The invention discloses a process for producing an automobile tyre, and relates to the field of production of automobile accessories. The process for producing the automobile tyre comprises the following steps: banburying of ingredients, preparation of a rubber component, the preparation of a semi-finished product, and forming procedure and vulcanization procedure of the tyre, wherein during the banburying of ingredients, dilute sulfuric acid is added, and the ingredients are refined in a hot sulfuric acid environment at the temperature of 320 to 350 DEG C, so that the mixing uniformity of various rubber materials is improved, and the physical and mechanical properties and the technological operation performance required by the technology are met better; the semi-finished product is treated in four steps and is extruded separately, so that the size and weight of respective components are improved, the standard specified by the technology is met better, the mutual effect and influence between respective components are avoided, and the effectiveness and safety of the production are ensured; the temperature range is controlled strictly in a calendaring process, so that a framework material is combined with the rubber material better to achieve a uniform cord density, and the thickness uniformity of rubber materials on two surfaces of a cord is improved.

Owner:丹阳市米可汽车零部件厂

Bearing cleaning device convenient to assemble and disassemble

The invention discloses a bearing cleaning device convenient to assemble and disassemble. The bearing cleaning device convenient to assemble and disassemble comprises a cleaning tank, an ultrasonic generator, fixing rings, fixing columns, installation tubes, rotary rods, pressing plates, stretching columns and a locking mechanism. The ultrasonic generator is arranged in the cleaning tank; a tank cover covers on the top part of the cleaning tank; a plurality of fixing rings are fixed onto a bottom wall of the cleaning tank; the fixing columns are inserted into the fixing rings; the installationtubes are fixed to the top ends of the fixing columns; each installation tube is provided with multiple layers of installation areas from top to bottom; each installation area is formed by multiple installation slots penetrating through side walls of the installation tubes and located on the same horizontal height; the rotary rods capable of rotating along a vertical square shape are arranged inthe installation slots; rotary shafts are arranged on the rotary rods, and are fixed onto side walls of the installation slots; and outer ends of the rotary rods are located outside the installation tubes. According to the bearing cleaning device convenient to assemble and disassemble provided by the invention, through the matching of the rotary rods and the pressing plates, a bearing can be quickly separated from the rotary rod after being cleaned so as to be convenient to discharge, so that the production efficiency is improved.

Owner:XINCHANG LONG HAO BEARING CO LTD

Hot-rail deformation hot box

The invention discloses a hot-rail deformation hot box, which comprises a shell, and a heating liner container, hot rails and temperature sensors, which are arranged inside the shell; a thermal insulation material is filled between the shell and the heating liner container; heating medium is arranged inside the heating liner container, and the outer wall of the heating liner container is detachably and fixedly provided with a plurality of groups of heating elements; the quantity of the hot rails is multiple, the hot rails are fixed on the shell, one end of each hot rail is in welding connection with the heating liner container, each hot rail is of a hollow structure, and an inner cavity of each hot rail is communicated with an inner cavity of the heating liner container; and the upper end and the lower end of the heating liner container are respectively provided with one temperature sensor. The outer wall of the heating liner container is provided with the groups of heating elements, which work simultaneously, so that not only is rapidness in heating speed realized, but also a yarn path is uniformly heated.

Owner:墨瑞新材料(常州)有限公司

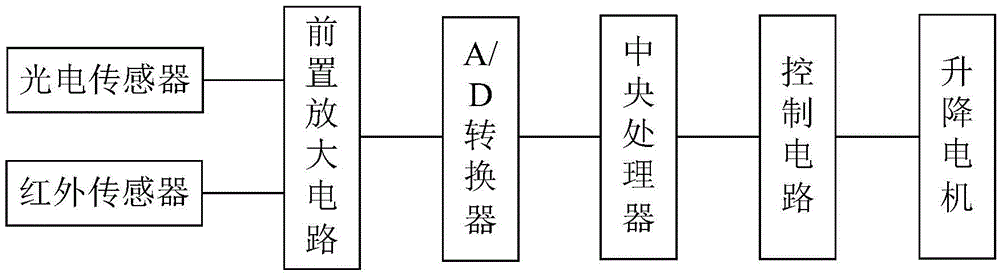

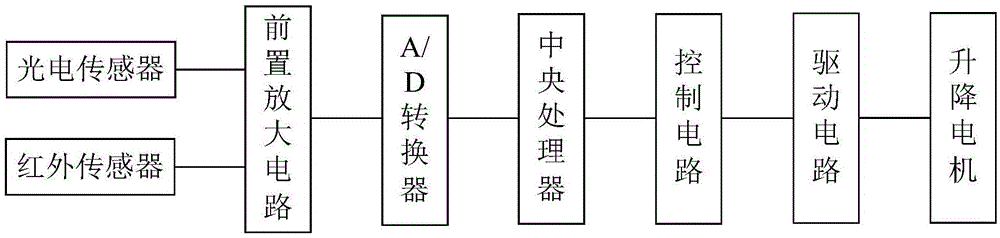

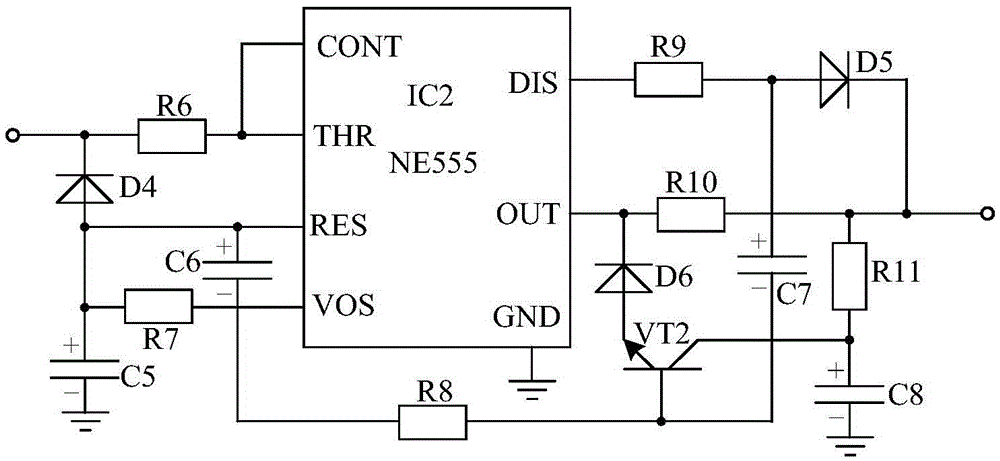

Pre-amplifier circuit based automatic control system for roller shutter door

InactiveCN105569550AGuaranteed Isolation ProductsGuaranteed production environmentProgramme controlDoor/window protective devicesAutomatic controlAutomatic train control

The invention discloses a pre-amplifier circuit based automatic control system for a roller shutter door. The automatic control system is characterized by mainly comprising a CPU (central processing unit), an A / D converter and a control circuit which are connected with the CPU, a pre-amplifier circuit connected with the A / D converter, a photoelectric sensor and an infrared sensor which are connected with the pre-amplifier circuit as well as a lifting motor connected with the control circuit, wherein the control circuit consists of a control chip IC (integrated chip), a signal trigger circuit with the input end connected with the CPU as well as a door opening control circuit and a door closing control circuit with output ends connected with the lifting motor; the signal trigger circuit, the door opening control circuit and the door closing control circuit are connected with the control chip IC. The automatic control system is simple in structure, low in cost and capable of automatically opening and closing the door, so that the roller shutter door can isolate products and the production environment, and the automatic control system is suitable for popularization and application.

