Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Good anti-reflection properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquid crystal display device

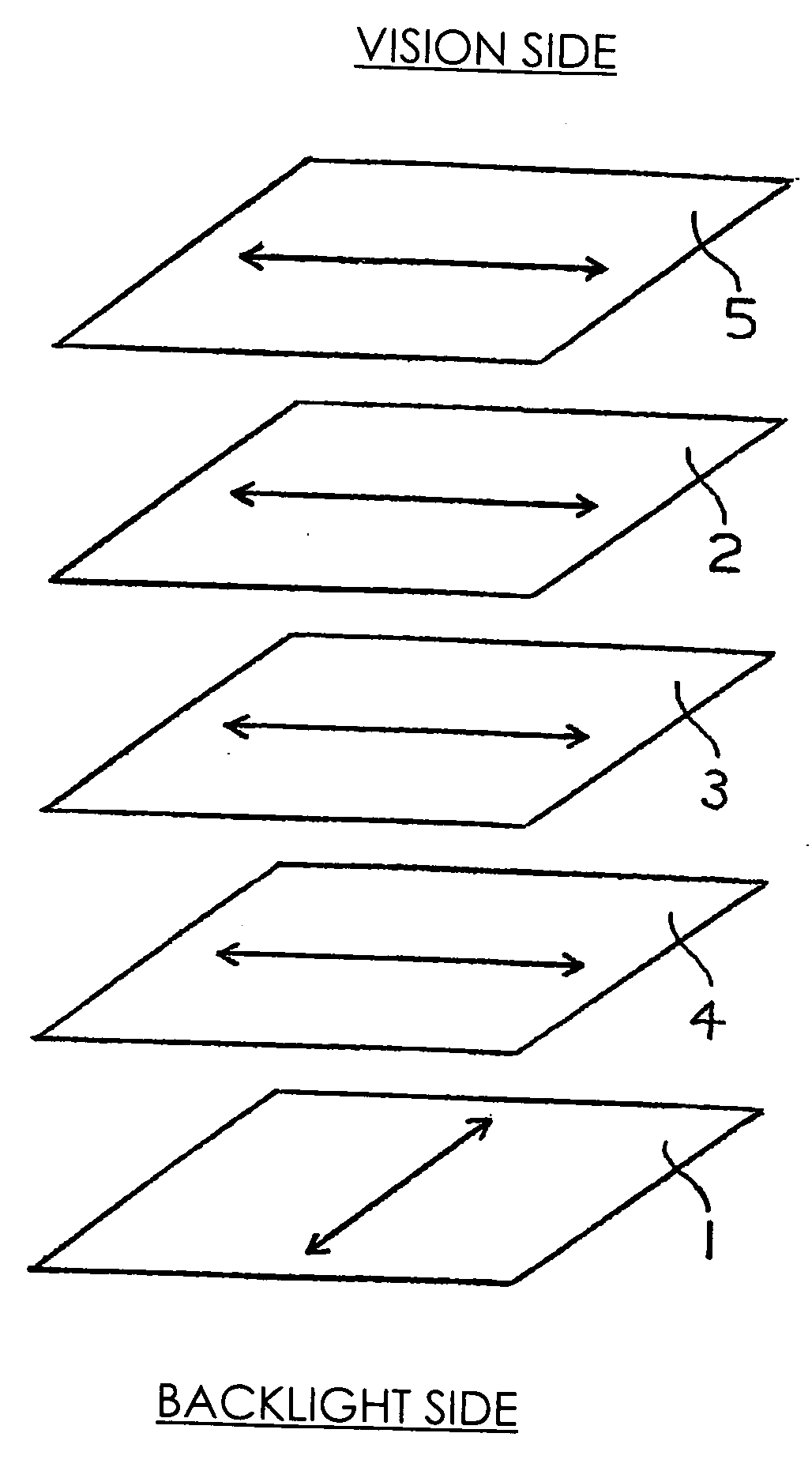

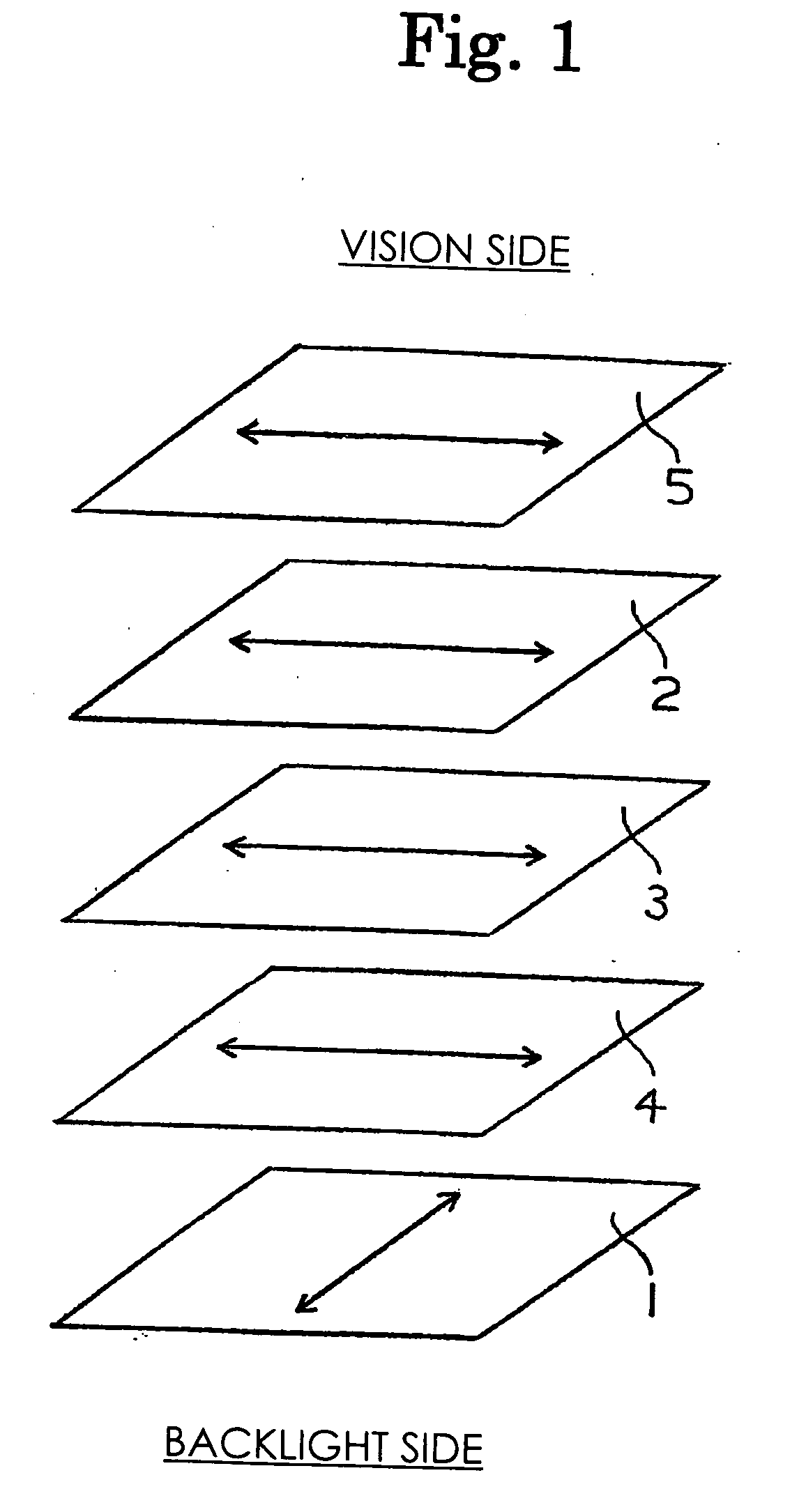

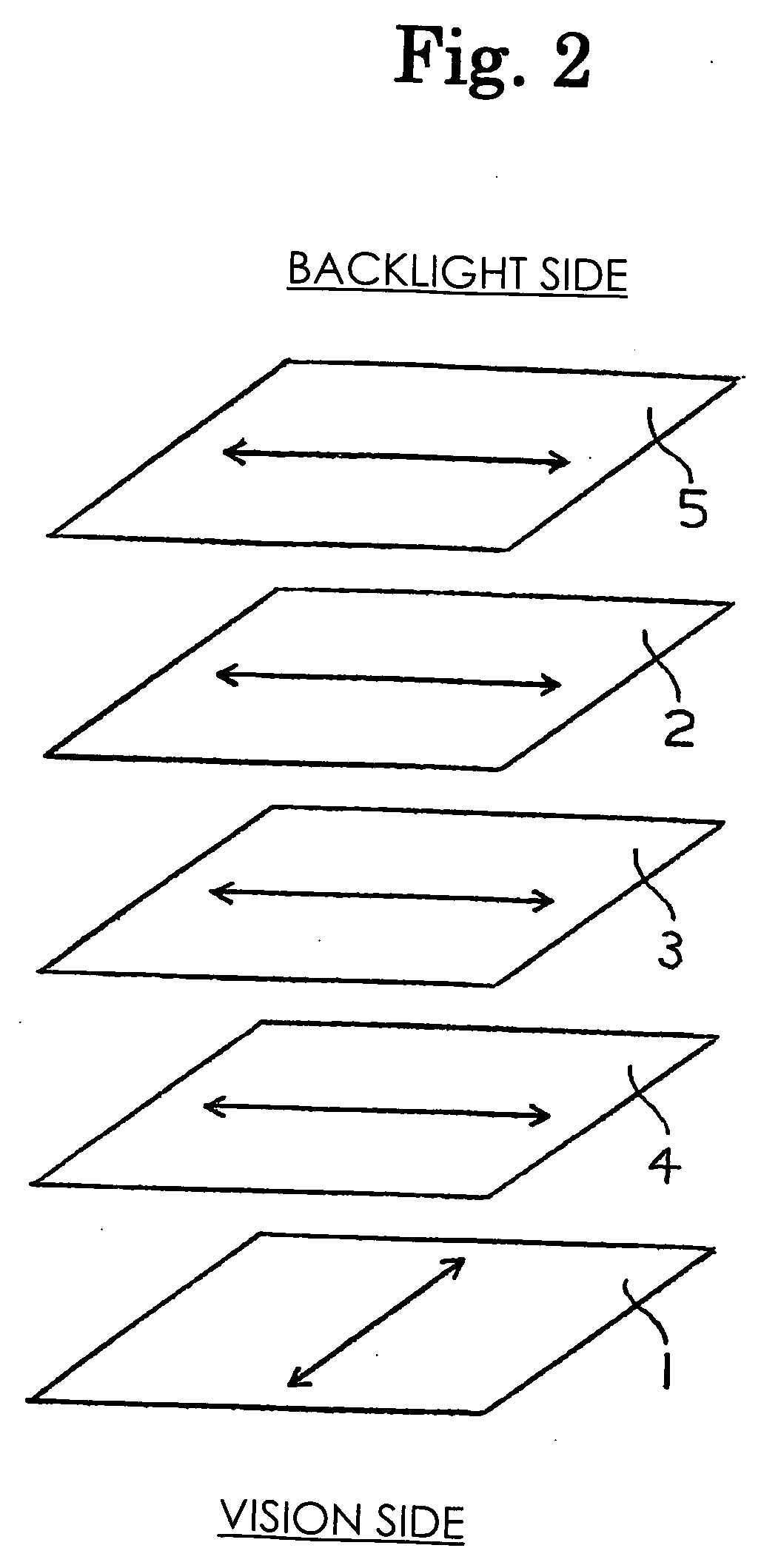

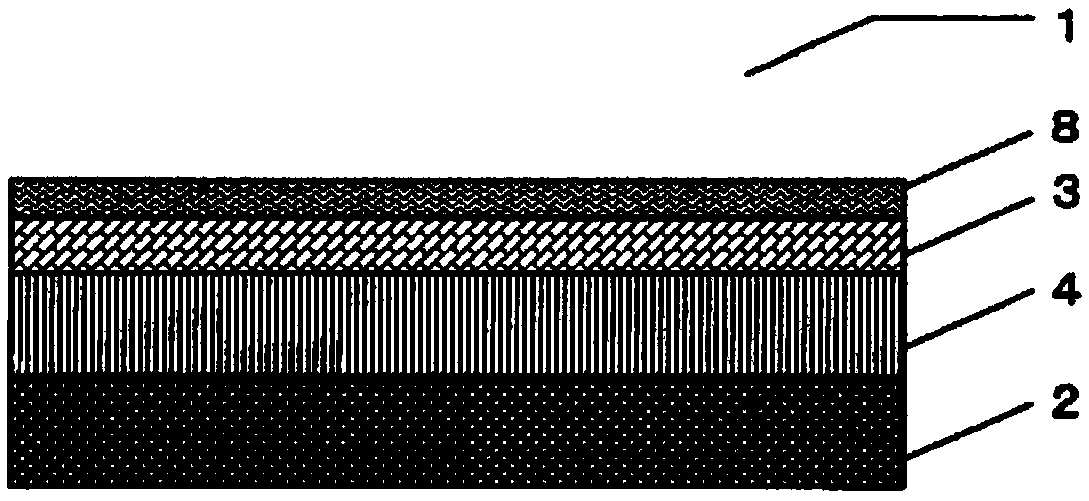

ActiveUS20070091228A1Good anti-reflection propertiesImprove scratch resistanceNon-linear opticsIn planeRefractive index

A liquid crystal display device of an in-plane switching mode comprises at least optically anisotopic members (A) and (B) and liquid crystal cell disposed between a pair of polarizers having absorrption axes disposed approximately perpendicularly to each other, wherein nzA>nyA and nxB>nzB (nxA, nxB: refractive indices (n) in the direction of the in-plane slow axis; nyA, nyB: n in the in-plane direction perpendicular to the above direction; nzA, nzB: n in the direction of thickness, each at 550 nm); the in-plane slow axes of (A) and (B) are approximately parallel or perpendicular to each other; and the in-plane slow axis of (A) is approximately parallel or perpendicular to the absorption axis of a polarizer closer to (A). The antireflection property, scratch resistance and durability are exellent, the angle of field is wide, and uniform display of images with great contrast can be achieved at any angle of observation.

Owner:ZEON CORP

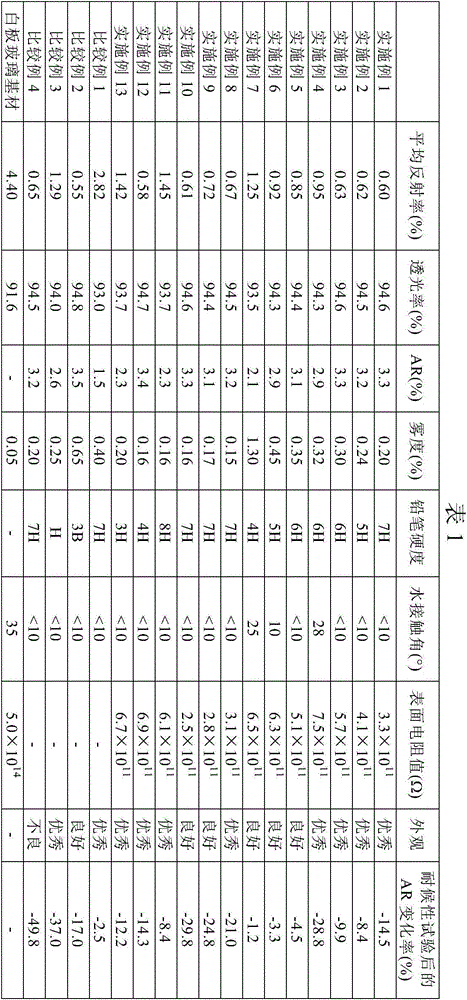

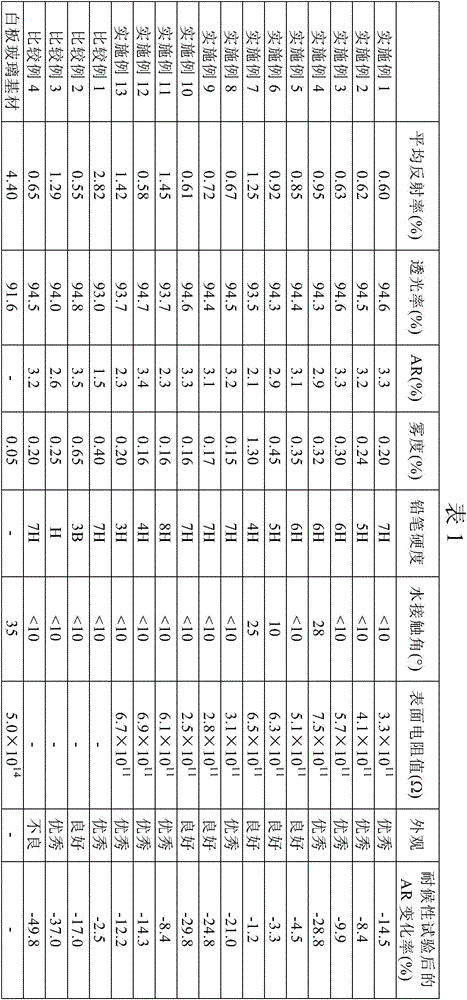

Method for producing antireflection film, antireflection film, polarizing plate, and image display device

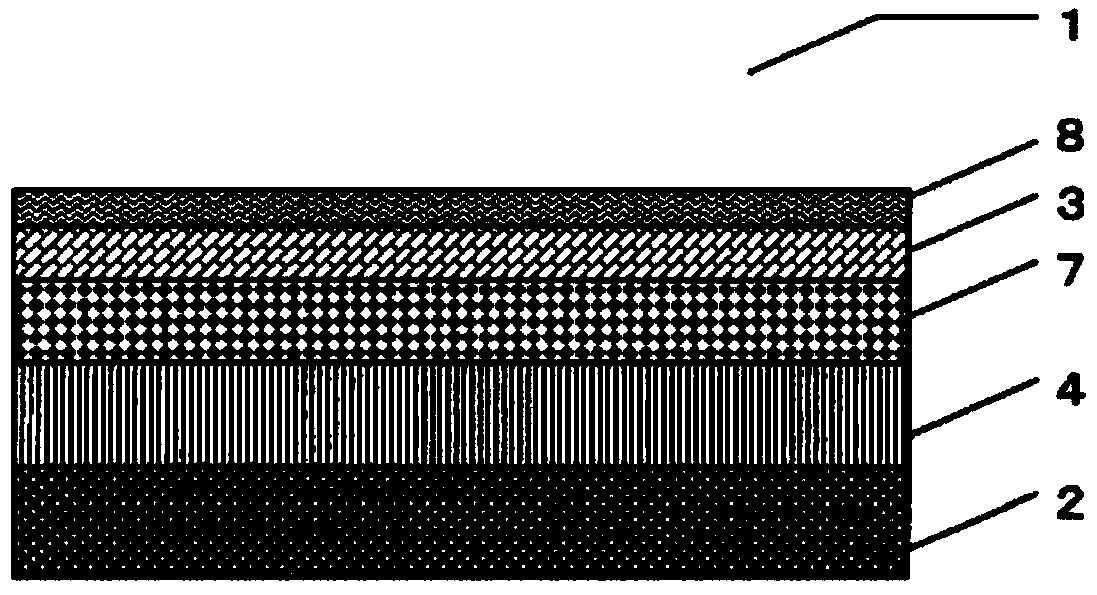

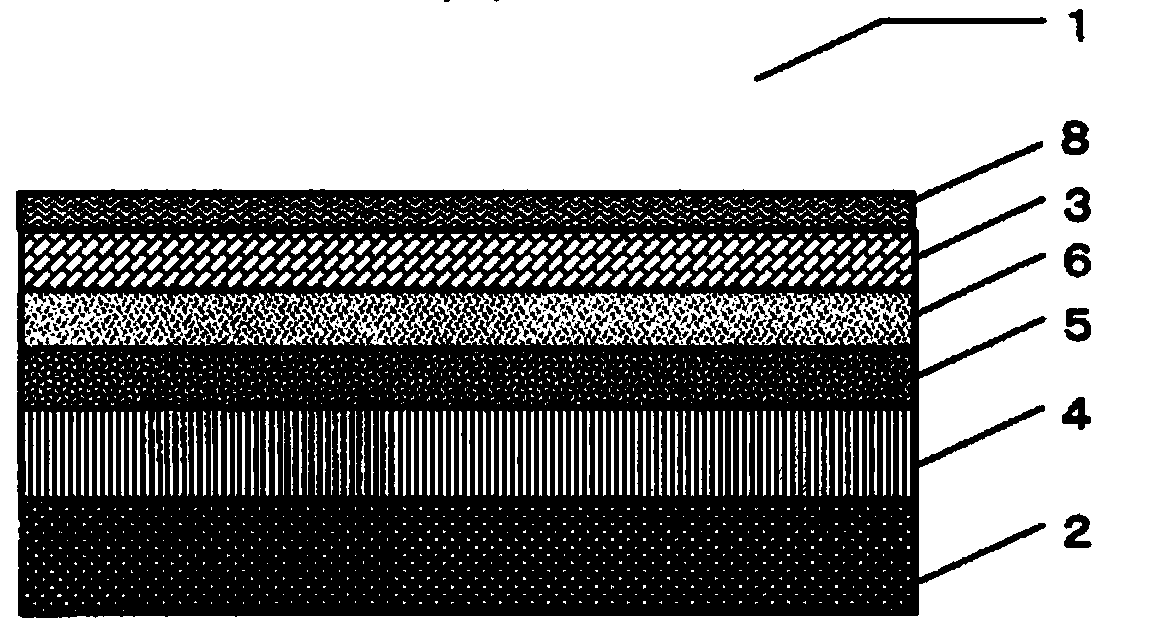

ActiveCN103765249AGood anti-reflection propertiesImprove scratch resistancePolarising elementsCoatingsRefractive indexSurface roughness

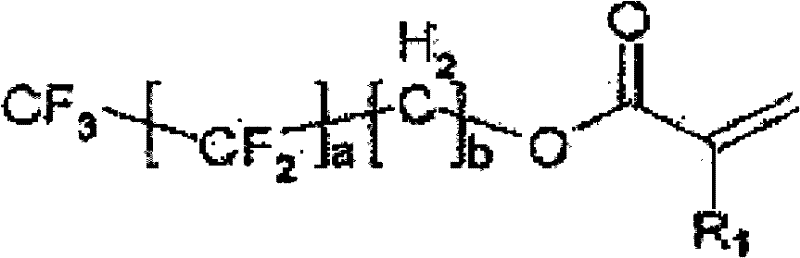

The present invention provides a production method for the easy production of an antireflection film which has excellent antireflection properties, excellent scratch resistance, and antifouling performance and with which the occurrence of faint whitening that has thus far not been addressed is controlled, as well as an antireflection film, and a polarizing plate and image display device that use the film. The production method for producing an antireflection film involves performing, in the following order, a step (1) for forming a coating film by applying, on a transparent substrate, a composition containing at least a fluorine-containing compound, microparticles, and a binder resin and that is for forming a low-refractive-index layer, a step (2) for phase separation of the coating film into a low-refractive-index phase and an antifouling phase, and a step (3) for forming a low-refractive-index layer and an antifouling layer for covering the entire surface of the low-refractive-index layer by heating the low-refractive-index phase and the antifouling phase, or by exposing the low-refractive-index phase and the antifouling phase to ionizing radiation. In the production method, at least a transparent substrate, a low-refractive-index layer, and an antifouling layer are formed in that order, and the fluorine atom / carbon atom ratio measured by X-ray photoelectron spectroscopy (XPS) from the antifouling layer side is between 0.6 and 1.0, the silicon atom / carbon atom ratio is less than 0.25, and the average surface roughness of the antifouling layer (Ra') is 10 nm or less.

