Rapid treatment device for surface of steel plate

A processing device and fast technology, applied in grinding drive devices, surface polishing machine tools, grinding machines, etc., can solve the problems of low surface treatment of steel plates, poor removal effect, low rust removal efficiency, etc. Lacquer effect, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

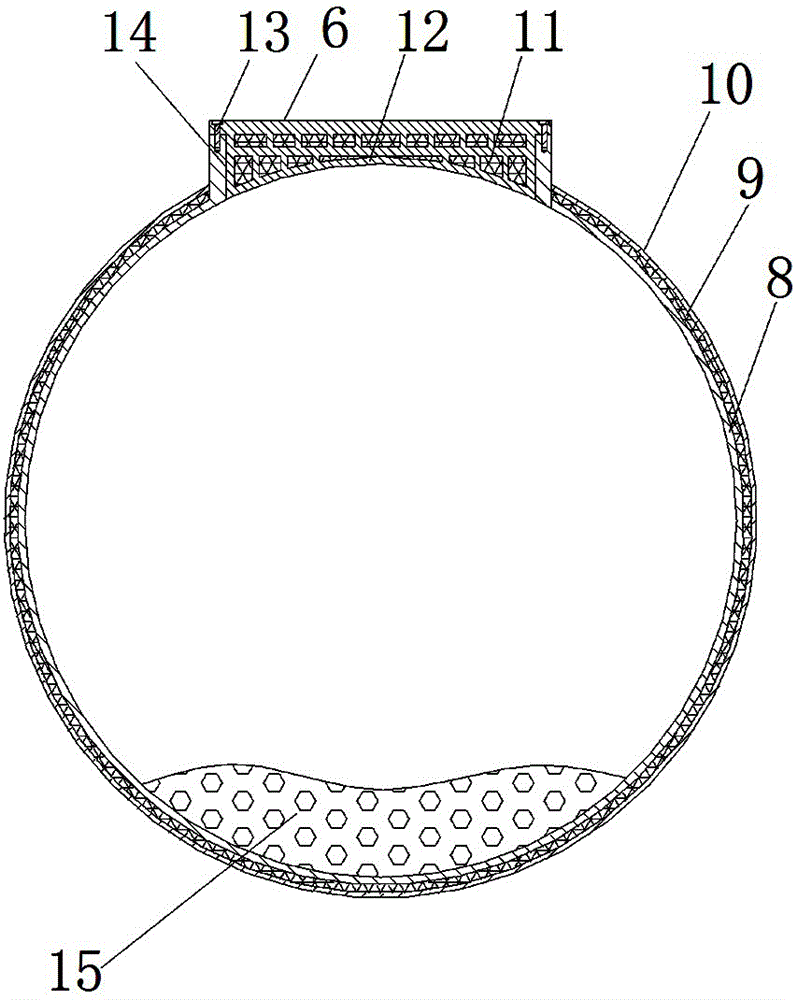

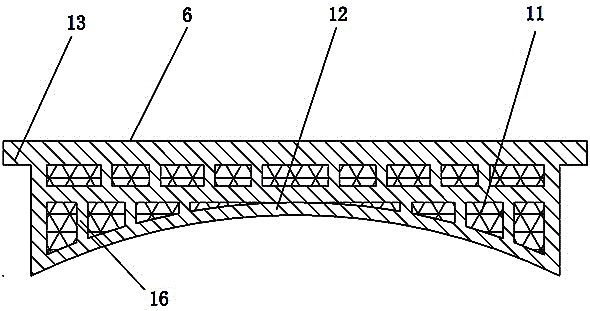

[0019] Such as Figure 1~Figure 3 As shown, a steel plate surface rapid processing device includes a mounting base 1, a driving device and a roller 7, the roller 7 is located on one side of the mounting base 1, the driving device is installed on the mounting base 1, and the The driving device drives the drum 7 to rotate, and the drum 7 is provided with a feeding hole 14, and the feeding hole 14 is sealed and connected with a cover plate 6, and several small steel balls 15 are housed in the drum 7, and the drum 7 When rotating, the small steel ball 15 collides with the steel plate, thereby removing rust and burrs on the surface of the steel plate, and also increasing the surface area of the steel plate, so that small concave-convex surfaces are produced on the surface of the steel plate, thereby inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com