Owner:CHENGDU CLAY STAR TECH CO LTD

A hand-held denture grinding device

The invention discloses a hand-held false tooth polishing device which comprises a shell; the shell is internally provided with a motor, a storage battery for supplying power for the motor, and a charger for charging the storage battery; a front end cover is arranged at the front end of the shell; the rear end of the shell is sealedly connected with a dust collecting seat; a main shaft of the motor passes through the front end cover; a polishing wheel is mounted on the main shaft; the front end cover is provided with a dust sucking pipe; the shell is provided with a vent hole; the dust collecting seat is provided with a dust collecting cavity; the dust collecting cavity is internally provided with a filter screen, the bottom of the dust collecting cavity is provided with an air compressor, and the rear end of the dust collecting seat is provide with a rear end cover; the rear end cover is provided with an exhaust hole for the air compressor to easily exhaust air; the dust sucking pipe communicates with the dust collecting cavity through the vent hole. The hand-held false tooth polishing device has the beneficial effect that the hand-held false tooth polishing device has the advantages of simple structure, convenience in operation and high milling and collection efficiency.

Owner:CHENGDU BESMILE BIOTECH

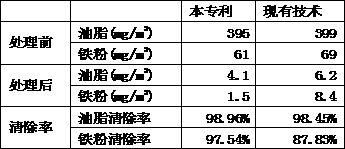

Steel belt cleaning device

PendingCN112371574AEasy to cleanReduce carry outDrying gas arrangementsCleaning using toolsProcess engineeringSteel belt

The invention discloses a steel belt cleaning device, and belongs to the technical field of drainage pipes. The steel belt cleaning device comprises a cleaning bin, an air cooling structure, a degreasing agent circulating pool and a clear water circulating pool; the interior of the cleaning bin is sequentially divided into a scrap iron cleaning chamber, a degreasing chamber and a cleaning chamberfrom front to back; the degreasing chamber is located above the degreasing agent circulating pool and connected with the degreasing agent circulating pool through a water return pipeline; the cleaningchamber is positioned above the clear water circulating pool and is connected with the clear water circulating pool through a water return pipeline; a rough surface rubber roller pair and a magneticrod are arranged in the scrap iron cleaning chamber; at least two sets of cleaning units are sequentially arranged in the degreasing chamber from front to back; at least two sets of cleaning units andat least one set of extrusion rubber roller pair are sequentially arranged in the cleaning chamber from front to back; each cleaning unit comprises a conveying rubber roller pair, a brush roller pairand a spraying structure, wherein the conveying rubber roller pair and the brush roller pair are arranged side by side front and back, and the spraying structure is arranged between the conveying rubber roller pair and the brush roller pair; a scraper pair is arranged or not arranged behind each cleaning unit; and the degreasing chamber and the cleaning chamber are each internally provided with at least one scraper pair.

Owner:HUBEI TUNCANG PIPE TECH DEV CO LTD

Dustproof ore crushing equipment

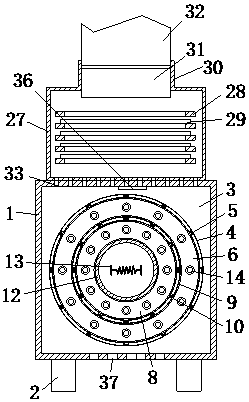

InactiveCN111013696APrevent leakageEasy to collectSievingCombination devicesMining engineeringBaghouse

The invention relates to the technical field of ore treatment equipment, in particular to dustproof ore crushing equipment which comprises a sealing bin, a crushing device and a material collecting bin. The crushing device is arranged at the top of the sealing bin, the material collecting bin is arranged in the sealing bin, and an air suction hole is formed in the sealing bin. The dustproof ore crushing equipment can continuously and efficiently crush ores, so that the crushed ores are more uniform in granularity, and the dustproof ore crushing equipment is miniaturized and energy-saving; thewhole process is carried out under a closed condition, dust explosion and dust leakage are prevented, and the field environment is good; an air suction hole is formed in the sealing bin in the tangential direction of the cylindrical surface of the sealing bin, negative pressure and annular air flow are formed in the sealing bin, dust can enter a cyclone dust collector and a bag type dust collectoralong with the air flow to be conveniently collected by workers, and therefore the dust concentration in the equipment cannot meet the dust explosion condition, and dust explosion is eradicated. External air is continuously sucked into the equipment, and air cooling can be carried out on the equipment while the air takes away the dust in the equipment.