Owner:DAI NIPPON PRINTING CO LTD

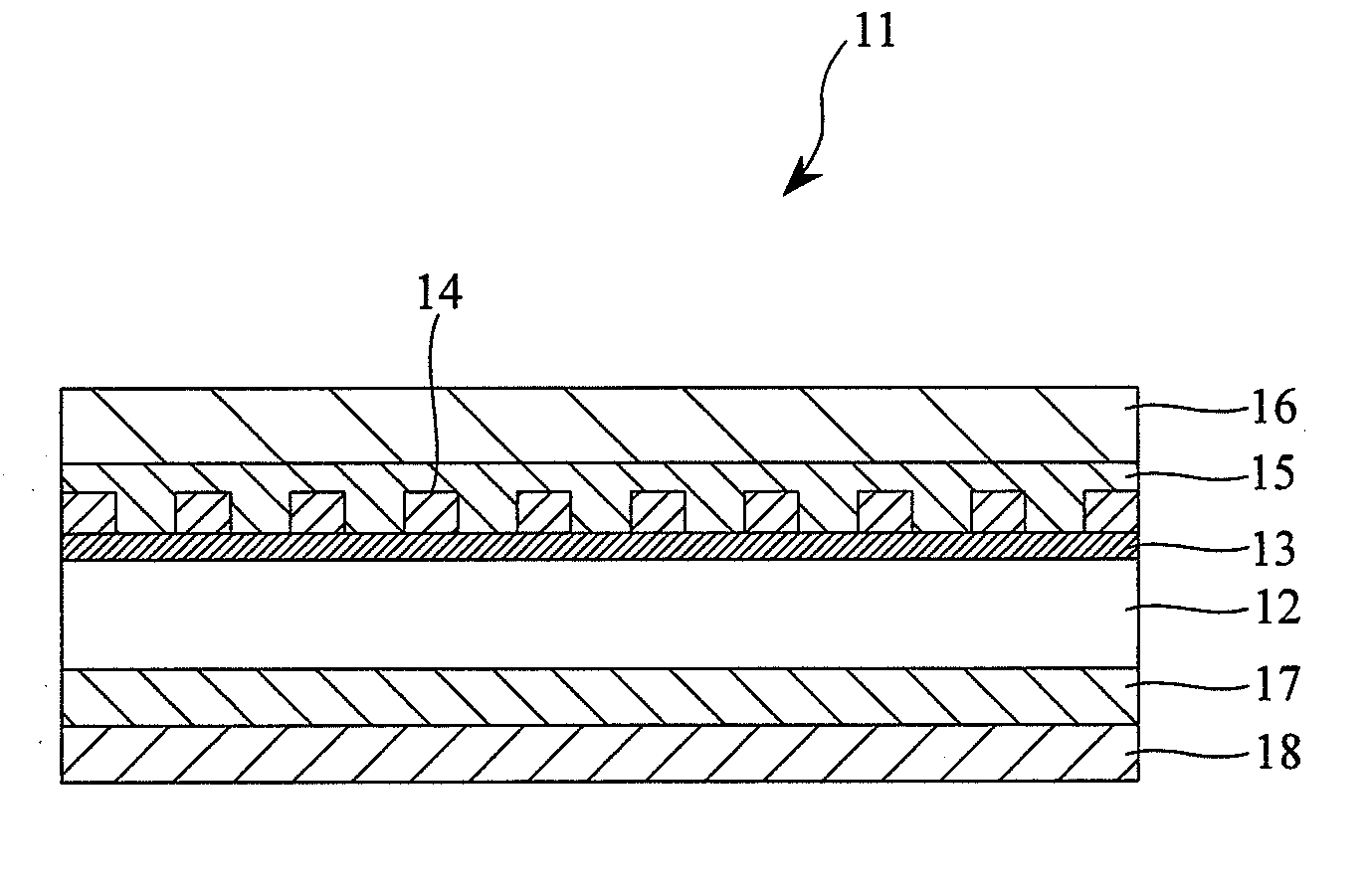

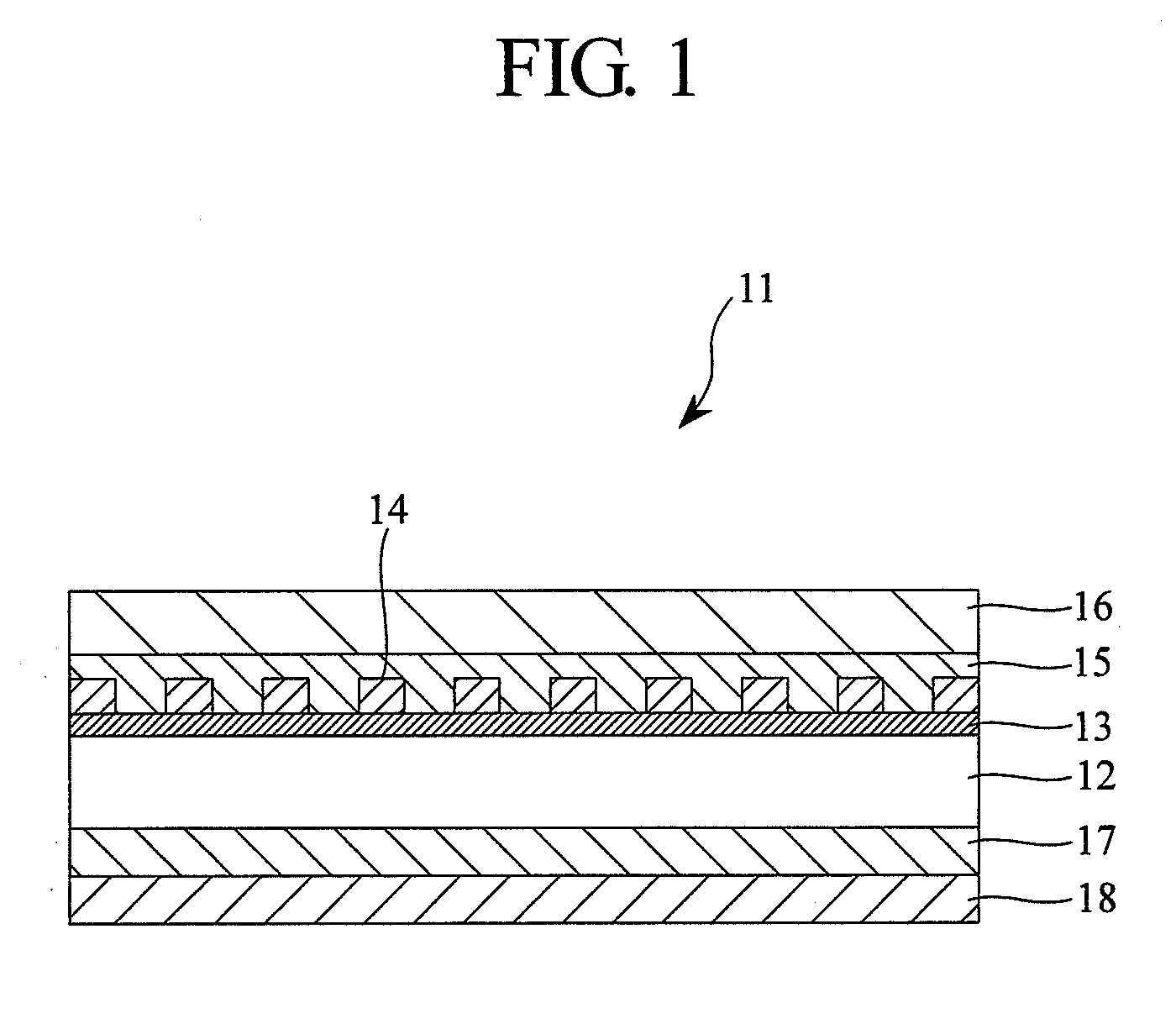

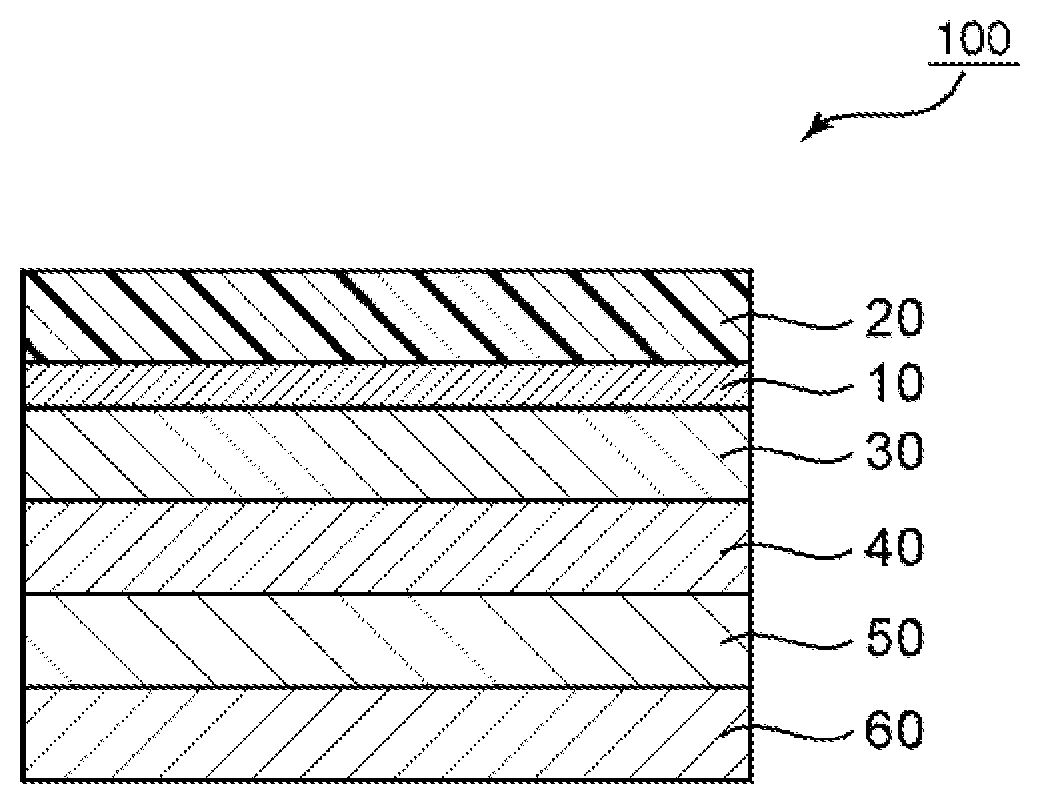

Optical filter for display, and display and plasma display panel provided with the optical filter

InactiveUS20100073764A1Easy to prepareGood electromagnetic wave shielding propertiesMirrorsMagnetic/electric field screeningInter layerDisplay device

[Problem to be Solved] To provide an optical filter for display which can be easily prepared, which is thin and light, which has excellent electromagnetic wave shielding property and antireflection property, and which scarcely suffers from occurrence of interference fringe.[Means for Solving Problem] An optical filter for display comprising at least one transparent film, a mesh-shaped conductive layer provided on the one transparent film, and a hard coat layer provided on the mesh-shaped conductive layer, wherein an intermediate layer is further provided between the transparent film and the mesh-shaped conductive layer, and the intermediate layer has refractive index of 1.60 to 1.80 and contact angle of 70 to 100 degrees.

Owner:BRIDGESTONE CORP

Coating composition for antireflection, antireflection film and method for preparing the same

InactiveUS20100265580A1Excellent abrasionExcellent characteristicsSynthetic resin layered productsPolarising elementsManufacturing cost reductionPolymer science

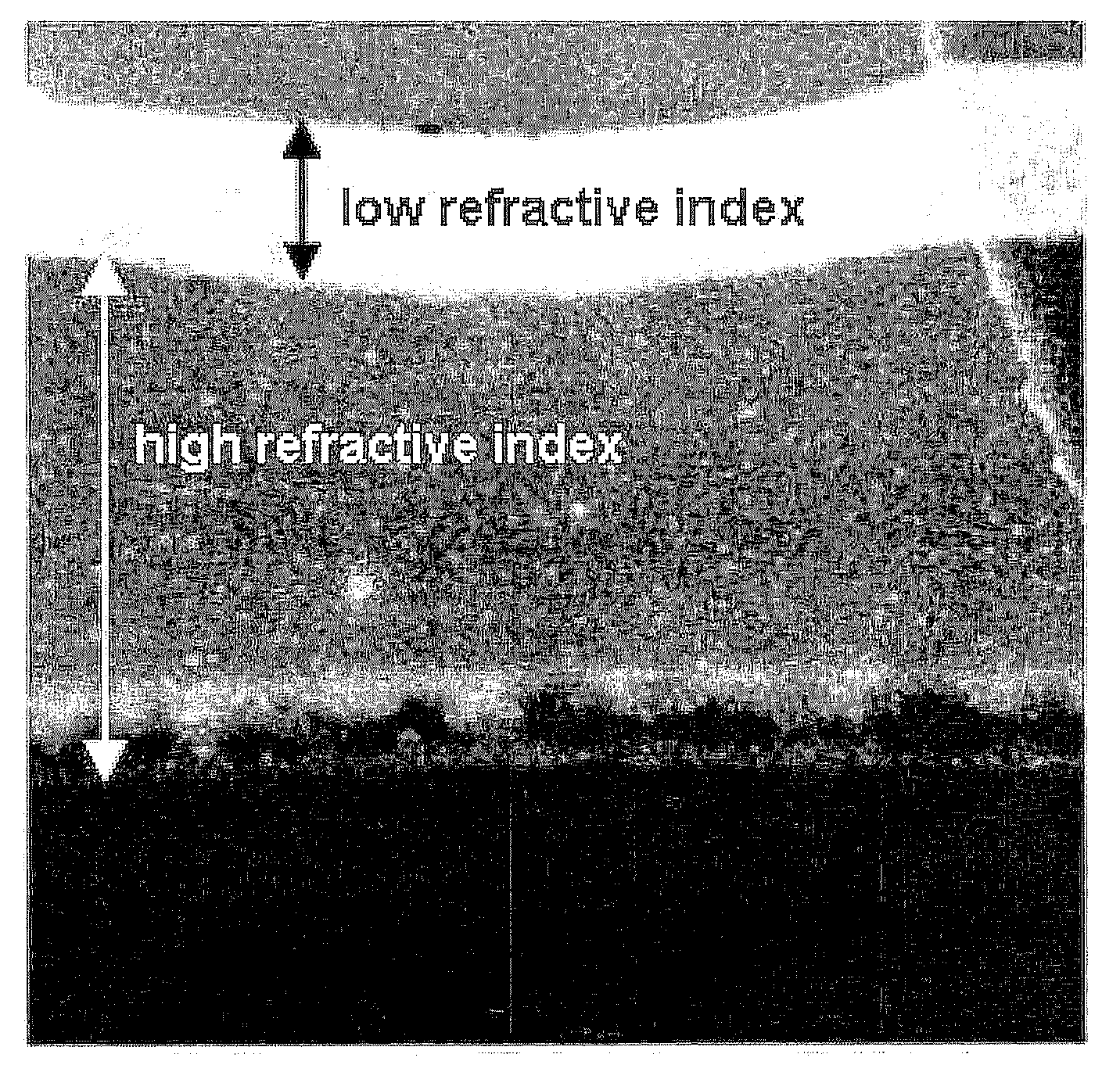

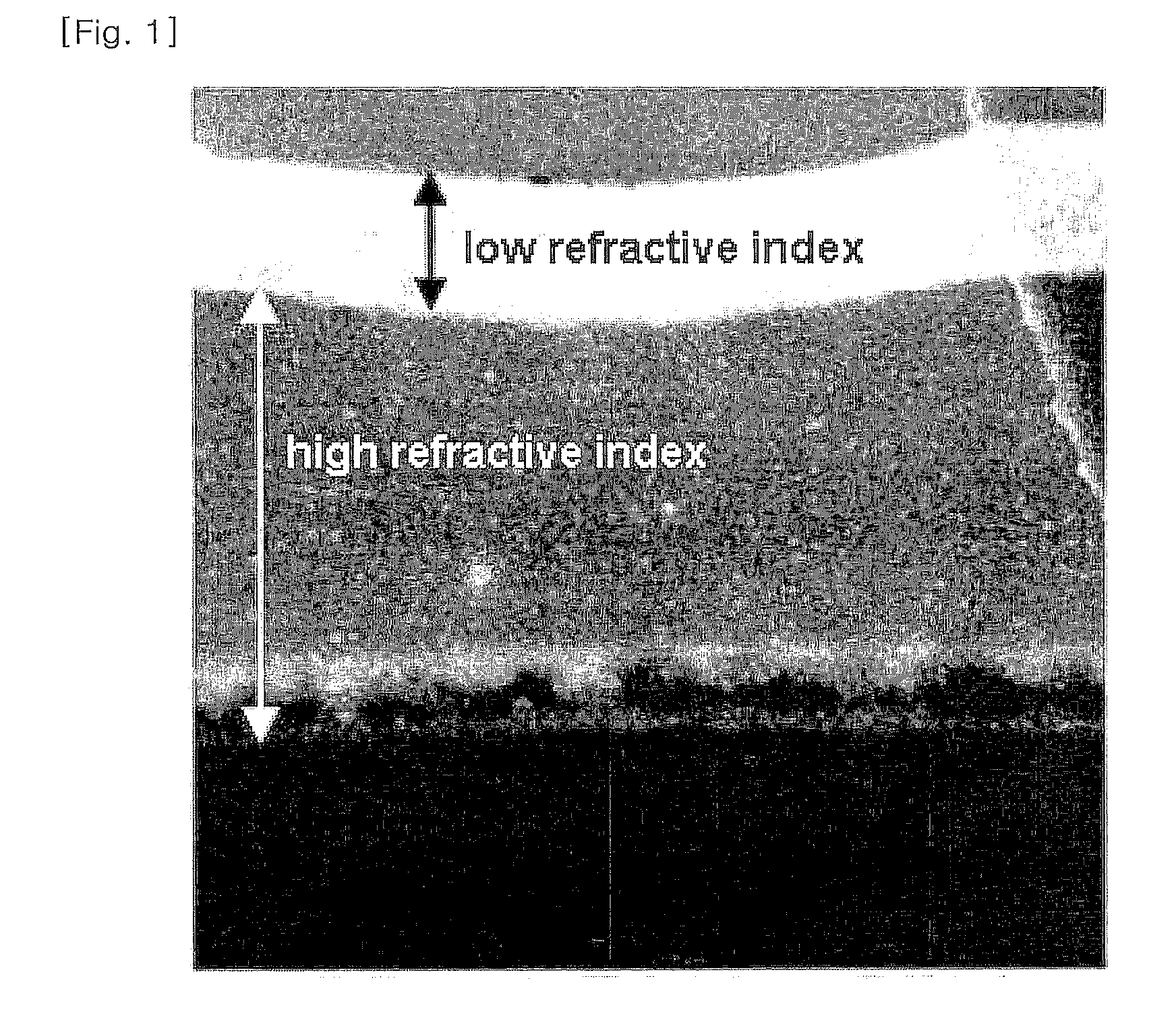

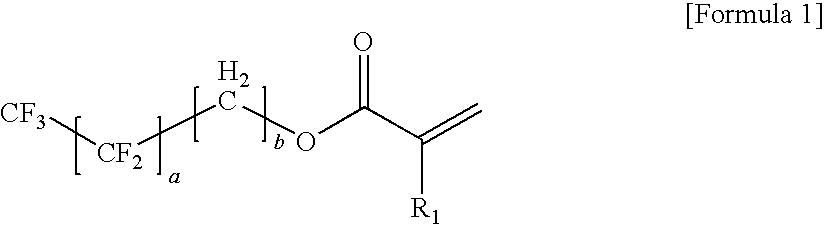

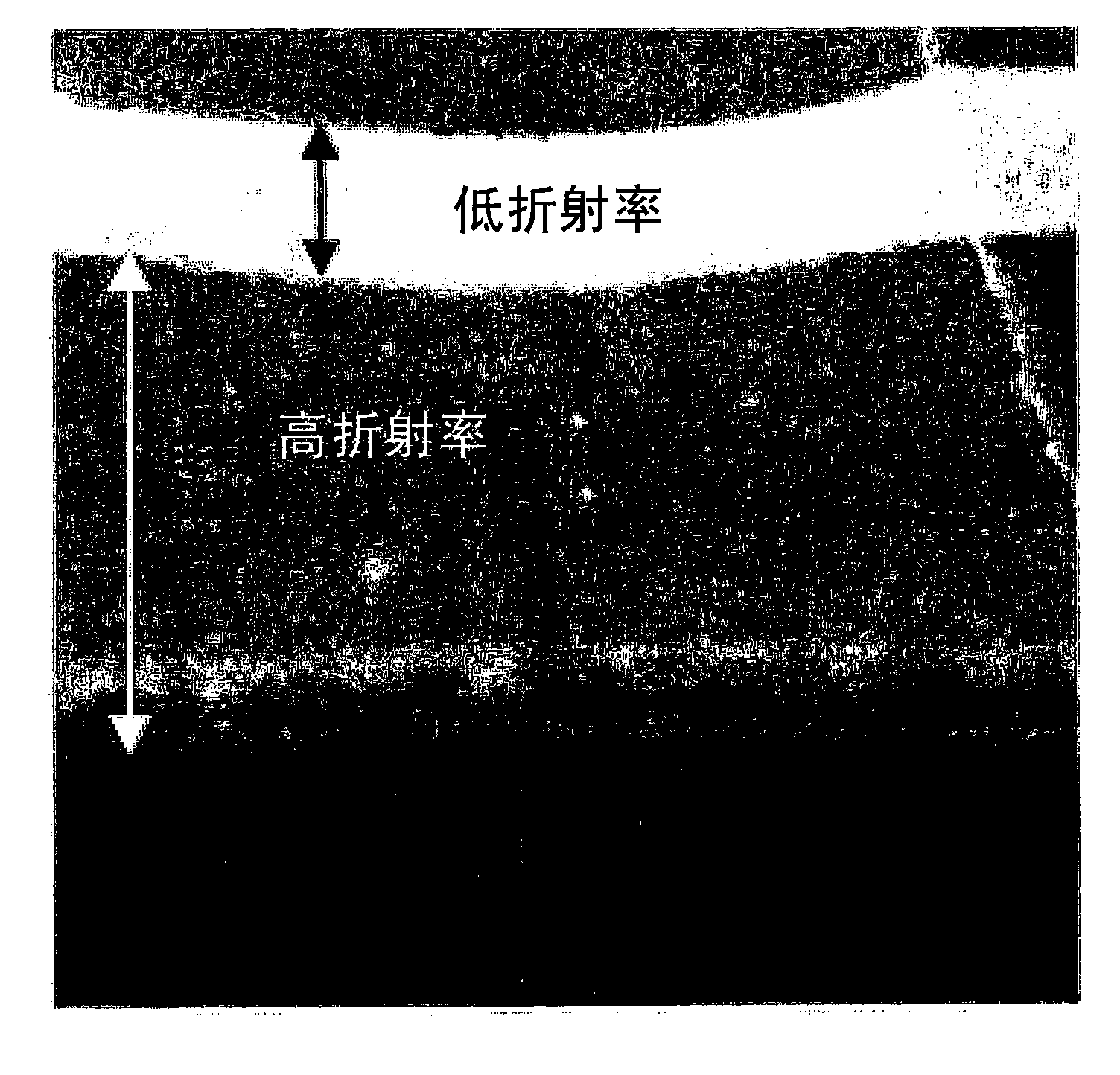

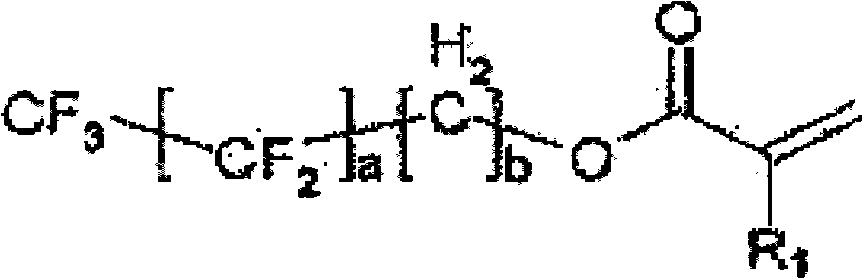

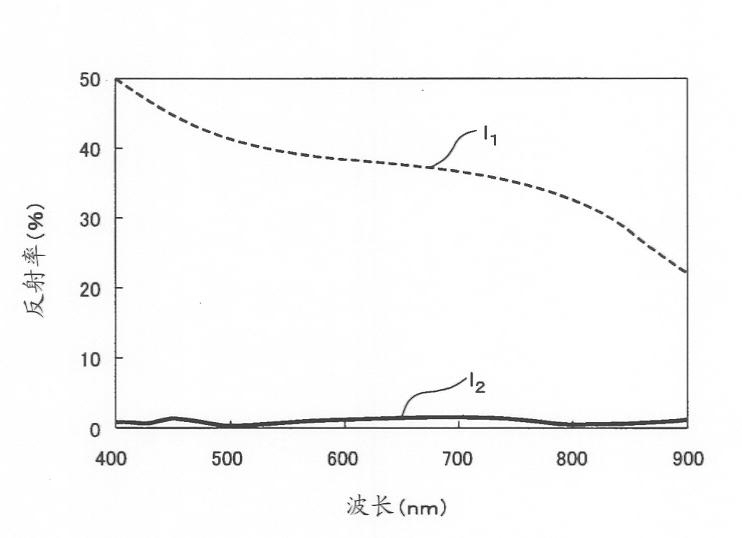

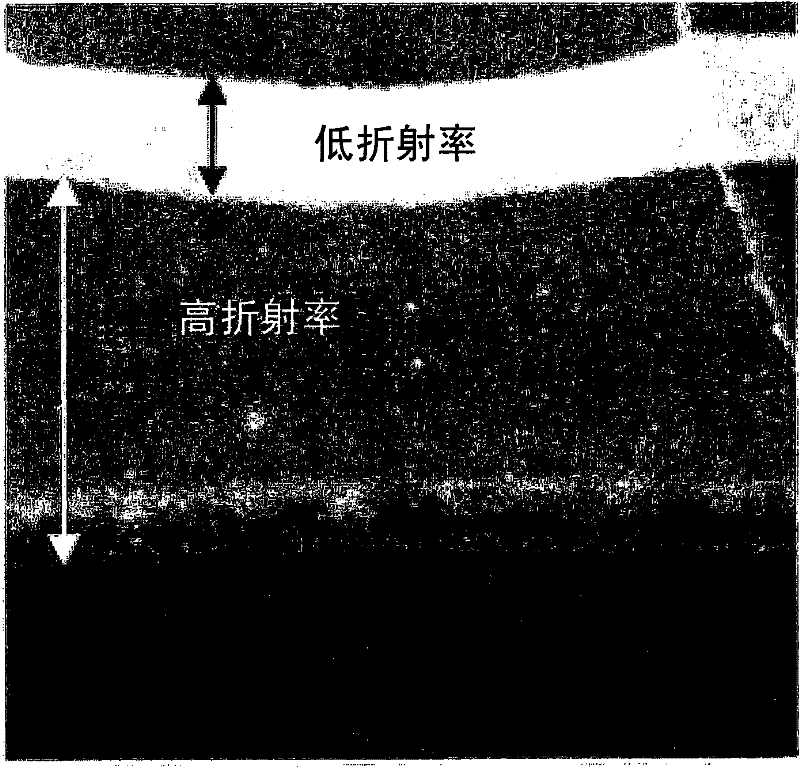

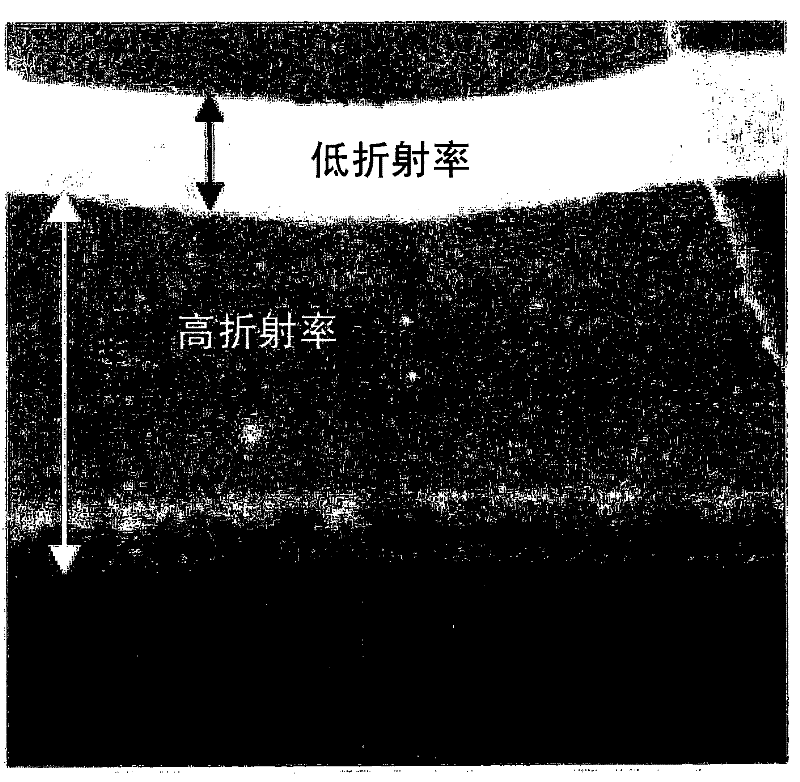

The present invention provides a coating composition for antireflection that includes a low refractive material having a refractive index of 1.2 to 1.45 and a high refractive resin having a refractive index of 1.46 to 2, in which the difference in the surface energy between two materials is 5 mN / m or more; an antireflection film manufactured using the coating composition for antireflection; and a method of manufacturing the antireflection film. According to the present invention, the antireflection film having excellent abrasion resistance and antireflection characteristic can be manufactured using a single composition by one coating process, thereby reducing manufacturing cost.

