Xanthate primary drying machine

A primary dryer and xanthate technology, applied in drying, drying of solid materials, drying of granular materials, etc., can solve problems such as easy moisture absorption, easy spontaneous combustion, and inability to effectively deal with xanthate, and achieve an increase in cooling area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

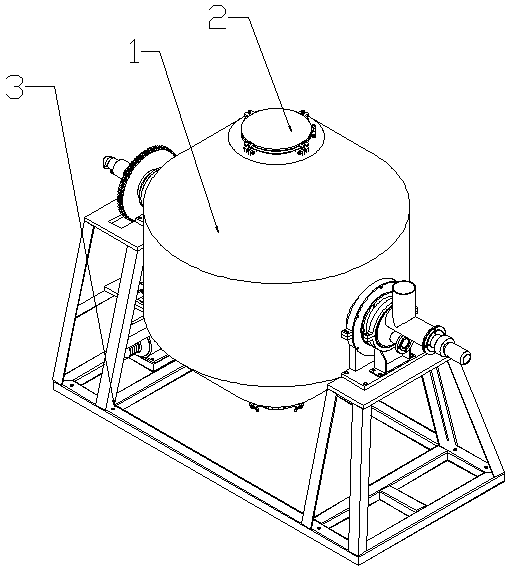

[0017] For better understanding and implementation, the present invention will be further described below in conjunction with the accompanying drawings: a kind of xanthate primary drying machine, comprising a base 3, a cylinder 1 is provided on the base 3, a jacket 5 is provided on the cylinder 1, and a jacket 5 is provided on the cylinder 1. The outer side of the sleeve 5 is provided with an insulation board layer 4, the barrel 1 is provided with a discharge port 2, and the side of the barrel 1 is provided with a shaftless auger 6 and a feeding port 7 through the bearing Ⅱ16, and the shaftless auger feeds, so that the granulation process The gas and dust released from the tank are not easy to be released into the external air. The feeding port 7 is located above the center line of the shaftless auger, which increases the volume of the material in the kettle and enables the material to cool down rapidly during the granulation process. The cylinder body 1 The other side is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com