Owner:福建省磊鑫环保科技有限公司

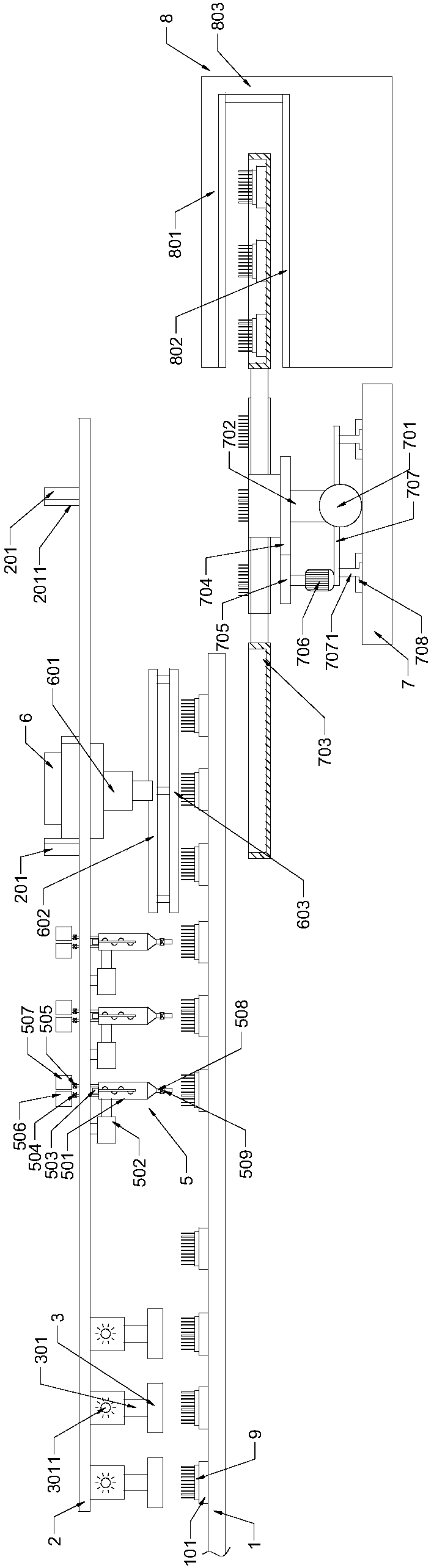

Automatic glue filling production line for nixie tubes

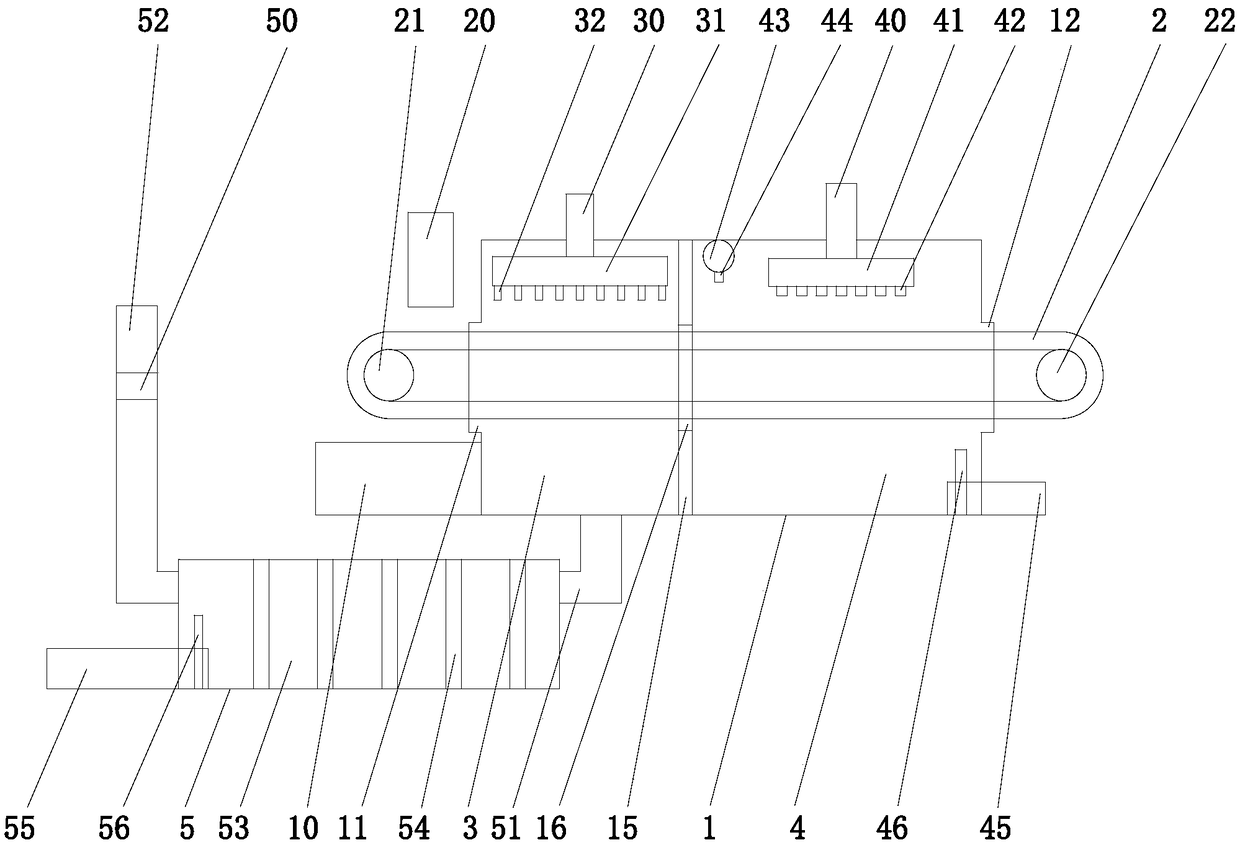

PendingCN107824391AIngenious structural designGuaranteed production environmentLiquid surface applicatorsCoatingsEngineeringReciprocating motion

The invention provides an automatic glue filling production line for nixie tubes. The automatic glue filling production line for the nixie tubes comprises a glue filling devices, a clamping device anda bearing device which are arranged in sequence from left to right; the glue filling device comprises a conveying belt which is driven by a driving unit; a plurality of clamping grooves which are used for holding the nixie tubes are formed in the conveying belt; the clamping grooves are distributed uniformly at intervals in the length direction of the conveying belt; automatic glue filling machines corresponding to the nixie tubes are arranged above the conveying belt; the side walls of the automatic glue filling machines are fixed to free ends of telescopic rods of glue filling hydraulic cylinders; the glue filling hydraulic cylinders can driven the automatic glue filling machines to move left and right; the clamping device comprises travelling devices which are arranged on a machine frame above the conveying belt; the travelling devices can perform straight reciprocating motion on the machine frame along the length direction of the conveying belt; the lower end of each travelling device is fixedly connected with a clamping mechanism can be ascended and descended; and the bearing device is used for bearing the nixie tubes which are clamped by the clamping device. The automatic glue filling production line for the nixie tubes can realize automatic production.

Owner:TIANJIN MEISEN ELECTRONICS CO LTD

Honey beverage machine with sterilizing and insect-preventing functions

The invention discloses a honey beverage machine with sterilizing and insect-preventing functions. The honey beverage machine comprises a beverage machine body with a shell. The inside of the shell comprises a honey storing area, a beverage preparing area and a drinking water storing area, wherein the honey storing area is positioned at the upper part in the shell, and comprises a plurality of honey storing tanks and a first ultraviolent sterilizing lamp used for realizing sterilizing; the beverage preparing area comprises a beverage preparing assembly connected below the honey storing tanks and a sheltering plate arranged in front of the shell, the beverage preparing assembly is provided with a liquid outlet, and a second ultraviolet sterilizing lamp is arranged at the position, above theliquid outlet, of the bottom end of the sheltering plate; and the drinking water storing area is positioned at the lower part in the shell, and comprises a bracket and a plurality of drinking water storing tanks arranged on the bracket, and a third ultraviolet sterilizing lamp realizing downward irradiation is arranged on the top of the bracket. For the honey beverage machine with the sterilizingand insect-preventing functions provided by the invention, the storing and preparing environments in the honey beverage machine can be effectively guaranteed, and thus the storage of honey and the preparing process are sanitary and healthy.