Owner:LG CHEM LTD

Coating composition for antireflection, antireflection film and method for preparing the same

ActiveCN101855303AExcellent abrasion resistance and low refractive propertiesImprove processing efficiencyMaterial nanotechnologyNanostructure manufactureSurface energyIon

The present invention provides a coating composition for ant iref lection that includes a low refractive material having a refractive index of 1.2 to 1.45 and a high refractive resin having a refractive index of 1.46 to 2, in which the difference in the surface energy between two materials is 5 mN / m or more; an ant iref lection film manufactured using the coating composition for ant iref lection; and a method of manufacturing the ant iref lect ion film. According to the present invention, the ant iref lect ion film having excellent abrasion resistance and antiref lection characteristic can be manufactured using a single composition by one coating process, thereby reducing manufacturing cost.

Owner:LG CHEM LTD

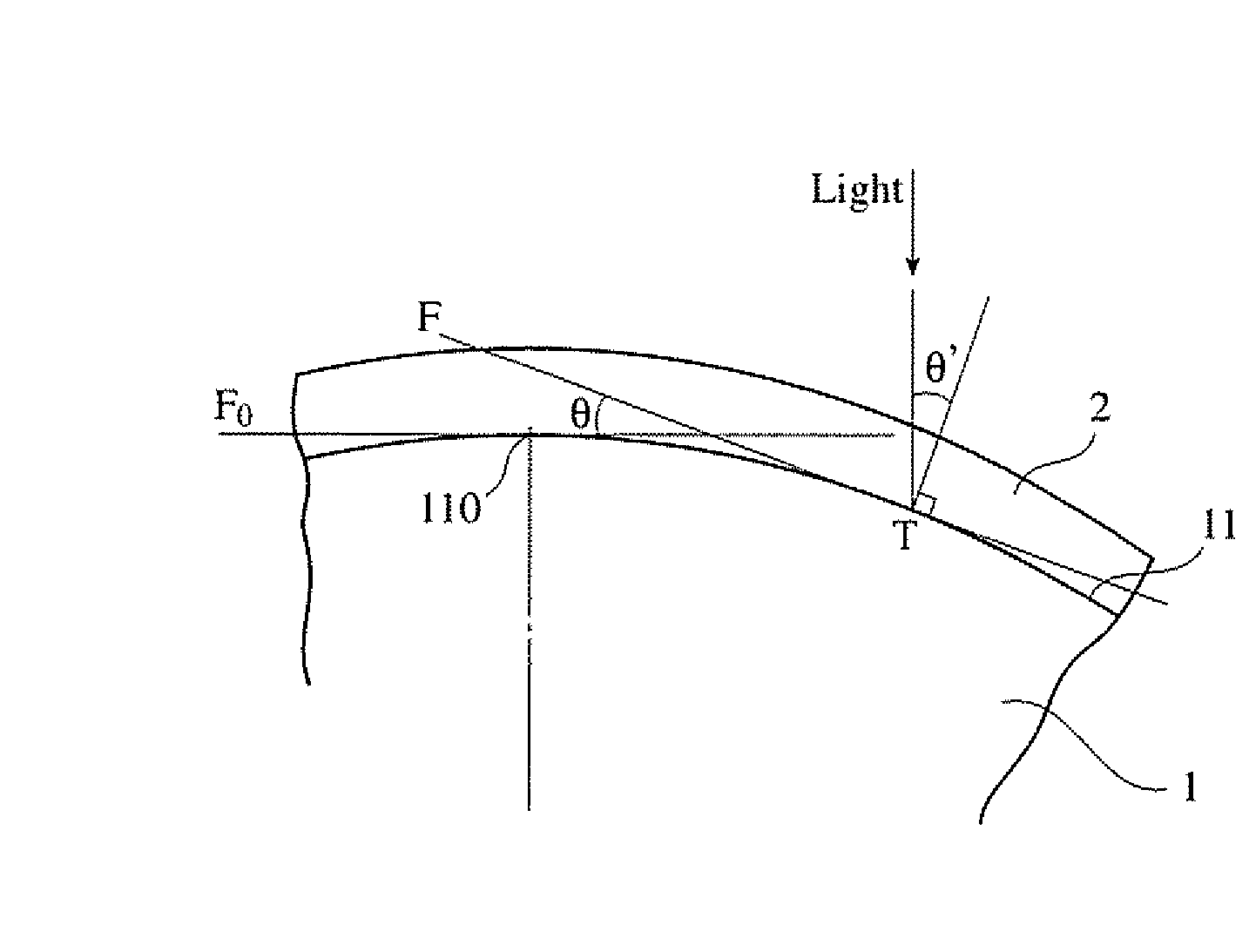

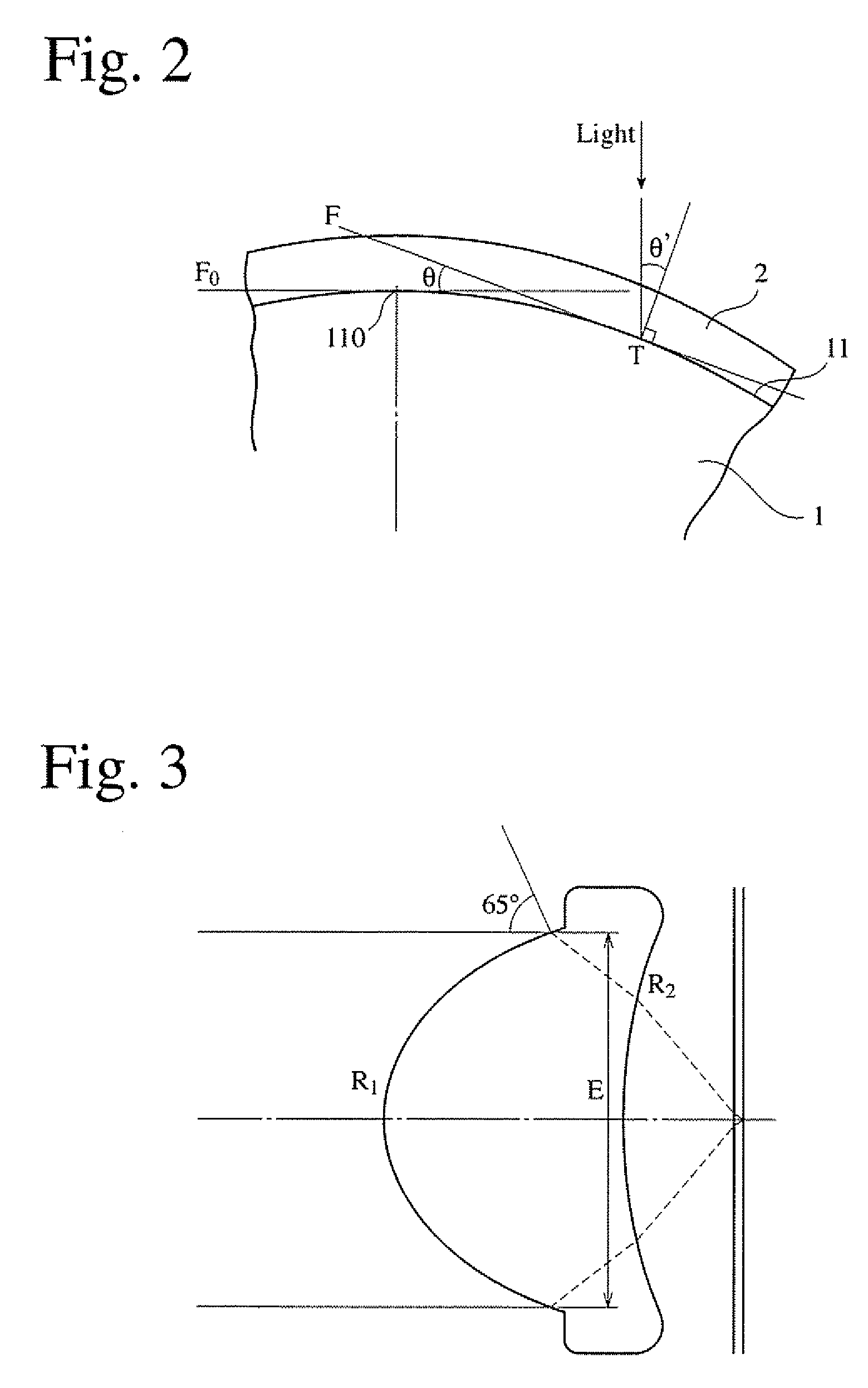

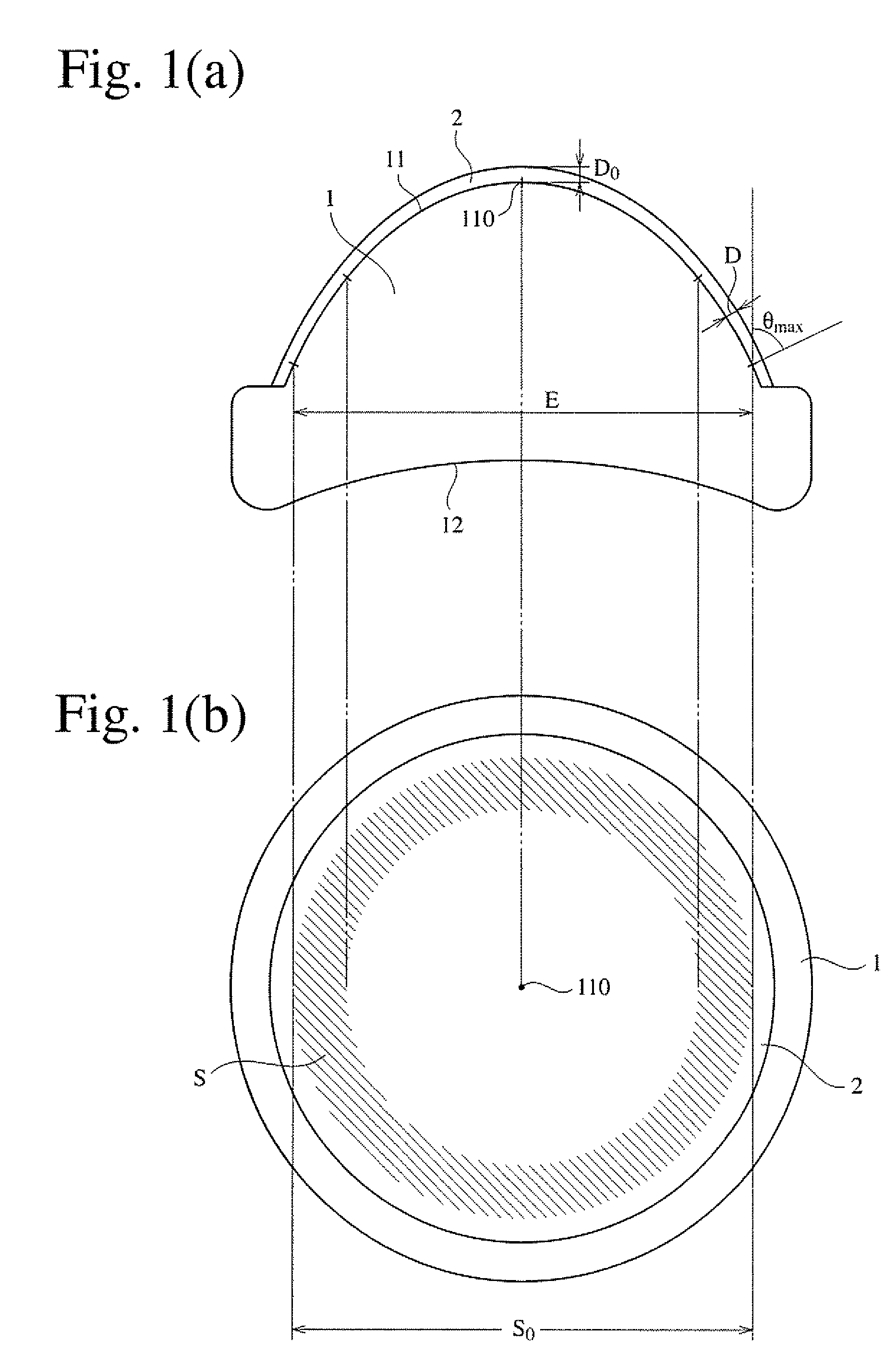

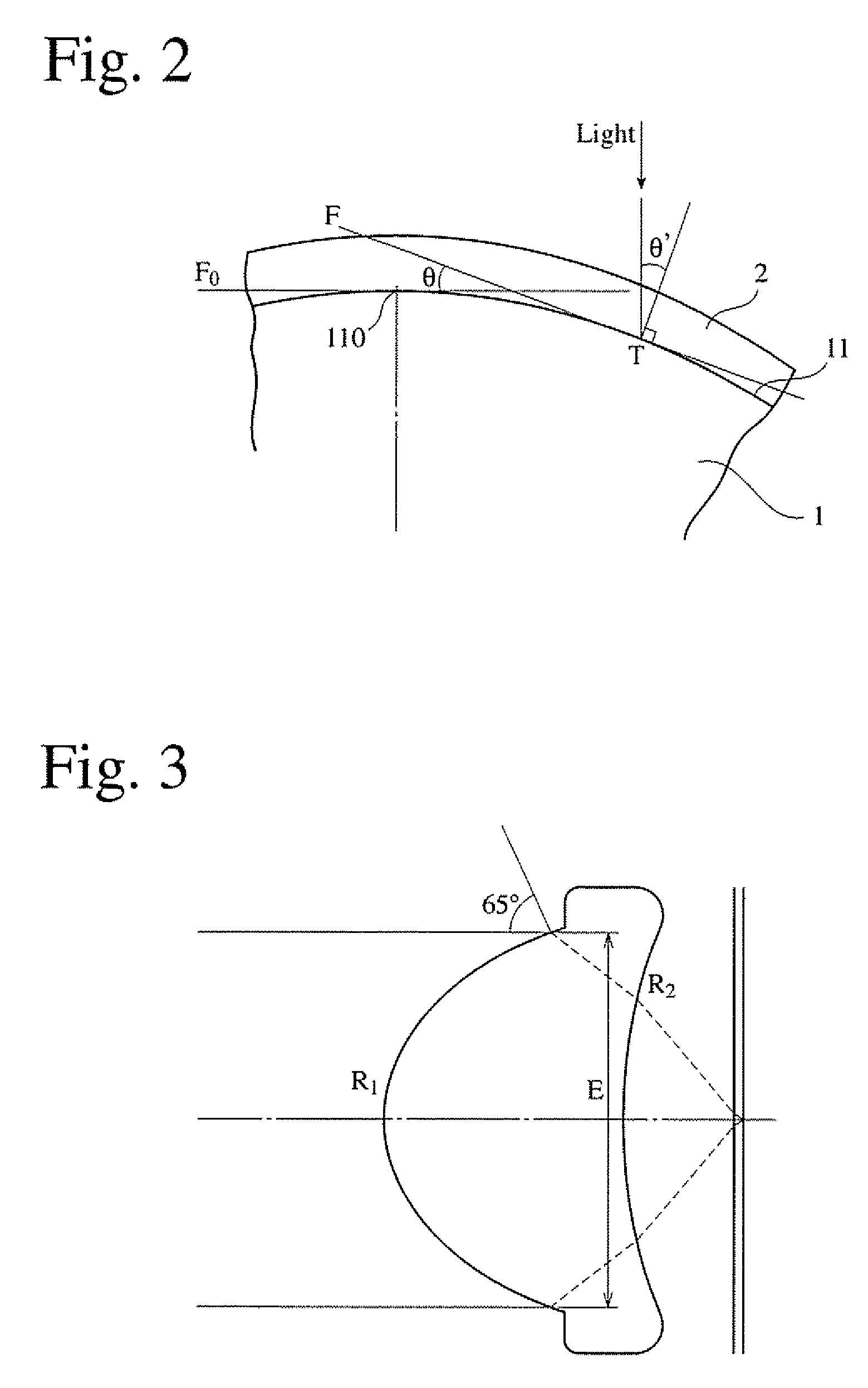

Optical element having Anti-reflection coating

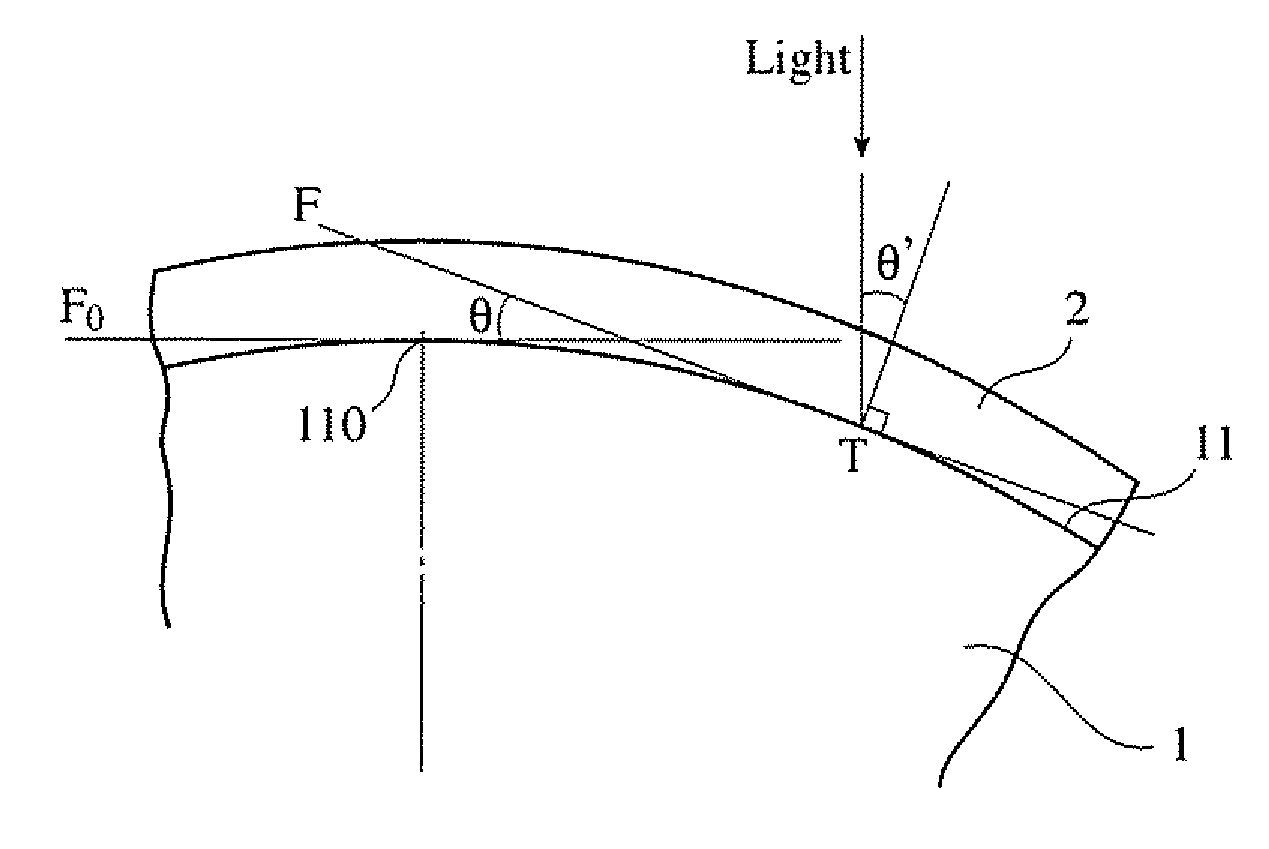

An optical element comprising a lens having a portion with a surface inclination angle of 50° or more within an effective-diameter region, the portion being 10% or more of the effective-diameter region in a projected area, and an anti-reflection coating formed on the lens, the anti-reflection coating having fine roughness with three-dimensional average surface roughness of 5-100 nm on the surface.

Owner:HOYA CORP

Circular polarizer and preparation method thereof

ActiveCN106353848AFast aggregationLow viscosityPolarising elementsNon-linear opticsPhase differenceUltraviolet lights

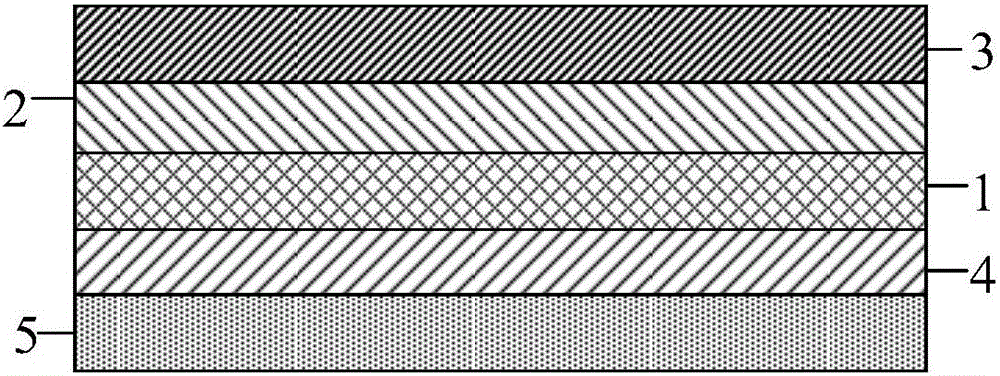

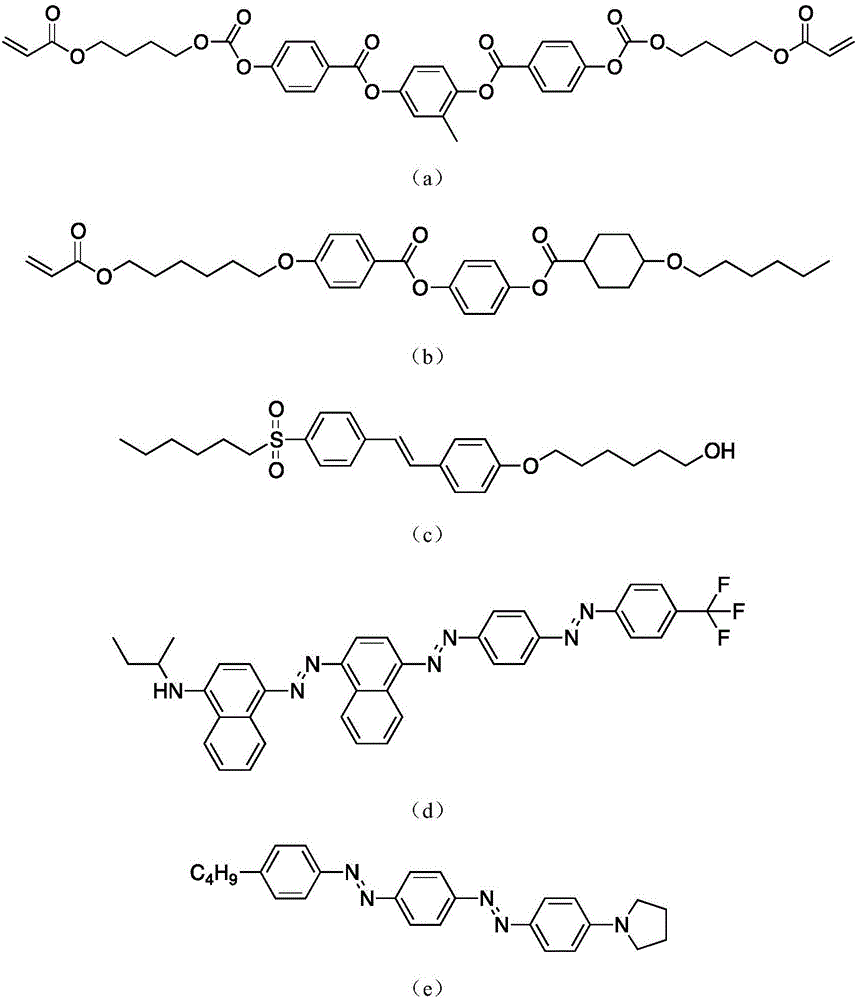

The invention discloses a circular polarizer and a preparation method thereof. In the invention, the surface of a base material is coated with a first orientation layer and a second orientation layer respectively; a phase difference layer is formed on the surface of the second orientation layer; the surface of the first orientation layer is coated with a polarization layer mixture; the polarization layer mixture comprises multiple polymerizable liquid crystal monomers, a dichroic pigment and an ultraviolet absorber; under ultraviolet irradiation, the polymerizable liquid crystal monomers with more polymerizable groups on the side close to the ultraviolet light source are enriched, and the polymerizable liquid crystal monomers with fewer polymerizable groups on the side far from the ultraviolet light source are enriched; the polymerizable liquid crystal monomers with more polymerizable groups are in a nematic phase, the viscosity of the nematic phase is relatively low, and a continuous and perfect cured film is formed; the polymerizable liquid crystal monomers with fewer polymerizable groups are in a smectic phase, and the smectic phase is an ideal two-dimensional ordered structure and realizes a polarization effect to form a polarization layer; and the circular polarizer has a thinning property and a good flexural property as well as a good anti-reflection property in the whole visible light range.

Owner:BEIJING LYRA MATERIAL TECH CO LTD

Optical element having anti-reflection coating

InactiveUS7619821B2Good anti-reflection propertiesCoatingsLensAnti-reflective coatingSurface roughness

An optical element comprising a lens having a portion with a surface inclination angle of 50° or more within an effective-diameter region, the portion being 10% or more of the effective-diameter region in a projected area, and an anti-reflection coating formed on the lens, the anti-reflection coating having fine roughness with three-dimensional average surface roughness of 5-100 nm on the surface.

