Dustproof ore crushing equipment

An ore crushing and dust-proof technology, applied in the direction of removing smoke and dust, sieves, grilles, etc., can solve problems such as unevenness, and achieve the effect of avoiding dust explosion, good site environment, and eliminating dust explosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

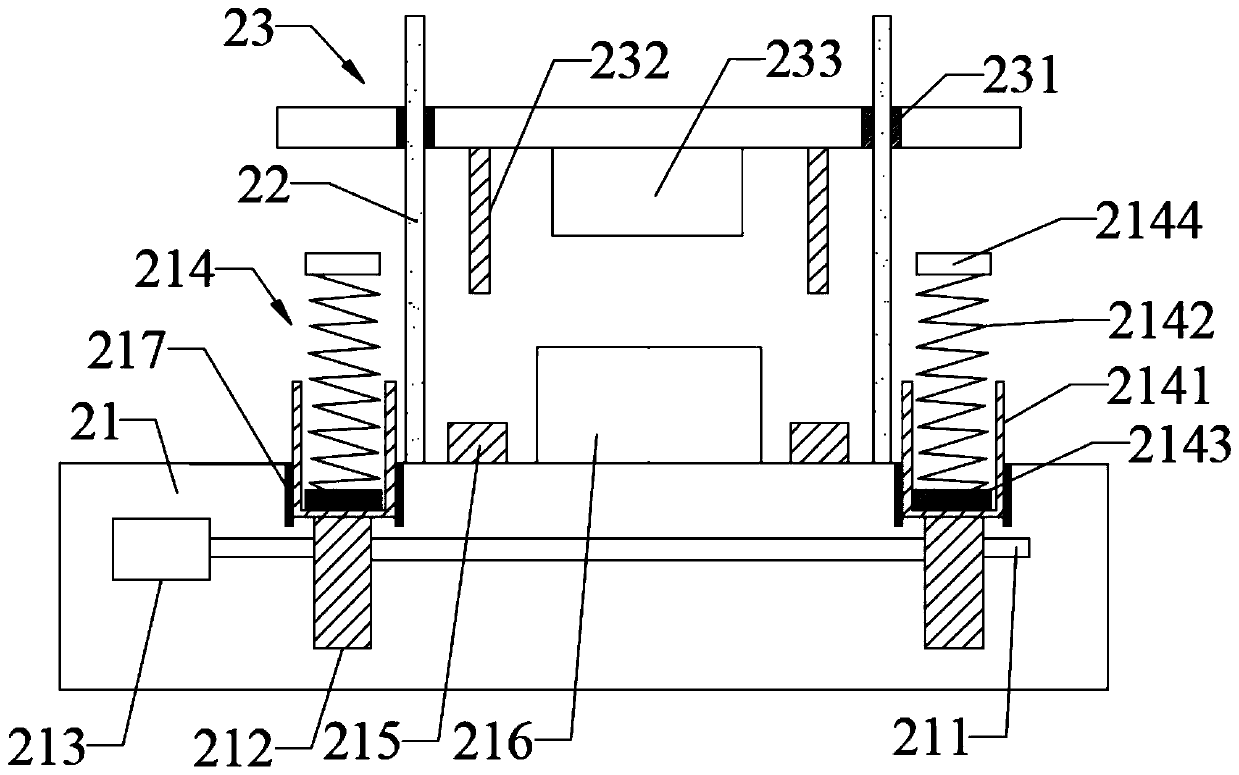

[0031] A dust-proof ore crushing equipment, comprising a sealed bin 1, a crushing device 2 and a collection bin 3, the crushing device 2 is arranged on the top of the sealed bin 1, and the collection bin 3 is arranged in the sealed bin 1, the Said sealed chamber 1 is provided with an air suction hole along the tangential direction of its cylindrical surface;

[0032] The crushing device 2 includes a hammering device 23 provided with a fixed plate, and a workbench 21 located below the hammering device 23. An electromagnetic moving head 232 and a hammering moving head 233 are arranged below the hammering device 23. The workbench 21 is provided with an electromagnetic fixed head 215 directly below the electromagnetic moving head 232 and a pounding fixed head 216 directly below the striking moving head 233. When the electromagnetic fixed head 215 and the electromagnetic moving head 232 maintain opposite sex , when the described hammering device 23 moves downward through the guide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com