Owner:杭州为我健康新零售科技有限公司

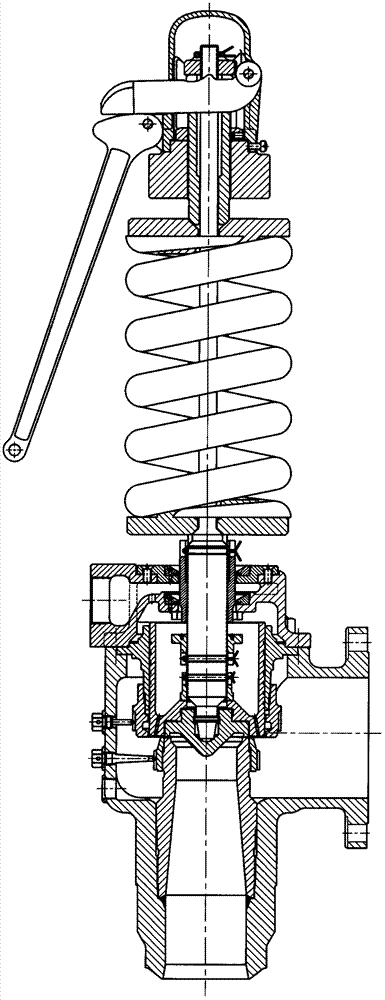

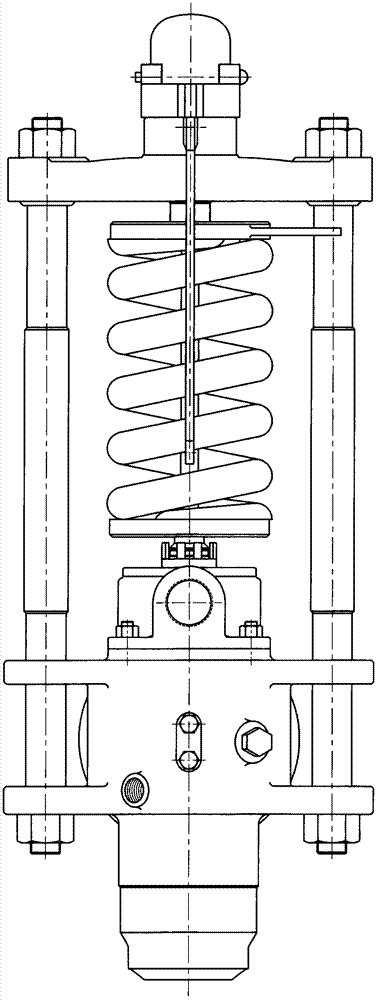

High temperature and high pressure spring safety valve with thermal compensation and elastic compensation sealing surface

ActiveCN104482261BImproves sealing reliabilityNot easy to jamEqualizing valvesSafety valvesSites treatmentSpray nozzle

The invention discloses a high-temperature and high-pressure spring safety valve with a heat compensation and elastic compensation sealing surface. A valve flap of the valve consists of a heat valve flap and a valve flap body, wherein a heat compensation part, an elastic compensation part and an anti-clamping structure are arranged on the valve flap, the upper end of a steam discharge chamber is provided with a steam escaping structure, the valve body and a spray nozzle adopt a split assembly structure, the valve flap adopts a more reasonable back pressure inlet structure, the valve rod and the valve flap adopt a hard alloy steel ball jacking and pressing structure, a support frame adopts an integral casting structure with a valve rod for guide, and the valve is also provided with a structure convenient for in-site disposition. The high-temperature and high-pressure spring safety valve has the main advantages that better heat compensation and elastic compensation capability is realized, the sealing reliability of the valve can be improved, the occurrence of the front leakage phenomenon can be effectively delayed, an elastic deformation gap cannot be easily clamped and blocked, no steam escapes out from the upper end of the steam discharge chamber, the reliable work of the spring can be ensured, the sealing surface is convenient to restore and grind during the repair, the valve installation, the boiler water pressure test and the valve checking are more convenient, and the in-site treatment can be easily realized when the valve generates certain leakage.

Owner:陕西航天泵阀科技集团有限公司

A device for removing iron oxide and improving the detection rate of surface problems and its operation process

ActiveCN112264472BEasy to useAccurate identificationWork cleaning devicesMetal rolling arrangementsAir compressionSteel belt

The invention discloses a device for removing iron oxide and improving the detection rate of surface problems and its operation process. The device includes an ultra-thin strip casting and rolling process line, and is characterized in that it also includes an iron oxide powder collecting device, a compressed air pipeline, a High-pressure nozzle, air compression pump and steel strip to be cleaned, the steel strip to be cleaned advances along with the ultra-thin strip casting and rolling process line, and passes through the iron oxide powder collection device; the compressed air pipeline is arranged in the iron oxide powder Above and below the outlet of the powder collecting device, the compressed air pipeline is connected to an air compression pump; the high-pressure nozzle is arranged on the compressed air pipeline, and the nozzle of the high-pressure nozzle is connected to the surface of the steel strip to be cleaned at 30°. The device is suitable for ultra-thin strip products, which can ensure that the surface of the strip is clean, ensure the efficient use and accurate identification of the surface detector, and ensure a clean production environment.