Owner:HOYA CORP

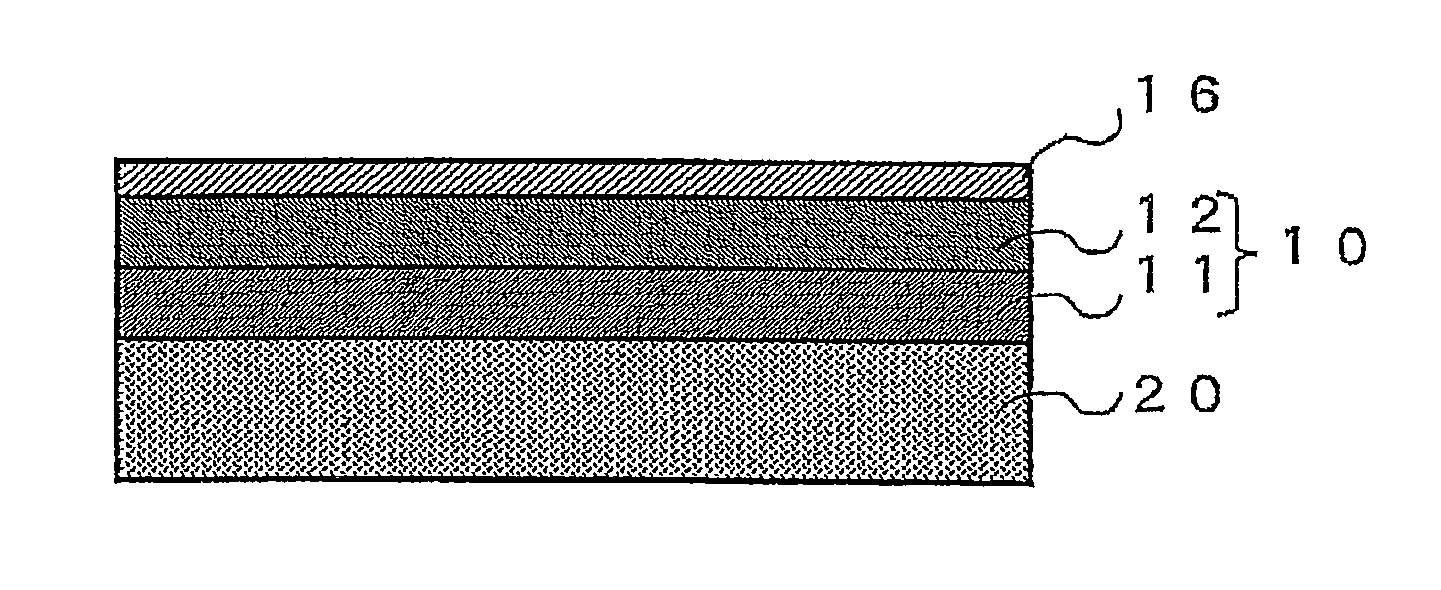

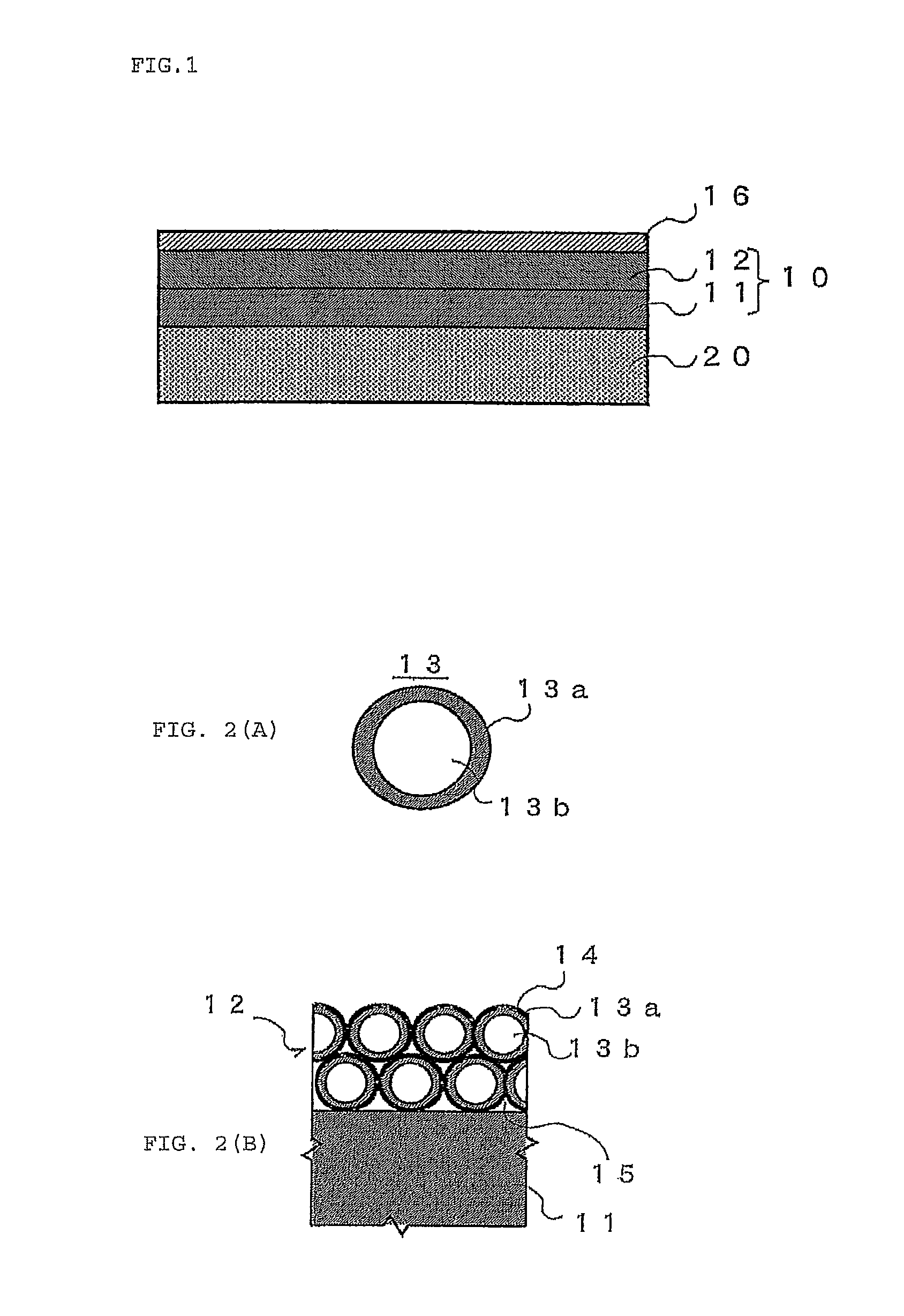

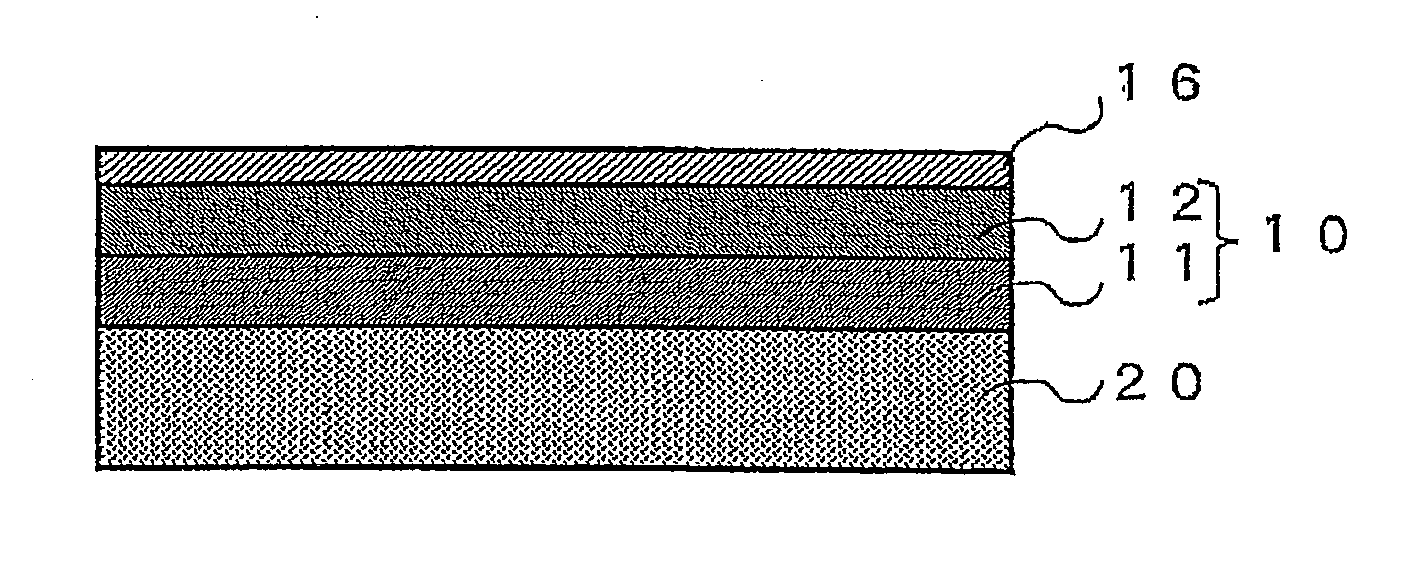

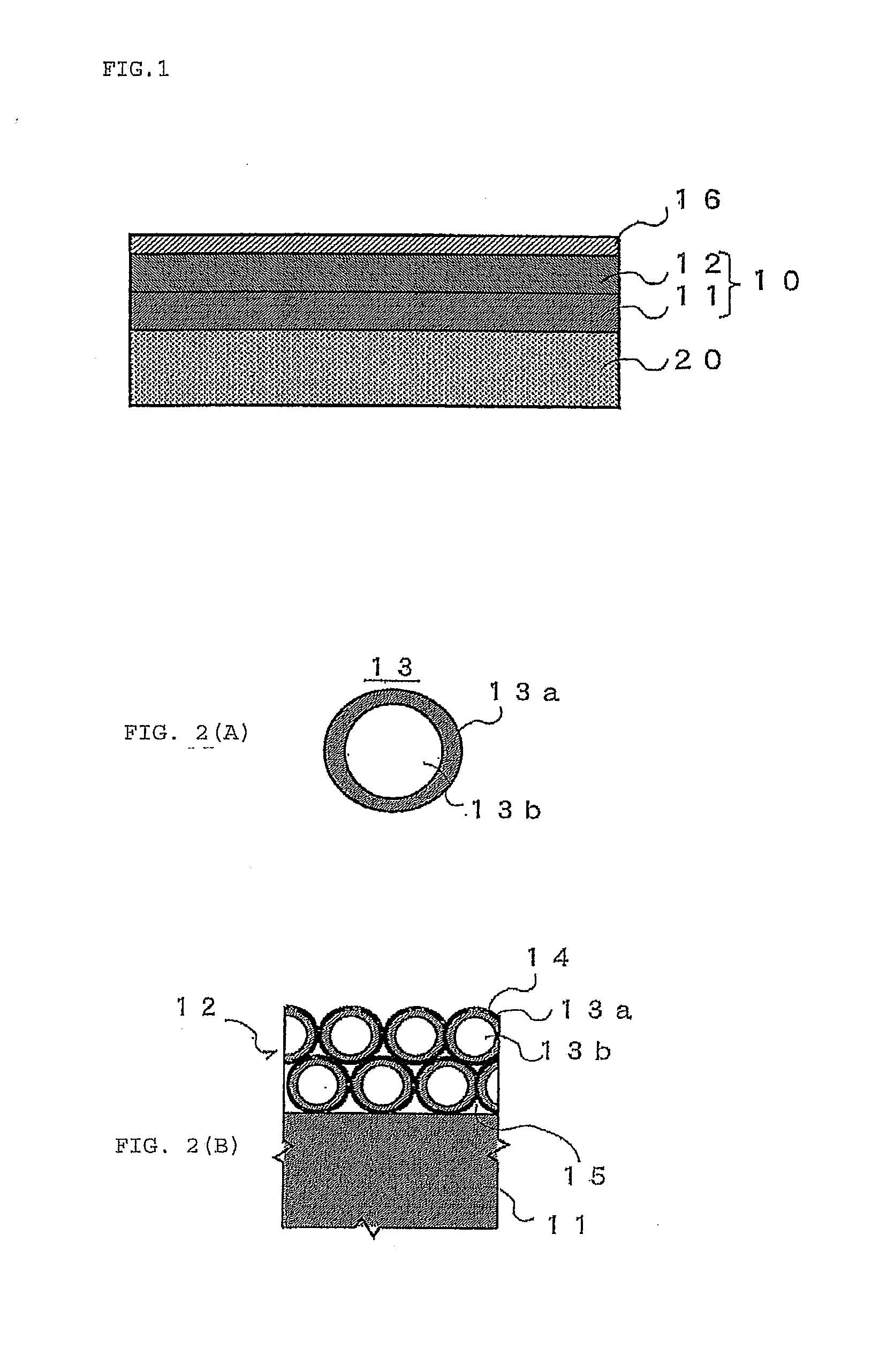

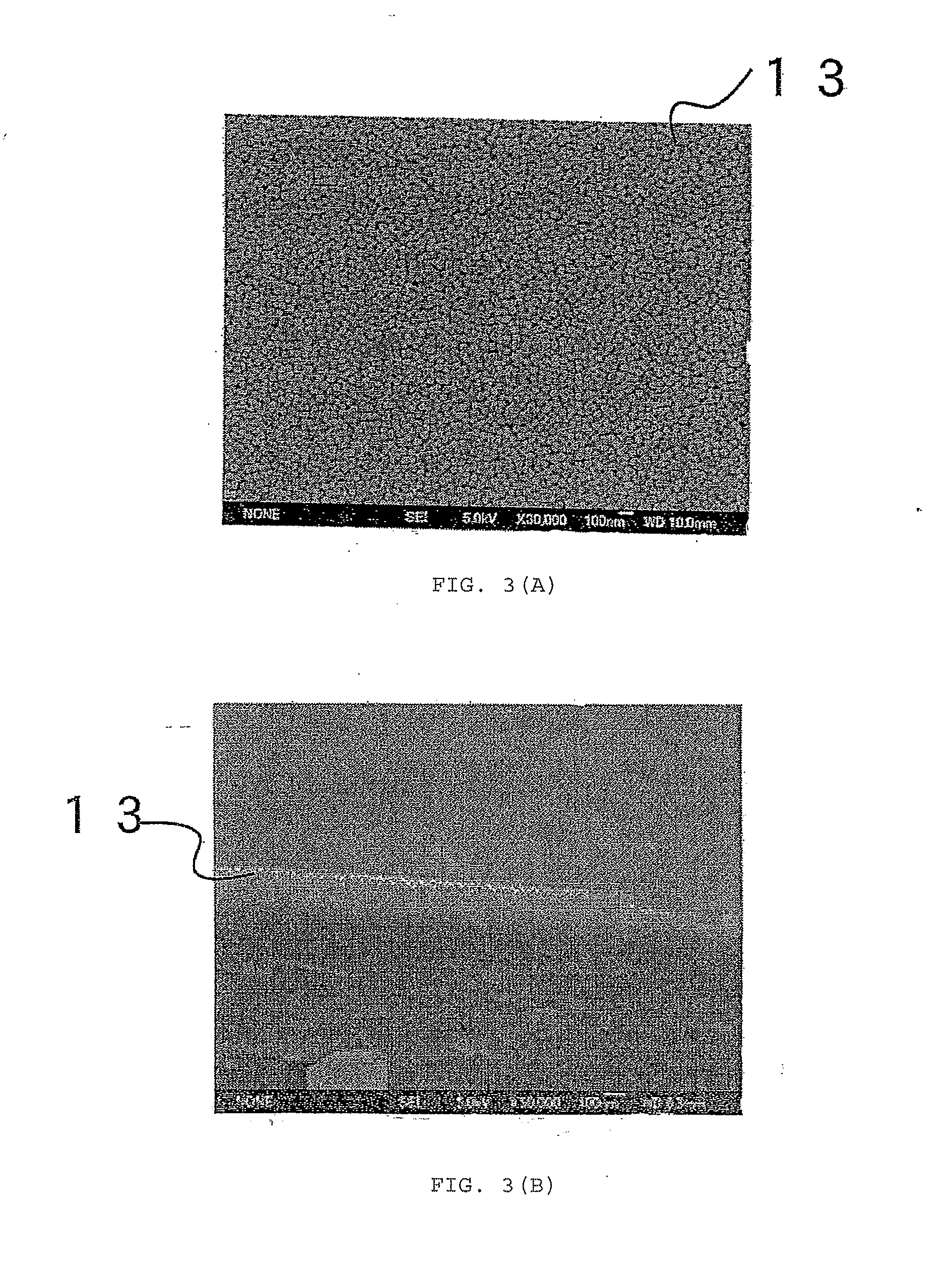

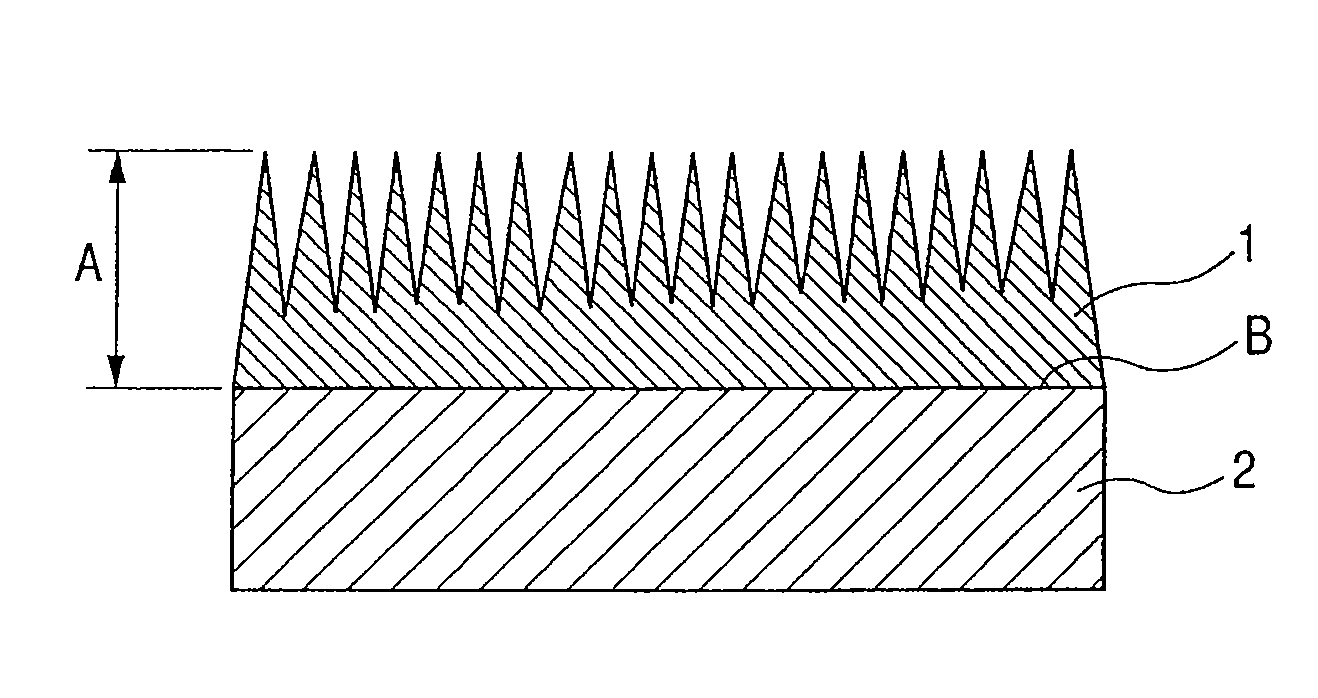

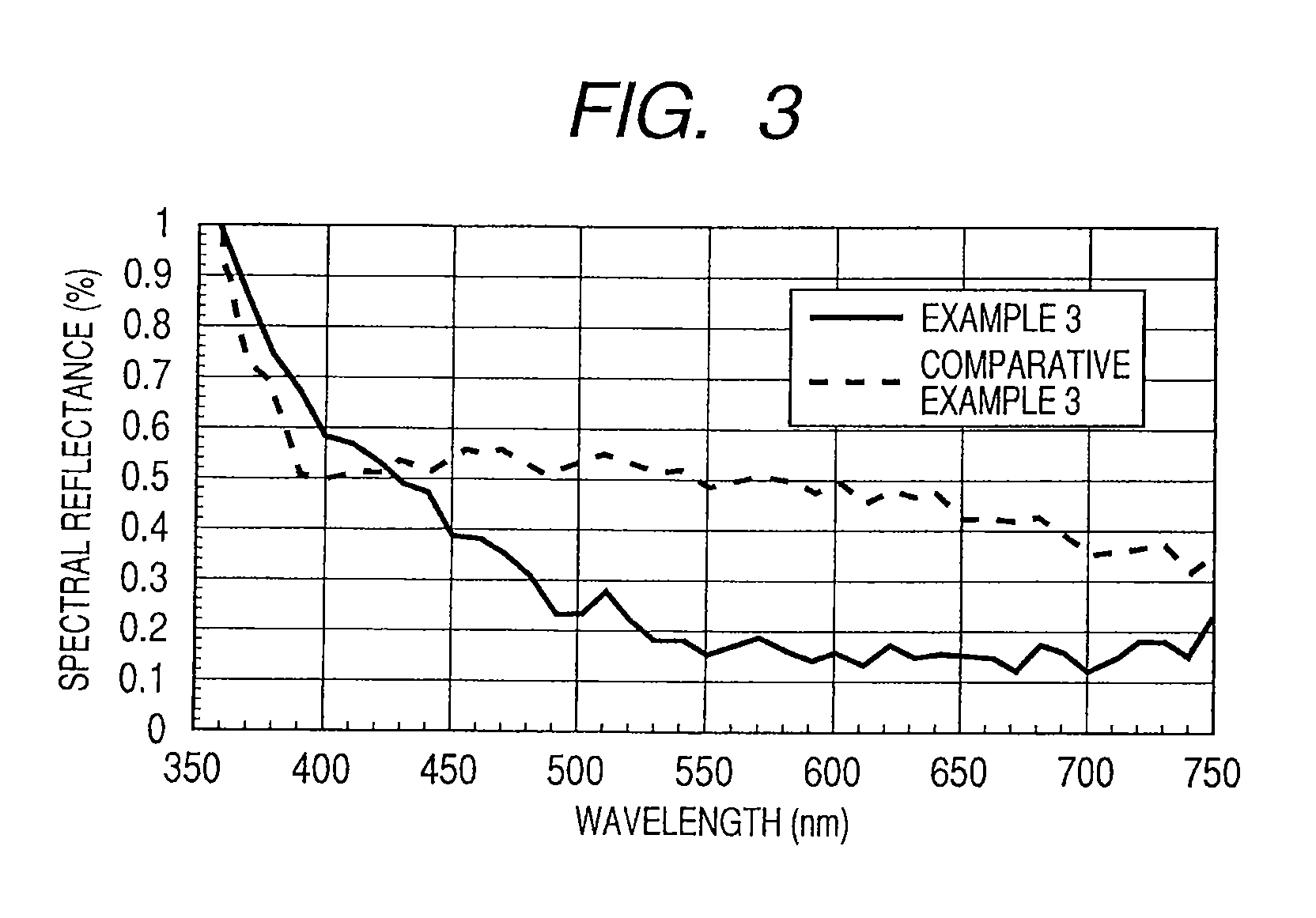

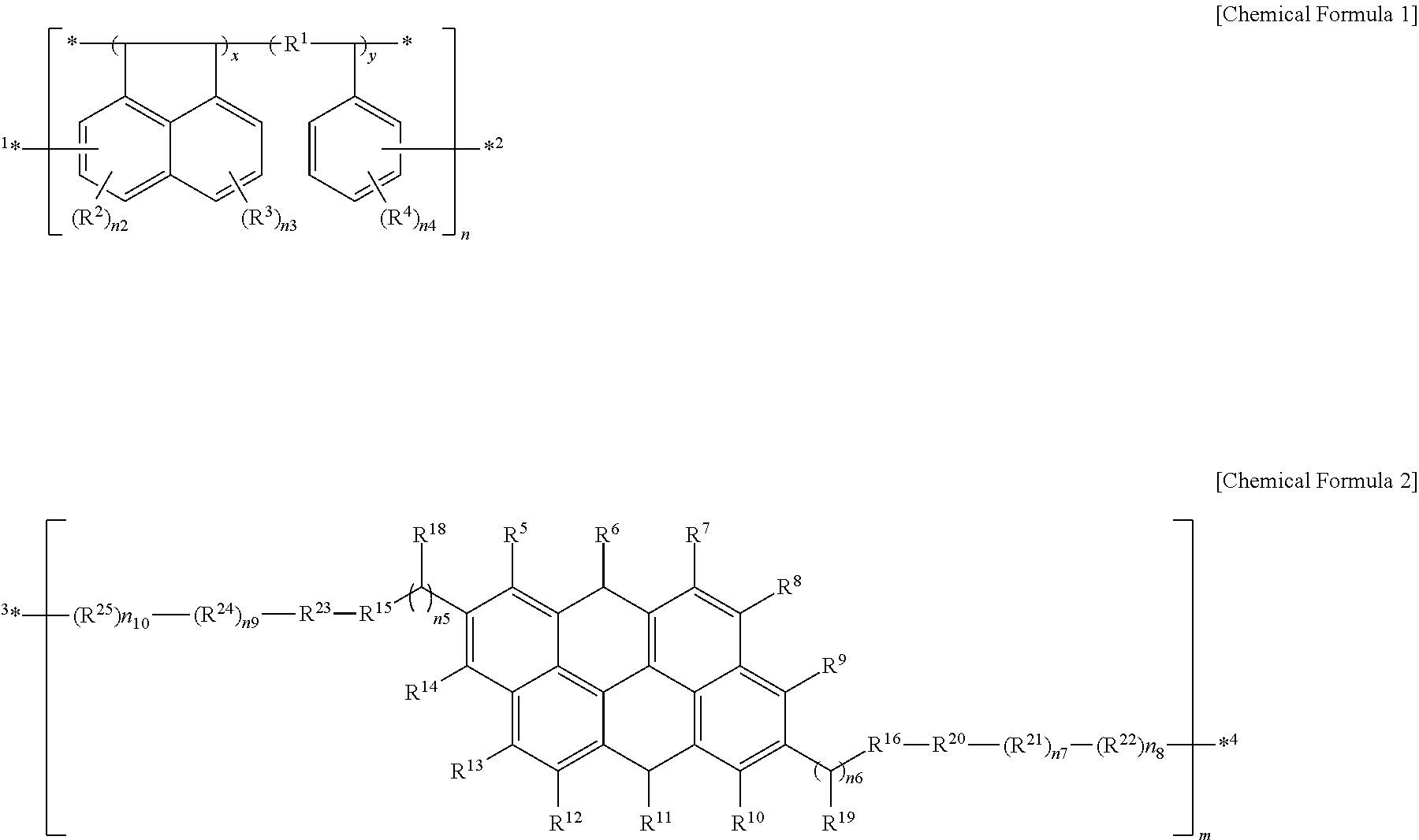

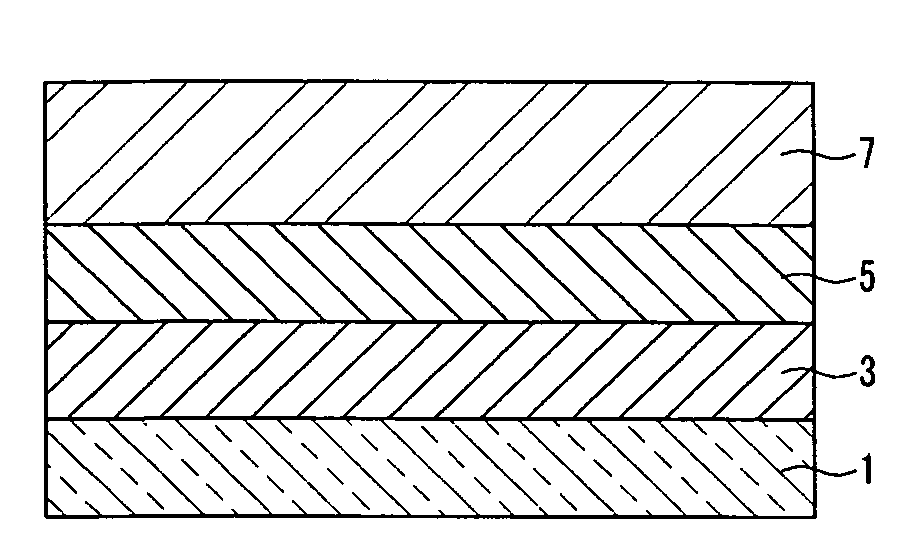

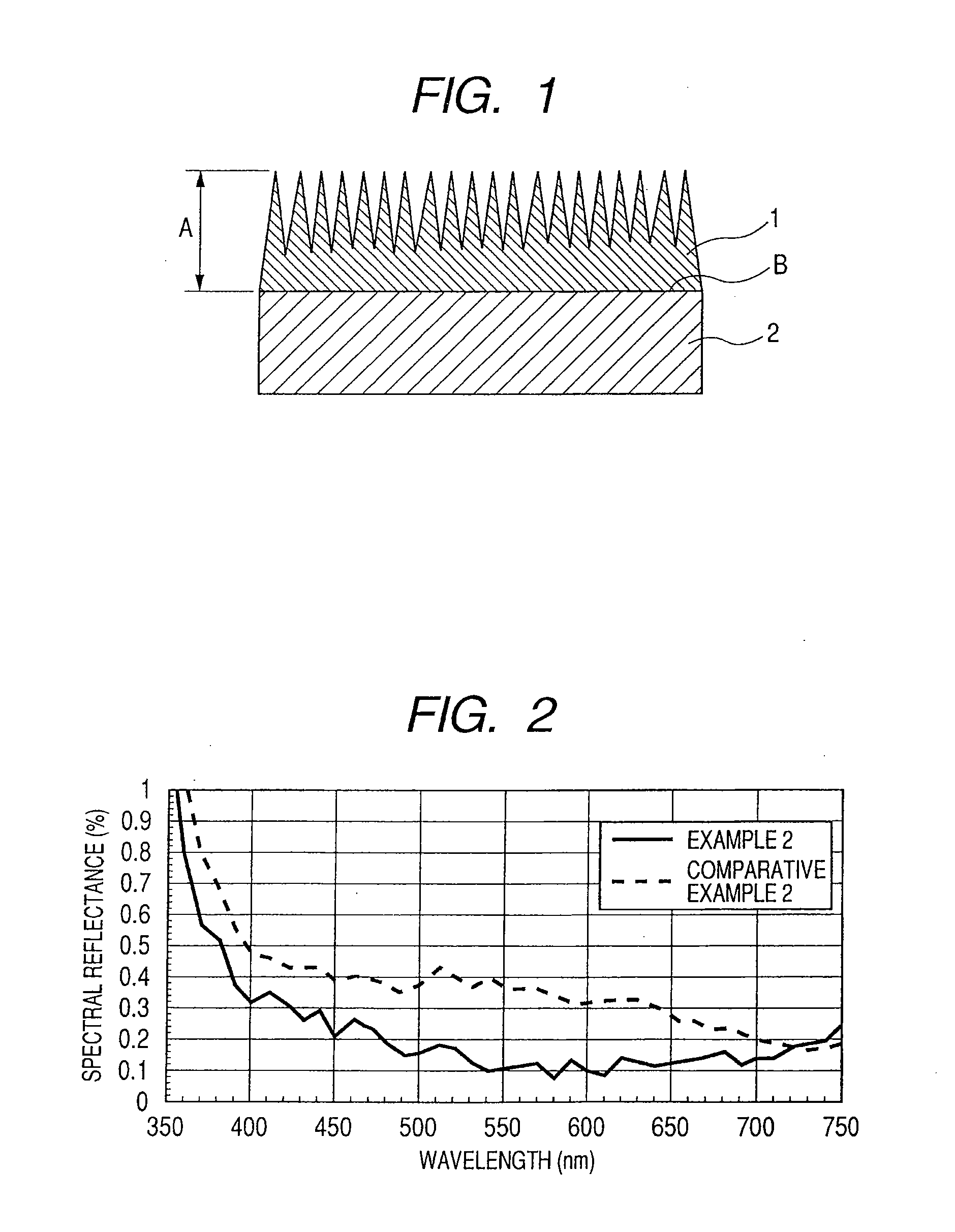

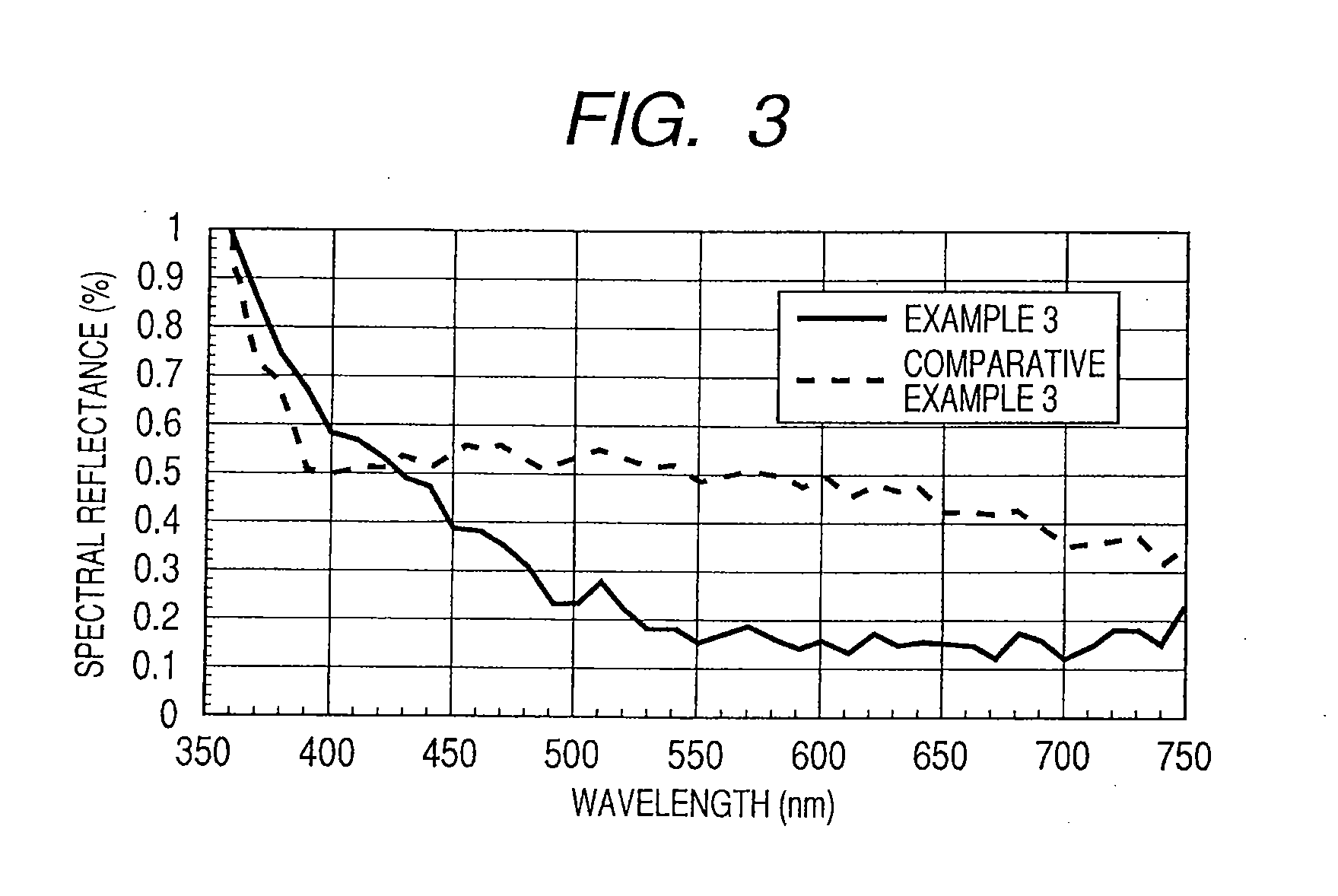

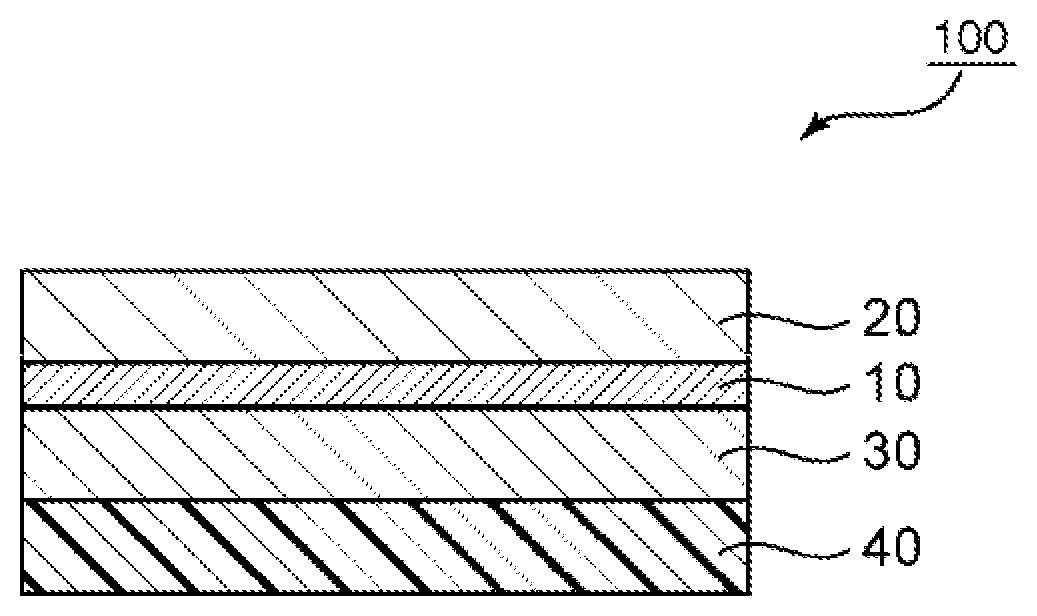

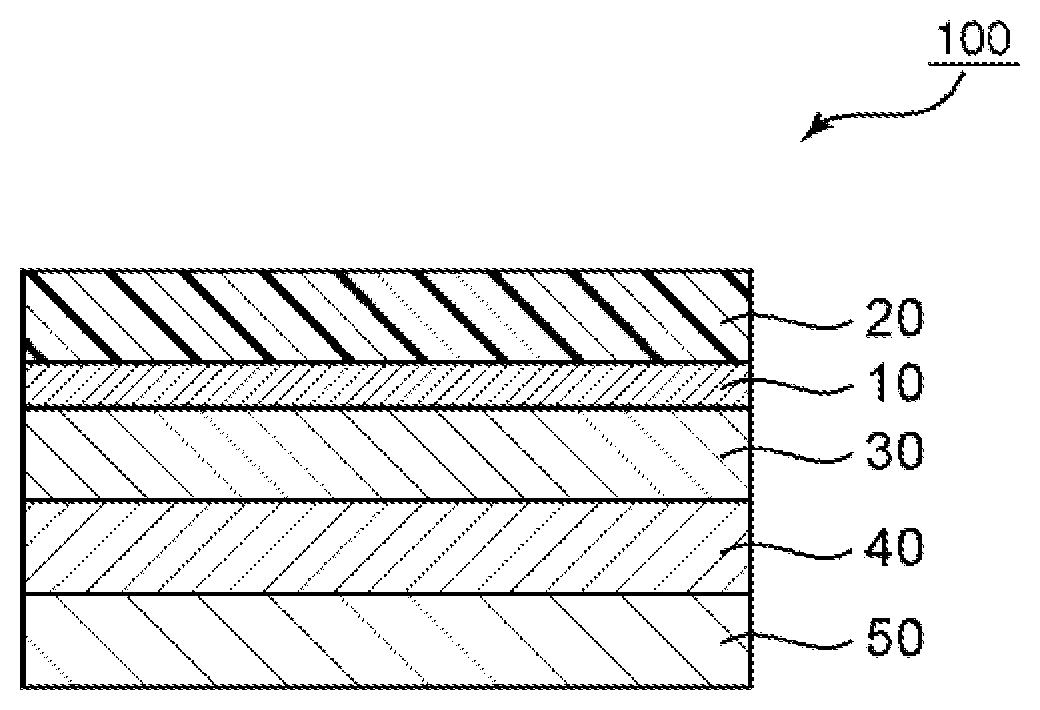

Antireflection film and optical device

ActiveUS9310525B2Good anti-reflection propertiesSolve the lack of durabilityLayered productsCoatingsAngle of incidenceLight beam

An object of the present invention is to provide an antireflection film and an optical device having excellent antireflection characteristics against a light beam having a wide wavelength range at a wide range of an incident angle, and also having practically sufficient durability. To achieve the above object, the present invention adopts an antireflection film having an optical two-layer structure composed of an intermediate layer provided on a base material and a low refractive index layer provided on a surface of the intermediate layer, wherein the low refractive index layer is a layer obtained by binding hollow silica by a binder, a refractive index n(1) thereof is between 1.15 and 1.24 inclusive, and a refractive index n(2) of the intermediate layer satisfies a relation in the expression (1) below assuming a refractive index of the base material n(sub).n(1)×√{square root over (n(sub))}×0.930≦n(2)≦n(1)×√{square root over (n(sub))}×0.985 (1).

Owner:TAMRON

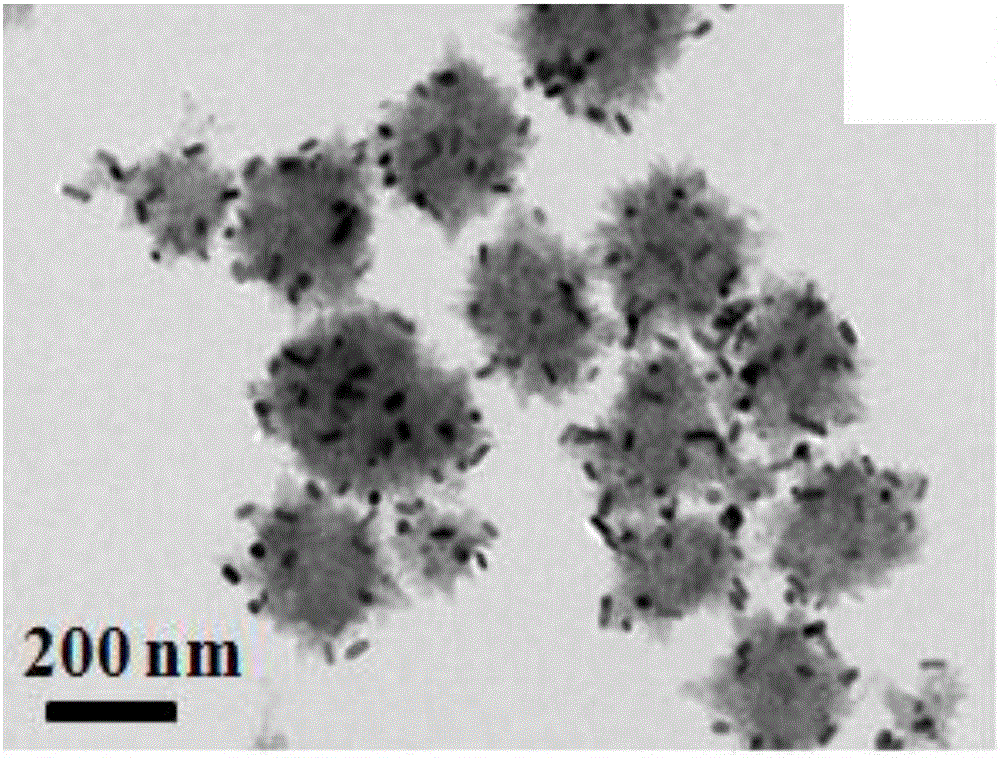

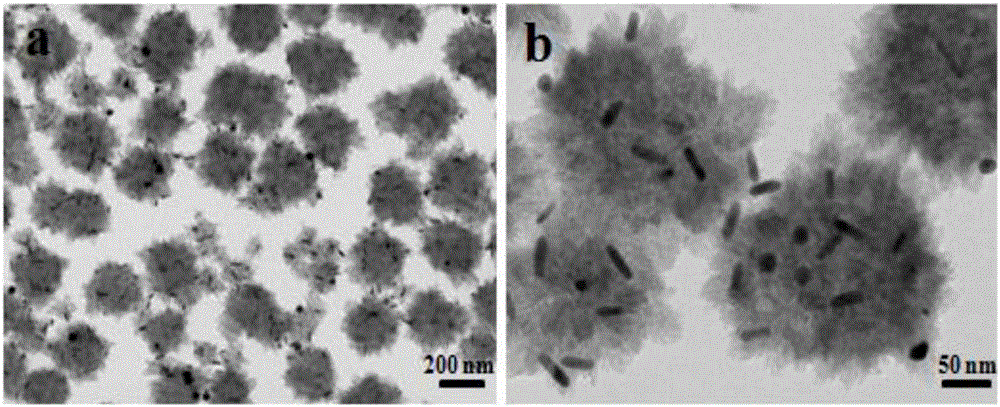

TiO2/Au nano-rod urchin-like heterostructure photocatalyst and preparation method thereof

ActiveCN106179337ALarge specific surface areaImprove separation efficiencyMetal/metal-oxides/metal-hydroxide catalystsRoom temperatureColloid

The invention relates to a TiO2 / Au nano-rod urchin-like heterostructure photocatalyst and a preparation method thereof, and belongs to the technical field of semiconductor photocatalysts. The method comprises the following steps: concentrating 8-16 mL of an Au nano-rod colloid solution with the Au nano-rod mass being 0.78-1.56 mg in a centrifuge manner to make the final volume be 2-3% of the original volume, adding 10-30 mL of deionized water to a lower layer concentrate product, carrying out room temperature stirring for 10-20 min, adding 0.5-1 mL of an aqueous titanium salt solution with the concentration of 5-10 mg / mL, continuously stirring the above mixture at room temperature for 30-50 min, and heating the stirred mixture at 100-130 DEG C for 2-6h to obtain the lavender TiO2 / Au nano-rod urchin-like heterostructure photocatalyst. The TiO2 / Au nano-rod urchin-like heterostructure photocatalyst prepared in the invention has a strong SPR absorption effect on Au nano-rods in the visible light region, has excellent anti-reflection characteristic, and can capture sunshine, AuNR can improve the separation efficiency of photoinduced electrons and holes, and the urchin-like structure has a large specific surface area, so the increase of the catalysis efficiency of the photocatalyst is facilitated.

Owner:JILIN UNIV

Antireflection Film and Optical Device

ActiveUS20120251803A1Solve the real problemImprove anti-reflection effectLayered productsCoatingsAngle of incidenceLight beam

An object of the present invention is to provide an antireflection film and an optical device having excellent antireflection characteristics against a light beam having a wide wavelength range at a wide range of an incident angle, and also having practically sufficient durability. To achieve the above object, the present invention adopts an antireflection film having an optical two-layer structure composed of an intermediate layer provided on a base material and a low refractive index layer provided on a surface of the intermediate layer, wherein the low refractive index layer is a layer obtained by binding hollow silica by a binder, a refractive index n(1) thereof is between 1.15 and 1.24 inclusive, and a refractive index n(2) of the intermediate layer satisfies a relation in the expression (1) below assuming a refractive index of the base material n(sub).n(1)×√{square root over (n(sub))}×0.930≦n(2)≦n(1)×√{square root over (n(sub))}×0.985 (1)