Owner:SHAGANG GROUP +1

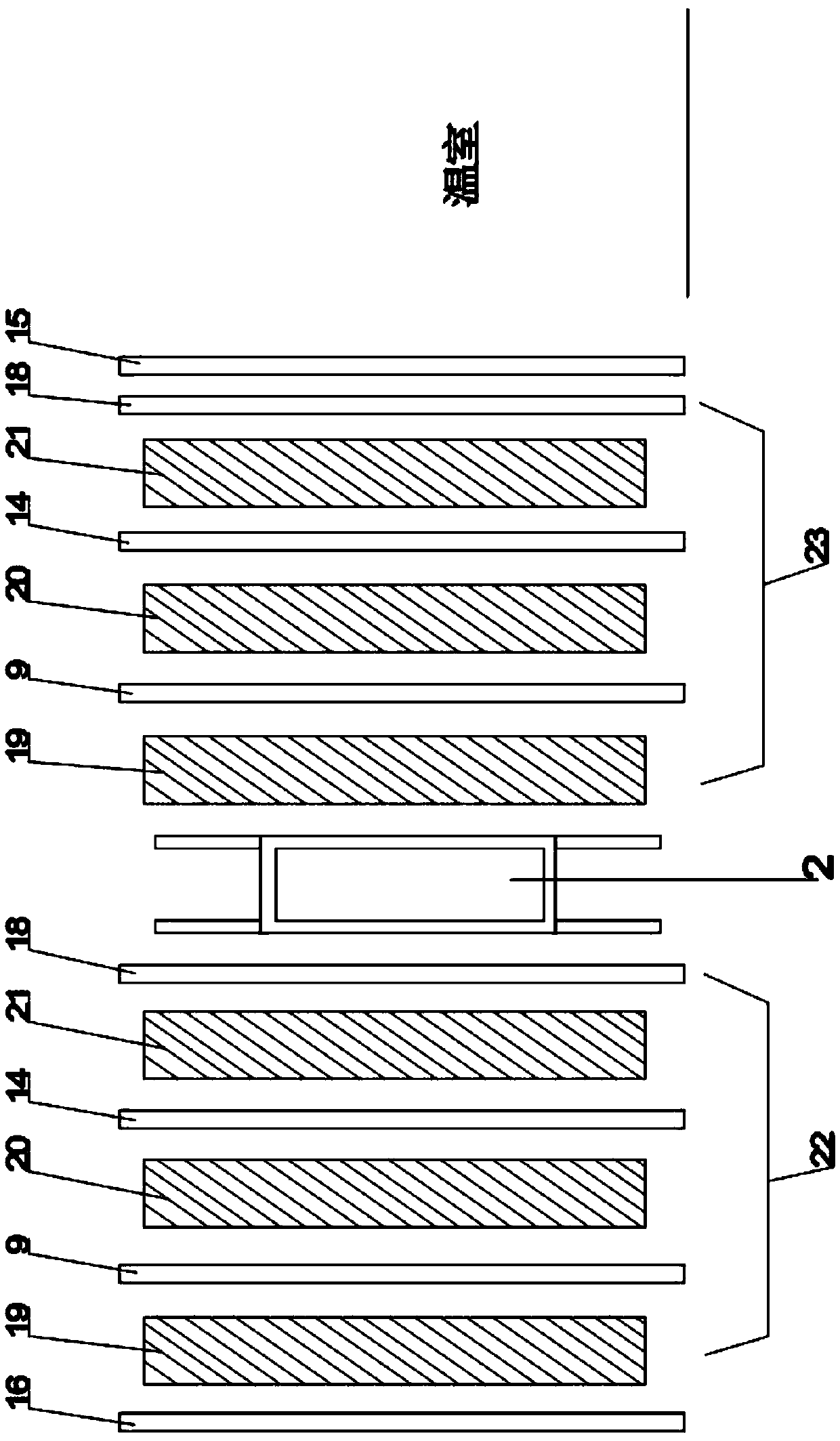

Openable type energy-saving side wall of sunlight greenhouse

PendingCN109661932ASolve the problem of not being able to produceReduce energy consumptionClimate change adaptationSaving energy measuresBrickGreenhouse

The invention belongs to the technical field of vegetable planting, and particularly relates to an openable type energy-saving side wall of a sunlight greenhouse. The openable type energy-saving sidewall comprises a ceiling, wherein the ceiling is in an arch shape; side wall bodies are arranged between the ceiling and the ground; a support wall is arranged between every two side wall bodies; thetop end of each support wall is fixedly arranged at the lower bottom surface of the ceiling; the bottom end of each support wall is fixedly arranged on the ground; a door body is arranged on each sidewall body, and consists of columns and masonry bricks; each side wall body comprises a first quilt group and a second quilt group; each first quilt group comprises a quilt layer A, a quilt layer B, aquilt layer C, a plastic film layer A, a plastic film layer B and a plastic film layer C; the plastic film layers A are positioned between the quilt layers A and the quilt layers B; the plastic filmlayers B are positioned between the quilt layers B and the quilt layers C; the quilt layers C are positioned between the plastic film layers B and the plastic film layers C; the structure of the second quilt groups are the same with the structures of the first quilt groups; and an insect-proof net layer is arranged at the inner side of each second quilt group.

Owner:农政齐民科技(天津)有限公司

Control system applied to rolling gates of plant

InactiveCN109458120ASave human effortImprove efficiencyDoor/window protective devicesSpecial door/window arrangementsClient-sideNetwork camera

The invention discloses a control system applied to rolling gates of a plant, and relates to the technical field of control over mechanical equipment. The control system is characterized by comprisinga plant gate local control device, a WIFI module and a plant gate monitoring platform. Through the plant gate monitoring platform at a computer end, one or more plant gate motors are controlled, thusthe purposes of opening and closing the gates or opening the plant gates to a certain height are achieved, and the situation that the environment with constant temperature and constant humidity and without dust of the plant is influenced when the plant gates are not timely closed after being opened is avoided. The control system also has the functions of monitoring, automatic closing and the like, a wireless network camera is arranged in each plant gate, besides monitoring and video recording, a client side confirms whether or not there are people or objects in front of the gates through real-time image comparison, and if not, electric signals for automatically closing the plant gates are transmitted. Besides, the control system comprises a mobile phone APP, the APP has permissions, timereservation and entrance-exit record put-on for transport vehicles outside the plant can be conducted through the APP, an administrator can conduct online examination and approval through the computerend or the mobile phone APP to save the time and reduce common steps, and the working efficiency is improved.