Owner:TAMRON

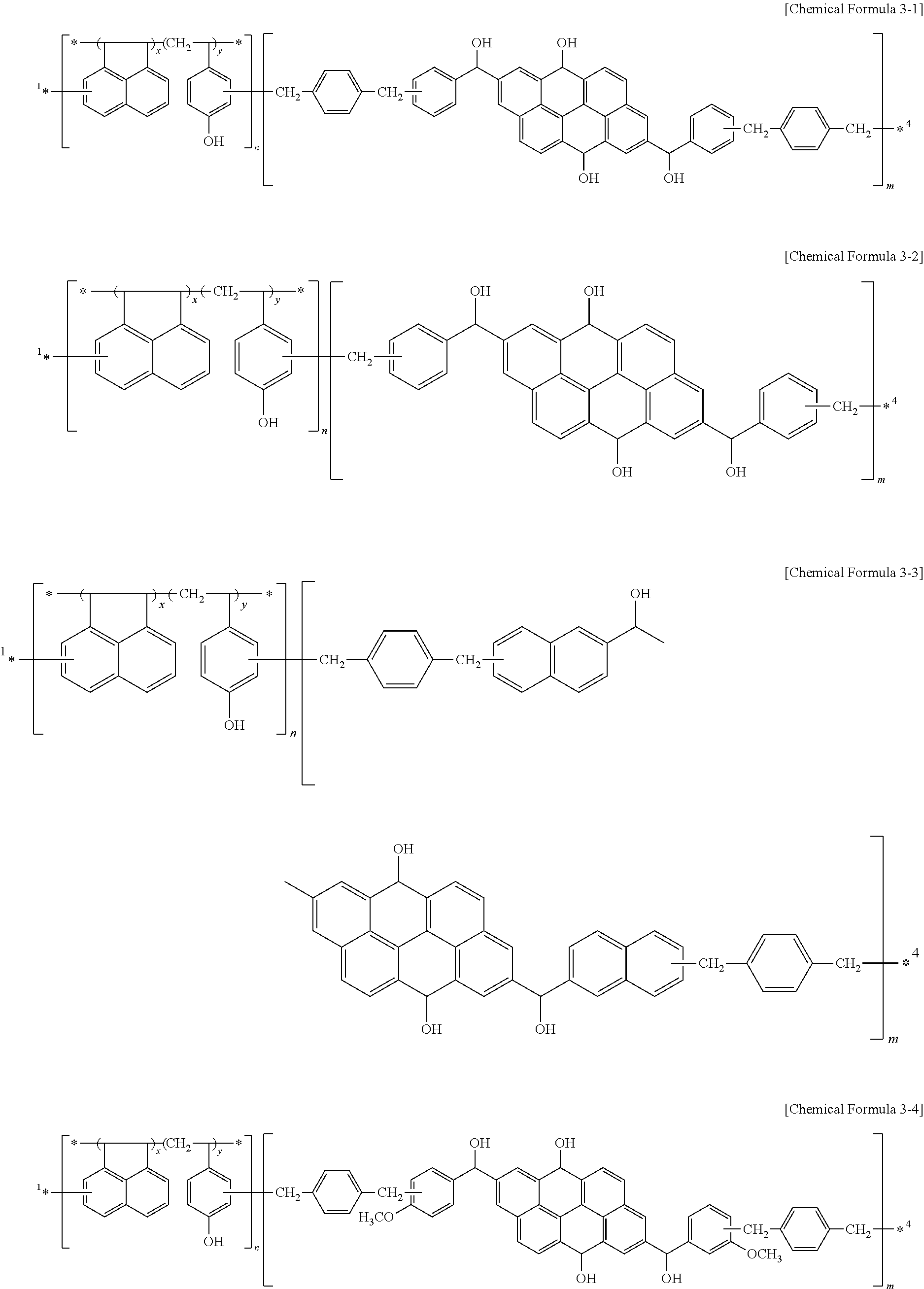

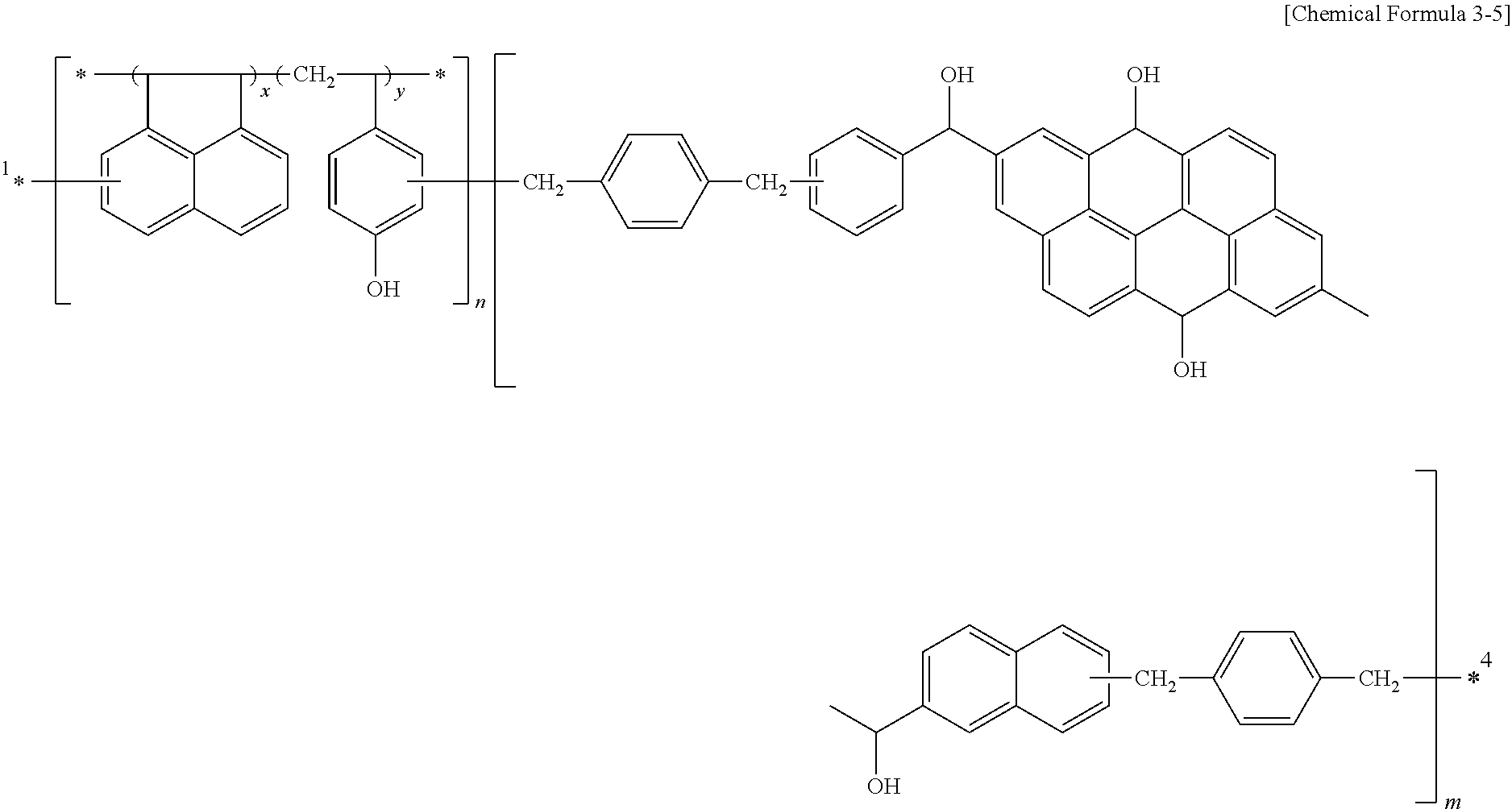

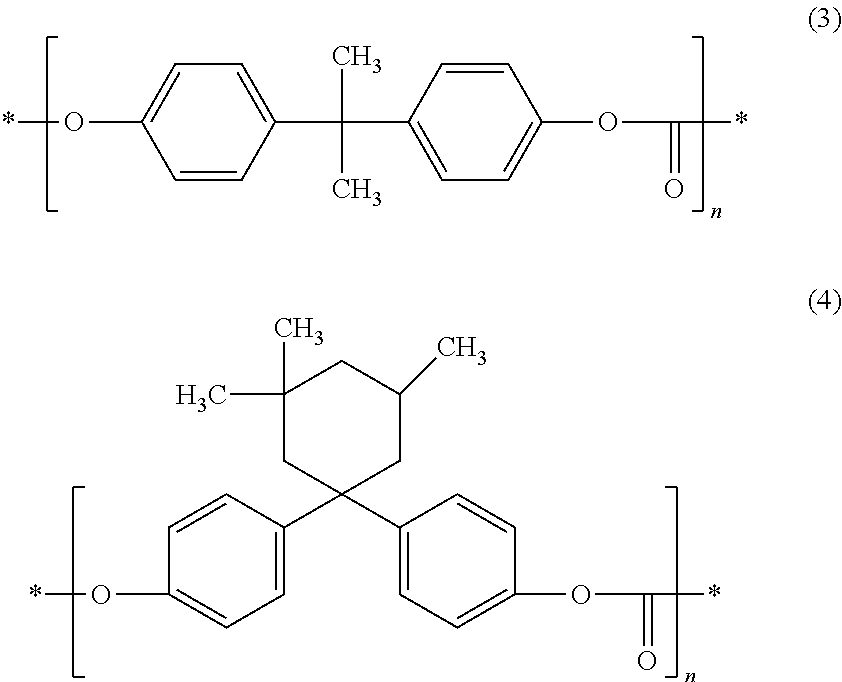

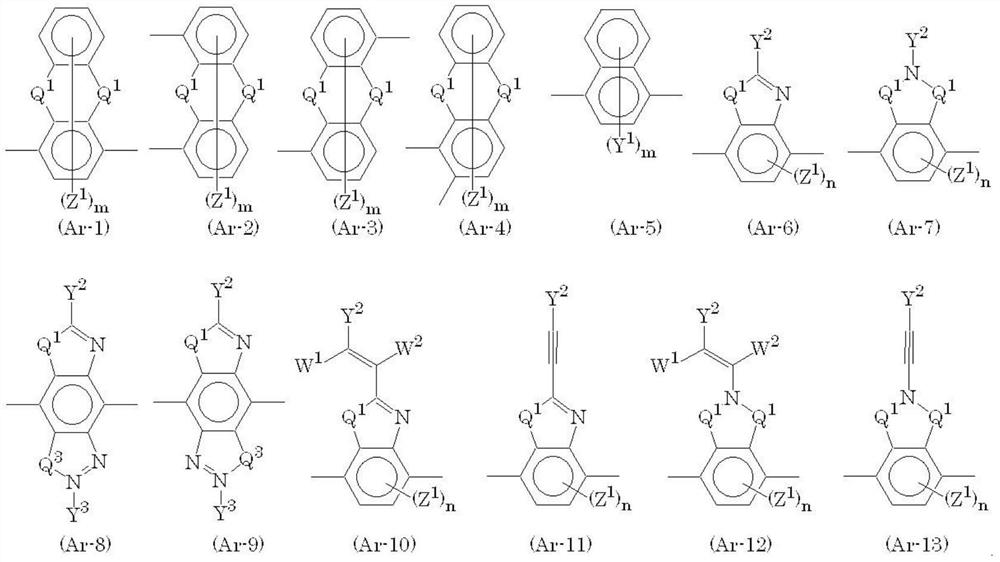

Resist underlayer composition and method of manufacturing semiconductor integrated circuit device using the same

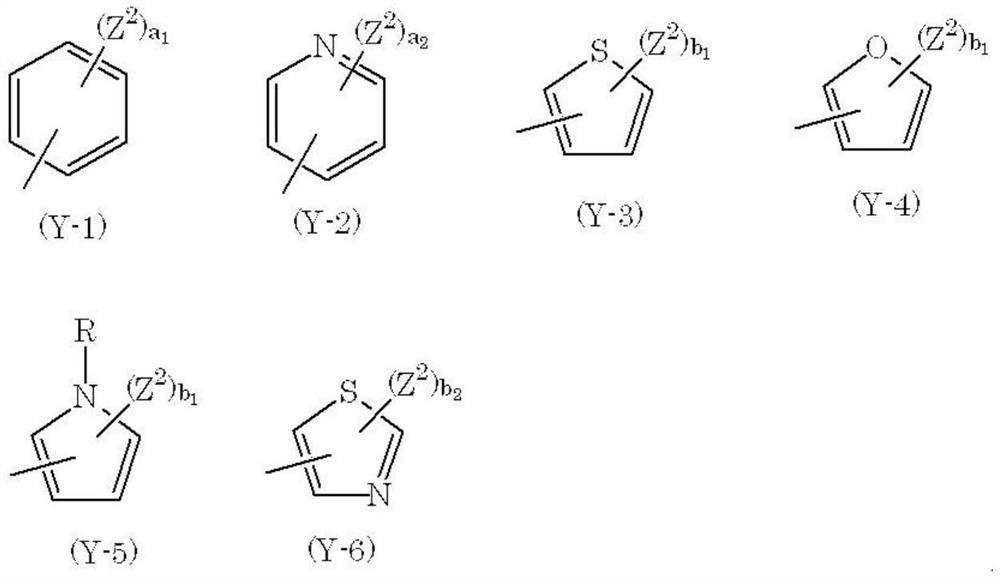

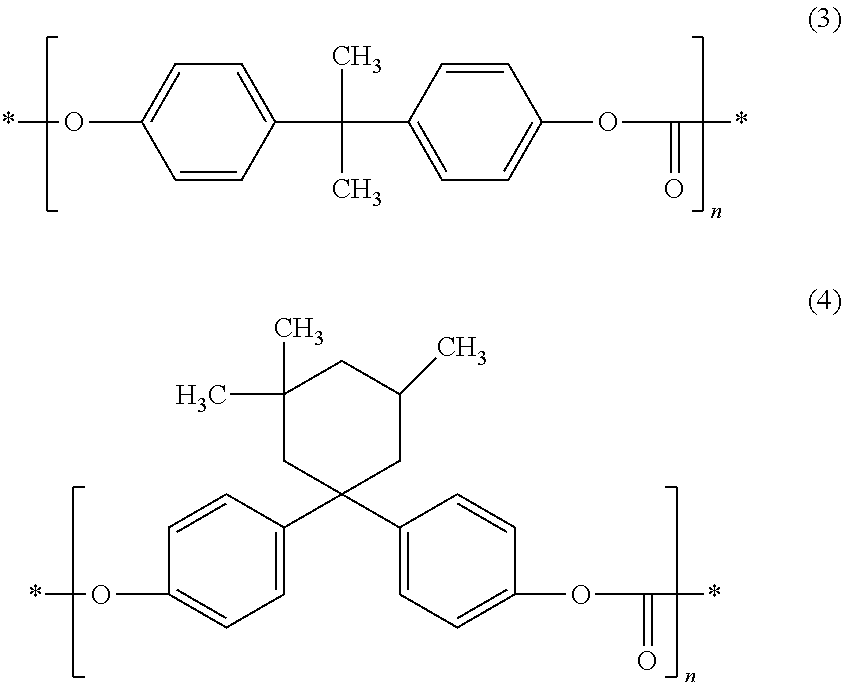

ActiveUS20100167203A1Good anti-reflection propertiesPhotosensitive materialsSemiconductor/solid-state device manufacturingResistCompound (substance)

A resist underlayer composition and a method of manufacturing a semiconductor integrated circuit device, the composition including a solvent and an organosilane polymer, the organosilane polymer being a condensation polymerization product of at least one first compound represented by Chemical Formulae 1 and 2 and at least one second compound represented by Chemical Formulae 3 to 5.

Owner:CHEIL IND INC

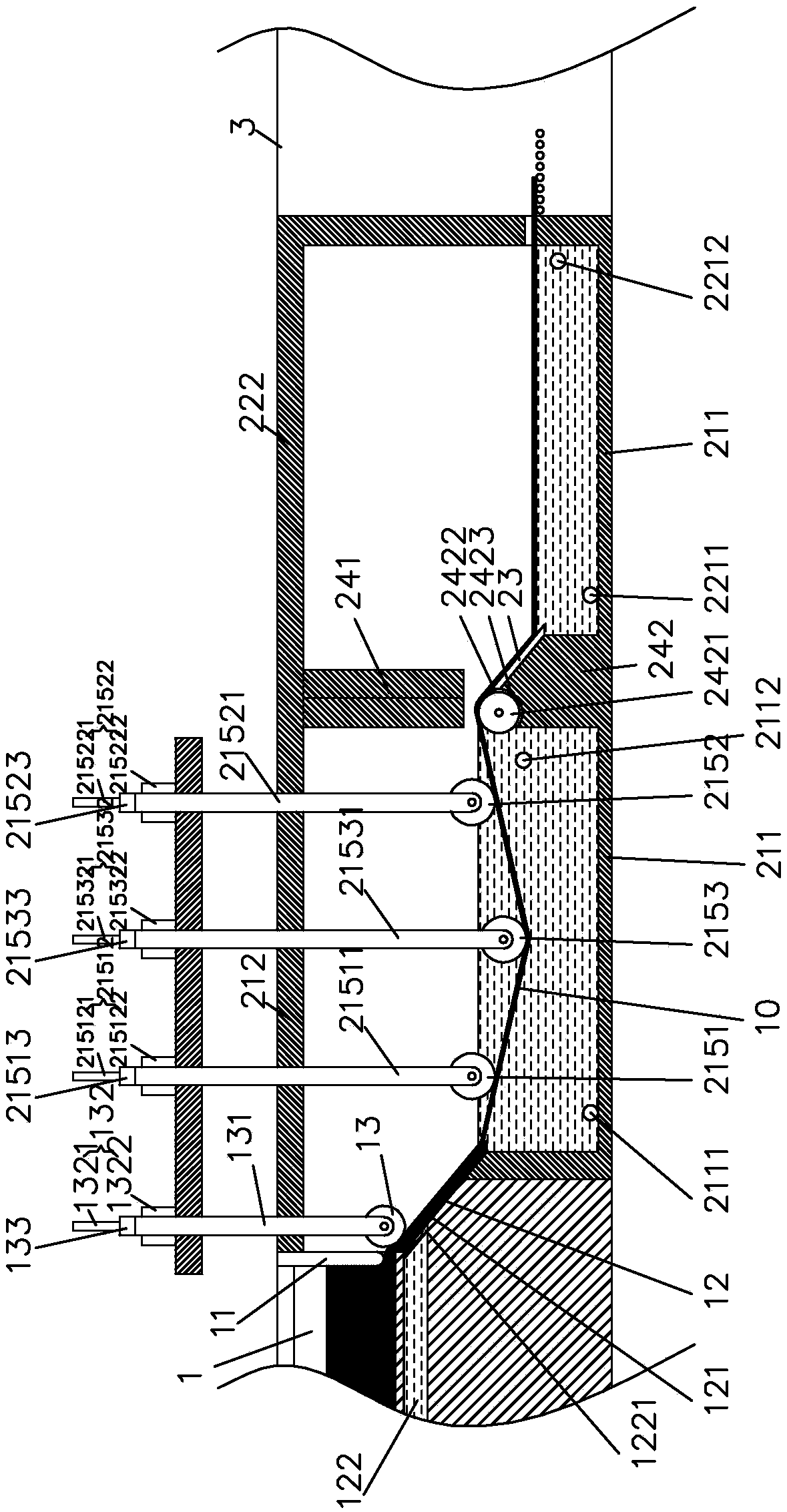

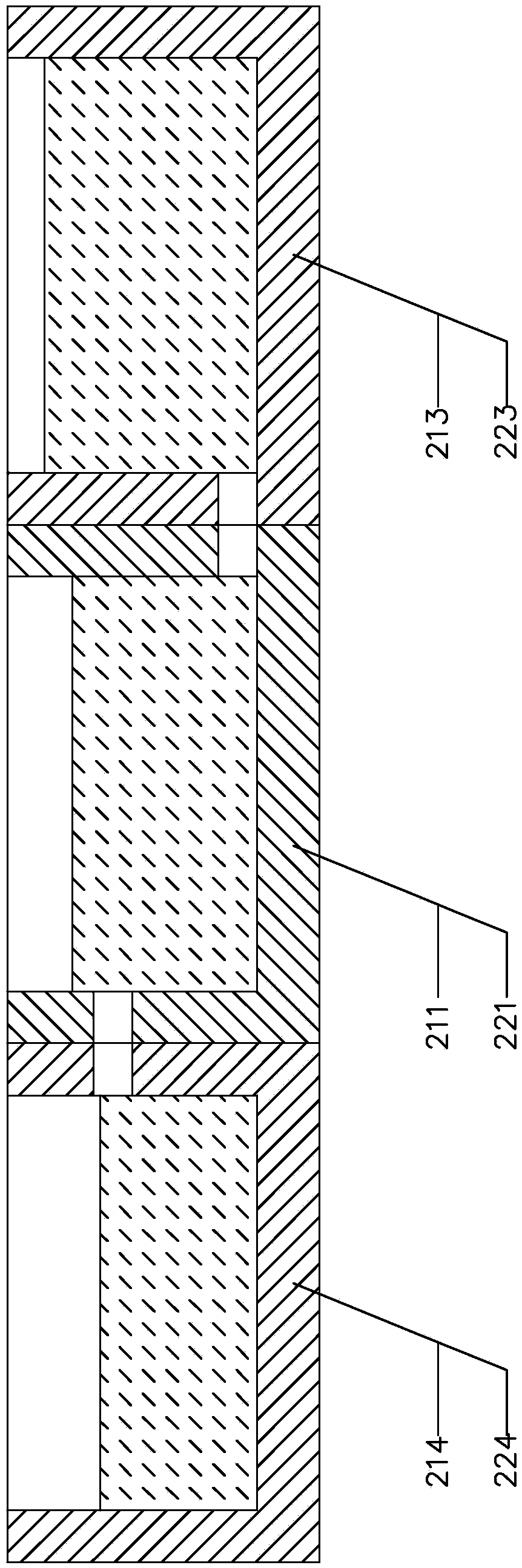

Production process of AG (anti-glare) glass

The invention provides a production process of AG (anti-glare) glass. The process comprises the following steps of smelting glass raw materials by utilizing a smelting furnace so as to form glass fluid; then enabling glass to be molded through a fusion tin chamber by using a float glass process to form an earlier-stage glass pane; then annealing the earlier-stage glass pane by utilizing an annealing chamber to form a finished glass pane; then cutting and edging the finished glass pane to make a glass template; then polishing the glass template; then washing the glass template; then making hardmasking film; then making an ultraviolet curing polymer layer; then making a model; then making a curing layer with the model; then demolding; then etching the glass template by using one of reactiveion etching or inductive coupling plasma etching or using both, wherein the etching speed of the hard masking film is lower than the etching speed of the glass template. Compared with the prior art,the production process of the AG glass can be used for high-efficiency and high-quality production of the AG glass, and the AG glass has excellent performance.

Owner:福建成达玻璃有限公司

Coating composition and antireflection film

ActiveCN104066805AEasy to manufactureSimple manufacture of anti-reflective propertiesAntifouling/underwater paintsPhotovoltaicsPolymer emulsionSilicon

This coating composition comprises (A) a metal oxide that comprises (a1) a spherical metal oxide and (a2) a chain-shaped metal oxide having an aspect (length / breadth) ratio of 3 to 25 and (B) polymer emulsion particles. It is preferable that the coating composition further contains (C) a hydrolyzable silicon compound. Further, this antireflection film can be formed by applying the coating composition to a substrate and drying the resulting coating.

Owner:ASAHI KASEI KK

Method of manufacturing optical element, and optical element

InactiveUS7767287B2Avoid performanceGood anti-reflection propertiesRecord information storageMagnetic recordingWarm waterMetal alkoxide

A method of manufacturing an optical element having a good reflection preventing characteristic is provided in which an irregularity structure having a reflection preventing function can be formed at low temperature. The method includes forming a film on the optical substrate by using a coating liquid containing a metal alkoxide containing at least aluminum, immersing the film in a water-containing liquid, baking the film having been immersed in the water-containing liquid, and subjecting the film having been baked to treatment with warm water to form an aluminum-containing film having a fine irregularity structure.

Owner:CANON KK

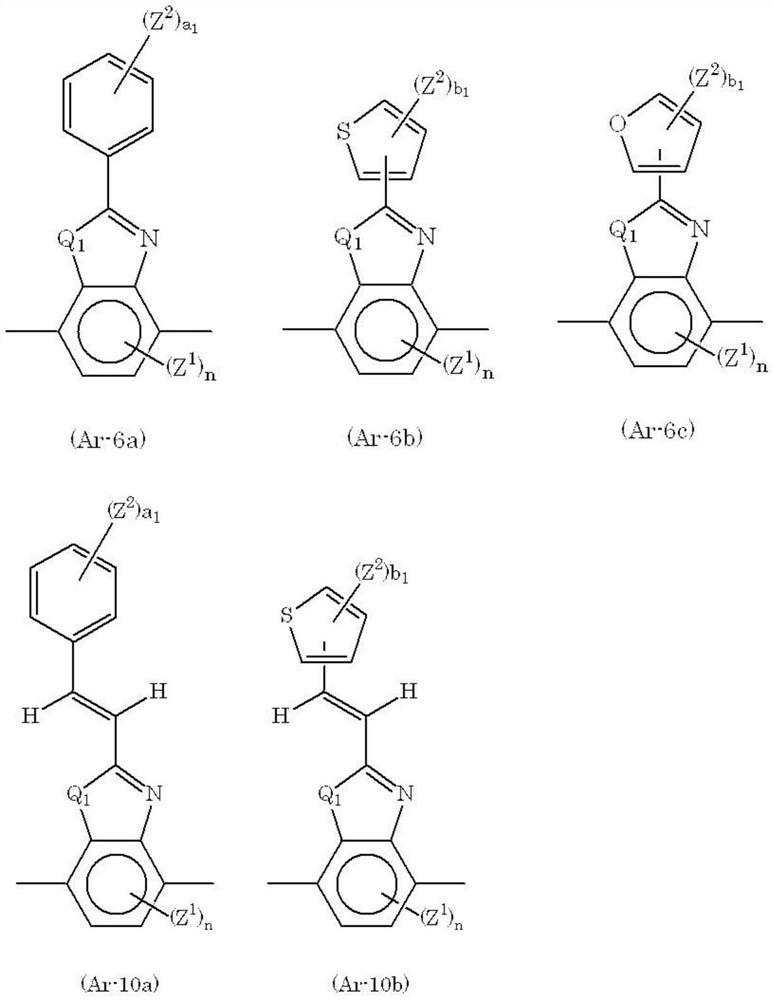

Composition for hardmask, method of forming patterns using the same, and semiconductor integrated circuit device including the patterns

ActiveUS20140335447A1Excellent etch resistanceGood anti-reflection propertiesSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusSolventSemiconductor

A composition for a hardmask including copolymer including repeating units represented by Chemical Formulae 1 and 2 and a solvent, a method of forming a pattern using the same, and a semiconductor integrated circuit device including a pattern formed using the method are provided.

Owner:CHEIL IND INC

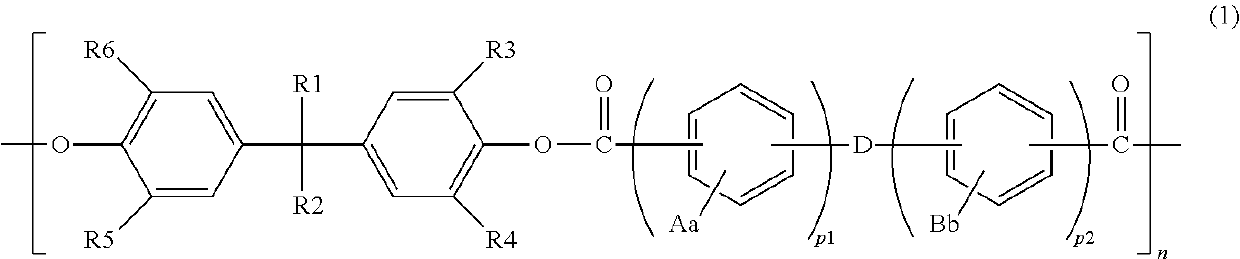

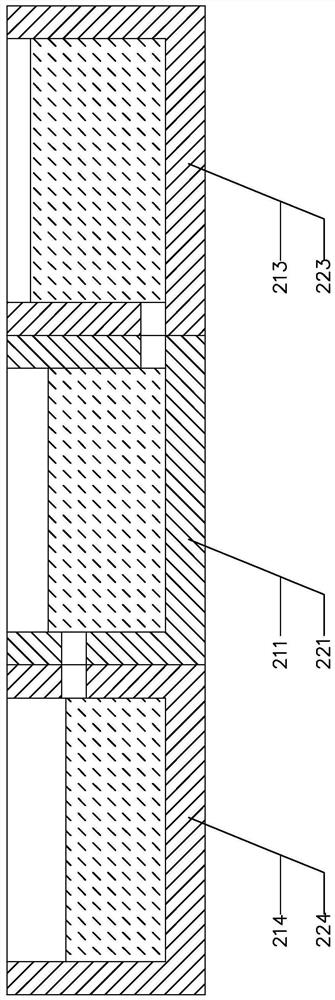

Polarizing plate with optical compensation layer and organic EL panel using same

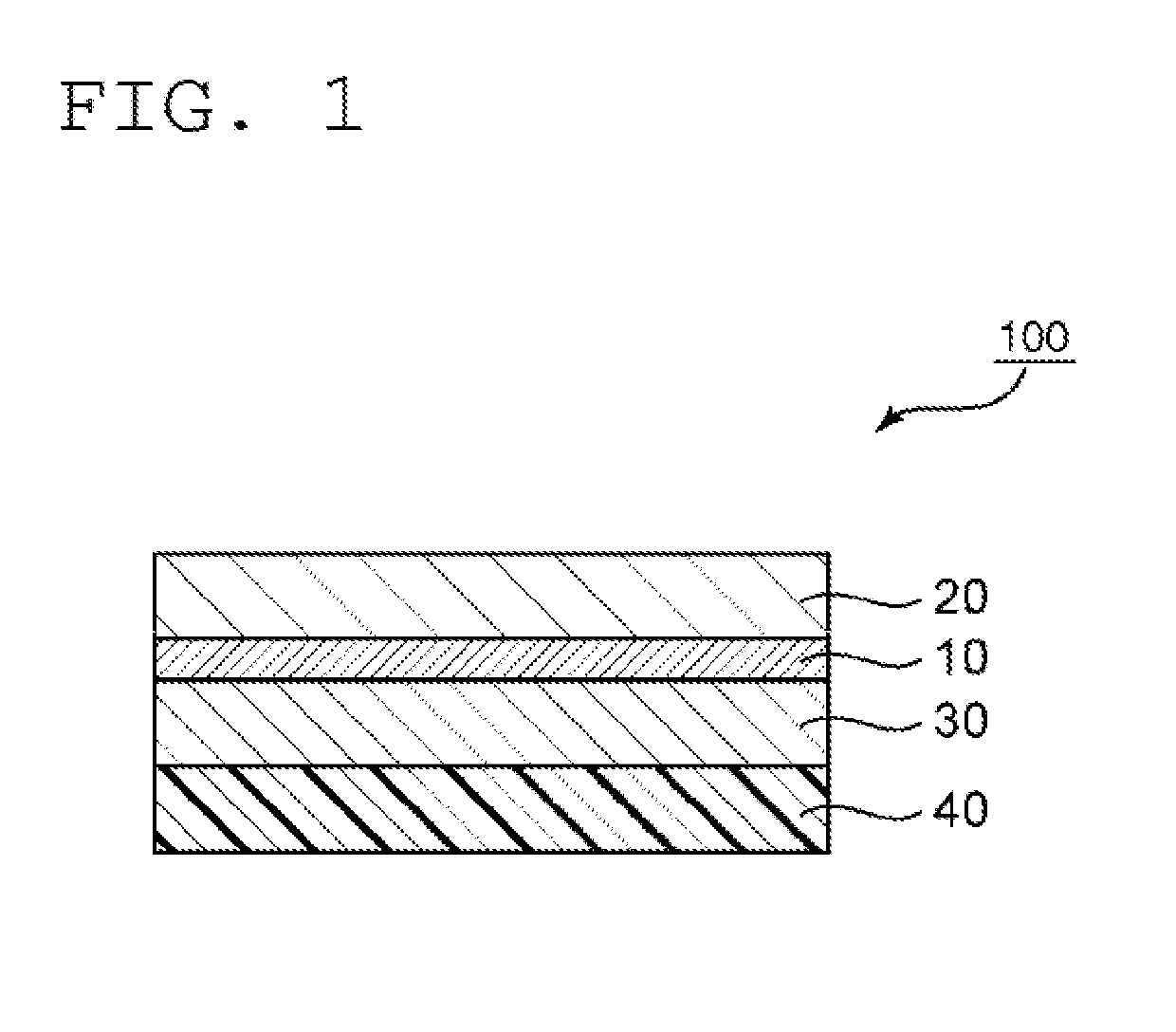

ActiveUS10914881B2Good anti-reflection propertiesImprove featuresLayered productsSolid-state devicesRefractive indexPolarizer

There is provided a polarizing plate with optical compensation layers having the following features: the polarizing plate is excellent in antireflection characteristic in an oblique direction while maintaining an excellent antireflection characteristic in a front direction; the polarizing plate can achieve such excellent antireflection characteristics over a wide wavelength band; and the polarizing plate has a neutral hue in the oblique direction. A polarizing plate with optical compensation layers according to the present invention is used for an organic EL panel. The polarizing plate with optical compensation layers includes: a polarizer; a first optical compensation layer; a second optical compensation layer; a third optical compensation layer; and a fourth optical compensation layer. Each of the first optical compensation layer, the second optical compensation layer, the third optical compensation layer, and the fourth optical compensation layer shows a refractive index characteristic of nx>nz>ny.

Owner:NITTO DENKO CORP

Resist underlayer composition and method of manufacturing semiconductor integrated circuit device using the same

ActiveUS9291899B2Good anti-reflection propertiesPhotosensitive materialsSemiconductor/solid-state device manufacturingResistCompound (substance)

A resist underlayer composition and a method of manufacturing a semiconductor integrated circuit device, the composition including a solvent and an organosilane polymer, the organosilane polymer being a condensation polymerization product of at least one first compound represented by Chemical Formulae 1 and 2 and at least one second compound represented by Chemical Formulae 3 to 5.

Owner:CHEIL IND INC

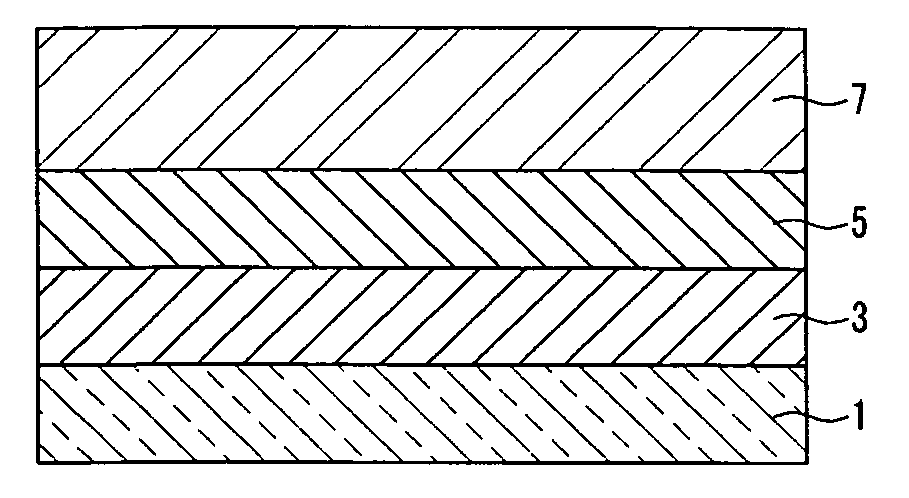

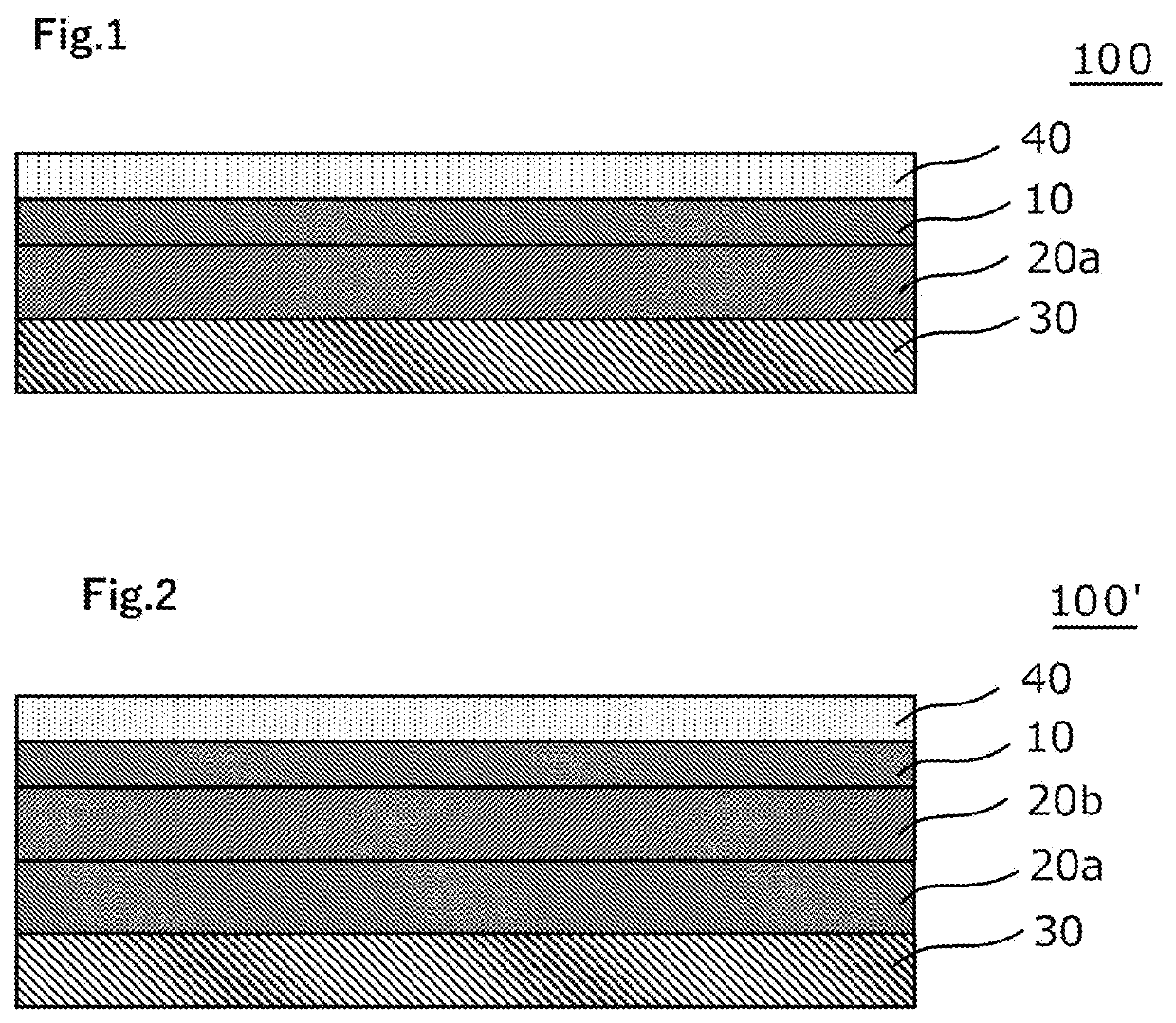

Polarizing plate with optical compensation layer and organic el panel using same

ActiveUS20190103589A1Excellent characteristicGood anti-reflection propertiesElectroluminescent light sourcesSolid-state devicesPolarizerEngineering

There is provided a polarizing plate with optical compensation layers that is excellent in antireflection characteristic: in an oblique direction while maintaining an excellent antireflection characteristic in a front direction, and that has a neutral hue in the oblique direction. A polarizing plate with optical compensation layers according to the present invention is used for an organic EL panel The polarizing plate with optical compensation layers according to an embodiment of the present invention includes in the following order: a polarizer; a first optical compensation layer; and a second optical compensation layer. The first optical compensation layer shows a refractive index characteristic of nx>nz>ny and has an Re (550) of from 230 nm to 310 nm. The second optical compensation layer shows a refractive index characteristic of nx>nz>ny and satisfies a relationship of Re (450)<Re (550).

Owner:NITTO DENKO CORP

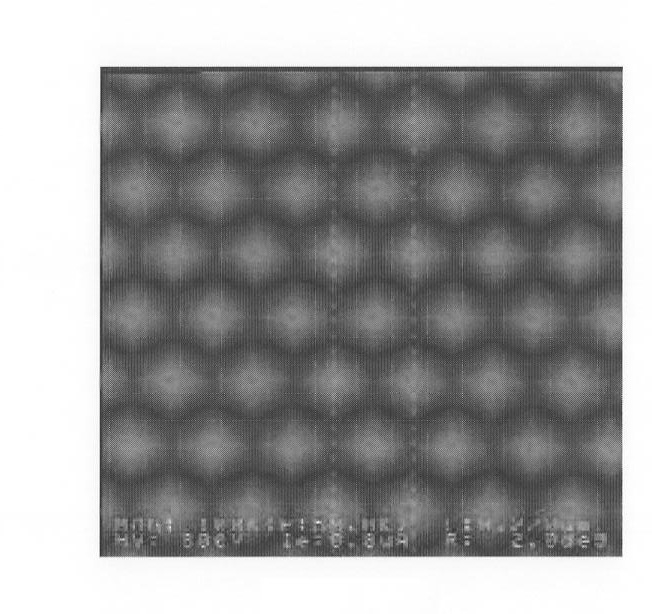

Optical element

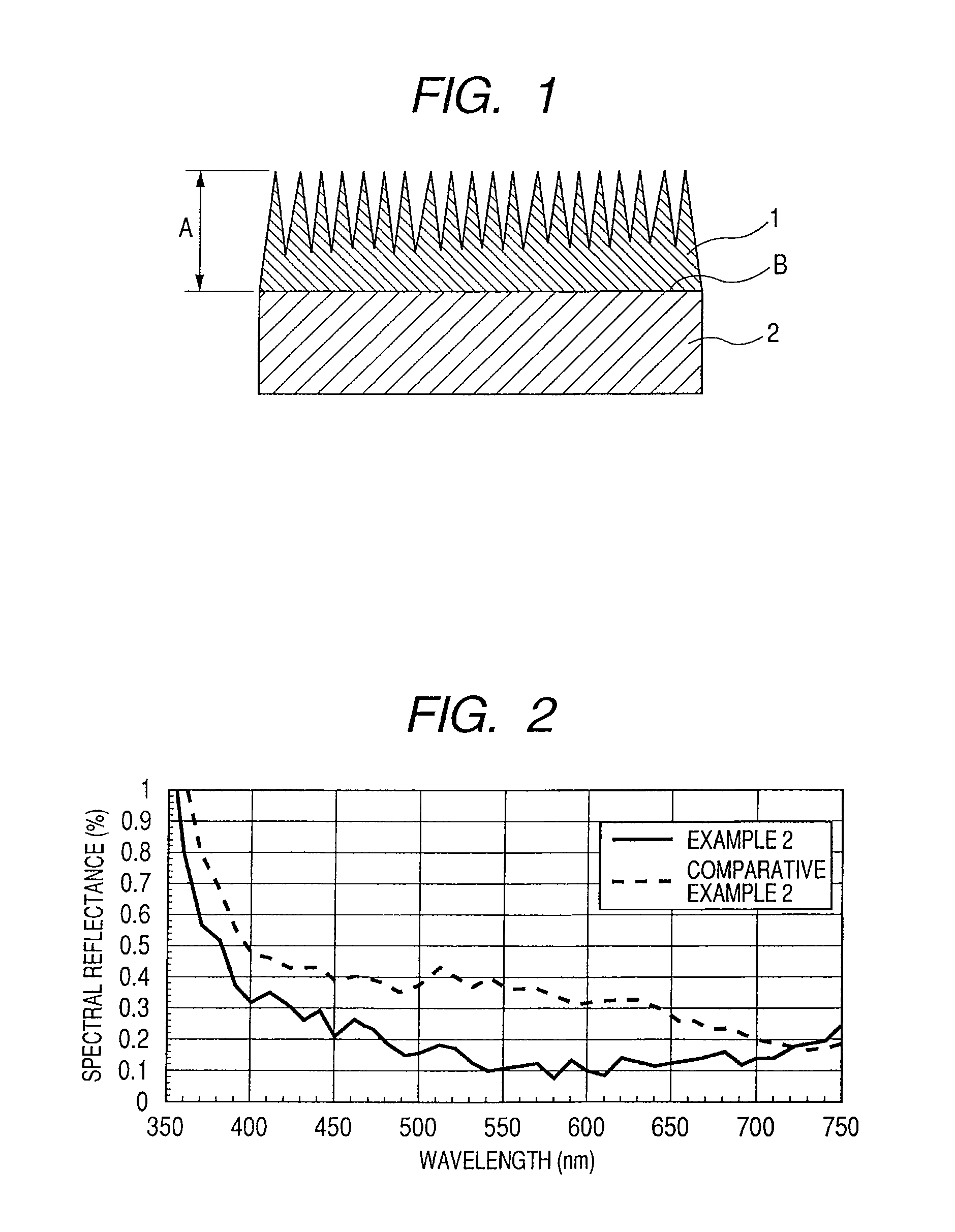

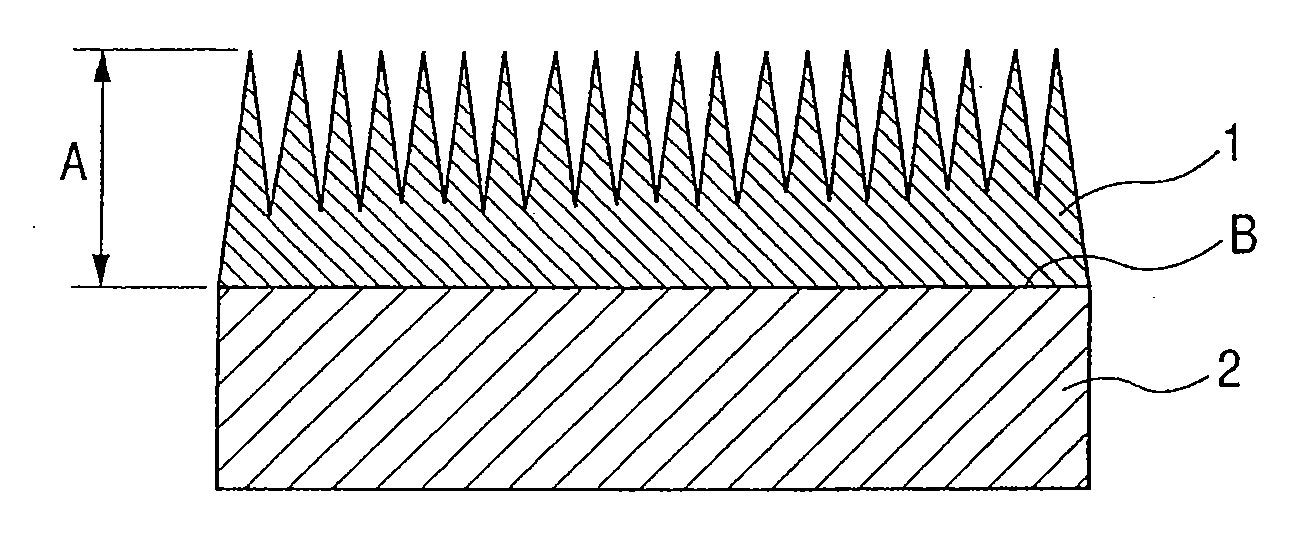

InactiveCN101952746AImprove productivityGood anti-reflection propertiesCoatingsOptical elementsEngineeringLength wave

An optical element is provided with a base body, and a main structure, i.e., a protruding section or a recessed section, and a sub-structure, which are formed on a surface of the base body. The main structure forms a plurality of rows of tracks on the surface of the base body, and is repeatedly arranged periodically at a fine pitch of a visible light wavelength or smaller. The sub-structure is smaller than the main structure, and is arranged between the main structures or in a gap in the arrangement of the main structures or on a surface of the main structure.

Owner:SONY CORP

Coating composition for antireflection, antireflection film and method for preparing the same

ActiveCN101855303BGood anti-reflection propertiesImprove featuresMaterial nanotechnologyNanostructure manufactureRefractive indexWear resistance

The present invention provides a coating composition for ant iref lection that includes a low refractive material having a refractive index of 1.2 to 1.45 and a high refractive resin having a refractive index of 1.46 to 2, in which the difference in the surface energy between two materials is 5 mN / m or more; an ant iref lection film manufactured using the coating composition for ant iref lection;and a method of manufacturing the ant iref lect ion film. According to the present invention, the ant iref lect ion film having excellent abrasion resistance and antiref lection characteristic can bemanufactured using a single composition by one coating process, thereby reducing manufacturing cost.

Owner:LG CHEM LTD

Method of manufacturing optical element, and optical element

InactiveUS20090280335A1Avoid performanceGood anti-reflection propertiesGlass/slag layered productsCoatingsWarm waterMetal alkoxide

A method of manufacturing an optical element having a good reflection preventing characteristic is provided in which an irregularity structure having a reflection preventing function can be formed at low temperature. The method includes forming a film on the optical substrate by using a coating liquid containing a metal alkoxide containing at least aluminum, immersing the film in a water-containing liquid, baking the film having been immersed in the water-containing liquid, and subjecting the film having been baked to treatment with warm water to form an aluminum-containing film having a fine irregularity structure.

Owner:CANON KK

Coating composition and antireflection film

ActiveCN104066805BEasy to manufactureSimple manufacture of anti-reflective propertiesAntifouling/underwater paintsPhotovoltaicsPolymer emulsionSilicon

The coating composition of the present invention, which contains a metal oxide (A) and polymer emulsion particles (B), the metal oxide (A) contains a spherical metal oxide (a1) and an aspect ratio (long diameter / short diameter) A chain-like metal oxide (a2) having a diameter) of 3 to 25. In addition, the coating composition of the present invention preferably contains a hydrolyzable silicon compound (C). Moreover, the antireflection film of this invention is obtained by apply|coating the said coating composition to a base material, and drying.

Owner:ASAHI KASEI KK

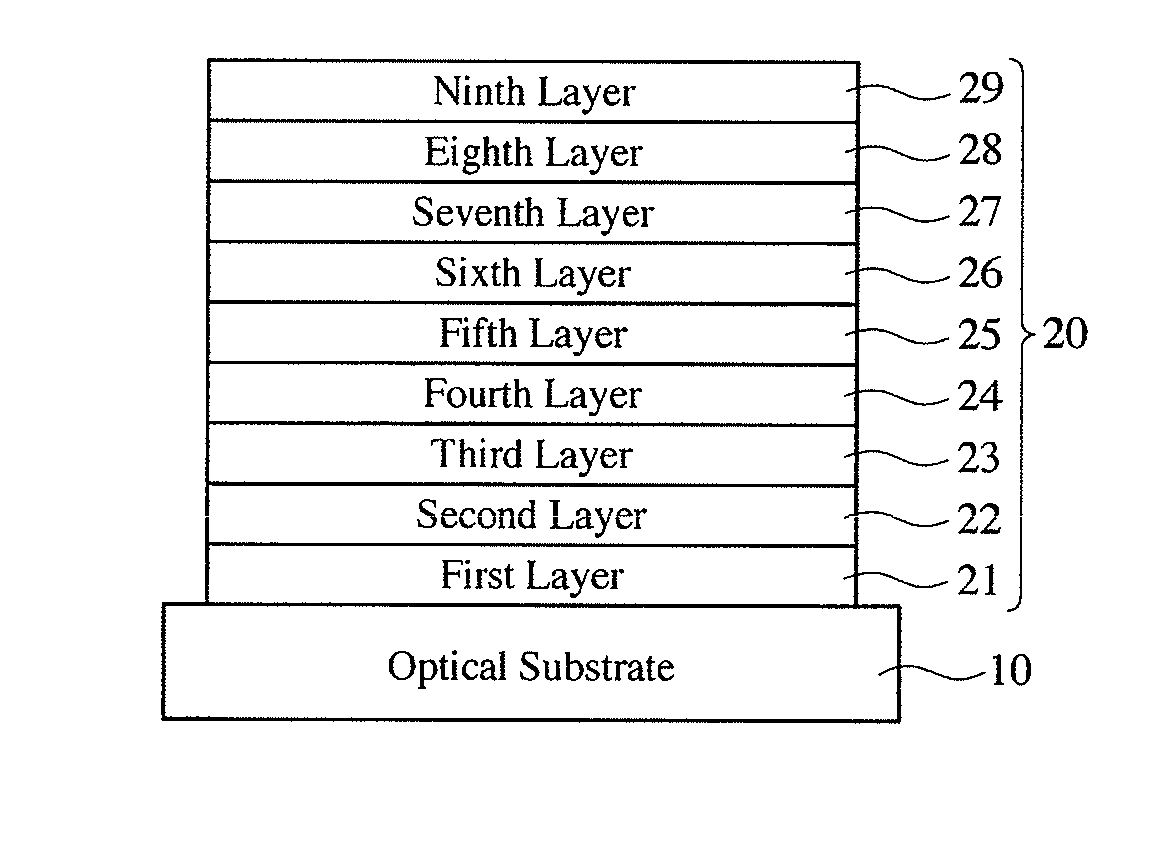

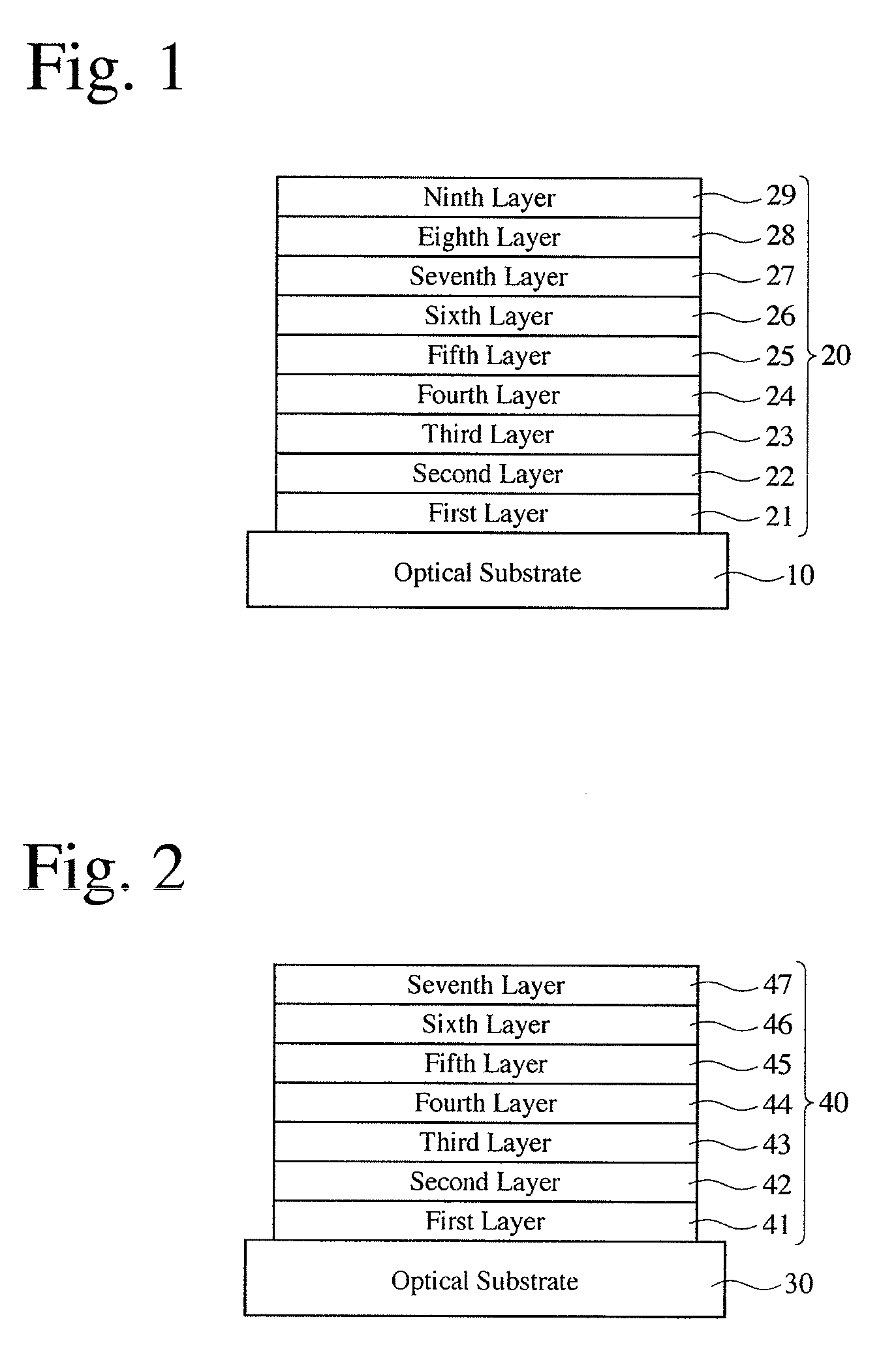

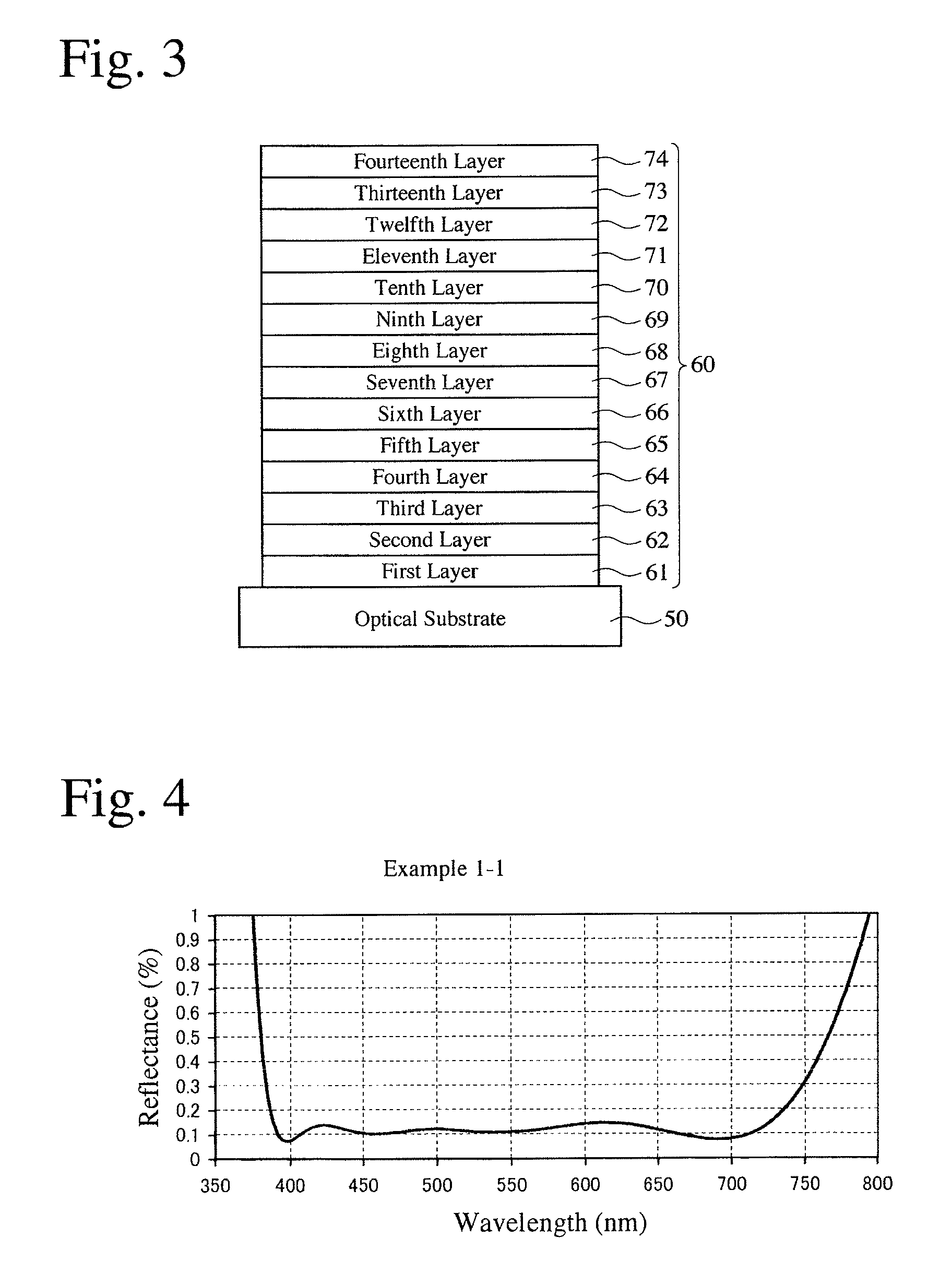

Anti-reflection coating, optical member having it, and optical equipment comprising such optical member

A anti-reflection coating comprising first to ninth layers laminated in this order on a substrate for having reflectance of 0.2% or less to light in a visible wavelength range of 390-720 nm, the second, fourth, sixth and eighth layers being high-refractive-index layers formed by high-refractive-index materials having refractive indices of 2.21-2.70 to a helium d-line having a wavelength of 587.56 nm; the first, third, fifth and seventh layers being intermediate-refractive-index layers formed by an intermediate-refractive-index material having a refractive index of 1.40 or more and less than 1.55 to the d-line; and the ninth layer being a low-refractive-index layer formed by a low-refractive-index material having a refractive index of 1.35 or more and less than 1.40 to the d-line.