Owner:袁时俊

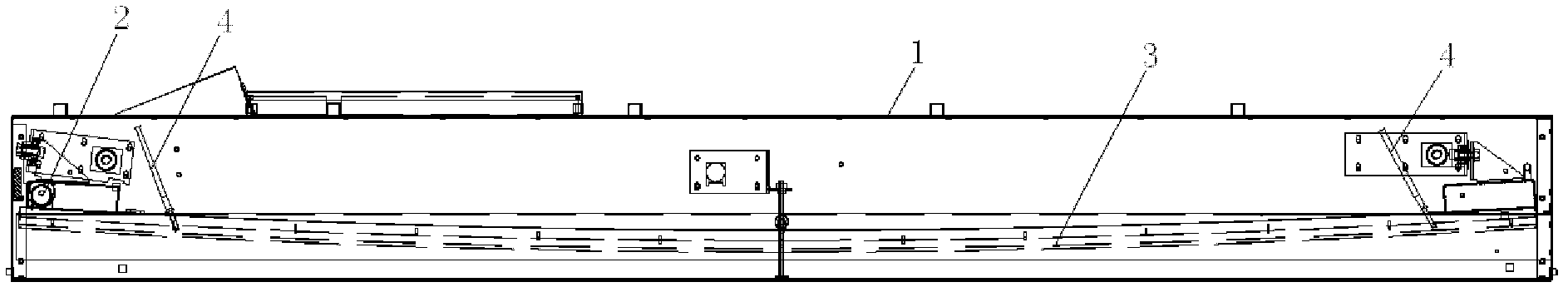

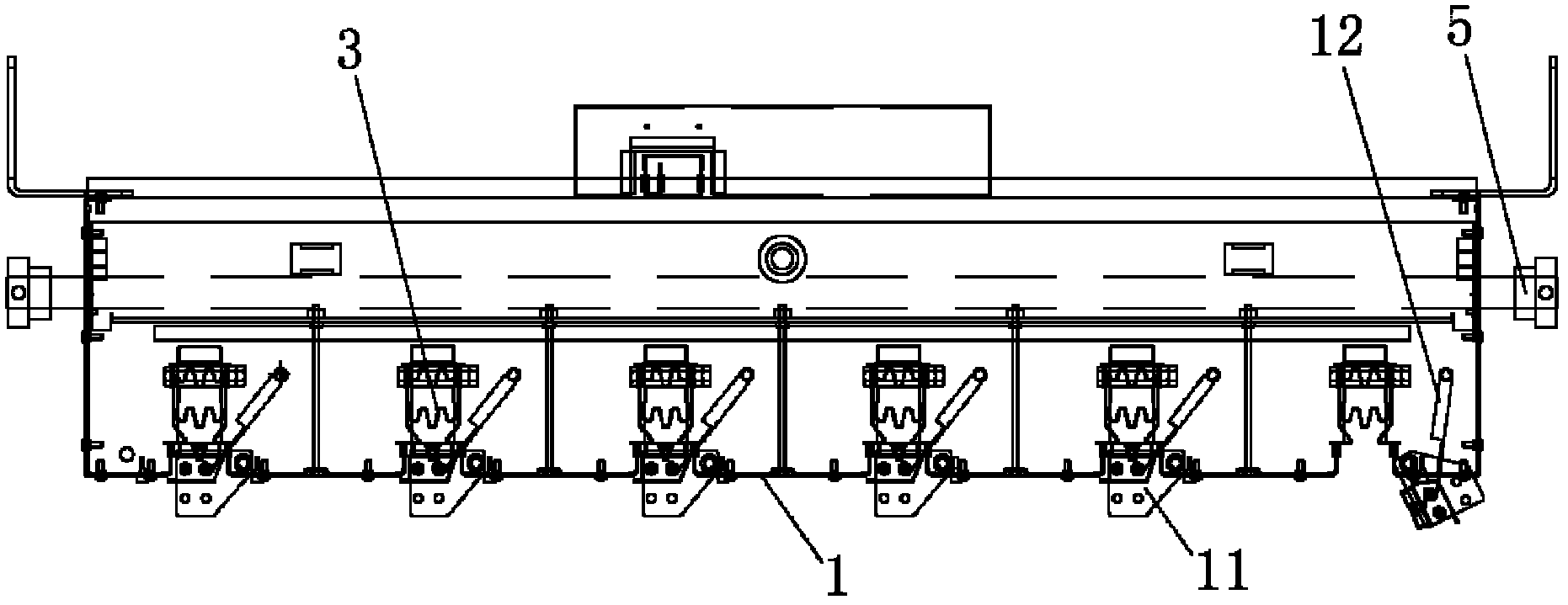

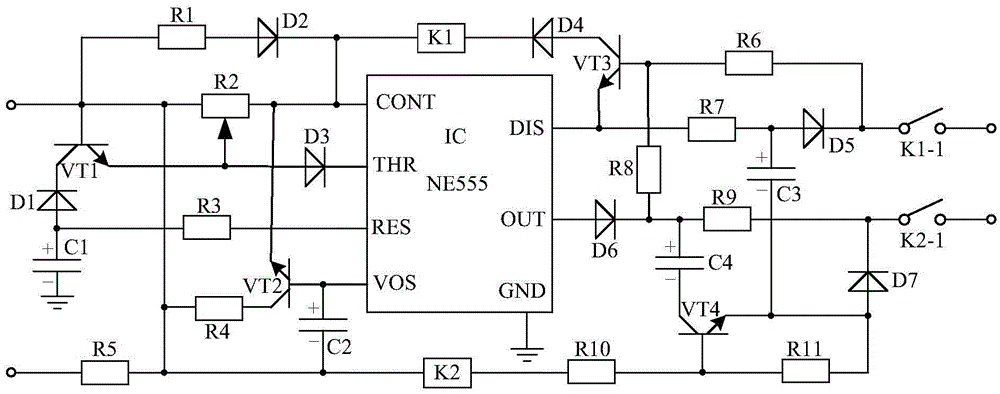

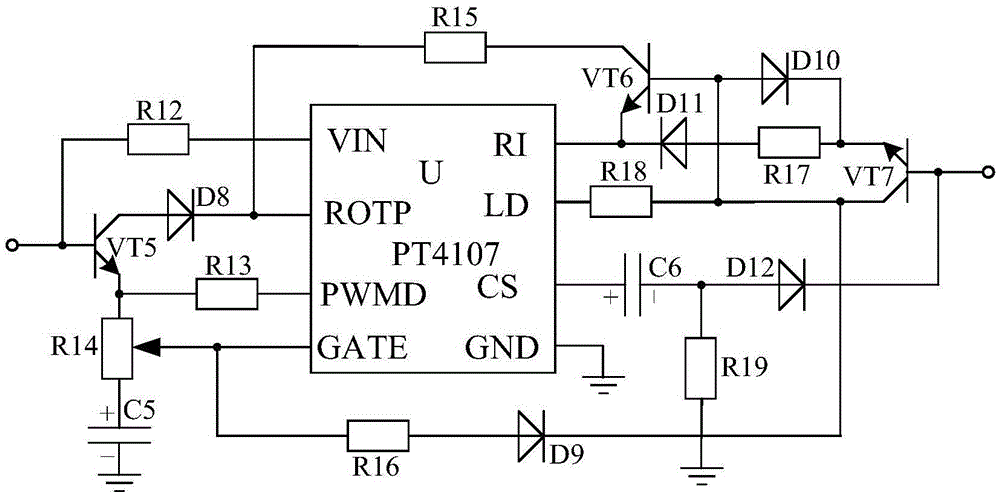

Automatic control system for rolling door based on driving pre-amplification electric circuit

InactiveCN105607531AGuaranteed Isolation ProductsGuaranteed production environmentProgramme controlDoor/window protective devicesAutomatic controlAutomatic train control

The invention discloses an automatic control system for a rolling door based on a driving pre-amplification electric circuit, the system is characterized in that: the system is formed by a CPU, an A / D converter and a control circuit which are connected with the CPU, a pre-amplification electric circuit connected with the A / D converter, a photoelectric sensor and an infrared sensor which are connected with the pre-amplification electric circuit, a drive circuit connected with the control circuit, and a lifting motor connected with the drive circuit; wherein the control circuit is formed by a control chip IC, a signal trigger circuit of which an input end is connected with the CPU, and a door opening control circuit and a door closing control circuit of which output ends are connected with the drive circuit; and the signal trigger circuit, the door opening control circuit and the door closing control circuit are connected with the control chip IC. According to the invention, the system has simple structure and low cost and can automatically open and close the door, so that the system can ensure that the rolling door isolates the product and production environment, and the system is suitable for generalizing and applying.