Owner:RICOH IMAGING COMPANY

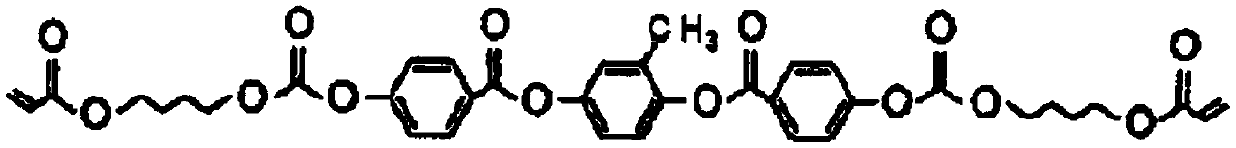

Circularly polarizing plate and image display device using same

InactiveCN112639552AGood anti-reflection propertiesLayered productsElectroluminescent light sourcesOptical polarizationMaterials science

A circularly polarizing plate provided with a polarizing film and a retardation film for functioning as a lambda / 4 plate, in this order, the angle formed by the absorption axis of the polarizing film with the slow axis of the retardation film being 35 degrees to 55 degrees, the retardation film including a liquid crystal material, the retardation film satisfying expressions (alpha) and (beta) ((alpha): Re(450) / Re(550)<=1.00; (beta):1.00<=Re(650) / Re(550)), the retardation film including an impurity, the thickness of the retardation film being 1.5 [mu]m or greater, and the surface of the retardation film being essentially flat.

Owner:SUMITOMO CHEM CO LTD

Polarizing plate with optical compensation layer and organic EL panel using same

ActiveUS11018326B2Good anti-reflection propertiesImprove featuresElectroluminescent light sourcesSolid-state devicesRefractive indexPolarizer

There is provided a polarizing plate with optical compensation layers that is excellent in antireflection characteristic: in an oblique direction while maintaining an excellent antireflection characteristic in a front direction, and that has a neutral hue in the oblique direction. A polarizing plate with optical compensation layers according to the present invention is used for an organic EL panel The polarizing plate with optical compensation layers according to an embodiment of the present invention includes in the following order: a polarizer; a first optical compensation layer; and a second optical compensation layer. The first optical compensation layer shows a refractive index characteristic of nx>nz>ny and has an Re (550) of from 230 nm to 310 nm. The second optical compensation layer shows a refractive index characteristic of nx>nz>ny and satisfies a relationship of Re (450)<Re (550).

Owner:NITTO DENKO CORP

Polarizing plate with optical compensation layer and organic el panel using same

ActiveCN110192130AInhibition of revealingSuppresses unwanted effects on display performanceElectroluminescent light sourcesSolid-state devicesRefractive indexPolarizer

Provided is a polarizing plate with an optical compensation layer, which is extremely thin and has excellent anti-reflection characteristics, while being suppressed in adverse effects on the display performance of an image display device caused by foreign substances. A polarizing plate with an optical compensation layer according to the present invention is sequentially provided with a polarizer,a first optical compensation layer and a second optical compensation layer in this order. The first optical compensation layer exhibits refractive index characteristics expressed by formula nx = nz >ny, while having an in-plane retardation Re(550) of from 220 nm to 320 nm. The second optical compensation layer exhibits refractive index characteristics expressed by formula nx > ny = nz, while having an in-plane retardation Re(550) of from 100 nm to 200 nm. The first optical compensation layer contains foreign substances; and the thickness of the first optical compensation layer is 1.5 [mu]m ormore. In addition, the surface of the first optical compensation layer is substantially flat.

Owner:NITTO DENKO CORP

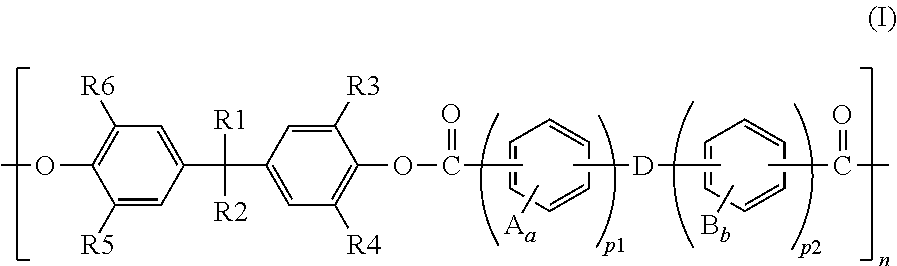

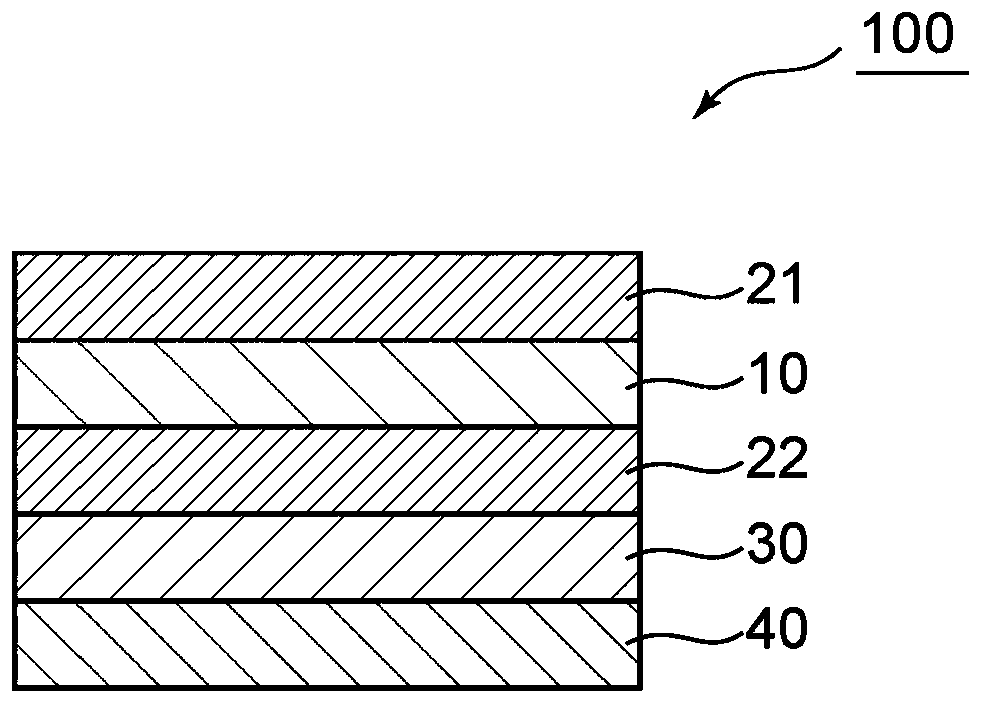

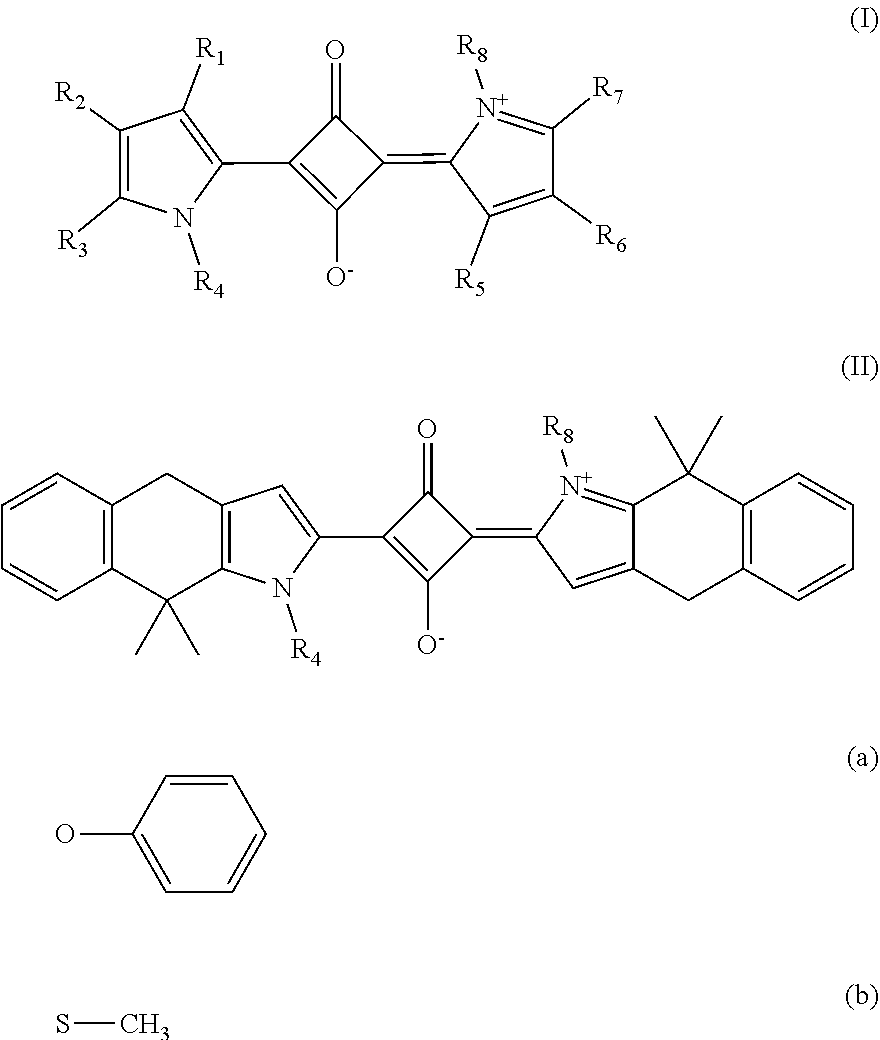

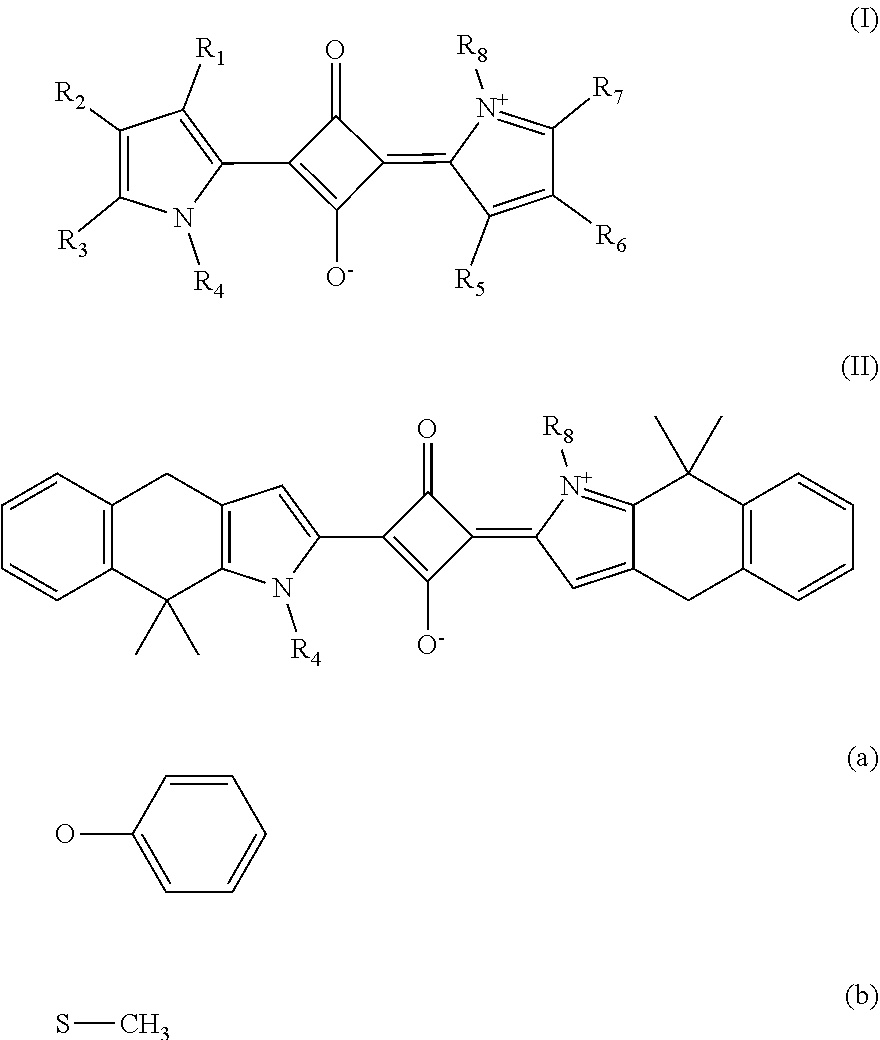

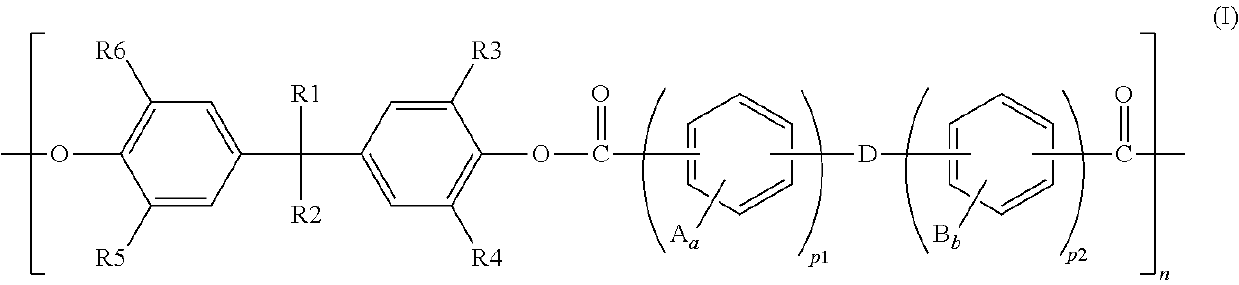

Circularly polarizing plate

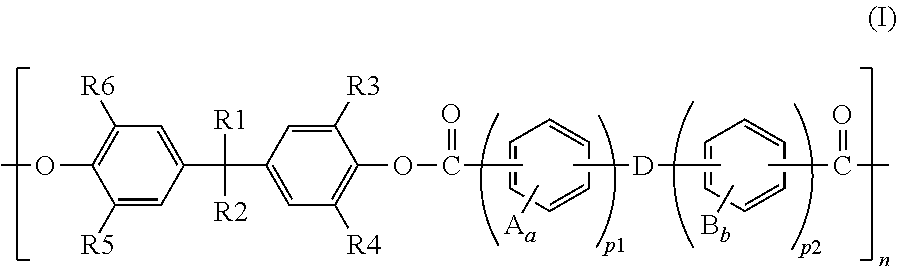

InactiveUS20200355962A1Good anti-reflection propertiesImprove color gamutOrganic chemistryNon-macromolecular adhesive additivesPolarizerMaterials science

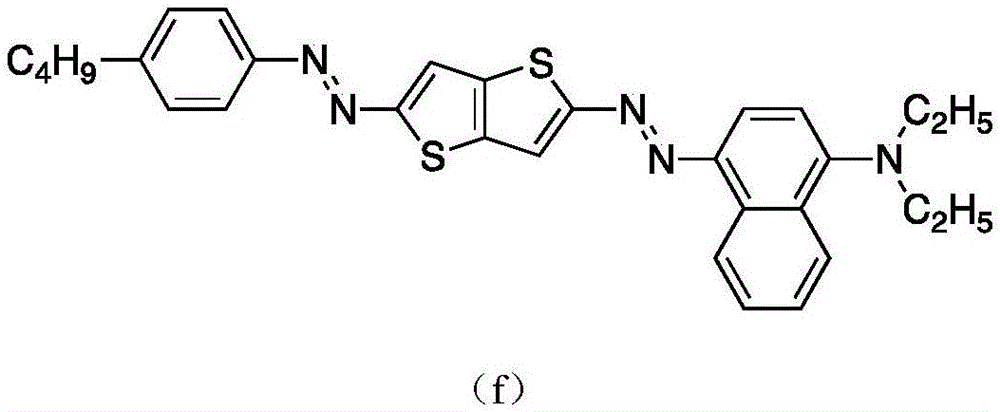

Provided is a circularly polarizing plate that is excellent in antireflection characteristic, and that can be produced at low cost. The circularly polarizing plate of the present invention includes in the stated order: a polarizer; a retardation layer (20a) configured to function as a λ / 4 plate; and a colored layer, wherein an angle formed by an absorption axis of the polarizer and a slow axis of the retardation layer (20a) is from 35° to 55°, wherein the colored layer has an absorption peak in a wavelength band in a range of from 580 nm to 610 nm, and wherein the colored layer contains a compound X represented by the general formula (I) or the general formula (II).

Owner:NITTO DENKO CORP

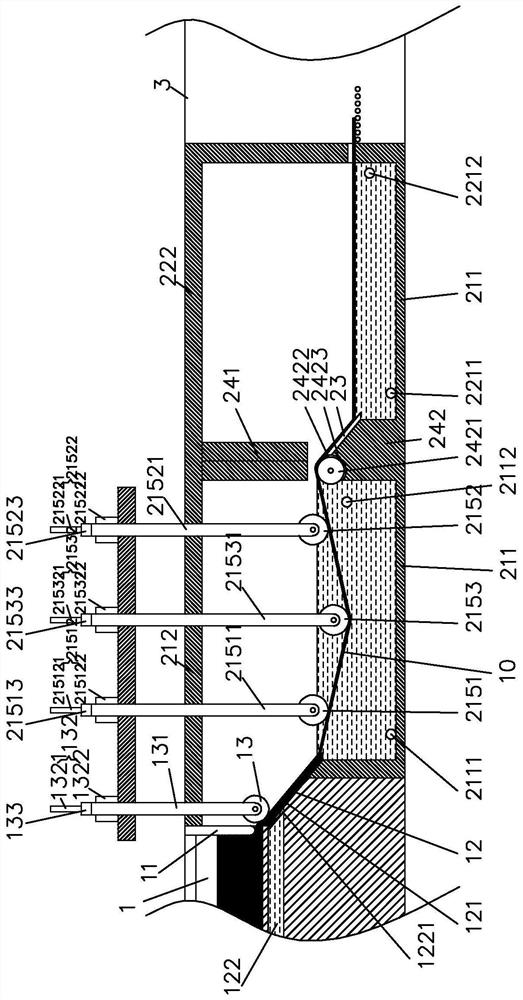

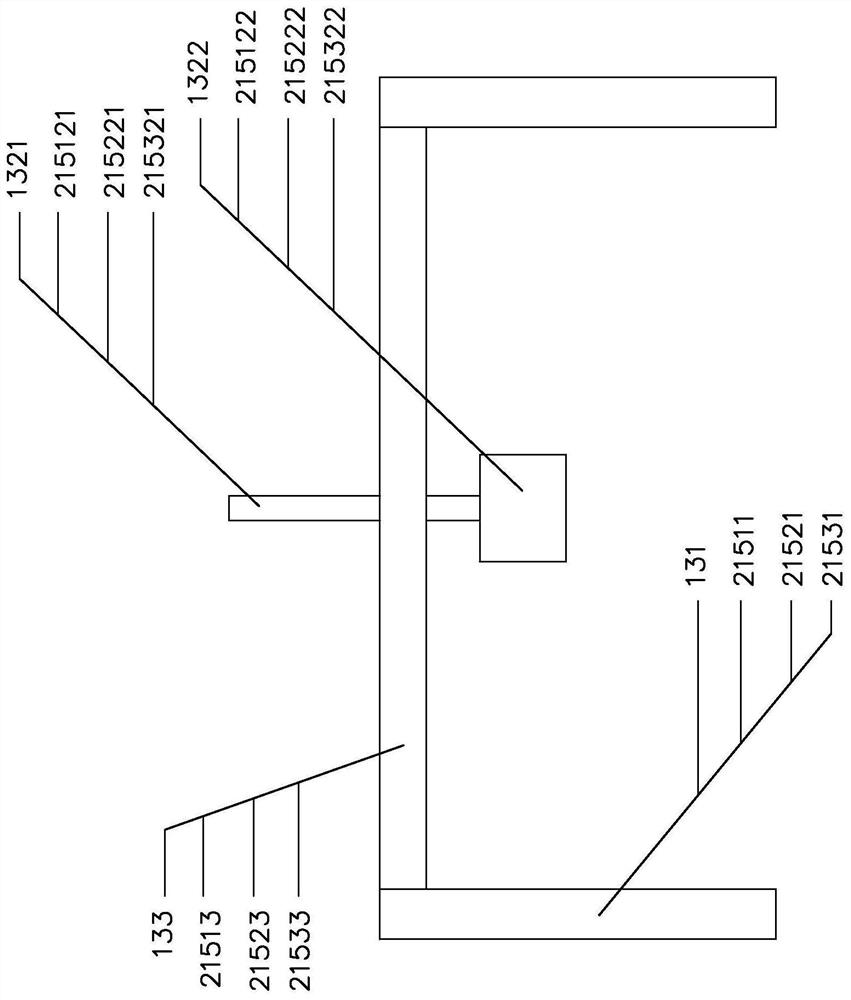

A production process of ag glass

ActiveCN108751730BSpeed up the flowSmall contact forceInductively coupled plasmaReactive-ion etching

The invention proposes a production process of AG glass, which uses a melting furnace to melt glass raw materials to form a glass fluid; then floats the glass fluid in a melting tin room to form a glass plate in the early stage; and then uses an annealing chamber to anneal the glass plate in the early stage to form Finished glass sheet; then the finished glass sheet is cut and edged to make a glass template; then the glass template is polished; then the glass template is cleaned; then the hard mask film is made; then the UV curable polymer layer is made; then the model; then make a solidified layer with the model; then release the mold; then etch the glass template with one or both of reactive ion etching or inductively coupled plasma etching, and the etching of the hard mask film The speed is lower than the etching speed of the glass template. Compared with the prior art, the production process of the AG glass of the present invention can produce the AG glass with high efficiency and high quality, and the performance of the AG glass is superior.

Owner:福建成达玻璃有限公司

Polarizing plate with optical compensation layer and organic EL panel using same

ActiveUS10989853B2Good anti-reflection propertiesImprove featuresLayered productsSolid-state devicesRefractive indexPolarizer

There is provided a polarizing plate with optical compensation layers having the following features: the polarizing plate is excellent in antireflection characteristic in an oblique direction while maintaining an excellent antireflection characteristic in a front direction; the polarizing plate can achieve such excellent antireflection characteristics over a wide wavelength band; and the polarizing plate has a neutral hue in the oblique direction. A polarizing plate with optical compensation layers according to the present invention is used for an organic EL panel. The polarizing plate with optical compensation layers includes: a polarizer; a first optical compensation layer; a second optical compensation layer; and a third optical compensation layer. Each of the first optical compensation layer, the second optical compensation layer, and the third optical compensation layer shows a refractive index characteristic of nx>nz>ny.

Owner:NITTO DENKO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com