Owner:CHENGDU CLAY STAR TECH CO LTD

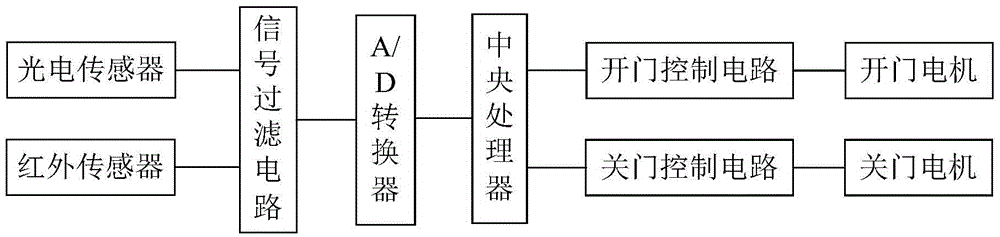

Signal filtering circuit-based intelligent control system for roller shutter door

InactiveCN105573203AGuaranteed production environmentSimple structureProgramme controlDoor/window protective devicesElectric machineOpto electronic

The invention discloses a signal filtering circuit-based intelligent control system for a roller shutter door. The intelligent control system is characterized in that the system mainly comprises a central processing unit, and an A / D converter, a door opening control circuit and a door closing control circuit which are connected with the central processing unit, a signal filtering circuit connected with the A / D converter, a photoelectric sensor and an infrared sensor which are connected with the signal filtering circuit, a door opening motor connected with the door opening control circuit, and a door closing motor connected with the door closing control circuit. The intelligent control system is simple in structure and low in cost, can also automatically open and close the door, and thus can ensure that the roller shutter door isolates products and production environment, and is suitable for popularization and application.

Owner:CHENGDU CLAY STAR TECH CO LTD

A bearing cleaning equipment with convenient loading and unloading

ActiveCN108176668BEasy to cleanEasy to separateCleaning using liquidsEngineeringStructural engineering

The invention discloses a bearing cleaning device which is convenient for loading and unloading, which comprises a cleaning box, an ultrasonic generator, a fixed ring, a fixed column, a mounting cylinder, a rotating rod, a pressure plate, a stretching column, and a locking mechanism. There is an ultrasonic generator, the top of the cleaning box is covered with a box cover, and a number of fixing rings are fixed on the bottom wall of the cleaning box. There are several layers of installation areas below, and each installation area is composed of a number of installation grooves that run through the side wall of the installation cylinder at the same level, and a rotating rod that can rotate along the vertical square is arranged in the installation groove. A rotating shaft is arranged on the rotating rod, and the rotating shaft is fixed on the side wall of the installation groove, and the outer end of the rotating rod is located outside the installation cylinder. In the present invention, by matching the rotating rod with the pressure plate, the bearing can be quickly separated from the rotating rod after cleaning, so that unloading becomes convenient and the production efficiency is improved.

Owner:XINCHANG LONG HAO BEARING CO LTD

Assembly welding tool generally used for hot blast main pipe elbows

InactiveCN103302434BQuality assuranceGuaranteed cleanlinessWelding/cutting auxillary devicesAuxillary welding devicesHot blastFlange

The invention provides an assembly welding tool generally used for hot blast main pipe elbows, aims to solve the problems in assembling and welding a hot blast main pipe elbow with different specifications, and comprises an assembling and welding platform base, a outlet flange positioning plate, an inlet flange center distance adjustment mechanism, an inlet flange height adjustment mechanism, an inlet flange angle adjustment mechanism, an inlet flange mounting hole center distance adjustment mechanism and a supporting frame adjusting mechanism, wherein the assembling and welding platform base is fixed on the horizontal plane, the outlet flange positioning plate and the supporting frame adjusting mechanism are mounted on the assembly welding platform base, the inlet flange center distance adjustment mechanism is mounted on one side of the assembling and welding platform base, and the inlet flange height adjustment mechanism and the inlet flange angle adjustment mechanism are fixed on the inlet flange center distance adjustment mechanism. The tool provided by the invention has the characteristics of compact structure and strong universality, guarantees the quality of products with different specifications, improves the working efficiency of welding and assembling, decreases the cost of rolled steel raw material, reduces the space occupied by equipment storage, and ensures the clean and civilized production environment of an enterprise.

Owner:QINGHUANGDAO NORTH METAL HOSE

Disc type electrostatic spraying device and process for low-temperature quick-drying water-based paint

The invention relates to the technical field of electrostatic spraying, in particular to a disc type electrostatic spraying device and process for low-temperature quick-drying water-based paint. The disc type electrostatic spraying device comprises a device body and an electric telescopic rod. The device body comprises a main bottom plate, and an auxiliary bottom plate is fixedly installed at one end of the main bottom plate. The electric telescopic rod is connected to the portion, on one face of the auxiliary bottom plate, of the main bottom plate, and an electrostatic sprayer body is fixedly installed at one end of the electric telescopic rod. According to the disc type electrostatic spraying device and process for low-temperature quick-drying water-based paint, a U-shaped strip plates and clamping tooth sleeves are arranged, so that clamping tooth strips are engaged with the clamping tooth sleeves, a U-shaped conveying chain body can drive a workpiece to rotate during movement, when the workpiece is subjected to electrostatic spraying, paint can be more evenly attached to the whole workpiece, then the spraying quality of the workpiece is improved, the situation of uneven spraying is reduced, the qualified rate of the workpiece is increased, the production cost of enterprises is indirectly reduced, and follow-up personnel maintenance and detection are indirectly reduced.

Owner:南通普菲特涂装有限公司

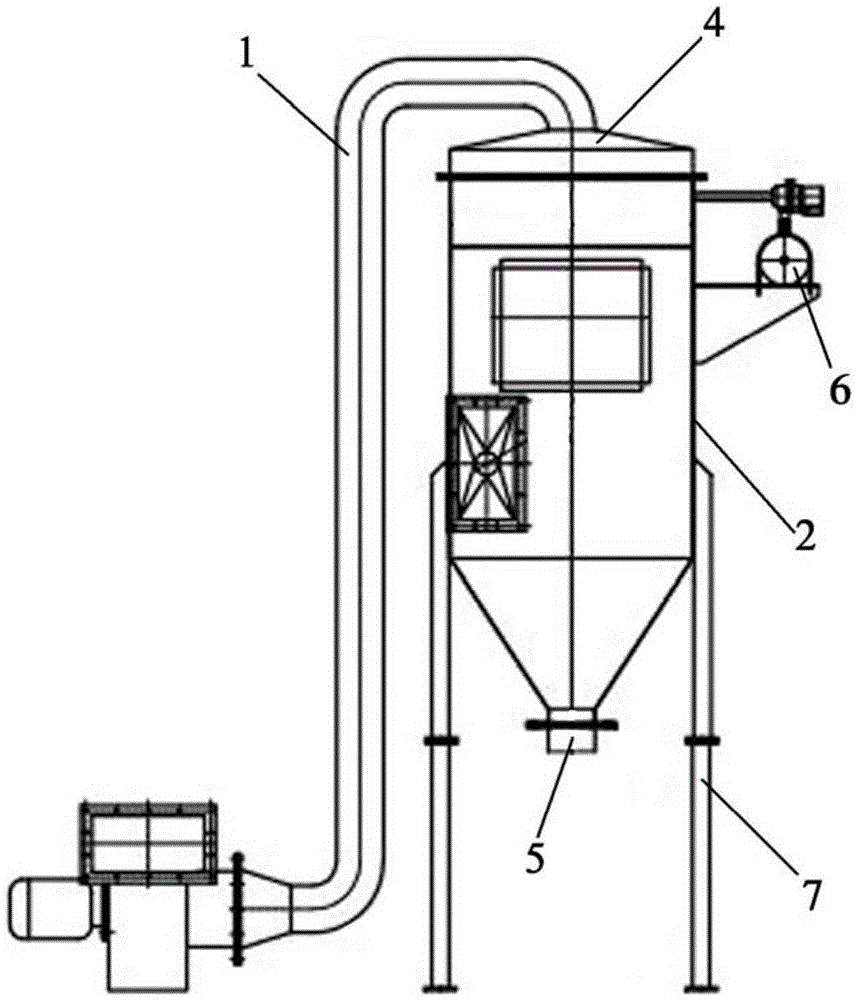

Dust collection system for dust workshop

InactiveCN105521681AWill not cause blockageNo cloggingCombination devicesEngineeringDust collection system

The invention discloses a dust collection system for a dust workshop. The dust collection system comprises a dust collector and a gas inlet pipe, the dust collector comprises a shell, a support and a dust discharge port, the gas inlet pipe is connected with the top of the dust collector, the support supports the dust collector, gas inlet holes are formed in the shell, the dust discharge port is formed in the conical lower end of the shell, and an end cover is arranged at the top of the shell. The dust collection system for the dust workshop has the advantages that cleaning frequency is decreased, working efficiency is improved, a workshop production environment is guaranteed and food safety risks are reduced.

Owner:郭昱辰

A method and system for recycling waste glue in viscose production

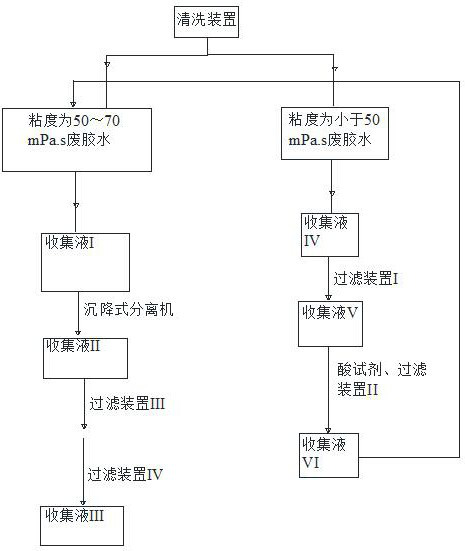

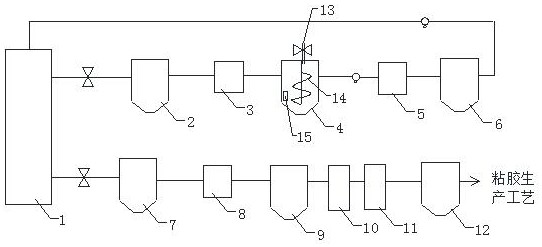

ActiveCN109322011BEmission reductionReduce pressure on environmental protectionArtificial filament recoveryTreatment involving filtrationViscoseAdhesive glue

The invention discloses a method and a system for comprehensive utilization of waste viscose water in viscose production, and belongs to the technical field of production of viscose short fibers. Themethod and the system are characterized in that the obtained waste viscose water can be separately treated according to viscosity in a cleaning device; the waste viscose water with viscosity smaller than 50 mPa.s is simply filtered and neutralized, and then is used for replacing fresh water to primarily wash a spray head and an assembly; the waste viscose water with viscosity of 50 to 70 mPa.s isseparated and filtered by a precipitating type separator and a filtering device, and is directly used for preparing the viscose, so that the usage amounts of water and viscose raw material for viscoseproduction can be reduced, and the production cost is reduced.

Owner:YIBIN GRACE +1

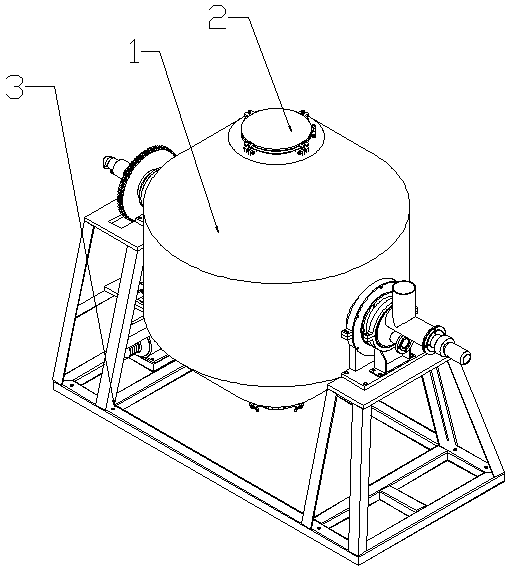

Xanthate primary drying machine

PendingCN108759448AImprove distributionIncrease cooling areaGranular material dryingDrying solid materialsSpontaneous combustionMoisture absorption

The invention provides a xanthate primary drying machine. The xanthate primary drying machine comprises a machine base. A barrel is arranged on the machine base. A jacket is arranged on the barrel. Aheat insulation plate layer is arranged on the outer side of the jacket. A discharging port is arranged on the barrel. A shaftless auger and a charging port are arranged on one side of the barrel through a bearing II. The charging port is arranged above the central line of the shaftless auger. A gear and a bearing I are arranged on the other side of the barrel. The gear is connected with a speed reducer on the machine base. The speed reducer is connected with a motor. A heat exchange pipe is arranged in the barrel. The xanthate primary drying machine is in seal connection with a granulator, gas produced in the granulating process does not overflow, and the production environment is ensured; xanthate granules are prevented from making contact with damp air, and the situation that xanthate is decomposed due to moisture absorption, consequently, the content of xanthate is lowered, and a spontaneous combustion phenomenon occurs is avoided; and the shaftless auger is additionally arranged,charging of the primary drying machine is conducted under the sealing and vacuum conditions, meanwhile, rotation can be conducted, the granules can be rapidly cooled, and the effective volume of the primary drying machine is increased by additionally designing the shaftless auger above the central line of the axis.

Owner:YANTAI HUMON CHEM AUX CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com